Microwave pretreatment desulfurization coking method and device

A pretreatment device and pretreatment technology, applied in coking ovens, charging devices, petroleum industry, etc., to achieve the effects of increasing bulk density, ensuring residence time, and reducing processing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Embodiment 1: the coking method includes method and device;

[0022] A microwave pretreatment coking method, including a coal blending process, a coal charging process, and a coking process, and also includes a microwave pretreatment process added between the coal blending process and the coal charging process, and the microwave pretreatment process adopts a microwave pretreatment device, The microwave frequency is 300MHz~300GHz, and the coal blending is irradiated, dehydrated, and desulfurized. The temperature of the pretreated coal sample is controlled at 150°C~250°C, and it is ready to be loaded into the furnace and enter the coking process.

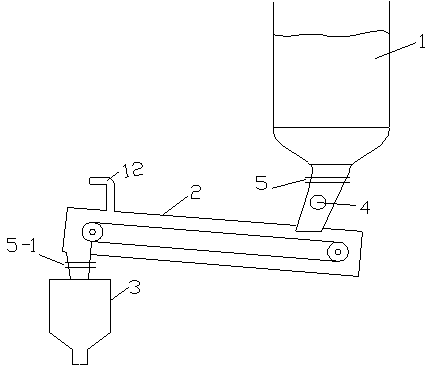

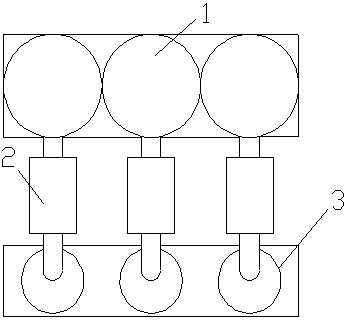

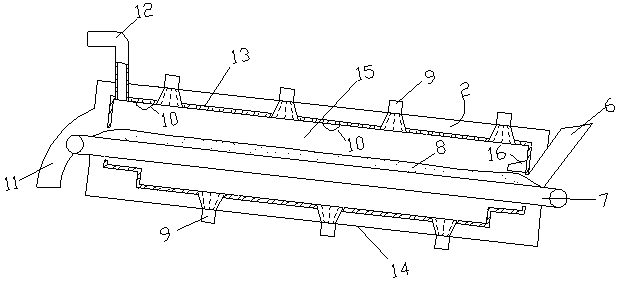

[0023] The device for realizing the coking method includes: coal tower 1, microwave pretreatment device 2, coal loading car or silo 3, feeder 4, flow regulating valve 5, feeding hopper 6, conveyor 7, microwave waveguide 9, temperature detection Device 10, hopper 11, exhaust pipe 12, microwave reaction chamber wall 13, shell 14,...

Embodiment 2

[0034] Embodiment 2: The difference between this embodiment and the first embodiment is that the size of the conveyor 7 can be adjusted according to production needs. The microwave pretreatment device 2 can be used as a module in a single group or in multiple groups, and is connected with the coal tower 1 and the coal loading car or the silo 3 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com