Method for preparing molten salt-grade sodium nitrate through accurately controlled separation of sodium nitrite and sodium chloride

A sodium nitrite, precise control technology, applied in the production and preparation of sodium nitrite, in the field of sodium nitrite, can solve the problems of impurity separation, etc., and achieve the effects of low production cost, pollution elimination, and accurate parameter values

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

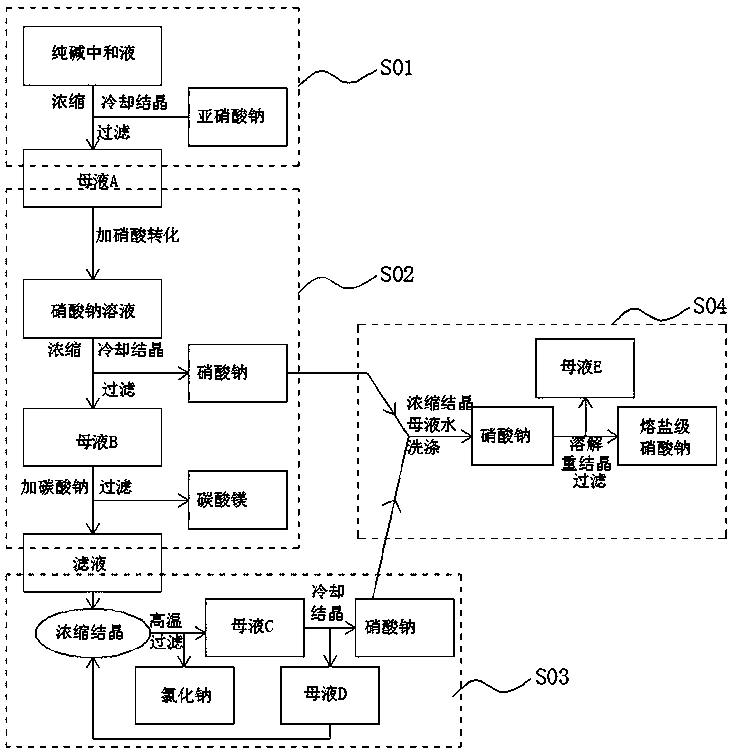

[0019] Embodiment 1, S01, the separation of sodium nitrite, 1000Kg soda ash and the neutralization solution of nitrogen oxides are concentrated to the concentration of sodium nitrate is 50g / L, under the condition of temperature 10 ℃, crystallization, filtration obtains sodium nitrite Product 210Kg and mother liquor A; the obtained sodium nitrite product has a main content of 98.5 (dry basis), which has reached the first-class and above standards of industrial sodium nitrite;

[0020] S02, the separation of magnesium chloride impurity, S01 obtains mother liquor A and adds 172Kg nitric acid (concentration 40%) conversion, makes remaining sodium nitrite all generate sodium nitrate, and sodium nitrate solution liquid is through 3-6 times concentrated crystallization, when sodium chloride in solution Accumulated to Cl - The concentration of sodium chloride and sodium nitrate is 50g / L. At room temperature, sodium chloride and sodium nitrate reach the co-saturation point, and 45Kg of...

Embodiment 2

[0023] Embodiment 2, S01, the separation of sodium nitrite, 2200Kg soda ash and the neutralization solution of nitrogen oxides are concentrated to the concentration of sodium nitrate is 300g / L, under the condition of temperature 40 ℃, crystallization, filtration obtains sodium nitrite Product 445Kg and mother liquor A; the main content of sodium nitrite product obtained is 99.1% (dry basis), which has reached the first-class and above standards of industrial sodium nitrite;

[0024] S02, the separation of magnesium chloride impurity, S01 obtains mother liquor A and adds 387Kg nitric acid (concentration 40%) conversion, makes remaining sodium nitrite all generate sodium nitrate, and sodium nitrate solution is separated into technical grade sodium nitrate 99Kg and mother liquor through 5 times of concentrated crystallization B, the accumulation of sodium chloride in solution to Cl - The concentration of sodium chloride is 100g / L, and sodium chloride and sodium nitrate reach the ...

Embodiment 3

[0027] Example 3, S01, the separation of sodium nitrite, 3000Kg soda ash and the neutralization solution of nitrogen oxides are concentrated to a concentration of 500g / L of sodium nitrate, and at a temperature of 60°C, crystallize and filter to obtain sodium nitrite The product is 590Kg and mother liquor A; the main content of sodium nitrite product is 99.5% (dry basis), which has reached the first-class and above standard of industrial sodium nitrite;

[0028] S02, the separation of magnesium chloride impurity, S01 obtains mother liquor A and adds 541Kg nitric acid (concentration 40%) conversion, makes remaining sodium nitrite all generate sodium nitrate, and sodium nitrate solution liquid is through 3-6 times concentrated crystallization, when sodium chloride in solution Accumulated to Cl - The concentration of sodium chloride and sodium nitrate is 150g / L. At room temperature, sodium chloride and sodium nitrate reach the co-saturation point, and 135Kg of industrial grade sod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com