Nitrogen oxide absorption device and method for realizing separation of absorption products by using device

An absorption device, a technology of nitrogen oxides, applied in the direction of separation methods, nitrogen oxides/oxyacids, chemical instruments and methods, etc., can solve difficult separation and purification problems, and achieve the effects of easy separation, simple structure, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

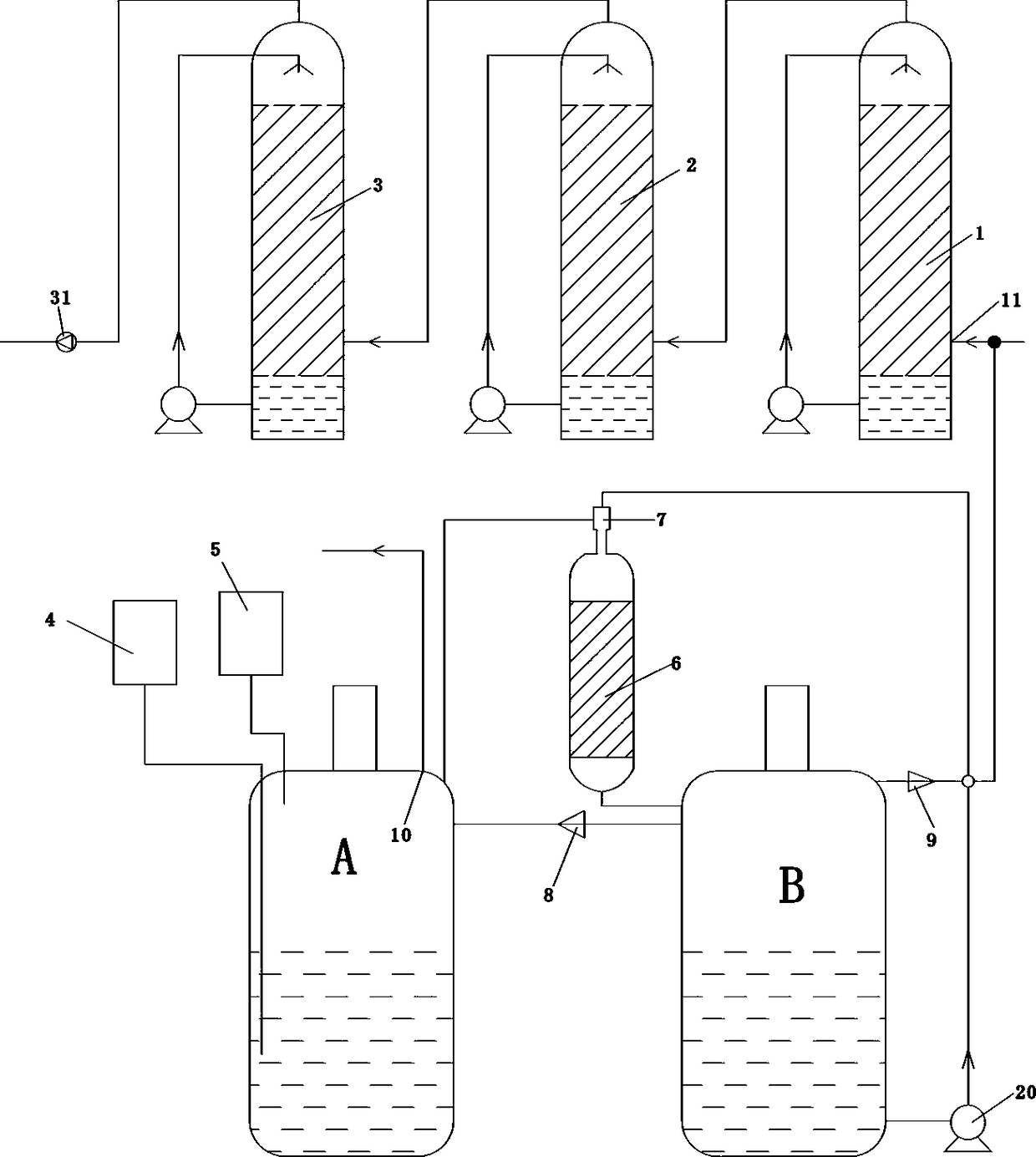

[0024] (1), the NO generated in the previous process X Enter the absorption towers 1, 2, and 3 in turn through negative pressure diversion, and absorb with 25% sodium hydroxide solution. When the pH value of the lye in a certain absorption tower drops to 11, the lye in the tower is pumped out. The liquid is a mixed salt solution, which contains 21% sodium nitrate, 16.5% sodium nitrite, and 1.2% sodium carbonate after testing, and the absorption tower is replaced with a new 25% sodium hydroxide solution;

[0025] (2) Pump 1500L of the mixed salt solution in step (1) into reaction kettle A, control the temperature below 30°C under stirring, open the liquid outlet of high-level storage tank 4, and let the nitric acid with a mass concentration of 25% flow from the mixed Slowly add under the liquid level of the solution until the solution pH=5.5, stop adding acid, and control the speed of acid addition so that there is no overflow of nitrogen oxides on the liquid surface, and the g...

Embodiment 2

[0030] (1), the NO generated in the previous process X Enter absorption towers 1, 2, and 3 sequentially through negative pressure diversion, and absorb with 20% sodium hydroxide solution. The liquid is a mixed salt solution, which contains 18% sodium nitrate, 13% sodium nitrite, and 1% sodium carbonate after testing, and the absorption tower is replaced with a new 20% sodium hydroxide solution;

[0031] (2) Pump 1500L of the mixed salt solution in step (1) into the reaction kettle A, control the temperature below 30°C under stirring, open the liquid outlet of the high-level storage tank 4, and let the nitric acid with a mass concentration of 20% flow from the mixed Slowly add under the liquid level of the solution until the pH of the solution is 5, stop adding acid, and control the speed of adding acid so that there is no overflow of nitrogen oxides on the liquid surface, and the generated CO 2 Discharge through the induced draft fan at the top of the reactor A;

[0032] (3)...

Embodiment 3

[0036] (1), the NO generated in the previous process X Enter the absorption towers 1, 2, and 3 in turn through negative pressure diversion, and absorb with 30% sodium hydroxide solution. When the pH value of the lye in a certain absorption tower drops to 11, the lye in the tower is pumped out. The liquid is a mixed salt solution, which contains 25% sodium nitrate, 19% sodium nitrite, and 1.3% sodium carbonate after testing, and the absorption tower is replaced with a new 30% sodium hydroxide solution;

[0037] (2) Pump 1500L of the mixed salt solution in step (1) into reaction kettle A, control the temperature below 30°C under stirring, open the liquid outlet of high-level storage tank 4, and let the nitric acid with a mass concentration of 30% flow from the mixed Slowly add the solution under the liquid level until the pH of the solution is 6, stop adding acid, and control the speed of adding acid so that there is no overflow of nitrogen oxides on the liquid level, and the ge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com