High-concentration organic wastewater and organic solid waste treatment process and high-concentration organic wastewater and organic solid waste treatment system

A technology for organic waste water and organic solid waste, applied in the high-concentration organic waste water and organic solid waste treatment system, high-concentration organic waste water and organic solid waste treatment process field, can solve the problems of safety, slow speed, expensive oxygen production equipment and so on , to achieve the effect of improving high value, reducing energy loss, and good gas production effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

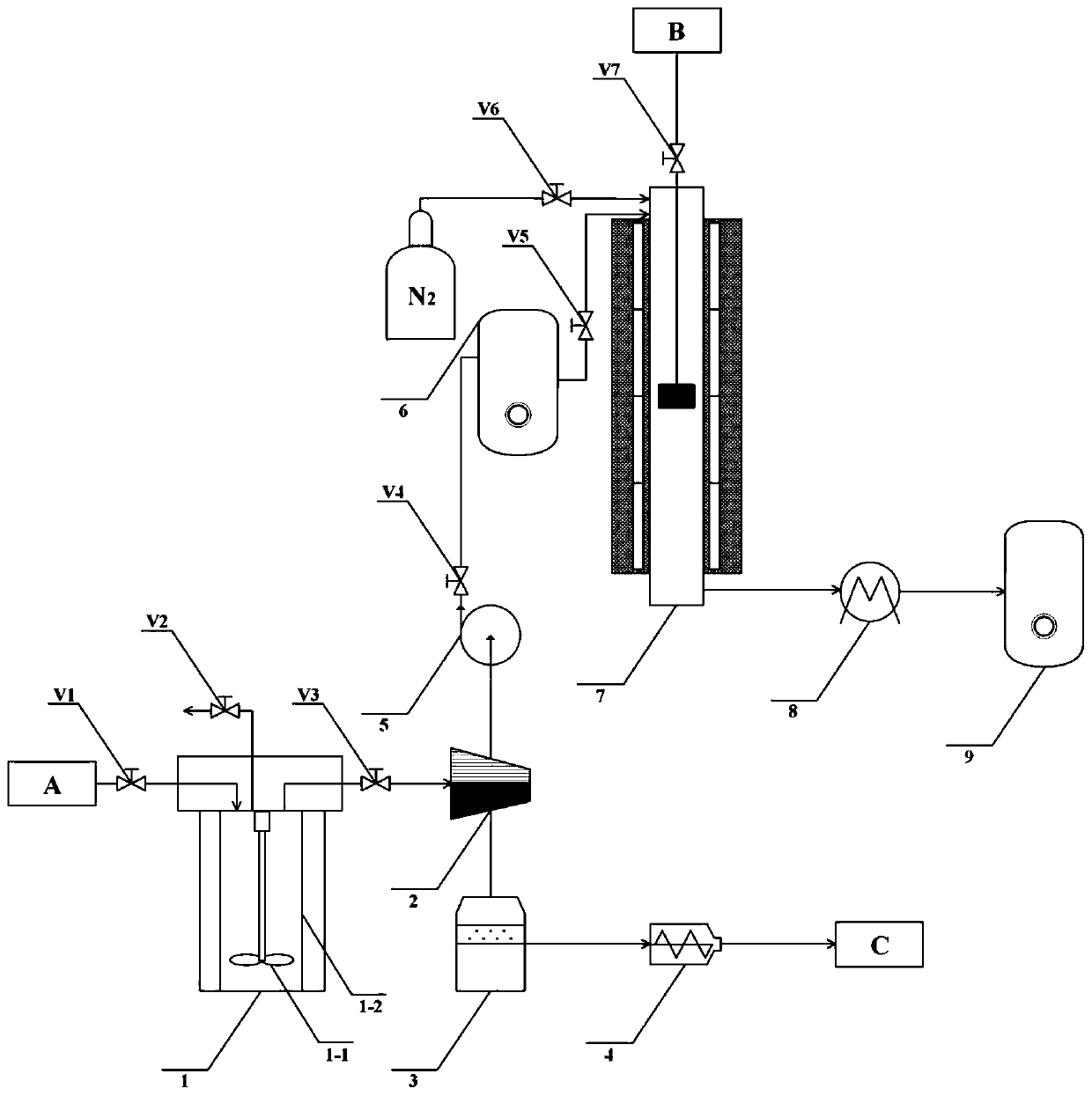

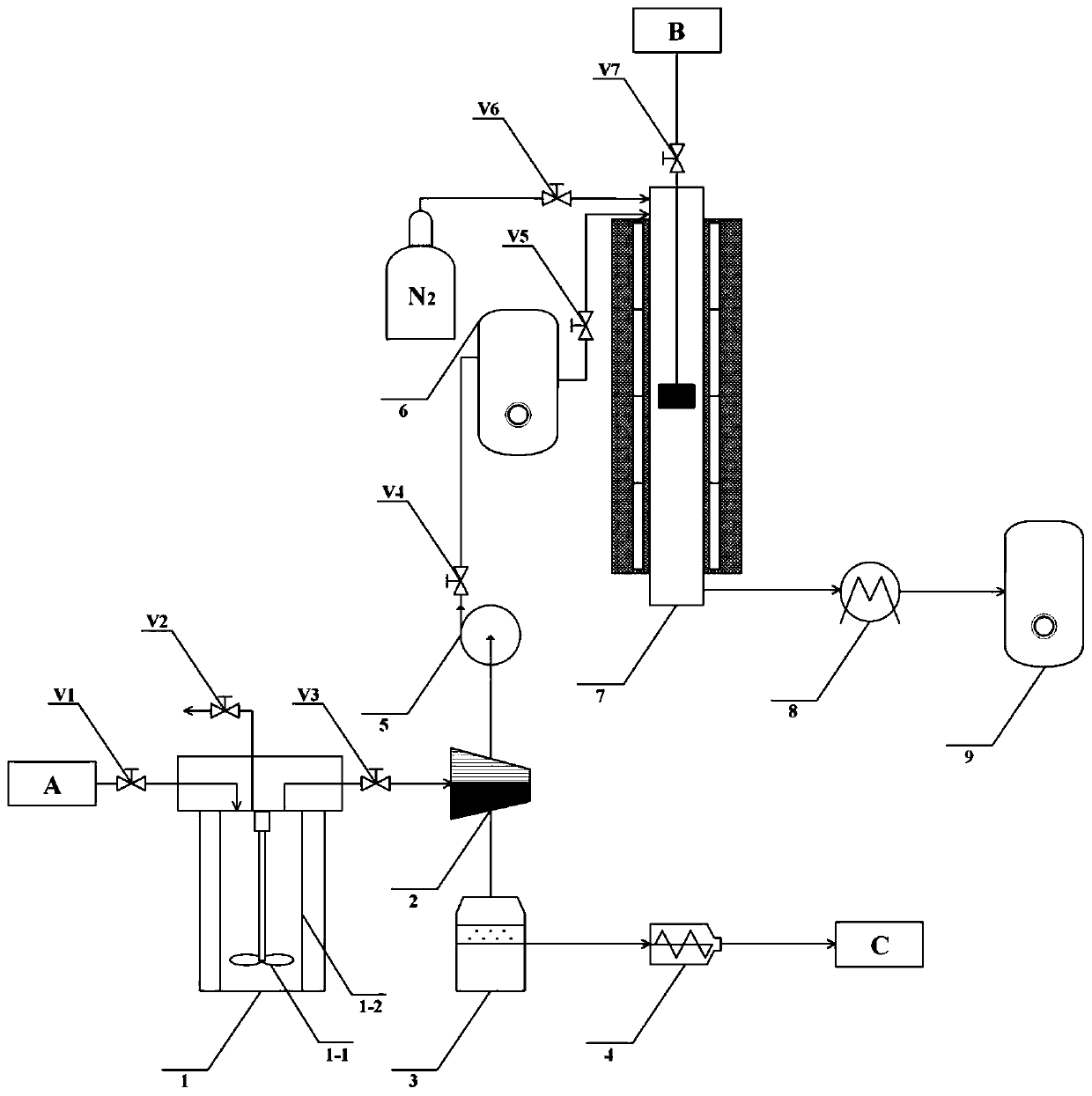

[0025] Such as figure 1 As shown, the high-concentration organic wastewater and organic solid waste treatment system is composed of a high-pressure hydrothermal reactor 1, a solid-liquid separator 2, and a gasification reactor 7; wherein the high-pressure hydrothermal reactor 1 is equipped with a pressure vessel 1-2 , there is a stirring paddle 1-1 in the pressure vessel 1-2, the top is provided with an air outlet connected to the second valve V2, one side of the top of the pressure vessel 1-2 is connected to the first storage tank A through the first valve V1, and the other The side is connected to the input end of the middle part of the solid-liquid separator 2 through the third valve V3; the solid-liquid separator 2 bottom outlet is connected to the dryer 3 and then connected to the compression molding machine 4, and the top liquid outlet is sequentially passed through the air circulation pump 5, The fourth valve V4 is connected to one side of the liquid storage tank 6, the...

Embodiment 2

[0036] High-concentration organic waste water and organic solid waste treatment system are the same as embodiment 1;

[0037] The basic steps for the treatment of high-concentration organic wastewater and high-water organic solid waste are as follows:

[0038] Step 1. Grinding high-water organic solid waste, preparing high-concentration organic waste water, putting it into the first storage tank as a raw material, opening the first valve V1, adding the raw material into the pressure vessel 1-2 of the hydrothermal reaction kettle 1, and determining the high The mass ratio of aqueous organic solid waste to high-concentration organic wastewater is 1:15.

[0039] Organic solid waste with high water content can be selected as: duckweed, which is taken from a lake in Nanjing City, with a water content of 87%.

[0040] High-concentration organic wastewater can be selected as: domestic wastewater after concentrated treatment, which is taken from a sewage treatment plant in Nanjing, w...

Embodiment 3

[0047] High-concentration organic waste water and organic solid waste treatment system are the same as embodiment 1;

[0048] The basic steps for the treatment of high-concentration organic wastewater and high-water organic solid waste are as follows:

[0049] Step 1. Grinding high-water organic solid waste, preparing high-concentration organic waste water, putting it into the first storage tank as a raw material, opening the first valve V1, adding the raw material into the pressure vessel 1-2 of the hydrothermal reaction kettle 1, and determining the high The mass ratio of aqueous organic solid waste to high-concentration organic wastewater is 1:15.

[0050] The organic solid waste with high water content can be selected as: black algae, which is taken from a lake in Nanjing City, with a water content of 89%.

[0051] High-concentration organic wastewater can be selected as: domestic wastewater after concentrated treatment, which is taken from a sewage treatment plant in Nan...

PUM

| Property | Measurement | Unit |

|---|---|---|

| heating value | aaaaa | aaaaa |

| heating value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com