Direct heating type coal pyrolysis device

A heating type, coal pyrolysis technology, applied in the direction of direct heating dry distillation, direct and indirect heating combined dry distillation, special form dry distillation, etc., can solve the problems of high energy consumption, poor coal adaptability and low thermal efficiency in coke quenching process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

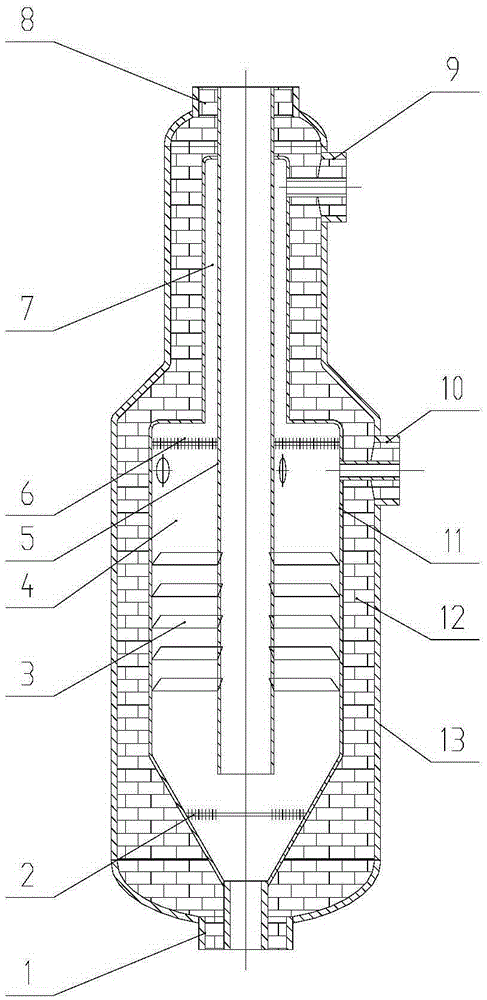

[0031] Attached below Figure 1~4 The present invention is further described in detail, and the description in this part is only exemplary and explanatory, and should not have any limiting effect on the protection scope of the present invention.

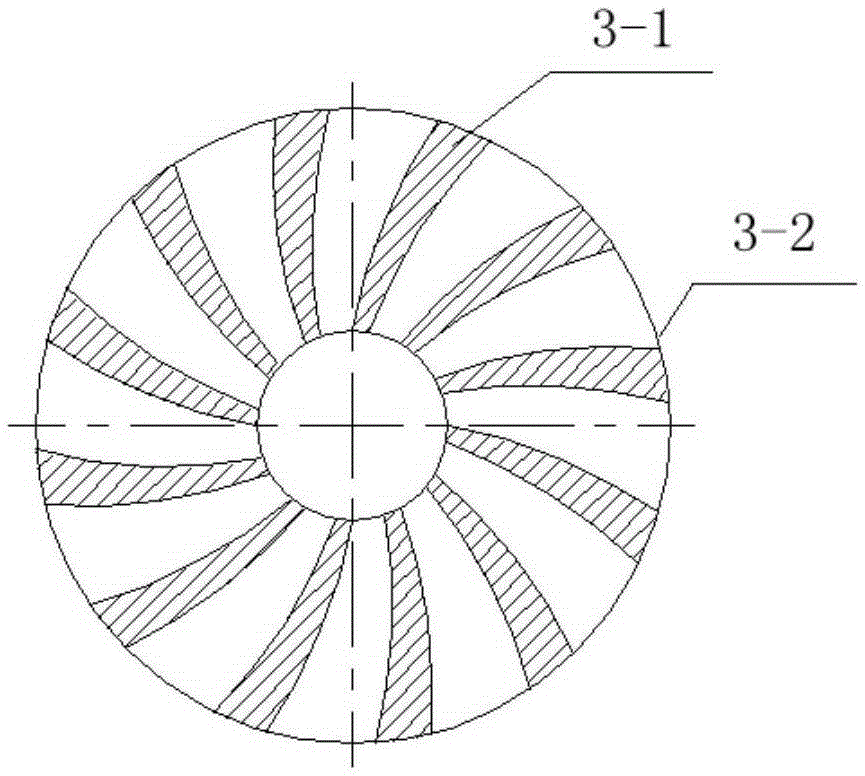

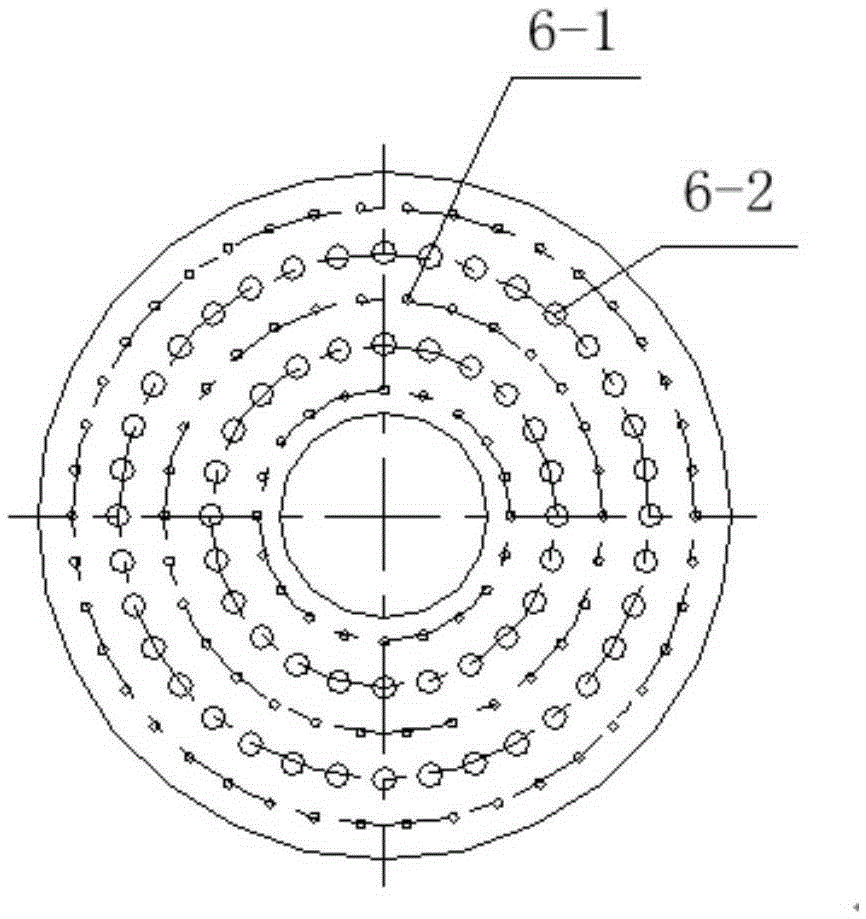

[0032] like figure 1 As shown, the direct heating type coal pyrolysis device proposed by the present invention includes: bottom inlet 1, lower air distribution plate 2, baffle and reversing device 3, lower fluidization section 4, center pipe 5, upper air distribution plate 6, Upper temperature regulation section 7 , upper outlet 8 , upper inlet 9 , feed inlet 10 , wear-resistant layer 11 , heat insulating layer 12 , and pressure-bearing shell 13 . Wherein the upper temperature regulating section 7 is located above the lower fluidized section 4, and the diameter of the upper temperature regulating section 7 is smaller than the diameter of the lower fluidized section (4). The central pipe 5 is located in the cavity formed by the uppe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com