Patents

Literature

93 results about "Chromium phosphate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

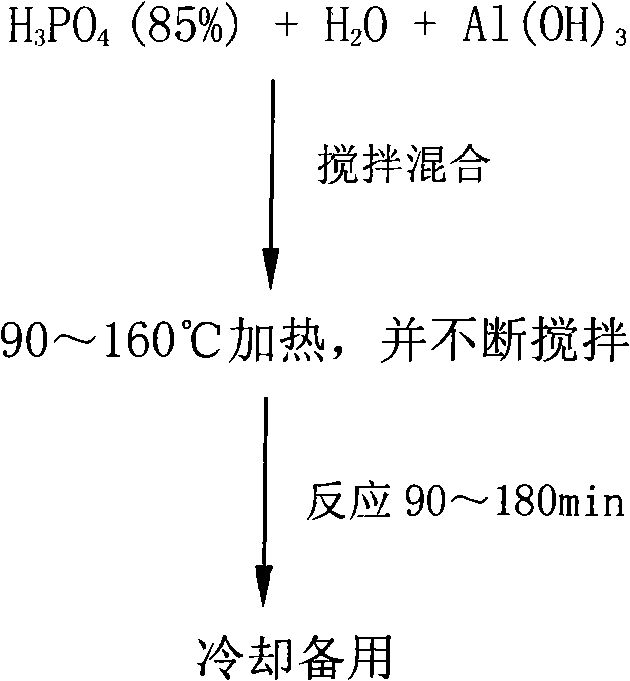

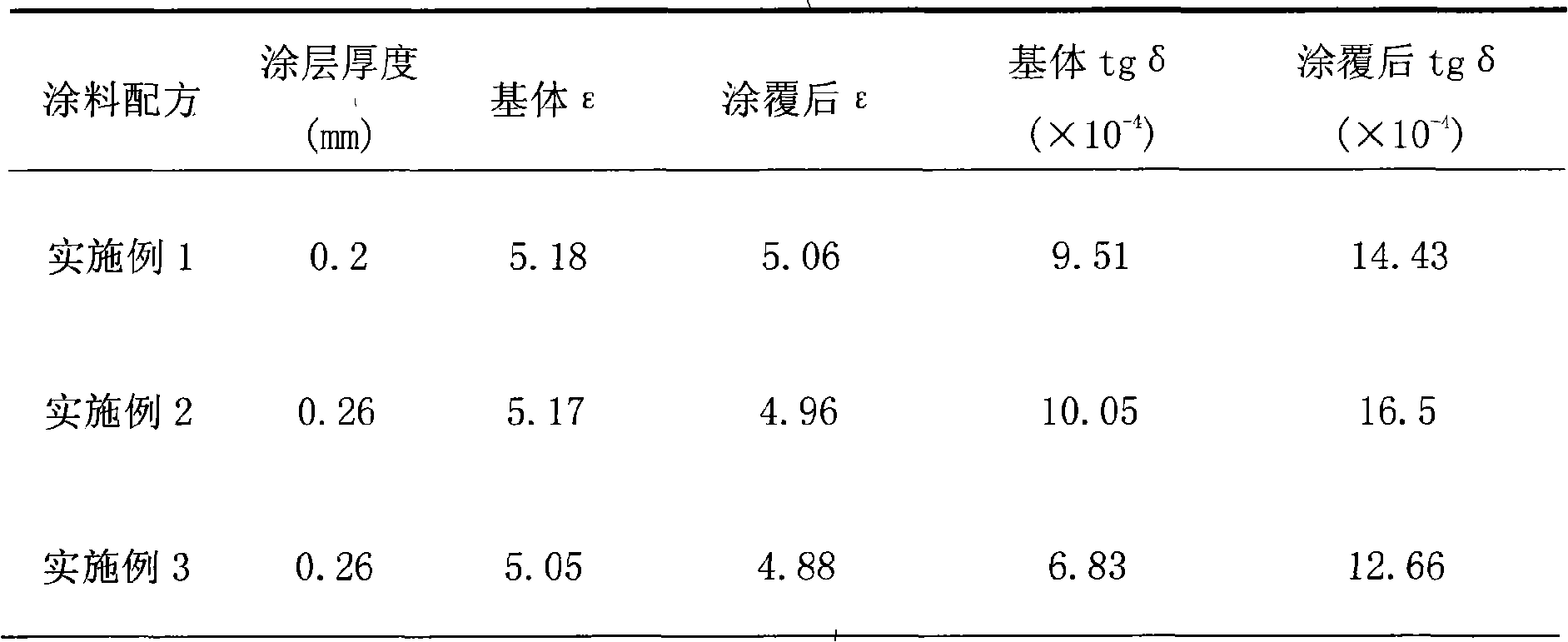

Phosphate-silicon dioxide low-dielectric high temperature-resistant coating and preparation thereof

The invention discloses a low-dielectric high-temperature-resistant phosphate-silicon dioxide coating, with the mass percentage content between the components and the raw material as follows: 50-80% of percentage content of inorganic compound binder, 15-50% of high-temperature filler, 0.5-1.5 wt% of curing agent, 2-5 wt% of thickener, and 0.3-1.5wt% of surfactant; the inorganic compound binder is the mixture of aluminum phosphate or aluminium-chromium phosphate and silicon collosol; the high-temperature resistant filler is the mixture of fused quartz powder and refined quartz powder or alpha-Al2O3 power; the curing agent is MgO; the thickener is fumed silica; the surfactant is non-ionic surfactant. The phosphate binder is firstly prepared, followed by phosphate / silicon collosol compound binder; then the non-ionic surfactant and the high-temperature resistant filler are added to the compound binder, followed by the thickener and the curing agent, then the mixture is evenly mixed. The invention can be used for the surface protection of porous inorganic materials or non-porous inorganic materials and is typically used as wave-transparent material for aerospace crafts.

Owner:TIANJIN UNIV

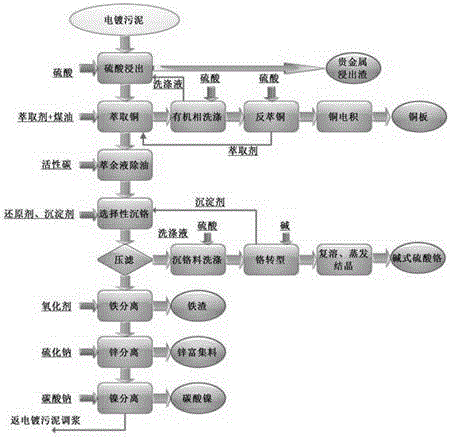

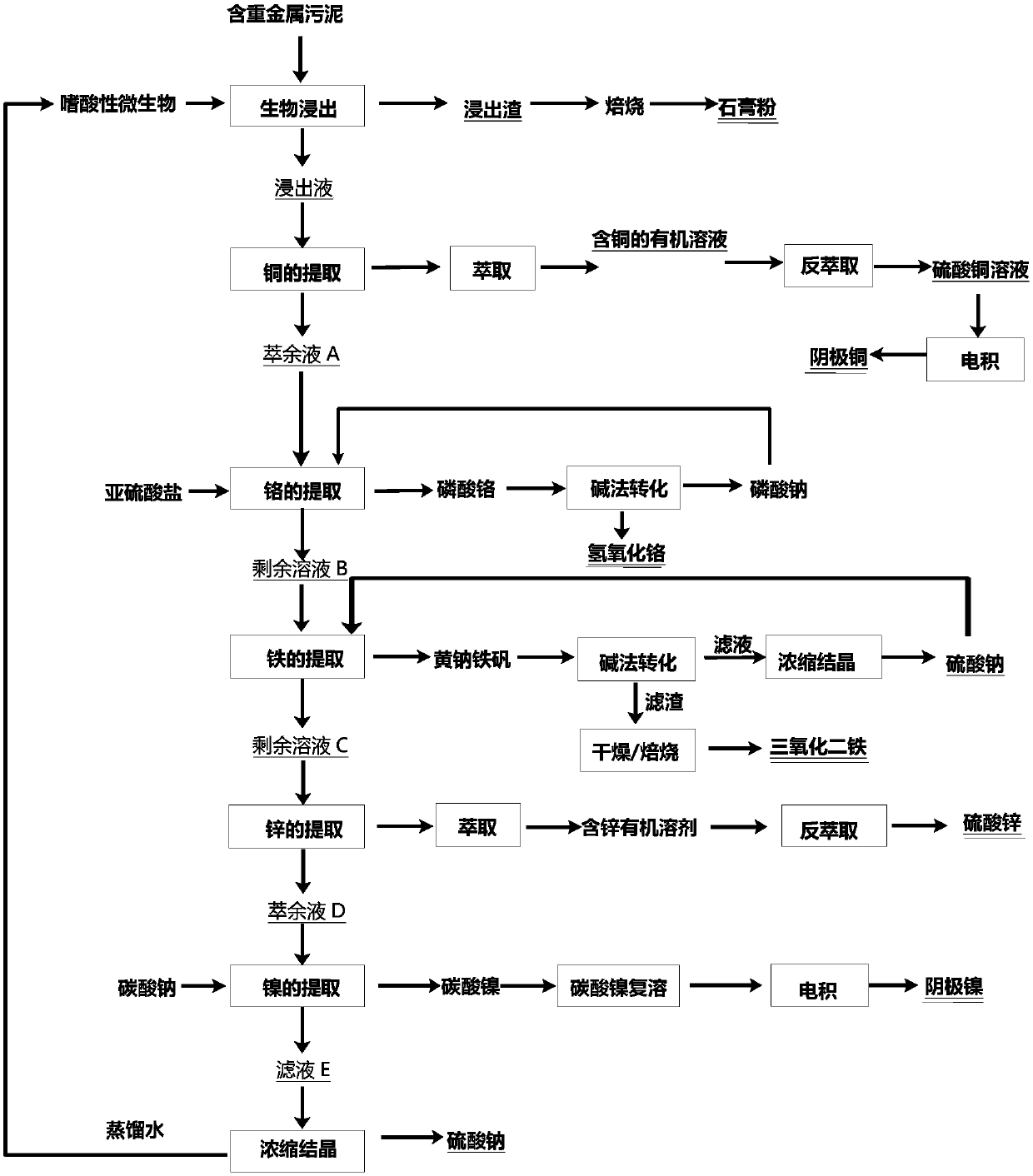

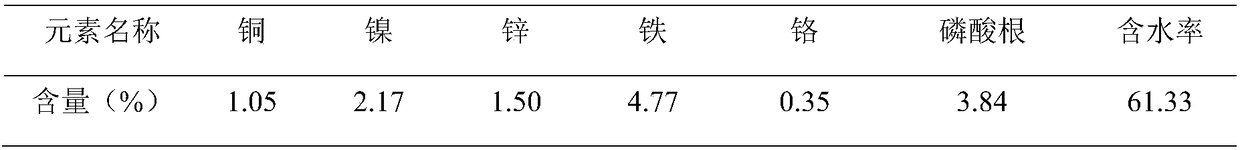

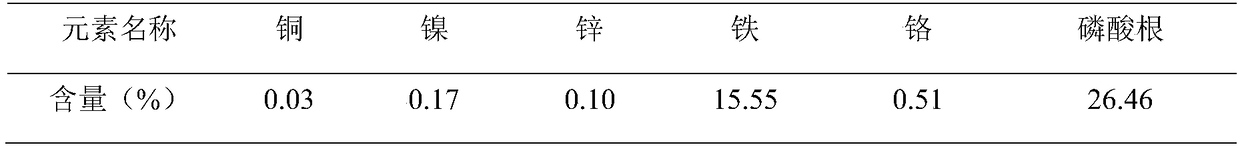

Method for resource utilization of various metals in electroplating sludge

InactiveCN104593598AHigh recovery rateBroaden sources of raw materialsProcess efficiency improvementResource utilizationSludge

Owner:BEIJING GENERAL RES INST OF MINING & METALLURGY +1

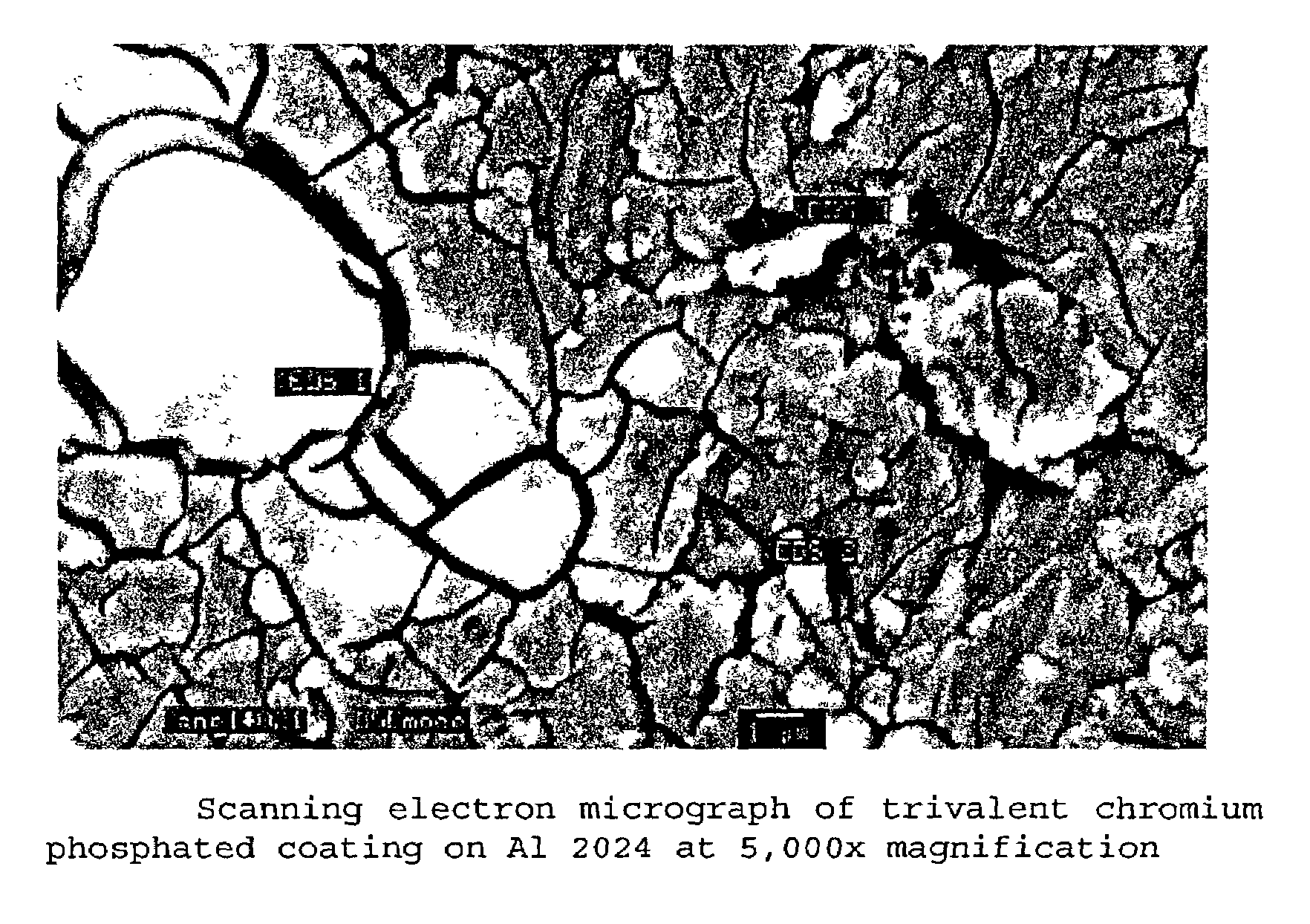

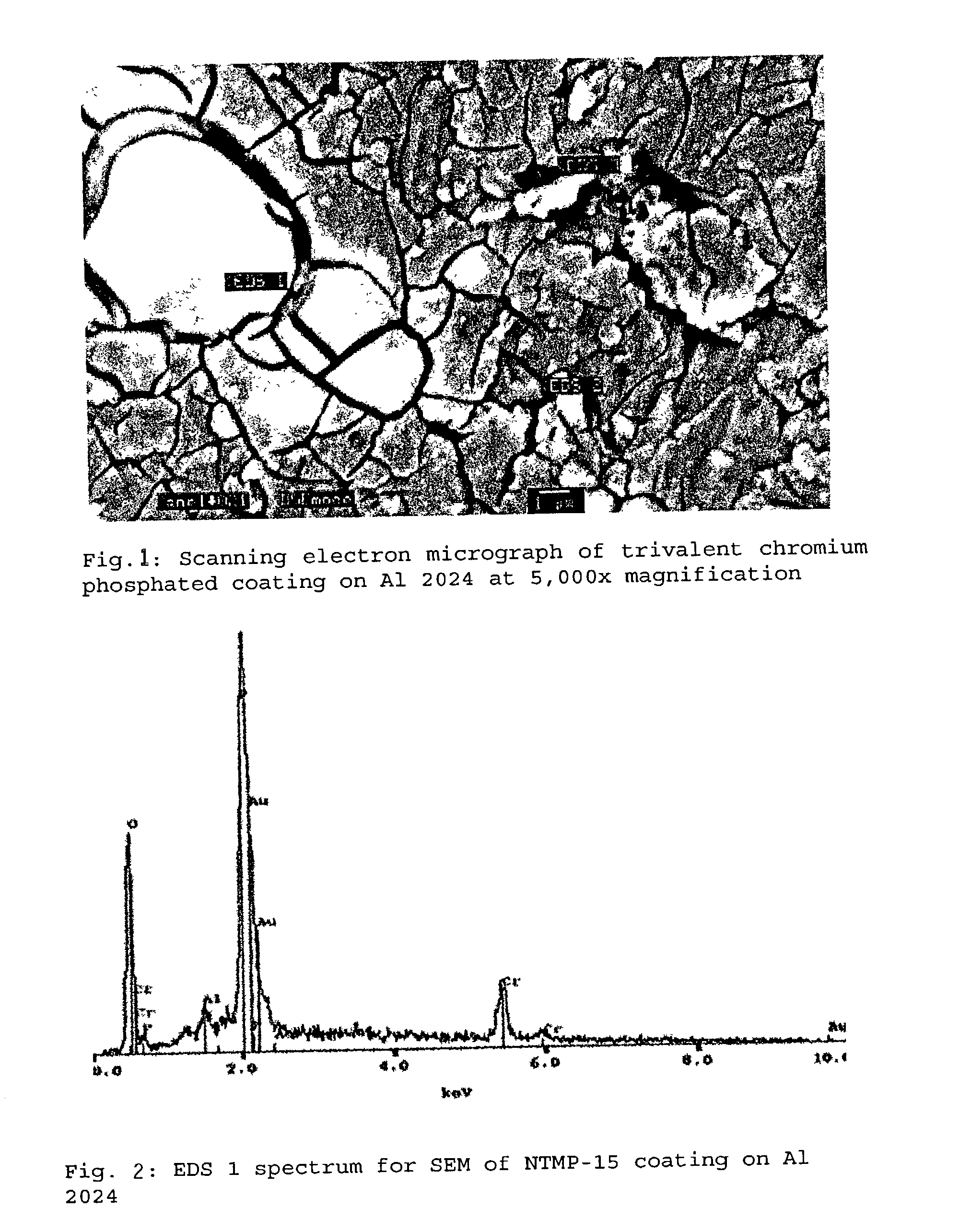

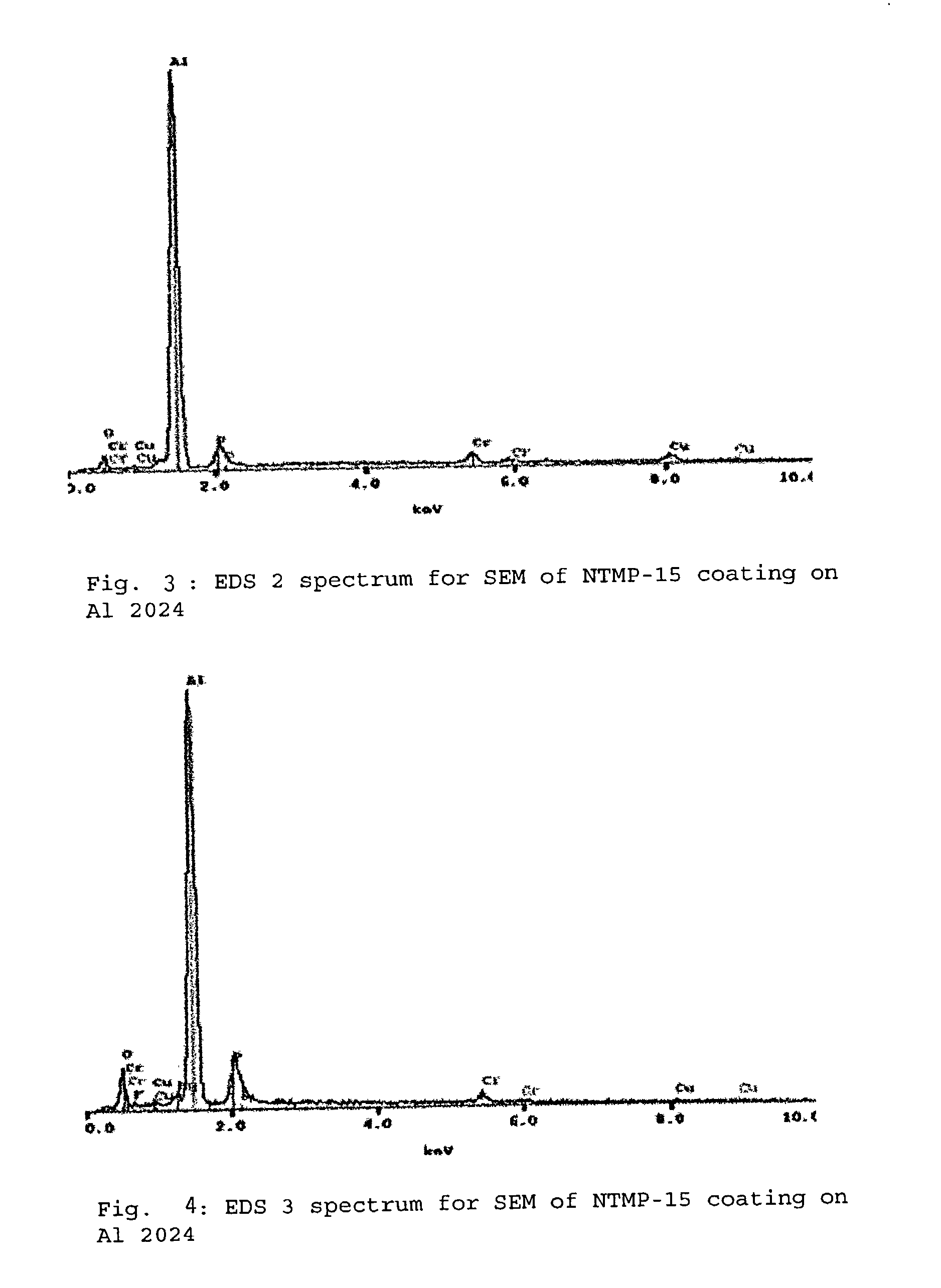

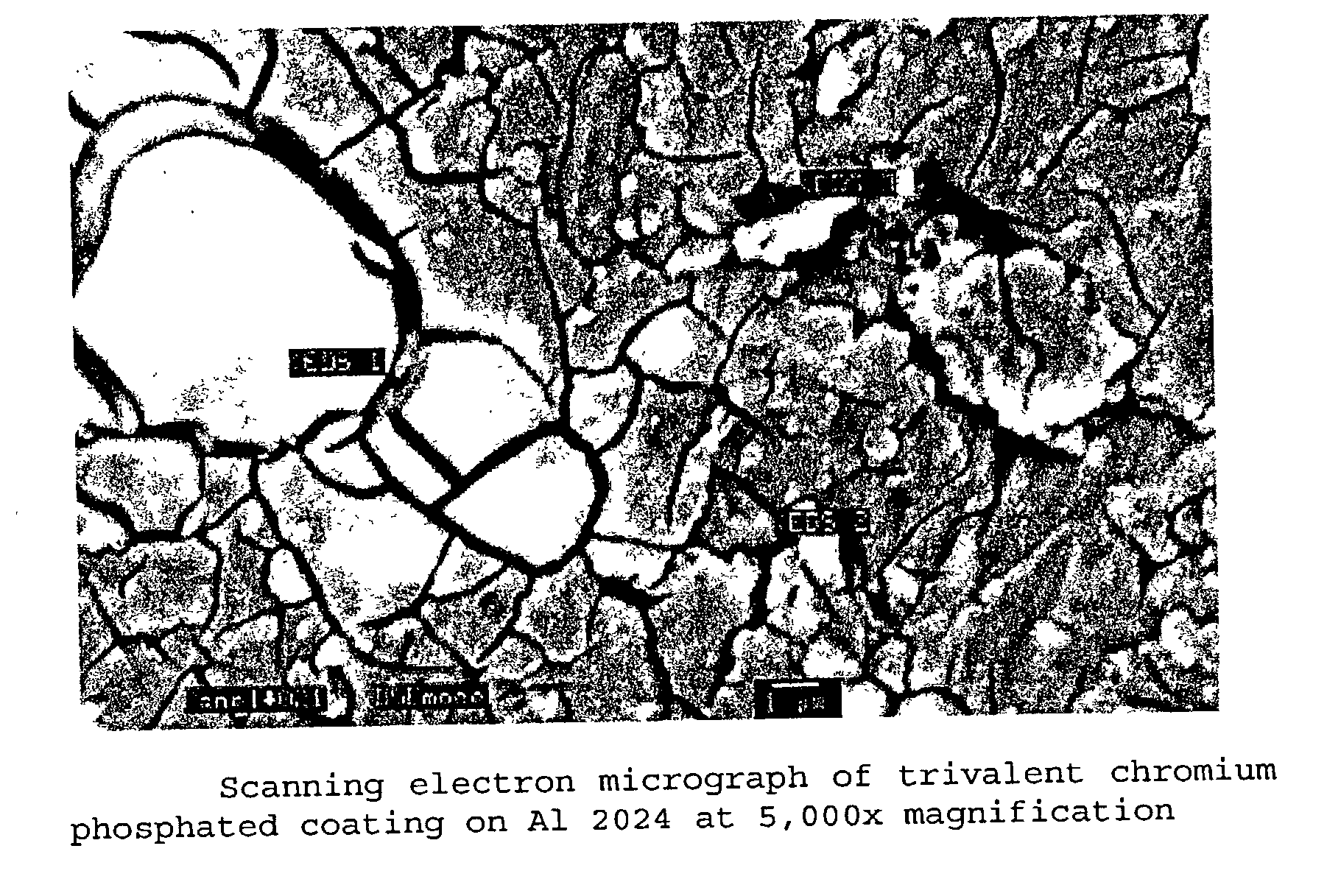

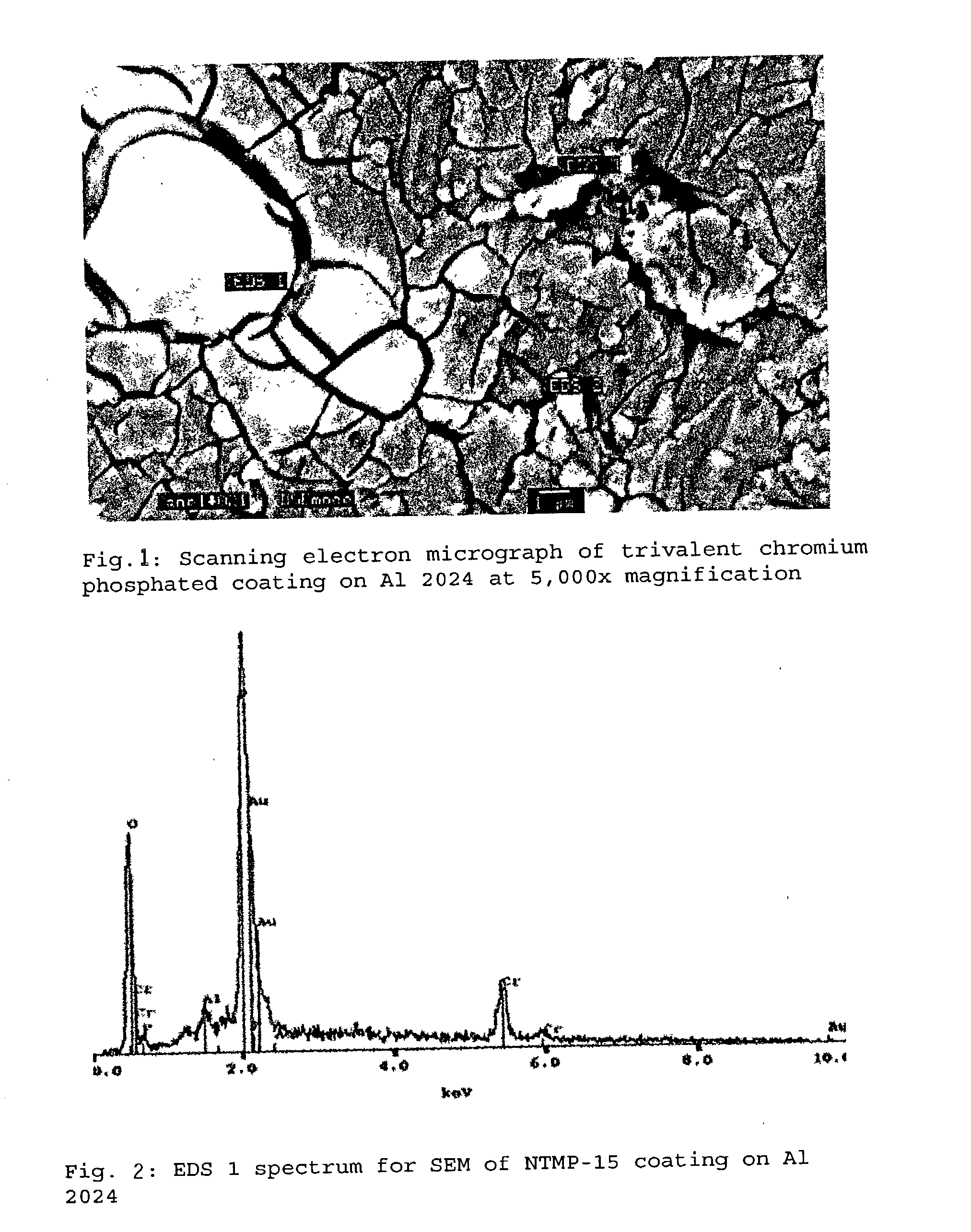

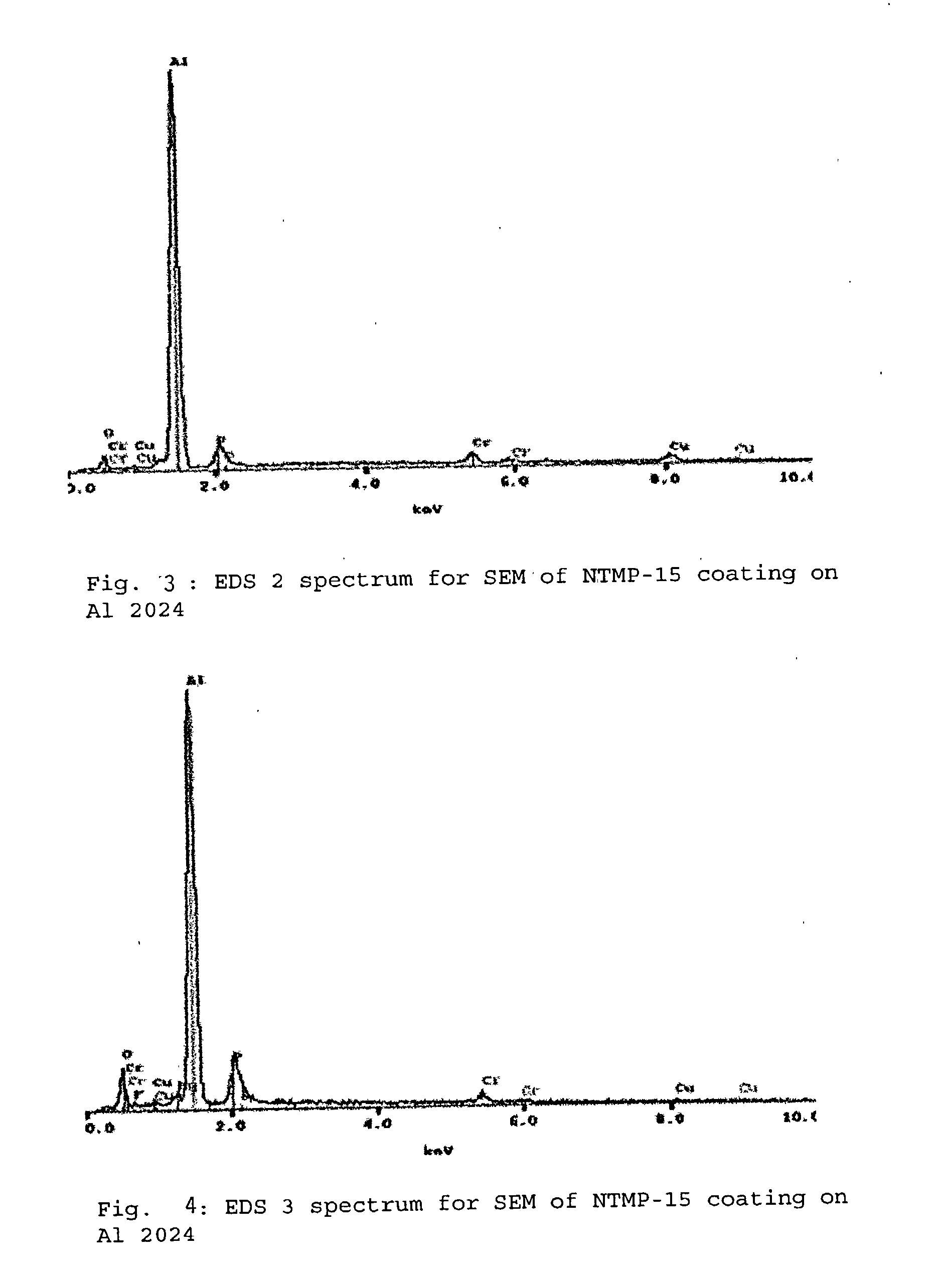

Corrosion resistant trivalent chromium phosphated chemical conversion coatings

InactiveUS7018486B2Reduce precipitationImprove protectionSurface reaction electrolytic coatingSolid state diffusion coatingChromium CompoundsChromate conversion coating

An acidic aqueous solution containing a water soluble trivalent chromium compound is provided with a additive for improving corrosion resistance and reducing precipitation of trivalent chromium over time. A suitable additive is nitrilotris (methylene) triphosphonic acid (NTMP).

Owner:RTX CORP

Method for manufacturing high insulation resistor FeSiCr metal soft-magnetic material

ActiveCN106816252AAvoid unevennessOvercoming inhomogeneityInductances/transformers/magnets manufactureMagnetic materialsChromium phosphateMetal

The invention discloses a method for manufacturing a high insulation resistor FeSiCr metal soft-magnetic material. The method includes melting; gas and water combined atomization; screening; powder classification matching; mixing; powder passivating; stirring and coating; pelletizing; compression moulding; and sintering. (6) powder passivating: preheating powder to the temperature of 75-90 DEG C, adding a mixed solution of 0.1-0.35 wt% of manganese phosphate and 0.1-0.35 wt% of chromium phosphate with respect to the powder, performing stirring for 10-15 min, performing drying at the temperature of 120 DEG C for 2 hours, and performing screening through a 100-mesh screen. The method can effectively overcome the defects that the insulation resistance is low, the withstand voltage is low, and the coating layer is not even and is not compact in the conventional processes; and according to the high insulation resistor FeSiCr metal soft-magnetic material acquired by the method, the insulation resistance IR is greater than 1G Ohm, the withstand voltage is greater than 100 V, and the magnetic conductivity is 60 (1+ / -20%).

Owner:TDG HLDG CO LTD

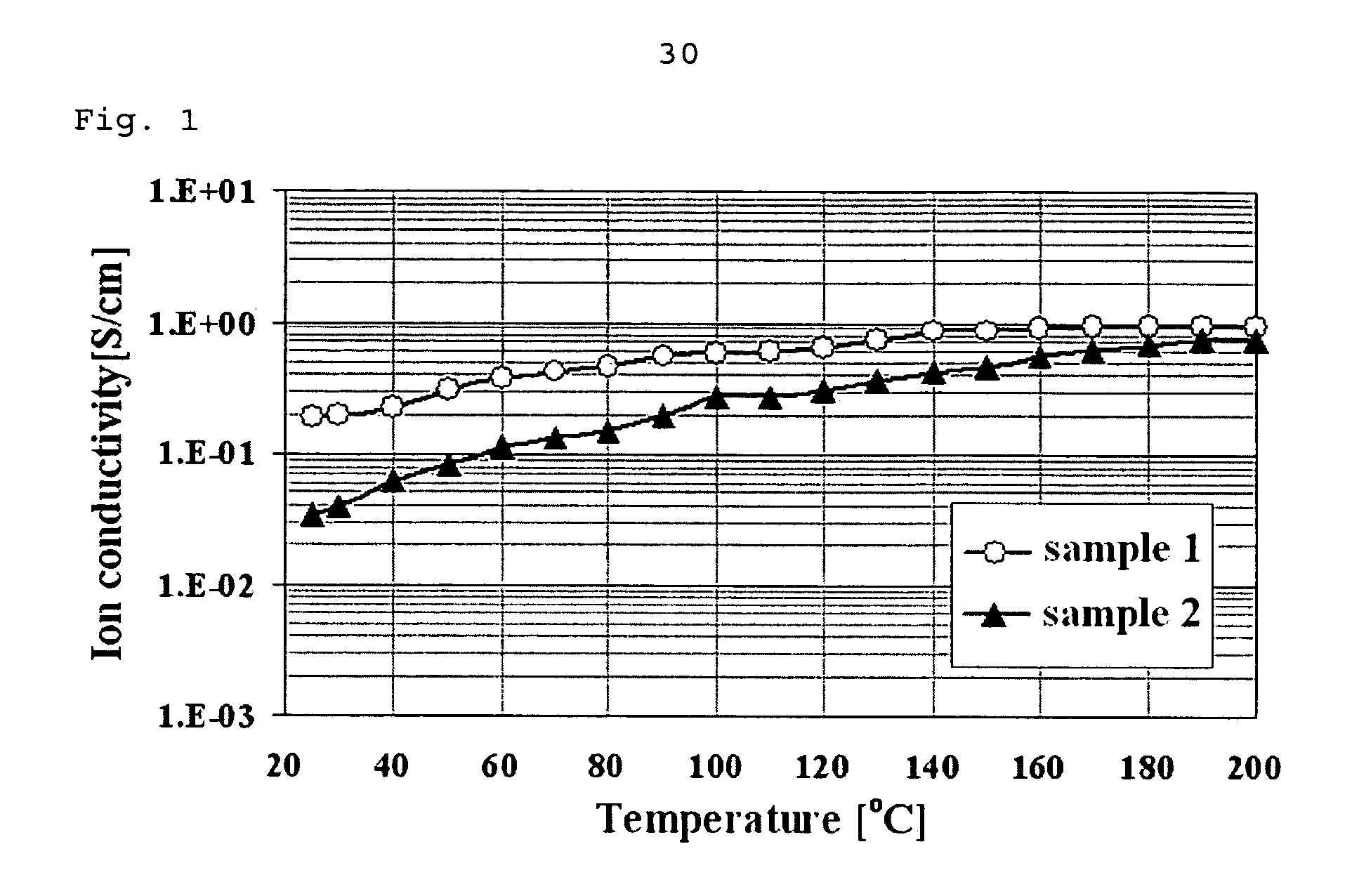

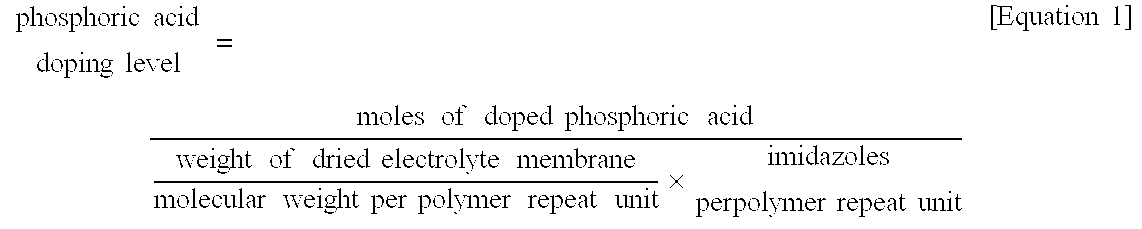

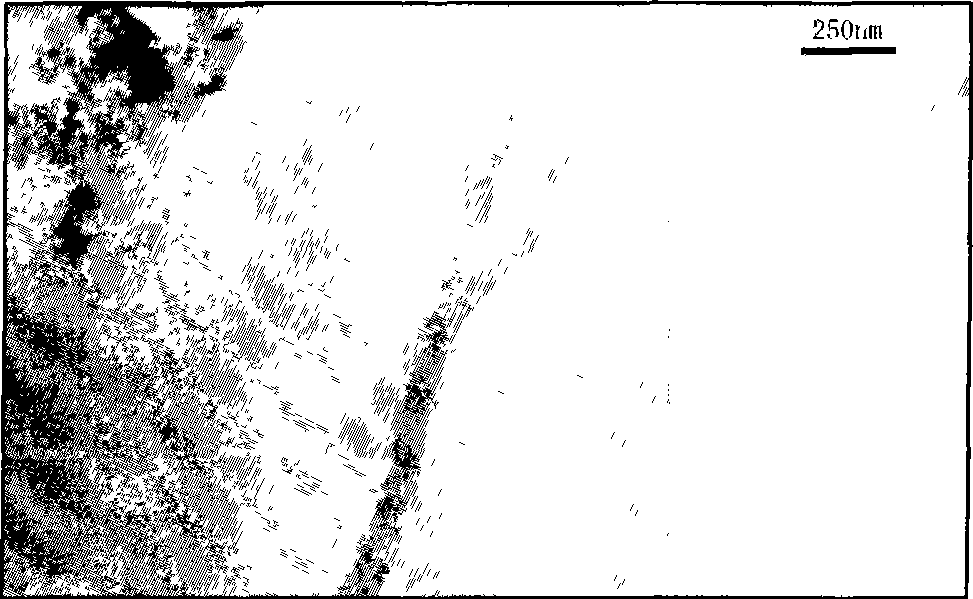

Novel metal (III) -chromium-phosphate complex and use thereof

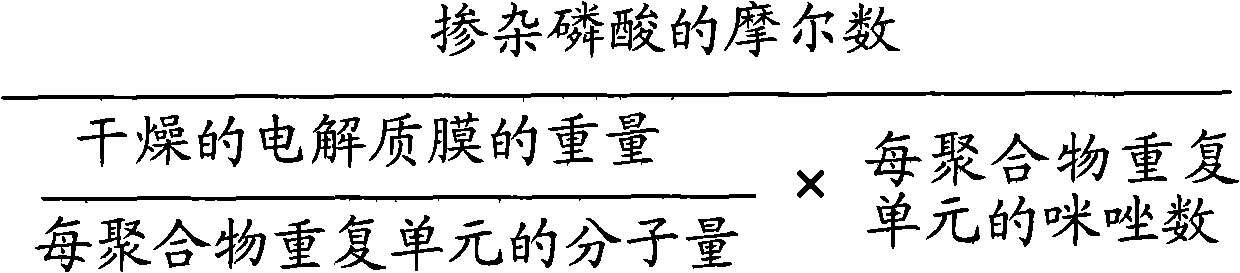

InactiveUS20070148520A1High hydrogen ion conductivityLow decreaseSolid electrolytesAluminium compoundsComposite electrolyteFuel cells

Disclosed herein are a metal(III)-chromium-phosphate complex represented by a formula of M(III)xCr(HPO4)y(H2PO4)z and the use thereof. More particularly, disclosed are an organic / inorganic composite electrolyte membrane comprising said complex, an electrode comprising said complex, a membrane-electrode assembly (MEA) comprising said organic / inorganic composite electrolyte membrane and / or electrode, and a fuel cell comprising said membrane-electrode assembly.

Owner:LG CHEM LTD

Method for preparing porous alumina formwork with Y type structure

The invention discloses a method for preparing a porous aluminum oxide mould plate with Y-shaped structure. The method comprises the following steps: firstly, an aluminum sheet is annealed and chemically polished; secondly, the treated aluminum sheet is subjected to anode oxidation at a low voltage for some time; thirdly, the oxide layer generated during the first-time oxidation is washed off in an phosphoric acid / chromic acid mixing solution; fourthly, at a low voltage, the aluminum sheet is subjected to secondary anode oxidation for some time, and during the period of time, the oxidation voltage is raised, and the aluminum sheet is subjected to anode oxidation at a high voltage for some time; and finally, the prepared aluminum oxide mould plate is taken out, the barrier layer on the bottom part of the mould plate is further removed by phosphoric acid, so that the two-way porous aluminum oxide mould plate with Y-shaped structure. The method is not only widely applied to the preparation of various materials with one-dimensional nano structure, but also has potential purposes in the fields of the preparation of nano devices, photonic crystals and the like.

Owner:ANHUI UNIVERSITY

Fibre reinforcing zinc aluminum phosphate based composite material and method for manufacturing the same

ActiveCN101219886AOvercome the illsExcellent formabilityCeramic shaping apparatusCompression moldingFlexural strength

The invention relates to a fiber-reinforced zinc and aluminum phosphate matrix composite and a preparation method thereof, relating to a fiber-reinforced composite and a preparation method thereof. The invention solves the problems of high curing temperature of the prior aluminum phosphate material or the carcinogenicity of chrome in a chrome and aluminum phosphate material. The fiber-reinforced zinc and aluminum phosphate matrix composite of the invention is prepared from the fiber-reinforced material and a gelation material of zinc and aluminum phosphate; the preparation method comprises the following processes that under condition of 200 to 600 DEG C, heat treatment is carried out for the fiber-reinforced material for 10 minutes to an hour; then the fiber-reinforced zinc and aluminum phosphate matrix composite is prepared according to a compression molding technology; the process parameters are the molding temperature of 85 to 300 DEG C, the molding pressure of 2 to 15MPa, and the molding time of 6 to 35 hours. The product of the invention has high temperature resistance and good mechanical properties, without toxic substance; the product of the invention can be cured under 170 DEG C, with the bending strength under the room temperature up to 70 to 140MPa; the thermal weight loss is less than 8 percent when the composite is heated to 600 DEG C. The method of the invention is simple in technology, easy in material obtaining, low in cost, easy in popularization and utilization, and suitable for large-scale industrial production.

Owner:HARBIN INST OF TECH

Aqueous solution of chromium salt and method for producing same

InactiveUS20070086938A1Overcome disadvantagesPigmenting treatmentNitrogen compoundsOXALIC ACID DIHYDRATEChloride

Disclosed is an aqueous solution of a chromium salt, in which the oxalic acid content is 8% by weight or less relative to chromium. In the aqueous solution of the chromium salt, the total organic carbon content is 4% by weight or less relative to chromium. The chromium salt is preferably a chromium chloride, a chromium phosphate, or a chromium nitrate. The chromium chloride preferably contains a basic chromium chloride represented by the composition formula Cr(OH)xCly (wherein 0<x≦2, 1≦y<3, and x+y=3). The chromium phosphate is preferably one represented by the composition formula Cr(H3−3 / nPO4)n (wherein n is a number satisfying 2≦n≦3). The chromium nitrate is preferably a basic chromium nitrate represented by the composition formula Cr(OH)x(NO3)y (wherein 0<x≦2, 1≦y<3, and x+y=3).

Owner:NIPPON CHECMICAL IND CO LTD

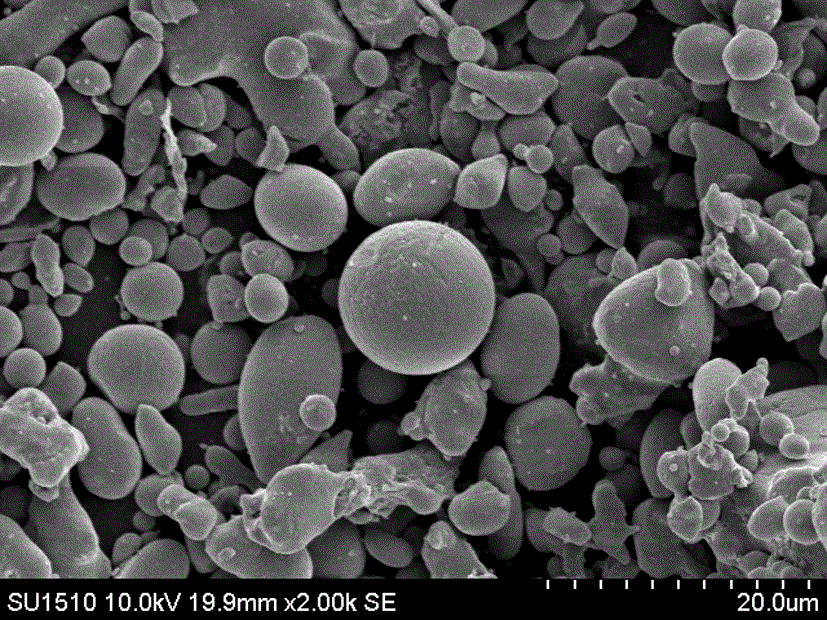

High-entropy alloy matrix self-lubrication composite with imitation lattice structure and containing solid lubricant

ActiveCN111390166AImprove mechanical propertiesImprove wear resistanceAdditive manufacturingIncreasing energy efficiencySelective laser meltingHigh entropy alloys

The invention relates to a high-entropy alloy matrix self-lubrication composite with an imitation lattice structure and containing a solid lubricant. The high-entropy alloy matrix self-lubrication composite is composed of a porous matrix and the solid lubricant which is filled in the matrix and contains aluminum chromium phosphate as a binder. A matrix refers to a porous high-entropy alloy with the imitation lattice structure prepared by metal 3D printing technologies, such as selective laser melting molding or selective electron beam melting molding with high-entropy alloy powder as a raw material. The high-entropy alloy matrix self-lubrication composite has the characteristics of light weight, high strength and toughness, and good tribological performance in a wide temperature range, andhas a good application prospect in high-tech fields such as aviation, aerospace and weapons.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

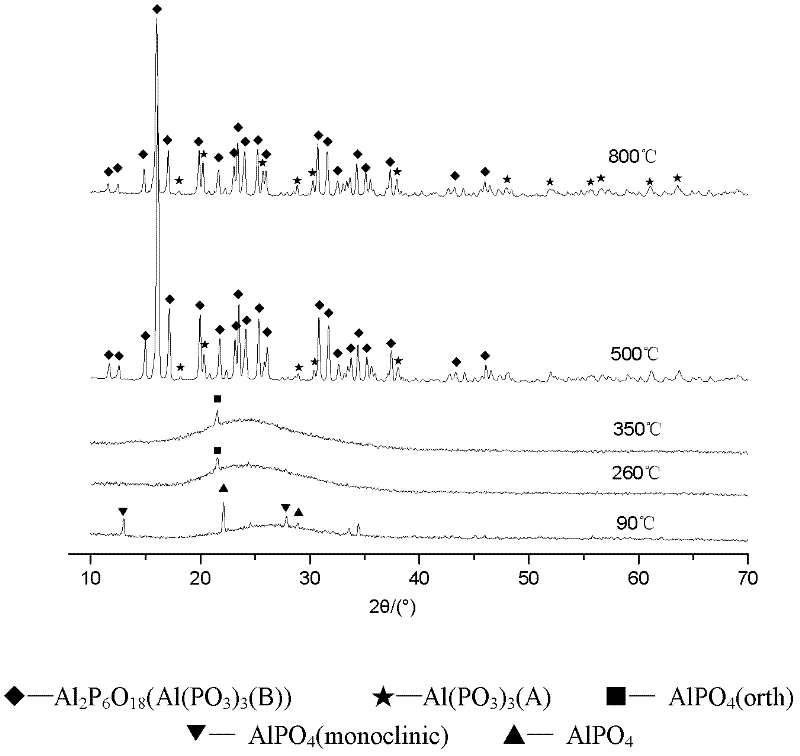

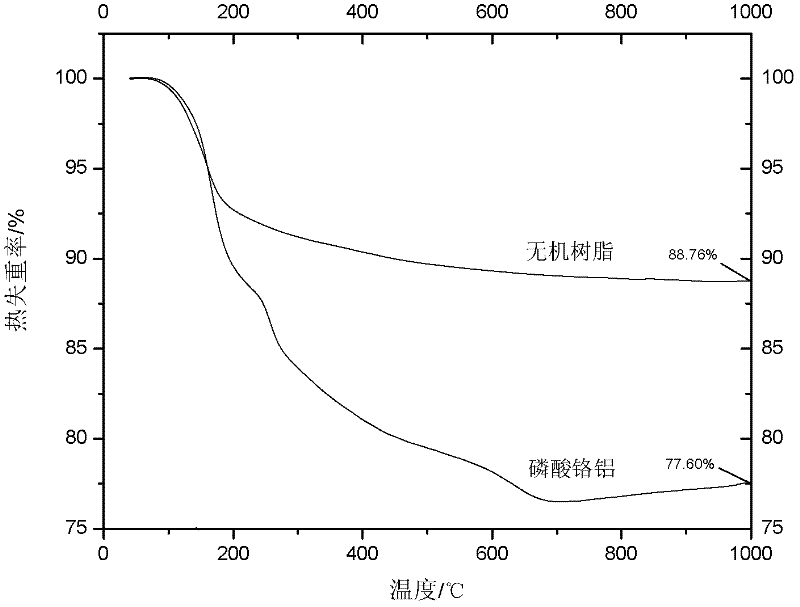

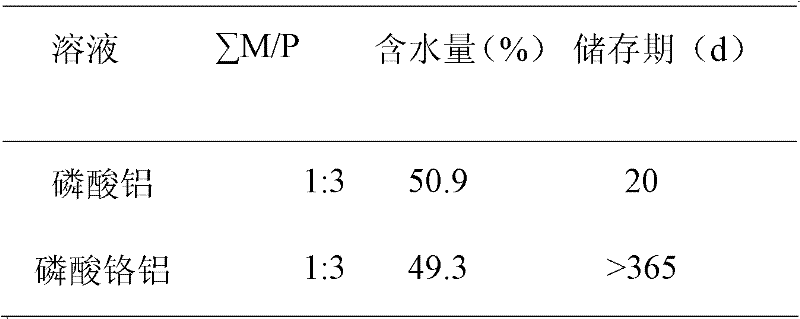

High-temperature resistant low dielectric phosphorus-containing inorganic resin capable of compositing with fiber, preparation and application

The invention discloses a high-temperature resistant low dielectric phosphorus-containing inorganic resin capable of compositing with fiber, and a preparation method and application of the inorganic resin, which belongs to the technical field of inorganic resin. The high-temperature resistant low dielectric phosphorus-containing inorganic resin capable of compositing with fiber comprises a chrome-alumina phosphate solution, melted quartz powder, alumina powder and aluminium nitride. The preparation method comprises the following steps: adding chromium trioxide and selecting different reductants to reduce Cr6+ to Cr3+ based on preparation of an aluminium phosphate solution to prepare the chrome-alumina phosphate solution; and adding oxide and nitride with high- temperature resistance and low dielectric constant to obtain the high-temperature resistant low dielectric phosphorus-containing inorganic resin. The high-temperature resistant low dielectric phosphorus-containing inorganic resin capable of compositing with fiber has a simple preparation technology and a universal device, is easy to achieve industrial production, can be completely cured at 150 DEG C, and has better high-temperature mechanical property, excellent dielectric property and moisture absorption resistant property. A wave-transmitting material used for making an antenna housing can be obtained by soaking quartzfibers or quartz fiber fabrics with surfaces being specially treated in the inorganic resin, airing in room temperature and hot-pressing.

Owner:BEIJING UNIV OF CHEM TECH

Preparation method of corundum honeycomb ceramic with slag resistance

The invention discloses a preparation method of corundum honeycomb ceramic with slag resistance. The method comprises the following steps: following raw materials of bauxite, kaolin, soapstone and feldspar are added in a ball mill according to proportion and are mulled into mixed material, then the mixed material is added in a kneader, then a proper amount of water and adhesive agent are added in the kneader, then the triteness, the pug milling, the drying, the cutting and the high-temperature sintering are performed after kneading to obtain a honeycomb ceramic, aluminium-chromium phosphate solution is coated on the surface of the inner wall of a corundum honeycomb ceramic hole, then the corundum honeycomb ceramic is dried and then baked at 1380 DEG C, and the aluminium-chromium phosphate is dehydrated, cured and stuck on the surface of the inner wall of the corundum honeycomb ceramic hole. The prepared honeycomb ceramic not only has high specific surface area, high porosity and good heat storage property; since an aluminium-chromium phosphate compound protective layer is coated on the surface of the inner wall of the honeycomb ceramic hole, the protective layer does not react with the ferrous oxide in the iron scale and is not stuck with the liquid-phase residue formed by the iron scale at the high temperature to ensure that the honeycomb ceramic hole is not blocked, the slag resistance of the corundum honeycomb ceramic is enhanced and the service life of the corundum honeycomb ceramic is prolonged.

Owner:姚光纯

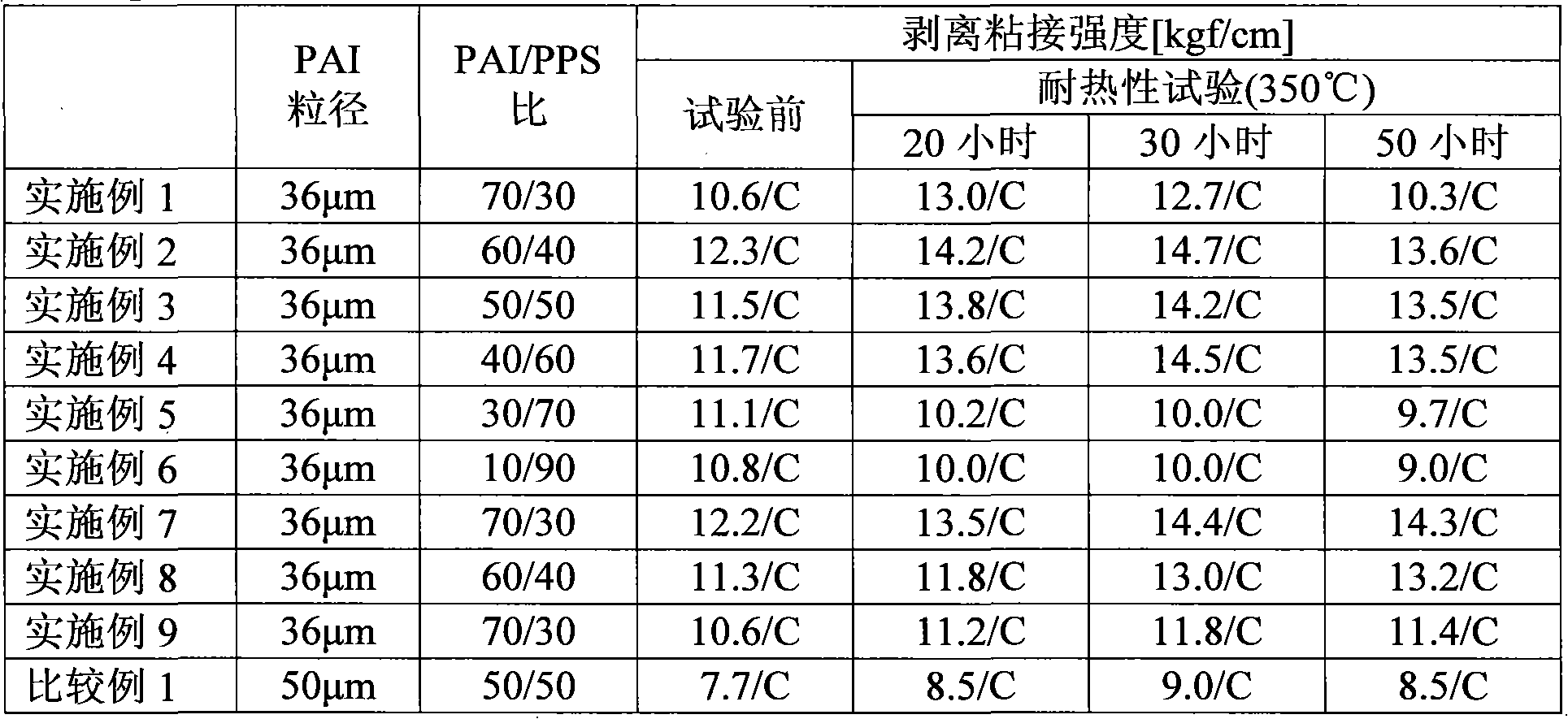

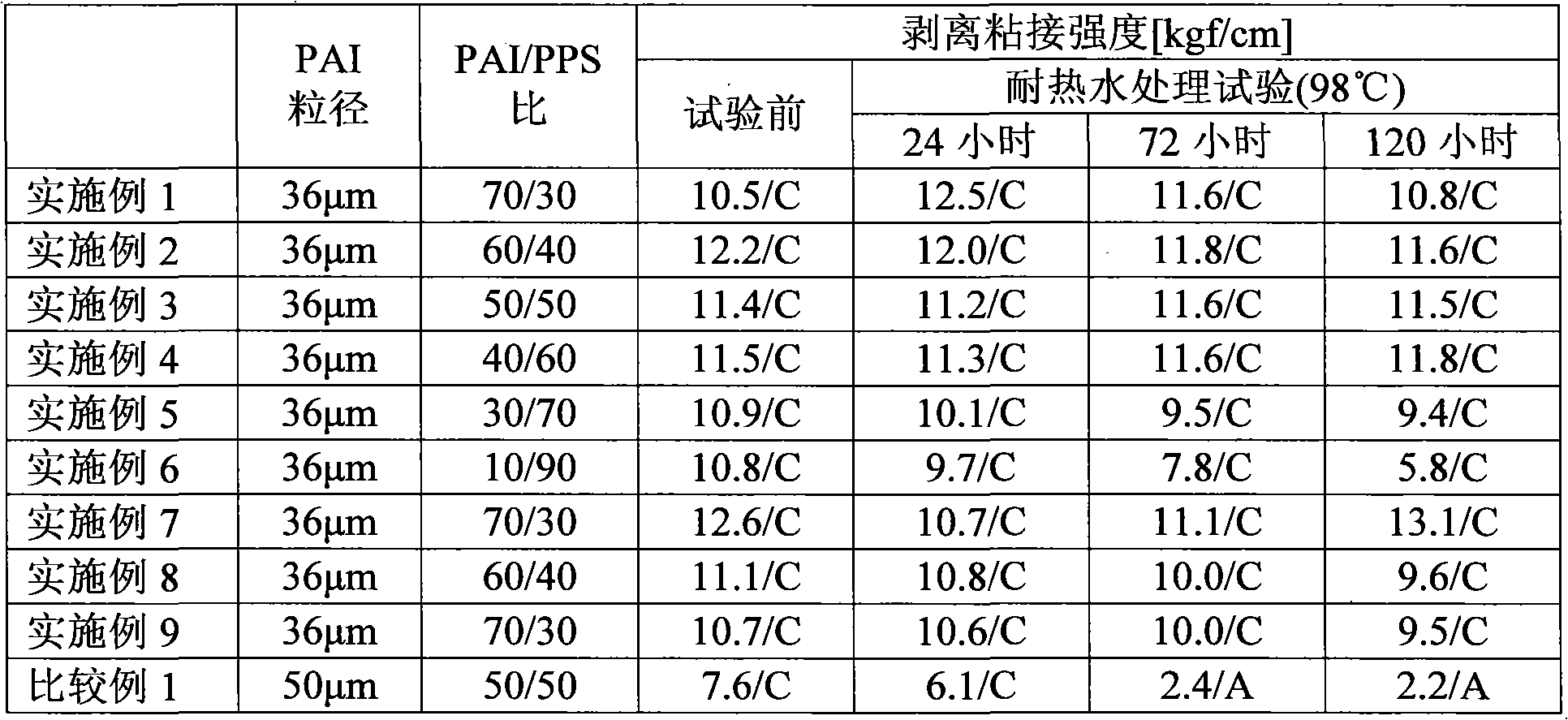

Powder coating material and fluorine-containing laminate

ActiveCN101952375AHas heat-resistant sealabilityHard to reduce adhesionLiquid surface applicatorsPowdery paintsImideChromium phosphate

Disclosed is a powder coating material which does not contain hexavalent chromium that serves as a binder component but exhibits adhesion comparable to that of a chromium phosphate primer even after being subjected to firing at high temperatures for a long time. The powder coating material is characterized by containing a polymer compound (A) having an amide group and / or an imide group, an antioxidative substance (B) and a fluororesin (C). The powder coating material is also characterized in that the polymer compound (A) has an average particle diameter of less than 50 [mu]m.

Owner:DAIKIN IND LTD

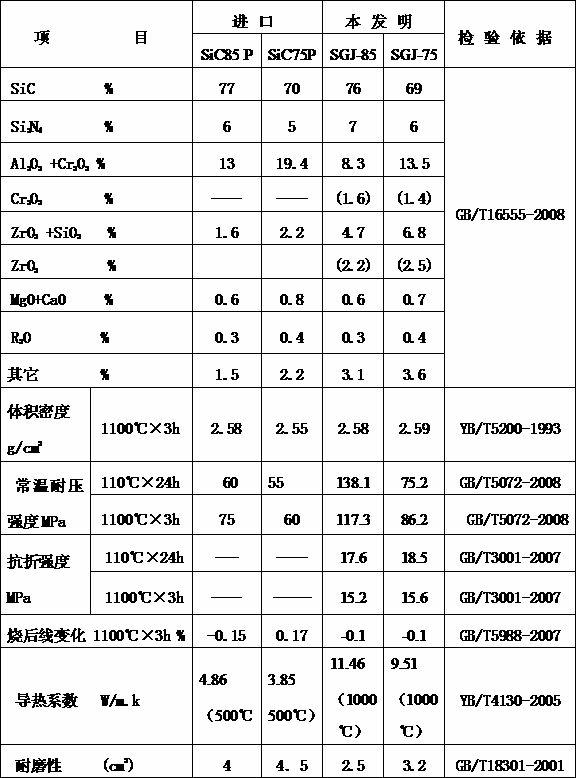

Silicon carbide ramming material high in abrasion resistance and application thereof

The invention relates to a silicon carbide ramming material high in abrasion resistance, which comprises the following components in part by weight: 55-78 parts of superfine silicon carbides, 5-15 parts of alpha type silicon nitrides, 5-10 parts of zirconium corundum, 1-7 parts of aluminum oxide powder and silicon dioxide powder, 9-13 parts of aluminum chromium phosphates, 0.5-5 parts of coagulation accelerators, 0-2.5 parts of iodine bismuth oxyiodide tannates and 0.3-0.7 parts of anti-explosion fibers, wherein the mixture of active rho-aluminum oxide and magnesium oxide is taken as the coagulation accelerators, and the diameter of the anti-explosion fibers is 1.5-2.5 microns. The silicon carbide ramming material high in abrasion resistance, which is provided by the invention, is high instrength after being naturally dried, is excellent in abrasion resistance at high temperature, is high in heat transfer coefficient, is low in linear contractibility rate and is long in service life.

Owner:上海皕涛耐火材料有限公司

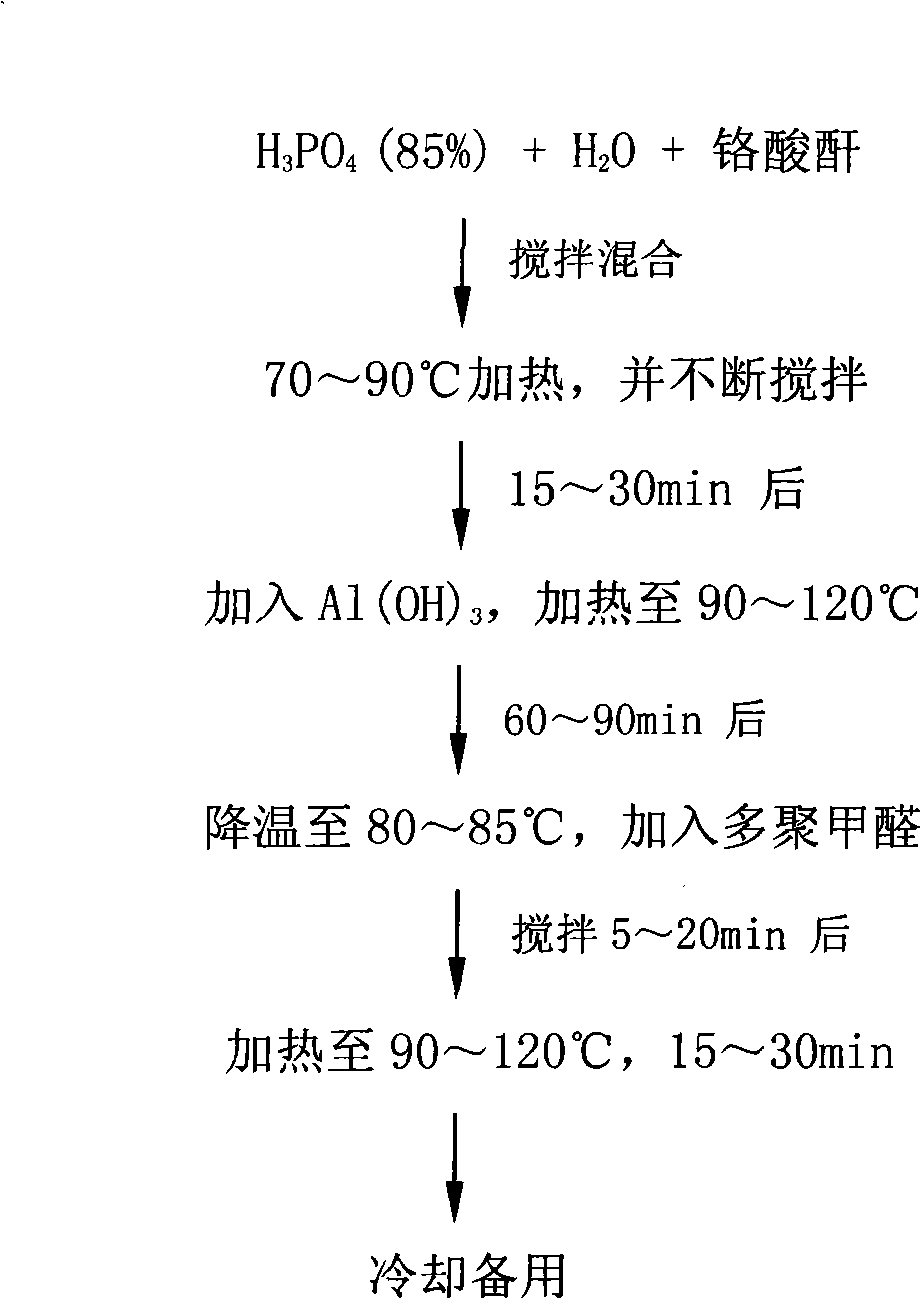

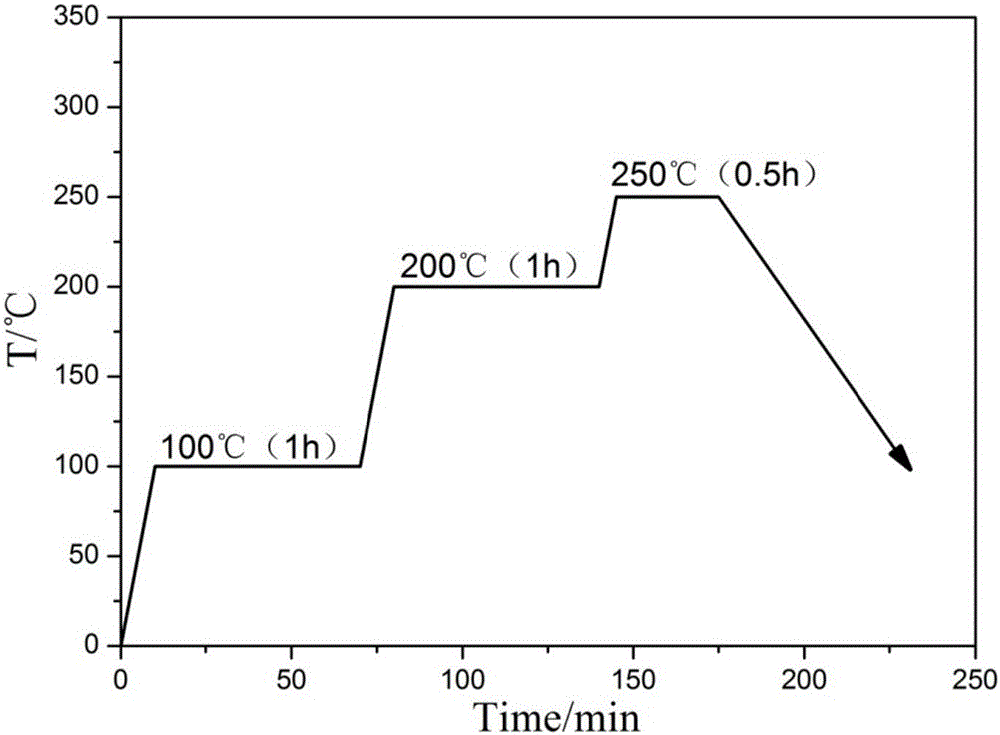

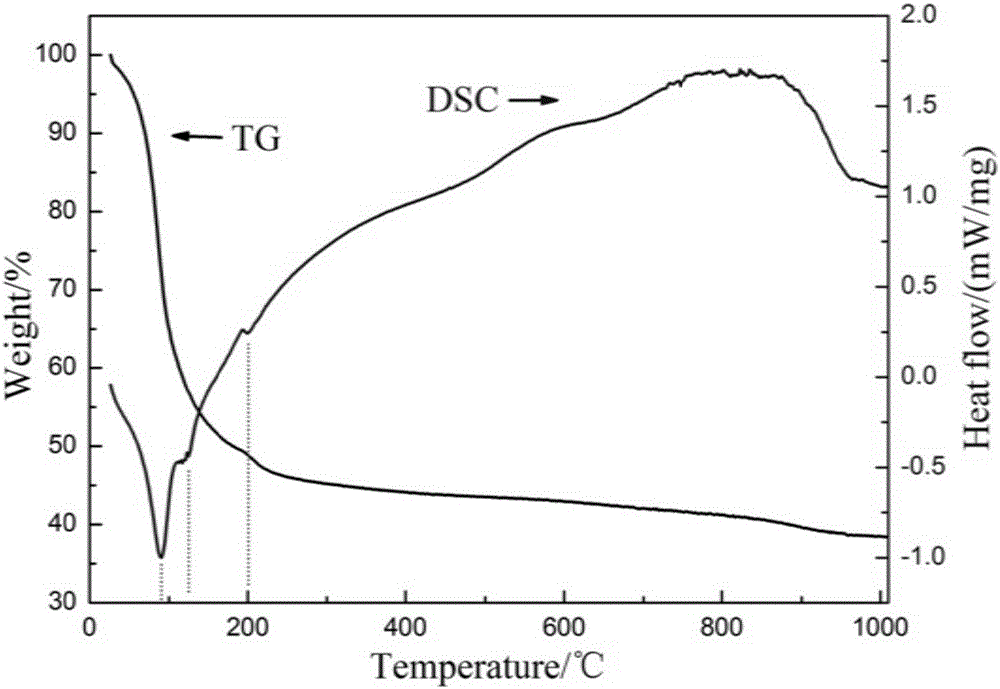

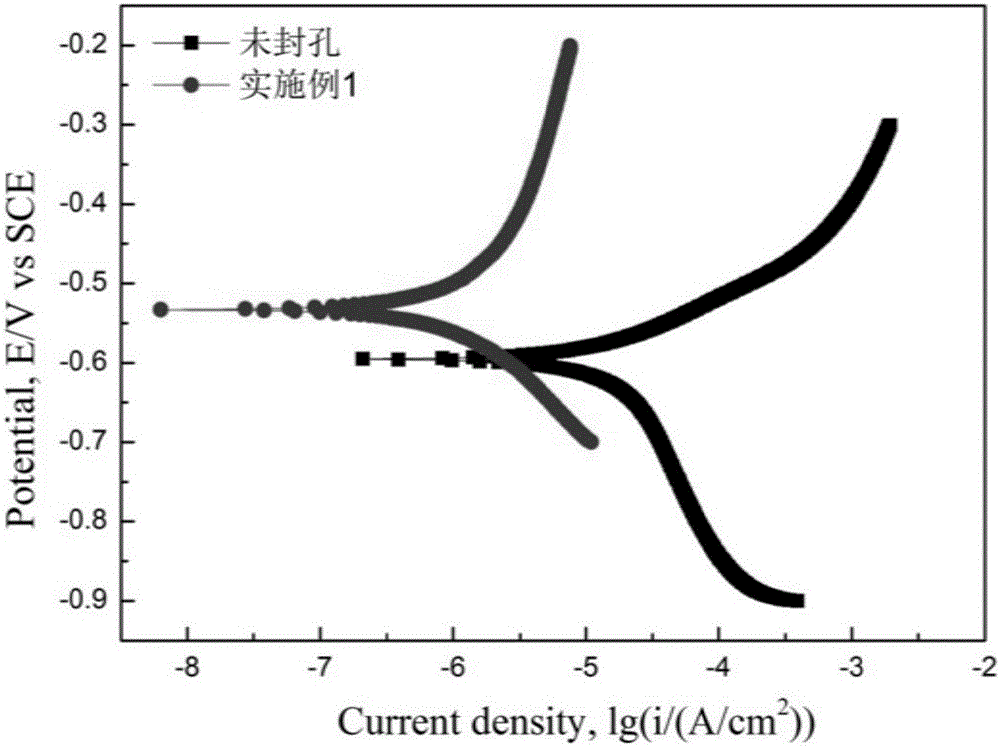

Thermal-spraying coating hole sealing agent, preparation method and using method

InactiveCN106009797AAccelerates the dehydration processImprove thermal stabilityMolten spray coatingWater bathsThermal spraying

The invention discloses a thermal spraying coating sealing agent, a preparation method and a use method, comprising aluminum chromium phosphate and filler in a weight ratio of 10:1-3; the aluminum chromium phosphate comprises 95-105 parts by weight of phosphoric acid , 23-26.5 parts of aluminum hydroxide, 9.5-11.5 parts of chromic anhydride and 4-6 parts of methanol, and the filler is Cr 2 o 3 . Mix phosphoric acid and chromic anhydride, stir in water bath at 70-90°C until fully dissolved; then add aluminum hydroxide and stir until fully dissolved; then slowly drop methanol to make it fully react, and bathe in water at 70-90°C for 15- 25min, obtain dark green viscous aluminum chromium phosphate solution; Add Cr 2 o 3 The filler is uniformly dispersed in the aluminum chromium phosphate solution to obtain the sealing agent. After the system is solidified, as the temperature continues to rise, there will be no thermal effect in the system within 1000 ° C. Aluminum chromium phosphate has good high temperature resistance. The raw material of the sealing agent of the invention is cheap and easy to obtain, the application process is simple, the operation is convenient, and the sealing period is short.

Owner:ANHUI MA STEEL SURFACE TECH CO LTD

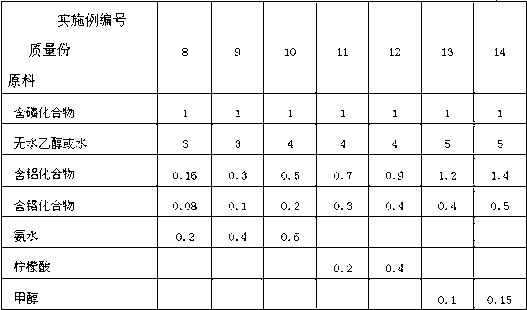

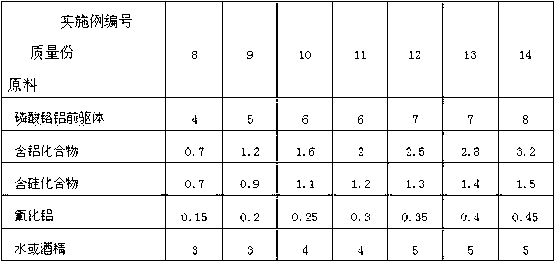

Preparation method of mullite whisker in-situ toughened chromium phosphate aluminum wave-transmitting material

The invention discloses a preparation method of a mullite whisker in-situ toughened chromium phosphate aluminum wave-transmitting material. The method is characterized by the following steps of: dissolving a phosphorus-containing compound into absolute ethyl alcohol or water, adding an aluminum-containing compound and a chromium-containing compound at the temperature of 50-100 DEG C while stirring for reacting, and adding ammonia water, citric acid or methanol for reacting to obtain a chromium phosphate aluminum precursor; putting the chromium phosphate aluminum precursor, the aluminum-containing compound, a silicon-containing compound, aluminum fluoride and water or alcohol into a ball milling device for performing ball milling to obtain a mixture; and drying the mixture, grinding, sieving, performing press forming on the minus sieve, i.e., sintering precursor powder, and calcining in an enclosed container at the temperature of 1,200-1,500 DEG C for 1-24 hours to obtain the mullite whisker in-situ toughened chromium phosphate aluminum wave-transmitting material. The method has the advantages of in-situ growth of mullite whiskers, uniform distribution of the whiskers, dense substrate sintering, good toughening effect, high performance of the wave-transmitting material, applicability of the wave-transmitting material to antenna covers of flying vehicles, radar antenna covers and the like.

Owner:SOUTHWEAT UNIV OF SCI & TECH

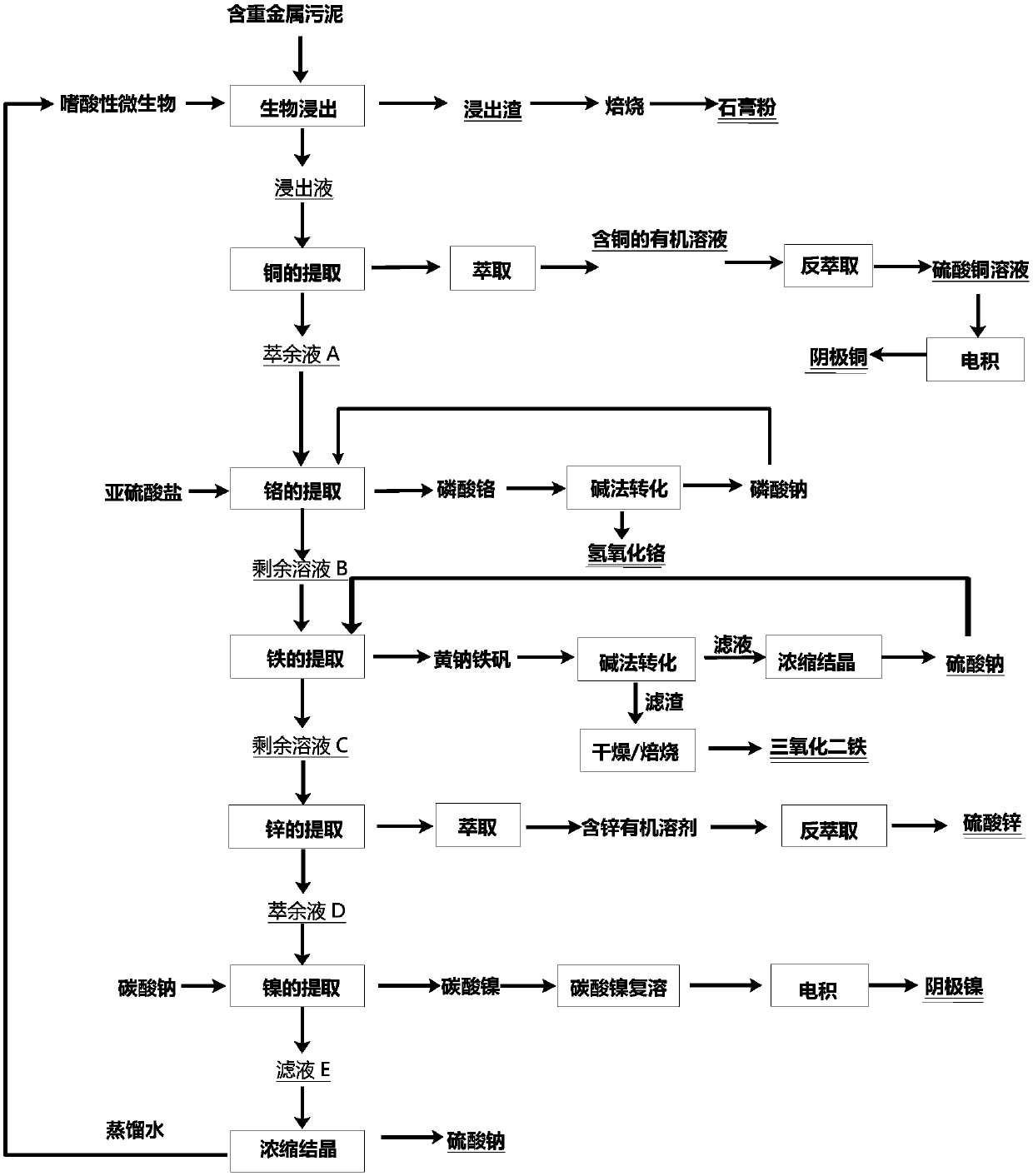

No-waste utilization method of heavy metal-contained sludge

ActiveCN106987721AReasonable resource conversionReduce displacementProcess efficiency improvementSludgeSlag

The invention provides a no-waste utilization method of heavy metal-contained sludge. The heavy metal-contained sludge includes copper, chromium and iron elements; and the no-waste utilization method comprises the following steps: (S1) acidophilia microorganisms are added in the heavy metal-contained sludge for biological leaching treatment and solid-liquid separation to prepare leaching slag and leaching liquid; (S2) hydroxamic extracting agent solution with selectivity on copper is adopted to extract the leaching liquid prepared in the step (S1) to prepare copper-contained extracting liquid capable of singly recovering copper and raffinate A; (S3) sulfite is added in the raffinate A to adjust the solution pH value of not more than 2.0, is heated, and is added in phosphate to prepare chromium phosphate precipitates capable of singly recovering chromium; and (S4) remained solution B after chromium precipitation in the step (S3) is treated by an oxidizing agent; the solution pH value is adjusted within 1.0-1.5; and sodium sulfate is added under the condition of 80-95 DEG C to prepare sodium jarosit capable of singly recovering iron. The no-waste utilization method has the advantages of comprehensive sludge utilization, high utilization rate and no pollution.

Owner:HUNAN AIGE ENVIRONMENTAL PROTECTION TECH CO LTD

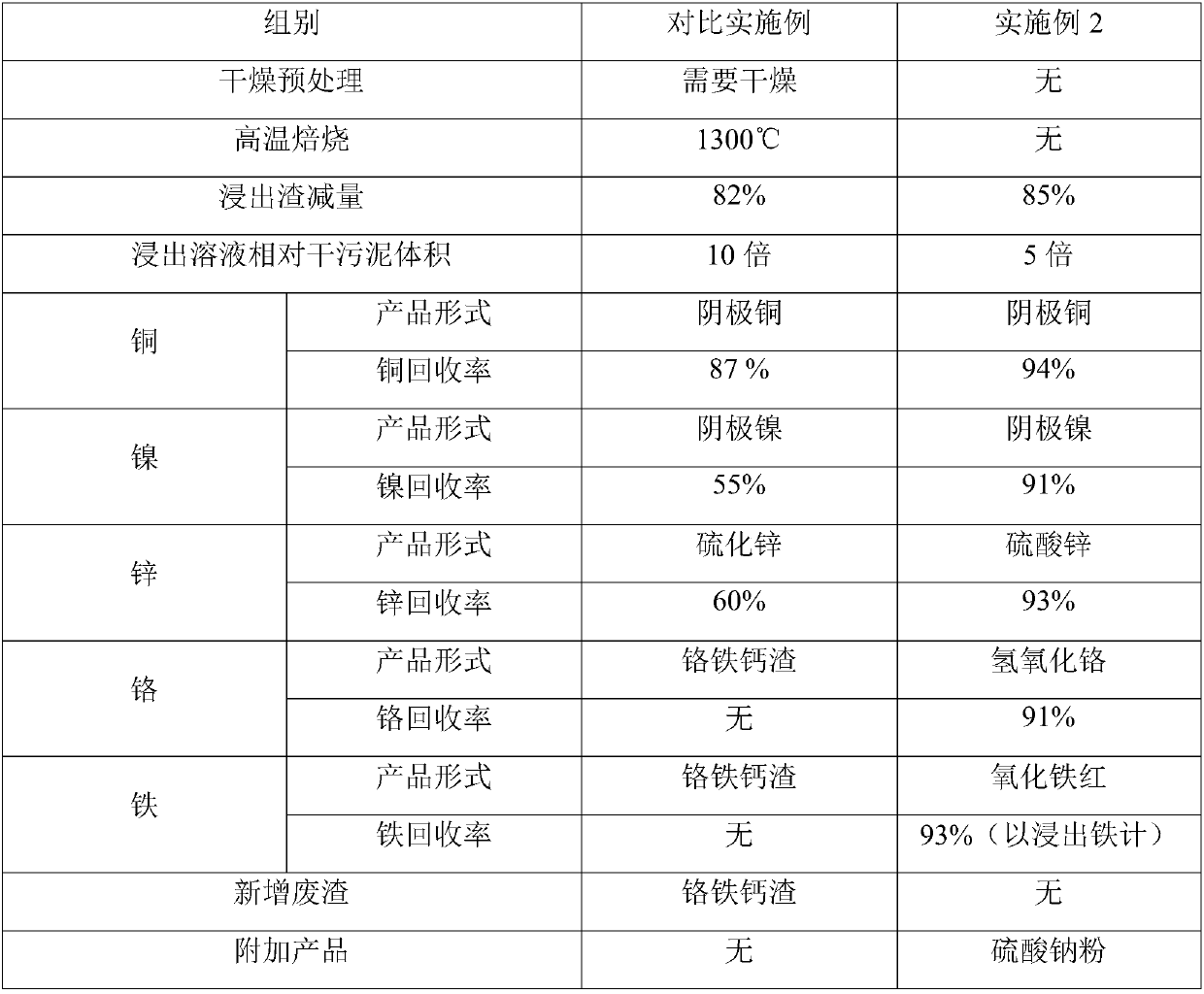

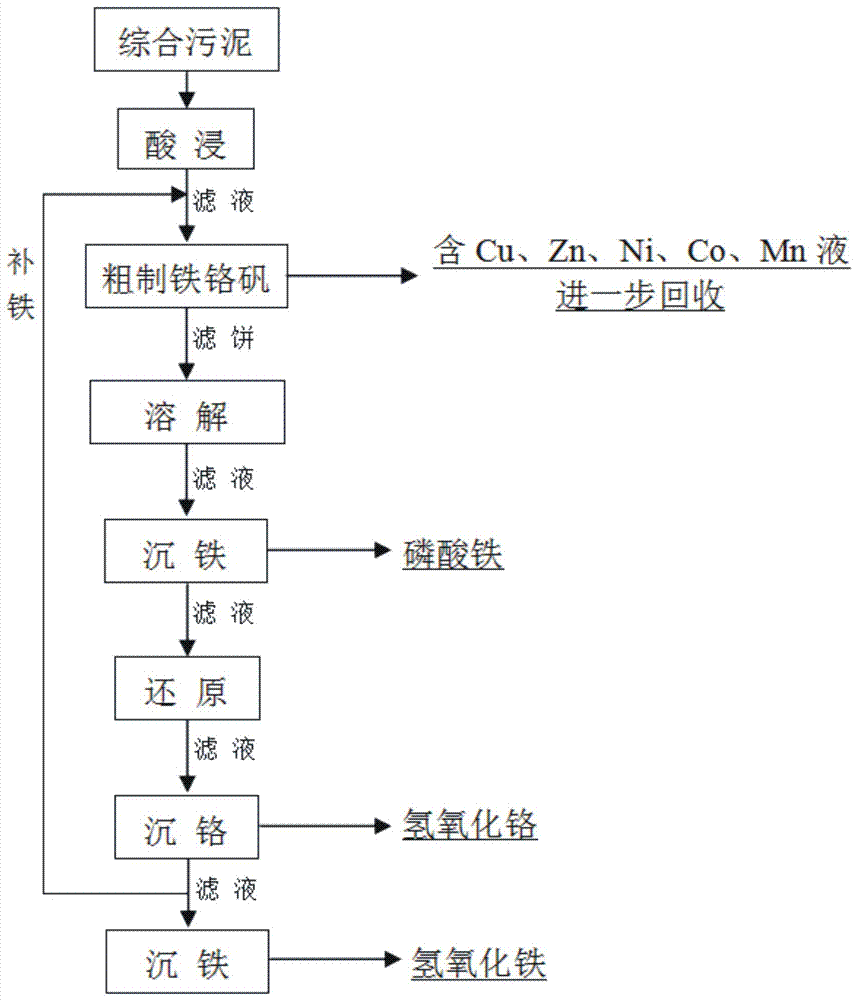

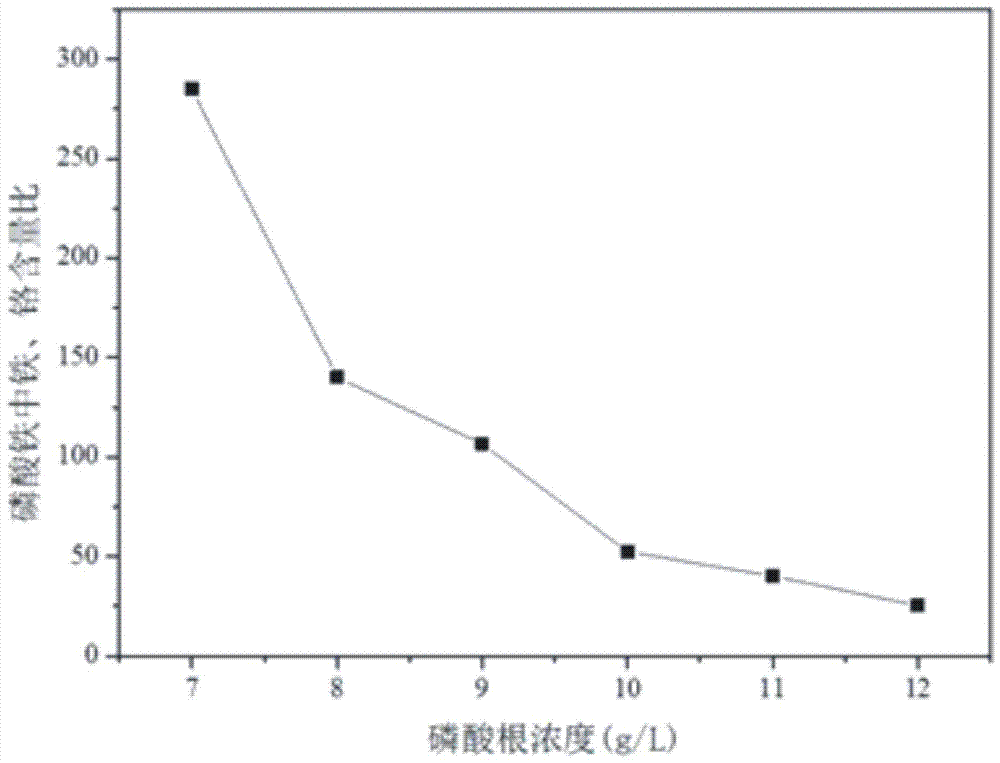

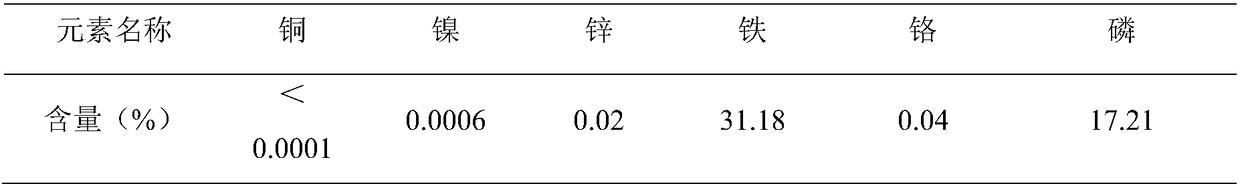

Method for separating and refining iron and chromium from polymetallic hazardous waste

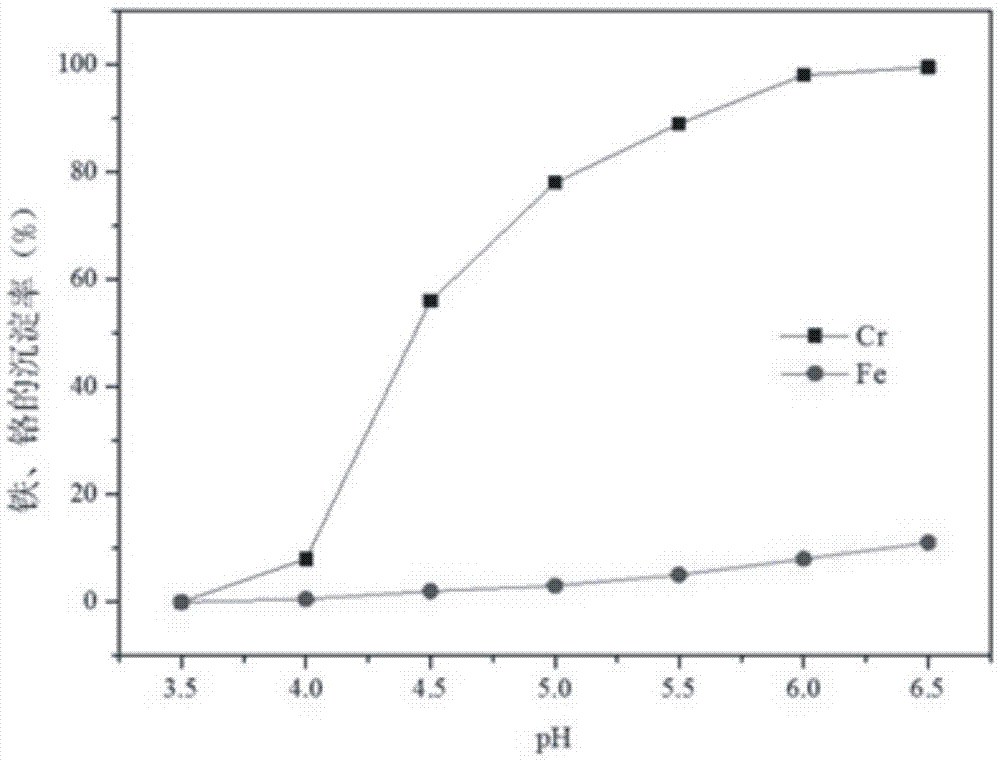

ActiveCN107324303AReduce processing timeReduce processing costsIron oxides/hydroxidesCalcium/strontium/barium sulfatesChromium(III) hydroxideSludge

The invention discloses a method for separating and refining iron and chromium from polymetallic hazardous waste. The phosphate radicals carried by sludge are utilized to precipitate Fe<3+> selectively for preparing iron phosphate and isolating Fe<3+> from Cr<3+>, and since Cr<3+> can be precipitated by the phosphate radicals, a method of excessive Fe<3+> is adopted to prevent the formation of chromium phosphate precipitation in the process; the residual Fe<3+> can be reduced to Fe<2+> by scrap iron, then an alkaline solution is added to adjust the pH to a certain value so as to selectively precipitate Cr<3+> for preparing chromium hydroxide, and further separation of iron and chromium can be achieved. According to the method for separating and refining iron and chromium from the polymetallic hazardous waste, no heating is needed during the whole process, ferric ions and the phosphate radicals in the hazardous waste are comprehensively utilized, and thus the cost is low; meanwhile, no waste water and waste residues are produced, and thus the method is environment-friendly; iron phosphate and chromium hydroxide can be obtained from respective extraction, wherein iron phosphate has high economic values and can be used in battery materials, ceramics and other raw materials, and chromium hydroxide can be used in pigments, chemicals and other industry raw materials.

Owner:青川县天运金属开发有限公司

Method for cleaning bonding pads

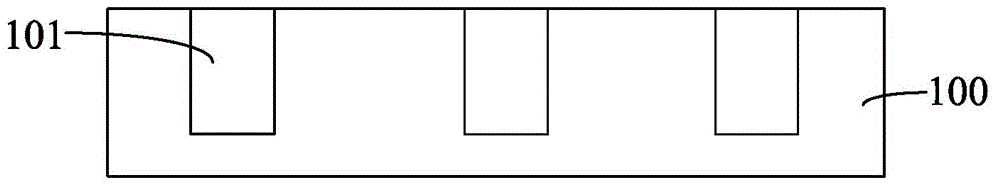

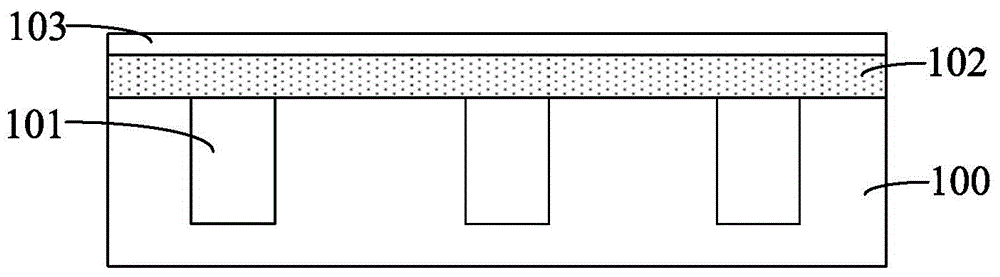

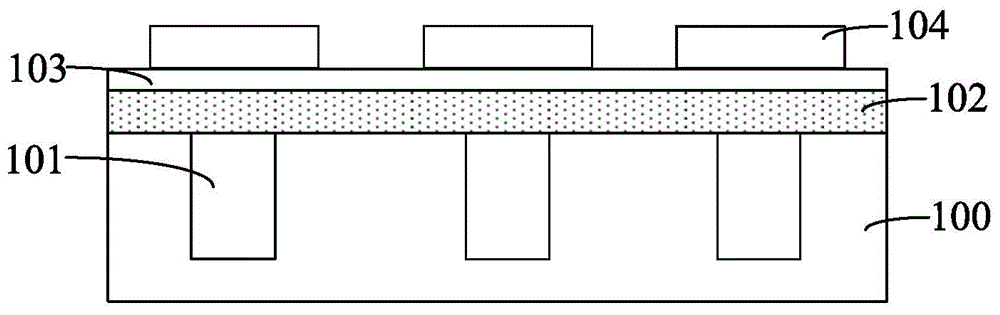

ActiveCN104900481AHigh tensile strengthImprove joint strengthSemiconductor/solid-state device manufacturingHalogenEngineering

Provided is a method for cleaning bonding pads. The method comprises: providing a substrate on which an interconnection line layer is formed, wherein bonding pads are formed on the surface of the interconnection line layer and passivation layers are formed on the surfaces of the bonding pads; removing the passivation layers on the surfaces of the bonding pads by etching until the surfaces of the bonding pads are exposed and halogen family ions are left on the surfaces of the bonding pads; and performing acidic cleaning on the bonding pads in order to remove the halogen family ions left on the surfaces of the bonding pads, wherein cleaning liquid used by the acidic cleaning is chromium phosphate solution. The method cleans the bonding pads with acidic cleanout liquid, effectively removes the halogen family ions left on the surfaces of the bonding pads, prevents the bonding pads from corroding, and improves the tensile strength and bonding intensity of the bonding pads so as to improve the conductivity and the reliability of a semiconductor device.

Owner:SEMICON MFG INT (SHANGHAI) CORP

Corrosion resistant trivalent chromium phosphated chemical conversion coatings

InactiveUS20050178475A9Corrosion protection is enhancedReduce precipitationSurface reaction electrolytic coatingSolid state diffusion coatingChromium CompoundsWater soluble

An acidic aqueous solution containing a water soluble trivalent chromium compound is provided with a additive for improving corrosion resistance and reducing precipitation of trivalent chromium over time. A suitable additive is nitrilotris (methylene) triphosphonic acid (NTMP).

Owner:RTX CORP

Preparation method of quartz fiber strengthening chromium phosphate radome material

InactiveCN102653147AAvoid indentationImprove acid resistanceLamination ancillary operationsLaminationChromium phosphateAluminium oxides

The invention discloses a preparation method of a quartz fiber strengthening chromium phosphate radome material. The preparation method comprises the following steps of: coating a protective coating on quartz fiber cloth and coating chromium a phosphate aluminium base material, and the preparation method is characterized in that the protective coating is coated in the following steps of: preparing a first layer of masking liquid and a second layer of masking liquid by taking organic siliconresin, ethyl orthosilicate, aluminium oxide colloidal sol, silica sol, chromic oxide sol, zirconia sol and a silane coupling agent; placing quartz fiber in the first layer of masking liquid for dipping and pulling, drying the surface at room temperature, placing in the second layer of masking liquid for dipping and pulling, and drying the surface at room temperature; and placing for 4-6h under 80-110 DEG C, and carrying out precuring; and curing the quartz fiber cloth coated with the masking liquid after the precuring at 130-170 DEG C for 5-8 h, thus preparing the quartz fiber cloth with the protective coating. The material prepared by the preparation method provided by the invention has the advantages of high temperature resistance, low cost electricity, abrasion proof performance and the like, and is used for the field of aerospace, and has good property.

Owner:SOUTHWEAT UNIV OF SCI & TECH

Aqueous solution of chromium salt and method for producing same

Disclosed is an aqueous solution of a chromium salt which is characterized in that the oxalic acid content is not more than 8 weight% relative to chromium. In this aqueous solution of a chromium salt, the total organic carbon is not more than 4 weight% relative to chromium. The chromium salt may preferably be a chromium chloride, a chromium phosphate or a chromium nitrate. The chromium chloride may preferably contain a basic chromium chloride represented by the following composition formula: Cr(OH)xCly (wherein 0 < x <= 2, 1 <= y < 3, and x + y = 3). The chromium phosphate may preferably be one represented by the following composition formula: Cr(H3-3 / nPO4)n (wherein n is a number satisfying 2 <= n <= 3). The chromium nitrate may preferably be a basic chromium nitrate represented by the following composition formula: Cr(OH)x(NO3)y (wherein 0 < x <= 2, 1 <= y < 3, and x + y = 3).

Owner:NIPPON CHECMICAL IND CO LTD

Method for producing anisole by catalyzing phenol and methanol

ActiveCN109809970ASimple preparation processLow costPhysical/chemical process catalystsEther preparation by compound dehydrationCerium nitratePhosphate

The invention discloses a method for producing anisole by catalyzing phenol and methanol. According to the method, a fixed bed reactor is adopted, carriers such as zinc phosphate, iron phosphate, copper phosphate and chromium phosphate load modified components such as cerium nitrate, zirconium nitrate, lanthanum nitrate, cobalt nitrate and nickel nitrate and assistants such as potassium fluoride,cesium fluoride and sodium fluoride to serve as a catalyst, the anisole is efficiently synthetized, the phenol conversion rate and anisole selectivity are high, and the catalyst is simple in preparation process, low in cost, high in stability and long in service life, and meets the application requirements of industrial catalysts.

Owner:BAOJI UNIV OF ARTS & SCI

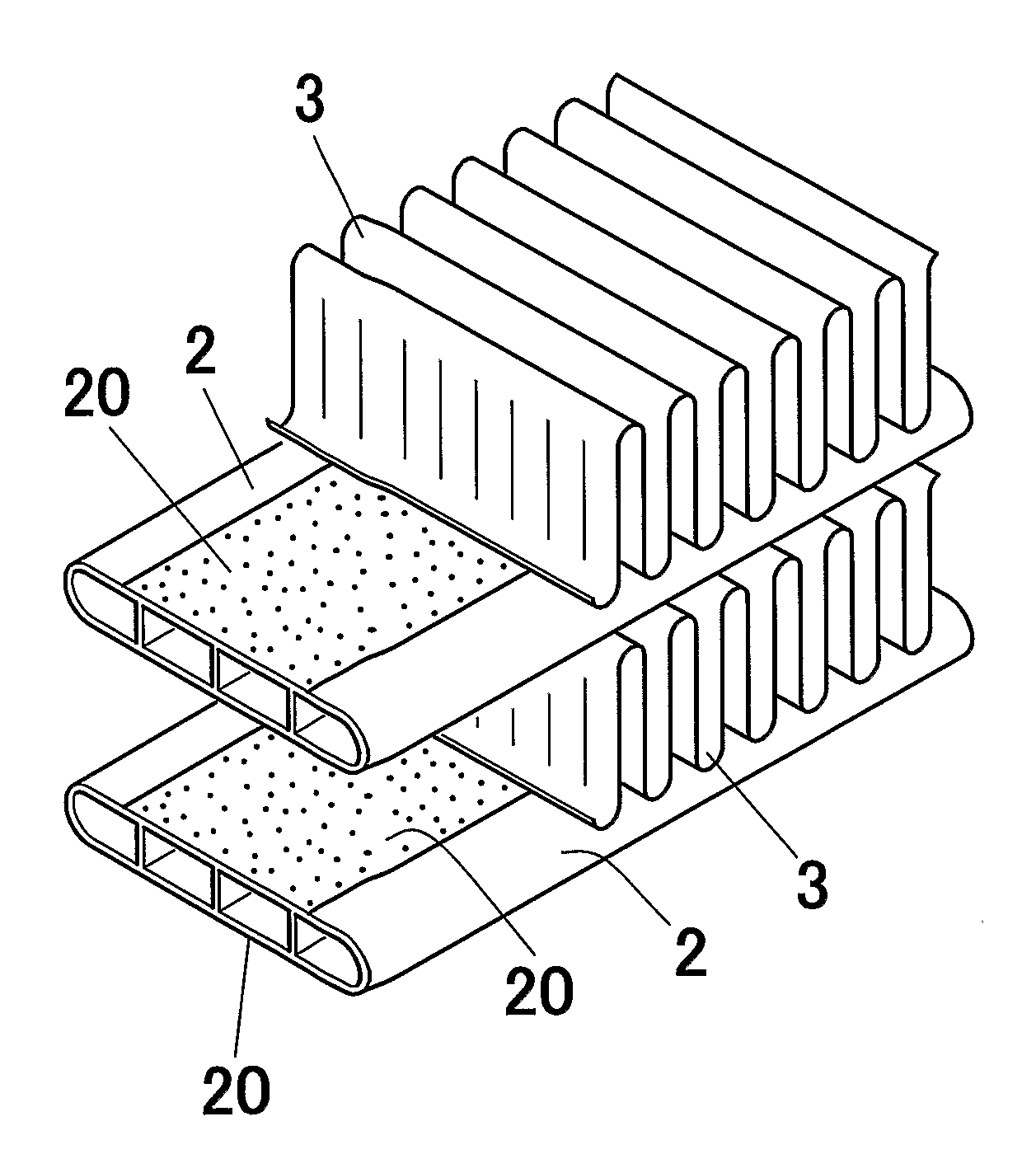

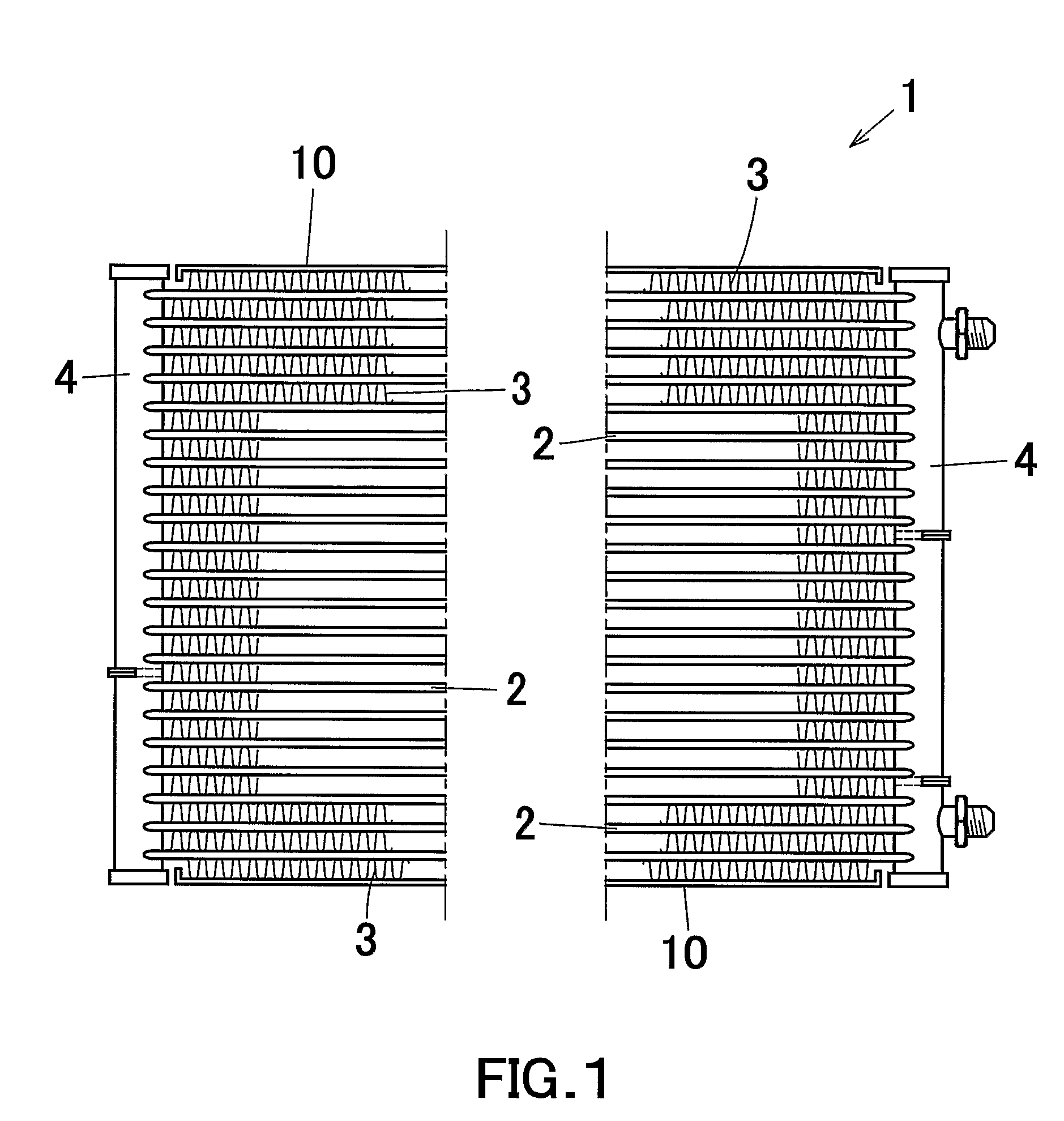

Heat exchanger and method for manufacturing the same

InactiveUS20070163761A1Improve corrosion resistanceAvoid it happening againEvaporators/condensersCorrosion preventionO-Phosphoric AcidEngineering

A method for manufacturing an aluminum heat exchanger includes the steps of: obtaining a heat exchanger tube 2 by forming a Zn thermally sprayed layer on a surface of an aluminum flat tube core so as to adjust Zn adhesion amount to 1 to 10 g / m2; obtaining a heat exchanger core by alternatively arranging the heat exchanger tube 2 and an aluminum fin 3 and brazing the heat exchanger tube and the fin with end portions of the heat exchanger tube connected to aluminum headers in fluid communication; and forming a chemical conversion treatment coat (corrosion resistance coat) on a surface of the heat exchanger core by subjecting the surface of the heat exchanger core to chemical conversion treatment using at least one chemical conversion treatment agent selected from the group consisting of phosphoric acid chromate, chromic acid chromate, phosphoric acid zirconium series, phosphoric acid titanium series, fluoridation zirconium series, and fluoridation titanium series. The obtained heat exchanger has a long last good corrosion resistance and can prevent occurrence of fin detachment and pit corrosion.

Owner:SHOWA DENKO KK

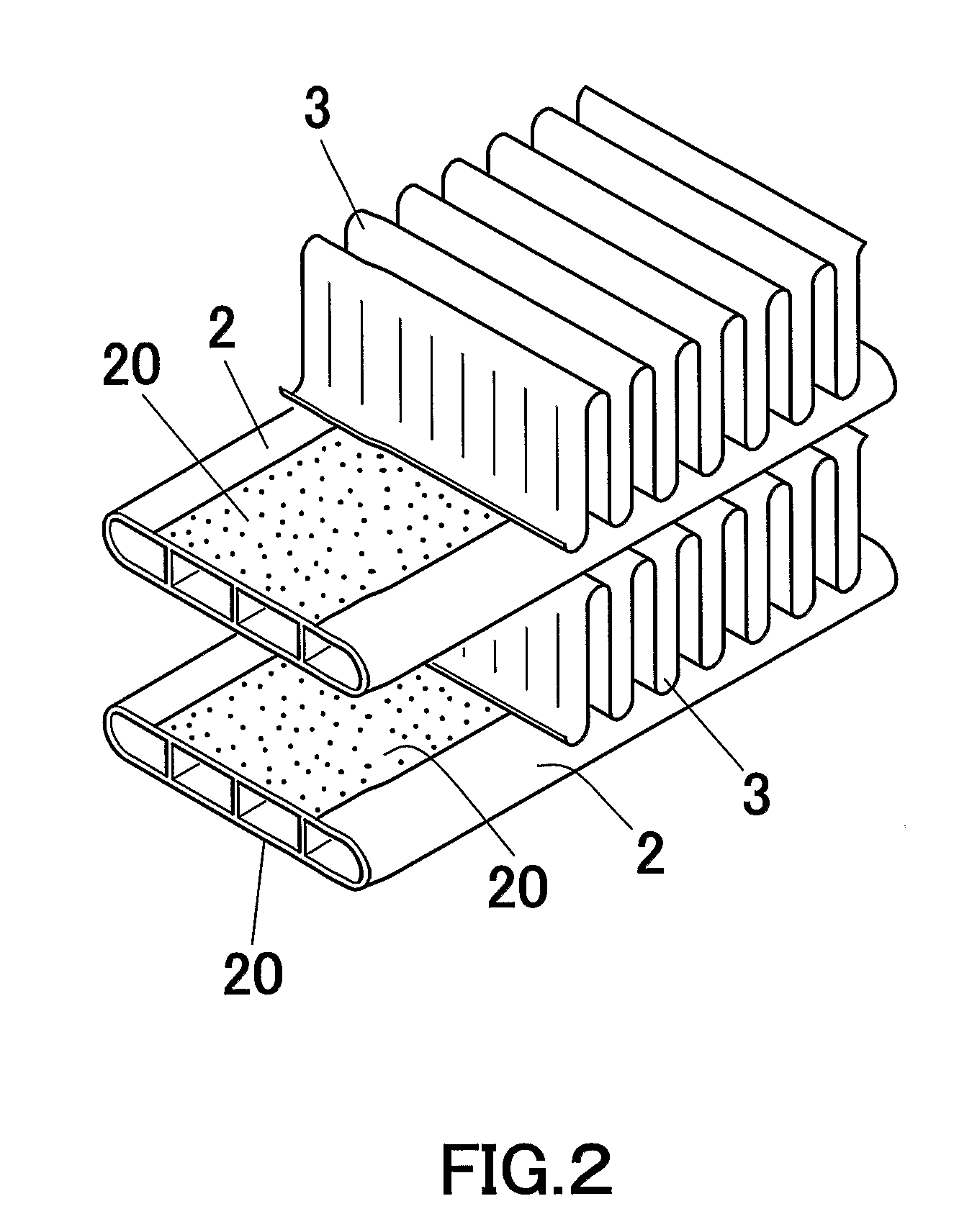

Preparation method of hydrophobic aluminum chromium phosphate

InactiveCN102516828AEasy reunionGood compatibilityCoatingsPigment treatment with organosilicon compoundsFilling materialsPhosphoric acid

The invention discloses a preparation method of hydrophobic aluminum chromium phosphate. The preparation method is characterized in that the preparation method comprises the following steps: 1, taking aluminum chromium phosphate, and taking a modifier with the weight accounting for 0.5-20% of the aluminum chromium phosphate; and 2, mixing the aluminum chromium phosphate with the modifier, and stir-reacting for 10-120min at 50-150DEG C to obtain the hydrophobic aluminum chromium phosphate, wherein the modifier is methyltriethoxysilane. By adopting the preparation method, raw materials are easy to obtain, the production technology is easy to carry out, and the prepared hydrophobic aluminum chromium phosphate is specially suitable for being used as a filler of a resin matrix composite material or a paint and has a wide application prospect.

Owner:SOUTHWEAT UNIV OF SCI & TECH

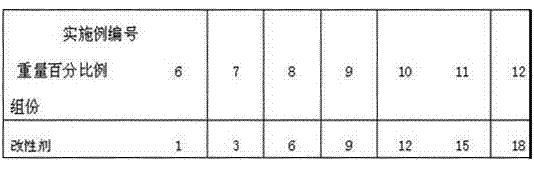

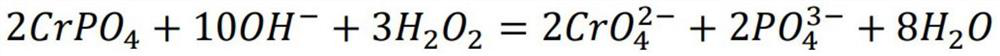

Recycling treatment method of electroplating sludge

ActiveCN112853101AHigh recovery rateEliminate emissionsIron oxides/hydroxidesProcess efficiency improvementFerric hydroxideSodium phosphates

The invention relates to the field of resource utilization of electroplating sludge, in particular to a recycling treatment method of electroplating sludge. The recycling treatment method comprises the following steps: carrying out oxidation alkaline leaching on electroplating sludge after leaching, copper extraction and impurity removal, wherein the oxidation alkaline leaching is carried out in sodium hydroxide and an oxidizing agent, and the terminal alkalinity of the oxidation alkaline leaching is 10-80 g / L in terms of sodium hydroxide. According to the method, high-quality crystallized copper salt, crystallized nickel salt, crystallized zinc salt, crystallized sodium salt, chromium phosphate, sodium phosphate and other products can be produced, detoxified gypsum can be used for cement and brick making, ferric hydroxide and aluminum hydroxide can be sent to a steel plant or an aluminum plant for use, and no waste residues are discharged in the whole technological process. All process wastewater is recycled, so that zero discharge of wastewater can be realized. Copper, nickel, zinc, chromium, phosphorus and the like in the electroplating sludge are all efficiently recovered, the technological process is simple, the production efficiency is high, industrialization is easy to achieve, the equipment composition is simple, the product quality is good, and the recovery rate is high.

Owner:北京首创环境科技有限公司

Environment-friendly waterproof corrosion-resistant marine coating

InactiveCN104927553AImprove mechanical propertiesImprove waterproof performanceAnti-corrosive paintsPolyester coatingsLead ChromatePhosphate

The invention discloses an environment-friendly waterproof corrosion-resistant marine coating. The environment-friendly waterproof corrosion-resistant marine coating consists of the following materials in parts by weight: 30 to 40 parts of polyvinyl acetal-modified phenolic resin, 10 to 15 parts of poly(ethyl acrylate) emulsion, 20 to 30 parts of organic silicon-modified polyester resin, 10 to 15 parts of isophthalic unsaturated polyester resin, 3 to 13 parts of lead chromate, 3 to 12 parts of hydroxypropyl methylcellulose, 2 to 6 parts of sodium carboxymethylcellulose, 1 to 5 parts of hydroquinone, 5 to 15 parts of aluminium nanopowder, 10 to 15 parts of modified mica, 10 to 15 parts of aluminium hydroxide, 15 to 20 parts of nano calcium oxide, 5 to 10 parts of zinc oxide, 2 to 4 parts of chromium phosphate, 1 to 3 parts of barium phosphate, 5 to 10 parts of calcium phosphate, 1 to 3 parts of iron oxide red and 2 to 5 parts of phthalocyanine blue. The waterproofness of the environment-friendly waterproof corrosion-resistant marine coating is good, the corrosion resistance of the environment-friendly waterproof corrosion-resistant marine coating is excellent, and moreover, the environment-friendly waterproof corrosion-resistant marine coating does not pollute the environment.

Owner:WUHU SHUANGBAO BUILDING MATERIAL

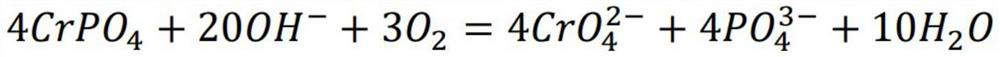

Novel metal (III) -chromium-phosphate complex and use thereof

InactiveCN101346314AHigh hydrogen ion conductivityImprove ionic conductivitySolid electrolytesAluminium compoundsComposite electrolyteFuel cells

Disclosed herein are a metal(III)-chromium-phosphate complex represented by a formula of M(III)xCr(HPO4)y(H2PO4)z and the use thereof. More particularly, disclosed are an organic / inorganic composite electrolyte membrane comprising said complex, an electrode comprising said complex, a membrane-electrode assembly (MEA) comprising said organic / inorganic composite electrolyte membrane and / or electrode, and a fuel cell comprising said membrane- electrode assembly.

Owner:LG CHEM LTD

Method for recycling ceramic-grade iron phosphate for multi-metal dangerous waste

The invention relates to a method for recycling ceramic-grade iron phosphate for multi-metal dangerous waste. The method comprises the steps that phosphorization wastewater treatment sludge containingmulti-metal is matched with sludge containing Fe3+, acid pickling is conducted, iron phosphate sediment is generated under pH of 2.0-2.5 and separated from other kinds of metal, dissolution and reduction are conducted, and a small number of copper ions are removed; the pH is adjusted to 3.5-3.8, and a small amount of chromium is removed through a chromium phosphate form; finally, hydrogen peroxide is added for generating iron phosphate whit Fe3+ and phosphate groups, the pH of diluted acid is adjusted to 2.1-2.5, stirring and filtering are conducted, and filter cake is ceramic-grade iron phosphate. According to the method, a full-wet-method process is adopted, heating is not needed, the equipment and the operation method are simple, and the cost is low; the medical agent is monotonous inkind and environmentally friendly; the extracted ceramic-grade iron phosphate products are high in additional value and can be directly applied to raw materials of industries such as ceramics, adhesive, pigment and chemical engineering.

Owner:重庆太锦环保科技有限公司

Preparation method of inorganic suspension coating

ActiveCN102219472AAvoid issues like performance degradationImprove sealing efficiencyMetallurgyPhosphate

The invention discloses a preparation method of inorganic suspension coating which is prepared by the mixing of phosphate binder and metal ceramic composite powder. The phosphate binder comprises the following components according to proportion: the concentration of AL(H2PO4)3 is 30-60 percent, and the concentration of CrO3 is 60-80g / l; and the composite powder comprises the following components according to mass percentage: 1-25 percent of Ti, 1-15 percent of Si, 5-25 percent of BN, and the balance of Al. The preparation method comprises the following steps: firstly preparing aluminium-chromium phosphate solution, then preparing the metal ceramic composite powder, and finally uniformly mixing the phosphate binder with the metal ceramic composite powder in a mechanical blending manner to prepare the inorganic suspension coating. The coating prepared by the method has the characteristics of being low in cost, easy for maintenance and adjustment, free from thermal influence on substrate during coating, good in obturage effect and the like, can meet the low temperature and obturage requirements of various aircraft engine parts, and has wide application prospect.

Owner:BEIJING GENERAL RES INST OF MINING & METALLURGY

Catalyst specially for preparing gasoline and diesel oil with waste plastics

InactiveCN1740272AImprove the effect of chemical reactionsHigh activityLiquid hydrocarbon mixture productionChemical reactionSodium Bentonite

The catalyst specially for preparing gasoline and diesel oil with waste plastics consists of Pt, Re, aluminum hydride, nickel fluoride, nickel nitrate, alumina, silica, chromium oxide, chromium phosphate, magnesium carbonate, bentonite, No. 101 white acid pickling carrier, aluminum sulfate, sodium silicate and distilled water in certain weight proportion. Compared with available technology, the catalyst specially for preparing gasoline and diesel oil with waste plastics has the features of powerful reaction capacity, high activity, powerful antitoxication capacity, long service life, high heat stability, high steam stability, high mechanical strength, etc.

Owner:严国斌 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com