Patents

Literature

235results about "Calcium/strontium/barium nitrates" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

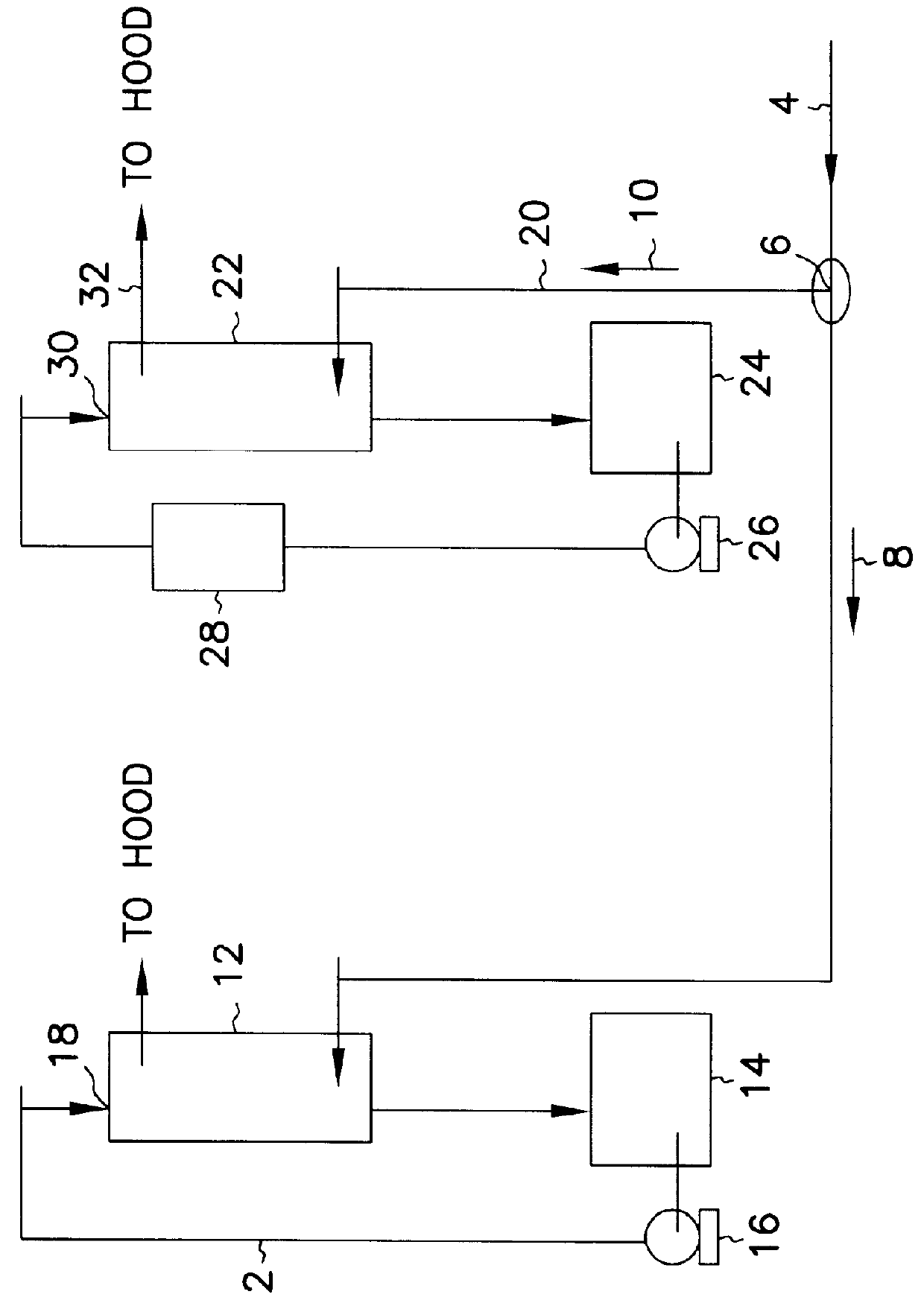

Process and equipment for nitrogen oxide waste conversion to fertilizer

The present invention describes a process for converting vapor streams from sources containing at least one nitrogen-containing oxidizing agent therein to a liquid fertilizer composition comprising the steps of: a) directing a vapor stream containing at least one nitrogen-containing oxidizing agent to a first contact zone, b) contacting said vapor stream with water to form nitrogen oxide(s) from said at least one nitrogen-containing oxidizing agent, c) directing said acid(s) as a second stream to a second contact zone, d) exposing said second stream to hydrogen peroxide which is present within said second contact zone in a relative amount of at least 0.1% by weight of said second stream within said second contact zone to convert at least some of any nitrogen oxide species or ions other than in the nitrate form present within said second stream to nitrate ion, e) sampling said stream within said second contact zone to determine the relative amount of hydrogen peroxide within said second contact zone, f) adding hydrogen peroxide to said second contact zone when a level of hydrogen peroxide less than 0.1 % by weight in said second stream is determined by said sampling, g) adding a solution comprising potassium hydroxide to said second stream to maintain a pH between 6.0 and 11.0 within said second stream within said second contact zone to form a solution of potassium nitrate, and h) removing said solution of potassium nitrate from said second contact zone.

Owner:NAT AERONAUTICS & SPACE ADMINISTATION U S GOVERNMENT AS REPRESENTED BY THE ADMINISTATOR

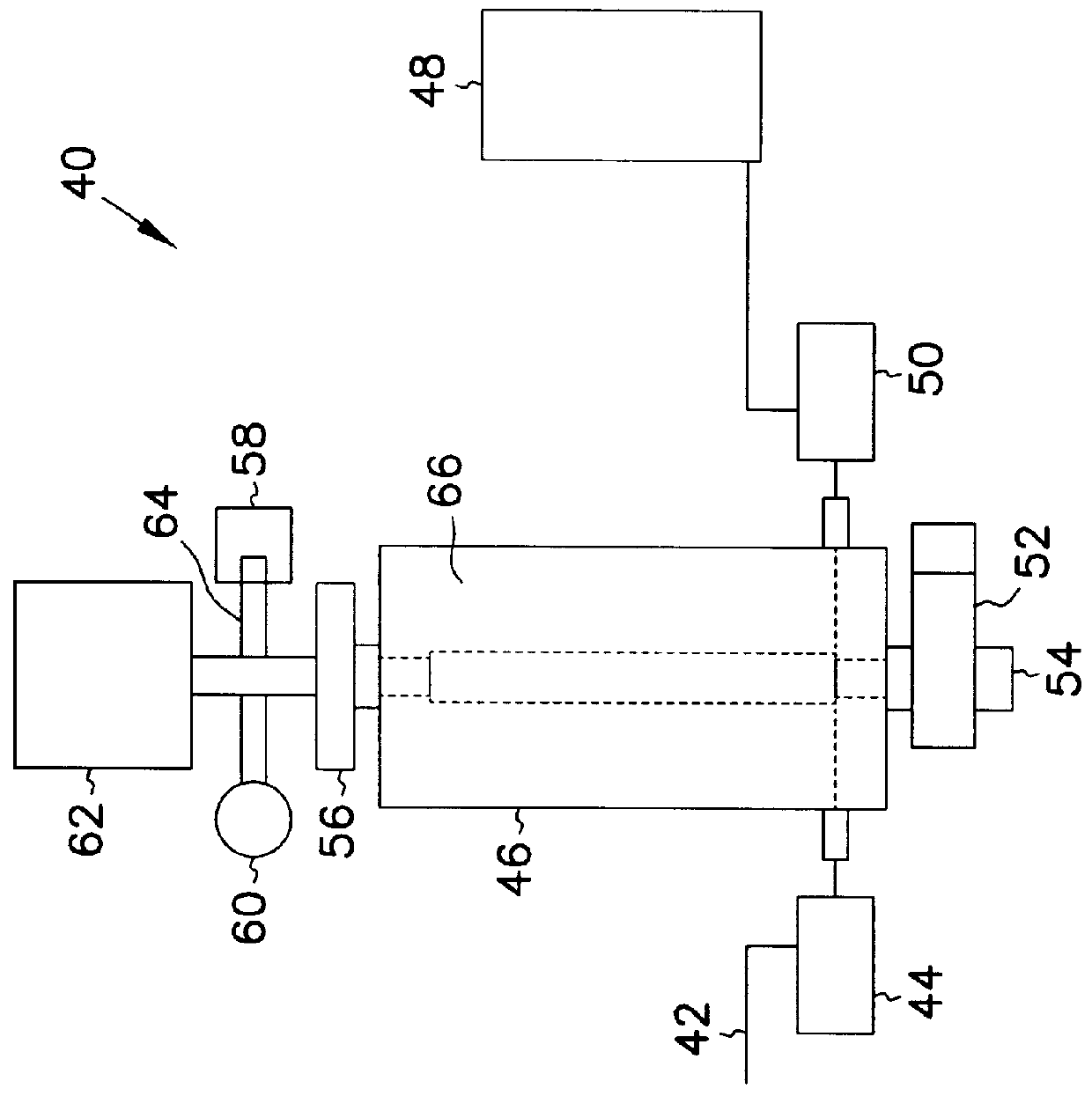

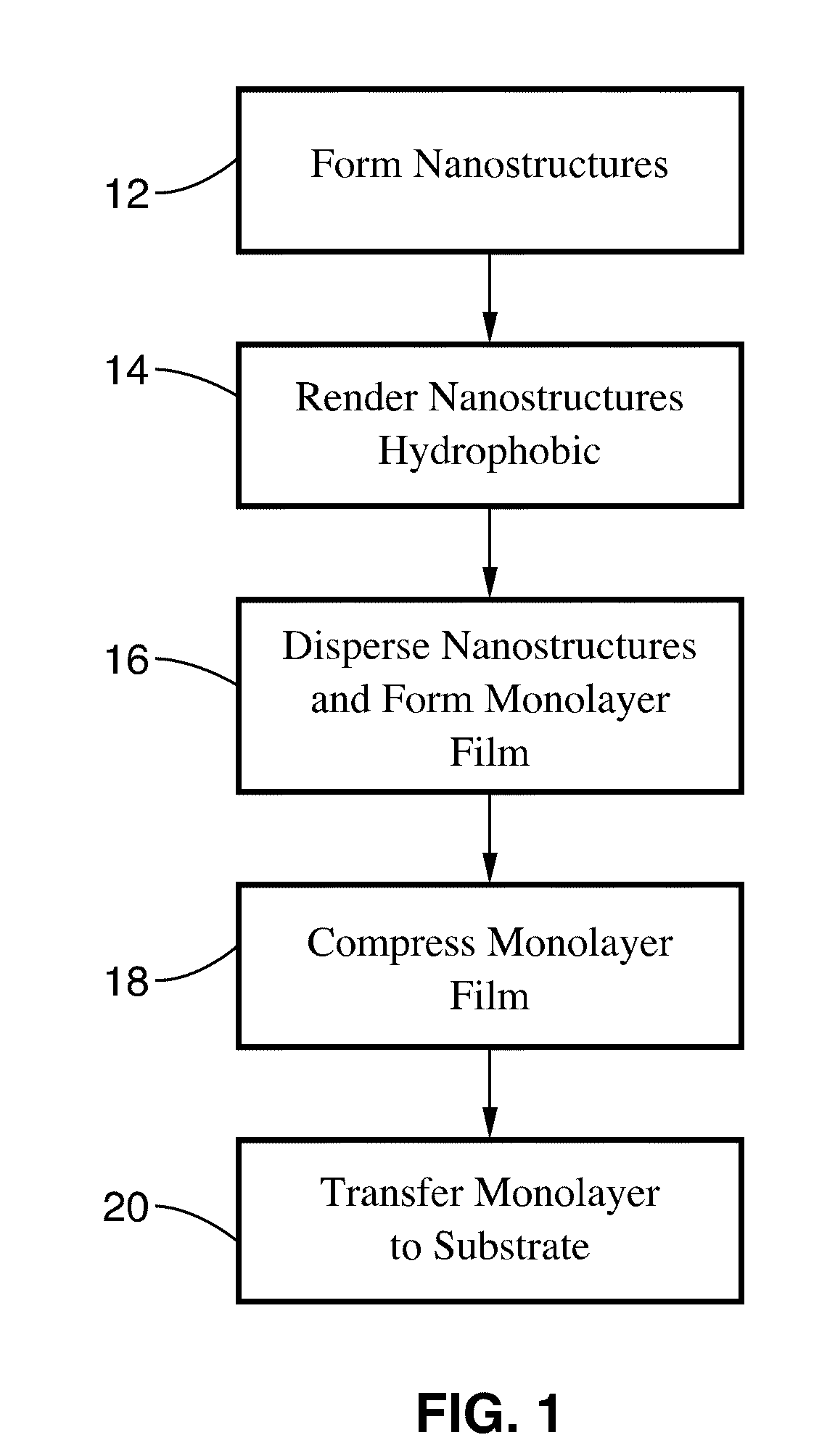

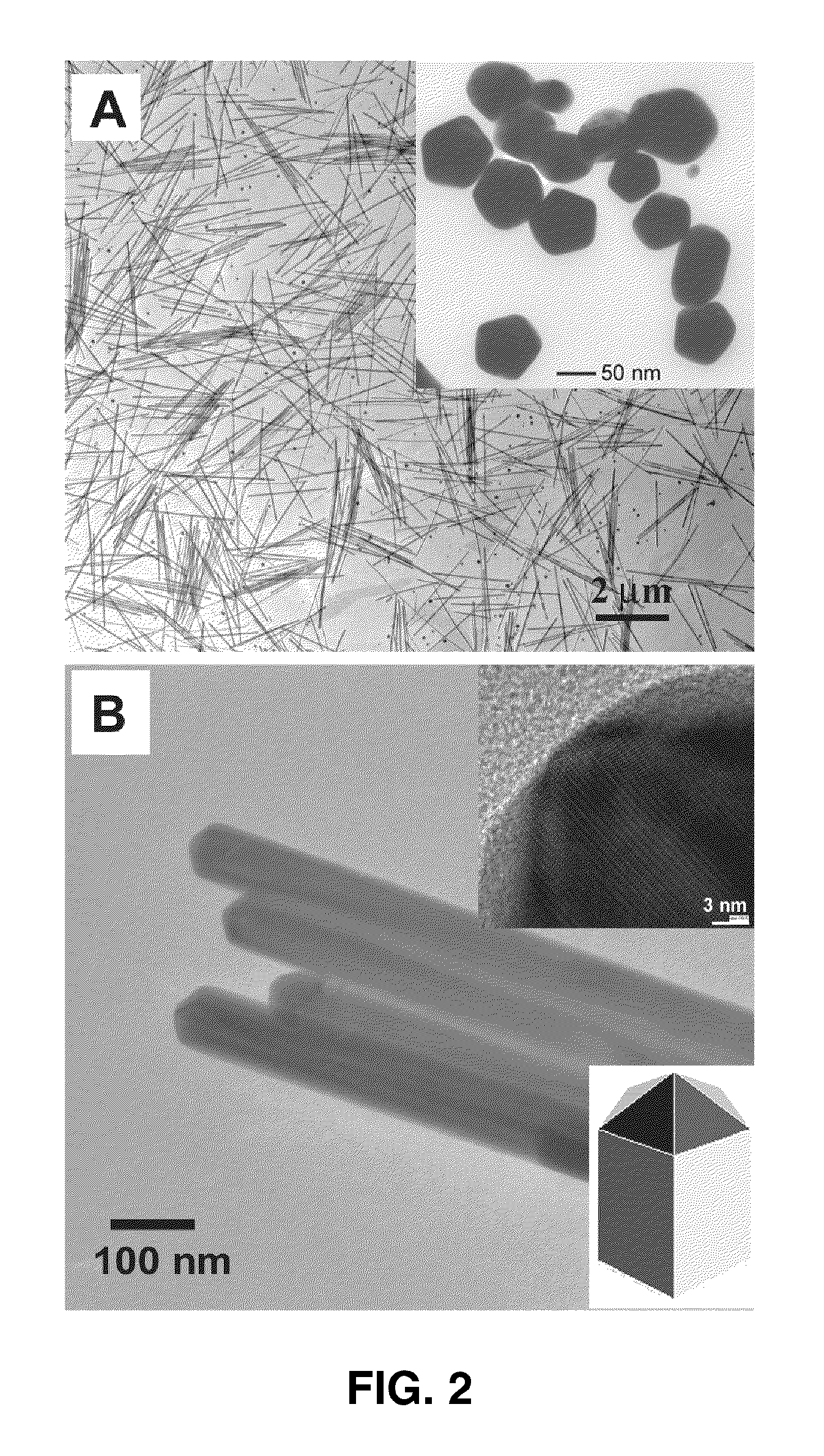

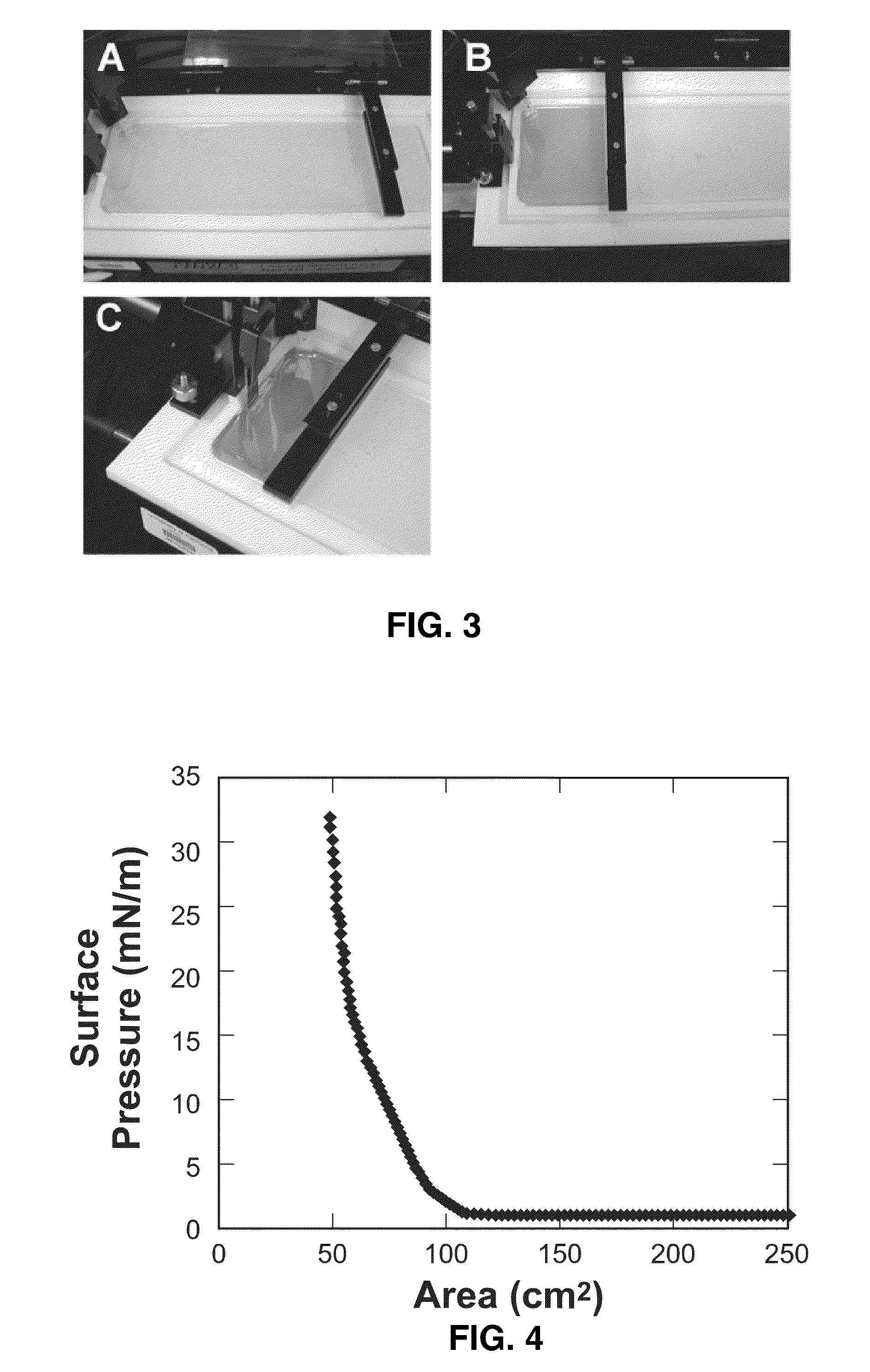

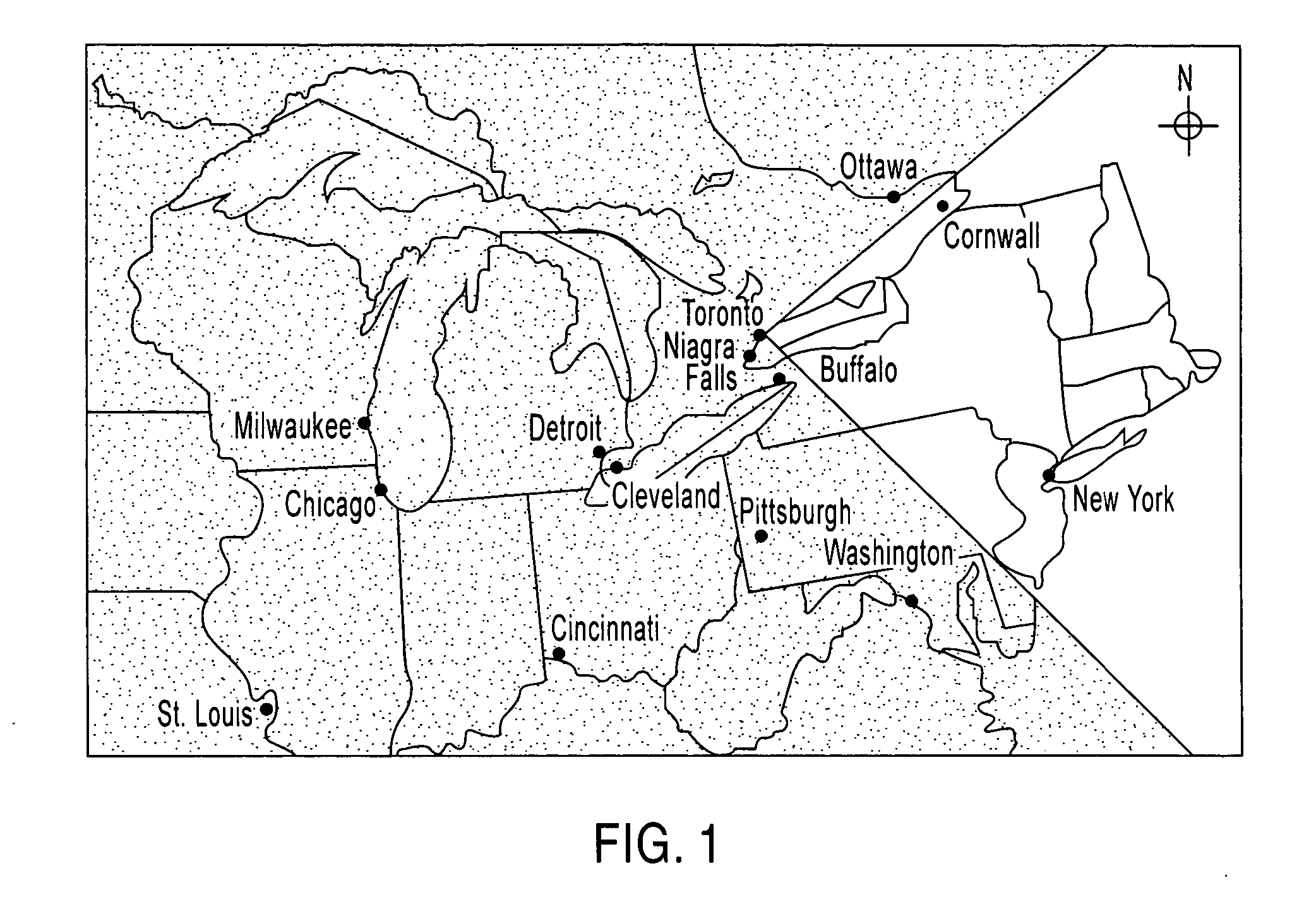

Langmuir-blodgett nanostructure monolayers

InactiveUS20090169807A1Easy to useLarge field enhancementLiquid surface applicatorsNanostructure manufactureNanoparticleEngineering

Methods for assembly of monolayers of nanoparticles using the Langmuir-Blodgett technique, as well as monolayers, assemblies, and devices are described. The surface properties of these monolayers are highly reproducible and well-defined as compared to other systems. These monolayers can readily be used for molecular detection in either an air-borne or a solution environment, and sensors using the monolayer could have significant implications in chemical and biological warfare detection, national and global security, as well as in medical detection applications.

Owner:RGT UNIV OF CALIFORNIA

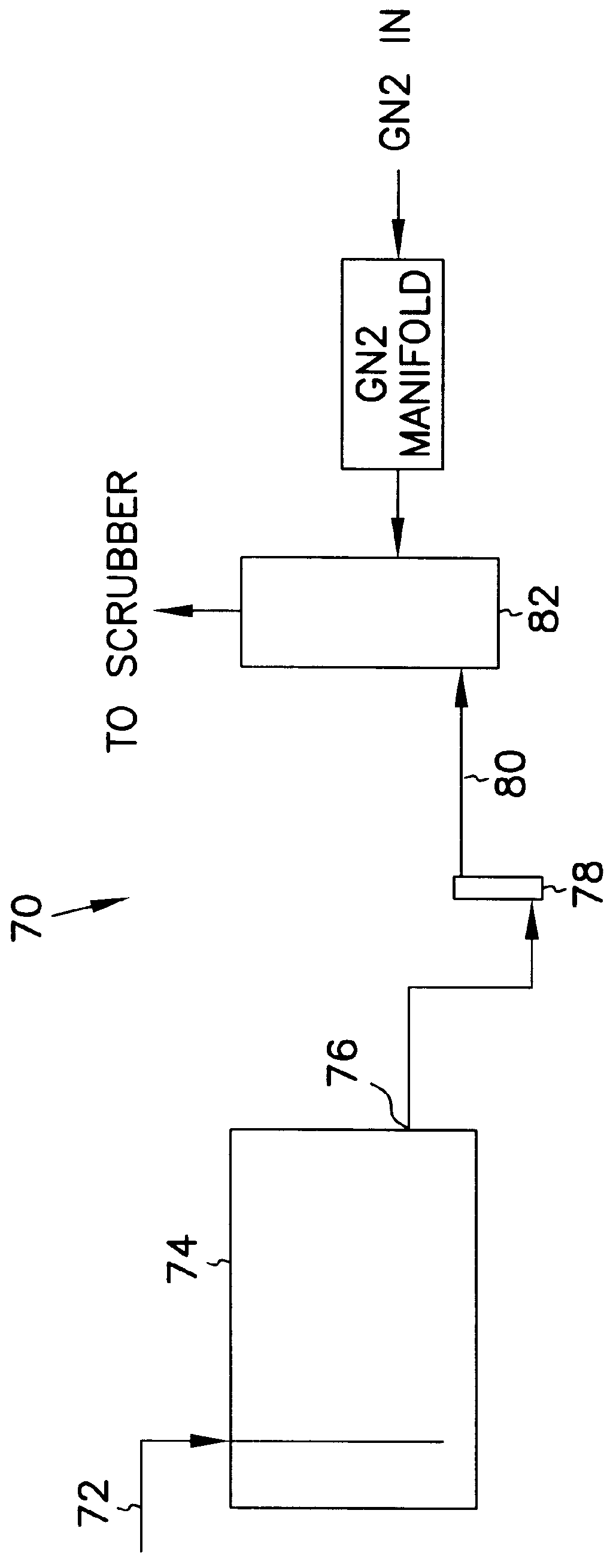

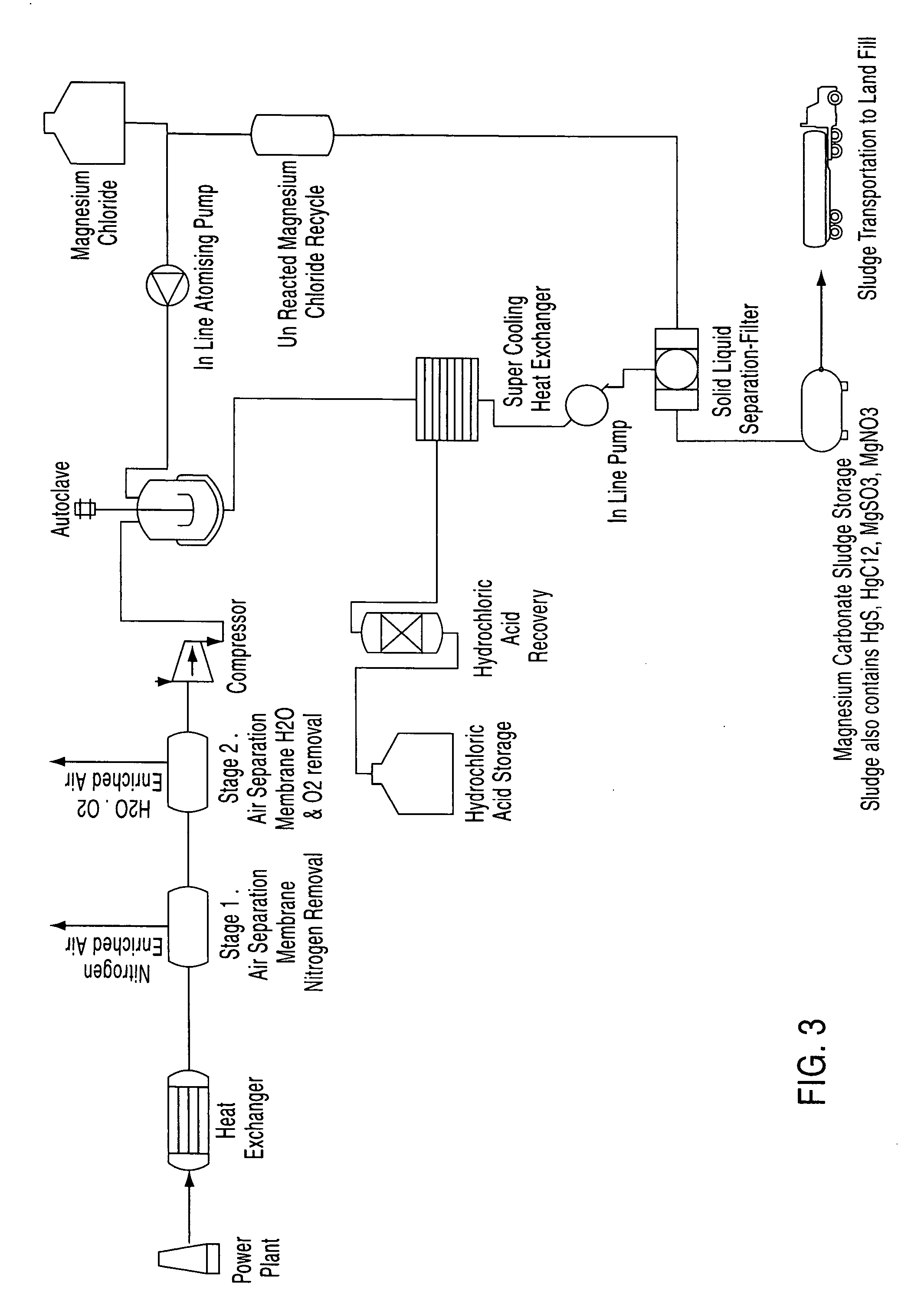

Process for removal of pollutants

A process for the removal of pollutants from a combustion process and, more particularly, a process for removing pollutants such as carbon dioxide, mercury, sulphur dioxide, nitrogen compounds and oxygen compounds from a combustion process. The process includes the removal of pollutants from a combustion process that produces an emission comprising: cooling the emission to a temperature of about 200° C.; removing nitrogen, water and oxygen from the emission to produce a gas containing a concentration of pollutants; contacting the gas with an aqueous magnesium chloride solution, wherein a slurry mixture is formed; and cooling the gas and the slurry mixture, wherein hydrochloric acid vapour and a sludge are formed.

Owner:CLEAN WORLD STRATEGIES CORP

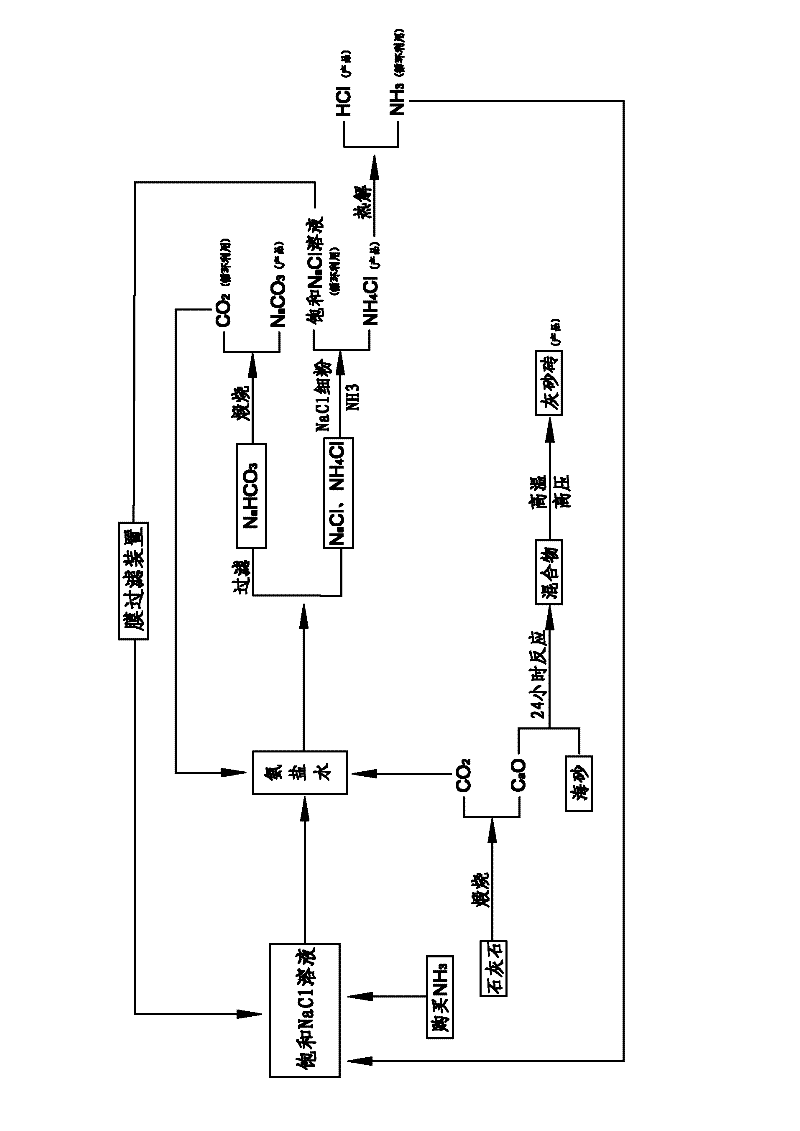

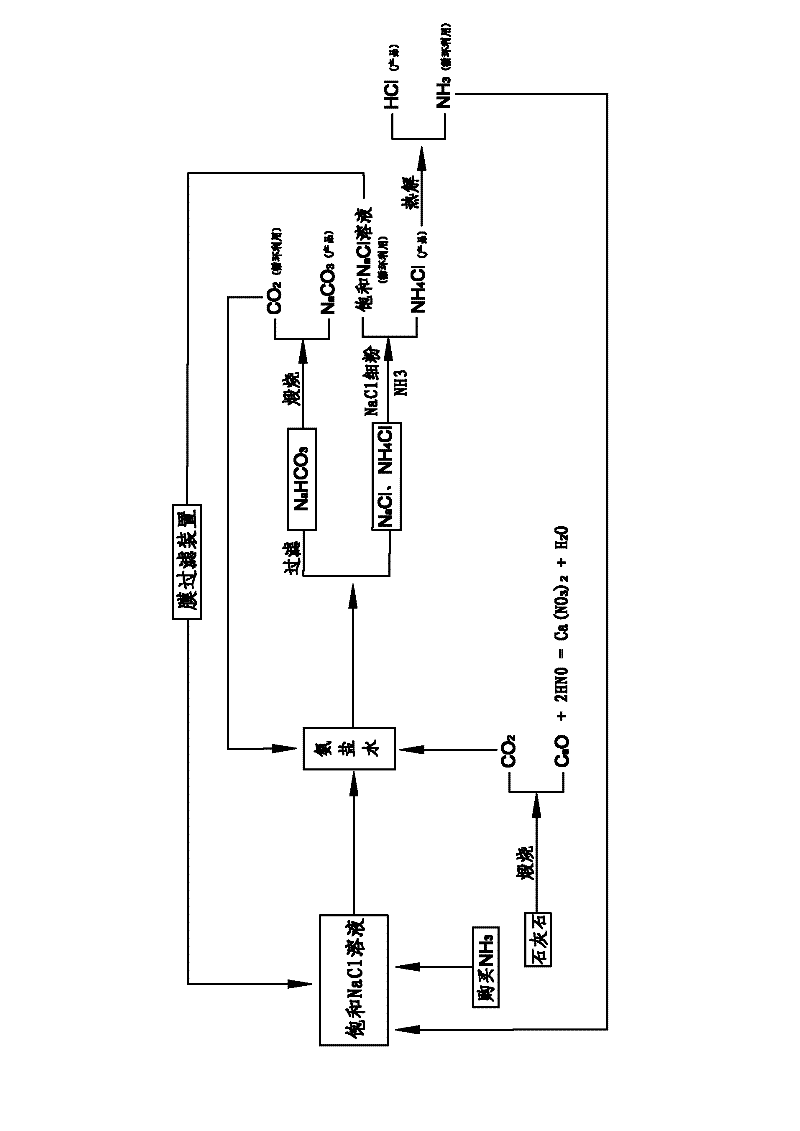

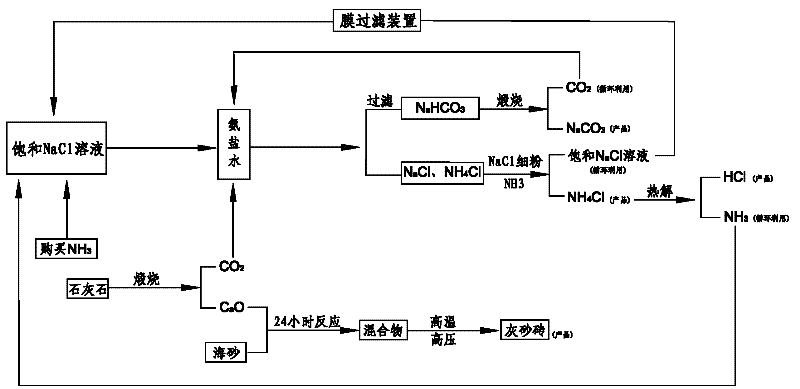

Comprehensive soda ash producing process and product application thereof

ActiveCN102531001AIncrease profitReduce manufacturing costCalcium/strontium/barium nitratesAmmonium halidesSodium bicarbonateProcess engineering

The invention relates to the technical field of soda ash production, and especially relates to a comprehensive soda ash producing process and product applications thereof; the process comprises the following process steps: introducing ammonia gas into a saturated sodium chloride solution to prepare ammoniacal brine; introducing carbon dioxide generated in limestone calcination into the ammoniacal brine to generate a mixture of sodium bicarbonate, sodium chloride and ammonium chloride; filtering the mixture to obtain sodium bicarbonate, sodium chloride and ammonium chloride; calcining the sodium bicarbonate to generate soda ash and carbon dioxide, recycling the carbon dioxide; adding sodium chloride fine powder and ammonia gas into the mixed filtrate of ammonium chloride and sodium chloride to generate ammonium chloride and sodium chloride solutions; separating impurities from the sodium chloride solution by a membrane filter, recycling the sodium chloride solution. The process has the advantages of low production cost, high soda ash whiteness, high sodium chloride utilization rate, no water waste or solid waste generation, environment protection, safety, simple processes, full use of geographic advantages in our country, low raw material purchase cost, waste change into things of value, high economic benefits, and good social benefits.

Owner:GUANGDONG DAZHONG AGRI SCI CO LTD

Recycling method of circuit board tin stripping wastewater

InactiveCN102086073AReduce processing costsEasy to handleTin compoundsMultistage water/sewage treatmentCalcium nitrate tetrahydrateTreatment effect

The invention provides a recycling method of circuit board tin stripping wastewater and the method can be used in the resource treatment of the tin stripping wastewater of the circuit board factory, belonging to the technical field of environmental protection. The method has the following process flows: adding refined lime slurry in the tin stripping wastewater to adjust the pH value to be alkaline and ensure that a part of beta-stannic acid sol with positive charges is coagulated, another part of beta-stannic acid sol is converted to beta-stannic acid sol with negative charges, and adding the tin stripping wastewater to adjust the pH value to be neutral and ensure that the beta-stannic acid sol with negative charges performs charge neutralization with the beta-stannic acid sol particles with positive charges and is completely coagulated, performing solid-liquid separation, and rinsing to obtain solid beta-stannic acid precipitate which is used as the raw material of tin smelting to produce metal tin. The separated solution is mixed with the same rinse water and then the mixture is evaporated and concentrated to obtain a calcium nitrate tetrahydrate product. The recycling method is characterized by low treatment cost, simple treatment process, good treatment effect, high treatment efficiency, total recycling, zero emission and the like and is suitable for the resource treatment of the tin stripping wastewater of the circuit board factory.

Owner:HUIZHOU DAYAWAN HUILU ENVIRONMENT PROTECTION SERVICE +1

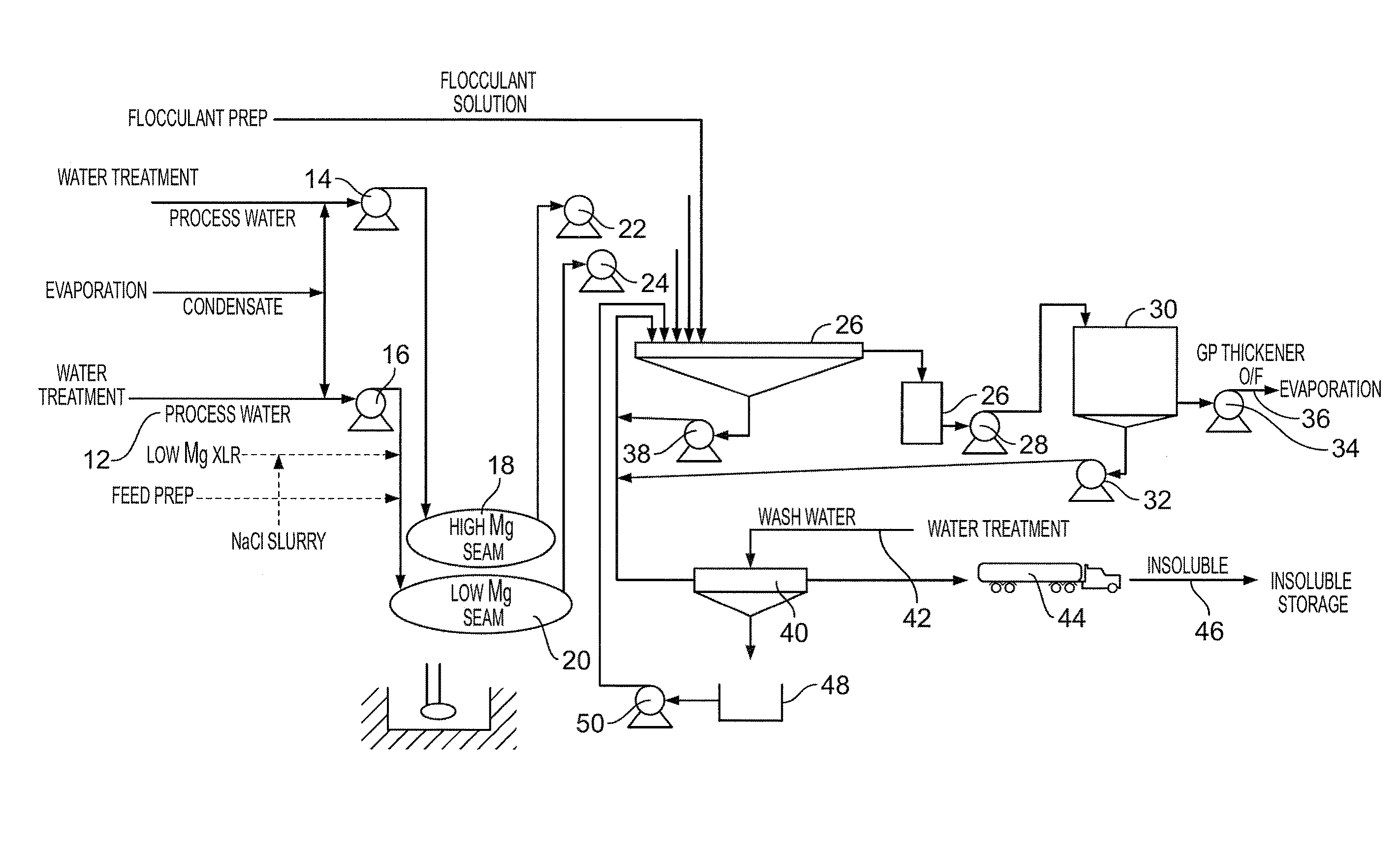

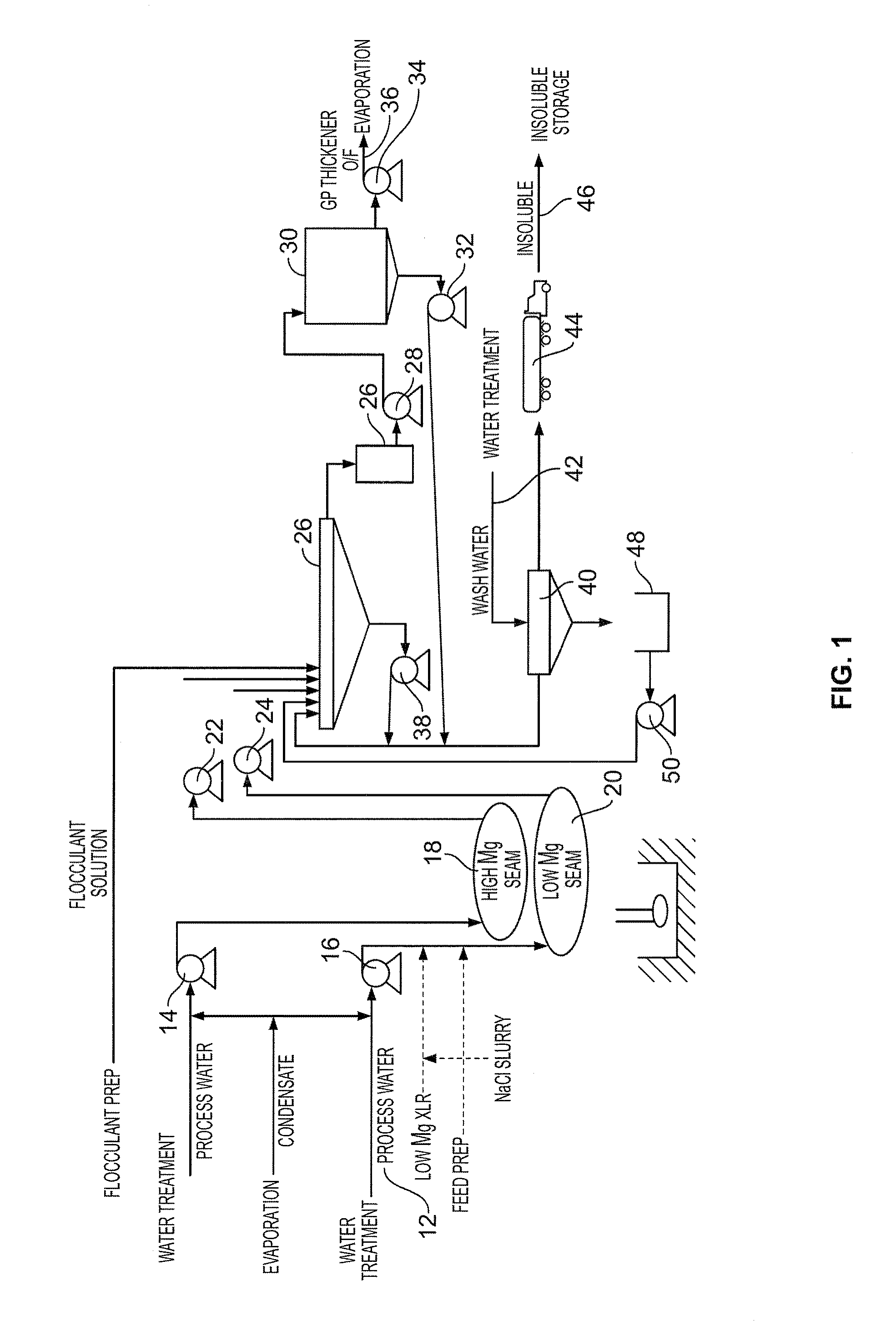

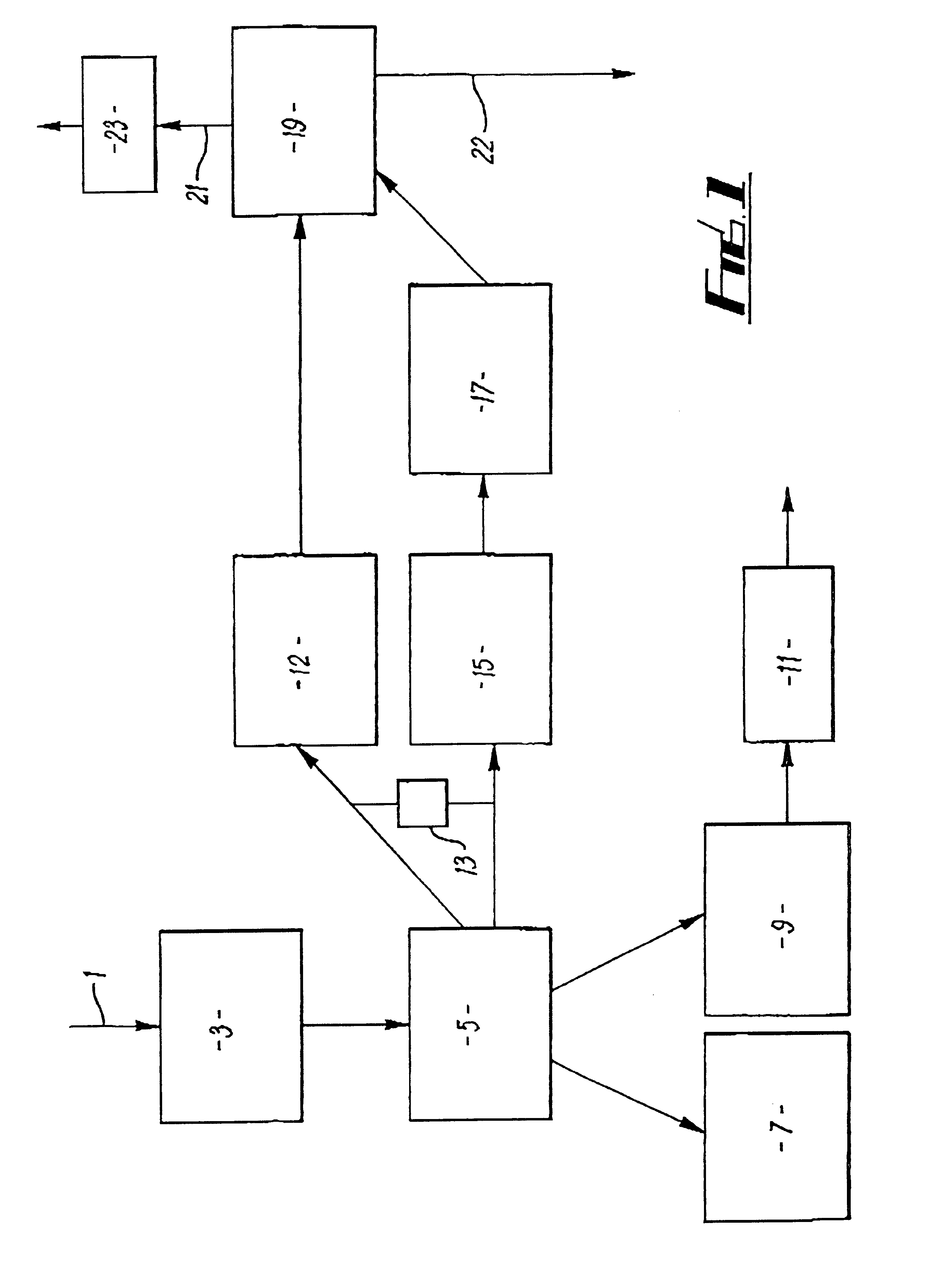

Simultaneous recovery of potassium chloride and KCL enriched edible salt

The present invention relates to recovery of industrial grade potassium chloride and low sodium edible salt from bittern as part of an integrated process. The process comprises, mixing low sulphate concentrated feed bittern (a by-product of salt industry) of density 31.5 to 32.5° Be (sp.gr. 1.277-1.289) with high density end bittern of density 36.5 to 37.5° Be′ (sp.gr. 1.336-1.35), thereby producing low sodium carnallite, from which industrial grade potassium chloride is produced. The resultant bittern is evaporated in forced evaporation system, thereby producing crude carnallite, from which low sodium salt that would be beneficial to persons suffering from hypertension is produced. When sulphate-rich bittern is used, such bittern is desulphated with CaCl2 that is generated from carnallite decomposed liquor through reaction with lime, and wherein low B2O3-containing Mg(OH)2 is a by-product. The entire content of potassium in feed bittern is recovered in the process of the invention.

Owner:COUNCIL OF SCI & IND RES

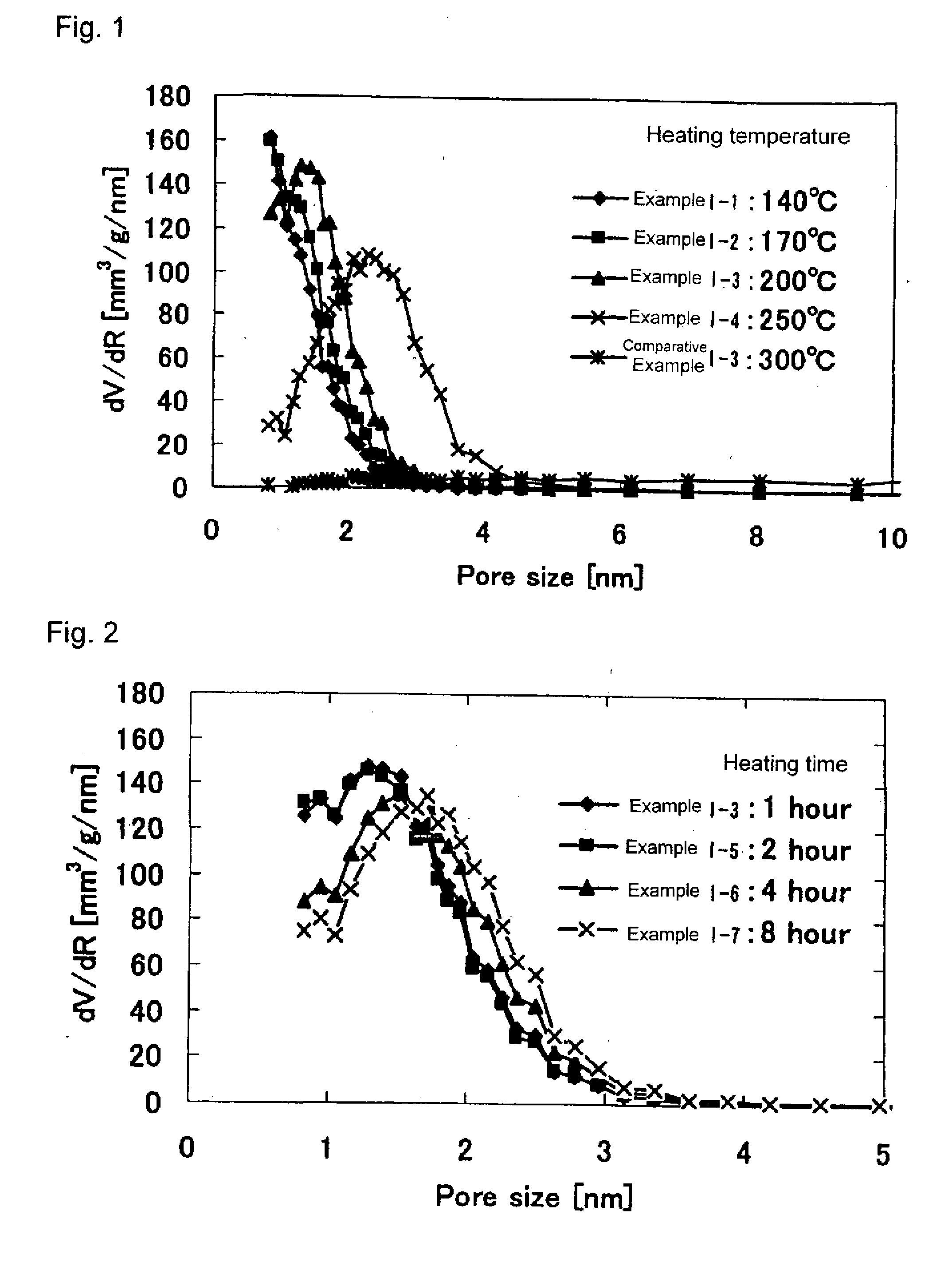

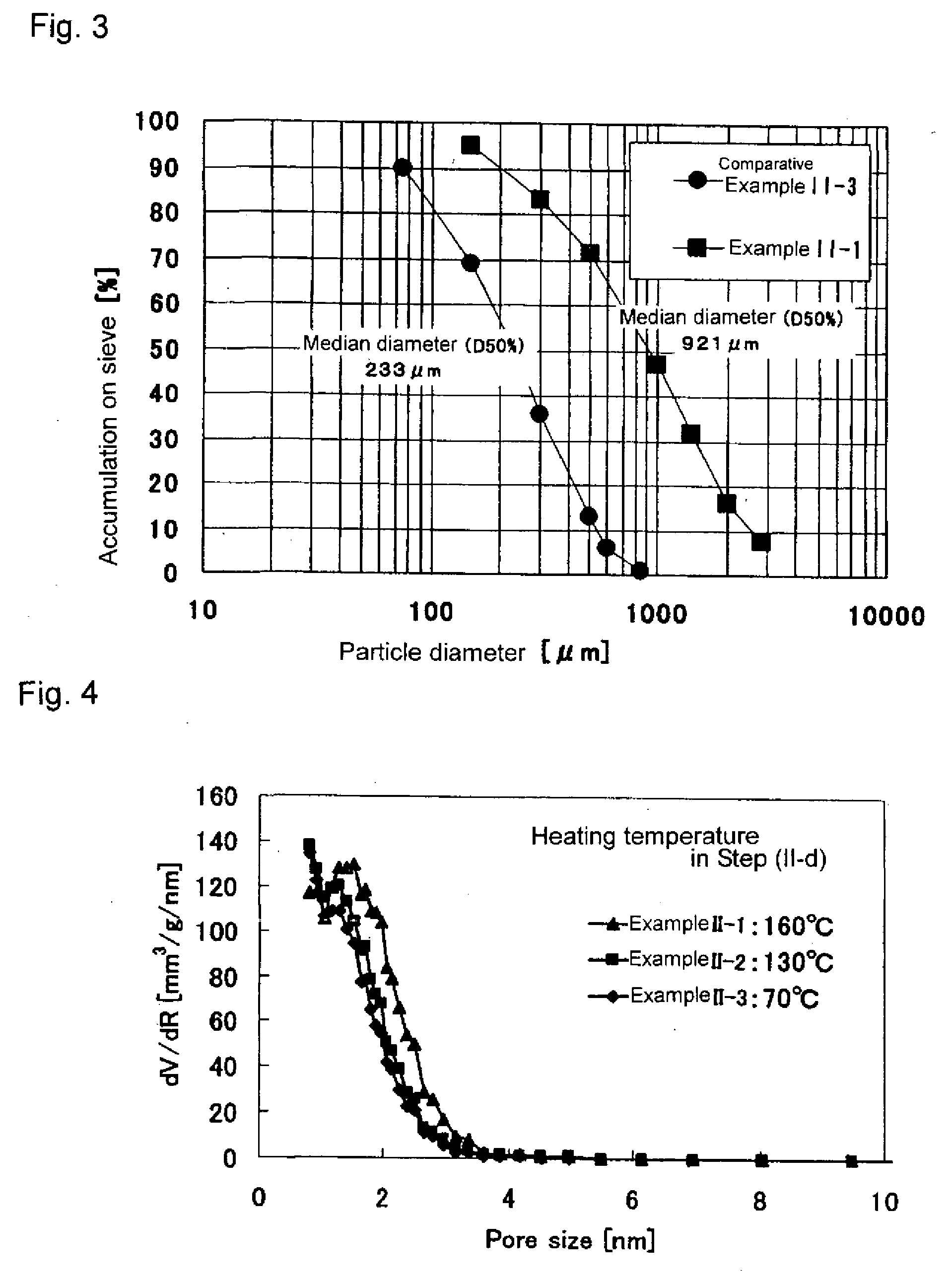

Method for producing iron oxyhydroxide and adsorbing material comprising iron oxyhydroxide

InactiveUS20090028770A1Improve adsorption capacityEfficient productionPhosphorus oxidesNitrogen compoundsIndustrial effluentHazardous substance

The present invention provides a method for advantageously producing an iron oxyhydroxide exhibiting excellent capability of adsorbing harmful substances, such as a phosphrous components and endocrine disrupting chemicals, which are contained in industrial wastewater, exhaust gases, etc., and an adsorbent material comprising the iron oxyhydroxide produced by the method as a main component. Specifically, the present invention provides an adsorbent material produced by a method comprising the steps of:(a) adding a base to an aqueous iron ion-containing solution, adjusting the pH of the resultant mixture to 9 or less, to form a precipitate that contains an iron oxyhydroxide;(b) drying the precipitate at a temperature of 100° C. or lower to obtain an iron oxyhydroxide;(c) contacting the resultant iron oxyhydroxide with water; and(d) subjecting the resultant iron oxyhydroxide to a heat treatment under a gas atmosphere having an inert gas concentration of 80% or greater at a temperature of 100 to 280° C.

Owner:JAPAN SCI & TECH CORP +2

Treatment method for multi-crystalline silicon texturization etching waste liquid

InactiveCN104986771ASilicon halogen compoundsFluoride preparationAlkaline earth metalEconomic benefits

The invention relates to a treatment method for multi-crystalline silicon texturization etching waste liquid. The treatment method comprises the following steps: (a) under the stirring condition, adding an alkali metal compound in the waste liquid for reaction till precipitates are not generated any more, and filtering to obtain a first precipitate and first filtrate; (b) under the stirring condition, adding an alkaline earth metal compound in the first filtrate for reaction till precipitates are not generated, and filtering to obtain a second precipitate and second filtrate; (c) conducting condensation crystallization on the second filtrate to obtain a nitrate solid. The treatment method has the advantages that the alkali metal compound is added in the waste liquid for reaction till the precipitates are not generated any more, filtering is conducted, the alkaline earth metal compound is added in the another filtrate, filtering is conducted again, and finally, concentration is conducted, so that fluosilicic acid radical ions and fluorinions in the waste liquid can be removed, a fluosilicate solid, a fluoride salt solid and the nitrate solid can be obtained, and not only can the environment be protected, but also new economic benefits can be generated.

Owner:SUZHOU KZONE EQUIP TECH

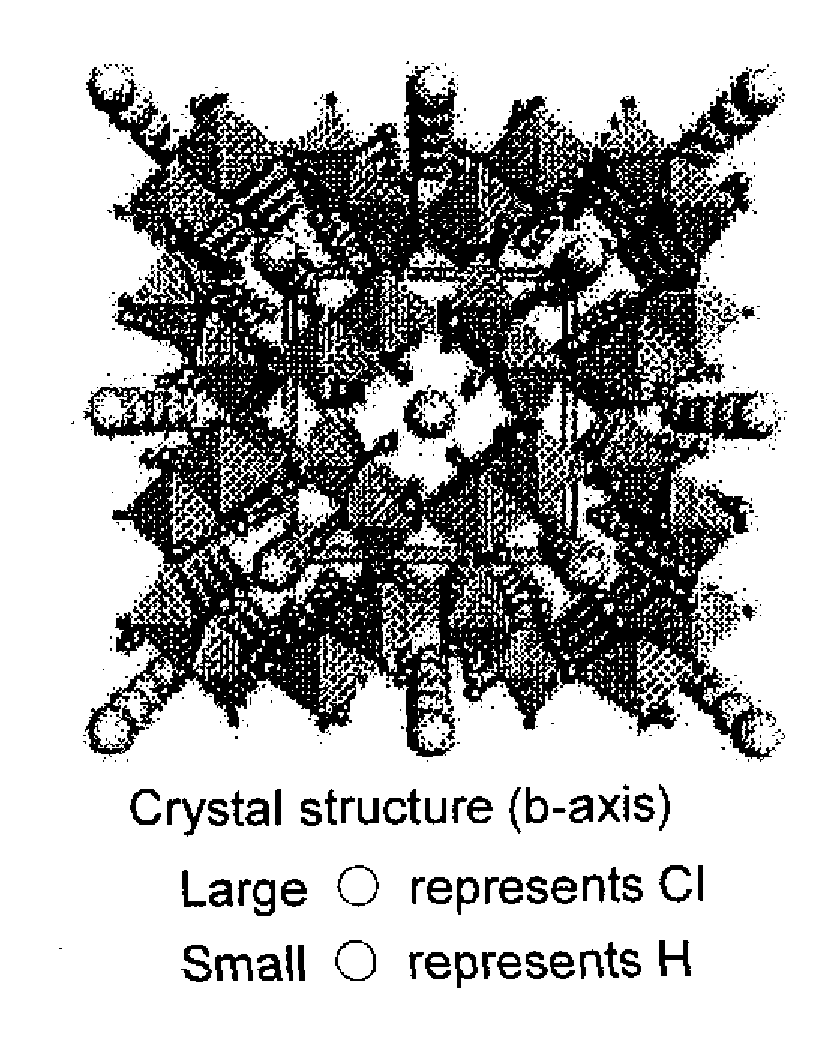

Aqueous solution of chromium salt and method for producing same

InactiveUS20070086938A1Overcome disadvantagesPigmenting treatmentNitrogen compoundsOXALIC ACID DIHYDRATEChloride

Disclosed is an aqueous solution of a chromium salt, in which the oxalic acid content is 8% by weight or less relative to chromium. In the aqueous solution of the chromium salt, the total organic carbon content is 4% by weight or less relative to chromium. The chromium salt is preferably a chromium chloride, a chromium phosphate, or a chromium nitrate. The chromium chloride preferably contains a basic chromium chloride represented by the composition formula Cr(OH)xCly (wherein 0<x≦2, 1≦y<3, and x+y=3). The chromium phosphate is preferably one represented by the composition formula Cr(H3−3 / nPO4)n (wherein n is a number satisfying 2≦n≦3). The chromium nitrate is preferably a basic chromium nitrate represented by the composition formula Cr(OH)x(NO3)y (wherein 0<x≦2, 1≦y<3, and x+y=3).

Owner:NIPPON CHECMICAL IND CO LTD

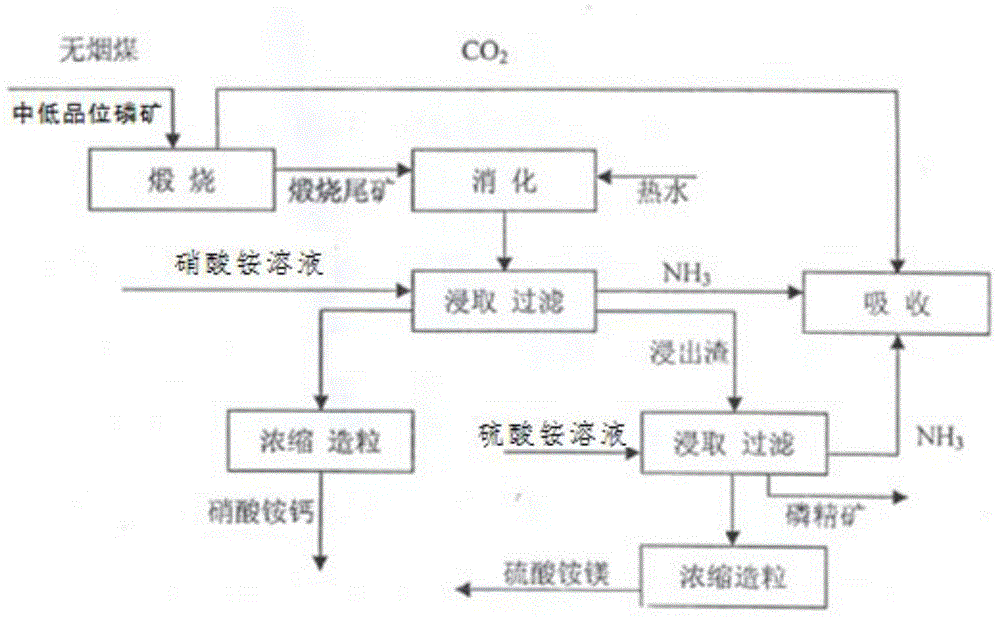

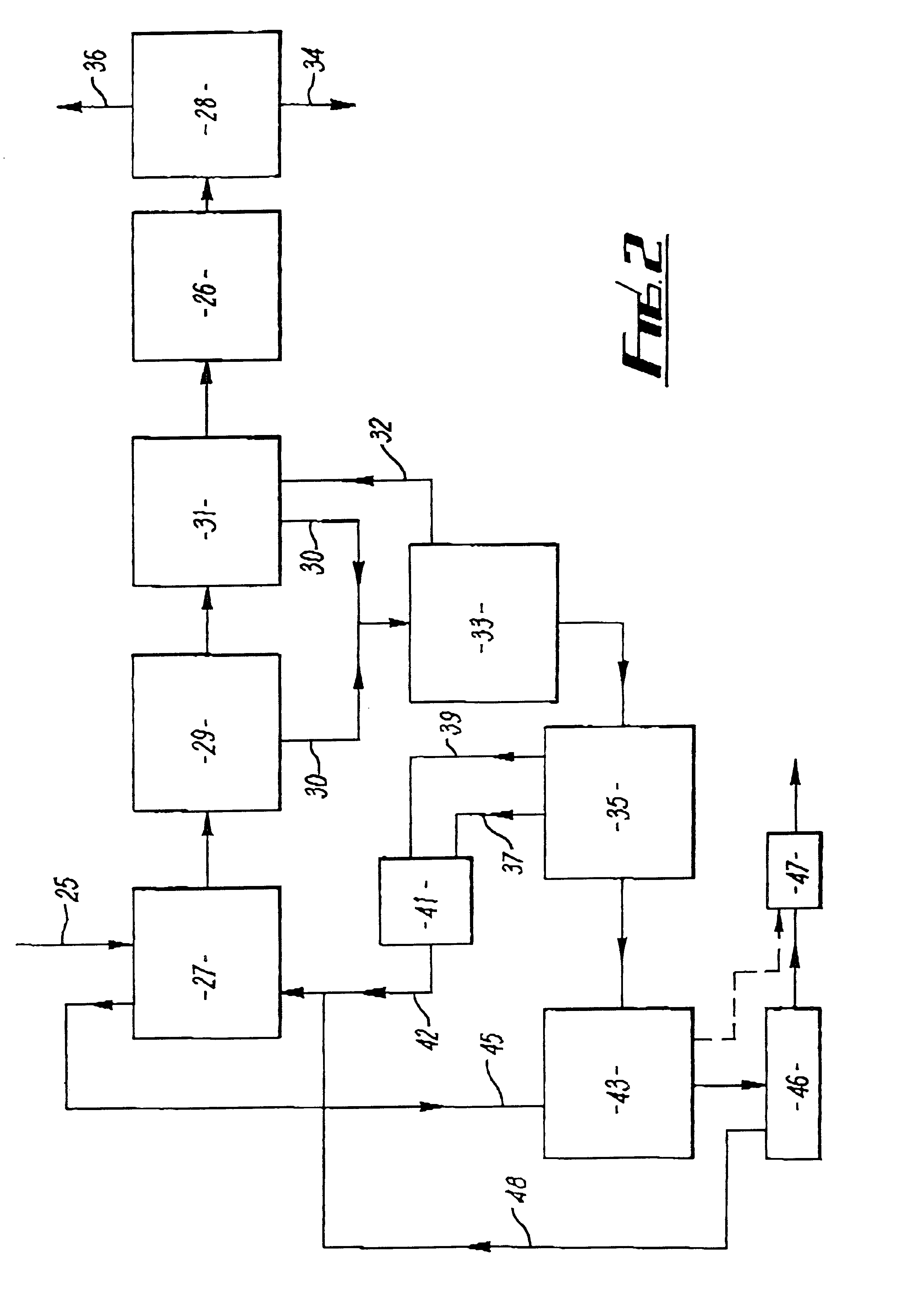

Process for preparing phosphate concentrate as well as byproducts magnesium ammonium sulfate and calcium ammonium nitrate by use of medium and low grade phosphorus ores

ActiveCN104803367AEfficient recyclingSolve being occupiedMagnesium sulfatesCalcium/strontium/barium nitratesInorganic ChemicalFiltration

The invention provides a process for preparing phosphate concentrate as well as byproducts of magnesium ammonium sulfate and calcium ammonium nitrate by use of medium and low grade phosphorus ores and belongs to the technical field of inorganic chemical engineering. The process comprises the following steps of calcining, digesting, leaching with ammonium nitrate, then filtering, concentrating and pelletizing a leachate, adding ammonium sulfate into leaching residues for leaching, then filtering, drying filtration residues to obtain the phosphate concentrate, and concentrating a filtration solution to obtain the magnesium ammonium sulfate. According to the process, phosphorus element can be preserved in the prepared phosphate concentrate to the greatest extent; furthermore, the byproducts of the magnesium ammonium sulfate and the calcium ammonium nitrate can be produced at the same time, so that calcium, magnesium and phosphorus elements in the medium and low grade phosphorus ores are fully utilized.

Owner:贵州盛源新材料股份有限公司

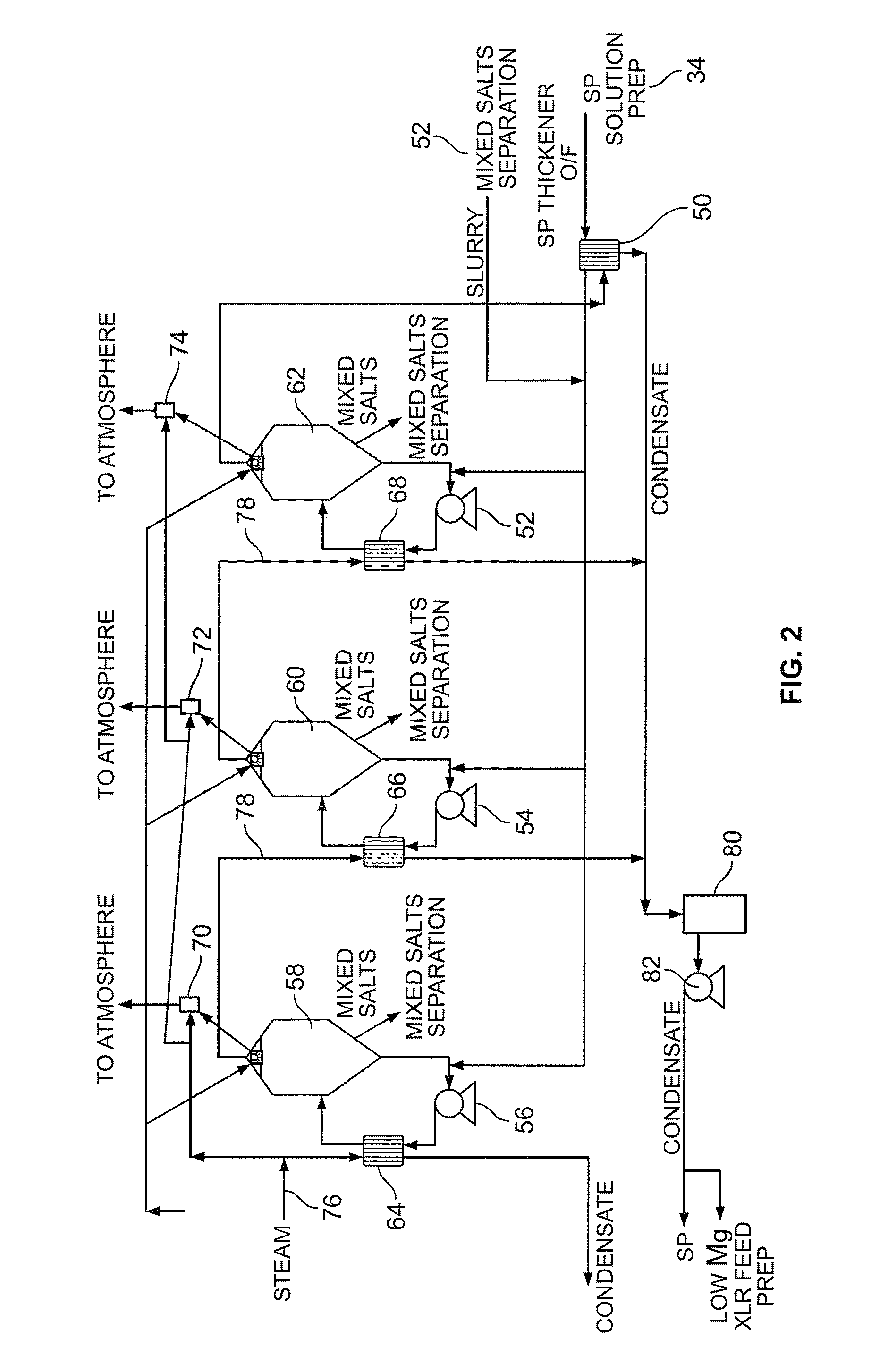

Simultaneous recovery of potassium chloride and KCL enriched edible salt

The present invention relates to recovery of industrial grade potassium chloride and low sodium edible salt from bittern as part of an integrated process. The process comprises, mixing low sulphate concentrated feed bittern (a by-product of salt industry) of density 31.5 to 32.5° Be (sp.gr. 1.277–1.289) with high density end bittern of density 36.5 to 37.5° Be′ (sp.gr. 1.336–1.35), thereby producing low sodium carnallite, from which industrial grade potassium chloride is produced. The resultant bittern is evaporated in forced evaporation system, thereby producing crude carnallite, from which low sodium salt that would be beneficial to persons suffering from hypertension is produced. When sulphate-rich bittern is used, such bittern is desulphated with CaCl2 that is generated from carnallite decomposed liquor through reaction with lime, and wherein low B2O3-containing Mg(OH)2 is a by-product. The entire content of potassium in feed bittern is recovered in the process of the invention.

Owner:COUNCIL OF SCI & IND RES

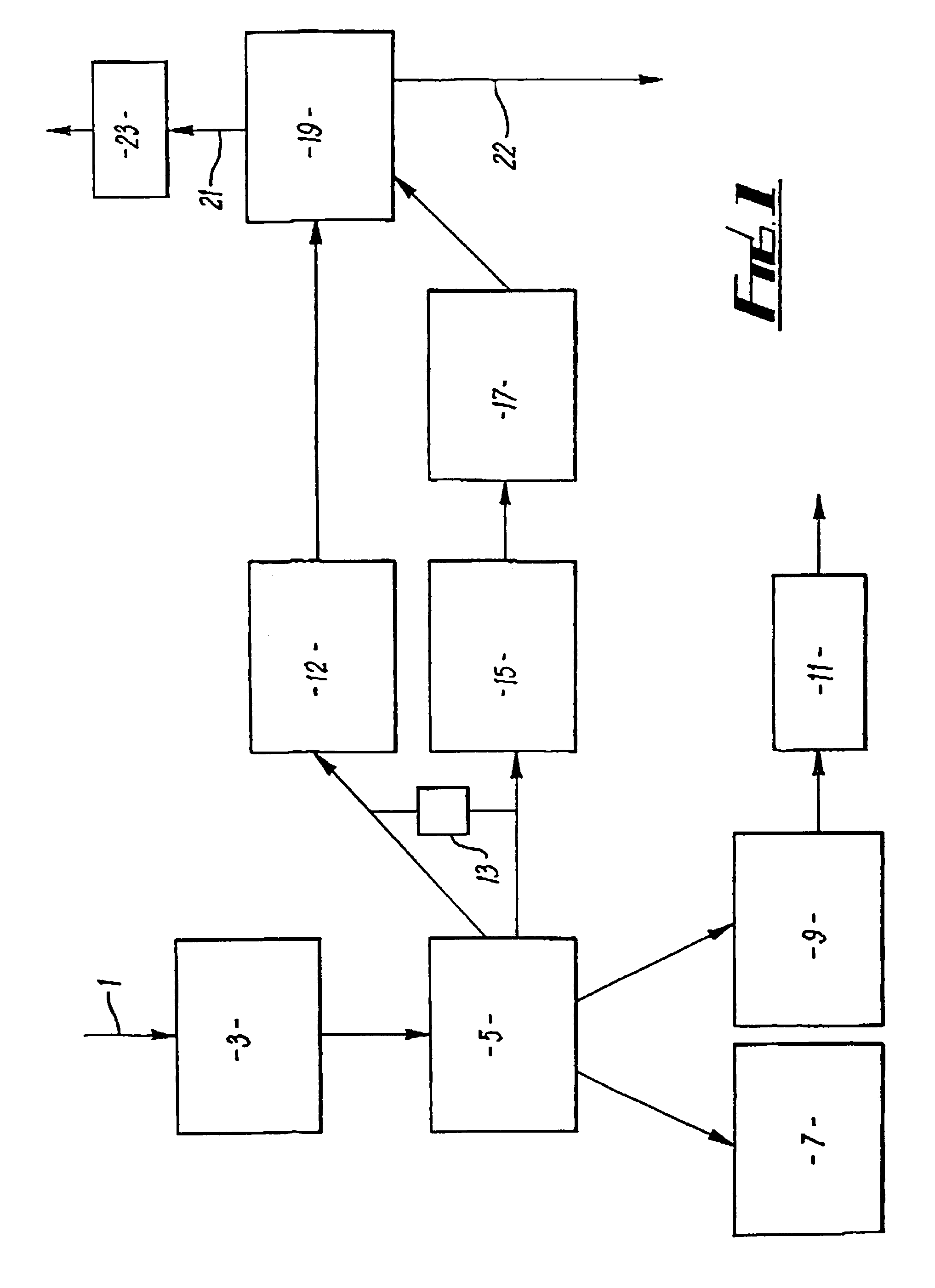

Pastillation of Ammonium Sulfate Nitrate

A process is presented for the production of ammonium sulfate nitrate. The process provides for producing a highly uniform product and having a substantially uniform size. The process includes reacting ammonium sulfate and ammonium nitrate to form an FASN slurry melt. The slurry melt is continuously stirred and heated to keep the slurry melt under a shear thinned condition and at a uniform temperature until the slurry melt is extruded, cooled and solidified.

Owner:ADVANSIX RESINS & CHEM LLC

Methods of making cesium salts and other alkali metal salts

A method of making a cesium salt is described and involves reacting a cesium sulfate containing solution with lime to form 1) a solution containing at least cesium hydroxide and 2) a residue comprising calcium sulfate. The method further involves removing the residue from the solution and converting the cesium hydroxide that is present in the solution to at least one type of cesium salt. The present invention further relates to uses of the cesium salt as well as methods of making cesium hydroxide using lime. Also, methods of making alkali metal salts and alkali metal hydroxides are also described.

Owner:CABOT SPECIALTY FLUIDS

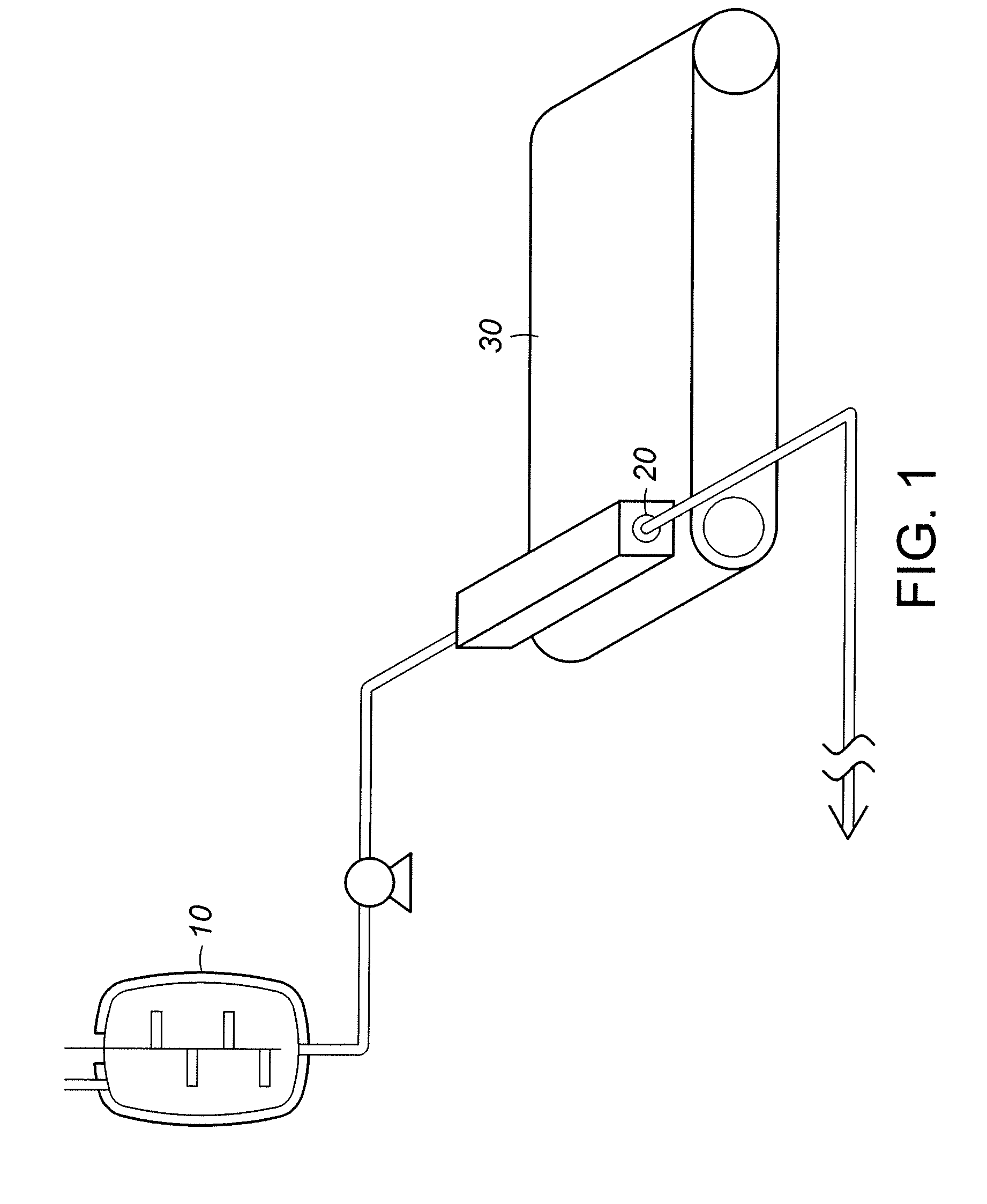

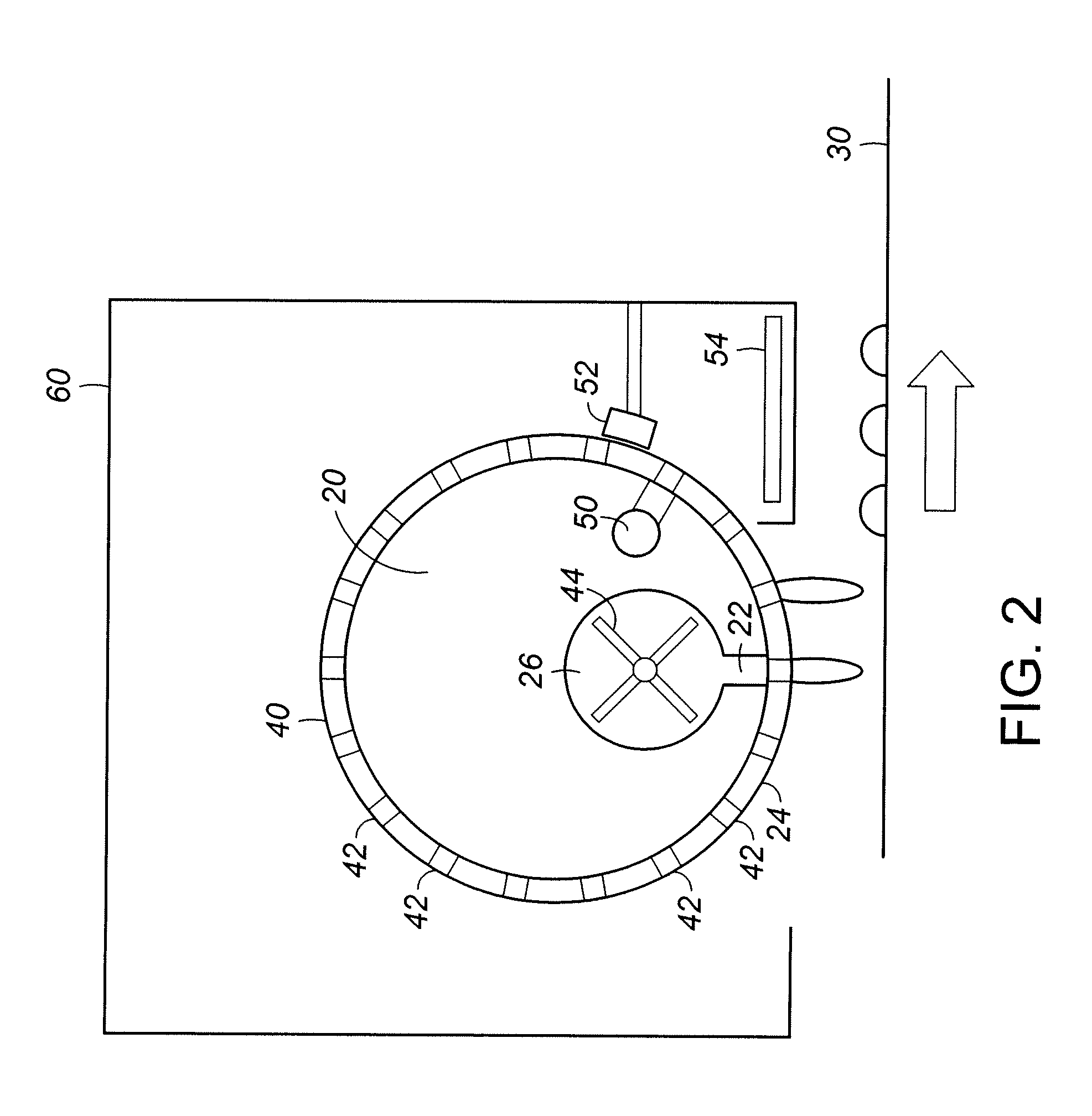

Process for the formulation of potassium chloride from a carnallite source

A process for formulating high purity potassium chloride from a carnallite source. The process takes advantage of solubility differences and saturation levels in a multiple salt system generated upon dissolution of carnallite. In the system, the sodium chloride is kept in solution and the magnesium chloride present in the system is controlled to be in a concentration range of between 12% and 25% by weight. This avoids co-precipitation of sodium chloride with the potassium chloride during crystallization and therefore prevents the sodium chloride from contaminating the potassium chloride. The result is high grade potassium chloride.

Owner:KARNALYTE RESOURCES

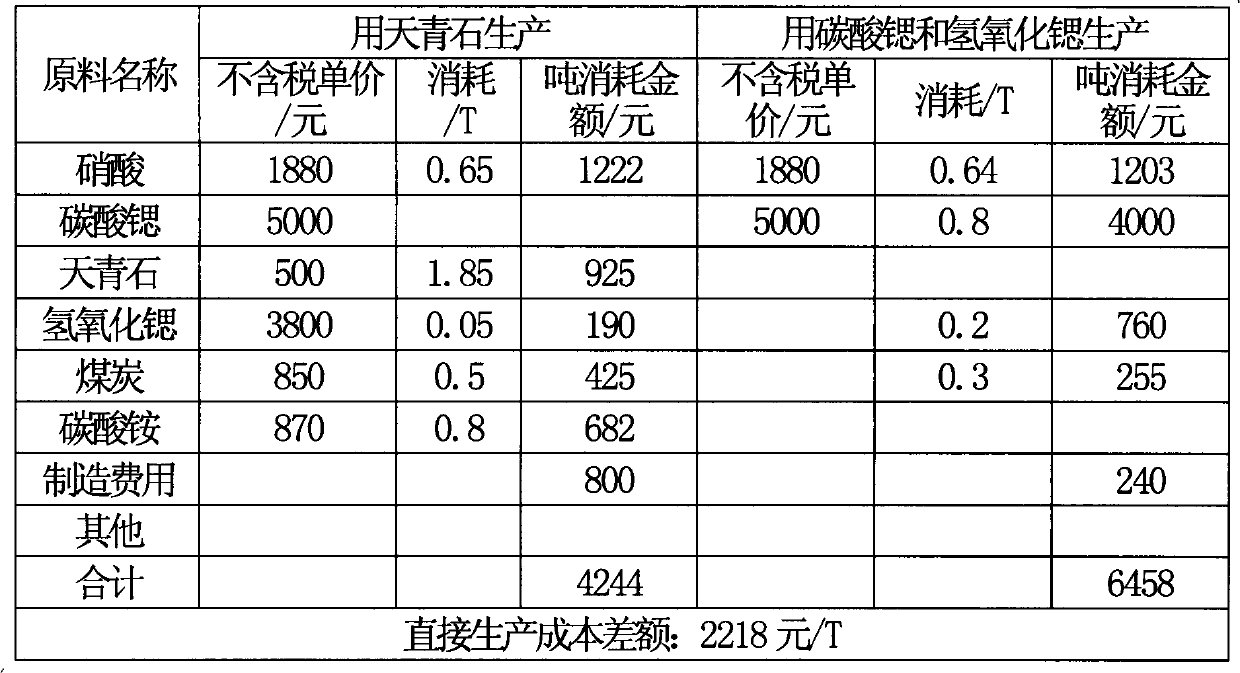

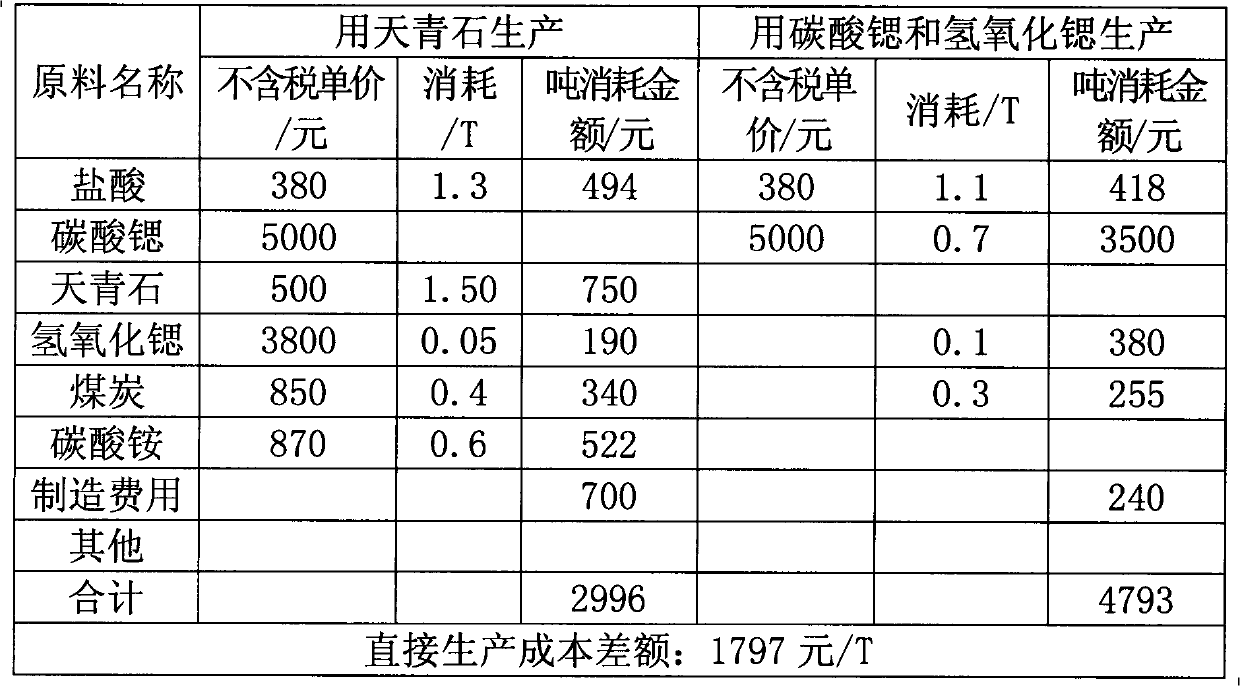

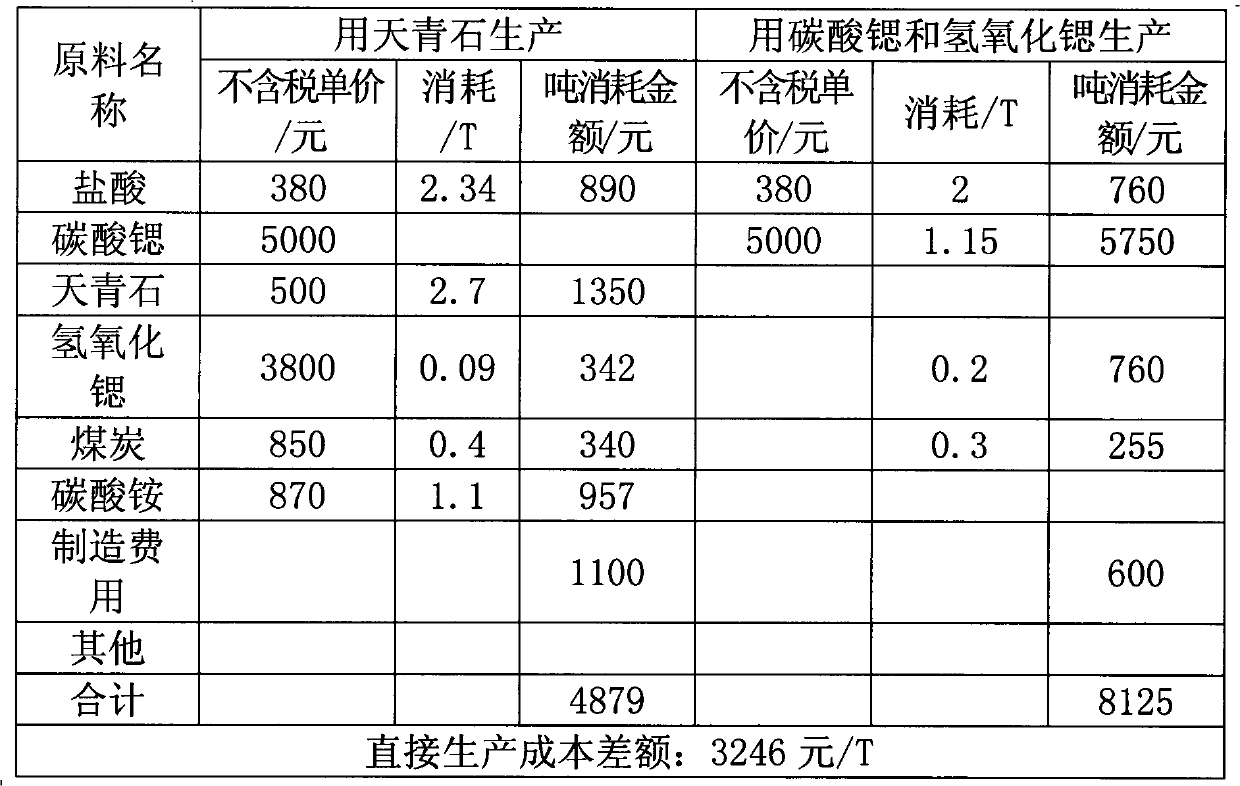

Method for producing less-barium fine strontium salts from celestite

ActiveCN102602974ALow bariumLow costCalcium/strontium/barium carbonatesCalcium/strontium/barium chloridesStrontium carbonateDecomposition

The invention mainly aims to provide a method for producing less-barium fine strontium salts from celestite, and the method is low in cost, which comprises the steps: refining: crushing or grinding the celestite to particles of less than 200 mesh; acid washing: reacting diluted hydrochloric acid with the levigated celestite, and removing a carbonate component in the celestite to obtain high-purity refined celestite; and double decomposition: adding the refined celestite to an ammonium carbonate aqueous solution, uniformly stirring, then reacting in an airtight condition at a reaction pressure of 0.2-0.3MPa and a reaction material temperature of 100-115 DEG C, stopping heating after the reaction is finished, filtering and washing obtained solid to obtain a strontium carbonate crude product, and further refining the strontium carbonate crude product to obtain a product. The method has the advantages that during the double decomposition reaction, when reacting with the celestite, ammonium carbonate only reacts with strontium sulfate in the celestite without reacting with barium sulfate, so that the barium content of the obtained strontium carbonate crude product is very low and lower than 0.05%; and the method is low in production cost and has wide market prospect.

Owner:CHONGQING YUANHE FINE CHEM

Methods of making cesium salts and other alkali metal salts

A method of making a cesium salt is described and involves reacting a cesium sulfate containing solution with lime to form 1) a solution containing at least cesium hydroxide and 2) a residue comprising calcium sulfate. The method further involves removing the residue from the solution and converting the cesium hydroxide that is present in the solution to at least one type of cesium salt. The present invention further relates to uses of the cesium salt as well as methods of making cesium hydroxide using lime. Also, methods of making alkali metal salts and alkali metal hydroxides are also described.

Owner:CABOT SPECIALTY FLUIDS

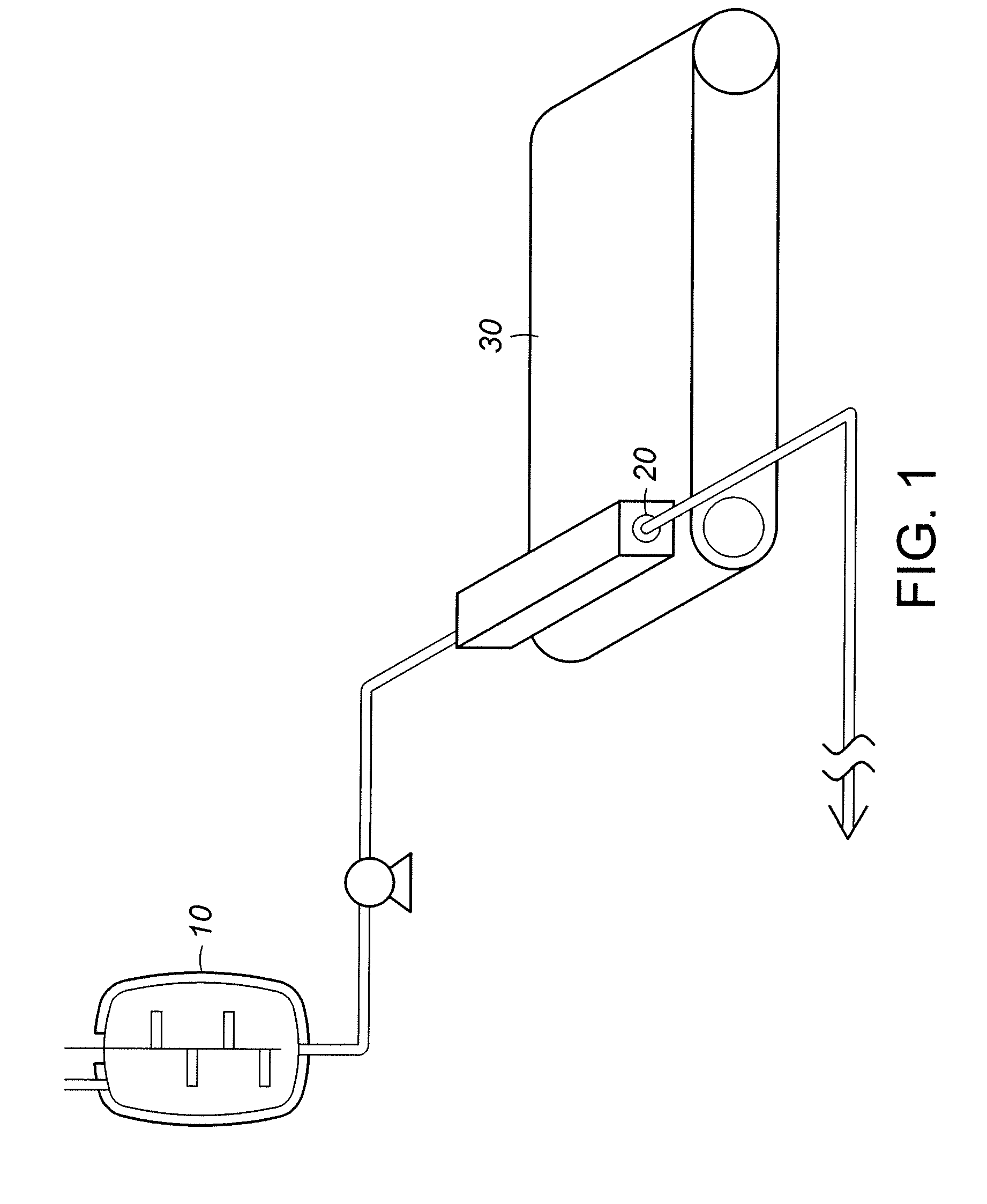

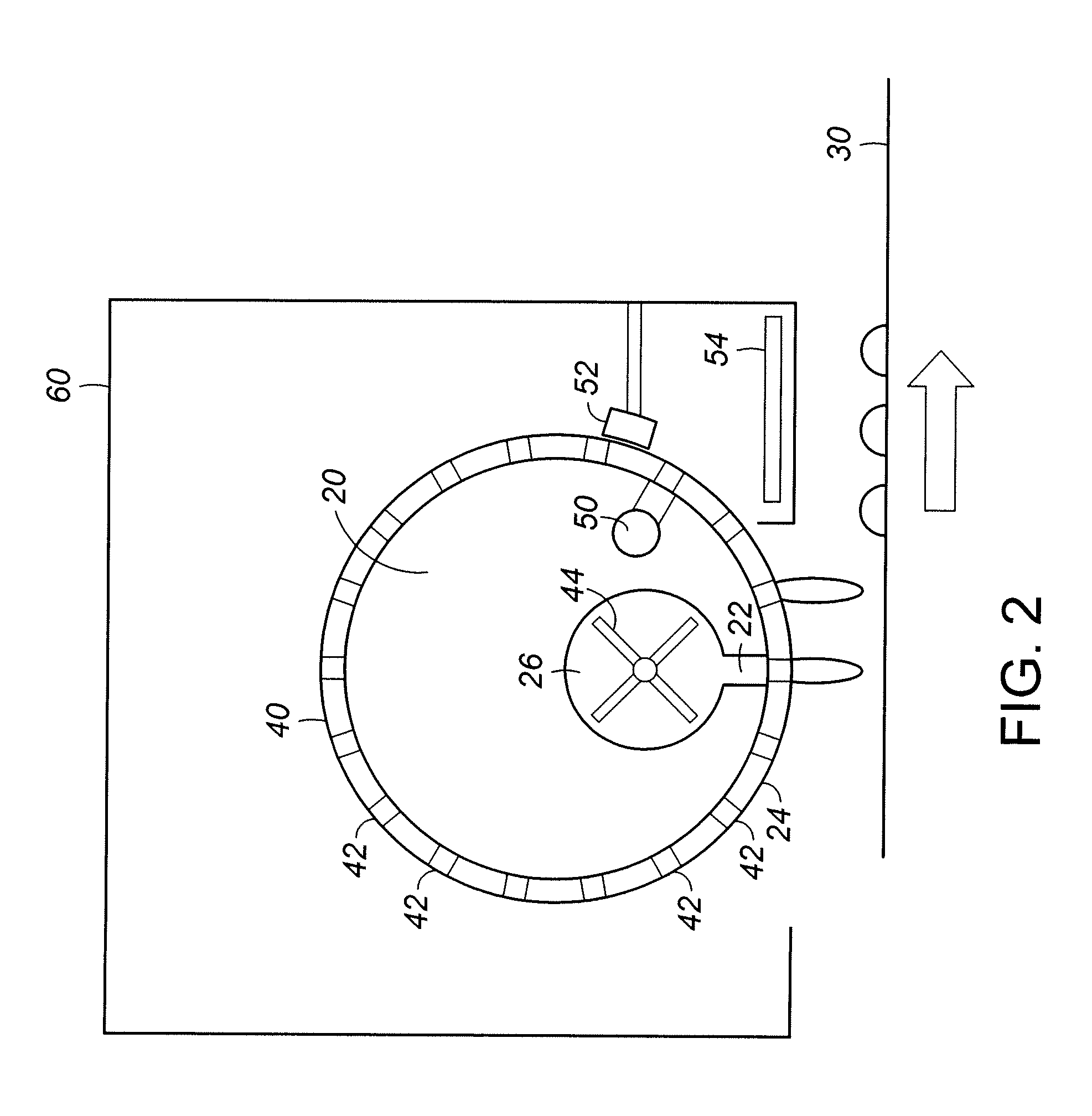

Method and apparatus for extraction of strontium from urine

InactiveUS20130017613A1Simple mixingSimple filter operationTransuranic element compoundsSolid sorbent liquid separationQuantitative determinationIon-exchange resin

The present invention provides an apparatus and rapid methods for extracting strontium ions from urine to provide a concentrated and purified strontium-90 extract suitable for scintillation measurements. The methods remove organic compounds, pigments, and alkali metal ions that can interfere with quantitative determination of strontium-90 in urine. A method of the invention comprises acidifying urine and removing organic pigments therefrom, loading a known quantity of so-treated urine onto a diphosphonic acid-based ion-exchange resin; flowing aqueous methanesulfonic acid through the diphosphonic acid-based ion-exchange resin to elute alkali metal ions therefrom; eluting strontium ions off of the diphosphonic acid-based resin and on to a strontium extraction chromatographic resin with a concentrated aqueous nitric acid solution; subsequently flowing water or a dilute acid stripping solution through the strontium extraction resin to strip the strontium from the strontium extraction resin; and collecting the strontium-containing stripping solution eluting from the strontium extraction resin.

Owner:UCHICAGO ARGONNE LLC

Process for the formulation of potassium chloride from a carnallite source

ActiveUS20110123420A1Speed up the processSolvent extractionCrystallization separationSolubilitySaturated Level

A process for formulating high purity potassium chloride from a carnallite source. The process takes advantage of solubility differences and saturation levels in a multiple salt system generated upon dissolution of carnallite. In the system, the sodium chloride is kept in solution and the magnesium chloride present in the system is controlled to be in a concentration range of between 12% and 25% by weight. This avoids co-precipitation of sodium chloride with the potassium chloride during crystallization and therefore prevents the sodium chloride from contaminating the potassium chloride. The result is high grade potassium chloride.

Owner:KARNALYTE RESOURCES

Reduction in mineral salt deposition

InactiveUS6881231B2Energy was cheapEffective controlCalcium/strontium/barium carbonatesMagnesium chloridesAqueous solutionSolid surface

A composition for reducing deposition of a mineral salt from an aqueous supersaturated solution onto a solid surface in contact with the aqueous supersaturated solution which composition comprises a dispersion of either (i) seed crystals of the mineral salt in an aqueous solution of the mineral salt or (ii) seed crystals of a salt isomorphous with the mineral salt in an aqueous solution of the isomorphous salt wherein the dispersed seed crystals are of Mean particle size of less than 2.5 microns.

Owner:ASYMPTOTE

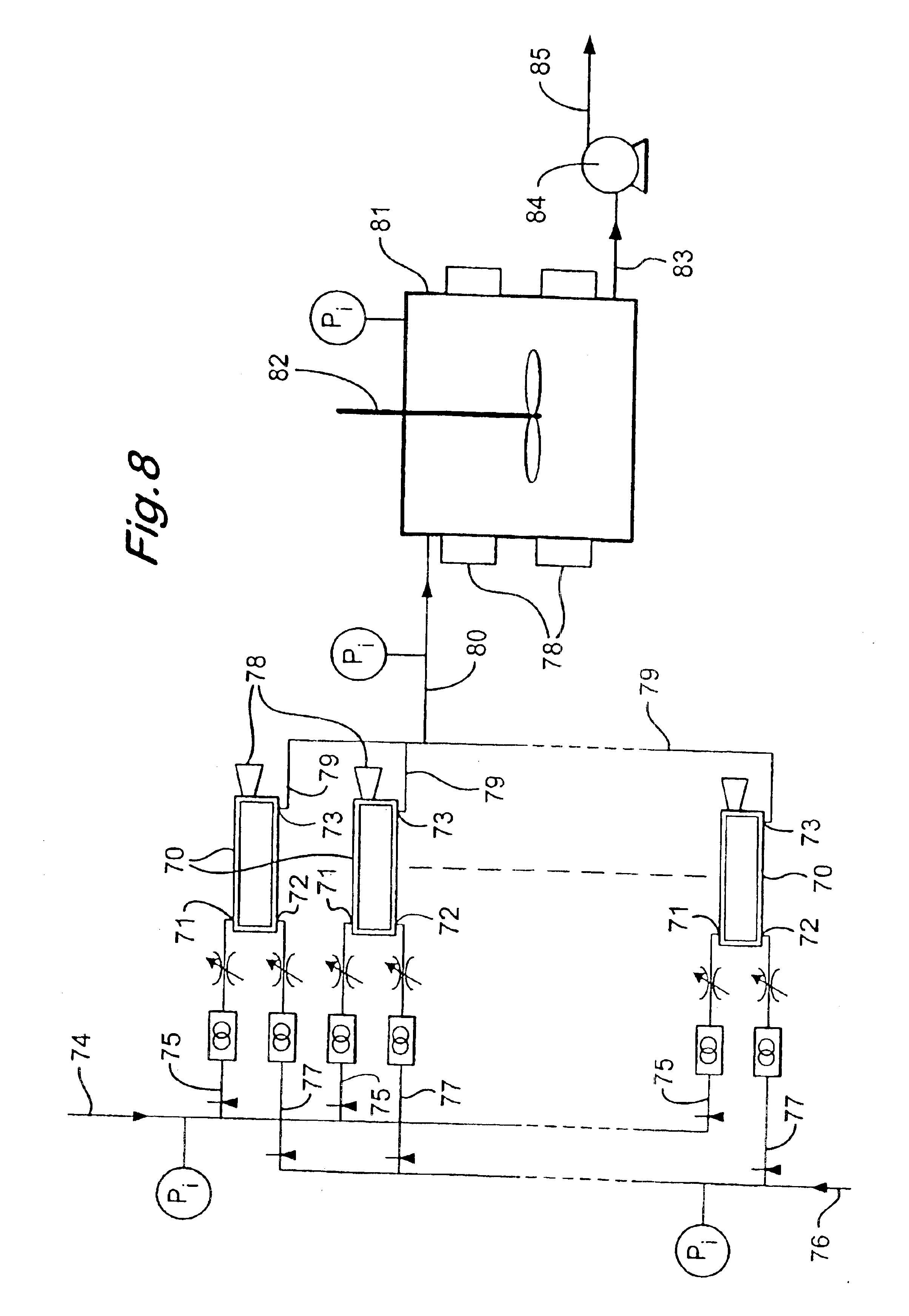

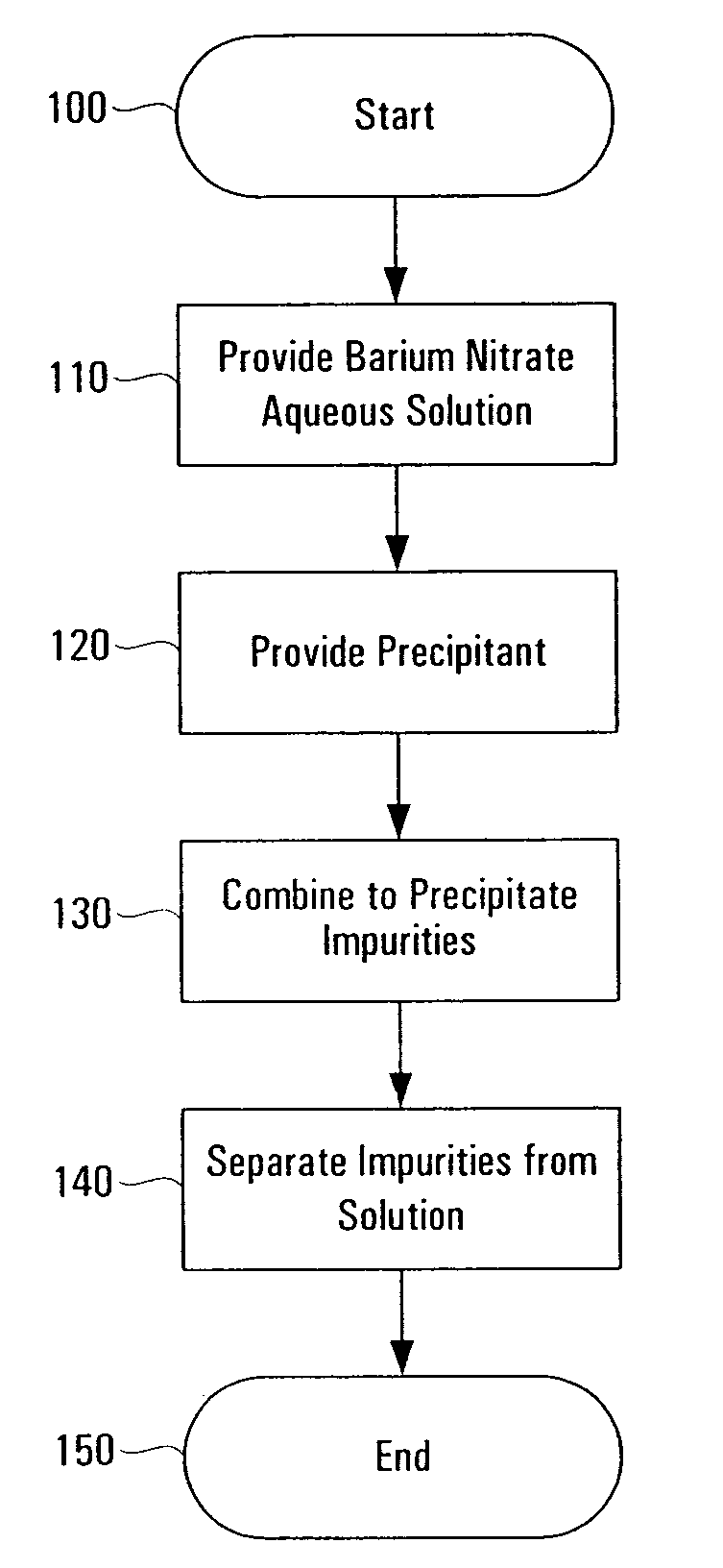

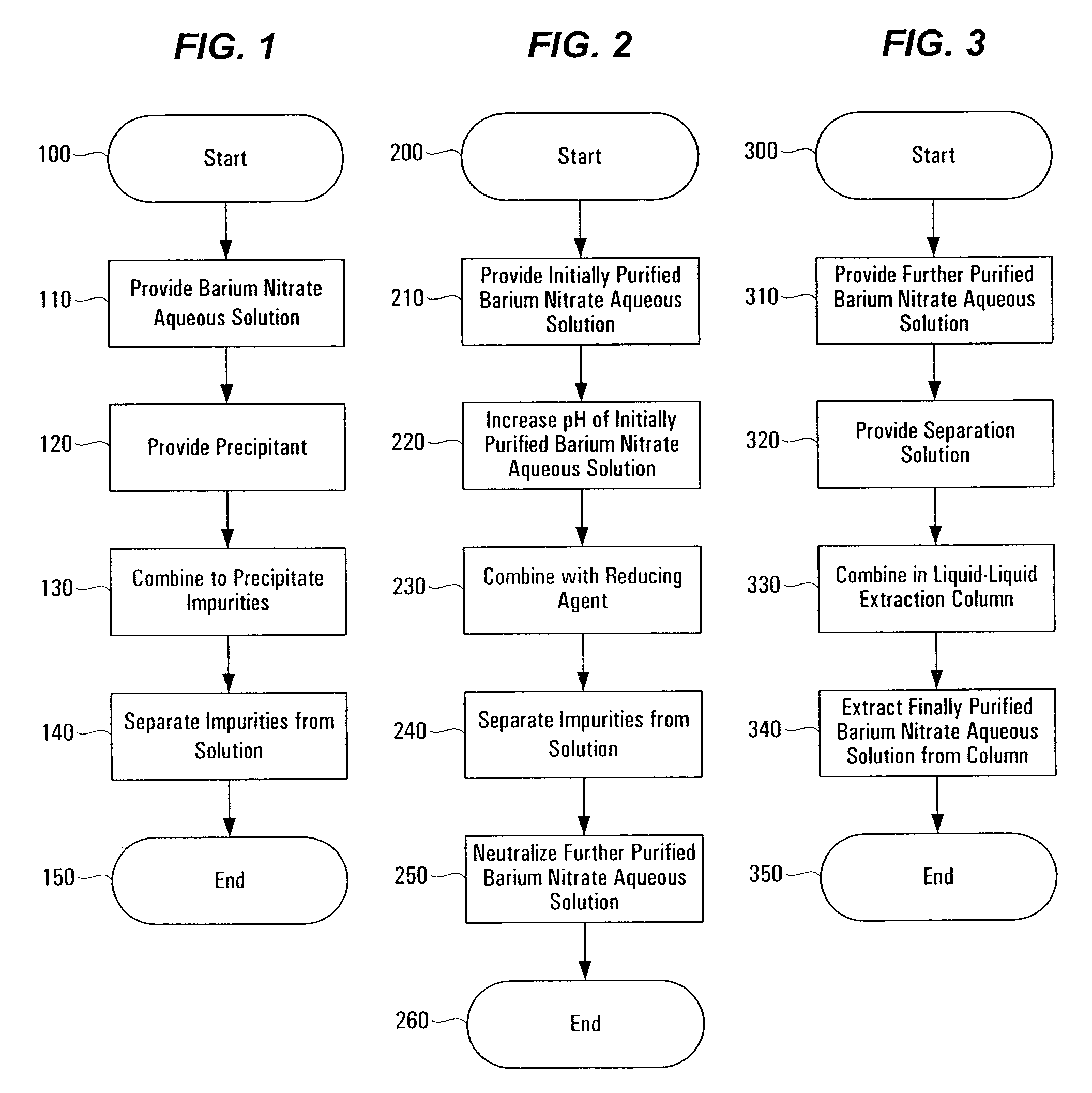

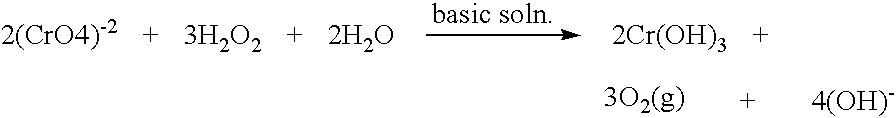

Method of purifying barium nitrate aqueous solution

InactiveUS7648687B1Solid sorbent liquid separationLiquid solutions solvent extractionBarium nitrateOxidation state

Purification techniques have been developed for ceramic powder precursors, e.g., barium nitrate. These techniques can be performed using one or more of the following operations: (1) removal of impurities by precipitation or coprecipitation and separation using a nonmetallic-ion-containing strong base, e.g., tetraalkylammonium hydroxides; (2) reduction of higher oxidation-state-number oxymetal ions and subsequent precipitation as hydroxides that are separated from the solution; and (3) use of liquid-liquid exchange extraction procedures to separate certain impurities.

Owner:EESTOR

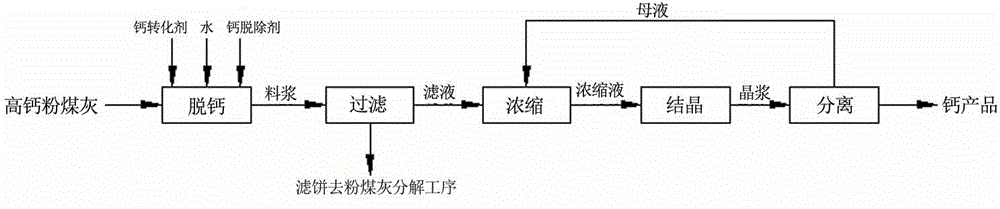

Method for treating calcium in high-calcium fly ash

ActiveCN104876253ARealize comprehensive utilizationReduce the amount of secondary residueCalcium/strontium/barium chloridesCalcium/strontium/barium nitratesAluminum ammonium sulfateAlkaline hydrolysis

The invention discloses a method for treating calcium in high-calcium fly ash, which comprises the steps of phase inversion reaction, decalcification reaction and calcium compound preparation. The technique principle comprises the following steps: converting calcium sulfate in fly ash into calcium compounds capable of reacting with hydrochloric acid and nitric acid by a phase inversion process, treating the fly ash with hydrochloric acid or nitric acid to convert the calcium compounds in the fly ash into soluble calcium chloride or calcium nitrate, and separating to collect a calcium chloride or calcium nitrate solution and a decalcified fly ash filter cake; and concentrating the calcium chloride or calcium nitrate solution, and crystallizing to collect the calcium chloride or calcium nitrate product. The decalcified fly ash filter cake is sent to a subsequent procedure and subjected to acid hydrolysis and alkaline hydrolysis, the acid leach solution is used for preparing aluminum ammonium sulfate, aluminum oxide, cryolite, aluminum fluoride, high-purity iron oxide or iron oxide red, the water glass is used for preparing silica white other silicon compounds, and the decomposition residues are mixed with coal to be used as a boiler fuel.

Owner:河南省睿博环境工程技术有限公司

Treatment of solid containing material derived from effluent

InactiveUS6425973B1Reducing and eliminating cost and environmental impactSimpler and cheapCalcium/strontium/barium carbonatesMagnesium halidesParticulatesSludge

A method of treating solid containing material derived from effluent or sludge from a plant for de-inking paper, the material containing calcium in the form of one or more insoluble calcium compounds, the method including the steps of treating the material with an acid to cause dissolution of the calcium thereby forming a calcium ion-containing solution in which insoluble solids are suspended, separating the solution from the insoluble solids and incinerating the separated solids. The solution containing calcium ions may be treated by adding one or more reagents to form a calcium compound precipitate, eg calcium carbonate. The particulate solids produced following the incineration step and following the precipitate formation may be employed as pigments or fillers in paper making or paper coating.

Owner:IMERYS MINERALS

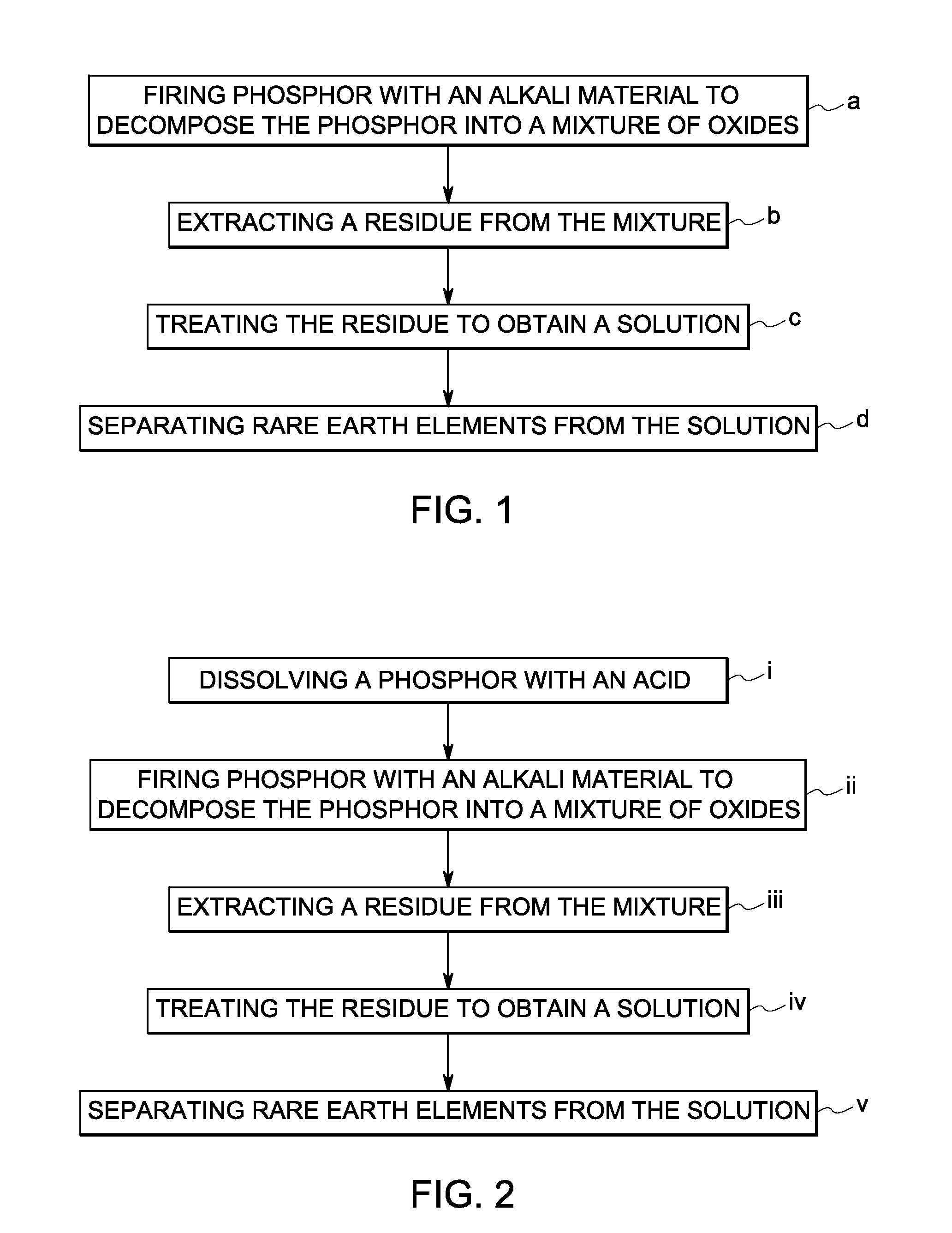

Rare earth recovery from fluorescent material and associated method

A method of recovering a rare earth constituent from a phosphor is presented. The method can include a number of steps (a) to (d). In step (a), the phosphor is fired with an alkali material under conditions sufficient to decompose the phosphor into a mixture of oxides. A residue containing rare earth oxides is extracted from the mixture in step (b). In step (c), the residue is treated to obtain a solution, which comprises rare earth constituents in salt form. Rare earth constituents are separated from the solution in step (d).

Owner:GENERAL ELECTRIC CO

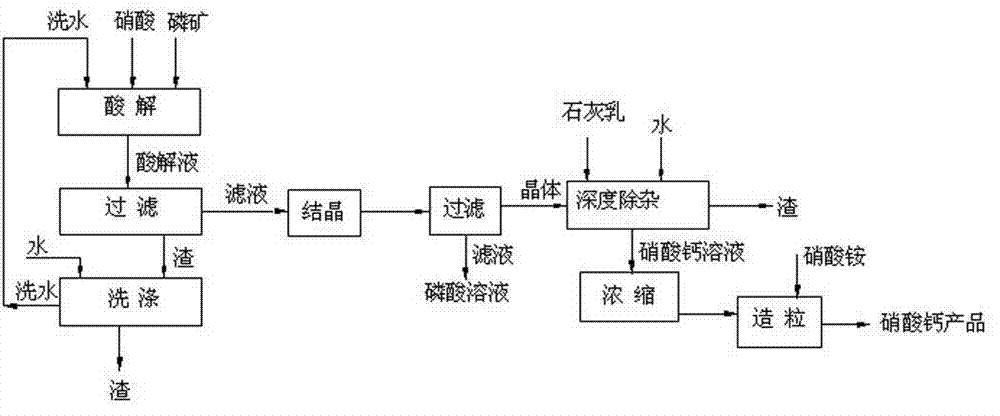

Method for producing water-soluble calcium nitrate dihydrate and phosphoric acid by decomposing phosphorite through nitric acid

InactiveCN103073041ABroaden the product chainPromote absorptionCalcium/strontium/barium nitratesPhosphoric acidSolubilitySulfate radicals

The invention relates to a water-soluble calcium nitrate production method, and especially relates to a method for producing water-soluble calcium nitrate dihydrate and phosphoric acid by decomposing phosphorite through nitric acid. The method comprises the following steps: decomposing phosphorite by nitric acid to prepare an acidolysis liquid, carrying out freezing crystallization of the acidolysis liquid to separate a calcium nitrate crystal and phosphoric acid, dissolving the calcium nitrate crystal, carrying out deep impurity removal of the obtained calcium nitrate solution, carrying out evaporative concentration of the calcium nitrate solution, removing water from the obtained crystal, and carrying out ammonium nitrate wrapping granulation to prepare calcium nitrate dihydrate having a water solubility of not less than 99.9%. The method avoids the insufficient utilization of sulfate radicals residual in phosphogypsum of sulfuric acid methods when wet phosphoric acid is simultaneously produced, and the production of the high-added-value calcium nitrate dihydrate through the combination of nitrate radicals with calcium ions has the advantages of widening of the product chains of phosphoric acid or nitric phosphate enterprises, economic utilization of the nitrogen element in nitric acid, and improvement of the competition advantages of the enterprises.

Owner:云天化集团有限责任公司 +2

Strontium nitrate and method for manufacturing same

Low-cost, high-purity strontium nitrate that is low in Ba, Na, Ca, Cr, and other impurities and that is suitable for use in airbags or the like is provided. High-purity strontium nitrate having a Ba content of 0.01 wt % or lower, an Na content of 0.005 wt % or lower, a Ca content of 0.01 wt % or lower, a Cr content of less than 0.001 wt %, and a purity of 99.5 wt % or higher is produced by a manufacturing method comprising a first step for performing crystallization by adding nitric acid to an aqueous solution obtained by dissolving a strontium compound as a starting material, a second step for separating the resulting crystals, a third step for crystallizing the resulting separated solution, and a fourth step for separating the resulting crystals.

Owner:DOWA METALS & MINING CO LTD +1

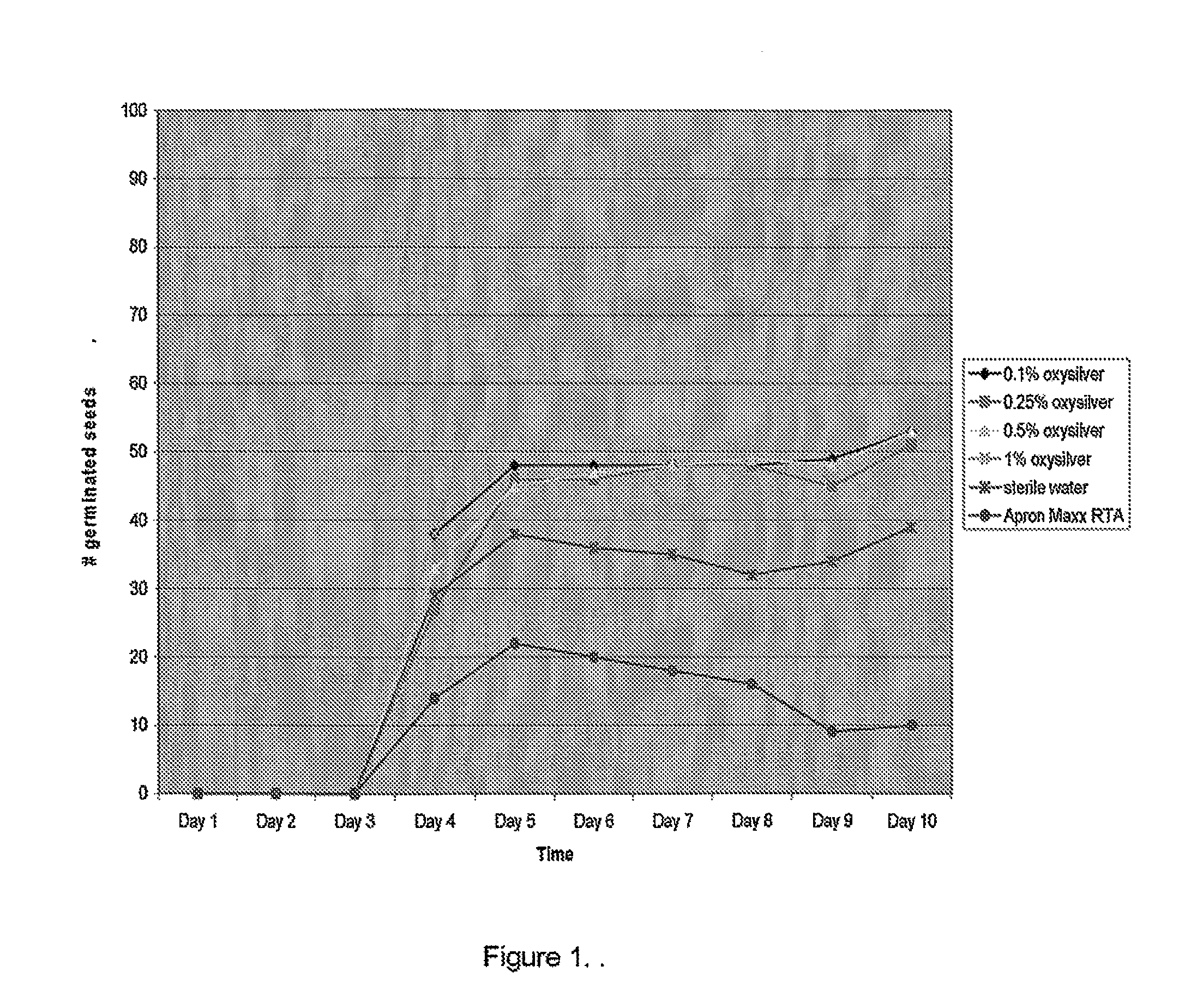

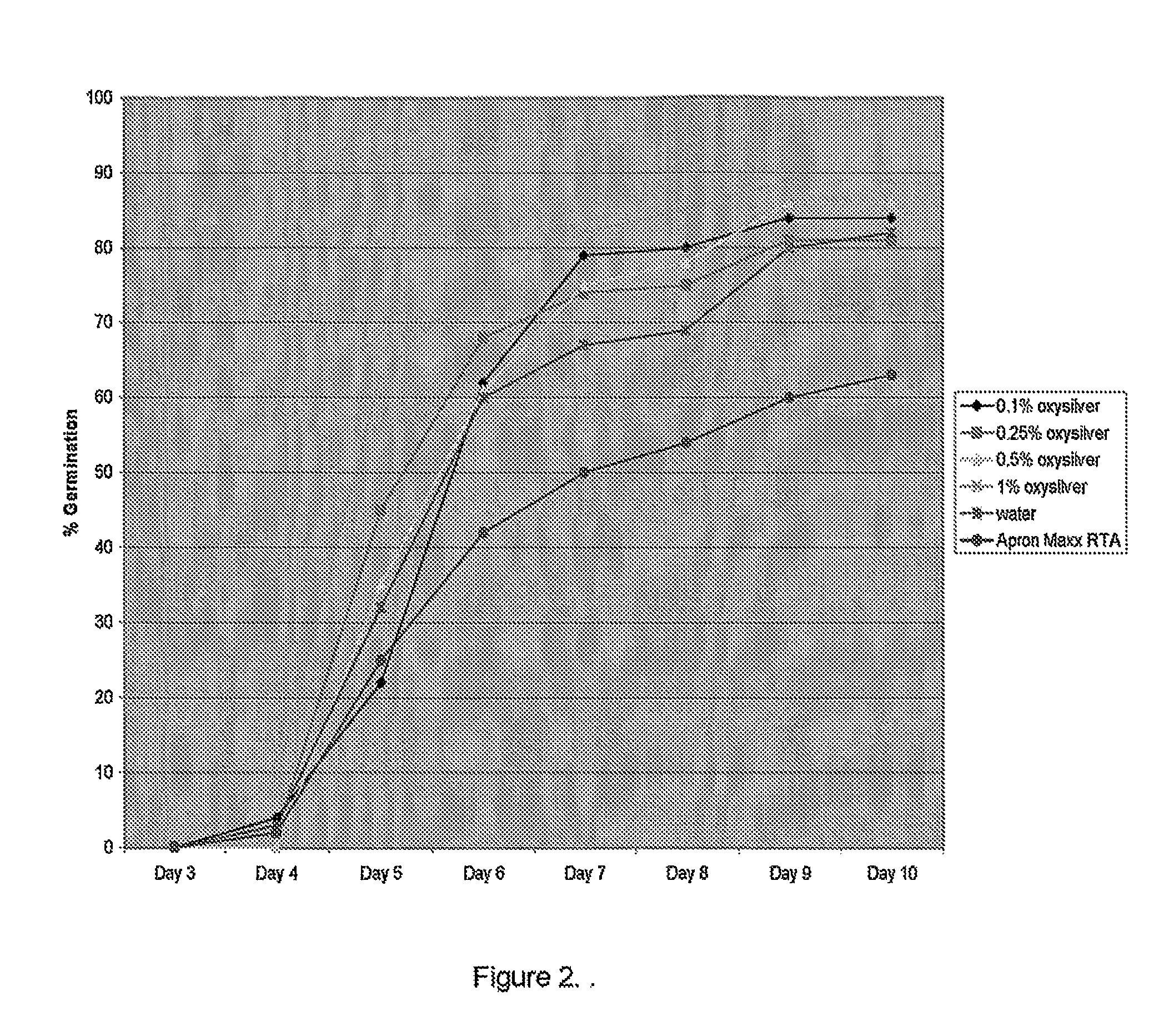

Compositions and Methods Comprising High Valency Silver for Increasing Seed Germination

InactiveUS20110275518A1Promote seed germinationImproved and efficient active agent delivery systemBiocideNitrogen compoundsBiofilmGermination

The present invention is compositions and methods for improving seed germination rates or speed using a composition comprising at least one high valency silver ion. The compositions and methods of the present invention are effective in treating biofilms.

Owner:MARQUES LYRIAM L +2

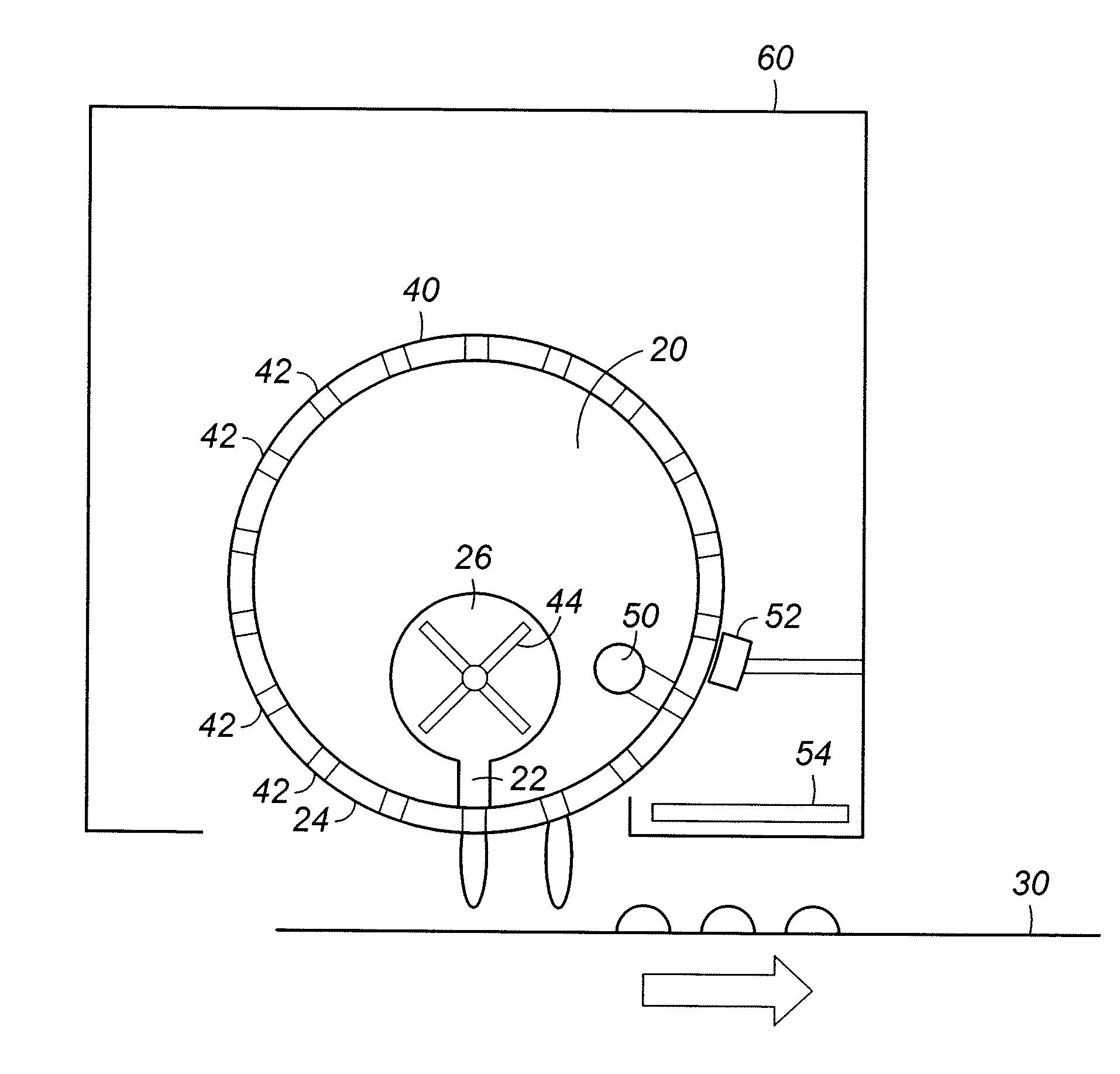

Pastillation of ammonium sulfate nitrate

A process is presented for the production of ammonium sulfate nitrate. The process provides for producing a highly uniform product and having a substantially uniform size. The process includes reacting ammonium sulfate and ammonium nitrate to form an FASN slurry melt. The slurry melt is continuously stirred and heated to keep the slurry melt under a shear thinned condition and at a uniform temperature until the slurry melt is extruded, cooled and solidified.

Owner:ADVANSIX RESINS & CHEM LLC

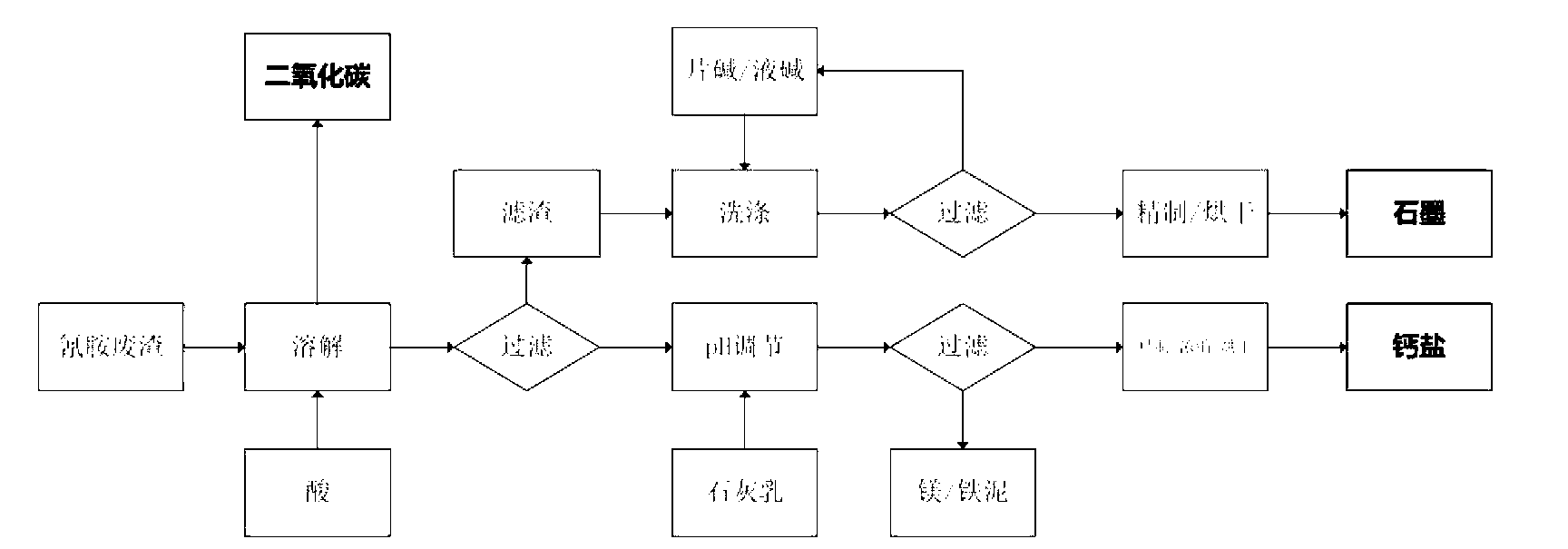

Comprehensive utilization method of cyanamide waste residue

InactiveCN103011161AAchieve reuseSimple processCalcium/strontium/barium chloridesCarbon compoundsCalcium formateNuclear chemistry

The invention relates to a comprehensive utilization method of a cyanamide waste residue. The comprehensive utilization method of the cyanamide waste residue comprises the following steps: firstly, adding an acid into the cyanamide waste residue for reaction, collecting carbon dioxide gas generated in the reaction, and filtering a reacted solution to obtain a filter residue A and a filtrate A; heating the filtrate A to 30-100 DEG C; regulating pH to 7.0-9.0 by using lime milk; filtering again; and evaporating for concentrating, crystallizing and drying an obtained filtrate Bto obtain a calcium salt. Through effective treatment of the cyanamide waste residue, inorganic calcium salts (such as calcium chloride, calcium nitrate and calcium nitrite) or organic calcium salts (such as calcium formate, calcium acetate and amino calcium sulfonate), graphite powder and carbon dioxide can be prepared, thus achieving recycle of industrial wastes; the comprehensive utilization method is simple in whole technical process and low in treatment cost; and the added valve of the product is greatly improved.

Owner:宁夏兴平精细化工股份有限公司

Method for extracting phosphate concentrate from phosphate tailings and cooperatively producing calcium ammonium nitrate and magnesium ammonium sulphate

InactiveCN104860279AEfficient recyclingAlleviate the status quo of depletionMagnesium compoundsCalcium/strontium/barium nitratesPhosphateDigestion Treatment

The invention discloses a method for extracting phosphate concentrate from phosphate tailings and cooperatively producing calcium ammonium nitrate and magnesium ammonium sulphate. Phosphate tailings are calcined under high temperature, hot water is added into the calcined material for digestion treatment, an ammonium nitrate solution is added to the calcined material, the mixture is stirred, calcium is extracted under a certain temperature, calcium-containing leaching liquid and leaching residues are obtained, phosphate concentrate and magnesium-containing leaching liquid are obtained after magnesium is extracted from the leaching residues with an ammonium sulfate solution, and calcium ammonium nitrate and magnesium ammonium sulphate are obtained after the calcium-containing leaching liquid and the magnesium-containing leaching liquid are concentrated and dried. According to the method, phosphate concentrate, calcium ammonium nitrate and magnesium ammonium sulphate are prepared with phosphate tailings as the main raw materials, large-scale treatment can be carried out on the phosphate tailings, the problem that because phosphate tailings pile up in quantity, the phosphate tailings occupy a lot of land and pollute the environment is solved, and the obtained phosphate concentrate, calcium ammonium nitrate and magnesium ammonium sulphate can bring certain economic interests.

Owner:GUIZHOU RES INST OF CHEM IND

Treatment of solid containing material derived from effluent

InactiveUS7300539B2Improve propertiesCalcium/strontium/barium carbonatesCellulosic pulp after-treatmentSludgeSolid matter

A method of treating solid containing material derived from effluent or sludge from a plant for deinking paper, the material containing calcium in the form of one or more insoluble calcium compounds, the method including the steps of treating the material with an acid to cause dissolution of the calcium thereby forming a calcium ion-containing solution in which insoluble solids are suspended, separating the solution from the insoluble solids and incinerating the separated solids. The solution containing calcium ions may be treated by adding one or more reagents to form a calcium compound precipitate, eg calcium carbonate. The particulate solids produced following the incineration step and following the precipitate formation may be employed as pigments or fillers in paper making or paper coating.

Owner:IMERYS MINERALS LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com