Process for producing sodium nitrite by direct crystallization process

A technology of sodium nitrite and crystallization method, applied in nitrous acid, chemical industry, sustainable manufacturing/processing and other directions, can solve the problems of inability to increase the concentration of lye, large one-time investment and high absorption tower, and achieve small investment and economical Steam, the effect of reducing the cost of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

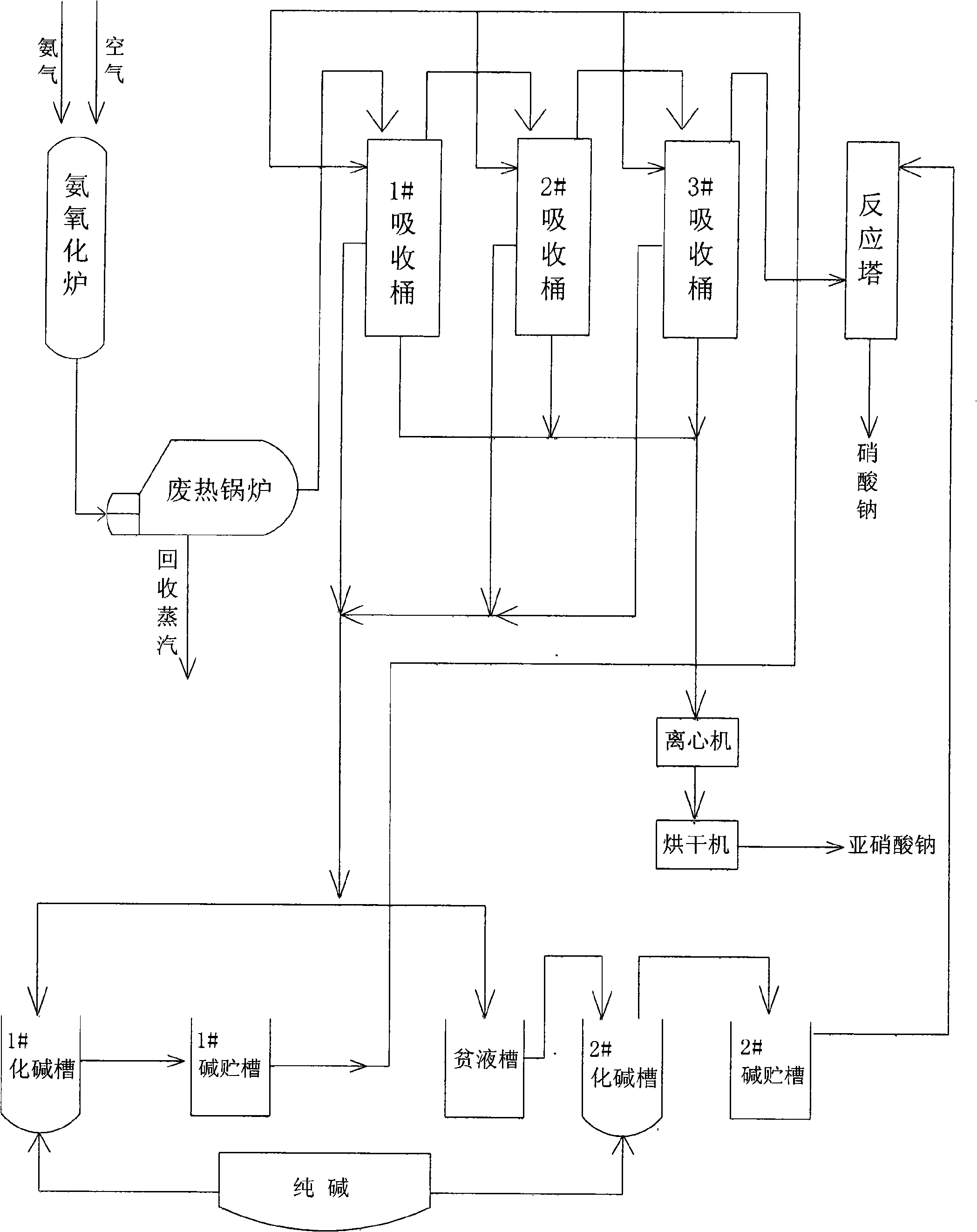

Method used

Image

Examples

Embodiment 1

[0043] (1) Soda-dissolving process:

[0044] Add soda ash and water into the 1# chemical alkali tank, stir evenly, and prepare lye, the concentration of the lye is controlled at 49Be', put it into the 1# liquid alkali storage tank, and then send it to 1# for absorption through the lye pump bucket, 2# absorption bucket and 3# absorption bucket;

[0045] 2# chemical soda tank, discharge the mother liquor after the reaction of 1# absorption barrel, 2# absorption barrel and 3# absorption barrel into the barren solution tank, and then send it to 2# chemical soda tank to supplement soda ash, the concentration of lye is controlled at 49Be ';

[0046] (2) Ammoxidation process:

[0047] Mix ammonia gas with air, control the ratio of ammonia gas and oxygen in the air at 1:13, transfer to the ammonia oxidation furnace, control the temperature at 750°C, carry out the ammonia oxidation reaction, and prepare the mixed gas, which comes out from the bottom of the ammonia oxidation furnace ...

Embodiment 2

[0063] (1) Soda-dissolving process:

[0064] Add soda ash and water into the 1# chemical soda tank, stir evenly, and prepare lye, the concentration of lye is controlled at 51Be', put it into the 1# liquid soda storage tank, and then send it to 1# for absorption through the lye pump bucket, 2# absorption bucket and 3# absorption bucket;

[0065] 2# chemical soda tank, discharge the mother liquor after the reaction of 1# absorption barrel, 2# absorption barrel and 3# absorption barrel into the barren solution tank, and then send it to 2# chemical soda tank to supplement soda ash, the concentration of lye is controlled at 51Be ', for the production of sodium nitrate;

[0066] (2) Ammoxidation process:

[0067] Mix ammonia gas with air, control the ratio of ammonia gas and oxygen in the air at 1:14, transfer to the ammonia oxidation furnace, control the temperature at 775°C, carry out the ammonia oxidation reaction, and prepare the mixed gas, which comes out from the bottom of t...

Embodiment 3

[0083] (1) Soda-dissolving process:

[0084] Add soda ash and water into the 1# alkali tank, stir evenly, and prepare lye, the concentration of the lye is controlled at 50Be', put it into the 1# liquid alkali storage tank, and then send it to 1# for absorption through the lye pump bucket, 2# absorption bucket and 3# absorption bucket;

[0085] 2# chemical soda tank, discharge the mother liquor after the reaction of 1# absorption barrel, 2# absorption barrel and 3# absorption barrel into the barren liquid tank, and then send it to 2# chemical soda tank to supplement soda ash, and the concentration of lye is controlled at 50Be ', for the production of sodium nitrate;

[0086] (2) Ammoxidation process:

[0087] Mix ammonia gas with air, control the ratio of ammonia gas and oxygen in the air at 1:16, transfer to the ammonia oxidation furnace, control the temperature at 760°C, carry out the ammonia oxidation reaction, and prepare the mixed gas, which comes out from the bottom of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com