Patents

Literature

97results about How to "Reduce nitrogen oxide content" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

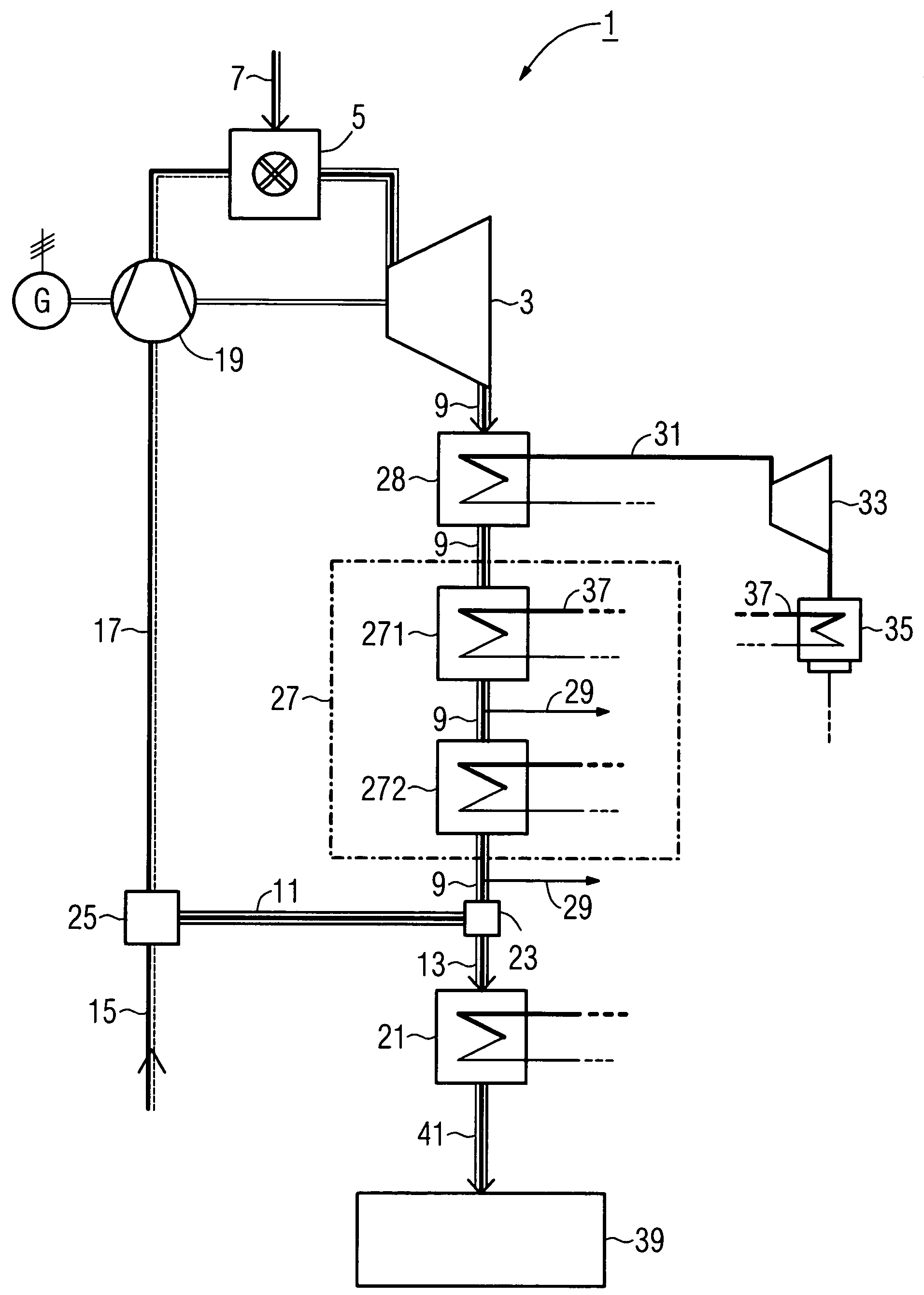

Method and device for operating a gas turbine with a fossil-fuel fired combustion chamber

InactiveUS7299637B2Reduce nitrogen oxide contentRisk minimizationGas turbine plantsDirect carbon-dioxide mitigationSteam-electric power stationCombustion chamber

A method according to the invention or a corresponding device (1) provides for dividing exhaust gas (9) exiting the gas turbine into a first (11) and a second partial stream (13), for mixing the first partial stream (11) with combustion air (15), and for channeling the resulting mixture (17) to the combustion chamber (5) and the second partial stream (13) to a carbon dioxide precipitation plant (21).In an advantageous embodiment the exhaust gas (9) exiting the gas turbine (3) is previously used to generate process steam (31) for a steam turbine (33) (gas and steam power station) then cooled before the exhaust gas (9) is divided into said partial streams (11,13). Water (29) precipitating during cooling is removed.

Owner:SIEMENS AG

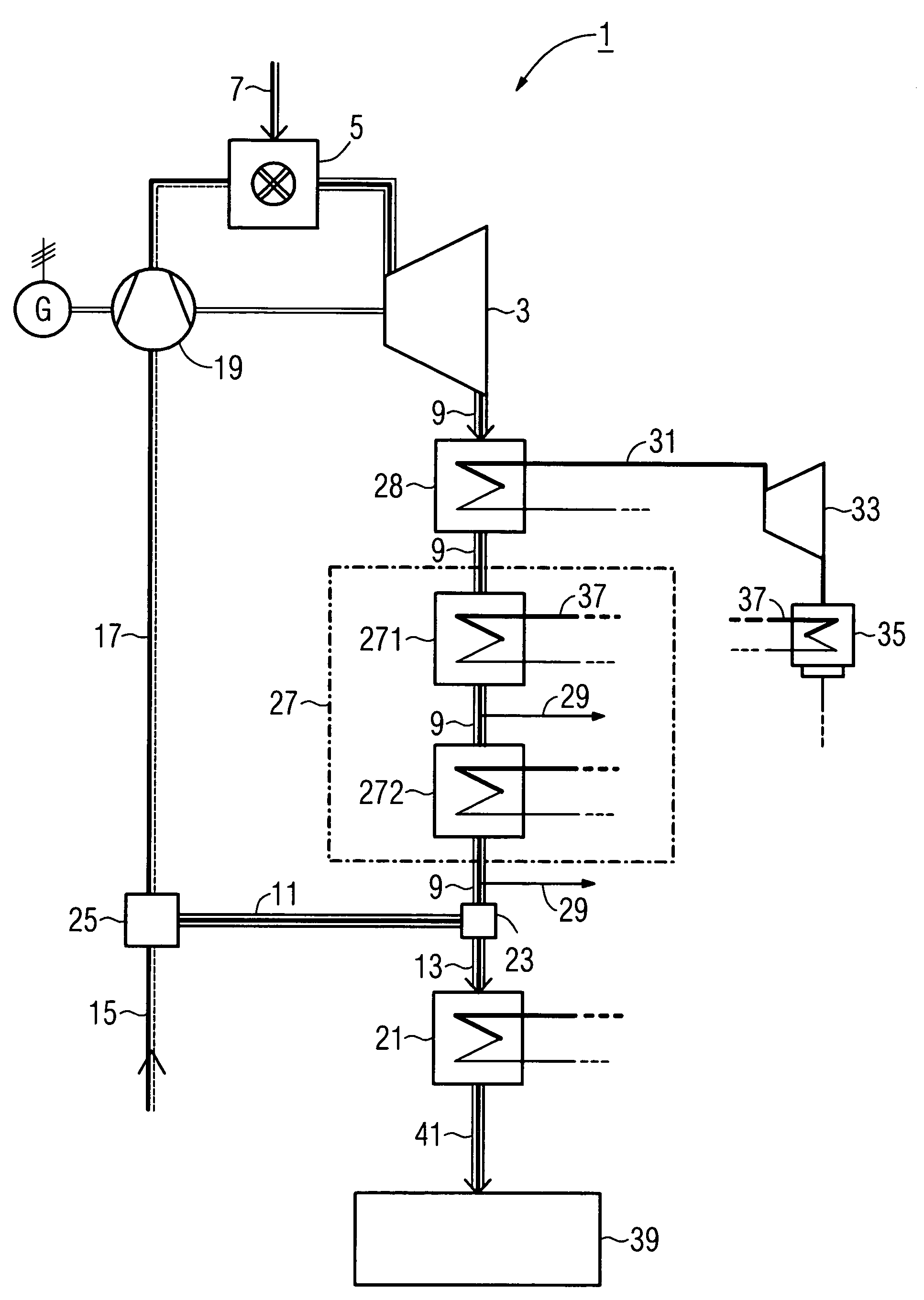

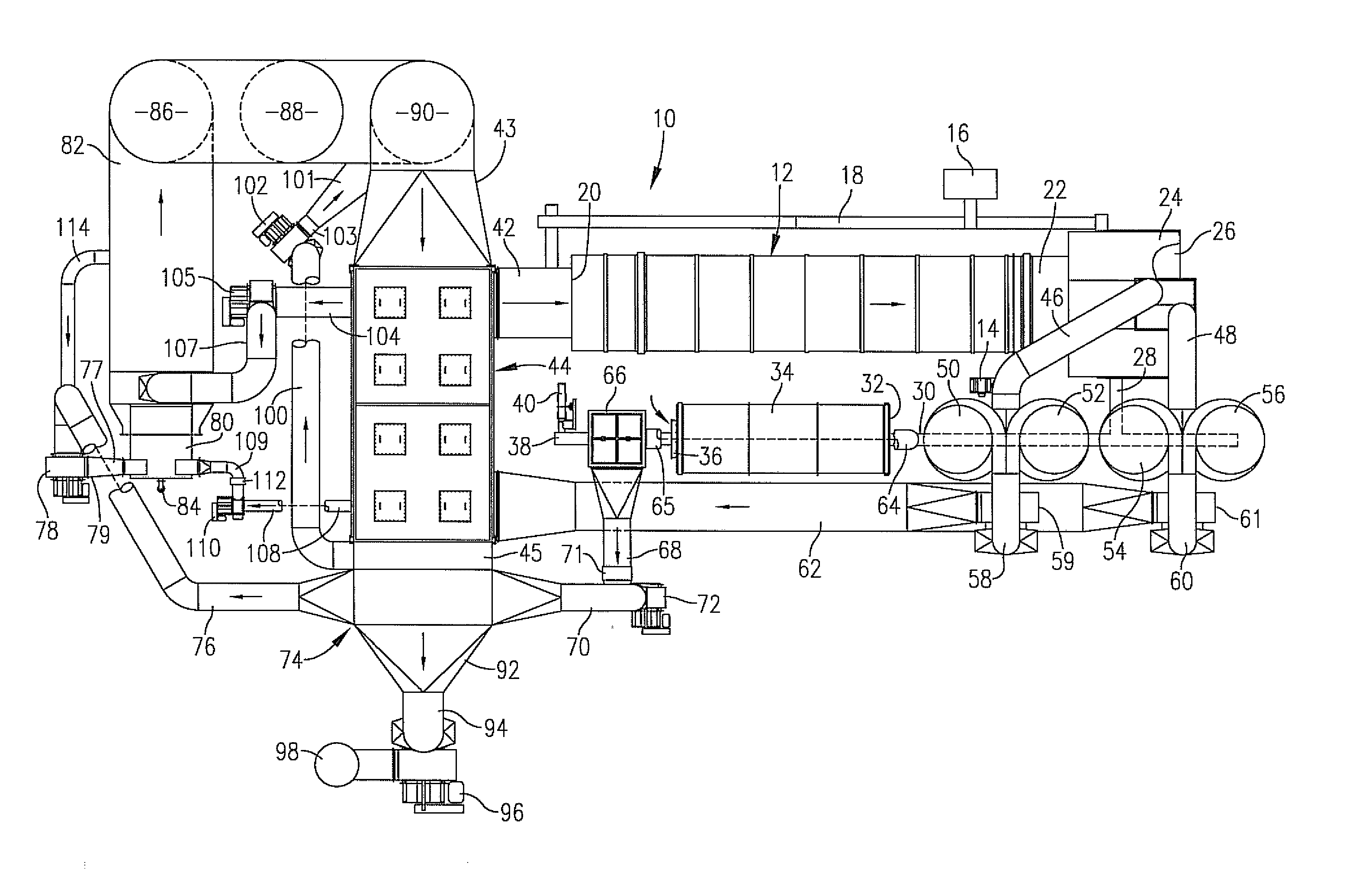

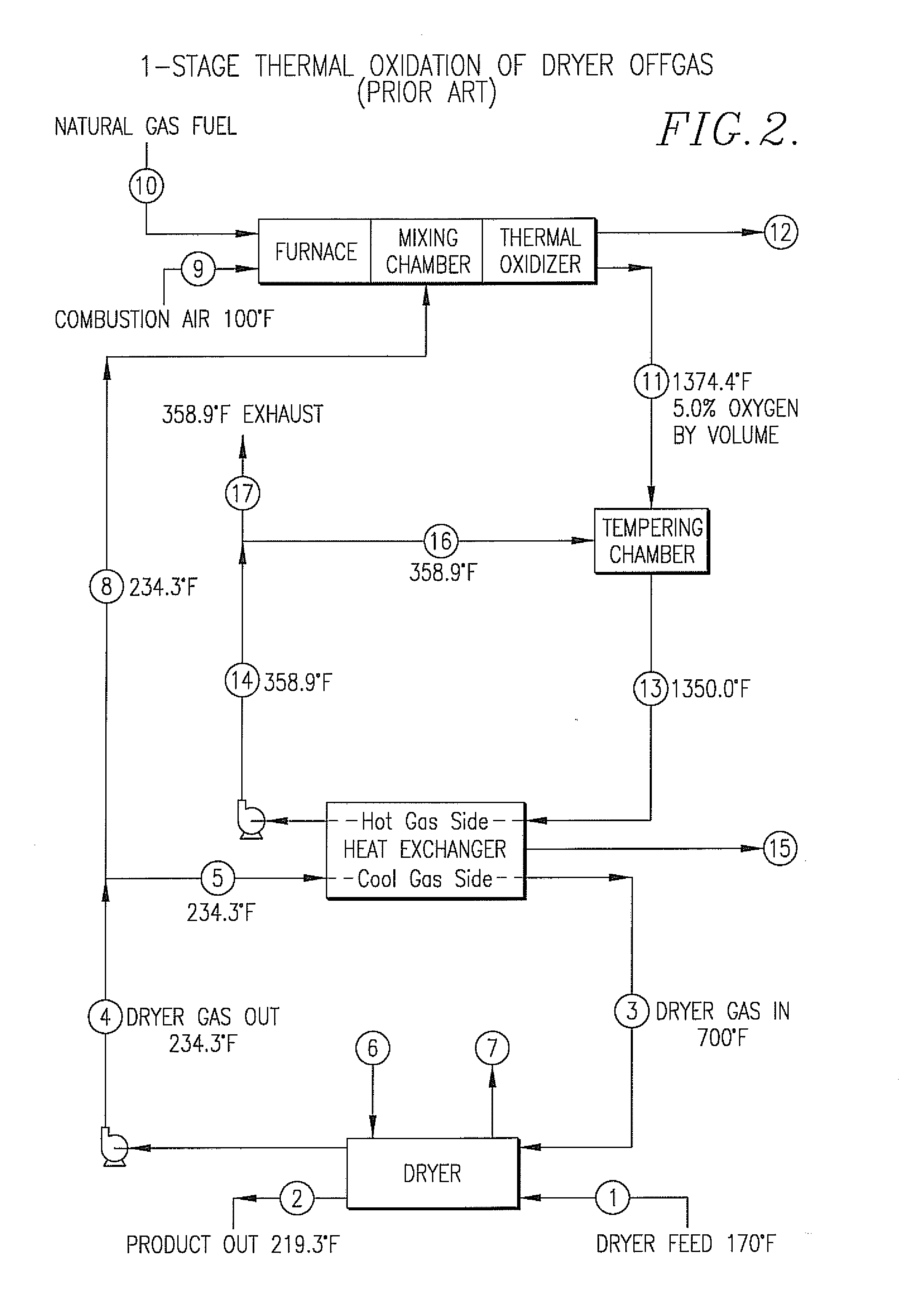

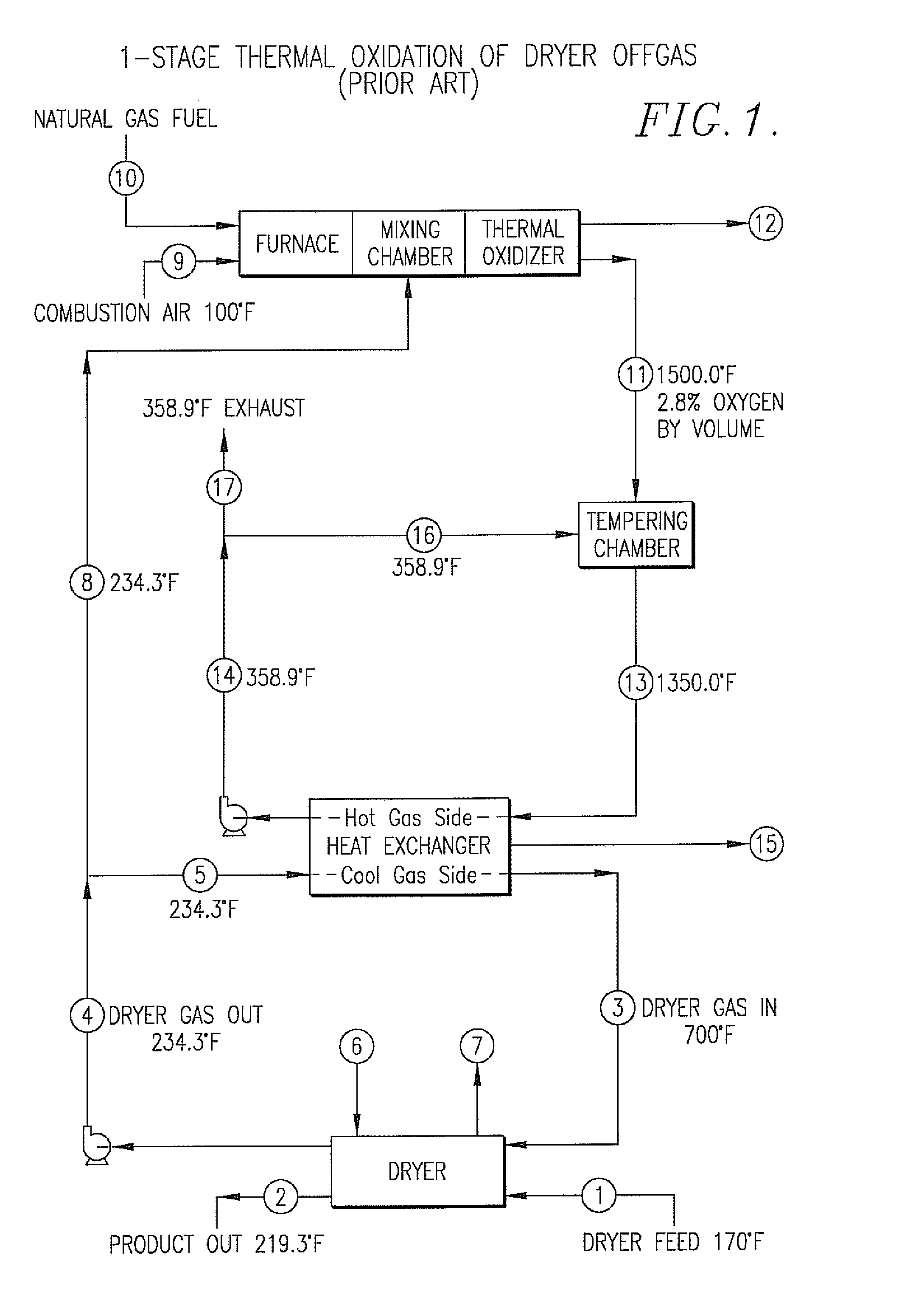

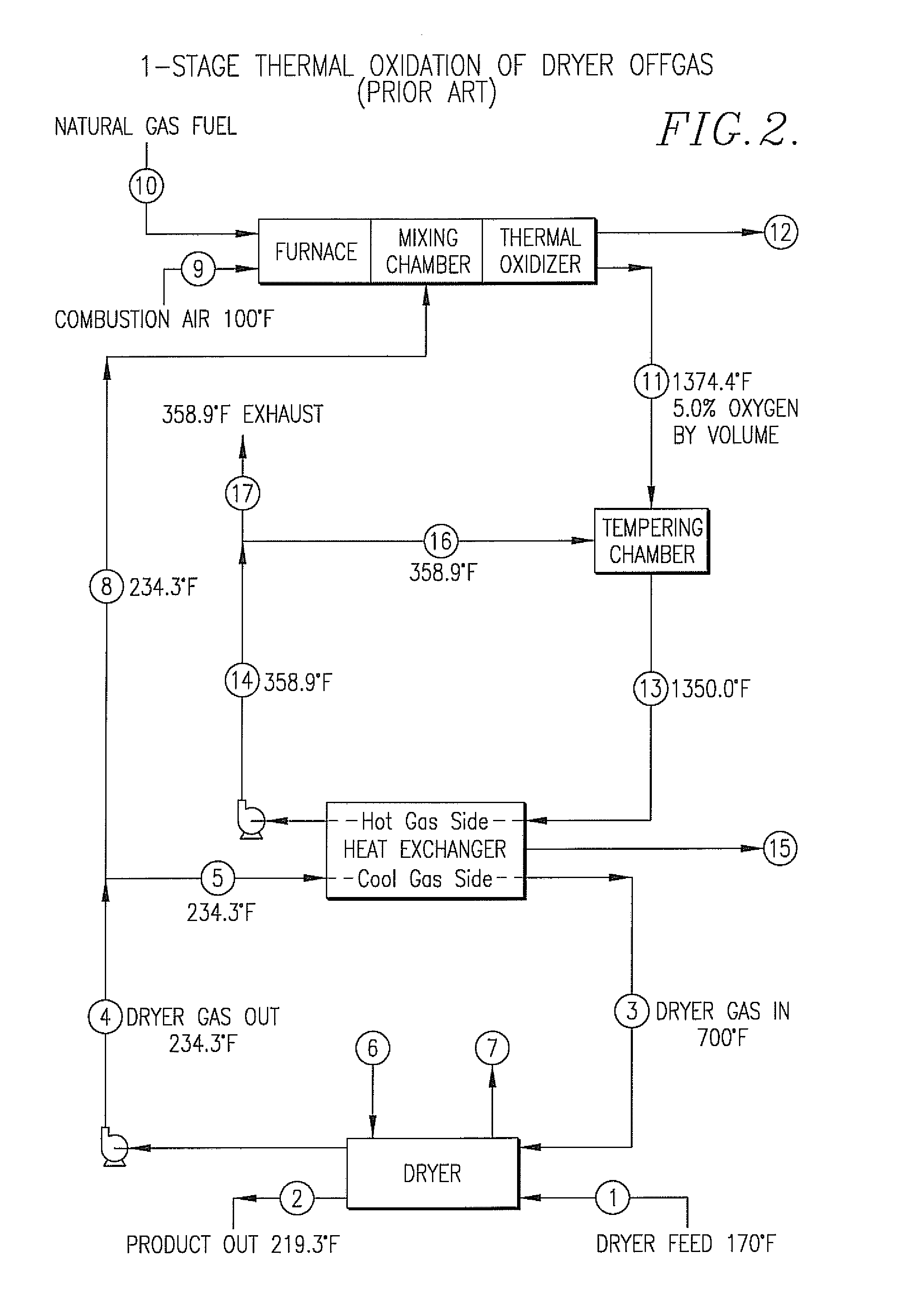

Two-stage thermal oxidation of dryer offgas

ActiveUS20080222913A1Increase temperatureReduce the temperatureDrying solid materials with heatDrying gas arrangementsAtmospheric airOxygen

A method and apparatus are provided for reducing the VOC, CO, and, alternatively, the NOx content of dryer offgas that is discharged into the atmosphere from a moist organic product drying process using thermal oxidizing apparatus that includes a burner, furnace, mixing chamber, thermal oxidizer, tempering chamber, and an indirect gas-to-gas heat exchanger. The dryer offgas is separated into two portions, with a larger portion being preheated by indirect heat exchange with the hot gaseous output from the thermal oxidizer. The non-preheated portion is directed to the burner in the function of flue gas recycle for NOx control. The preheated portion is separated into two portions, with one portion being directed to the furnace / mixing chamber of the thermal oxidizing apparatus. The other portion of the preheated offgas is recycled to the hot gas inlet of the dryer and serves the function of dryer heat transfer media. Ultimately, all the dryer offgas enters the thermal oxidizer, and comprises a smaller non-preheated portion directed to the burner and a larger preheated portion directed to the furnace / mixing chamber. By preheating a large proportion of the offgas directed to the thermal oxidizing apparatus, simultaneous achievement of an adequate thermal oxidizer temperature, 1600° F., and an adequate oxygen concentration of 5% by volume is achieved for optimized thermal oxidation of carbon monoxide and volatile organic compounds.

Owner:AEROGLIDE

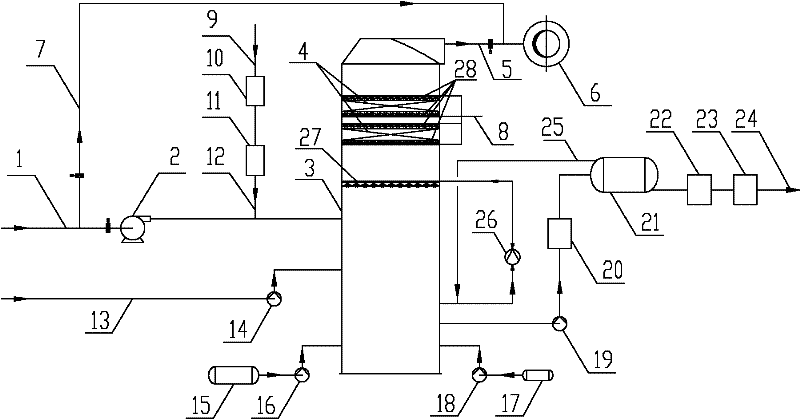

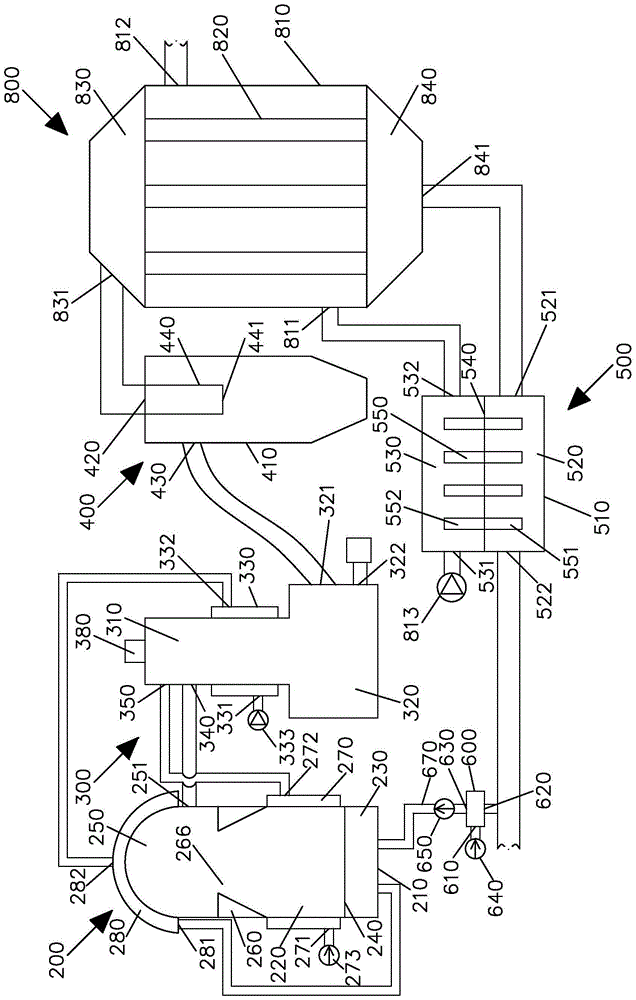

Integrated method for simultaneously realizing denitrification, desulfurization and heavy metal removal from flue gas, and special equipment suitable for the method

ActiveCN102188882ASimple systemEasy to implementDispersed particle separationAir quality improvementAmmonium sulfateFertilizer

The invention relates to an integrated method for simultaneously realizing denitrification, desulfurization and heavy metal removal from flue gas, and special equipment suitable for the method. The integrated method is characterized in that an acidic gas capture agent adopted by the invention captures SO2 and / or highly charged nitrogen oxides NOx in raw flue gas and thus ammonium sulfate as a by-product and / or ammonium nitrate as a by-product is obtained finally, and the acidic gas capture agent adsorbs heavy metals in the raw flue gas simultaneously, wherein the above processes are carried out in a same absorbing device. The special equipment suitable for the method of the invention comprises an absorbing tower, a raw flue gas input pipeline having an external connection with the absorbing tower body, a purified flue gas output pipeline having an external connection with the absorbing tower body, a system for supplying the acidic gas capture agent and absorbents, a demisting water input pipeline, an absorption liquid cycling system, a slurry discharge system, and a separation and treatment system, wherein the raw flue gas input pipeline is provided with a supercharging system anda forced oxidation system. Through the method of the invention, the integrated purification processes of denitrification, desulfurization and heavy metal removal from flue gas can be completed in a same device and by-products from the integrated purification processes are ammonium sulfate and ammonium nitrate, wherein ammonium sulfate and ammonium nitrate can be utilized as components of fertilizers. Through the method, waste water and waste residue are not produced in the integrated purification processes and the integrated purification processes have the advantages of simple system, low cost, high recovery rate, etc.

Owner:BEIJING SPC ENVIRONMENT PROTECTION TECH

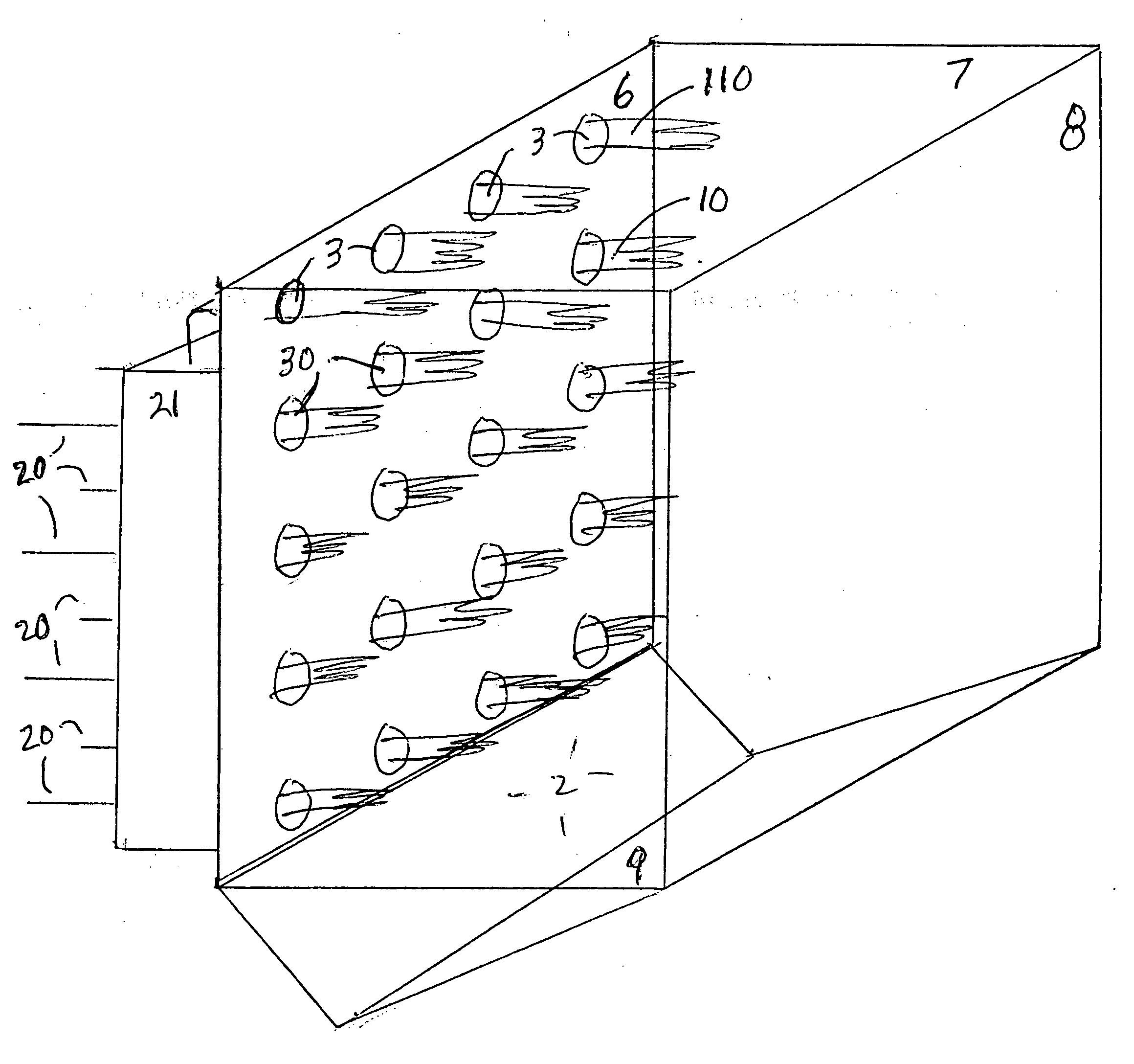

Method for generating multistage reburning controlling high-capacity coal fired boiler NOX

InactiveCN1584396AExtended stayImprove protectionDispersed particle separationSolid fuel combustionAir volumePower station

A method for eliminating NOx generation by large coal boiler in power plant is achieved by arranging multiple stage-and-section re-firing nozzles between the top primary nozzle and final nozzle. Fuels are supplied at some ratio at the stages and sections and blowing volumes are also regulated to form a re-firing area for complete combustion at top of the primary combustor to extend the time for reduction of NOx as pollutant. The re-firing nozzles are arranged beneath the primary combustor in several stages to reduce exhaust of NOx obviously.

Owner:SHANGHAI UNIVERSITY OF ELECTRIC POWER

Dual catalyst heating system

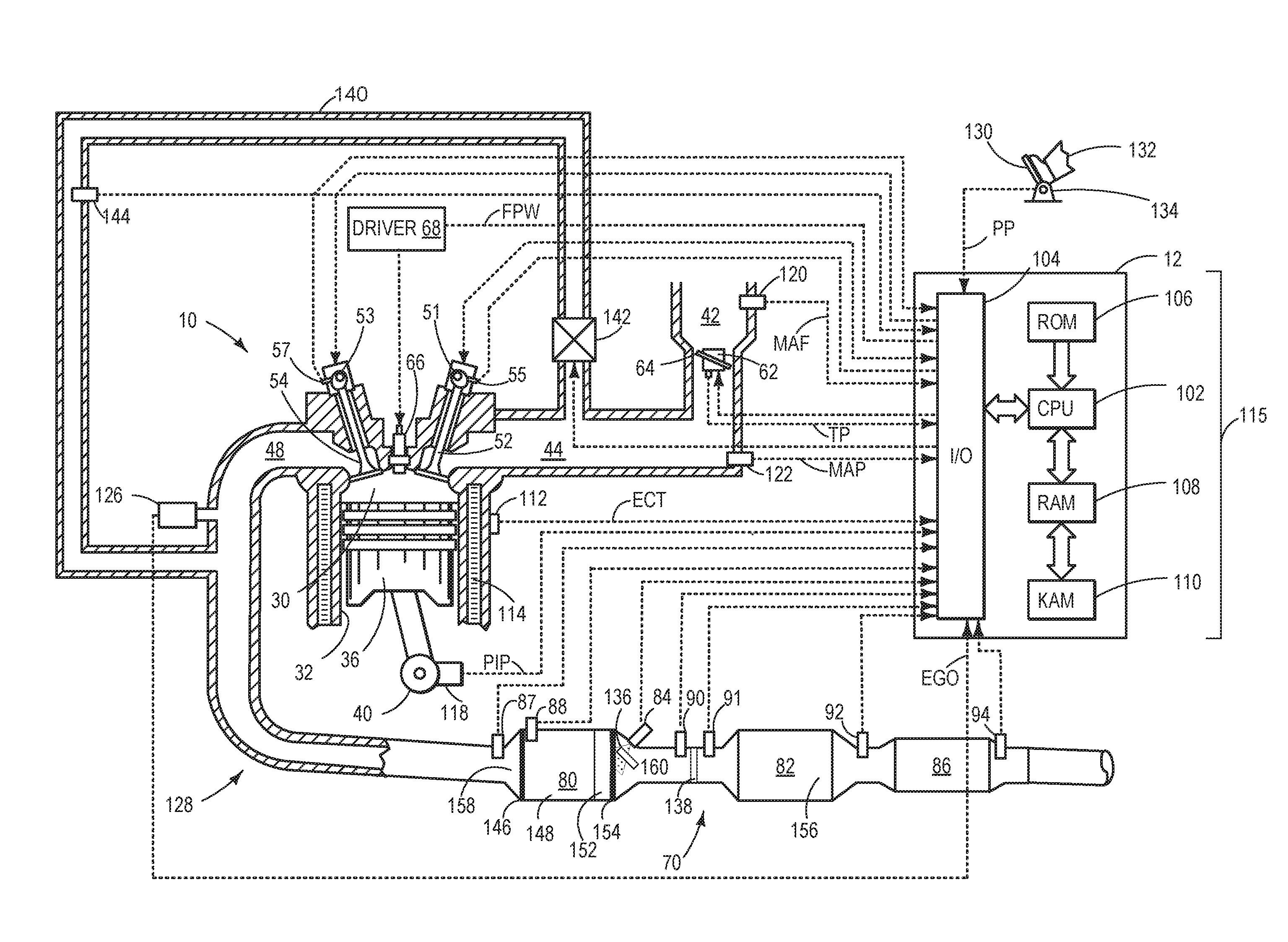

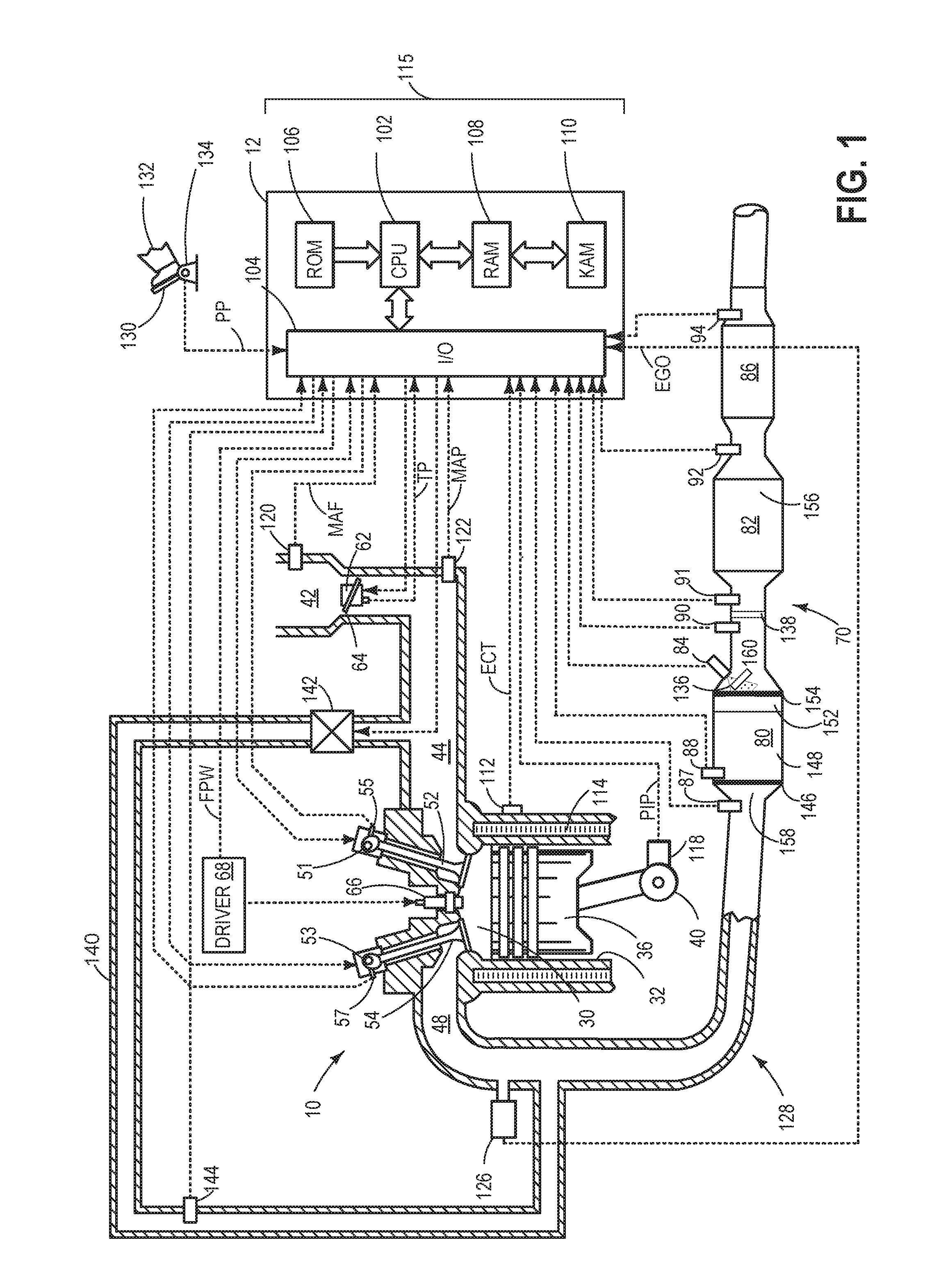

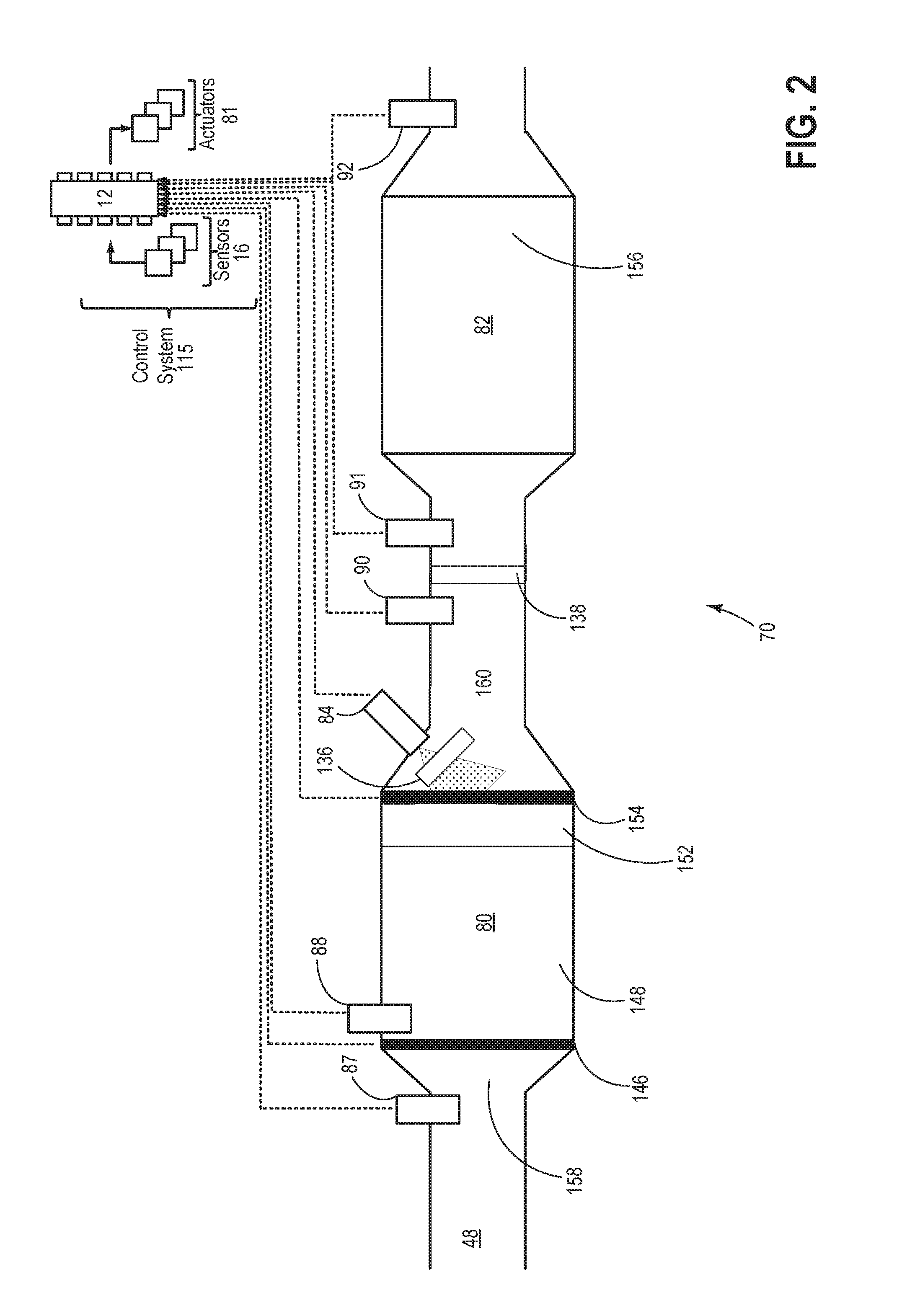

ActiveUS20170037799A1Reduce nitrogen oxide contentGas treatmentElectrical controlNitrogen oxidesCombustion

Methods and systems are provided for an exhaust gas aftertreatment system for a combustion engine in a motor vehicle. In one example, the exhaust gas aftertreatment comprises at least two catalyst devices arranged in an exhaust tract, and a feed device for a reducing agent arranged between the two catalysts, and which furthermore comprises a first heat device at the inlet of the first catalyst and a second heat device downstream thereof, the system adapted for the reduction of nitrogen oxides.

Owner:FORD GLOBAL TECH LLC

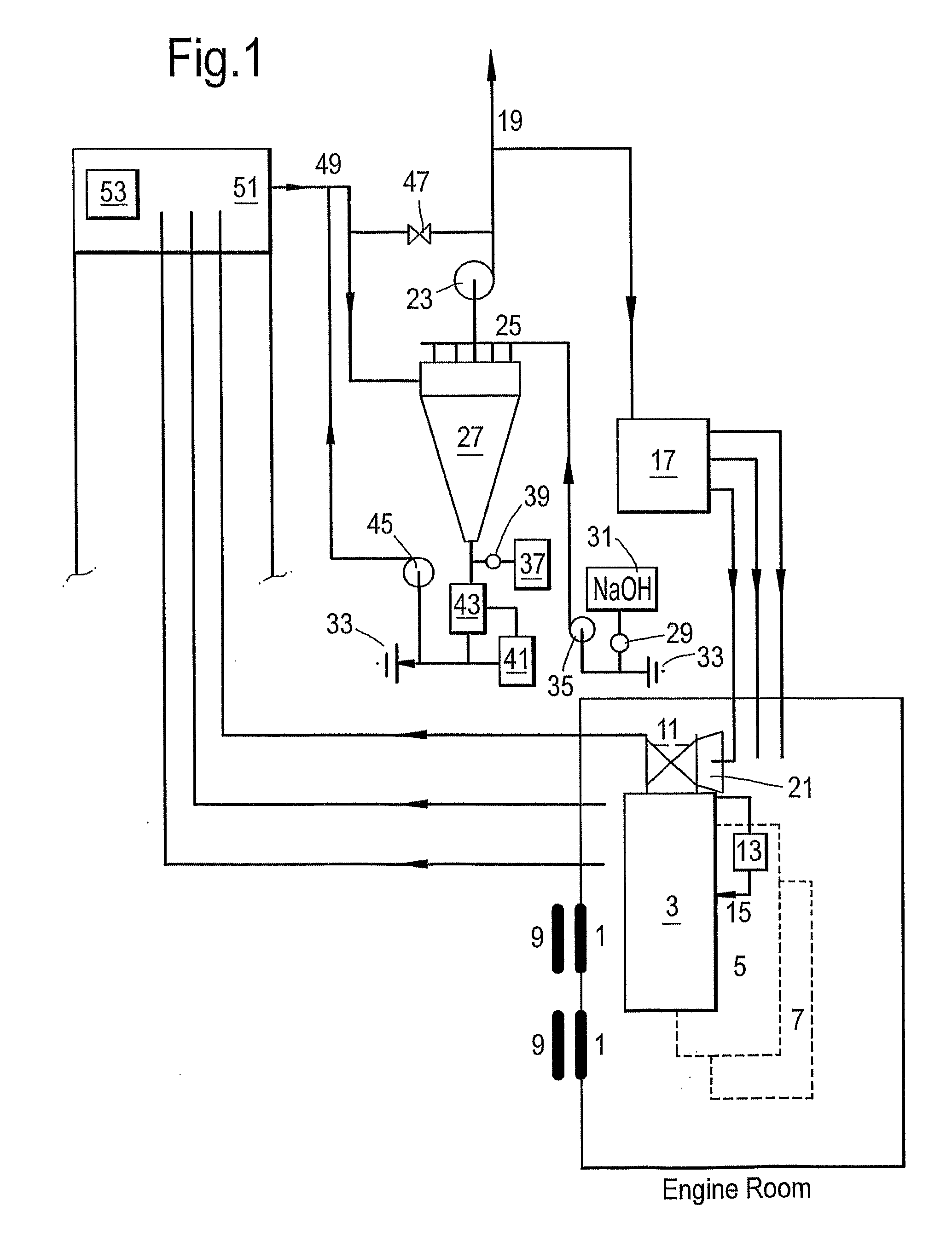

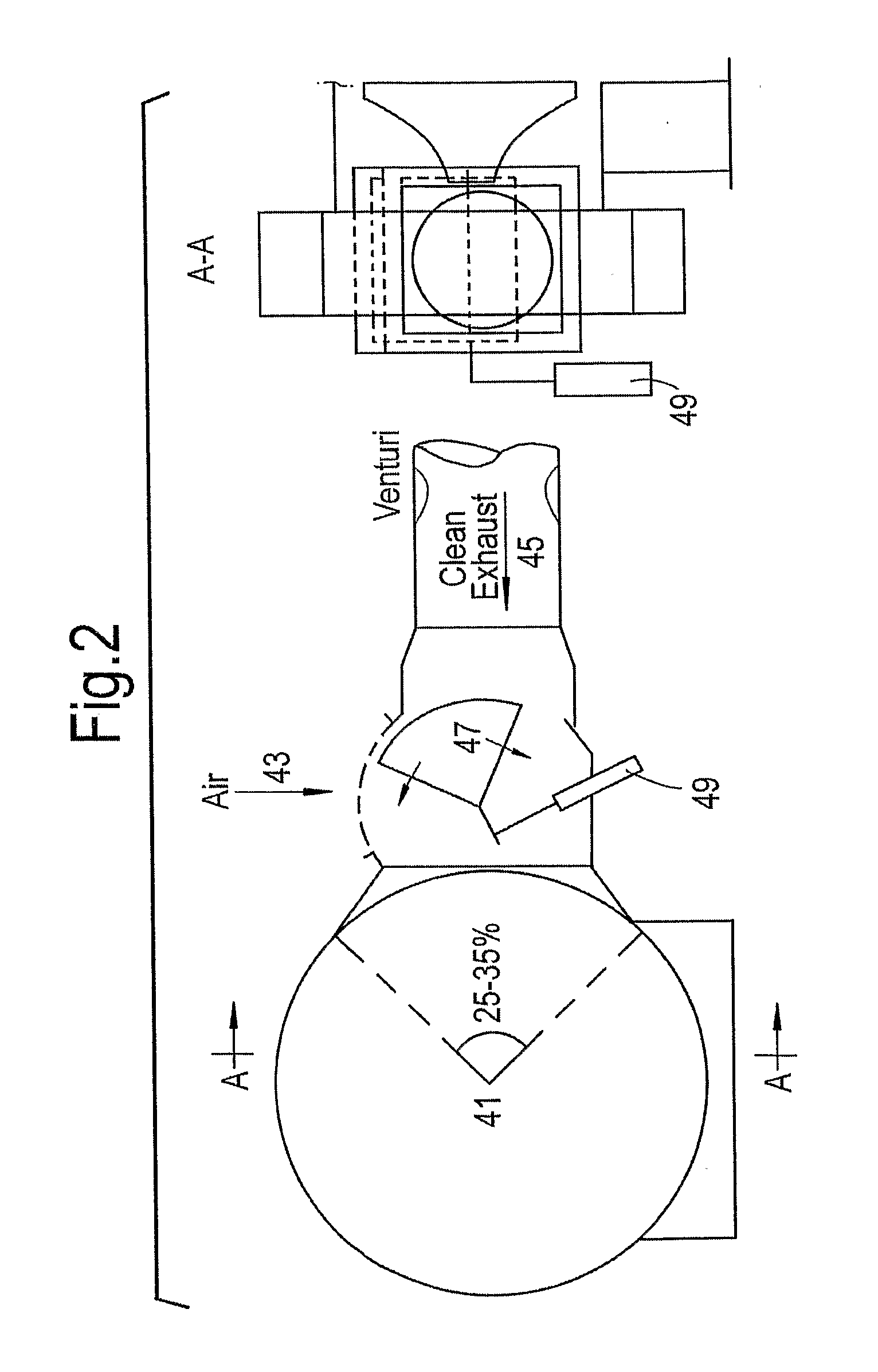

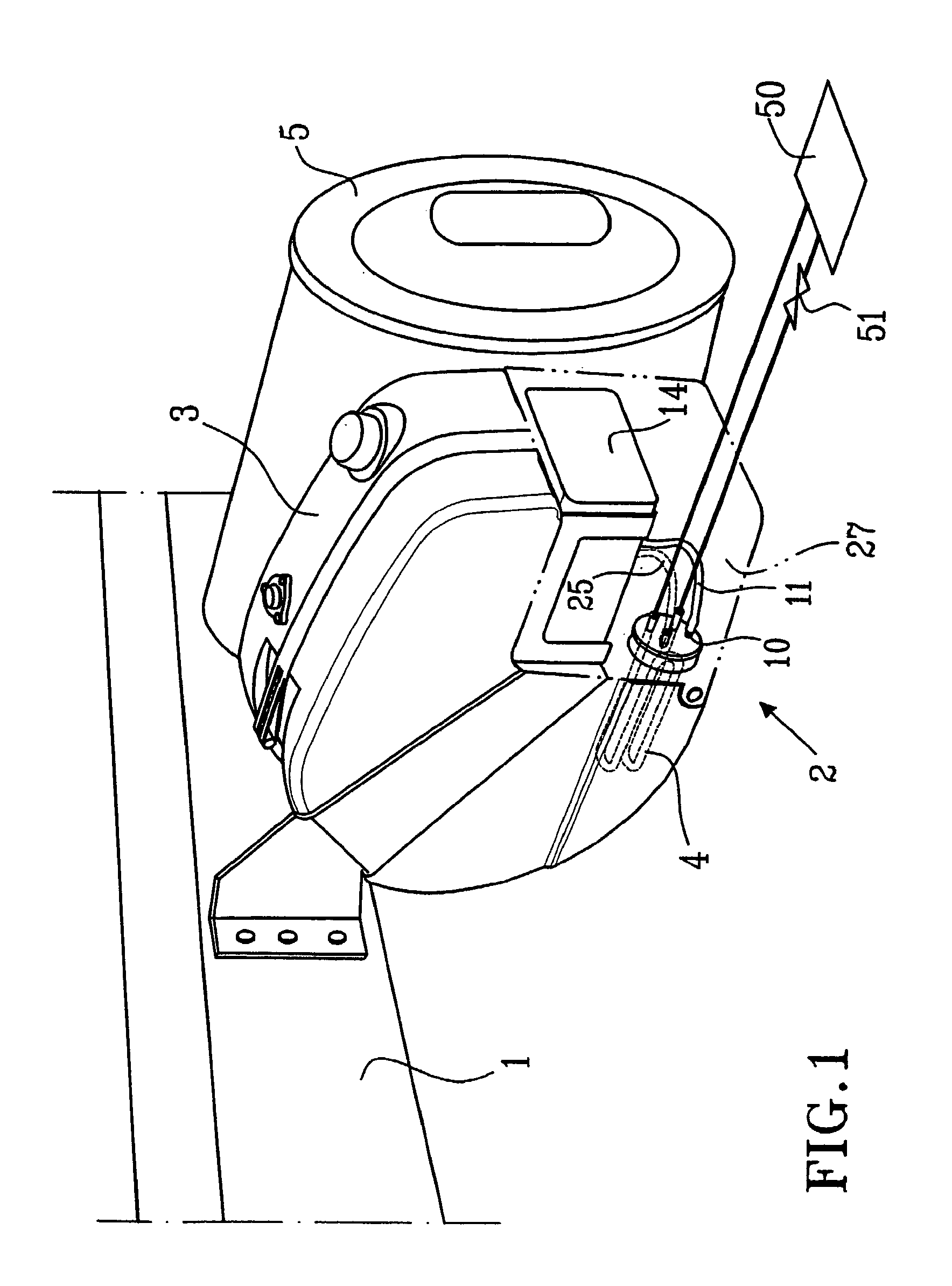

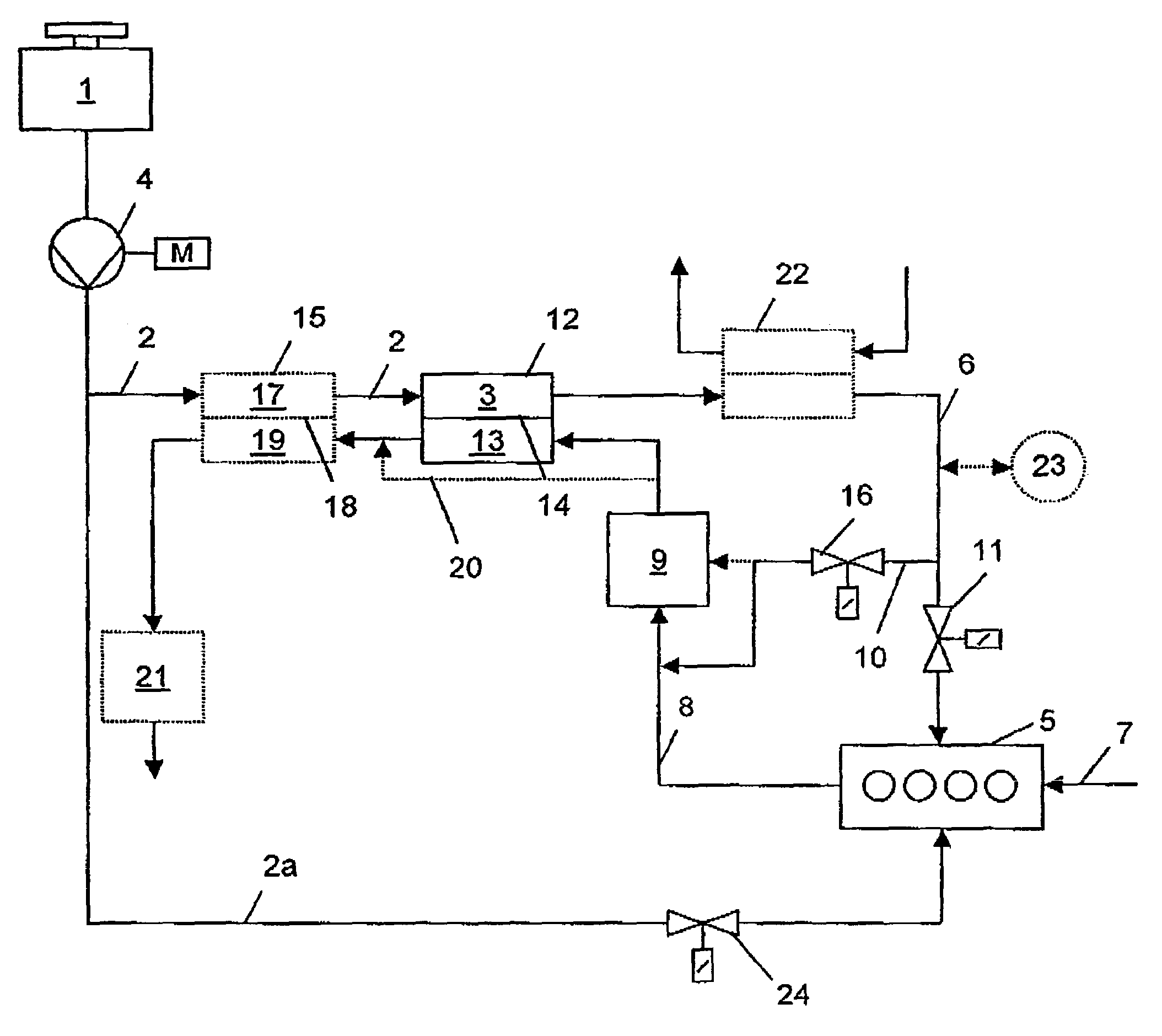

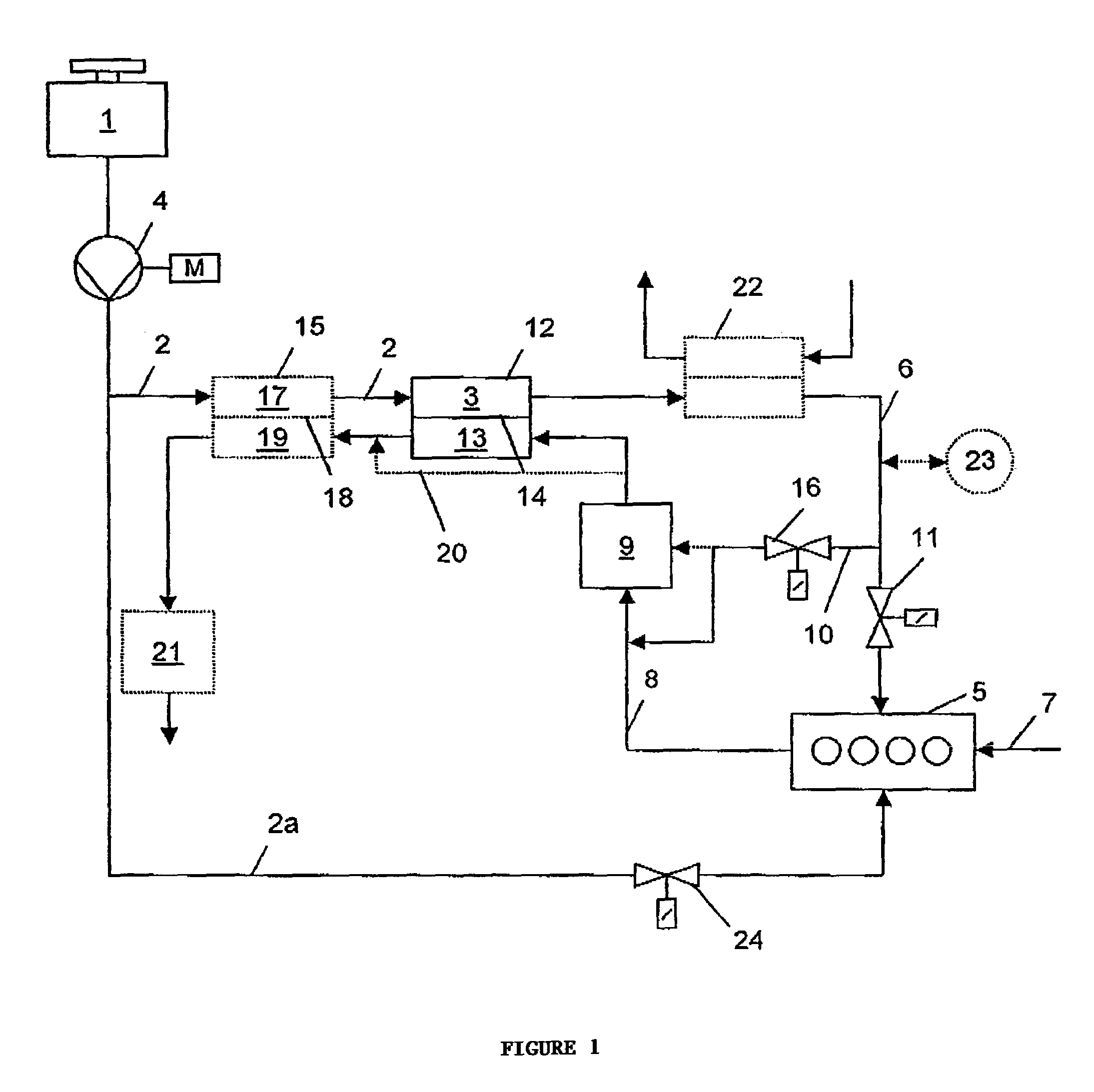

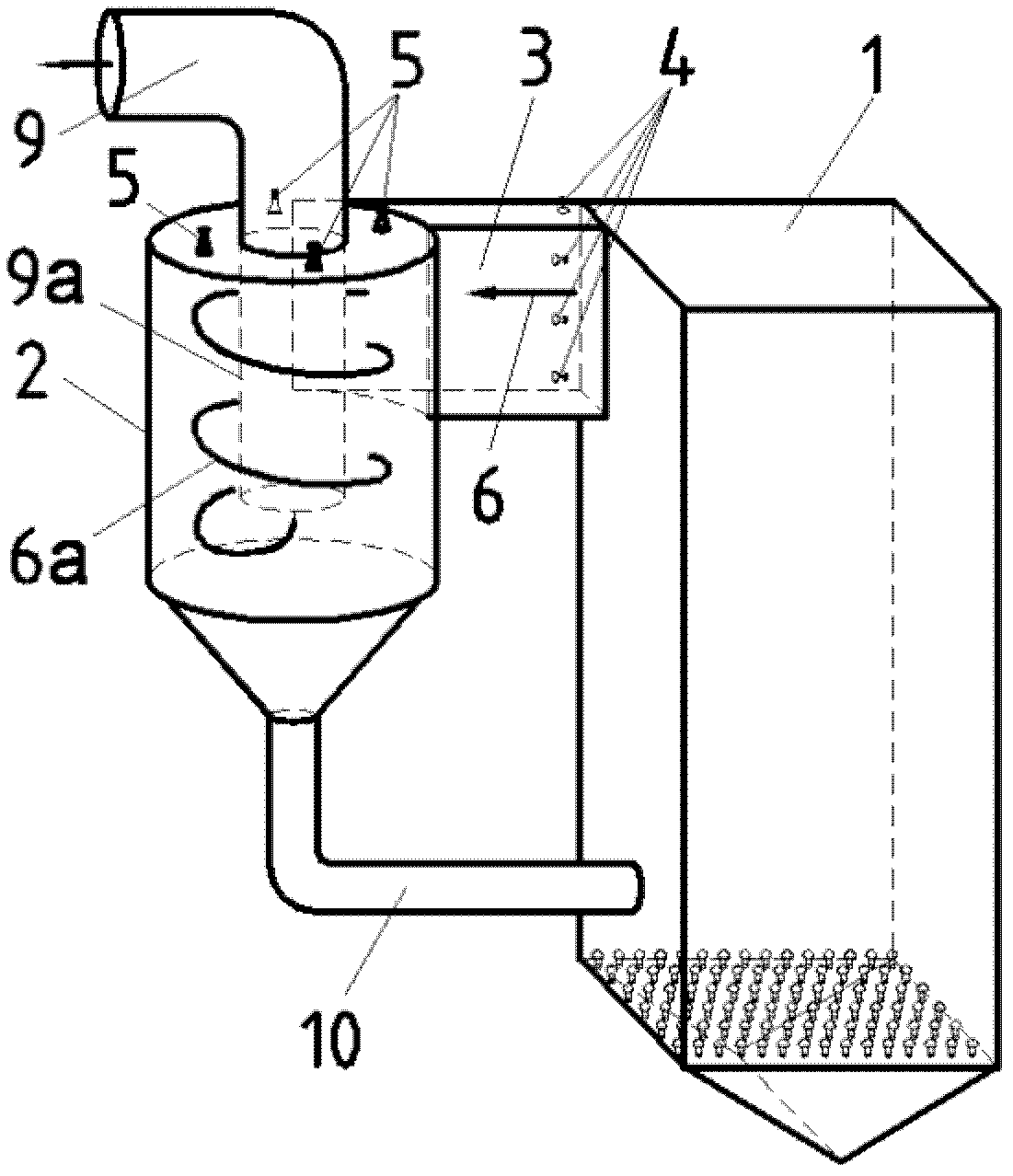

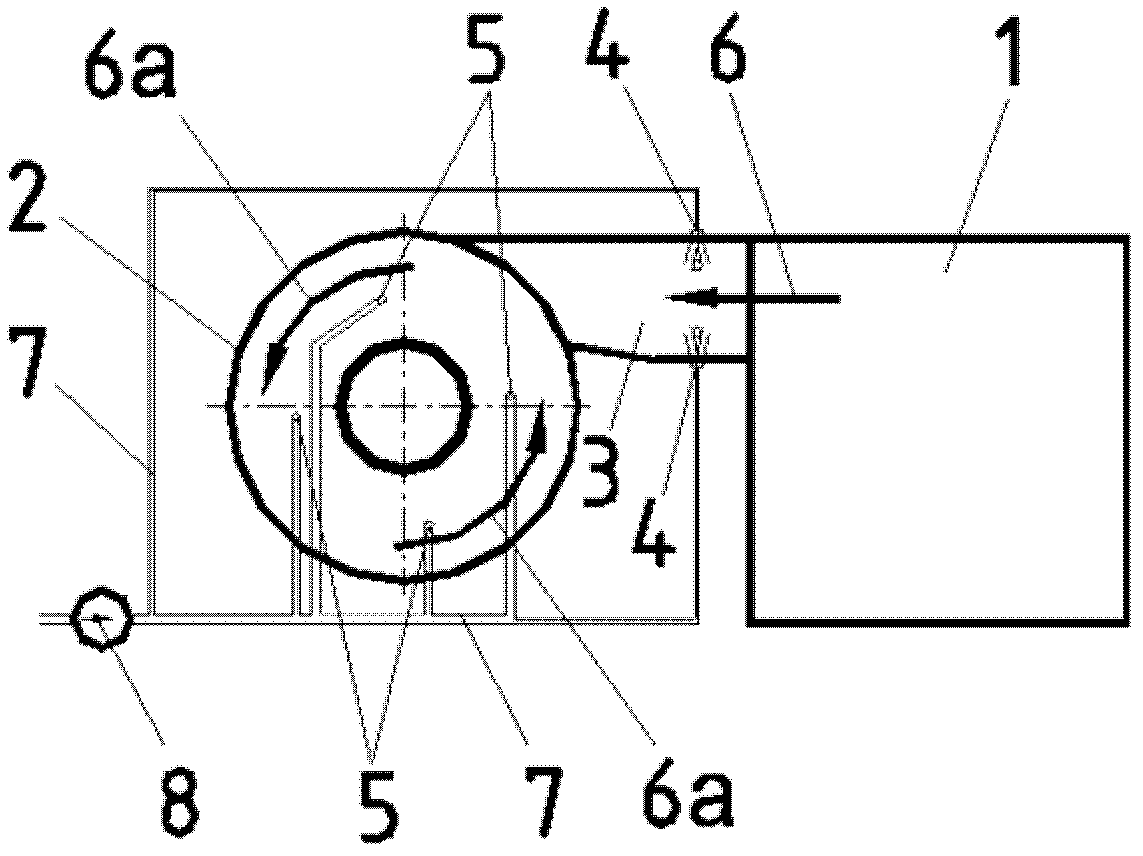

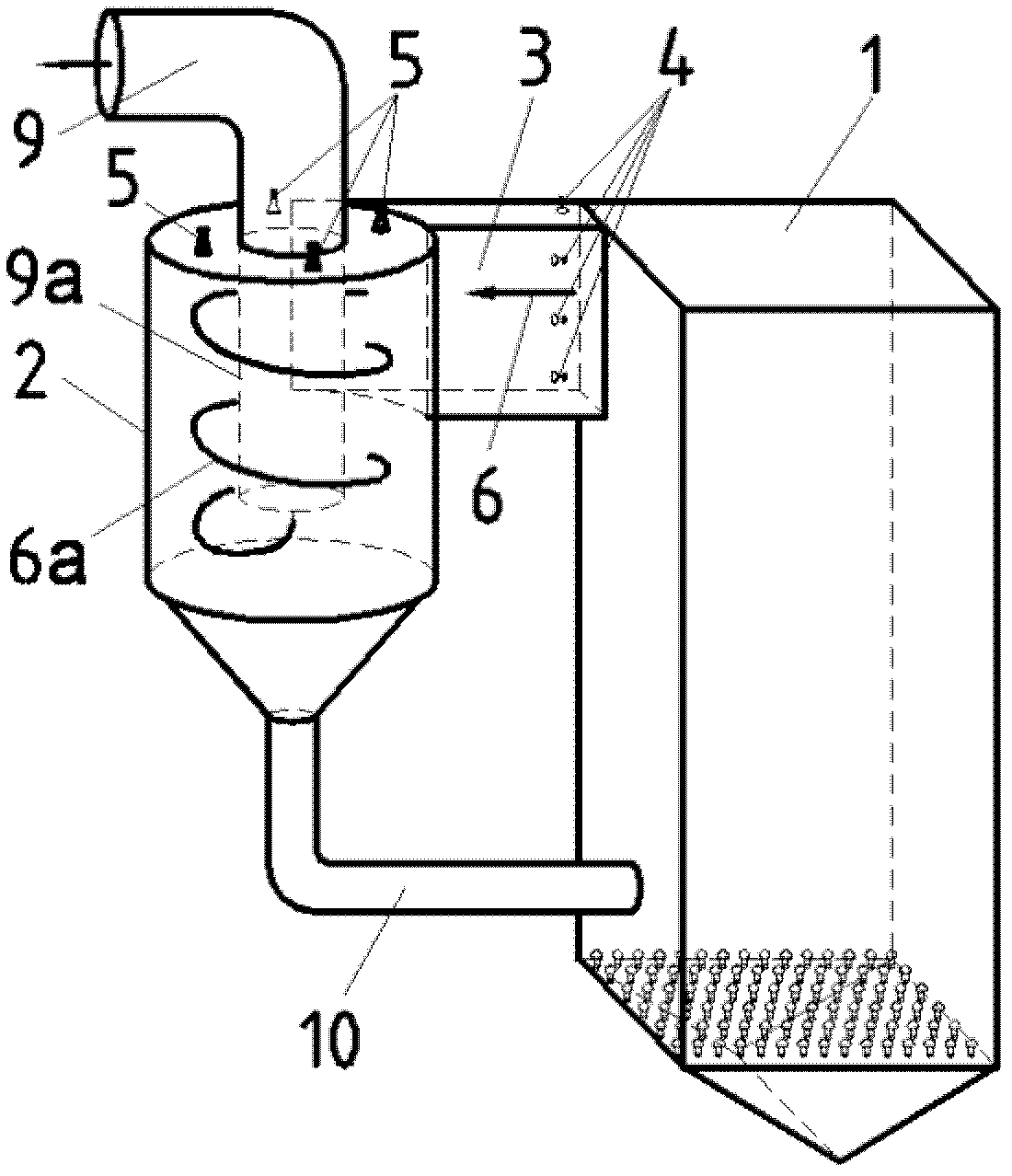

Methods and Device for Low Contamination Energy Generation

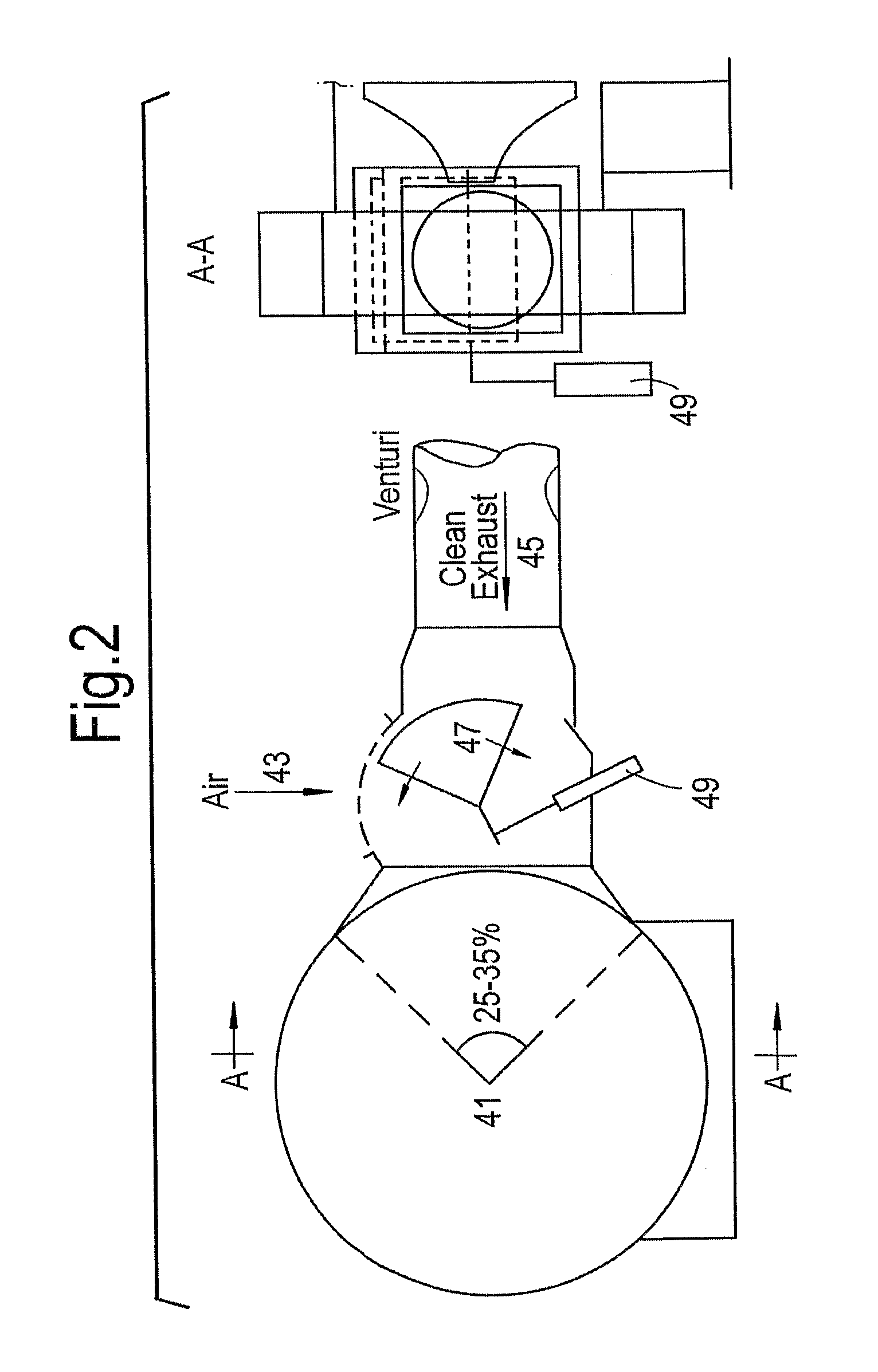

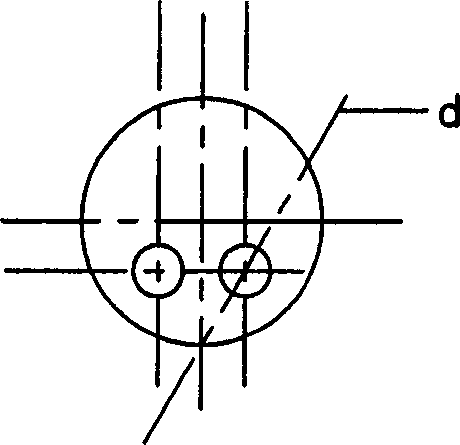

ActiveUS20120036832A1Reduce contentHigh engine loadCombination devicesInternal combustion piston enginesNitrogen oxidesProcess engineering

A method for low-contamination generation of energy comprising: (a) forming a gas mixture by mixing a treated gaseous effluent stream and air; (b) introducing the gas mixture and fuel at a given gas to fuel ratio into at least one diesel engine (3); (c) burning the fuel in the diesel engine to generate energy and a flue gas stream comprising particulate matter (PM), and nitrogen oxides (NOx); (d) treating at least a portion of the flue gas stream with an aqueous stream in a cyclone unit (27) comprising a housing defined by a cylindrical peripheral wall (2) and provided with at least one inlet opening (10) for receiving flue gas and at least one inlet opening for receiving fluids thereinto and with at least one swirling means, whereby a treated gaseous effluent stream and an aqueous effluent stream are formed; (e) emitting a portion of the treated gaseous effluent stream to form an emitted portion; (f) using a portion of the treated gaseous effluent stream to form the gas mixture, and (g) repeating steps (a) through (f) multiple times;

Owner:CLEAN MARINE

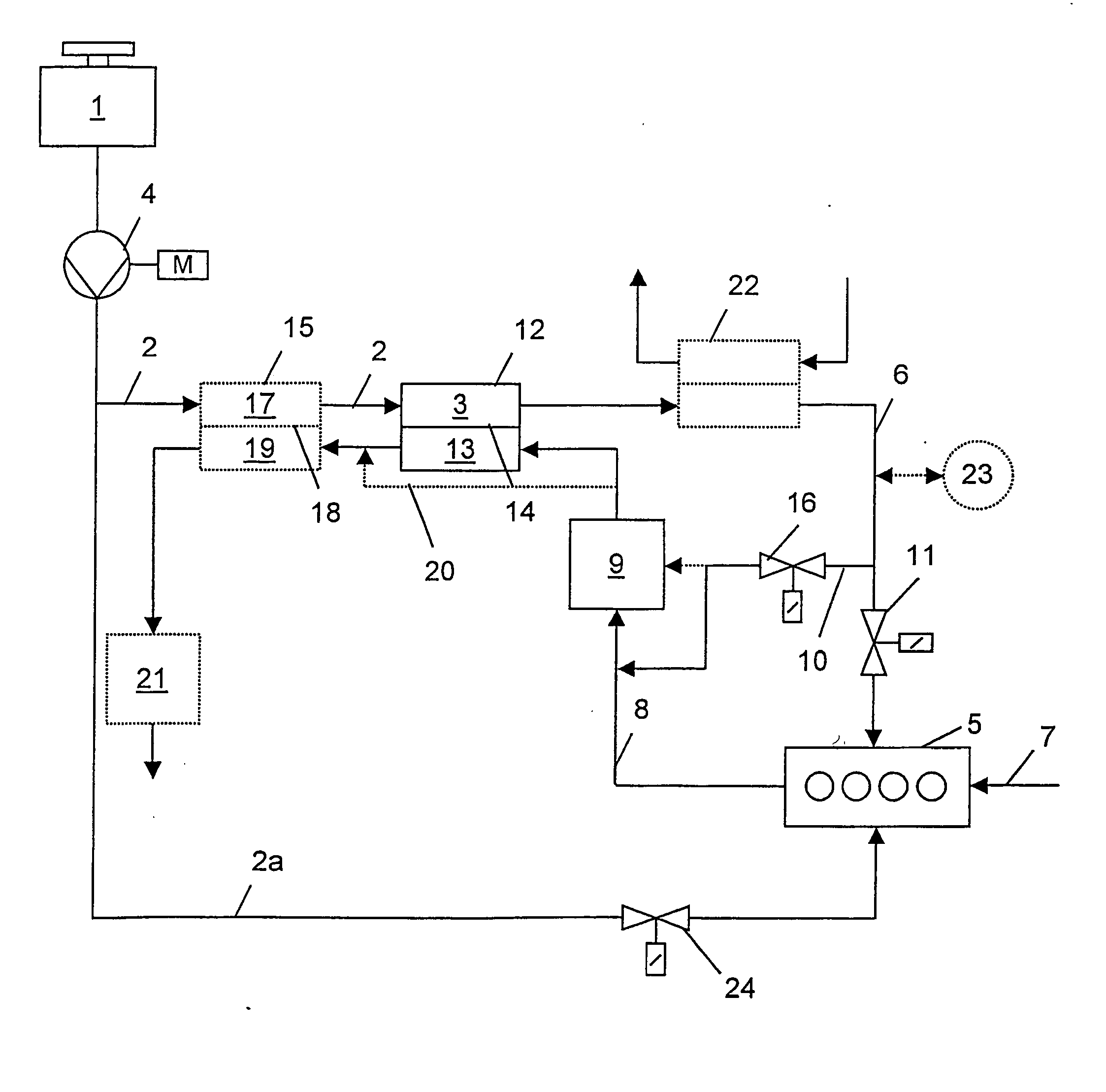

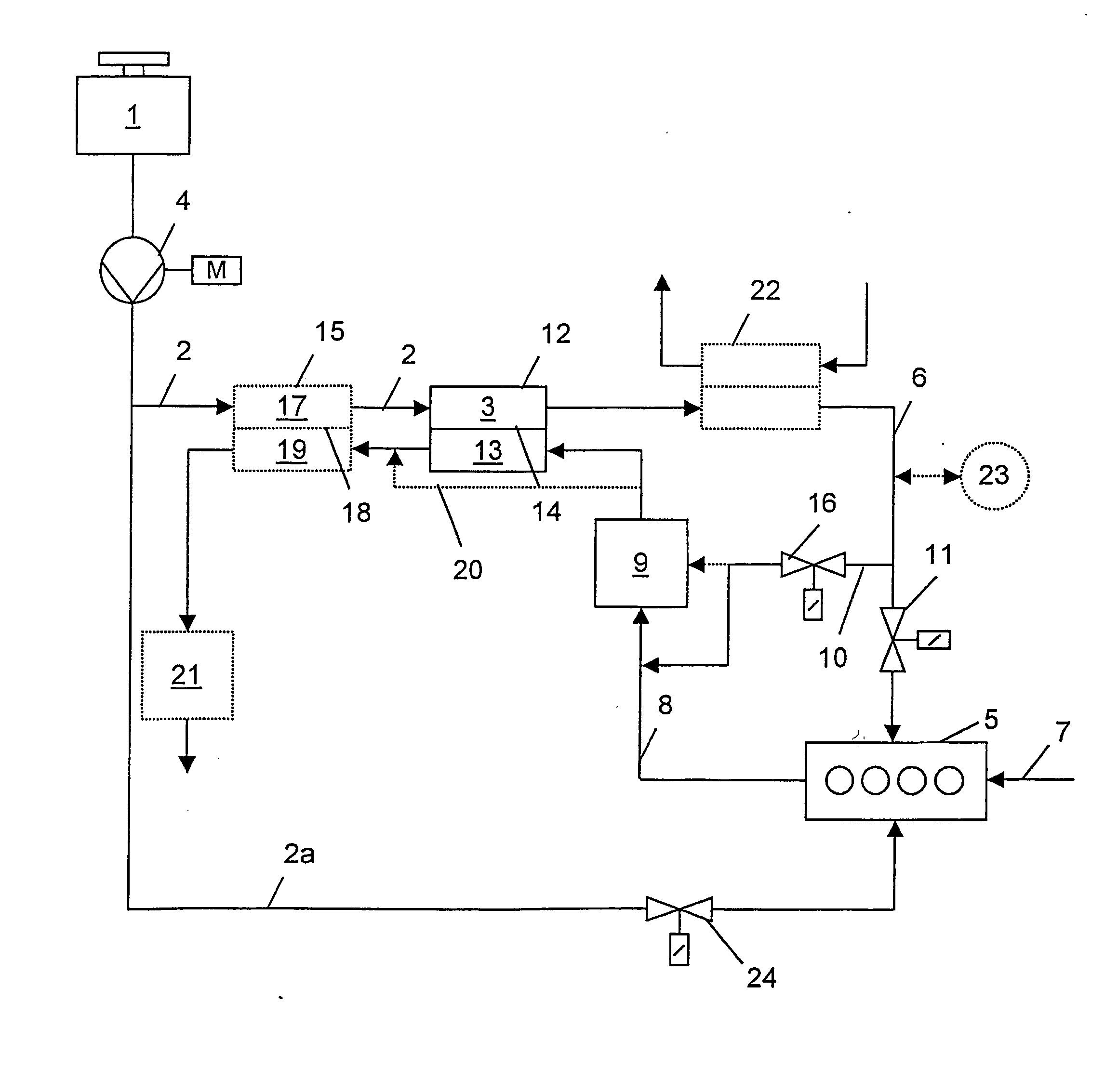

Internal combustion engine fuel supply system

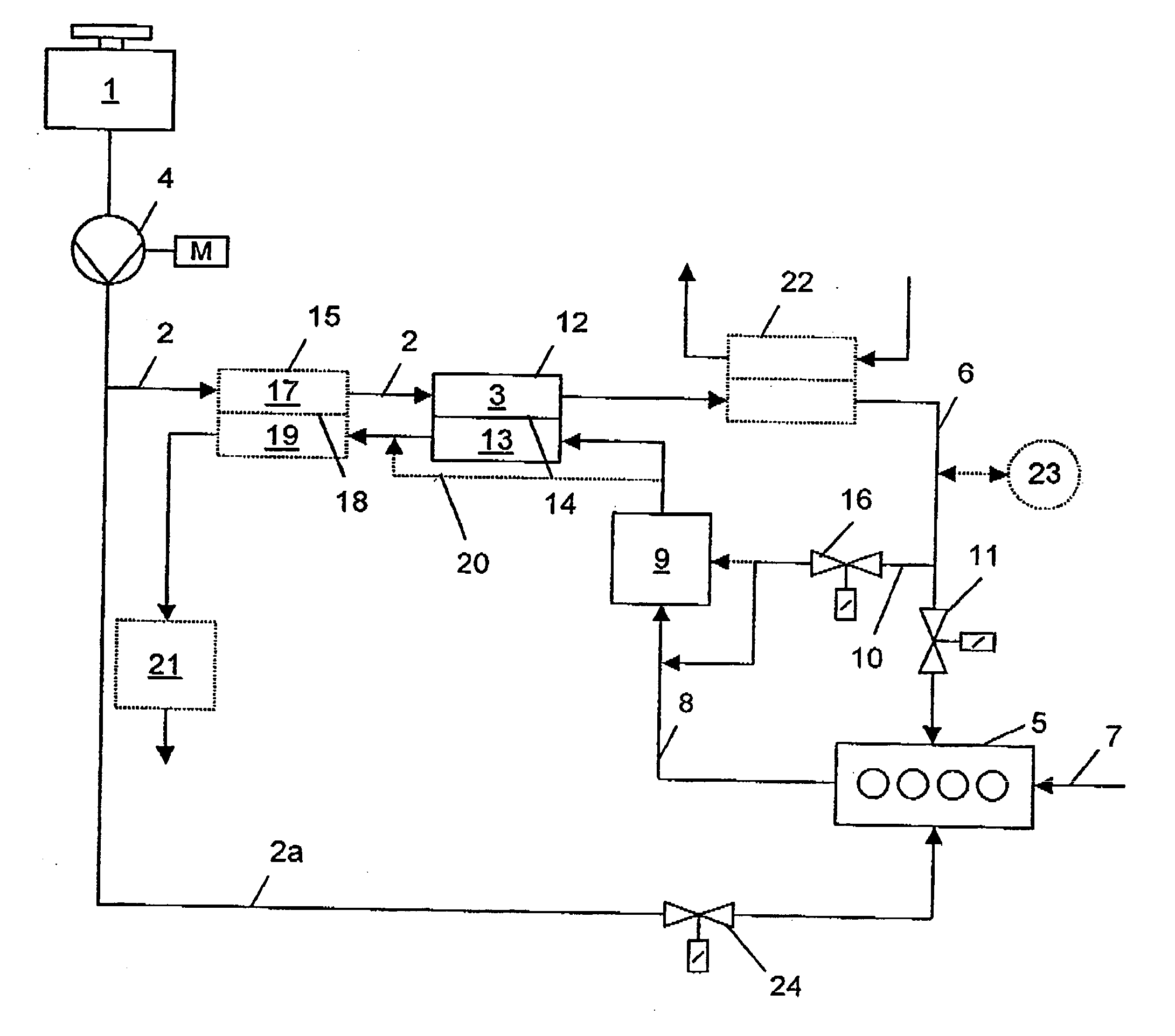

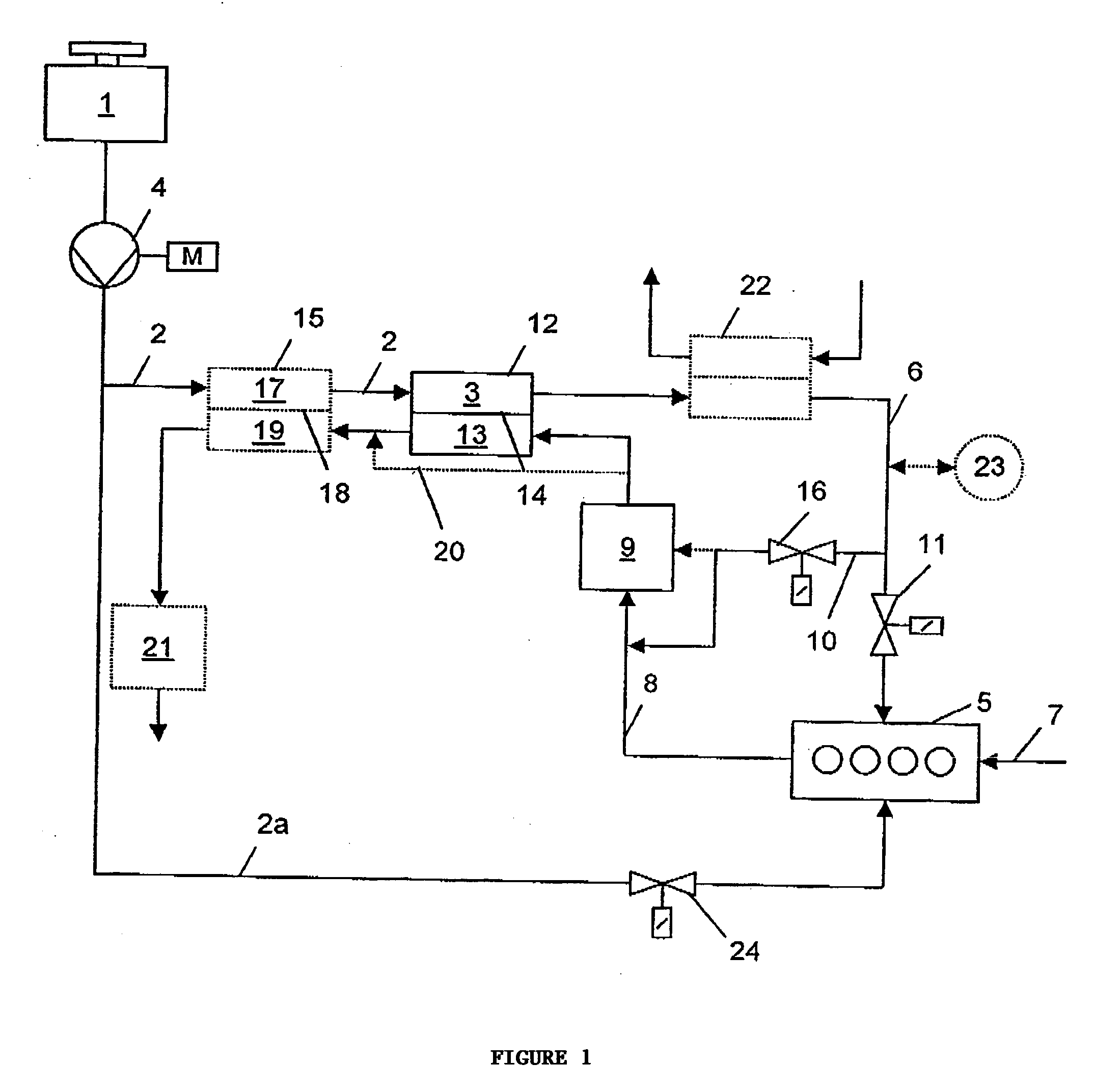

InactiveUS20060059897A1Reduce nitrogen oxide contentHigh calorific valueInternal combustion piston enginesExhaust apparatusThermal energyHydrogen

A system to supply hydrogen-rich fuel to an internal combustion engine, whereby a hydrogen-rich gas is produced from a liquid raw fuel by a hydrogen generator. The exhaust line of the internal combustion engine contains an exhaust purification system, such as a DeNOx catalytic converter, which is at least temporarily supplied with hydrogen-rich gas through a bypass line. In addition, the exhaust line is in thermal contact with the hydrogen generator in order to recover thermal energy.

Owner:NUCELLSYS GMBH

Internal combustion engine fuel supply system

InactiveUS20050115226A1Reduce nitrogen oxide contentHigh calorific valueInternal combustion piston enginesExhaust apparatusFuel supplyThermal energy

A system to supply hydrogen-rich fuel to an internal combustion engine, whereby a hydrogen-rich gas is produced from a liquid raw fuel by a hydrogen generator. The exhaust line of the internal combustion engine contains an exhaust purification system, such as a DeNOx catalytic converter, which is at least temporarily supplied with hydrogen-rich gas through a bypass line. In addition, the exhaust line is in thermal contact with the hydrogen generator in order to recover thermal energy.

Owner:NUCELLSYS

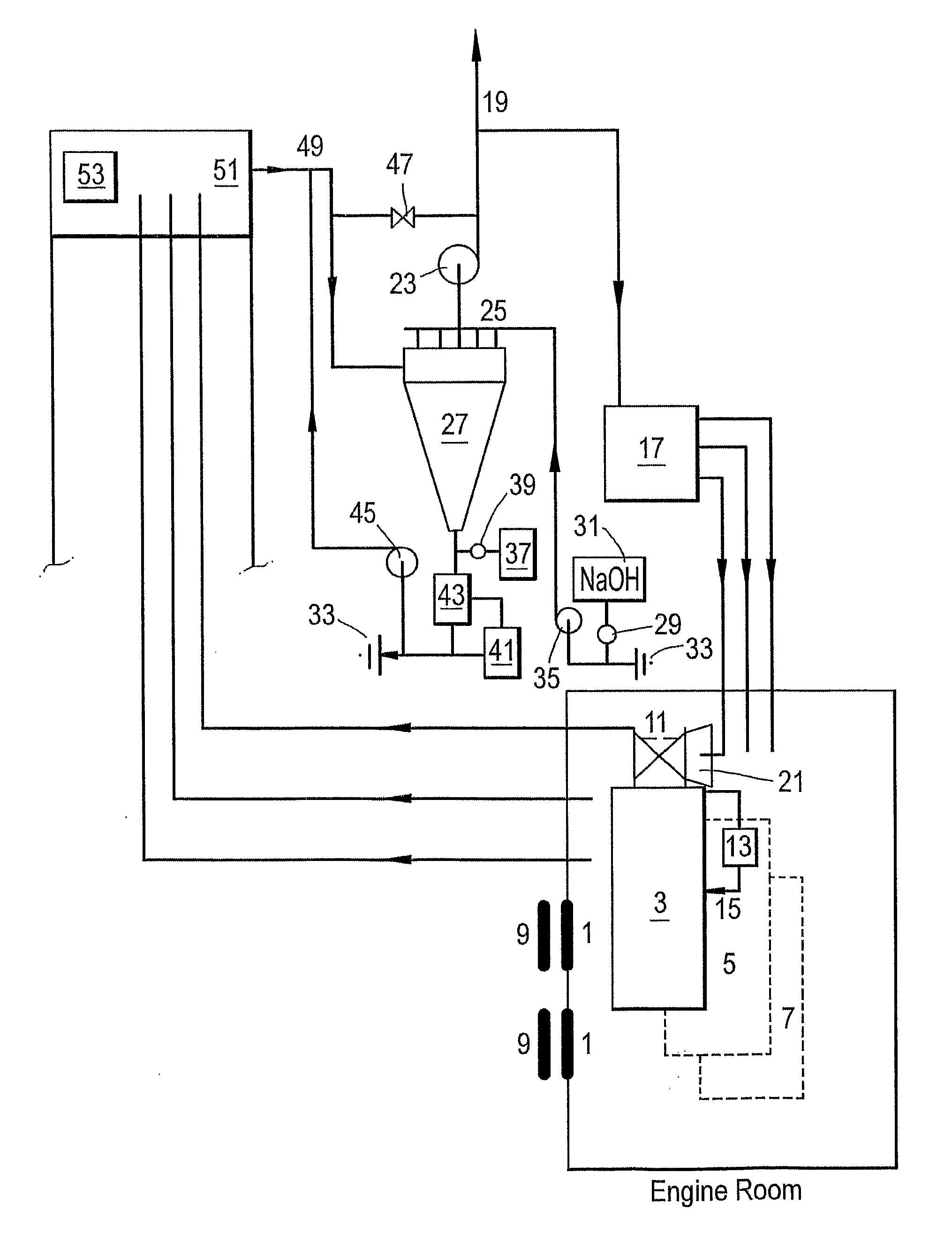

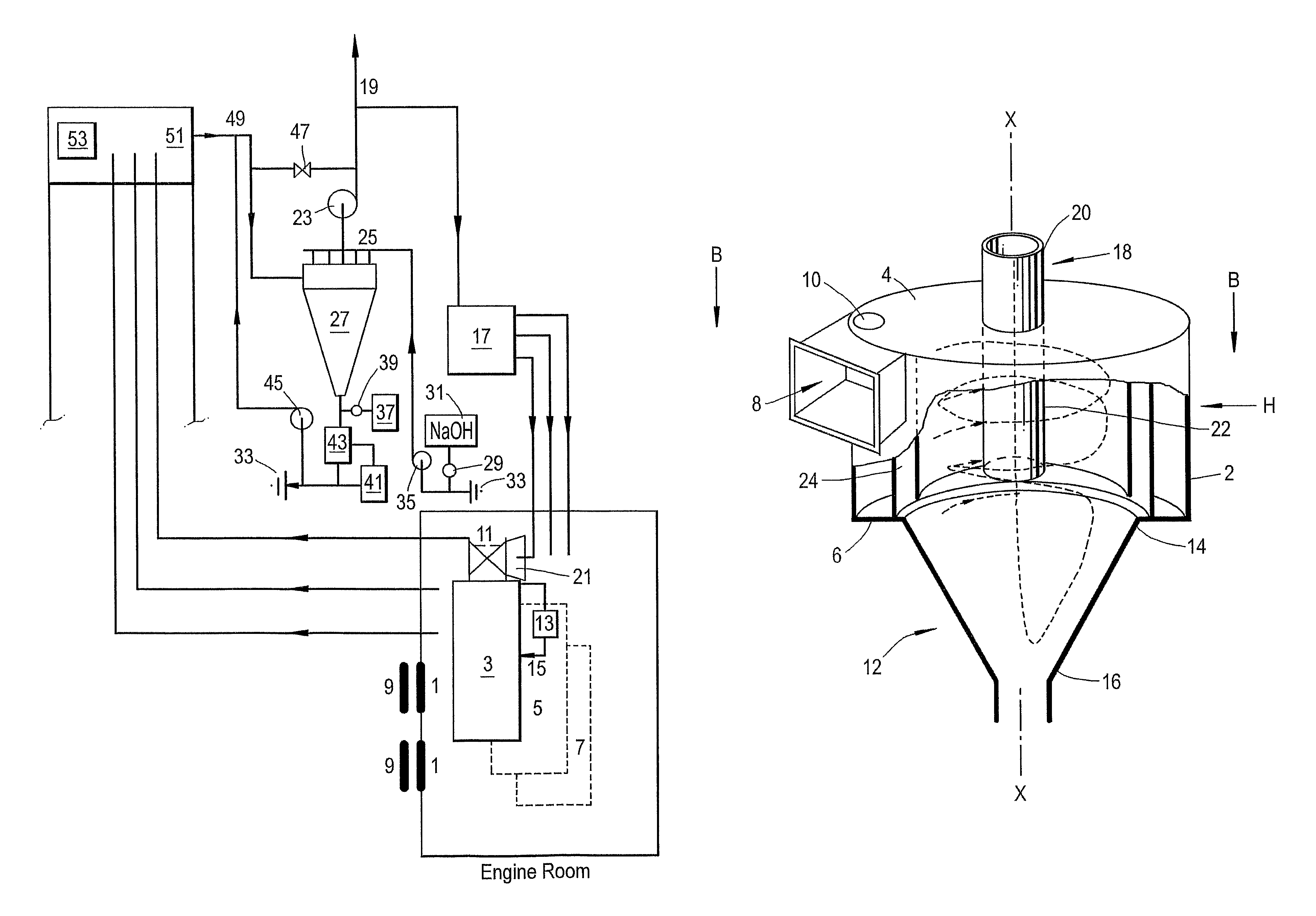

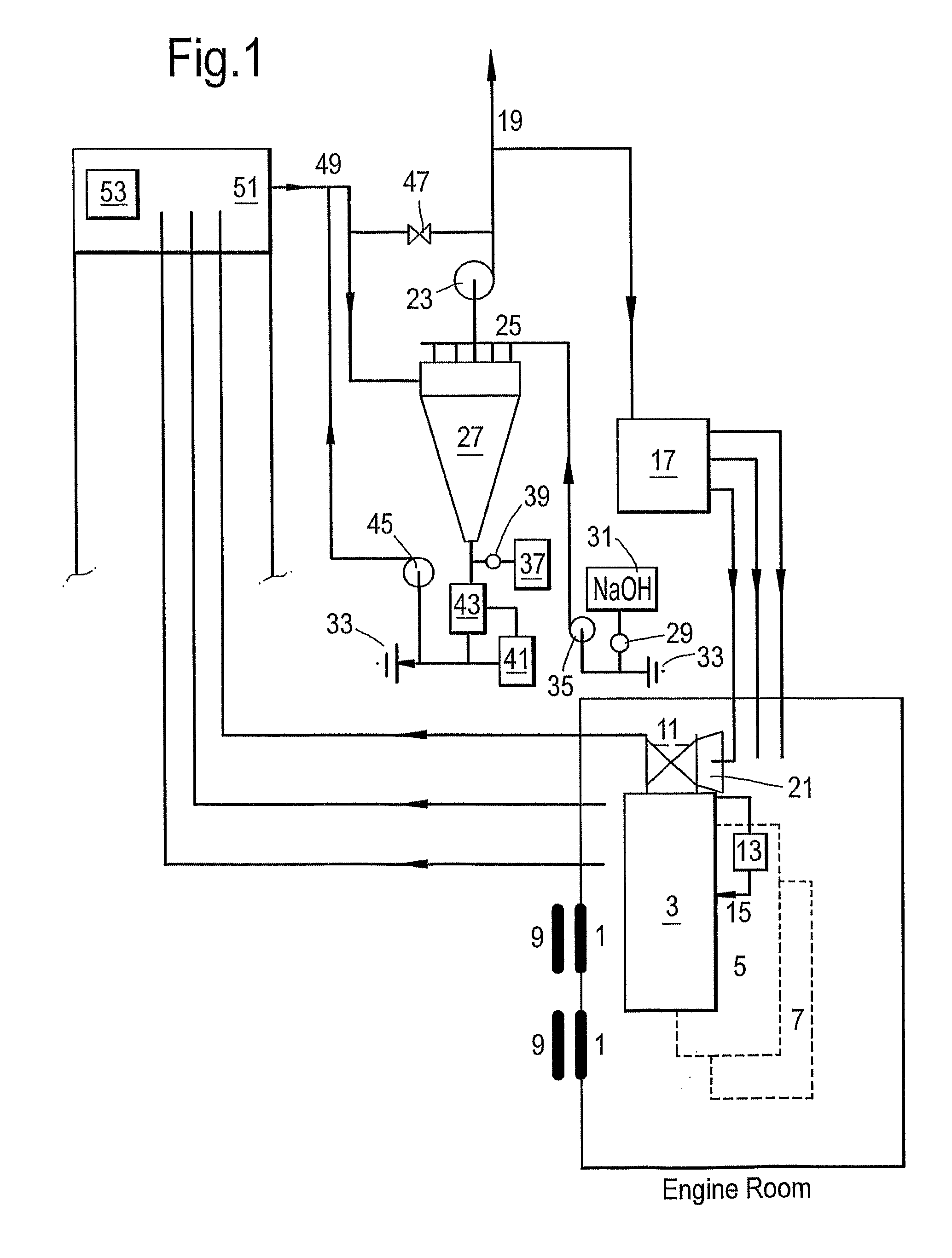

Methods and device for low contamination energy generation

InactiveUS9157360B2Reduce PM2.5Reduce nitrogen oxide contentCombination devicesInternal combustion piston enginesParticulatesNitrogen oxides

A method for low-contamination generation of energy comprising: (a) forming a gas mixture by mixing a treated gaseous effluent stream and air; (b) introducing the gas mixture and fuel at a given gas to fuel ratio into at least one diesel engine (3); (c) burning the fuel in the diesel engine to generate energy and a flue gas stream comprising particulate matter (PM), and nitrogen oxides (NOx); (d) treating at least a portion of the flue gas stream with an aqueous stream in a cyclone unit (27) comprising a housing defined by a cylindrical peripheral wall (2) and provided with at least one inlet opening (10) for receiving flue gas and at least one inlet opening for receiving fluids thereinto and with at least one swirling means, whereby a treated gaseous effluent stream and an aqueous effluent stream are formed; (e) emitting a portion of the treated gaseous effluent stream to form an emitted portion; (f) using a portion of the treated gaseous effluent stream to form the gas mixture, and (g) repeating steps (a) through (f) multiple times.

Owner:CLEAN MARINE

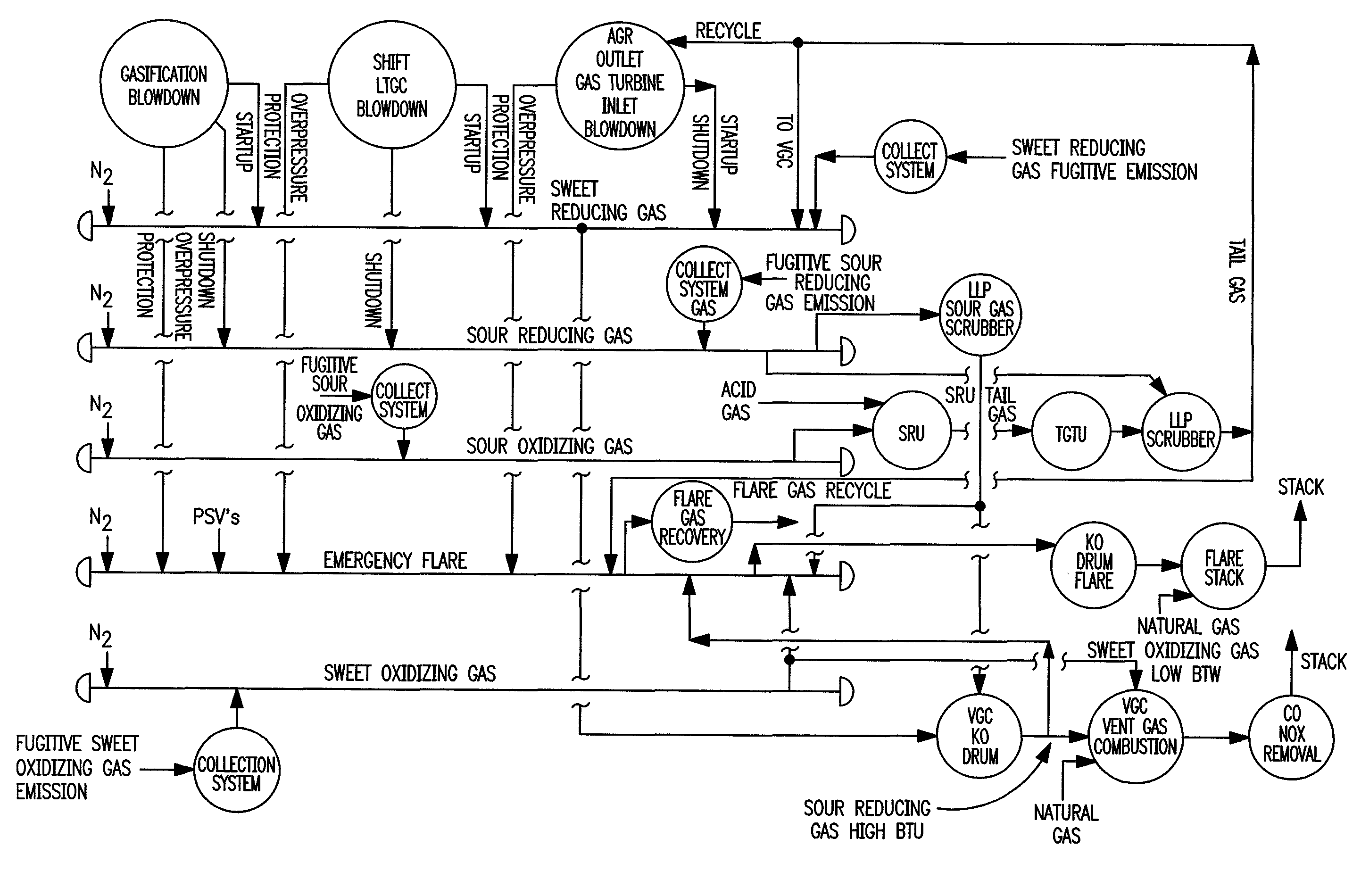

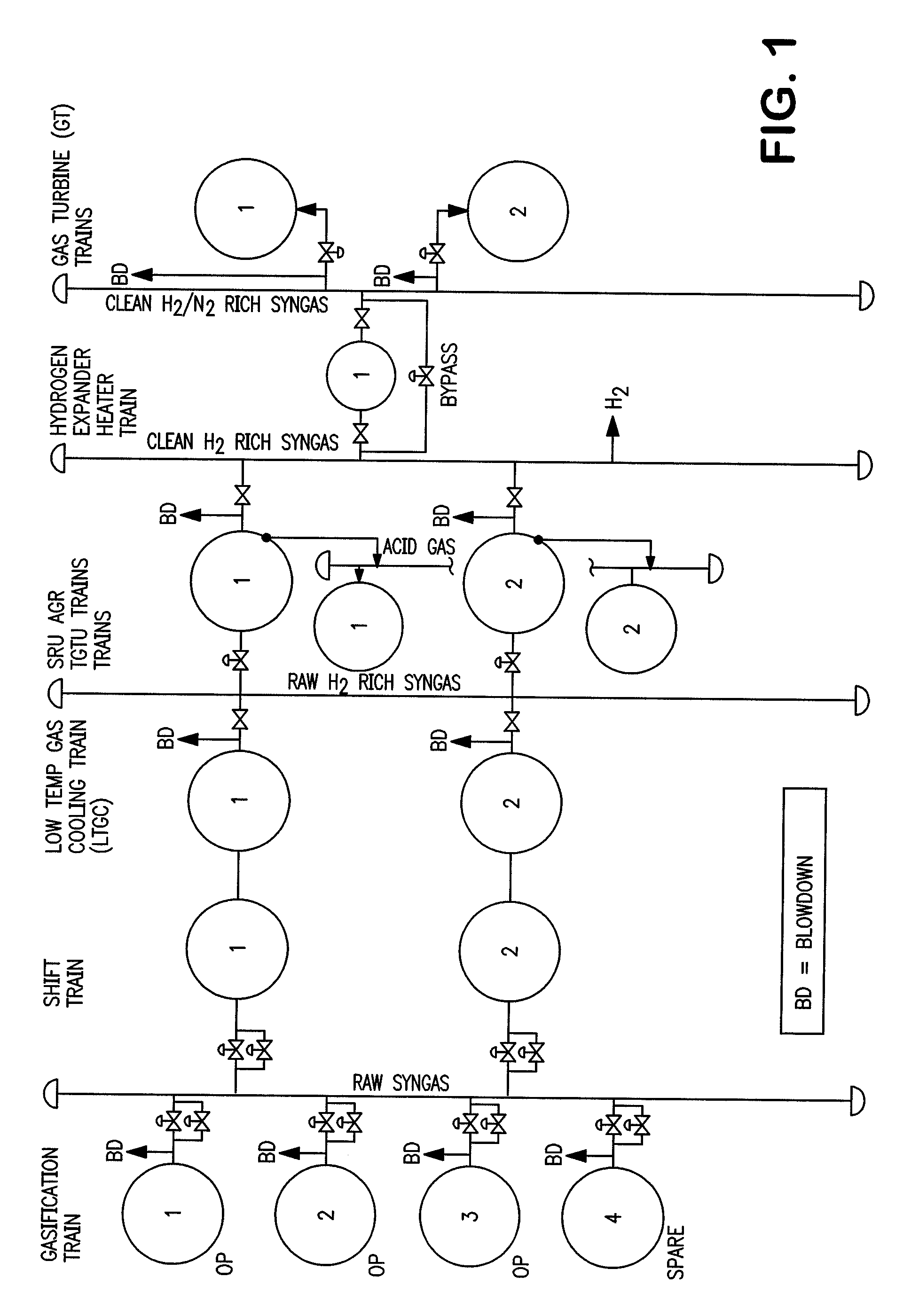

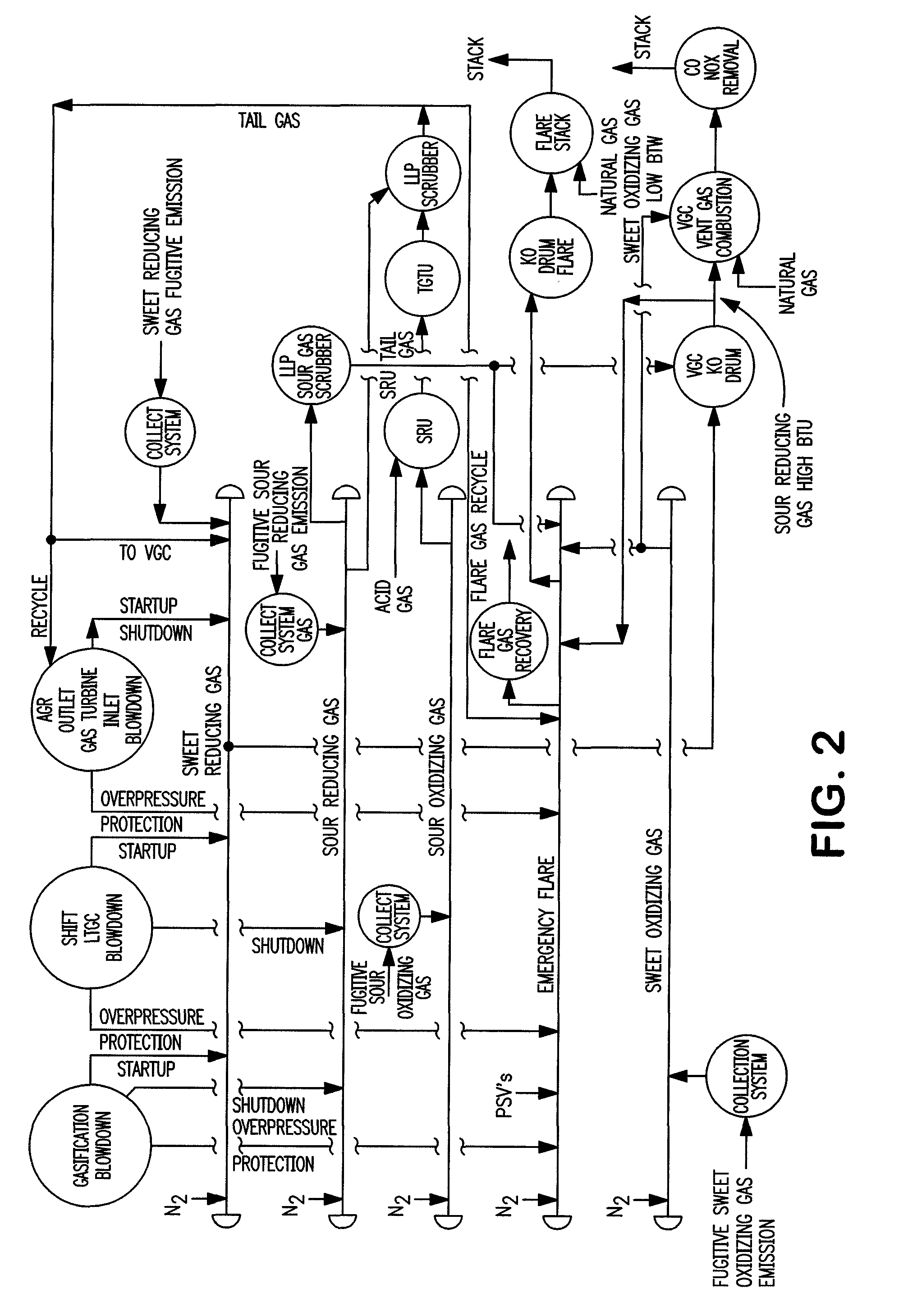

Emission free integrated gasification combined cycle

InactiveUS20100077767A1Improve efficiencyEmission reductionHydrogen separation using liquid contactGaseous fuelsBack burnsAtmospheric air

Disclosed is a process to start-up, operate, and shut down a gasifier and an integrated gasification combined cycle complex without flaring while additionally reducing the release of contaminants such as carbon monoxide, hydrogen sulfide, and nitrogen oxides. The process is accomplished by scrubbing ventable sour gases and passing scrubbed sour gases and ventable sweet gases to a vent gas combustor for controlled combustion prior to release of any such gases to the atmosphere. Additionally, the gases are subjected to a CO oxidation treatment and selective catalytic reduction treatment prior to release to the atmosphere.

Owner:HYDROGEN ENERGY INT

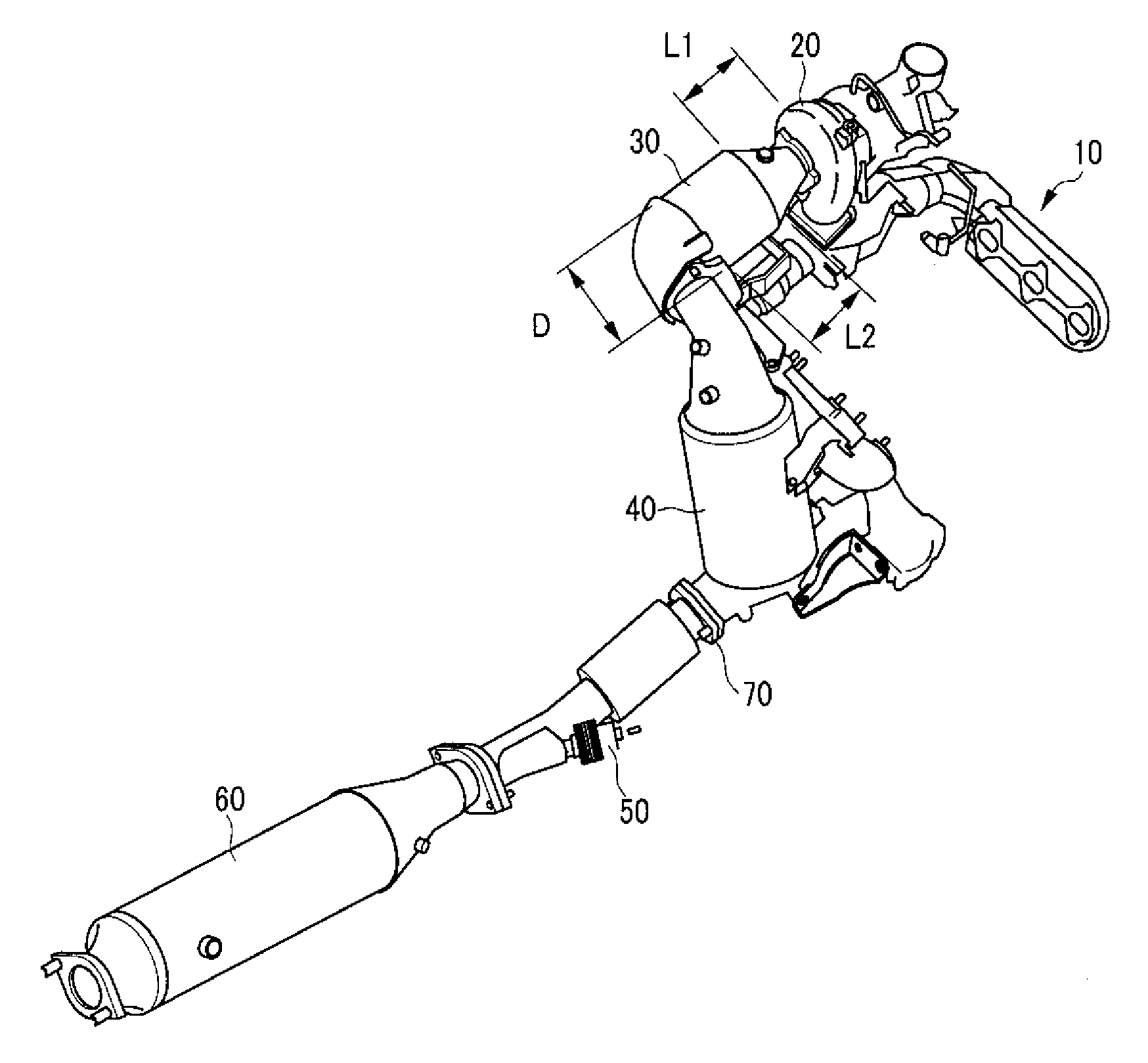

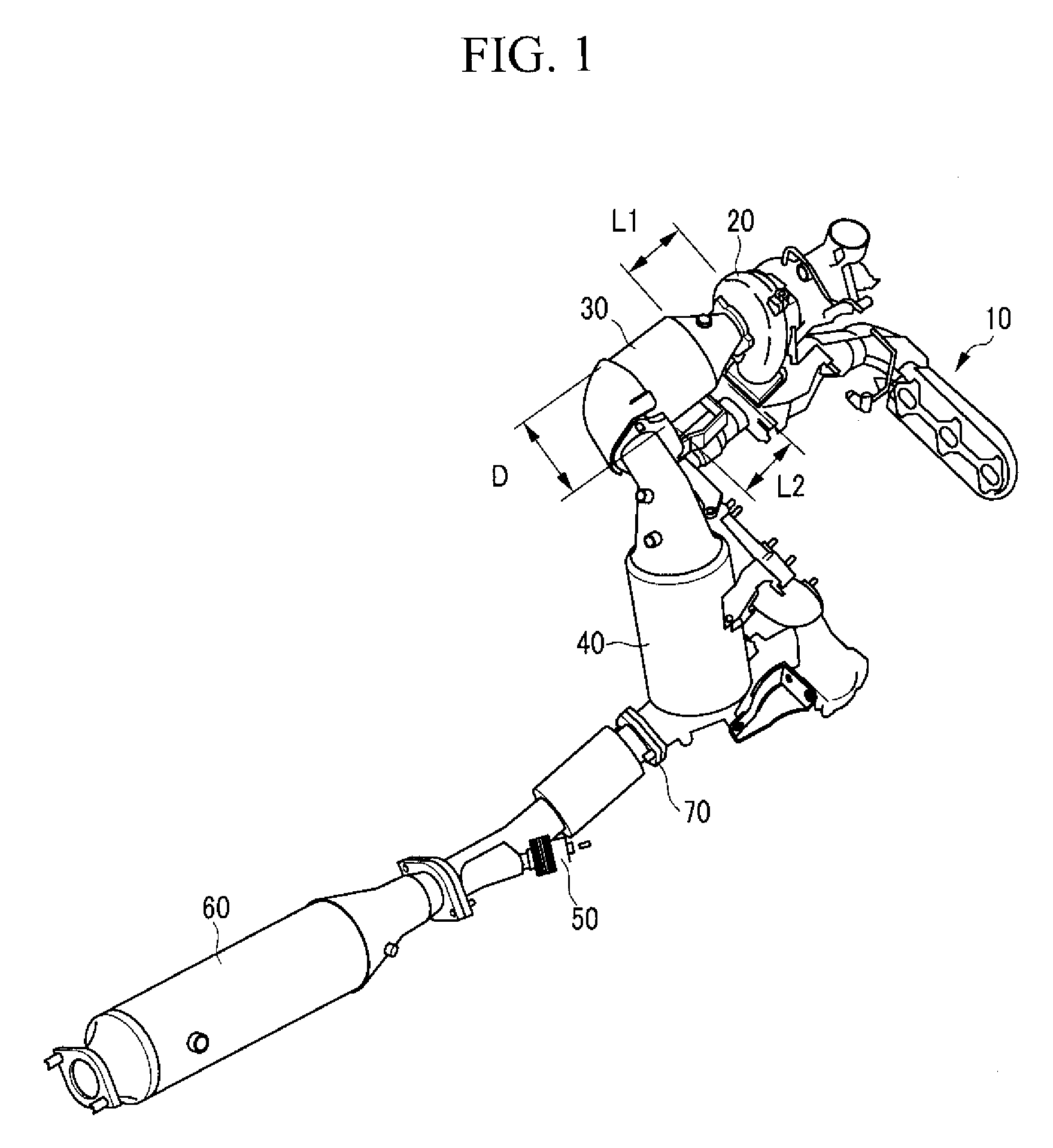

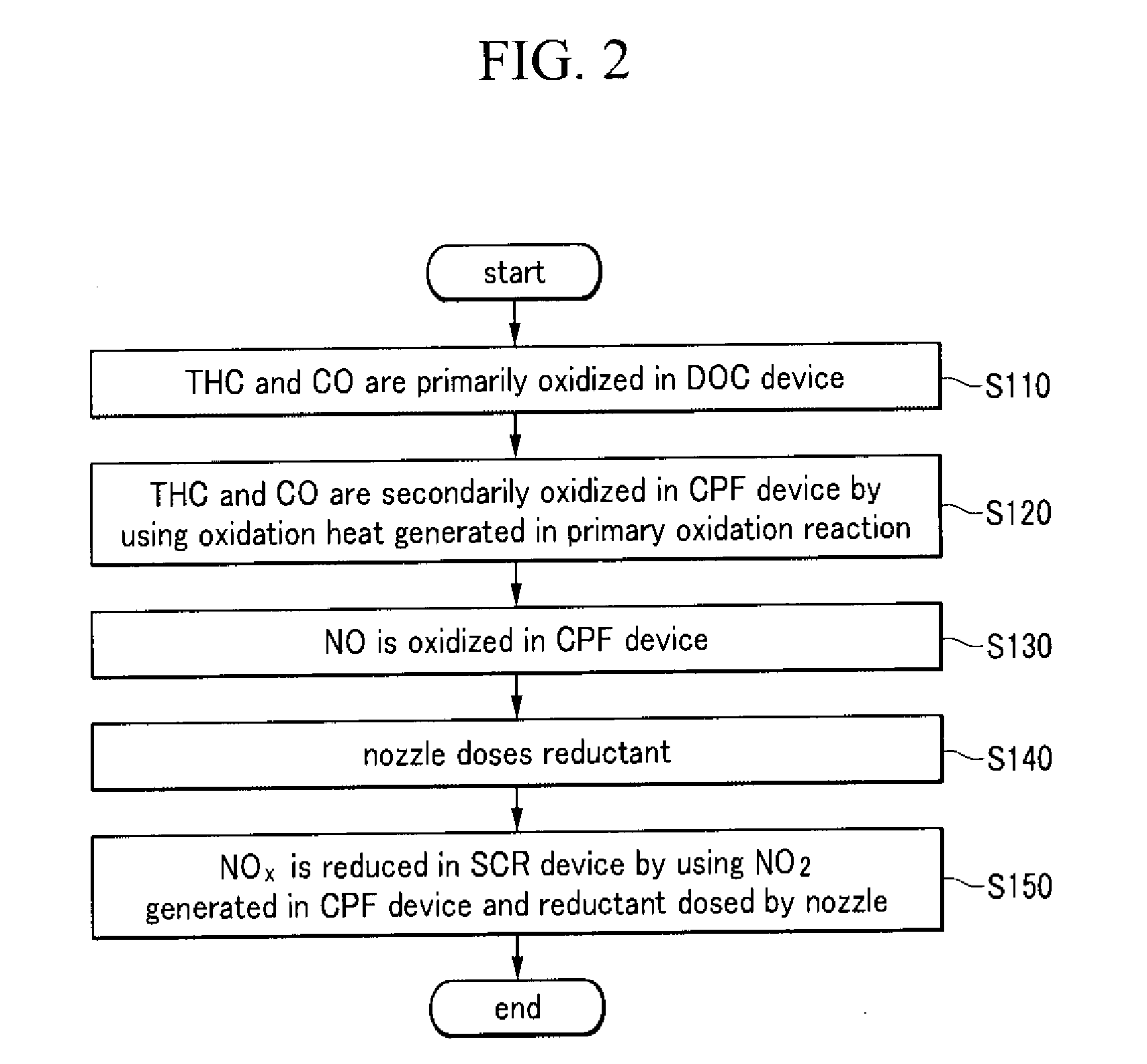

Apparatus for reducing nitrogen oxide contained in exhaust gas

InactiveUS20090151341A1Reduce NOxFully oxidizedGas treatmentInternal combustion piston enginesExhaust fumesNitrogen oxide

An apparatus for reducing NOx contained in exhaust gas as an exemplary embodiment of the present invention may include: a DOC device primarily oxidizing an exhaust materials containing THC and CO in the exhaust gas by using a first DOC; a CPF device mounted downstream of the DOC device to receive the exhaust gas primarily oxidized by the DOC device, further oxidizing the exhaust materials containing the THC and the CO by heat generated during the primary oxidation and an oxidizing agent coated therein, and oxidizing NO in the exhaust gas into NO2 by using the generated heat and the oxidizing agent coated therein; a nozzle mounted downstream of the CPF device, and dosing a reductant to the exhaust gas; and a SCR device mounted downstream of the nozzle, and reducing NOx in the exhaust gas into N2 by using the NO2 generated in the CPF device and the reductant.

Owner:HYUNDAI MOTOR CO LTD +1

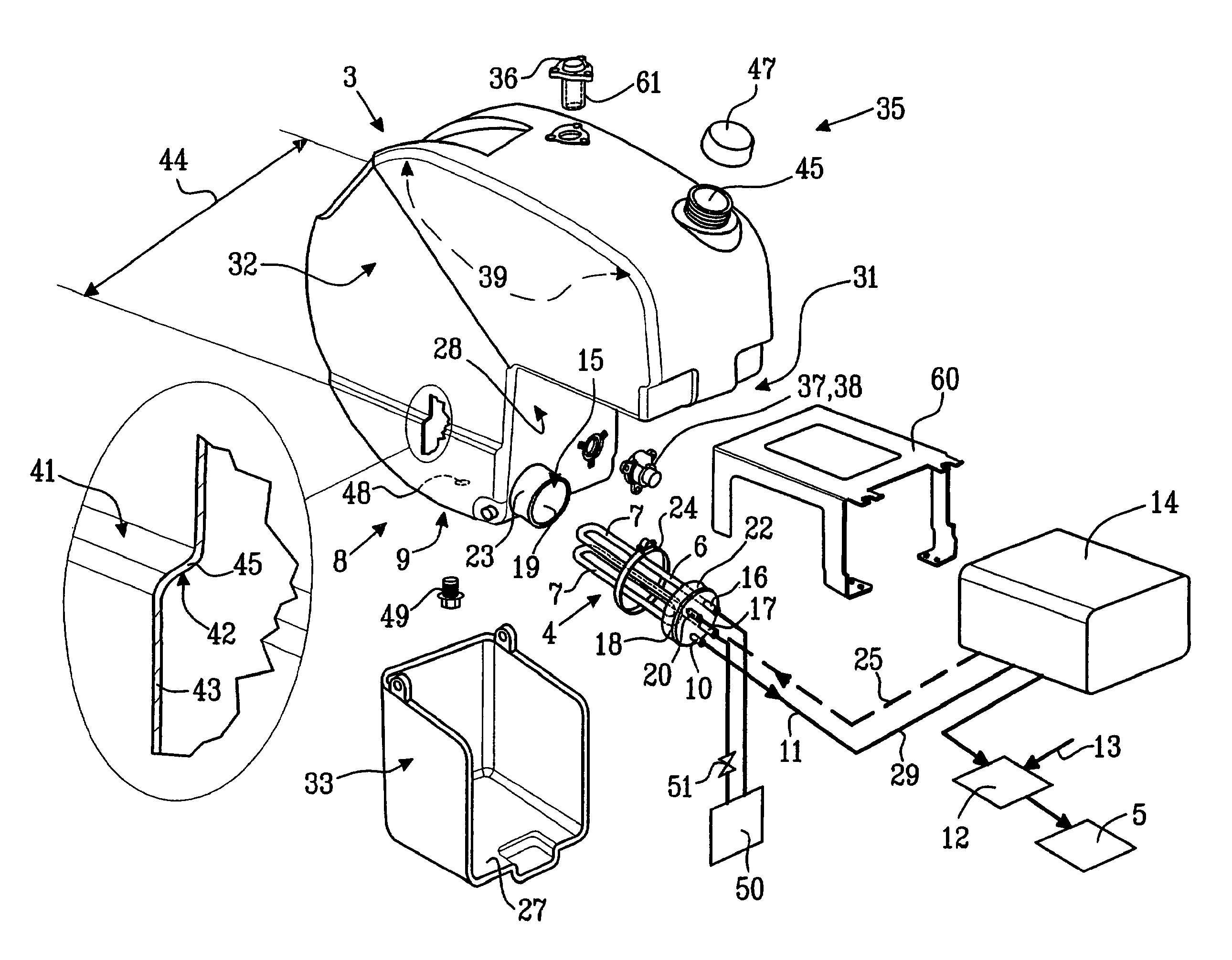

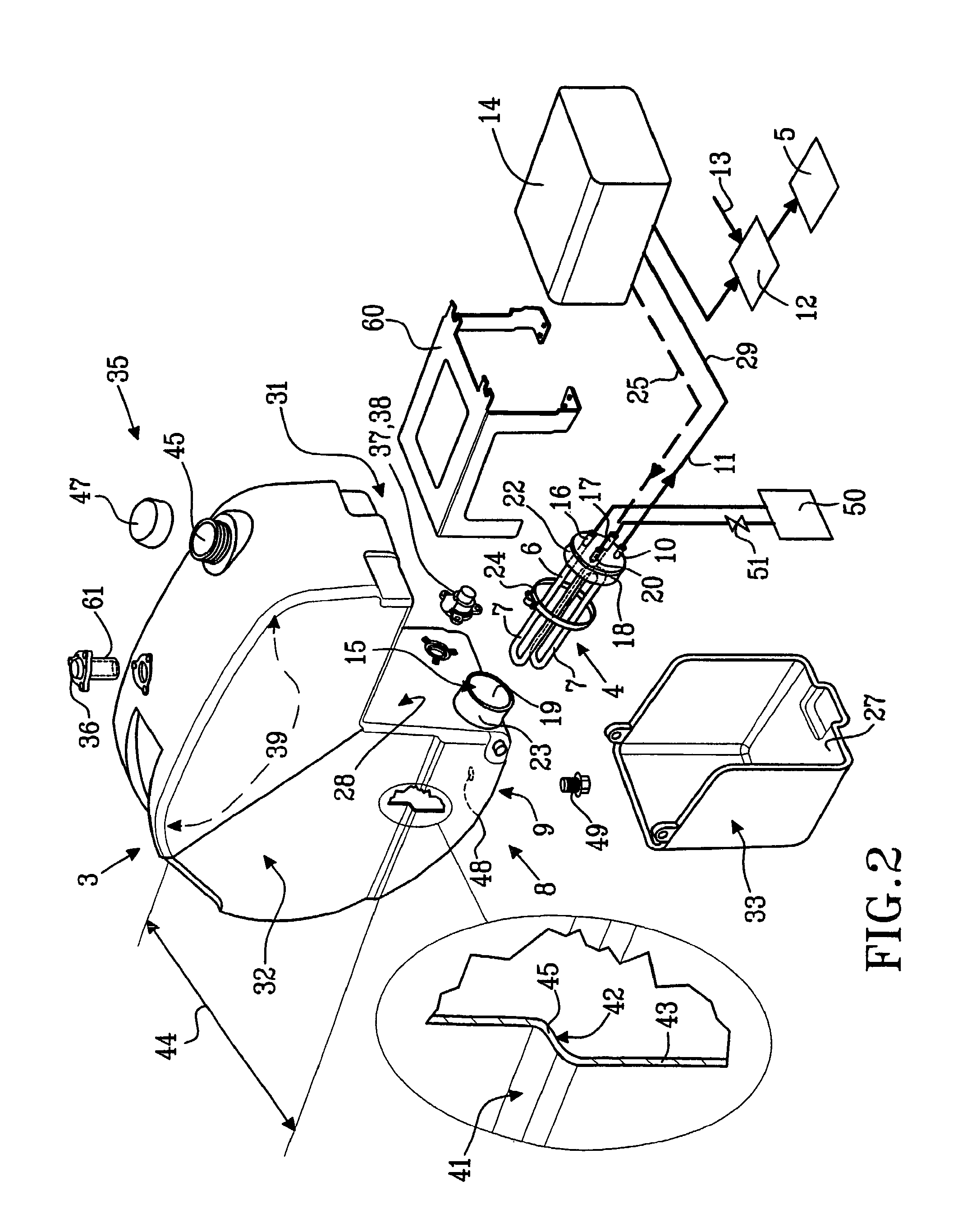

Device for heating

ActiveUS7398771B2Emission reductionReduce nitrogen oxide contentGas treatmentInternal combustion piston enginesLiquid stateEngineering

A device for heating a first medium which is in liquid state and / or frozen state includes a reservoir disposed on an engine-driven vehicle and an element for heating the first medium present in the reservoir. The heating element is disposed inside the reservoir for direct heating of the first medium.

Owner:VOLVO LASTVAGNAR AB

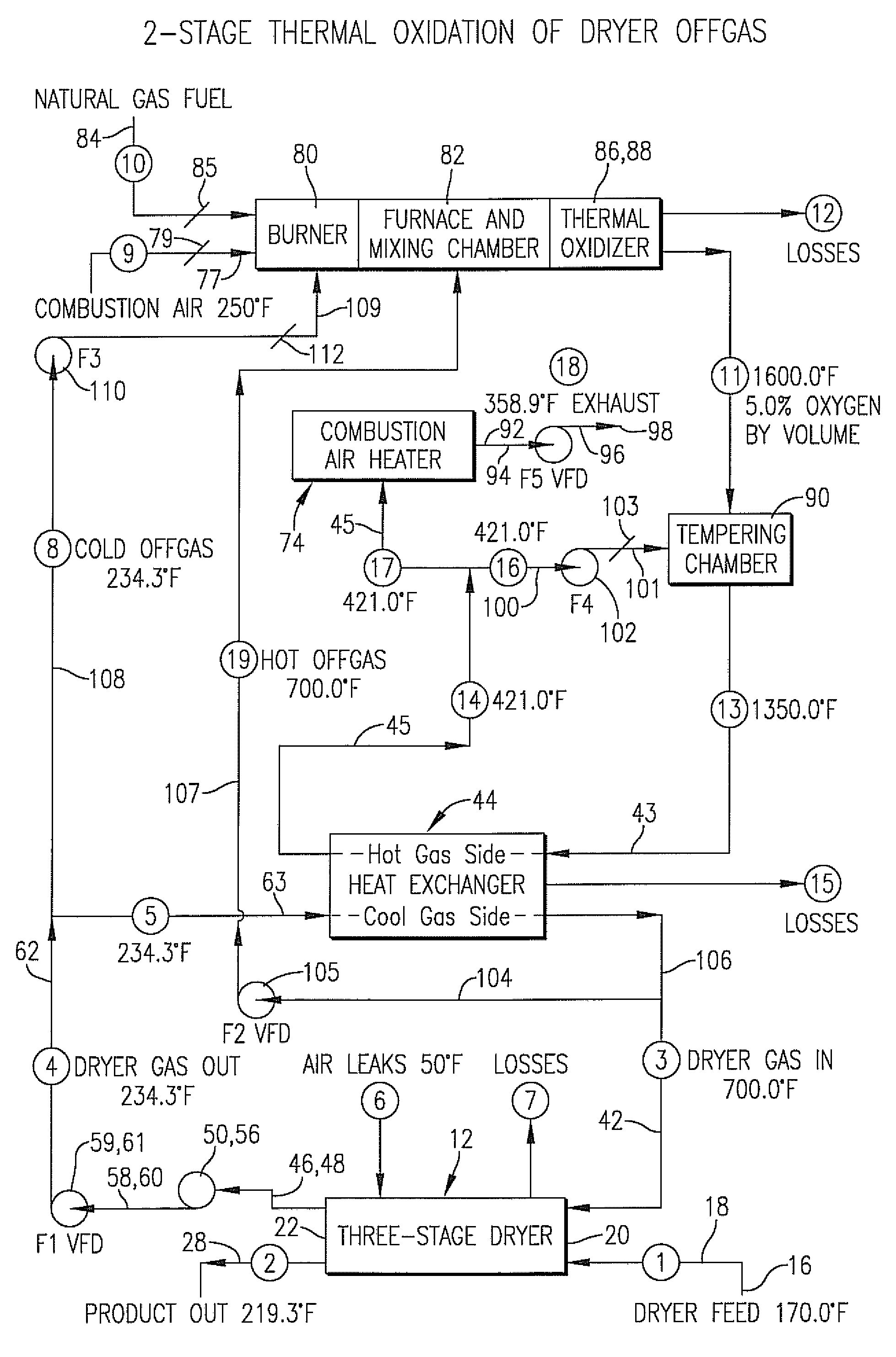

Two-stage thermal oxidation of dryer offgas

ActiveUS7654011B2Reducing VOC and CO contentLimit production of NOxDrying solid materials with heatDrying gas arrangementsAtmospheric airOxygen

A method and apparatus are provided for reducing the VOC, CO, and, alternatively, the NOx content of dryer offgas that is discharged into the atmosphere from a moist organic product drying process using thermal oxidizing apparatus that includes a burner, furnace, mixing chamber, thermal oxidizer, tempering chamber, and an indirect gas-to-gas heat exchanger. The dryer offgas is separated into two portions, with a larger portion being preheated by indirect heat exchange with the hot gaseous output from the thermal oxidizer. The non-preheated portion is directed to the burner in the function of flue gas recycle for NOx control. The preheated portion is separated into two portions, with one portion being directed to the furnace / mixing chamber of the thermal oxidizing apparatus. The other portion of the preheated offgas is recycled to the hot gas inlet of the dryer and serves the function of dryer heat transfer media. Ultimately, all the dryer offgas enters the thermal oxidizer, and comprises a smaller non-preheated portion directed to the burner and a larger preheated portion directed to the furnace / mixing chamber. By preheating a large proportion of the offgas directed to the thermal oxidizing apparatus, simultaneous achievement of an adequate thermal oxidizer temperature, 1600° F., and an adequate oxygen concentration of 5% by volume is achieved for optimized thermal oxidation of carbon monoxide and volatile organic compounds.

Owner:AEROGLIDE

Internal combustion engine fuel supply system

InactiveUS7051518B2Reduce nitrogen oxide contentHigh calorific valueInternal combustion piston enginesExhaust apparatusThermal energyHydrogen

A system to supply hydrogen-rich fuel to an internal combustion engine, whereby a hydrogen-rich gas is produced from a liquid raw fuel by a hydrogen generator. The exhaust line of the internal combustion engine contains an exhaust purification system, such as a DeNOx catalytic converter, which is at least temporarily supplied with hydrogen-rich gas through a bypass line. In addition, the exhaust line is in thermal contact with the hydrogen generator in order to recover thermal energy.

Owner:NUCELLSYS GMBH

Built-in biomass gasification combustion hot water boiler

ActiveCN105485895AAvoid safety hazardsReduce wasteSolid fuel combustionWater heatersCold airCombustion chamber

The invention discloses a built-in biomass gasification combustion hot water boiler which comprises a water heater, a biomass gasification device and a combustion chamber. The water heater comprises a water tank and a plurality of smoke pipes. The biomass gasification device is used for generating biomass gas. The combustion chamber is arranged between the water heater and the biomass gasification device and used for combusting the biomass gas and conveying smoke generated after combustion into the water heater so as to heat water in the water tank. The biomass gasification device comprises a device body, a fire grate, a fire barrier, an air sleeve and a first water jacket, wherein the interior of the device body is divided by the fire grate into a gasification reaction chamber in the middle and an air chamber on the lower portion, and the interior of the device body is divided by the fire barrier into a gas storage chamber on the upper portion and the gasification reaction chamber in the middle. Generated water vapor is supplied to the gasification reaction chamber through the first water jacket to serve as a gasification agent, cold air is preheated in the air sleeve into hot air through the air sleeve, then the hot air is supplied to the combustion chamber for combustion supporting, and the biomass gas is supplied to the combustion chamber to be combusted through the gas storage chamber.

Owner:GUANGZHOU QIYADIAN BOILER CO LTD

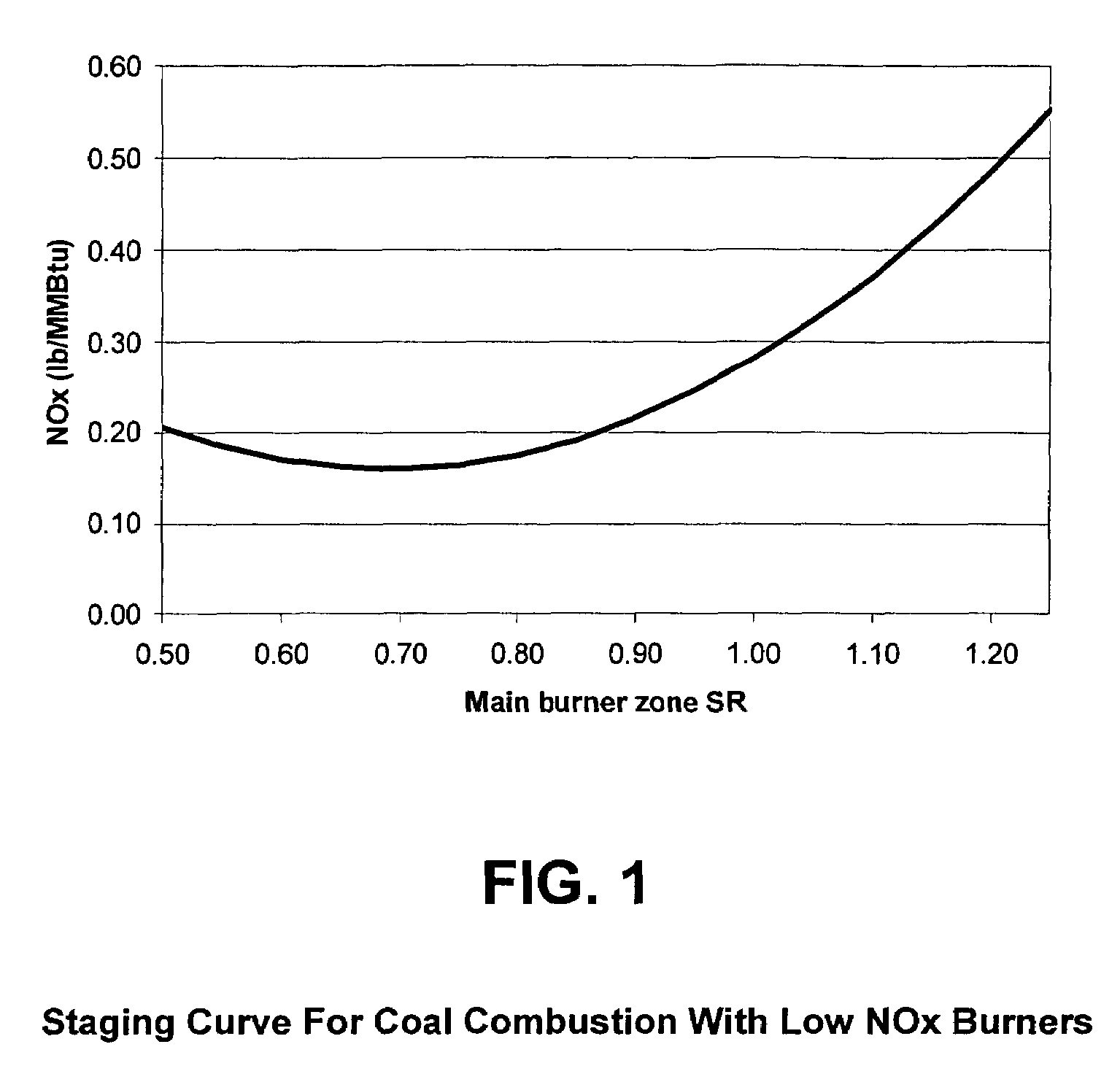

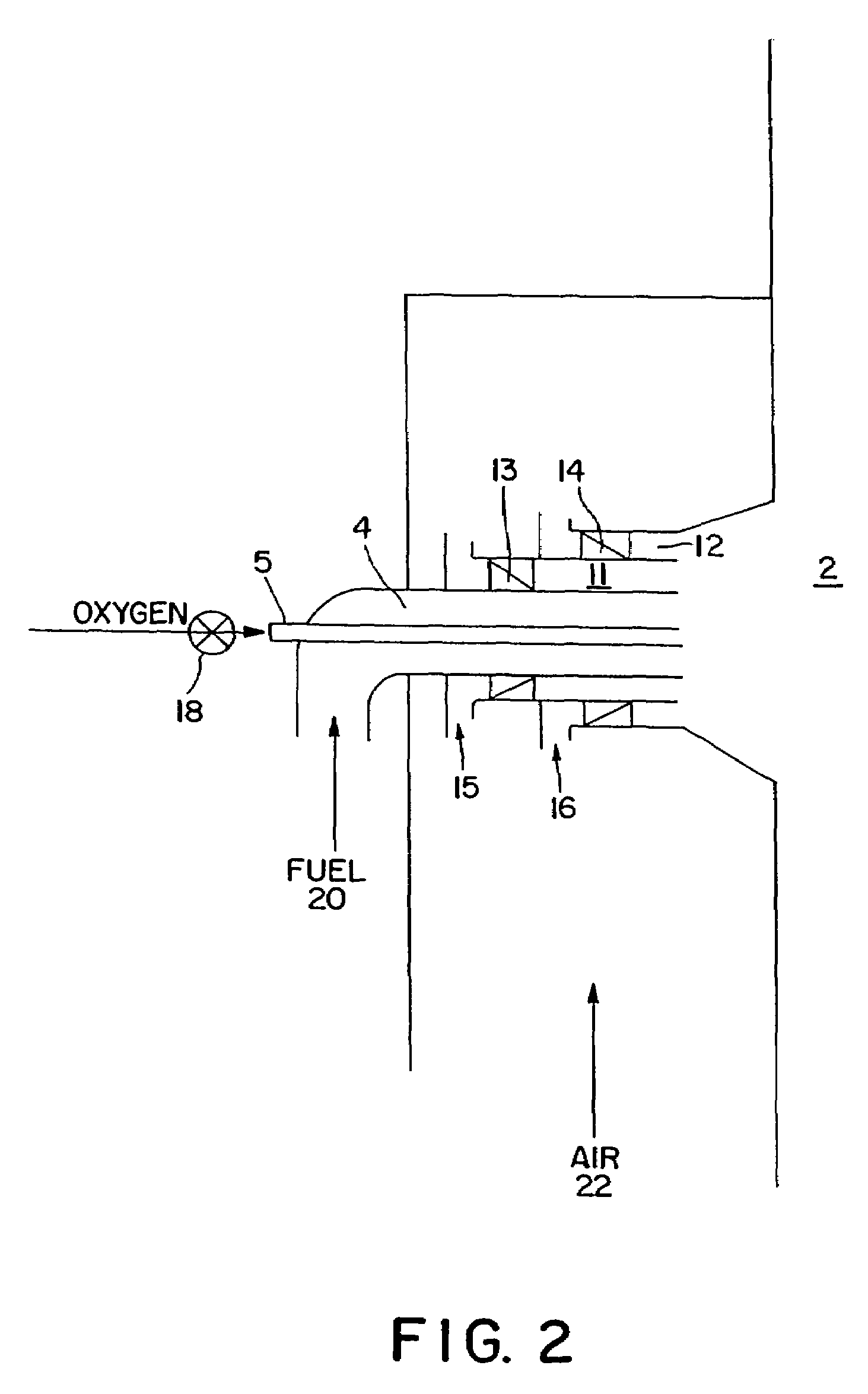

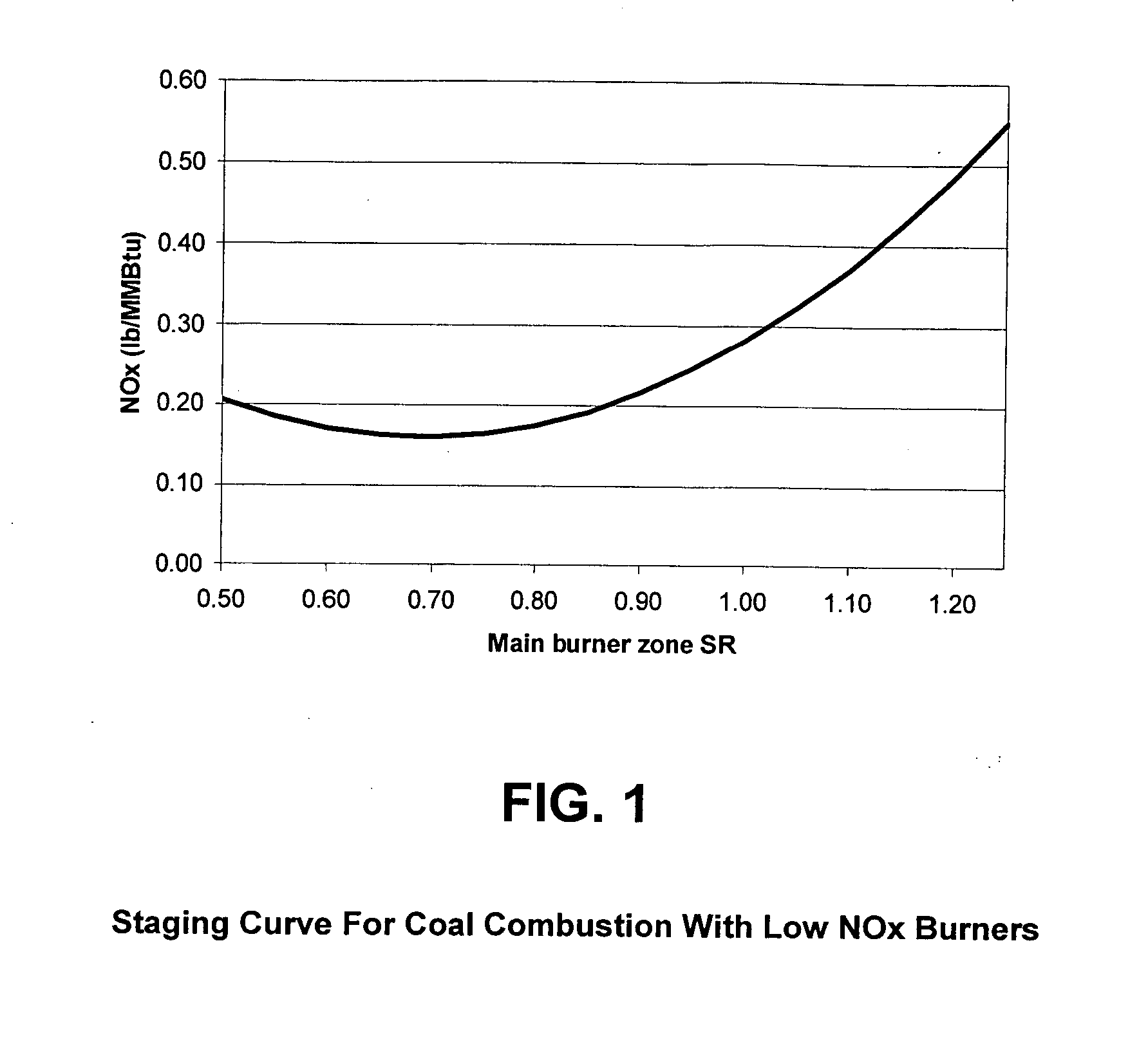

Method of operating furnace to reduce emissions

InactiveUS7497682B2Reduce nitrogen oxide contentRaise the ratioStaged combustionSolid fuel combustionCombustorEngineering

Emissions of NOx and CO are reduced from combustion devices such as coal-fired furnaces by increasing the stoichiometric ratio of burner(s) having a lower average temperature and increasing the stoichiometric ratio of burner(s) having a higher average temperature.

Owner:PRAXAIR TECH INC

Coal water slurry additive

InactiveCN106118764AReduce moisture contentGood flow dispersionLiquid carbonaceous fuelsFuel additivesMoistureHeat energy

The invention belongs to the technical field of a concrete additive, in particular to a coal water slurry additive. The problems that the existing coal water slurry has poor flow dispersibility, high moisture content of coal water slurry, large loss of energy consumption and large loss of heat energy are mainly solved. The water coal slurry additive comprises the following components in parts by weight: 35 to 50 parts of naphthalene water reducing agent, 5 to 20 parts of sodium silicate, 1 to 4 parts of sodium hydroxide, 1 to 4 parts of sodium gluconate, 1 to 2 parts of sodium citrate, 1 to 2 parts of sodium lignosulfonate and 5 to 16 parts of water. The additive provided by the invention has the advantages of reducing the moisture content of the coal water slurry, improving the flow dispersibility and suspension property, speeding up the precipitation speed, reducing the used amount, and reducing the nitrogen oxide content after adding urea.

Owner:艾永生

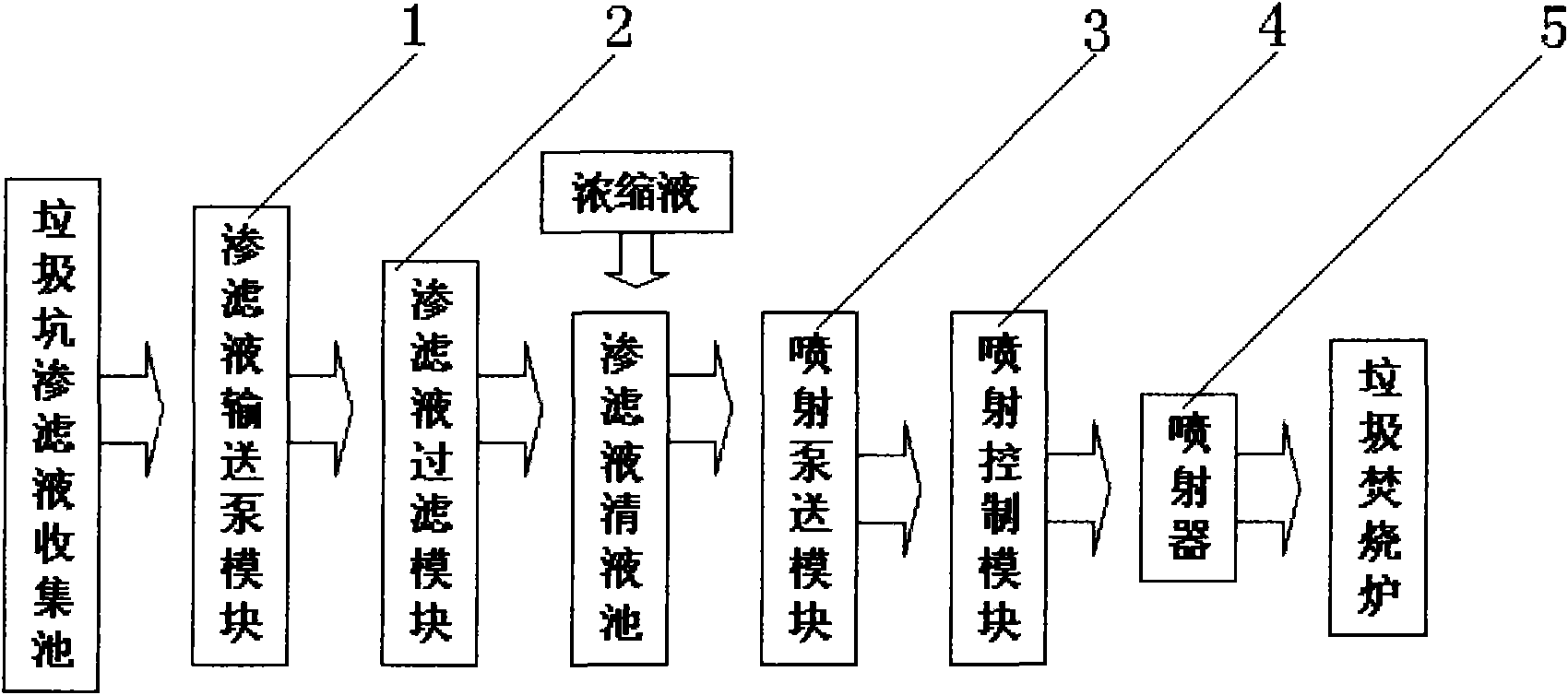

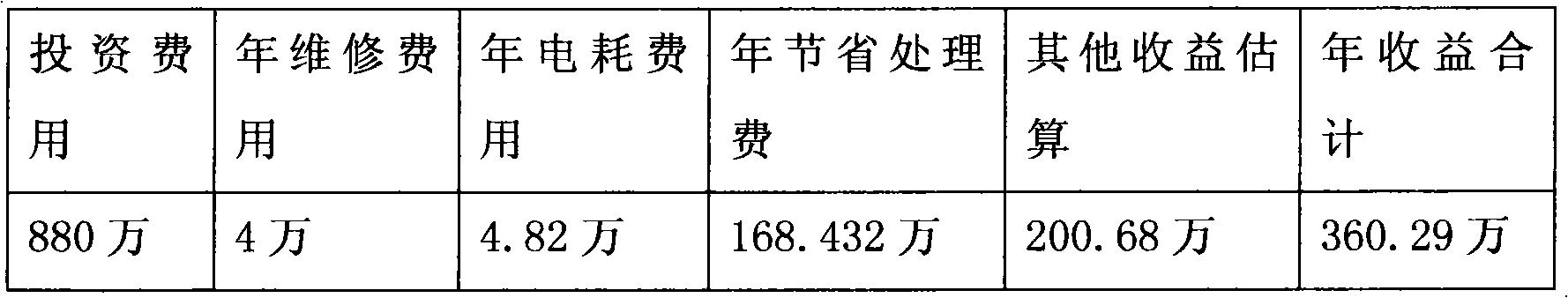

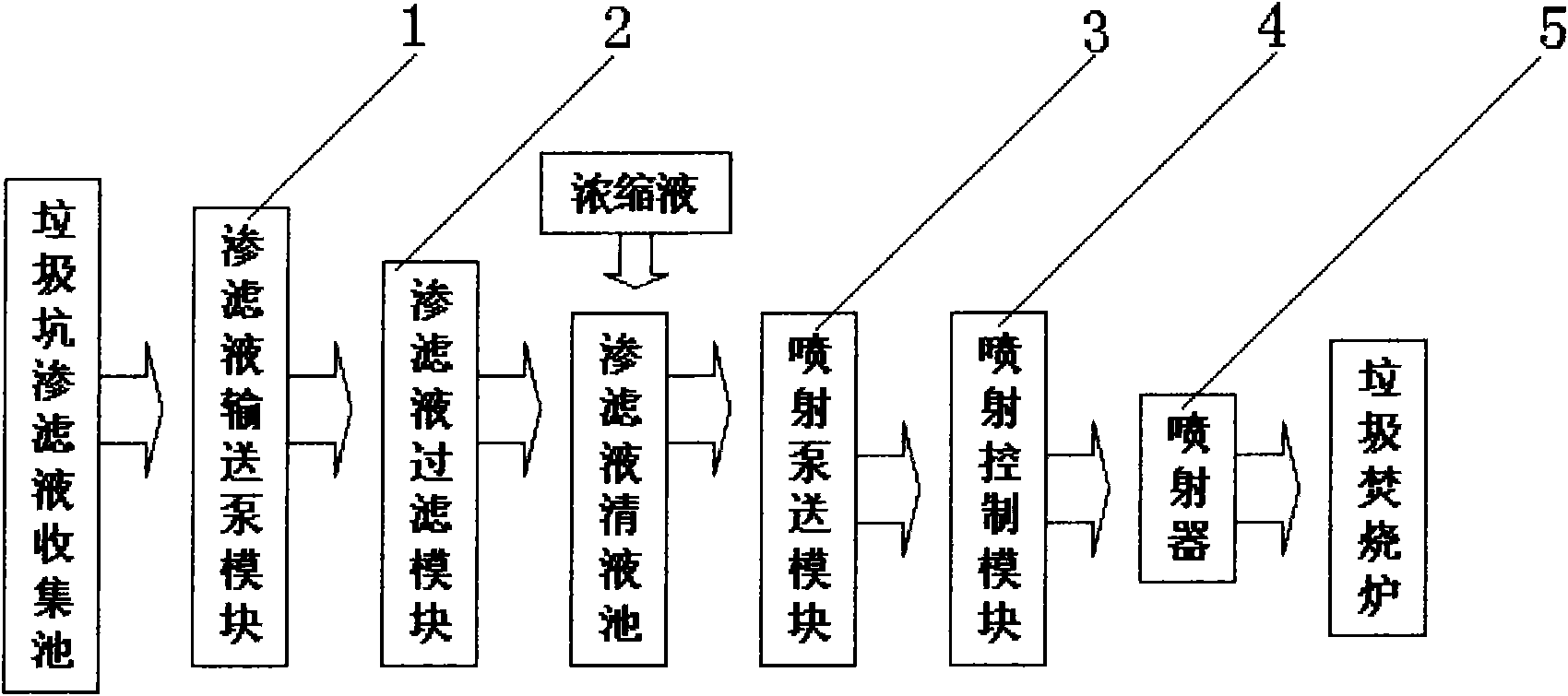

Process for spraying and treating percolate

ActiveCN101979921AExtended operating cycleReduce cokingIncinerator apparatusAutomatic controlBurn treatment

The invention relates to a process for treating garbage percolate, in particular to a process for spraying and treating percolate and aims to provide a reliable and efficient garbage percolate treatment method for spraying the garbage percolate for burning treatment. The garbage percolate can be prevented from polluting the environment and the pollution problem can be solved completely. In order to fulfill the aim, the process for spraying and treating the percolate is provided and comprises the following steps of: collecting the percolate; filtering the percolate; and spraying the percolate. A technical process for spraying, burning and treating the percolate is simple and is convenient to operate. Stock garbage percolate can be decomposed fully or concentrated solution produced in other treatment modes can be treated simultaneously and secondary pollution is avoided; and compared with other treatment modes, the process has low construction, operation and maintenance costs, small floor area and high automatic control degree and is convenient to operate.

Owner:SHANGHAI TECHSPRAY ENG

Catalytic composition for treating coal combustion gases, method for preparing same, catalytic system including same, and use thereof

InactiveUS20120027653A1Reduce nitrogen oxide contentUsing liquid separation agentHeterogenous catalyst chemical elementsCoalProduct gas

The invention relates to a catalytic composition for treating coal combustion gases, to a method for preparing said composition, to a catalytic system having such a composition, and to the use of the catalytic composition for treating coal combustion gases. The catalytic composition is made of particles of a solid composition cCeO2zZrO2 containing rhodium in the form of Rh2O3 and rhodium in the form of Rh4+.

Owner:UNIV PIERRE & MARIE CURIE +2

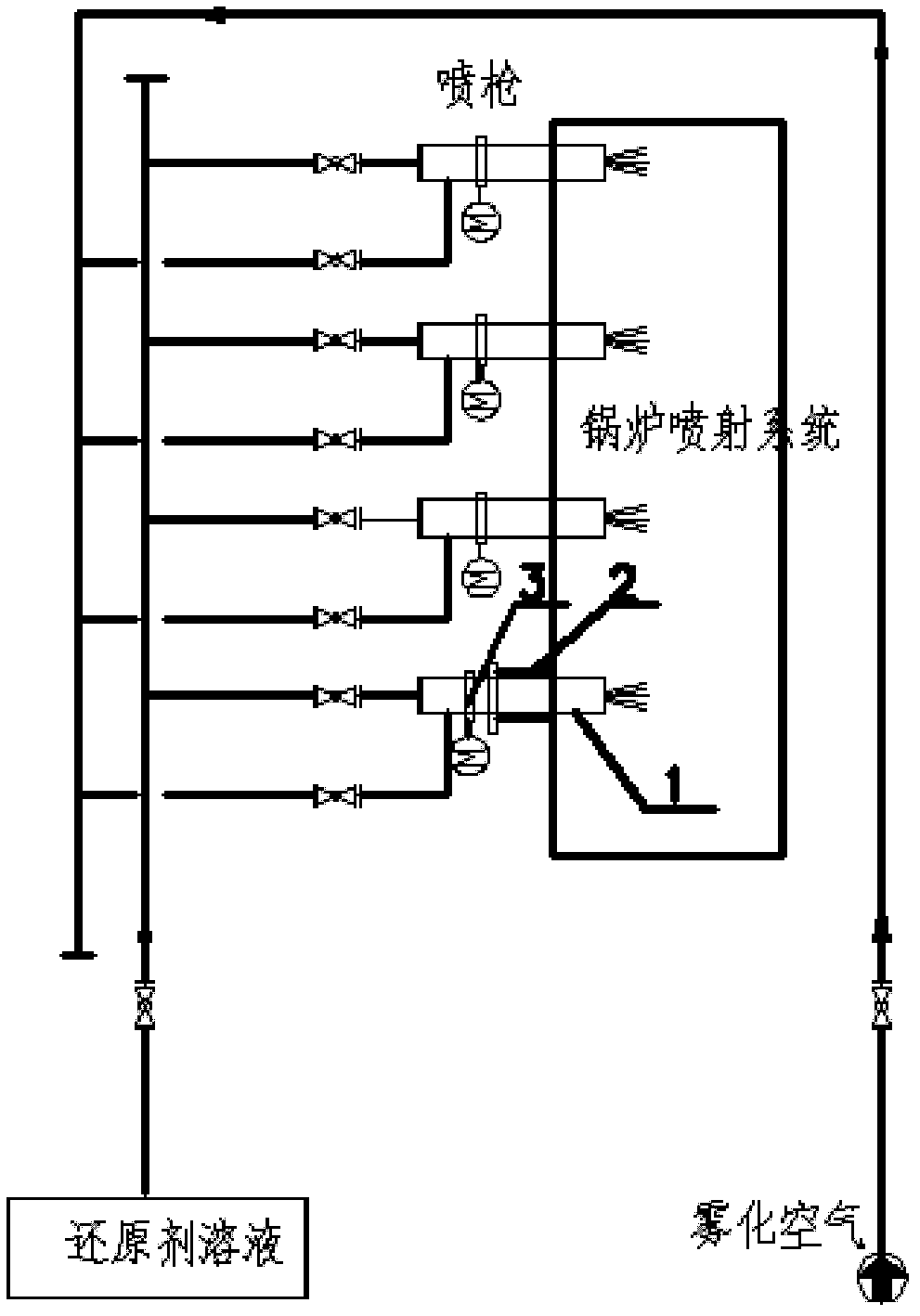

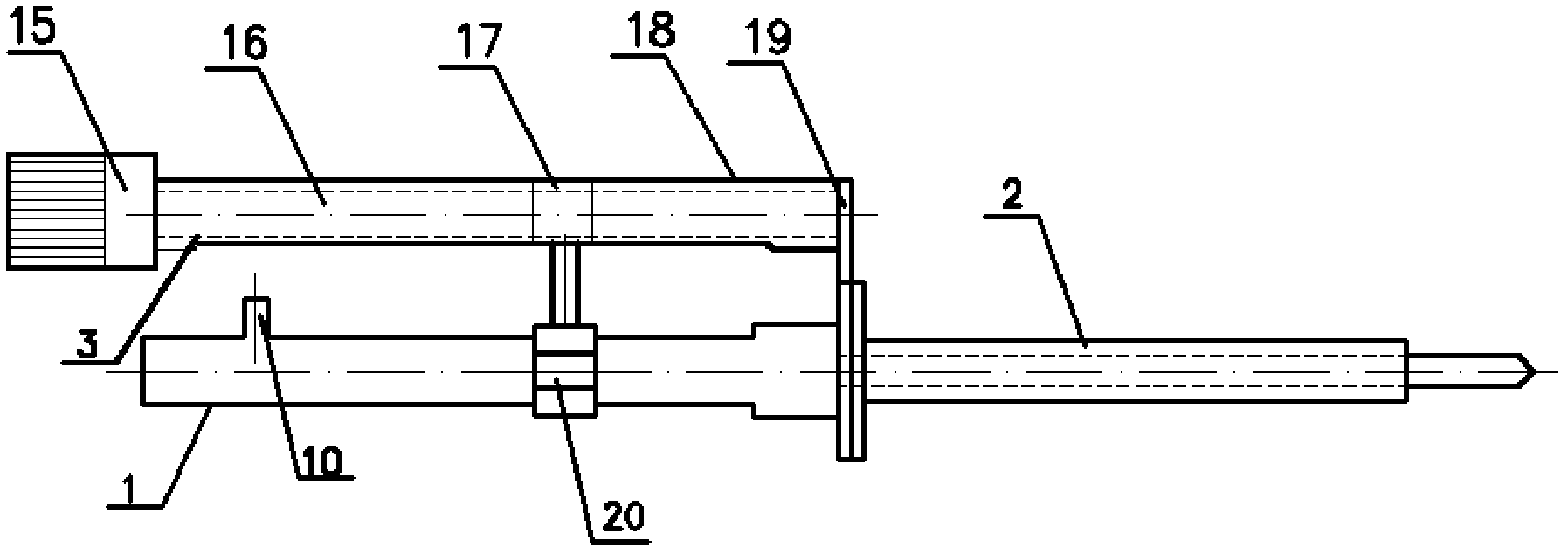

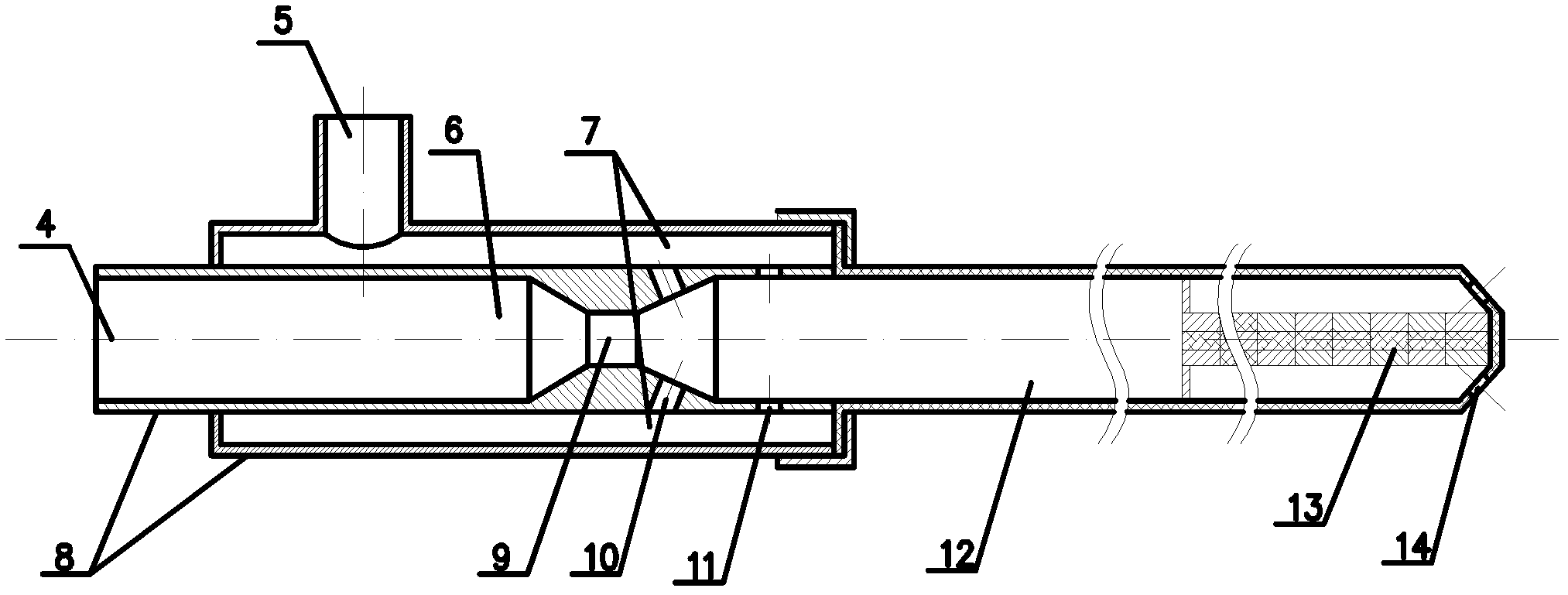

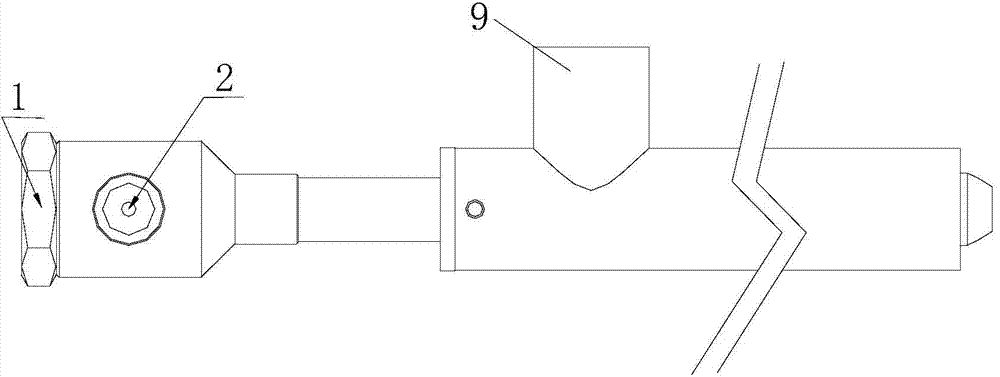

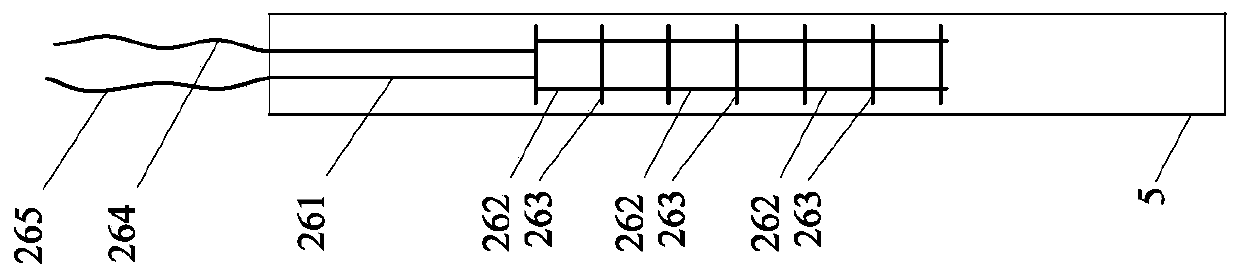

Inside-mixing type reducing agent atomizing spray gun for SNCR (Selective Non-Catalytic Reduction) denitration process

InactiveCN102580506AReduce nitrogen oxide contentDispersed particle separationRotation - actionFluidized bed

The invention discloses an inside-mixing type reducing agent atomizing spray gun for an SNCR (Selective Non-Catalytic Reduction) denitration process, belonging to the technical field of boiler denitration devices. The inside-mixing type reducing agent atomizing spray gun comprises a spray gun sleeve, an electric propulsion plant and a spray gun and is characterized in that the spray gun sleeve is installed on the external wall of a boiler and communicated with a boiler hearth; the spray gun sleeve is inclined downward and has an included angle of 5-15 degrees with the horizontal plane; and the electric propulsion plant is fixedly connected with the spray gun and fixedly connected with the spray gun sleeve. When the system is put into operation, a motor is rotated forward and drives a screw rod to rotate through a coupler, a screw nut is moved forward in the rotation action of the screw rod and drives the spray gun to move forward and enter the hearth to spray; and when the system is shut down, the motor is rotated reversely and the screw nut moves backward to drive the spray gun to exit the hearth. The inside-mixing type reducing agent atomizing spray gun disclosed by the invention has the advantages of good atomizing effect, high degree of automation, low rate of gas consumption and prevention of corrosion to a water-cooled wall and is applicable to boilers such as a medium-small coal-powder boiler and a circulating fluidized bed the like; and the atomizing medium can be compressed air or steam.

Owner:SHANDONG SHANDA WIT ENVIRONMENTAL ENGINEERING CO LTD

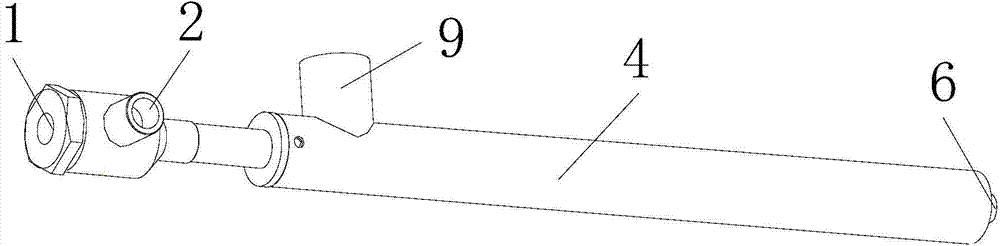

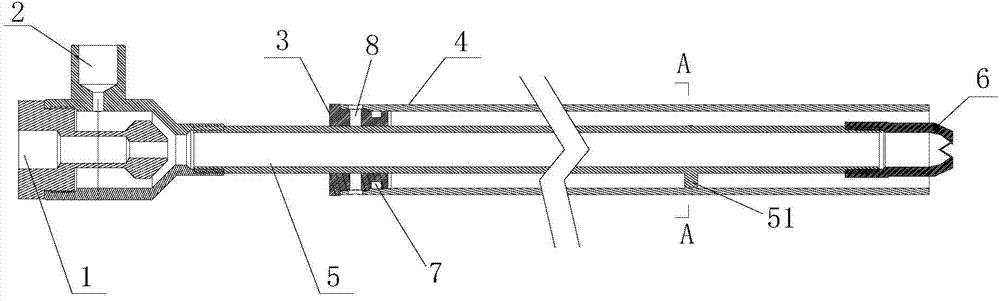

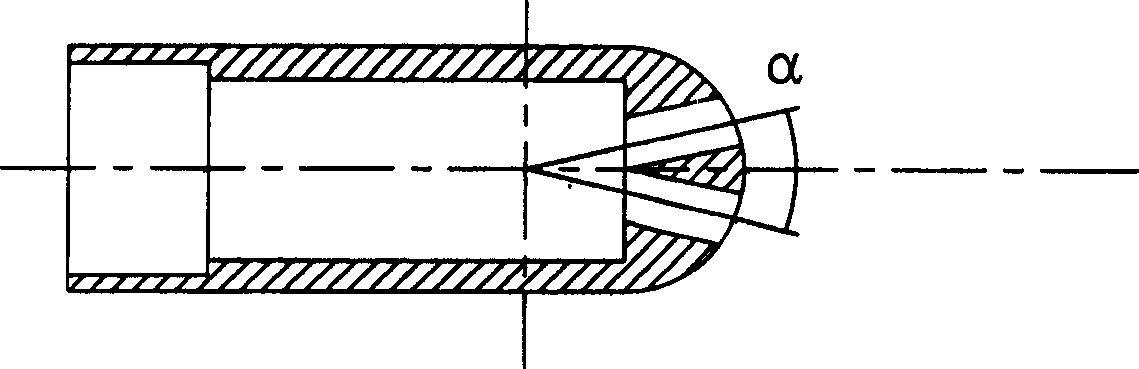

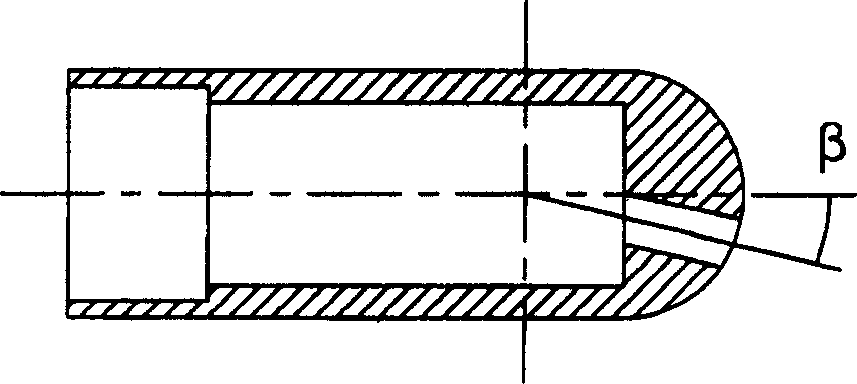

Atomizing spray gun

ActiveCN103759260APower Generation Efficiency ImpactAvoid damageBurnersIncinerator apparatusEngineeringScrew thread

The invention relates to an atomizing spray gun. Four leachate return and spray nozzles are arranged on two sides of the outlet sidewall of a burning hearth furnace and are parallel to a secondary air inlet. The atomizing spray gun comprises a compressed air nozzle, a leachate nozzle, a flange, a protective sleeve, a gun rod and an atomizing nozzle. The compressed air nozzle is screwed to the larger end of the leachate nozzle in a threaded manner, the gun rod is screwed to the smaller end of the leachate nozzle in a threaded manner, and one end of the atomizing nozzle provided with a thread is screwed to the outer thread of one end of the gun rod. The gun rod is fixed to the flange in a welded manner, and the flange is sleeved with a seal ring. One end of the protective sleeve with a mounting hole sleeves the flange and is fixed through a screw to prevent from dropping. The atomizing spray gun has the advantages that dual-fluid design is adopted, the leachate and the compressed air are mixed in the nozzle under certain pressure, fine atomized particles are produced, and service life is super long.

Owner:无锡卓能环境科技有限公司

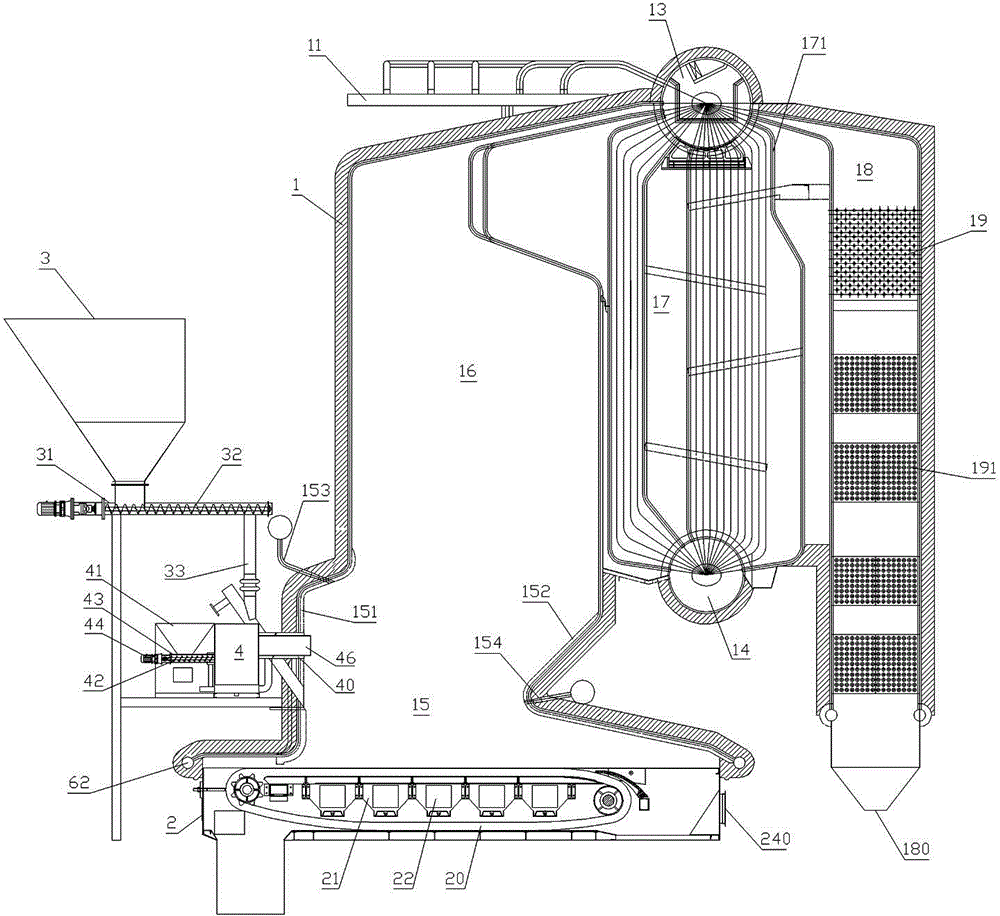

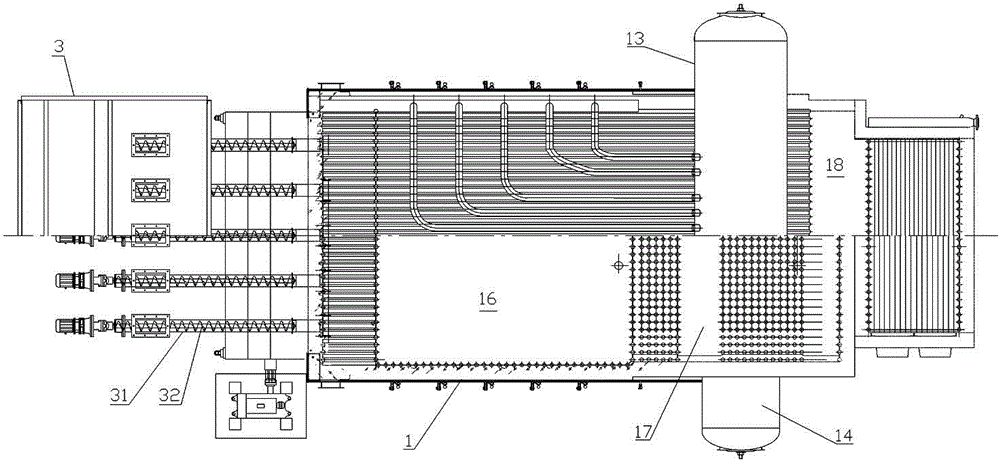

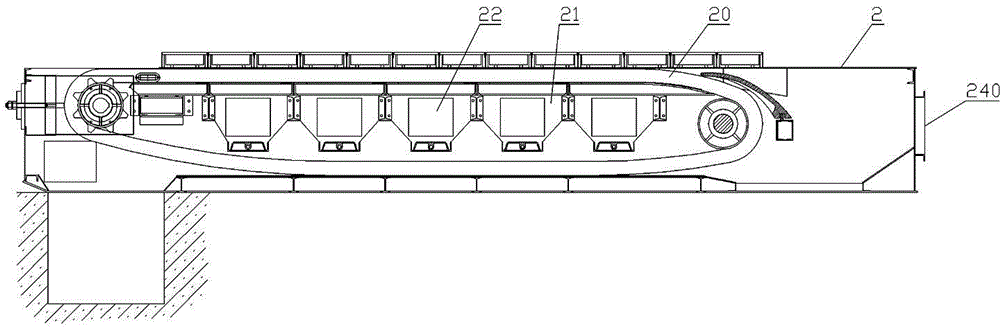

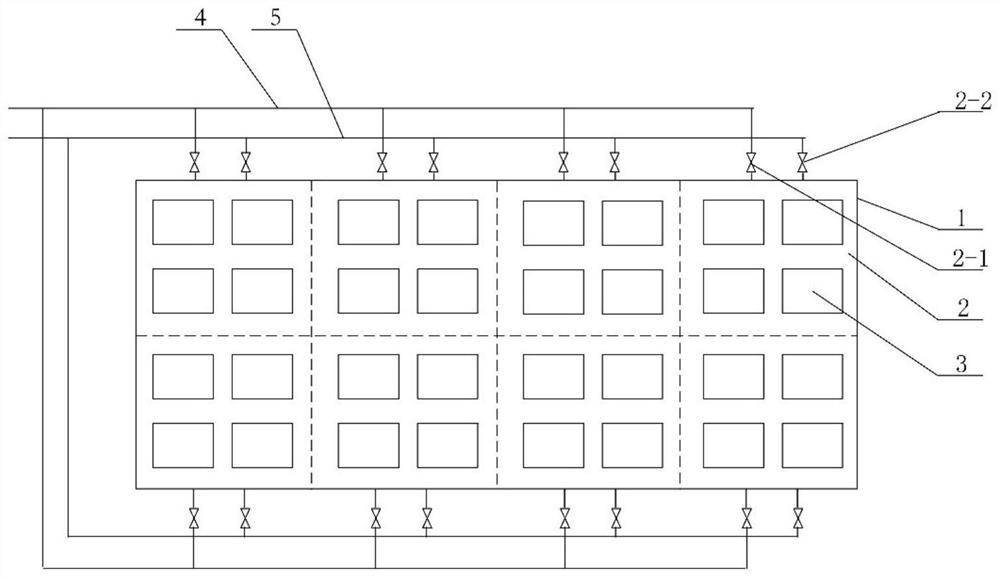

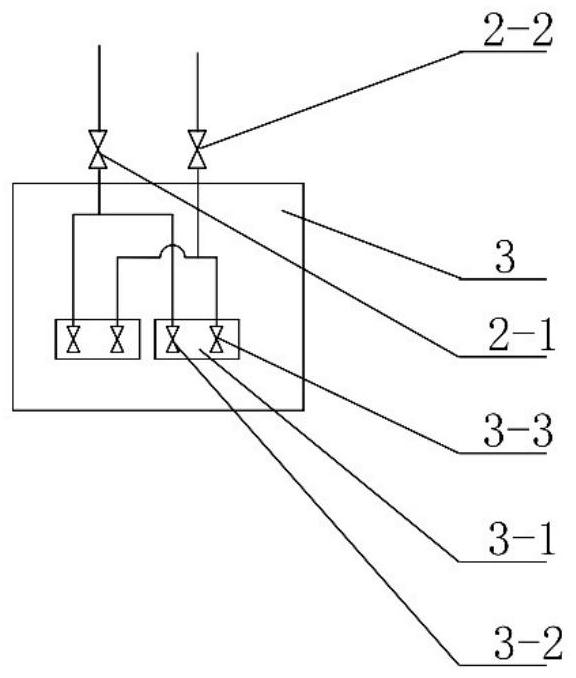

Ultralow-emission nitrogen oxide biomass chain boiler

ActiveCN104654265AAvoid secondary wind dead angleReduce nitrogen oxide contentWater-tube boilersSolid fuel combustionBiomassZero emission

The invention provides an ultralow-emission nitrogen oxide biomass chain boiler. The ultralow-emission nitrogen oxide biomass chain boiler comprises a boiler body, a chain grate and a spiral feeder, wherein an upper header, a lower header, an upper boiler barrel and a lower boiler barrel are arranged in the boiler body; a hearth, a flue gas radiation chamber, a flue gas convection box and a smoke exhaust box are arranged in the boiler body; an air preheater is arranged in the smoke exhaust box; the chain grate is arranged at the bottom of the hearth; primary air is supplied from the air chamber of the chain grate; in particular, hearth front and back air jet pipes are arranged on front and back arch throats respectively, and are connected with front and back air jet pipe fans; secondary air is supplied in two segments from front and back arches. Furthermore, the primary air can be supplied in two segments from the air chamber of the chain grate; the air source of the primary air and / or the secondary air can be hot air output by the air preheater; 1-3 afterburning ports are formed beside a feeding hole in the front arch throat; a denitrification combustion device is correspondingly arranged on each afterburning port. By adopting the ultralow-emission nitrogen oxide biomass chain boiler, zero emission of carbon dioxide is basically realized, and the effect of low emission of dust, nitrogen oxide and sulfur dioxide is achieved.

Owner:迪森(常州)能源装备有限公司 +1

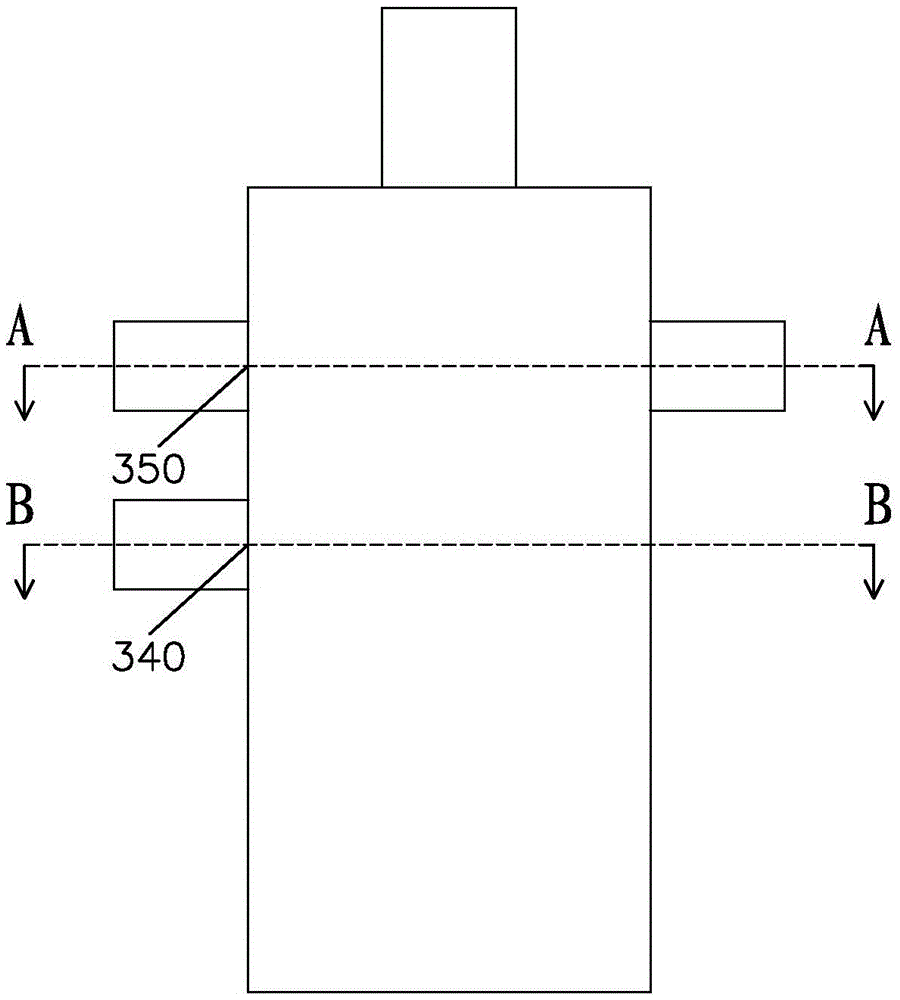

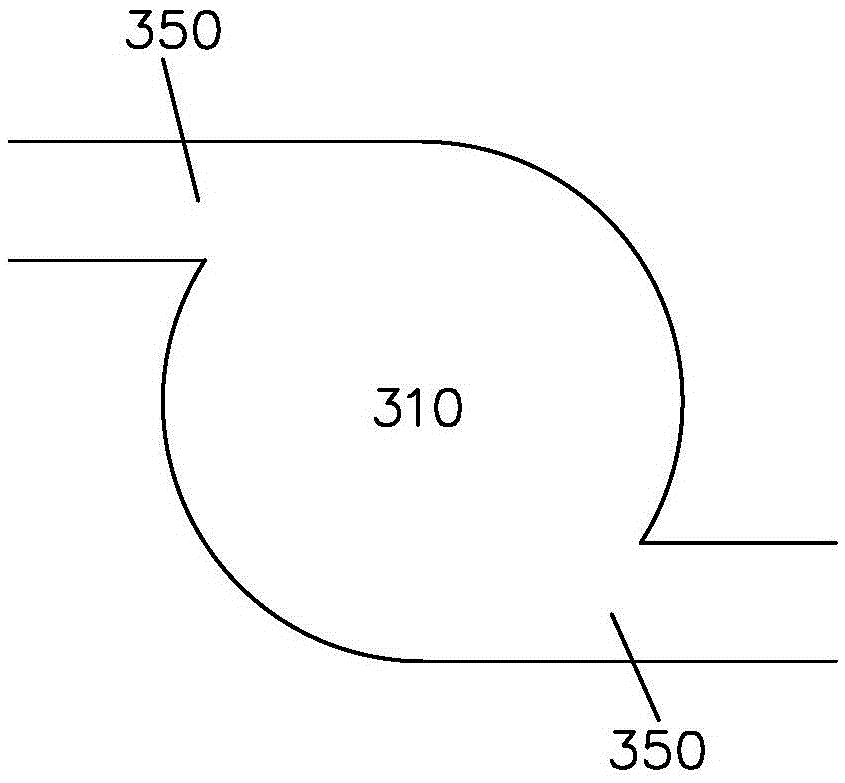

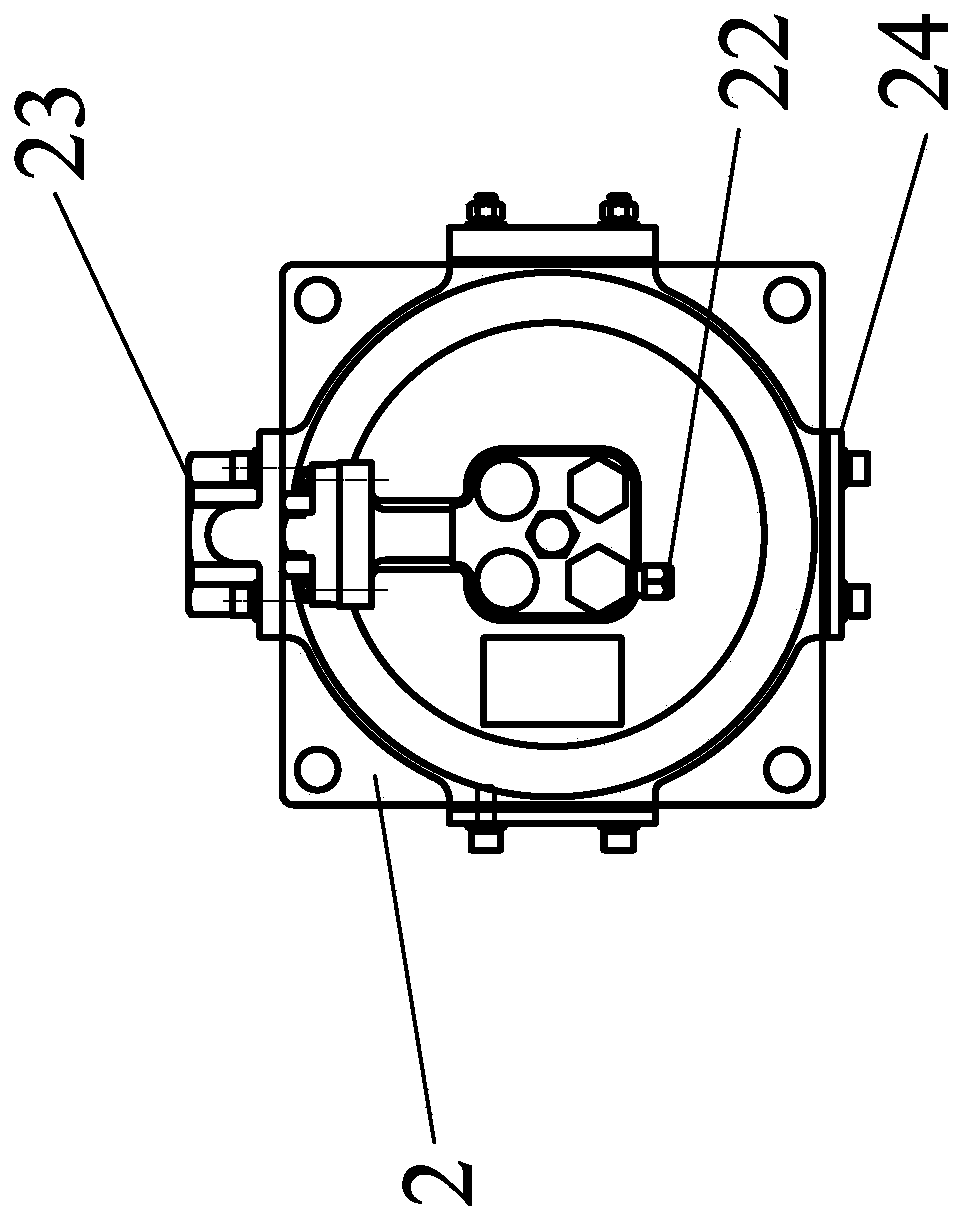

Efficient denitrifying device of circular fluidized bed boiler

The invention provides an efficient denitrifying device of a circular fluidized bed boiler, and belongs to the technical field of efficient denitrification of coal-fired boilers. In the invention, an original cyclone separator of a boiler is utilized, and a denitrifying device is arranged on the cyclone separator; smoke of the boiler enters the cyclone separator in a tangential direction through a flue after being discharged out of a hearth; and nozzles are respectively arranged on the flue and the top of the cyclone separator, and are used for spraying denitrifying agent. When the efficient denitrifying device is adopted, a strong whirl is formed after the denitrifying agent and the smoke enter the cyclone separator from the flue in the tangential direction, so that the speed of mixing the denitrifying agent and nitric oxide in the smoke, the reduction of the nitric oxide in the smoke is accelerated, and the content of the nitric oxide in the smoke is obviously reduced; further reconstruction on the flue of the boiler is not needed; and the efficient denitrifying device has the advantages of simple structure, low cost and high denitrifying efficiency.

Owner:中能东讯新能源科技(大连)有限公司 +1

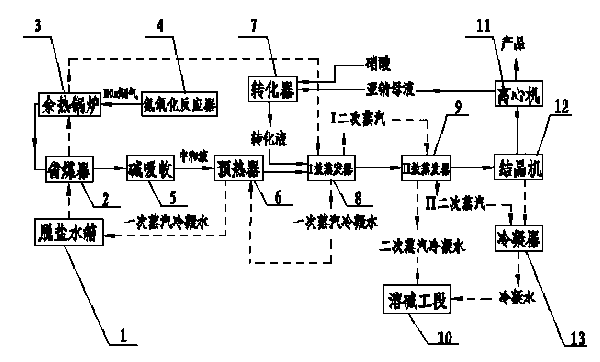

Steam self-supply system for producing sodium nitrate/sodium nitrite

ActiveCN103848443AConducive to emission reductionReduce the temperatureEnergy inputAlkali metal nitrate preparationEngineeringSodium nitrite

The invention discloses a steam self-supply system for producing sodium nitrate / sodium nitrite, which is suitable for preparing sodium nitrate / sodium nitrite. A desalination water tank is connected with a waste heat boiler through a coal economizer, and the waste heat boiler is connected with an ammoxidation reactor; the coal economizer is communicated with a crystallizer through an alkaline absorber, a preheater, an I-effect evaporator and an II-effect evaporator; the preheater is connected with the desalination water tank; a converter is respectively connected with the I-effect evaporator and a centrifugal machine; the II-effect evaporator is respectively connected with an alkaline dissolving workshop section and the crystallizer; the alkaline dissolving workshop section is connected with the centrifugal machine through a condenser and the crystallizer. The steam self-supply system is remarkable in energy saving benefit, convenient for process regulation and pollutant discharge reduction, high in degree of automation, remarkable in steam saving effect and high in recycling ratio.

Owner:襄阳泽东化工集团股份有限公司

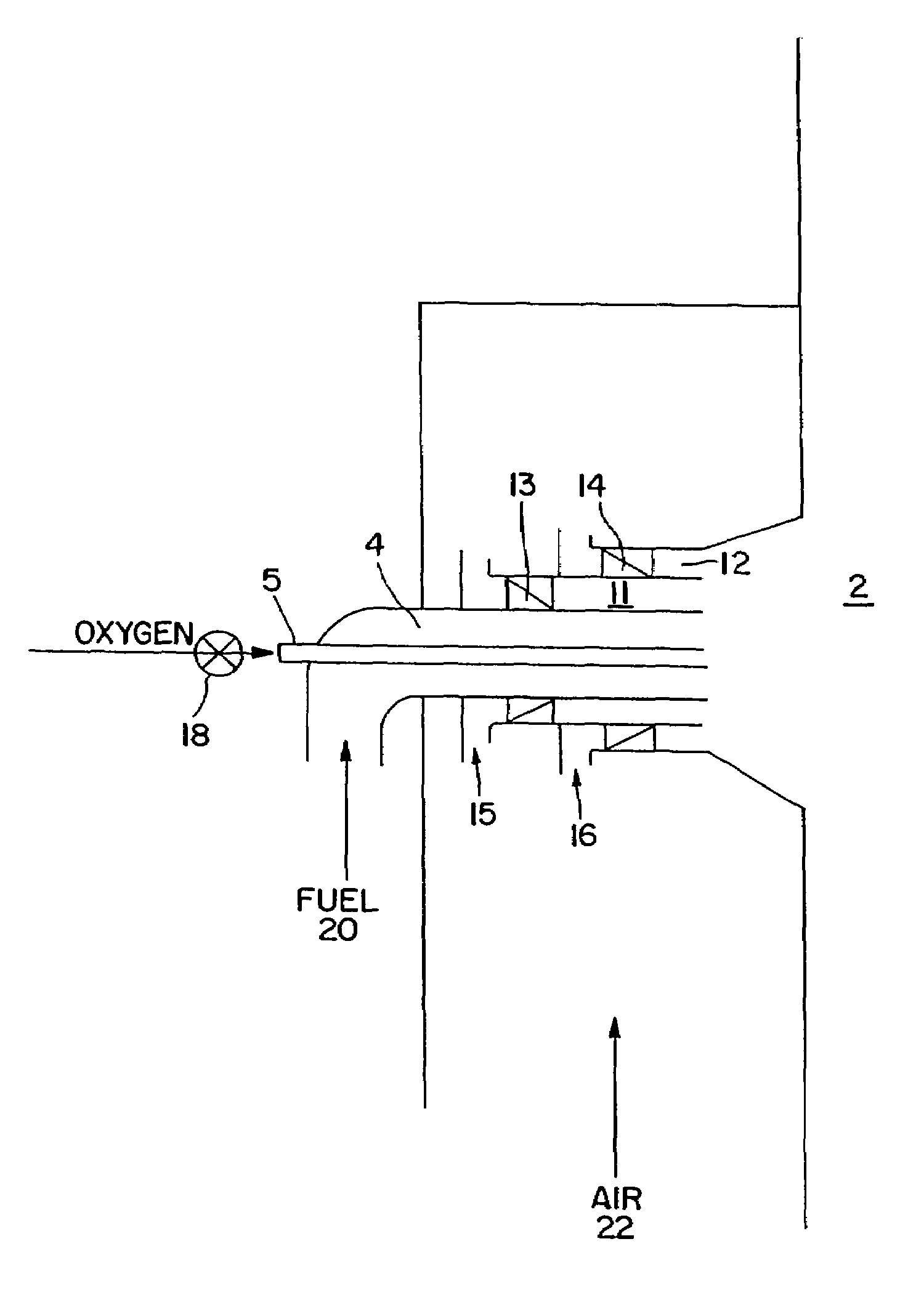

Method of operating furnace to reduce emissions

InactiveUS20060230996A1Reduce nitrogen oxide contentRaise the ratioStaged combustionSolid fuel combustionCombustorEngineering

Emissions of NOx and CO are reduced from combustion devices such as coal-fired furnaces by increasing the stoichiometric ratio of burner(s) having a lower average temperature and increasing the stoichiometric ratio of burner(s) having a higher average temperature.

Owner:PRAXAIR TECH INC

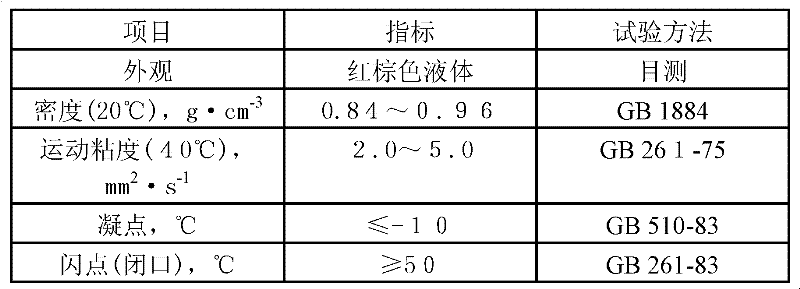

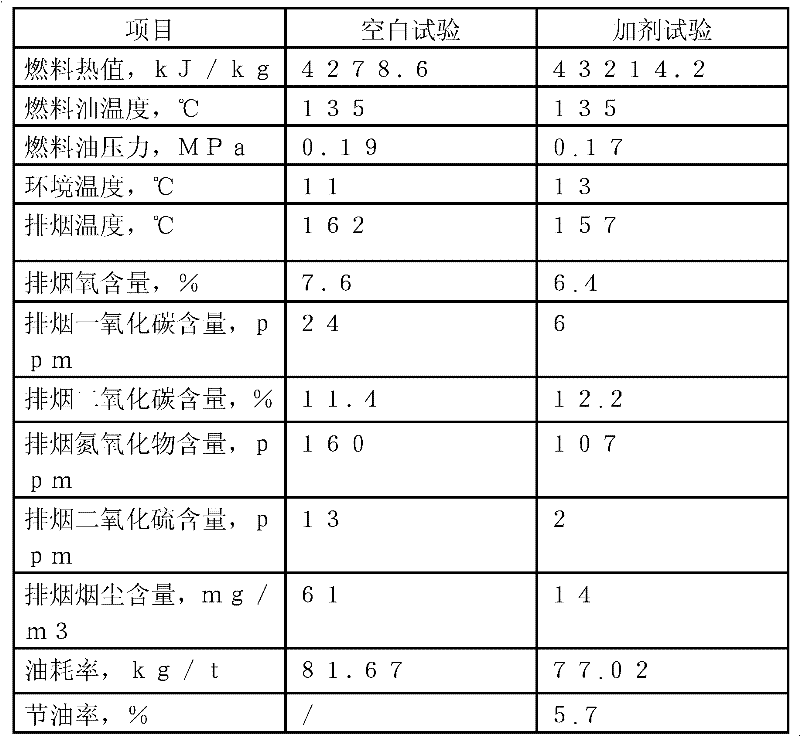

Multifunctional ashless combustion accelerant of heavy oil

InactiveCN102199458AHigh thermal efficiencyReduce consumptionLiquid carbonaceous fuelsAir quality improvementFuel oilNitric oxide

The invention relates to a multifunctional ashless combustion accelerant of heavy oil. The multifunctional ashless combustion accelerant is characterized by comprising a free oxygen generating agent, a catalyst, a dispersing agent and a solvent. The invention aims at solving the technical problem of providing a multifunctional ashless combustion accelerant, which has the advantages of combustion acceleration (oil saving), smoke abatement and reduced emission of harmful gases. According to the multifunctional ashless combustion accelerant of the heavy oil, the calorific value of a fuel can be increased, and the discharged smoke content and the oil consumption are reduced; the fuel oil undergoes a more complete combustion after the multifunctional ashless combustion accelerant of the heavy oil is added; in addition, the nitric oxide content and the sulfur dioxide content in discharged smoke are remarkably reduced, and the atmospheric pollution can be improved after the multifunctional ashless combustion accelerant of the heavy oil is added. When the addition amount of the multifunctional ashless combustion accelerant of the heavy oil is 0.3 percent, the oil saving ratio can reach more than 5 percent.

Owner:JIANGSU KECHUANG PETROCHEM

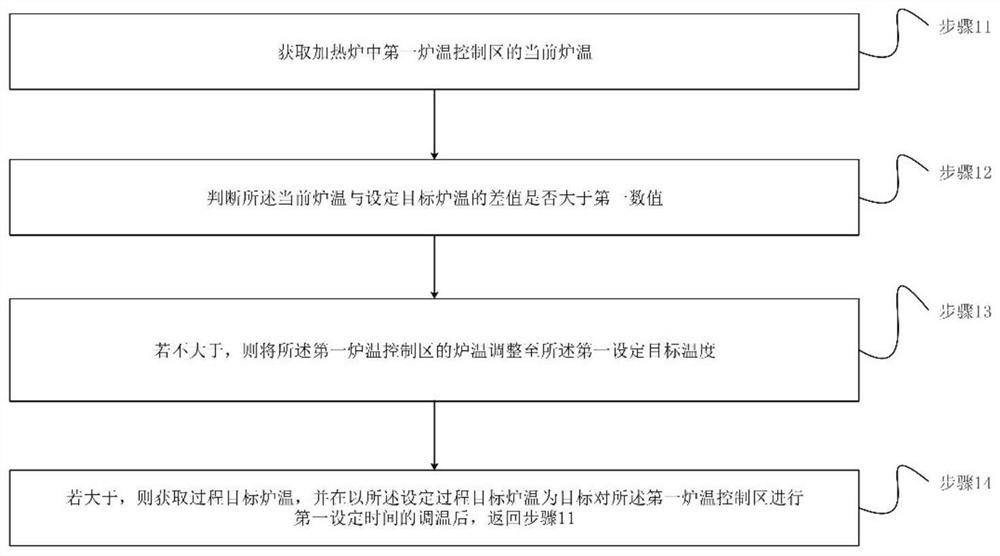

Control method and device for reducing nitrogen oxide content in heating furnace combusting waste gas

ActiveCN111795584AReduce nitrogen oxide contentAvoid Furnace Pressure Sudden ChangesControl devices for furnacesFurnace temperatureThermodynamics

The invention relates to the technical field of heating furnaces, in particular to a control method and device for reducing the nitrogen oxide content in the heating furnace combusting waste gas. Themethod comprises the steps that the current furnace temperature of a first furnace temperature control area in a heating furnace is acquired; it is judged whether the difference value of the current furnace temperature and the set target furnace temperature is greater than a first numerical value or not; if the different value is not greater than the first numerical value, the furnace temperatureof the first furnace temperature control area is adjusted to first set target temperature; and if the different value is greater than the first numerical value, the process target furnace temperatureis acquired, and after temperature adjustment of first set time is conducted on the first furnace temperature control area with the process target furnace temperature as the aim, the current furnace temperature is acquired again, wherein the process target furnace temperature is between the current furnace temperature and the set target furnace temperature. According to the control method for thereducing the nitrogen oxide content in the heating furnace combusting waste gas, when the current furnace temperature and the first set target furnace temperature differ much, the lower process targetfurnace temperature is used to conduct in-furnace multi-stage temperature adjustment so that the furnace temperature in the furnace temperature control area is stably adjusted to the set target furnace temperature, and the nitrogen oxide content generated when combustion is conducted in the heating furnace is reduced.

Owner:SHOUGANG JINGTANG IRON & STEEL CO LTD

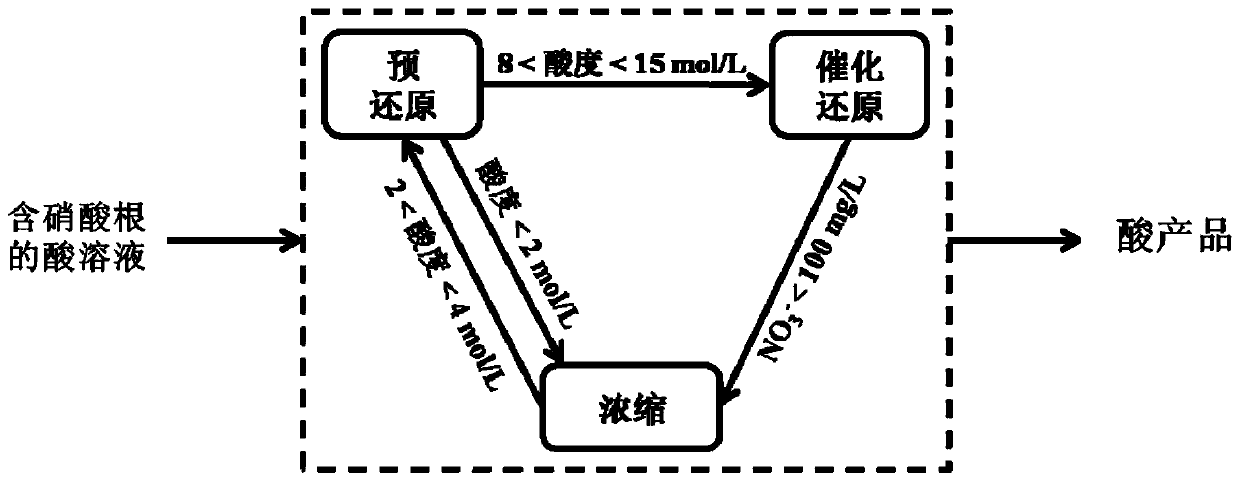

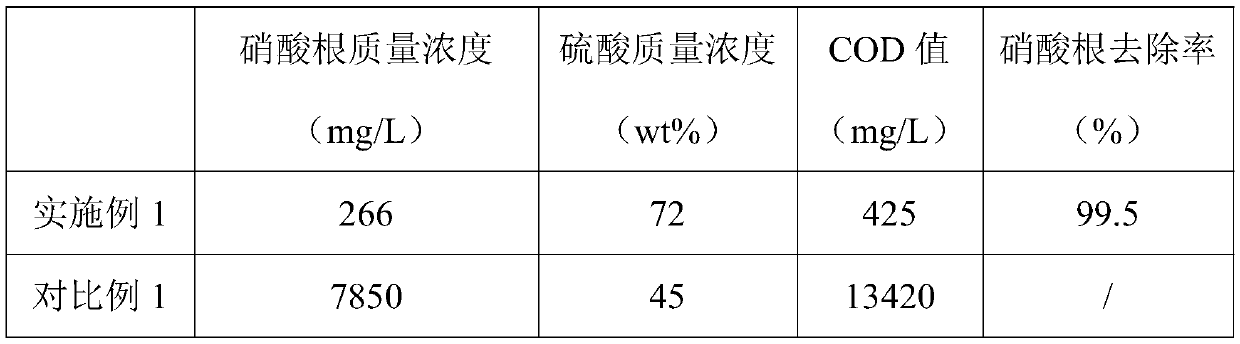

Method and device for reducing nitrate radicals in acid solution

ActiveCN111484117AReduce contentReduce pollutionWater contaminantsWater/sewage treatment by reductionNitrogen oxideNitrogen gas

The invention provides a method for reducing nitrate radicals in an acid solution. According to the method, an acid solution containing the nitrate radicals is subjected to pre-reduction, the nitrateradicals are reduced to be in a nitrite radical state, then catalytic reduction is carried out, the nitrite radicals are directly reduced to be nitrogen, nitrate radical ions in the acid solution areremoved, and a generated gas is low in nitrogen oxide content, free of pollution to air and harmless to a human body; meanwhile, the method has the advantages of simple operation conditions and process, the invention further provides a device for reducing the nitrate radicals in the acid solution, and the device is simple and easy to operate and has great industrial application value.

Owner:WUXI ZHONGTIAN SOLID WASTE DISPOSAL CO LTD

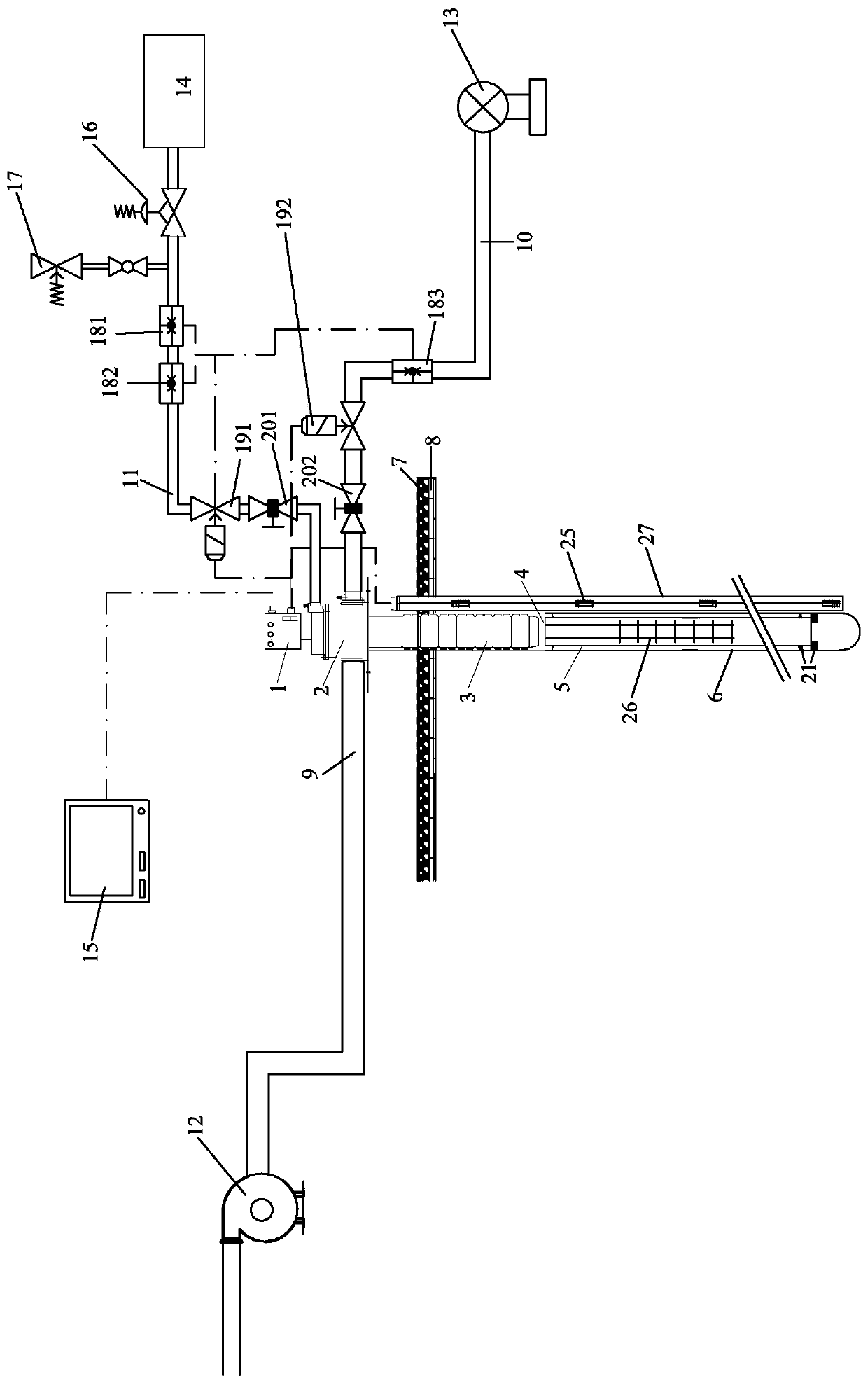

Efficient and energy-saving gas thermal desorption equipment

PendingCN110508604AReduce nitrogen oxide contentFast transmissionContaminated soil reclamationCombustion chamberRecuperator

The invention provides efficient and energy-saving gas thermal desorption equipment. A heating well is provided with an outer radiation pipe and an inner pipe which are mutually sleeved and form a backflow gap, and a heat exchanger is arranged above the inner pipe; a burner is arranged above the heating well, sprayed high-temperature flue gas can reach the bottom of the heating well through the inner pipe, the burner has a gas inlet, a combustion-supporting air inlet and a smoke exhaust port, wherein the gas inlet is connected with a gas station, the outer side of the combustion-supporting airinlet is communicated with a combustion-supporting fan, the inner side of the combustion-supporting air inlet is communicated with a combustion chamber of the burner through the heat exchanger, the smoke exhaust port is connected with a smoke exhaust fan and is used for discharging flue gas at the top of the heating well. A gap is left between the heat exchanger and the top of the inner pipe to form a flue gas return channel. According to the invention, the flue gas backflow channel is adopted, so that the combustion can be more complete, the nitrogen oxide content in the flue gas can be reduced, and the overall temperature of the heating well can be more uniform.

Owner:ZHONGKE DINGSHI ENVIRONMENTAL ENG CO LTD

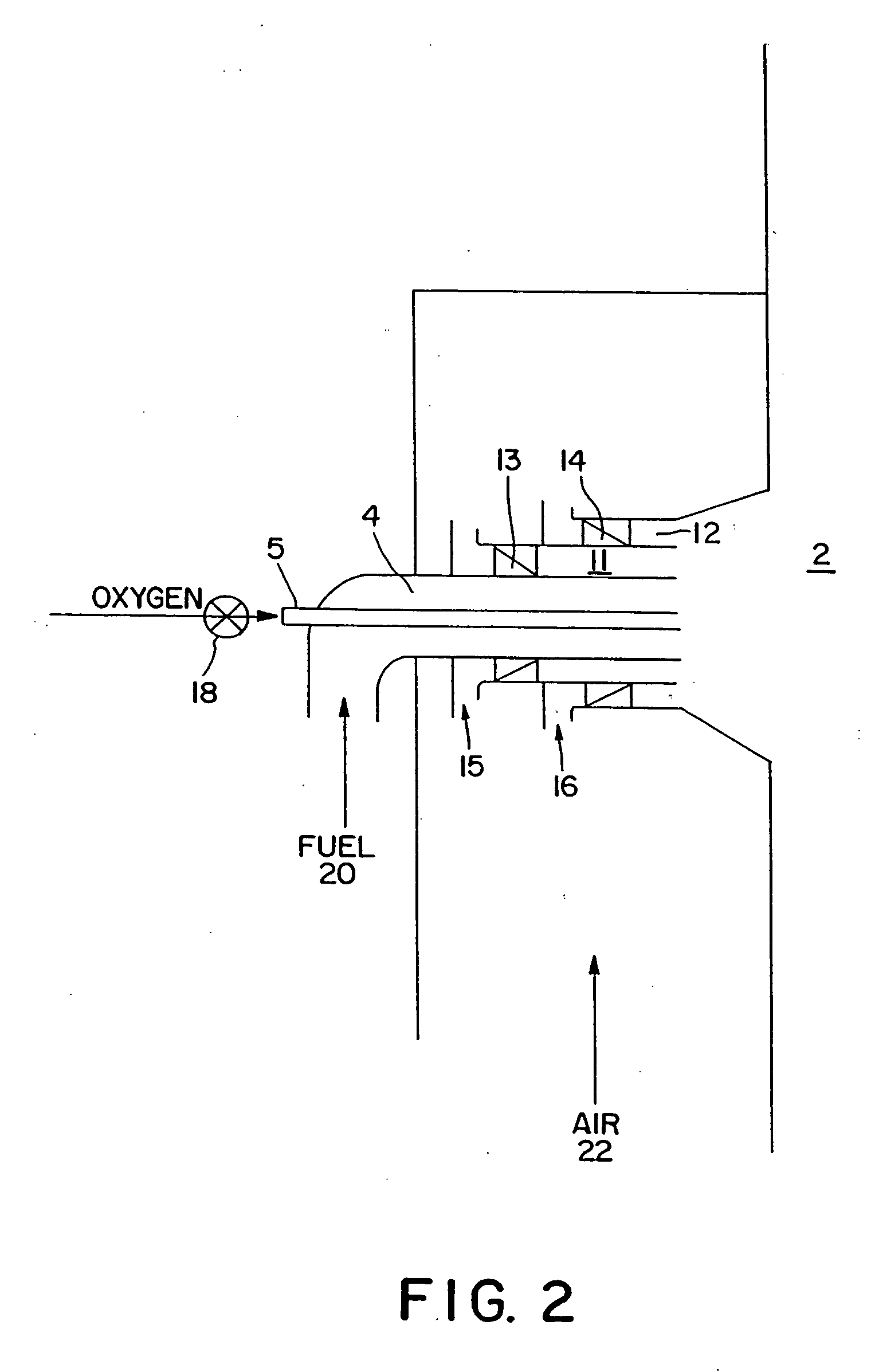

Fuel staging process for low NOx operations

ActiveCN1616884AEmission reductionReduce nitrogen oxide contentLiquid fuel feeder/distributionFuel supply regulationStream flowEngineering

A method for diluting a fuel to reduce NOx uses a fuel dilution device, which includes: a first conduit having an inlet and an outlet, the first conduit adapted to transmit a stream of a fuel entering the inlet and exiting the outlet at a first thermodynamic state and a first fuel index; and a second conduit having an intake and an outtake, the second conduit adapted to transmit a stream of a fluid entering the intake and exiting the outtake at a second / different thermodynamic state and a second fuel index different from the first fuel index by at least about 0.1, whereby a potential for mixing exists between the two streams exiting the outlet and the outtake, and at least some of the fuel mixes with at least some of the fluid near the outlet and the outtake, thereby generating a diluted fuel stream having an intermediate fuel index. <IMAGE>

Owner:AIR PROD & CHEM INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com