Patents

Literature

37results about "Alkali metal nitrate shape formation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

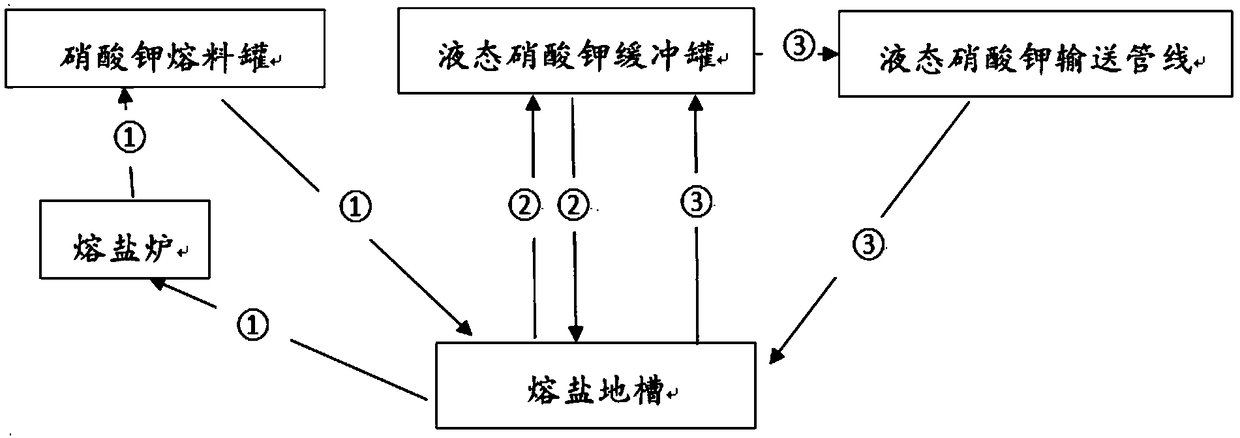

Method for producing fused salt level potassium nitrate

InactiveCN107128953AGood industrial valueEasy to controlAlkali metal nitrate shape formationPotassium nitrateSpray Granulation

The invention discloses a method for producing molten salt-grade potassium nitrate, comprising the following steps: Step S1 neutralization process: potassium hydroxide solution and nitric acid solution are mixed to undergo neutralization reaction to generate potassium nitrate to obtain the first potassium nitrate raw material solution, hydrogen The ratio of the amount of substances of potassium oxide and nitric acid is 1:1.01~1.02; step S2 evaporation process: the first potassium nitrate raw material liquid is evaporated and concentrated until the mass percentage concentration of potassium nitrate is 65~70%, and the second potassium nitrate is obtained Raw material liquid; step S3 spraying and granulating process: spraying and granulating the second potassium nitrate raw material liquid to obtain molten salt grade potassium nitrate as a final product. The method of the invention can directly produce potassium nitrate of high-purity molten salt grade, and has very good industrial value. Moreover, the process of the process of the present invention is simple and efficient in operation, easy to realize automatic production, strong in safety, and suitable for continuous, stable and rapid production of high-purity potassium nitrate.

Owner:ЦИНХАЙ СОЛТ ЛЕЙК ИНДАСТРИ ГРУП КО ЛТД

Industrial sodium nitrite new product and its preparation method

InactiveCN1400161AReduce moisture contentReduce contact areaGranulation by liquid drop formationAlkali metal nitrate shape formationState of artSodium nitrite product

The present invention discloses an industrial sodium nitrite product and its production method. The physical and chemical properties of said product are as follows: it is made into the form of ball or egg granular body, grain size is 0.5-3 mm, and the water content of the described granule body is less than or equal to 0.5%. Its production method uses the existent industrial sodium nitrite product as raw material, the above-mentioned raw material is heated and moten into liquid phase, and said liquid phase is sprayed and granulated so as to obtain the invented product. Said product features low water content, no blocking and good fluidity.

Owner:TIANJIN UNIV +1

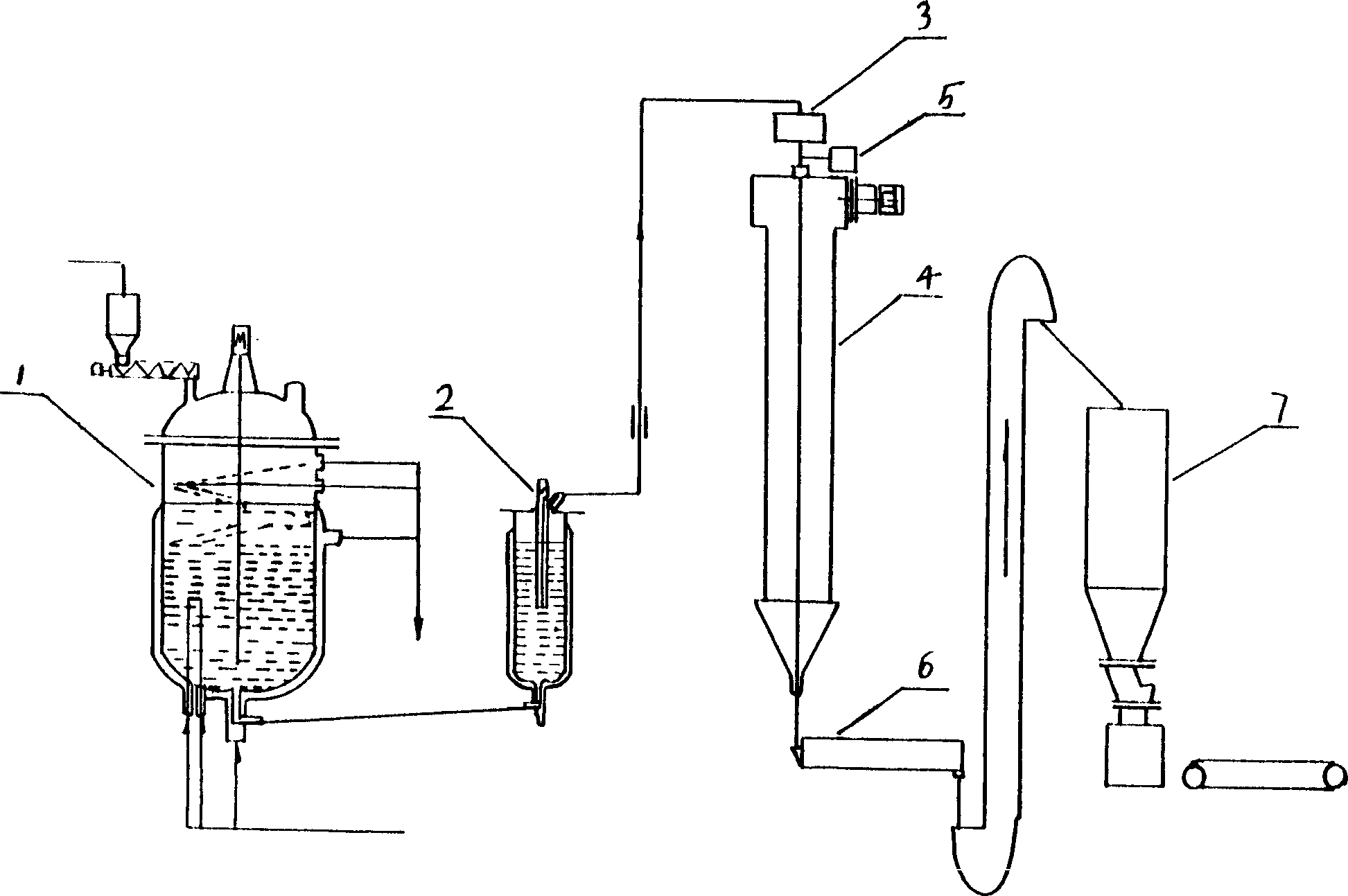

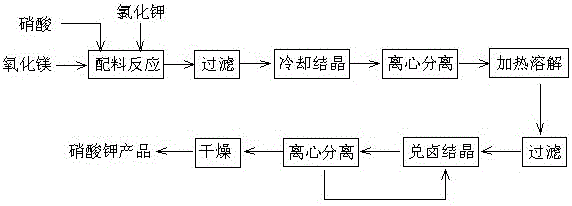

Production method of potassium nitrate

PendingCN110902700AImprove qualityUniform particlesAlkali metal nitrate preparationAlkali metal nitrate shape formationPotassium nitrateStrong acids

The invention discloses a production method of potassium nitrate. The method includes the steps of: adding nitric acid and magnesium oxide into a reactor, carrying out reaction for 2-3h, then adding potassium chloride, and carrying out reaction for 1.5-3h to obtain a reaction mixture; conveying the reaction mixture into a crystallizer for cooling crystallization, and performing separation by a centrifugal machine to obtain potassium nitrate wet crystals and mother liquor; and conveying the potassium nitrate wet crystals to a dryer, and performing drying to obtain potassium nitrate crystals. The potassium nitrate production method provided by the invention adopts nitric acid, potassium chloride and magnesia as the raw materials, and the raw materials are cheap, easily available and low in cost; and the process flow is simple, does not generate corrosive strong acid, and has small equipment corrosion.

Owner:安徽胜达化工科技有限公司

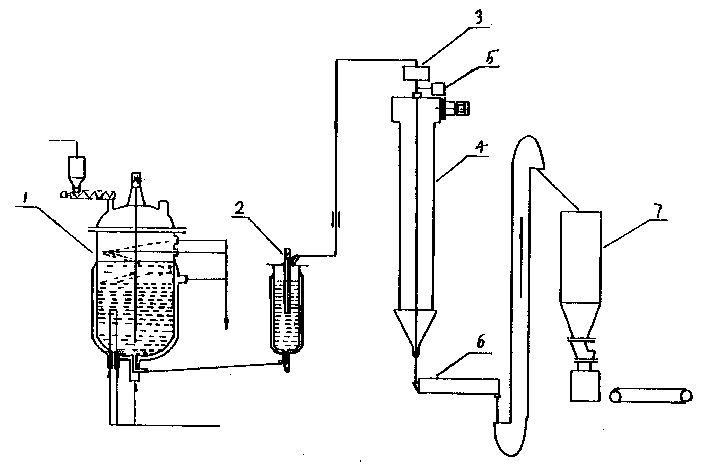

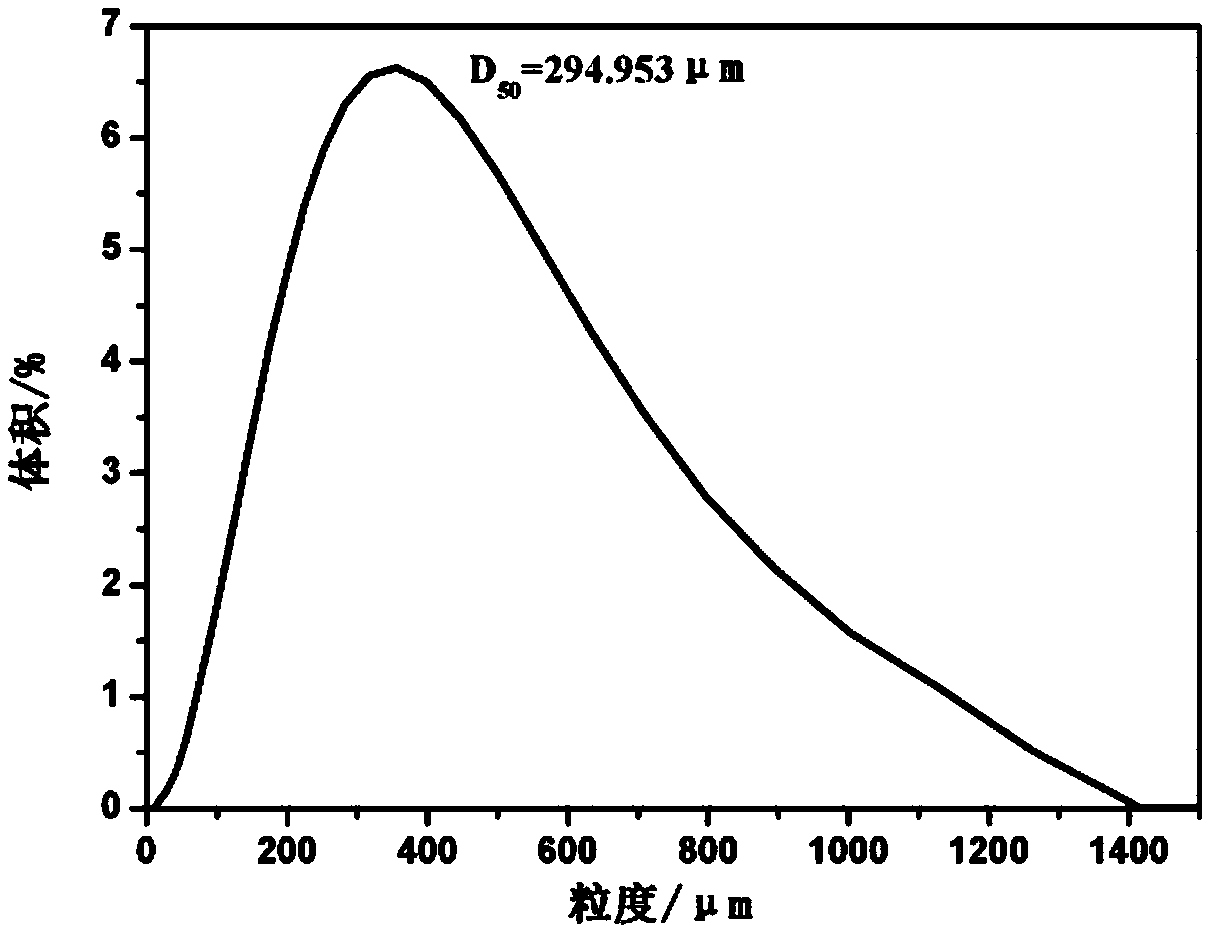

Process for producing rice-shaped crystalline potassium nitrate by brine mixing method

ActiveCN106629784AHigh purityLarge particle sizeAlkali metal nitrate purificationAlkali metal nitrate preparationSeed crystalImpurity

The invention discloses a process for producing rice-shaped crystalline potassium nitrate by a brine mixing method. The process comprises the following steps: reacting nitric acid, magnesium oxide and potassium chloride serving as raw materials; cooling for crystallization to obtain crude potassium nitrate; mixing a high-temperature solution and a low-temperature solution of the potassium nitrate according to a certain proportion by the brine mixing method; adding a potassium nitrate seed crystal at the same time; controlling the temperature and stirring speed of a mixed solution; crystalizing to obtain the rice-shaped crystalline potassium nitrate. In the production process, a reaction solution is heated by heat produced in a reaction of the nitric acid and the magnesium oxide, so that the reaction speed is high, and energy is saved; cooling crystallization is performed in a way of mixing brine and adding the seed crystal, so that the crystallization speed is high, the efficiency is high, and the obtained potassium nitrate product is an elliptical rice-shaped crystal, and has the advantages of high purity, low impurity content, large crystal particle size, uniform granularity, high fluidity, no tendency to agglomeration, convenience in use and wide application.

Owner:浙江联大化工股份有限公司

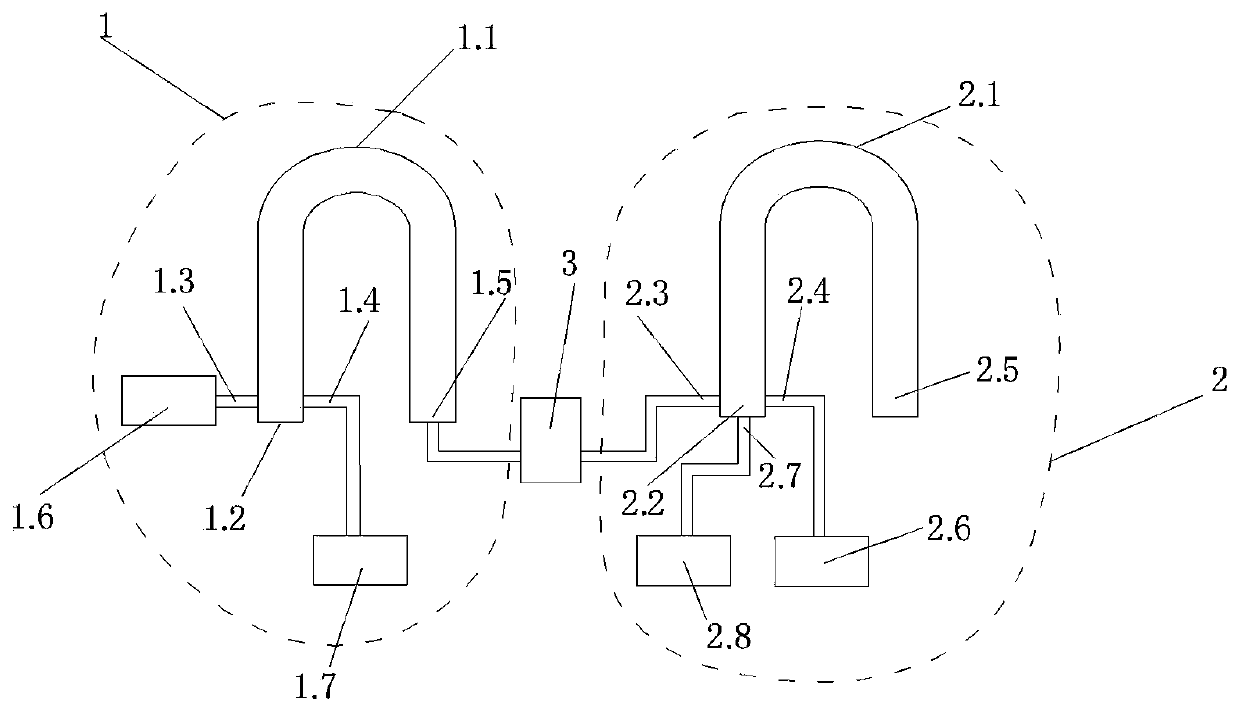

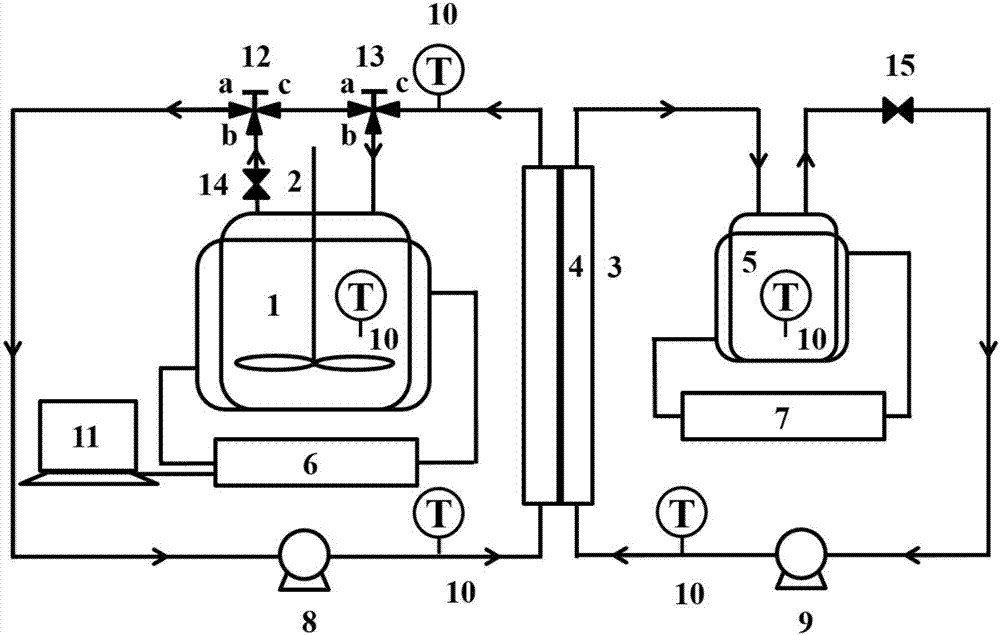

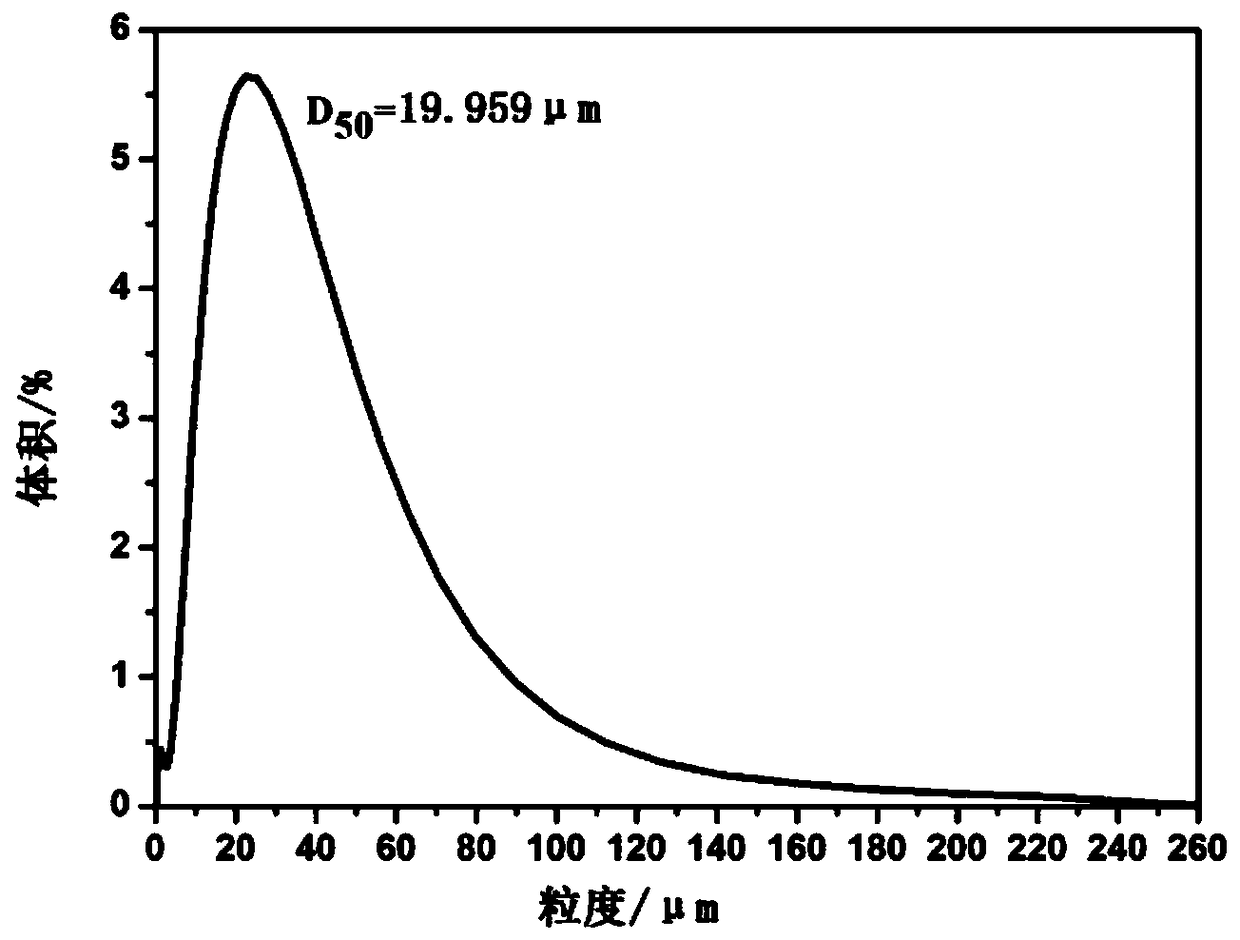

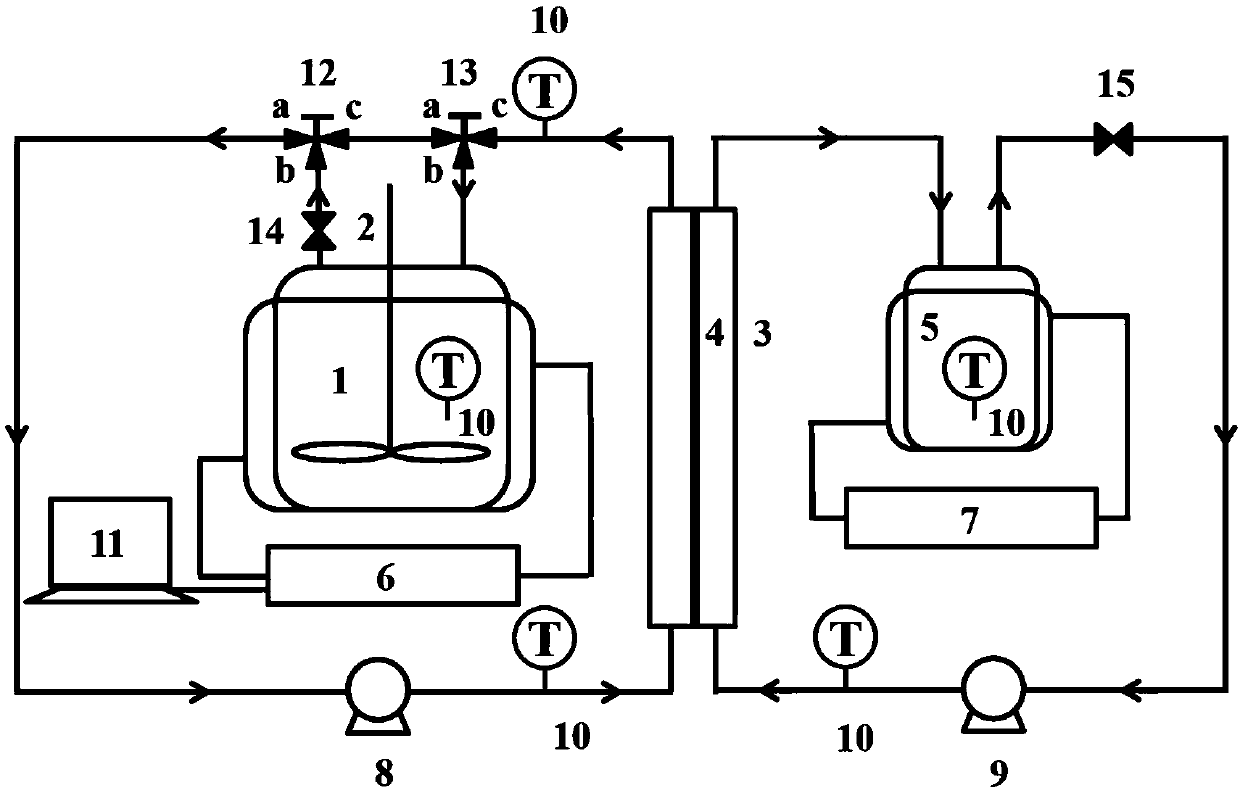

Membrane-assisted nucleation cooling crystallization method

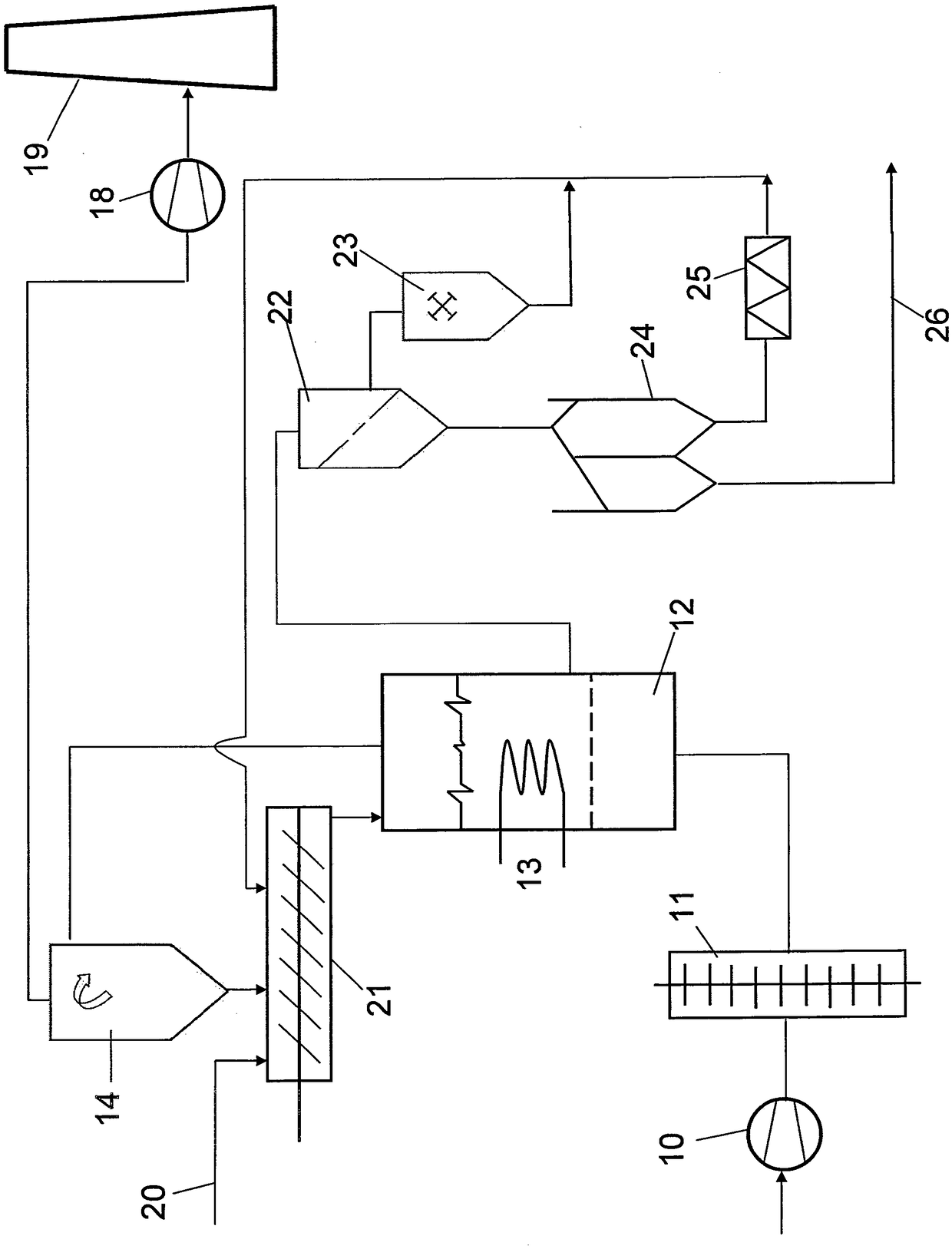

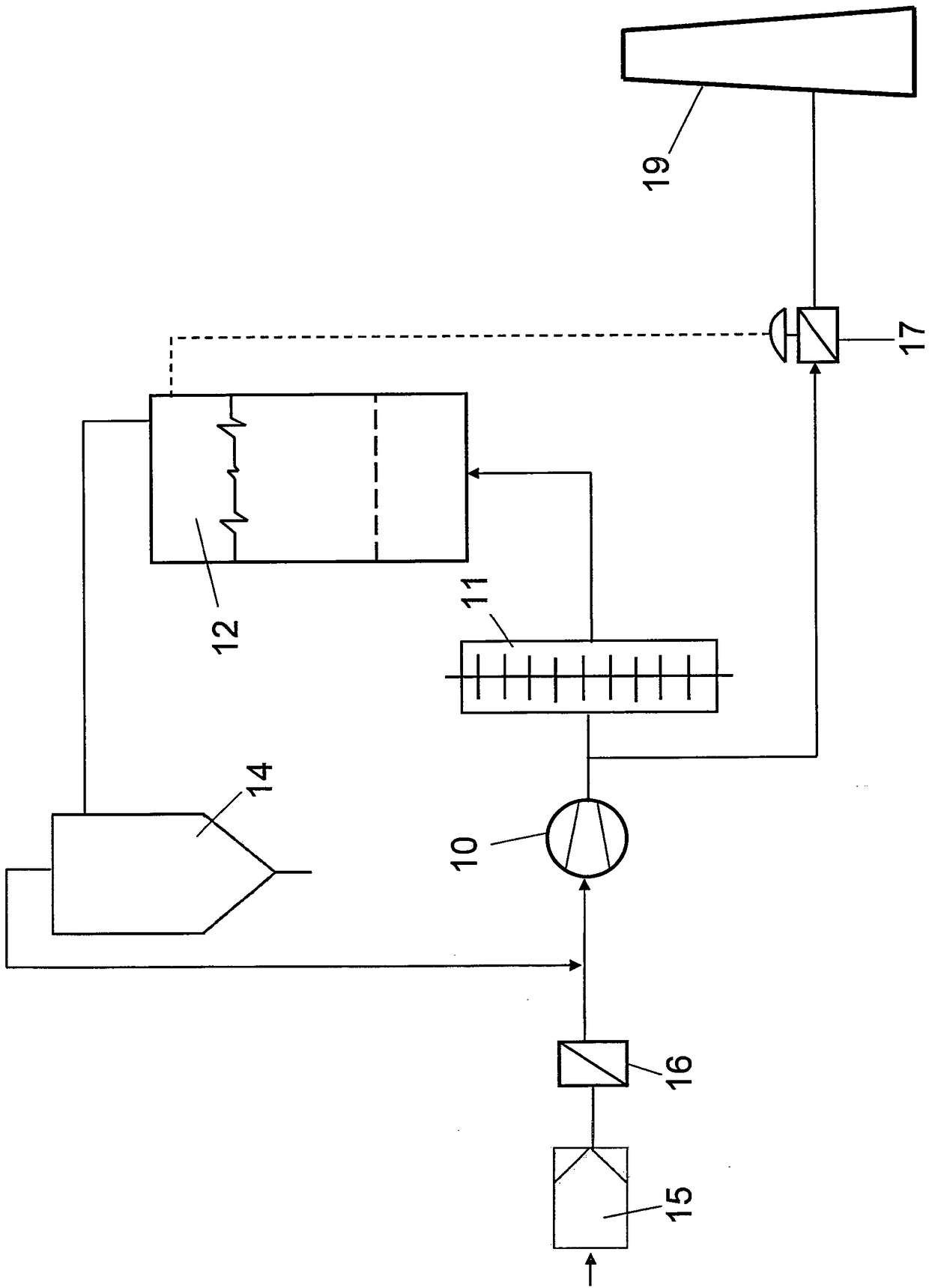

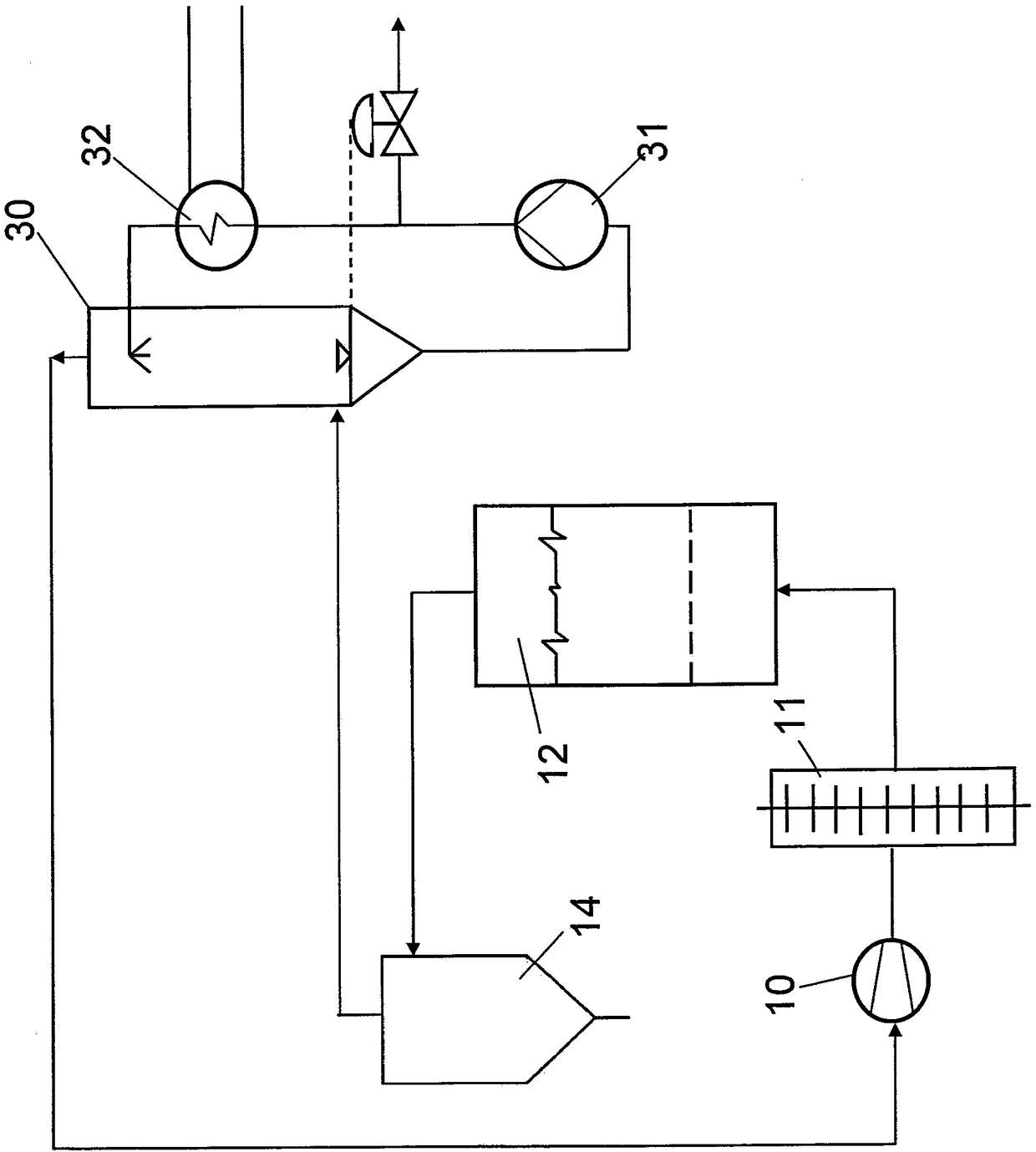

ActiveCN107233744AThe size is easy to controlNarrow particle size distributionCobalt sulfatesSolution crystallizationPeristaltic pumpTemperature control

The invention provides a membrane-assisted nucleation cooling crystallization method, and belongs to the technical field of crystallization engineering. Solution to be crystallized is added into a crystallizing kettle, a computer and a stirring and temperature control device is started, and a cooling liquid loop is started. After a system is stabilized, a peristaltic pump is started, and the solution to be crystallized is conveyed to a membrane component. When crystal nucleuses appear in the membrane component, mother solution with the crystal nucleuses is conveyed to the crystallizing kettle and subjected to crystal growth. By controlling cooling liquid and operation conditions, generation of the crystal nucleuses and crystal growth are systematically regulated, so that an ideal crystal product is obtained.

Owner:DALIAN UNIV OF TECH

Oxidizing method for nitrite ions in desulfurization and denitrification waste liquid

InactiveCN107973323AAvoid secondary pollutionLow costMagnesium nitratesCalcium/strontium/barium nitratesNitrite ionUltraviolet lights

The invention provides an oxidizing method for nitrite ions in desulfurization and denitrification waste liquid. The oxidizing method comprises the following steps of firstly carrying out solid-liquidseparation and deep dedusting on the desulfurization and denitrification waste liquid, then adjusting the pH value of the solution to be in the suitable range for oxidation treatment, completely oxidizing nitrites in the waste liquid into nitrates through a manner of combining an oxidizing agent and ultraviolet light to produce free radical, and finally obtaining a nitrate product. The oxidizingmethod provided by the invention has the beneficial effects that the operation is simple and convenient, the cost is low, the oxidizing efficiency is high, the problem of secondary pollution easily caused by the nitrite waste liquid is solved, and the recycling of all nitrogen elements in the waste liquid is realized, so that the application prospect is good.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

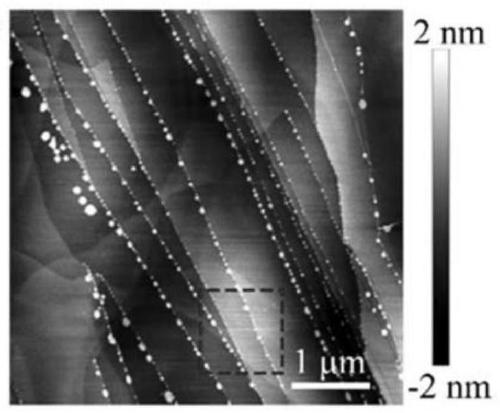

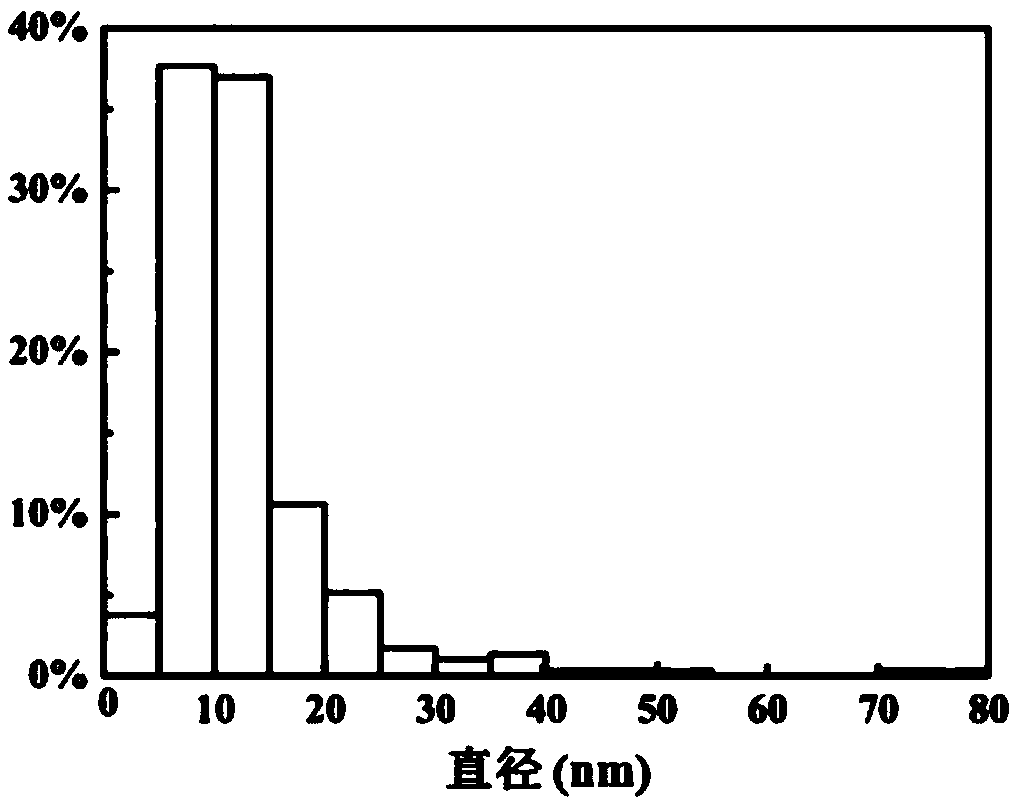

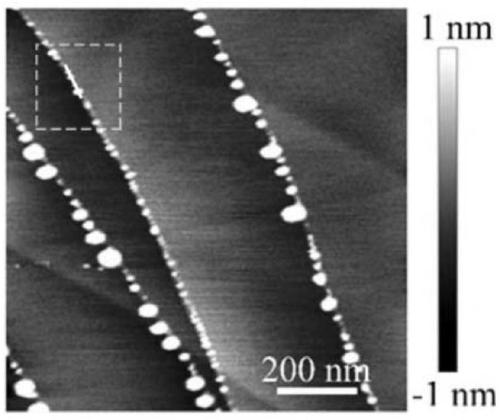

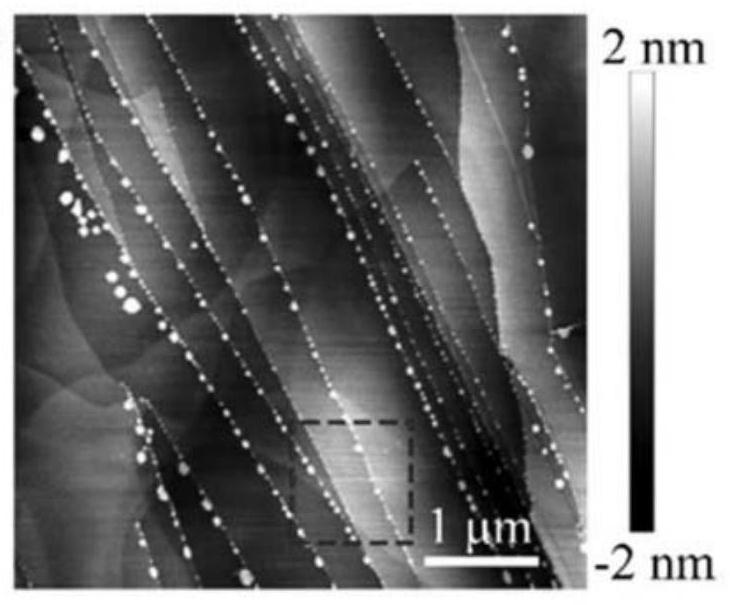

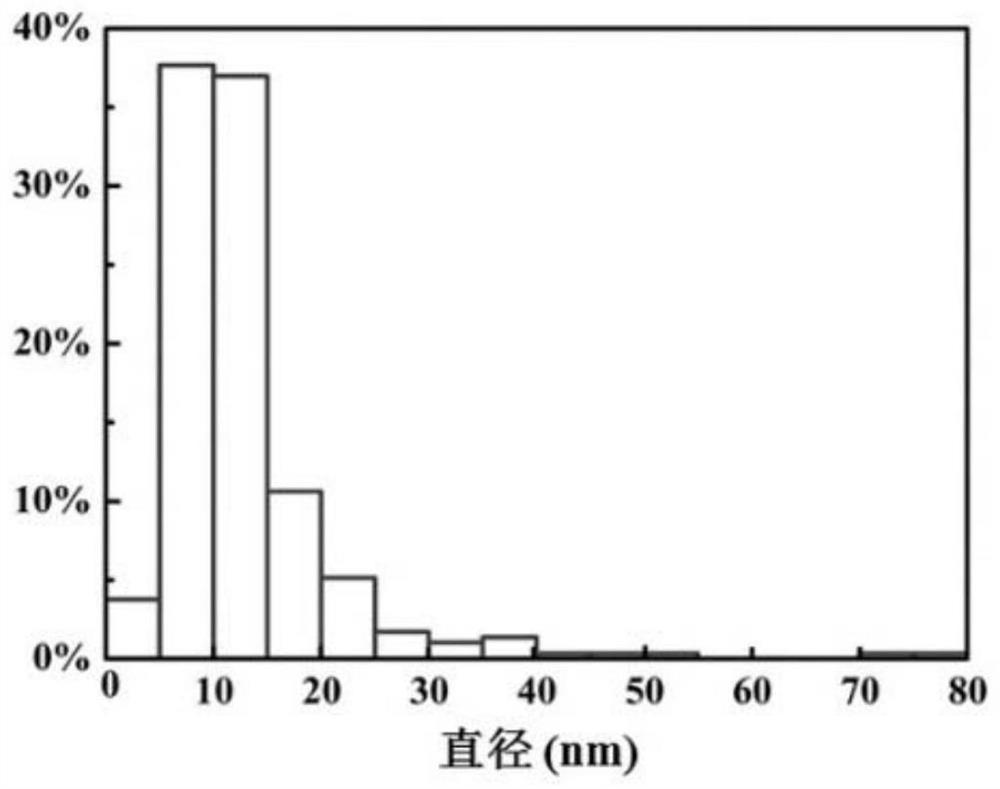

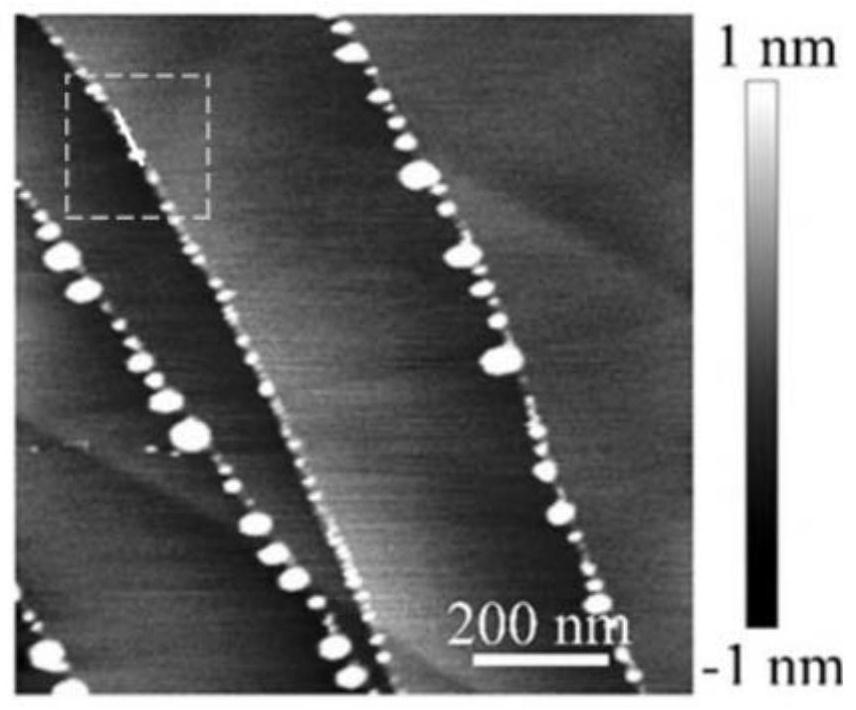

Preparation method of salt nano-particles

ActiveCN109231241ASimple stepsLow costMaterial nanotechnologyAlkali metal nitrate shape formationBasementInorganic salts

The invention relates to a preparation method of salt nano-particles. The preparation method comprises the following steps of putting inorganic salt of a solid in a vessel, and providing a basement with a smooth surface; regulating a temperature of a heating device to be higher than a melting point of the inorganic salt and lower than a decomposition temperature of the inorganic salt, and heatingthe vessel and the basement with the heating dvice to enable the solid inorganic salt to be molten into a molten liquid state; and dipping the molten inorganic salt with a rod body which is not reacted with the molten inorganic salt, dripping the molten inorganic salt on the basement, into which the molten inorganic salt does not infiltrate, then removing droplets of the molten inorganic salt fromthe basement, and performing cooling to obtain inorganic salt nano-particles on the surface of the basement. In the preparation method provided by the invention, by using a melting-cooling method toprepare the salt nano-particles, the salt nano-particles with the particle size being between several nanometers and several micrometers can be obtained; and particularly, through the preparation method provided by the invention, the salt nano-particles with the size being 6nm or below can be obtained, so that the preparation method exploits a new measure of preparation of small-particle size saltnano-particles.

Owner:SHANGHAI INST OF APPLIED PHYSICS - CHINESE ACAD OF SCI

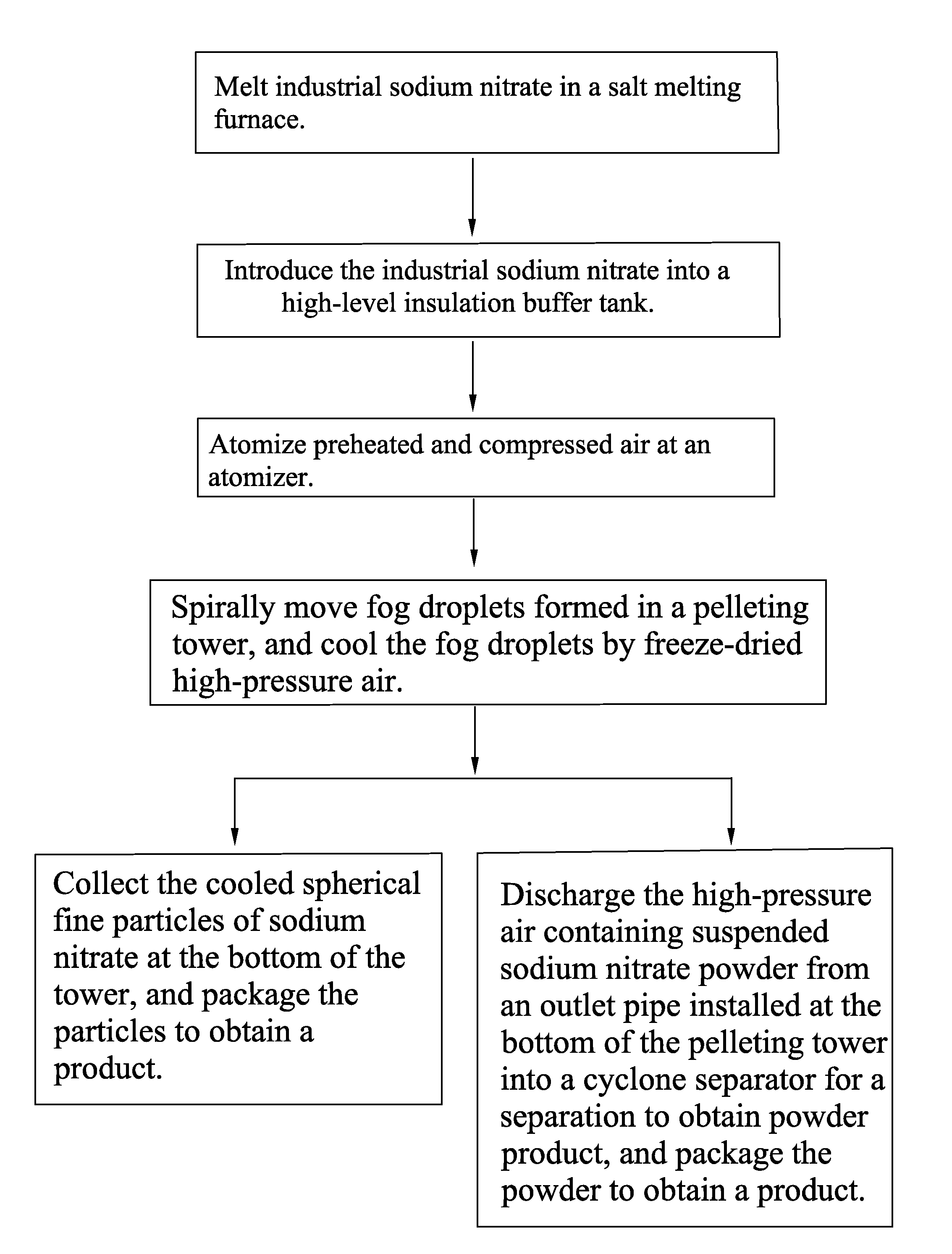

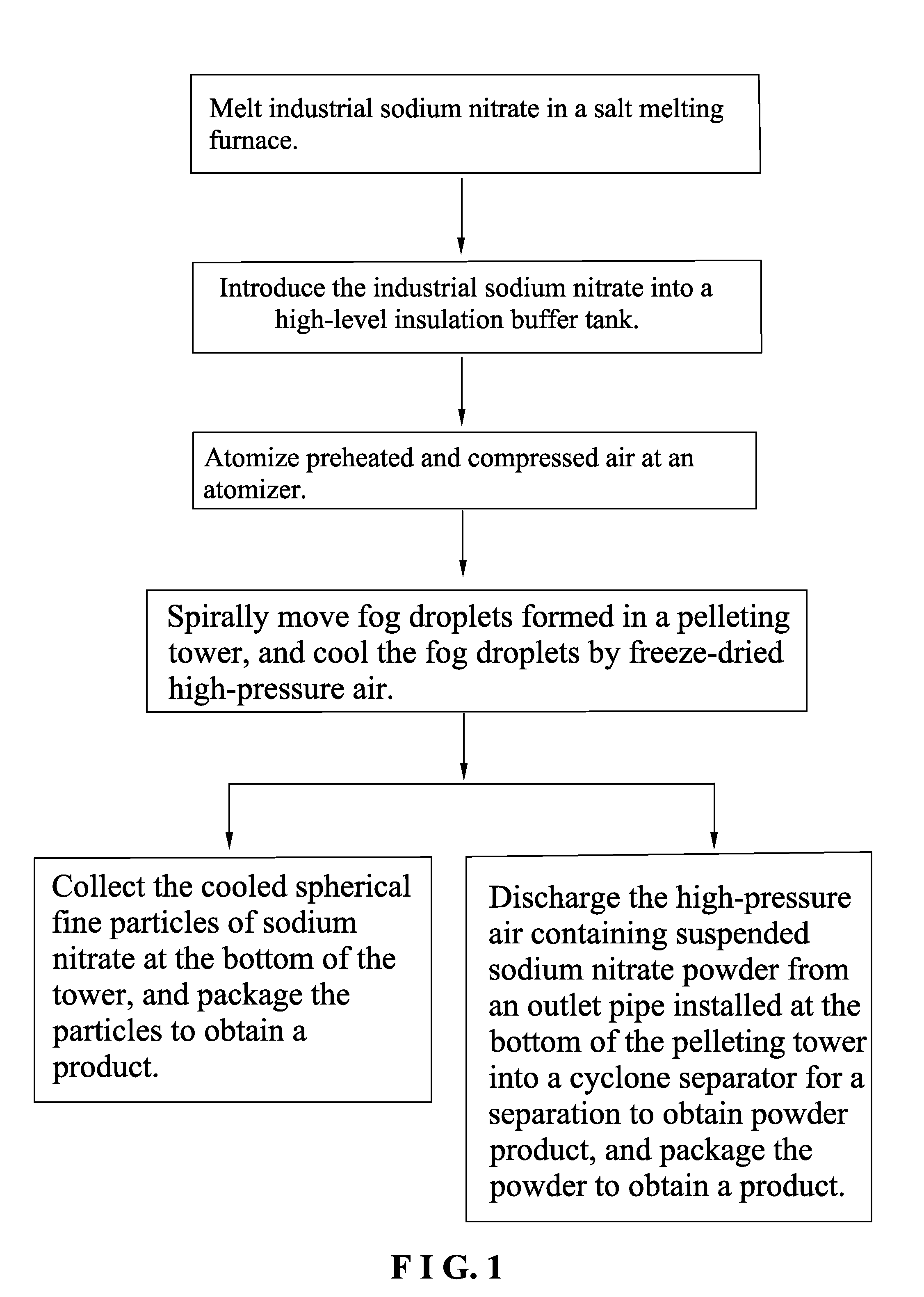

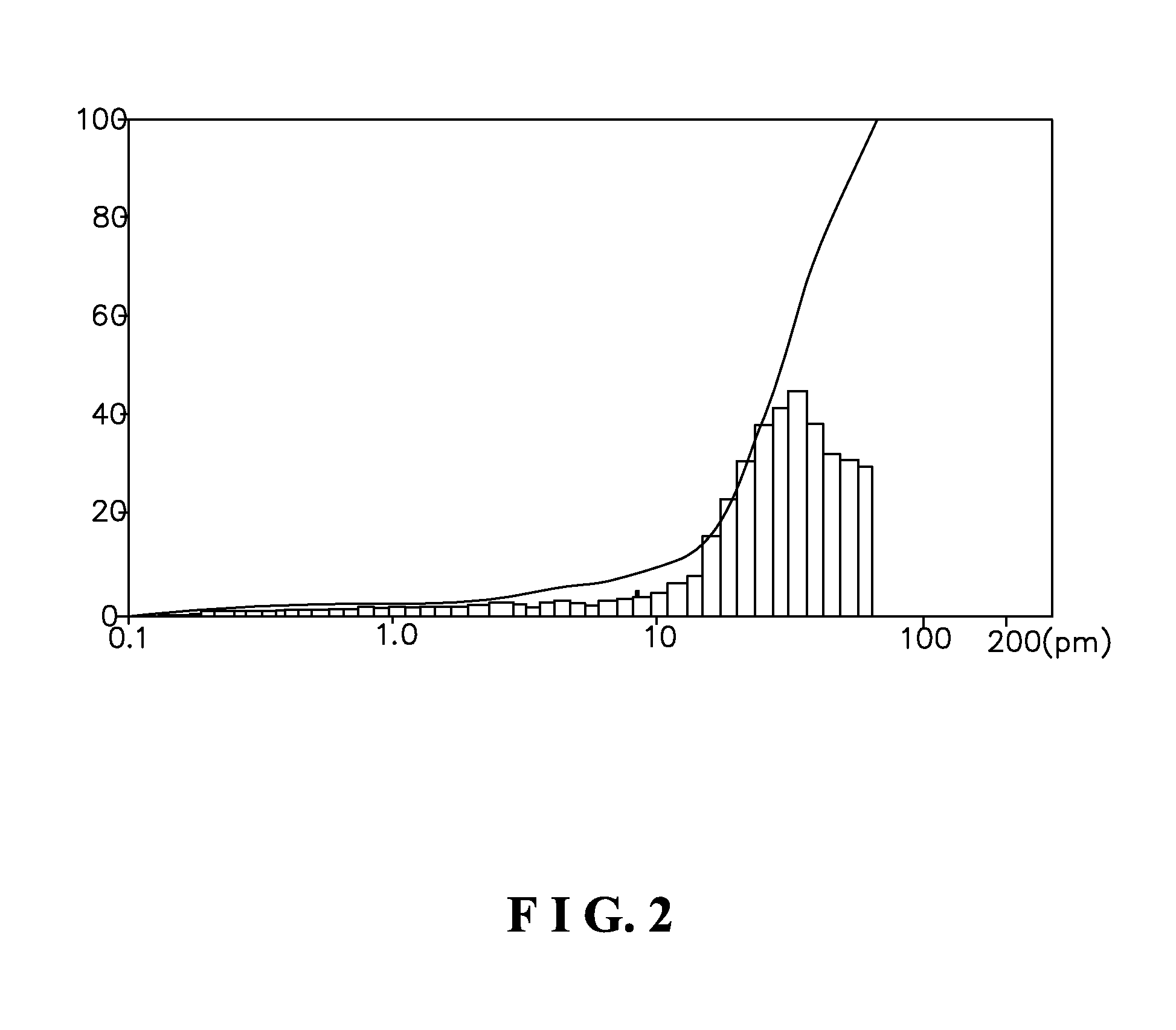

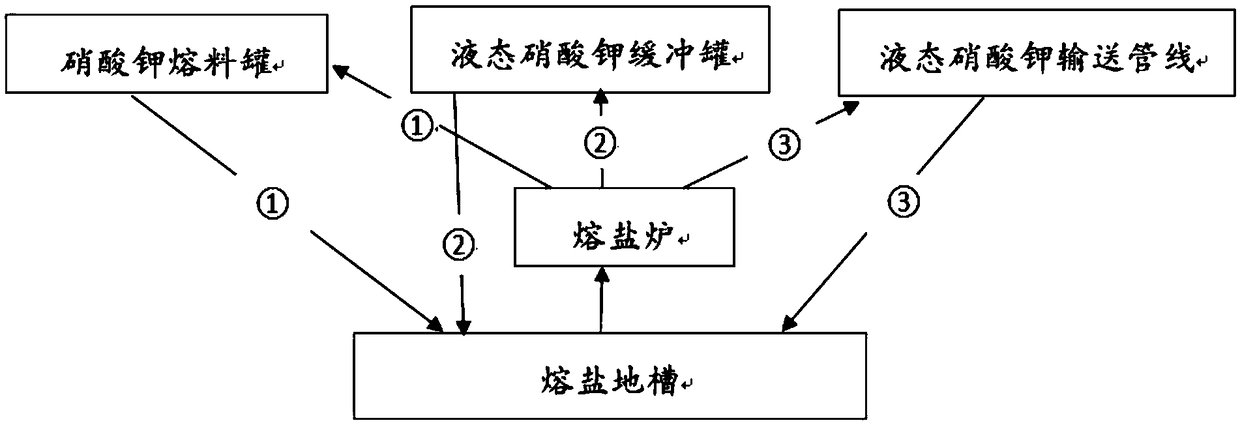

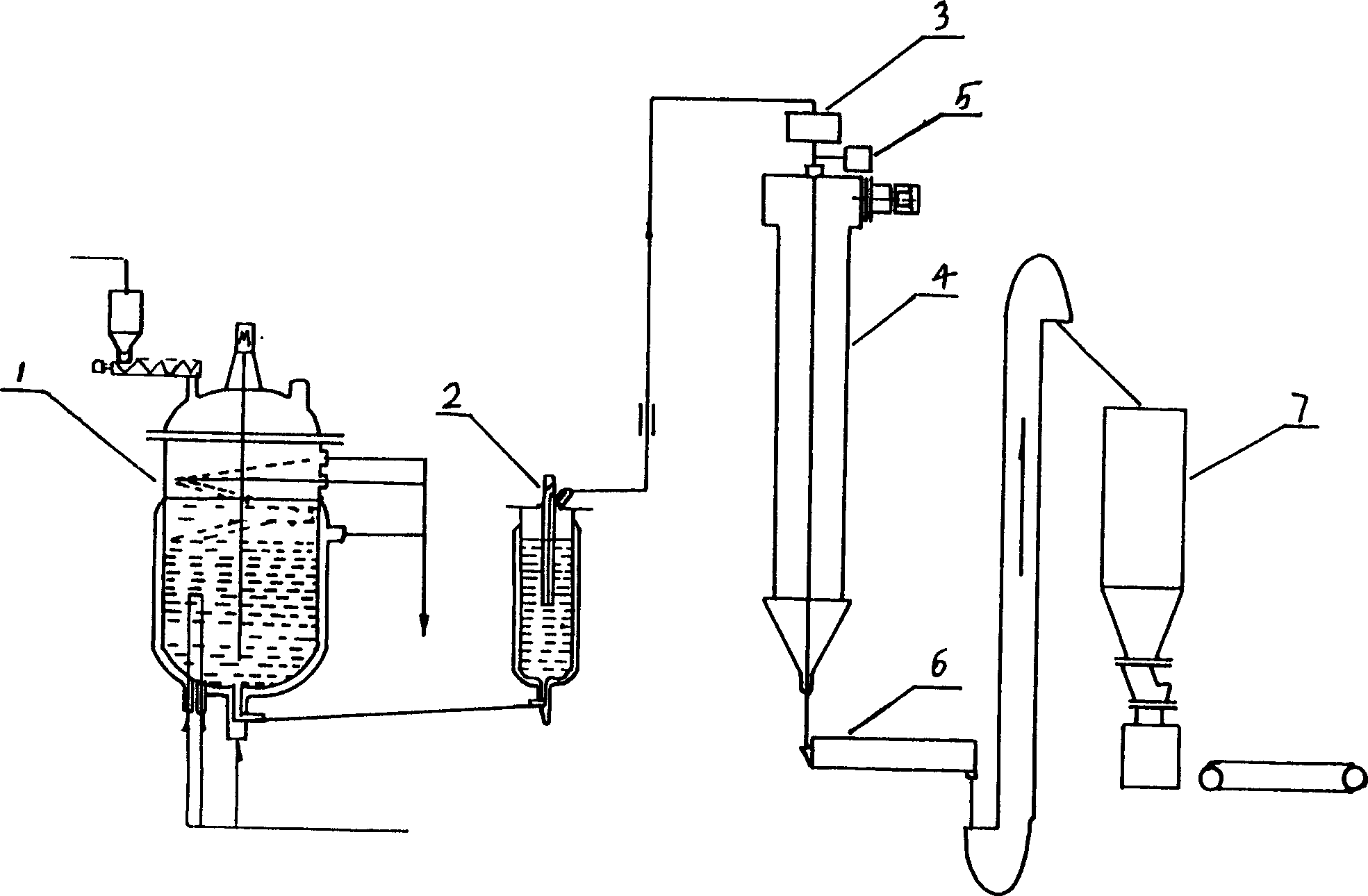

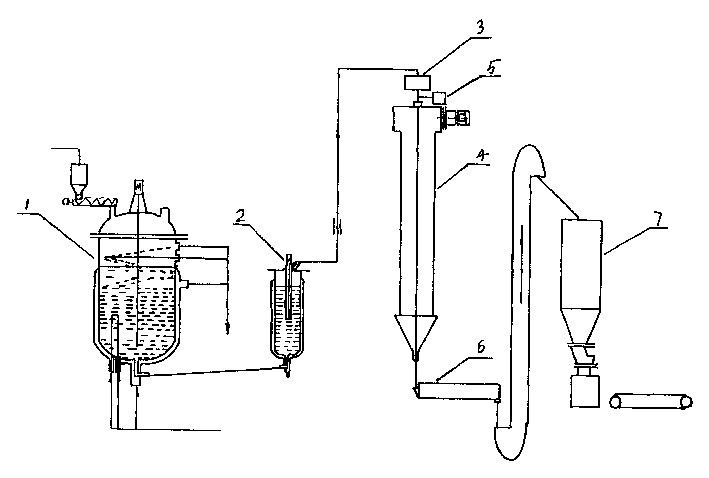

Method for pelleting spherical fine particle of sodium nitrate

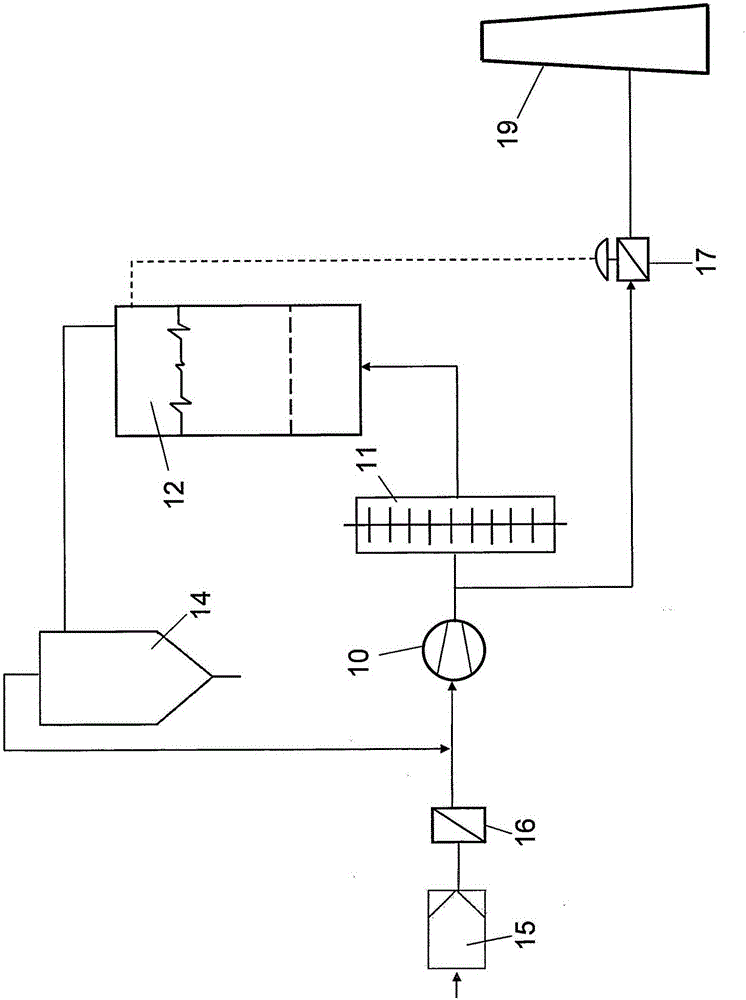

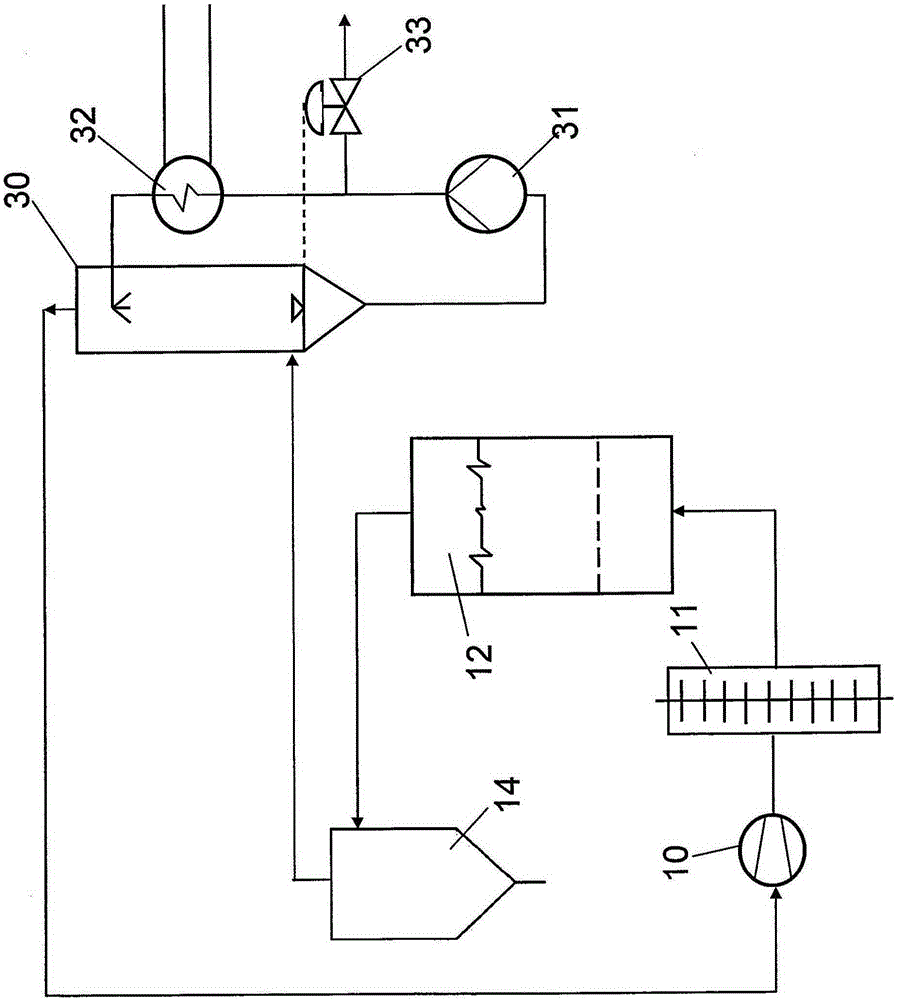

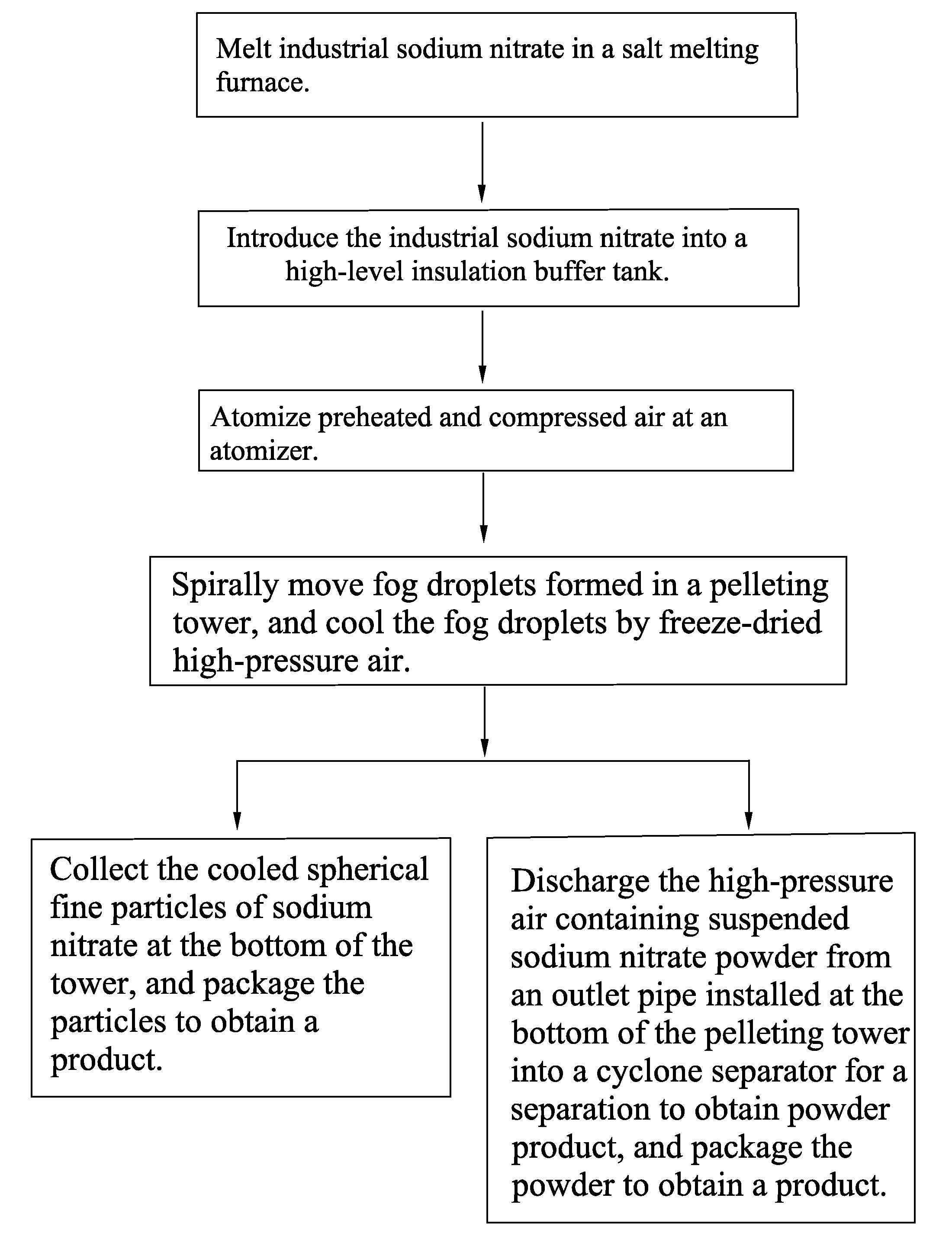

InactiveUS20120098151A1Reduce moistureImprove roundnessGranulation by liquid drop formationAlkali metal nitrate purificationPrillFreeze-drying

Provided is a method for pelleting spherical fine particle of sodium nitrate, which comprises the following steps: 1) melting industrial sodium nitrate in a salt melting furnace, introducing into a high-level insulation buffer tank, placing in an atomizer located on top of the pelleting tower, atomizing to obtain fog droplets with size of 30 μm-0.5 mm; 2) introducing freeze-dried high-pressure air into the pelleting tower in a tangent direction from the upper inlet pipe of the tower, so that the sodium nitrate fog droplets obtained in step 1) fall spirally along the wall in the pelleting tower, to obtain sodium nitrate particle; 3) collecting the cooled sodium nitrate particle at the bottom of the tower, and packaging. Sodium nitrate particle with lower water content, higher roundness, and smaller size can be obtained, and continuous production can be realized by the method.

Owner:DAI LIANGYU +1

Production method for co-producing high-purity magnesium hydroxide and high-purity potassium nitrate

InactiveCN109721082AHigh puritySave resourcesAlkali metal nitrate shape formationAmmonium halidesPotassium nitrateAmmonium chloride mixture

The invention discloses a production method for co-producing high-purity magnesium hydroxide and high-purity potassium nitrate. According to the present invention, high-purity magnesium hydroxide, high-purity potassium nitrate crystal and ammonium chloride crystal containing calcium, magnesium, potassium and other elements are prepared by using low-quality magnesium oxide or magnesium hydroxide asa raw material through acidolysis, alkali precipitation and other steps, wherein the by-products produced in the process are effectively utilized; and the whole production process is performed at a low temperature, no by-product is formed, and the method is efficient and environmentally friendly.

Owner:QINGHAI ENESOON NEW MATERIAL TECH & SCI CO LTD

Difference controllable potassium nitrate crystal synthesis method based on cold shock mode

PendingCN110817903ASave cost of explorationHigh crystallinityAlkali metal nitrate preparationAlkali metal nitrate shape formationPotassium nitratePhysical chemistry

The invention relates to a difference controllable potassium nitrate crystal synthesis method based on a cold shock mode, the difference controllable potassium nitrate crystal synthesis method is a potassium nitrate crystallization method based on temperature gradient intervention, potassium nitrate is used as a widely applied chemical raw material, and in order to obtain better crystal size, morphology and quality, the existing method is mainly improved from the aspects of crystallization process condition optimization and crystal growth kinetics. The improved methods require strict control of experimental conditions, are complex in principle and process, and are not beneficial to large-scale popularization. Therefore, a crystallization improvement method based on temperature gradient intervention is provided, solid-liquid separation is performed, and refined potassium nitrate crystals are prepared. The method is easy and fast to implement, and a good crystallization effect is obtained. Factory production can select suitable production conditions according to own needs.

Owner:QILU NORMAL UNIV

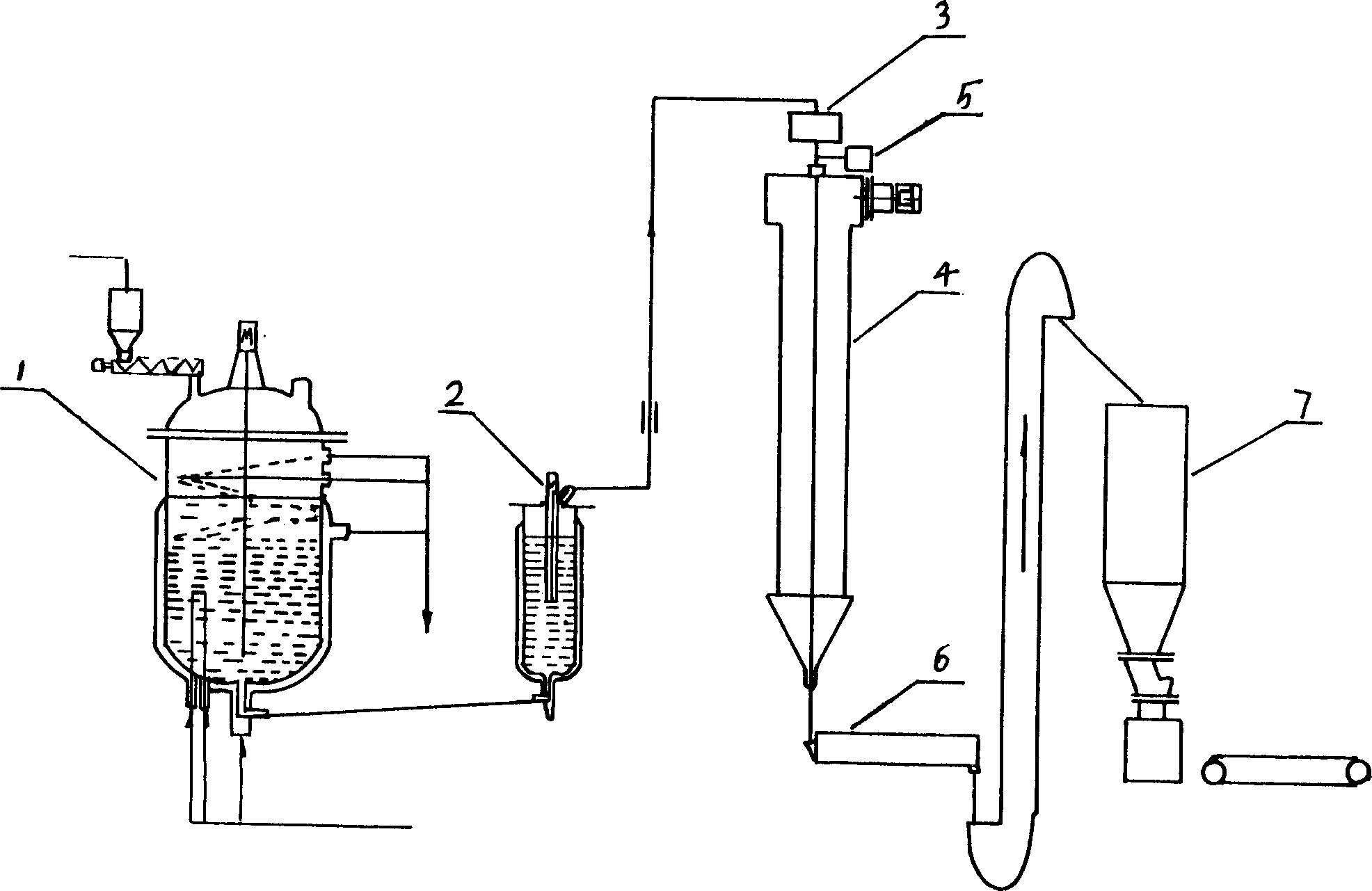

Recrystallization method for preparing small-particle nitrate

InactiveCN108946768AEasy to operateMild reaction conditionsSolution crystallizationCalcium/strontium/barium nitratesSolventSodium nitrate

The invention provides a recrystallization method for preparing small-particle nitrate, aiming at the problems that nitrate has a poor appearance, and has sharp edges and corners, relatively great granularity and the like. The recrystallization method comprises the following steps: 1) completely dissolving the nitrate into a solvent; filtering to obtain filtrate for later use, wherein the nitrateis one of sodium nitrate, potassium nitrate, cesium nitrate, barium nitrate, calcium nitrate and lithium nitrate, and the solvent is water; 2) injecting a counter solvent into a crystallization kettleand starting to stir, wherein the counter solvent is absolute ethyl alcohol or methanol or acetone and the volume of the counter solvent is 2 to 5 times as much as that of the solvent; 3) after dropwise adding the filtrate into the crystallization kettle, continually stirring to carry out crystallization; and 4) filtering, washing and drying a mixture in the crystallization kettle.

Owner:XI'AN INST OF OPTICS & FINE MECHANICS - CHINESE ACAD OF SCI

Granulation method of potassium nitrate and potassium nitrate particles prepared with method

InactiveCN109384251AHigh purityReduce moistureAlkali metal nitrate shape formationPotassium nitrateHigh volume manufacturing

The invention discloses a granulation method of potassium nitrate. The method comprises following steps: (1), preparation of powdery potassium nitrate; (2), heating of carriers; (3), fusing of solid potassium nitrate; (4), tower granulation of potassium nitrate; (5), cooling packaging. The granulation method of potassium nitrate particles is simple, easy to operate, high in stability, good in granulation molding effect, good in drying effect and suitable for continuous mass production; the potassium nitrate particles prepared with the method are uniform in size, high in potassium nitrate purity and low in moisture content.

Owner:QINGHAI SALT LAKE IND

Calcium nitrate and potassium nitrate fertiliser particles

ActiveUS20190389783A1Low viscosityShort setting timeCalcareous fertilisersMagnesium fertilisersPotassium nitrateViscosity

The present disclosure concerns fertilizer particles comprising calcium nitrate and potassium nitrate. It is found that fertilizer particles comprising 43 to 47% w / w calcium nitrate and 46 to 54% w / w potassium nitrate can be produced by melt granulation. Due to undercooling problems, such particles were not expected to be suitable for industrial production by melt granulation. However, the present disclosure provides a composition which forms a low viscosity melt with short solidification time. This was successfully achieved by reducing the water content of a fertilizer melt comprising 43 to 47% w / w calcium nitrate and 46 to 54% w / w potassium nitrate to less than 3% w / w of the melt.

Owner:YARA INT ASA

A Cooling Crystallization Method for Membrane Assisted Nucleation

ActiveCN107233744BThe size is easy to controlNarrow particle size distributionCobalt sulfatesSolution crystallizationTemperature controlPeristaltic pump

The invention provides a membrane-assisted nucleation cooling crystallization method, and belongs to the technical field of crystallization engineering. Solution to be crystallized is added into a crystallizing kettle, a computer and a stirring and temperature control device is started, and a cooling liquid loop is started. After a system is stabilized, a peristaltic pump is started, and the solution to be crystallized is conveyed to a membrane component. When crystal nucleuses appear in the membrane component, mother solution with the crystal nucleuses is conveyed to the crystallizing kettle and subjected to crystal growth. By controlling cooling liquid and operation conditions, generation of the crystal nucleuses and crystal growth are systematically regulated, so that an ideal crystal product is obtained.

Owner:DALIAN UNIV OF TECH

Industrial sodium nitrate new product and its preparation method

InactiveCN1400165AReduce moisture contentReduce contact areaGranulation by liquid drop formationAlkali metal nitrate shape formationState of artSodium nitrate

The present invention discloses an industrial sodium nitrate product and its production method. The physical and chemical properties of said product are: it is spherical or egg-shaped granule, grain size is 0.5-3 mm, and its water content is less than or equal to 0.5%. Its production method is as follows: using industrial sodium nitrate in the existent technology as raw material, heating and melting the above-mentioned raw material to obtain liquid phase material, and spray-granulating said liquid phase so as to obtain the invented product. Said invented product features low water content, nocaking and good fluidity.

Owner:TIANJIN UNIV +1

Nitrate system molten salt heat conduction material and preparation method thereof

InactiveCN109835923AGood industrial valueEasy to controlAlkali metal nitrate preparationAlkali metal nitrate shape formationNitrateMolten salt

The invention discloses a nitrate system molten salt heat conduction material and a preparation method thereof. The method comprises the following steps: S1, neutralizing: neutralizing a sodium sulfate solution and a nitric acid solution to form a first sodium nitrate raw material solution having a pH value of 3.5-4.5 and a mass percentage concentration of 23-28%; S2, removing carbon oxides: removing the carbon oxides in the first sodium nitrate raw material solution to form a second sodium nitrate raw material solution; S3, evaporating: carrying out evaporative concentration on the second sodium nitrate raw material solution to obtain a third sodium nitrate raw material solution having a mass percentage concentration of 63-67%; S4, crystallizing and dehydrating: crystallizing and dehydrating the third sodium nitrate raw material solution to obtain a solid sodium nitrate raw material; and S5, drying: drying the solid sodium nitrate raw material to obtain the final product molten salt grade sodium nitrate. The method allows the high-purity molten salt grade sodium nitrate to be directly produced, and has the advantages of simplicity, easiness in control, realization of automatic production, and suitableness for safe, continuous, stable and rapid production of high-purity sodium nitrate.

Owner:张珍华

Extraction agent for preparing potassium nitrate with nitric acid-potassium chloride extraction method

InactiveCN107840354AEffectively removedReduce lossChlorine/hydrogen-chloride purificationAlkali metal nitrate preparationN-Butyl AlcoholHigh selectivity

The invention discloses an extraction agent for preparing potassium nitrate with a nitric acid-potassium chloride extraction method. The extraction agent is prepared from isoamyl alcohol, n-butyl alcohol, tri-n-octylaminetri-octyl tertiary amine, n-caprylic alcohol according to a volume ratio of 1 to (0.1 to 0.5) to (3 to 10) to (1.3 to 3). The extractant provided by the invention has a good extraction effect and high selectivity for hydrochloric acid in a nitric acid-potassium chloride reaction system, the hydrochloric acid can be extracted without while not extracting nitric acid, the nitricacid serving as a raw material is saved, the purity of the nitric acid serving as a by-product is improved; the nitric acid prepared by back extraction can be directly taken as a product for selling.

Owner:安徽胜达化工科技有限公司

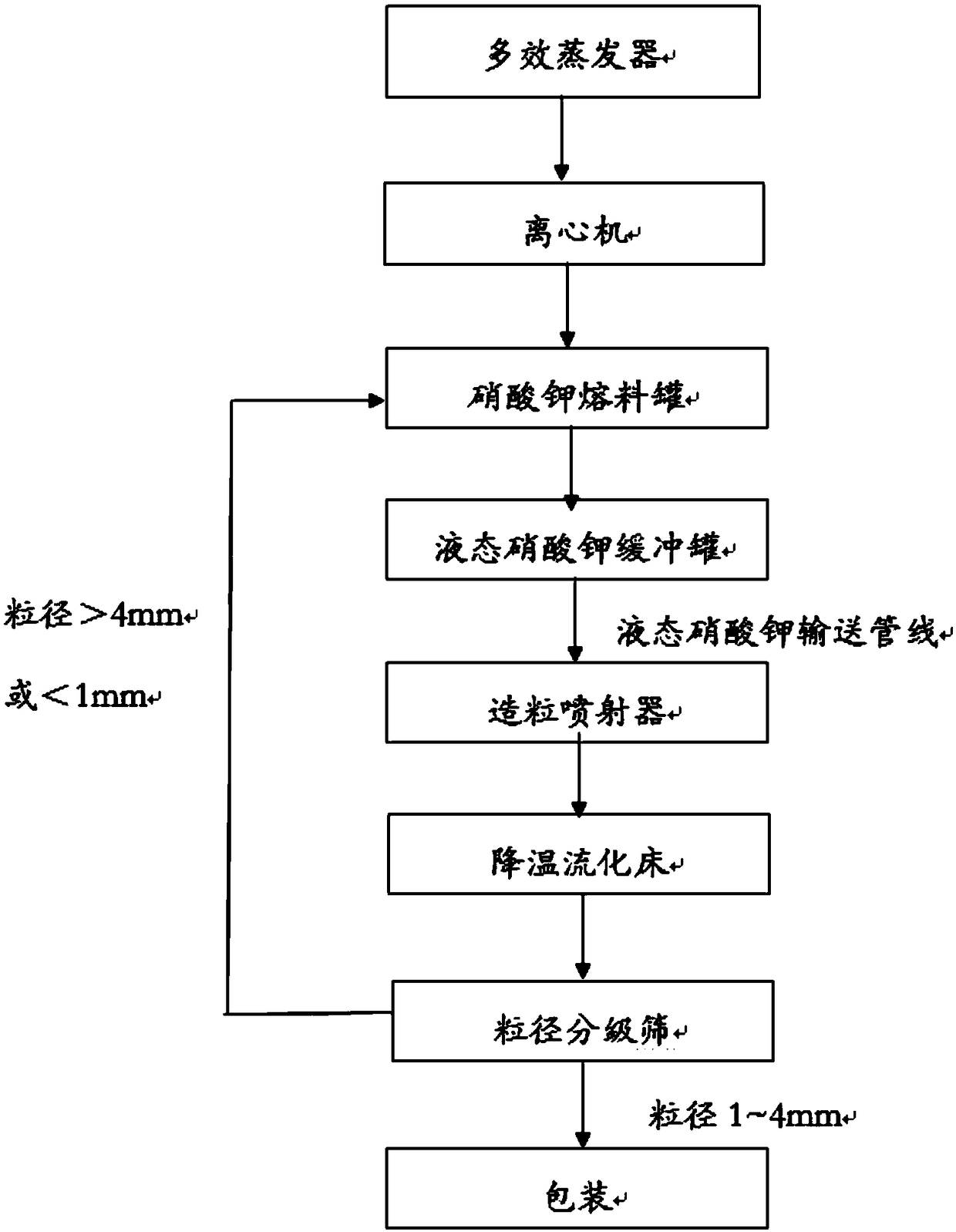

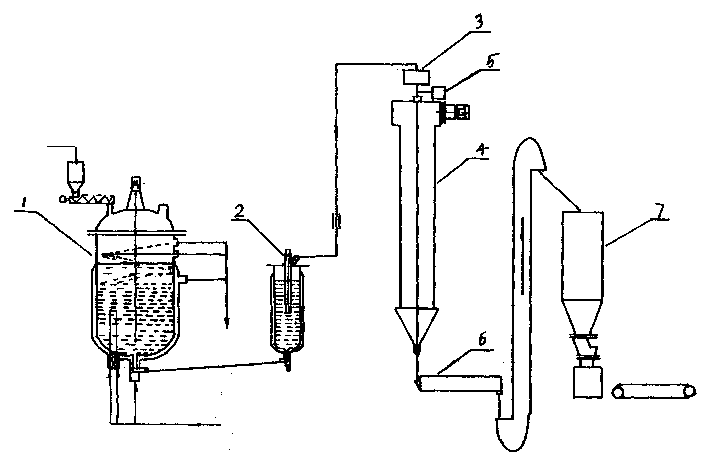

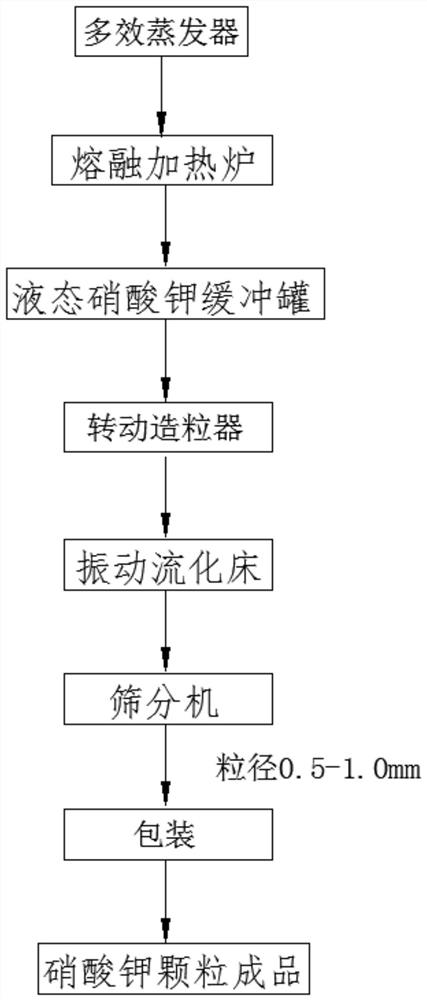

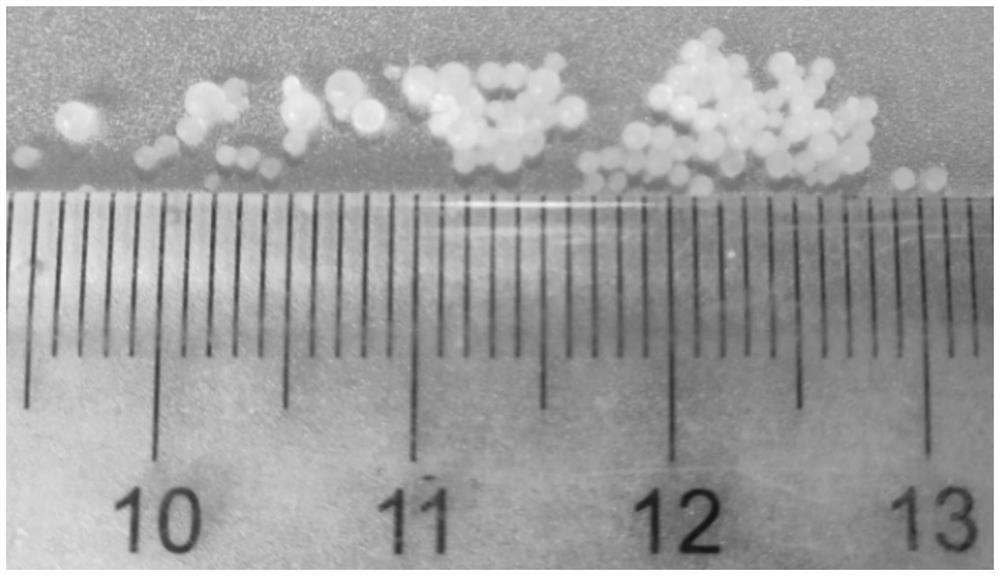

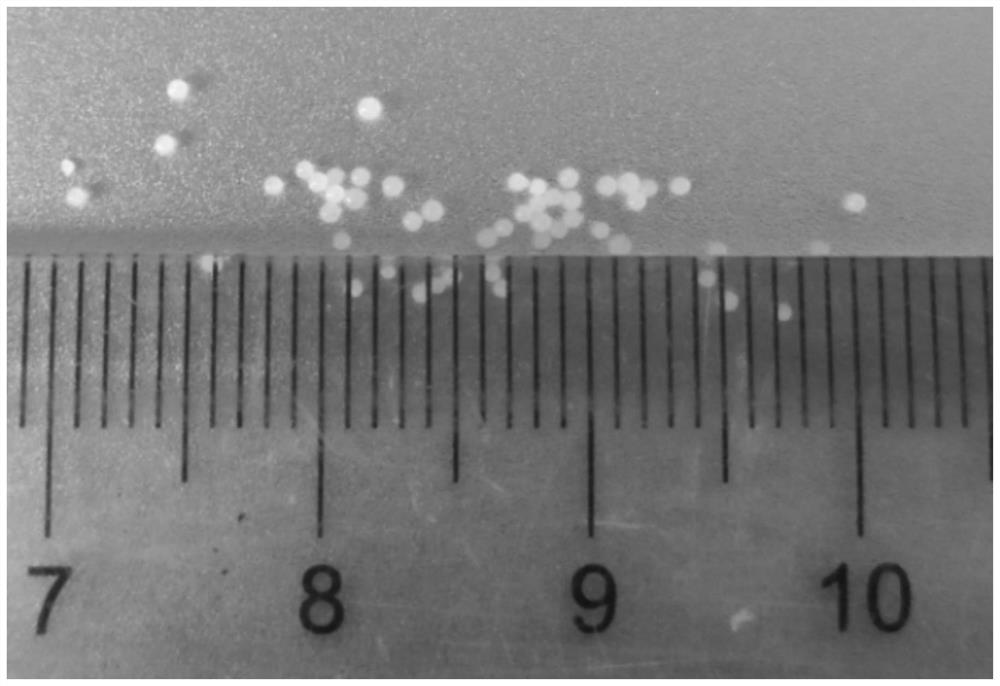

Potassium nitrate low-tower granulation method and potassium nitrate particles prepared thereby

ActiveCN112645359AAvoid breakingSimple processChemical industryAlkali metal nitrate shape formationPotassium nitrateFluidized bed

The invention belongs to the technical field of potassium nitrate manufacturing, and provides a potassium nitrate low-tower granulation method and potassium nitrate particles prepared thereby. The potassium nitrate low-tower granulation method comprises the following steps of: putting powdery potassium nitrate into a melting heating furnace for heating and melting, continuously stirring until the raw materials are completely melted to obtain liquid potassium nitrate, sending the liquid potassium nitrate into a rotary granulator at the upper part of a granulation tower, enabling the liquid potassium nitrate to uniformly disperse and fall under the action of a granulation head of the rotary granulator to form spherical potassium nitrate particles, cooling the spherical potassium nitrate particles through a vibrated fluidized bed, screening, and packaging to obtain finished potassium nitrate particles. The granulation method provided by the invention is simple in process and low in energy consumption, and the prepared finished potassium nitrate particles are less broken, uniform and round, free of material returning, almost zero in empty shell rate, good in product flowability, high in pressure resistance, long in caking period, beneficial to storage and transportation and convenient to use.

Owner:四川省什邡市农科化工有限公司

A kind of preparation method of salt nanoparticles

ActiveCN109231241BSimple stepsLow costMaterial nanotechnologyAlkali metal nitrate shape formationInorganic saltsNanoparticle

Owner:SHANGHAI INST OF APPLIED PHYSICS - CHINESE ACAD OF SCI

Preparation method of sodium nitrate

InactiveCN109835925AAlkali orthophosphate fertiliserAmmonium orthophosphate fertilisersDecompositionSlurry

The invention discloses a preparation method of sodium nitrate. The method comprises the following steps: (1) double decomposition: mixing calcium nitrate with a gypsum filter residue washing liquid in the subsequent procedure and a returned sodium nitrate mother liquor, stirring and adding sodium sulfate to carry out double decomposition, filtering out generated dihydrate gypsum, washing with clear water, and returning washing liquor; and leaving the generated sodium nitrate in the filtrate; (2) purification for removal of calcium: neutralizing by adding stone flour and soda ash into the filtrate in the last step, heating to boiling, filtering, filtering out calcium carbonate, and drying to prepare fertilizer-grade dicalcium phosphate; and (3) evaporative crystallization separation: concentrating by sending the neutralized filtrate in the last step into a double-effect evaporator, and cooling for crystallization to obtain sodium nitrate crystal slurry: adding the sodium nitrate crystal slurry into a centrifugal separator, and separating to obtain a sodium nitrate product. The method can be adopted to convert waste residue calcium nitrate discharged from nitrophosphate fertilizer equipment by a freezing method into the sodium nitrate product, and has good economic benefit and environmental protection effect.

Owner:安建春

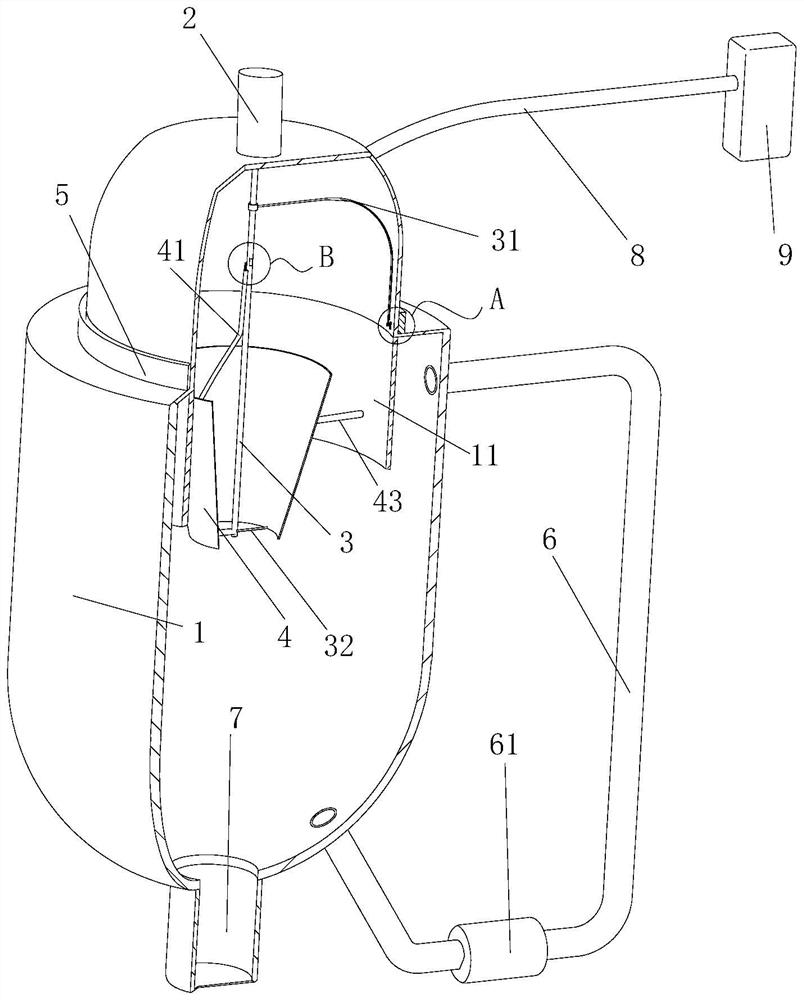

Preparation equipment and preparation method of sodium nitrate

PendingCN114733226AAvoid yield lossExtended working hoursProductsReagentsPhysical chemistryEngineering

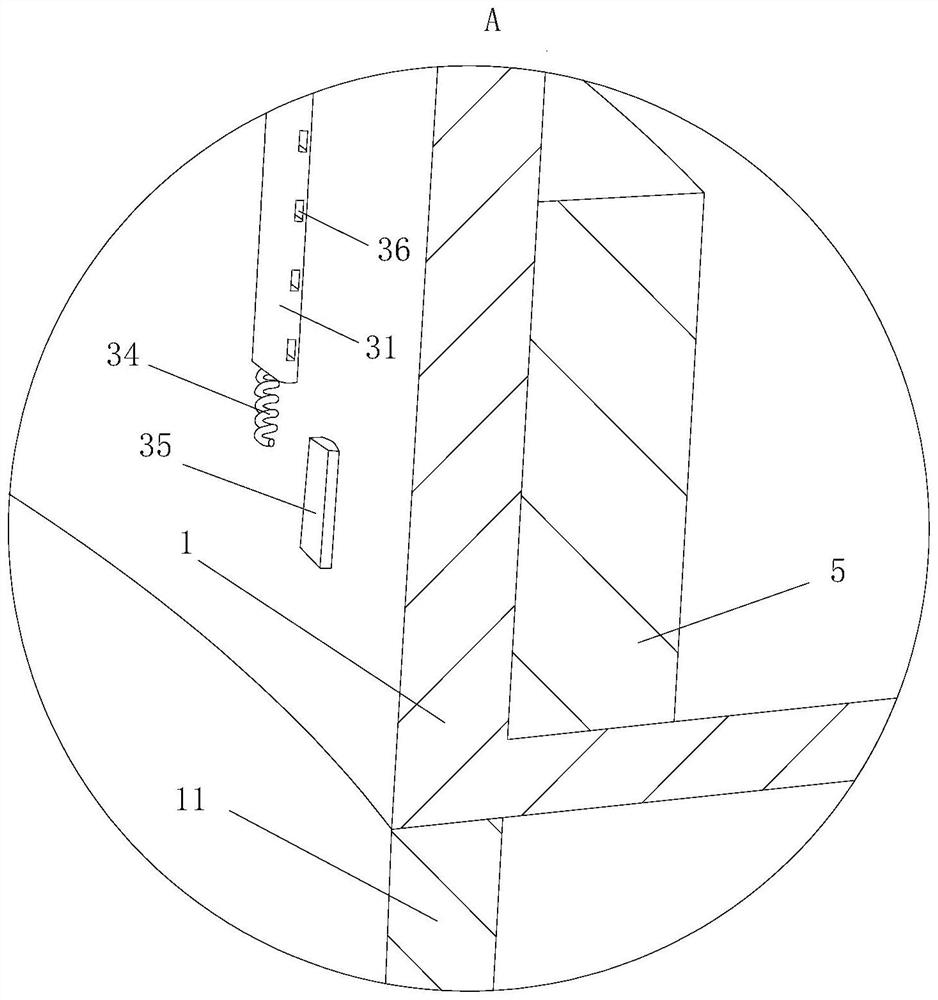

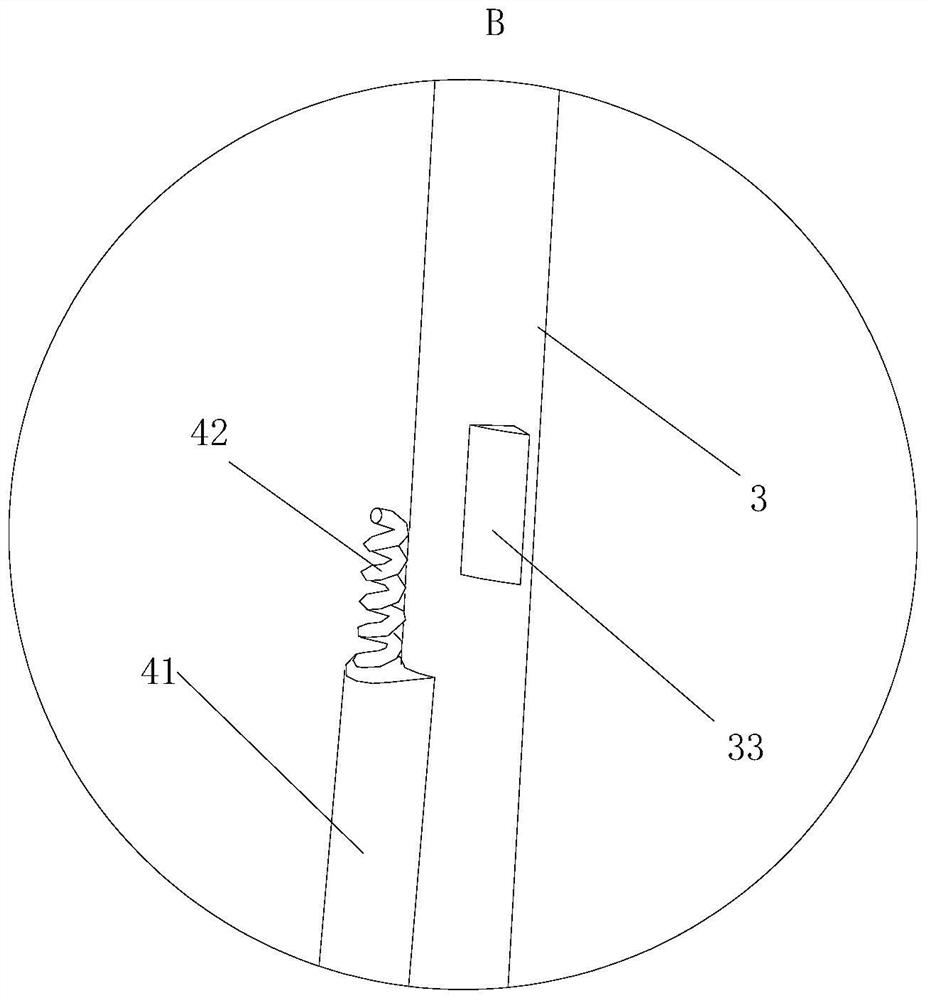

The invention belongs to the technical field of chemical engineering, and particularly relates to a sodium nitrate preparation device and method.The sodium nitrate preparation device comprises a crystallizer, a device body, a guide cylinder and a stirring shaft, a first scraping plate and a second scraping plate are installed on the stirring shaft and the guide cylinder, and crystal scars generated on the inner surface of the crystallizer and the surface of the stirring shaft are removed; re-dissolving and crystallizing in the mother liquor; a spring is mounted on the second scraping plate, the second scraping plate is driven to vibrate under the action of a convex block on the stirring shaft, and crystal scars attached to the second scraping plate are removed; the device is simple in structure, effectively removes crystal scars on the stirring shaft and the inner wall of the crystallizer, and re-dissolves and crystallizes the crystal scars in mother liquor, so that yield reduction caused by the crystal scars on the inner wall of the crystallizer is avoided, meanwhile, the cleaning time of the inner wall of the crystallizer is shortened, and the working time and yield of the crystallizer are increased.

Owner:鲁贞满

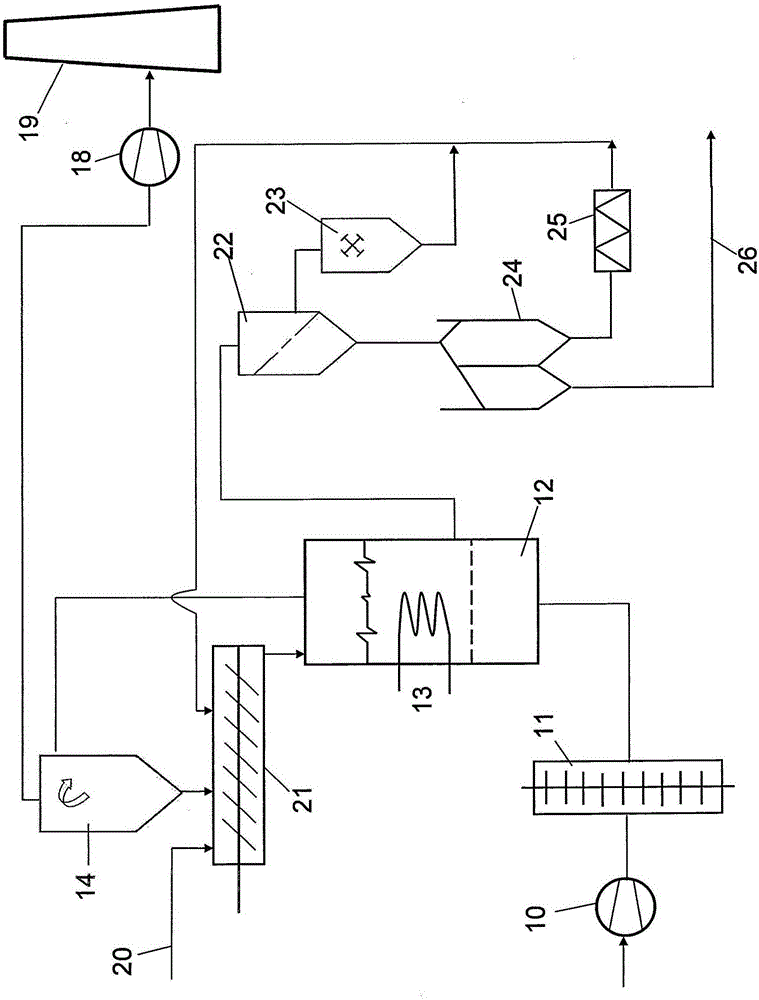

A system and method for the reduction and recycling of landfill leachate membrane concentrate

InactiveCN110818000BImprove economyPromote environmental protectionAlkali metal sulfites/sulfates preparation formChlorine/hydrogen-chlorideResource recoveryEnvironmental engineering

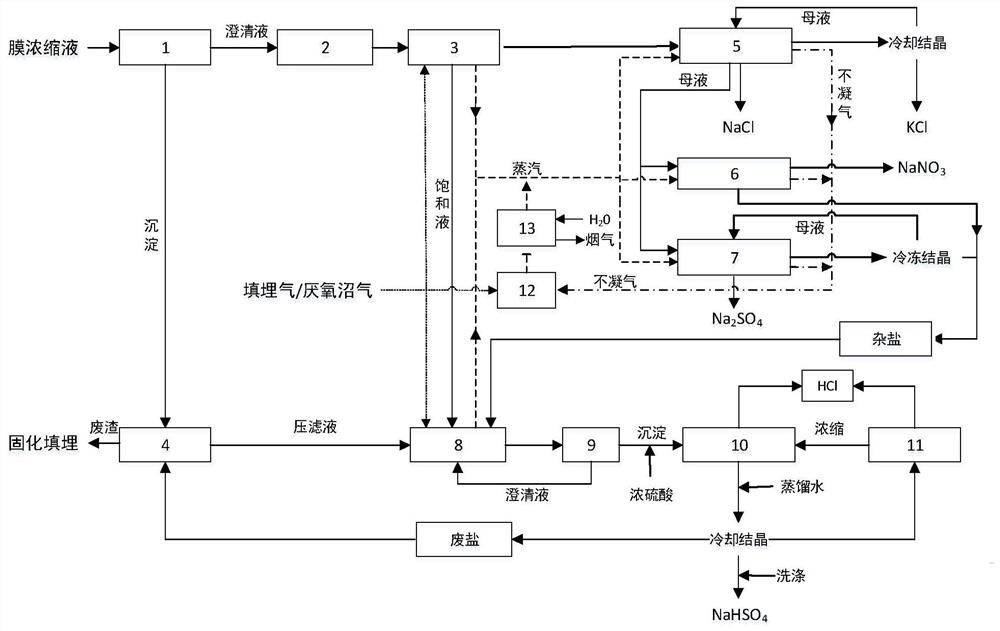

The invention discloses a landfill leachate film concentrate reduction and resource recovery treatment system and method. The treatment system includes a submerged combustion evaporation device, an industrial salt production device, a miscellaneous salt resource recovery device, and a waste residue processing device; The extraction device includes a forced circulation evaporation crystallizer for producing industrial salt KCl and NaCl with saturated membrane concentrate, and an industrial salt NaNO with the mother liquor from the forced circulation evaporation crystallizer. 3 、Na 2 SO 4 The flash cooling crystallizer and sodium sulfate evaporator, the miscellaneous salt resource recovery device includes a reaction kettle, and concentrated sulfuric acid is added to the reaction kettle, and the miscellaneous salt produced after the production of industrial salt enters the reaction kettle to react to produce NaHSO 4 , HCl, and the reacted waste salt enters the waste residue treatment device to be solidified and landfilled. The treatment system realizes the separation of industrial salt while immersing, burning, evaporating and reducing the membrane concentrate, reduces the circulation of salt in the environment and makes it a resource, and further improves the economy and environmental protection of landfill leachate membrane concentrate treatment. .

Owner:SOUTHEAST UNIV +1

Method for improving the hardness of granular sodium nitrate

ActiveCN104591230BHigh hardnessReduce moisture contentAlkali metal nitrate shape formationNitrate fertilisersMelting tankEvaporation

The invention relates to a method of improving the hardness of granular sodium nitrate. According to the method, a waste salt is added by using a hopper and a screw conveyer in the process of conveying the wet sodium nitrate which is obtained by crystallizing through evaporation to a melting tank, wherein the waste salt contains 60-90% by weight of sodium chloride or 10-40% by weight of sodium sulfate. Due to the addition of 0.01-2.5% of the waste salt which contains sodium chloride or sodium sulfate, the hardness of the granular sodium nitrate can be up to 2-4kgf, and the granular sodium nitrate with a size of 2-4mm accounts for more than 96%. Due to the added waste salt which is rich in sodium chloride, the hardness of the granular sodium nitrate can be improved. By adopting the method provided by the invention, the granular sodium nitrate which has a lower content of water, higher roundness and more uniform size than the existing granules can be obtained. In addition, the method can realize continuous production, consumes less energy, is high in efficiency and low in cost and can be particularly applied to the field of tower-based chemical granulation.

Owner:TURPAN BRANCH OF SINKIANG NITRATE MINERALS

High-purity potassium nitrate tablet and preparation method thereof

PendingCN113120929ASimple processEasy to operateAlkali metal nitrate shape formationCrystallographyPotassium nitrate

The invention discloses a high-purity potassium nitrate tablet which is formed by extruding potassium nitrate crystal particles with the mesh number of 25-150 and the purity of 99.7% or above. The thickness of the high-purity potassium nitrate tablet is 3-15 mm, and the diameter of the high-purity potassium nitrate tablet is 5-15 mm. A layer of anti-blocking agent film is arranged on the surface of the high-purity potassium nitrate tablet, or a layer of anti-blocking agent film is arranged on the surface of the potassium nitrate crystal particles forming the high-purity potassium nitrate tablet. The invention relates to a preparation method of the high-purity potassium nitrate tablet, which comprises the following steps: screening high-purity potassium nitrate crystals with the purity of more than 99.7%, selecting crystal particles with the particle size of 25-150 meshes, and tabletting, or uniformly spraying an anti-blocking agent on the high-purity potassium nitrate crystals before tabletting, or coating the surface of the high-purity potassium nitrate tablet with the anti-blocking agent after tabletting. The high-purity potassium nitrate tablet has the advantages that the high-purity potassium nitrate tablet is difficult to cake and more convenient to store, transport and use.

Owner:长沙鑫本助剂有限公司

Method for manufacturing granulated sodium nitrite

InactiveCN1182024CReduce moisture contentImprove liquidityGranulation by liquid drop formationAlkali metal nitrate shape formationSodium nitrite productWater content

The present invention discloses an industrial sodium nitrite product and its production method. The physical and chemical properties of said product are as follows: it is made into the form of ball or egg granular body, grain size is 0.5-3 mm, and the water content of the described granule body is less than or equal to 0.5%. Its production method uses the existent industrial sodium nitrite product as raw material, the above-mentioned raw material is heated and moten into liquid phase, and said liquid phase is sprayed and granulated so as to obtain the invented product. Said product features low water content, no blocking and good fluidity.

Owner:TIANJIN UNIV +1

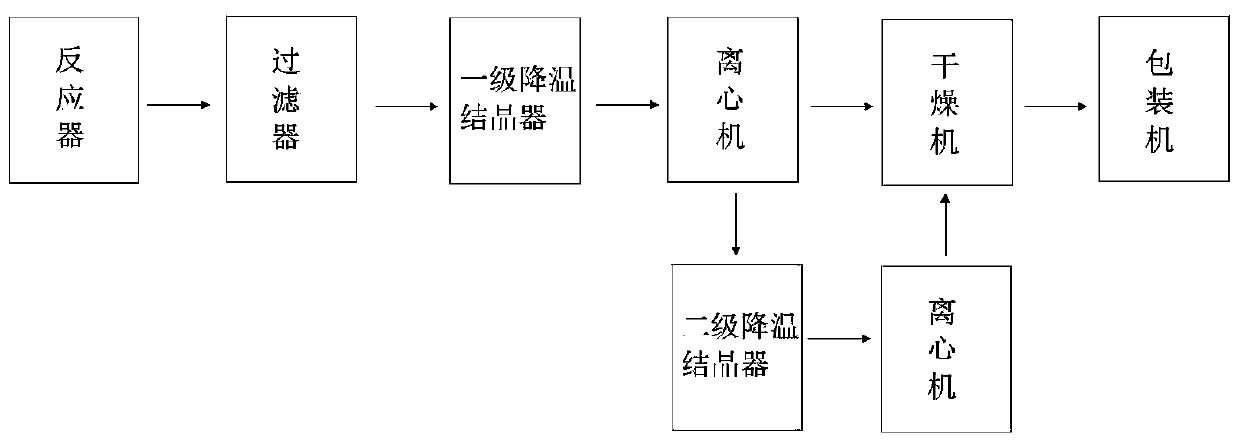

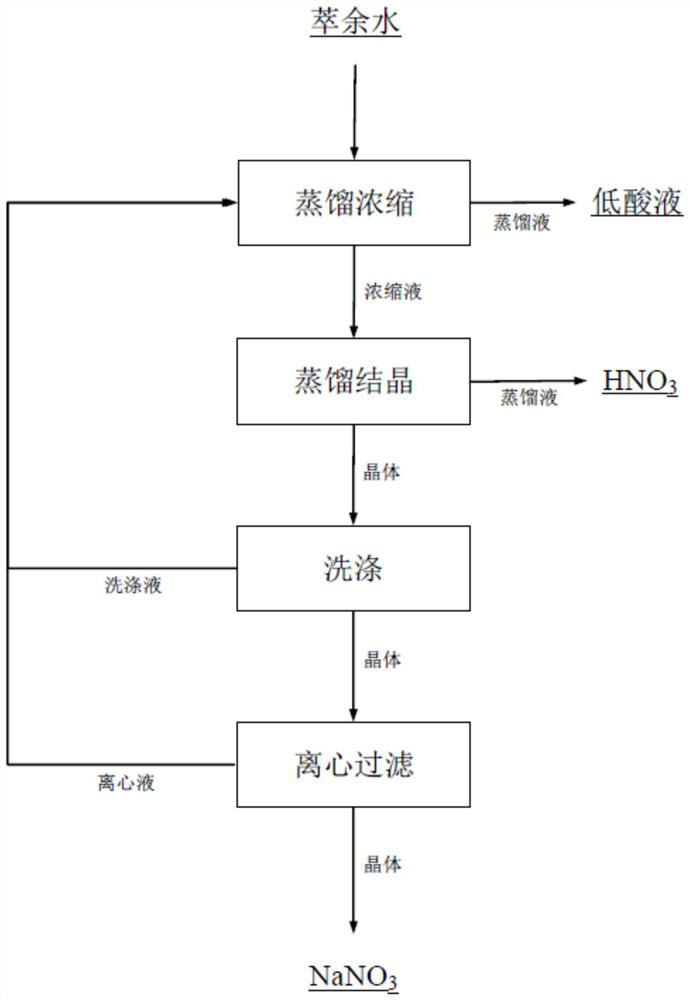

Method for producing nitric acid and sodium nitrate by using nuclear-grade hafnium oxide production discharged wastewater

PendingCN114275748AAchieve friendlyFully utilized resourcesAlkali metal nitrate purificationAlkali metal nitrate shape formationDistillationEngineering

The invention belongs to the technical field of radioactive waste utilization, and particularly relates to a method for producing nitric acid and sodium nitrate by using nuclear-grade hafnium oxide production discharged wastewater. The raffinate generated after extraction and enrichment of hafnium in the production process of nuclear-grade hafnium dioxide is used as feed liquid for producing nitric acid and sodium nitrate. Feeding the material liquid into a double-effect evaporation crystallizer for reduced pressure distillation, feeding the material liquid into a first-effect evaporator for distillation and concentration, feeding the concentrated liquid into a second-effect evaporator for distillation and crystallization, collecting second-effect distillate to obtain a nitric acid product, and filtering crystal mush by a centrifugal machine to obtain a sodium nitrate product. The method is simple in technological process, full in resource utilization and low in cost, the recovery rate of nitric acid in the raffinate can reach 80% or above, the recovery rate of sodium nitrate can reach 95% or above, the reduction amount of waste liquid is 90% or above, environment friendliness is achieved, and obvious social benefits and economic benefits are achieved.

Owner:中核二七二铀业有限责任公司

Process for producing salts with reduced water of crystallization content

ActiveCN105190211BMoisture adjustmentDrying solid materials with heatCalcium/strontium/barium chloridesPolymer scienceMoisture

The invention relates to a method for drying salts containing crystallization water in a convection device, which can additionally also be heated indirectly. The method is particularly characterized in that the drying takes place above a defined moisture content of the drying gas. The gas surrounding the salt particles during drying has a specific humidity. As a result, the drying speed is favorably influenced.

Owner:ANDRITZ TECH & ASSET MANAGEMENT

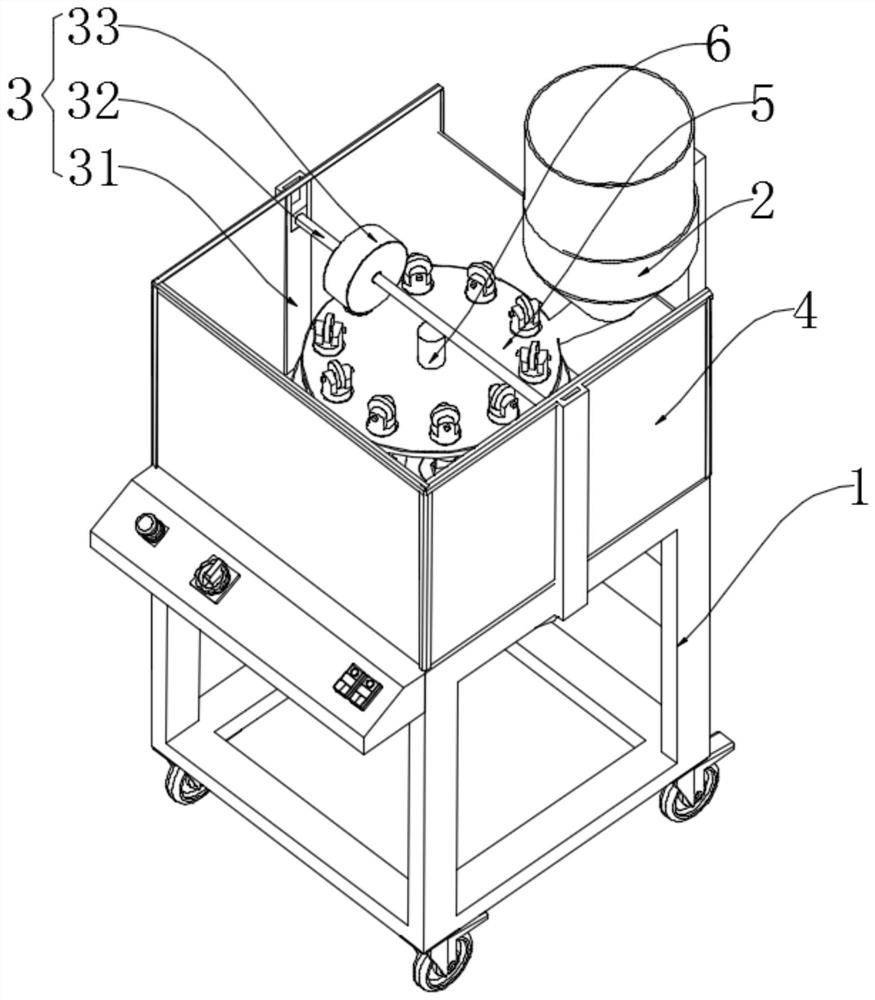

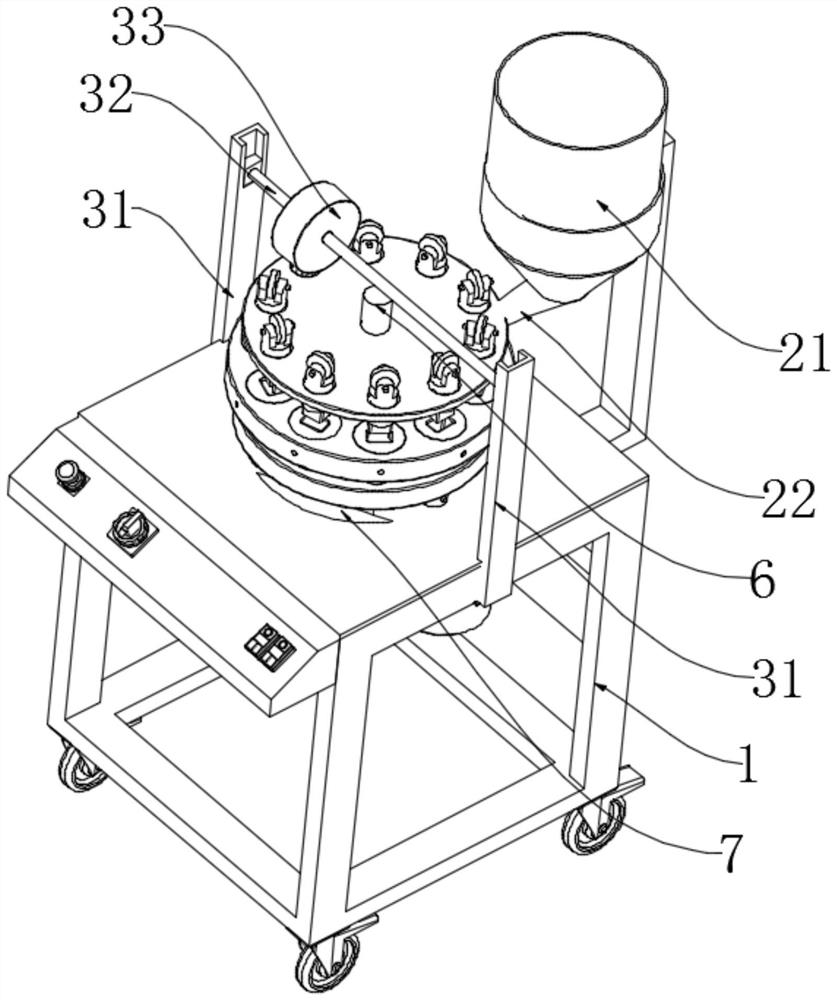

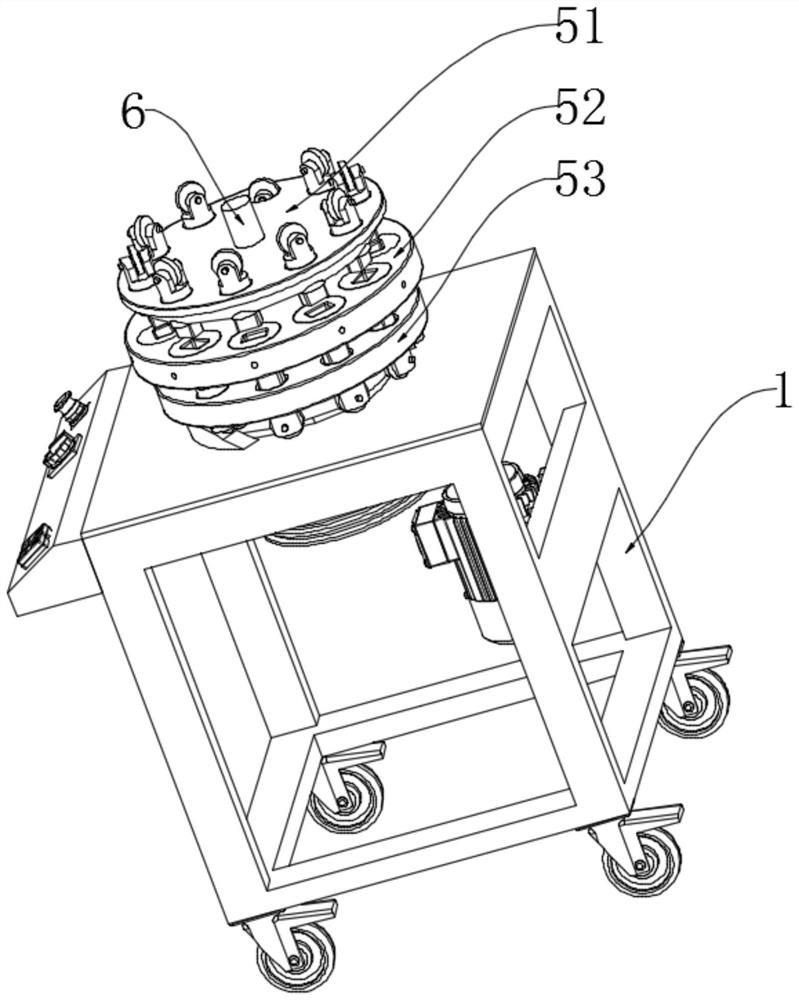

Potassium nitrate tablets and production equipment and production process thereof

PendingCN112645360ASolid particlesUniform sizeAlkali metal nitrate shape formationShaping pressPotassium nitratePhysical chemistry

The invention relates to a potassium nitrate slice and production equipment and a production process thereof, wherein a potassium nitrate slice body is of a circular flaky or spherical particle structure and comprises a slice making assembly (5), the slice making assembly (5) comprises a punch die (54), the punch die (54) is provided with a die hole (541), the die hole (541) is replaceable, the die hole (541) is circular, and the diameter of the die hole (541) is 2 mm-2 cm. The potassium nitrate tablet and the production equipment and the production process thereof are simple to operate and low in production cost, and the produced granular potassium nitrate is uniform in size, firm in granules, not easy to break and free of caking.

Owner:浙江联大化工股份有限公司

Method for producing salts with a reduced water of crystallisation content

ActiveCN105190211AMoisture adjustmentDrying solid materials with heatCalcium/strontium/barium chloridesProduct gasMoisture

The invention relates to a method for drying salts with a water of crystallisation content in convective apparatuses that can additionally be indirectly heated. The invention is primarily characterised in that the drying process takes place with a moisture content of the drying gas above a determined level. The gas surrounding the salt particles during the drying process therefore has a specific humidity. In this way, the rate of drying is positively influenced.

Owner:ANDRITZ TECH & ASSET MANAGEMENT

Method for pelleting spherical fine particle of sodium nitrate

InactiveUS8465680B2Reduce moistureImprove roundnessBiocideAlkali metal nitrate purificationPrillFreeze-drying

Provided is a method for pelleting spherical fine particle of sodium nitrate, which comprises the following steps: 1) melting industrial sodium nitrate in a salt melting furnace, introducing into a high-level insulation buffer tank, placing in an atomizer located on top of the pelleting tower, atomizing to obtain fog droplets with size of 30 μm-0.5 mm; 2) introducing freeze-dried high-pressure air into the pelleting tower in a tangent direction from the upper inlet pipe of the tower, so that the sodium nitrate fog droplets obtained in step 1) fall spirally along the wall in the pelleting tower, to obtain sodium nitrate particle; 3) collecting the cooled sodium nitrate particle at the bottom of the tower, and packaging. Sodium nitrate particle with lower water content, higher roundness, and smaller size can be obtained, and continuous production can be realized by the method.

Owner:DAI LIANGYU +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com