Patents

Literature

98results about How to "Clean and efficient use" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for recycling lithium from lithium ion battery waste electrolyte

ActiveCN108155434AClean and efficient useEfficient use ofWaste accumulators reclaimingBattery recyclingLithium carbonatePhysical chemistry

The invention relates to a method for recycling lithium from a lithium ion battery waste electrolyte, and belongs to the technical field of resources cyclic utilization. The invention aims to providethe method for recycling the lithium from the lithium ion battery waste electrolyte. The method is mainly characterized by mixing and reacting the waste electrolyte and a halogenide solution containing a large positive ionic radius, wholly separating PF6- in the electrolyte, deeply purifying the lithium-containing solution after separation, and precipitating the lithium to obtain lithium carbonate, so that the aim of cleanly and high-efficiently utilizing the lithium ion battery waste electrolyte is achieved.

Owner:CENT SOUTH UNIV

Clean green fuel and its prepn process

InactiveCN101067100AClean and efficient useLarge specific surface areaSolid fuelsLiquid carbonaceous fuelsCombustionGranularity

The present invention discloses one kind of clean green fuel and its preparation process. The preparation process includes the steps of: crushing coal to average size smaller than 2 mm, adding water to form slurry, superfine treating the slurry and adding desulfurizing agent. The present invention applies superfine treating technology and separating technology in treating coal to increase the specific surface area, raise combustion efficiency and raise desulfurizing rate, so as to realize the clean efficient combustion of coal at low cost.

Owner:武汉隆兴裕环保设备有限公司

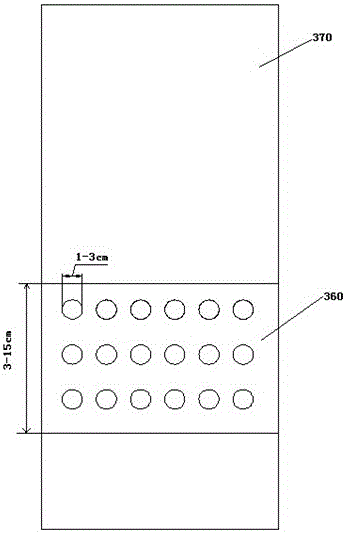

Method for producing corrugated base paper pulp by utilizing scrap materials of fibre board

InactiveCN102677498ASimple pulping processCompact equipmentPaper recyclingWaste paper working-upScrapPulp fibre

The invention discloses a method for producing corrugated base paper pulp by utilizing scrap materials of a fibre board. The method comprises the main steps of: preparing, soaking, steaming, spirally extruding, chemically processing, grinding, eliminating, washing and purifying materials. A majority of free formaldehyde in the raw material is removed and recycled possibly in a pulping process; a little of chemical solution is added from the rear part of a twin screw extruder, and the liquid medicine is uniformly mixed with the fibre and then subjected to mild chemical reaction by utilizing high-concentration mixing action of an extruder and heat energy generated in extruding and mixing processes, so that the high pulping yield is kept, the damage to the fibre in a grinding process is alleviated, the excellent physical strength of the pulp fibre is ensured, and the pollution load in the pulping process is reduced at the same time.

Owner:INST OF CHEM IND OF FOREST PROD CHINESE ACAD OF FORESTRY

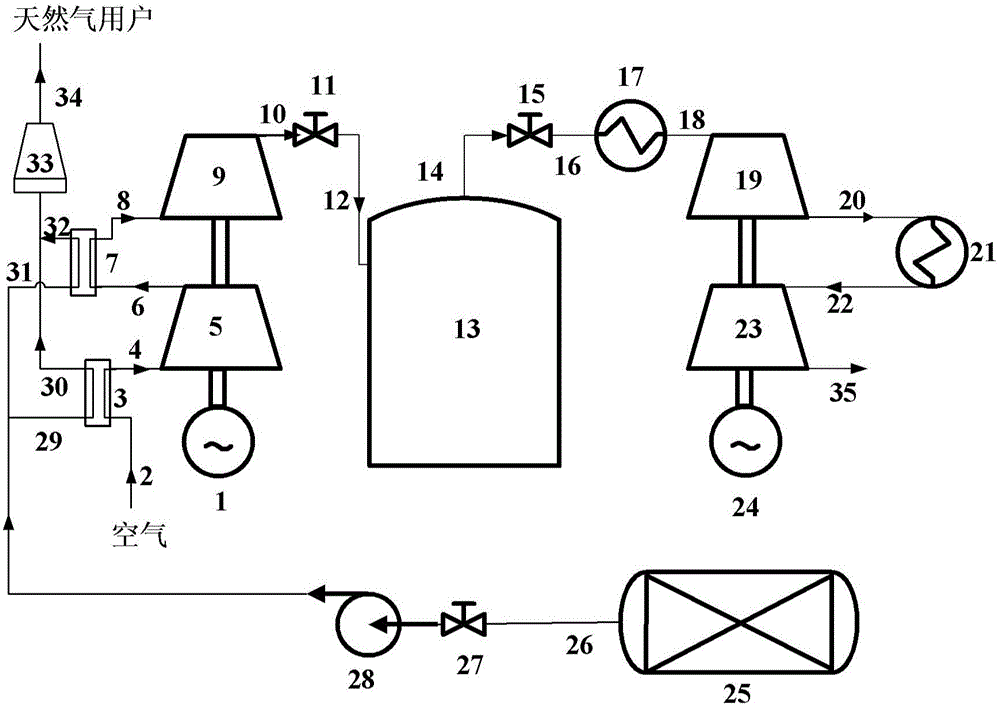

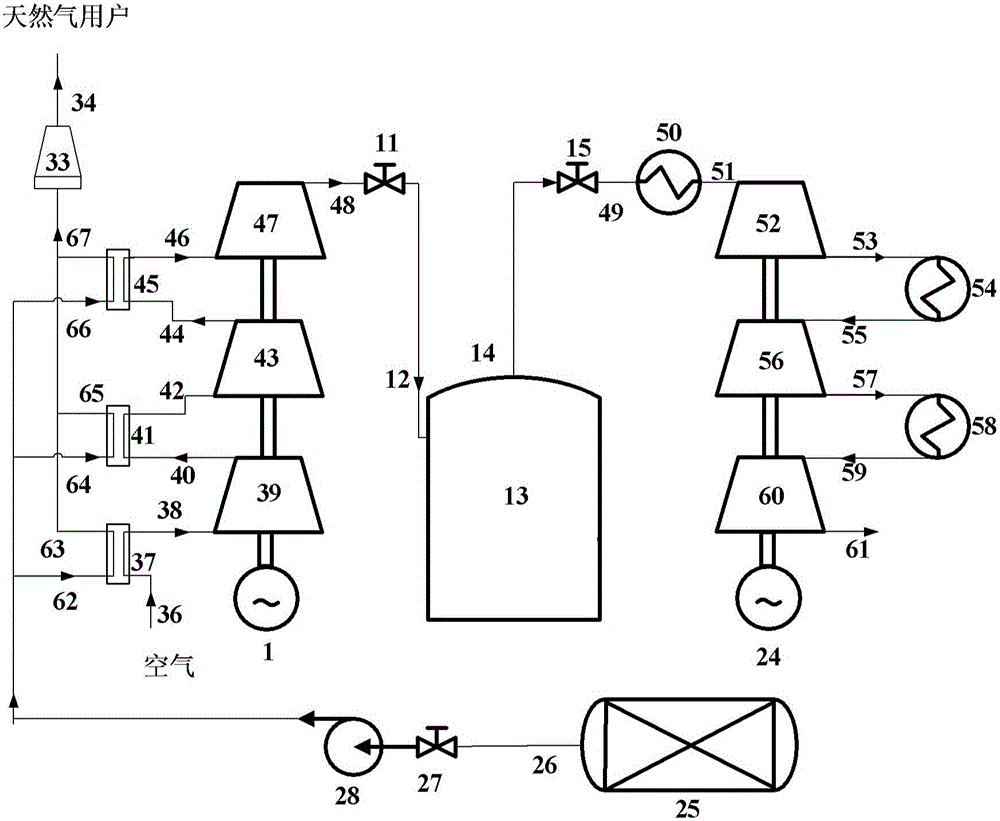

Compressed air energy storage system and method utilizing cold energy of liquefied natural gas

InactiveCN105863752AReduce power consumptionAchieve recyclingPositive displacement pump componentsPiston pumpsTotal efficiencyThermal energy storage

The invention provides a compressed air energy storage system utilizing cold energy of liquefied natural gas (LNG). The compressed air energy storage system comprises a first heat exchanger unit, an air compressor set, an air storage device and an expansion machine set, wherein air in the first heat exchanger unit is subjected to heat exchange with the liquefied natural gas and heat-exchanged and cooled air is output; the air compressor set is used for inputting the heat-exchanged and cooled air and outputting compressed air; the air storage device is used for inputting the compressed air in an energy storage process or outputting the stored compressed air in an energy releasing process; and the expansion machine set is used for inputting the stored compressed air and applying work to the expansion machine set after the compressed air is heated by a second heat exchange unit in the expansion machine set. The invention further provides a compressed air energy storage method utilizing the cold energy of the liquefied natural gas. According to the energy storage system and the energy storage method, provided by the invention, a compressed air energy storage technology is combined with cold energy recycling of the LNG, the output power of a unit working medium of an expansion machine is improved by utilizing stage heating, and the total efficiency of the system is improved; and the energy storage system and the energy storage method are applicable to various types of power supplies, are environmentally friendly, and have a wide application prospect.

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

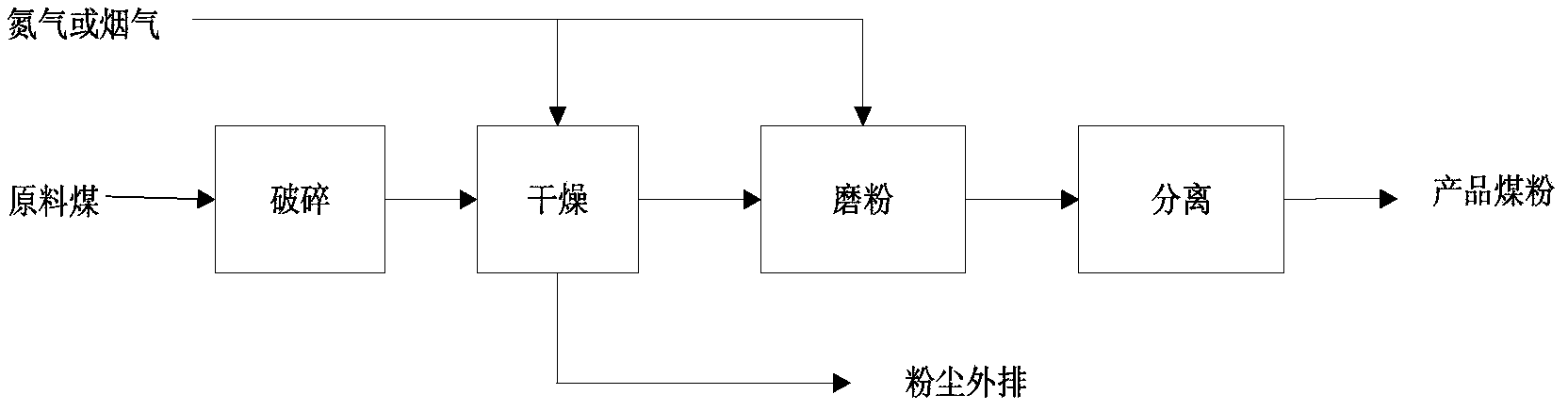

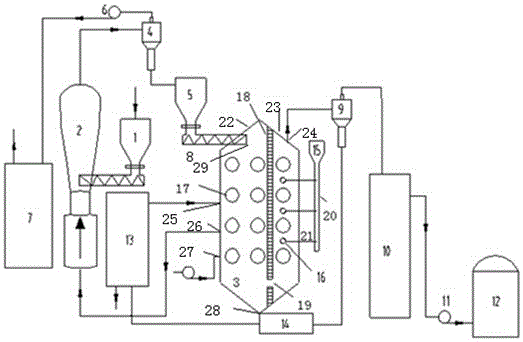

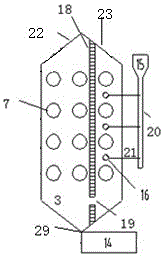

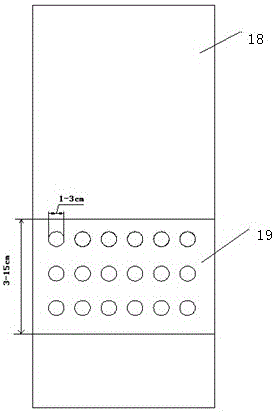

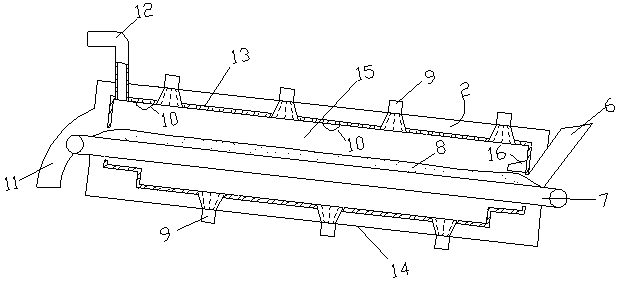

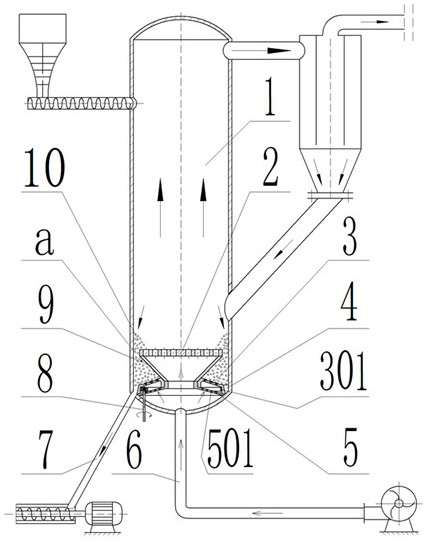

Safe and efficient system and safe and efficient method for preparing powdered coal

ActiveCN103447137AReduce processing costsAvoid security issuesGrain treatmentsShielding gasPollutant emissions

The invention provides a safe and efficient system and a safe and efficient method for preparing powdered coal. The system comprises a coal preparation system, a coal grinding system, a separating system and a superheated steam generating system, wherein the coal grinding system is provided with a material inlet, a superheated steam inlet, a powered coal outlet and a hot dust steam outlet; an outlet of the coal preparation system is communicated with the material inlet of the coal grinding system; an outlet of the superheated steam generating system is communicated with the superheated steam inlet of the coal grinding system; a hot dust steam outlet of the coal grinding system is communicated with an inlet of the separating system; the separating system is provided with a powered coal outlet and a hot steam outlet; the hot steam outlet of the separating system is communicated with a circulating steam inlet of the superheated steam generating system. Superheated steam is taken as protective gas, and thus the safety problem during the preparation of powered coal is solved; the protective medium of superheated steam can be basically subjected to full cyclic utilization, and thus the problems of pollutant discharge and heat waste are solved; the powered coal is dried by the superheated steam in a coal grinding machine, and thus the drying process is eliminated, the technical process is simplified, and the material processing cost is reduced.

Owner:SHAANXI COAL & CHEM TECH INST

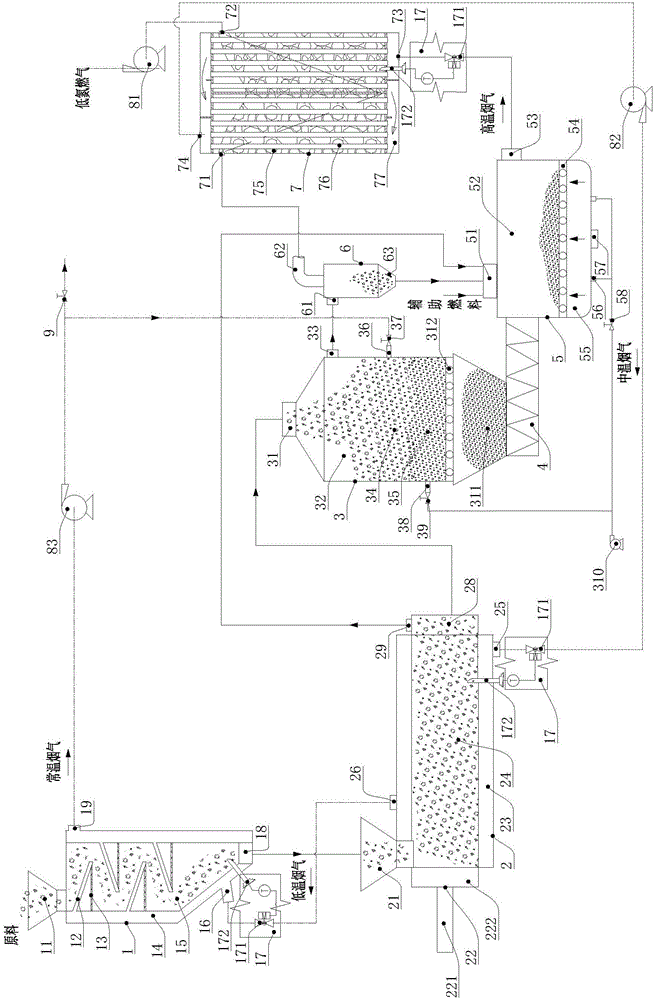

High-nitrogen biomass waste gasification combustion heat supply system and process

PendingCN107760387AReduce conversionReduce the effect of secondary reactionsCombustible gas productionEnergy inputNitrogenTar

The invention provides a high-nitrogen biomass waste gasification combustion heat supply system and a process. The system comprises a pyrolysis gasification furnace, a baking gas absorption device, avolatile component combustion boiler and a semicoke combustion heat utilization device in different zones, wherein the purpose that high-nitrogen biomass waste fuel volatile components and semicoke are firstly separated and are further respectively gasified and combusted independently is achieved, interaction of semicoke N and tar N is effectively weakened, conversion of fuel nitrogen to an NOx precursor is reduced, and meanwhile instable nitrogen structures in fuel are removed in a baking zone through pretreatment, so that the fuel nitrogen is reduced from sources, and NOx generated in laterheat supply process is effectively reduced. On premise that system energy is reasonably utilized, through pretreatment on instable fuel nitrogen and separation gasification combustion heat supply of semicoke nitrogen and volatile component nitrogen, conversion of the fuel nitrogen to NOx is weakened or inhibited in the high-nitrogen biomass waste gasification combustion heat supply process, and clean and efficient utilization of energy of high-nitrogen biomass wastes is achieved.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI

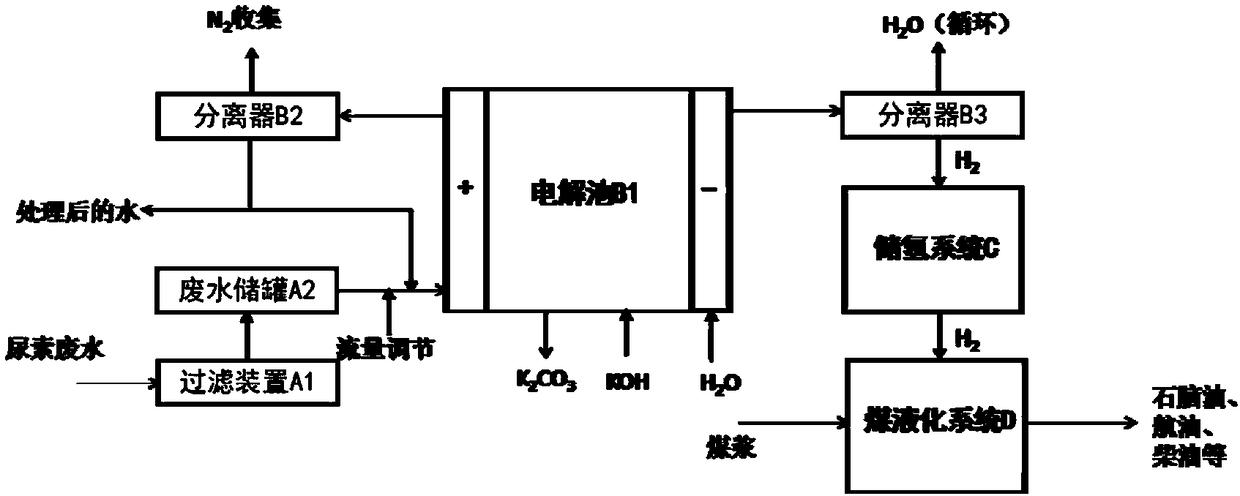

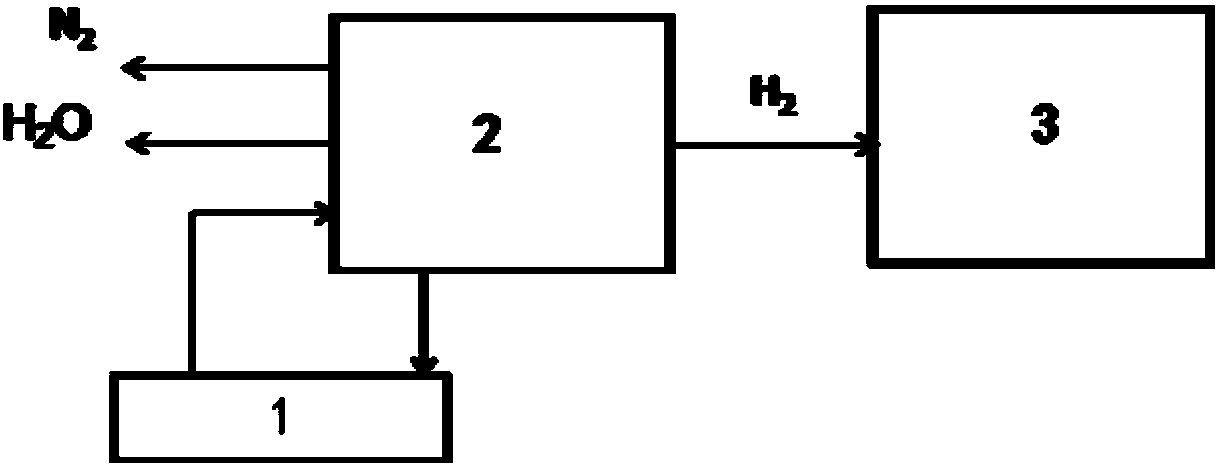

System and method for electrolyzing urea for wastewater treatment and coal liquefaction hydrogen supply

PendingCN108374181ARealize processingPromote environmental protectionCellsEnergy inputElectrolysisDecomposition

The invention discloses a system and a method for electrolyzing urea for wastewater treatment and coal liquefaction hydrogen supply. According to the system and the method, high-content urea in wastewater is oxydatively degraded by virtue of an electrolytic method so as to obtain high-purity hydrogen, and hydrogen is supplied to a coal liquefaction system to generate hydro-liquefaction reaction, so that the clean utilization of coal resources is promoted; the energy consumption of electrolytic hydrogen production can be reduced, and the urea in the wastewater is taken as the raw material, so that the electrolytic hydrogen production cost is further lowered, and the popularization of an environment-friendly and harmless electrolytic hydrogen production manner is promoted; the urea in the wastewater is removed by virtue of the electrolytic method, reaction conditions are mild, the treatment effect is good, and the environmental pollution caused due to NH3 released during the decomposition of the urea can be avoided; and the coupling of urea wastewater treatment and efficient electrolytic hydrogen production is realized, and electrolytically produced hydrogen is applied to a coal liquefaction process, so that the clean and efficient utilization of the coal resources is realized, and the system and the method have a relatively high environmental protection significance and comprehensive benefits.

Owner:HUANENG CLEAN ENERGY RES INST

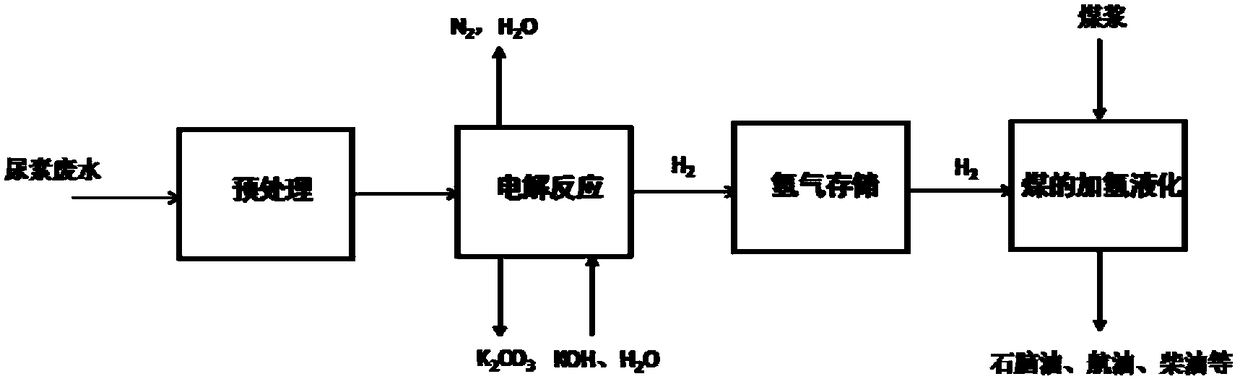

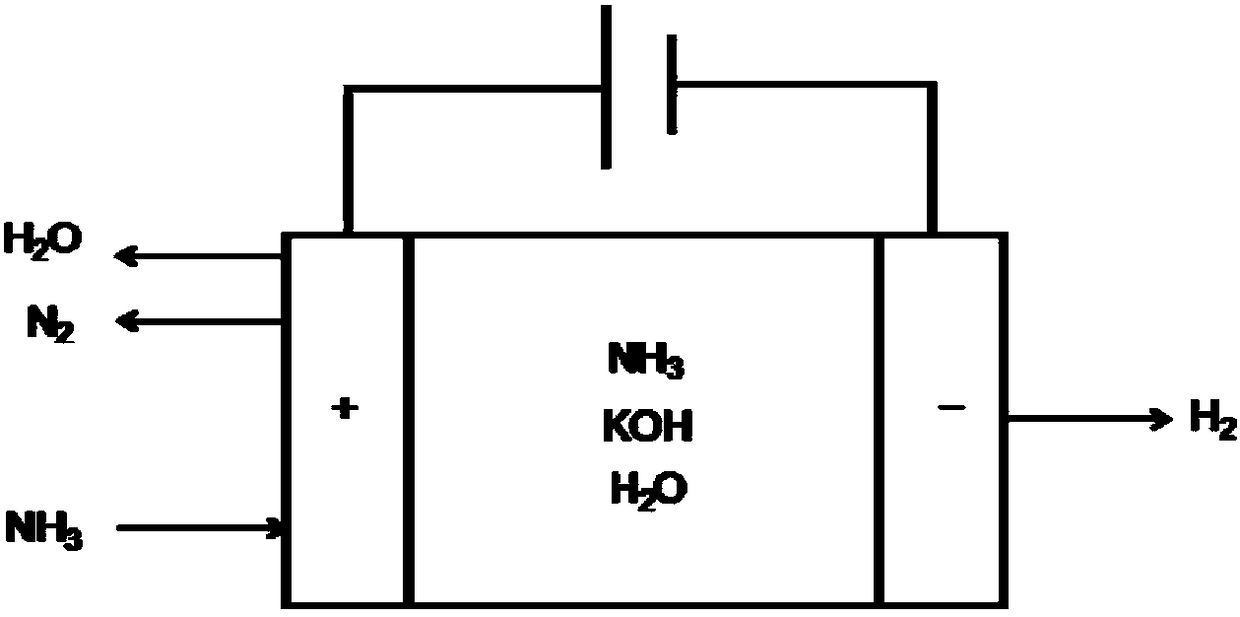

System and method for making hydrogen through ammonia electrolysis and applying hydrogen to coal liquefaction

PendingCN108360011AReduce energy consumptionLow priceCellsLiquid hydrocarbon mixture productionChemistryEnvironmental resistance

The invention relates to a system and a method for making hydrogen through ammonia electrolysis and applying the hydrogen to coal liquefaction. The system comprises an electrolyte supplying system, anelectrolysis bath and a coal liquefaction system; the outlet of the electrolyte supplying system is connected with the electrolyte inlet of the electrolysis bath; the cathode hydrogen outlet of the electrolysis bath is connected with the inlet of the coal liquefaction system; the conventional alkali electrolysis bath is utilized; the high-purity hydrogen is obtained through ammonia electrolysis and is supplied to the coal liquefaction system; hydro-liquefaction reaction is performed, so that clean utilization of coal resources is promoted; by adopting the method and the system, energy consumption of electrolytic hydrogen production can be lowered; cost of electrolytic hydrogen production is lowered, and promotion of a green and harmless electrolytic hydrogen production mode is facilitated; ammonia in waste water can be removed with the electrolysis method, so that coupling of waste water treatment and high-efficient electrolytic hydrogen production is realized; the hydrogen made through electrolysis is further applied to the process of coal liquefaction, so that clean and high-efficient utilization of the coal resources is promoted; and the method and the system are of high environment-protection significance and comprehensive benefits.

Owner:HUANENG CLEAN ENERGY RES INST

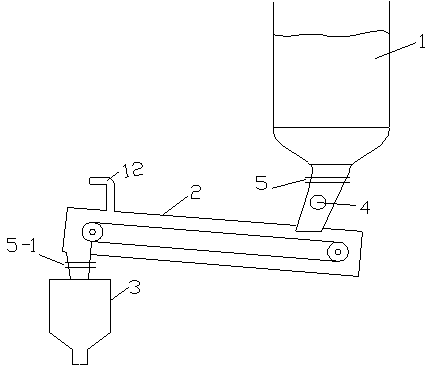

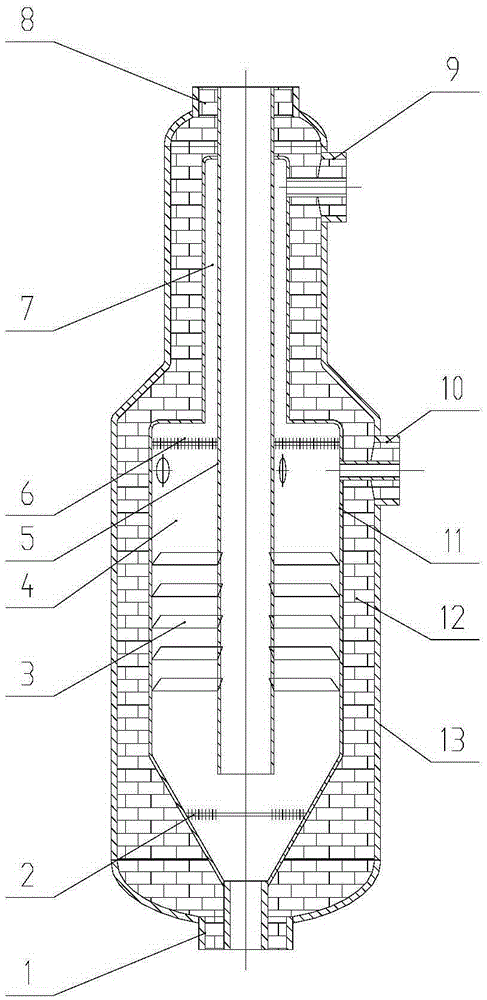

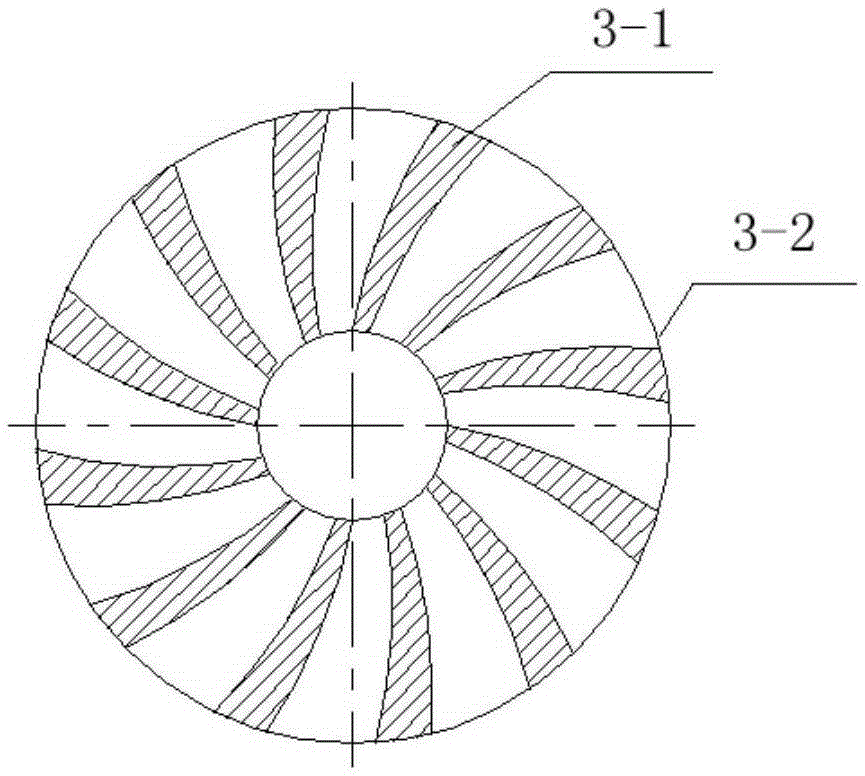

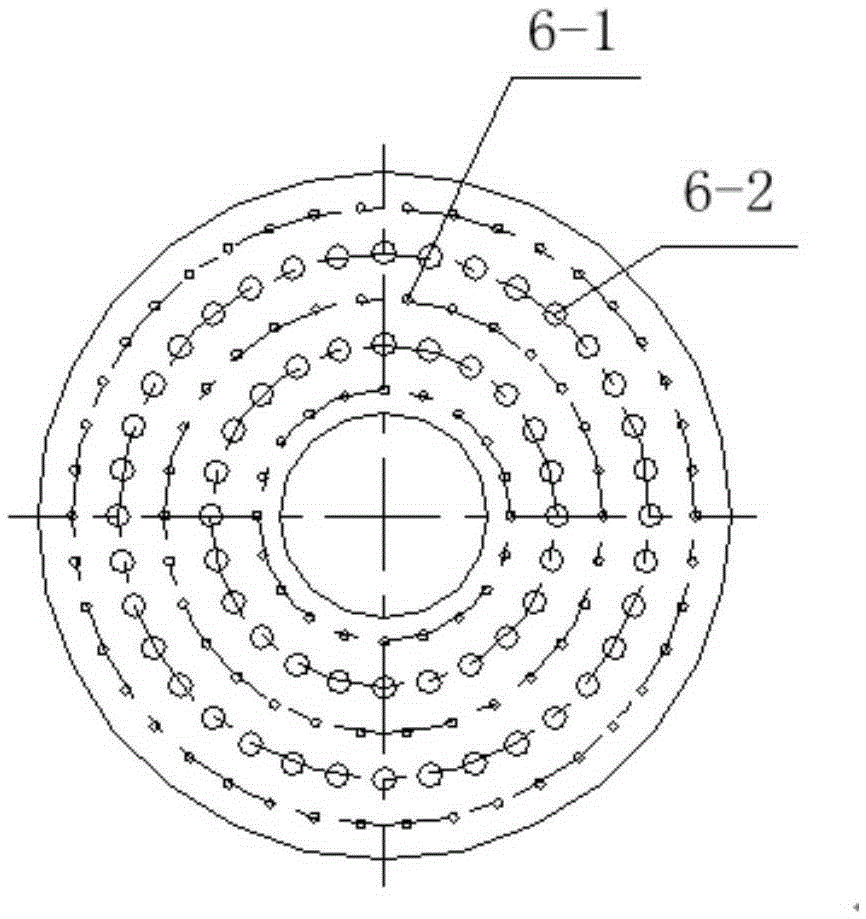

Biomass pyrolysis and catalytic cracking system

The invention belongs to the technical field of biomass pyrolysis and mainly provides a biomass pyrolysis and catalytic cracking system based on regenerative radiant tube heating. The system comprises the following parts: a pyrolysis hopper, a first feeding device, a pyrolysis and catalytic cracking reactor, a cracked gas cyclone separator, a spray tower and a gas tank, wherein the pyrolysis and catalytic cracking reactor comprises a feeding hole, a pyrolysis chamber, a cracking chamber, a cracked gas outlet, regenerative radiant tubes, a heat insulating brick wall, a catalyst adding device and a communicating component. The system has the beneficial effects that the reaction system has a simple structure, is convenient to operate, is uniform in temperature distribution and has good heating effects; the oil gas generated in the pyrolysis chamber can undergo deep cracking in the cracking chamber to crack macromolecular tar molecules into micromolecular gaseous hydrocarbon; the reaction system can generate plenty of cracked gas products, thus avoiding the problem that the pyrolysis oil contains dust and truly achieving clean and efficient utilization of fossil fuel.

Owner:SHENWU TECH GRP CO LTD

Microwave pretreatment desulfurization coking method and device

InactiveCN103059889AReduce heat consumptionReduce processingCharging devicesMicrowave frequency rangeProcess engineering

The invention discloses a microwave pretreatment desulfurization coking device, and particularly provides a device for coking coal. The device comprises a coal blending process, a coal charging process and a coking process; and the method further comprises a microwave pretreatment process between the coal blending process and the coal charging process. The microwave pretreatment process adopts a microwave pretreatment device with the microwave frequency ranged from 300MHz to 300GHz for irradiating, dewatering and desulfurizing the blended coal; and the temperature of the pretreated coal sample is controlled between 150 and 250 DEG C; and then coal is prepared to be charged into a stove and coked. The microwave pretreatment device comprises a microwave reaction chamber body, a connecting device, a conveyor, an exhaust duct and a detection control system, wherein the connecting device, the conveyor, the exhaust duct and the detection control system are arranged among the microwave reaction chamber body, a coke stove coal tower and a coal charging trolley or a material bin. The device is simple; after being quickly preheated, dewatered and desulfurized, the blended coal can be coked so as to improve the bulk density, shorten the coking time and promote the yield of a single furnace as well as the coal quality; and clean and effective utilization of energy can be realized.

Owner:CHINA UNIV OF MINING & TECH

Method for preparing chemical-mechanical pulp for fluting medium by using fresh empty fruit bunches

ActiveCN103103864ASimple pulping processLess investmentPretreatment with water/steamPulp beating/refining methodsPalm fruitPalm fiber

The method discloses a method for preparing chemical-mechanical pulp for fluting medium by using fresh empty fruit bunches, mainly aiming at the characteristics that the water content of the fresh empty fruit bunches is high, hard impurities such as residual palm fruit granules, sands and the like are carried in the fruit bunches and the palm silk surfaces of the empty fruit bunches contain more non-fiber surfaces; and on the basis of the technology process and the equipment configuration, the processing steps of granule removing, slicing, extruding, washing with water, pre-steaming, chemical soaking, pulping, washing and the like are performed gradually to materials. Before the pulp is formed, the non-fiber parts such as non-fiber surfaces with higher content on the fiber surface and the carried palm fruit granules in the EFP (empty fruit bunches) fiber raw materials are effectively removed as much as possible in the whole process and are used. The dosage of chemical product needed in the pulping process and the pollution load generated by pulping are effectively reduced, the paper pulp prepared by refining the palm fibers has the advantages of less dust, high strength and the like and is suitable for blending of the fluting medium; and by adopting the method, the clean and high-efficiency comprehensive utilization of the EFP raw materials in pulping and paper making is achieved.

Owner:INST OF CHEM IND OF FOREST PROD CHINESE ACAD OF FORESTRY

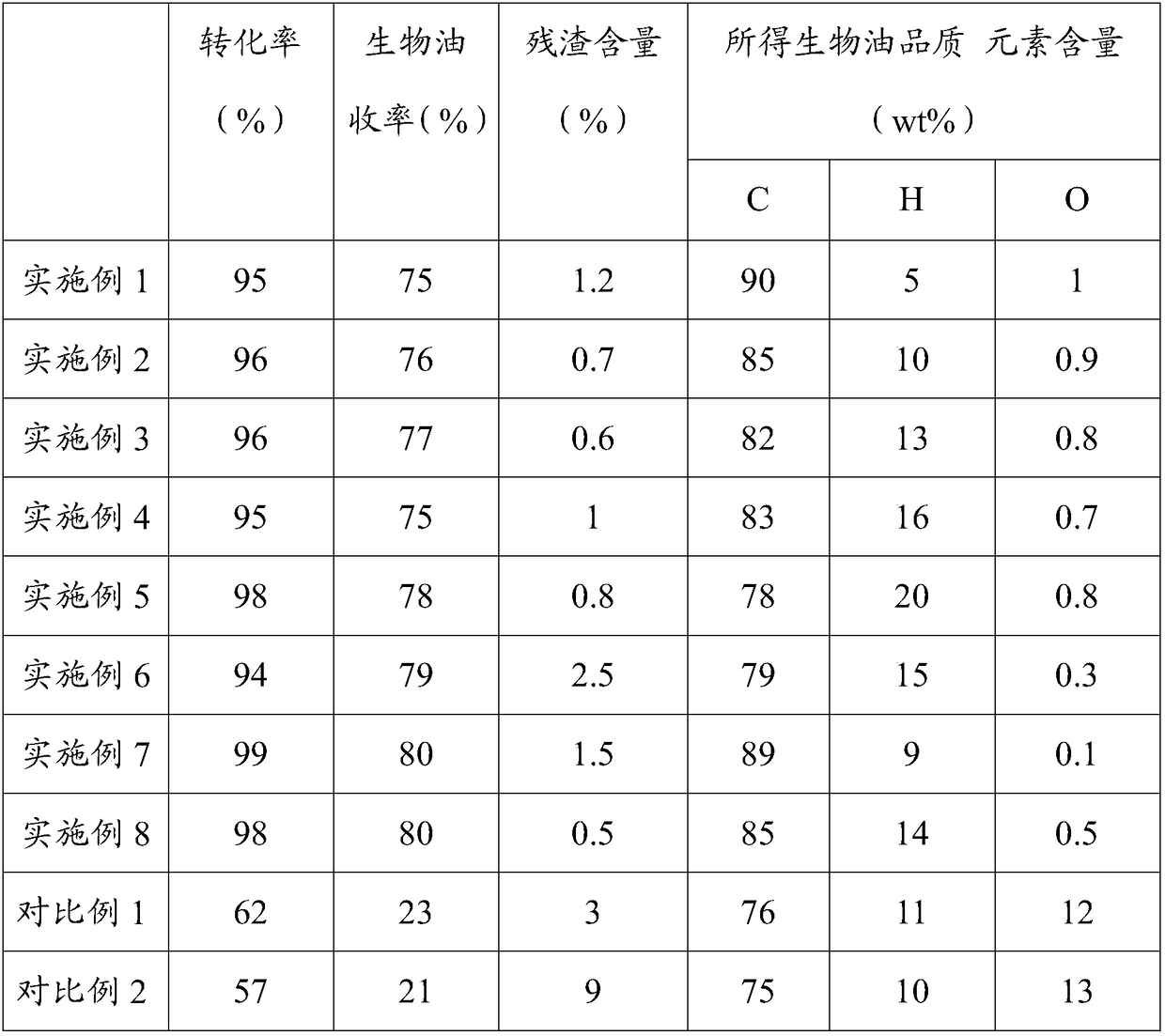

Multi-grade liquefying technology of coal and biomass

ActiveCN108285808ARealize mixing and liquefactionIncrease contactBiofuelsLiquid hydrocarbon mixture productionSolventBiomass

The invention relates to the technical field of clean energy, and specifically provides a multi-grade liquefying technology of coal and biomass. The technology is characterized in that the coal and the biomass raw materials are processed by crushing, compressing and crushing again, then the sizing is prepared, so that biomass diesel oil which is high in solid content and can be stably conveyed through a pump can be obtained; high-viscosity waste oil which cannot be used as a coal and biomass liquefying solvent in the prior art can be utilized. According to the technology, coal and biomass canbe liquefied under high pressure and high temperature in the existence of proper volume of water; the liquefying product is sequentially subjected to primary cracking, hydrogenation reaction and deepcracking and hydrogenation reaction under the effects of resisting hydrogen and a first catalyst and a second catalyst, so that the coal and the biomass can be converted into biomass oil, and the biomass oil can be refined; the conversion rate of the biomass and the coal is up to 95-99%; the yield of the biomass oil is up to 70-80%; and moreover, the residue content is less than 2.5%.

Owner:BEIJING SJ ENVIRONMENTAL PROTECTION & NEW MATERIAL CO LTD

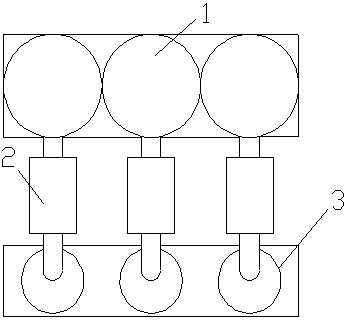

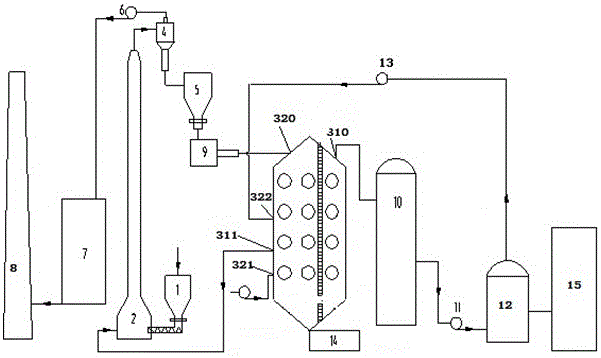

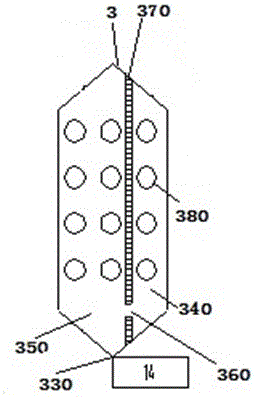

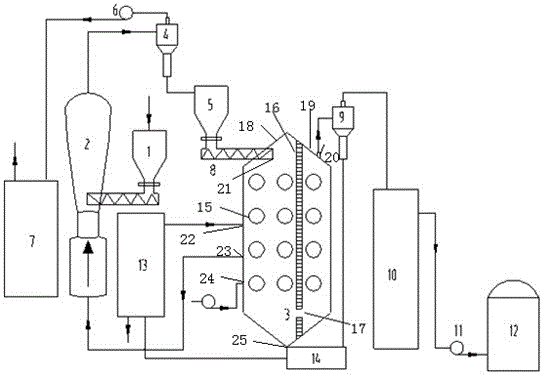

Technique and system for preparing low-nitrogen biomass gas from high-nitrogen antibiotic mushroom dregs

PendingCN107523361ASuppress generationReduce concentrationGas purification by catalytic conversionGasification processes detailsLow nitrogenProcess engineering

The invention discloses a system for preparing low-nitrogen biomass gas from high-nitrogen antibiotic mushroom dregs. The system comprises a drying room 1, a baking device 2, a vaporizer 3, a combustion furnace 5, a fuel gas purification room 7 and a gas-solid separator 6; the drying room 1, the baking device 2, the vaporizer 3, the gas-solid separator 6 and the fuel gas purification room 7 are connected in sequence; the combustion furnace 5 is connected with the baking device 2, the vaporizer 3 and the gas-solid separator 6; and the combustion furnace 5, the fuel gas purification room 7, the baking device 2, the drying room 1 and the vaporizer 3 are connected through smoke tubes in sequence. The system has the advantages that the generation of an NOx precursor in fuel gas is effectively inhibited in three aspects, or the concentration of the NOx precursor is reduced, so that low-nitrogen biomass gas is obtained.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI

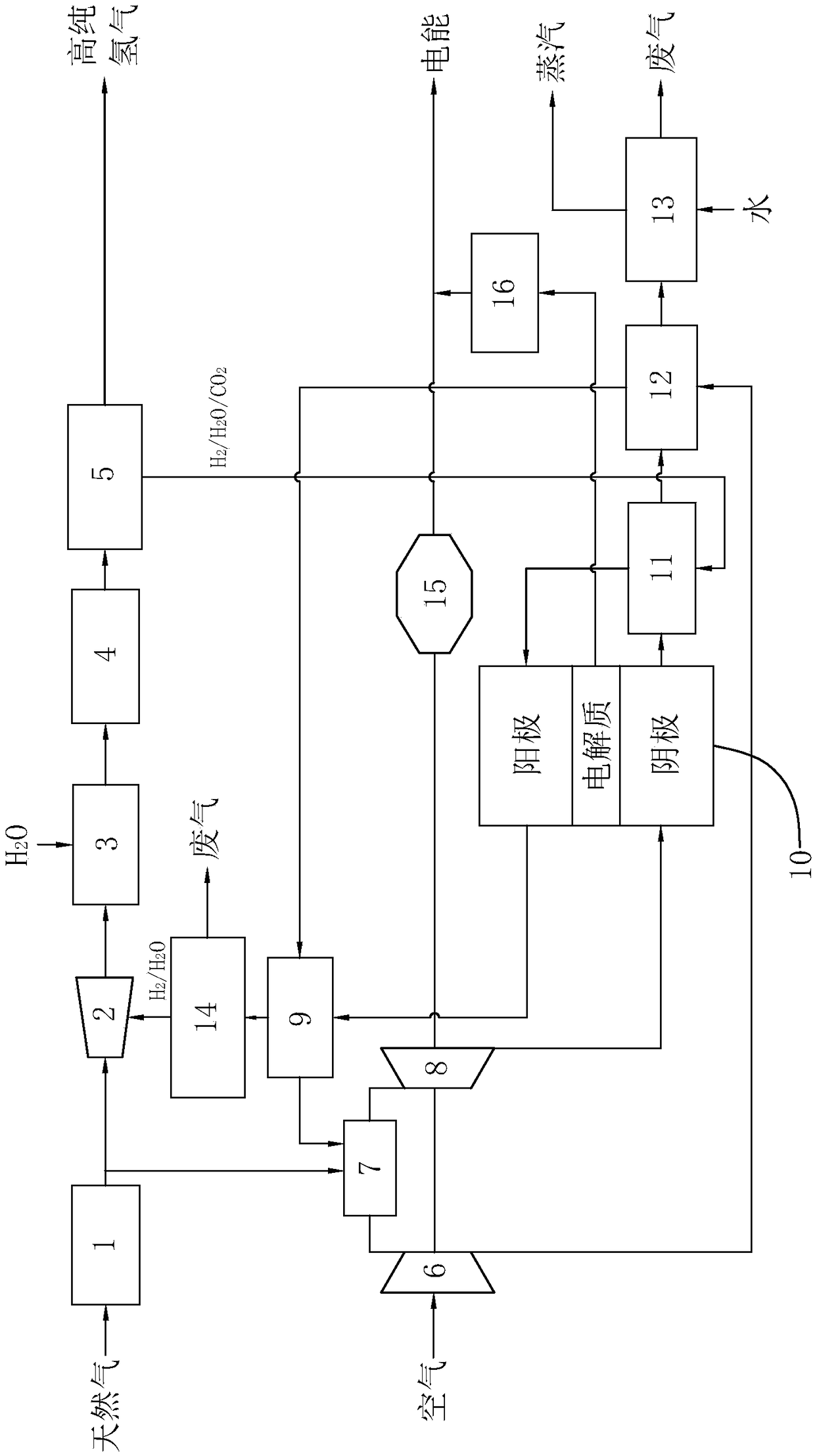

Polygeneration system of thermoelectric hydrogen based on urban natural gas

PendingCN109119660AClean and efficient useEmission reductionFuel cellsCombustion chamberElectronic systems

The invention discloses a polygeneration system of thermoelectric hydrogen based on urban natural gas, comprising a natural gas reforming hydrogen production subsystem, a micro gas turbine power generation subsystem and a solid oxide fuel cell power generation subsystem, the natural gas reforming hydrogen production subsystem comprises a desulfurization device, an ejector, a reformer, a water gasshift reaction device and a palladium membrane purification device connected in sequence, the micro gas turbine power generation subsystem comprises a compressor, a combustion chamber, a turbine and agenerator connected in sequence, and the solid oxide fuel cell power generation subsystem comprises a solid oxide fuel cell. The purpose of the invention is to provide a polygeneration system of thermoelectric hydrogen based on urban natural gas, which organically combines the natural gas reforming hydrogen production technology, the micro gas turbine technology and the solid oxide fuel cell technology, and improves the overall utilization efficiency of heat energy.

Owner:BEIJING GAS & HEATING ENG DESIGN INST

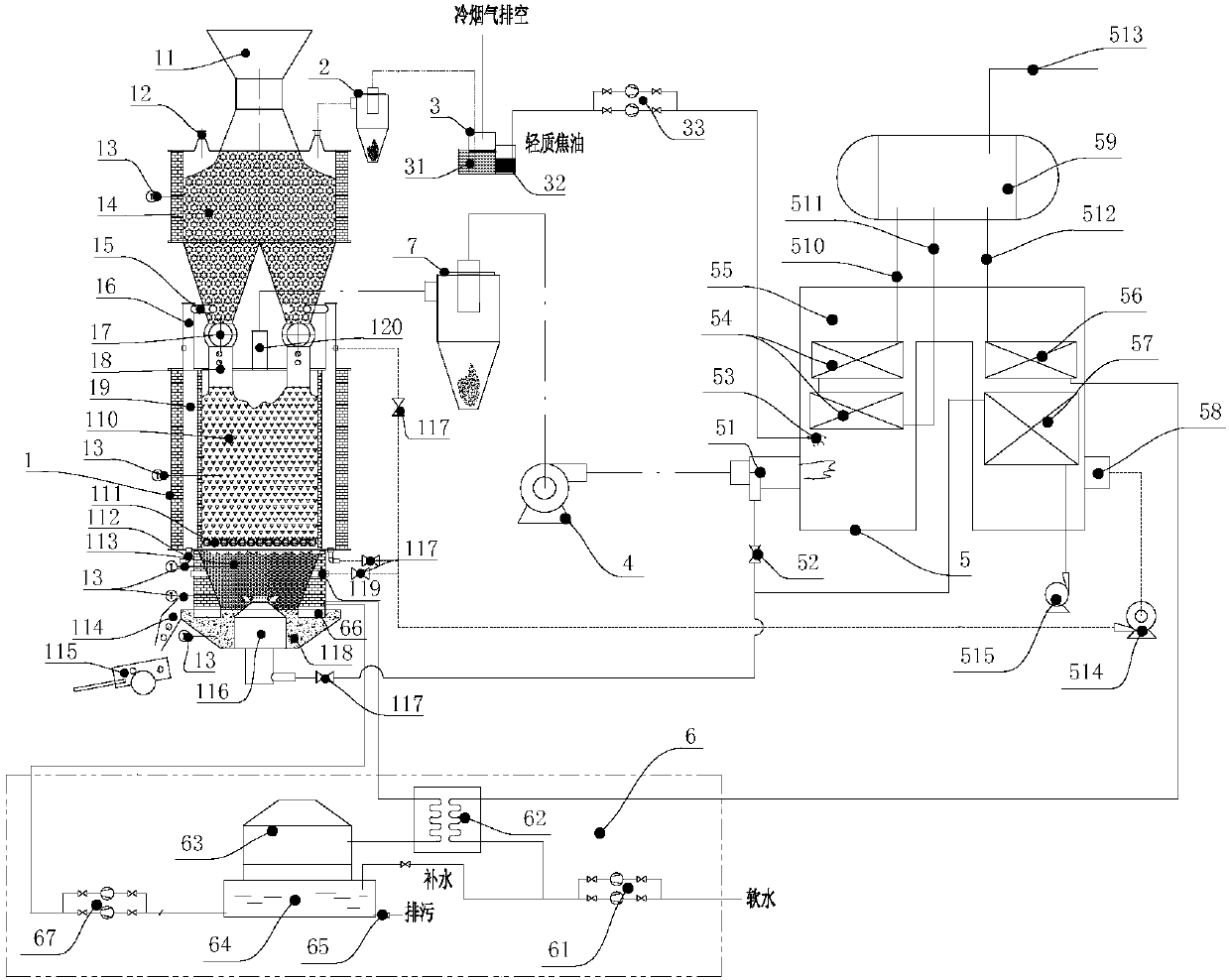

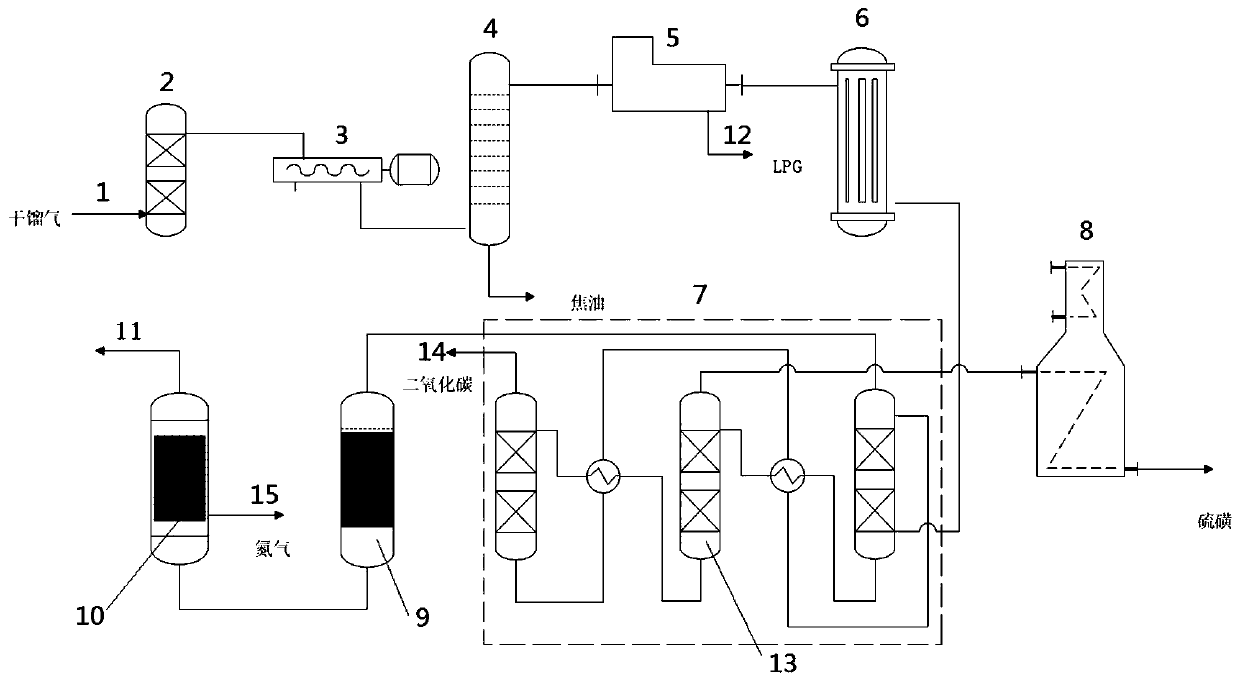

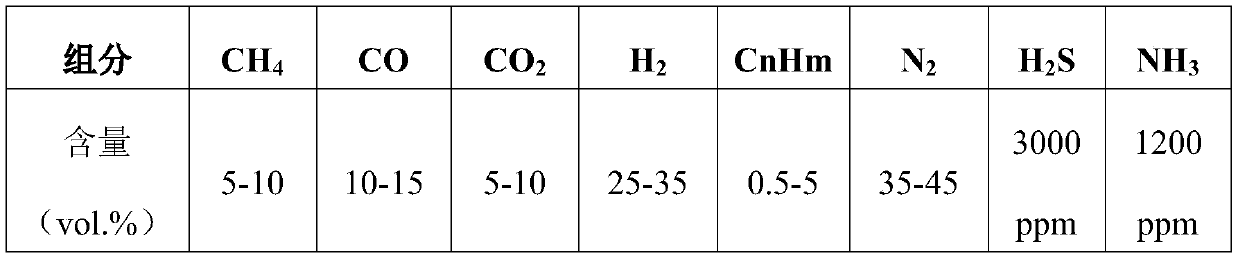

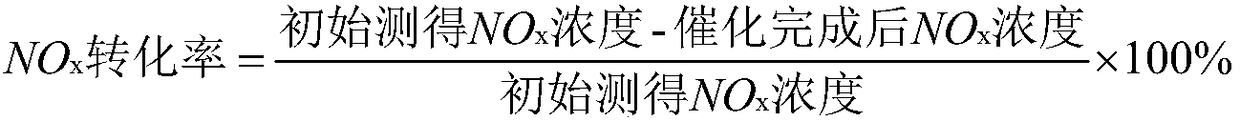

System and method for preparing LNG from medium and low temperature dry distillation raw coke oven gas through sulfur-resistant uniform-temperature methanation

PendingCN110655939AReduce carbon loadImprove thermal stabilityCombustible gas chemical modificationChemical industryMethanationProcess engineering

The invention discloses a system and method for preparing LNG from medium and low temperature dry distillation raw coke oven gas through sulfur-resistant uniform-temperature methanation, and belongs to the technical field of clean and efficient utilization of coal. Tar recovery is carried out after dedusting, deamination and purification on the dry distillation raw coke oven gas to obtain a high-value by-product; and advanced hydrocarbons such as propane, butane and the like are pressurized, liquefied and separated to directly prepare LPG. H2S gas desorbed by a desulfurization and decarburization device is high in purity, and sulfur can be recovered by adopting a Claus sulfur recovery process. The content of an LNG component CH4 obtained after cryogenic liquefaction separation is high andis greater than 95%, so that the requirements of a first-grade natural gas product are met. The system is easy and convenient to operate, clean and efficient utilization of low-rank coal is achieved through the low-temperature dry distillation poly-production technology of coal, liquefied natural gas with the high calorific value is produced, byproducts such as tar, LPG, sulfur and carbon dioxideare by-produced, energy is saved, and economic benefits are high.

Owner:CHINA HUANENG GRP CO LTD +1

Method of realizing clean combustion of petroleum coke

InactiveCN1931979AClean and efficient useLarge specific surface areaSolid fuelsCombustionReaction rate

The present invention is method of realizing clean combustion of petroleum coke. The method includes the following steps: crushing petroleum coke with high pressure roller, adding water to form slurry, adding desulfurizer, and superfine treating. The present invention has submicron superfine technology and separating technology applied in the treatment of petroleum coke, and the treated petroleum coke with greatly increased specific surface area can raise the combustion efficiency greatly and raise the desulfurizing reaction rate greatly to realize the clean combustion of petroleum coke.

Owner:汪景武

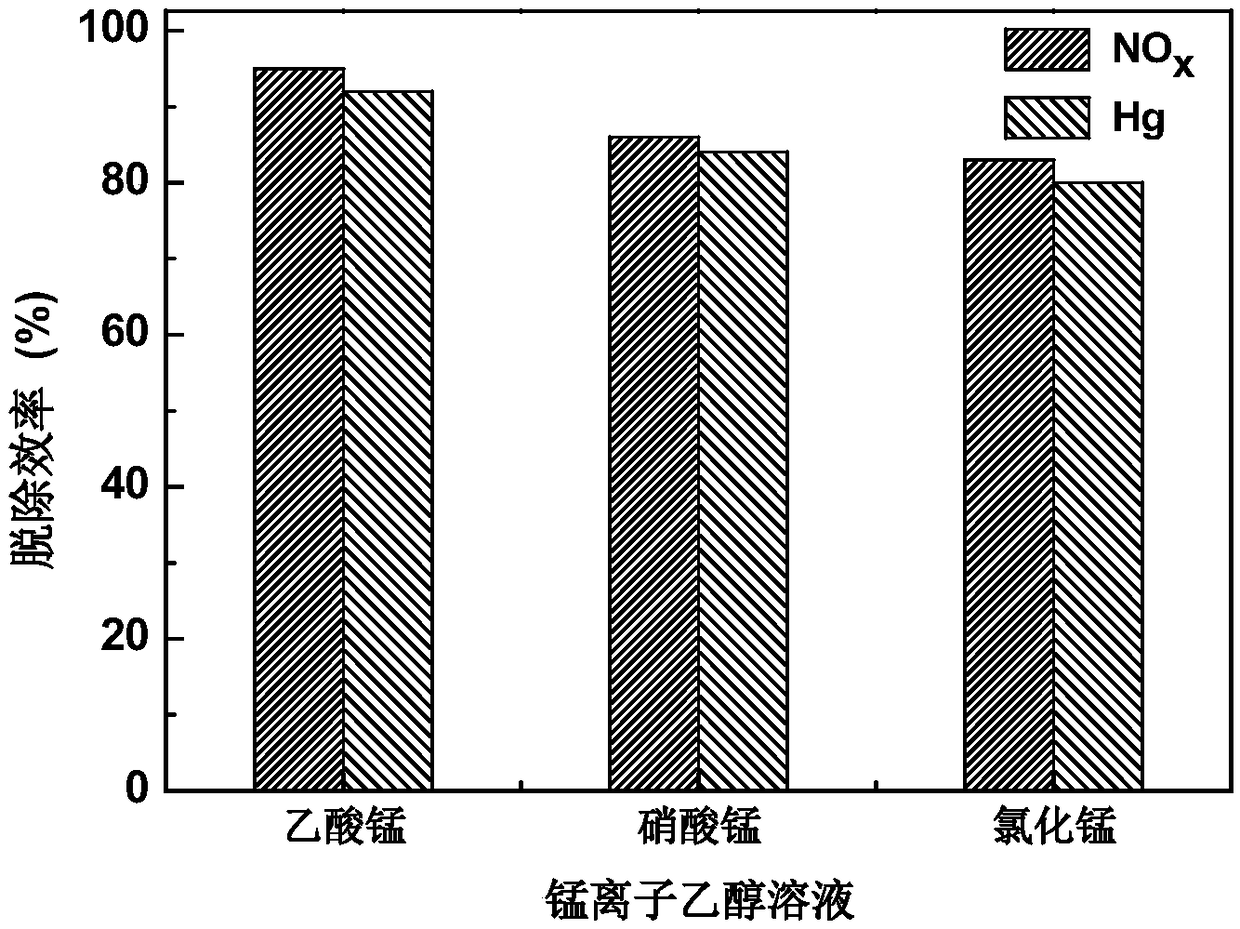

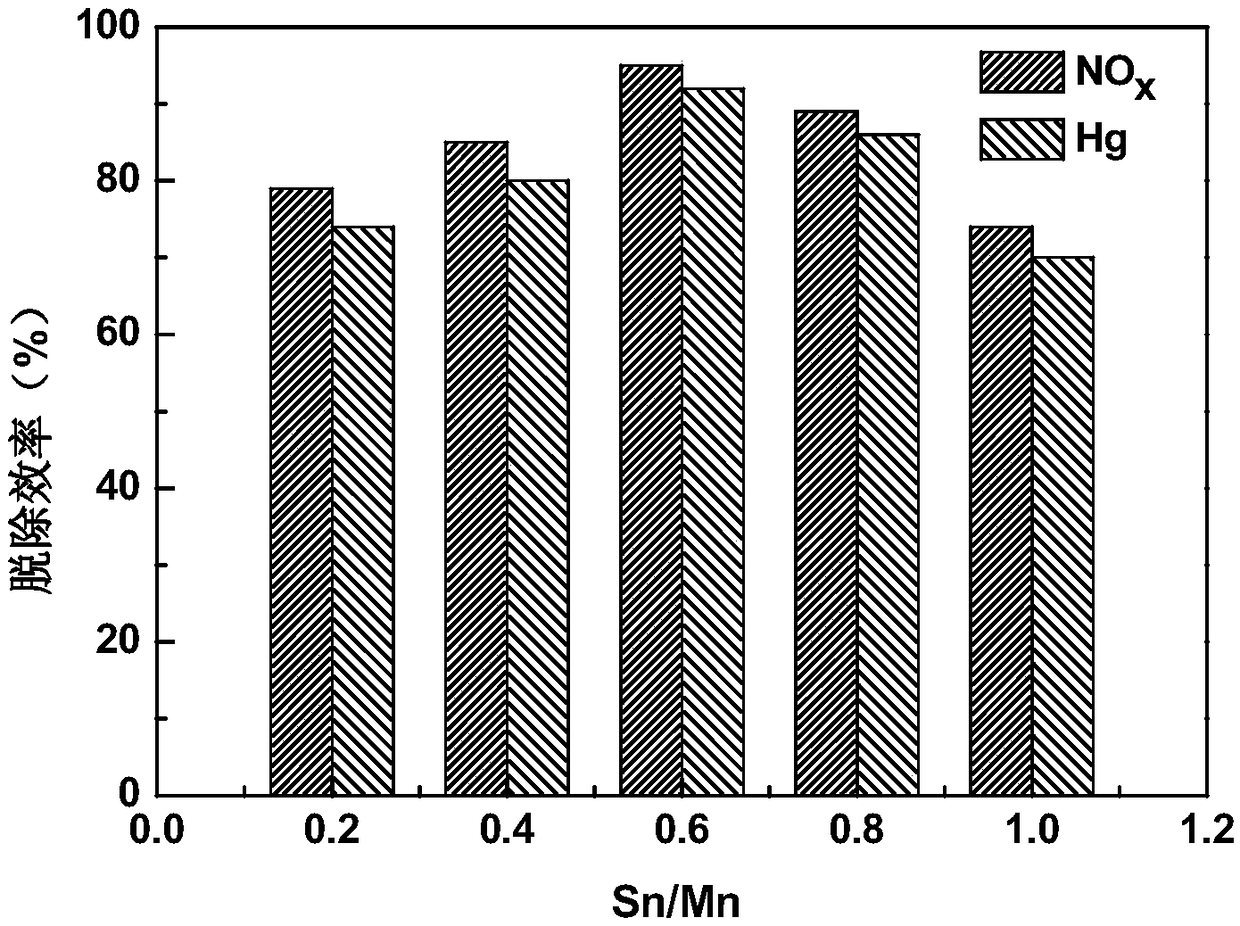

Method for preparing coal tar-based carbon material catalyst for combined removal of nitric oxide and mercury in coal-fired flue gas

ActiveCN108889298AGreat potential for development and utilizationRealize rational utilizationGas treatmentDispersed particle separationCarbonizationNitric oxide

The invention discloses a method for preparing a coal tar-based carbon material catalyst for combined removal of nitric oxide and mercury in coal-fired flue gas, belongs to the technical field of energy chemical engineering and aims to achieve combined removal of pollutants in coal flue gas. The method comprises the following steps: firstly, carrying out purification pretreatment on coal tar; andmixing with polyvinylpyrrolidone (PVP), and soaking into a SnCl2 and Mn<2+> ethanol solution to carry out in-situ carrying; and carrying out carbonization and oxidation in sequence, thereby obtaininga coal tar carbon material catalyst. The coal tar carbon material catalyst prepared by using the method is of a rich pore structure and has a high specific surface area. As the coal tar is adopted asa raw material, the raw material is cheap and easy to obtain, the prepared catalyst is high in mercury removal and denitration efficiency, that is, the efficiency is up to 95% or greater, the catalystis long in service life and good in regenerability and can be popularized and applied, and a novel technical scheme is provided for novel and efficient utilization of the coal tar, and can be popularized and applied.

Owner:SHANDONG UNIV OF SCI & TECH

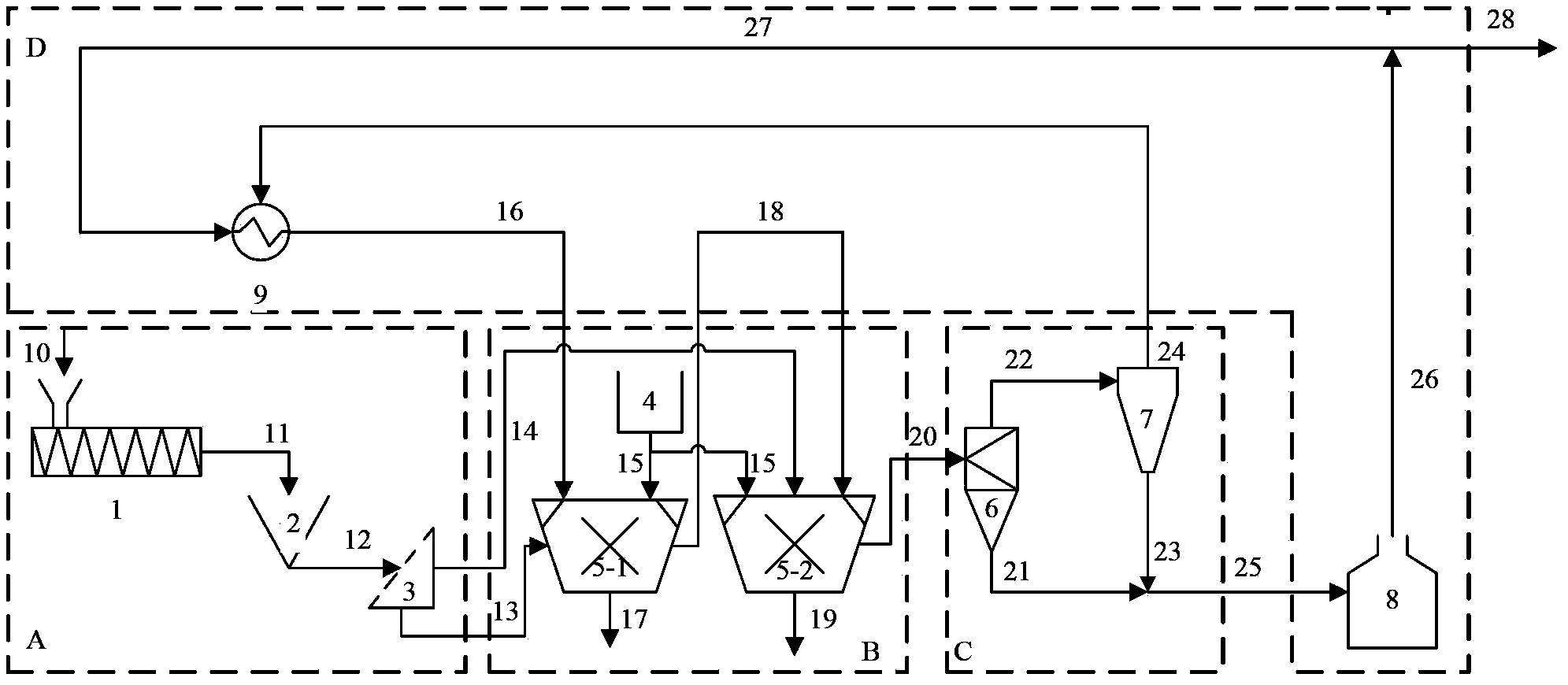

High-concentration organic wastewater and organic solid waste treatment process and high-concentration organic wastewater and organic solid waste treatment system

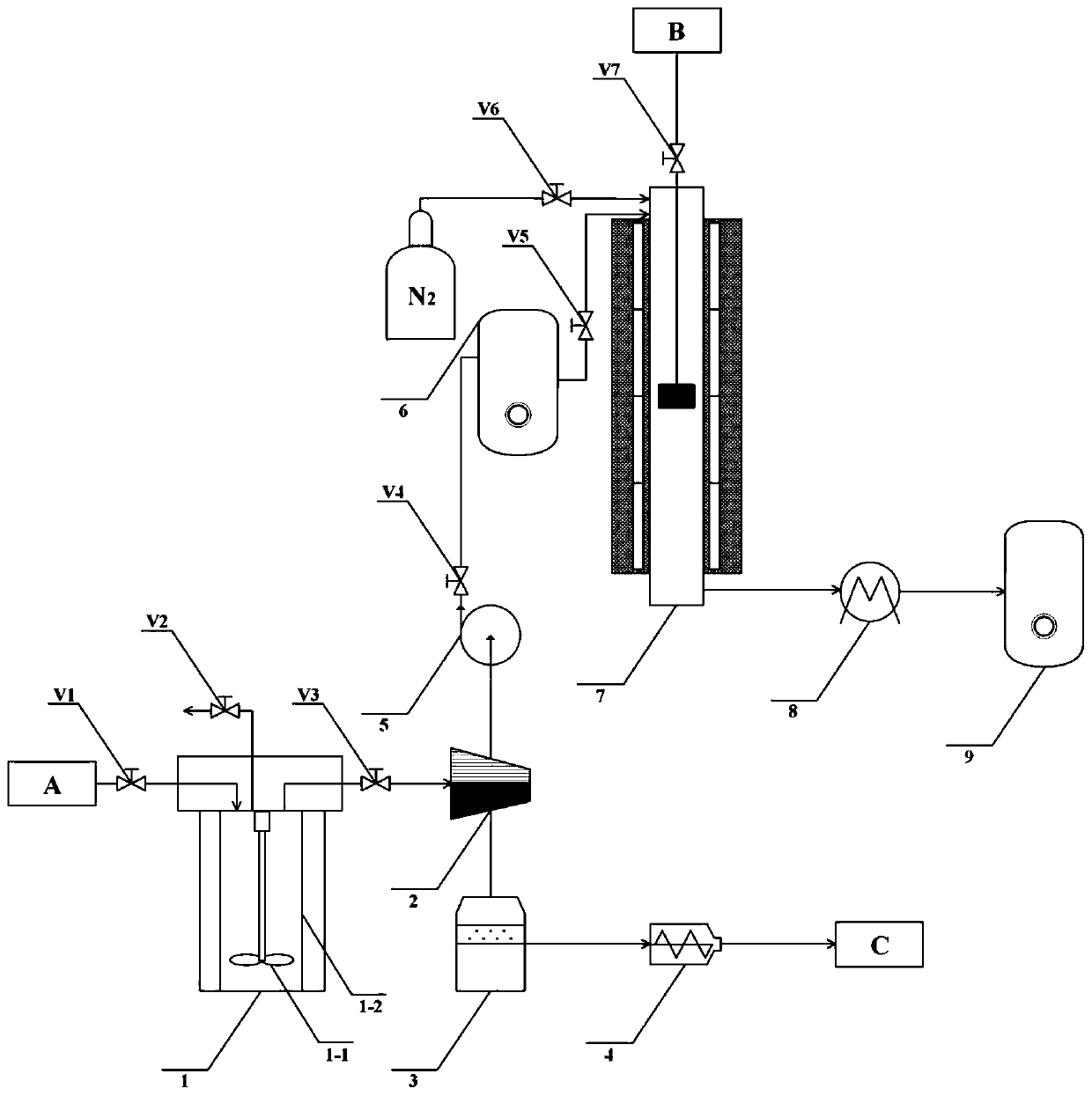

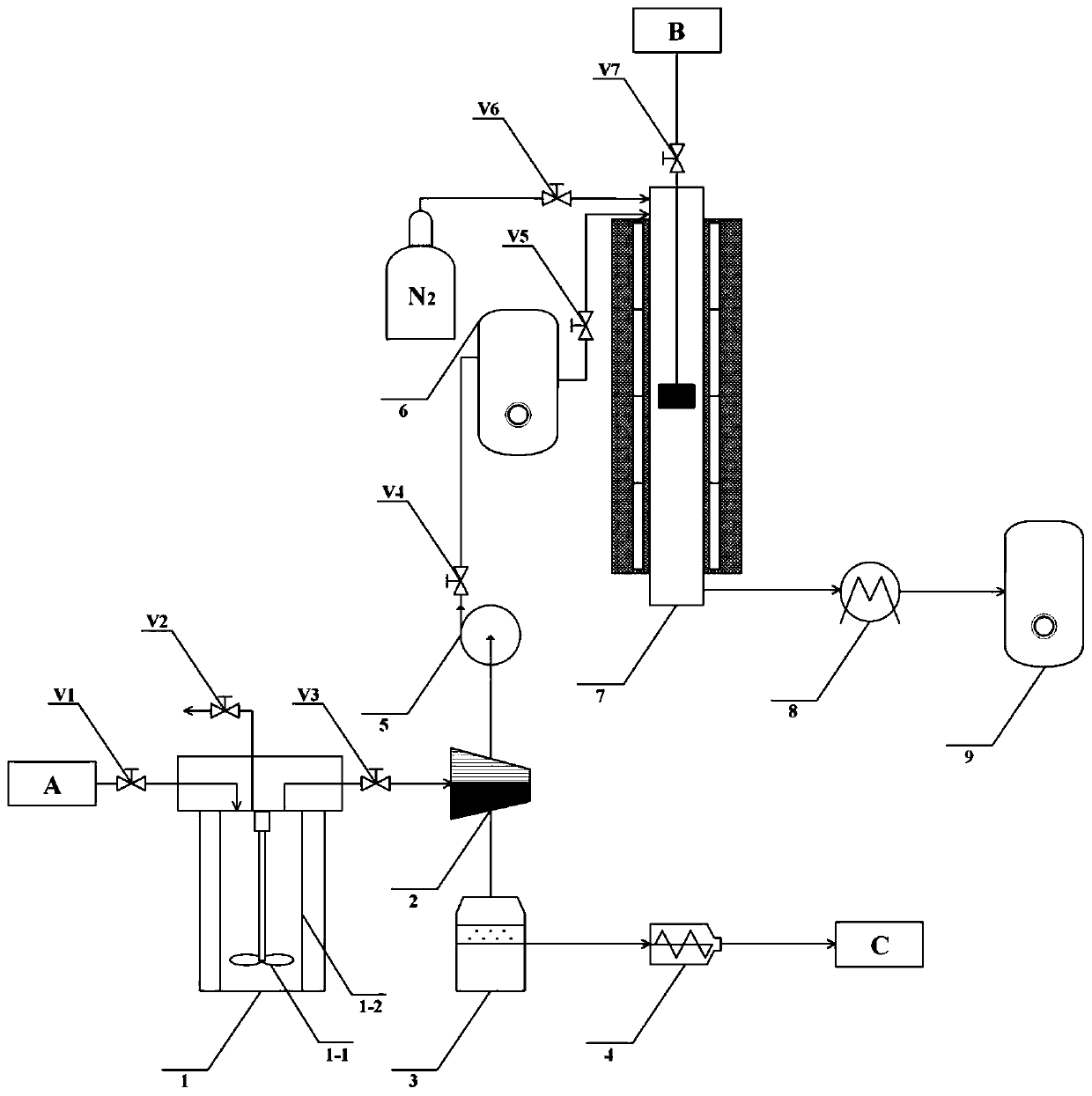

ActiveCN111171889AClean and efficient useImprove gas production effectGaseous fuelsBiofuelsMolding machineLiquid storage tank

The invention relates to a high-concentration organic wastewater and organic solid waste treatment process and a high-concentration organic wastewater and organic solid waste treatment system. The device comprises a high-pressure hydrothermal reaction kettle (1), wherein a pressure container (1-2) is arranged in the hydrothermal reaction kettle (1) and connected with a solid-liquid separator (2),the solid outlet end of the solid-liquid separator (2) is connected with a dryer (3) and a compression molding machine (4), the liquid outlet end of the solid-liquid separator (2) is communicated witha liquid storage tank (6), the liquid storage tank (6) is connected with a gasification reactor (7) through an air circulating pump (5), and the gasification reactor (7) is connected with a gas storage tank (9) through a condenser (8). According to the invention, high-concentration organic wastewater and organic solid waste are converted into coke forming fuel with high additional value and high-quality hydrogen-rich combustible gas, so that the hydrothermal liquid phase and the high-concentration organic wastewater are cleanly recycled, and the content of H2 in the organic solid waste gasification produced gas is increased so as to achieve the high-value utilization of the high-concentration organic wastewater and the organic solid waste.

Owner:NANJING UNIV OF TECH

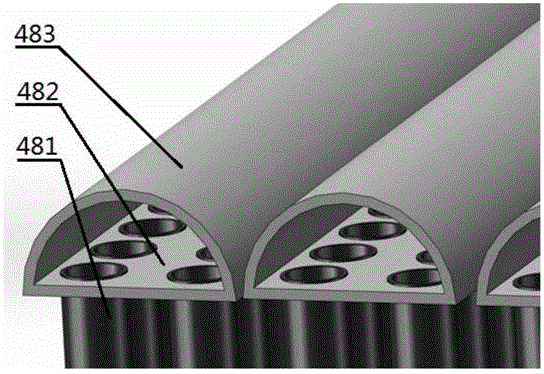

Tubular indirect heating coal pyrolysis device

InactiveCN105219409AEasy to manufactureLittle erosion and corrosion effectIndirect heating destructive distillationSpecial form destructive distillationThermal insulationEngineering

The invention discloses a coal pyrolysis device, and particularly relates to a tubular indirect heating coal pyrolysis device. The tubular indirect heating coal pyrolysis device comprises a semi-coke outlet, a pyrolysis section, a pulverized coal inlet, a pressure bearing shell, a thermal insulation layer and a pyrolysis gas outlet. The semi-coke outlet is located in the bottom end of the pyrolysis device. The pulverized coal inlet is located in the top end of the pyrolysis device. The tubular indirect heating coal pyrolysis device further comprises a preheating section located above the pyrolysis section. The diameter of the preheating section is smaller than that of the pyrolysis section. The tubular indirect heating coal pyrolysis device is simple in structure, high in heat exchange efficiency and capable of cleanly and efficiently using coal resources.

Owner:CHANGZHENG ENG

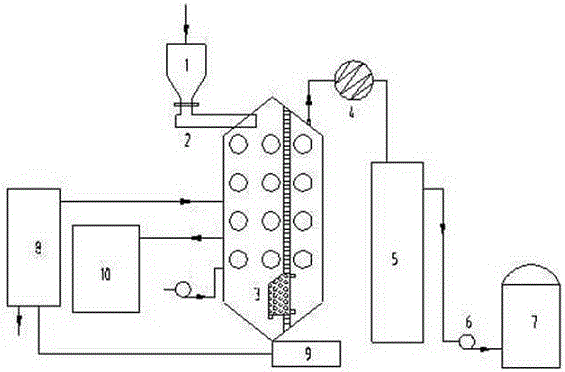

Self-dust-removal type pyrolyzing and cracking system for waste tires

ActiveCN105925293ARealize clean and efficient useReduce dust removal pressureProductsReagentsTarCombustible gas

The invention belongs to the technical field of pyrolysis of waste tires and mainly relates to a self-dust-removal type pyrolyzing and cracking system for the waste tires based on regenerative radiant tube heating. The self-dust-removal type pyrolyzing and cracking system is used for preparing clean combustible gases. Aiming at the defects in the prior art, the invention designs and develops a self-dust-removal type pyrolyzing and cracking reaction system for the waste tires. The reaction system can perform two operations of pyrolyzing and cracking; oil gas generated by pyrolyzing enters into a particle bed dust removing device; after the oil gas is subjected to filtering and dust removal, clean oil gas enters a cracking chamber, so that the dust removing pressure of a subsequent process is reduced, and tar macromolecules are cracked into small molecule gaseous hydrocarbons. According to a reactor, a large amount of cracking gases can be generated, thereby solving the problem that produced pyrolytic tar is difficult to utilize, and really realizing clean and efficient utilization of the waste tires.

Owner:SHENWU TECH GRP CO LTD

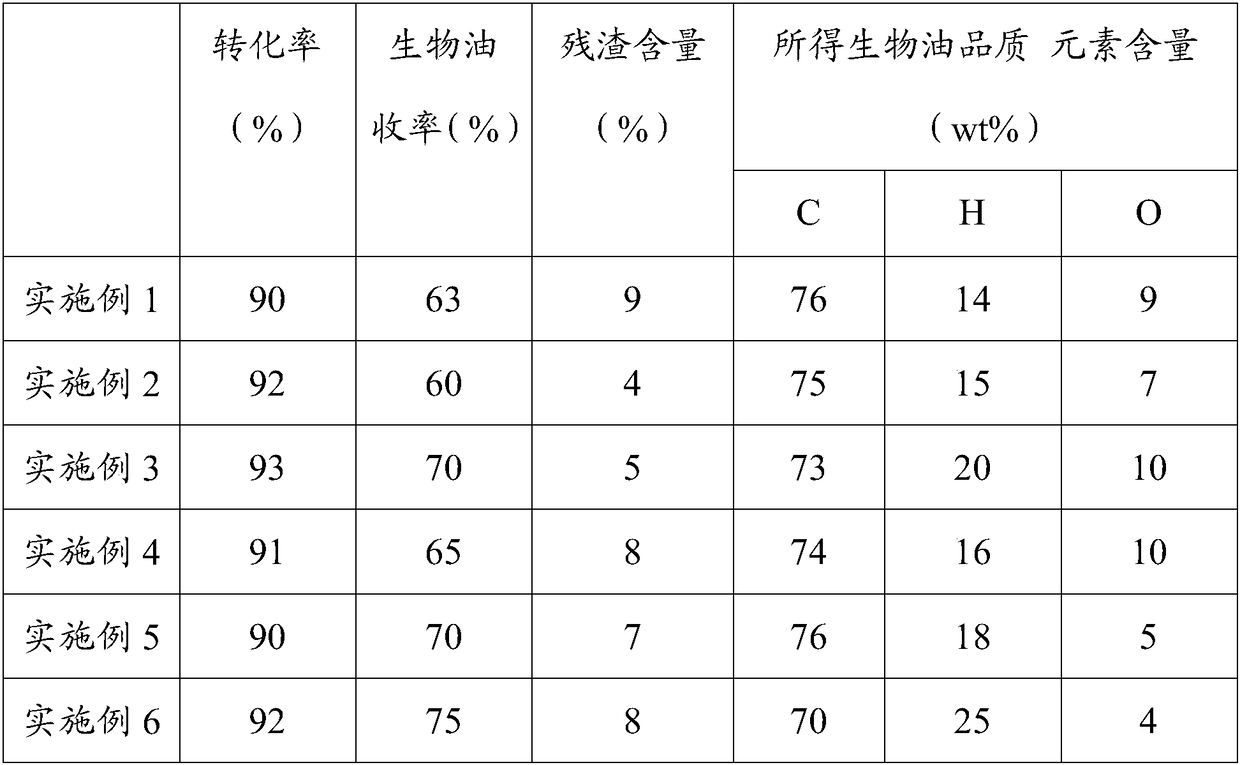

Co-hydrolysis hydrogenation process for coal and biomass

ActiveCN108277038AHigh densityIncreased accessible areaLiquid hydrocarbon mixture productionHydrocarbon oils treatmentHydrogenation reactionReaction temperature

The invention relates to the technical field of clean energy, in particular to a blending process of coal and biomass. The invention provides a co-hydrolysis hydrogenation process for coal and biomass, the coal and biomass raw materials are subjected to crushing, compression and re-crushing, then the slurry is prepared, and the biomass water coal slurry which is high in solid content and capable of being stably conveyed by a pump is successfully obtained. Hydrogen is introduced into the biomass water coal slurry, the reaction pressure is controlled to be 15-25 MPa, the reaction temperature iscontrolled to be 300-420 DEG C, and finally the biological oil is prepared. The process disclosed by the invention is characterized in that the coal and the biomass are subjected to high-pressure high-temperature hydrolysis under a subcritical or a supercritical state of water, furthermore subjected to cracking and hydrogenation reaction, so that the conversion of the coal and the biomass into thebiological oil is realized. In the process disclosed by the invention, the conversion rate of the coal and the biomass can reach 85-95%, the yield of the biological oil can reach 60-80%, and the residue amount is less than 5%.

Owner:BEIJING SJ ENVIRONMENTAL PROTECTION & NEW MATERIAL CO LTD

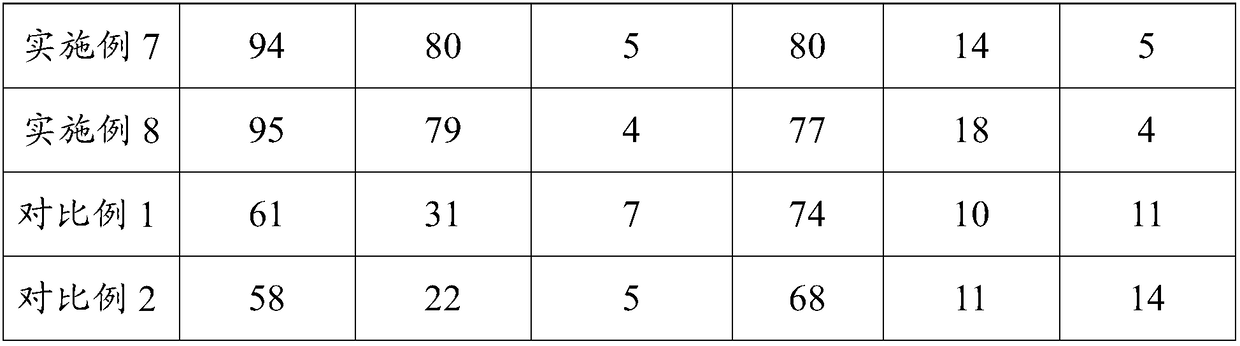

Coal and biomass co-liquefaction technology

ActiveCN108192652ARealize mixing and liquefactionIncrease contactHydrocarbon oil crackingLiquid hydrocarbon mixture productionKeroseneReaction temperature

The invention relates to the technical field of clean energy, in particular to a coal and biomass co-liquefaction technology. According to the coal and biomass co-liquefaction technology, coal and biomass materials are subjected to crushing, compression and re-crushing treatment, and then slurry is prepared, so that biomass coal oil slurry, with high solid content, capable of being stably conveyedthrough a pump, is obtained, and high-viscosity waste oil which can not serve as a coal and biomass liquefaction solvent in the prior art can be utilized. By leading hydrogen into the biomass coal oil slurry and controlling the reaction pressure to be 15 to 25MPa and the reaction temperature to be 380 to 480 DEG C, biomass oil is formed finally. The technology ensures that coal and biomass are liquefied in high pressure and high temperature environment, and cracking and hydrogenation reaction are further produced, so that the conversion of coal and biomass to biomass oil is realized. In the technology, the conversion ratio of coal and biomass can reach 90 to 95 percent, the yield of biomass oil can reach 40 to 75 percent, and the amount of residue is not greater than 3 percent.

Owner:BEIJING SJ ENVIRONMENTAL PROTECTION & NEW MATERIAL CO LTD

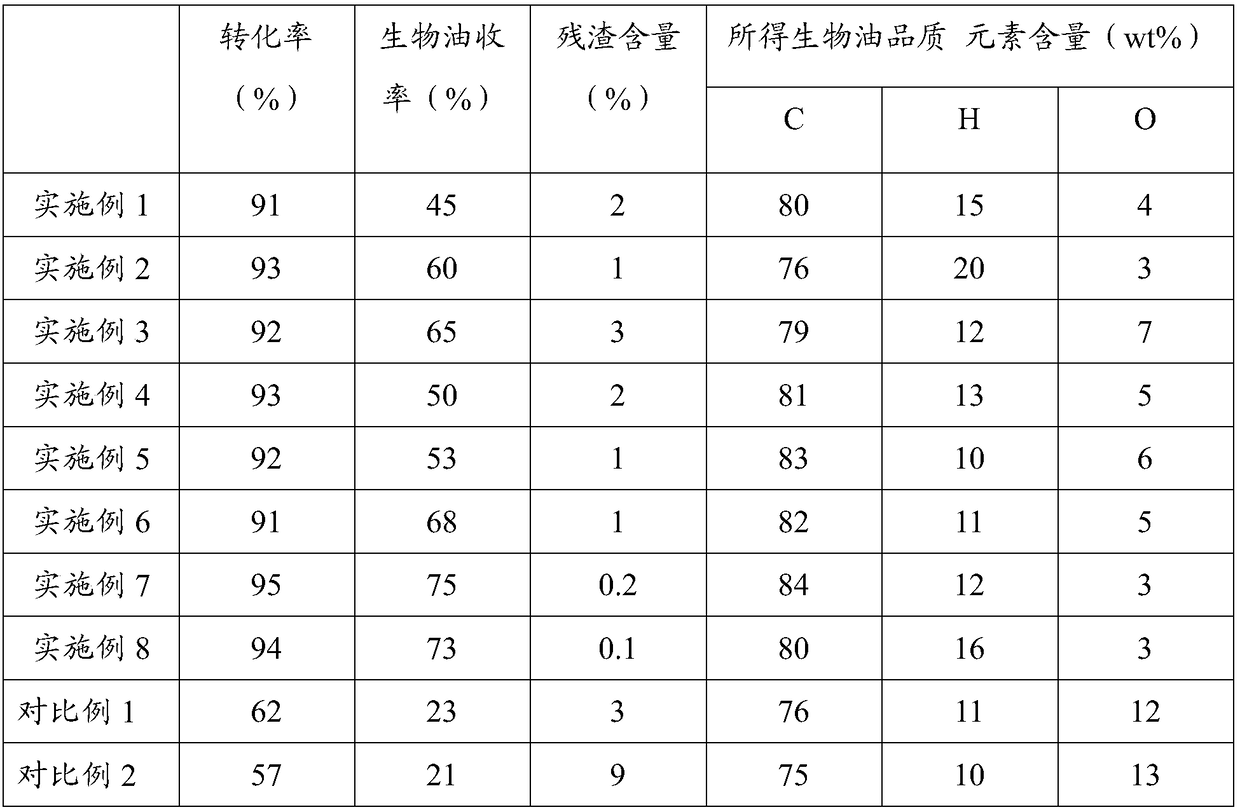

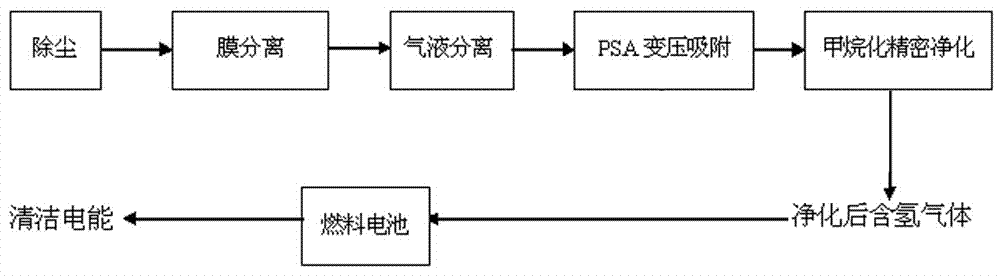

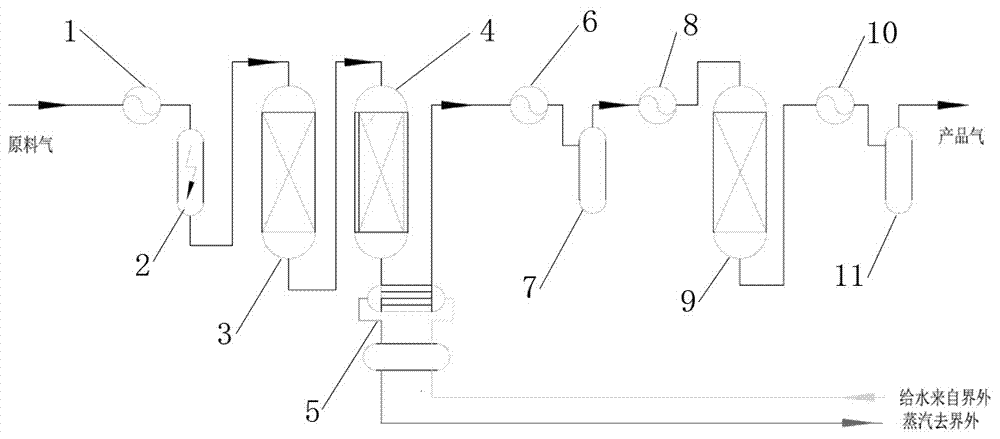

Resourceful utilization method and system for combining waste gas containing hydrogen and fuel cell clean power generation

ActiveCN108011119ASolve the problem of resource utilizationImprove resource utilizationGas treatmentDispersed particle separationAfter treatmentResource utilization

The invention belongs to the technical field of chemical exhaust gas resource utilization, and particularly relates to a resourceful utilization method and system for combining waste gas containing hydrogen and fuel cell clean power generation. The method comprises the following steps that 1, preliminary separation is conducted, wherein the concentration of CO in virgin gas is 7-50%, and is then lowered within 5%; 2, the virgin gas enters a PSA pressure swing adsorption device to be subjected to pressure swing adsorption after being subjected to buffering and liquid separation through a gas and liquid separation unit; 3, after the concentration of CO in the virgin gas is lowered to 10 ppm or below from 5% after treatment, hydrogen is obtained at the tower top; then the virgin gas of whichthe concentration of CO is smaller than or equal to 10 ppm is regarded as fuel cell virgin gas, and fuel cell power generation is conducted through a proton membrane hydrogen cell stack system. The output electric energy is in parallel use, and the generated water enters an origin water pipe network for use. The resourceful utilization method and system have high industrial economic value.

Owner:SHAANXI RES DESIGN INST OF PETROLEUM CHEM IND

Coal pyrolysis and cracking gas production combined gas power generation system

The invention provides a coal pyrolysis and cracking gas production combined gas power generation system, which comprises a pyrolysis hopper, a first feeding device, a pyrolysis and cracking reactor, a spraying tower, a gas tank and a generator set, wherein the pyrolysis and cracking reactor comprises a heat insulation brick wall and a communicating component; the internal space of the reactor is divided into a pyrolysis chamber and a cracking chamber by the heat insulation brick wall; the communicating component is arranged at the lower part of the heat insulation brick wall; the spraying tower is connected with a cracking gas outlet; the gas tank is connected with the spraying tower; the generator set is connected with the gas tank. The reactor of the power generation system is divided into the pyrolysis chamber and the cracking chamber, and oil gas generated by the pyrolysis chamber can enter the cracking chamber for deep cracking, so that the problem that produced pyrolitic oil contains dust is solved, and clean and efficient utilization of coal is really implemented. Two kinds of operation can be integrally executed in one furnace body, so that construction cost is reduced, and the occupied area is saved; a small part of pyrolysis gas is supplied to a radiator tube for combustion, and the rest gas enters the gas generator set to be combusted for power generation.

Owner:SHENWU TECH GRP CO LTD

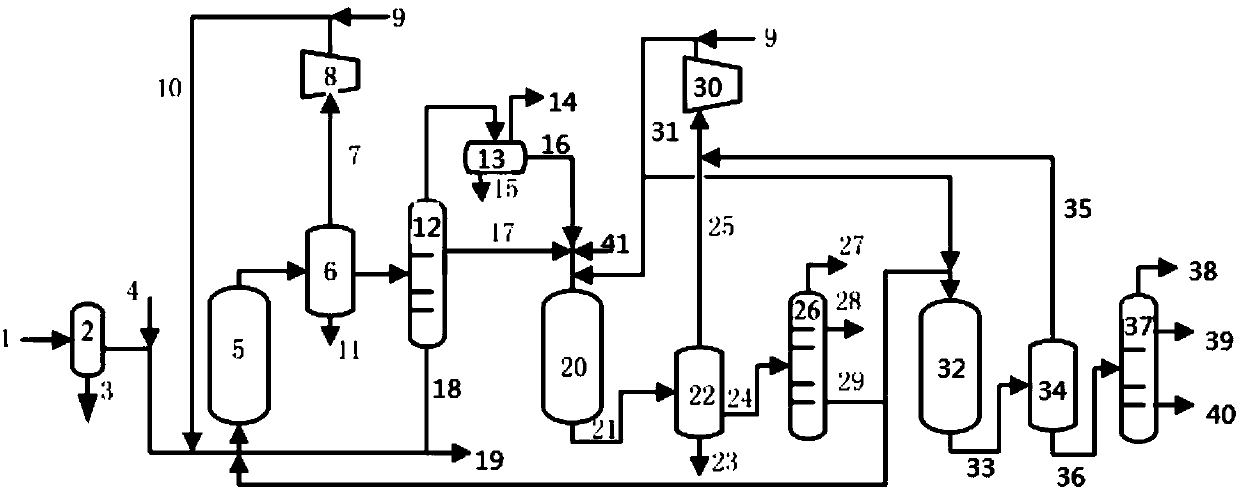

Method for producing clean diesel oil through coal tar hydrogenation, and system for method

ActiveCN107557065APrevent precipitationLarge hydrogenation depthTreatment with hydrotreatment processesFractionationSlurry

The present invention relates to the field of coal tar processing, and discloses a method for producing clean diesel oil through coal tar hydrogenation, and a system for the method. The method comprises: introducing a coal tar raw material into a pretreatment unit; introducing the obtained material into a slurry bed hydrogenation reactor; sequentially carrying out separation and fractionation on the obtained material to obtain a light distillate, a middle distillate and a heavy distillate; throwing out part of the heavy distillate; introducing an anthracene oil raw material, the middle distillate and the light distillate into a refining reactor; recycling the remaining heavy distillate back to the slurry bed hydrogenation reactor; sequentially carrying out separation and fractionation on the effluent from the refining reactor; recycling part of a first diesel oil distillate back to the slurry bed hydrogenation reactor; and introducing the remaining first diesel oil distillate into a hydrogenation modification reactor. With the method of the invention, the yield of the liquid can be maximized, the utilization ratio and the utilization value of coal tar resources are improved, and the operation cycle of the equipment is prolonged.

Owner:CHINA PETROLEUM & CHEM CORP +1

Fluidized combustion and mobile pyrolysis double-furnace compounded circulating fluidized bed

ActiveCN113583717AClean and efficient useImprove carbon conversionChemical industryGasification processes detailsCombustionSlag

The invention relates to a fluidized combustion and mobile pyrolysis double-furnace compounded circulating fluidized bed. The fluidized combustion and mobile pyrolysis double-furnace compounded circulating fluidized bed comprises a gasification furnace, a gasification agent guide pipe and a slag discharging guide pipe; a circulating gasification furnace is arranged at the upper part of the gasification furnace, and a fixed gasification furnace is arranged at the lower part of the gasification furnace; an air distribution plate is arranged at the lower part of the circulating gasification furnace, a furnace core is arranged under the air distribution plate; the upper end of the furnace core is connected with the lower end of the air distribution plate; a gasification agent channel is arranged in the furnace core, and a gasification agent penetrates through the air distribution plate and enters the circulating gasification furnace to circularly gasify feed coal; an annular channel is arranged between the outer edge of the air distribution plate and the upper furnace body; an annular space between the outer side of the furnace core and the lower furnace body is a pyrolyzing furnace chamber of fixed the gasification furnace; the upper part of the pyrolyzing furnace chamber is an annular channel, and the lower part of the pyrolyzing furnace chamber is provided with an air distribution grate; a semicoke falling from thecirculating gasification furnace enters the pyrolyzing furnace chamber, and the gasification agent enters the pyrolyzing furnace chamber through the air distribution grate to re-gasify the fallen semicoke; and generated high-temperature coal gas enters the upper furnace chamber through the annular channel, and gasified slag is discharged through the slag discharging guide pipe. The circulating fluidized bed is high in carbon conversion rate, energy-saving and environment-friendly.

Owner:ZHONGKEJUXIN CLEAN ENERGY &HOT FORGING EQUIP RES & DEV CO LTD +1

Biomass pyrolysis and cracking system

The invention belongs to the technical field of biomass pyrolysis and mainly provides a biomass pyrolysis and cracking system based on regenerative radiant tube heating. The system comprises the following parts: a pyrolysis hopper, a first feeding device, a pyrolysis and cracking reactor, a cracked gas cyclone separator, a spray tower and a gas tank, wherein the pyrolysis and cracking reactor comprises a feeding hole, a pyrolysis chamber, a cracking chamber, a cracked gas outlet, regenerative radiant tubes, a heat insulating brick wall and a communicating component. The system has the beneficial effects that the reaction system has a simple structure, is convenient to operate, is uniform in temperature distribution and has good heating effects; the oil gas generated in the pyrolysis chamber can undergo deep cracking in the cracking chamber to crack macromolecular tar molecules into micromolecular gaseous hydrocarbon; the reaction system can generate plenty of cracked gas products, thus avoiding the problem that the pyrolysis oil contains dust and truly achieving clean and efficient utilization of fossil fuel.

Owner:SHENWU TECH GRP CO LTD

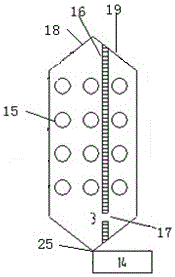

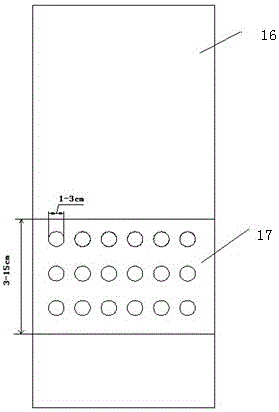

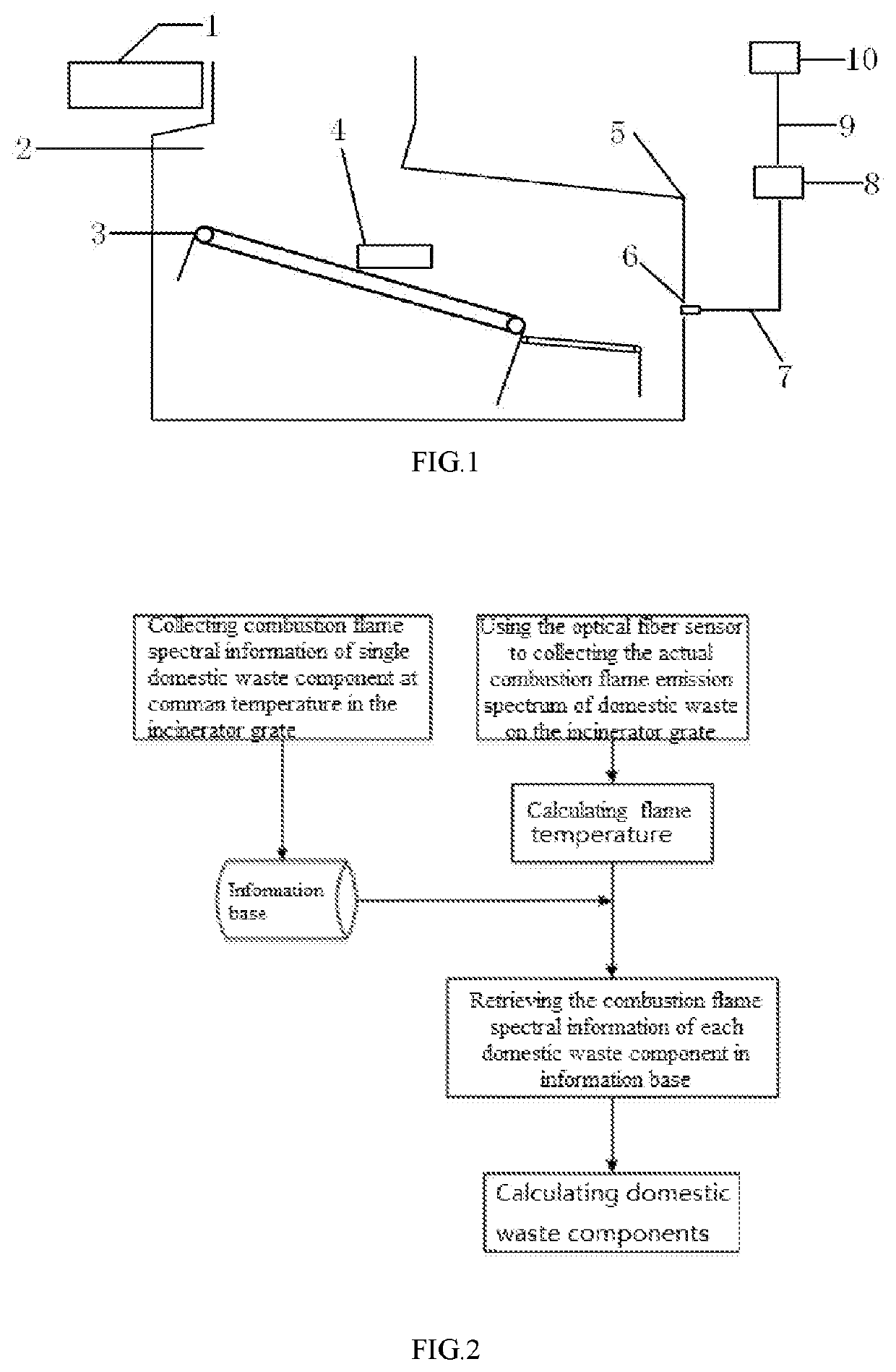

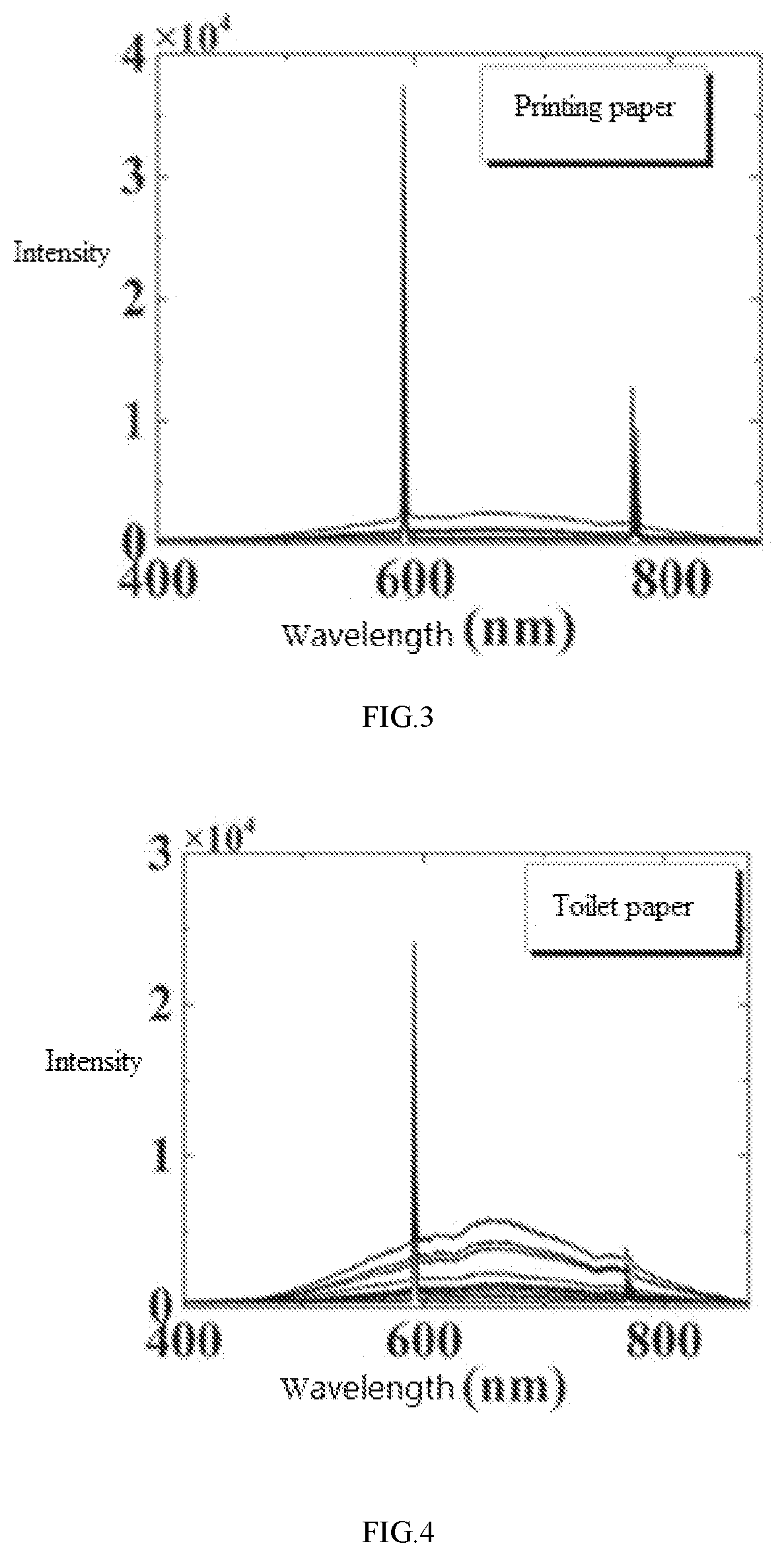

A real-time detection device and method for domestic waste components in an incinerator

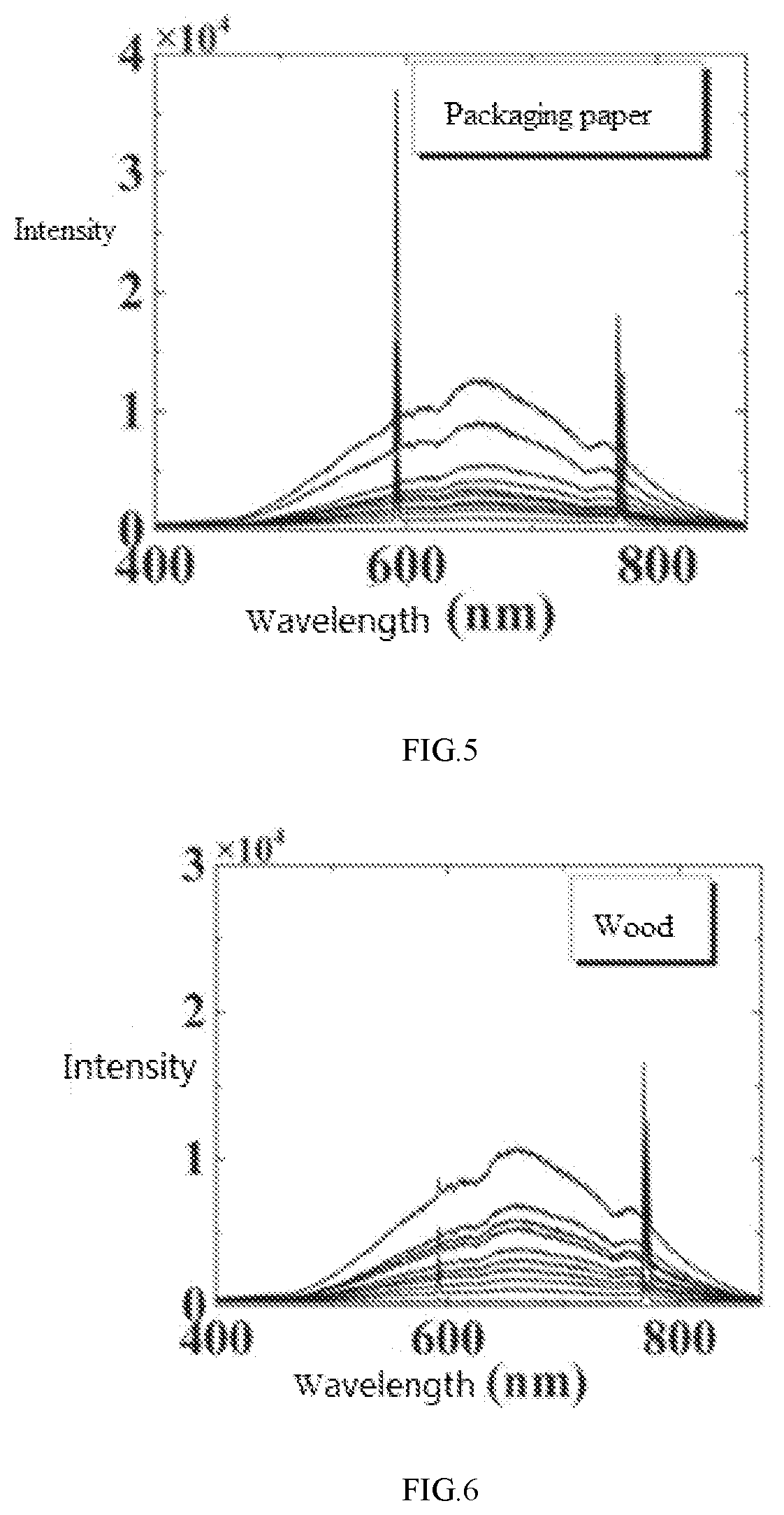

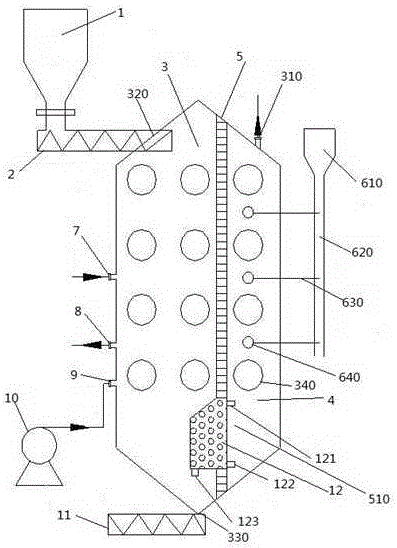

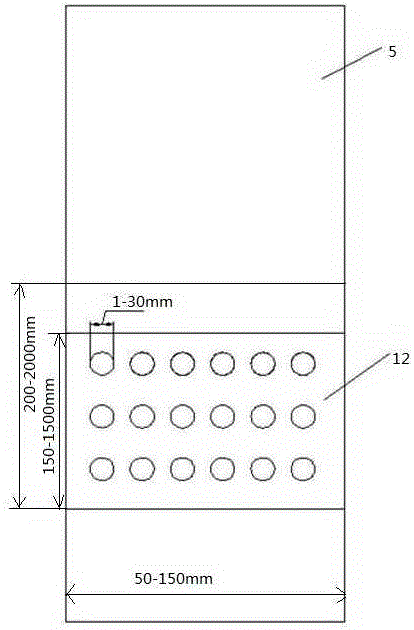

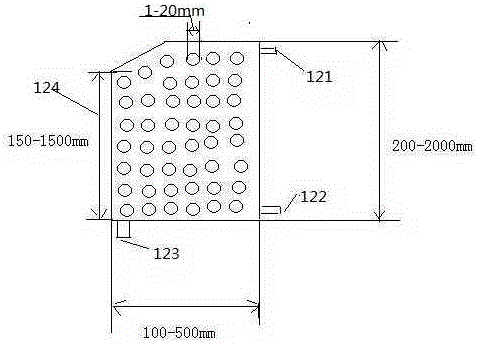

ActiveUS20200240920A1The test result is accurateProcess safetyRadiation pyrometryAnalysis by thermal excitationOptical spectrometerPollutant emissions

The present invention relates to a real-time detection device for municipal solid waste components in an incinerator. The real-time detection device includes: an optical fiber sensor, which faces combustion flame of municipal solid waste combustion region through an observation hole in the incinerator; a spectrometer, which is used for receiving optical signal of the optical fiber sensor; an industrial personal computer, which is used for receiving data of the spectrometer and outputting the municipal solid waste components according to a municipal solid waste component detection program; the municipal solid waste component detection program obtains combustion flame spectral information of municipal solid waste in the incinerator by utilizing the optical fiber sensor and the spectrometer, and detects the municipal solid waste components in real time based on combustion flame spectrum of a single waste component. The present invention further relates to a real-time detection method for municipal solid waste components in an incinerator. Compared with manual classified sampling and detection, the device and method provided by the present invention have the advantages of high efficiency, rapidness, accuracy, capability of being updated in real time; and can realize stable combustion of the municipal solid waste in the incinerator, and reduce emission of pollutants and realize efficient and clean utilization of the municipal solid waste.

Owner:ZHEJIANG UNIV

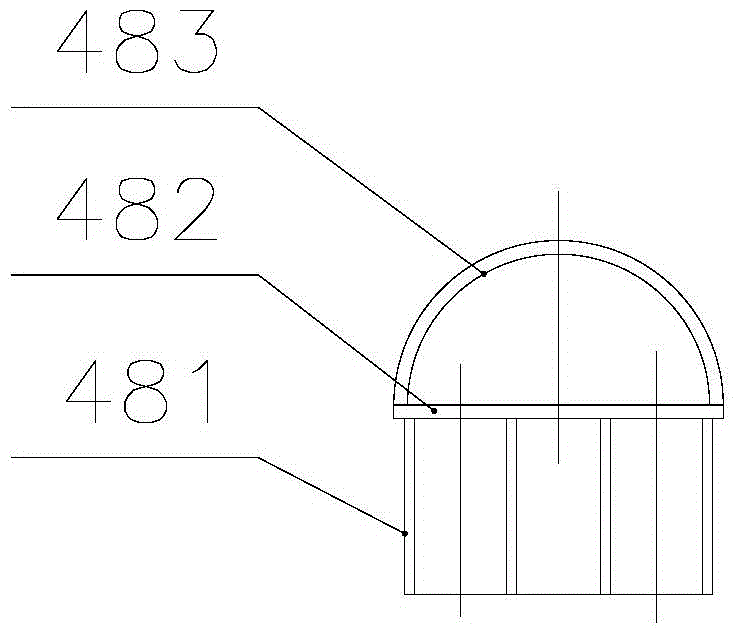

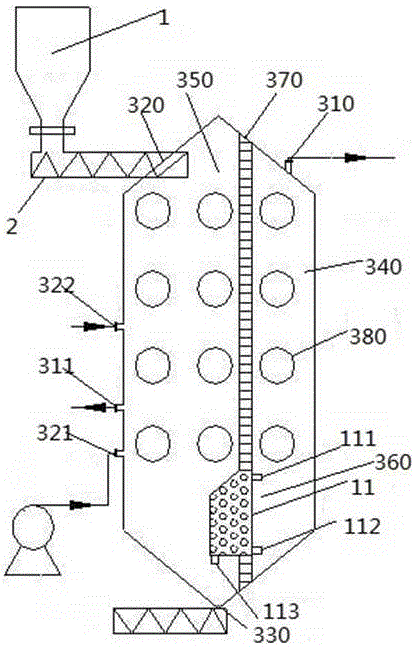

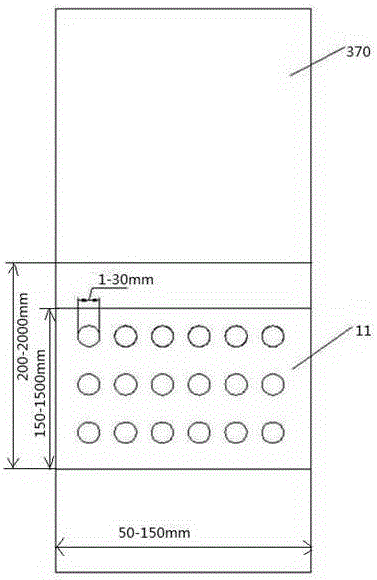

Self-dust-removal type pyrolysis and catalytic cracking reactor

ActiveCN105885898AHigh yieldSave floor space and construction costsSpecial form destructive distillationTarFossil fuel

The invention belongs to the technical field of pyrolysis and cracking of fossil fuel and in particular relates to a self-dust-removal type pyrolysis and catalytic cracking reactor which is mainly specific to resources such as oil shale and coal and used for preparing flammable gas and semicoke products. The invention, aiming at overcoming the defects of the prior art, designs and develops a self-dust-removal-type pyrolysis and catalytic cracking reactor. In the reactor, a pyrolysis chamber and a cracking chamber are designed in an integrated manner, oil gas produced in the pyrolysis chamber enters a particle bed dust removal device, after dust removal is carried out by the particle bed dust removal device, clean oil gas enters the cracking chamber to be deeply cracked, rear-end dust removal pressure is reduced, macromolecular tar molecular is cracked into micromolecular gaseous hydrocarbon, and a large amount of hydrogen is produced in a catalytic cracking manner, so that the problem that pyrolyzed oil contains dust is avoided and clean and efficient utilization of the fossil fuel is really realized.

Owner:SHENWU TECH GRP CO LTD

Direct heating type coal pyrolysis device

InactiveCN105255507AEasy to controlClean and efficient useDirect heating destructive distillationIndirect and direct heating destructive distillationProduct gasEngineering

The invention discloses a coal pyrolysis device and particularly provides a direct heating type coal pyrolysis device. The direct heating type coal pyrolysis device comprises a bottom inlet, a lower-portion fluidization section, an upper-portion outlet, an upper-portion inlet, a feeding port and a pressure-bearing housing and further comprises a central pipe and an upper-portion temperature regulating section, wherein the upper-portion temperature regulating section is located above the lower-portion fluidization section, the upper-portion inlet is communicated with the upper section of the upper-portion temperature regulating section, the central pipe is located in the cavity defined by the upper-portion temperature regulating section and the lower-portion fluidization section, the upper port of the central pipe is communicated with the upper-portion outlet, and the lower port of the central pipe is located in the lower-portion fluidization section. By arranging the upper-portion temperature regulating section and the central pipe and adopting an indirect heat exchange principle, different products are produced by controlling different temperatures, secondary reaction of pyrolysis products is prevented, and improvement of the methane concentration of product gas is facilitated.

Owner:CHANGZHENG ENG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com