A Cooling Crystallization Method for Membrane Assisted Nucleation

A technology of cooling crystallization and nucleation, which is applied in the selection of crystallization auxiliary conditions, crystallization separation, solution crystallization, etc., can solve the problems of difficult expansion of production, fluctuation of crystal product quality, etc. control effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

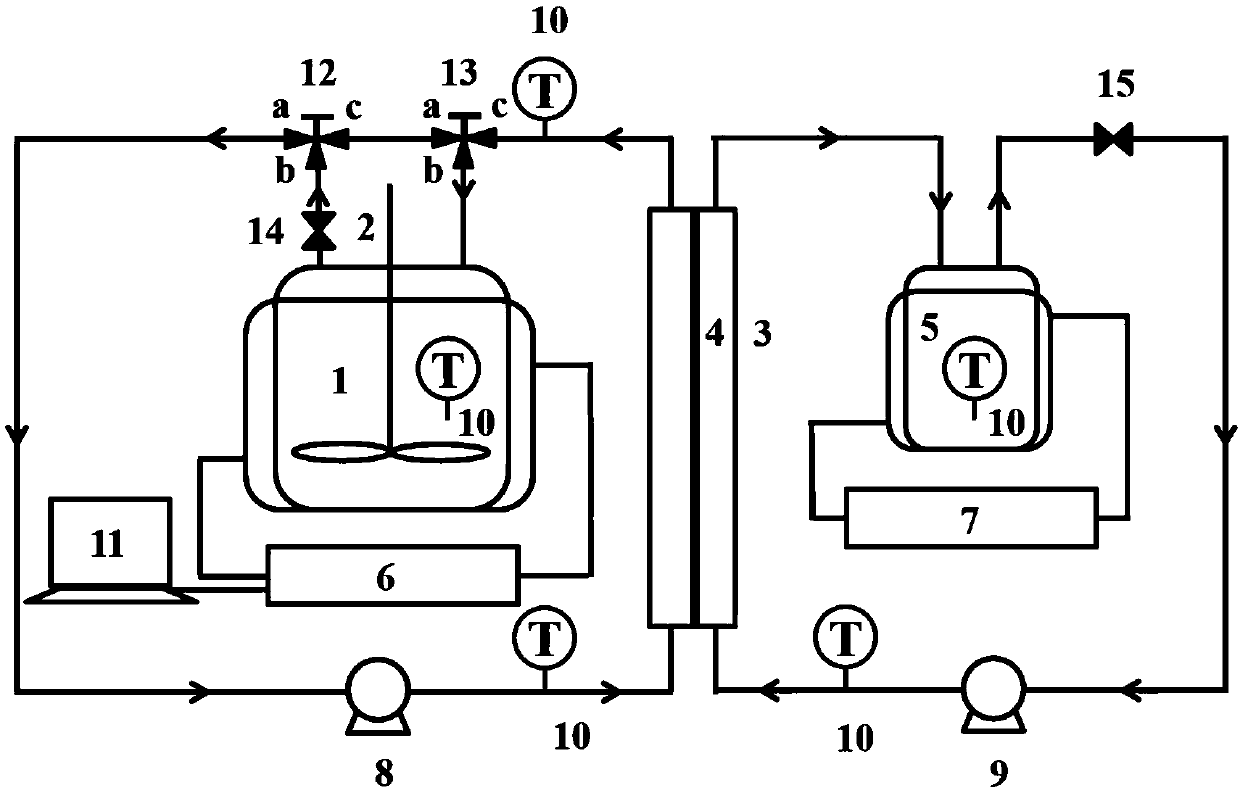

Embodiment 1

[0029] Take the PP hollow fiber membrane to make the membrane module 3. Prepare 300g of KNO at 50°C 3 Saturated aqueous solution, and it was added to the crystallization kettle 1, and the stirring device 2 was turned on. Turn on the computer, set the first-stage temperature to 50°C and the time to 1h in the computer, and set the second-stage temperature to 10°C and the time to 4h. Turn on the temperature control device 6, turn on the circulating water, and maintain the running state for 1h. Add an appropriate amount of water to the coolant tank 5, turn on the second temperature control device 7, set the temperature to 15°C, and adjust the first peristaltic pump 8 to 30rpm to maintain a stable circulation. After running for 55 minutes, open the first valve 14, open the a and b ports of the first three-way regulating valve 12, close the c port, open the b and c ports of the second three-way regulating valve 13, close the a port, and open the second peristaltic pump 9, and adj...

Embodiment 2

[0031] Take the PVDF flat membrane to make the membrane module 3. Prepare 200g of CoSO at 50°C 4 Saturated aqueous solution, and it was added to the crystallization kettle 1, and the stirring device 2 was turned on. Turn on the computer 11, and in the computer 11, the first stage temperature is set to 50° C., and the time is set to 40 minutes; the second stage temperature is set to 20° C., and the time is set to 3 hours. Turn on the first temperature control device 6, turn on the circulating water, and maintain the running state for 50 minutes. Add an appropriate amount of water to the coolant tank 5, turn on the second temperature control device 7, set the temperature to 15° C., and adjust the second peristaltic pump 2 to 70 rpm to keep the coolant flowing rapidly and stably. After running for 30 minutes, open the first valve 14, open ports a and b of the first three-way regulating valve 12, close port c, open ports b and c of the second three-way regulating valve 13, close...

Embodiment 3

[0033] Take the PTFE hollow fiber membrane to make the membrane module 3. Prepare 150g of NaNO at 40°C 3Saturated aqueous solution, and it was added to the crystallization kettle 1, and the stirring device 2 was turned on. Turn on the computer 11, set the temperature of the first stage to 40°C and the time to 50min in the computer 11, and set the temperature of the second stage to 10°C and the time to 3h. Turn on the first temperature control device 6, turn on the circulating water, and maintain the running state for 50 minutes. Add an appropriate amount of water into the coolant tank 5, turn on the second temperature control device 7, set the temperature to 14° C., and adjust the peristaltic pump to 50 rpm to keep the coolant circulating and flowing stably. After running for 50 minutes, open the first valve 14, open the a and b ports of the first three-way regulating valve 12, close the c port, open the b and c ports of the second three-way regulating valve 13, close the a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com