Patents

Literature

123 results about "Chromium(III) hydroxide" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Chromium(III) hydroxide is a gelatinous green inorganic compound with the chemical formula Cr(OH)₃. It is a polymer with an undefined structure and low solubility. It is amphoteric, dissolving in both strong base and strong acid.

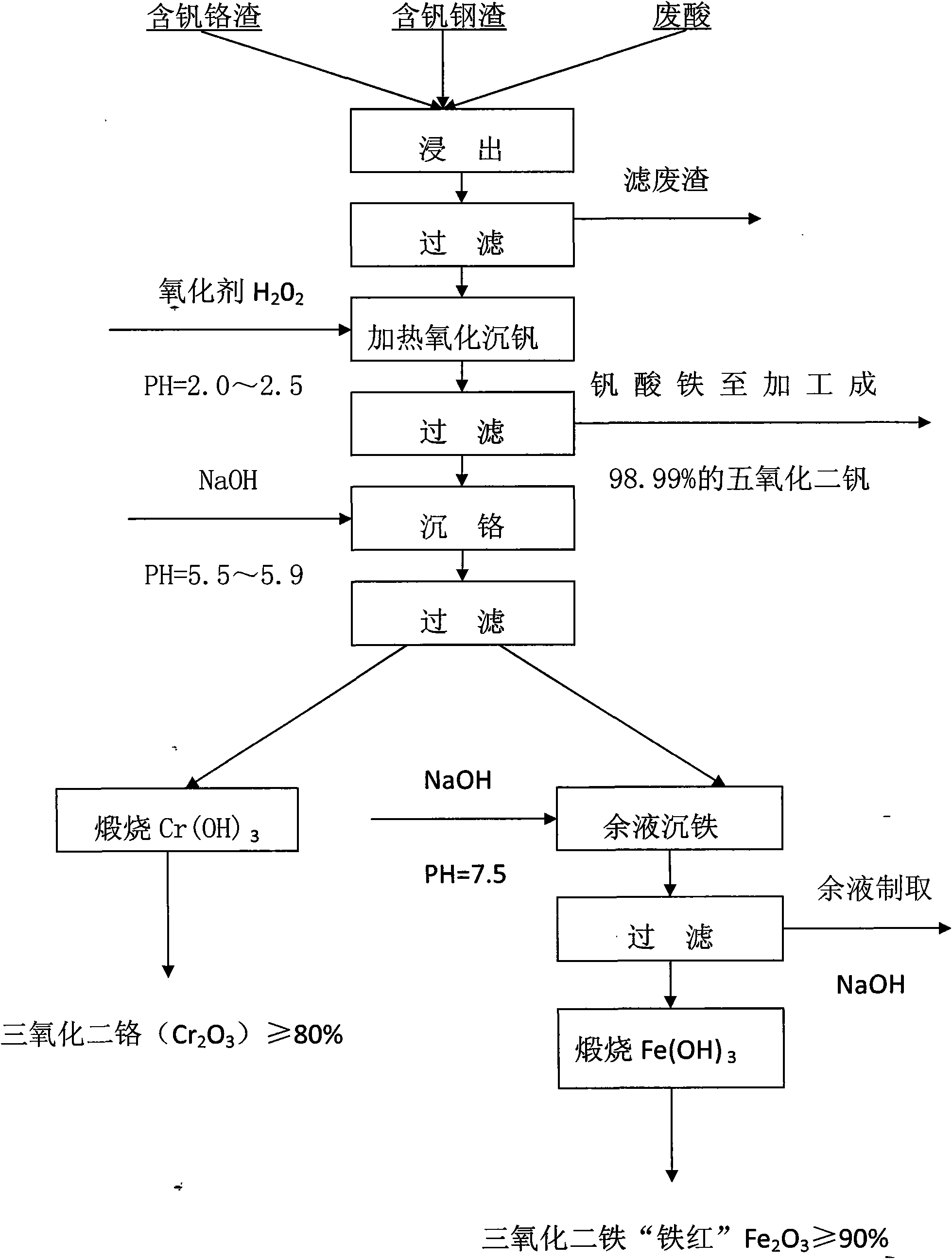

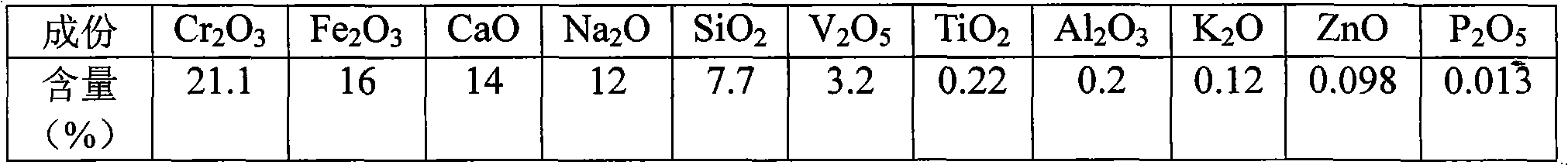

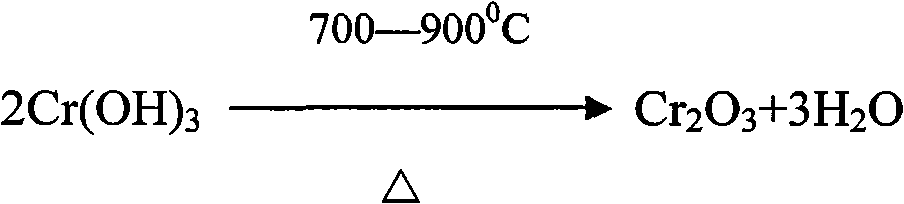

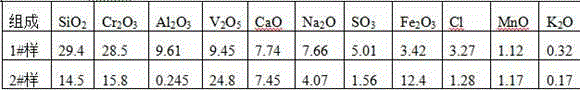

Process for extracting vanadium and chromium from chromic slag by using waste acid of titanium powder plant

InactiveCN101979683AFiltration process goes wellAchieve the purpose of separationProcess efficiency improvementChromium(III) hydroxideSlag

The invention discloses a method for separating and extracting vanadium and chromium. The method comprises the following steps of: (1) producing chromium fine sand (Cr2O3) of which the content is over 80 percent and ferric vandate of which the content is over 20 percent from two waste materials by taking waste acid of a titanium powder plant as a leaching agent and vanadium-chromium slag (containing 2.5 to 4.5 percent of vanadium and 14 to 25 percent of chromium) as a raw material; (2) putting the vanadium-chromium slag into the waste acid to allow the chromium and the vanadium in the slag to form chromium sulfate and vanadyl sulfate which can be dissolved in water very easily, wherein the leaching time is about 6 hours; (3) adding a certain amount of steel making steel slag during leaching to fulfill the aim of generating a great deal of calcium sulfate when a great deal of calcium oxide meets the acid during filtration, and wrapping, adsorbing or and stopping 'silica gel' formed by silicon dioxide in the chromium slag by the calcium sulfate which is used as a filter medium to ensure that the filtration is performed smoothly; (4) adjusting the pH value of the filtrate to be 2.5 by using sodium hydroxide, and then adding an oxidant and oxydol to ensure that the chromium in the solution is oxidized to be hexavalent, the iron is oxidized to be trivalent, and the vanadium is oxidized to be pentavalent; (5) heating the leaching solution to the temperature of between 70 and 90 DEG C to ensure that the vanadium and the iron is combined together to generate water-fast 'ferric vandate', wherein the time for thermal precipitation is about one hour, and the vanadium residual in the solution is not more than 0.4 g / L; (6) adding sodium hydroxide into the solution of which the ferric vandate is filtered out, and fully stirring the mixture until the pH value of the solution is between 5.5 and 5.9 to ensure that the chromium in the solution is completely converted into chromium.

Owner:PANZHIHUA SHUOSHENG IND & TRADING

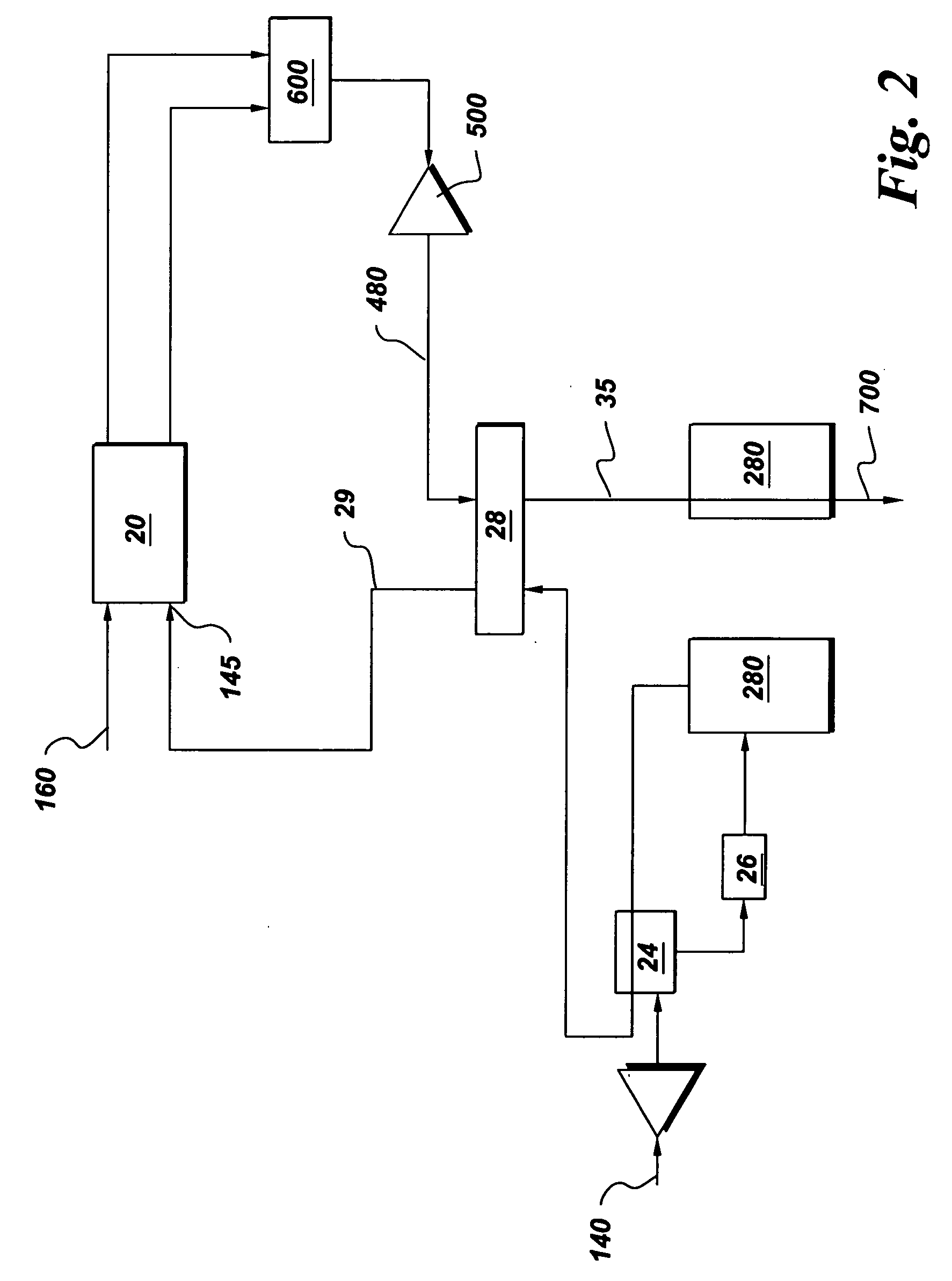

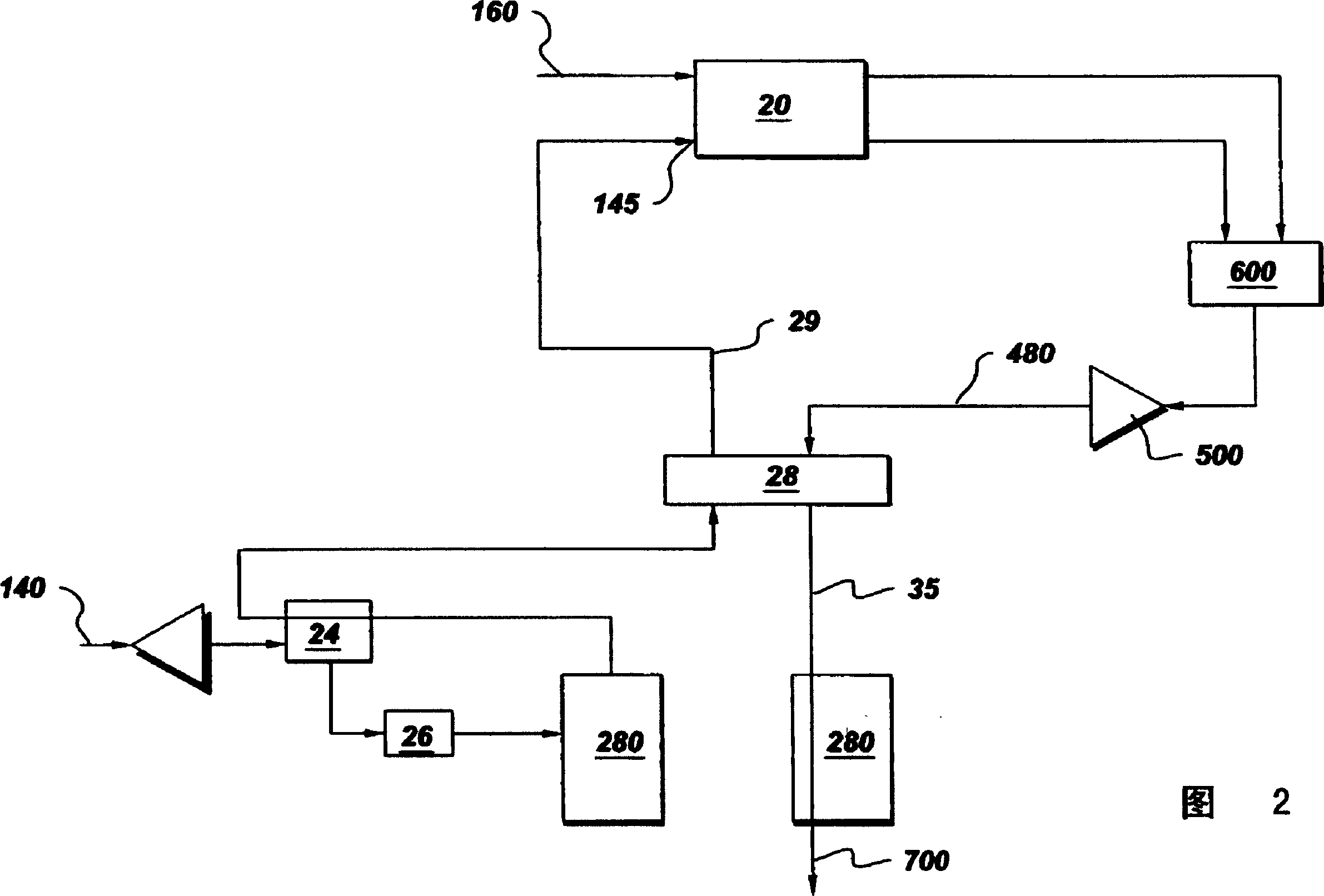

Prevention of chromia-induced cathode poisoning in solid oxide fuel cells (SOFC)

InactiveUS20050142398A1Minimize energy lossEnough timeCell electrodesFuel cell auxillariesFuel cellsChromium(III) hydroxide

A method is provided for increasing the life expectancy of a solid oxide fuel cell by preventing cathode poisoning due to chromium volatilization. Chromium hydroxide and oxyhydroxide formation and evaporation are prevented by continuously drying the cathode feed gas to low moisture levels. Power generation configurations that minimize the energy penalty associated with cathode gas drying are also disclosed.

Owner:GENERAL ELECTRIC CO

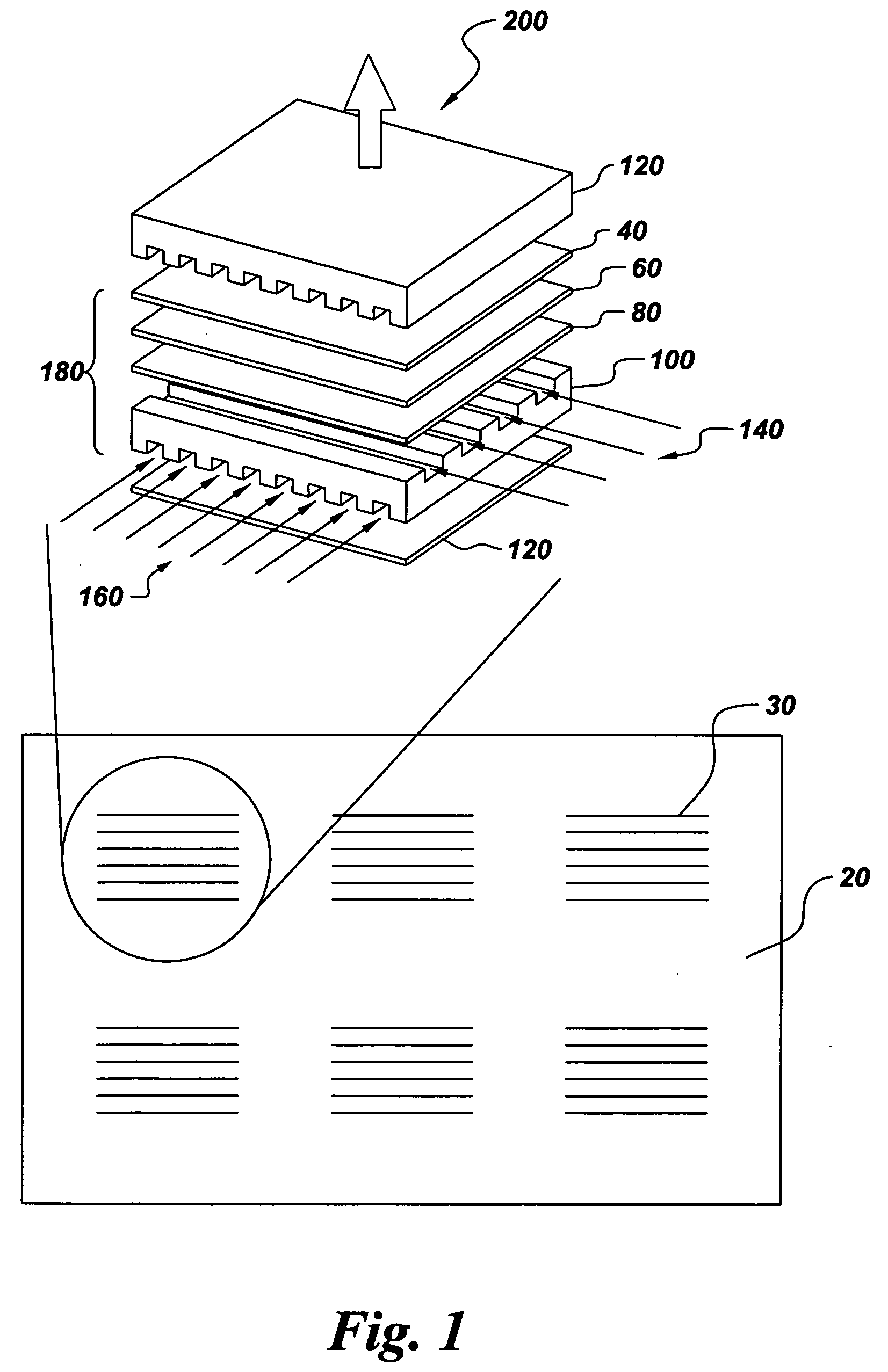

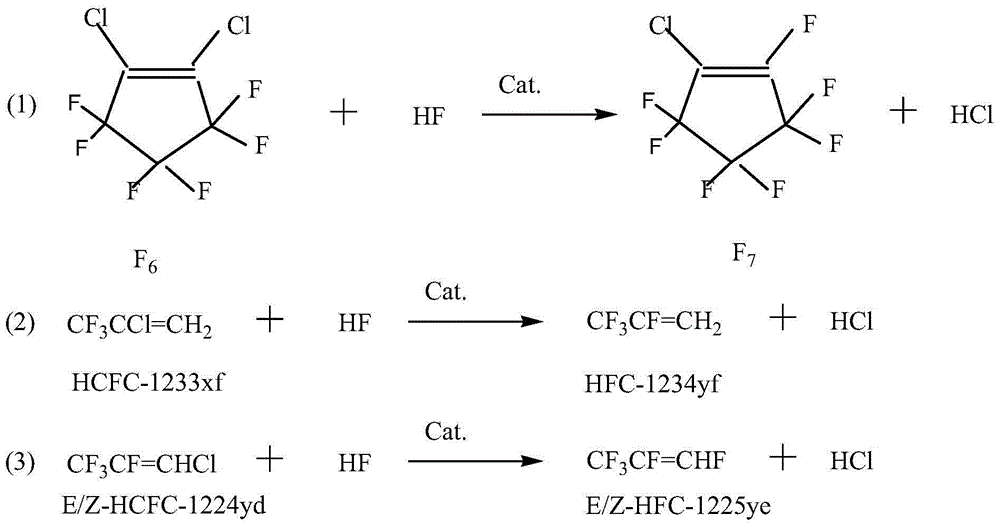

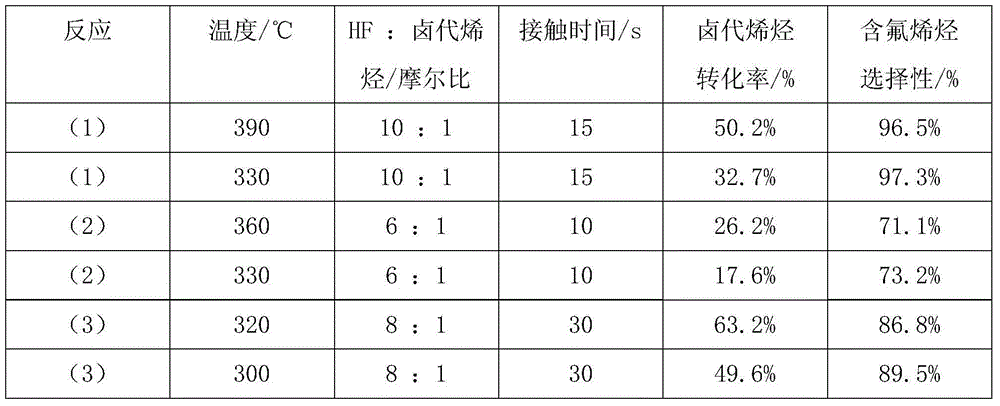

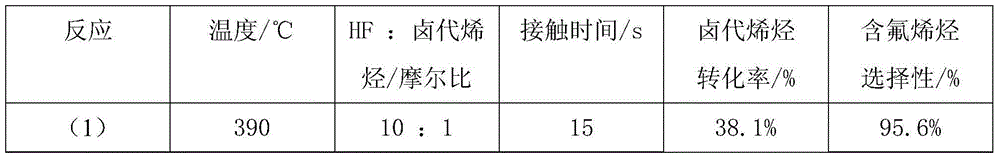

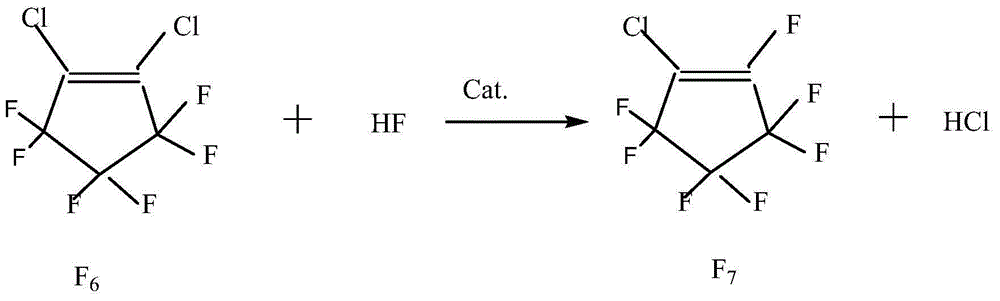

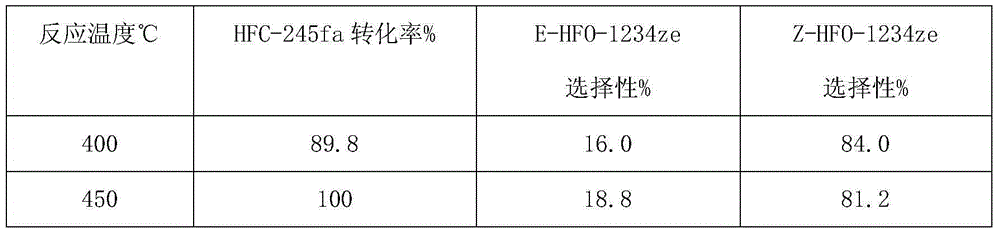

Fluorination catalyst, and preparation method and use thereof

ActiveCN104907065AIncrease the areaHigh pore volumePreparation by halogen replacementMetal/metal-oxides/metal-hydroxide catalystsChromium CompoundsChemical synthesis

The invention discloses a fluorination catalyst, and a preparation method and a use thereof, and belongs to the field of chemical synthesis. The precursor of the catalyst is formed by blending 40-95mass% of a trivalent chromium compound with 5-60mass% of tungstate, wherein the trivalent chromium compound can be chromic oxide or chromium hydroxide, and the tungstate can be zinc tungstate, nickel tungstate, magnesium tungstate, aluminum tungstate, silicotungstic acid, ammonium tungstate, ammonium paratungstate or ammonium metatungstate. The fluorination catalyst has the advantages of high use temperature, high catalysis activity and long service life, and can be mainly used in reactions for preparing fluorinated alkenes through gas phase catalysis of fluorination of alkenyl halides at a high temperature.

Owner:泉州宇极新材料科技有限公司

Treatment method for chromium-containing wastewater

InactiveCN104030478ALess investmentLow running costWater contaminantsMultistage water/sewage treatmentTreatment effectChromium(III) hydroxide

The invention discloses a treatment method for chromium-containing wastewater. The method comprises the steps of: a. adding acid into the chromium-containing wastewater to adjust the pH to 2-3; b. adding a reducing agent into the acidic chromium-containing wastewater to reduce hexavalent chromium ions to trivalent chromium ions; and c. adding alkali into the solution treated in step b to adjust the pH to 8-9, and converting the trivalent chromium ions into chromium hydroxide precipitates. The method provided by the invention has the characteristics of: small investment, low operation cost, good treatment effect, and simple operation and management.

Owner:LIDA ENVIRONMENT ENG DALIAN ECONOMIC TECH DEV ZONE

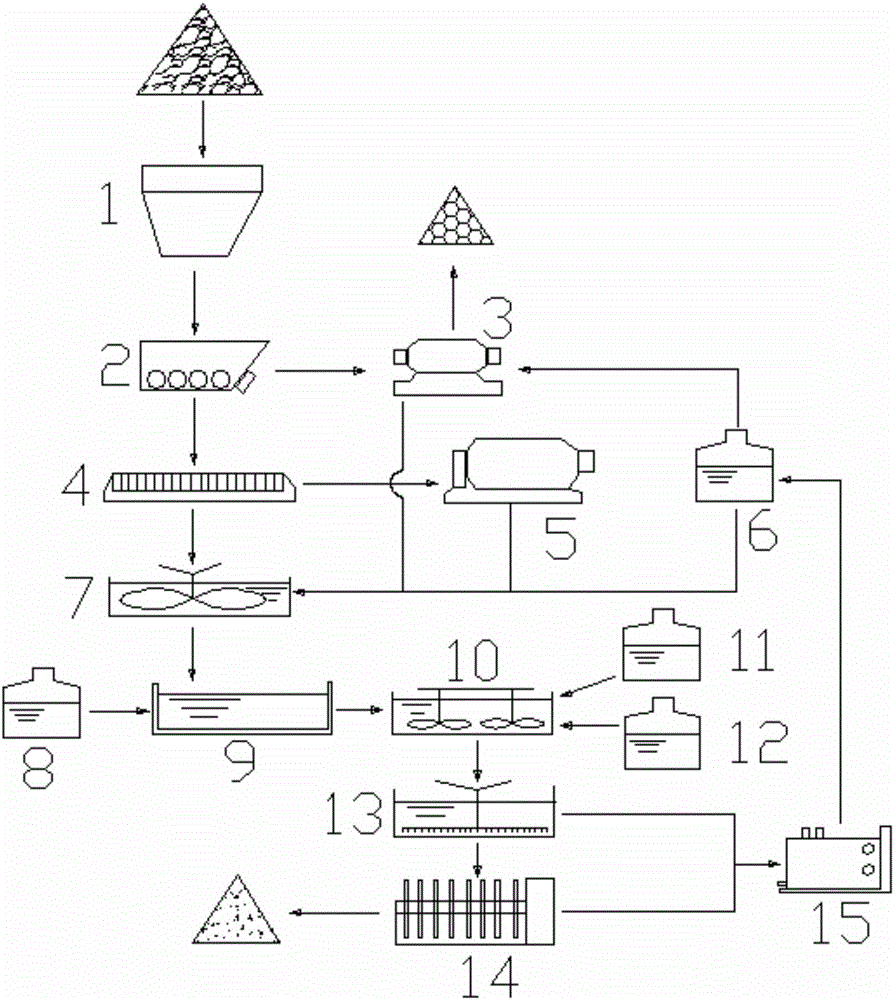

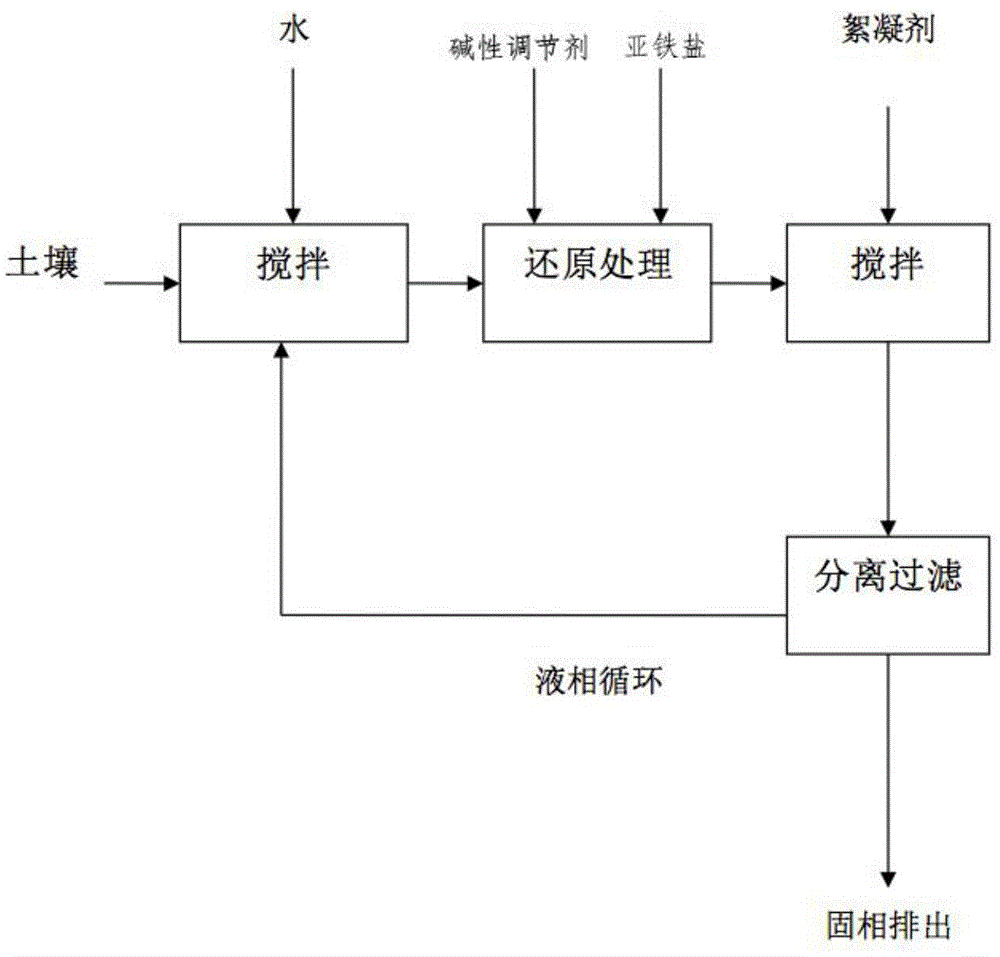

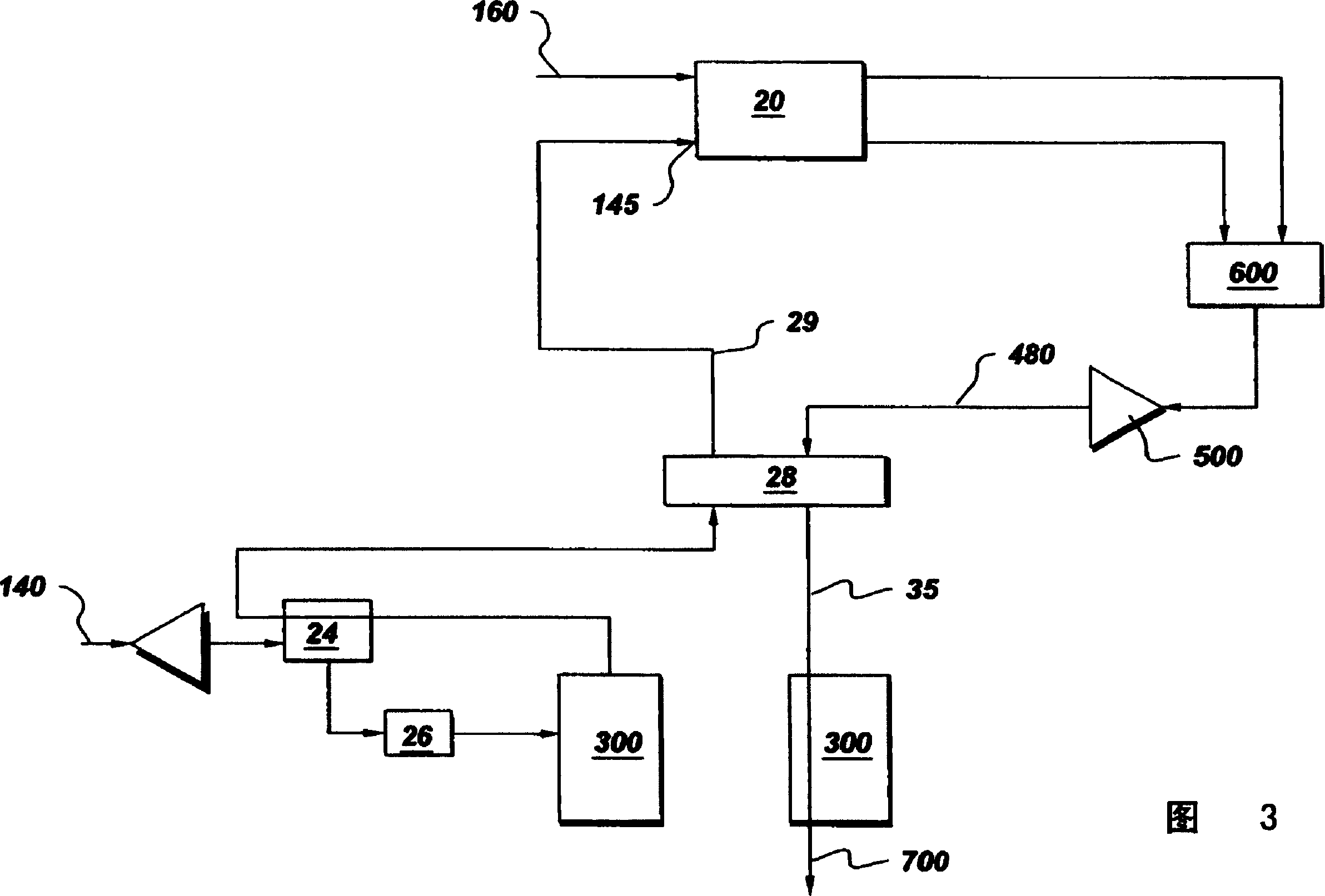

Treatment method and treatment equipment for remedying hexavalent chromium-polluted soil

The invention discloses a treatment method and treatment equipment for remedying hexavalent chromium-polluted soil. The treatment equipment comprises a vibrating feeding machine, a stone scrubber, a vibrating screen, a ball milling machine, a pulping machine, an adjusting tank, a stirring tank, a thickening machine, a plate-and-frame filter press and water treatment equipment. The treatment method comprises the steps as follows: (1) the polluted soil is screened or ground by the vibrating screen; (2) a material is sent into the pulping machine for pulping; (3) then pulp is sent to the adjusting tank, and the pH value is adjusted to range from 2 to 4; (4) the pulp is sent into the stirring tank to form chromium hydroxide precipitate, and the pH value is adjusted to range from 6 to 8; (5) solid-liquid separation and filter pressing dehydration are performed, and mud cakes are formed. The equipment runs stably and reliably, is convenient to mount and dismount and has the good elution effect; waste water is recycled after treatment and can be used for the cylinder stone scrubber and the pulping machine, water resources are greatly saved, and secondary pollution caused by discharge of sewage is also avoided; and the method and the equipment can also be applied to elution remediation projects of other heavy metal-polluted soil, and the use efficiency of the equipment is improved.

Owner:GUANGXI BOSSCO ENVIRONMENTAL PROTECTION TECH

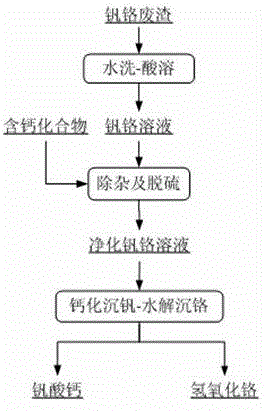

Method for synchronously recovering vanadium and chromium from vanadium-chromium slag by acid process

ActiveCN104805303AClean and efficient useReduce usageProcess efficiency improvementSlagCalcification

The invention relates to a method for synchronously recovering vanadium and chromium from vanadium-chromium slag by an acid process. The method comprises the steps: (1) carrying out water-washing desalting: washing water-soluble salts in the vanadium-chromium slag with water, filtrating so as to obtain a filter cake and a washing solution, cyclically washing the washing solution with water, and finally precipitating salts through cooling crystallization; (2) carrying out oxidizing acid-dissolving: adding the filter cake obtained in the step (1) into a sulfuric acid solution for acid dissolving, and adding an oxygen enrichment agent for closed oxygen-enriched leaching during acid dissolving, so as to obtain a vanadium-chromium solution and tailings; (3) carrying out purifying impurity removal: adding a calcium containing compound into the vanadium-chromium solution obtained in the step (2) for impurity removal-desulfurization, so as to obtain a purified vanadium-chromium solution; (4) carrying out calcification vanadium precipitating: adding a calcification agent into the vanadium-chromium solution obtained in the step (3) for calcification vanadium precipitating, so as to obtain calcium vanadate and a vanadium precipitated solution; (5) carrying out hydrolyzing chromium precipitating: reducing the vanadium precipitated solution obtained in the step (4) through a reducing agent, adding alkali to adjust the pH value of the solution to 7-9, precipitating to obtain chromic hydroxide, and calcining to obtain a chrome green product. According to the method provided by the invention, the consumption of additives is reduced, the production process is simplified, the production cost is reduced, and the clean and efficient utilization of the vanadium-chromium slag is realized.

Owner:孟立新

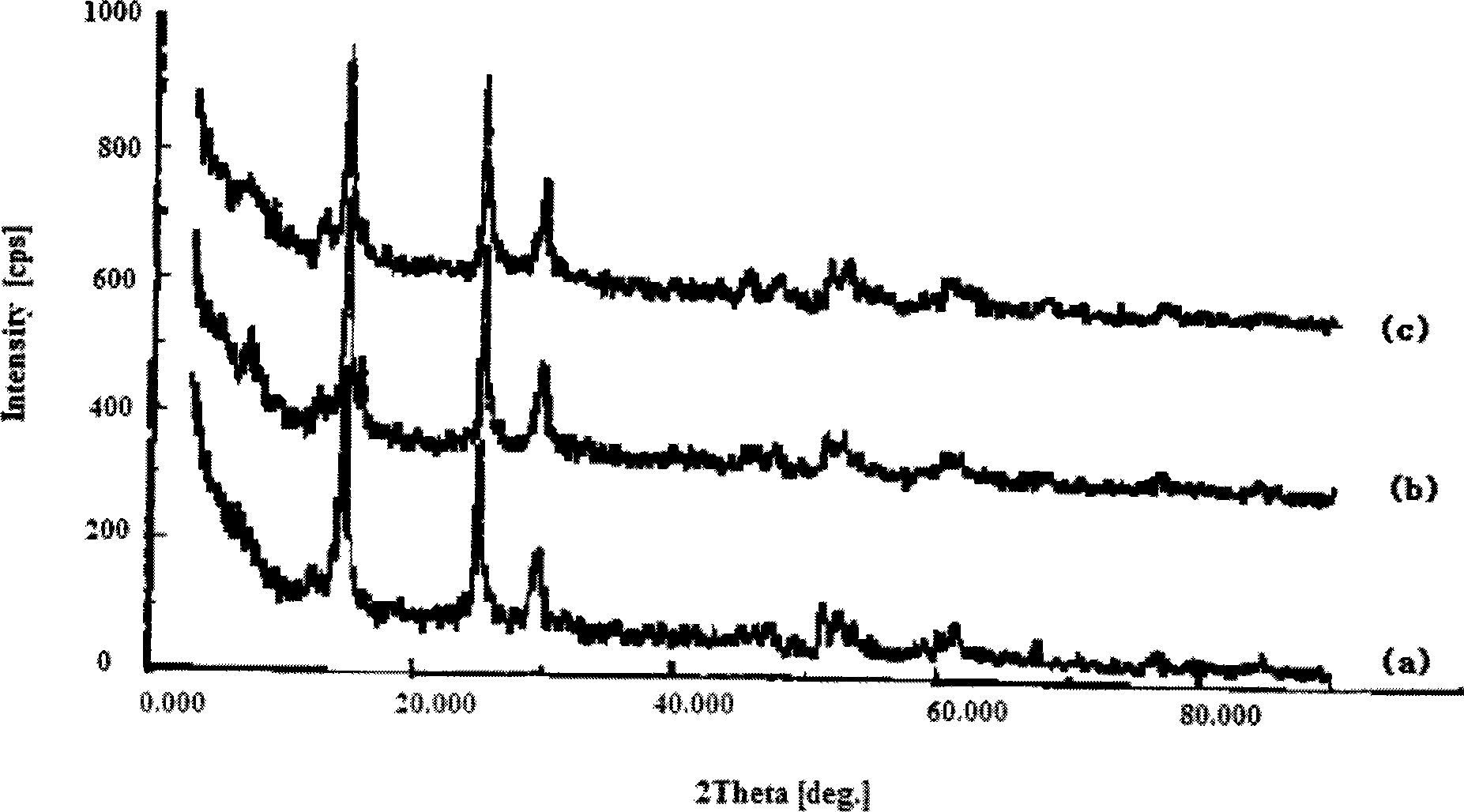

Chromium base fluorating catalyst and preparation thereof

ActiveCN101214448ALarge specific surface areaLarge hole volumePhysical/chemical process catalystsPreparation by halogen replacementChromium CompoundsHydrogen fluoride

The invention discloses a chromium-based fluorinated catalyst and a preparation method thereof. The invention is to solve the problems of complicacy and long time of fluorination activation treatment to the fluorinated catalyst as well as quite small specific surface area after calcination and fluoride. The precursor of the chromium-based fluorinated catalyst contains trivalent chromium compound and fluoride of ammonium, the mass ratio of which is 40 to 70 : 20 to 50, wherein, the trivalent chromium compound is chromic oxide or chromium hydroxide, and the fluoride of ammonium is ammonium fluoride or ammonium bifluoride. The preparation method of the chromium-based fluorinated catalyst of the invention includes the following steps: (1) the trivalent chromium compound and the fluoride of ammonium are evenly mixed by the mass ratio, pressed and shaped, and the precursor of the catalyst is obtained; (2) the catalyst precursor obtained in step (1) receives calcination under 350 DEG C to 450 DEG C, and then receives fluorination by hydrogen fluoride gas under 300 DEG C to 400 DEG C to obtain the chromium-based fluoride catalyst. The chromium-based fluoride catalyst of the invention is applicable to reaction for preparation of hydroflurocarbon with gas-phase fluorinated halohydrocarbon.

Owner:XIAN MODERN CHEM RES INST

Chromium base catalyst, and preparation method and use thereof

InactiveCN104907063AInhibit carbon depositionCatalytic activity unchangedPreparation by hydrogen halide split-offPreparation by halogen replacementCalcium silicateChemical synthesis

The invention discloses a chromium base catalyst, and a preparation method and a use thereof, and belongs to the field of chemical synthesis. The precursor of the catalyst is composed of 90-99.9mass% of a trivalent chromium compound and 0.1-10mass% of a silicon-containing compound, wherein the trivalent chromium compound is chromic oxide or chromium hydroxide, and the silicon-containing compound can be zinc silicate, nickel silicate, magnesium silicate, aluminum silicate, zirconium silicate, barium silicate, bismuth silicate, ammonium fluorosilicate, nickel hexafluorosilicate, zinc fluorosilicate, magnesium fluorosilicate, aluminum fluorosilicate or calcium fluorosilicate The chromium base catalyst has the advantages of large specific surface area, effective inhibition of carbon formation, and long service life, is mainly used for gas phase catalysis of reactions for preparing hydrofluorocarbons or fluorinated alkenes from halogenated hydrocarbons or halogenated alkenes at a high temperature, and can also be used for gas phase catalysis of reactions for preparing hydrofluoroalkenes through hydrogen fluoride removal of hydrofluorocarbons at a high temperature.

Owner:BEIJING YUJI SCI & TECH

Method for recovering hydrazine sulfate and chromium hydroxide from chromium-containing waste acid

InactiveCN102101732AReasonable useEasy to operateMultistage water/sewage treatmentHydrazineChromium(III) hydroxideSulfate

The invention discloses a method for recovering hydrazine sulfate and chromium hydroxide from chromium-containing waste acid, which comprises the following steps of: diluting hydrazine hydrate, slowly adding waste acid into the hydrazine hydrate with stirring, ensuring an acid adding end point when the pH of feed liquid is 0.8-1.2, and reacting hexavalent chromium in the waste acid with the hydrazine hydrate to reduce the hexavalent chromium into trivalent chromium and generate indissoluble hydrazine sulfate crystals; performing solid-liquid separation to obtain crude hydrazine sulfate and acidic chromium sulfate solution; adding alkali into acidic chromium sulfate solution for neutralization to obtain a chromium hydroxide precipitate, performing solid-liquid separation, washing with water, and drying to obtain an industrial product chromium hydroxide meeting quality requirement; and treating wastewater subjected to solid-liquid separation and washing in a wastewater treatment device for up-to-standard emission. The method is easy to operate, and the chromium-containing waste acid is treated for up-to-standard emission; meanwhile, the hydrazine sulfate and chromium hydroxide are recovered, so that the resources are reasonably utilized and the economic benefit is obvious.

Owner:NANJING UNIV

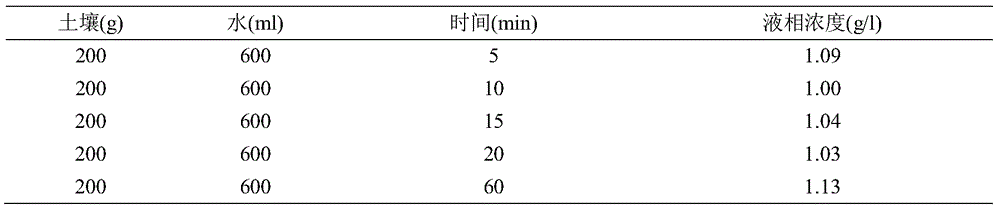

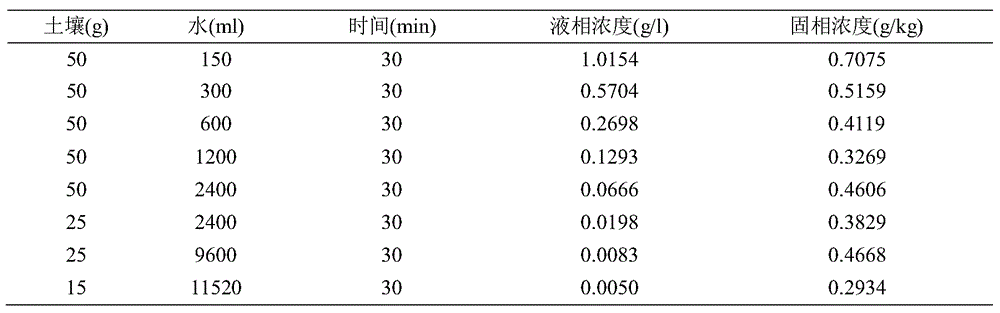

Method for removing hexavalent chromium from polluted soil

ActiveCN104307868AReduce the concentration of hexavalent chromiumContaminated soil reclamationFerrous saltsChromium(III) hydroxide

The invention discloses a method for removing hexavalent chromium from polluted soil. The method comprises the following steps: washing polluted soil in water, stirring, adding ferrous salt to reduce hexavalent chromium into trivalent chromium, and adding an alkaline conditioning agent while the addition of the ferrous salt in order to make the trivalent chromium form chromium hydroxide precipitate, wherein a weight ratio of soil to water to the ferrous salt to the alkaline conditioning agent is 100:300-2400:10-20:1-5, and the stirring reaction time is 10-60min. The method can effectively reduce the content of hexavalent chromium in soil.

Owner:青海省环境科学研究设计院有限公司

Fluorating catalyst and preparation thereof

ActiveCN101214449AReduced fluorination activation timeShort manufacturing cyclePreparation by halogen replacementMetal/metal-oxides/metal-hydroxide catalystsChromium CompoundsHalohydrocarbon

The invention discloses a fluorinated catalyst and a preparation method thereof. The invention is to solve the problems of complicacy and long time of fluorination activation treatment to the fluorinated catalyst as well as quite small specific surface area after calcination and fluoride. The precursor of the catalyst contains aluminium compound, trivalent chromium compound and fluoride of ammonium, the mass ratio of which is 40 to 80:10 to 30:10 to 30, wherein, the aluminium compound is aluminum oxide, aluminum fluoride, fluoride oxidize aluminum or aluminum hydroxide, the trivalent chromium compound is chromic oxide or chromium hydroxide, and the fluoride of ammonium is ammonium fluoride or ammonium bifluoride. The preparation method of the fluorinated catalyst of the invention includes the following steps: (1) the aluminium compound, the trivalent chromium compound and the fluoride of ammonium are evenly mixed by the mass ratio, pressed and shaped, and the precursor of the catalyst is obtained; (2) the catalyst precursor obtained in step (1) receives calcination under 350 DEG C to 450 DEG C, and then receives fluorination by hydrogen fluoride gas under 300 DEG C to 400 DEG C to obtain the fluoride catalyst. The catalyst is applicable to synthesis of gas-phase fluorinated halohydrocarbon into hydroflurocarbon.

Owner:XIAN MODERN CHEM RES INST

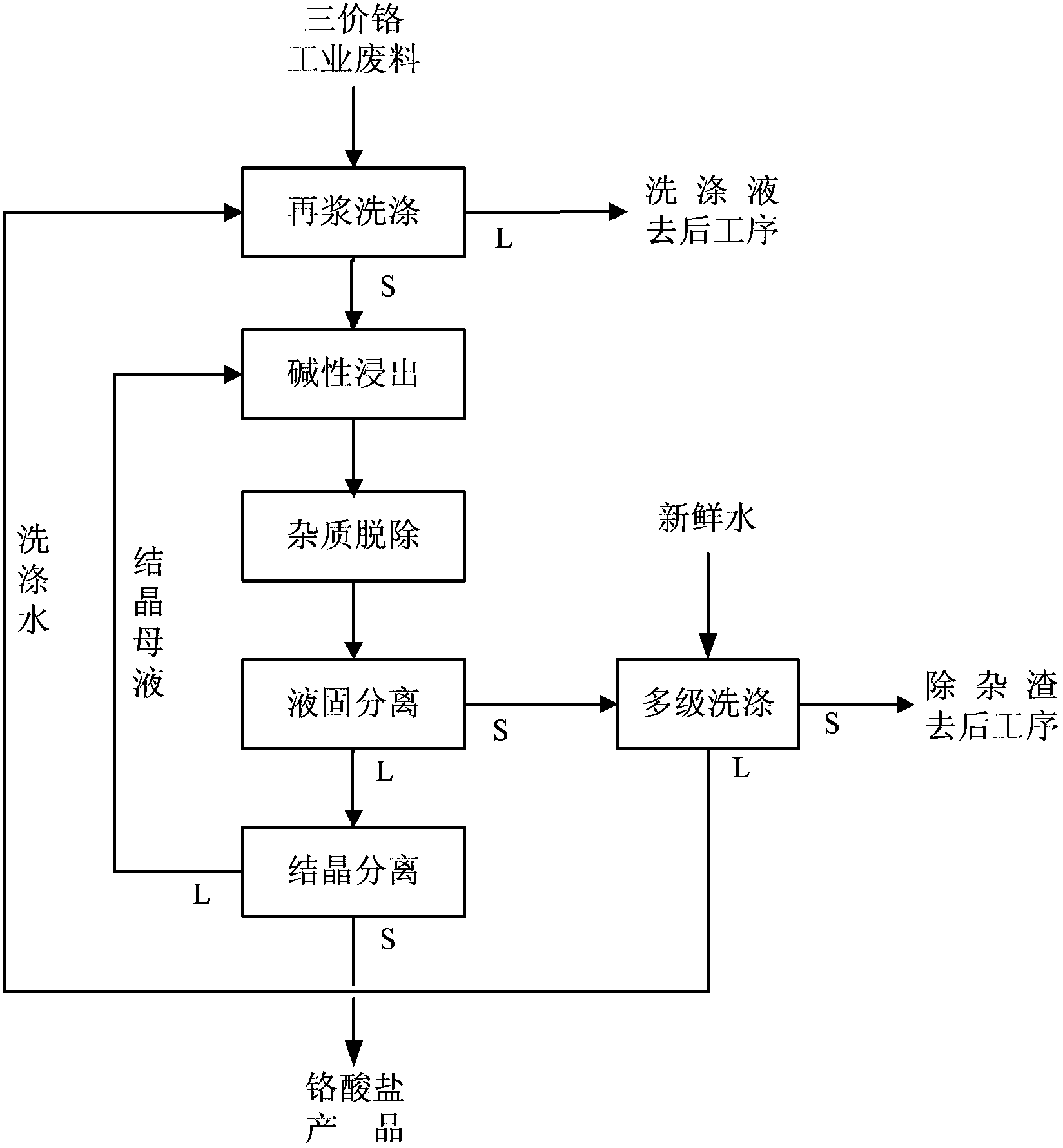

Method for producing chromates through using chromium-containing waste residues

ActiveCN103449522AAchieve recyclingAvoid pollutionChromates/bichromatesChemical industryChromium(III) hydroxide

The invention relates to a method for producing chromates through using chromium-containing waste residues. The method comprises the following steps: reacting pretreated chromium-containing waste residues with an oxidant in an alkaline solution, removing impurities of an obtained reaction solution, carrying out evaporative crystallization, and carrying out solid-liquid separation to obtain chromate products. The chromium-containing waste residues mainly comprise chromium hydroxide-containing waste residues and concretely are industrial chromium-containing wastes generated in the industrial processes comprising the metallurgy, the chemical industry, the pharmacy, the light industry and the like, wherein the main occurrence states of chromium comprise trivalent chromium salts, chromium hydroxide or hydrates thereof. The method has the advantages of short process flow, mild condition, small apparatus corrosion, low process cost, realization of the circulating regeneration of the chromium-containing waste residues, environmental pollution solving, exploitation of a new raw material for producing the chromates, and economic value creation.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

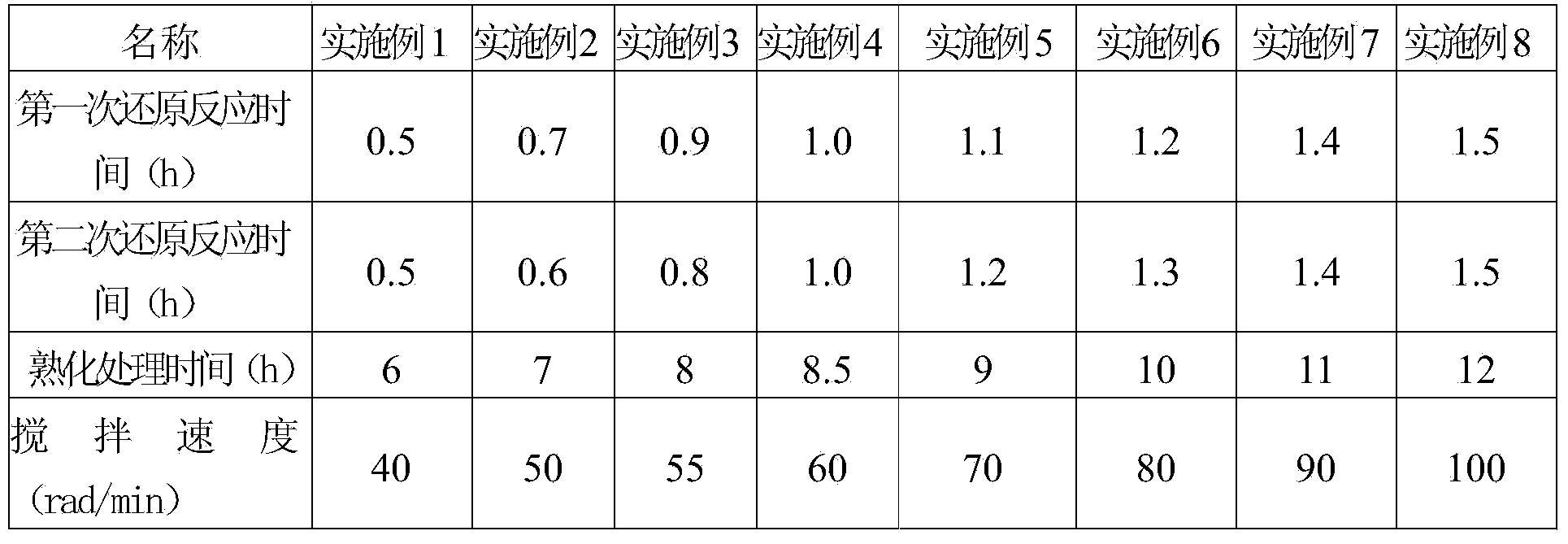

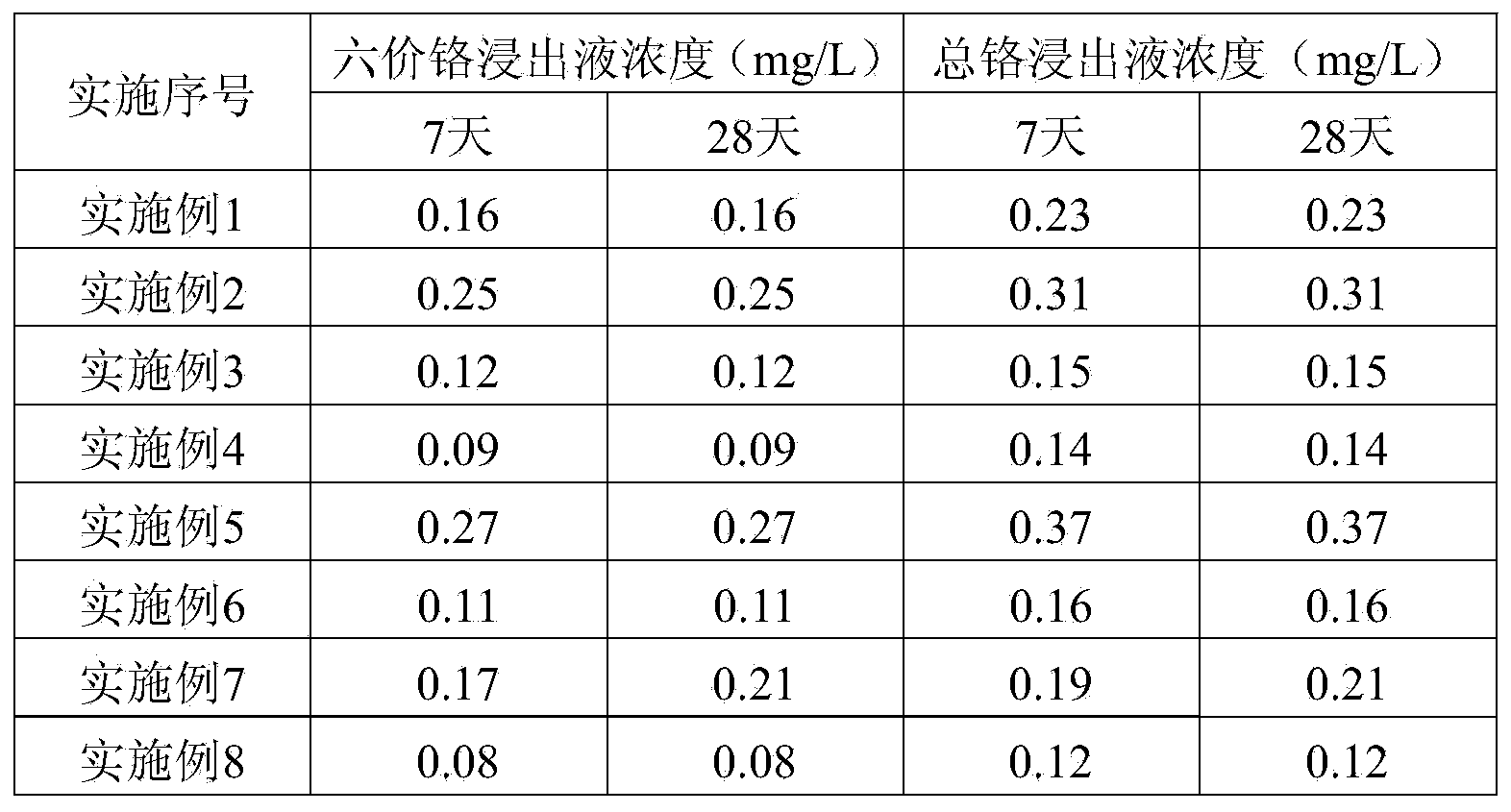

Wet detoxification method for chromium slag and chromium-containing pollutants

ActiveCN103934256AShorten the timeImprove ball milling efficiencySolid waste disposalSulfate radicalsChromium(III) hydroxide

The invention relates to a wet detoxification method for chromium slag and chromium-containing pollutants. The wet detoxification method comprises the following steps: screening and crushing the chromium slag and the chromium-containing pollutants, performing wet milling on the chromium slag and the chromium-containing pollutants in a ball mill, adding a filtrate containing sulfate ions, leaching out acid-soluble calcium chromate in chromium slag slurry, adding the chromium slag slurry and a first reducing agent sequentially into a reaction tank, stirring and mixing the chromium slag slurry with the first reducing agent to perform reduction reaction, reducing the acid-soluble calcium chromate in chromium slag slurry to trivalent chromium, adding concentrated sulfuric acid and to stirring and mixing for regulating, adjusting pH value of the chromium slag slurry to be 7+ / -0.5, then adding a second reducing agent into the reaction tank and stirring and mixing for reducing, stirring the reduced slag slurry to cure the reduced slag slurry, and converting hexavalent chromium in the chromium slag slurry to chromic hydroxide sediment; and separating solid and liquid of the cured chromium slag slurry. The wet detoxification method has the characteristics of low cost, no waste liquid, no slag returning phenomenon, good detoxification effect and capability of being applicable to the large-scale industrial production.

Owner:WELLE ENVIRONMENTAL GRP CO LTD

Method utilizing chromium-containing sodium bisulfate to produce chromium oxide green

InactiveCN106395904AEnvironmentally friendlyEnergy savingChromium oxides/hydratesChromium(III) hydroxideSodium bisulfate

The invention discloses a method utilizing chromium-containing sodium bisulfate to produce chromium oxide green. The method comprises the following steps: directly reducing chromium-containing sodium bisulfate, which is discharged in chromic anhydride production (sulfuric acid method), by a reducing agent, adjusting the pH value of the solution to a neutral range, press-filtering the solution by a filter presser, washing the obtained chromium hydroxide filter cakes, and burning the chromium hydroxide filter cakes to obtain a chromium oxide green product. The conventional technology that chromium-containing sodium bisulfate is recovered and applied to the neutralization and acidification of a chromium salt production system is replaced, the production procedure of the provided method is short, the method is simple; moreover, the wastes namely chromium-containing sodium bisulfate are effectively consumed; the environment pollution is reduced, at the same time, the production of commercial sodium bichromate and the production of commercial chromic anhydride in the chromium salt production system can be effectively balanced; the harmful impurity enrichment caused by recovery of sodium bisulfate is relieved, and thus the quality of sodium bichromate and chromic anhydride is guaranteed. The production technology is environment-friendly, energy-saving, and efficient.

Owner:GANSU JINSHI CHEM

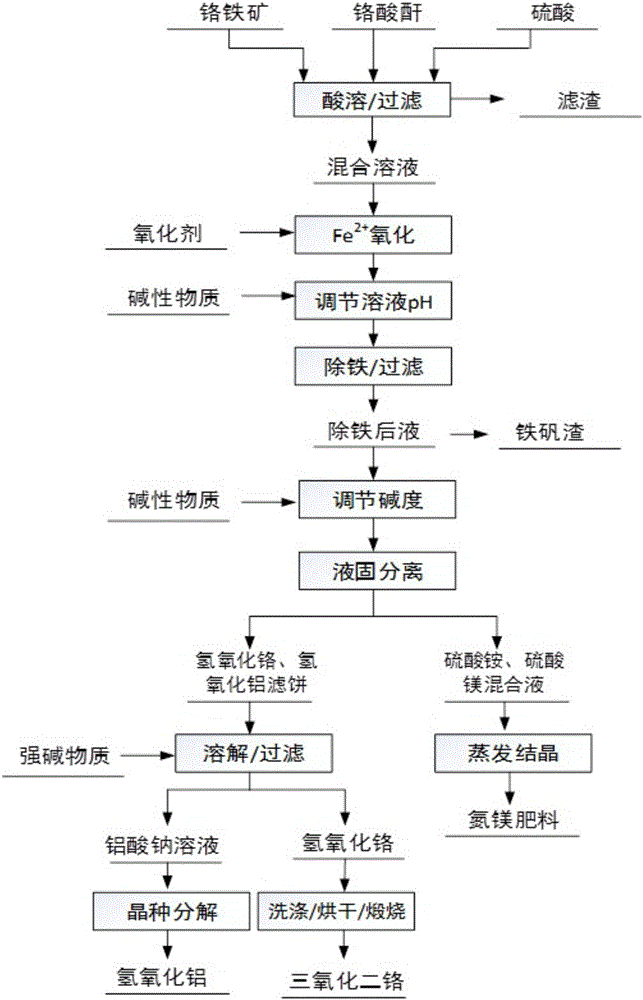

Method for clean production of chromium sesquioxide by using chromite as raw material

ActiveCN106186067AAchieve separationEasy to cleanChromium trioxideChromium(III) hydroxideFerrochrome

The invention discloses a method for clean production of chromium sesquioxide by using chromite as a raw material. The method comprises the following steps of by using the chromite as the raw material and chromic anhydride as an oxidizer, enabling the chromite and the chromic anhydride to be dissolved in sulphuric acid so as to obtain a mixed solution of elements of chromium sulfate, ferric sulfate and the like; by using an ammonium salt deferrization technique, realizing chromium-iron separation in the solution; adjusting the acidity of the mixed solution after separation so as to obtain precipitation of chromium hydroxide and aluminum hydroxide; performing evaporative crystallization on a mixed solution of ammonium sulphate and magnesium sulphate after chromium and aluminum are precipitated so that a nitrogen and magnesium fertilizer is prepared; performing liquid-solid separation on obtained liquid of chromium hydroxide and aluminum hydroxide after alkali dissolution so as to obtain and chromium hydroxide solids; performing washing and calcining on the chromium hydroxide solids so as to obtain chromium oxide products; and preparing aluminum hydroxide products by a Bayer method from a solution obtained through separation. The method disclosed by the invention is simple in preparation technology, by-products are mixtures of the aluminum hydroxide, the ammonium sulphate and the magnesium sulphate, waste and pollution are not generated, the synthesizing cost is low, and the energy consumption is low. The method has great popularization and application potentials in the field of green production of the chromium sesquioxide.

Owner:于佳湲 +3

Process for preparing chrome acid anhydride from ferrochrome through acid soluble electrolytic method

The invention relates to a process for preparing chrome acid anhydride from ferrochrome through an acid soluble electrolytic method. Ferrochrome is ground into fine powder and placed into a reaction still, acid is added to dissolve the ferrochrome, special substances are added for reaction with heating, trivalent chromium and ferrous ions are separated, then a trivalent chromium solution is placed into an electrolytic cell, the trivalent chromium is completely converted into hexavalent chromium through electrolytic oxidation, and chrome acid anhydride products are prepared. Through the process, series chromium compounds including dichromate, chromium sulfate, chromic chloride, chromic oxide, chromic hydroxide, a chrome tanning agent, chromium picolinate and chromium nicotinate, iron series pigment including ferrous oxalate, iron blue and ferbam, new materials including silicon and carbon, and new energy, namely hydrogen, are prepared simultaneously. The process is advanced, short in technological process, capable of saving energy and environmentally friendly, the produced products are good in quality, high in value and good in benefit, and the sustainable development of the chrome salt industry can be better prompted.

Owner:唐翔

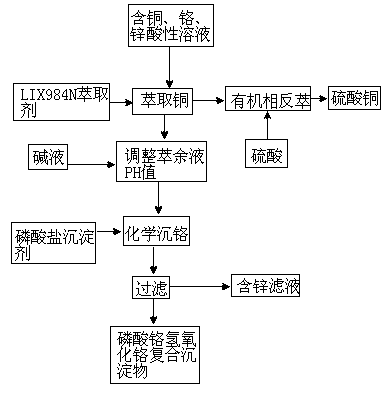

Method for separating copper, chromium and zinc in acid leaching solution

InactiveCN103014337AGood choiceStripping is easyProcess efficiency improvementPregnant leach solutionO-Phosphoric Acid

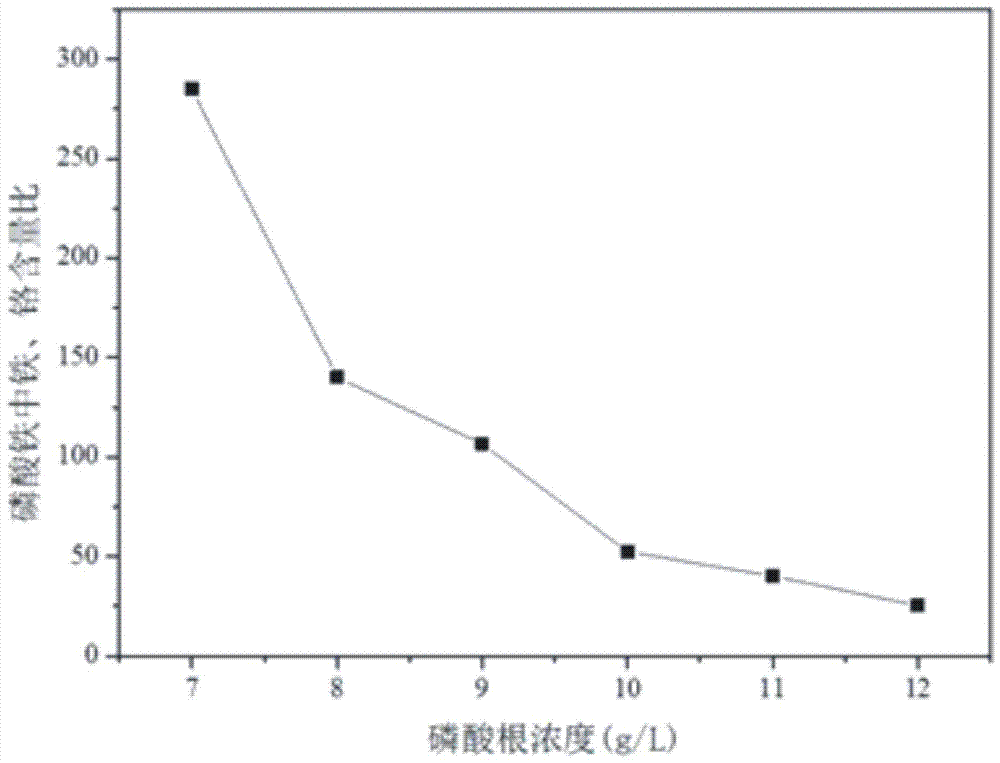

The invention provides a method for separating copper, chromium and zinc in an acid leaching liquid, and particularly relates to a method for separating copper, chromium and zinc in an acid leaching liquid containing electroplating sludge of copper, chromium and zinc components. The process sequentially comprises the following steps: (1) adding an extracting agent into an acid leaching liquid to extract copper, wherein the copper in an organic phase is separated and extracted through the back extraction of sulfuric acid; (2) deoiling the residual phase after extraction, regulating the pH value of the solution, and adding soluble phosphate to perform phosphoric acid chromium precipitation reaction; and (3) filtering, and separating to obtain a chromium phosphate / chromium hydroxide composite precipitate and a zinc-containing filtrate, thus realizing the selective separation of chromium and zinc. According to the method for separating copper, chromium and zinc in an acid leaching liquid, based on the characteristics that phosphates are different in solubility and chromium phosphate and chromium hydroxide can form a composite coprecipitate, optimization and control technologies such as extraction, chemical precipitation and the like are used to solve the problem on the separation and extraction of a high-content copper / chromium / zinc mixed solution in an acidic solution.

Owner:BEIJING GENERAL RES INST OF MINING & METALLURGY +1

Synthesis technique of chromium propionate

InactiveCN102351680ASimple process routeSimple and fast operationCarboxylic acid salt preparationRaw materialHydroxide

The invention relates to a synthesis technique of chromium propionate, which comprises the steps of synthesis of chromic hydroxide, synthesis of chromium propionate and refinement. The invention has the advantages of simple technical line, accessible raw materials and high yield, is simple to operate, and is suitable for industrial production; and the product is free of virulent sexavalent chrome.

Owner:GUANGXI UNIV

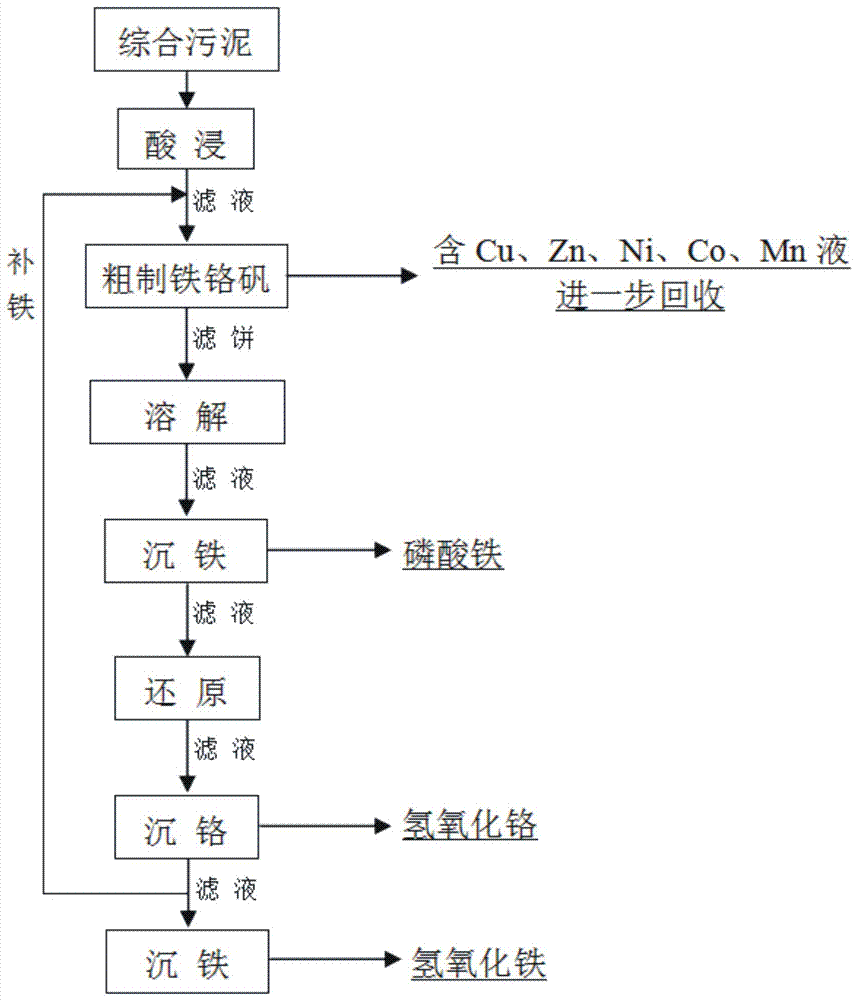

Method for separating and refining iron and chromium from polymetallic hazardous waste

ActiveCN107324303AReduce processing timeReduce processing costsIron oxides/hydroxidesCalcium/strontium/barium sulfatesChromium(III) hydroxideSludge

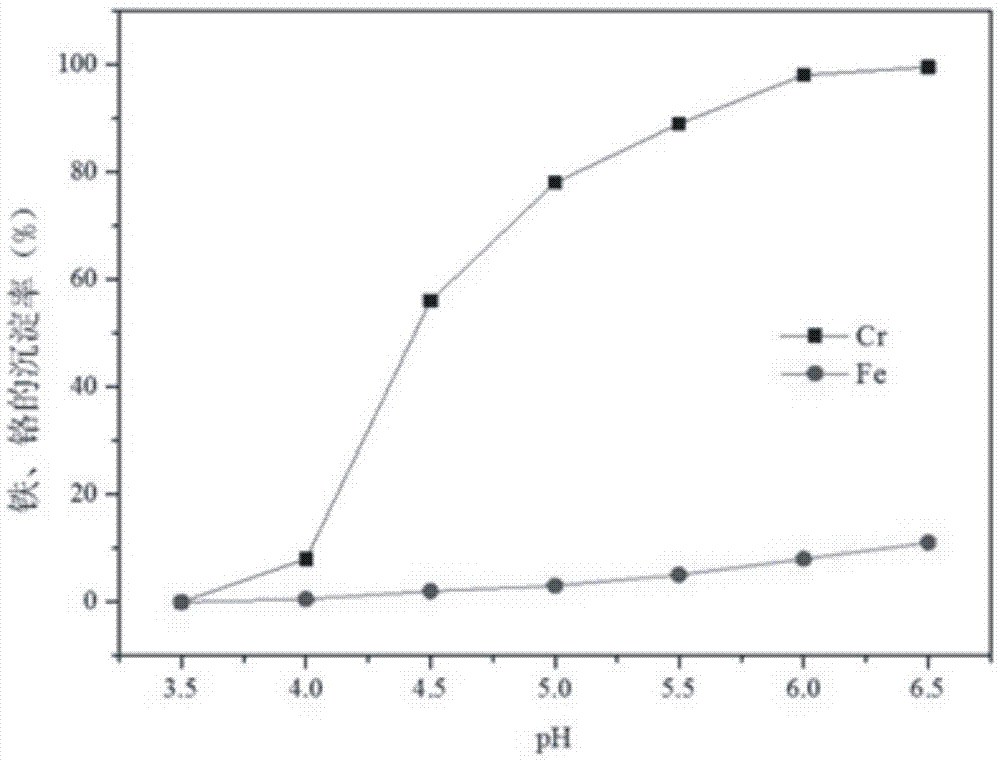

The invention discloses a method for separating and refining iron and chromium from polymetallic hazardous waste. The phosphate radicals carried by sludge are utilized to precipitate Fe<3+> selectively for preparing iron phosphate and isolating Fe<3+> from Cr<3+>, and since Cr<3+> can be precipitated by the phosphate radicals, a method of excessive Fe<3+> is adopted to prevent the formation of chromium phosphate precipitation in the process; the residual Fe<3+> can be reduced to Fe<2+> by scrap iron, then an alkaline solution is added to adjust the pH to a certain value so as to selectively precipitate Cr<3+> for preparing chromium hydroxide, and further separation of iron and chromium can be achieved. According to the method for separating and refining iron and chromium from the polymetallic hazardous waste, no heating is needed during the whole process, ferric ions and the phosphate radicals in the hazardous waste are comprehensively utilized, and thus the cost is low; meanwhile, no waste water and waste residues are produced, and thus the method is environment-friendly; iron phosphate and chromium hydroxide can be obtained from respective extraction, wherein iron phosphate has high economic values and can be used in battery materials, ceramics and other raw materials, and chromium hydroxide can be used in pigments, chemicals and other industry raw materials.

Owner:青川县天运金属开发有限公司

Prevention of chromia-induced cathode poisoning in solid oxide fuel cells (SOFC)

Owner:GENERAL ELECTRIC CO

Naluminum fluoride base fluorating catalyst and preparation thereof

ActiveCN101214447AReduced fluorination activation timeShort manufacturing cyclePreparation by halogen replacementMetal/metal-oxides/metal-hydroxide catalystsChromium CompoundsHydrogen fluoride

Owner:XIAN MODERN CHEM RES INST

Method for chrome and vanadium separating and recovery

ActiveCN106987732AReduce process stepsSimple processProcess efficiency improvementChromium(III) hydroxideVanadate

The invention belongs to the field of chemical engineering and particularly relates to a method for chrome and vanadium separating and recovery. The method for chrome and vanadium separating and recovery comprises the following steps that (A) precipitation is conducted, specifically, a precipitation reagent is added into a solution containing chrome and vanadium, and a chrome and vanadium precipitate is obtained after solid-liquid separation; (B) vanadium extraction is conducted, specifically, alkali liquid is added into the chrome and vanadium precipitate, and vanadium-containing liquid and chrome-containing solid are obtained after solid-liquid separation, an enough amount of ammonium salt is added into the vanadium-containing liquid, ammonium poly-vanadate precipitate is obtained, and a V2O5 product is obtained after the ammonium poly-vanadate precipitate is dried and roasted; and (C) chrome extraction is conducted, specifically, the chrome-containing solid is added into acid liquid, chrome-containing liquid is obtained through solid-liquid separation after stirring reaction, an enough amount of a reducing agent is added into the chrome-containing liquid, chrome reducing liquid is obtained after stirring reaction, then alkali liquid is added to adjust pH till the liquid is alkaline, chromic hydroxide precipitate is obtained, and a Cr2O3 product is obtained after the chromic hydroxide precipitate is dried and roasted. The method for chrome and vanadium separating recovery has the advantages of being simple and low in cost, and the yield and purity of the obtained products are high.

Owner:PANGANG GROUP RESEARCH INSTITUTE CO LTD

Production method for coproduction of chromium chloride and chromic carbonate

ActiveCN102718260AImprove solubilitySave configuration timeChromium halidesChromium(III) hydroxideSulfide

The invention discloses a production method for the coproduction of chromium chloride and chromic carbonate, and the production method is used for solving the problems that the chromic carbonate produced through the existing method is easy to age, and the solubility of the chromic carbonate in acidic aqueous solutions is greatly reduced after the chromic carbonate is subjected to long-term storage. According to the production method, an alkaline solution of sodium chromate is taken as a raw material, sulfur and alkali sulfide are taken as reducing agents to be subjected to redox reaction in a reaction tank so as to obtain chromic hydroxide, the obtained chromic hydroxide is filtered and washed and then reacts with hydrochloric acid to produce the chromium chloride, and the chromic carbonate is produced in a manner that the chromium chloride is subjected to the precipitation of a soda solution. The production method has the advantages that the process flow is short, the operation is simple, the redox reaction is complete, the chromium yield is high, and hexavalent chromium is not detected in the filtrate, so that the pollution to the environment cannot be caused.

Owner:GANSU JINSHI CHEM

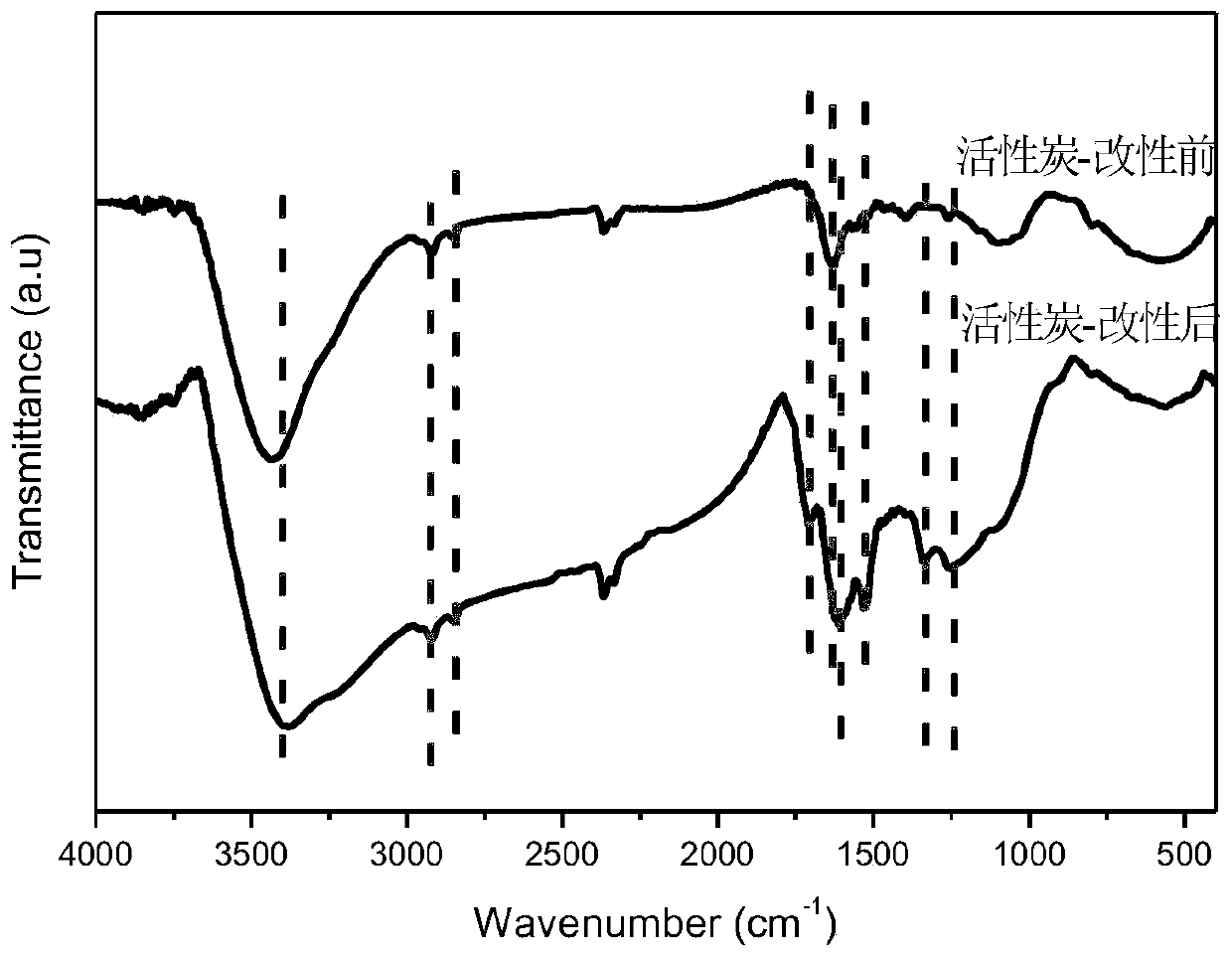

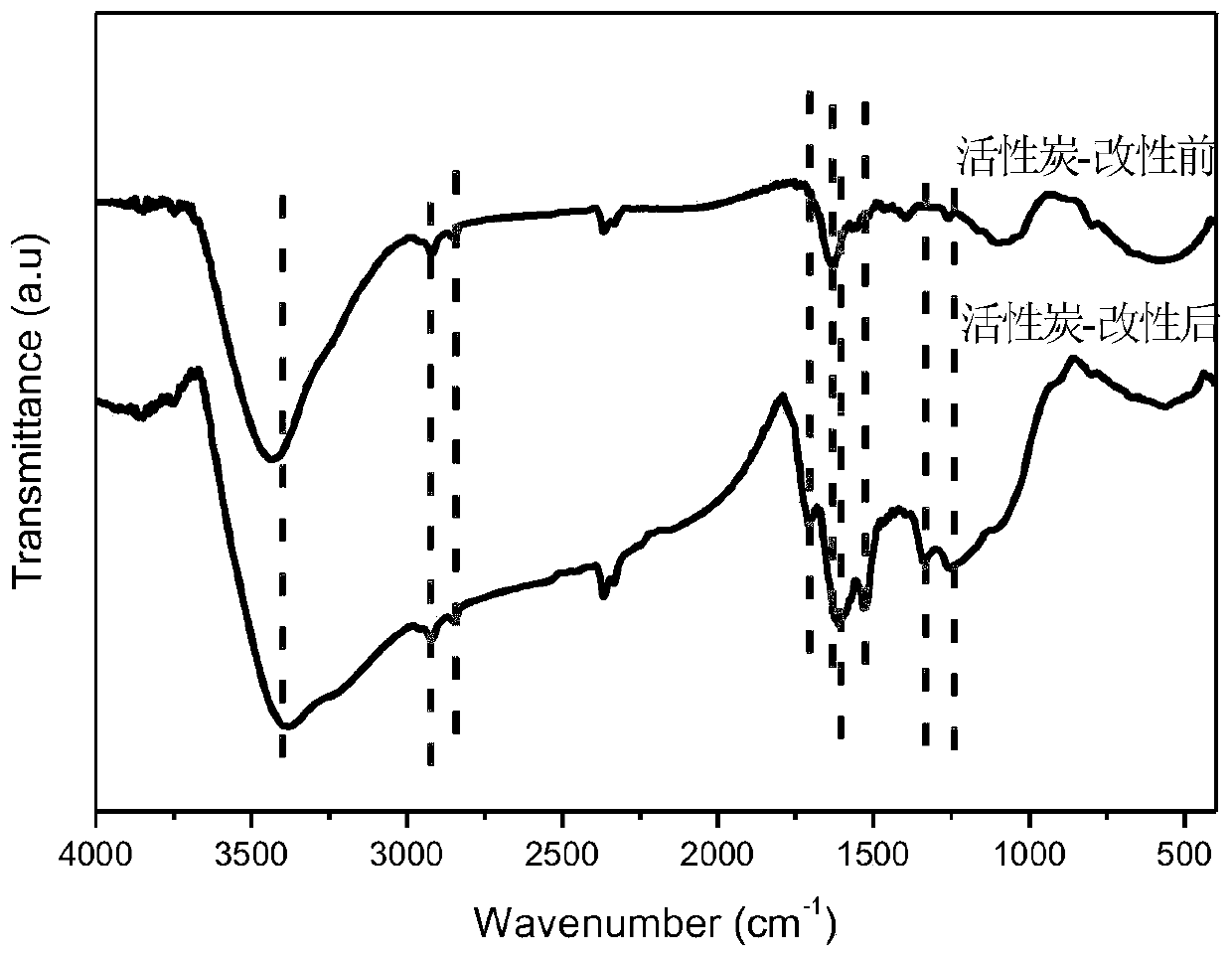

Treatment and resource recovery method for chromium and ammonia nitrogen in electroplating wastewater

PendingCN111170503ARealize resource utilizationTurn waste into treasureOther chemical processesWater contaminantsChromium(III) hydroxideMagnesium ammonium phosphate

The invention provides a treatment and resource recovery method for chromium and ammonia nitrogen in electroplating wastewater. The treatment and resource recovery method comprises the following steps: dropwise adding an inorganic alkali solution into the electroplating wastewater, and carrying out stirring, standing and filtering to obtain a mixed solution I and a chromium hydroxide precipitate;adding disodium hydrogen phosphate into the obtained mixed solution I, and carrying out stirring until the disodium hydrogen phosphate is dissolved; dropwise adding inorganic alkali liquor while stirring; adding a magnesium chloride solution, and carrying out stirring, standing and filtering to obtain a mixed solution II and a magnesium ammonium phosphate precipitate; and adding nitric acid modified activated carbon into the obtained mixed solution II, conducting oscillating and adsorbing in a water bath, and filtering and recycling the activated carbon. According to the invention, chromium and ammonia nitrogen in the electroplating wastewater are basically removed through two precipitation operations, the obtained precipitate chromium hydroxide can be used for preparing chemical reagentsor paint pigments, and the precipitate magnesium ammonium phosphate can be used as a nitrogen-phosphorus-magnesium slow-release fertilizer; and residual ammonia nitrogen is subjected to deep adsorption treatment through the modified activated carbon. The method develops an effective pollutant treatment and resource recovery treatment technology for the electroplating wastewater.

Owner:CENT SOUTH UNIV

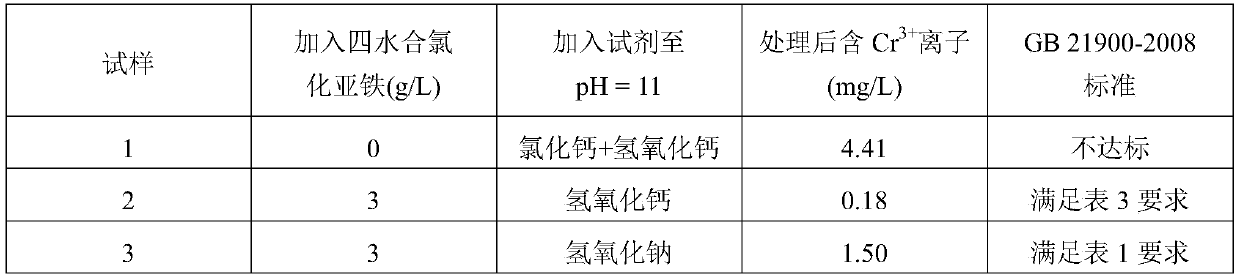

Method for treating trivalent-chromium chromium-plating wastewater

ActiveCN110818123AOvercome costly technical flawsSolve the difficulties that are not easy to meet the standardsWater contaminantsTreatment involving filtrationOrganic acidChemical oxygen demand

The invention provides a method for treating trivalent-chromium chromium-plating wastewater. Through a synergistic effect of ferrous ions and calcium ions, an organic acid coordination agent containing carboxyl groups in wastewater is precipitated by using ferrous ions and calcium ions, and trivalent chromium released from a complex generates chromium hydroxide precipitates, so that the trivalentchromium is effectively removed. In addition, a sodium hypochlorite solution is used as an oxidant to control the oxidation-reduction potential (ORP) value and the oxidation time, so that an oxidationreaction process is ensured, organic additives in the wastewater can be effectively destroyed, the chemical oxygen demand (COD) of the wastewater is reduced. Indexes meet the wastewater discharge standard, and wastewater treatment cost is reduced and the economic benefit is improved while the environment is protected.

Owner:GUANGZHOU ULTRA UNION CHEM LTD

Wastewater treatment process for wet-process chromium metallurgy

InactiveCN105923877AAchieve preparationEmission complianceTreatment involving filtrationWaste water treatment from metallurgical processChromium(III) hydroxideReverse osmosis

The invention discloses a wastewater treatment process for wet-process chromium metallurgy. The wastewater treatment process includes steps that wastewater enters a deaminizing reactor for extracting chromium hydroxide, with vanadium ions and chromium ions adsorbed by anion resin, and is connected with a denitriding reactor; sodion containing waste liquid enters a triple-effect multistage evaporator through a pipeline, is connected to a high-temperature evaporation crystallizer, and enters a low-temperature crystallizer to be frozen and crystallized in it; then the waste liquid enters an electrodialysis device, a sodium filter film to filter, and a reverse osmosis film. The wastewater treatment process for wet-process chromium metallurgy can reduce high-price chromium ions and realize preparation of sodium sulfate salt. In addition, sewage discharge can reach the standard.

Owner:太仓市顺邦防腐设备有限公司

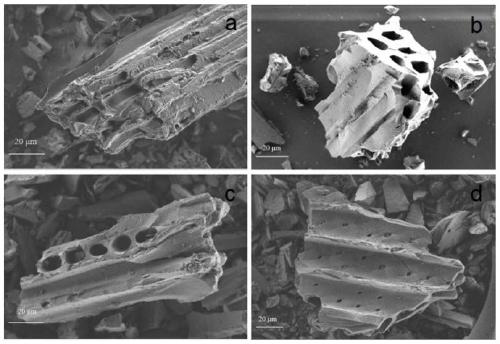

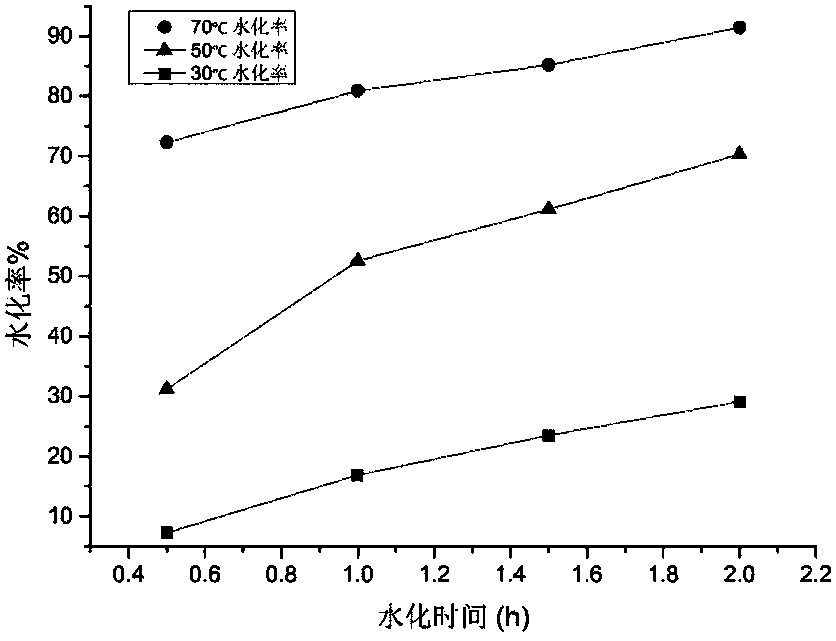

Method for preparing chromium-containing magnesia from magnesite light burning powder

InactiveCN108046620ASolve the technical problem of uneven precipitationImprove uniformityDispersityCalcium hydroxide

The invention discloses a method for preparing chromium-containing magnesia from magnesite light burning powder. The method is characterized by comprising the following steps: pretreating light burning powder at the temperature of 850 DEG C or higher to obtain pretreated light burning powder; hydrating the pretreated light burning powder with water to obtain ore pulp, adding a magnesium source tothe ore pulp, and removing calcium to obtain calcium-free ore pulp; adding a Cr source to the calcium-free ore pulp; performing chromium precipitation reaction, and performing solid-liquid separationto obtain a precursor; and sintering the precursor to obtain the chromium-containing magnesia. Through a lot of researches, inventors find that the light burning powder is preheated to the set temperature so as to be pretreated, then hydration is preformed, the magnesium source (providing Mg<2+>) is added to the ore pulp obtained by hydration, calcium hydroxide impurities are converted through theprecipitation conversion mechanism, and then, the Cr source (providing Cr<3+>) is added; and through the precipitation conversion mechanism, formed chromium hydroxide is avoided from falling and separating from the surface of a magnesium oxide source, and the uniform dispersity of the chromium hydroxide in the precursor is greatly improved, thereby obtaining the chromium-containing magnesia withexcellent performance.

Owner:CENT SOUTH UNIV

Desulfuration process for chromate waste water

InactiveCN102320697AReduce investmentReduce energy consumptionCalcium/strontium/barium sulfatesDispersed particle separationHigh concentrationChromium(III) hydroxide

The invention relates to the processing of an industrial three-waste product, in particular to a desulfuration process for chromate waste water, which comprises the following steps: sulfur tail gas is cooled and washed after being dedusted firstly; the pH value of the chromate waste water is adjusted to 2 to 3; the sulfur tail gas and the chromate waste water react in an absorption tower; alkali liquor and flocculating agent is added in reacted liquid in the absorption tower and then chromium hydroxide is separated out through deposition; and the tail gas which comes from the absorption tower is desulfurized thoroughly through a double alkali method. Proven by a test, the processing process of the chromate waste water is simple, so that the chromate waste water pollution and sulfur waste gas pollution can be solved simultaneously merely through one process, the device investment is less, the energy consumption is low, and the national requirements of energy conservation and emission reduction can be met; and moreover, the process is adaptable, so that both high-concentration chromate waste water and low-concentration chromate waste water can be processed.

Owner:CHONGQING MINFENG CHEM

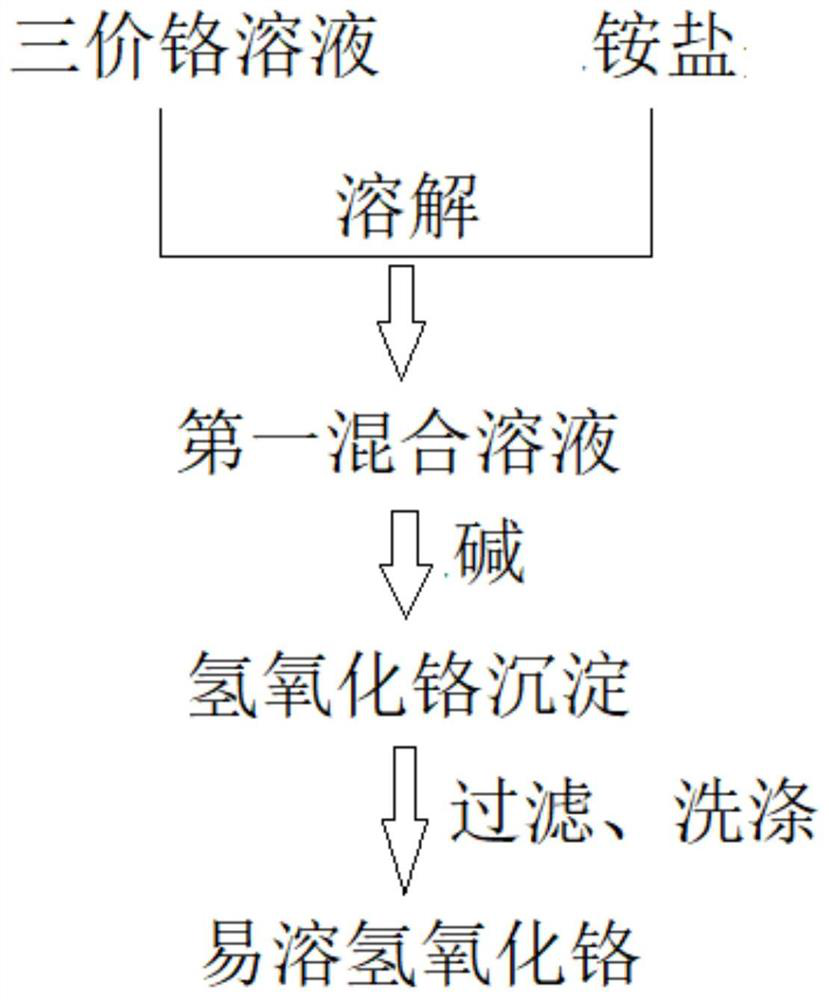

Preparation method of soluble chromium hydroxide

ActiveCN112110487AEasy to settleSlow down the sedimentation rateChromium compoundsProcess efficiency improvementChromium(III) hydroxidePhysical chemistry

The invention discloses a preparation method of soluble chromium hydroxide. The preparation method comprises the following steps: adding ammonium salt into a trivalent chromium solution and dissolvingthe ammonium salt to obtain a first mixed solution; under a preset reaction condition, adding alkali into the first mixed solution to obtain a chromium hydroxide precipitate; and filtering and washing the chromium hydroxide precipitate to obtain the soluble chromium hydroxide. By adding the ammonium salt into the trivalent chromium solution, the precipitation speed of trivalent chromium is reduced in the alkalifying process, the generation of a chromium hydroxide colloid is inhibited, and the soluble chromium hydroxide is prepared; on the basis of traditional alkali precipitation, only singleammonium salt needs to be added, and the adding amount the ammonium salt is small, so cost is low, and other impurities are not introduced; the process of the method is simple, reaction conditions are mild, and operability is high; and chromium hydroxide is easy to precipitate, does not need standing, can be easily dissolved in acid, and can be used as a trivalent chromium source for electroplating and metal surface treatment.

Owner:PANGANG GROUP RESEARCH INSTITUTE CO LTD

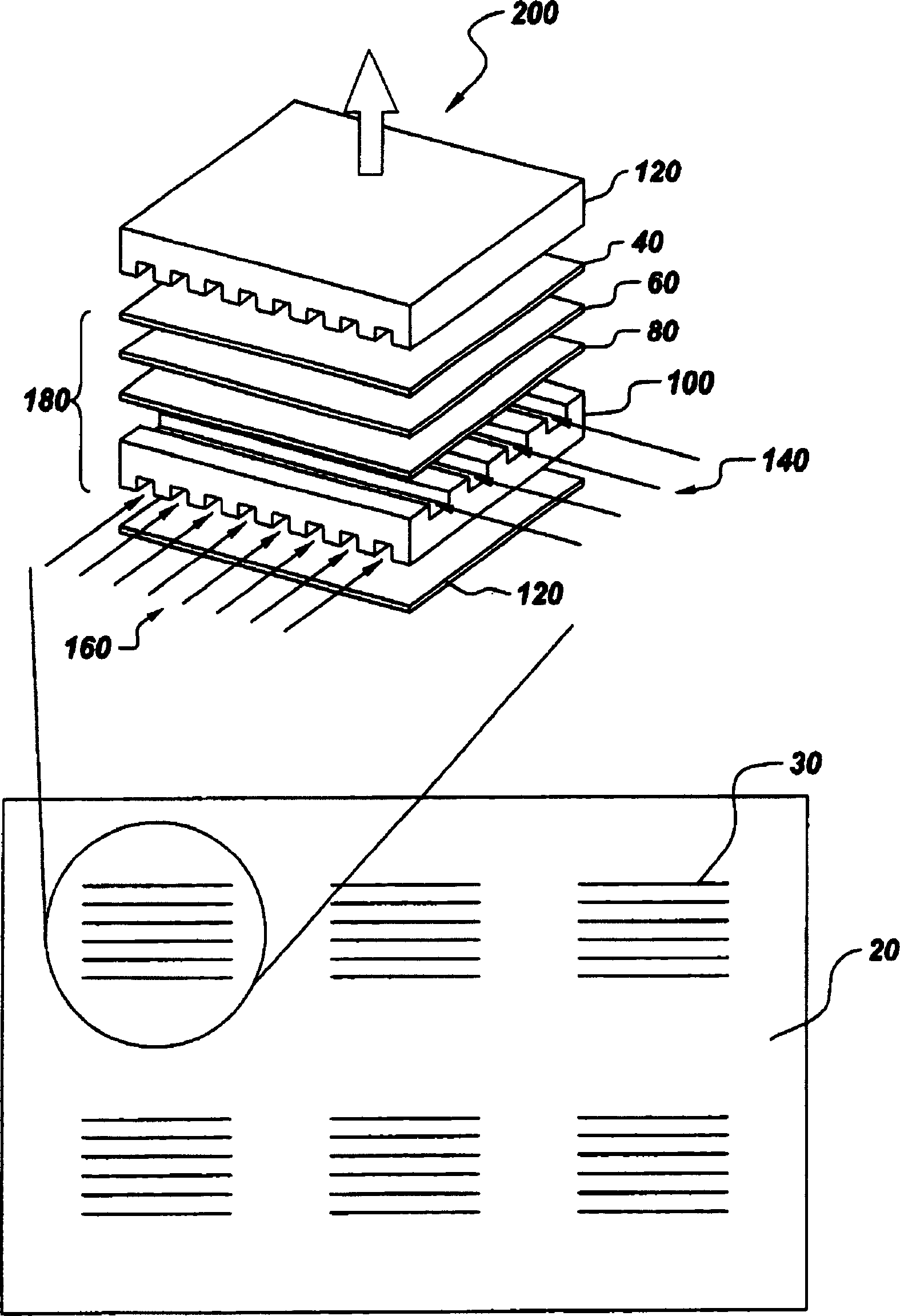

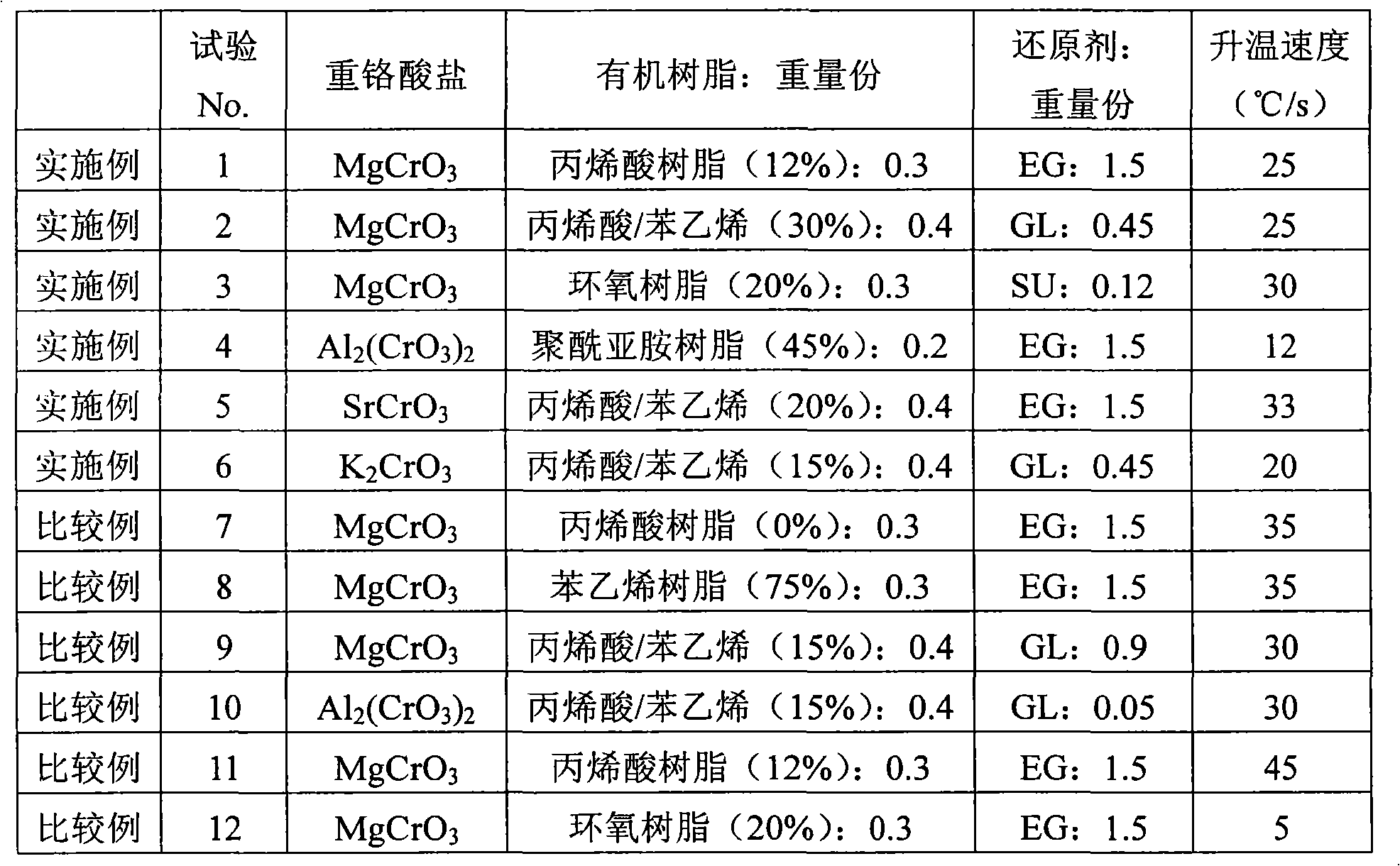

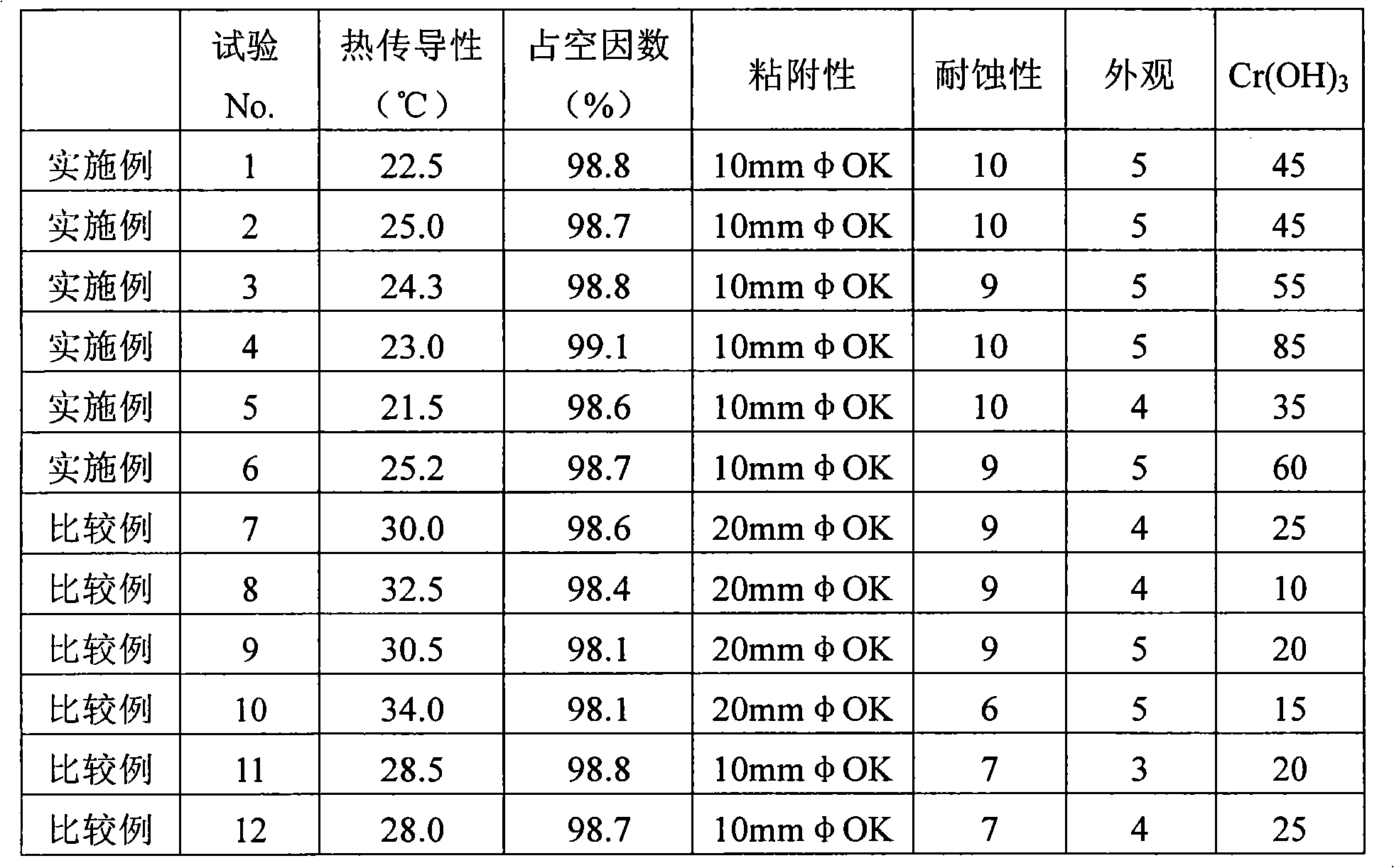

Electromagnetic steel sheet having insulating coating film with excellent thermal conductivity therein, and process for production thereof

ActiveCN101946024AImprove adhesionFast heat conductionInorganic material magnetismMetallic material coating processesEpoxyAcrylic resin

An electromagnetic steel sheet comprises an electromagnetic steel sheet and an insulating coating film formed on the surface of the electromagnetic steel sheet. The insulating coating film is mainly composed of: a chromic acid metal salt; and a mixture or a copolymer of one or more members selected from a styrene resin, an acrylic resin, an epoxy resin and a polyimide resin, which has a rate of crystallization of 10 to 50% and is contained in an amount of 0.01 to 0.5 part by weight relative to 1 part by weight of the chromic acid metal salt (in terms of the CrO3 content). In the insulating coating film, a chromium hydroxide compound is contained as a chromic acid compound in an amount of 30% or more in terms of the chromium (III) oxide (Cr2O3) content relative to the total amount (100%) of the chromic acid compound in terms of the chromium (III) oxide (Cr2O3) content.

Owner:NIPPON STEEL CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com