Steam self-supply system for producing sodium nitrate/sodium nitrite

A technology for producing steam and sodium nitrite, which is applied in the preparation of nitrous acid and alkali metal nitrate, sustainable manufacturing/processing, etc., and can solve the problems of low level of resource utilization, high production energy consumption, and small amount of self-sufficient steam. To achieve the effect of improving the level of resource utilization, reducing the content of nitrogen oxides, and reducing NOX emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

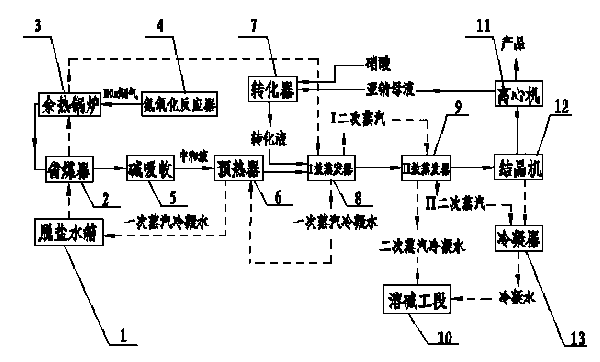

[0020] Such as figure 1 As shown, the desalted water tank 1 is connected to the waste heat boiler 3 through the economizer 2, and the waste heat boiler 3 is connected to the ammoxidation reactor 4; The evaporator 9 is connected to the crystallizer 12; the preheater 6 is connected to the desalted water tank 1; the converter 7 is connected to the I-effect evaporator 8 and the centrifuge 11 respectively; the II-effect evaporator 9 is connected to the alkali-dissolving section 10 and the crystallizer 12 respectively Connect; Alkali-dissolving workshop section 10 is connected with centrifuge 11 through condenser 13, crystallizer 12;

[0021] The desalted water from the economizer 2 absorbs the flue gas heat of the ammonia oxidation reactor 4 through the waste heat boiler 3, and the produced steam is incorporated into the steam pipe network for the concentrated material in the evaporation section; the cooled flue gas passes through the economizer 2 and Heat exchange with water from...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com