Efficient and energy-saving gas thermal desorption equipment

A high-efficiency energy-saving, thermal desorption technology, applied in the restoration of polluted soil, etc., can solve the problems of large exhaust heat loss, increased operating costs, poor heat utilization effect, etc., to reduce nitrogen oxide content and improve combustion efficiency , the effect of temperature equalization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Some specific embodiments of the present invention will be described in detail below in an exemplary and non-limiting manner with reference to the accompanying drawings. The same reference numerals in the drawings designate the same or similar parts or parts. It should be understood by those skilled in the art that these drawings are not necessarily drawn to scale.

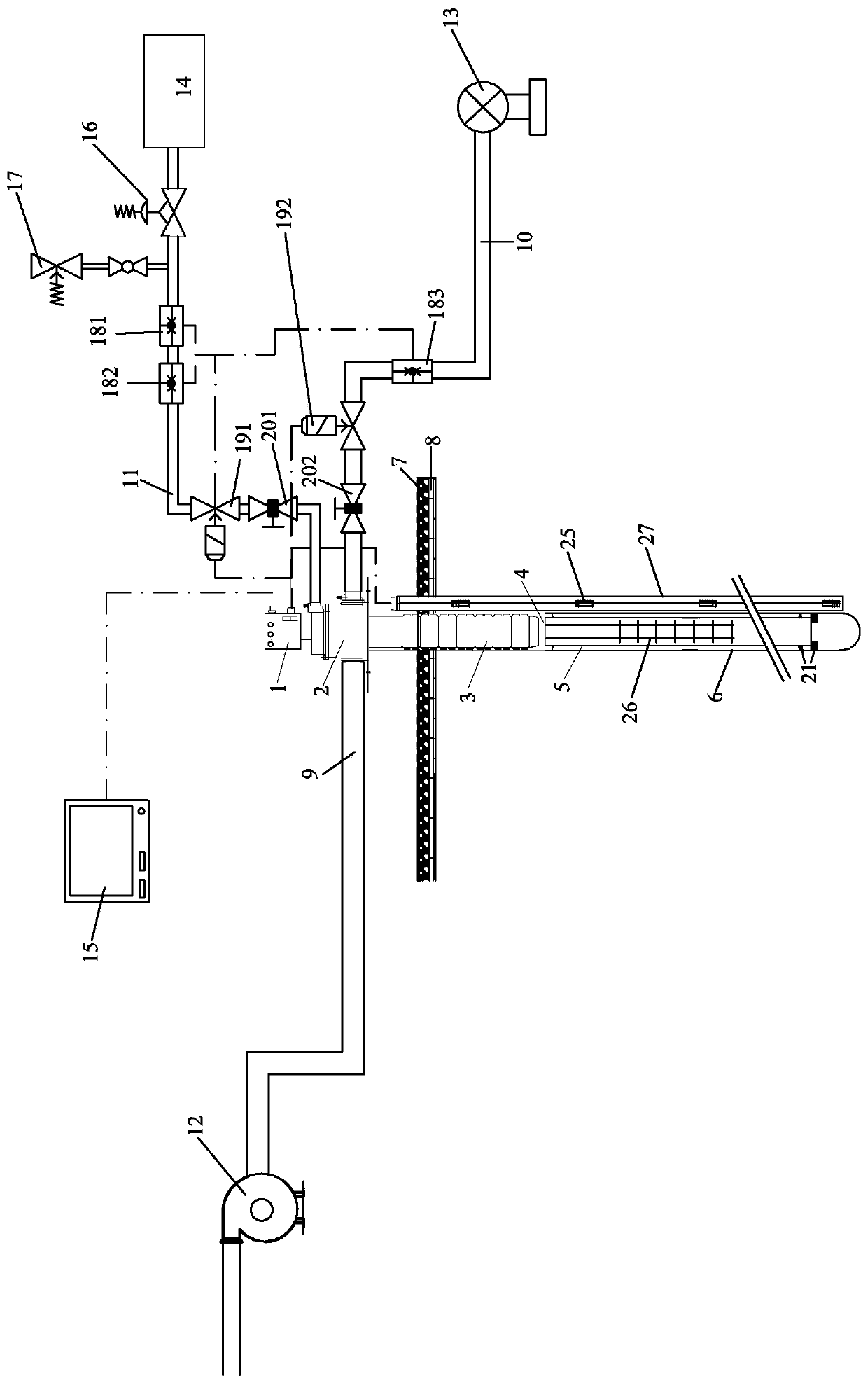

[0027] Such as figure 1 , figure 2 As shown, the high-efficiency and energy-saving gas thermal desorption equipment provided by the present invention includes:

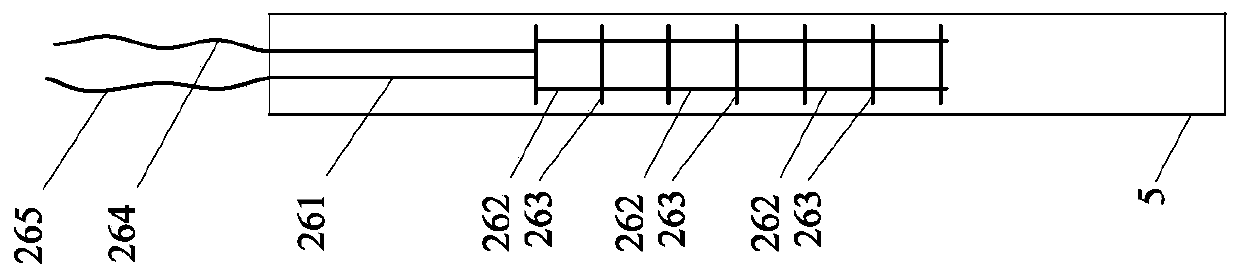

[0028] The heating well is arranged under the soil surface, and has an outer radiant tube 6 and an inner tube 5 (the lower end of the inner tube 5 is fixed by a support block 21 ) which are surrounded by each other to form a backflow gap. device 3, the heat exchanger 3 is located above the inner tube 5;

[0029] Insulation layer 7 is arranged on the soil surface layer 8 above the heating well;

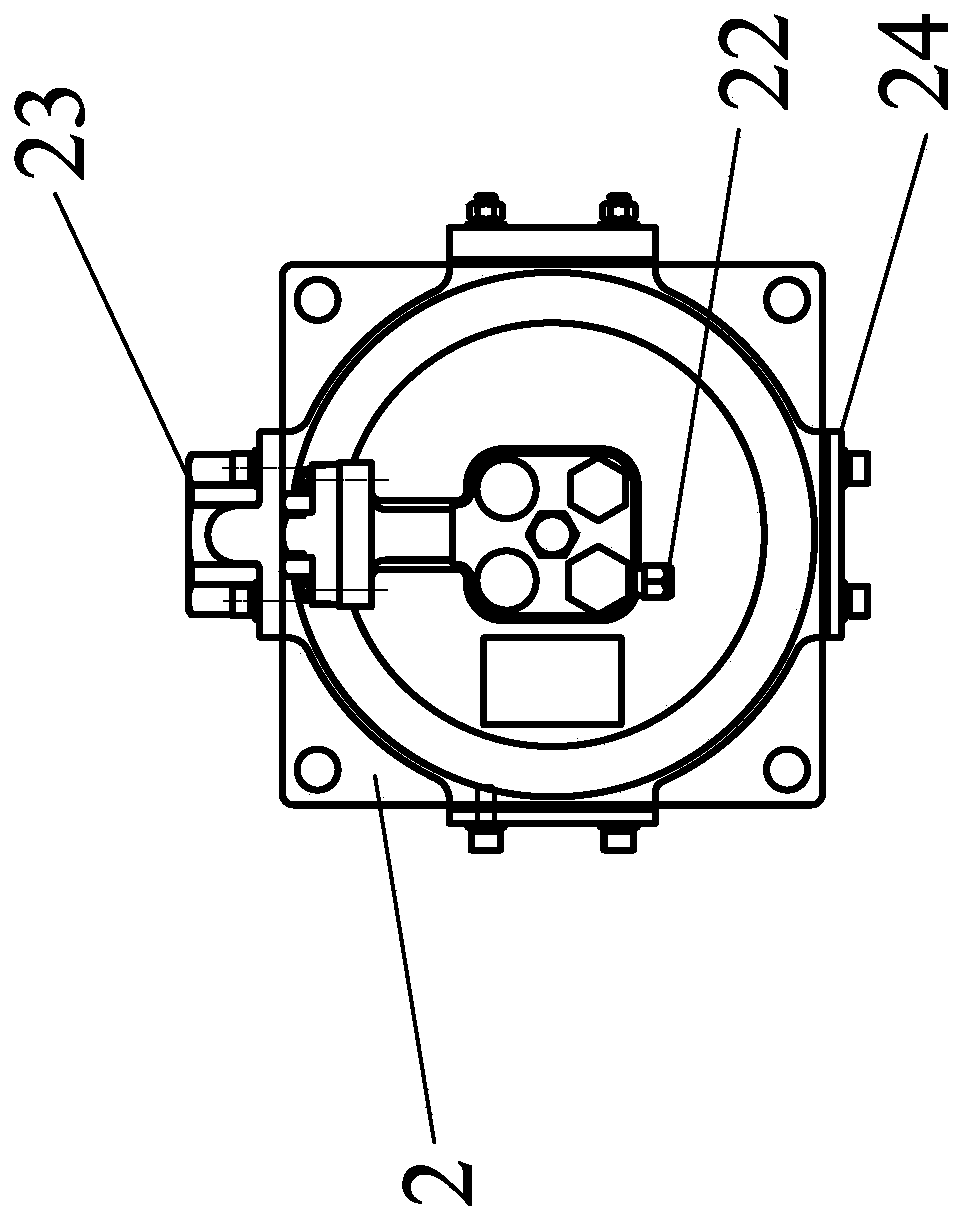

[0030] The burner 2 is arranged above the insul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com