Combustion method and device for saving energy and reducing NOx for petrochemical engineering heating furnace

A technology of petrochemical industry and combustion method, which is applied in the direction of combustion method, combustion using lump fuel and liquid fuel, combustion using lump fuel and gaseous fuel, etc. Seeing problems such as heating furnace and combustion control method, achieving energy saving effect, simple structure, and reducing nitrogen oxide content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

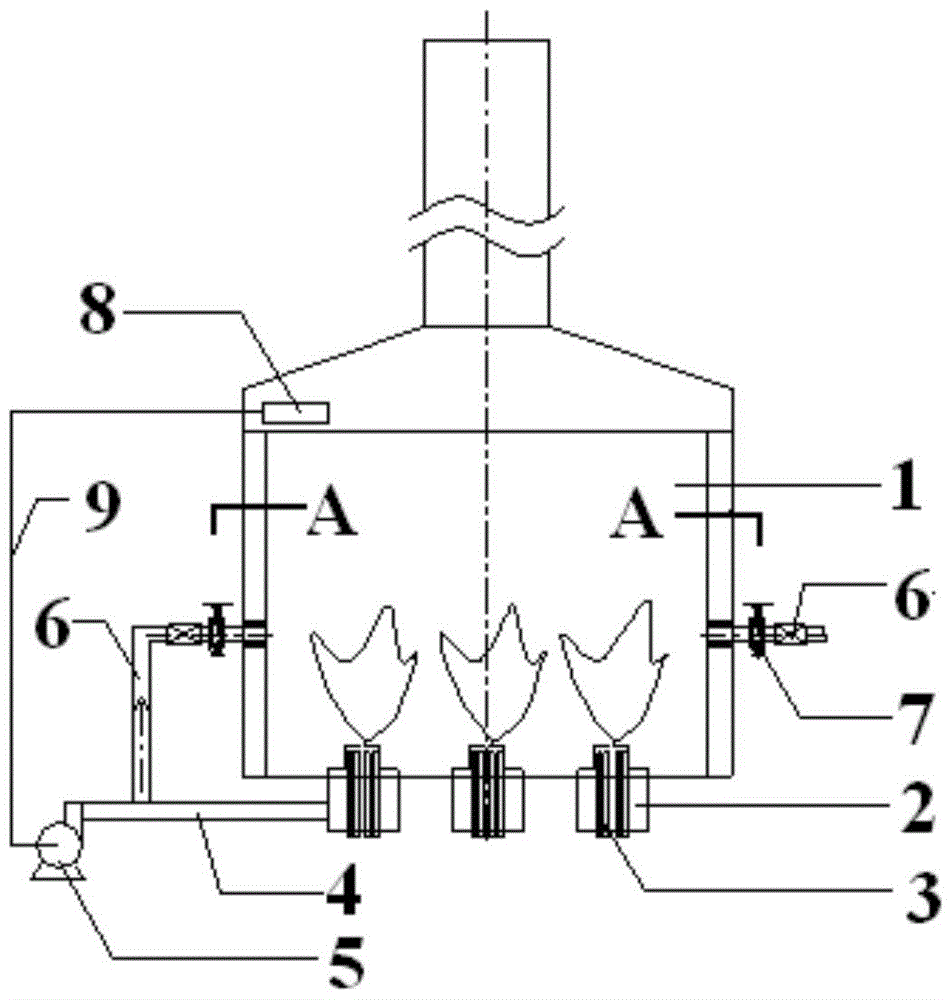

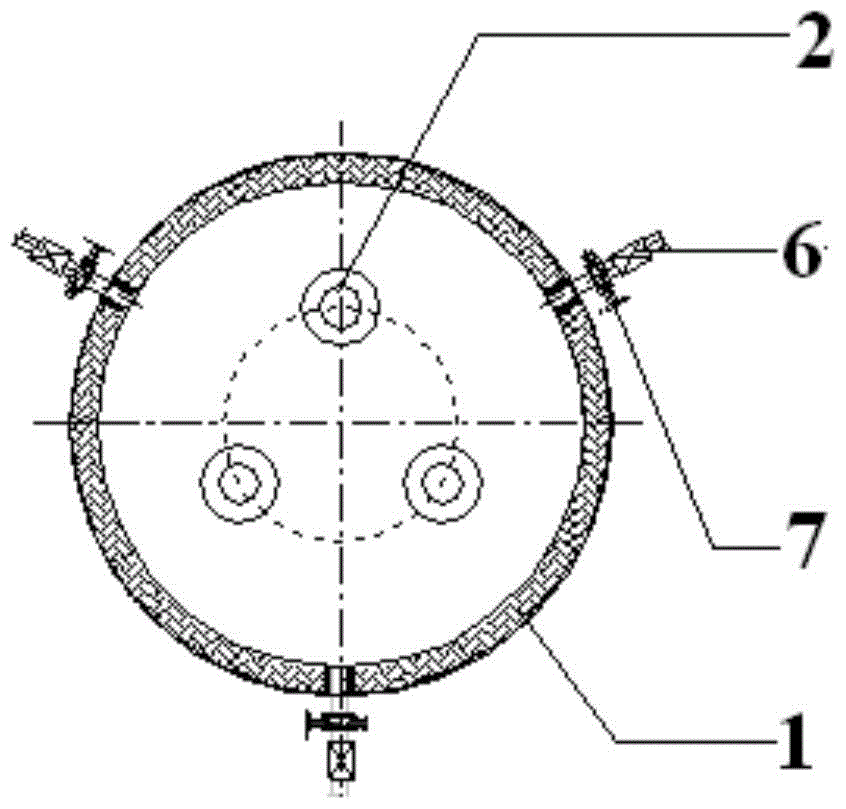

[0026] Such as figure 1 As shown, a heating furnace for saving energy and reducing NOx includes a cylindrical structure heating furnace body 1, and the bottom of the heating furnace body 1 is provided with three combustion nozzles 2, and two adjacent combustion nozzles 2 are connected to the heating furnace body 1. The center is arranged horizontally at an angle of 120°. The combustion nozzle 2 is respectively connected to a gas inlet pipe 3 and an air inlet pipe 4. The air inlet pipe 4 is connected to a fan 5. The heating The middle part of the furnace body 1 is provided with an intermediate air inlet pipe 6 and is connected to the main air inlet pipe 4, and the intermediate air inlet pipe 6 is provided with an intermediate air regulating valve 7;

[0027] The upper part of the heating furnace body 1 is provided with a heater 8, and the heater 8 is connected with the fan 5 through a hot air inlet pipe 9;

[0028] There are three intermediate air inlet pipes 6, all of which a...

Embodiment 2

[0031] A combustion method for saving energy and reducing NOx in a petrochemical heating furnace, comprising using the heating furnace described in Example 1, with a raw material production and processing capacity of 28t / h, and a combustible gas feed rate of 97Nm 3 / h, total air intake 15000m 3 / h, the air intake of the middle air is controlled at 7% of the total air intake, and the volume content of oxygen in the flue gas after combustion is controlled to be 5.8%.

[0032] After testing: saving gas 18Nm 3 / h, NO in flue gas X Content 185mg / m 3 .

Embodiment 3

[0034] A combustion method for saving energy and reducing NOx in a petrochemical heating furnace, comprising using the heating furnace described in Example 1, with a raw material production and processing capacity of 20t / h, and a combustible gas feed rate of 75Nm 3 / h, total air intake 11000m 3 / h, the air intake of the middle air is controlled at 5% of the total air intake, and the volume content of oxygen in the flue gas after combustion is controlled to be 5.2%.

[0035] After testing: saving gas 15Nm 3 / h, NO in flue gas X Content 175mg / m 3 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com