Preparation method of salt nano-particles

A technology of nanoparticles and inorganic salts, applied in the field of nanoparticles, can solve problems such as inability to obtain salt nanoparticles, and achieve the effects of low cost, high purity and fast speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] (1) Sample preparation: NaNO 3 The powder is placed in a quartz crucible and heated on a heating table. At the same time, freshly dissociated highly oriented pyrolytic graphite (Highly Oriented Pyrolytic Graphite, HOPG) was placed on a heating table for heating. Adjust the temperature of the heating table to 400 ° C, and use an infrared thermometer to measure NaNO in the crucible 3 The temperature, which is 319.2°C, is lower than that of NaNO 3 Decomposition temperature, heating makes NaNO 3 Gradually melts into a liquid state.

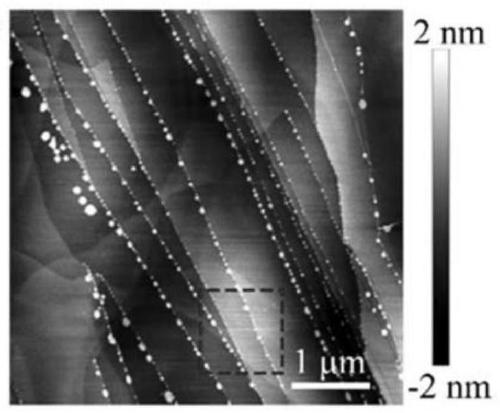

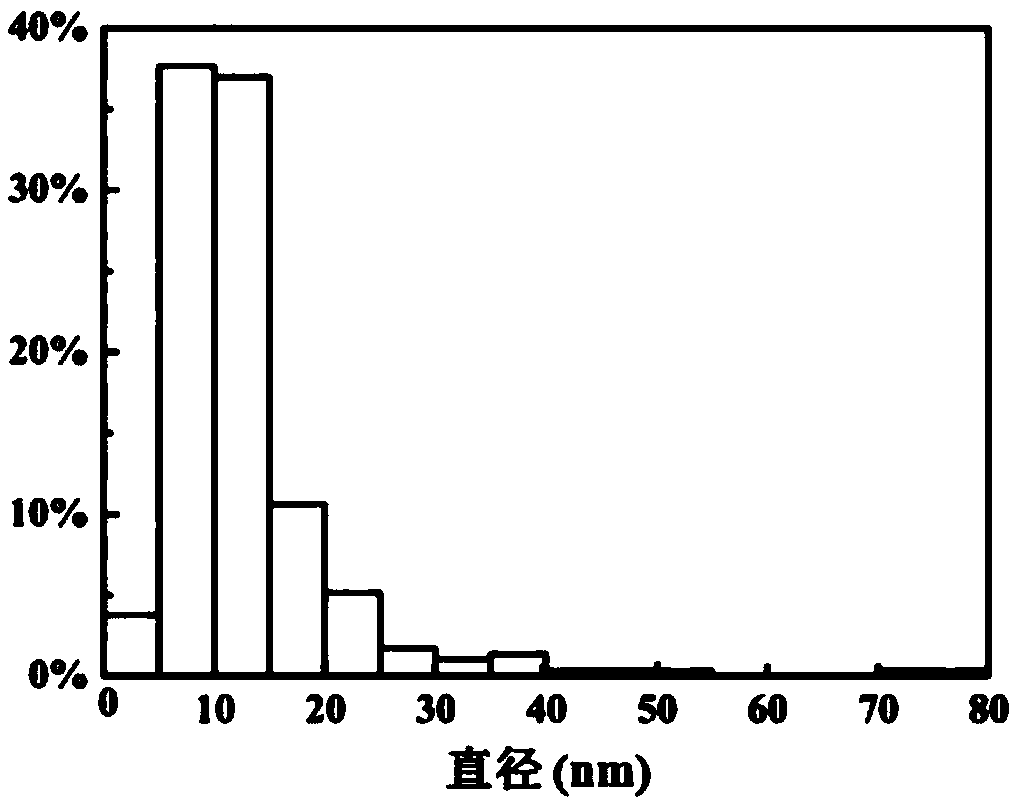

[0024] (2) Preparation of nanoparticles: Dip the molten salt with a glass rod, drop it on the HOPG, and after a brief contact for 1-5 seconds, use the glass rod to drive the molten salt droplet to move to the surface in contact with the molten salt droplet away from the HOPG, The molten salt droplets are removed from the HOPG, and the HOPG is allowed to cool. Atomic force microscopy (AFM) was used to observe the existing forms of inorganic...

Embodiment 2

[0026] (1) Sample preparation: firing nitrate mixed salt (LiNO 3 -NaNO 3 -KNO 3 -Ca(NO 3 ) 2 -CsNO 3 , 8-6-23-19-44wt.%), the mixed salt is placed in a quartz crucible, placed on a heating table for heating. At the same time, freshly dissociated HOPG was placed on a heating platform for heating. Adjust the temperature of the heating table to 500°C, and heat to gradually melt the mixed salt into a liquid state.

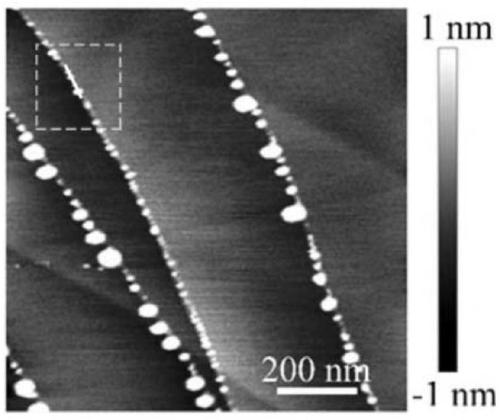

[0027] (2) Preparation of nanoparticles: Dip the molten salt with a glass rod, drop it on the HOPG, and after a brief contact for 1-5 seconds, tilt the HOPG to remove the molten salt drop from the HOPG, and then cool the HOPG. Use atomic force microscope (AFM) to observe the existence form of the mixed salt retained on the surface of HOPG, such as figure 2 As shown, the mixed salt nanoparticles of nitrate range in size from a few nanometers to a few micrometers.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com