Method for generating multistage reburning controlling high-capacity coal fired boiler NOX

A coal-fired boiler, large-capacity technology, applied in the direction of combustion method, separation method, solid fuel combustion, etc., can solve the problem of harmful emissions, achieve the effect of protecting social benefits, reducing nitrogen oxide content, and significant social benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

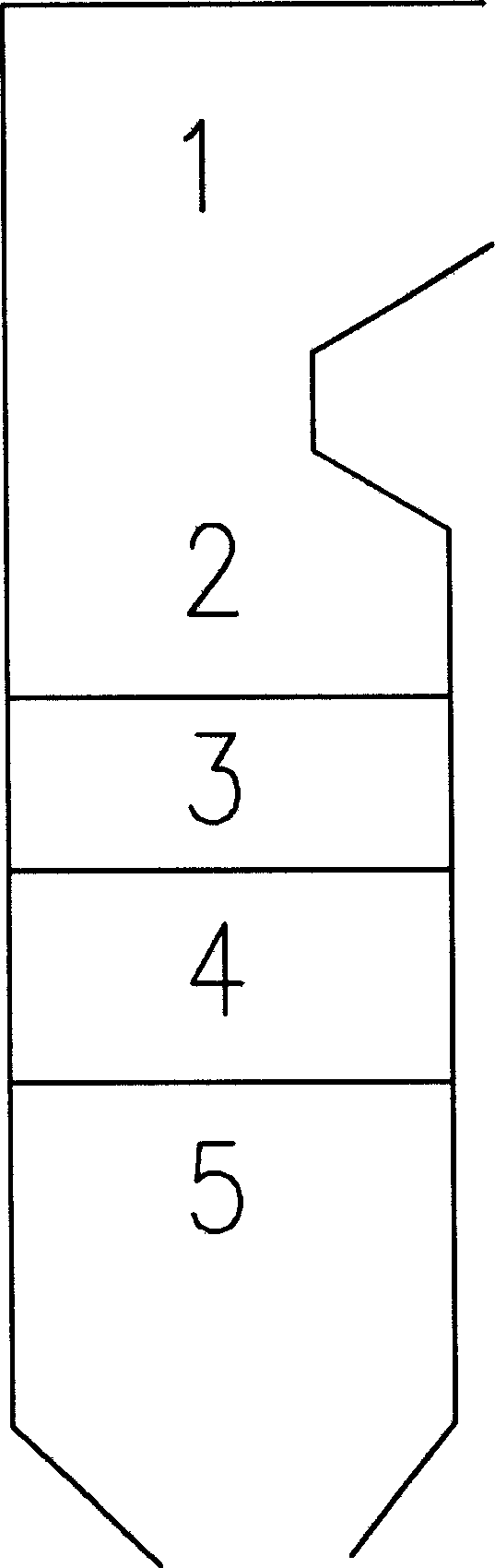

[0013] The multi-stage staged reburning technology is implemented on the main burner of the power plant boiler. Such as figure 1 As shown, along the boiler furnace 1 from bottom to top, it is divided into main combustion zone 5, primary reburning zone 4, secondary reburning zone 3 and burnout zone 2. One method is to inject about 75%-85% pulverized coal fuel into the main combustion zone 5 through the nozzle of the main burner, and the excess air coefficient α>1.0 forms low NO at a low combustion rate with rich oxygen x Combustion; the first-stage reburning nozzle in the lower layer is set above the primary air nozzle on the top of the main burner, and the injection amount of the first-stage reburning fuel is about 10%-15%, forming a slightly rich combustion-reducing atmosphere condition in the first-stage reburning area, The excess air coef...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com