Multifunctional ashless combustion accelerant of heavy oil

A heavy oil, multi-functional technology, applied in the field of oil refining, can solve problems such as less obvious effect, achieve the effect of improving heat transfer effect, reducing environmental pollution, and reducing initial temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] One, the present invention will be further described below:

[0020] A multifunctional ashless combustion aid for heavy oil, which includes a free oxygen generator, a catalyst, a dispersant and a solvent, the free oxygen generator accounts for 10-30% by mass, and the catalyst accounts for 25-50% by mass , The dispersant accounts for 20-40% by mass, and the solvent accounts for 20-40% by mass; the composition of the present invention is 100% based on the free oxygen generator, catalyst, dispersant and solvent.

[0021] Take the preparation of 100kg heavy oil multi-functional ashless combustion enhancer as an example, first add 20kg solvent to the reaction kettle, then add 15kg free oxygen generator, 35kg catalyst, 30kg dispersant in turn, and stir at 30-50°C for 20- 30 minutes.

[0022] Take the preparation of 100kg heavy oil multi-functional ashless combustion aid as an example, you can also add 22kg solvent to the reactor first, then add 20kg free oxygen generator, 30...

PUM

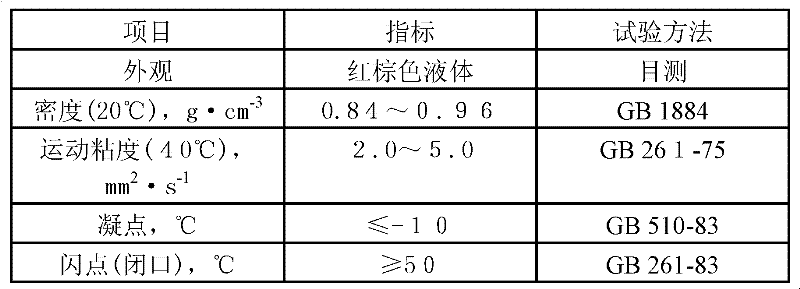

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| dew point | aaaaa | aaaaa |

| flash point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com