Safe and efficient system and safe and efficient method for preparing powdered coal

A coal powder preparation and high-efficiency technology, applied in grain processing, etc., can solve problems such as heat loss and environmental pollution, and achieve the effects of reducing wear, simplifying process flow, and reducing processing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

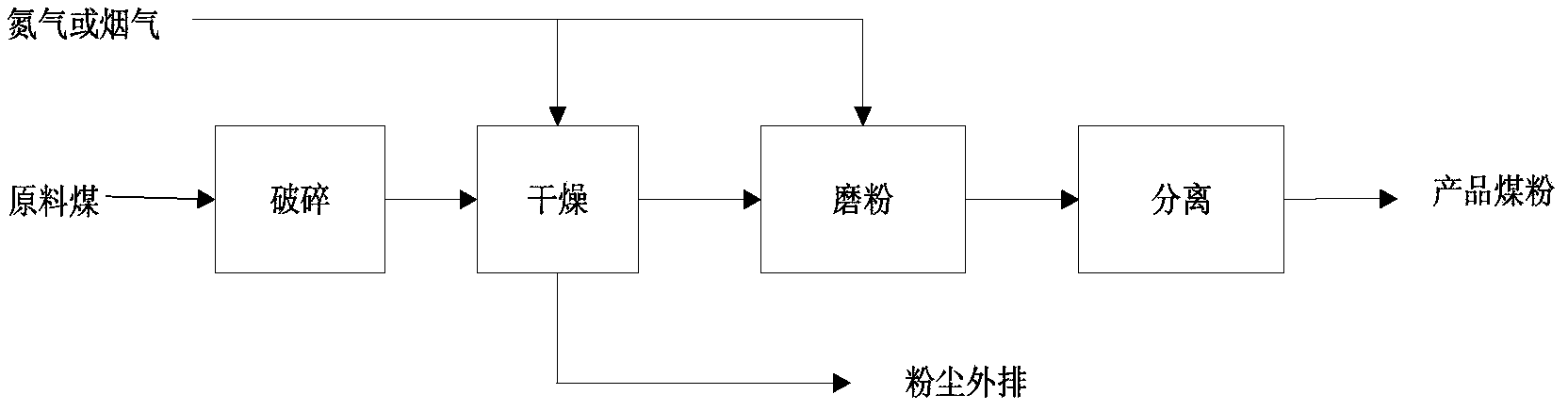

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

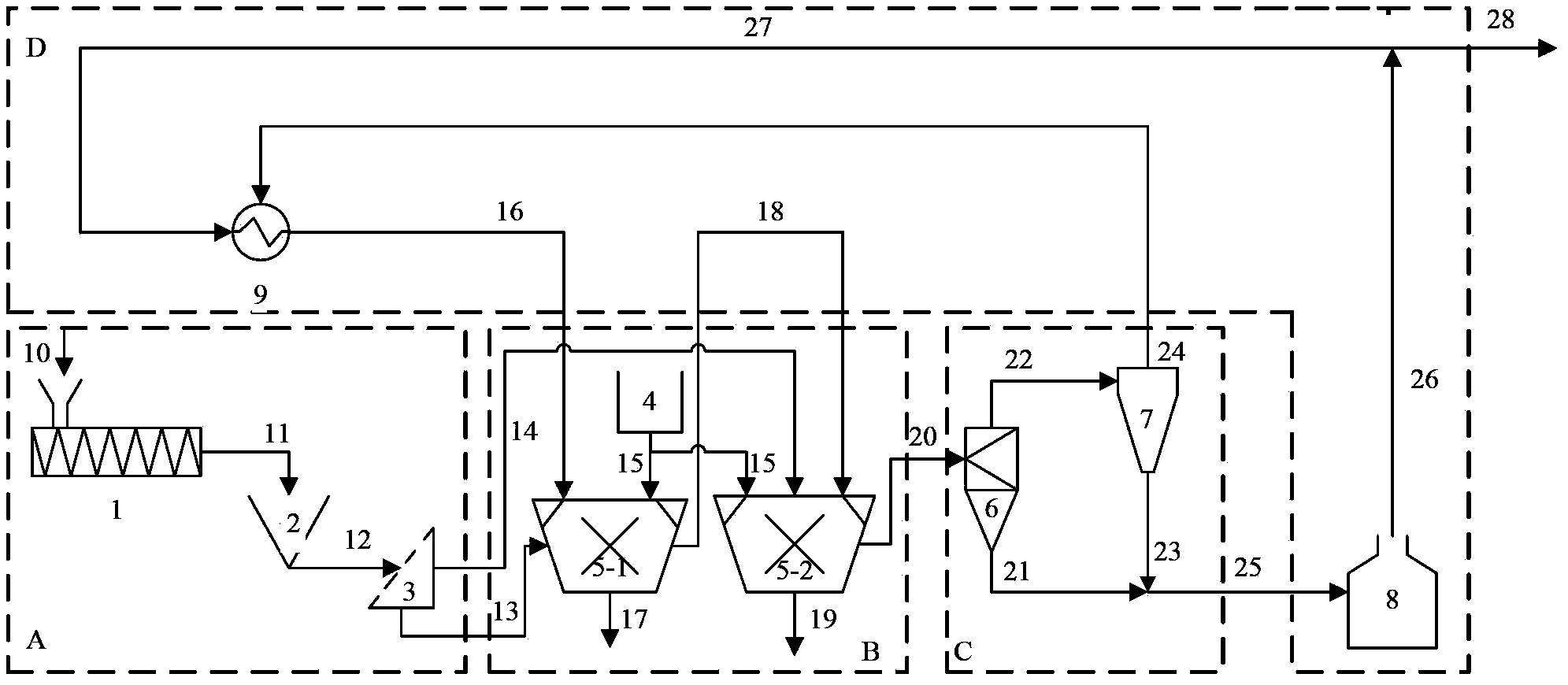

[0029] The present invention is described in detail below in conjunction with accompanying drawing:

[0030] Such as figure 1 As shown, the present invention includes 4 systems, A is a coal preparation system, B is a coal grinding system, C is a separation system, and D is a superheated steam generation system. Coal preparation system A includes feeder 1, crusher 2 and separator 3; coal grinding system B includes additive adding device 4, coarse coal mill 5-1 and fine coal mill 5-2; separation System C includes cyclone separator 6 and bag filter 7 ; superheated steam generation system D includes coal-fired boiler 8 and heater 9 .

[0031] In coal preparation system A, the outlet of feeder 1 is connected to the inlet of crusher 2, and the outlet of crusher 2 is connected to the inlet of separator 3. The outlets of the additive adding device 4 in the coal grinding system B are respectively connected to the additive inlets of the coarse coal mill 5-1 and the fine coal mill 5-2,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com