One-roadway dual-purpose gas extraction method for high-position roadway of fully-mechanized caving coal seam

A gas drainage and coal seam technology, which is applied in the field of gas drainage in fully mechanized caving mining of a single low-permeability thick coal seam, and gas drainage in fully mechanized caving working faces. Gas drainage and other issues, to achieve the effect of reducing gas volume, improving pre-pumping rate, and saving investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

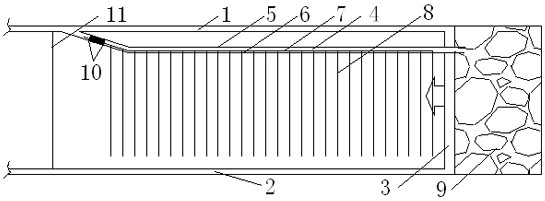

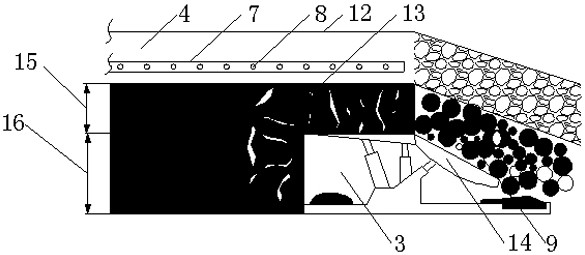

[0024] 1. See figure 1 , figure 2 , a dual-purpose gas drainage method for high-level alleyway and one alleyway in fully mechanized caving mining coal seams. The coal seam high-level roadway 4 is constructed along the coal seam roof 12, and the non-coal pillar side 6 in the coal seam high-level roadway 4 is constructed at a certain distance to the air inlet roadway 2. The high-level coal seam boreholes 8 with a certain inclination angle are constructed, and the high-level coal seam boreholes 8 are connected with mine gas drainage. System 7 is connected for sampling. During the recovery of the working face, all high-level coal seam boreholes 8 are disconnected from the drainage system 7 and made to be in an open state for natural gas discharge.

[0025] 2. Among them: the distance between the staggered return airway 1 in the high level roadway 4 of the coal seam is 25m, excavation along the roof 12 of the coal seam, and the distance 15 from the 3rd floor of the mining face i...

Embodiment 2

[0031] 1. See figure 1 , figure 2 , a dual-purpose gas drainage method for high-level alleyway and one-wayway in fully-mechanized caving mining coal seams. 1 Construct a high-level coal seam roadway 4 along the coal seam roof 12 at a certain distance. In the high-level coal seam roadway 4, the non-coal pillar side 6 is directed to the air inlet roadway 2. The high-level coal seam drilling 8 with a certain inclination is constructed at a certain distance, and the high-level coal seam drilling 8 is connected to the mine gas The extraction system 7 is connected for extraction. During the recovery of the working face, all high-level coal seam boreholes 8 are disconnected from the drainage system 7 and made to be in an open state for natural gas discharge.

[0032] 2. Among them: the distance between the staggered return airway 1 in the high level roadway 4 of the coal seam is 30m, and the distance 15 between the 3rd floor of the coal seam roof and the mining face is 5.25m.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com