High-purity potassium nitrate tablet and preparation method thereof

A potassium nitrate tablet and potassium nitrate technology, applied in the field of high-purity potassium nitrate, can solve problems such as difficult granulation, high cost, and difficult repair, and achieve the effects of simple process, convenient storage, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

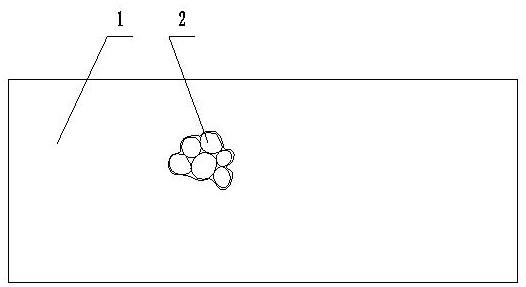

[0034] Example 1, such as figure 1 As shown, a high-purity potassium nitrate tablet 1 is formed by extruding crystal particles 2 of potassium nitrate with a mesh number of 25 mesh-150 mesh and a purity of more than 99.7%. The high-purity potassium nitrate tablet 1 The thickness is 4 mm and the diameter is 10 mm.

[0035] The preparation method of high-purity potassium nitrate tablet comprises the steps:

[0036] 1) Sieve high-purity potassium nitrate crystals with a purity of more than 99.7%, and select crystal particles 2 with a mesh size of 25 mesh to 150 mesh,

[0037] 2) Compress the crystal particles 2 selected in step 1) through a tablet press,

[0038] 3) Pass the finished product after tableting in step 2) through sampling inspection, and pack it into a finished product after passing the inspection.

[0039] The surface area of the high-purity potassium nitrate tablet 1 obtained in this embodiment has been greatly reduced relative to the surface area of the powd...

Embodiment 2

[0040] Example 2, such as figure 2 As shown, a high-purity potassium nitrate tablet 1 is formed by extruding crystal particles 2 of potassium nitrate with a mesh number of 25 mesh-150 mesh and a purity of more than 99.7%. The high-purity potassium nitrate tablet 1 Thickness is 4 millimeters, and diameter is 10 millimeters, and the surface of described high-purity potassium nitrate tablet 1 has one deck anti-caking agent film 3.

[0041] The preparation method of high-purity potassium nitrate tablet comprises the steps:

[0042] 1) Sieve high-purity potassium nitrate crystals with a purity of more than 99.7%, and select crystal particles 2 with a mesh size of 25 mesh to 150 mesh,

[0043] 2) Compress the crystal particles 2 selected in step 1) through a tablet press,

[0044] 3) Pass the high-purity potassium nitrate tablet compressed in step 2) through the anti-caking agent pool, so that the surface of the high-purity potassium nitrate tablet is coated with anti-caking agen...

Embodiment 3

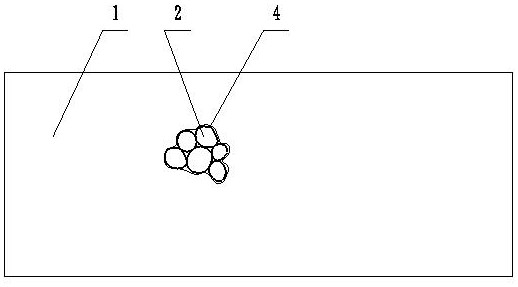

[0053] Example 3, such as image 3 As shown, a high-purity potassium nitrate tablet 1 is formed by extruding crystal particles 2 of potassium nitrate with a mesh number of 25 mesh-150 mesh and a purity of more than 99.7%. The high-purity potassium nitrate tablet 1 The thickness is 4 millimeters, and the diameter is 10 millimeters. The crystal particles 2 of potassium nitrate forming the high-purity potassium nitrate tablet 1 have a layer of anti-caking agent film 4 on the surface.

[0054] The preparation method of high-purity potassium nitrate tablet comprises the steps:

[0055] 1) Spray the anti-caking lubricant evenly on the high-purity potassium nitrate crystal with a purity of more than 99.7%, and then dry it at 120°C. The amount of anti-caking agent is 0.1% of the weight of potassium nitrate.

[0056] 2) Sieve the dried high-purity potassium nitrate crystals in step 1), and select crystal particles 2 with a mesh size of 25 mesh to 150 mesh,

[0057] 3) Compress the cr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com