Granulation method of potassium nitrate and potassium nitrate particles prepared with method

A potassium nitrate and granulation technology, applied in the field of potassium nitrate granules, can solve the problems of easy failure of granulation equipment, complicated granulation process, difficult repair, etc., and achieves good granulation and forming effect, simple process and good drying effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

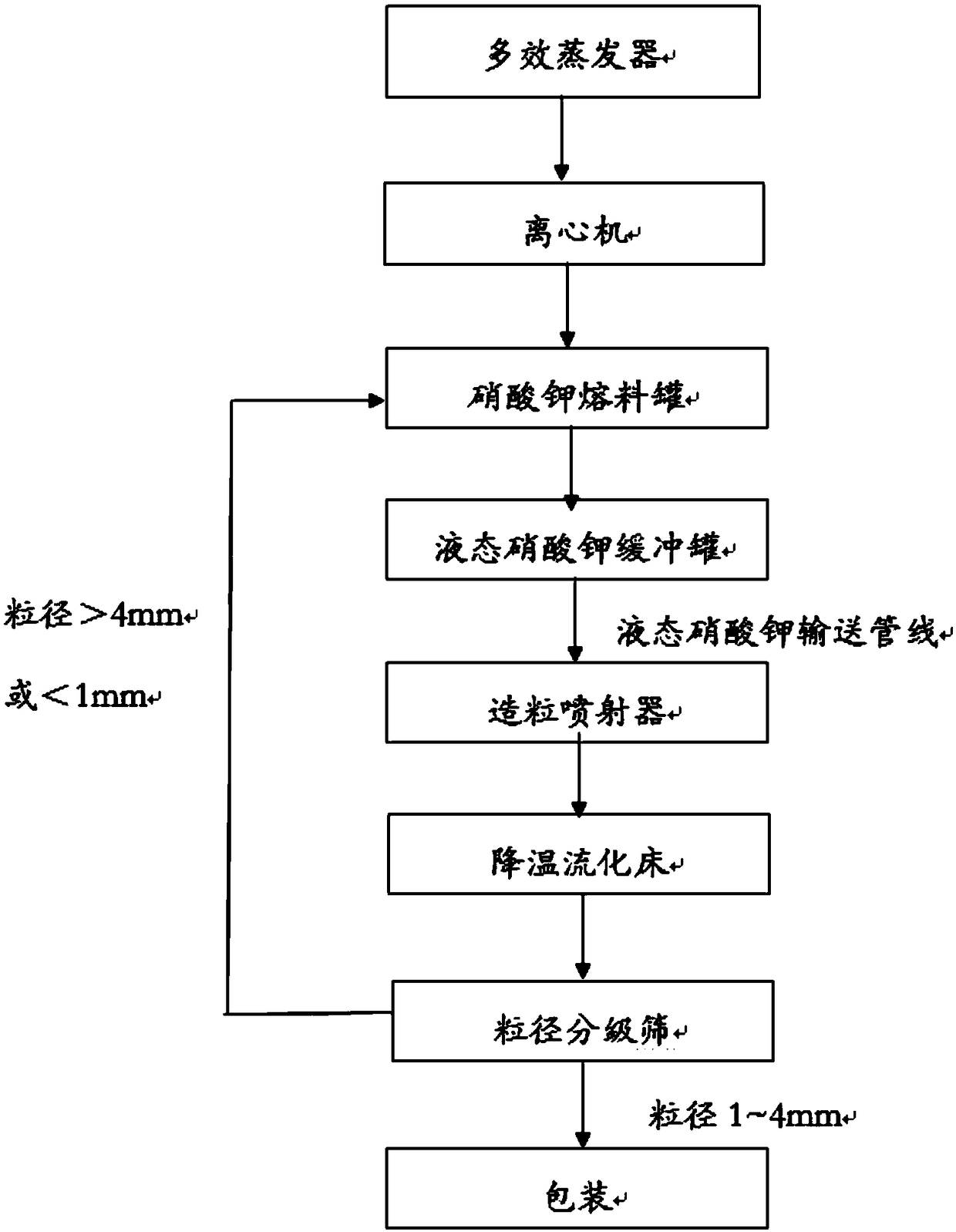

[0059] The first step: prepare powdery potassium nitrate

[0060] Using potassium chloride and ammonium nitrate as raw materials, potassium nitrate solution is prepared by ion exchange method, and evaporated and concentrated by multi-effect evaporators with one-effect evaporation at 120°C, second-effect evaporation at 100°C, third-effect evaporation at 90°C, and fourth-effect evaporation at 70°C , cooling and crystallization, the crystal temperature is 30°C, and the powdered potassium nitrate is separated from the solid and liquid by the centrifuge. Through laboratory analysis, the main content of powdery potassium nitrate is 99%.

[0061] The second step: preparation of high temperature heat carrier

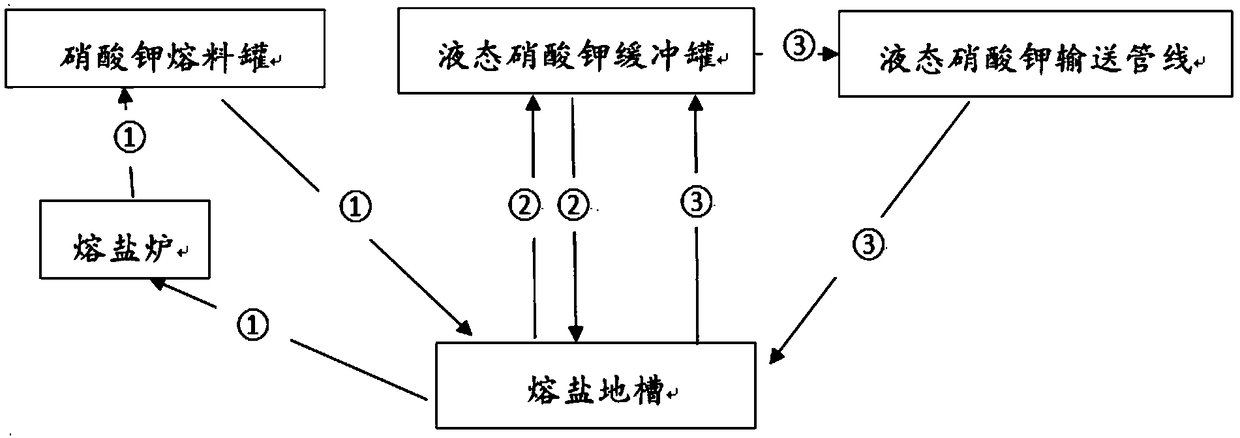

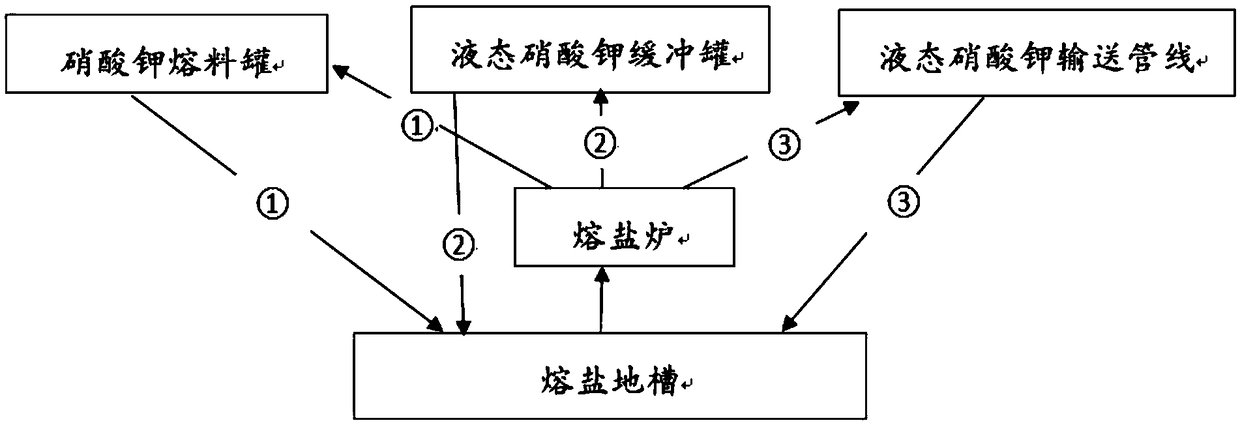

[0062] Heat the molten salt (ternary molten salt or binary molten salt) to 340°C, and select the above-mentioned first preferred circulation route.

[0063] During the high-temperature molten salt circulation process, the potassium nitrate melting tank, the liquid potassium ni...

Embodiment 2

[0071] The first step: prepare powdery potassium nitrate

[0072] Potassium nitrate solution is prepared by neutralization method of nitric acid and potassium hydroxide, evaporated and concentrated through multi-effect evaporators with 130°C first effect evaporation, 110°C second effect evaporation, 100°C third effect evaporation, and 80°C fourth effect evaporation, cooling and crystallization, crystallization The temperature is 40°C, and the powdered potassium nitrate is separated from the solid and liquid by the centrifuge. Through laboratory analysis, the main content of powdered potassium nitrate is 99.5%.

[0073] The second step: preparation of high temperature heat carrier

[0074] Heat the molten salt (ternary molten salt or binary molten salt) to 380°C, and select the above-mentioned first preferred circulation route.

[0075] During the high-temperature molten salt circulation process, the potassium nitrate melting tank, the liquid potassium nitrate buffer tank and...

Embodiment 3

[0083] The first step: prepare powdery potassium nitrate

[0084] Potassium nitrate solution is prepared by double decomposition method using potassium chloride and sodium nitrate as raw materials. It is evaporated and concentrated by multi-effect evaporators with 140°C first-effect evaporation, 120°C second-effect evaporation, 110°C third-effect evaporation and 90°C fourth-effect evaporation, and cooling crystallization , the crystal temperature is 50°C, and the powdery potassium nitrate is separated from the solid and liquid by the centrifuge. Through laboratory analysis, the main content of powdery potassium nitrate is 99.8%.

[0085] The second step: preparation of high temperature heat carrier

[0086] Heat the molten salt (ternary molten salt or binary molten salt) to 395°C, and select the above-mentioned first preferred circulation route.

[0087] During the high-temperature molten salt circulation process, the potassium nitrate melting tank, the liquid potassium nitr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com