Prevention of chromia-induced cathode poisoning in solid oxide fuel cells (SOFC)

A fuel cell, fuel cell system technology, applied in solid electrolyte fuel cells, fuel cell parts, fuel cells, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In the following description, the same reference numerals denote the same or corresponding parts throughout the several views shown in the drawings. It should also be understood that terms such as "above", "below", "inside", "outside" and similar words are used for convenience only and do not constitute limitations of the terms themselves.

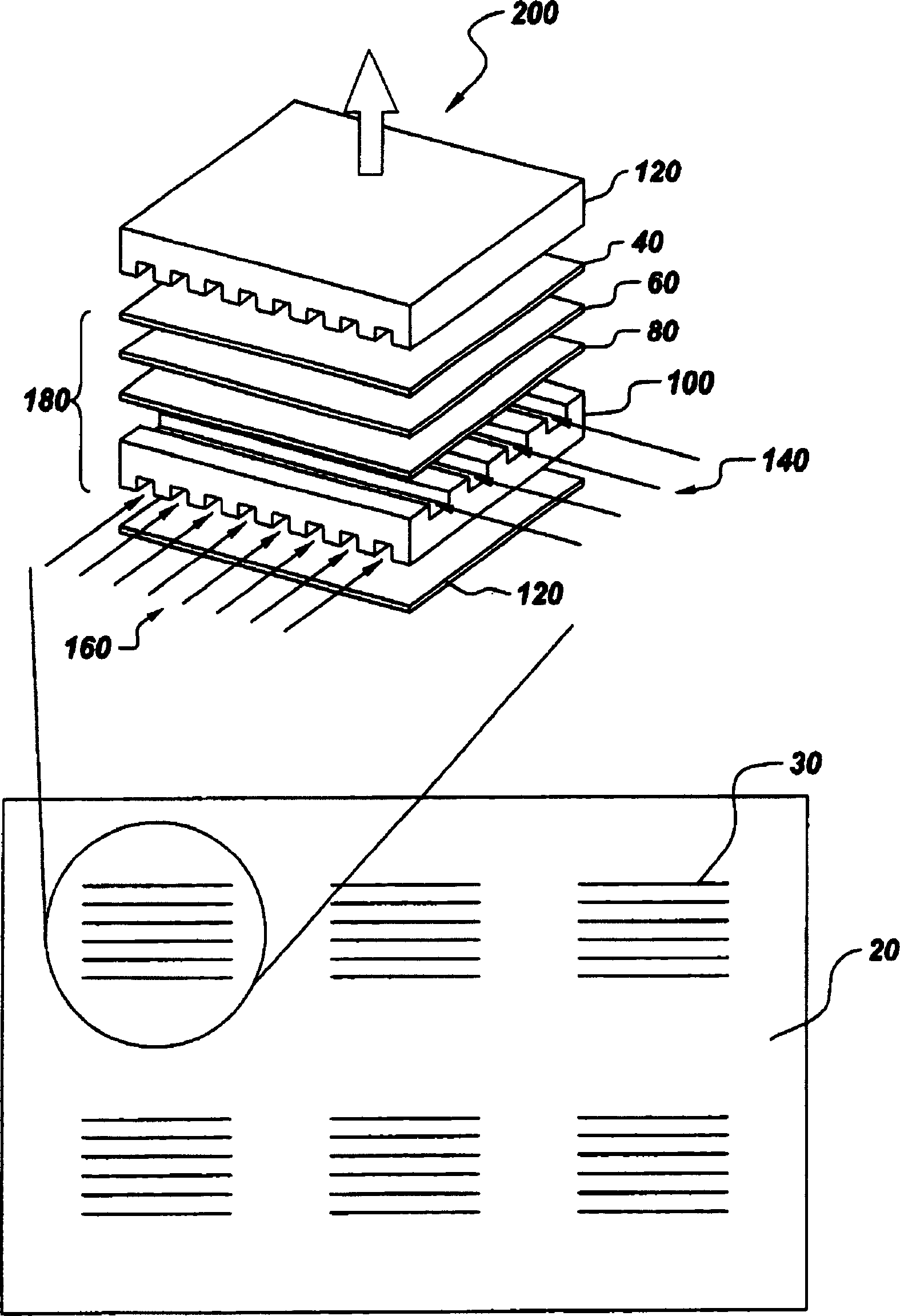

[0019] When referring generally to the drawings and in particular to figure 1 When shown, it should be understood that these views are for purposes of illustrating preferred embodiments of the invention and are not intended to limit the invention thereto.

[0020] Fuel cells directly convert gaseous fuels (hydrogen, natural gas, gasified coal) into electricity through an electrochemical process. Their efficiency is not limited by the Carnot cycle of heat engines, and the amount of pollutants emitted from the fuel cell is many times lower than in conventional processes. A fuel cell operates similarly to a battery, but it does not n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com