Patents

Literature

63results about "Nitrous acid" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

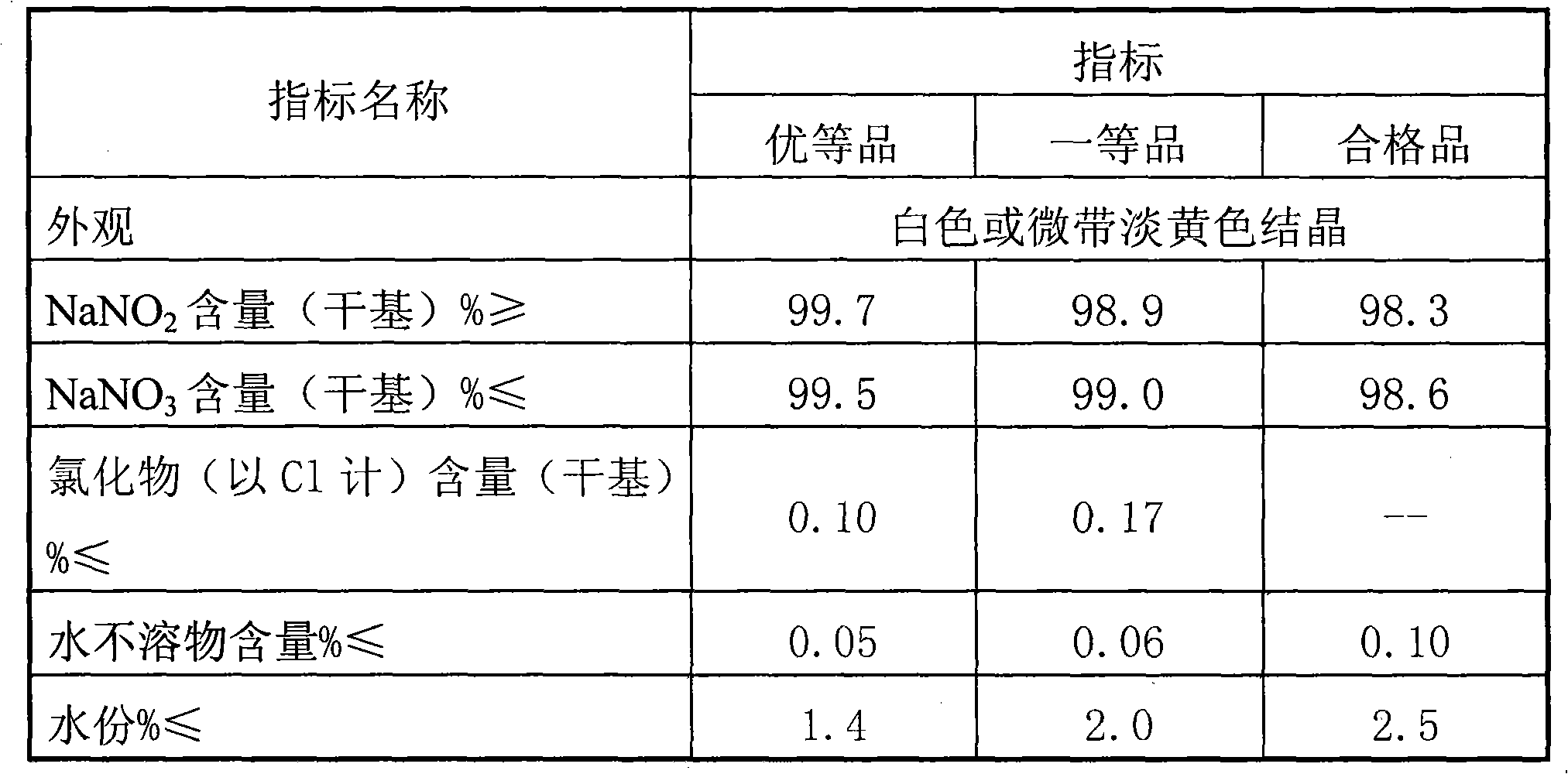

Sodium nitrite-containing pharmaceutical compositions

ActiveUS8568793B2Prevent and reduce riskBiocideInorganic active ingredientsVolatile organic carbonSodium nitrite

Provided herein are pharmaceutically acceptable sodium nitrite and pharmaceutical compositions thereof. Also provided herein are methods for determining the total non-volatile organic carbon in a sodium nitrite-containing sample. Further provided herein are methods for producing pharmaceutically acceptable sodium nitrite. Still further provided herein are methods of treatment comprising the administration of pharmaceutically acceptable sodium nitrite.

Owner:HOPE MEDICAL ENTERPRISES HOPE PHARMA

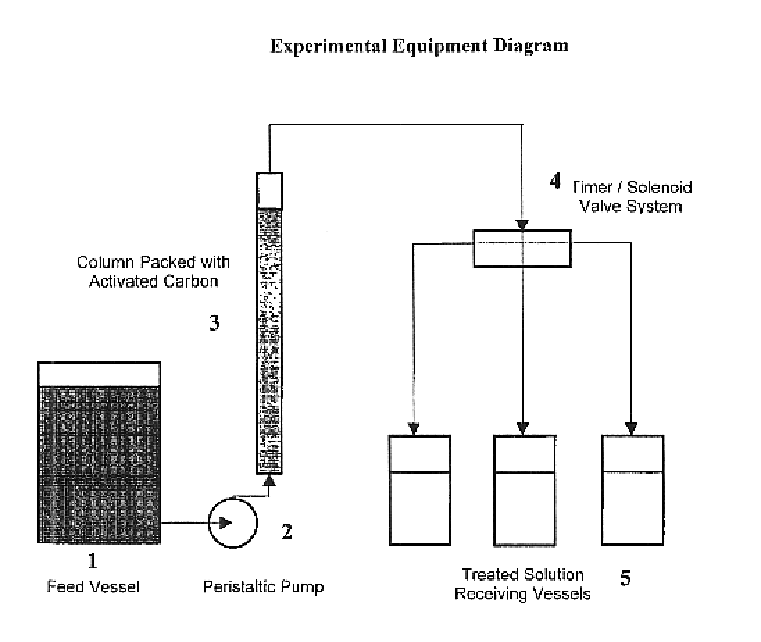

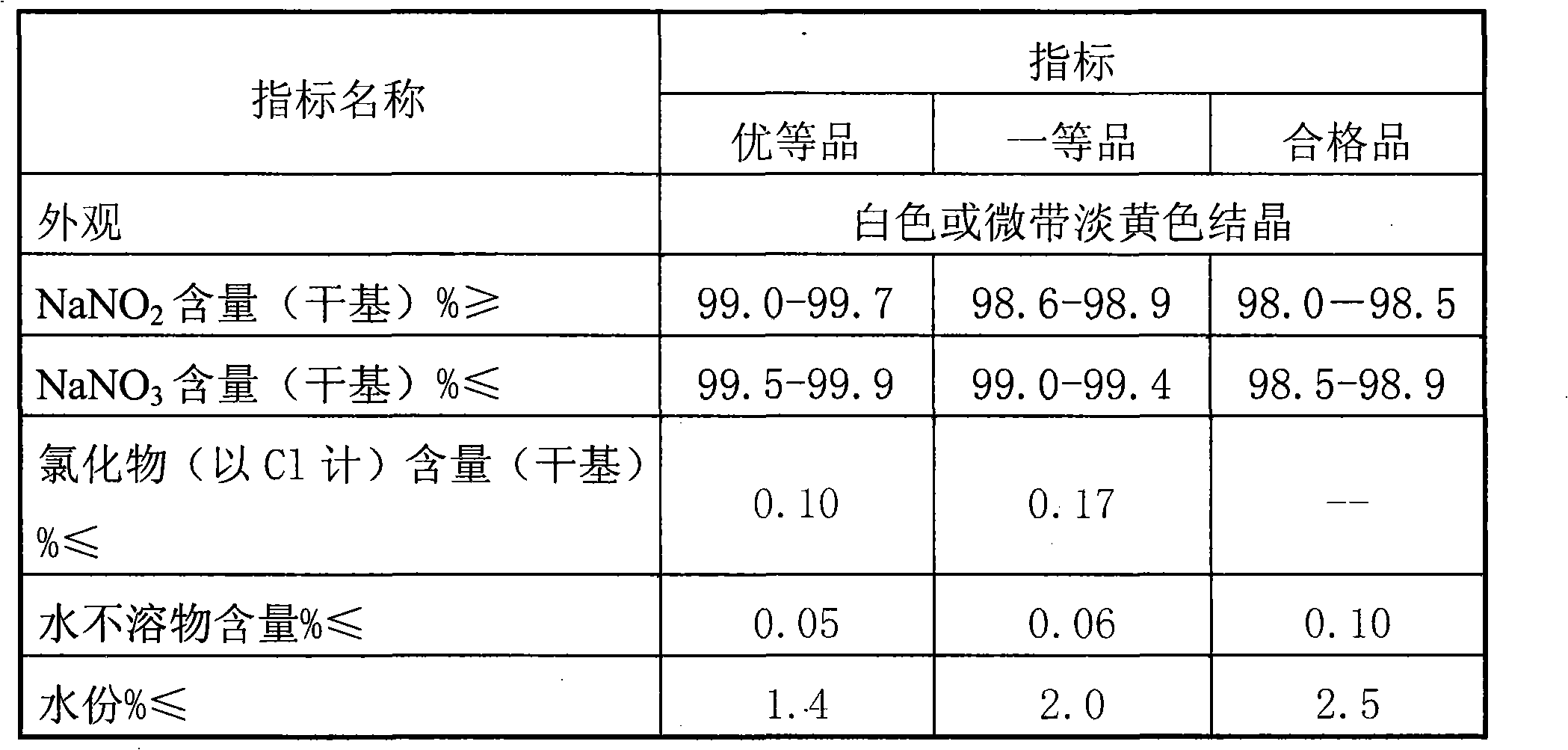

Process for the recovery of sodium nitrite

A process is provided for the removal of undesirable organic matter from solutions of sodium nitrite that are generated as byproducts in the manufacture of thermoplastic resins. The process employs certain activated carbon types derived from lignite granular material under conditions that are favorable to promote the absorption of the organic matter of a variety of organic substances that are residuals that remain from organic phase specifications in the plastics manufacture.

Owner:GEN CHEM PERFORMANCE PRODS +1

Sodium nitrite-containing pharmaceutical compositions

Owner:HOPE MEDICAL ENTERPRISES HOPE PHARMA

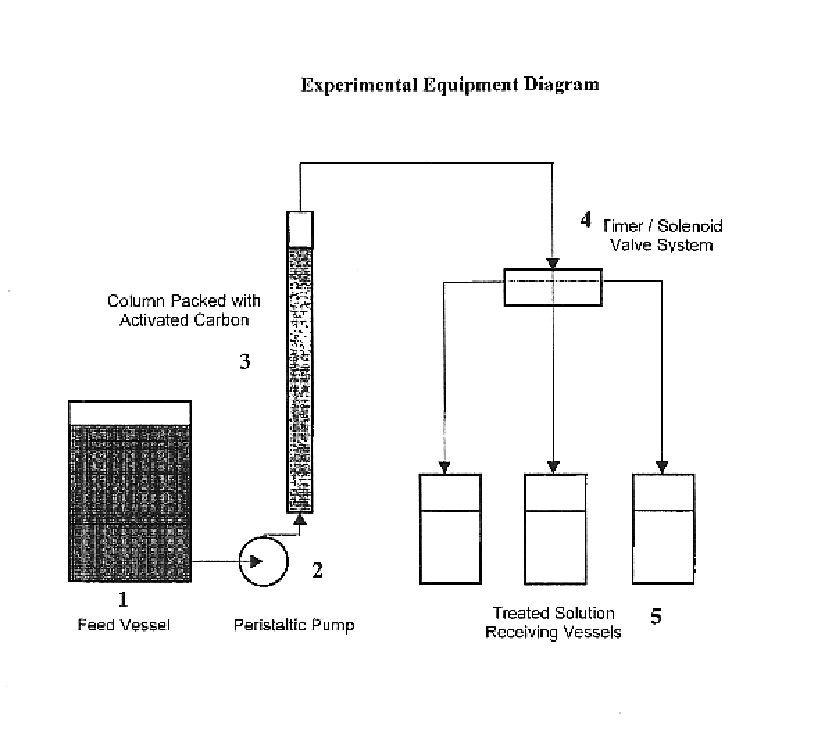

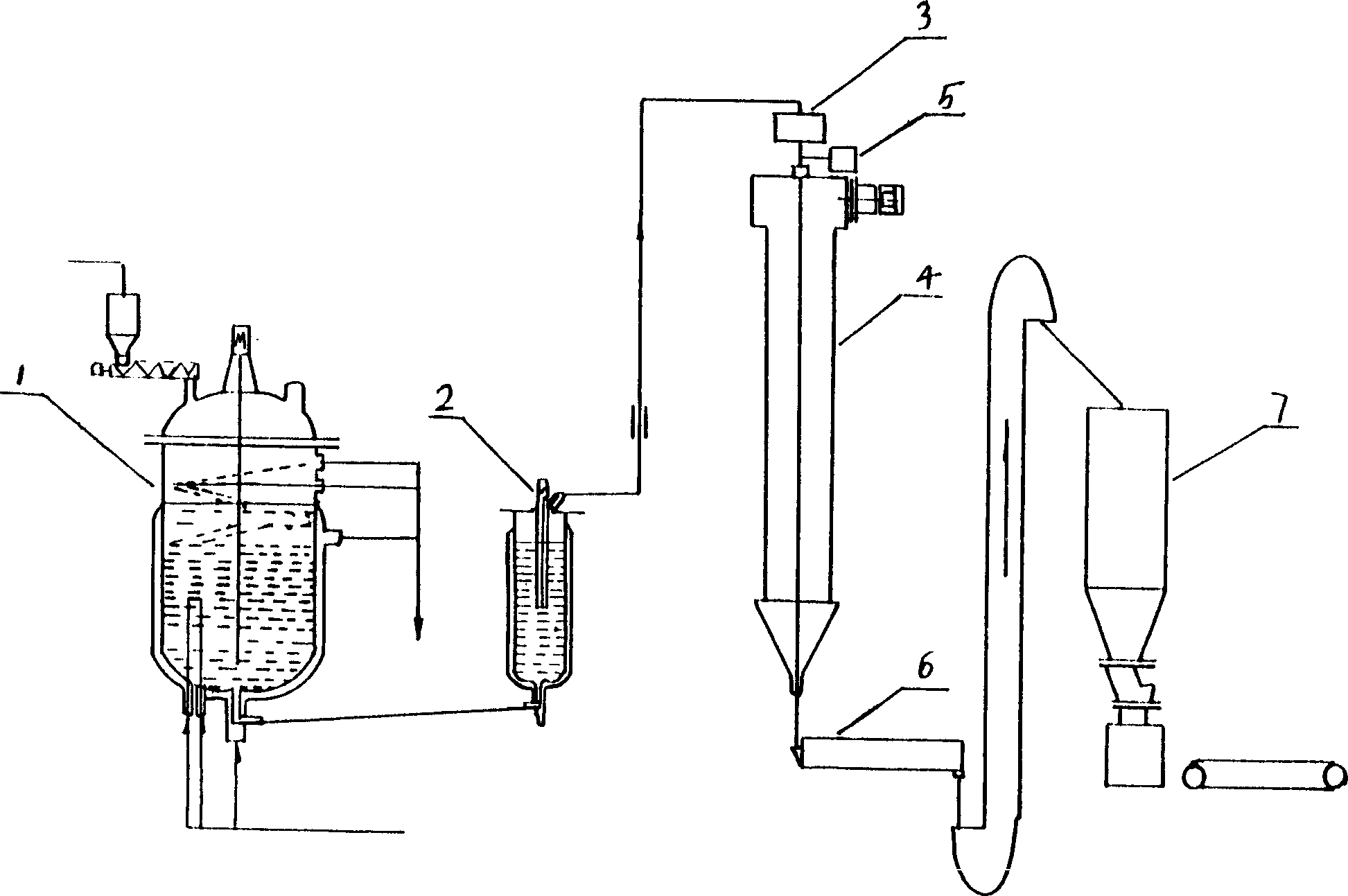

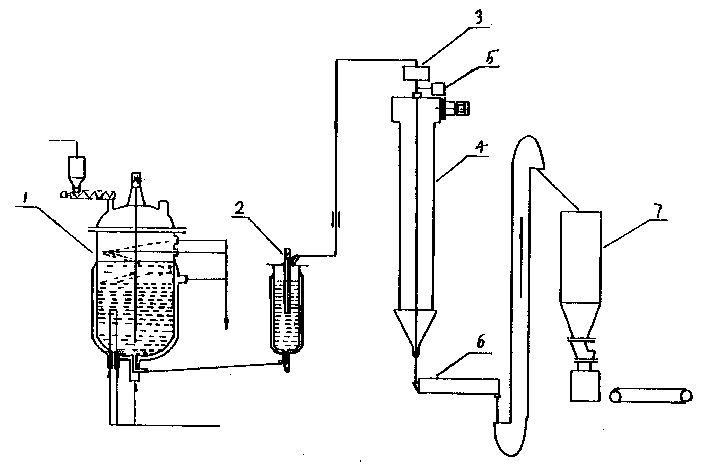

Process for producing sodium nitrite by direct crystallization process

The invention relates to a processing of producing sodium nitrite by using a direct crystallization process. By using the process, sodium nitrite crystalline substances are prepared under the condition without steam concentration, and the sodium nitrite crystalline substances are centrifuged and separated directly, and then dried to obtain sodium nitrite products. The process has the advantages of having simple process, reducing consumption, saving energy resources, reducing workshop consumption cost by about 20 percent compared with the prior process, etc. and can product sodium nitrate byproducts and recycle heat and the byproduct of saturated vapour.

Owner:贾令春

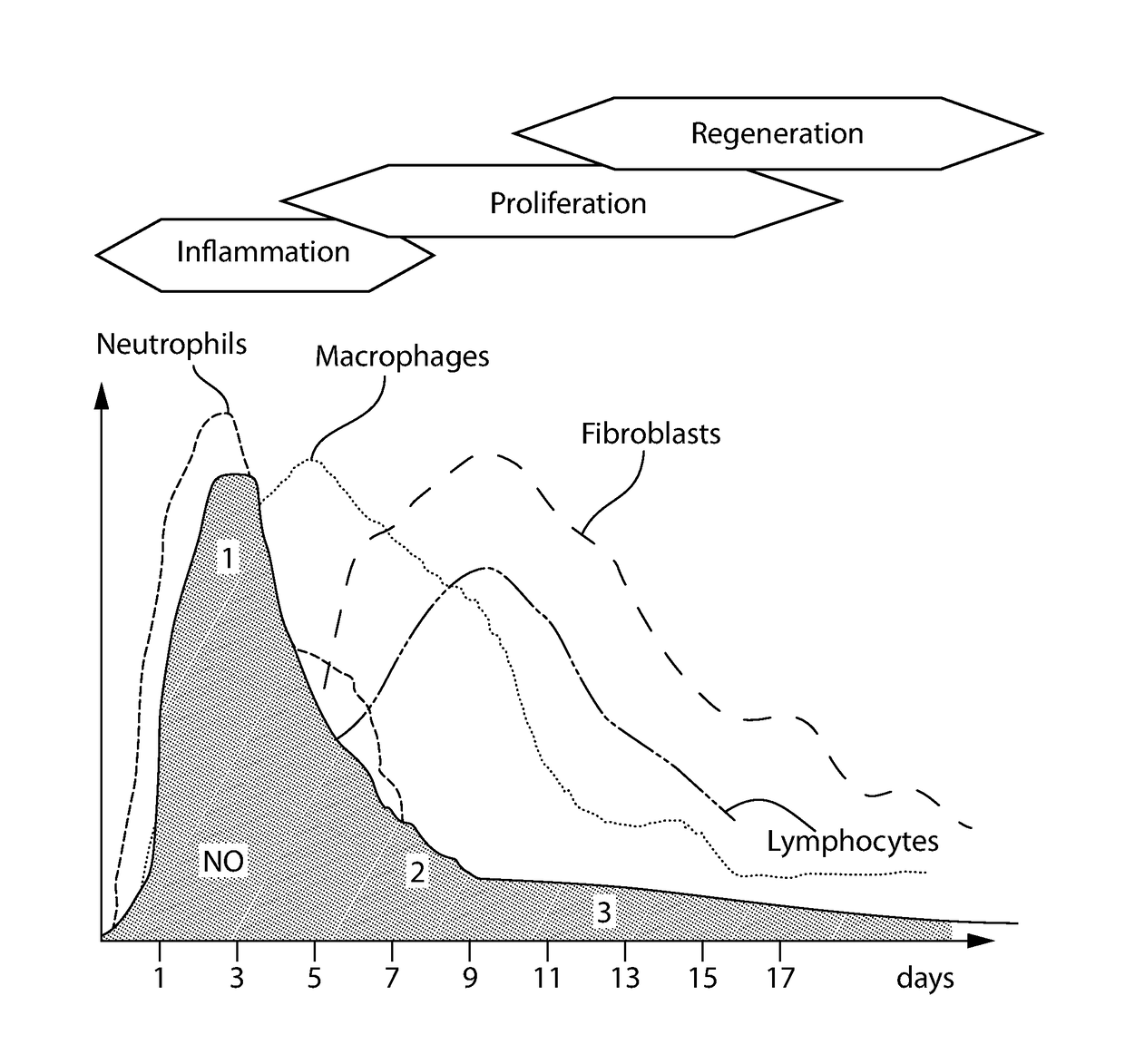

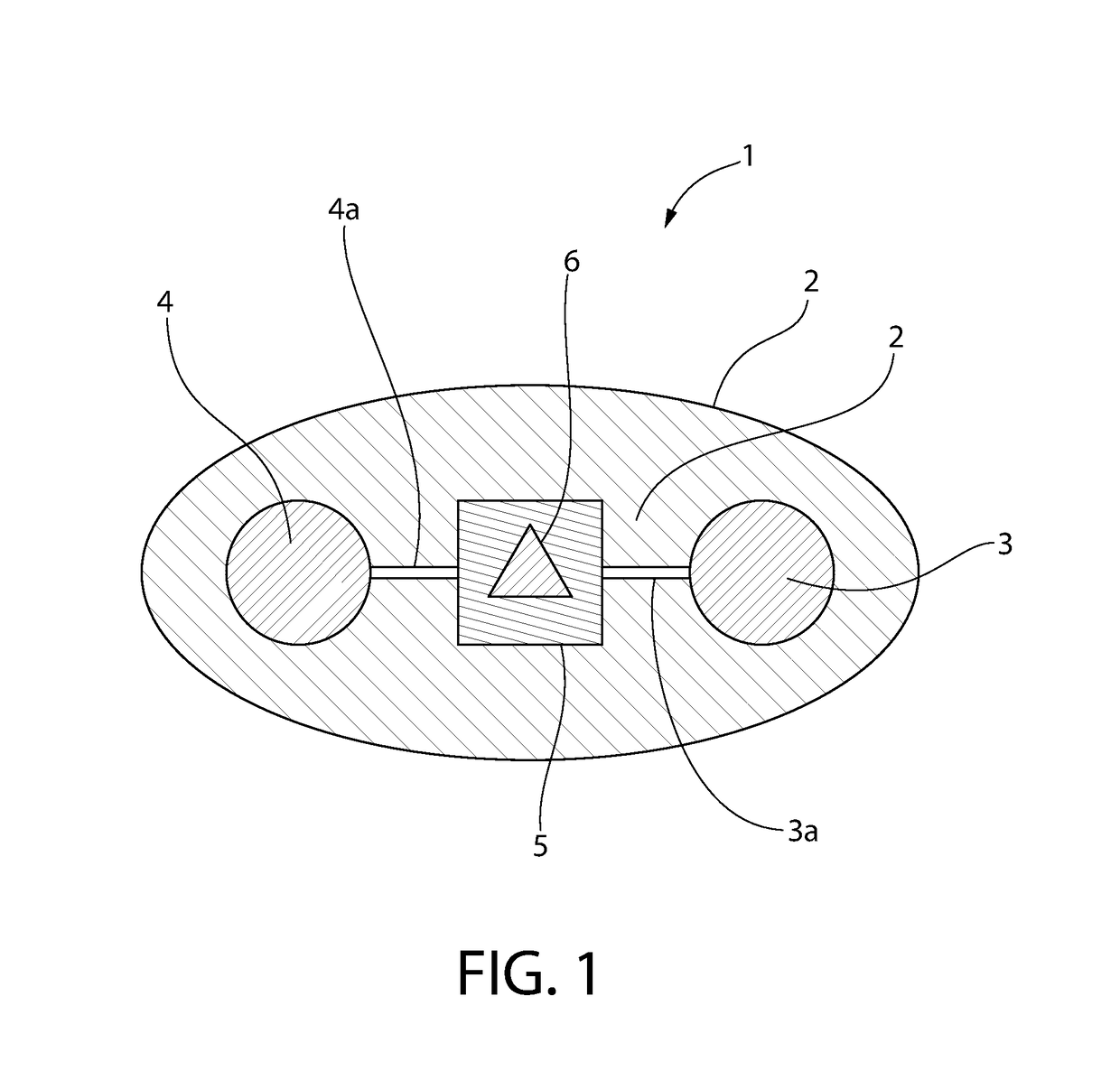

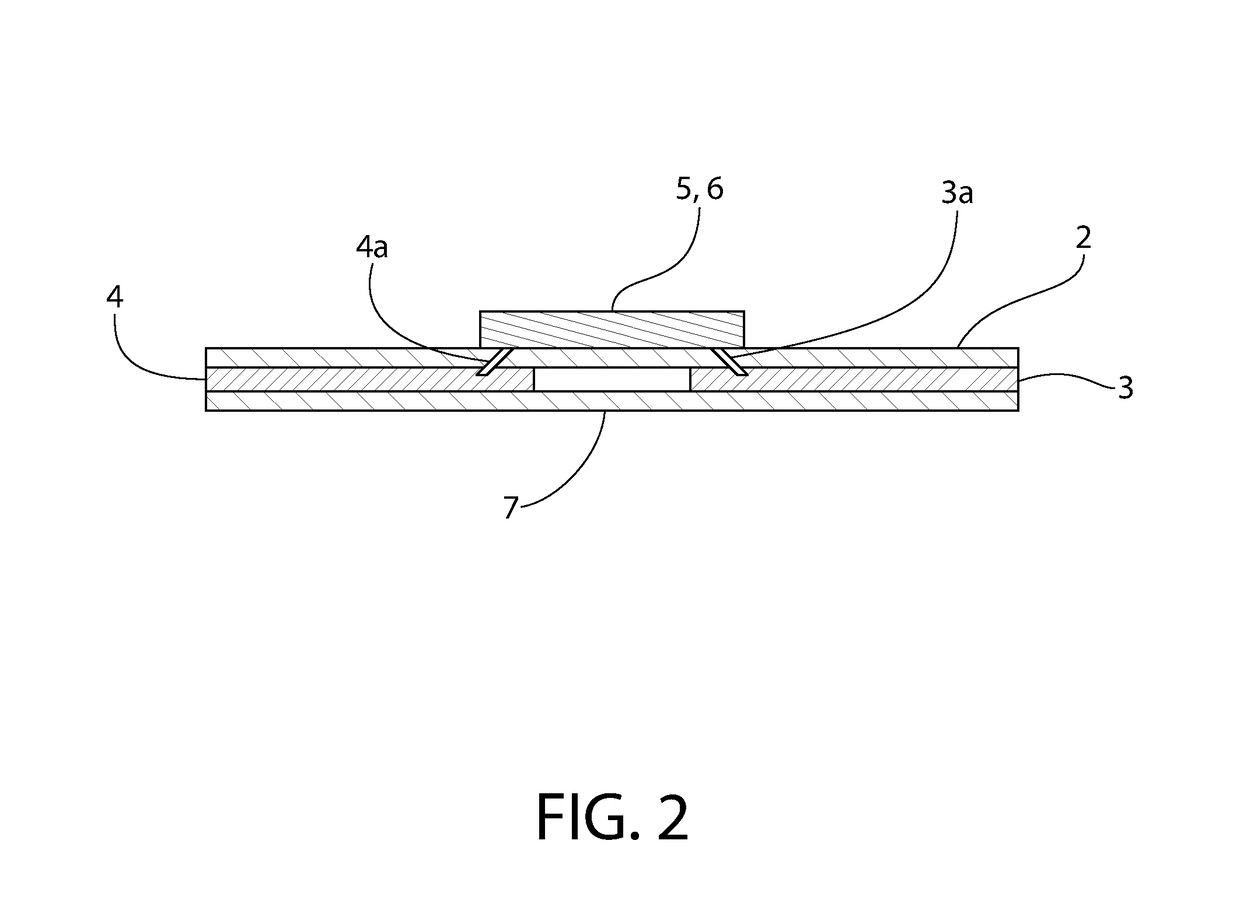

Electrochemical gasotransmitter generating compositions and methods of using same and dressings and treatment systems incorporating same

ActiveUS20180221210A1Reduced pressure tissuePromote growthNon-adhesive dressingsSulfur-dioxide/sulfurous-acidDiseaseElectrolysis

Disclosed are compositions that comprise an organic electrochemical mediator and a gasotransmitter salt which converts into a gasotransmitter via electron transfer. Also disclosed are bandages and wound dressings comprising the subject gasotransmitters, and methods of making a gasotransmitters, comprising exposing the compositions to a voltage sufficient to reduce the water soluble organic mediator. Further disclosed are methods of treating a variety of trauma and disease states by applying a therapeutically effective amount of at least one gasotransmitter thereto, and methods of generating an effective dose of the gasotransmitter generated from electrolytic reaction involving the gasotransmitter-generating compositions.

Owner:NOXSANO INC

A kind of preparation method of dinitrosodiammine platinum

InactiveCN102285693ASolve the problem of excessive potassium ion content in P saltReduce Chloride ContentAmmonium nitratesRuthenium/rhodium/palladium/osmium/iridium/platinum compoundsHydrazine compoundElemental analysis

The invention discloses a preparation method of noble metal compound dinitrosodiammine platinum [Pt(NH3)2(NO2)2] used in the process of cyanide-free electroplating and platinum plating. Chloroplatinic acid and hydrazine hydrochloride are used as a reducing agent to reduce chloroplatinic acid to chloroplatinous acid, prepare dichlorotetraammonium platinum by a one-pot method, and then react with excess sodium nitrite to obtain dinitrosodiammine platinum. The invention accurately reduces chloroplatinic acid to chloroplatinous acid, and then prepares dichlorotetraammonium platinum by one-pot cooking method, and further reacts with sodium nitrite to prepare P salt, which effectively solves the excessive potassium ion content of P salt in the traditional preparation method The problem. The elemental analysis of the P salt prepared by the invention is basically consistent with the theoretical value, does not contain potassium ions, and the contents of sodium ions and chloride ions are both lower than 50PPM.

Owner:陕西瑞科新材料股份有限公司

Treating process for multiple exhaust gases

PendingCN108499339ATo achieve the purpose of decarbonizationLess investmentGas treatmentDispersed particle separationScavengerNitrite

The invention provides a treating process for a plurality of exhaust gases. The process comprises the following steps: with an amino reagent as a carbon scavenger, subjecting a termination substance to a displacement reaction in virtue of a metal oxide, wherein separated ammonia-containing liquid is recycled, and a removed compound solid is used as an industrial raw material; and then oxidizing exhaust gases with a strong oxidant and then carrying out absorption with alkaline substances so as to form nitrites. Thus, the treating process achieves the purposes of decarbonization, desulfurization, denitrification, dechlorination, defluorination, mercury removal, dioxin removal and deodorization the exhaust gases in one shot.

Owner:SHANGHAI JINGTIAN EP TECH CO LTD

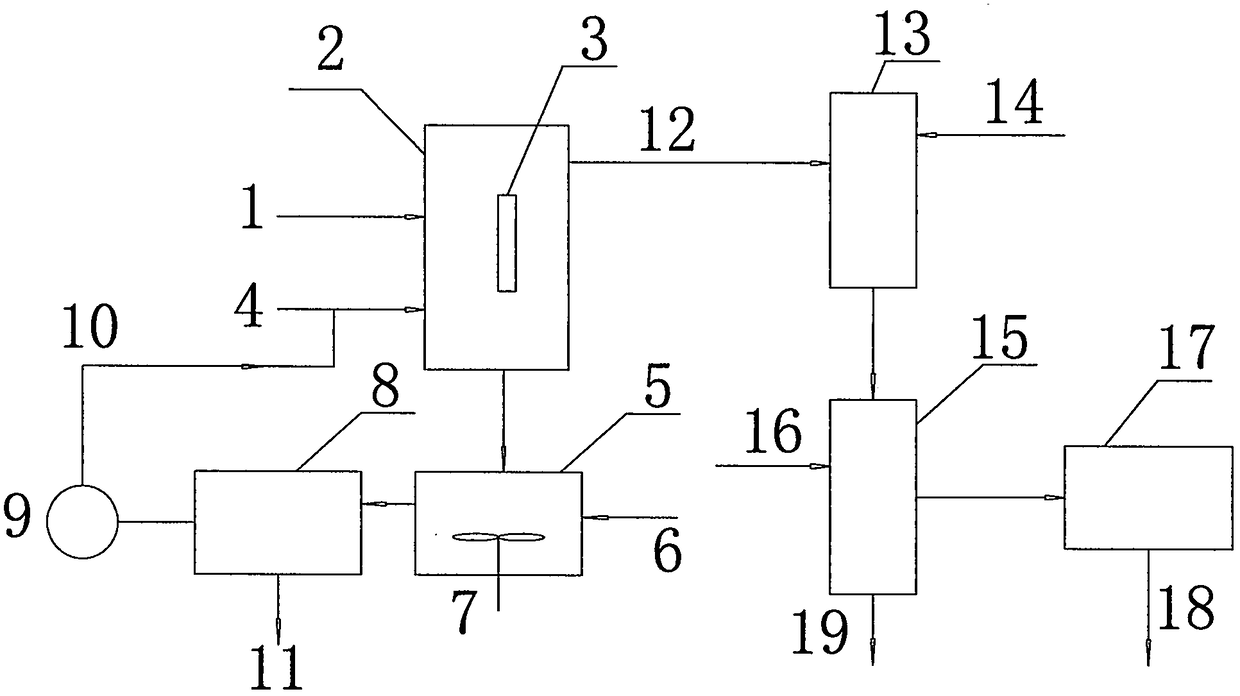

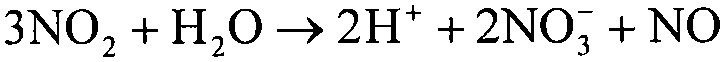

Hydrogen peroxide denitration process and denitration system

InactiveCN105289263AImprove denitrification performanceThe principle is simpleDispersed particle separationNitrous acidFlue gasNitrogen oxide

The invention relates to a hydrogen peroxide denitration process and a corresponding denitration system. According to the denitration process, hydrogen peroxide is taken as an oxidant; .OH is generated through high-temperature and high-pressure catalysis of hydrogen peroxide; .OH is mixed with flue gas, so that nitrogen oxides in the flue gas can be oxidized and recovered; finally, the obtained mixture is subjected to gas-liquid separation, denitration by-products, namely nitric acid and a nitrous acid liquid, are recovered, and the flue gas subjected to denitration is discharged to the outside. The denitration process and the denitration system have the advantages that hydrogen peroxide is taken as the denitration oxidant; through the mixing of hydrogen peroxide and high-temperature steam, hydrogen peroxide tends to be decomposed into hydroxy radical.OH and HO2., so that the nitrogen oxides oxidation and recovery effects are improved, the denitration rate is increased, and the temperature limitation is avoided.

Owner:湖北蔚天环保科技有限公司

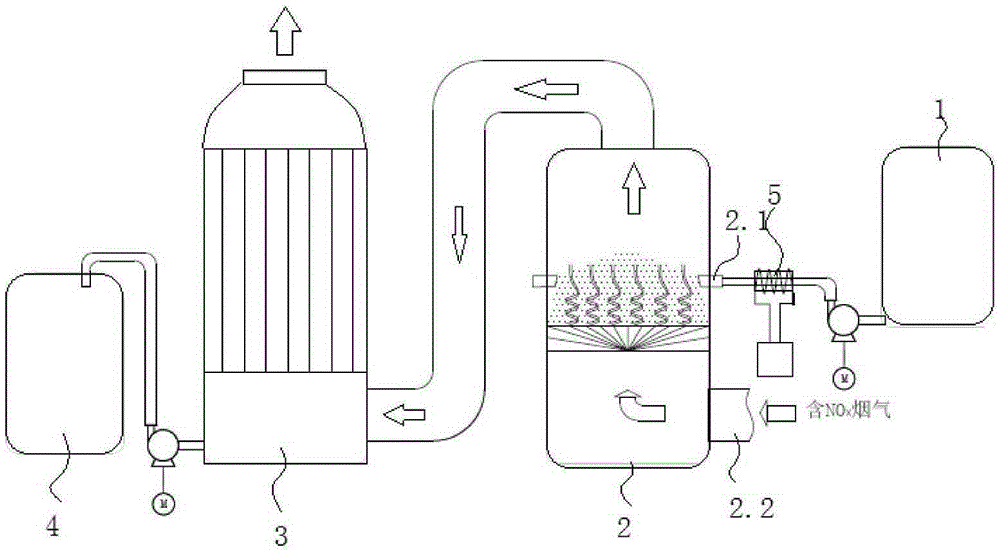

Low-temperature fume oxidizing and denitration method and system

InactiveCN104437037ARealize recyclingSolve processing problemsDispersed particle separationNitrous acidChlorine dioxideReaction temperature

The invention relates to a low-temperature fume oxidizing and denitration method and system. The method is characterized in that chlorine dioxide and low-temperature fume to be purified are subjected to gas-gas mixing in a fume channel and then are fed into an oxidizing tower; NO is oxidized into NO2 and NaO3 by chlorine dioxide in the oxidizing tower, and the reaction is performed under a temperature of 50 to 80 DEG C; the oxidizing and denitration are performed in the oxidizing tower, and the oxidizing reaction costs 1 to 2 seconds; the oxidized fume enters a spraying absorbing section and then is sprayed with a calcium oxide liquid at a mass concentration being 5 to 8%, and calcium nitrate and calcium nitrite liquids are generated after spraying and absorbing; and the calcium nitrite liquid is saturated and then is sequentially processed by impurity removing, evaporating, concentrating, crystallizing and purifying to obtain calcium nitrite. According to the low-temperature fume oxidizing and denitration method, ClO2 is selected and fully mixed with the fume to achieve denitration under a low temperature of 50 to 80 DEG C, and therefore, the problem of wastewater treatment can be solved; and meanwhile, the resource can be recycled; the denitration efficiency is up to more than 85%.

Owner:SHANDONG SHANDA WIT ENVIRONMENTAL ENGINEERING CO LTD

Method for reducing dilute nitric acid to nitrous acid

The invention relates to a method for reducing dilute nitric acid to nitrous acid; in a coal-to-ethylene glycol process, a large amount of dilute nitric acid waste liquid can be produced, is discharged after NaOH neutralization, and can pollute water resources. According to the method for reducing dilute nitric acid to nitrous acid, a reaction is continuously carried out in a fixed bed reactor under normal pressure; under the catalytic action, in an N2 atmosphere and at a temperature of 30-100 DEG C, dilute nitric acid is reduced to nitrous acid; and nitrous acid can be further participated in the coal-to-ethylene glycol process. The process not only can improve economic benefits, but also lowers pollution to the water resources.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

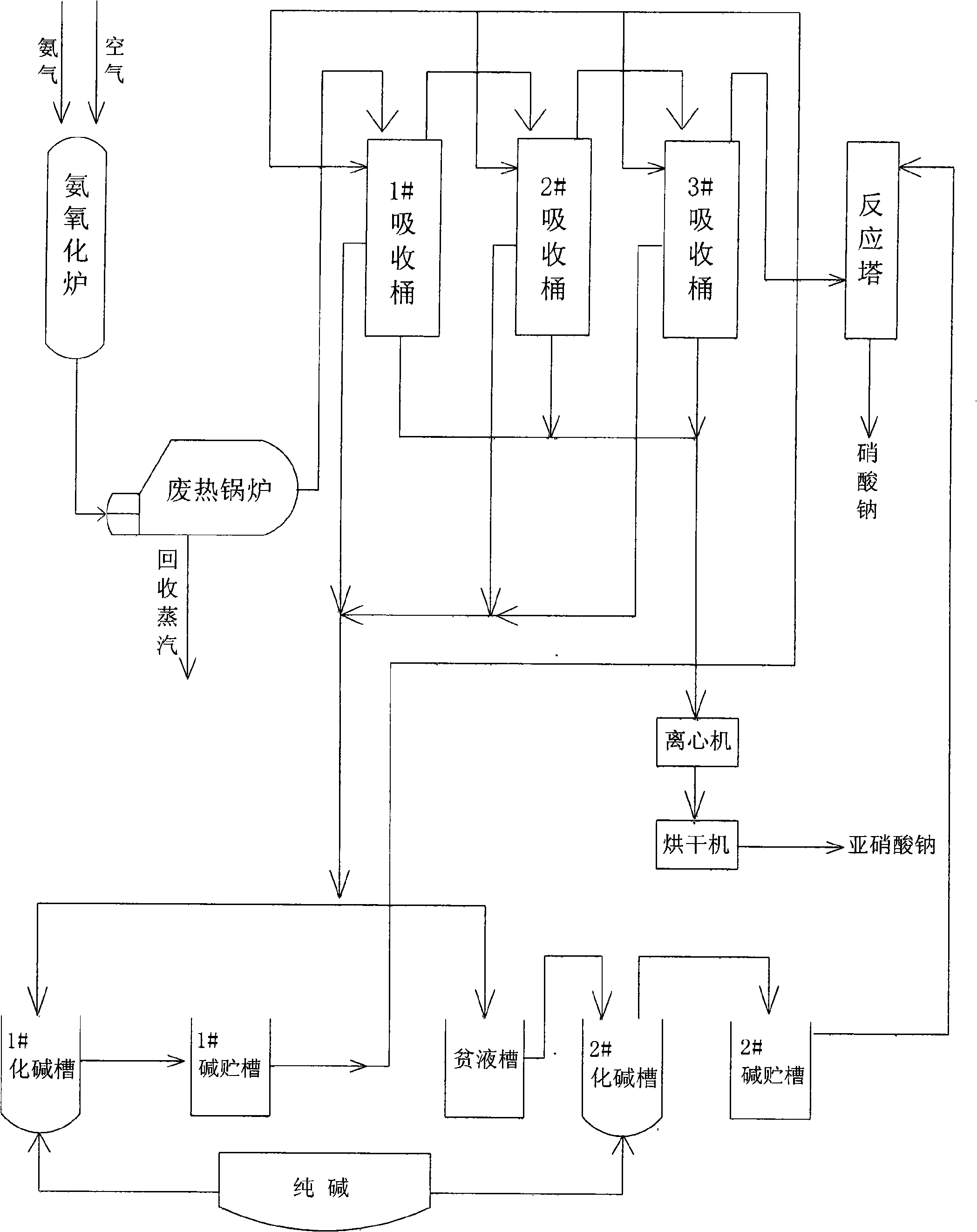

Industrial sodium nitrite new product and its preparation method

InactiveCN1400161AReduce moisture contentReduce contact areaGranulation by liquid drop formationAlkali metal nitrate shape formationState of artSodium nitrite product

The present invention discloses an industrial sodium nitrite product and its production method. The physical and chemical properties of said product are as follows: it is made into the form of ball or egg granular body, grain size is 0.5-3 mm, and the water content of the described granule body is less than or equal to 0.5%. Its production method uses the existent industrial sodium nitrite product as raw material, the above-mentioned raw material is heated and moten into liquid phase, and said liquid phase is sprayed and granulated so as to obtain the invented product. Said product features low water content, no blocking and good fluidity.

Owner:TIANJIN UNIV +1

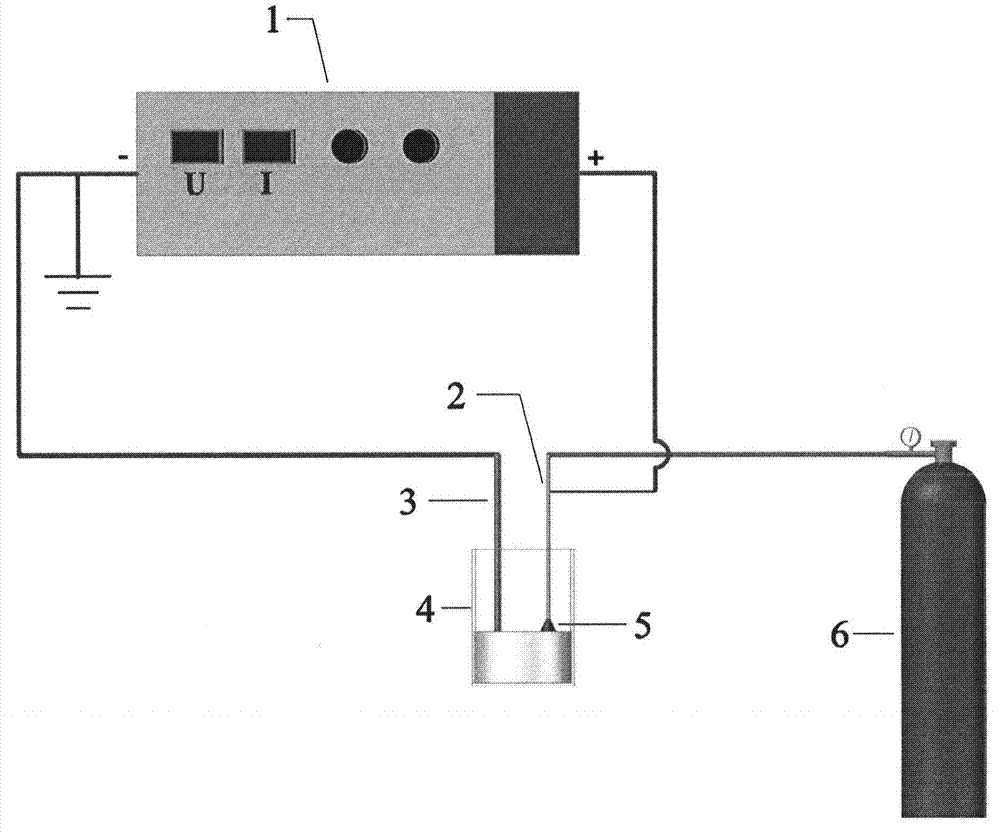

Method for preparing nitrogen-containing liquid fertilizer by adopting non-thermal arc plasma

The invention discloses a method for preparing a nitrogen-containing liquid fertilizer by adopting a non-thermal arc plasma. The method particularly comprises the following steps that: water is introduced into an non-thermal arc plasma device; a high-voltage power supply is started to generate a breakdown arc between a knife-shaped stainless steel electrode and a water level, an air flow from an air source drives the arc to slide along the knife-shaped electrode through a spray nozzle to form an air non-thermal arc plasma, and the plasma induces plasma chemical reaction between air and water to generate nitrate and nitrite, so that the liquid fertilizer which contains the nitrate and the nitrite is obtained. The method disclosed by the invention can obtain the liquid nitrogen fertilizer in one step through the plasma, and has the advantages of low nitrogen source cost, simple, small-sized and portable device and easiness for operation; and the liquid nitrogen fertilizer can be prepared when needed at any time, thereby preventing the troubles of transportation, storage and preservation.

Owner:SUN YAT SEN UNIV

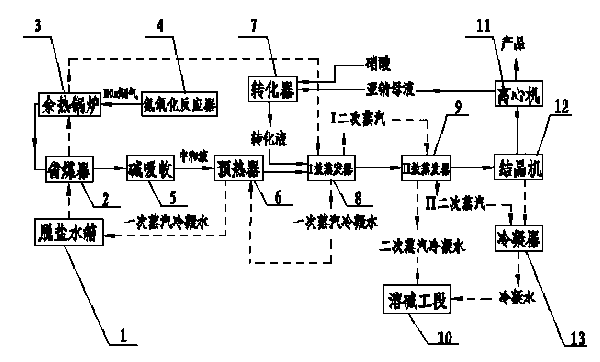

Steam self-supply system for producing sodium nitrate/sodium nitrite

ActiveCN103848443AConducive to emission reductionReduce the temperatureEnergy inputAlkali metal nitrate preparationEngineeringSodium nitrite

The invention discloses a steam self-supply system for producing sodium nitrate / sodium nitrite, which is suitable for preparing sodium nitrate / sodium nitrite. A desalination water tank is connected with a waste heat boiler through a coal economizer, and the waste heat boiler is connected with an ammoxidation reactor; the coal economizer is communicated with a crystallizer through an alkaline absorber, a preheater, an I-effect evaporator and an II-effect evaporator; the preheater is connected with the desalination water tank; a converter is respectively connected with the I-effect evaporator and a centrifugal machine; the II-effect evaporator is respectively connected with an alkaline dissolving workshop section and the crystallizer; the alkaline dissolving workshop section is connected with the centrifugal machine through a condenser and the crystallizer. The steam self-supply system is remarkable in energy saving benefit, convenient for process regulation and pollutant discharge reduction, high in degree of automation, remarkable in steam saving effect and high in recycling ratio.

Owner:襄阳泽东化工集团股份有限公司

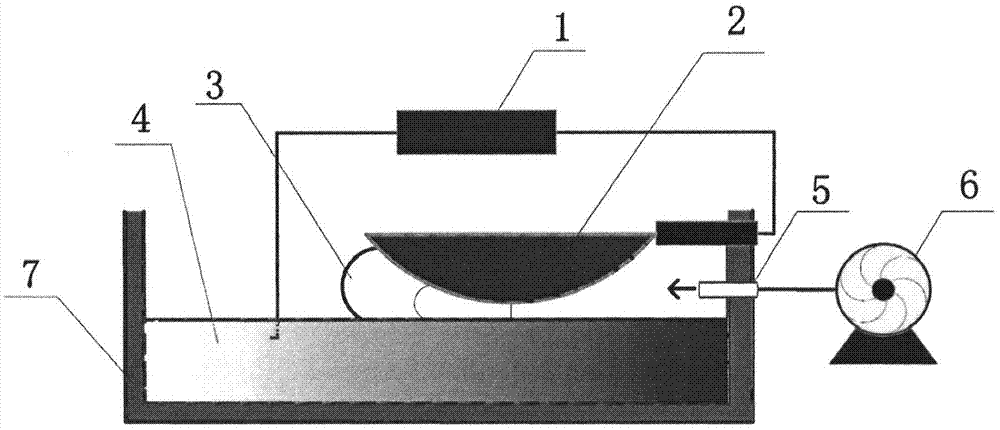

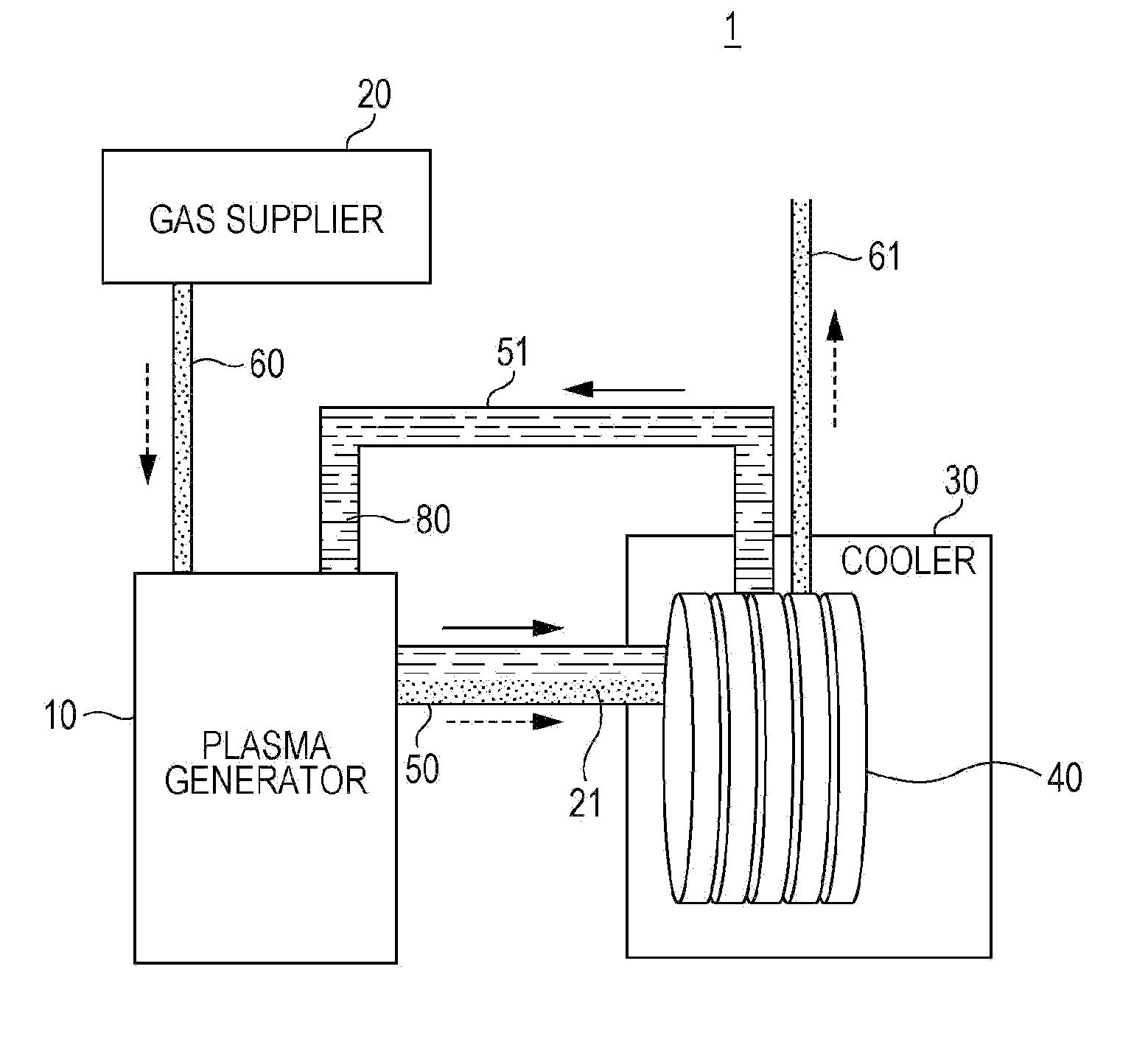

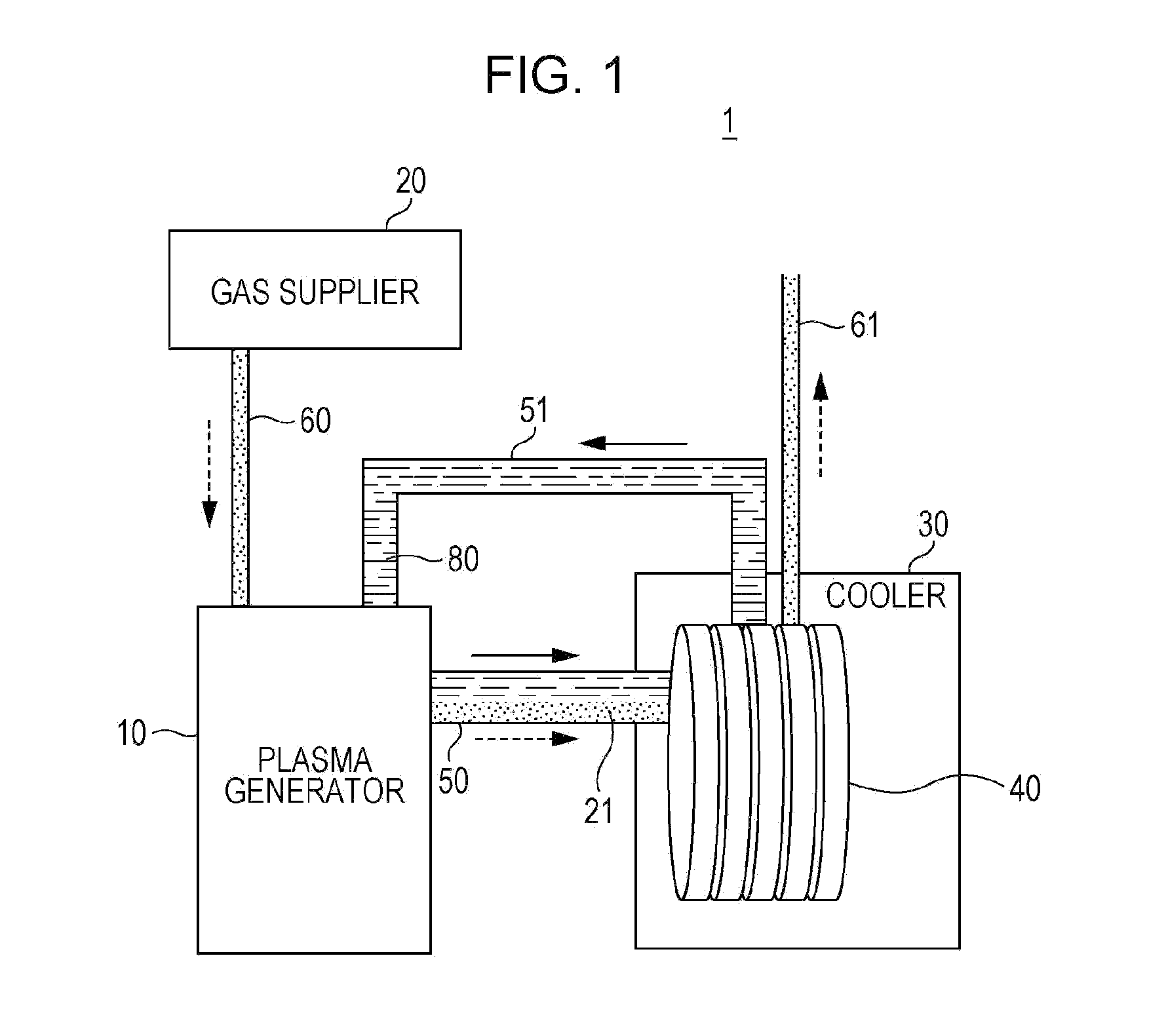

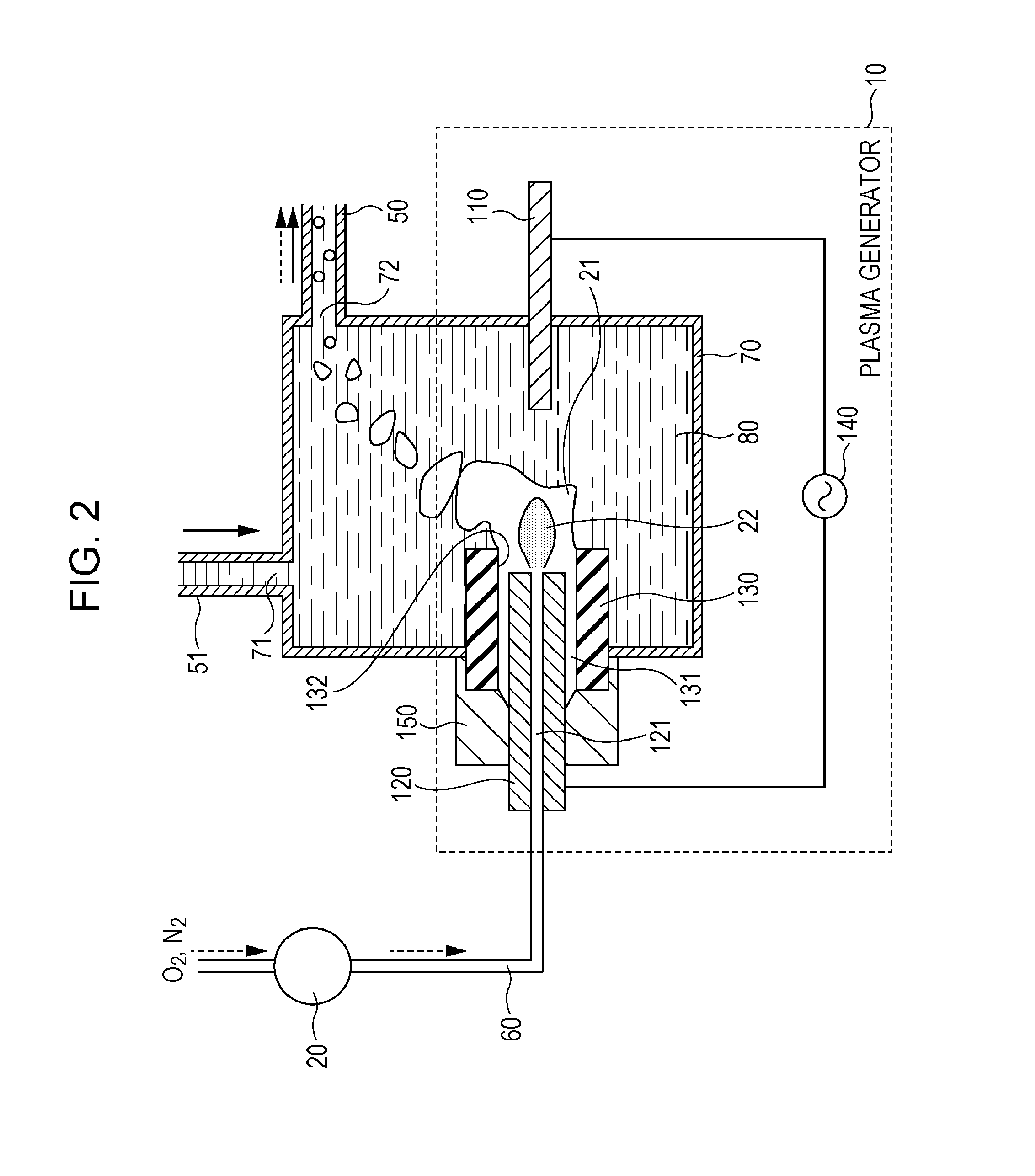

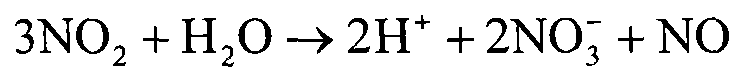

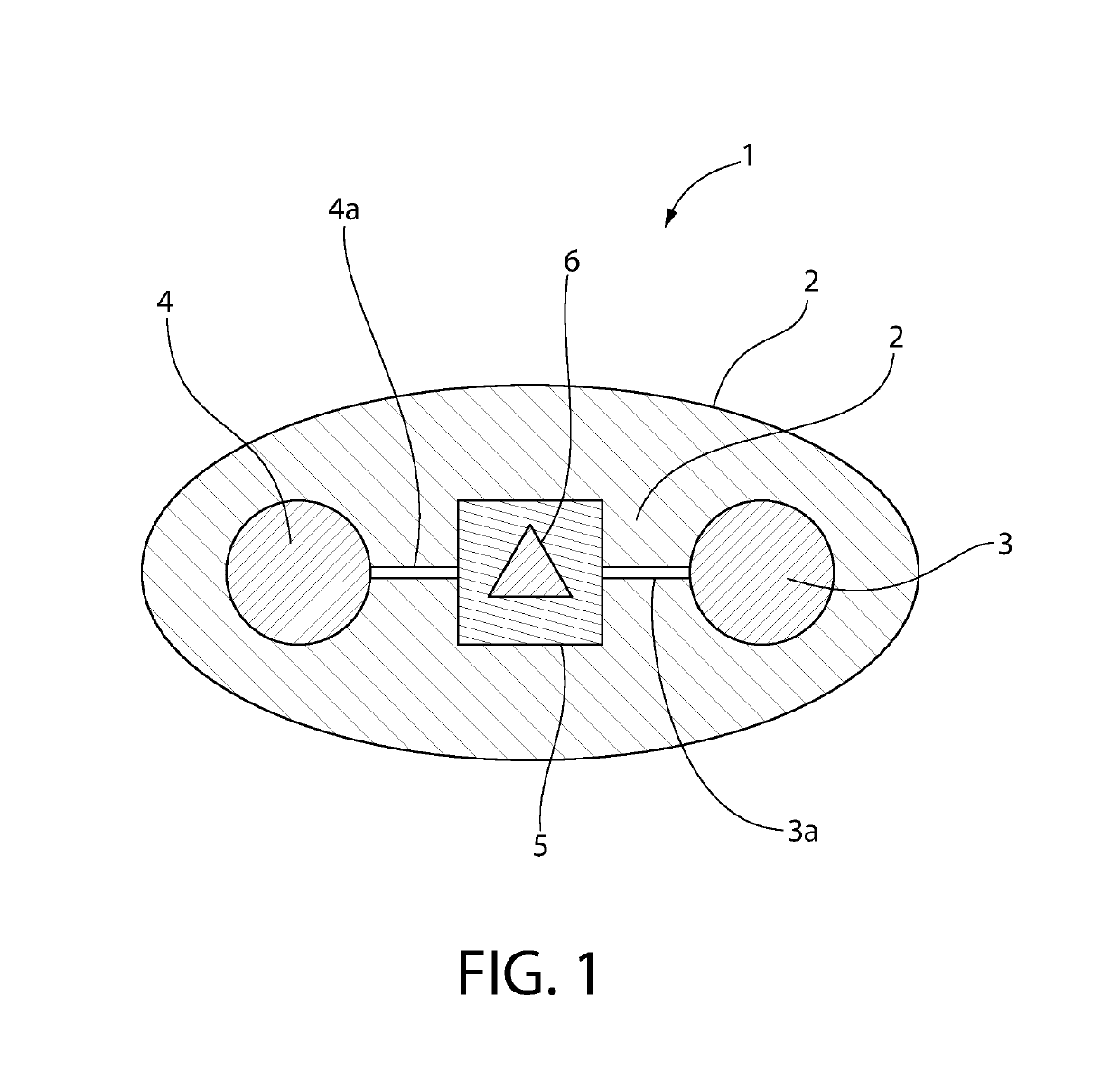

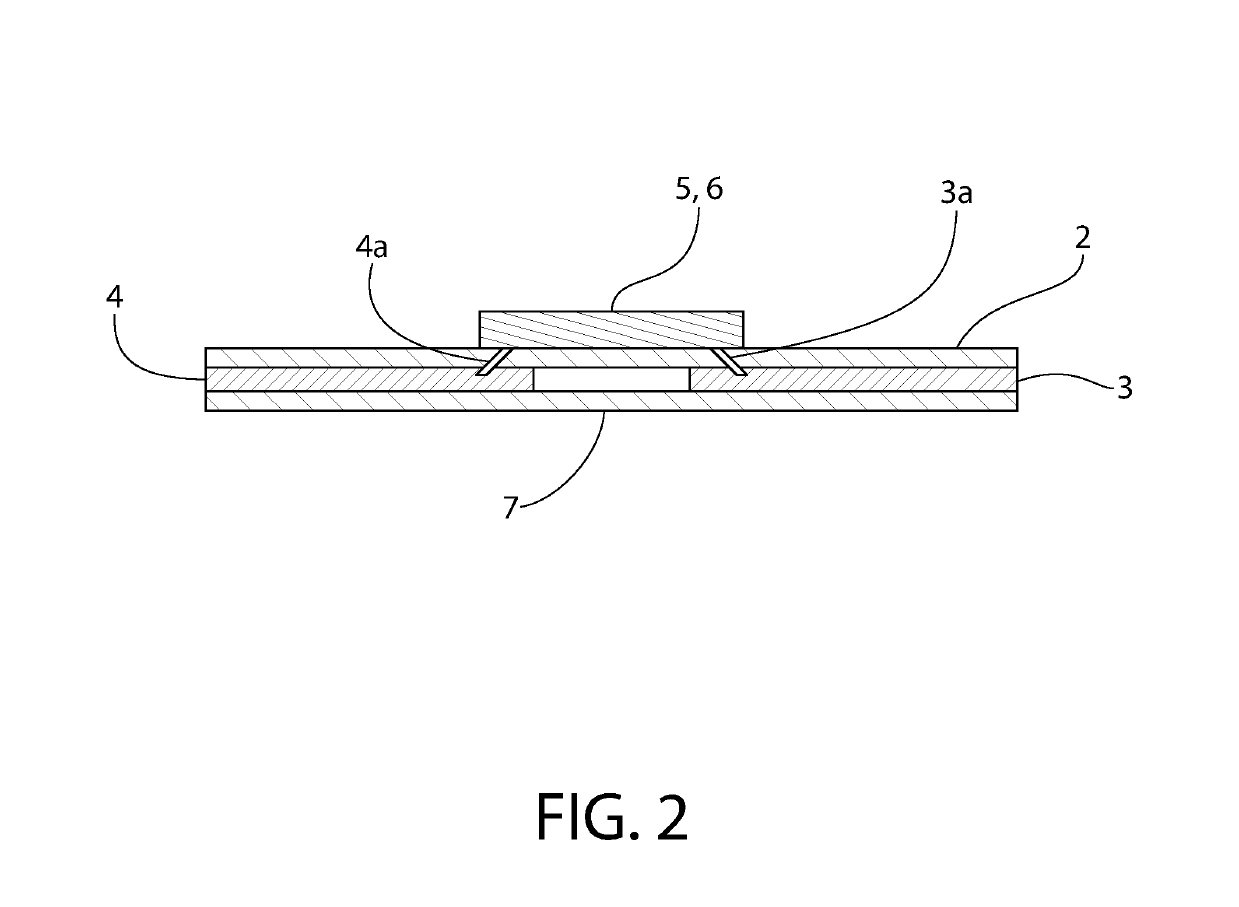

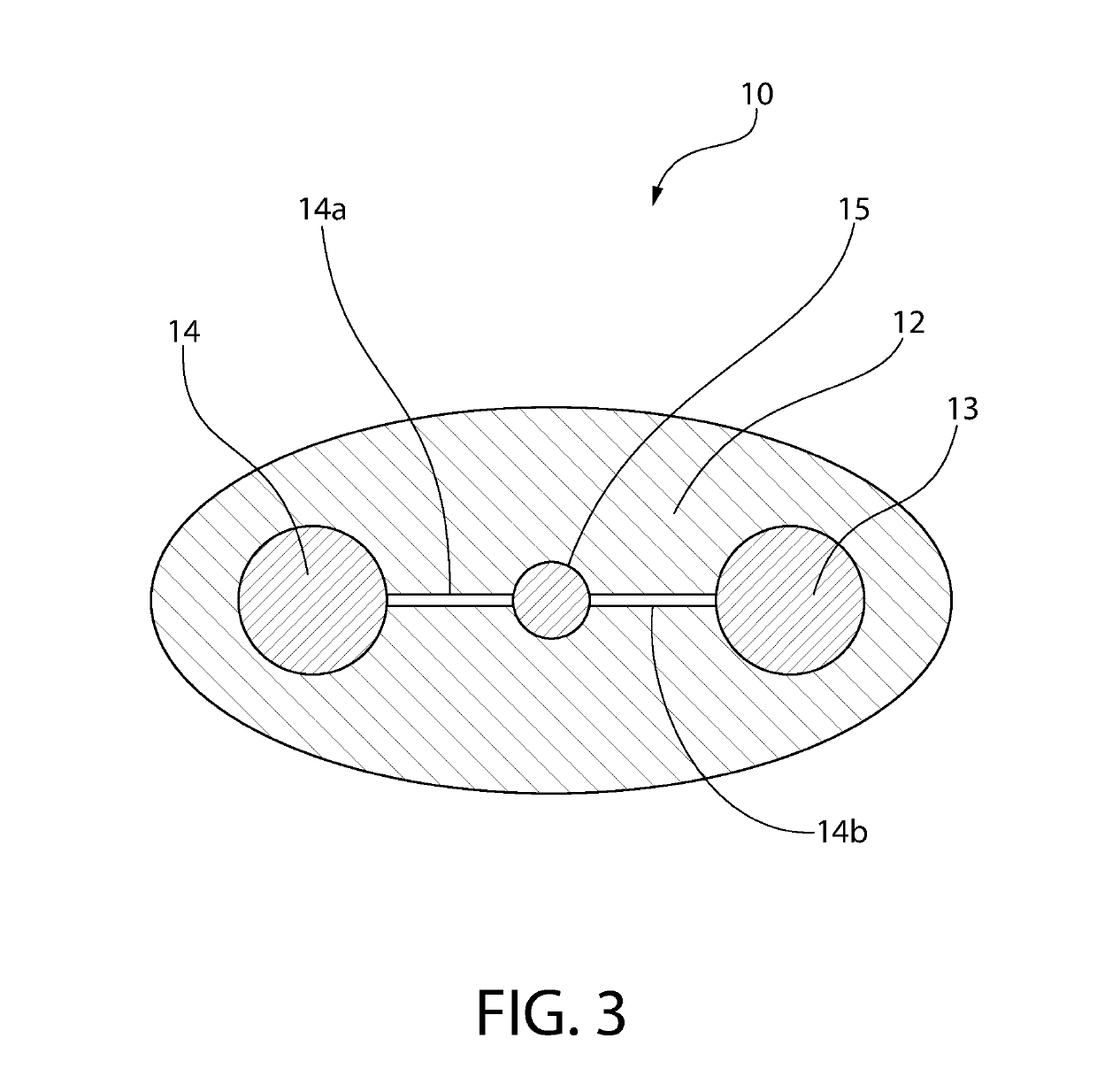

Nitrous acid generator

ActiveUS20160039675A1Generate efficientlyEnergy based chemical/physical/physico-chemical processesPlasma techniqueNitrogen monooxideNitrogen oxides

A nitrous acid generator includes a treatment vessel having an inner space being capable of holding a liquid; a gas supplier supplying a gas to the inner space such that the gas forms a bubble in the liquid, the gas containing oxygen and nitrogen; a plasma generator including a first electrode, a second electrode, and a power supply for applying a voltage therebetween, the plasma generator generating plasma in the bubble, the plasma producing nitrogen oxide including nitrogen monoxide and nitrogen dioxide; a gas-liquid contact member to which the nitrogen oxide and the liquid are introduced from the treatment vessel, the gas-liquid contact member causing the nitrogen oxide to be dissolved in the liquid while the nitrogen oxide and the liquid pass through the gas-liquid contact member; and a cooler cooling the nitrogen oxide and the liquid while the nitrogen oxide and the liquid pass through the gas-liquid contact member.

Owner:PANASONIC INTELLECTUAL PROPERTY MANAGEMENT CO LTD

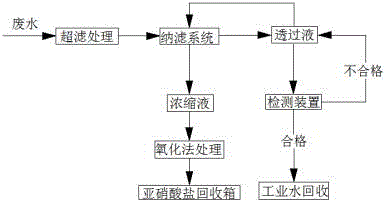

Method for treating nitrite in industrial wastewater

InactiveCN106365346AReasonable designImprove efficiencyWater contaminantsWater/sewage treatment bu osmosis/dialysisNitriteIndustrial effluent

The invention discloses a method for treating nitrite in industrial wastewater. The content of the nitrate in the industrial wastewater is higher, so that if being discharged to the environment without treatment, the industrial wastewater has a toxic action for a human body and aquatic life. The method comprises the following concrete operating steps: 1, carrying out ultrafiltration treatment on the industrial wastewater so as to remove macromolecular suspended matters; 2, treating ultrafiltration membrane permeate liquid without macromolecules in a way of nanofiltration, carrying out oxidation treatment on the obtained concentrated liquor and then enabling the product to enter a nitrite recycle bin; 3, enabling the ultrafiltration membrane permeate liquid of the step 2 to flow back for carrying out nanofiltration treatment, repeating the operation of the step 2 for two or three times, and then detecting whether the obtained water is qualified or not, and if so, recycling the water for use; 4, if not, enabling the obtained water to flow back to the ultrafiltration membrane permeate liquid, and repeating the operation of the step 3.

Owner:HEFEI XINDA MEMBRANE TECH

Nitrogen oxide absorption device and method for realizing separation of absorption products by using device

ActiveCN108380018ASimple structureEasy to operateDispersed particle separationAlkali metal nitrate purificationNitrogen oxidesHydrogen

Owner:XILONG SCI CO LTD

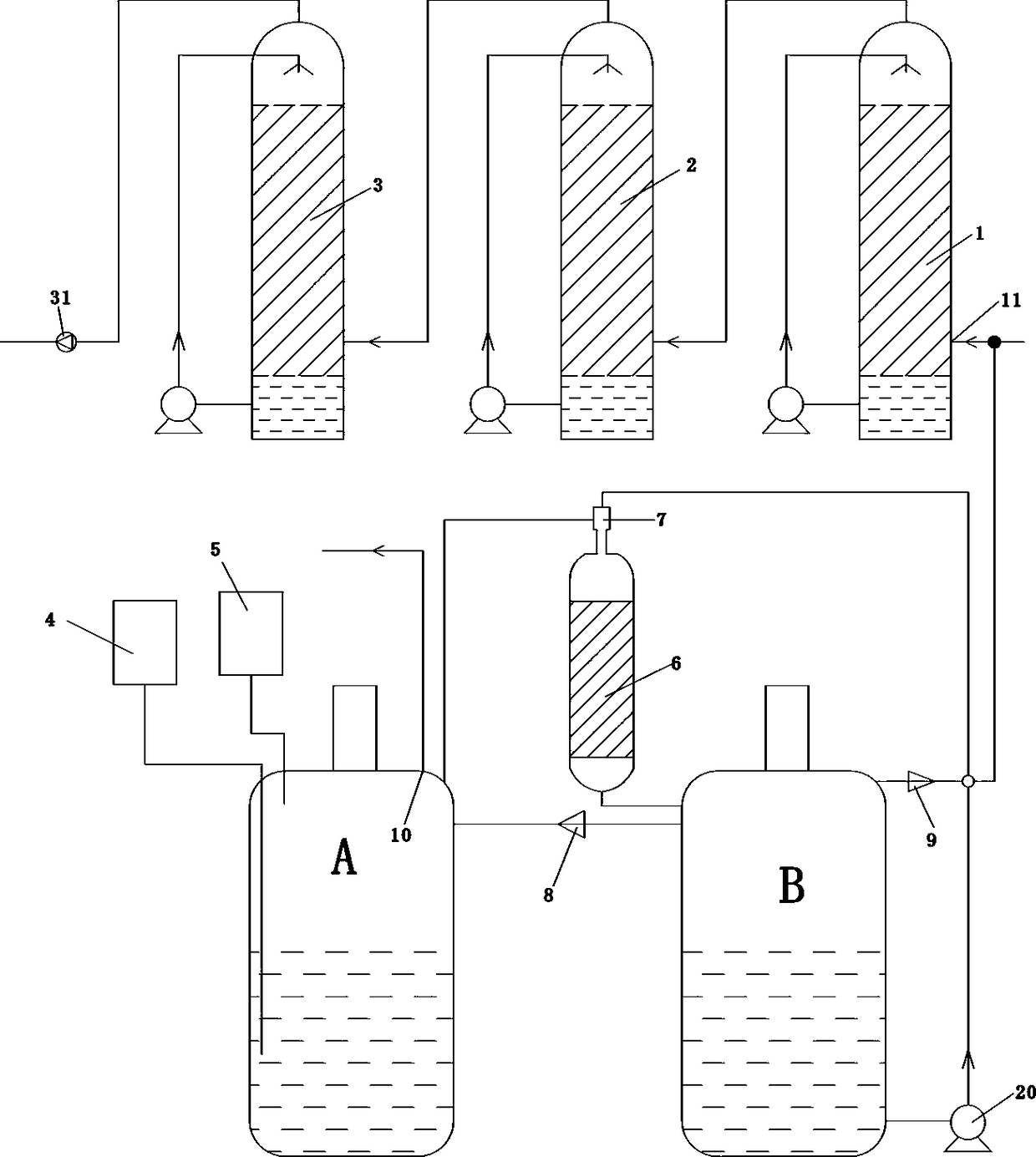

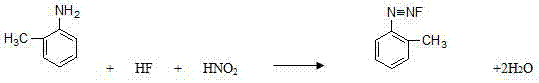

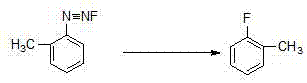

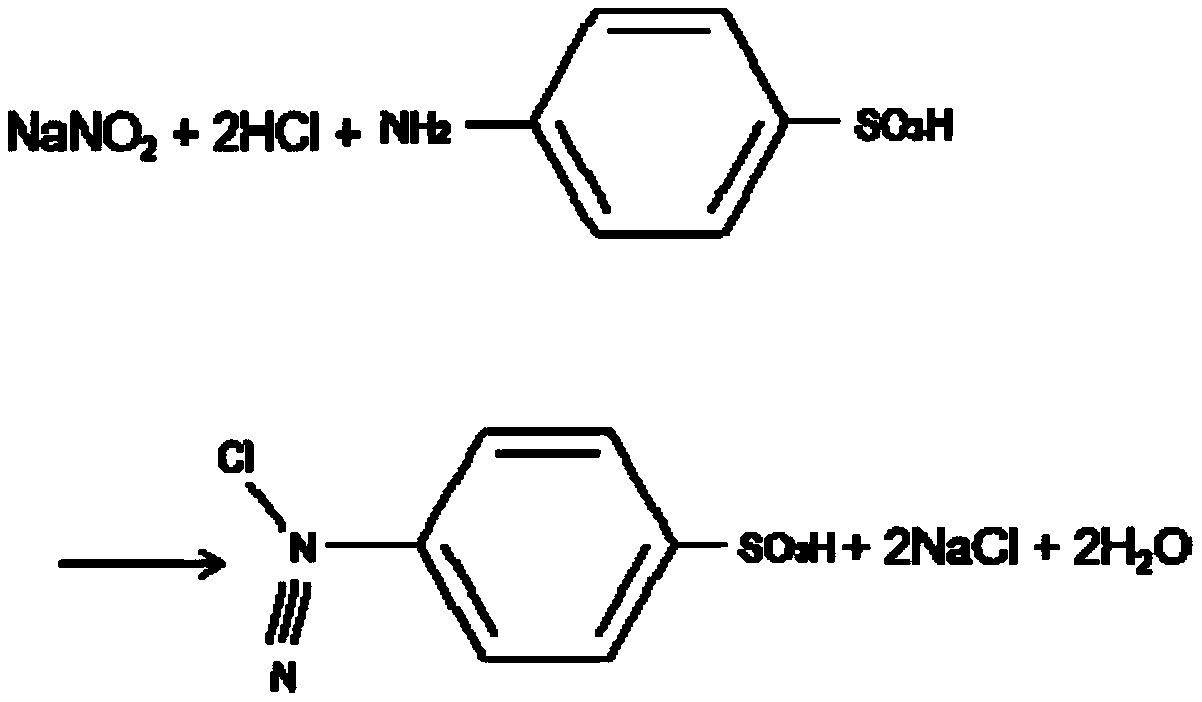

Preparation method of o-fluorotobuene

InactiveCN107445792ALess side effectsHigh yieldHalogenated hydrocarbon preparationNitrous acidSide reactionSodium nitrite

The invention discloses a preparation method of o-fluorotobuene. The method comprises the following steps: (1) acid formation reaction: adding an anhydrous hydrogen fluoride raw material into a reaction kettle and stirring; adding sodium nitrite into the reaction kettle, introducing frozen salt water to cool and carrying out reaction to obtain a nitrous acid; (2) diazotization reaction: adding o-toluidine into the reaction kettle containing the nitrous acid, stirring and carrying out the diazotization reaction; (3) thermal decomposition reaction: transferring diazonium liquid obtained in the step (2) into a tubular reactor; heating and carrying out the thermal decomposition reaction to obtain an o-fluorotobuene crude product; (4) post-treatment: carrying out washing and steam distillation on the o-fluorotobuene crude product obtained in the step (3), regulating a pH value, pressing into a rectifying tower for distillation to obtain the qualified o-fluorotobuene. The preparation method disclosed by the invention has the beneficial effects that energy consumption is low, continuous production is realized, the problems of long production period of fluorination reaction and low yield of products are solved, the occurrence of side reaction is reduced, and a good foundation is laid for preparing high-purity o-fluorotobuene.

Owner:山东福尔有限公司

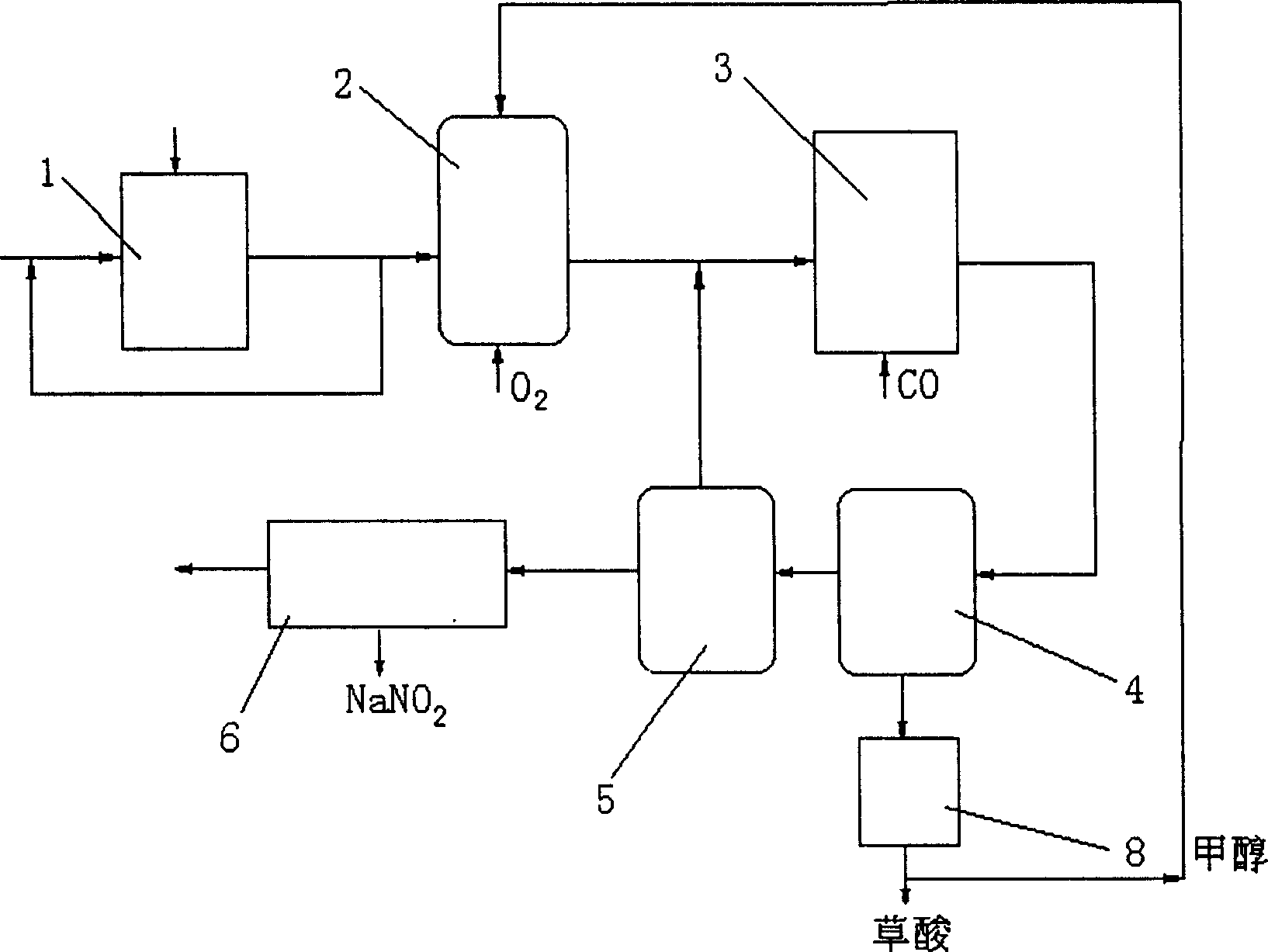

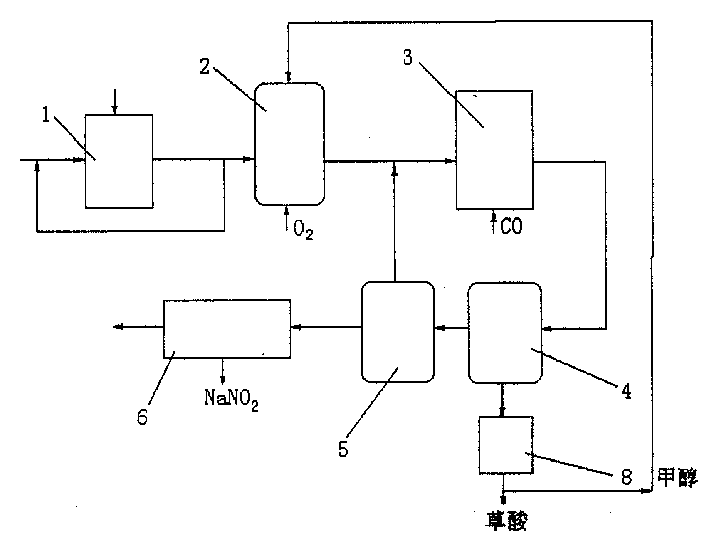

Method and device for producing oxalic acid and sodium nitrite

InactiveCN1569800ABroad marketReduce manufacturing costCarboxylic preparation from carbon monoxide reactionNitrous acidOxalateAmmonia

The invention discloses a method and device for producing oxalic acid and sodium nitrite, wherein the device comprises at least an ammoxidation furnace, an oxidation esterification reactor, a coupling synthesis reactor, a product condenser, a hydrolysis reactor, a refrigeration condenser and an alkali lye absorbing system.

Owner:SHANGHAI HUAYI ENERGY CHEM

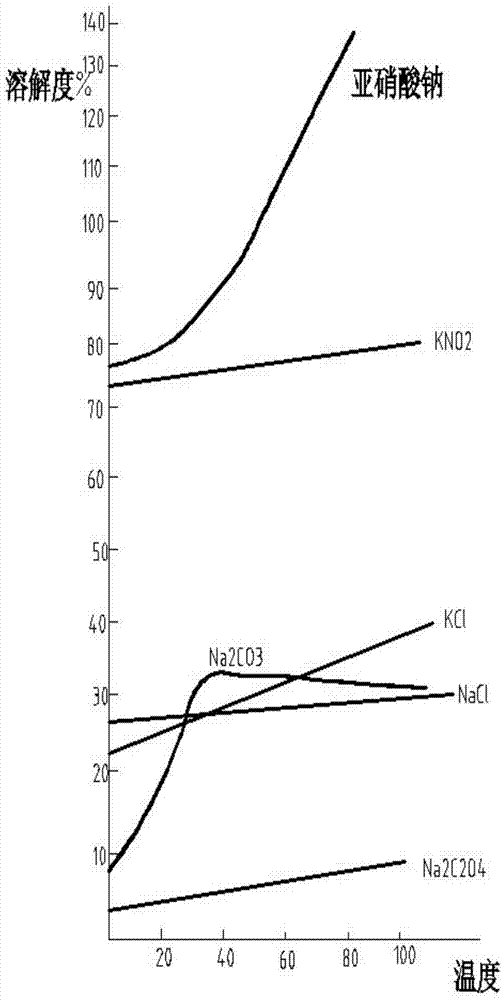

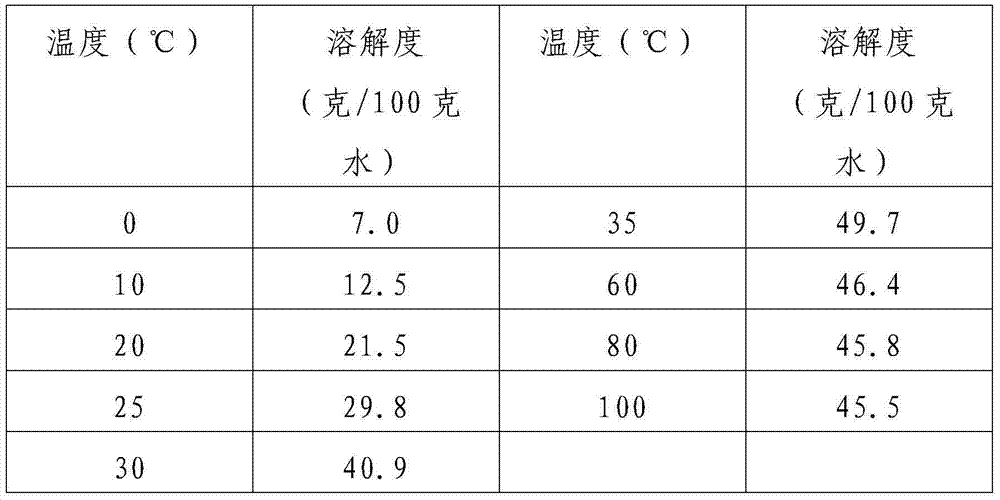

Environmental-friendly method used for preparation of potassium nitrite and regent-grade potassium nitrite, and combined production of regent-grade sodium oxalate

InactiveCN104495769AReduce solubilityReduce concentrationCarboxylic acid salt preparationNitrous acidSolubilityDecomposition

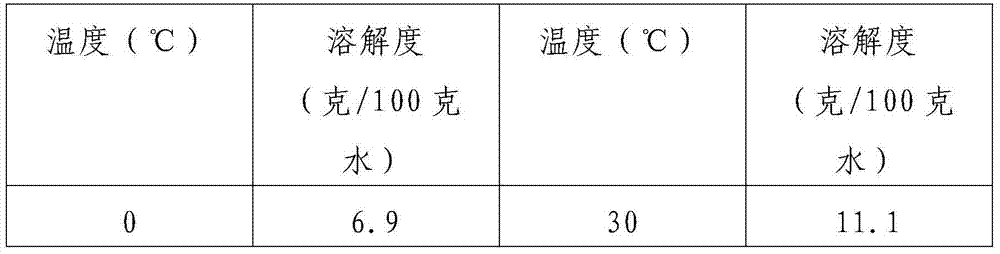

The invention relates to an environmental-friendly method used for preparation of potassium nitrite and regent-grade potassium nitrite, and combined production of regent-grade sodium oxalate. The environmental-friendly method comprises following steps: (1) potassium hydroxide and oxalic acid are mixed at a weight ratio of 1.5-1.6:1 so as to obtain an aqueous solution 1; (2) sodium nitrite is prepared into an aqueous solution 2, and the aqueous solution 2 is filtered, wherein the weight of sodium nitrite accounts for 1.6 times of the weight of oxalic acid used in step (1); (3) the aqueous solution 1 is heated to 85 DEG C, the aqueous solution 2 is added with stirring, and an obtained mixture is subjected to heat preservation at a temperature of 80 DEG C for 30min; (4) the mixture is filtered, filtrate and precipitate are collected respectively, and are processed so as to obtain products. According to the environmental-friendly method, double decomposition is adopted; the solubility of sodium oxalate is much lower than that of potassium carbonate and potassium oxalate, so that sodium oxalate is taken as a decomposing agent. It can be observed from a picture in the invention that solubility of the obtained sodium oxalate is very low, and changes little with temperature changing, and the solubility of potassium nitrite is relatively high, so that reaction of potassium oxalate with sodium nitrite is used, and industrial potassium nitrite standards can be achieved via one-time synthesis.

Owner:TIANJIN GUANGFU TECH DEV

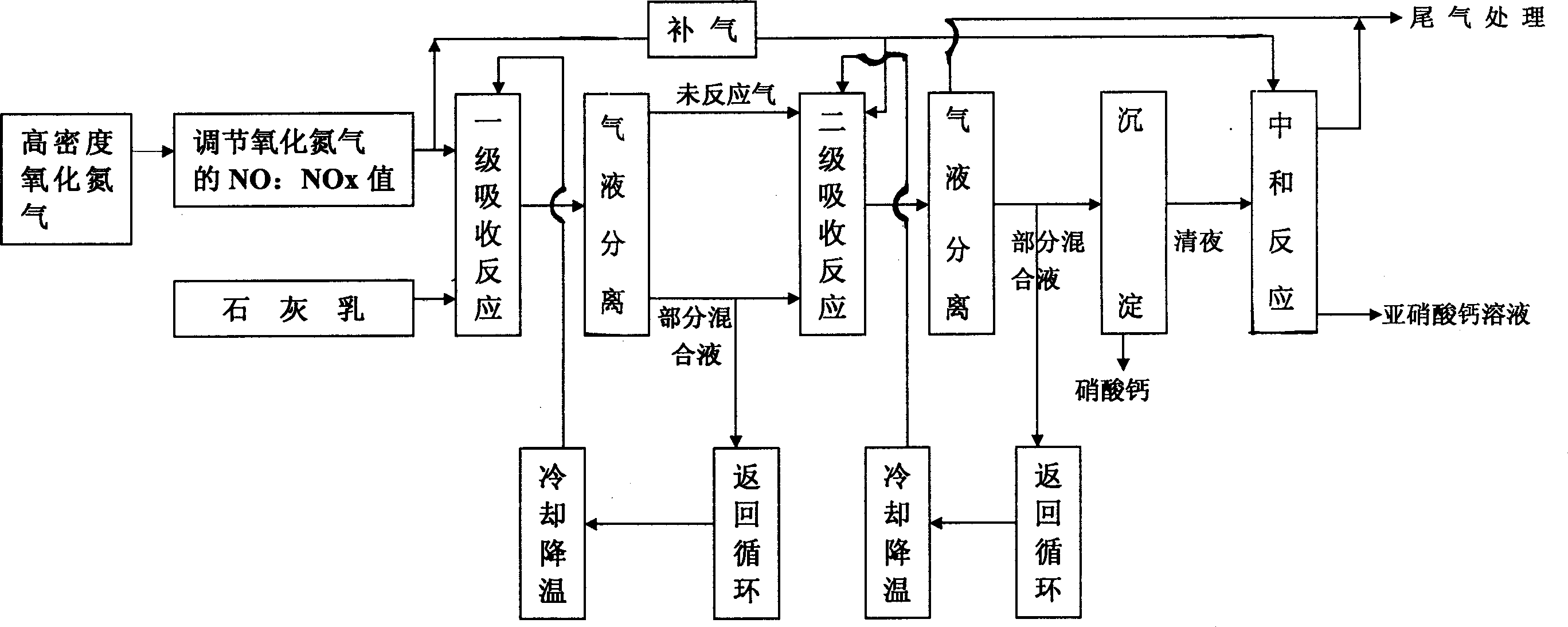

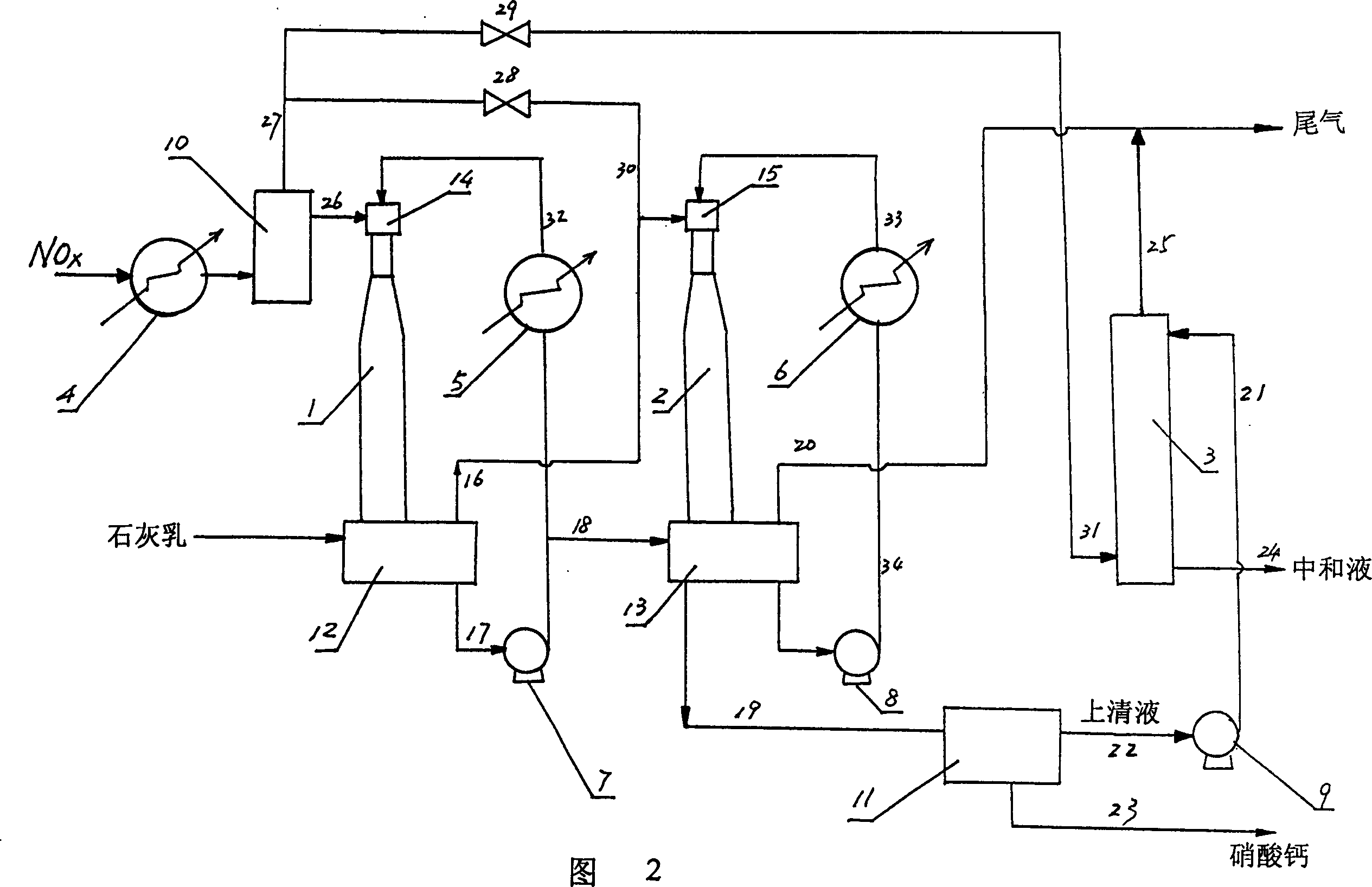

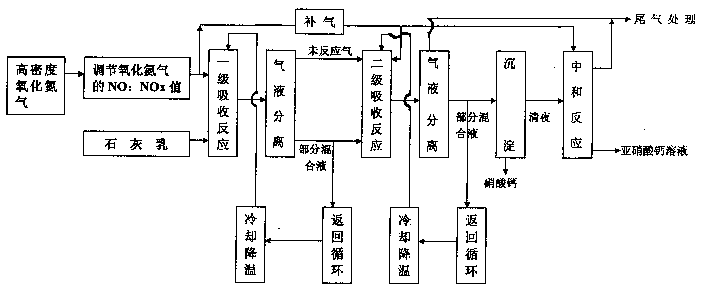

Novel process for producing calcium nitrite

InactiveCN1465528AEasy to adjustReduce volumeCalcium/strontium/barium nitratesNitrous acidNitrogen oxidesSlurry

A process for preparing calcium nitrite includes absorption reaction of nitrogen oxide and lime slurry in the reactor wherein nitrogen oxide and lime slurry are for warded feed and the followed gas-liquid separation, solid precipitation and neutralization of the Ca(OH)2 remained in the liquid. Specially there is a conditioning stage of NO density by controlling the ratio of NO:NOx before the absorption reaction to supply NO for the need of reaction.

Owner:SICHUAN GOLDEN ELEPHANT CHEM IND GRP CO LTD

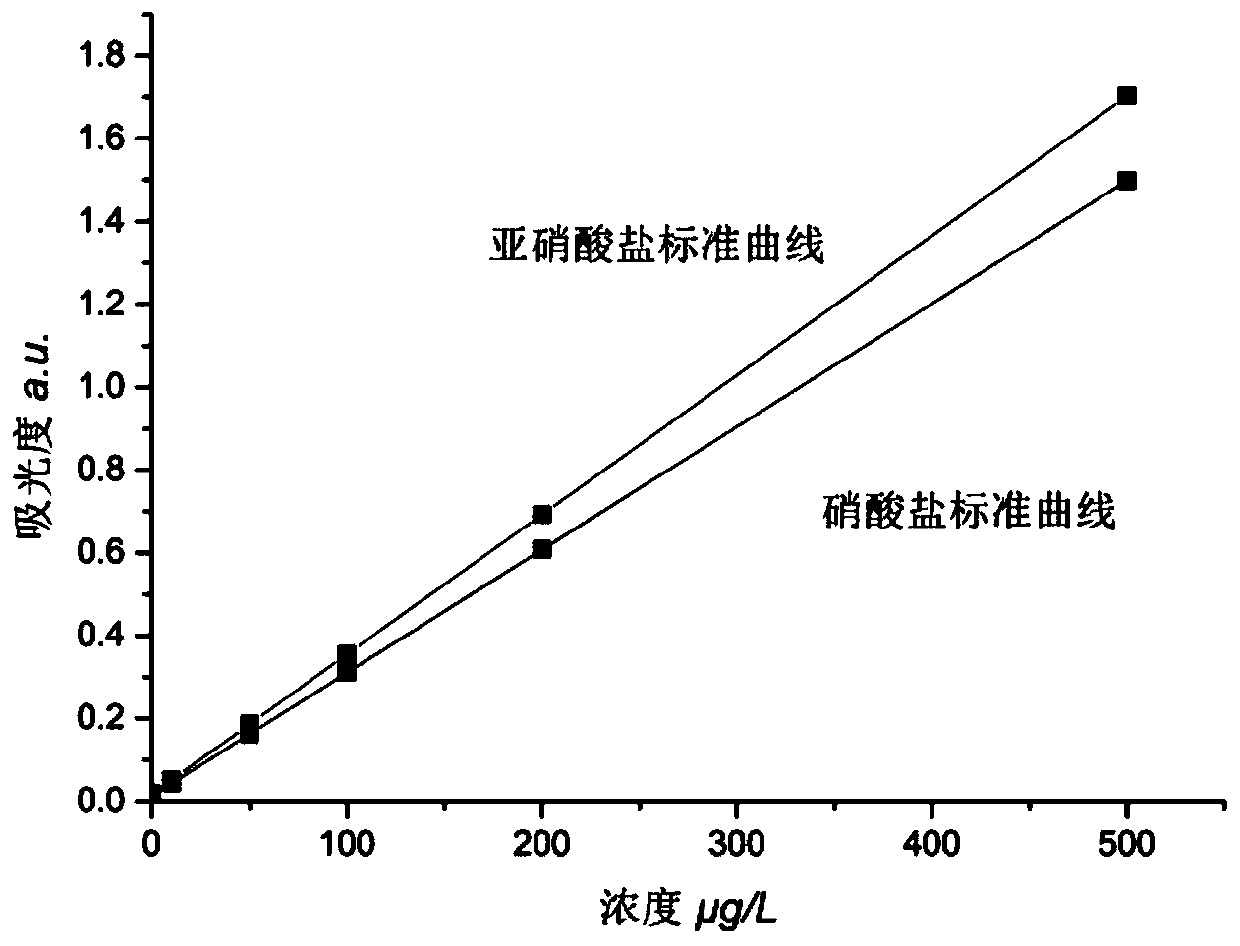

Reduction method for reducing nitrate into nitrite in water and application of reduction method to detection of content of nitrate in water body

InactiveCN111521573AEffective recoveryImprove recovery ratePreparing sample for investigationColor/spectral properties measurementsWater qualityReducing agent

The invention provides a reduction method for reducing nitrate into nitrite in water and application of the reduction method in detection of nitrate content in water, and relates to the technical field of water quality monitoring. According to the reduction method for reducing nitrate into nitrite in water, a reducing agent is an aqueous solution containing vanadium ions. According to the reduction method, the vanadium ions are used as the reducing agent, nitrate in water can be effectively reduced into nitrite, and the method has the characteristics of high reduction rate and good stability and has the advantages of being non-toxic and environment-friendly compared with an existing reduction method using cadmium ions. Meanwhile, the method for detecting the nitrate content in the water body by applying the reduction method has the advantages of simple operation process, easily available test reagent and no need of complex detection equipment in the detection process, and is very suitable for in-situ analysis of the nitrate content in seawater.

Owner:OCEANOGRAPHIC INSTR RES INST SHANDONG ACAD OF SCI +1

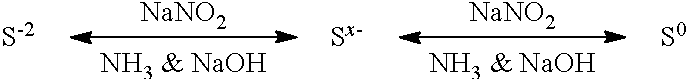

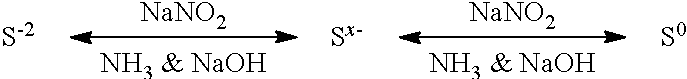

Pyrophoric iron sulfide treatment using sodium nitrite

ActiveUS9452941B2Surface-active detergent compositionsNon-surface-active detergent compositionsCause injurySodium nitrite

Pyrophoric material such as iron sulfide is frequently found in refinery equipment. When the equipment is opened to the atmosphere for maintenance, an exothermic reaction can take place that may cause injury to personnel and catastrophic damage to equipment. A process used to treat pyrophoric material uses sodium nitrite injected into a gaseous carrier stream to oxidize iron sulfides to elemental sulfur and iron oxides. The sodium nitrite solution may be buffered to a pH of about 9 with disodium phosphate or monosodium phosphate. A chemical additive that provides a quantitative measure of reaction completion may be added to the treatment solution.

Owner:REFINED TECH

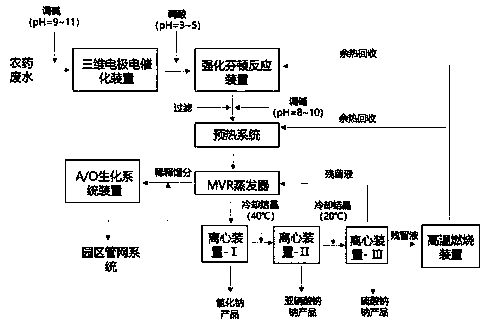

Method for disposing cymoxanil pesticide wastewater

InactiveCN110066077AImprove biodegradabilityGuaranteed uptimeWater contaminantsTreatment with aerobic and anaerobic processesFiltrationEvaporation

The invention relates to the field of advanced treatment of wastewater and provides a method for disposing cymoxanil pesticide wastewater. The method comprises the following steps that 1, solid sodiumhydroxide is utilized to perform alkali adjustment treatment on the cymoxanil wastewater; 2, after alkali adjustment, powdered activated carbon is added into the wastewater, stainless steel is used as a cathode, and graphite is used as an anode material to form a three-dimensional electrode to carry out an electrolytic catalytic reaction on the wastewater; 3, after the electrolytic catalytic reaction is finished, standing and filtering are carried out, and the acidity of a solution is adjusted by sulfuric acid after filtration; 4, after completion of an enhanced Fenton reaction, iron powder is filtered and recovered first, the pH is adjusted to be 8-9, standing is carried out, a supernatant is taken and placed into a preheating system, and the wastewater is conveyed into an evaporator forevaporation; 5, fractions obtained during evaporation are diluted with effluent of an A / O biochemical system and then subjected to biochemical treatment, and the wastewater after A / O biochemical treatment directly enters a garden pipe network system; 6, a residual liquid after evaporation is centrifuged and dried to obtain a sodium chloride product, a sodium nitrite product and a sodium sulfate product; 7, the remaining residual liquid is burned at the high temperature, and residual heat is recovered.

Owner:QUANZHOU INST FOR ENVIRONMENTAL PROTECTION IND NANJING UNIV

Method for extracting and detecting nitrate and nitrite in Chinese sauerkraut

InactiveCN102009964ASimple processShort timeChemiluminescene/bioluminescenceNitrous acidWater bathsNitrite

The invention discloses a method for extracting and detecting nitrate and nitrite in Chinese sauerkraut and relates to an extracting and detecting method. The invention solves the problems of long time, low efficiency and complex operation existing in the traditional method for extracting nitrate and nitrite in Chinese sauerkraut and overcomes the defects of complex process, long time, narrow linear range, and the like existing in the method for nitrate and nitrite in Chinese sauerkraut. A microwave method is used for assisting to extract nitrate and nitrite in the Chinese sauerkraut. The nitrate is reduced by utilizing a zinc-cadmium water bath oscillating method, and the nitrate and the nitrite are detected by adopting a photochemical method. The extracting method of the invention has the characteristics of simple process, short time, high extracting efficiency, simple equipment, wide application range, high repeatability, time saving, reagent saving, less pollution, and the like. The detecting method of the invention has the advantages of simple process, short time, high sensitivity, wide linear range and simple instrument equipment.

Owner:HARBIN UNIV OF COMMERCE

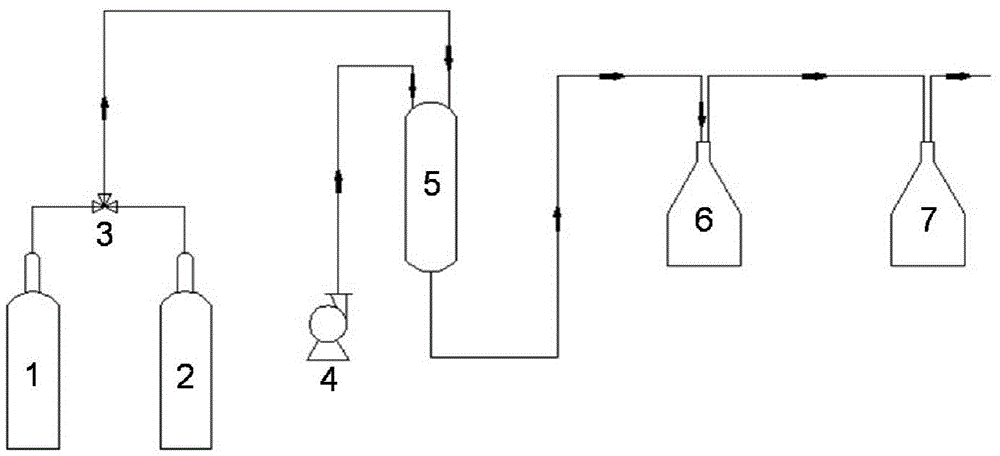

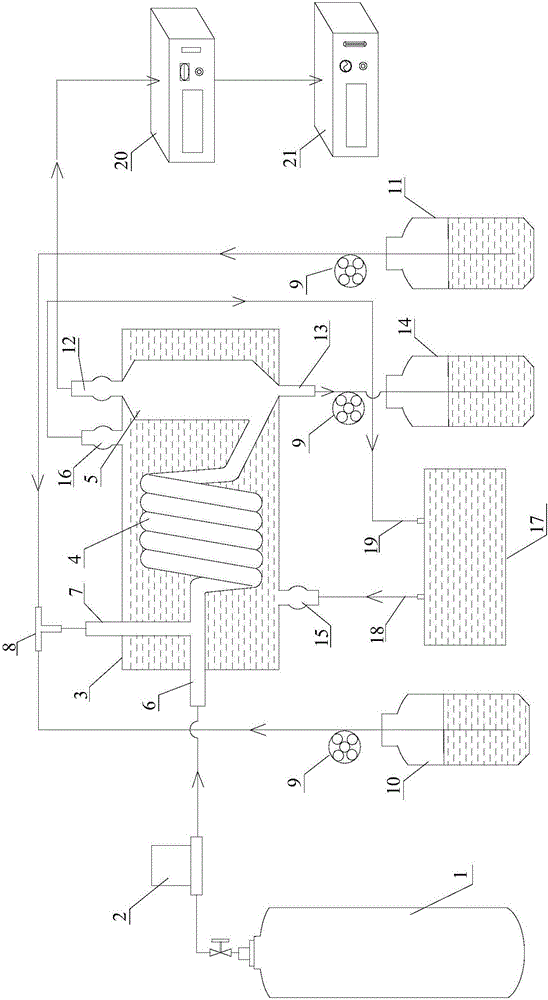

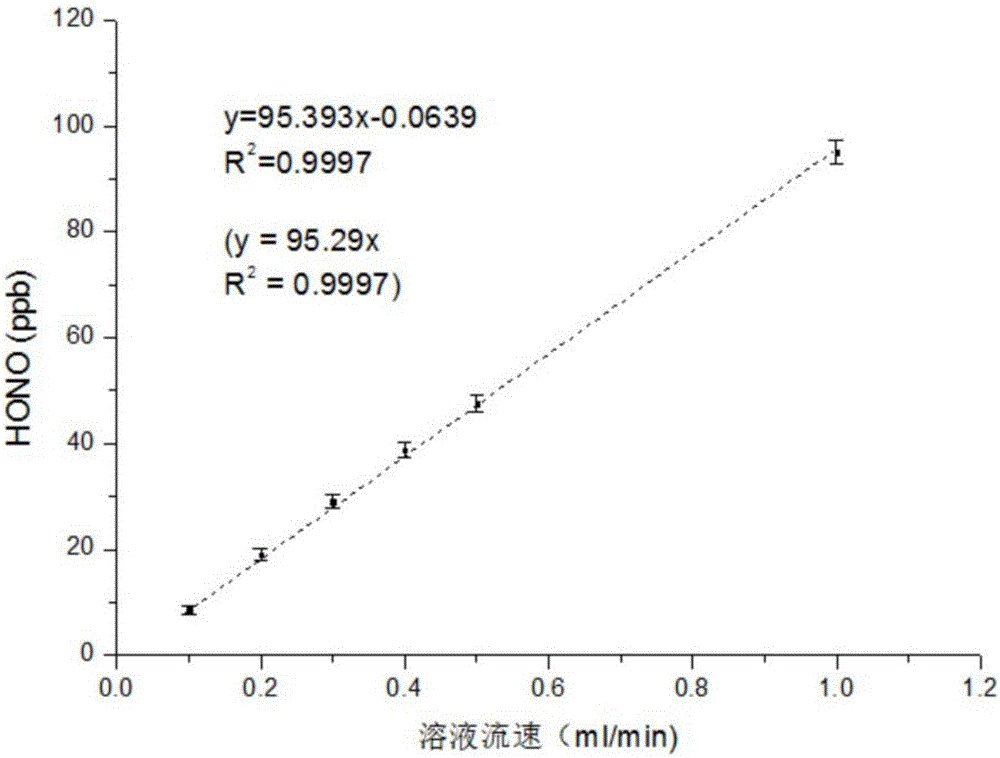

Gaseous nitrous acid generating device and technology thereof

The invention provides a gaseous nitrous acid generating device and a technology thereof. The device comprises a mass flow controller and a gas transportation pipeline which are connected with a compressing steel cylinder, an output end of the mass flow controller is connected with a spiral pipe gas generator, the spiral pipe gas generator is sequentially connected with a glass spiral pipe and a gas-liquid separation bottle which are integrally formed in the spiral pipe gas generator through a gas input pipe, a bypass input pipe is formed in the gas input pipe of the glass spiral pipe, and the bypass input pipe is connected with a dilute sulphuric acid reagent bottle and a sodium nitrite solution reagent bottle through a three-way valve connected with the bypass input pipe and liquid transportation pipelines at the two ends of the three-way valve and peristaltic pumps respectively; the upper end of the gas-liquid separation bottle is provided with a gas outlet, and a liquid transportation connector at the lower end of the gas-liquid separation bottle is connected with a waste liquid bottle through a liquid transportation pipeline and a peristaltic pump. According to the gaseous nitrous acid generating device and the technology thereof, the flowing path of a mixed solution is lengthened through the glass spiral pipe in the spiral pipe gas generator, gas and liquid are fully mixed in a turbulent mode, nitrous acid molecules spread to the gas phase, separation is achieved in the gas-liquid separation bottle, and high-purity gaseous nitrous acid is produced.

Owner:JINAN UNIVERSITY

Pyrophoric Iron Sulfide Treatment Using Sodium Nitrite

ActiveUS20150273533A1Surface-active detergent compositionsNon-surface-active detergent compositionsCause injurySodium nitrite

Pyrophoric material such as iron sulfide is frequently found in refinery equipment. When the equipment is opened to the atmosphere for maintenance, an exothermic reaction can take place that may cause injury to personnel and catastrophic damage to equipment. A process used to treat pyrophoric material uses sodium nitrite injected into a gaseous carrier stream to oxidize iron sulfides to elemental sulfur and iron oxides. The sodium nitrite solution may be buffered to a pH of about 9 with disodium phosphate or monosodium phosphate. A chemical additive that provides a quantitative measure of reaction completion may be added to the treatment solution.

Owner:REFINED TECH

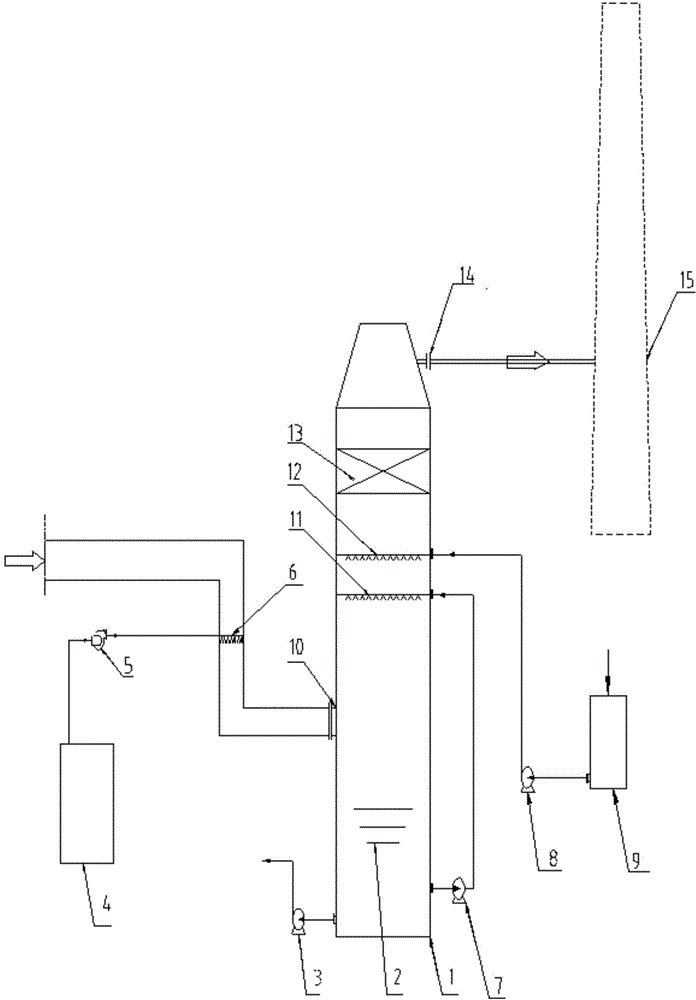

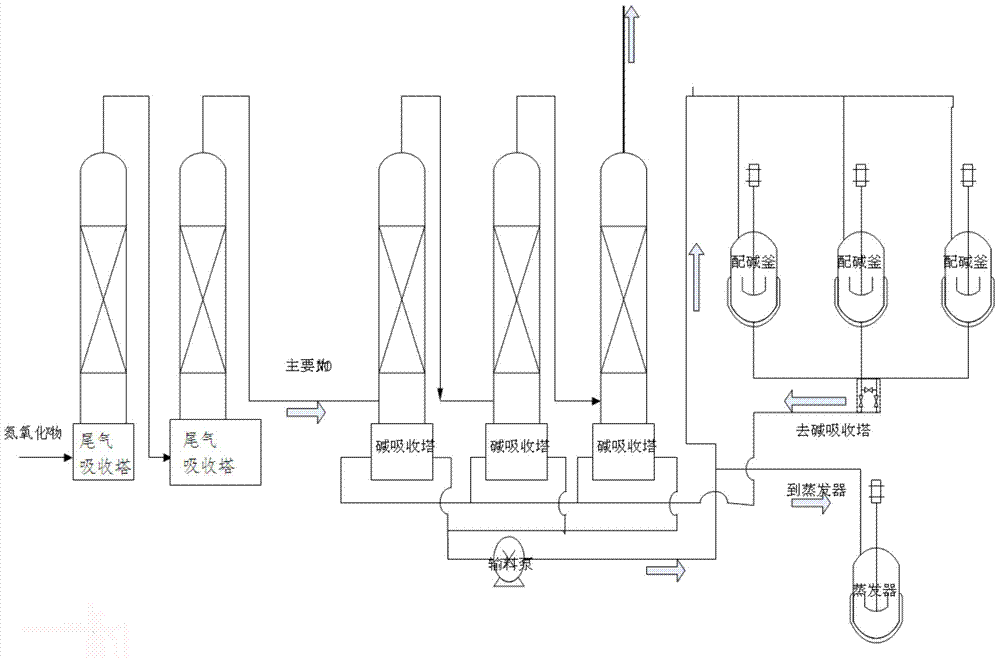

Method for reducing energy consumption in preparing sodium nitrite through nitrogen oxide

The invention relates to a method for reducing energy consumption in preparing sodium nitrite through nitrogen oxide. The method comprises the following steps of: (1) preparing 10%-30% sodium carbonate solution at 30-40DEG C in a primary alkali preparing vessel; (2) collecting and introducing nitrogen oxide, generated in a factory, into a tail gas absorption tower; (3) putting the sodium carbonate solution prepared in the step (1) into the alkali absorption tower, introducing the tail gas treated by the tail gas absorption tower in the step (2), and reacting to produce sodium nitrite; (4) when reaction is carried out in the alkali absorption tower until the pH value of the solution is 5-8, delivering the produced sodium nitrite to a secondary alkali preparing vessel, thus preparing secondary sodium carbonate solution containing sodium nitrite. The method has the beneficial effects of greatly decreasing the evaporation amount of water in the traditional method, extremely reducing the vapor consumption for producing the sodium nitrite, having no need of investing any cost, as well as no influence on the quality of the sodium nitrite; the method is high in safety, convenient to operate, and extremely easy to popularize.

Owner:HUBEI YITAI PHARMA

Preparation method of reagent grade potassium nitrite and sodium oxalate

InactiveCN105016318AAvoid decompositionAvoid pollutionCarboxylic acid salt preparationNitrous acidOXALIC ACID DIHYDRATEPotassium nitrate

The invention relates to a preparation method of potassium nitrite and sodium oxalate and in particular relates to a preparation method of reagent grade potassium nitrite and sodium oxalate, aiming to solve the problems that existing potassium nitrite preparation methods cause more severe environmental pollution and are complex and tedious in processes. The preparation method comprises the following specific steps: adding potassium hydroxide and oxalic acid to a 50L reaction kettle, adding water to prepare a water solution, filtering the water solution and collecting filtrate; adding sodium nitrite and water to the other reaction kettle to prepare a water solution, insulating and precipitating the water solution and taking supernatant; filtering mixed liquor and collecting filtrate and a precipitate respectively; pulping and washing the precipitate twice with hot water and spin-drying the precipitate, thus obtaining reagent grade sodium oxalate; preparing a water solution with industrial grade potassium nitrite and hot water and then carrying out fine filtration; concentrating mother liquor obtained after fine filtration, spin-drying and washing the concentrate twice, then spin-drying the concentrate and drying the concentrate, thus obtaining reagent grade potassium nitrite. The preparation method is used in the field of chemical reagents.

Owner:TIANJIN GUANGFU TECH DEV

Method for preparing nitrogen-containing liquid fertilizer by using microplasmas

The invention discloses a method for preparing a nitrogen-containing liquid fertilizer by using microplasmas. The method comprises the following specific steps that: water is introduced into a microplasma device; and an air source is switch on; air flow is adjusted; after the air flow is stable, a direct-current high-voltage power supply is switched on, a discharge reaction begins, air microplasma is formed between the positive pole of the power supply and the liquid surface of water, the air microplasma induces the plasma to have a chemical reaction so as to excite nitrogen molecules and oxygen molecules to form a large number of active particles, the active particles are combined so as to form a nitric oxide, the nitric oxide is dissolved into water to form nitric acid and nitrous acid, and an aqueous solution containing nitrate radical and nitrite radical is formed. According to the invention, a nitrogen fertilizer can be prepared in one step by using plasma; nitrogen source is low in cost; the operation is simple; the preparation equipment is small-sized and portable; and the nitrogen-containing liquid fertilizer can be prepared conveniently as required, thereby avoiding the troubles in transportation, storage and preservation.

Owner:SUN YAT SEN UNIV

Electrochemical gasotransmitter generating compositions and methods of using same and dressings and treatment systems incorporating same

ActiveUS10342706B2Efficient dosingNon-adhesive dressingsSulfur-dioxide/sulfurous-acidDiseaseWound dressing

Disclosed are compositions that comprise an organic electrochemical mediator and a gasotransmitter salt which converts into a gasotransmitter via electron transfer. Also disclosed are bandages and wound dressings comprising the subject gasotransmitters, and methods of making a gasotransmitters, comprising exposing the compositions to a voltage sufficient to reduce the water soluble organic mediator. Further disclosed are methods of treating a variety of trauma and disease states by applying a therapeutically effective amount of at least one gasotransmitter thereto, and methods of generating an effective dose of the gasotransmitter generated from electrolytic reaction involving the gasotransmitter-generating compositions.

Owner:NOXSANO INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com