Patents

Literature

66results about How to "Reduce the amount of gas" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Operation technology used for maintaining direct motion of large blast furnace through low-heat state strength coke

InactiveCN108359760AImprove responseBreaking the hot state strength must be greater than 60%Blast furnace detailsAir volumeSlag

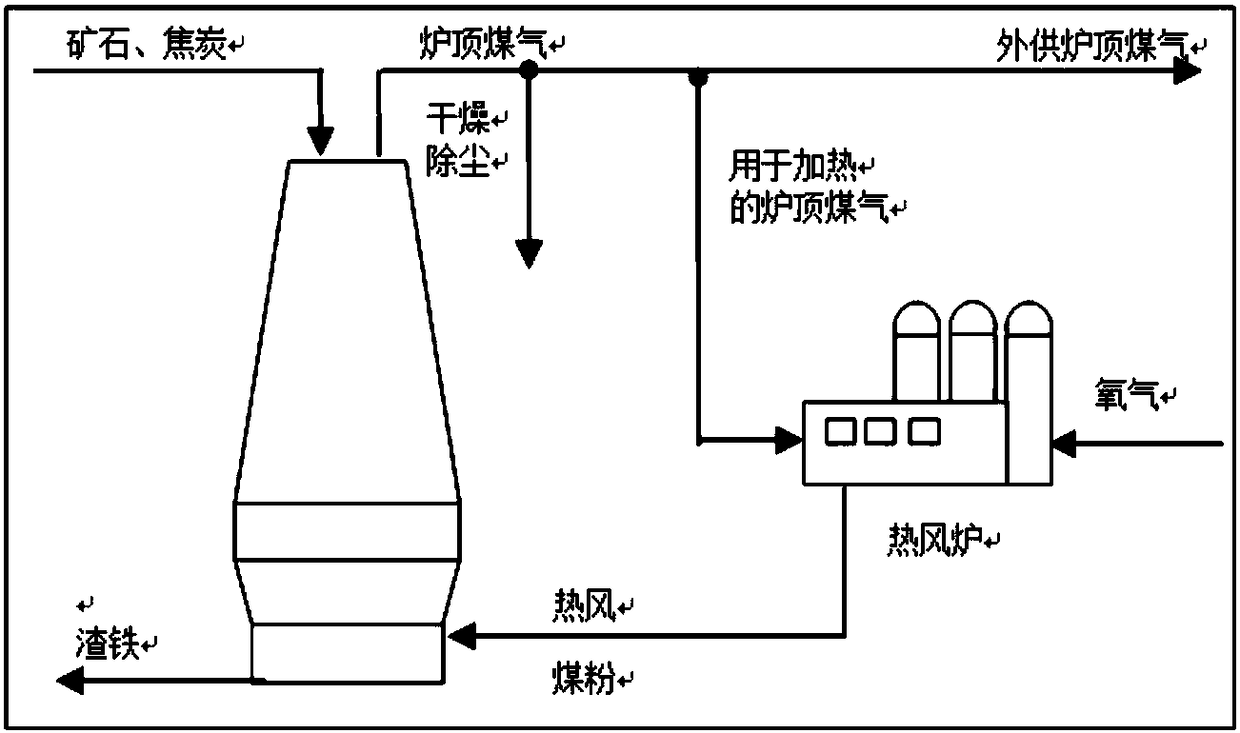

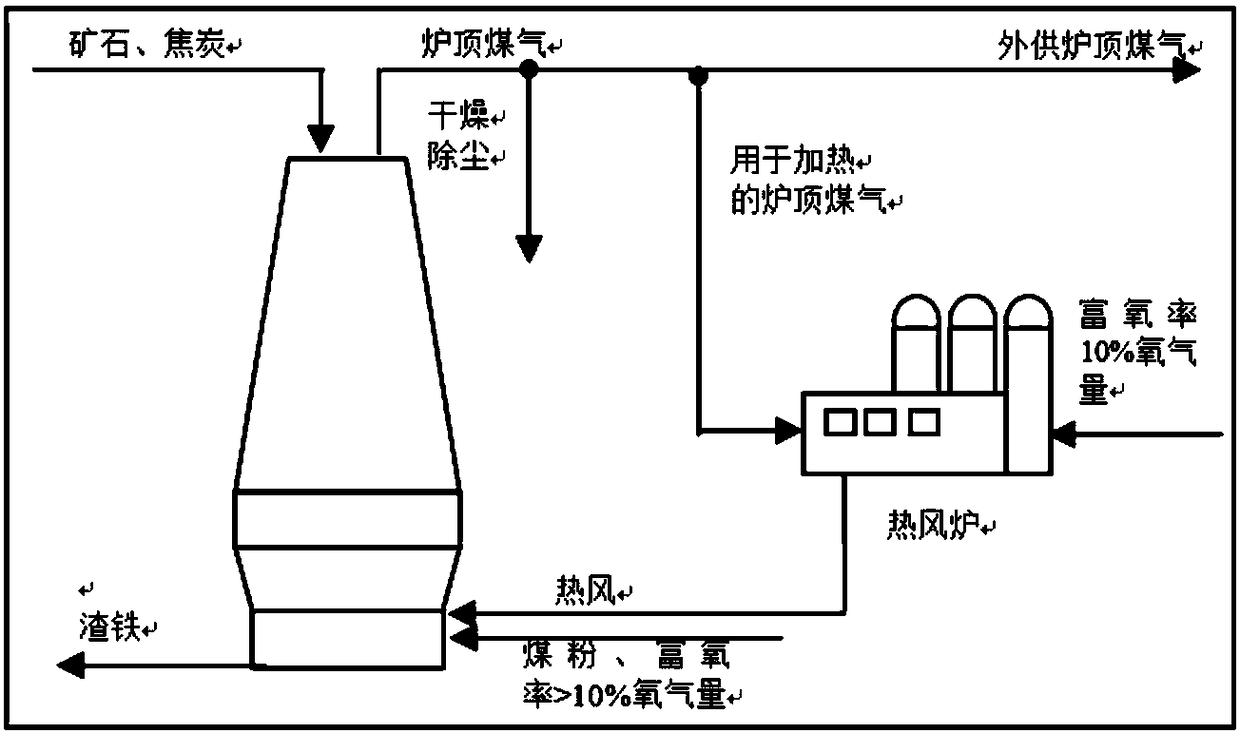

The invention discloses an operation technology used for maintaining direct motion of a large blast furnace through low-heat state strength coke. Local coal is used, the heat state strength of the coke is 29.8%, the O / C is 4.142, oxygen enrichment is maintained to be 15500+ / -100 m<3> / h, the oxygen enrichment rate is 4.5%-5%, the top temperature is 105+ / -5 DEG C, PT ranges from 1490 DEG C-1510 DEGC, Si ranges from 0.5-0.7, and the fuel ratio ranges from 541 kg / t-557 kg / t. The operation technology comprises the following steps that (1) the coke ratio is reduced, the blowing-in area is adjustedfrom 0.34 m<2> to 0.311 m<2>, and the air speed is 265+ / -5 m / s; (2) according to a charging rule, the air volume is reduced to 4000 Nm<3> / min,and the material speed per batch is 44+ / -1; (3) accordingto a heating rule, the molten iron temperature is 1490 DEG C+ / -10 DEG C; (4) according to a slagging rule, the blast-furnace slag basicity ranges from 1.1-1.5; and (5) according to a tapping deslagging rule, the iron notch depth is 3600 mm-3800 mm, the mud ramming quantity is 200 kg-250 kg, and the mud emitting rate is smaller than 1%. According to the new technology, the large blast furnace completely uses the low-heat state strength coke, by increasing oxygen enrichment and decreasing the air quantity, the coal gas component is improved, the bosh coal gas quantity is decreased, the blast furnace pressure difference is reduced, the air feeding rule, the charging rule, the heat rule and the slagging rule are adjusted, the direct motion of the furnace condition is maintained, a foothold iskept at the local coal resource, and the competitive power is improved.

Owner:XINJIANG BAYI IRON & STEEL

Blast furnace vanadium-titanium magnetite smelting method by utilizing ultra-high oxygen enriching air blasting

ActiveCN108330238AImprove combustion efficiencyIncrease profitBlast furnace detailsBlast furnace smeltingHigh oxygen

The invention relates to the technical field of vanadium-titanium magnetite smelting, and provides a blast furnace vanadium-titanium magnetite smelting method by utilizing ultra-high oxygen enrichingair blasting. The content of oxygen in hot air of a blast furnace is increased to 26-41% level, the corresponding air blasting oxygen enrichment rate is 5-20%, and the combustion rate of coal powder at the front end of a tuyere is increased; the coal gas reducing potential is increased; the reducing, soft melting, dripping and slag forming process of the vanadium-titanium magnetite in the blast furnace is optimized, breathability of the blast furnace is improved, and it is guaranteed that production of the blast furnace is stably and smoothly performed; and the problems that in the process ofsmelting the vanadium-titanium magnetite through the blast furnace process, the coal ratio is low, the energy consumption is high, furnace slag is viscous and thick, breathability is poor and intensified smelting is difficult are solved. According to the method, it is adopted that high-concentration oxygen is extra added in the hot air of the blast furnace, the oxygen content in the hot air is increased, the coal spraying ratio can be increased, the coke ratio is reduced, the iron making energy consumption of the blast furnace is reduced, the smelting strength is improved, production of the blast furnace is stabilized, and the blast furnace smelting cost of the vanadium-titanium magnetite is reduced.

Owner:UNIV OF SCI & TECH BEIJING

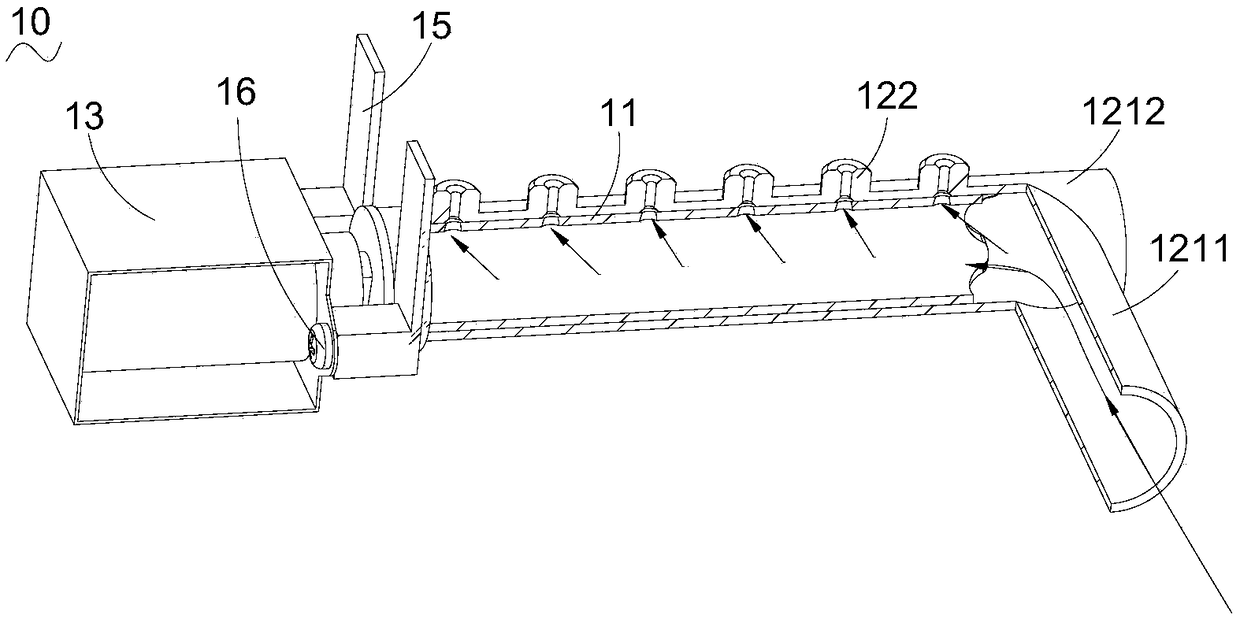

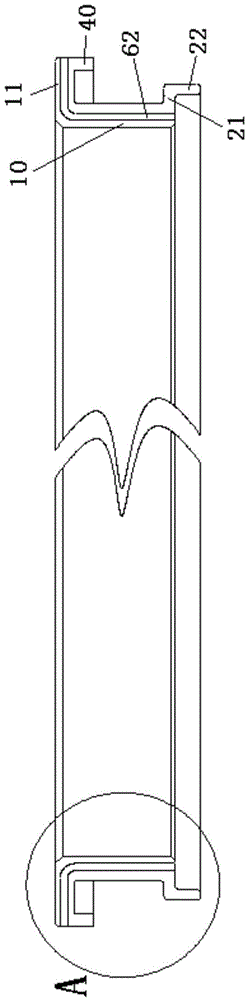

Gas separating rod, gas water heater and gas control method

PendingCN109341089AReduce deflagrationAdjustable connecting areaFluid heatersGaseous fuel feeder/distributionEngineeringFuel gas

The invention relates to a gas separating rod, a gas water heater and a gas control method. The gas separating rod comprises an inner liner tube and an outer liner tube, wherein the inner liner tube is provided with a gas inlet end and a sealing end; a gas outlet communicating the interior of the inner liner tube with the outside world is formed in peripheral surface of the inner liner tube; the outer liner tube comprises an outer liner tube body and a nozzle connected with each other; the outer liner tube body is connected with the external part of the inner liner tube in a sleeving manner; the nozzle is provided with a gas spraying hole capable of communicating the interior of the outer liner tube body with the outside world; and one of the inner liner tube and the outer liner tube bodycan be movably assembled relative to the other of the inner liner tube and the outer liner tube body to adjust the communicating area of the gas spraying hole and the gas outlet. As the outer liner tube body can move relative to the inner liner tube, and the communicating area of the gas spraying hole and the gas outlet is adjustable, the gas quantity sprayed out of the gas spraying hole of the nozzle is adjustable; as the communicating area of the gas spraying hole and the gas outlet can be selected at random, the gas quantity can be adjusted within a larger range; and as the communicating area of the gas spraying hole and the gas outlet can be selected at random, a smaller communicating area can be selected during ignition to spray a smaller quantity of gas, and the detonation phenomenonis reduced.

Owner:GREE ELECTRIC APPLIANCES INC

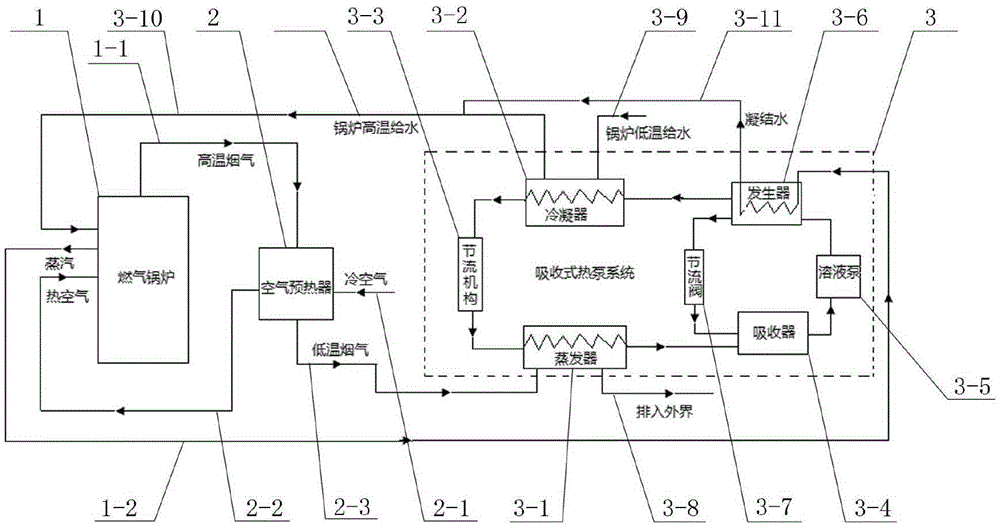

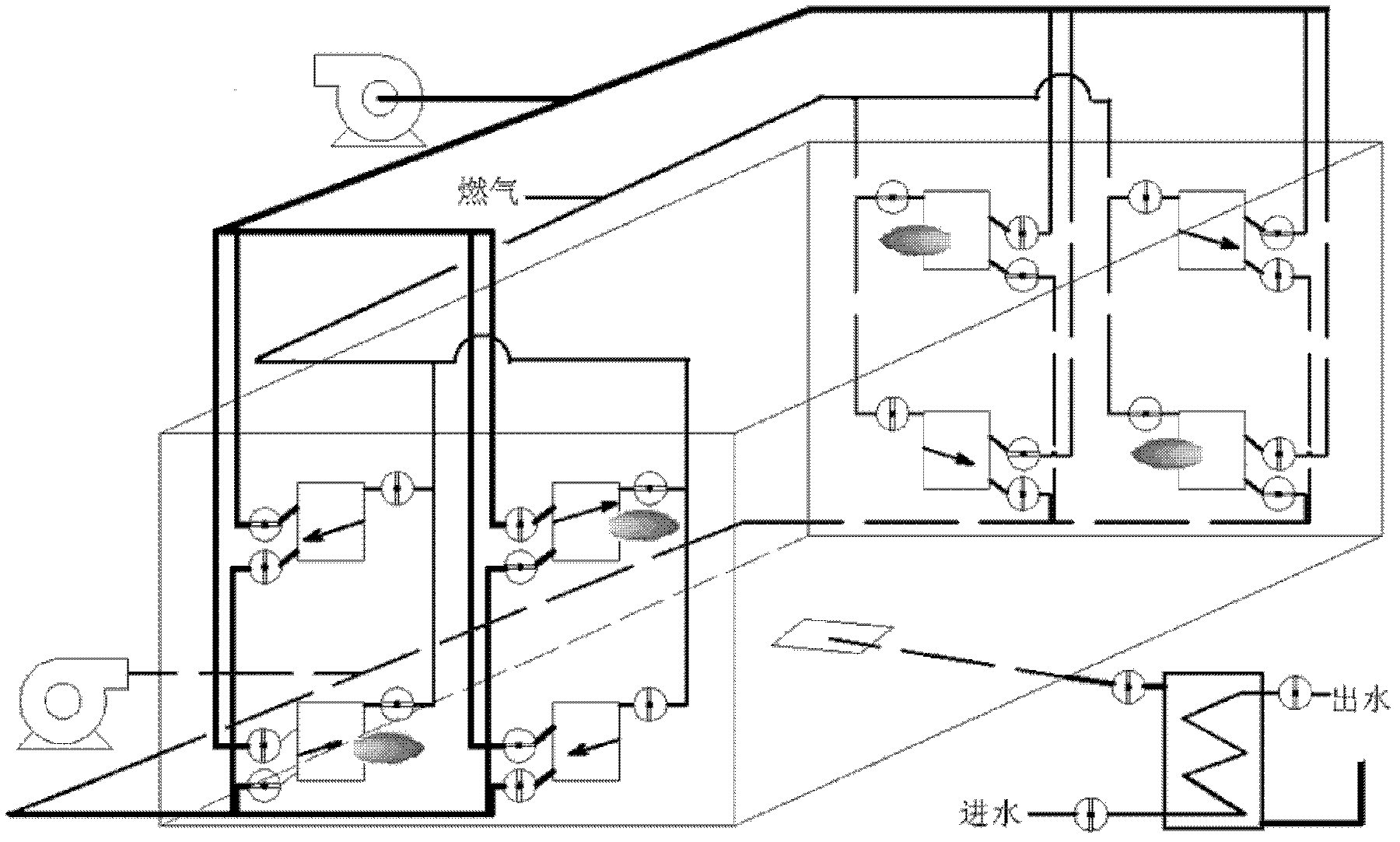

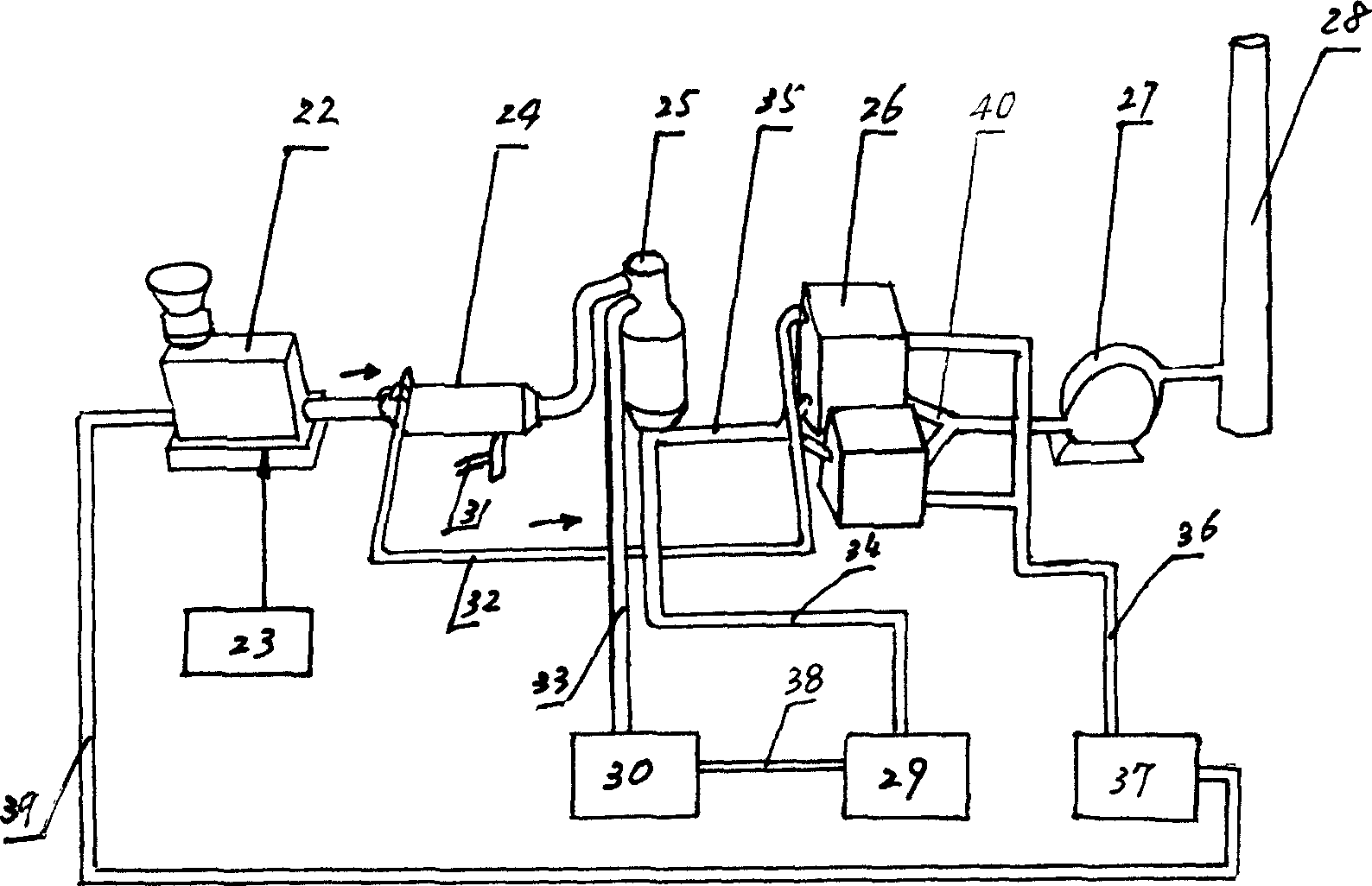

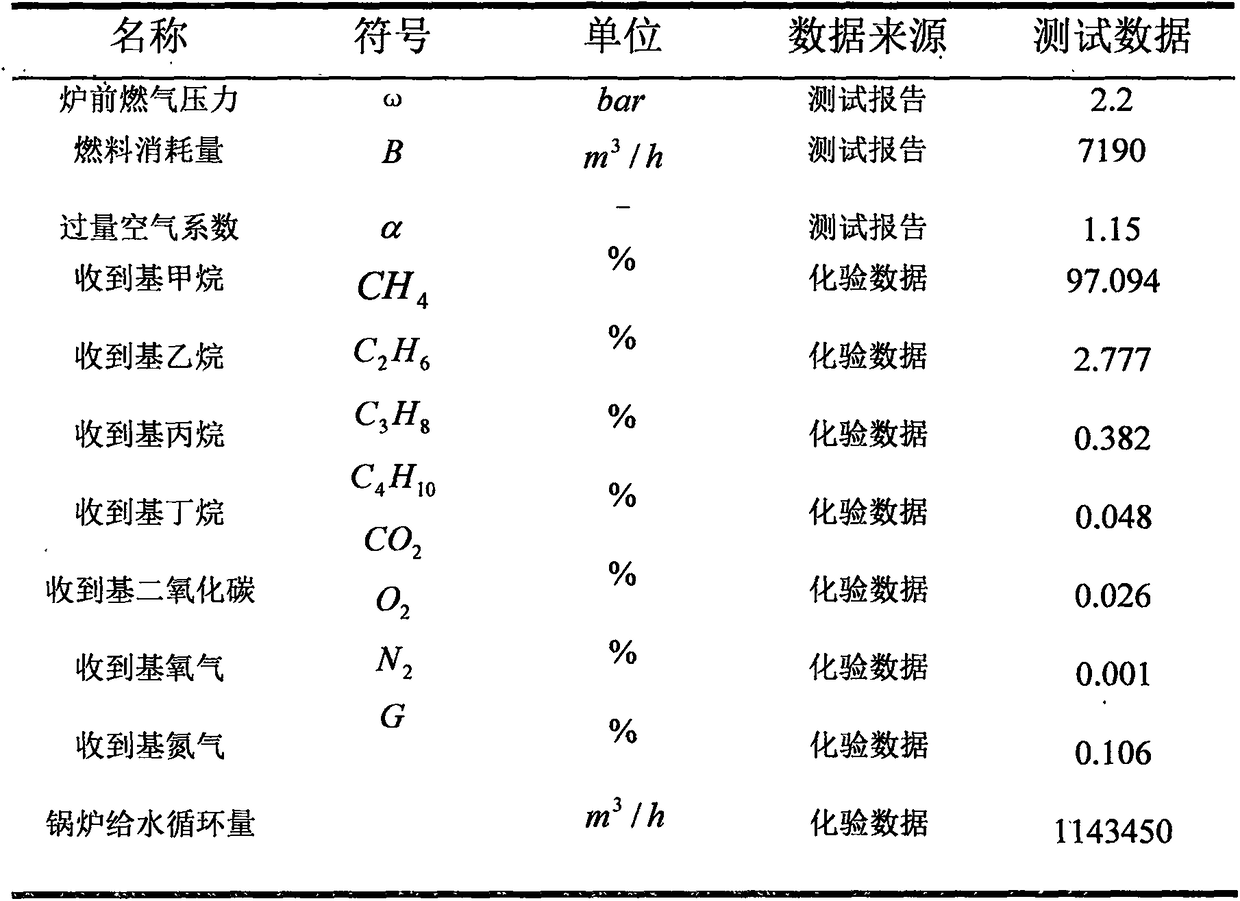

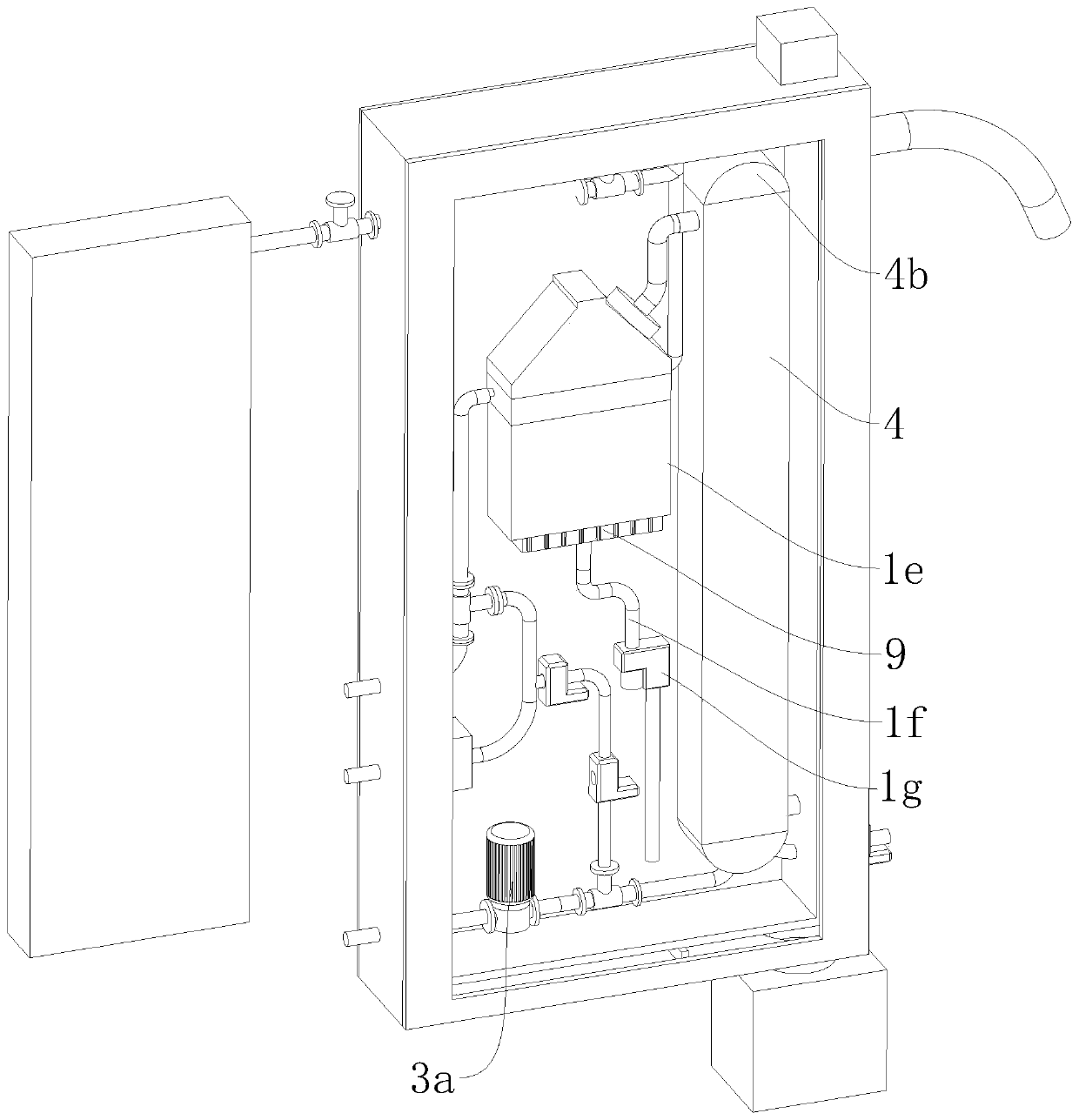

Flue gas residual heat recovery system with absorption type heat pump circulation

InactiveCN104359103AReduce the amount of gasIncrease temperatureHeat recovery systemsFeed-water heatersProcess engineeringEvaporator

The invention discloses a flue gas residual heat recovery system with absorption type heat pump circulation. The system comprises a gas boiler, an air preheater and an absorption type heat pump device, wherein the absorption type heat pump device comprises an evaporator, a condenser, a throttle mechanism, an absorber, a solution pump, a generator and a throttle valve, the absorber, the solution pump, the generator and the throttle valve are connected sequentially, so as to form a loop, and the generator is sequentially connected with the condenser, the throttle mechanism and the evaporator and is finally connected to the absorber; the evaporator is provided with discharging pipes which are used for discharging flue gas and condensation water, the condenser is provided with a boiler low-temperature water supplying passage and a boiler high-temperature water supplying passage, and the boiler high-temperature water supplying passage is connected to the gas boiler; the gas boiler is provided with a high-temperature flue gas passage and a steam branch passage. Compared with the prior art, the system has the advantages that the temperature of supplied water is increased by 5-8 DEG C, and the heat absorption capacity of the supplied water in the boiler is lowered, so that the volume of combusted gas is reduced, and the aims of energy saving and emission reduction are achieved.

Owner:XINJIANG INST OF ENG

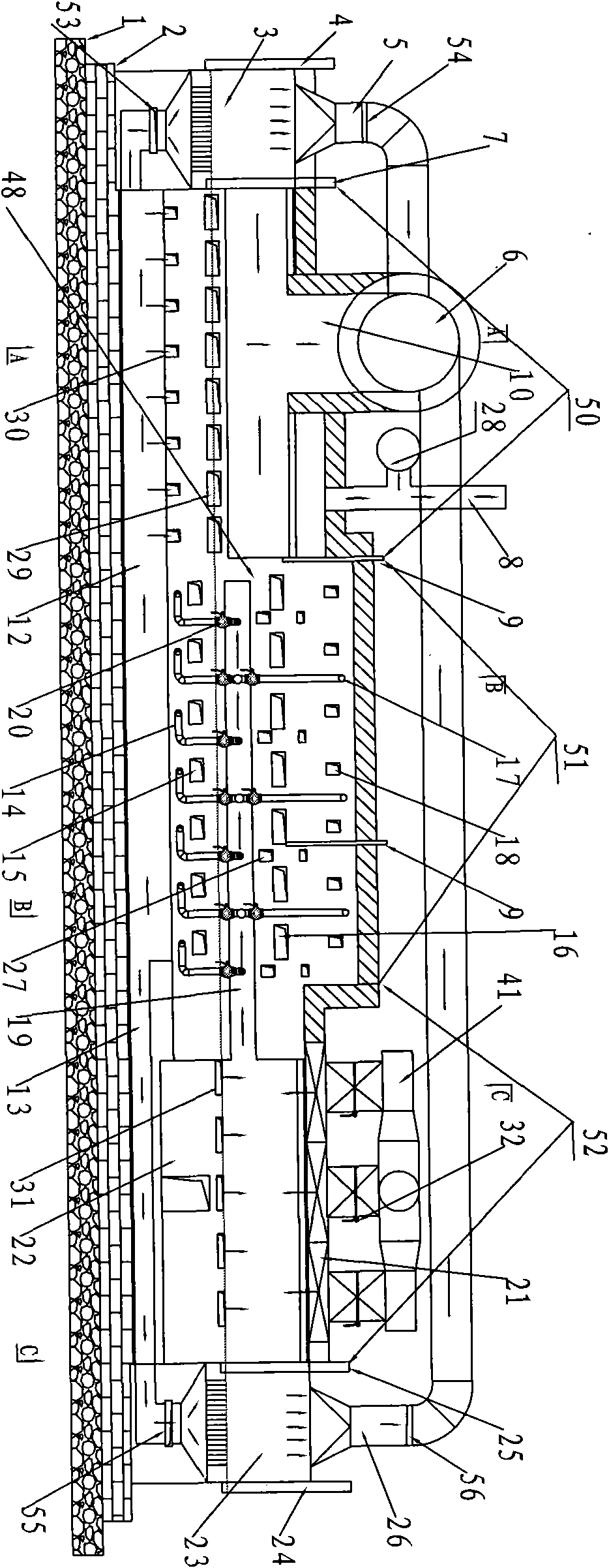

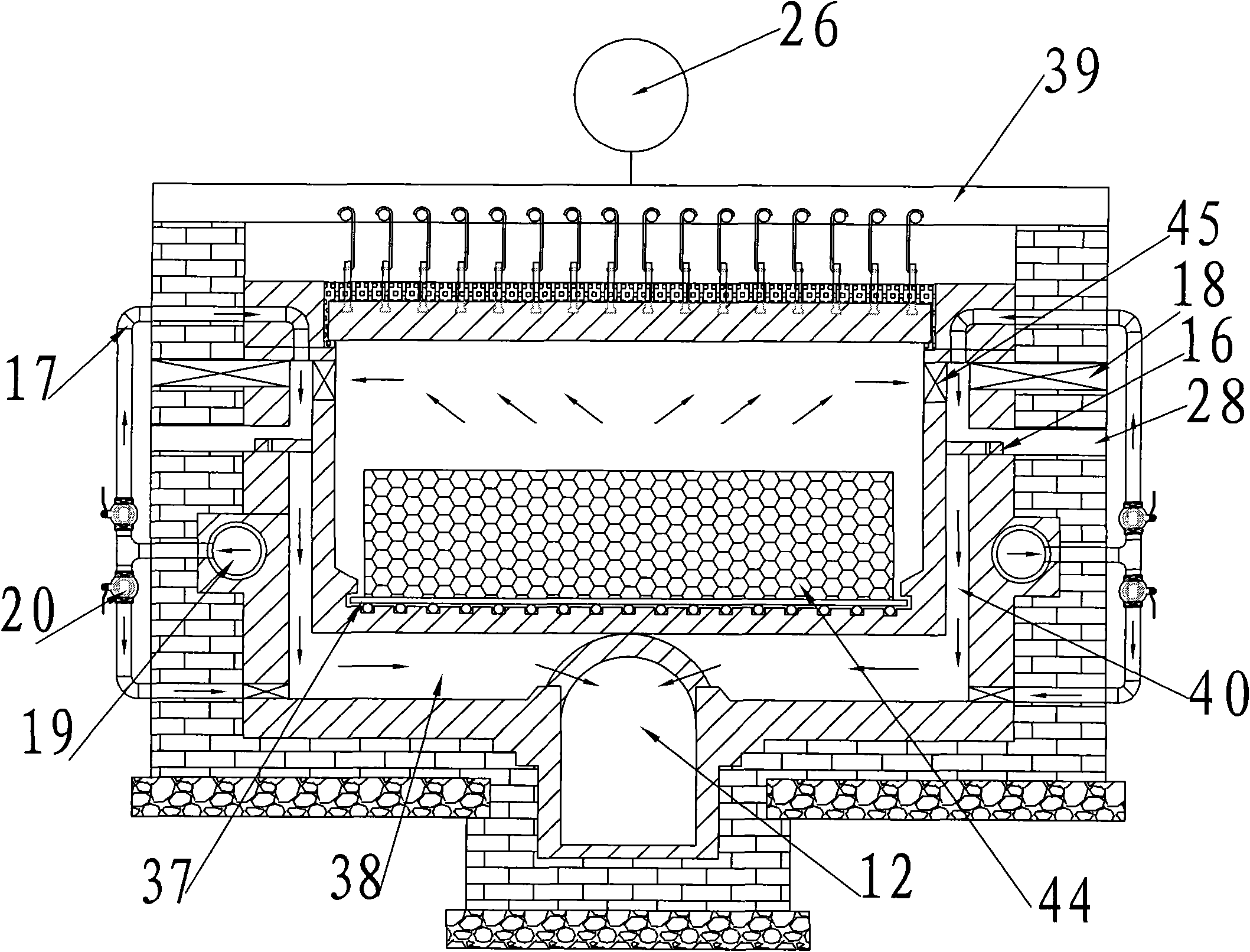

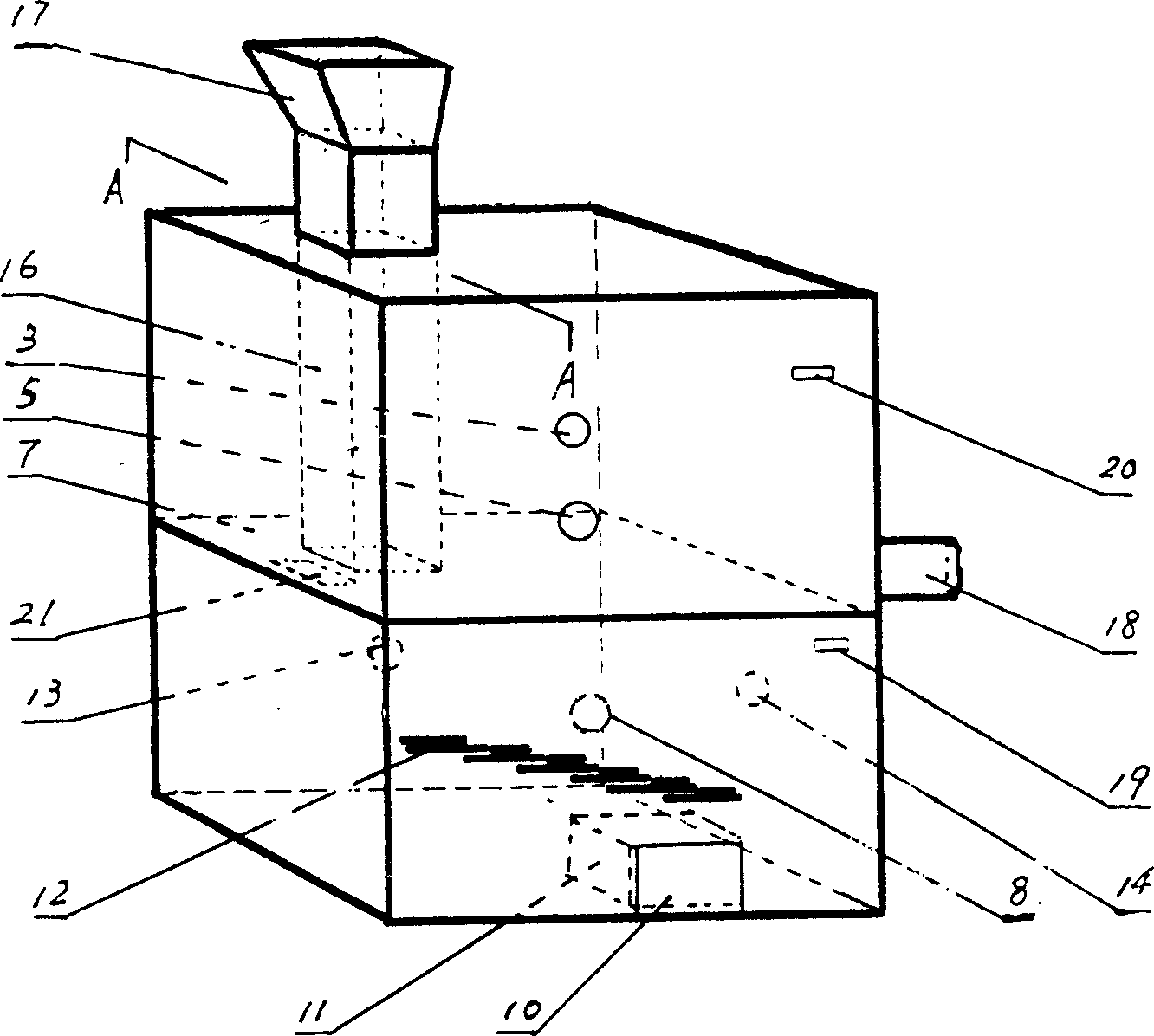

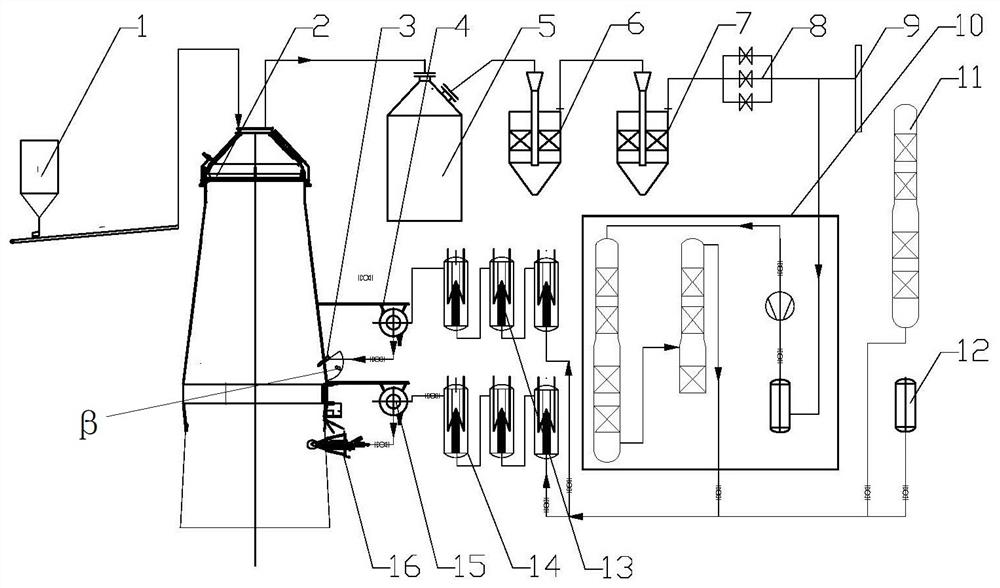

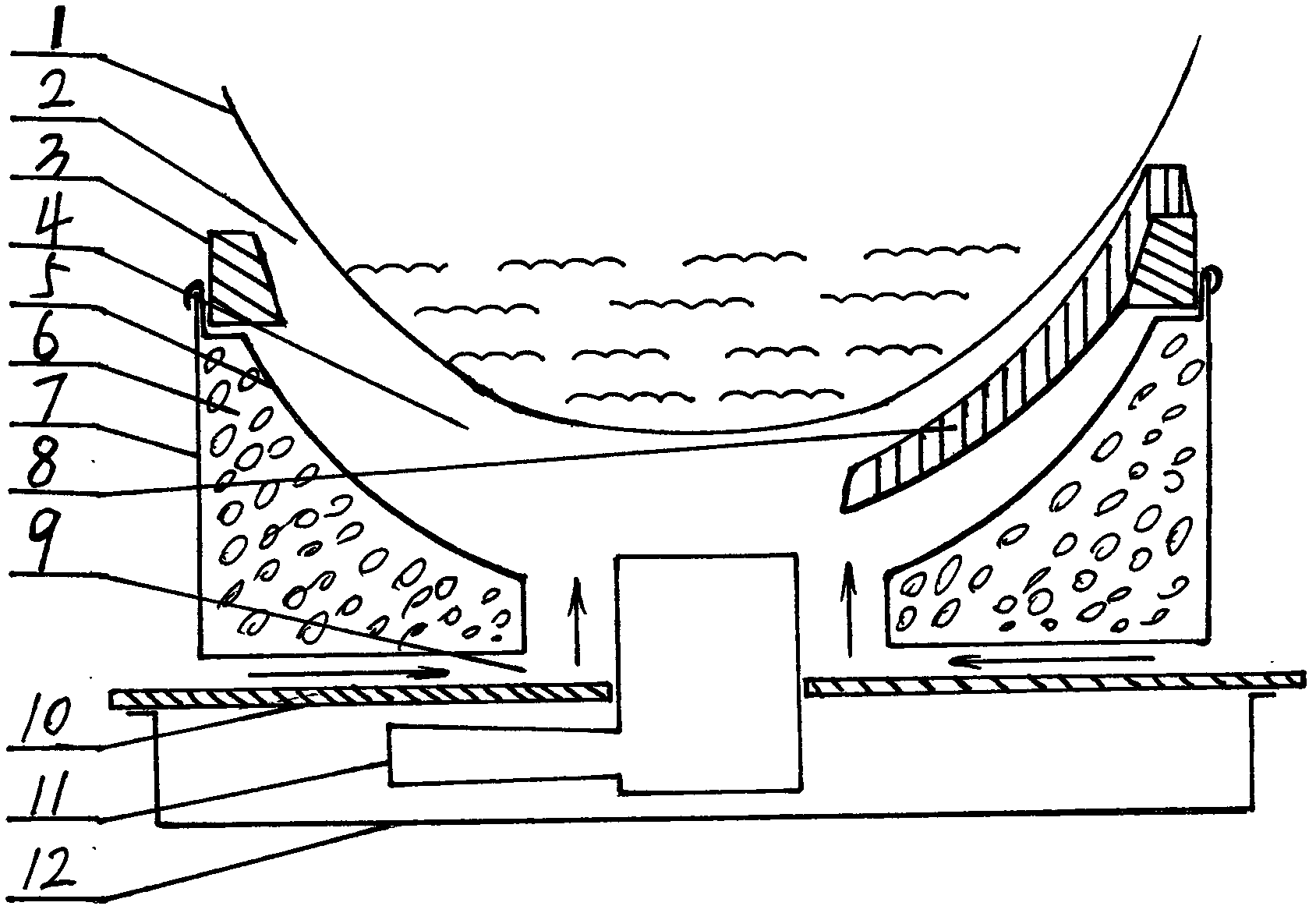

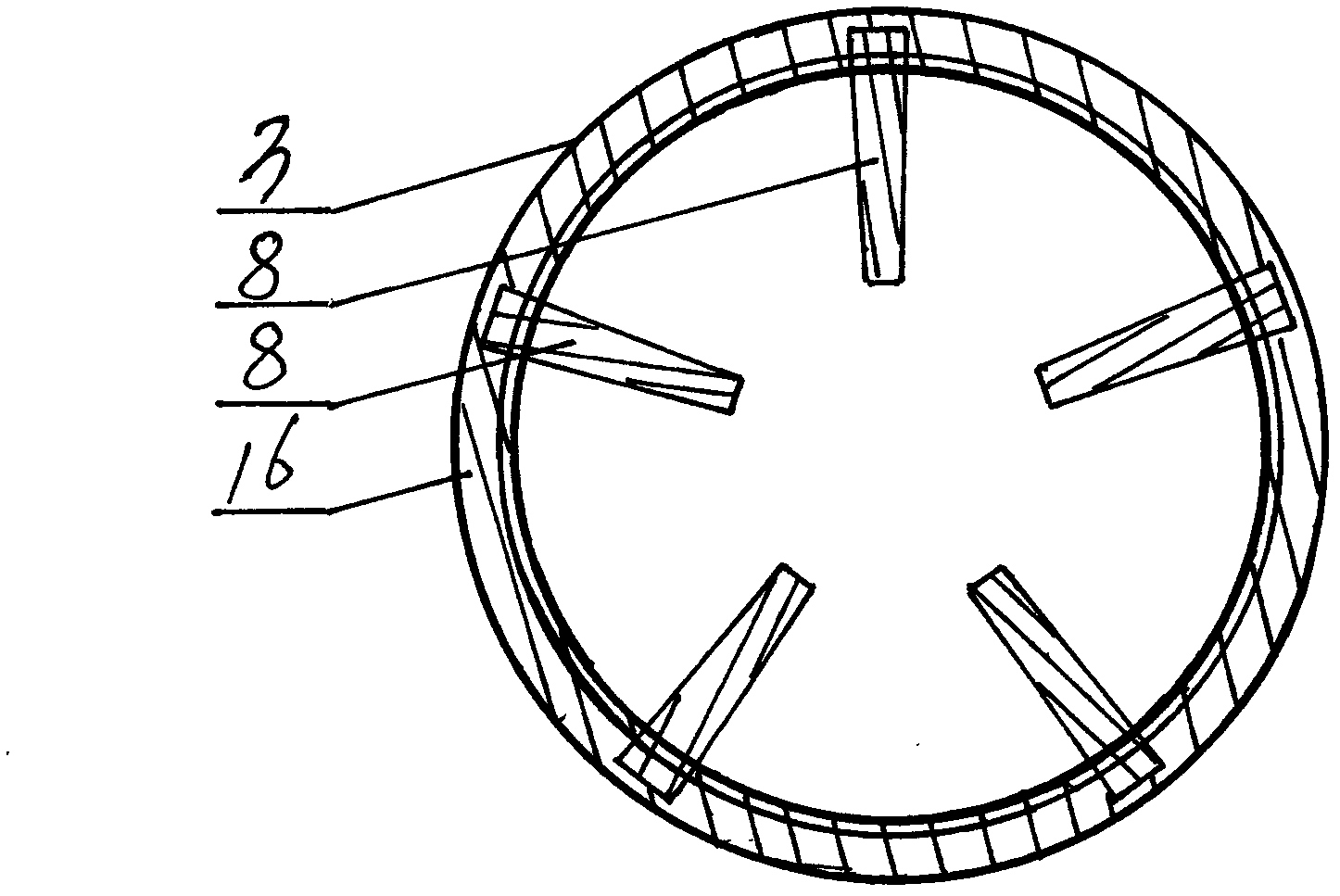

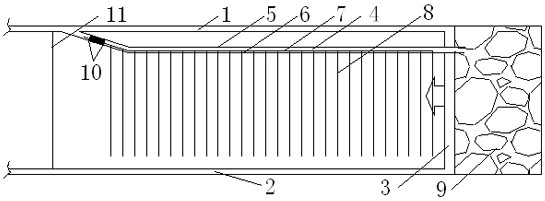

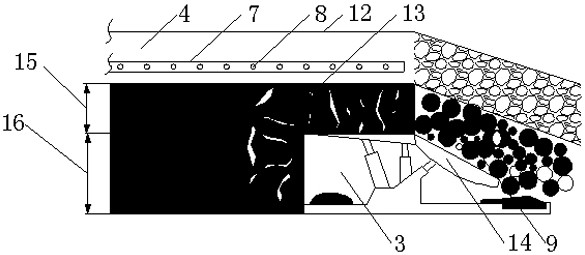

Movable slide bed tunnel type coke oven and use method thereof

InactiveCN101792676AReduce the amount of gasLow energy consumption for cokingMechanical conveying coke ovensHorizontal chamber coke ovensWater sourceFlue gas

The invention relates to a movable slide bed tunnel type coke oven and a use method thereof, and belongs to the field of coal processing and conversion and coking equipment. The coke oven comprises an oven body (48), a front sealing door (7) of the coke oven body, a back sealing door (25) of the coke oven body, a sub-flue (10), a bottom flue (12) and a main flue (6), and is characterized by comprising a coaling preparation chamber (3), a preheating section (50), a carbonization section (51), coke dry quenching section (52) and a coke outlet preparation chamber (23), each part has different structures, and the five parts are connected in series and communicated with each other; and a movable slide bed (37) of loading briquettes or tamping coal materials (44) sequentially pass through the five parts of the coke oven by intermittently moving on a slideway (35) of the slide bed, so that the coal materials are carbonized into coke. The produced coke has uniform specification, large lumpiness, good strength, high heat energy utilization rate, high degree of mechanization, and clean emission of flue gas, and the invention effectively protects atmosphere and water sources and realizes clean production.

Owner:GUIZHOU SUNNY CLEAN ENERGY TECH DEV

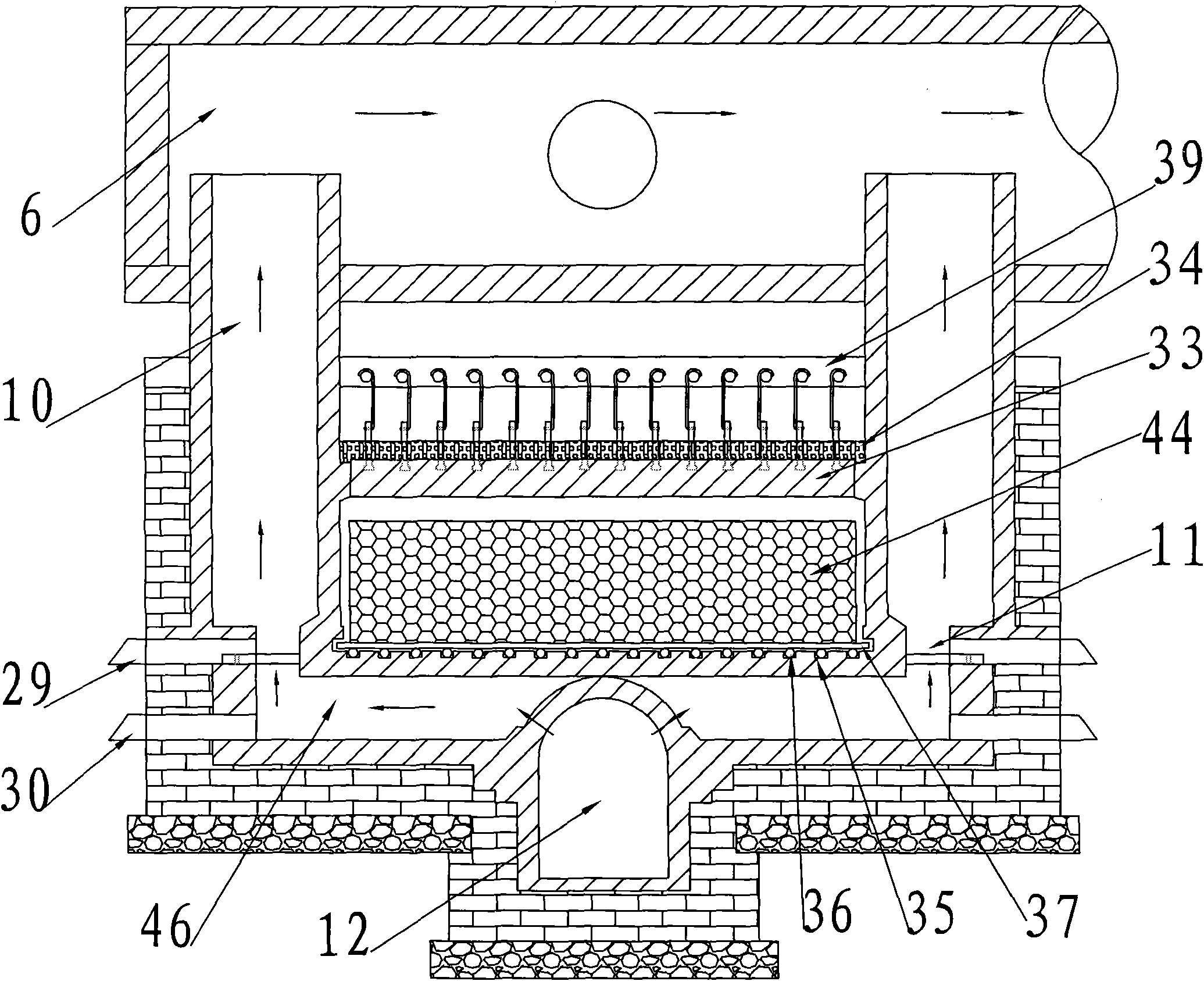

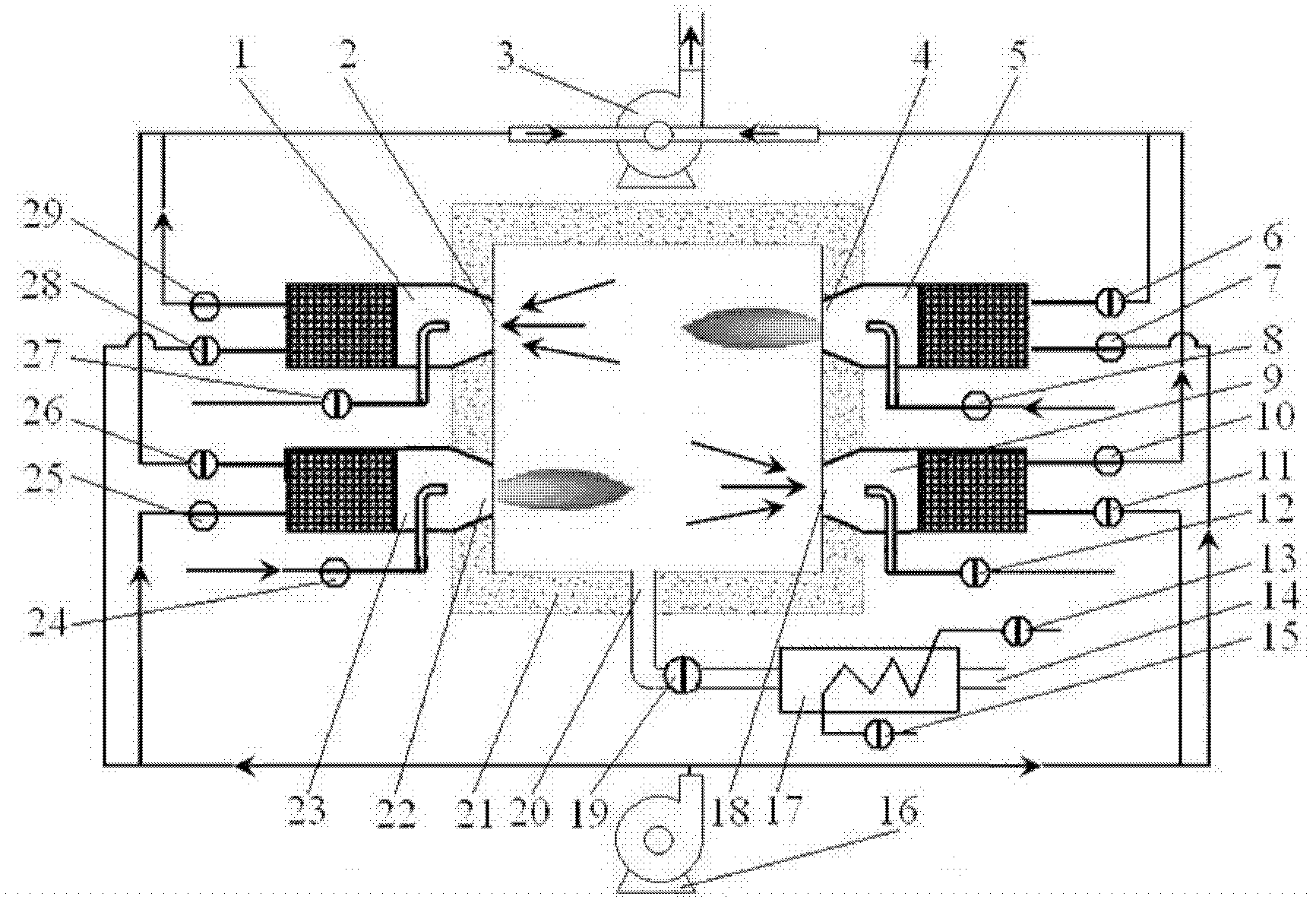

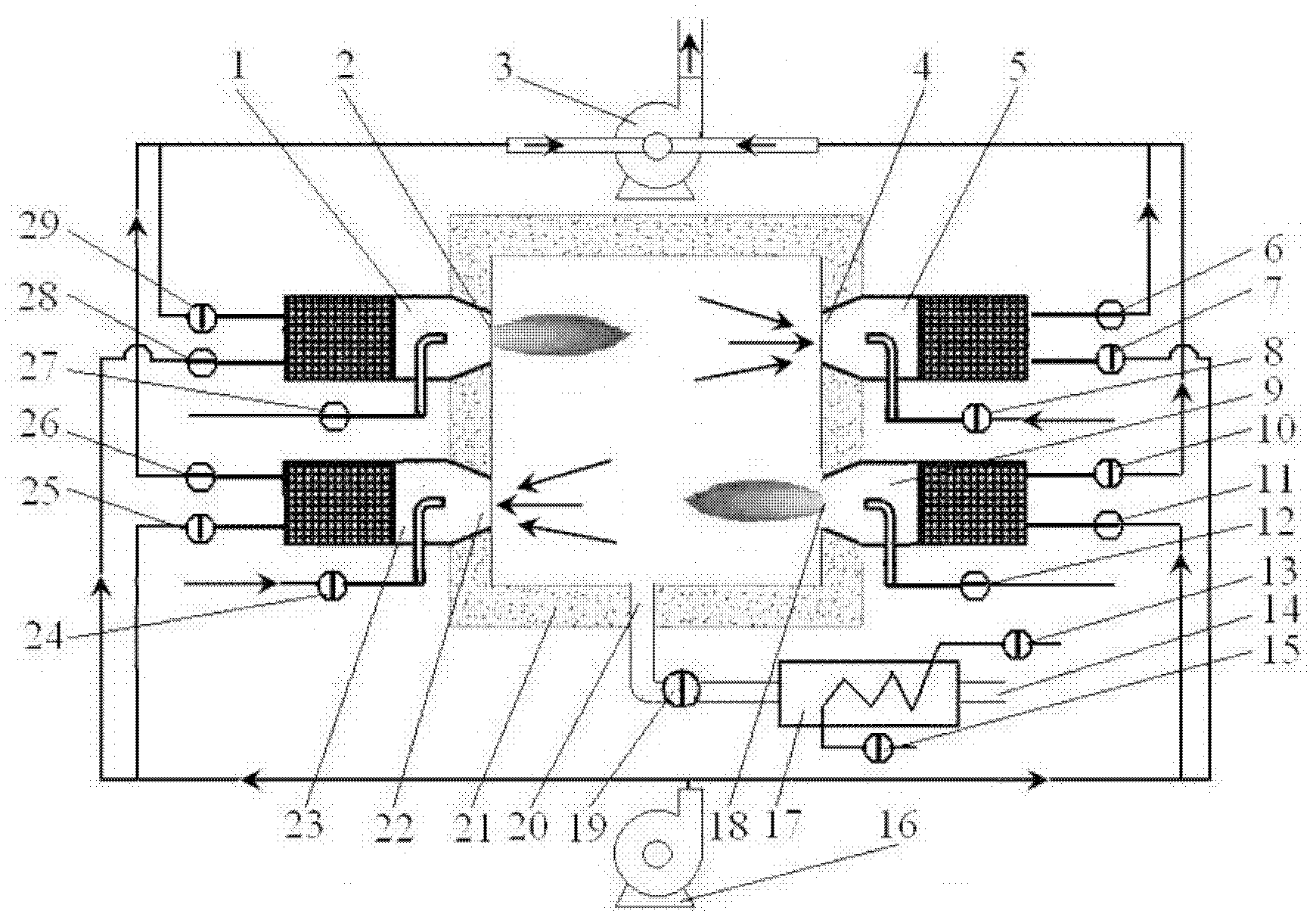

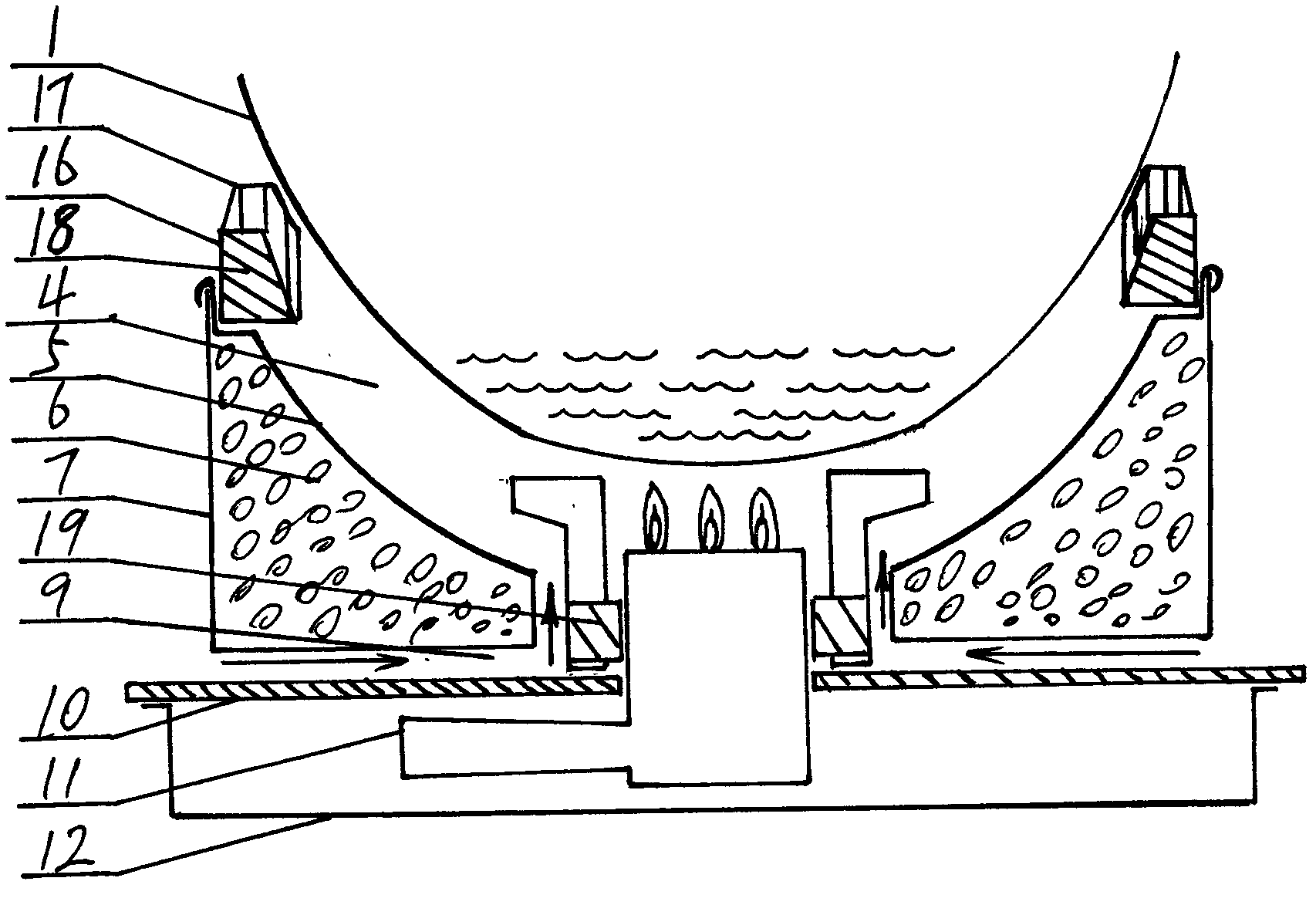

Energy-saving type shuttle type kiln

InactiveCN102564127AIncrease disturbanceUniform pressure distributionFurnace typesIncreasing energy efficiencyCombustorEngineering

The invention discloses an energy-saving type shuttle type kiln. The energy-saving type shuttle type kiln comprises a furnace body, at least one pair of heat-accumulating type combustors, a heat exchanger, corresponding valves, pipelines and a fan, wherein the combustors are arranged on the furnace body and are connected with the fan and a gas pipeline by the pipelines and the valves. When one of the combustors is in a combusting state, the other one is in a smoke-exhausting state, and the smoke stores heat in a heat-accumulating material in the combustors, and then is exhausted out of the system. When the preset time is up, the valves of the two combustors are switched, the combustor in the smoke-exhausting state is changed to be in the combusting state, and air absorbs the heat stored in the heat-accumulating material when passing through the combustor and carries the heat into a furnace so as to realize heat recovery. When a plurality of pairs of combustors are arranged, the working state of each combustor is opposite to that of the peripheral combustors so as to realize cross combustion. In the cooling process, heating and water supply are performed on the hot air by the heat exchanger on a spare flue, and the heat is absorbed by water so as to be utilized. The energy-saving type shuttle type kiln has the advantages that not only is the energy-saving effect obvious, but also the temperature distribution in the hearth is uniform, the temperature rising speed is high and the combustion temperature is high.

Owner:WUHAN ANHE ENERGY SAVING TECH

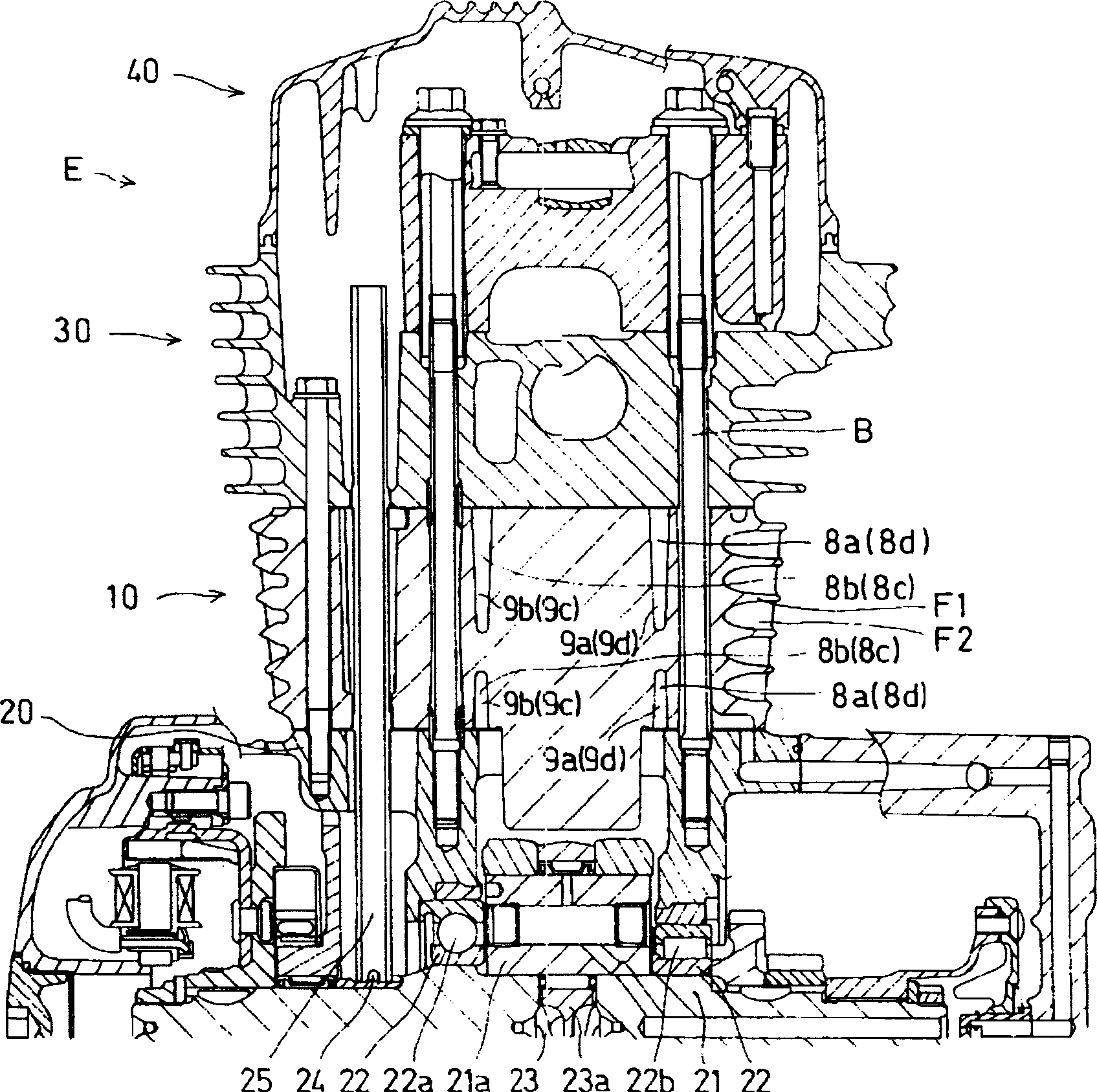

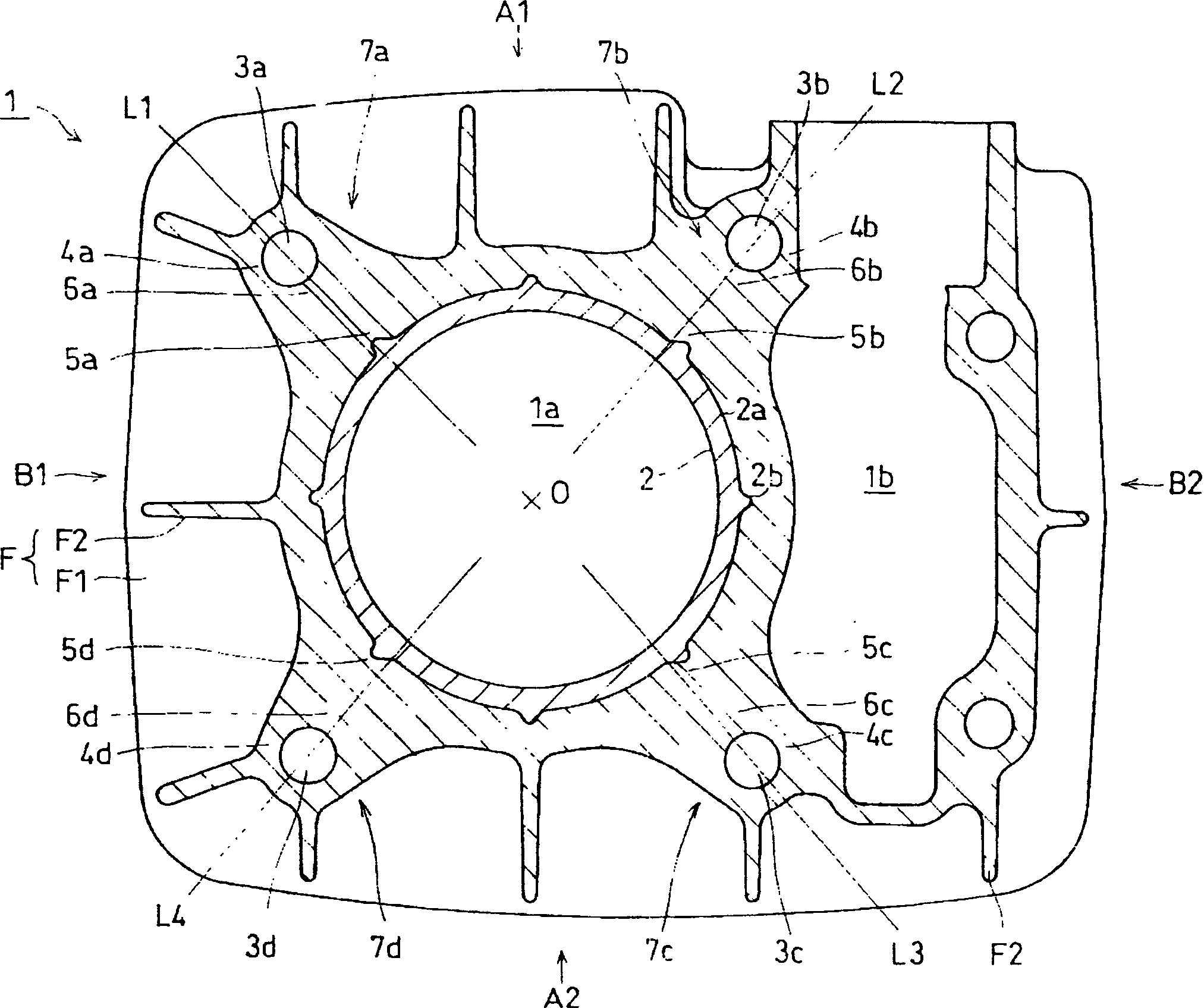

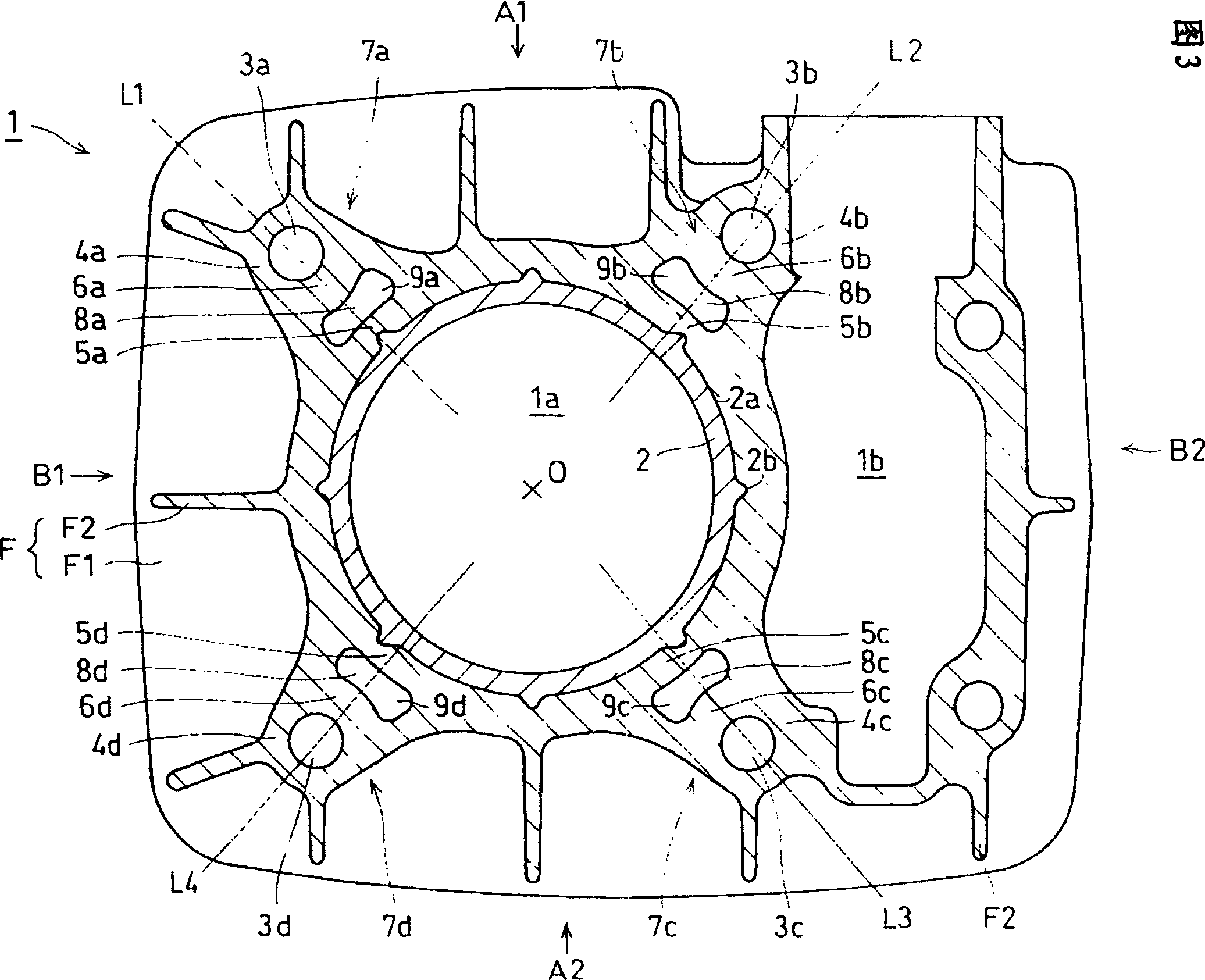

Valve device with cylinder stop mechanism of ic engine

InactiveCN1598277AEliminates partial clotting time differencesPrevent thermal deformationCylinder headsCylindersThick wallCylinder block

A cylinder block for an internal combustion engine, which is a cast cylinder block made of a light alloy that is integrally cast into the cylinder liner, and the wall thickness of the cast wall thickness part is uniform, so as to eliminate the solidification time difference of the cast wall thickness part in casting, And make the force holding the cylinder liner even. An iron cylinder liner (2) is integrally cast into the aluminum alloy cylinder block (1), and bolt holes for fixing the above-mentioned cylinder block (1) are provided on the aluminum casting part enclosing the outer peripheral portion (2a) of the cylinder liner (3a-3d). Therefore, the connecting portion connecting the peripheral portion of the bolt holes (3a-3d) and the outer peripheral portion of the cylinder liner (2a) is a wide and thick-walled connection casting portion (6a-6d), and the wide and thick-walled connection casting portion (6a-6d ) are provided with weight-reducing parts (8a-8d), thereby achieving uniform wall thickness of the aluminum casting part wrapped in the outer peripheral part (2a) of the cylinder liner.

Owner:HONDA MOTOR CO LTD

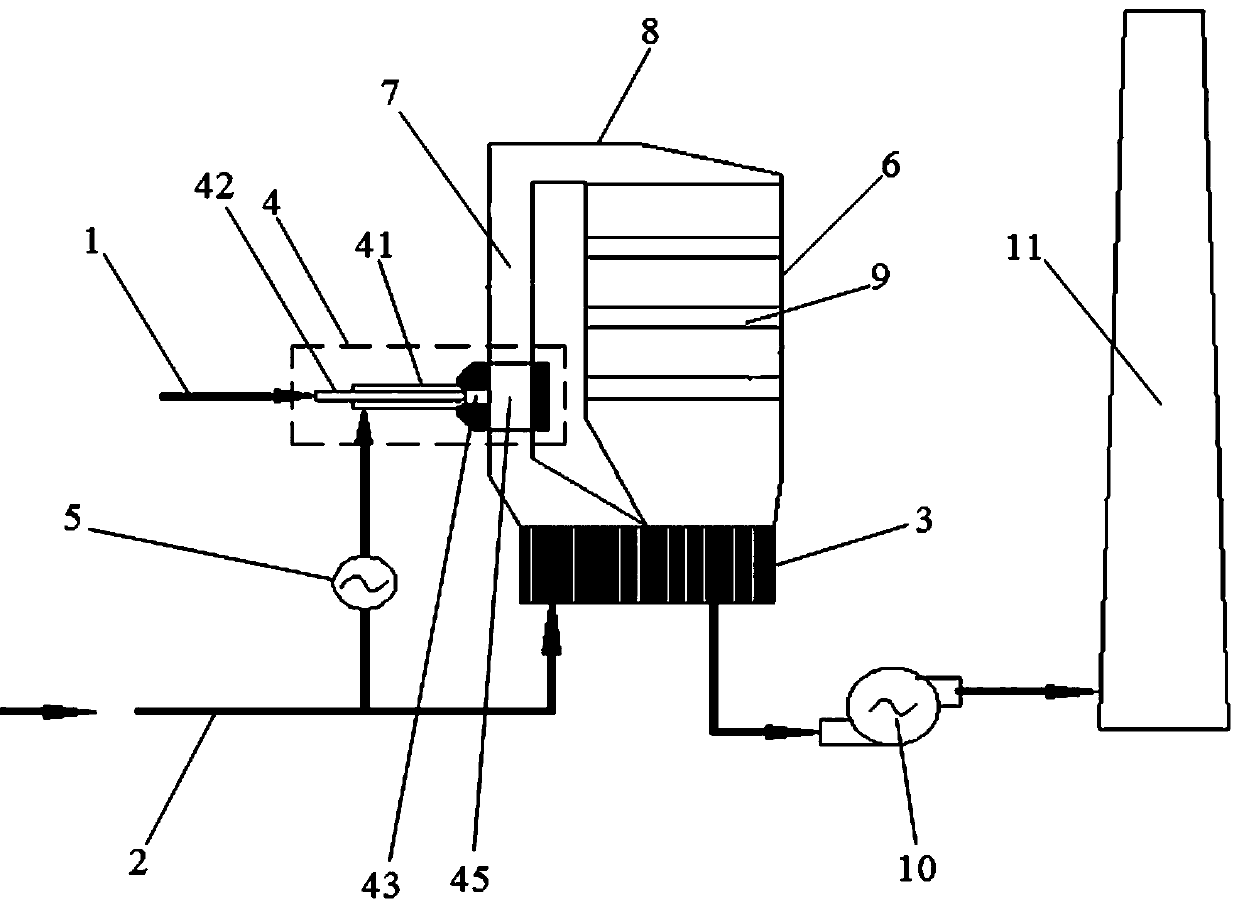

Sintering flue gas denitration direct-fired type heating device and method

PendingCN111306564AReduce CO contentEmission reductionEmission preventionIndirect carbon-dioxide mitigationPtru catalystCombustion chamber

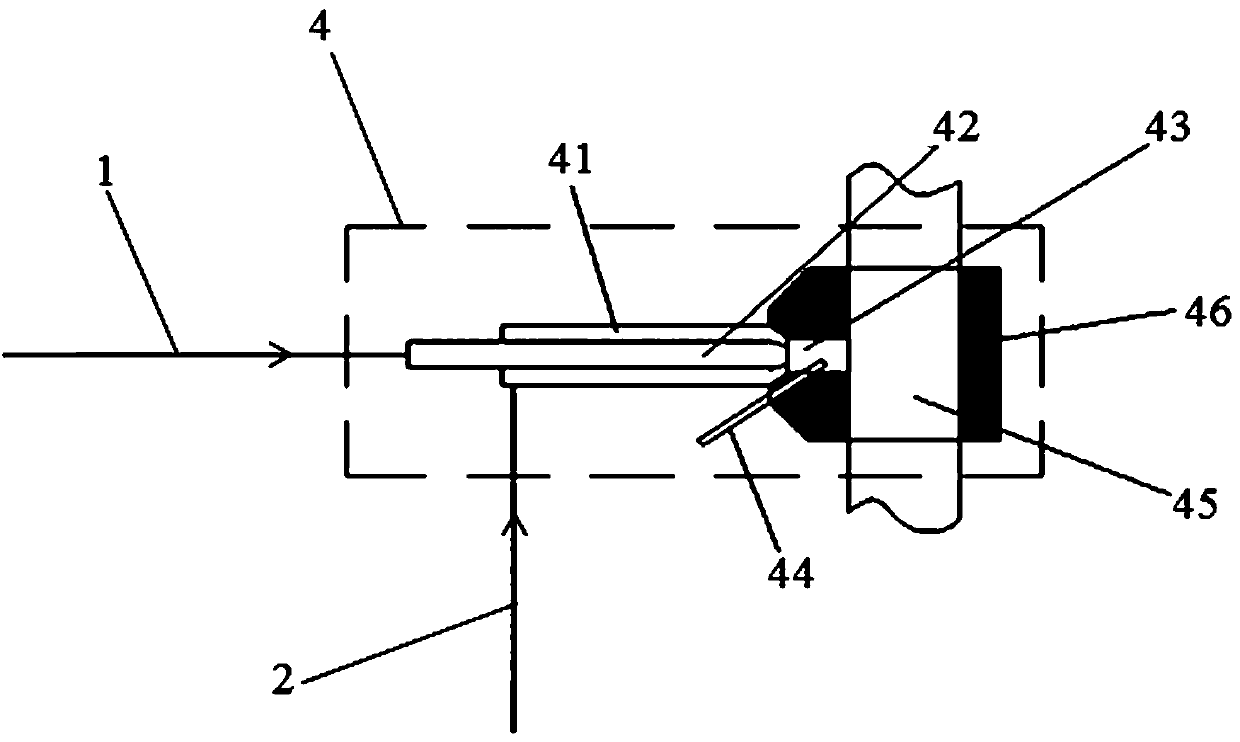

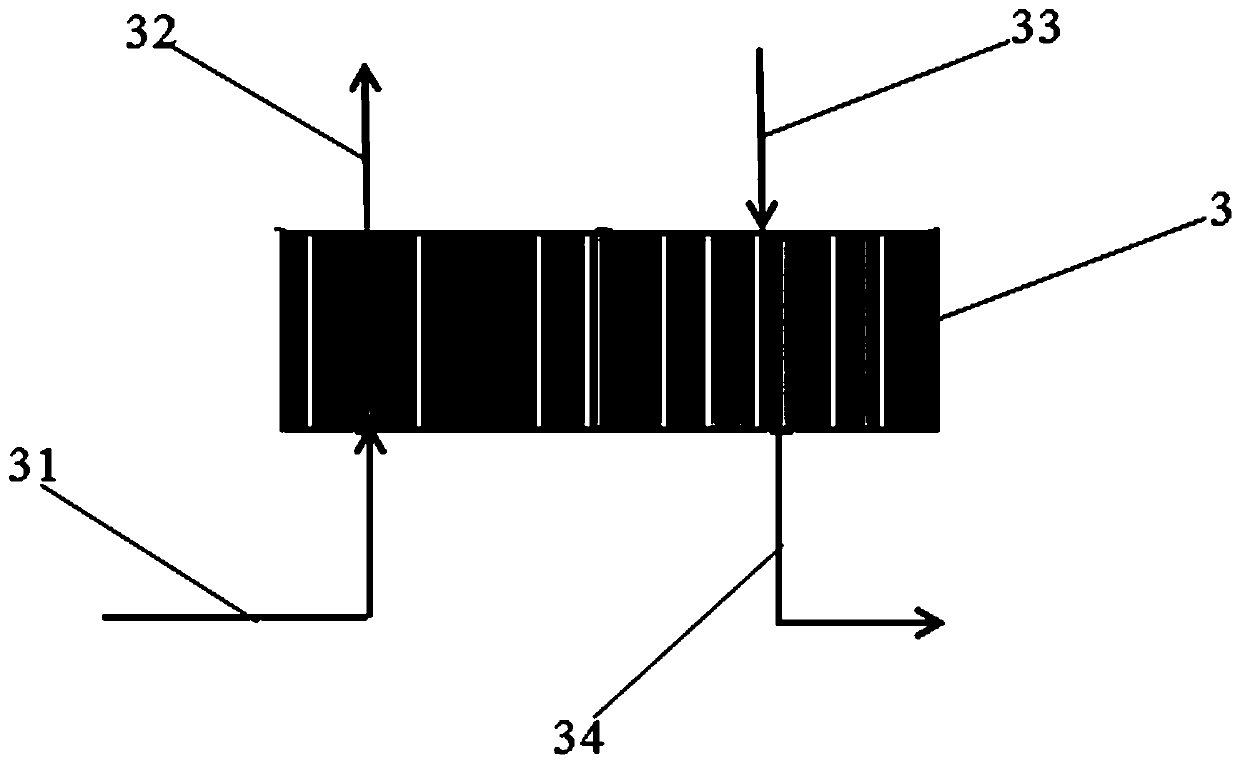

The invention relates to a sintering flue gas denitration direct-fired type heating device. The sintering flue gas denitration direct-fired type heating device comprises a gas pipe (1) and a sinteringflue gas pipe (2), wherein the gas pipe and the sintering flue gas pipe are respectively connected with a gas chamber (42) and an oxidant gas chamber (41) of a direct-fired heating device body (4), and the oxidant gas chamber (41) and the gas chamber (42) are sequentially connected with a mixing combustion chamber (43) and a flue gas heating chamber (45), an inlet of flue gas heating chamber (45)is connected with a GGH heat exchanger (3), an outlet of the flue gas heating chamber (45)is connected with a denitration flue (7), an ammonia injection gird (8) is arranged above the denitration flue (7), a denitration catalyst (9) is arranged in a denitration reactor (6), the denitration reactor (6) is connected with the GGH heat exchanger (3), the GGH heat exchanger (3) is connected with an induced draft fan (10), and an outlet of the induced draft fan (10) is connected with one chimney (11). The sintering flue gas denitration direct-fired type heating device has the advantages of ensuringthe denitration efficiency, reducing CO content in flue gas and heated gas volume, and energy conservation and emission reduction.

Owner:NANJING JINHAN ENVIRONMENTAL PROTECTION TECH CO LTD

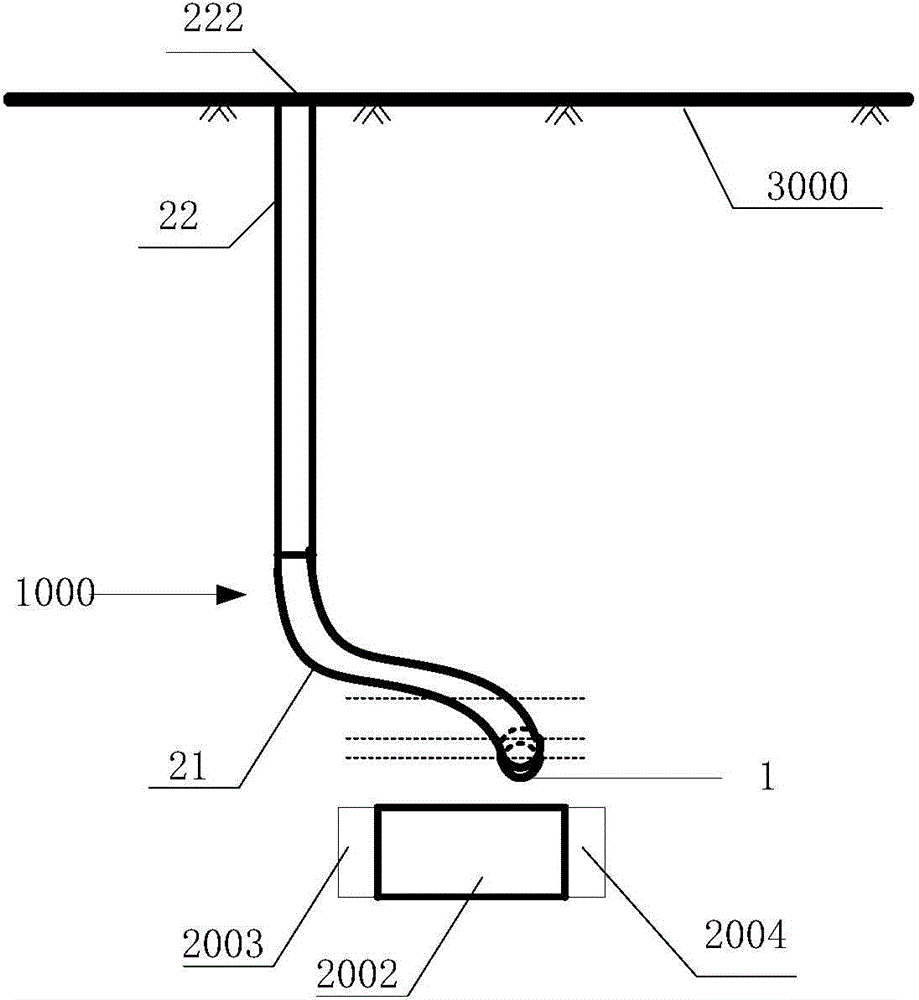

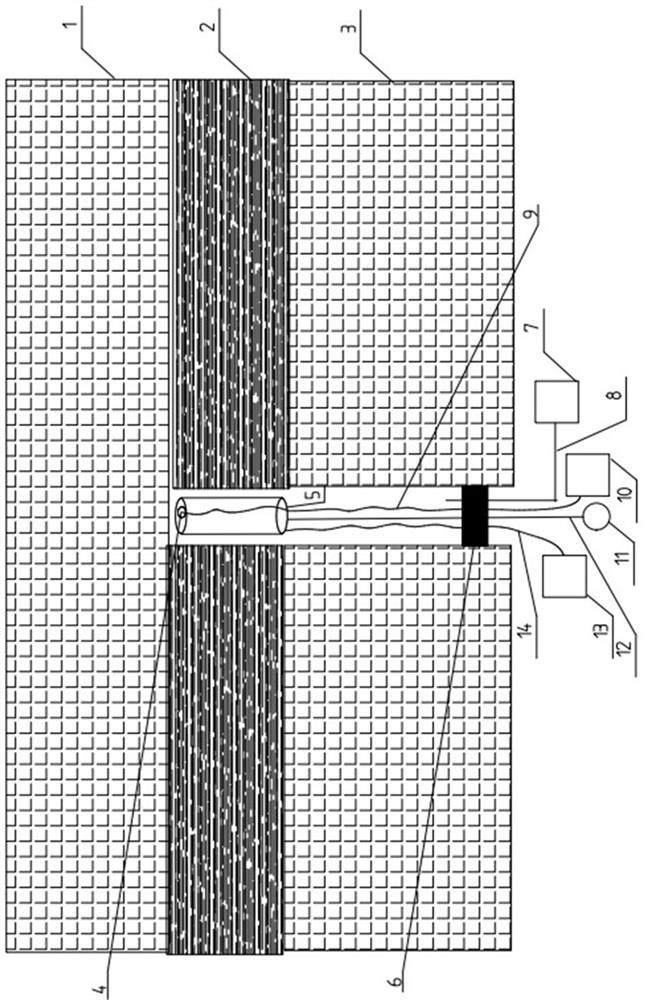

Ground composite L-shaped drilling well for gas control and gas control method

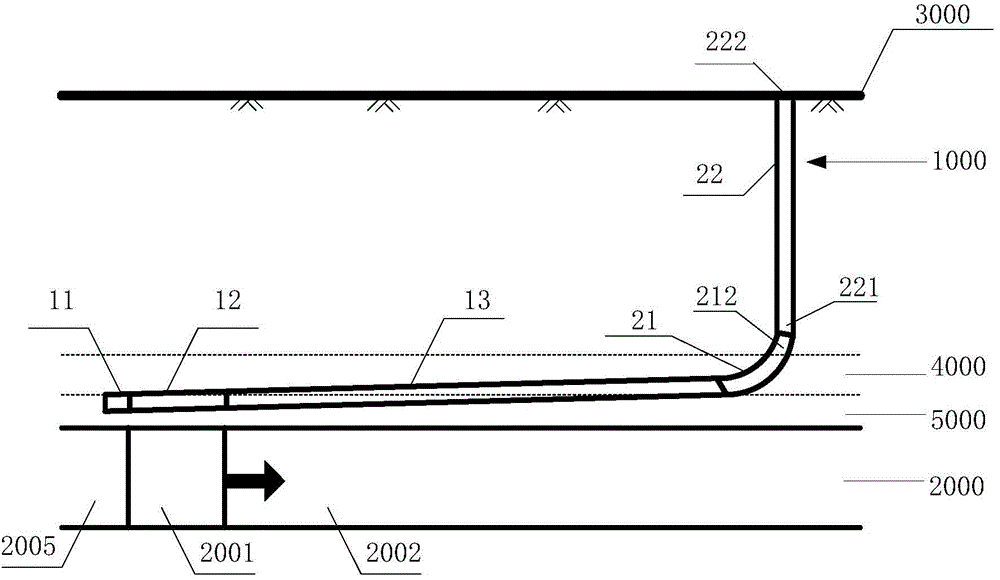

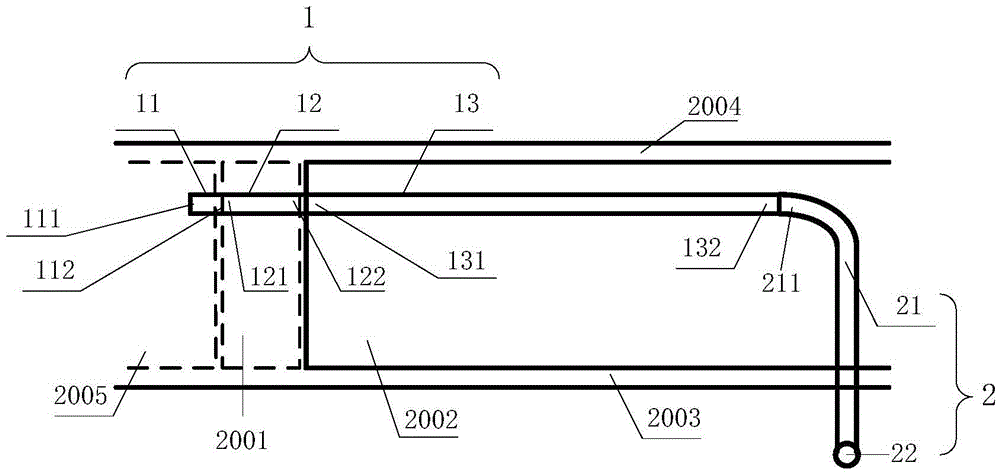

InactiveCN104594943ALess gushImprove securityFluid removalDirectional drillingProduction areaFissure

The invention provides a ground composite L-shaped drilling well for gas control and a gas control method. The ground composite L-shaped drilling well comprises a horizontal well section and an output well section, wherein the horizontal well section is positioned between a caving zone and a fissure zone above a first production layer, and comprises a first well passage, a second well passage and a third well passage, the first well passage is positioned above a goaf of the first production layer, the second well passage is positioned above a working surface of the first production layer, the third well passage is positioned above a to-be-produced mine body of the first production layer, the working surface is positioned at one side of the to-be-produced mine body, the goaf is positioned at one side, away from the to-be-produced mine body, of the working surface, the output well section comprises a first pipeline and a second pipeline, the second pipeline is positioned at the outer side of the first production layer, a first pipe opening of the first pipeline is communicated with a sixth opening end of the third well passage, and a fourth pipe opening of the second pipeline is connected with ground. The ground composite L-shaped drilling well is used for sucking and producing the gas enriched in the production area of the first production layer.

Owner:DATONG COAL MINE GRP +3

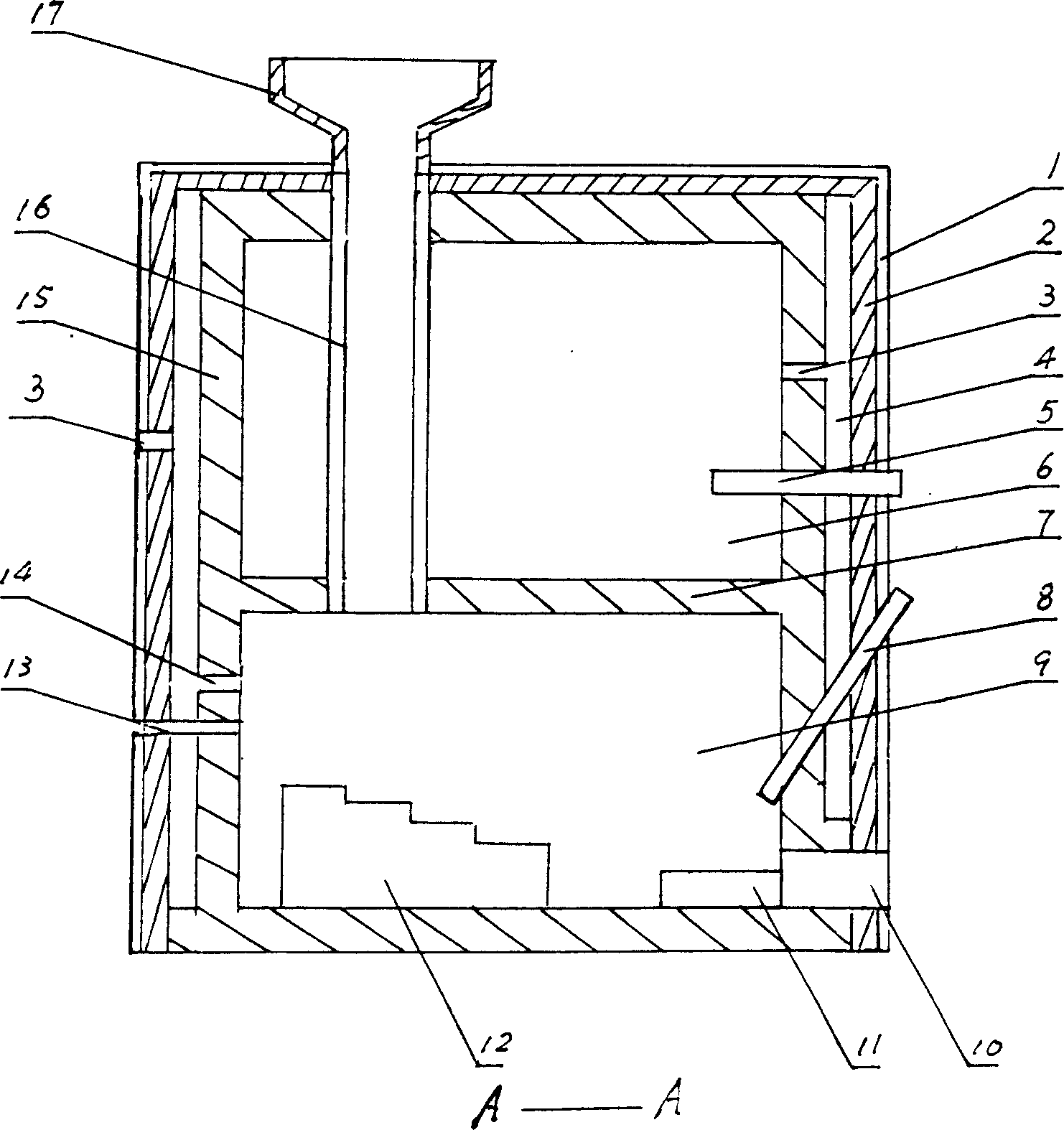

Garbage treating plant with low energy consumption and treating method thereof

InactiveCN1737427AImprove energy consumptionReduce energy consumptionIncinerator apparatusCombined combustion mitigationFiberCarbon fibers

This invention discloses a garbage disposal device, which comprises plasma garbage incineration furnace, fuel system, air supply system and tail-gas processing system, wherein the incineration furnace burning room are separated into two chambers, the top chamber has feeding box, low-power plasma generator, lateral air inlet, tail-gas discharging port and temperature testing system, the lower chamber has lateral gas air spout, air inlet and temperature testing system, the bottom has slag mobile stokers; the dissepiment of the two chambers have a gas channel port; the tail-gas processing system comprises chiller which is connected with the tail-gas discharging port, the neutralizing washing tower, carbon fiber absorption tower, draught fan, air-out chimney, washing liquid supplying box and waste liquid tank connecting with the neutralizing washing tower, the chiller hot-water pipe and waste water tank connecting with the carbon fiber absorption tower.

Owner:董俊

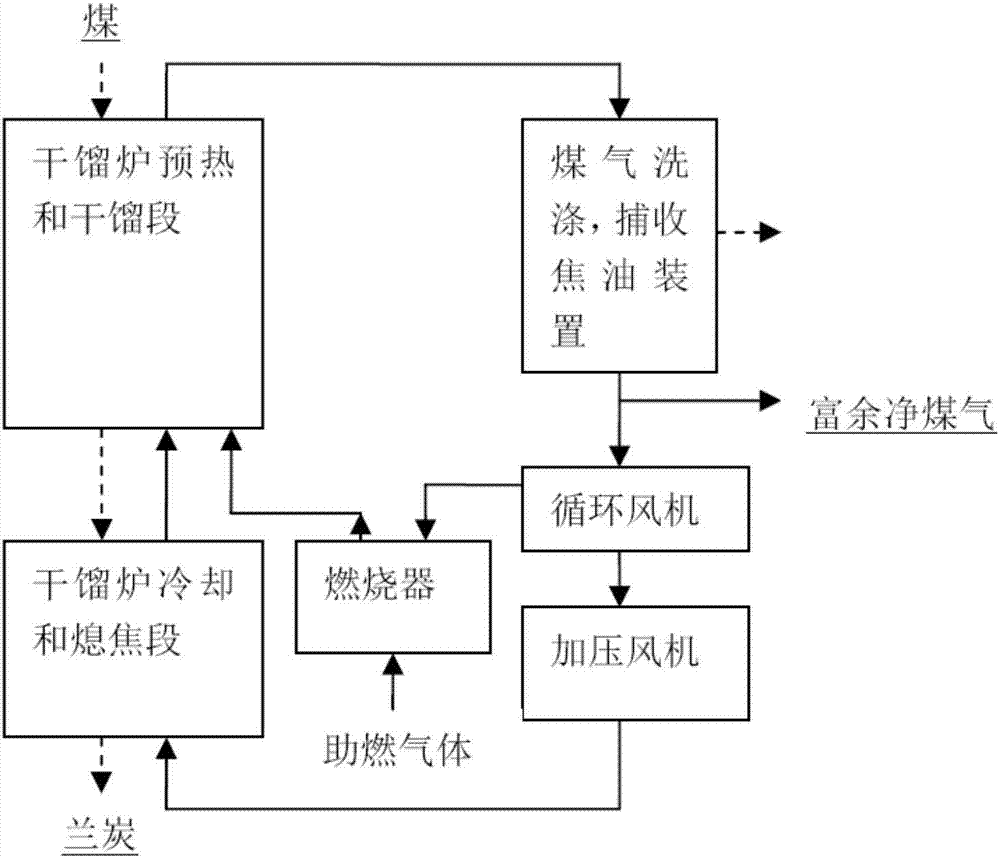

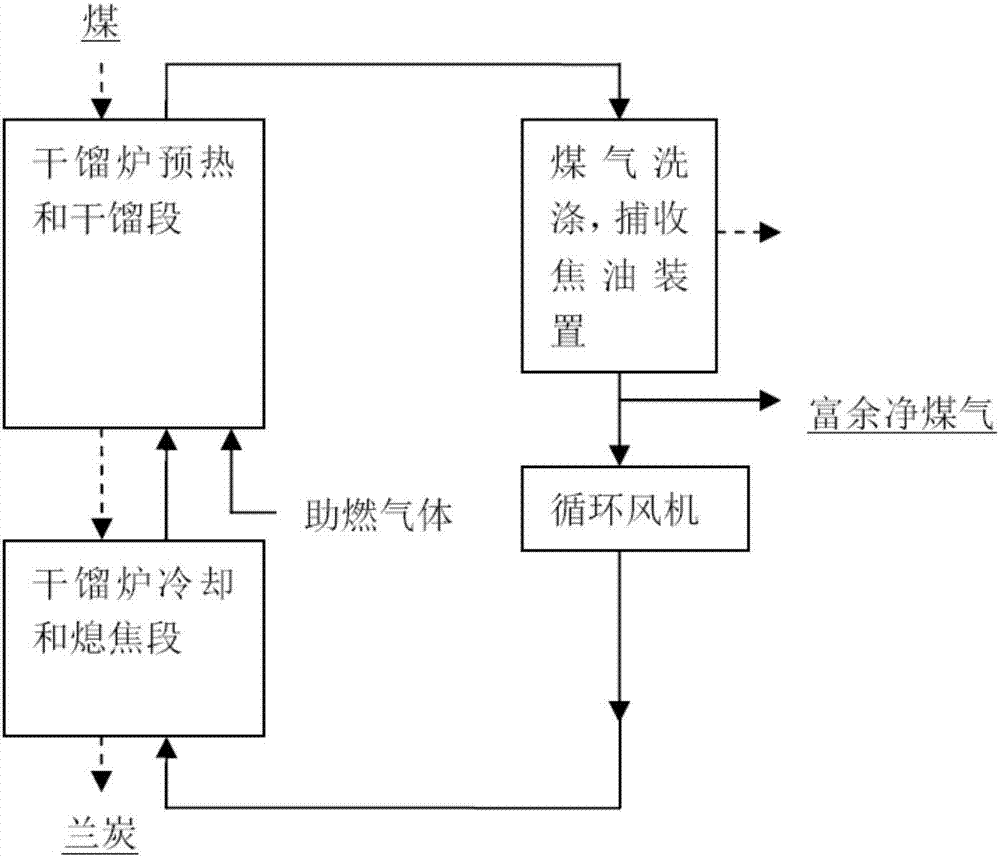

Dry quenching gas regulation method of coal internal heat low temperature pyrolysis

InactiveCN107189794AAchieve flameless combustionFlexible adjustmentCoke quenchingCombustible gas coke oven heatingCombustorQuenching

The invention discloses a dry quenching gas regulation method of coal internal heat low temperature pyrolysis. The method comprises: performing tar separation and collection to gas which is generated from a pyrolysis segment through pyrolysis, returning a part of cool purified gas to a quenching segment, allowing heat transfer to be carried out between hot semi-coke in the quenching segment and the part of cool purified gas to reduce the temperature of semi-coke to a non-reignition temperature, and discharging the hot gas; leading the hot gas after heat transfer from the quenching segment to the pyrolysis segment; leading a combustion-supporting gas from micropores of a lattice wall or a gas distribution channel to the pyrolysis segment, allowing the combustion-supporting gas to meet the hot gas for combustion; and mixing high-temperature gas produced from combustion with uncombusted hot gas to form high-temperature mixed gas meeting the temperature and flow of low temperature pyrolysis requirements, and performing heat transfer between the high-temperature mixed gas and coal in the pyrolysis segment so as to carry out coal pyrolysis. According to the method, in a situation that the circulating gas amount in the pyrolysis segment is basically kept constant, the gas circulating amount in the quenching segment is further increased, so that the quenching effect is ensued, and the physical heat of semi-coke can be fully used, and therefore, the energy saving effect is good. According to the method, since no dependent combustor, combustion gas blower fan, pipeline or valve is required, so that the system is further simplified.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

Iron-making system of hydrogen-rich and carbon-rich circulating blast furnace

ActiveCN114438267AIncrease gas production capacityIncreased degree of indirect reductionBlast furnace componentsBlast furnace detailsSlagCoke

The invention discloses an iron-making system of a hydrogen-carbon-rich circulating blast furnace, which comprises a hydrogen-carbon-rich circulating blast furnace, the hydrogen-carbon-rich circulating blast furnace is used for iron-making to obtain molten iron and generate slag and blast furnace top gas; the dust removal device is respectively communicated with a blast furnace top gas outlet of the hydrogen-rich carbon circulating blast furnace, the top gas circulating CO2 carbon removal device and the heating device; pure oxygen with the oxygen content of 100%, heated high-temperature coke oven gas and high-temperature decarburized gas are sprayed into the hydrogen-rich carbon circulating blast furnace, ore and coke are added to the furnace top, furnace top gas is introduced into a decarburization device, CO2 in the furnace top gas is removed through an alcohol amine method, high-temperature gas is formed, and the high-temperature gas is sprayed into the hydrogen-rich carbon circulating blast furnace; the ironmaking system comprises a hydrogen-carbon-rich circulating blast furnace and a furnace top gas circulating decarburization and heating injection system, an oxygen tuyere and a composite tuyere device for injecting gas are annularly arranged on a hearth of the hydrogen-carbon-rich circulating blast furnace, and a furnace body heating gas inlet is formed in the middle lower part of a blast furnace body.

Owner:XINJIANG BAYI IRON & STEEL

Energy-saving gas stove

InactiveCN103032904AReduce lossesEmission reductionDomestic stoves or rangesLighting and heating apparatusRadiation lossCombustion chamber

The invention relates to an energy-saving gas stove, which comprises an energy-gathering heat-insulation reflecting cover 7, a stove end 11, a stove body panel 10, a combustion cavity 4, a stove frame A3, a stove frame B18, a support frame 19, a gas control ring 22 and a bottom case 12. The energy-saving gas stove is characterized in that a pot 1, the energy-gathering heat-insulation reflecting cover 7, the stove end 11, the stove frame A3 or the stove frame B18 and the gas control ring 22 jointly form the combustion cavity 4, fuel gas is sprayed out from the stove end 11 for combustion, supplementary secondary air enters the combustion cavity 4 via a secondary supplementary air passage 9 and gas holes 23, the combustion of the fuel gas is carried out in the combustion cavity 4, and combusted smoke gas is exhausted from a smoke gas outlet 2 or a smoke gas outlet 13. The energy-gathering heat-insulation reflecting cover technology is adopted, the open external combustion type combustion of a domestic gas stove is changed into the semi-closed internal combustion type combustion, the heat radiation loss and the convection loss caused by the open state are reduced, the temperature in a combustion chamber is raised, the generation of harmful gas is reduced because of full combustion, the heat utilization rate is increased, the fuel gas consumption is saved, and the goals of energy protection and energy saving are reached.

Owner:张金毅

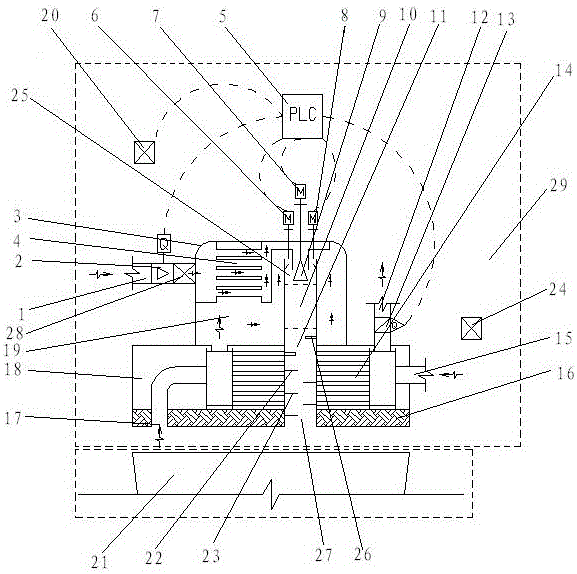

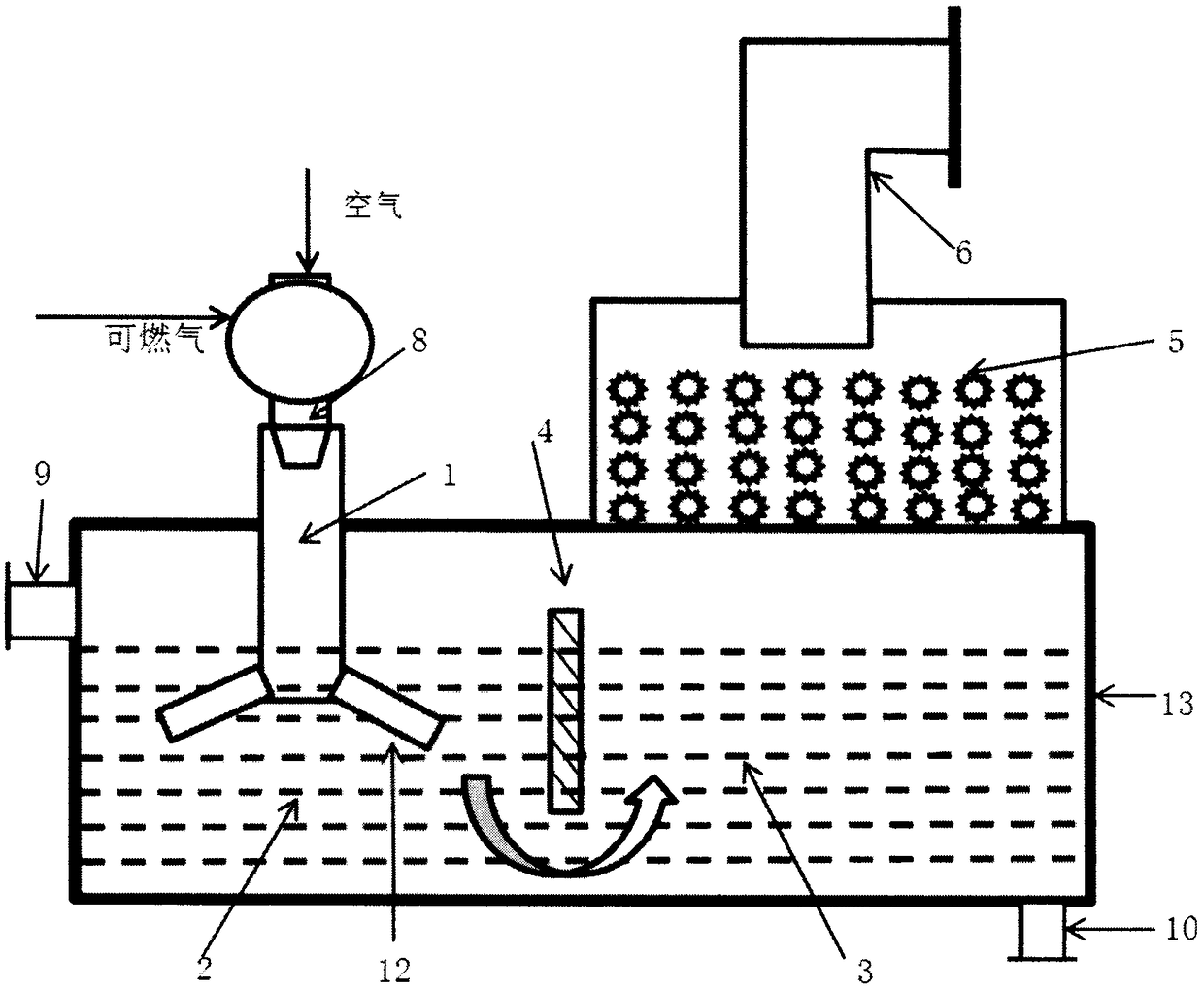

Efficient ladle baking device

The invention provides an efficient ladle baking device. The efficient ladle baking device comprises a baking device body, a cover and a flame retardant layer, wherein the lower end of the baking device body is connected with the upper end of the cover; the lower end of the cover is connected with the flame retardant layer; the lower end of a burner composed of a conical body, a flow mixing cavity, an electronic igniter, a combustion cavity and a firing stabilizer is arranged at the lower end of the flame retardant layer, and the upper end of the burner is arranged on the upper portion inside the baking device body; the upper end of the burner is connected with an air cavity through an electric adjustment valve; an air heat exchanger is installed on the lower portion of the air cavity; one end of the air heat exchanger is connected with a smoke inlet, and the other end of the air heat exchanger is connected with a smoke outlet; an air inlet is formed in the lateral surface of the cover; the upper end of the burner is provided with a fuel gas inlet communicating with an outlet of a fuel gas heat exchanger; the conical body is arranged at the fuel gas inlet of the burner; an inlet of the fuel gas heat exchanger is connected with a fuel gas pipeline through a fuel gas valve and a flowmeter; and the ladle baking device is further provided with an intelligent control device. The efficient ladle baking device has the advantages of saving energy and labor, improving safety performance and the like.

Owner:大连新瑞晨环保科技有限公司

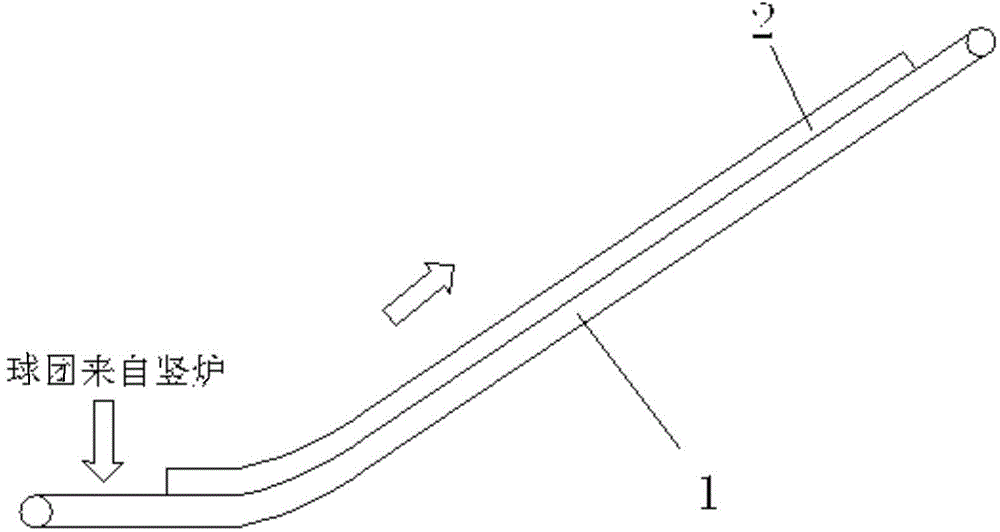

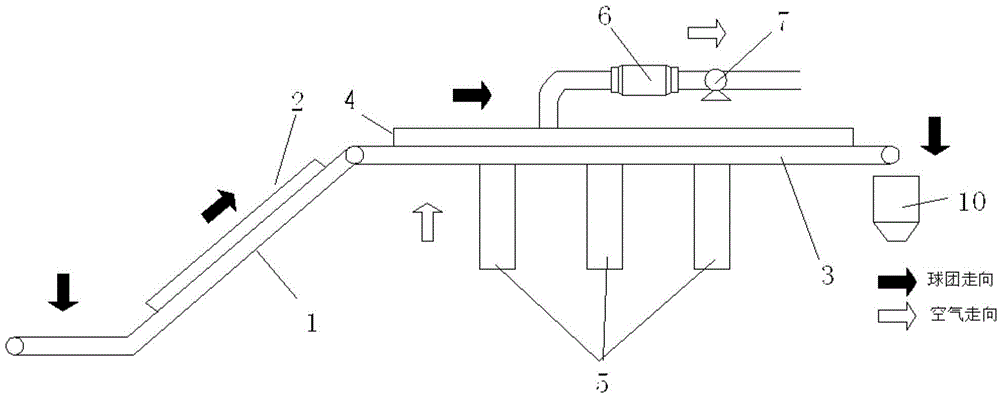

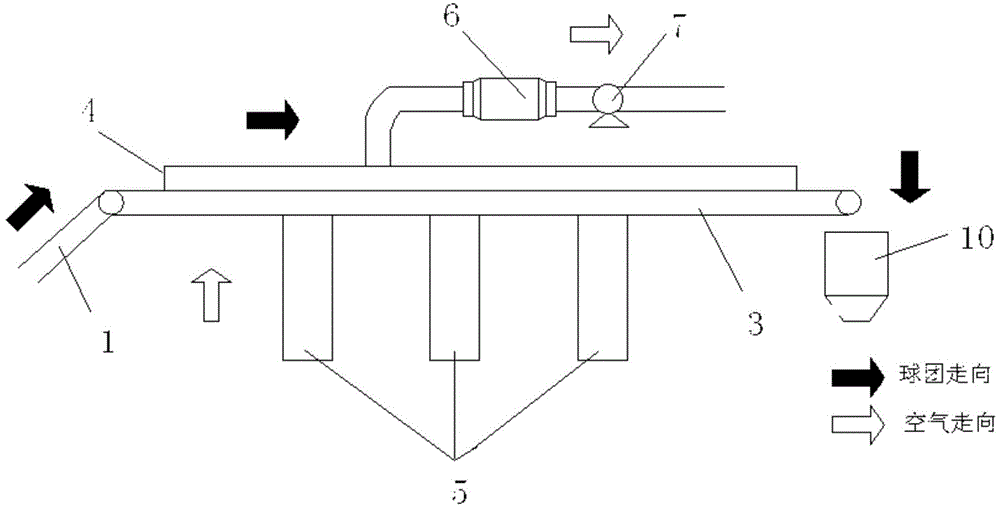

Shaft furnace pellet clinker waste heat recycling method and device

ActiveCN104913652AReduce moisture contentEvenly heatedHandling discharged materialWaste heat treatmentThermodynamicsClinker (waste)

The invention discloses a shaft furnace pellet clinker waste heat recycling method and device. The temperature of pellet clinkers coming from a shaft furnace exceeds 550 DEG C, then the clinkers are conveyed to a clinker bin through a chain-slat conveyer and a belt cooler, and in this process, pellets dissipate heat outwards in a radiation mode. The pellet clinker waste heat can heat cooling air of the belt cooler through sealing of the chain-slat conveyer and the belt cooler, then hot air is subjected to dedusting processing through a dust remover and then is distributed by a pipeline, and a part of hot air is used for the shaft furnace and a drying kiln to support combustion of air, so that the temperature of combustion-supporting air of the shaft furnace and the drying kiln is improved and gas is saved; another part of hot air is used for predrying wet pellets on a discharging belt of the shaft furnace, and the gas consumption is reduced; the left air is used for the shaft furnace to cool air. The shaft furnace pellet clinker waste heat recycling method and device is obvious in energy conservation effect, small in operation and maintenance workload, low in operation cost, high in economic benefit and capable of reducing the enterprise cost and reducing environment pollution.

Owner:CENT SOUTH UNIV

Low-heating-value gas burner and hot blast heater

The invention relates to the technical field of hot blast heaters, in particular to a low-heating-value gas burner and a hot blast heater. The low-heating-value gas burner comprises an external main burner and an internal auxiliary burner; the external main burner comprises an outer distribution tube, a plurality of first gas pipelines and a plurality of first nozzles, wherein the first gas pipelines are arranged in the outer distribution tube, and the first nozzles are correspondingly connected to the first gas pipelines one to one; the internal auxiliary burner comprises an inner distribution tube, a plurality of second gas pipelines and a plurality of second nozzles, wherein the second gas pipelines are arranged in the inner distribution tube, and the second nozzles are correspondinglyconnected to the second gas pipelines one to one. The low-heating-value gas burner and the hot blast heater have the advantages that the structure is reasonable, the size is moderate, the low-heating-value gas burner is suitable for the hot blast heater with large water content and high heat supply capacity requirements, especially when low-heating-value gas is used, the heating supply problem ofthe whole hot blast heater can be completely solved by using a single burner, the adjustment range is wide, the combustion efficiency is high, the energy consumption is reduced, the volume of the hotblast heater can be reduced accordingly, and the investment is reduced.

Owner:ZHONGYE-CHANGTIAN INT ENG CO LTD

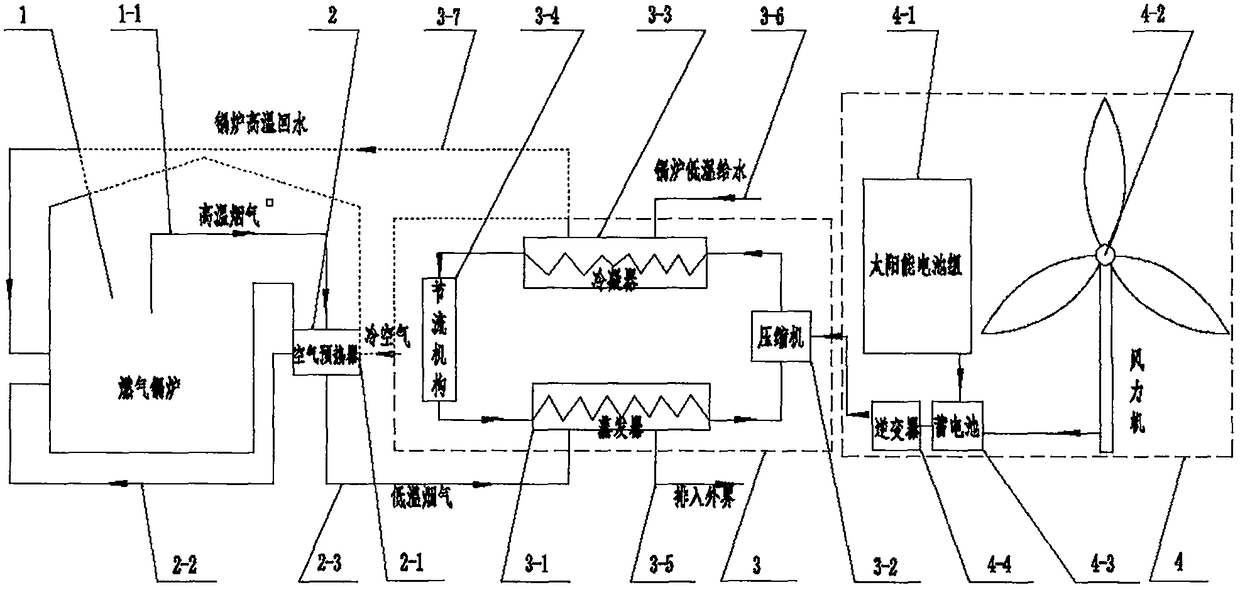

Flue gas waste heat recovery system for solar energy and wind energy hybrid-driven mechanical compression type heat pump circulation

PendingCN109386837AReduce the amount of gasReduce consumptionHeat pumpsHeat recovery systemsHybrid driveEngineering

The invention discloses a flue gas waste heat recovery system for solar energy and wind energy hybrid-driven mechanical compression type heat pump circulation. The system comprises a gas boiler, an air preheater, a mechanical compression type heat pump device, a wind turbine device and a solar battery pack. Compared with the prior art, the system has the advantages that by utilizing a wind energyand solar energy hybrid driving mode, the temperature of supplied water is increased, and the heat absorption amount of the supplied water in the boiler is reduced, so that the gas amount is reduced,and the purposes of energy conservation and emission reduction are achieved.

Owner:代元军

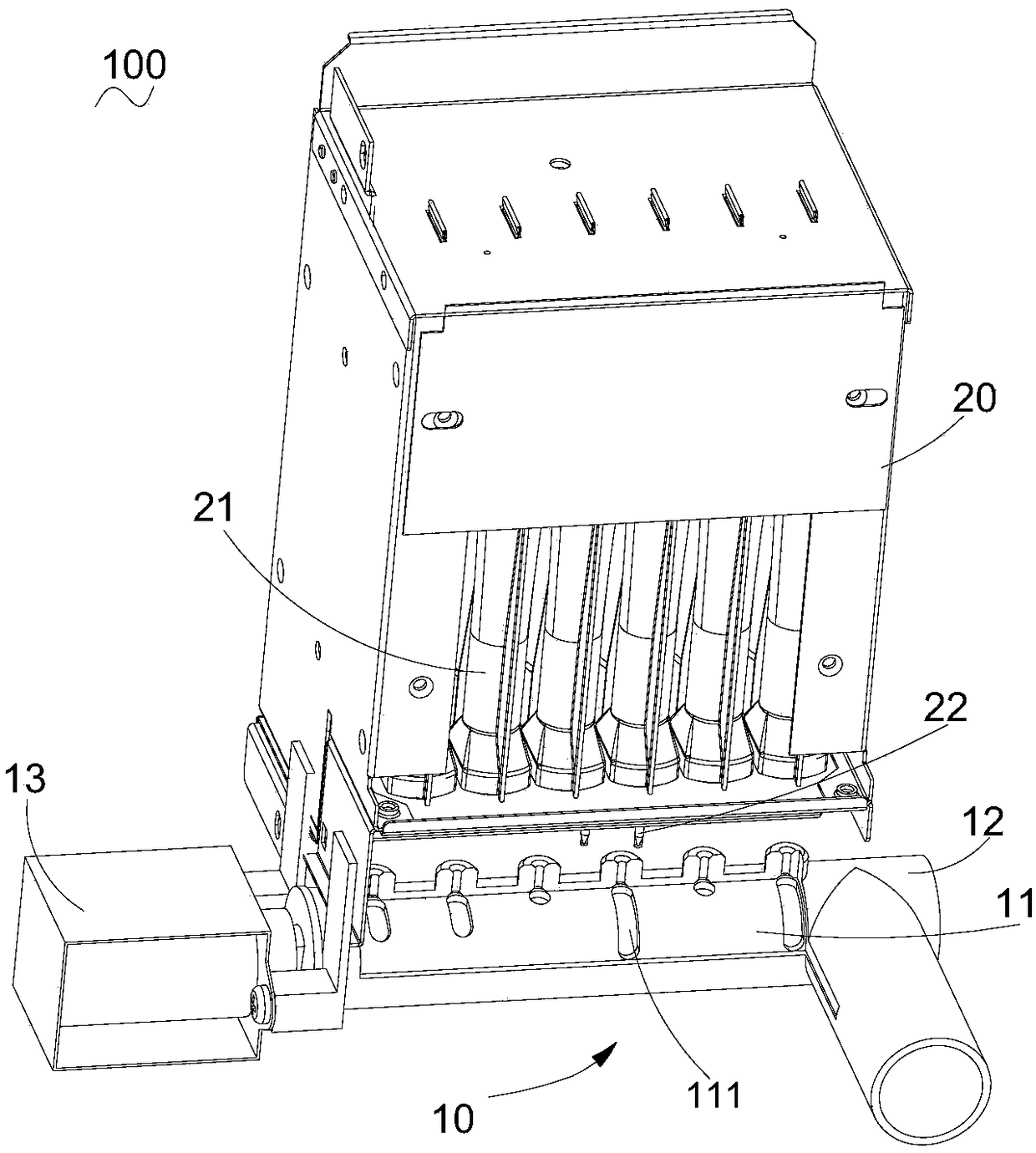

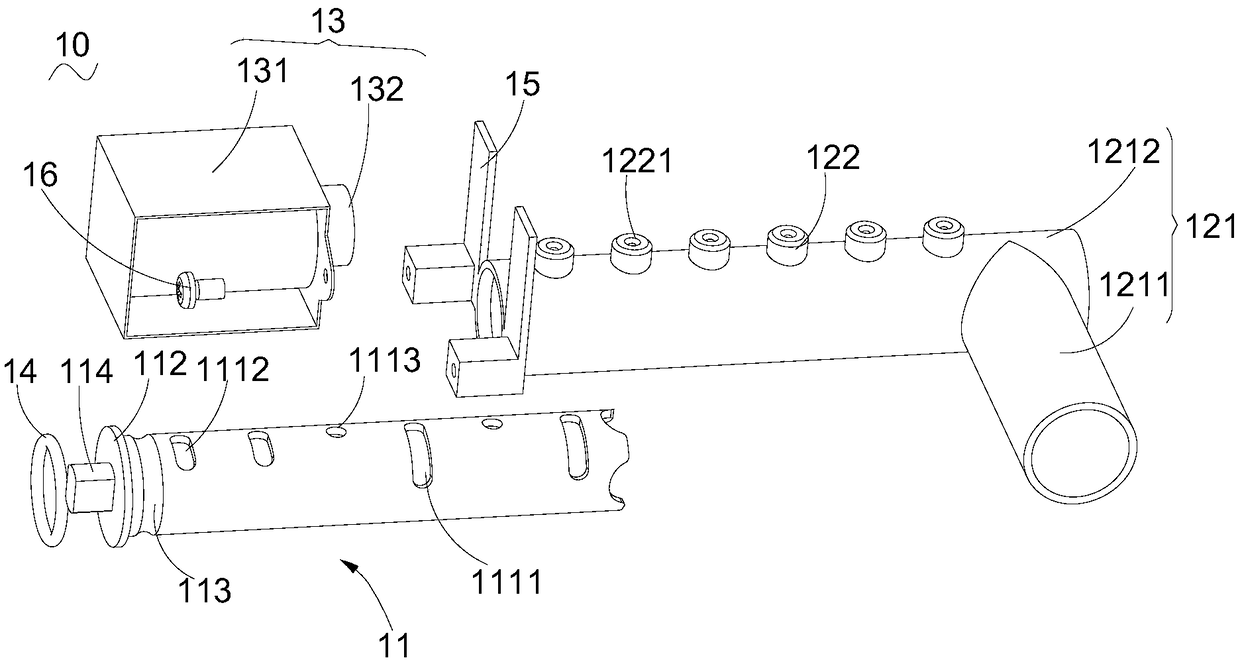

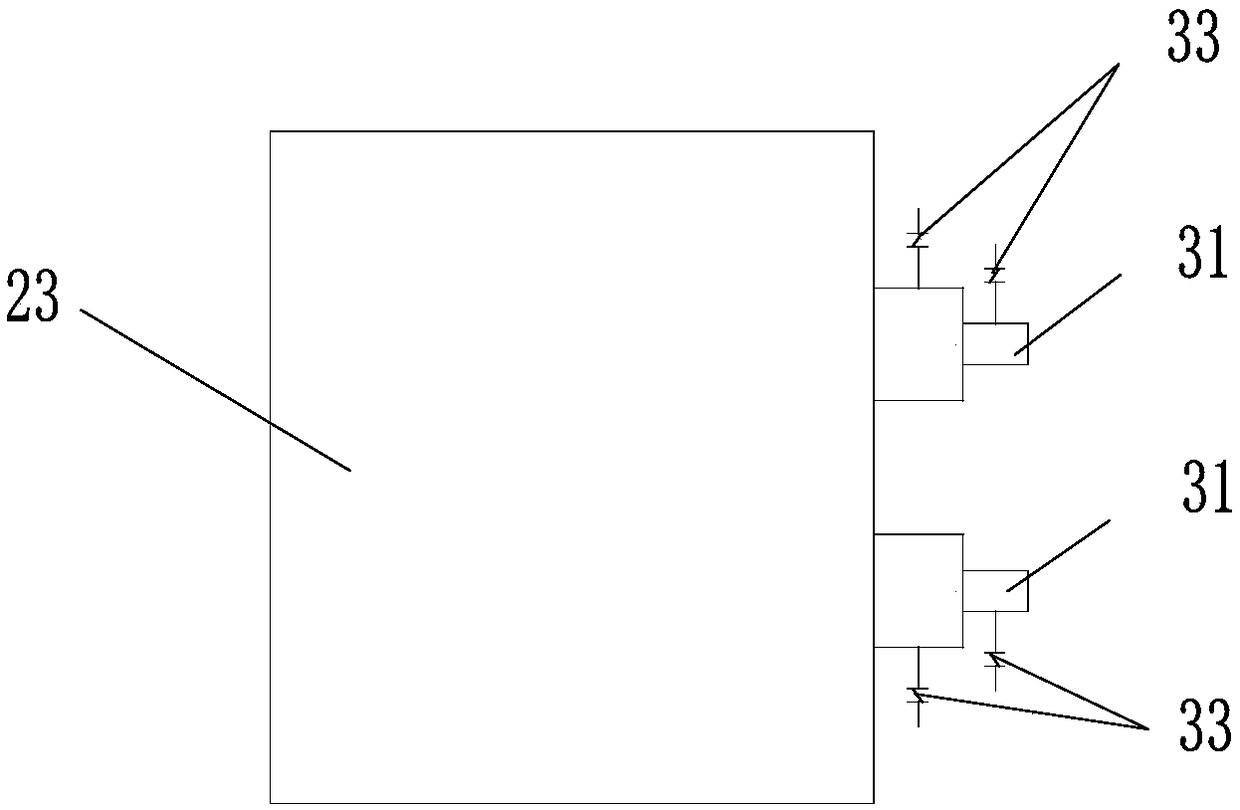

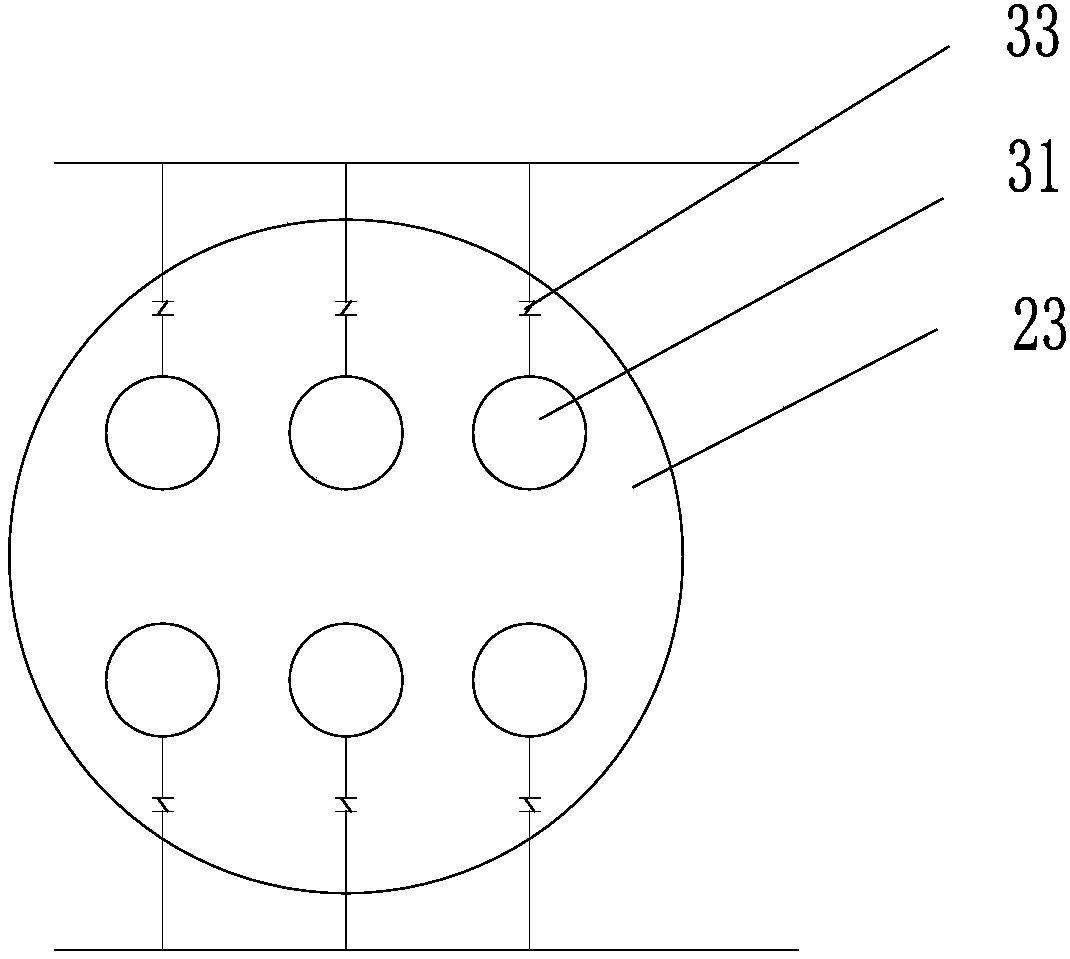

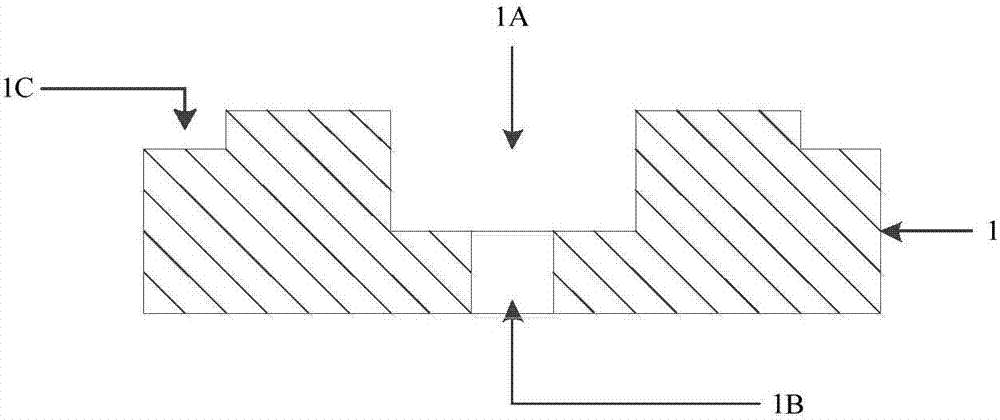

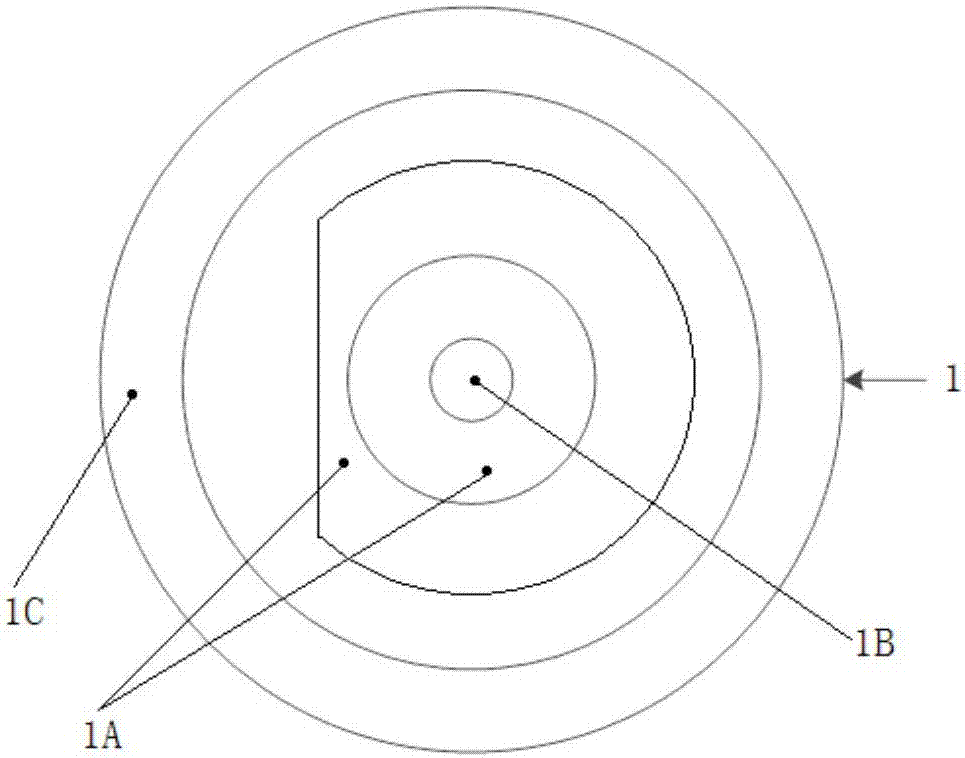

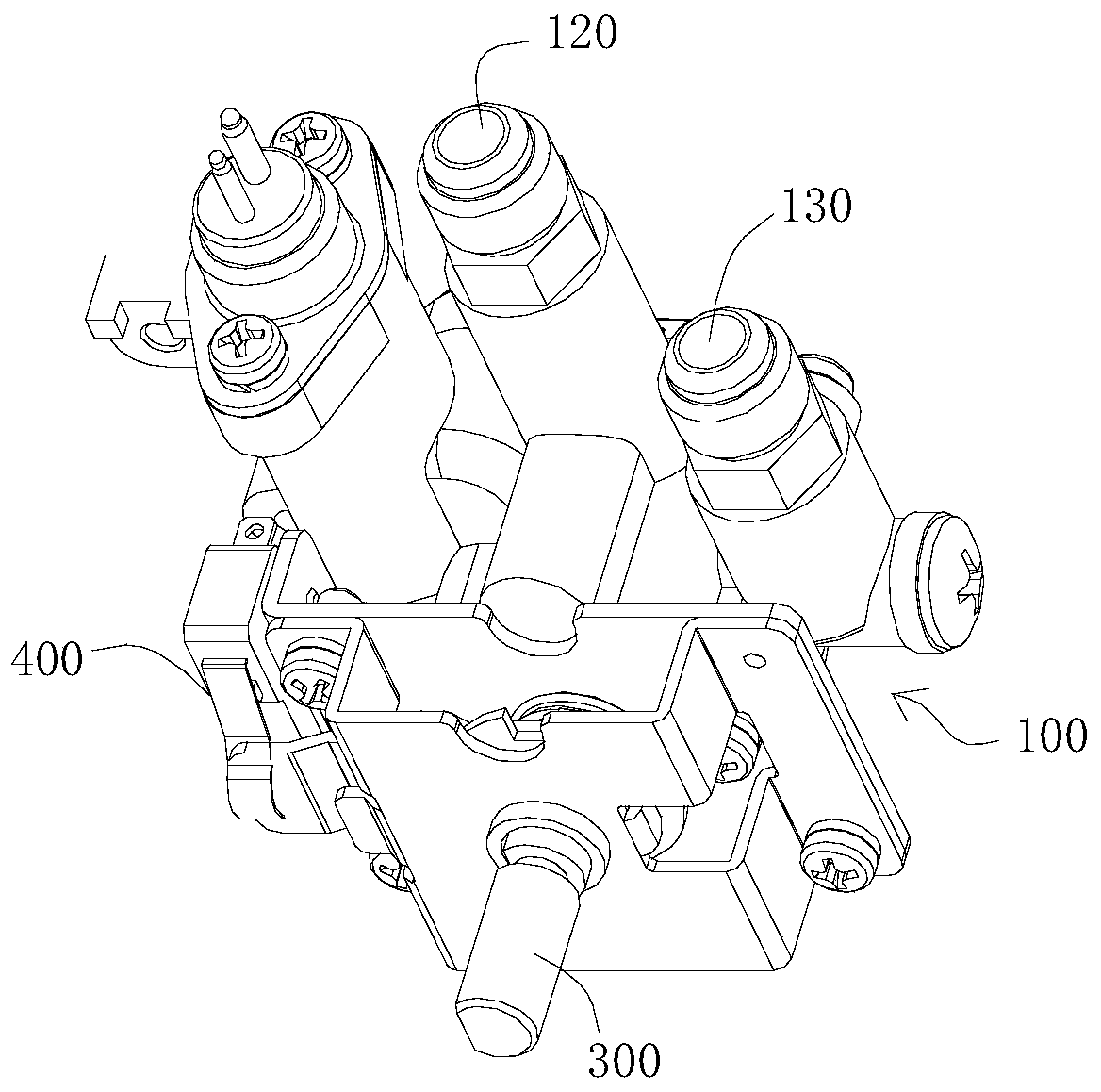

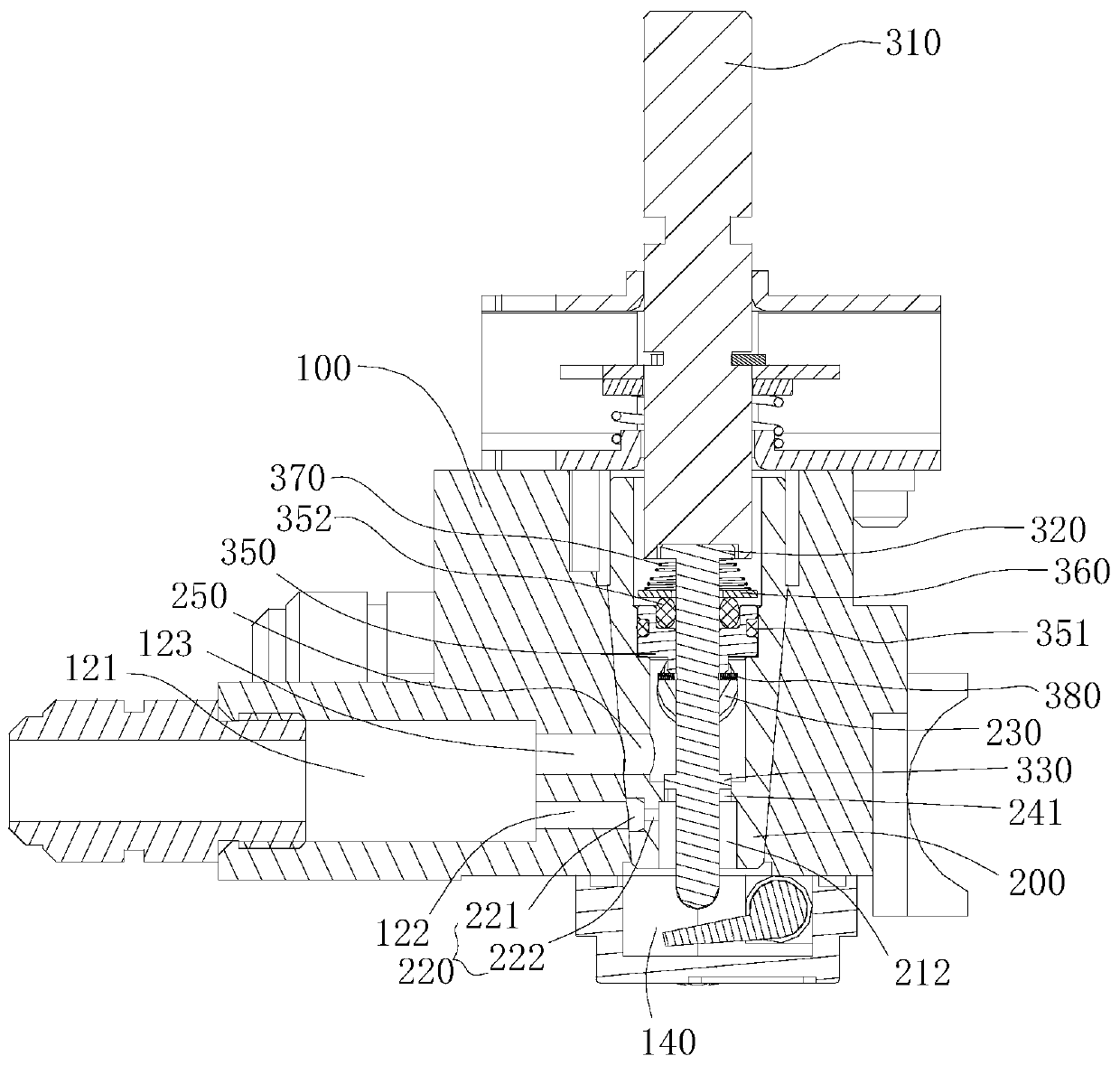

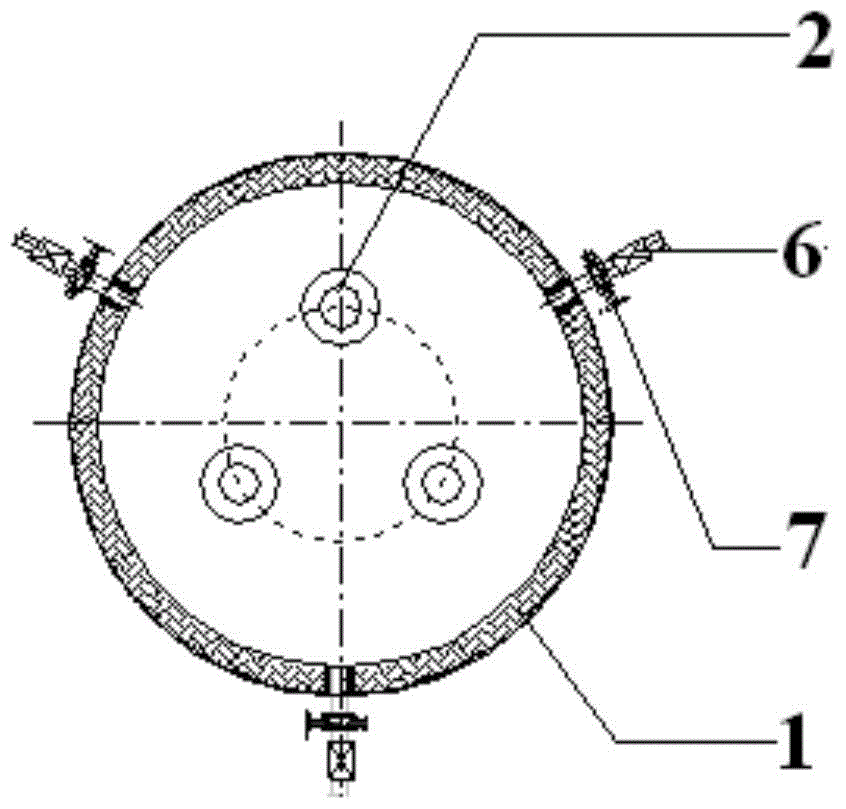

Microcircuit internal atmosphere detection test clamp

ActiveCN107389867AReduce cavity volumeReduce the amount of gasGas analyser construction detailsEngineeringAtmosphere

The invention discloses a microcircuit internal atmosphere detection test clamp and relates to the field of reliability and environment tests of electronic products. The clamp comprises a primary clamp body, a secondary clamp body and a cover body, wherein an inwards concave press cavity is formed in the central position of one end of the primary clamp body and used for accommodating the secondary clamp body, a through connecting channel is formed in the press cavity and used for accommodating a to-be-tested device, a yield part is arranged on the peripheral edge, located on the same side of an opening part of the press cavity, of the primary clamp body and used for mounting a seal ring, and the cover body covers the opening of the press cavity and the seal ring. The clamp provides a new thought for accommodating of the to-be-tested device, that is, the connecting channel with the diameter slightly larger than that of the to-be-tested device is designed, the to-be-tested device is put in the connecting channel, the sealing property of the clamp and protection of the to-be-tested device are greatly improved, besides, the matched secondary clamp body is designed, can fix the to-be-tested device and can greatly reduce vacant space in the clamp, and influence of the atmosphere of the clamp on the detection result is further reduced.

Owner:NO 24 RES INST OF CETC

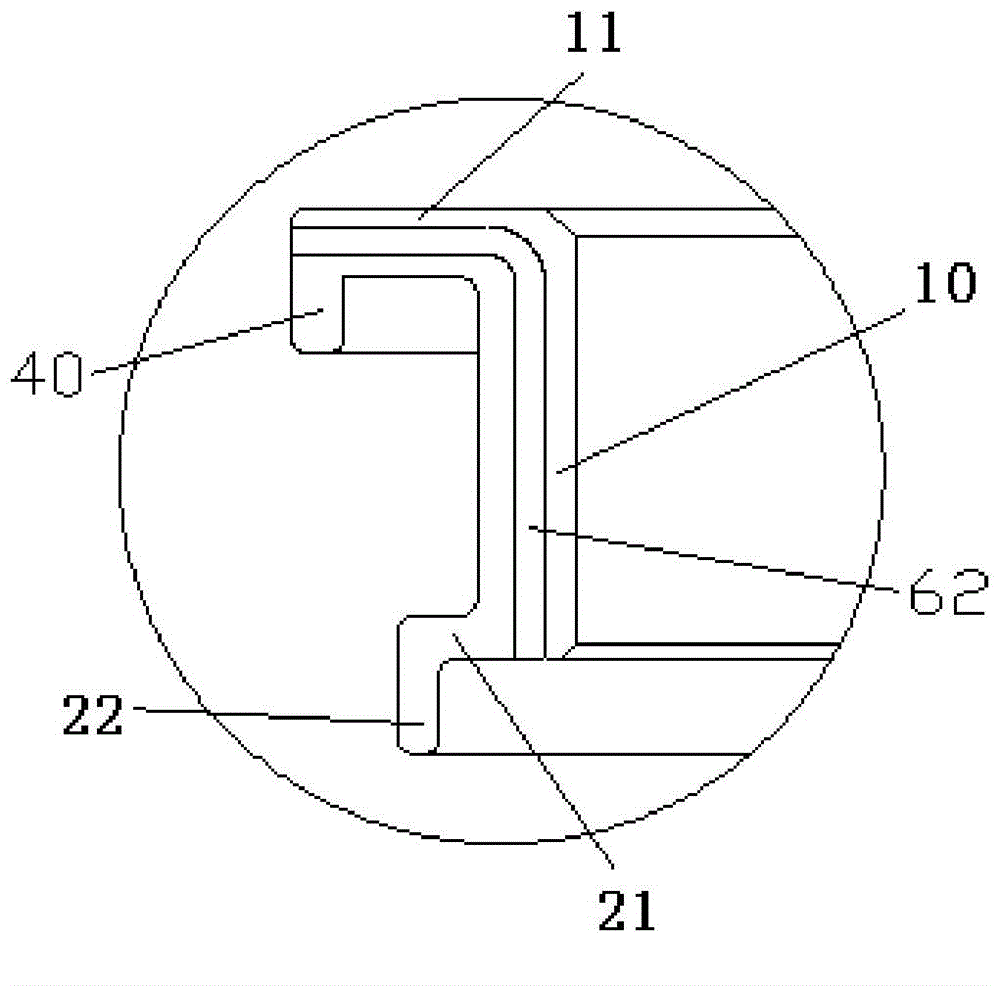

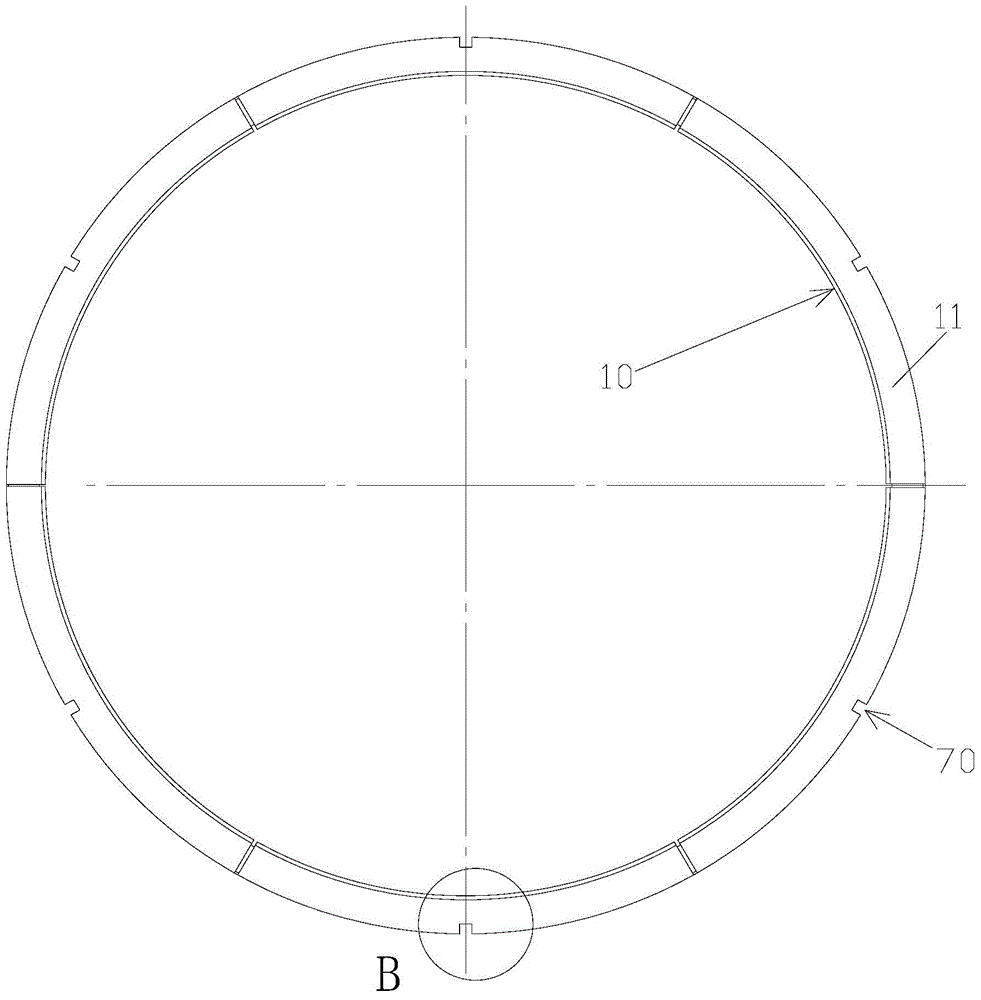

Sealing ring and gas turbine with same

ActiveCN104454033AExtended service lifePrevent leakageLeakage preventionMachines/enginesHookingGas turbines

The invention provides a sealing ring and a gas turbine with the same. The sealing ring comprises a plurality of arc sections which are connected end to end through connecting components to form the annular sealing ring, and each arc section comprises a sealing portion, a first hooking portion and a second hooking portion, wherein the sealing portions are arc plate sections, the first hooking portions are arranged at the first ends of the sealing portions, and the second hooking portions are arranged on the second ends of the sealing portions. According to the technical scheme, the sealing ring can move along with radial displacement generated by vibration of a rotor, so that blades and the sealing portions of the sealing ring are well protected against damage, and the service life of the sealing ring is prolonged.

Owner:CHINA HANGFA SOUTH IND CO LTD

Gas plug valve and gas stove

PendingCN111425627AReduce misfireImprove ignition stabilityOperating means/releasing devices for valvesMultiple way valvesEngineeringMechanical engineering

The invention provides a gas plug valve and a gas stove, and relates to the technical field of stoves. The gas plug valve comprises a valve body, a valve element and a valve rod. A valve cavity is formed in the valve body, and the side portion of the valve cavity communicates with an inner ring passageway and an outer ring passageway. The valve element is rotationally embedded into the valve cavity, a vent cavity is formed in the valve element, and an inner ring vent hole and an outer ring vent hole are formed in the side wall of the vent cavity. An annular boss is arranged on the inner wall of the vent cavity in the circumferential direction of the vent cavity. The valve rod is inserted into the vent cavity from top to bottom, the valve rod is provided with a partition part, when the valve rod is pressed down, the vent cavity can be partitioned into an upper chamber and a lower chamber through the partition part and the annular boss, and the upper chamber and the lower chamber can communicate with each other through a pressure relief passageway. The gas stove comprises a burner and the gas plug valve. The outer ring passageway communicates with an outer ring nozzle of the burner,and the inner ring passageway communicates with an inner ring nozzle. During ignition of the gas plug valve, inner ring fire of the burner is stably ignited, the ignition time is also short when outerring fire needs to be used, and the use experience of a user is good.

Owner:HANGZHOU ROBAM APPLIANCES CO LTD

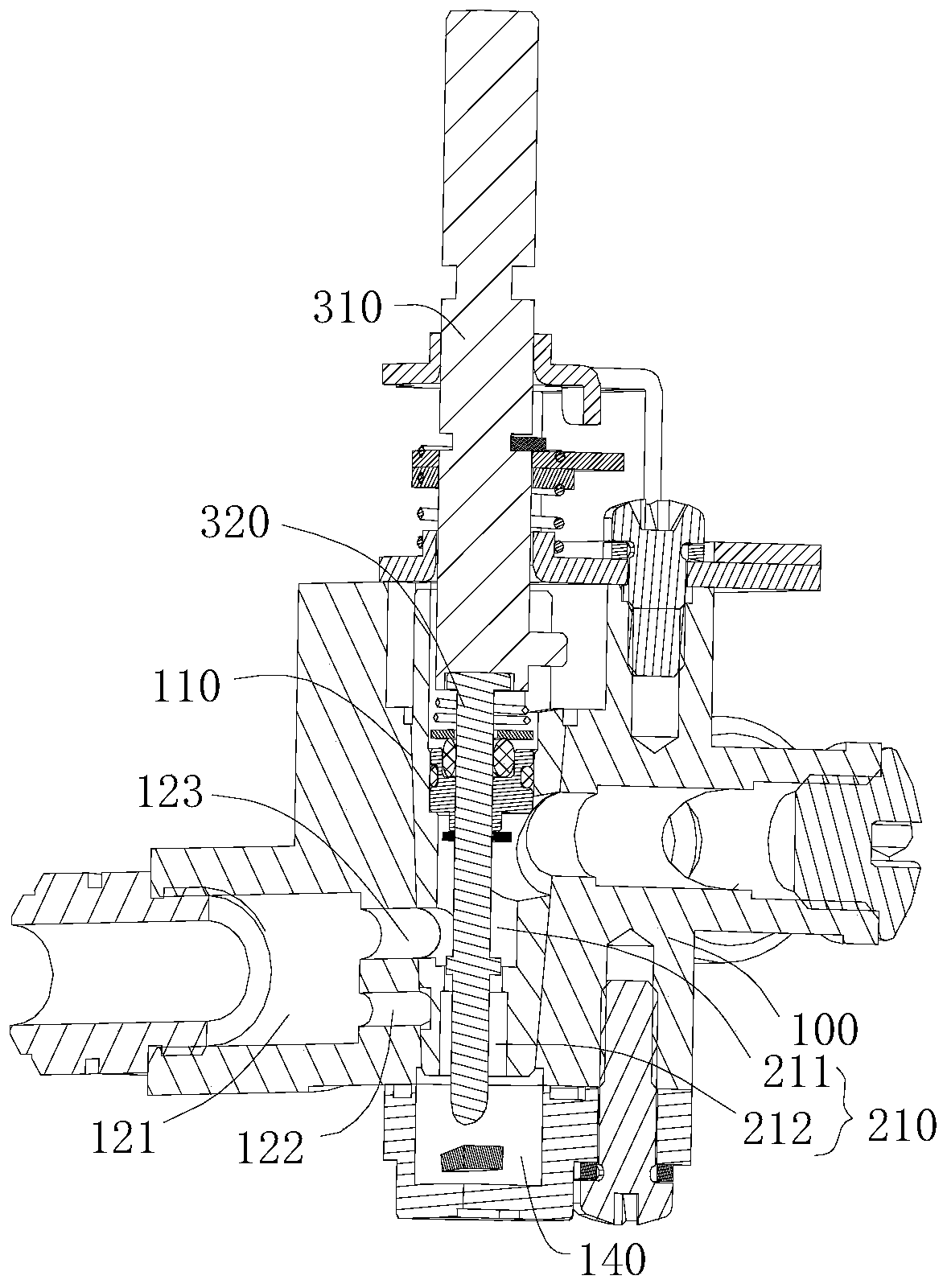

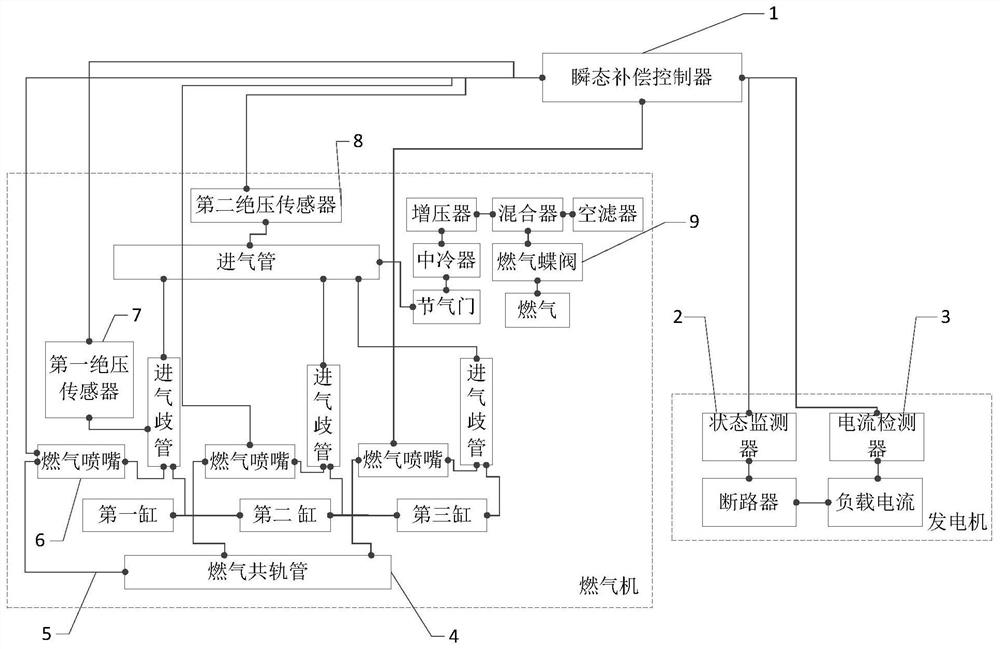

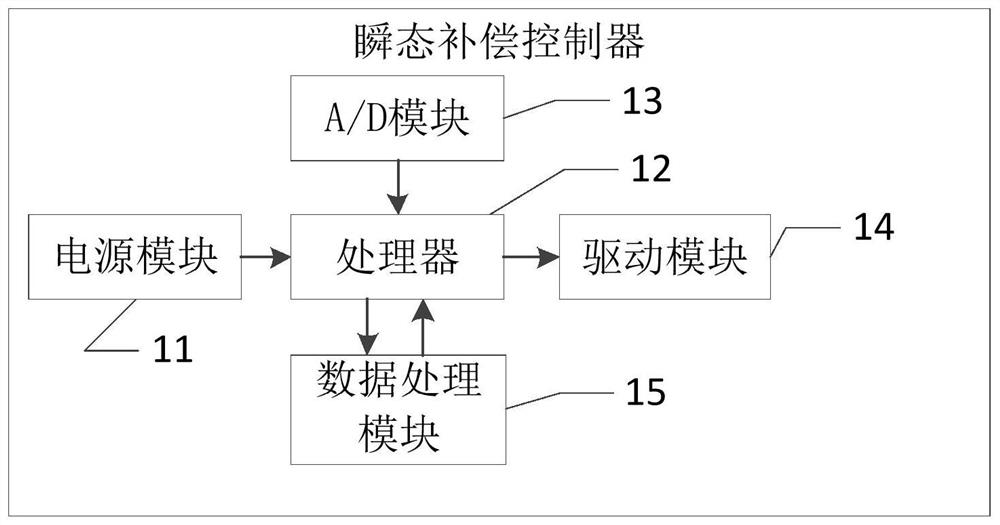

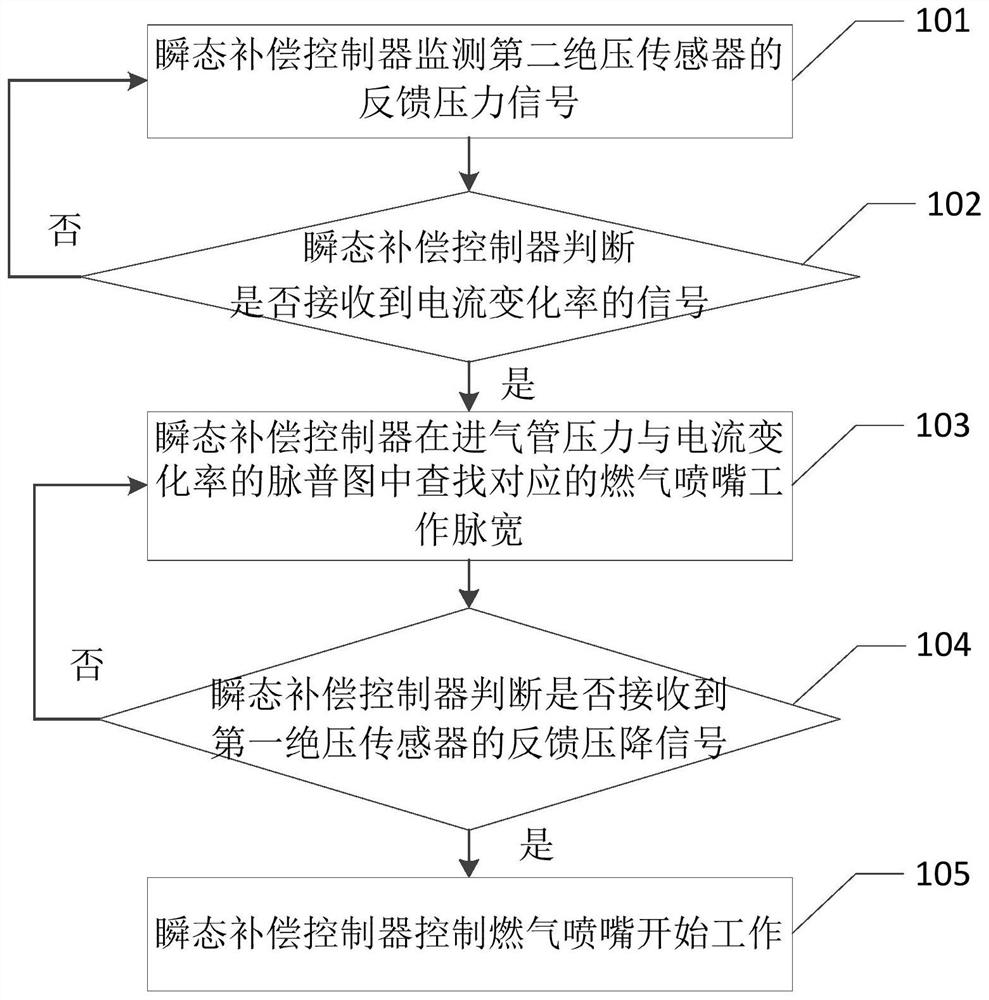

Transient compensation control system and method for gas generator

PendingCN112196679AReduce openingImprove dynamic response performanceElectrical controlInternal combustion piston enginesPhysicsGas generator

The embodiment of the invention discloses a transient compensation control system and method for a gas generator. The transient compensation control system and method for the gas generator can effectively improve the dynamic responsiveness of the gas generator and meet the requirements of certain standards or working conditions. According to the system, a transient compensation controller is electrically connected with a state monitor; the state monitor is electrically connected with a circuit breaker; the transient compensation controller is electrically connected with a current detector; thetransient compensation controller is electrically connected with a first absolute pressure sensor, a second absolute pressure sensor, a gas nozzle and a gas butterfly valve; the current detector is used for detecting the current change rate, and the transient compensation controller controls the gas nozzle to be opened and closed according to a signal of the current change rate in cooperation with a load pressure signal fed back by the second absolute pressure sensor and a pressure drop signal fed back by the first absolute pressure sensor; and the state monitor is used for sending a signal that the circuit breaker is in a disconnected state to the transient compensation controller, and the transient compensation controller reduces the opening degree of the gas butterfly valve according to the signal that the circuit breaker is in the disconnected state.

Owner:广西玉柴船电动力有限公司

Device and method for shortening coal seam gas pressure measurement observation time

ActiveCN113818921AReduce volumeFast balanceFluid pressure measurementGas removalThermodynamicsMeasurement device

The embodiment of the invention discloses a device and a method for shortening coal seam gas pressure measurement observation time, relates to the technical field of coal seam gas pressure measurement, and mainly aims to solve the problems of low gas flow field balance speed and long observation time in the conventional coal seam gas pressure measurement device and method. The device comprises a grouting mechanism, a capsule located in a drill hole, a pressure measuring mechanism, a water conveying mechanism and an expansion liquid conveying mechanism, wherein the surface of the capsule is wrapped with a light, flexible and water-absorbing material, a plurality of sprayers are arranged at the top end of the capsule, and a pressure measuring pipe in the pressure measuring mechanism is fed into the capsule at the front end of the drill hole, so that not only can the pipe be tightly attached to the coal wall around the drill hole before the pressure measuring drill hole is sealed, to hinder flowing of gas in the coal seam around the drilled hole towards the drilled hole, but also can occupy most space of a pressure measuring chamber after the pressure measuring drill hole is sealed, and therefore, the size of the pressure measuring chamber is reduced, the amount of gas flowing into the pressure measuring chamber from the coal wall around the drill hole is reduced, the balance speed of a gas flow field can be increased, and the observation time is shortened.

Owner:NORTH CHINA INST OF SCI & TECH

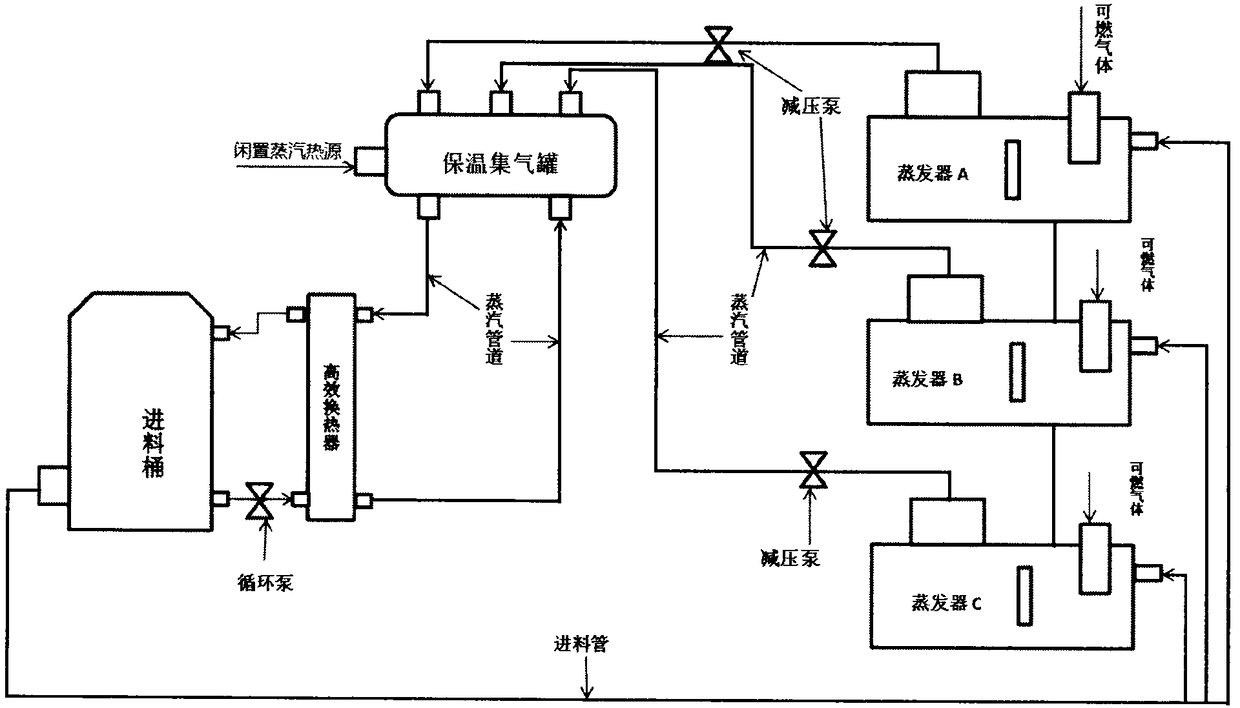

Circulating heat exchange multiple-effect evaporation system for high-concentration wastewater and evaporation process of evaporation system

PendingCN108840385AReduce the amount of gasRelieve pressureWater/sewage treatment by heatingMultiple-effect evaporationHigh concentrationLiquid temperature

The invention discloses a circulating heat exchange multiple-effect evaporation system for high-concentration wastewater and an evaporation process of the evaporation system. A feeding barrel is connected with a submerged combustion evaporator through a feeding pipe; a steam exhaust pipeline of the submerged combustion evaporator is connected with one end of a thermal-insulation steam collecting tank; the other end of the thermal-insulation steam collecting tank is connected with an efficient heat exchanger; the thermal-insulation steam collecting tank is also connected with an idle steam heatsource; the feeding barrel is connected with one end of the efficient heat exchanger through a circulating pump. A low-temperature stock solution is pumped to the submerged combustion evaporator, combustible gas is directly sprayed to the evaporator after being ignited, so that the temperature of the solution in the evaporator is increased, and produced steam enters the thermal-insulation steam collecting tank, is mixed with the idle steam heat source and enters the efficient heat exchanger; the low-temperature stock solution in the feeding barrel enters the efficient heat exchanger, exchanges heat with high-temperature steam and returns to the feeding barrel, and the steam in the efficient heat exchanger is circulated again to enter the thermal-insulation steam collecting tank. The gas consumption is reduced by 60% or above through secondary utilization of the heat source and circulating heat exchange.

Owner:北京鑫磊华易达技术有限公司

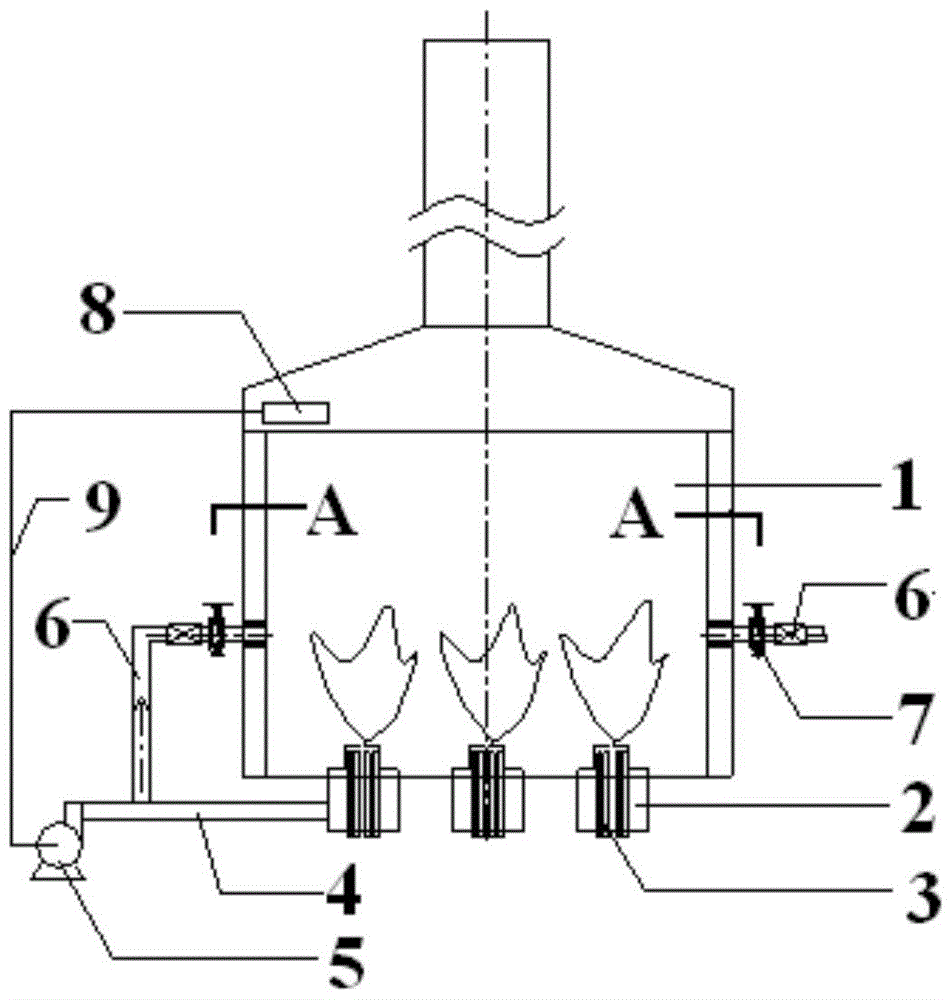

Combustion method and device for saving energy and reducing NOx for petrochemical engineering heating furnace

ActiveCN105698212AReduce nitrogen oxide contentReduce the amount of gasCombustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelNitric oxidePetrochemical

Provided are a combustion method and device for saving energy and reducing NOx for a petrochemical engineering heating furnace. The method includes the steps that air and fuel gas are blown to the bottom and middle of the heating furnace for mixed combustion, and the volume percentage of oxygen in exhaust gas after combustion is controlled to be 4-6%. The heating furnace comprises a heating furnace body with a combustion sprayer at the bottom. The combustion sprayer is connected with a fuel gas intake pipe and an air intake header pipe. The air intake header pipe is connected with a draught fan. A medium air intake pipe is arranged in the middle of the heating furnace body and connected with the air intake header pipe. The medium air intake pipe is provided with a medium air regulating valve. The combustion method can effectively reduce the nitric oxide content and save the amount of fuel gas, thereby saving energy and being environmentally friendly; the structure of the heating furnace is simple; and the effects of saving energy and reducing the nitric oxide content in exhaust gas are remarkable.

Owner:SHANDONG ORIENT HONGYE CHEM

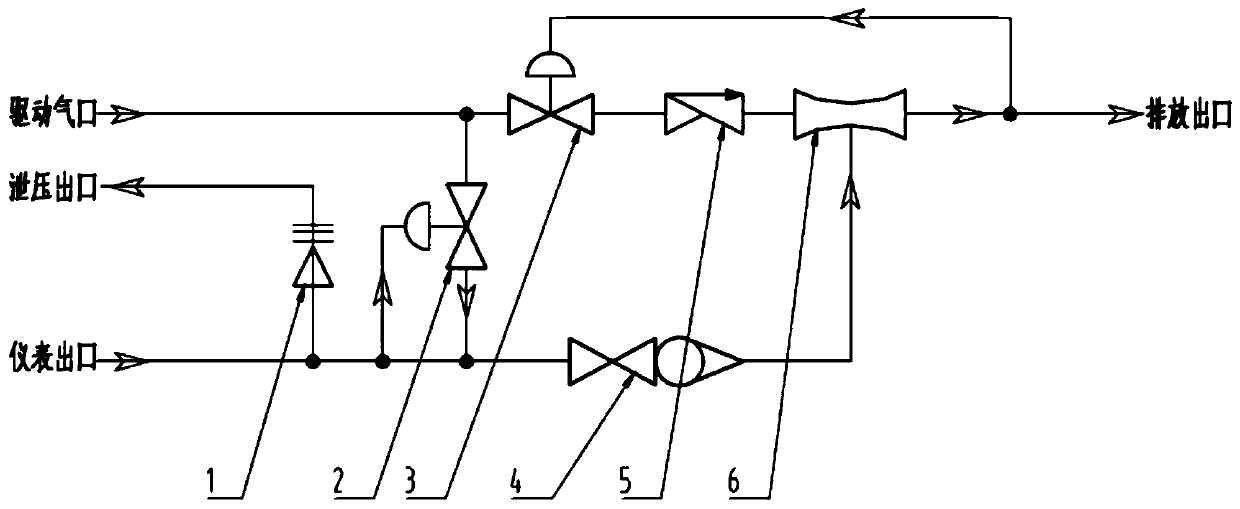

Constant pressure discharge system

PendingCN109882734AKeep the pressure steadyReduce the amount of gasPipeline systemsEngineeringBack pressure

The invention discloses a constant pressure discharge system. The constant pressure discharge system comprises a driving air port, a first adjusting valve, a second adjusting valve, a Venturi tube, adischarge outlet and an instrument outlet; the driving air port, the second adjusting valve, the Venturi tube and the discharge outlet sequentially communicate, the driving air port communicates withan air source of high-pressure driving air, the second adjusting valve is in signal connection with the discharge outlet, the instrument outlet communicates with a throat tube of the Venturi tube, oneend of the first adjusting valve is arranged between the driving air port and the second adjusting valve in a communication manner, the other end of the first adjusting valve is arranged between theinstrument outlet and the throat tube of the Venturi tube in a communication manner, and the first adjusting valve is in signal connection with the instrument outlet. Backpressure of an instrument canbe stabilized within the preset numerical value, the measuring accuracy is greatly improved, the structure is simple, and the use is convenient.

Owner:苏州祖宁自动化仪器仪表有限公司

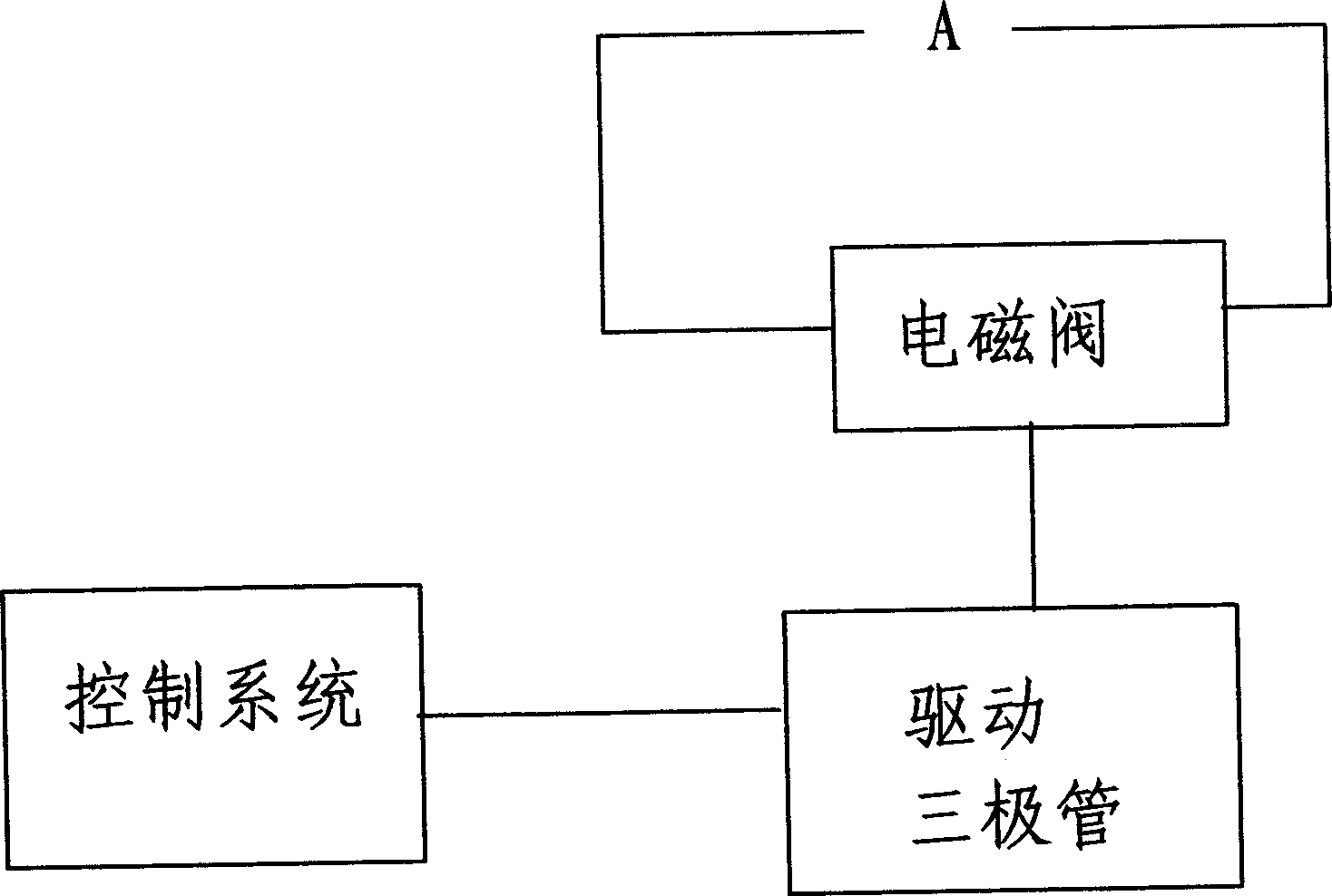

Method for controlling gas quantity in combustion charnber in lighting stage of gas water heater

The control method of gas dose in combustion chamber in lighting stage of gas wter-heater includes control system, drive triode and electromagnetic valve mounted on the gas pipe. The control system outputs the signal to drive triode, then the signal can be transferred into electromagnetic valve by means of the drive triode. In the lighting period, the signal outputted by control system is pulse signal so as to make the electromagnetic valve circularly act between opening and closing and make the gas channel be in opening and closing circulation state, so that the gas consumption dose before lighting can be reduced, after it is lighted, the signal outputted by control system is an opening signal, the gas channel is in opening state, the water-heater can be worked normally.

Owner:张卓文

One-roadway dual-purpose gas extraction method for high-position roadway of fully-mechanized caving coal seam

ActiveCN113513359ANormal mining replacementLess investmentGas removalTunnelsMining engineeringCoal pillar

The invention discloses a one-roadway dual-purpose gas extraction method for a high-position roadway of a fully-mechanized caving coal seam, and belongs to the technical field of gas extraction, which can solve the problem of gas overrun of a fully-mechanized caving face of a high-gas low-permeability thick coal seam. Before the fully-mechanized caving face of the high-gas low-permeability thick coal seam adopting a U-shaped ventilation mode is extracted, the high-position roadway of the coal seam is constructed along a top plate of the coal seam in an inner staggered working face air return roadway, high-position coal seam drill holes are constructed in the high-position roadway of the coal seam from a non-coal pillar side to an air inlet roadway, and the high-position coal seam drill holes are connected with a mine gas extraction system for extraction. When the working face is extracted, all the high-position coal seam drill holes are disconnected from the extraction system and are in an open natural gas discharging state, and additionally, closed insertion pipe extraction is constructed at the opening of the high-position roadway of the coal seam. According to the method, one roadway has two purposes, and the gas extraction method has the characteristics of investment saving, easiness in management, high gas extraction rate and the like.

Owner:TAIYUAN UNIV OF TECH

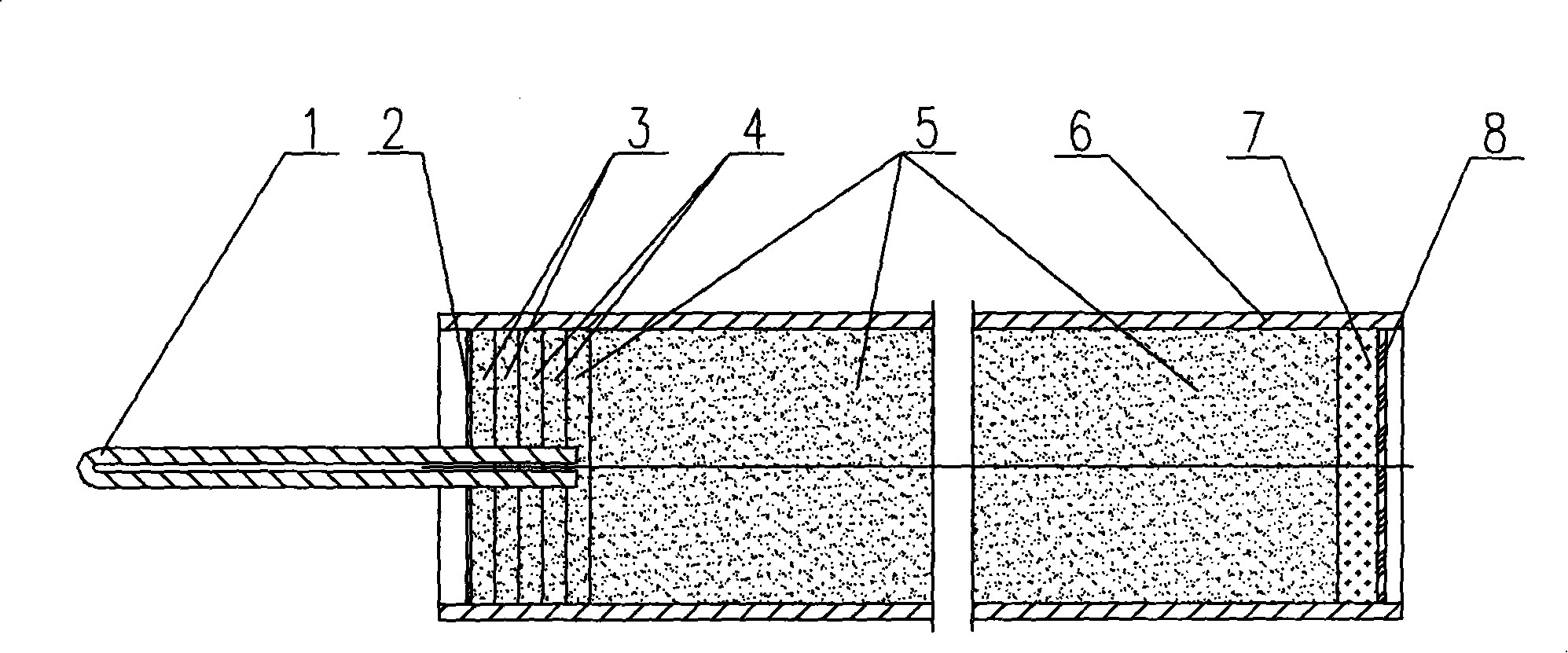

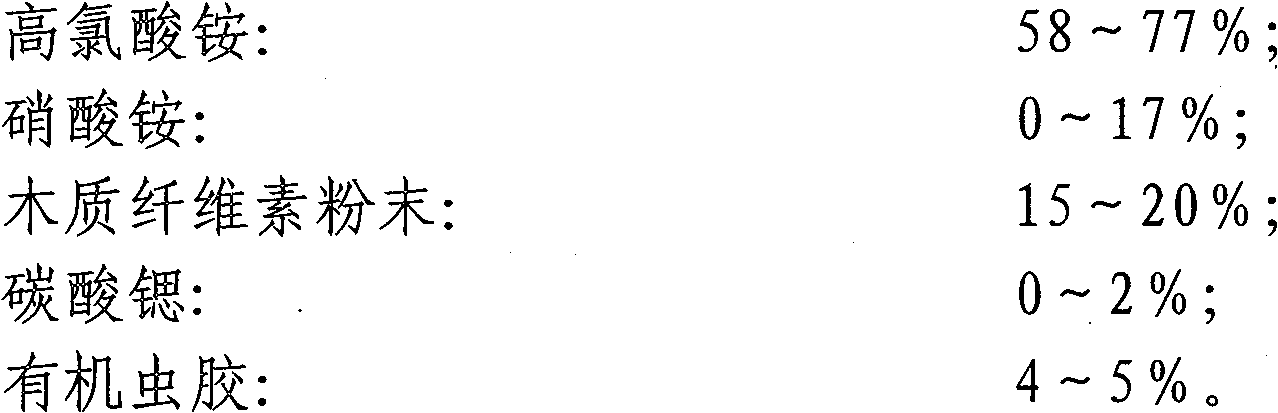

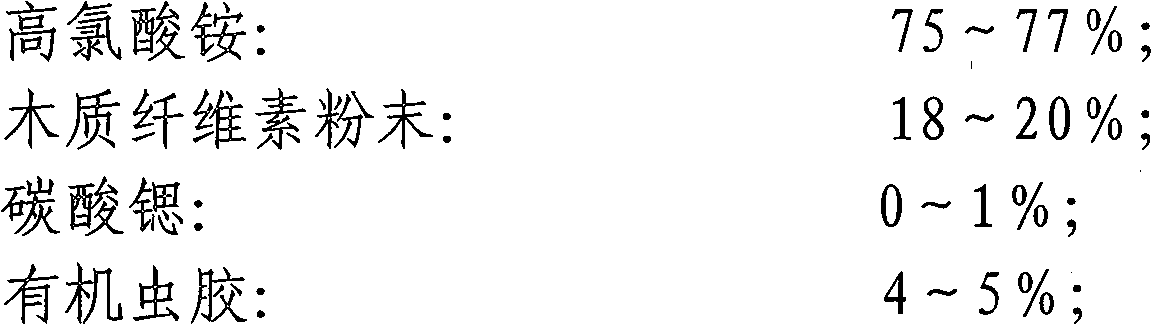

Solid fuel for torch burner and preparation method thereof

ActiveCN101519615BReduce burning rateGood lookingSolid fuelsWaste based fuelStrontium carbonateShellac

The invention pertains to the technical field of solid fuel and provides a solid fuel for a torch burner and a preparation method thereof. The components of the solid fuel are as follows: ammonium perchlorate and ammonium nitrate; lignocellulose powder; strontium carbonate; and organic shell-lac[shellac]. The preparation method comprises the following steps: oxidants such as ammonium perchlorate, ammonium nitrate, lignocellulose powder, strontium carbonate are crushed; shell-lac alcoholic solution is prepared from the shell-lac; then the shell-lac alcoholic solution is poured into a screen and mixed evenly and the materials are wetted and mixed evenly; granules are made with 20-mesh screens, air-dried for 2h and then oven-dried for 24h at the temperature of 50 DEG C; and the dried and analyzed grains are layered and press-packaged into a cladding sleeve through multiple times a valving die coining press and shaped after being filled with drugs. The solid fuel and the preparation method have the advantages that the filled solid drug for the burning system can be burned reliably at an average linear burning speed of 0.45mm / s to 0.55mm / s in the environment where the temperature is always minus 45 DEG C and the pressure is always low and about 0.3 bar and in the raining and snowing environment or windstorm environment at a speed of 50m / s.

Owner:THE 31TH INST OF THE THIRD ACAD OF RES CASIC

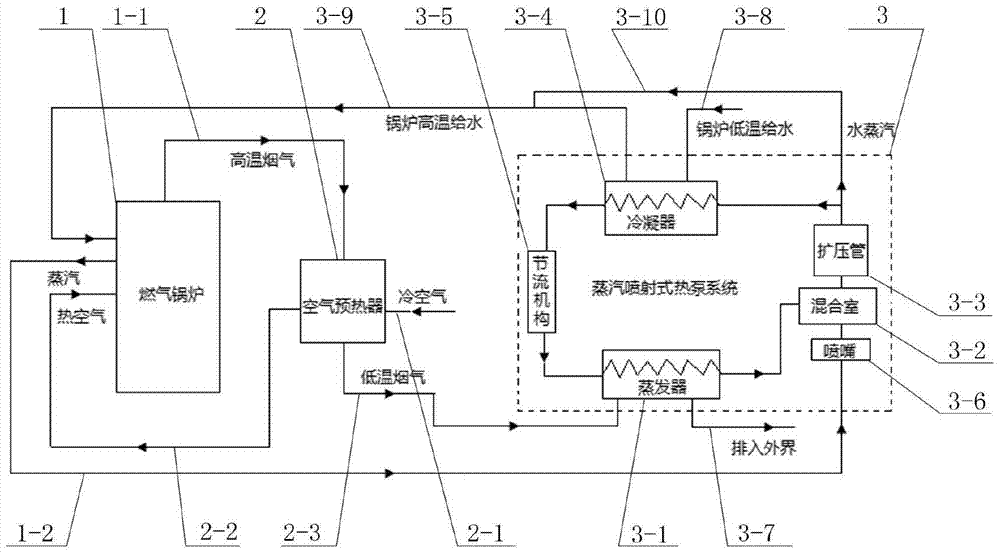

A flue gas waste heat recovery system for a steam injection heat pump cycle

InactiveCN104456610BIncrease temperatureReduce heat absorptionHeat pumpsHeat recovery systemsAir preheaterEngineering

The invention discloses a steam jet type heat pump circulating flue gas waste heat recovery system. The steam jet type heat pump circulating flue gas waste heat recovery system comprises a gas-fired boiler, an air preheater and a steam jet type heat pump device, wherein the steam jet type heat pump device comprises an evaporator, a mixing chamber, a diffuser pipe, a condenser and a throttle mechanism, which are sequentially connected to form a loop, as well as a nozzle connected with the mixing chamber; a blow-off pipe is arranged on the evaporator and used for discharging flue gas and condensate water; a boiler low-temperature water supplying channel and a boiler high-temperature water supplying channel are formed in the condenser; the boiler high-temperature water supplying channel is connected to the gas-fired boiler; a high-temperature flue gas channel and a steam branch channel are formed in the gas-fired boiler. Compared with the prior art, the steam jet type heat pump circulating flue gas waste heat recovery system has the advantages that the water supplying temperature can be increased by 5-8 DEG C, and the heat absorption capacity of the supplied water in the boiler is reduced to reduce the fuel gas using amount, so as to achieve the purposes of saving energy and reducing emission.

Owner:XINJIANG INST OF ENG

Fuel gas water heater and control method thereof

InactiveCN110108022AReduce outputImprove heat transfer efficiencyWater heatersCombustorCombustion chamber

The invention relates to the field of water heaters, in particular to a fuel gas water heater and a control method thereof. The fuel gas water heater comprises a heater body and a burner, a soundproofchamber is arranged between the outer wall and the inner wall of the heater body, the burner is located inside the heater body, the top of the burner is provided with a combustion chamber, a sensibleheat exchanger is arranged above the combustion chamber, and a smoke guiding mechanism is arranged above the sensible heat exchanger, a cyclic utilization bin is arranged in the heater body, and thesmoke guiding mechanism communicates with the soundproof chamber through the cyclic utilization bin; and a plurality of water inlet pipes are arranged in the cyclic utilization bin, the upper and lower ends are each provided with a flow guide cover, each flow guide cover communicates with the corresponding water inlet pipes, the flow guide cover at the upper end of the cyclic utilization bin communicates with the input end of the sensible heat exchanger, the output end of the sensible heat exchanger is provided with a flow dividing system, and a first temperature sensor and a second temperature sensor are arranged in the flow dividing system and the cyclic utilization bin correspondingly. By means of the fuel gas water heater and the control method, corresponding adjustment can be dynamically carried out according to the real-time temperature, the temperature keeps in the normal state under the condition of the low energy consumption, energy saving and environmental protection are achieved, meanwhile, noise is low, and the comfort is strong.

Owner:BEIJING BEIRAN HEATING CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com