Fluidized combustion and mobile pyrolysis double-furnace compounded circulating fluidized bed

A circulating fluidized bed and fluidized combustion technology, which is applied in the field of coal gasification, can solve the problems that are not suitable for technological transformation and equipment transformation and upgrading of small and medium-sized enterprises, do not meet environmental protection requirements, and low carbon conversion rate, so as to meet the adaptability of coal types and coal particles Strong performance, complementary advantages of gasification process, high carbon conversion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

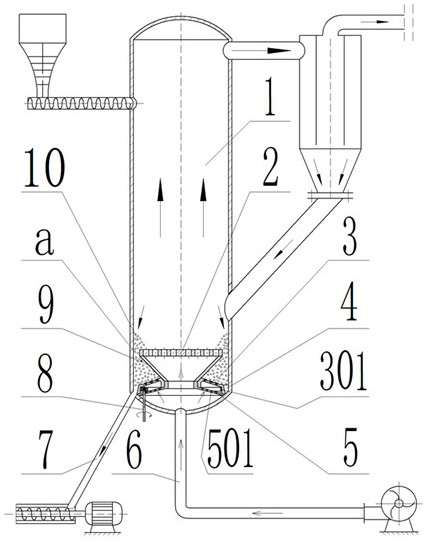

[0017] as attached figure 1 Shown is an embodiment of the present invention, which is provided with two gasifiers with different gasification methods in the gasifier body 1 .

[0018] The gasification agent enters the circulating gasification furnace from the air distribution plate 2, and performs boiling combustion gasification on the raw coal. Part of the semi-coke entrained by the gas enters the cyclone separator, and the separated semi-coke is returned to the circulating gasification furnace for recirculation gasification. During the cycle, the falling coke 10 enters the fixed-bed gasifier from the annular channel a.

[0019] In this design, the upper part of the fixed gasification furnace is an annular channel a, the lower part is an air distribution grate 3, and the outer side of the furnace core 9 corresponds to the annular space between the furnace bodies as a pyrolysis furnace chamber, and the falling semi-coke 10 enters the heat from the annular channel a. Decompose...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com