Fuel staging process for low NOx operations

A technology of fuel and fuel flow, which is applied in the field of fuel dilution nozzles and fuel dilution devices, and can solve problems such as low efficiency, low-efficiency steam injection mode, and uneconomical economy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

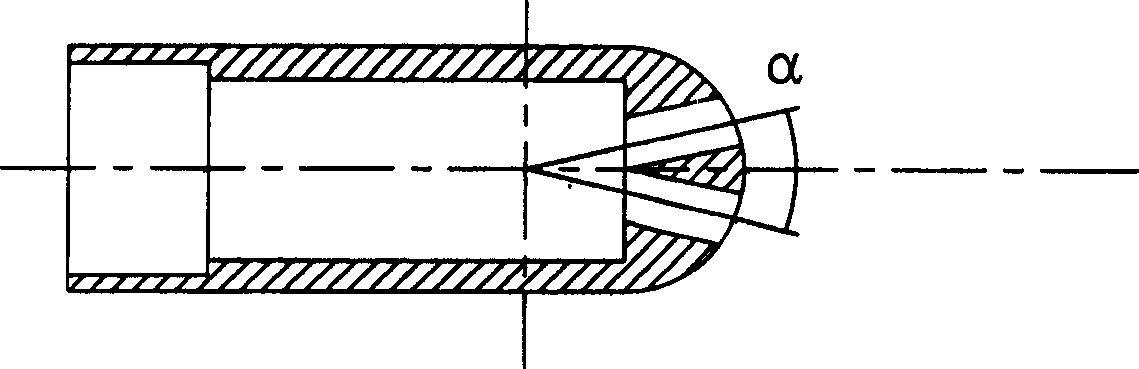

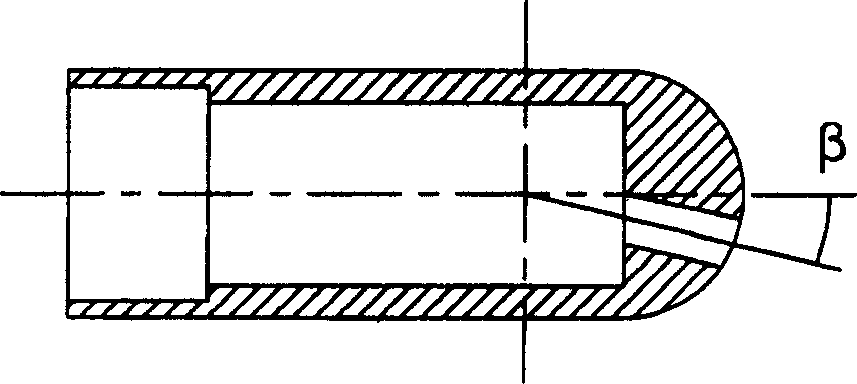

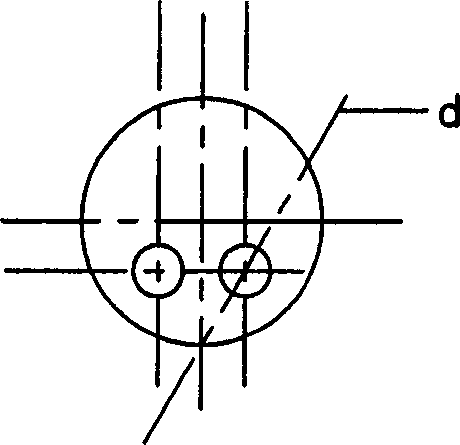

[0059] The present invention solves a series of problems faced in the design of combustion equipment, such as burners for heating reformers, thermal processors, boilers, ethylene cracking furnaces or other high temperature furnaces. The present invention relates to an improved fuel staging process. In particular, two general methods to achieve rapid dilution and blending according to the desired processing purpose are:

[0060] I. Use another fuel to segment fuel (F-F): inject high-pressure refinery waste fuel, atomized liquid fuel, etc. into the vicinity of cleaner low-pressure gaseous fuel to achieve clean, maintenance-free, low NOx working conditions ;and

[0061] II. Fuel staging with inert gas (F-I): splitting high-pressure inert fluids such as water vapor, nitrogen, CO 2 Injection near low-pressure gaseous fuel to reduce NOx.

[0062] As used herein, the term "fuel index" (FI) is defined as the weighted total number of carbon atoms in a fuel, where H 2 is assigned a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com