Compressed air energy storage system and method utilizing cold energy of liquefied natural gas

A compressed air energy storage and liquefied natural gas technology, which is applied in the direction of liquid variable capacity machinery, steam engine equipment, mechanical equipment, etc., can solve the problems of long-distance transmission that cannot recover energy, low efficiency of cold energy recovery, energy waste, etc., and achieve clean Efficient utilization, improved recycling efficiency, and environmentally friendly effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

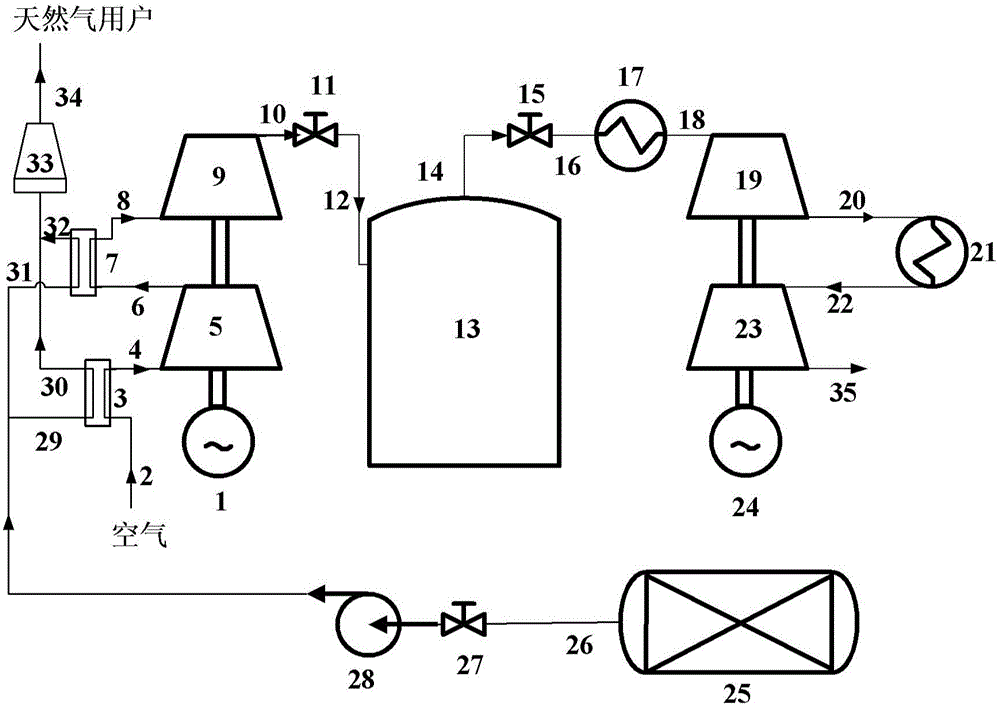

[0054] figure 1 Shown is Embodiment 1 of the compressed air energy storage system using LNG cold energy of the present invention, which adopts two-stage compression, inter-stage cooling and two-stage expansion, and inter-stage heating. figure 1 The reference signs in have the following meanings:

[0055] Motor 1, low-pressure compressor 5, high-pressure compressor 9, high-pressure expander 19, low-pressure expander 23, heat exchanger 3, 7, 17, 21, valve 11, 15, 27, pipeline 2, 4, 6, 8, 10, 12, 14, 16, 18, 20, 22, 26, 29, 30, 31, 32, 34, 35, gas storage device 13, generator 24, LNG pump 28, LNG storage device 25, vaporizer 33 , air and LNG.

[0056] The electric motor 1 is connected with the common transmission shaft of the compressor unit, and the generator 24 is connected with the common transmission shaft of the expansion unit. The low-pressure compressor 5 communicates with the atmosphere through the pipelines 2 and 4 and the heat exchanger 3; the low-pressure compressor...

Embodiment 2

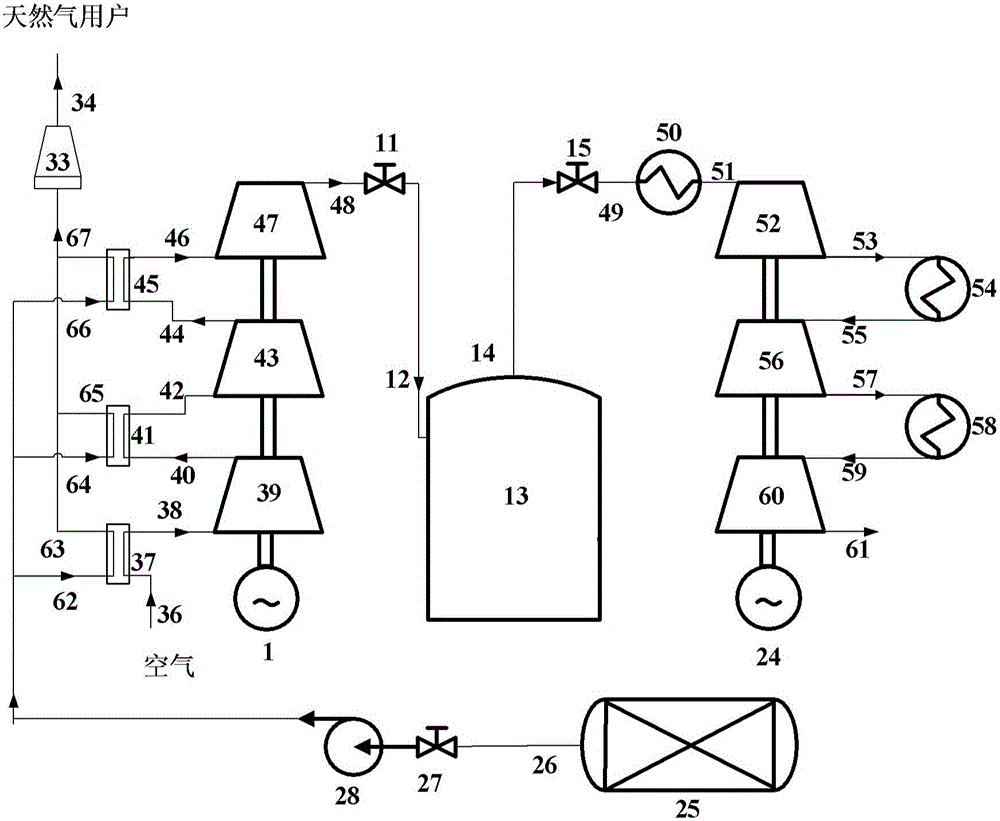

[0060] figure 2 Shown is Embodiment 2 of the compressed air energy storage system using LNG cold energy of the present invention, its main structure is the same as Embodiment 1, but it uses three-stage compression, inter-stage cooling, three-stage expansion, and inter-stage heating to replace the embodiment 1 in two-stage compression, interstage cooling and two-stage expansion, interstage heating. in, figure 2 The reference signs in have the following meanings:

[0061] Motor 1, low-pressure compressor 39, medium-pressure compressor 43, high-pressure compressor 47, high-pressure expander 52, medium-pressure expander 56, low-pressure expander 60, heat exchangers 37, 41, 45, 50, 54, 58, Gas storage device 13, pipelines 36, 38, 40, 42, 44, 46, 48, 12, 14, 49, 51, 53, 55, 57, 59, 61, 26, 62, 63, 64, 65, 66, 67, 34, generator 24, valves 11, 15, 27, LNG pump 28, LNG storage device 25, vaporizer 33, air and LNG.

[0062] The connection of each component is basically the same as...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com