Method for synchronously recovering vanadium and chromium from vanadium-chromium slag by acid process

A vanadium-chromium slag acid method and a vanadium-chromium slag technology are applied in the direction of improving process efficiency, etc., which can solve the problems of low vanadium-chromium separation efficiency, affecting industrialized production, and high production cost, and achieve clean and efficient utilization, production cost reduction, and high production cost. The effect of simplifying the production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

[0031] (1) Water washing and desalting: wash the water-soluble salt in 1kg vanadium-chromium slag with 2kg water slurry, the slurry washing temperature is 60 ℃, obtain filter cake 880g and washing liquid respectively after filtering, the washing liquid salt concentration (in Na 2 SO 4 Total) is 25g / L, is used for next time water washing desalting step;

[0032] (2) Oxidation and acid dissolution: the filter cake obtained in step (1) is acid-dissolved in 2.64 kg of 80% sulfuric acid solution. During the acid-dissolution process, sodium chlorate with a slag content of 20% is added for oxygen-enriched acid dissolution. The reaction temperature is 80°C , the reaction process liquid-solid ratio is 3:1, obtains vanadium-chromium solution and tailings;

[0033] (3) Purification and impurity removal: add CaCl to the vanadium-chromium solution obtained in step (2) 2 Impurity removal-desulfurization, the addition amount is Si, P, SO in the solution 4 2- 3 times the total molar weigh...

Embodiment 3

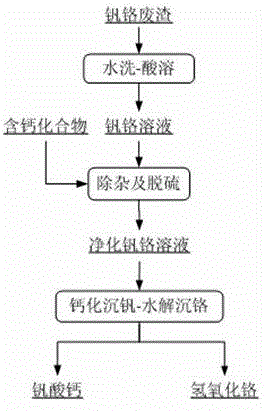

[0037] Example 3: figure 1 Shown, the method processing step of this vanadium chromium slag acid method synchronously reclaiming vanadium chromium is as follows:

[0038] (1) Water washing and desalting: wash the water-soluble salt in 1kg vanadium-chromium slag with 7kg water slurry, the washing temperature is 80 ℃, obtain filter cake 870g and washing liquid respectively after filtering, the washing liquid salt concentration (in Na 2 SO 4 Calculated) is 15g / L, is used for next water washing desalting step;

[0039] (2) Oxidative acid dissolution: the filter cake obtained in step (1) is acid-dissolved in 4.35kg of 50% sulfuric acid solution, and the acid-dissolution process adds potassium permanganate with 10% slag amount to carry out oxygen-enriched acid dissolution, and the reaction temperature is 120 ℃, the liquid-solid ratio in the reaction process is 5:1, and vanadium-chromium solution and tailings are obtained;

[0040] (3) purification and impurity removal: the vanadium...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com