Method for separating and refining iron and chromium from polymetallic hazardous waste

A hazardous waste and polymetallic technology, applied in the direction of non-metallic elements, chemical instruments and methods, phosphorus compounds, etc., can solve the problems of increasing the cost of hazardous waste disposal, limited service life, high energy consumption of electrolysis, etc., to save processing time, Reduced processing costs and high economic value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] A method for separating refined iron and chromium from polymetallic hazardous waste (phosphate-free sludge)

[0053] (1) Raw material analysis

[0054] Take comprehensive sludge without phosphate radicals, add Fe salt to the sludge and mix evenly to make Fe:Cr=2.5~3.5:1, analyze its metal content with flame atomic absorption spectrophotometer, the results are shown in Table 1.

[0055] Table 1 Contents of metal components in comprehensive sludge

[0056] .

[0057] (2) Acid leaching experiment

[0058] Take 500g of the above-mentioned mixed comprehensive sludge into a 2000mL beaker, add 1200mL of water, put mechanical stirring into the beaker, adjust the rotation speed to 300 r / min to make the sludge slurry, and then slowly add 98% sulfuric acid to the slurry, and the sludge in the process The mud gradually dissolves, add sulfuric acid until the sludge no longer reacts, continue to stir for 30 min, and keep the pH value at about 0.5 to completely leach the metals i...

Embodiment 2

[0073] A method for separating refined iron and chromium from polymetallic hazardous waste (adding phosphate to phosphate-free sludge to separate iron and chromium)

[0074] (1) Preparation of iron and chromium filtrate

[0075] Get 500g of sludge prepared in Example 1, add 1000mL of water to make slurry, carry out acid leaching, crude ferrochrome, and coarse ferrochrome dissolving operations according to the method in Example 1, finally obtain 816mL of filtrate, and use flame The concentration of metals in the filtrate was measured by an atomic absorption spectrophotometer, and the results are shown in Table 4.

[0076] Table 4 Composition list of filtrate containing iron and chromium

[0077] .

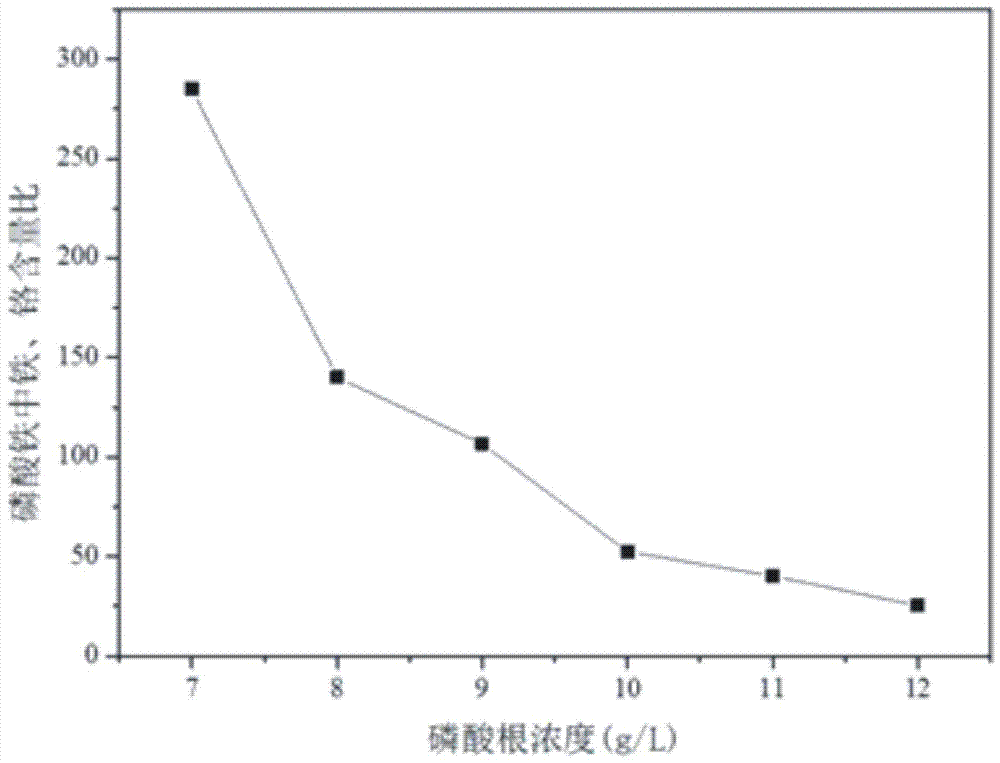

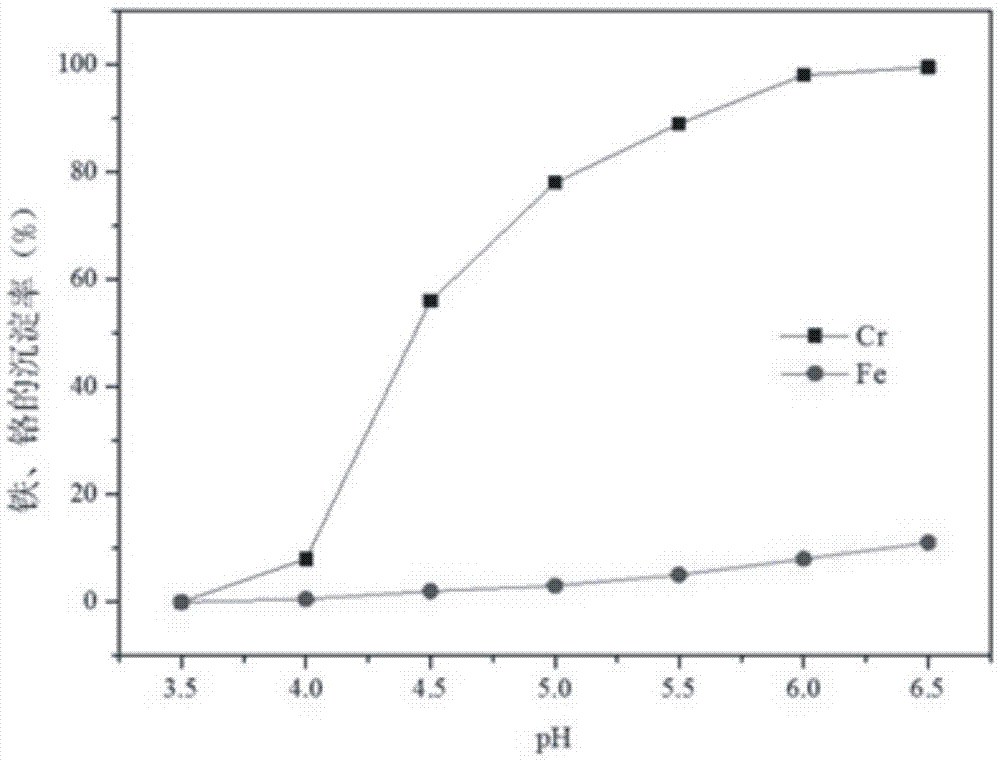

[0078] (2) Add phosphate to produce iron phosphate

[0079] Get 5 parts of 150mL above-mentioned iron, chromium filtrate (Fe 3+ : 11.05g / L, Cr 3+ : 4.48g / L, the concentration ratio of iron and chromium is 2.47), respectively placed in 500mL beakers, and 85% phosphoric acid ...

Embodiment 3

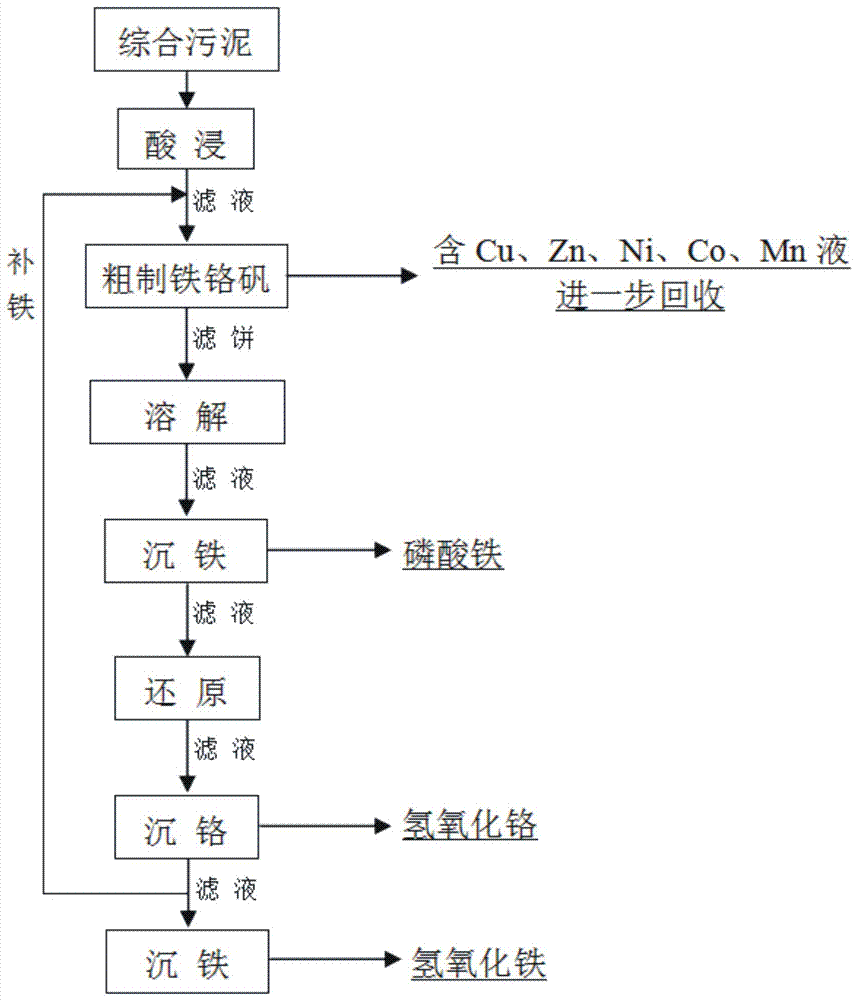

[0083] A method for separating refined iron and chromium from polymetallic hazardous waste (for the process flow of phosphate-containing sludge, see figure 1 )

[0084] (1) Raw material analysis

[0085] Take the comprehensive sludge containing phosphate and add Fe to the sludge 3+ Salt mix well to make Fe:Cr - =2.5~3.5:1, the metal content was analyzed with a flame atomic absorption spectrophotometer, and the phosphate content was analyzed with a visible spectrophotometer. The results are shown in Table 5.

[0086] Table 5 Metal composition list of phosphate-containing comprehensive sludge

[0087] .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com