Energy-saving gas stove

A technology of gas stoves and gas, which is applied in household stoves, heating fuels, household stoves/stoves, etc. It can solve the problems of low heat utilization rate and achieve the effects of improving combustion quality, reducing emissions, and improving utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

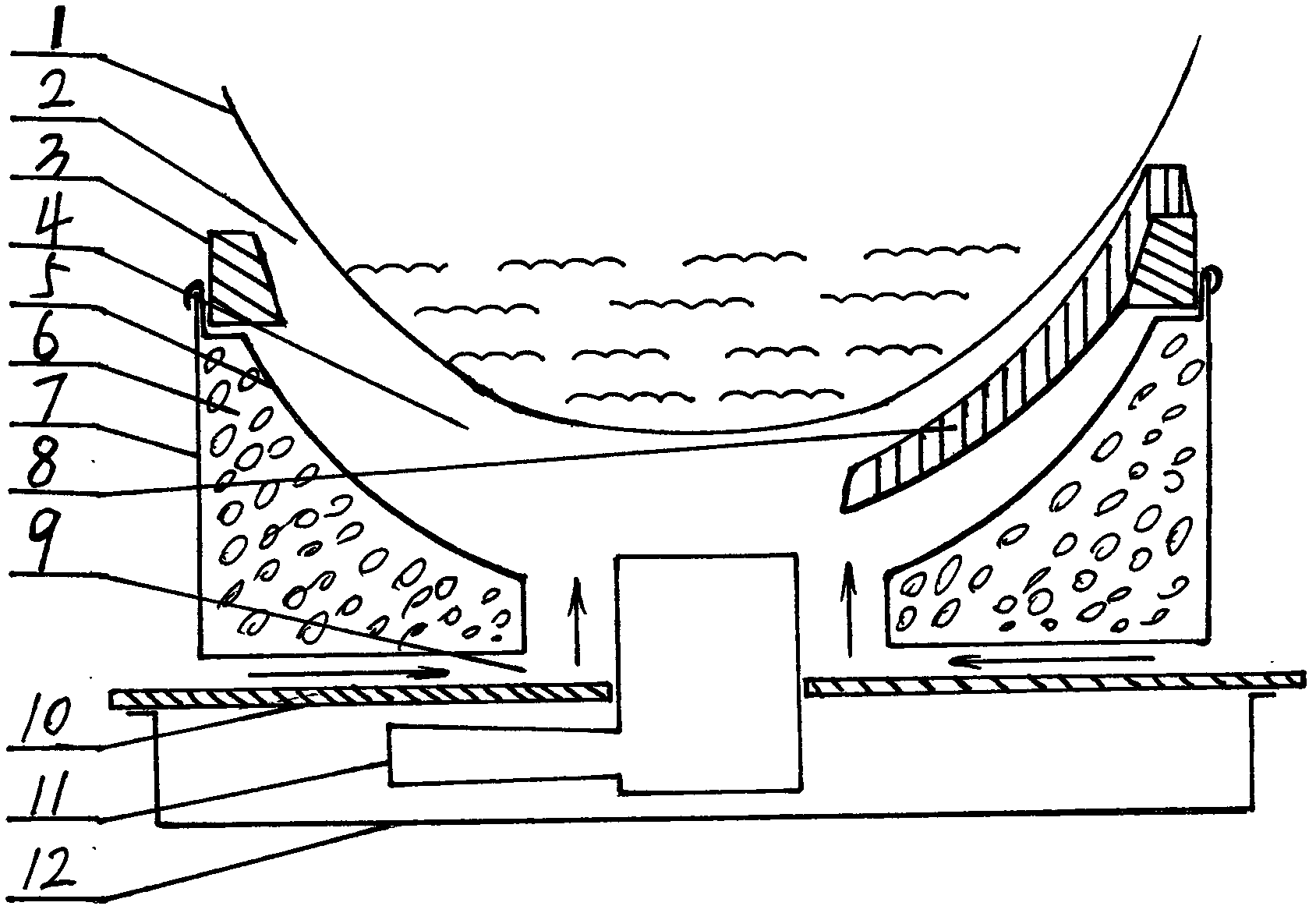

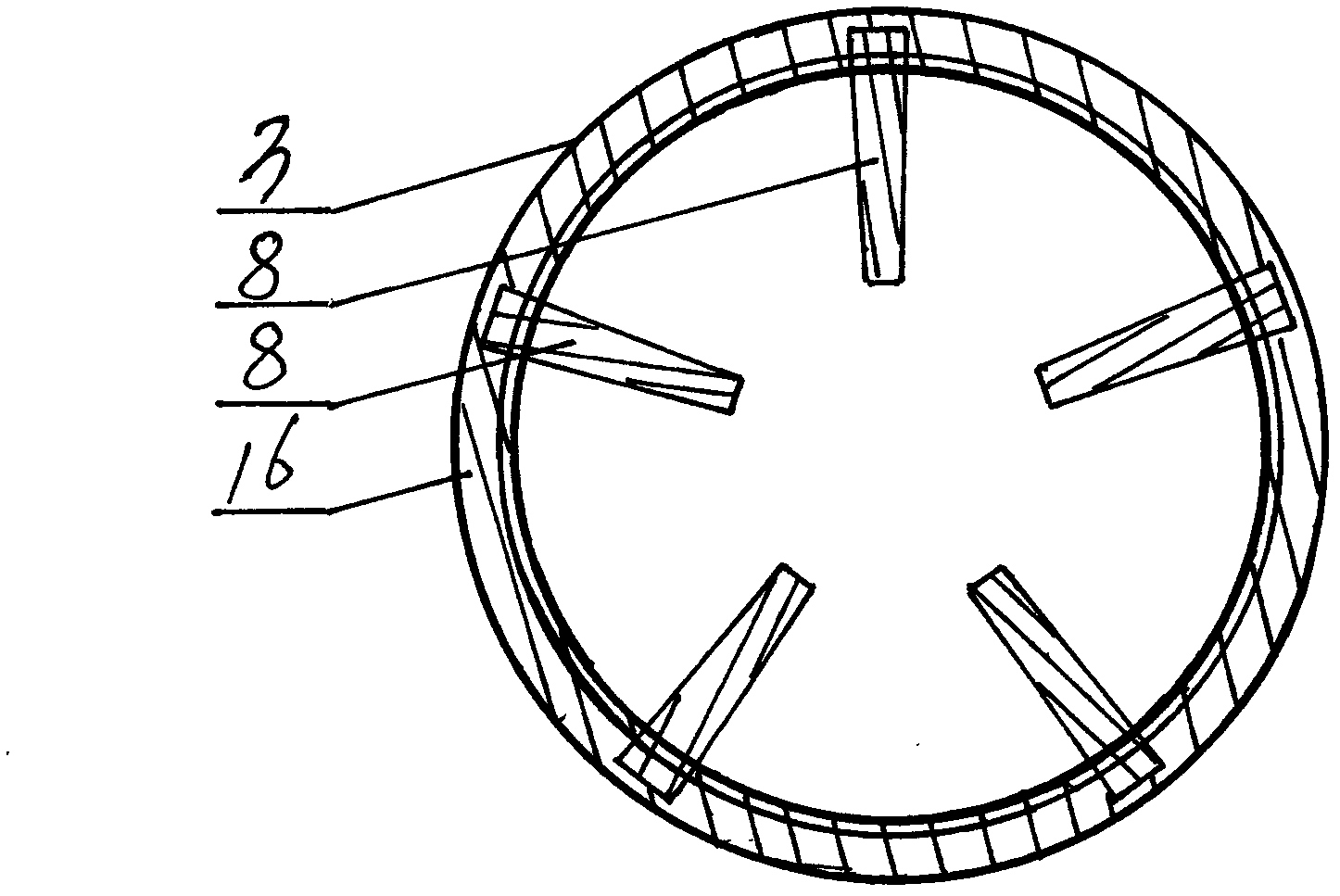

[0019] Specific embodiment one: as figure 1 As shown, the gas cooker of the present invention comprises: an energy-gathering and heat-insulating reflector 7, a burner 11, a cooker body panel 10, a combustion chamber 4, a stove frame A3, a gas control ring 22, and a bottom shell 12, and is characterized in that: the pot 1 , energy-gathering and heat-insulating reflector 7, burner head 11, burner rack A3, and gas control ring 22 together constitute combustion chamber 4, gas is ejected from burner head 11 for combustion, and the supplementary secondary air is provided by secondary supplementary air channel 9, air hole 23 enters the combustion-supporting gas, the combustion of the gas is carried out in the combustion chamber 4, and the flue gas after combustion is discharged from the flue gas outlet 2. In this new technology, the selection of pot 1 is required, specifically there are two points: one, the outer surface of pot 1 will all contact the inner side of the upper end of al...

specific Embodiment 2

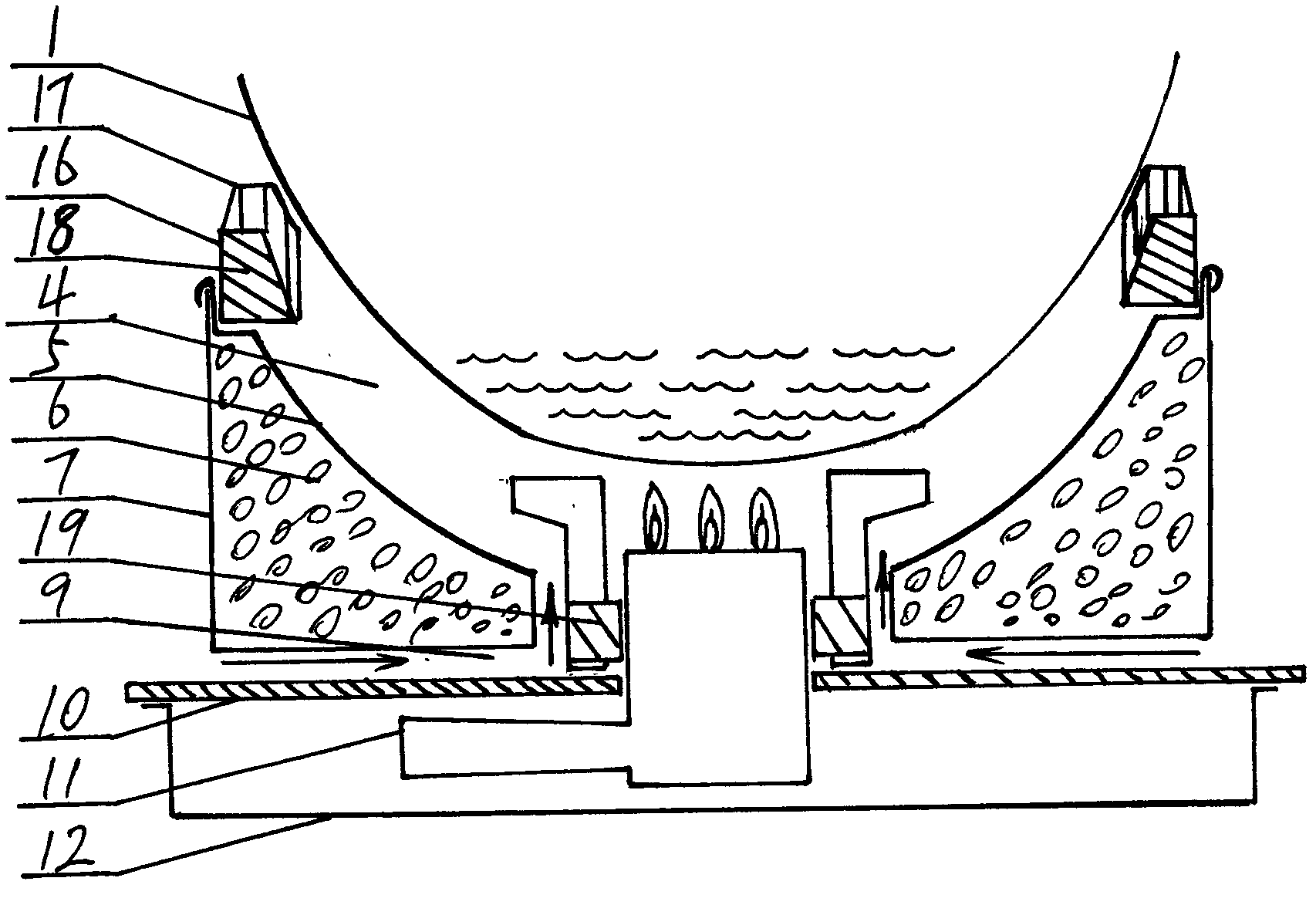

[0022] Specific embodiment two: as image 3 As shown, the gas stove of the present invention includes: energy-gathering heat-insulating reflector 7, burner head 11, stove body panel 10, combustion chamber 4, stove frame B18, support frame 19, bottom shell 12, described by pot 1, energy-gathering The heat-insulating reflector 7, the burner head 11, and the burner frame B18 together constitute the combustion chamber 4. Gas is ejected from the burner head 11 for combustion, and the supplementary secondary air enters the combustion-supporting channel 9 through the secondary supplementary air channel. The combustion of the gas is carried out in the combustion chamber 4. It is carried out inside, and the flue gas after combustion is discharged from the flue gas outlet 2. In this new technology, there are requirements for the selection of pot 1, specifically there are two points: one, the outer surface of pot 1 will all touch the inner side of the upper end of all support points 17 o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com