Patents

Literature

43results about How to "Shorten coking time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

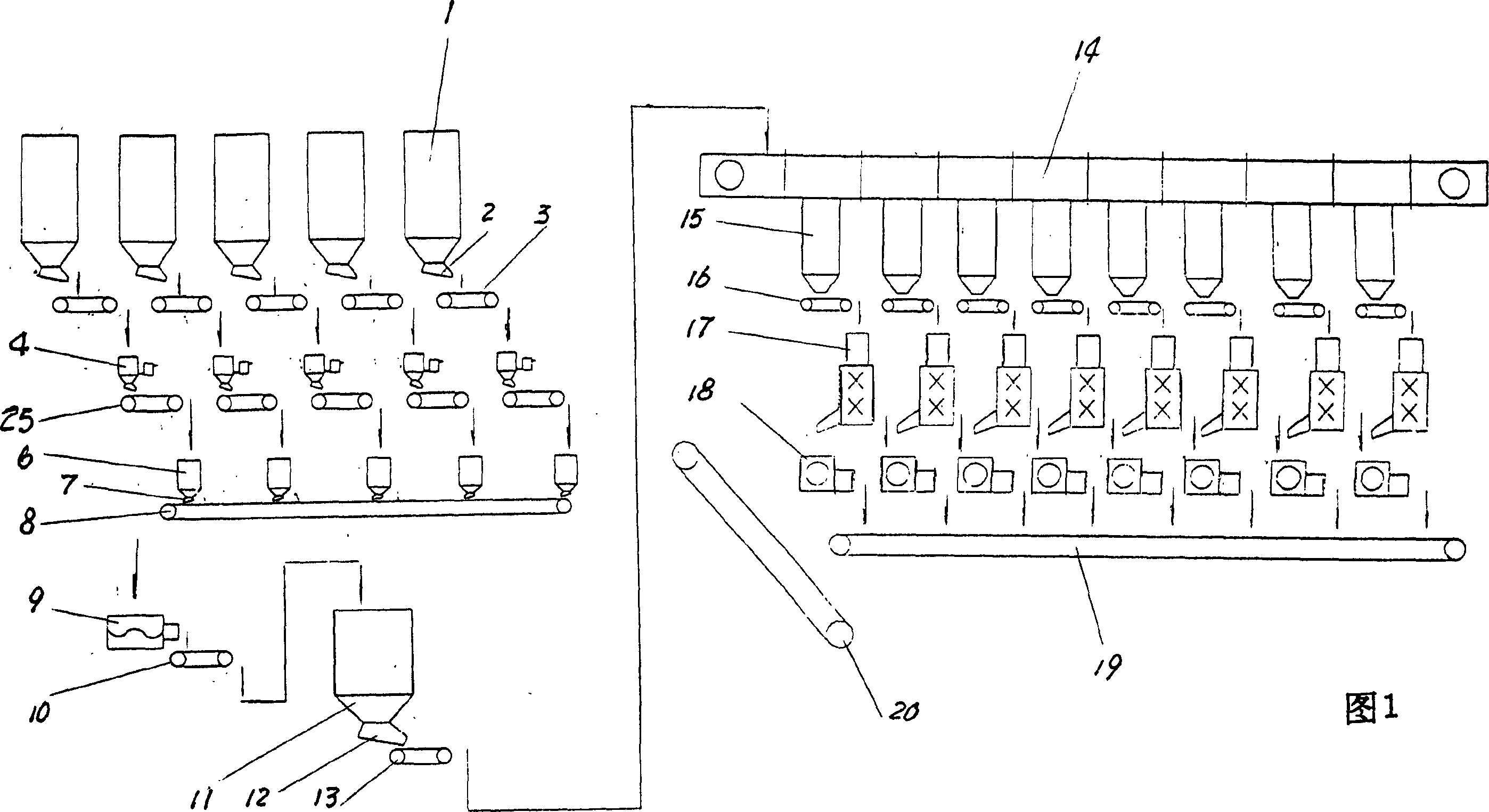

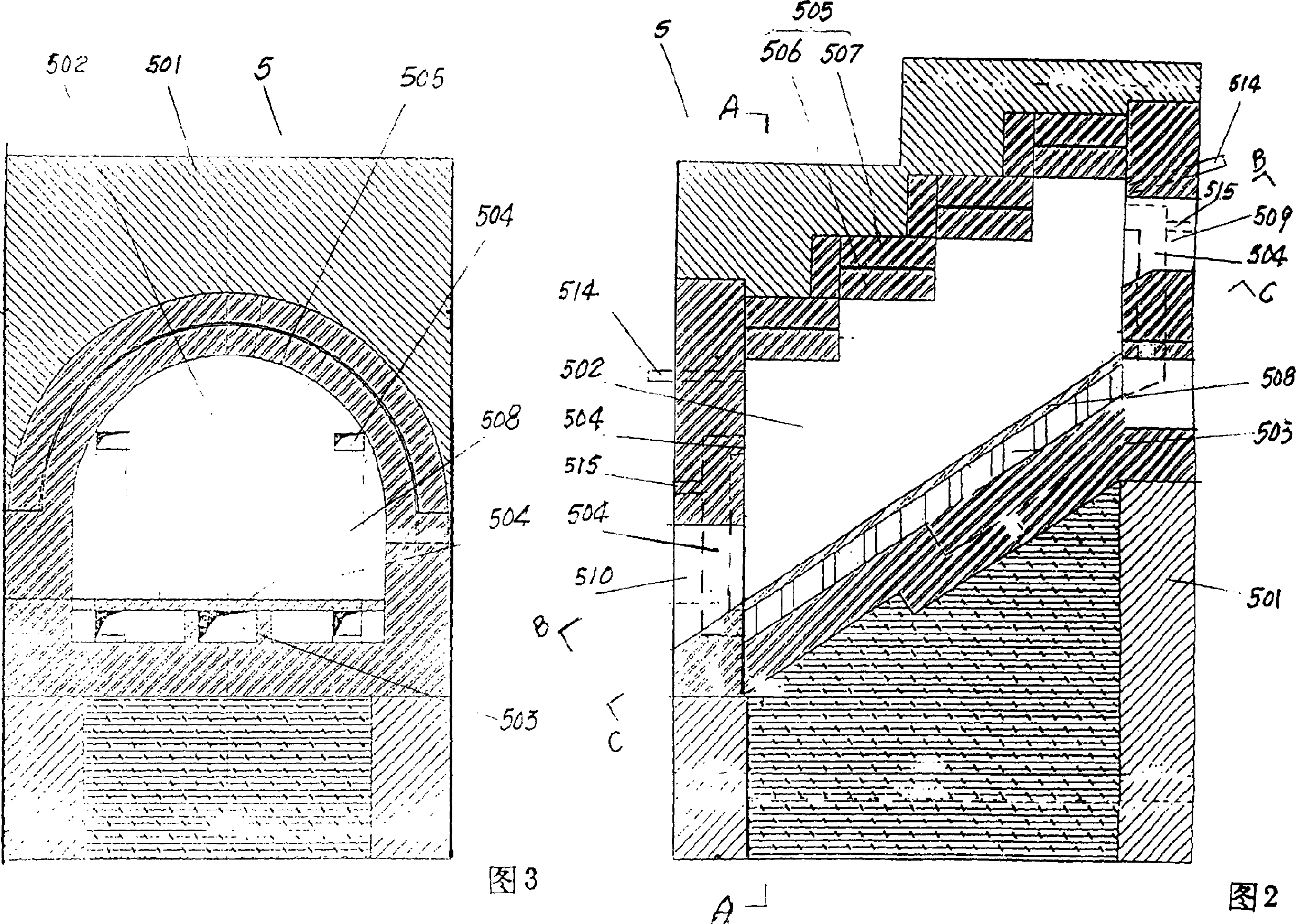

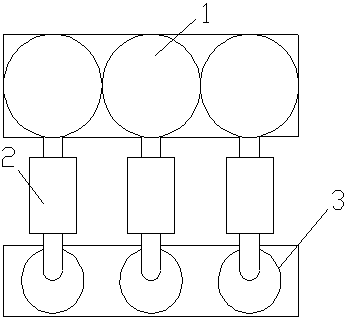

Casting type coke production method and apparatus system used thereof

The present invention relates to a production method of foundry shaped coke and its equipment system for producing said foundry shaped coke. Said method includes the procedures of preparing material,pulverizing, cold stirring, hot stirring, forming and carbonization and coking, and its equipment system includes material-preparing chamber, pulverizing machine, cold stirring machine, hot stirring machine, forming machine and carbonizing furnace, etc.

Owner:商丘市普天工贸有限公司煤化工研究所

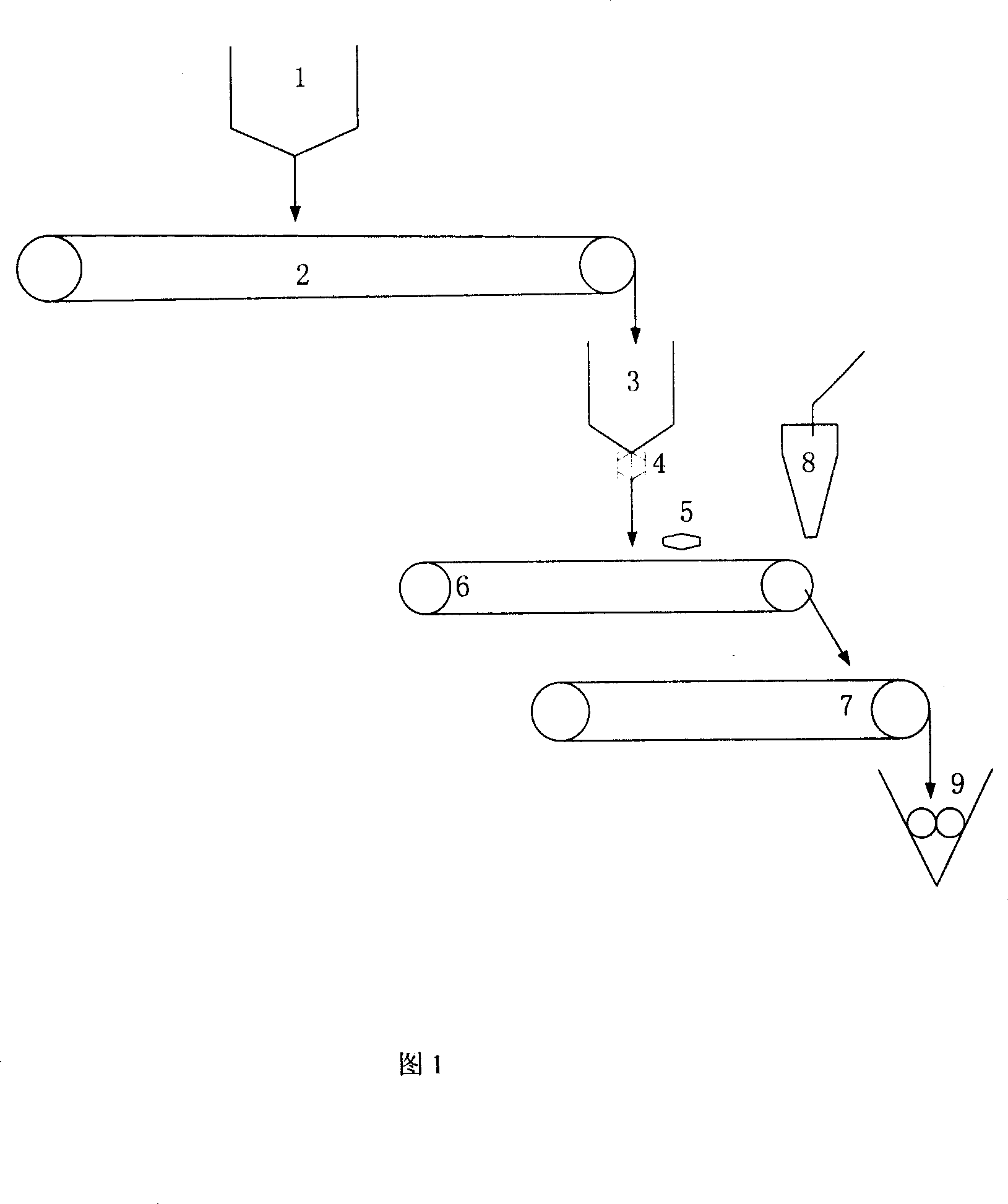

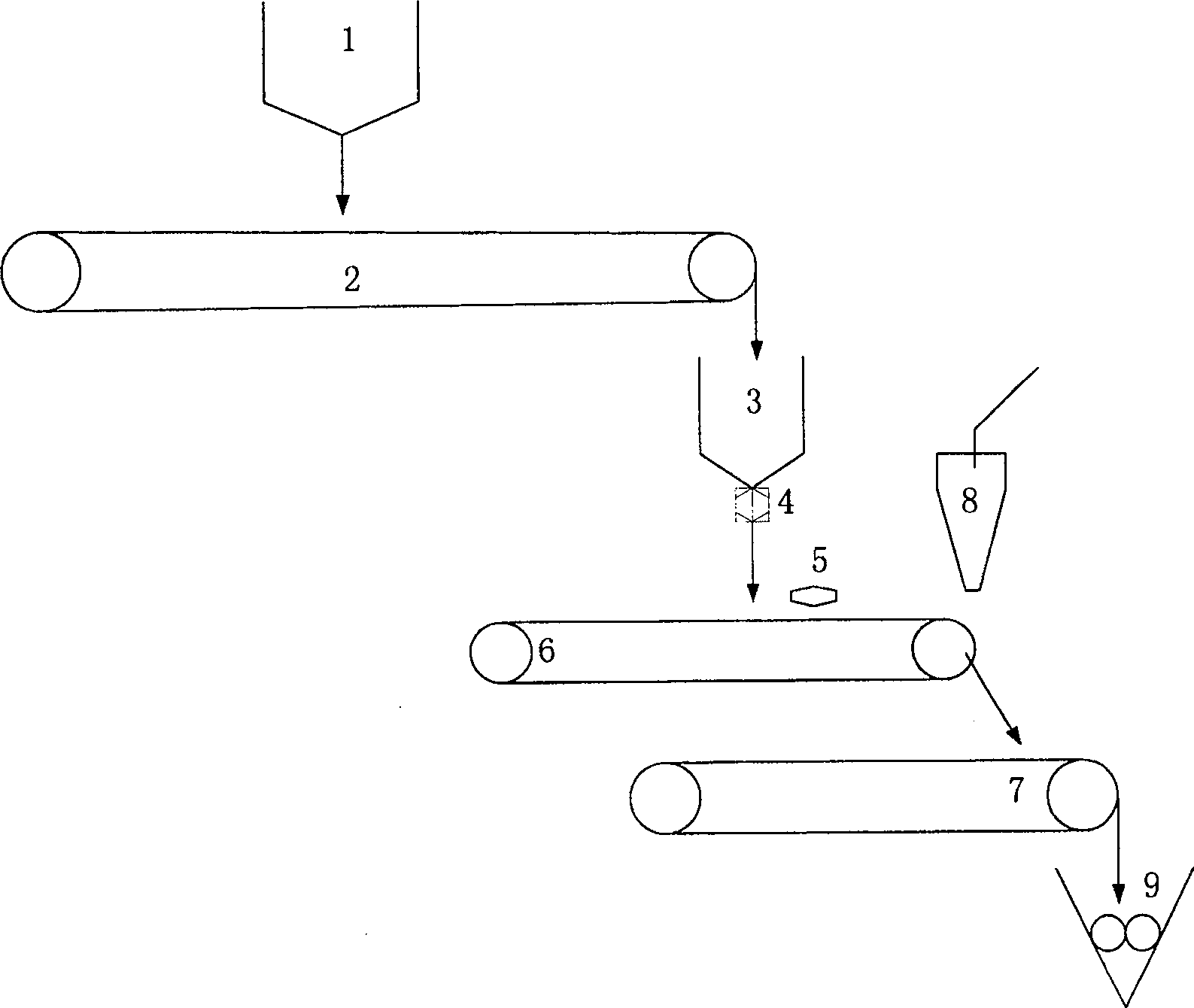

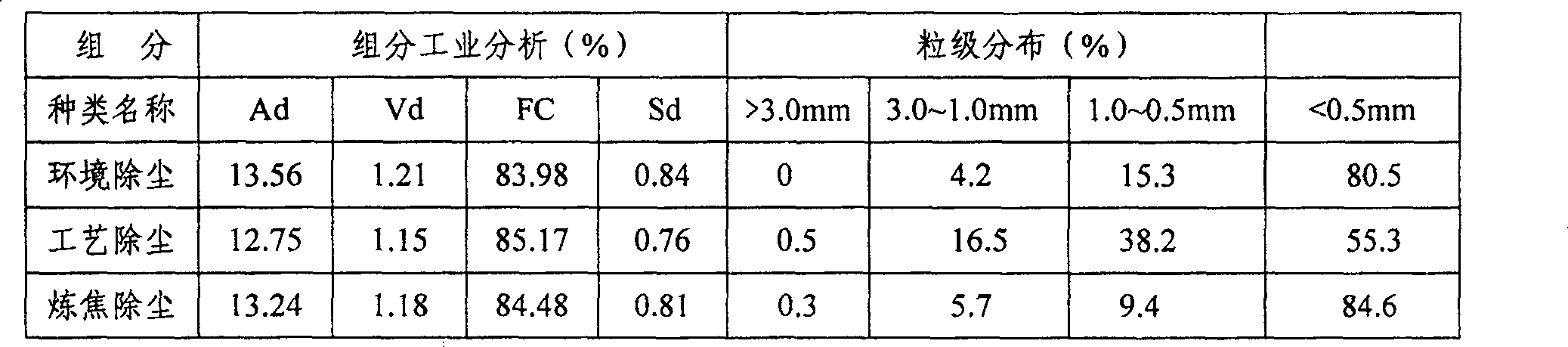

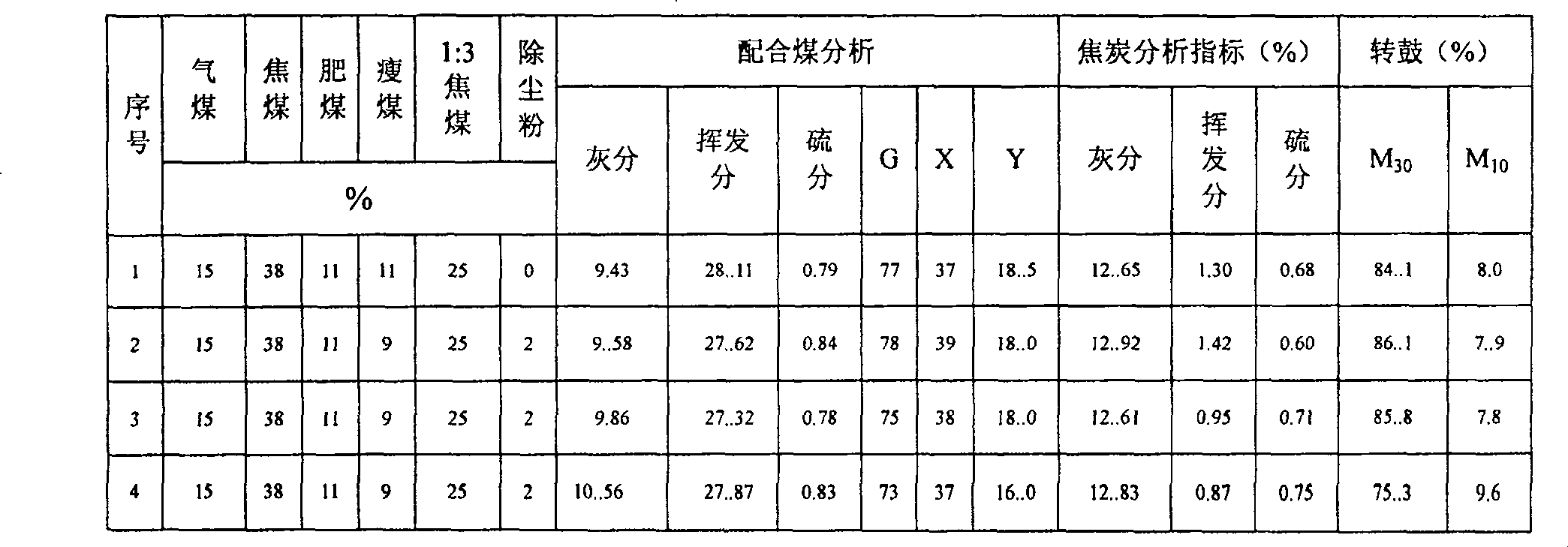

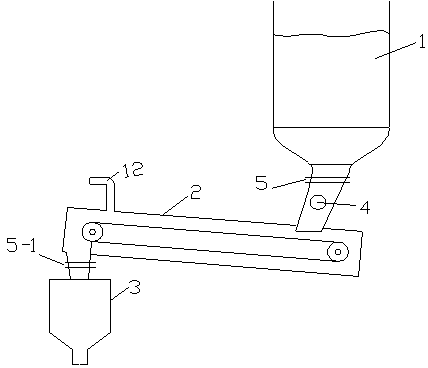

Dust settling fine coke reblending coal coking method and its technology

This invention discloses a coal blending method and its technology of dust removal coking coal powder using as lean agent to substitute clean coal. It collects coke dry quenching environmental dust removal coking coal powder, coke dry quenching technological dust removal coking coal powder, coking ground dust moving station dust removal powder, mixing them homogeneously, and then putting them into stockhouse, and then transporting into dosage bunker by leather belt transport machine, and then transporting to leather belt transport machine equipped with electronic scale by dosage plate, and then quantitively transporting to leather belt transport machine equipped with dust fall equipment, and at last, sending into crusher together with other coal for coking and mixing them homogeneously in blending coal room for coking at coking chamber of coke oven.

Owner:WUHAN IRON & STEEL GRP ECHENG IRON & STEEL CO LTD

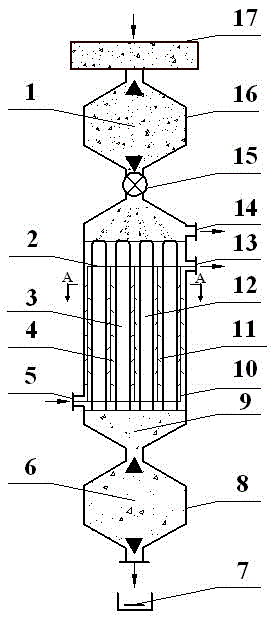

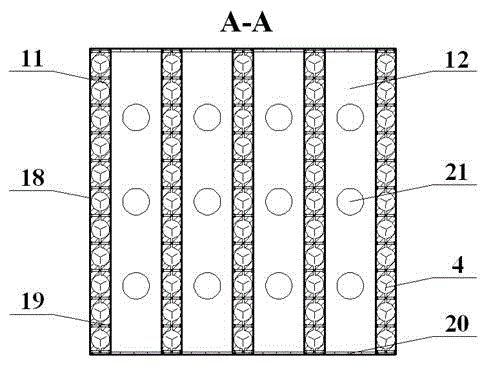

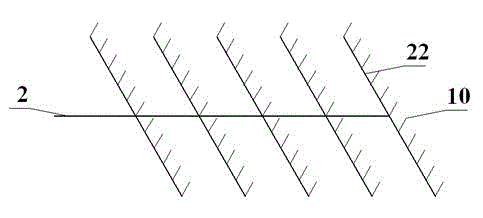

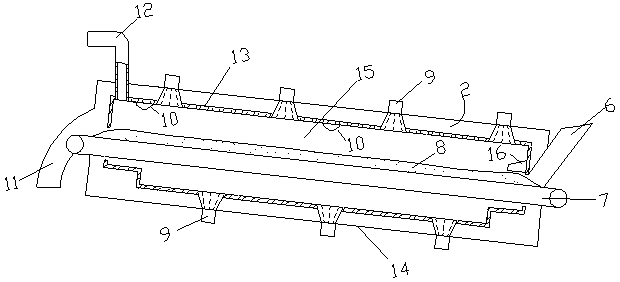

Coal thermolysis device for heat-carrying gas

InactiveCN102911677AHigh thermal conductivityLarge heat transfer temperature differenceHydrocarbon from carbon oxidesGaseous fuelsHeat transmissionProcess engineering

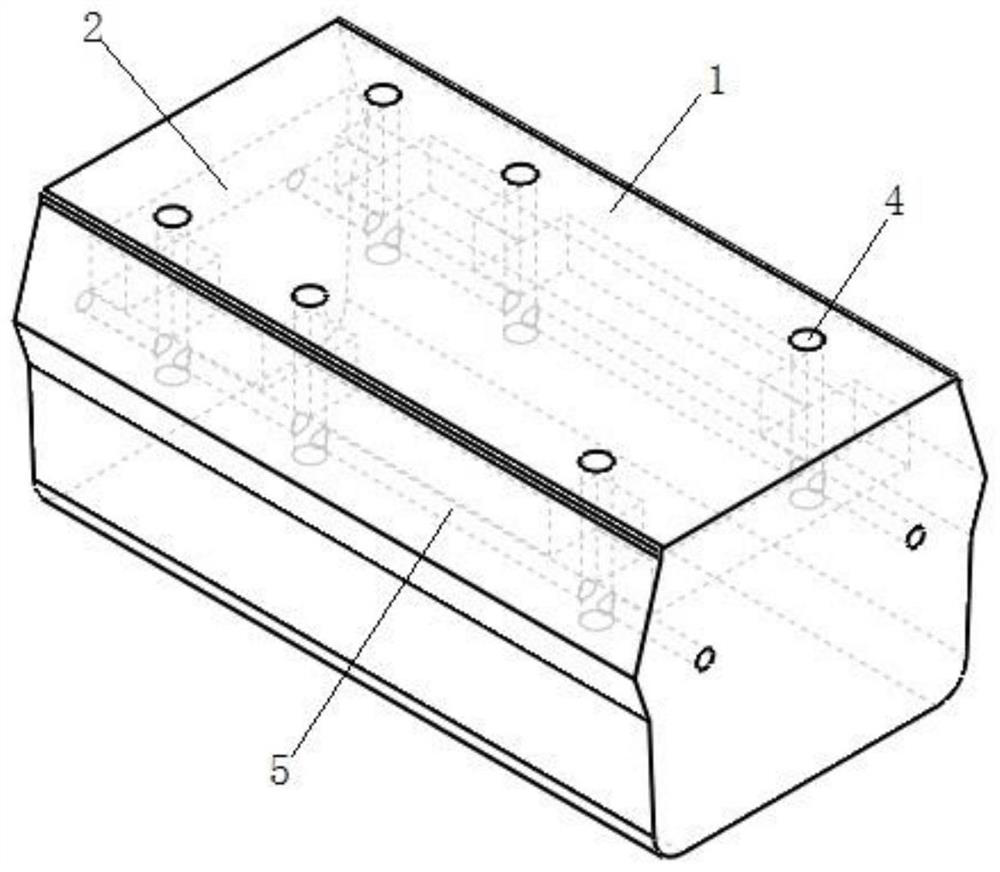

The invention provides a coal thermolysis device for heat-carrying gas. The coal thermolysis device is formed by correspondingly fastening two metal plates in which a plurality of semicircular concave grooves are arranged according to the concave grooves, wherein the plurality of semicircular concave grooves are combined to form a plurality of heat-carrying gas heat transmission pipes; the heat transmission pipes are sequentially communicated with a small vertical pipe, a transverse pipe, a main pipe, a heat-carrying gas inlet and a heat-carrying gas outlet, so as to form a heat-carrying gas heat transmission system. According to the coal thermolysis device, the heat-carrying can be used for directly drying the coal in a destructive distillation chamber through a metal heat intromission pipe, so as to achieve normal-pressure or destructive distillation; and the coal thermolysis device has the characteristics of being fast in transmission rate, high in heat utilization rate, simple in structure and low in cost.

Owner:TAIYUAN UNIV OF TECH

High thermal conductivity silica brick for coke oven and preparation method thereof

ActiveCN104119081ADense microstructureImprove thermal conductivitySilica particleCarboxymethyl cellulose

The invention relates to a high thermal conductivity silica brick for coke oven and a preparation method thereof. The high thermal conductivity silica brick for a coke oven comprises the following components by weight: 68.0%-82.0% of natural silica particles, 13.0%-26.0% of natural silica powder, 0.5%-2.0% of an additive containing dispersant, 1.5%-5.0% of siliceous non oxide, 1.0%-3.0% of a mineralization agent, and an additional binder in the weight 1.5%-3.0% of the total weight of the previous materials. The additive comprises a dispersant carboxymethyl cellulose (CMC) with granularity less than 0.088 mm and siliceous non-oxide Si with granularity less than 0.043 mm, wherein the content of Si is greater than 96 wt.%. The silica brick provided by the invention has high thermal conductivity and keeps other comprehensive excellent performances of silica brick, and can satisfy the demands of coke oven for longevity, energy saving and high efficient production.

Owner:BAOSHAN IRON & STEEL CO LTD +1

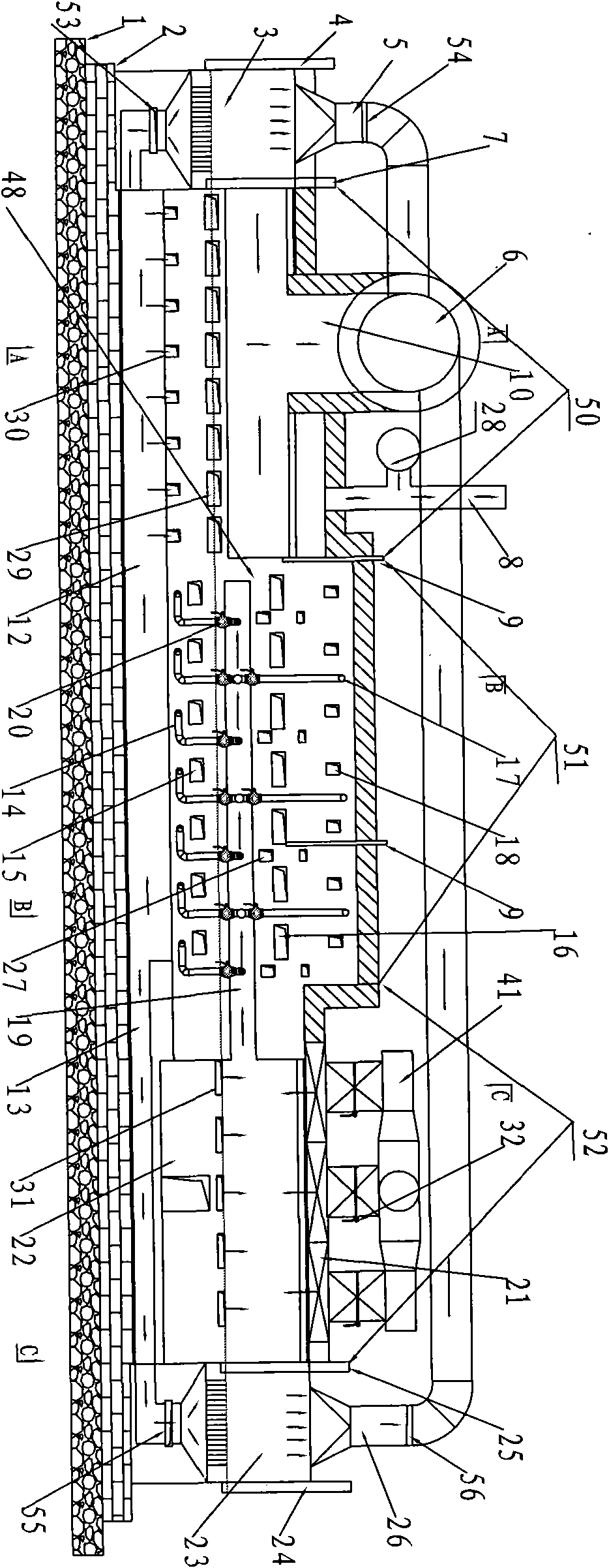

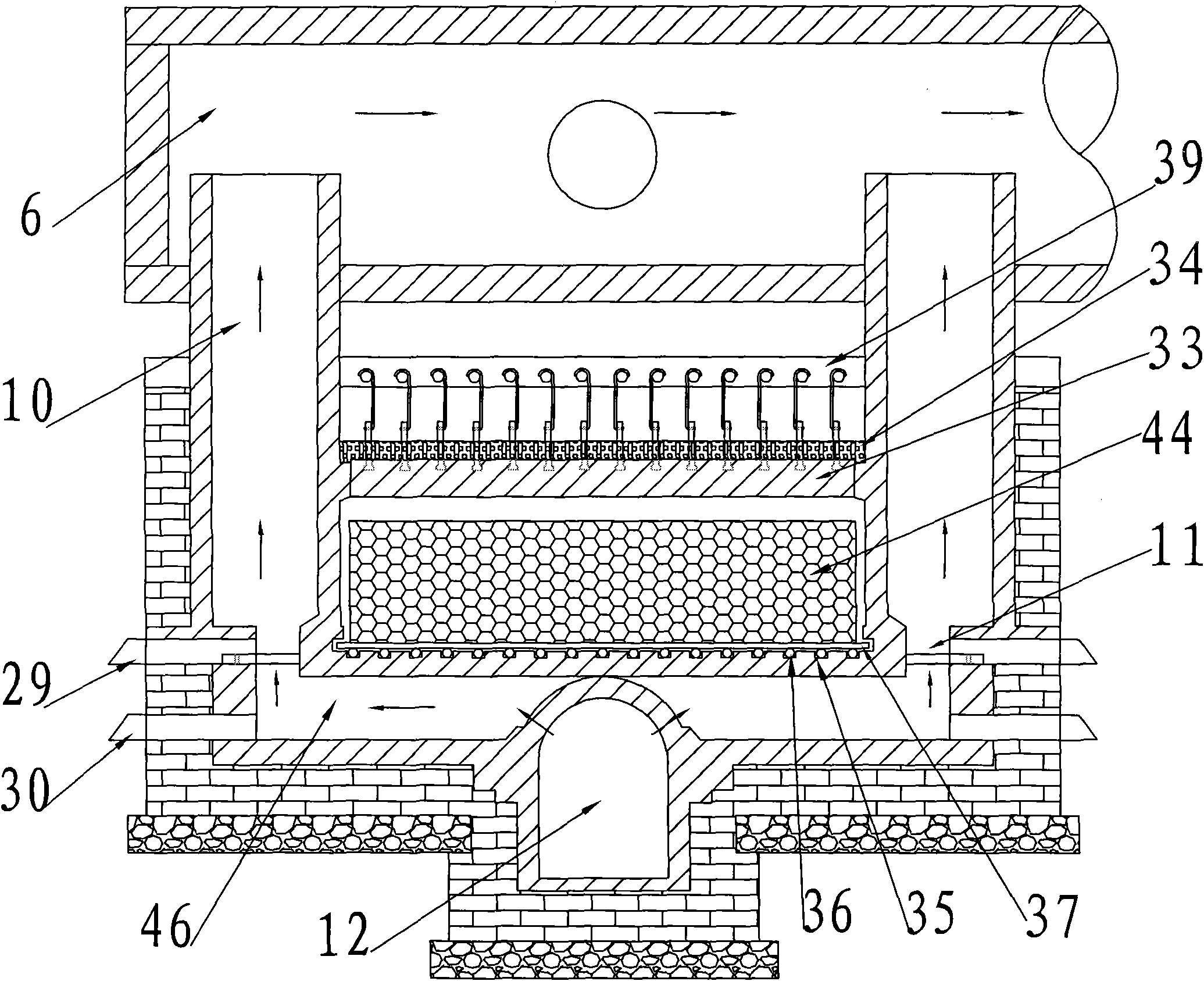

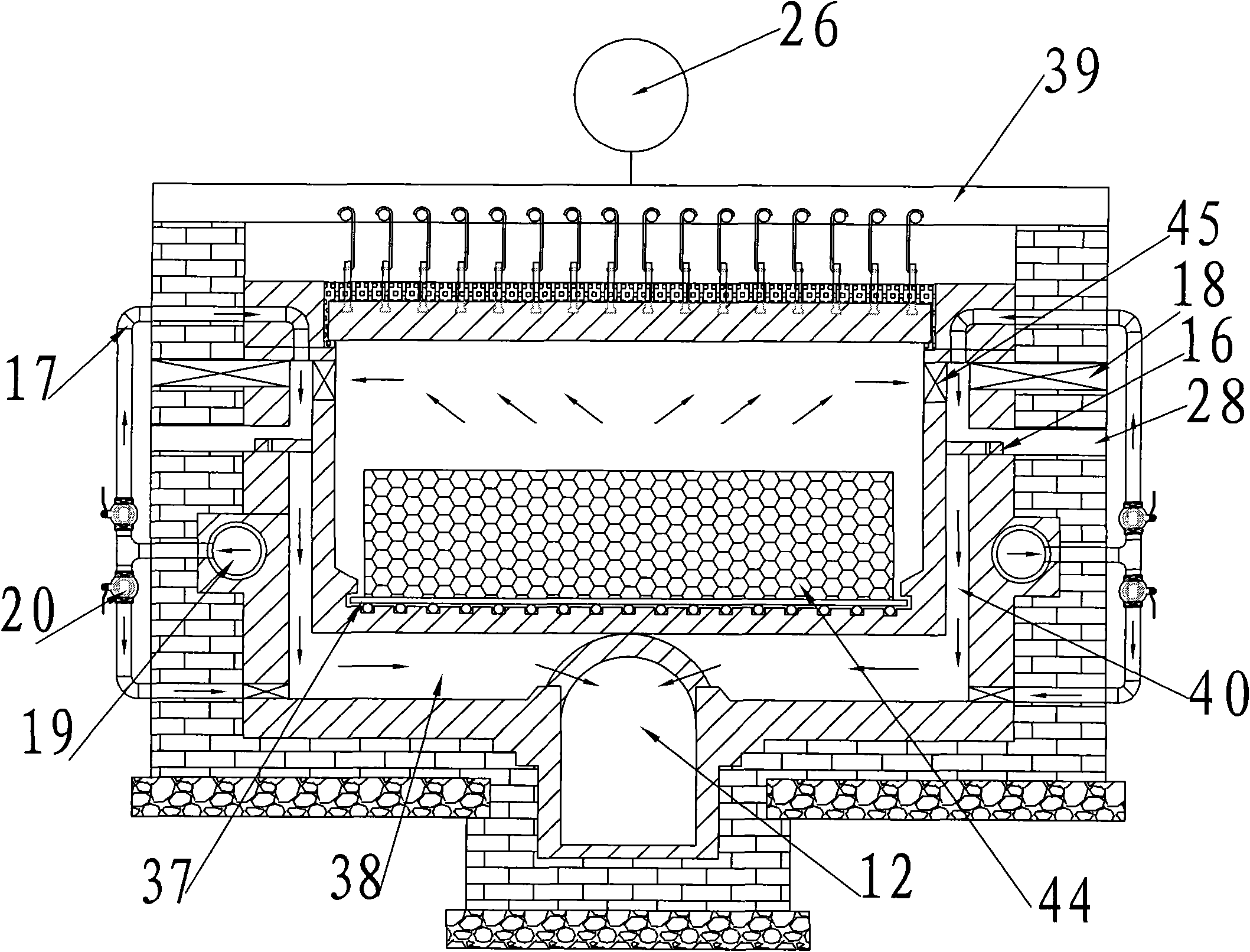

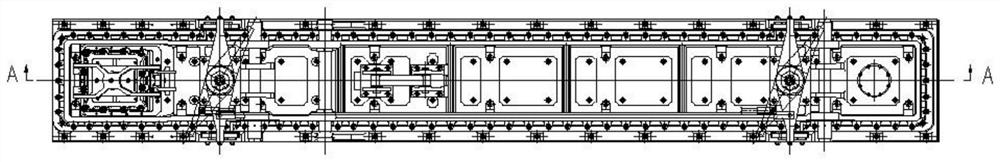

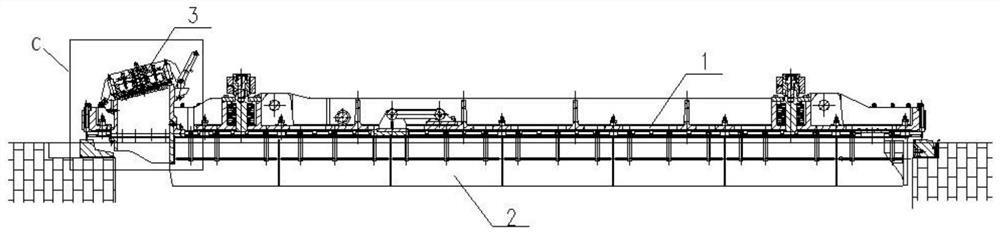

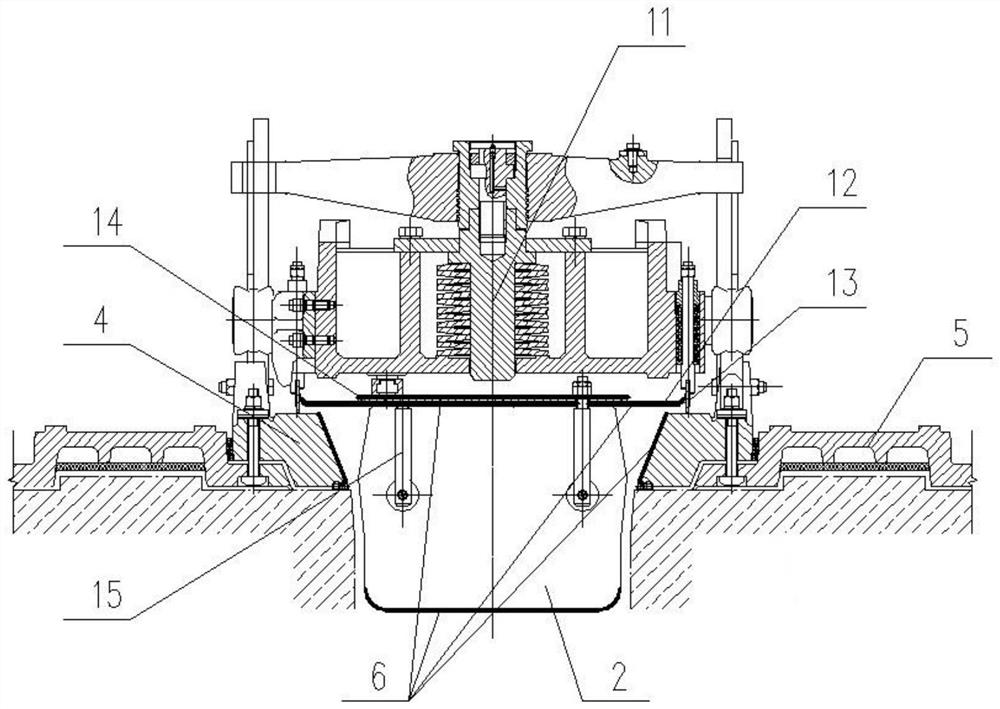

Movable slide bed tunnel type coke oven and use method thereof

InactiveCN101792676AReduce the amount of gasLow energy consumption for cokingMechanical conveying coke ovensHorizontal chamber coke ovensWater sourceFlue gas

The invention relates to a movable slide bed tunnel type coke oven and a use method thereof, and belongs to the field of coal processing and conversion and coking equipment. The coke oven comprises an oven body (48), a front sealing door (7) of the coke oven body, a back sealing door (25) of the coke oven body, a sub-flue (10), a bottom flue (12) and a main flue (6), and is characterized by comprising a coaling preparation chamber (3), a preheating section (50), a carbonization section (51), coke dry quenching section (52) and a coke outlet preparation chamber (23), each part has different structures, and the five parts are connected in series and communicated with each other; and a movable slide bed (37) of loading briquettes or tamping coal materials (44) sequentially pass through the five parts of the coke oven by intermittently moving on a slideway (35) of the slide bed, so that the coal materials are carbonized into coke. The produced coke has uniform specification, large lumpiness, good strength, high heat energy utilization rate, high degree of mechanization, and clean emission of flue gas, and the invention effectively protects atmosphere and water sources and realizes clean production.

Owner:GUIZHOU SUNNY CLEAN ENERGY TECH DEV

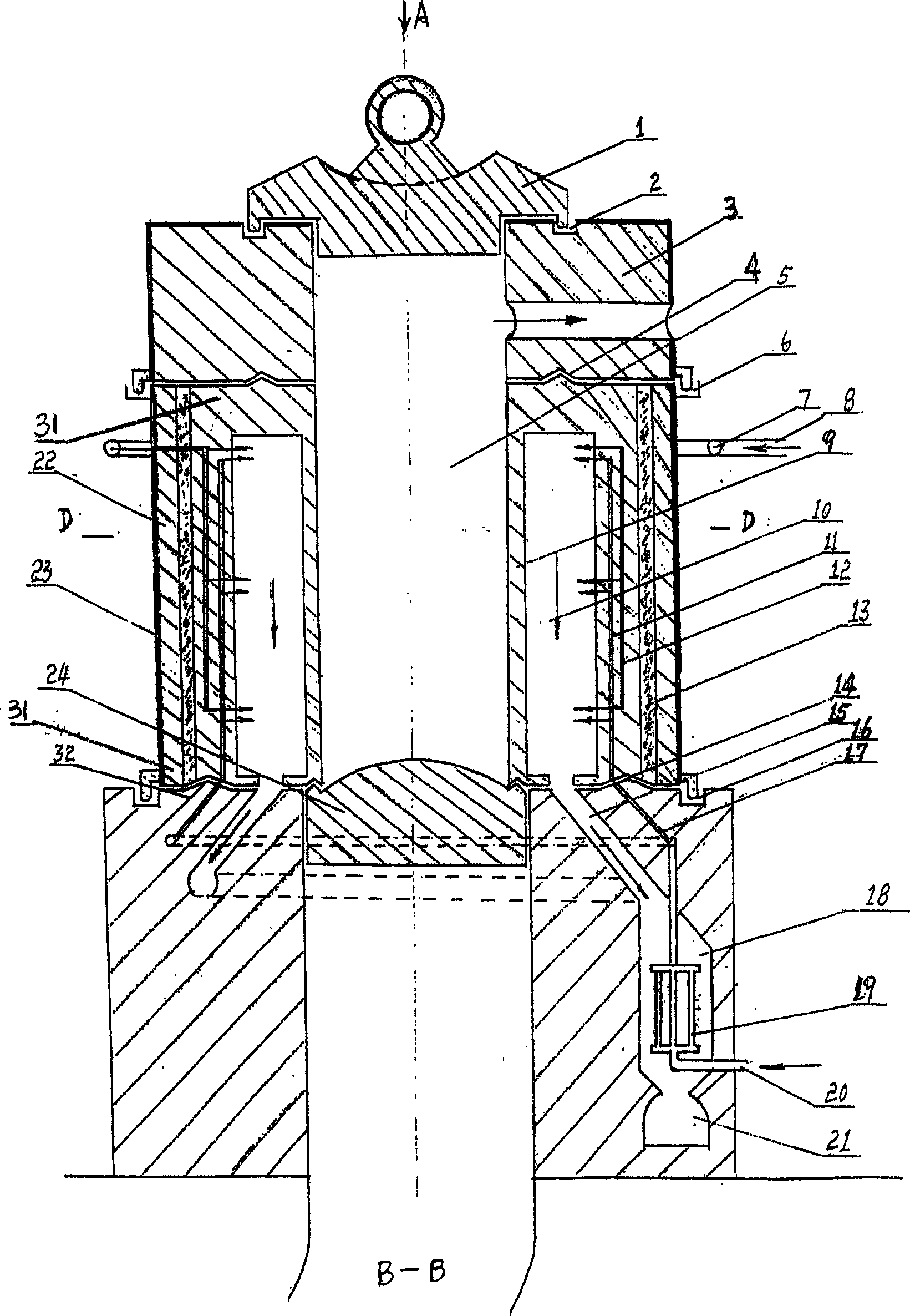

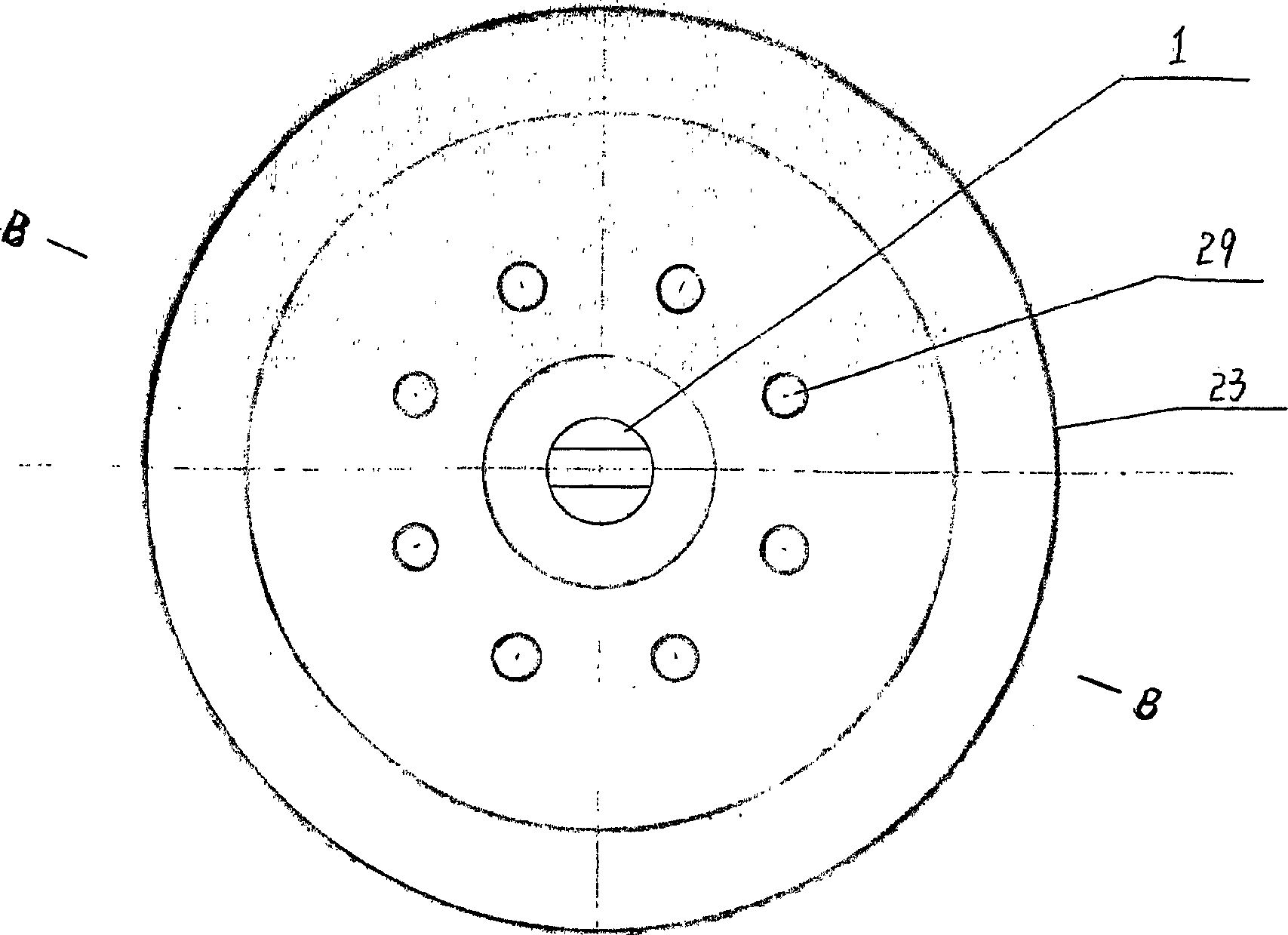

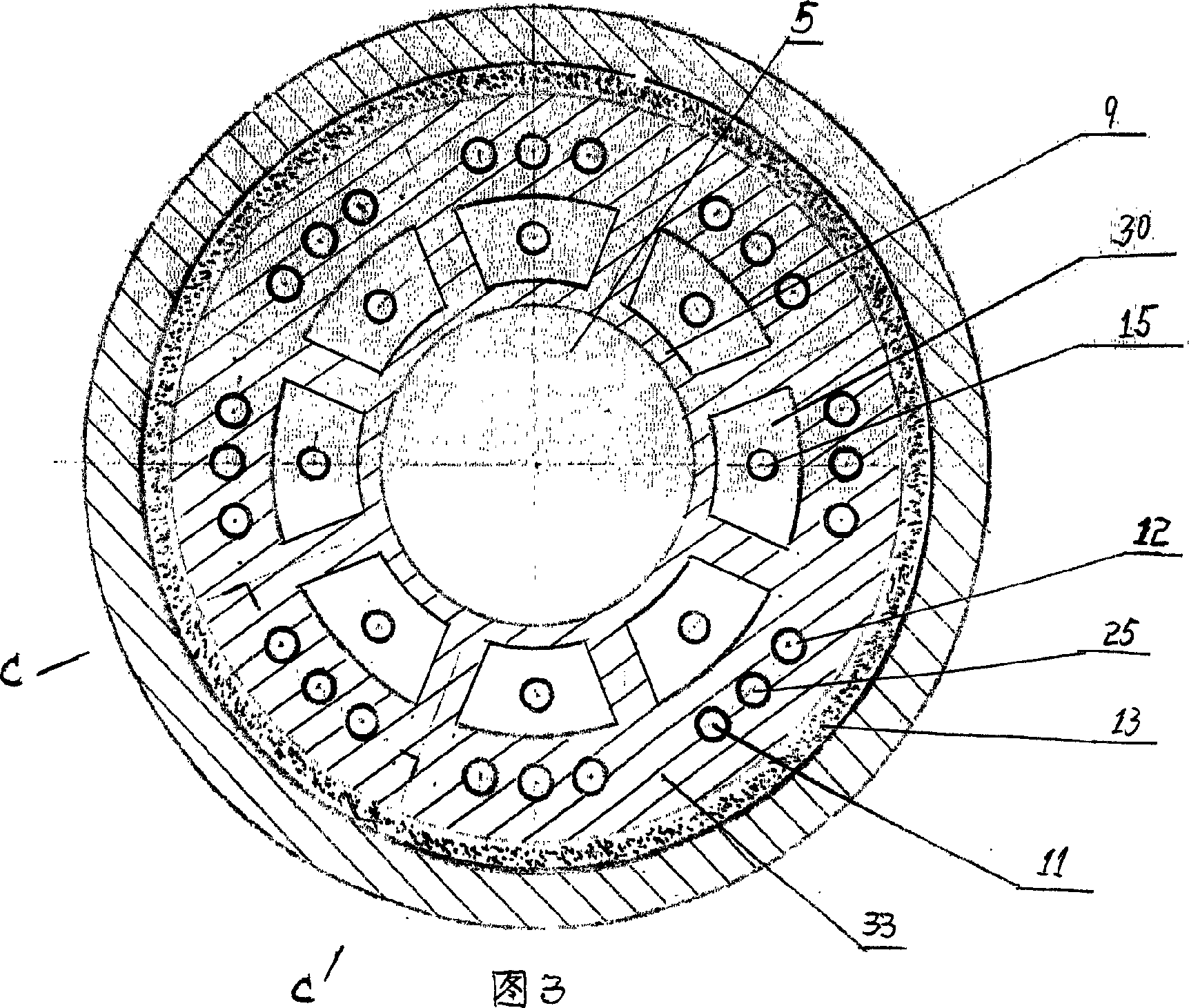

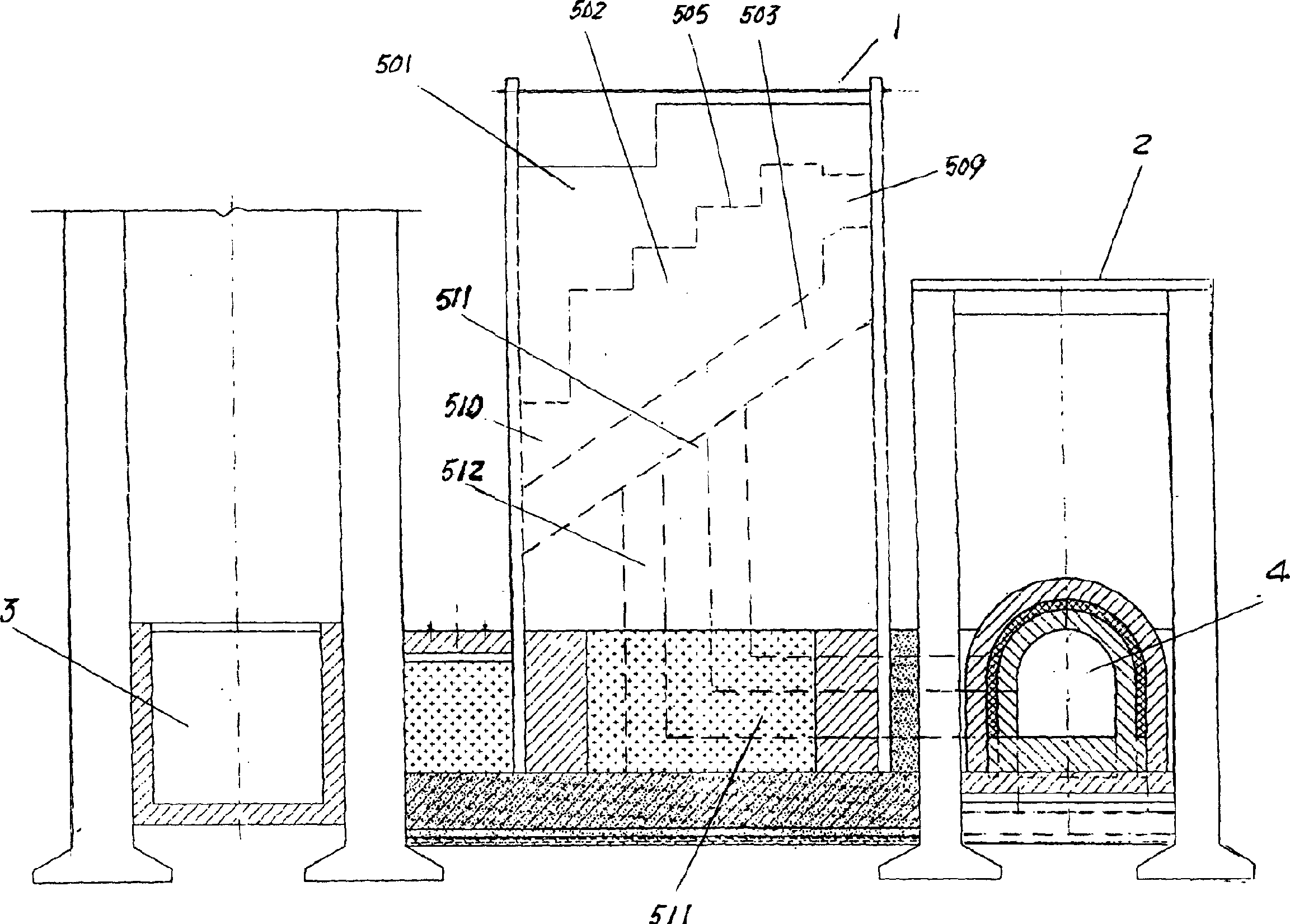

Vertical cylidndrical coke oven and submerging coke quenching method

InactiveCN1657591AIncrease the heating areaImprove productivityCoke quenchingVertical chamber coke ovensProduction rateCombustion chamber

A vertically cylindrical coke oven with high heat efficiency and productivity and no dust pollution features that it has the cylindrical carbonizing chamber and the ring-shaped combustion chamber with several individual vertical fire channels having waste gas circulating holes. A water immersion method for quenching coke is also disclosed, which can prevent the pollution of dust to environment.

Owner:康应龙

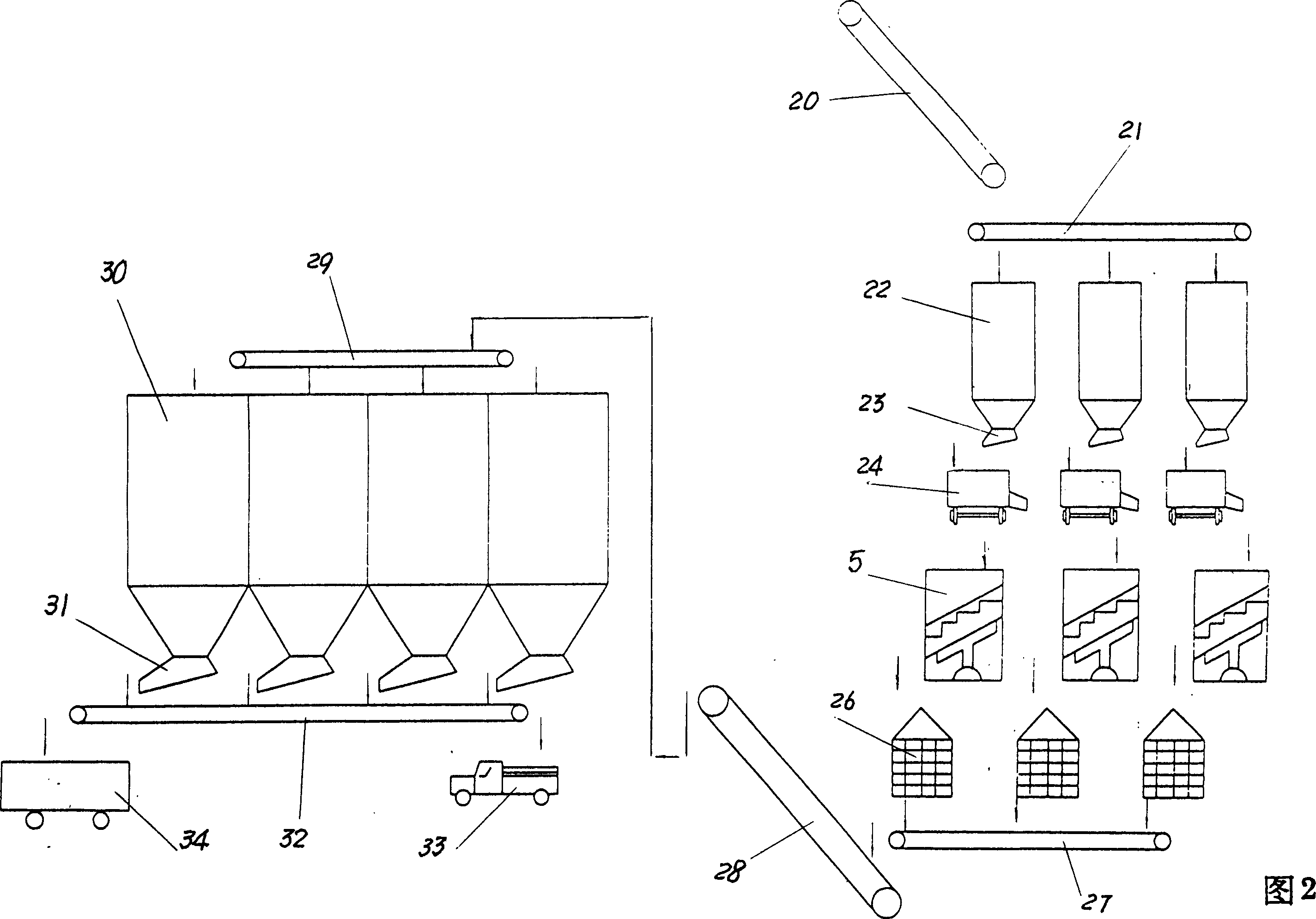

Production process of coke by preheating coal and stacking

InactiveCN107400527AIncrease stickinessIncrease dosageSpecial form destructive distillationCoking wastewaterQuenching

The invention relates to a production process of coke by preheating coal and stacking. The production process comprises the following steps of pretreatment: preheating and crushing a coal material according to the property of a coal type, and then weighing and taking the corresponding crushed coal material according to a coal proportion, adding or not adding a binder, and then mixing to obtain raw-material coal; molding: carrying out hot press molding on the raw-material coal to obtain molded coal; stacking: stacking the molded coal to be a coal wall, and laterally loading into a vertical coke oven; coking: carrying out dry distillation in the vertical coke oven; coke quenching: pushing the coke into a coke quenching car, screening and storing after the coke quenching, and carrying out recovery treatment on coal gas generated during the dry distillation. According to the technical scheme of the production process, the viscosity of the coal is effectively improved through preheating the coal; the use level of weak caking coal can be increased by 45 percent or above; the density of the weak caking coal is improved by adopting a hot molding technique; the coking time can be greatly shortened; the initial temperature of the dry distillation can be effectively improved, the generation of coking wastewater is reduced and the quality of the coal gas is improved by preheating the coal entering the oven and the production process is used for realizing energy-saving and environment-friendly effects through recovering the sensible heat of the generated coal gas.

Owner:山西博嘉慧科技有限公司

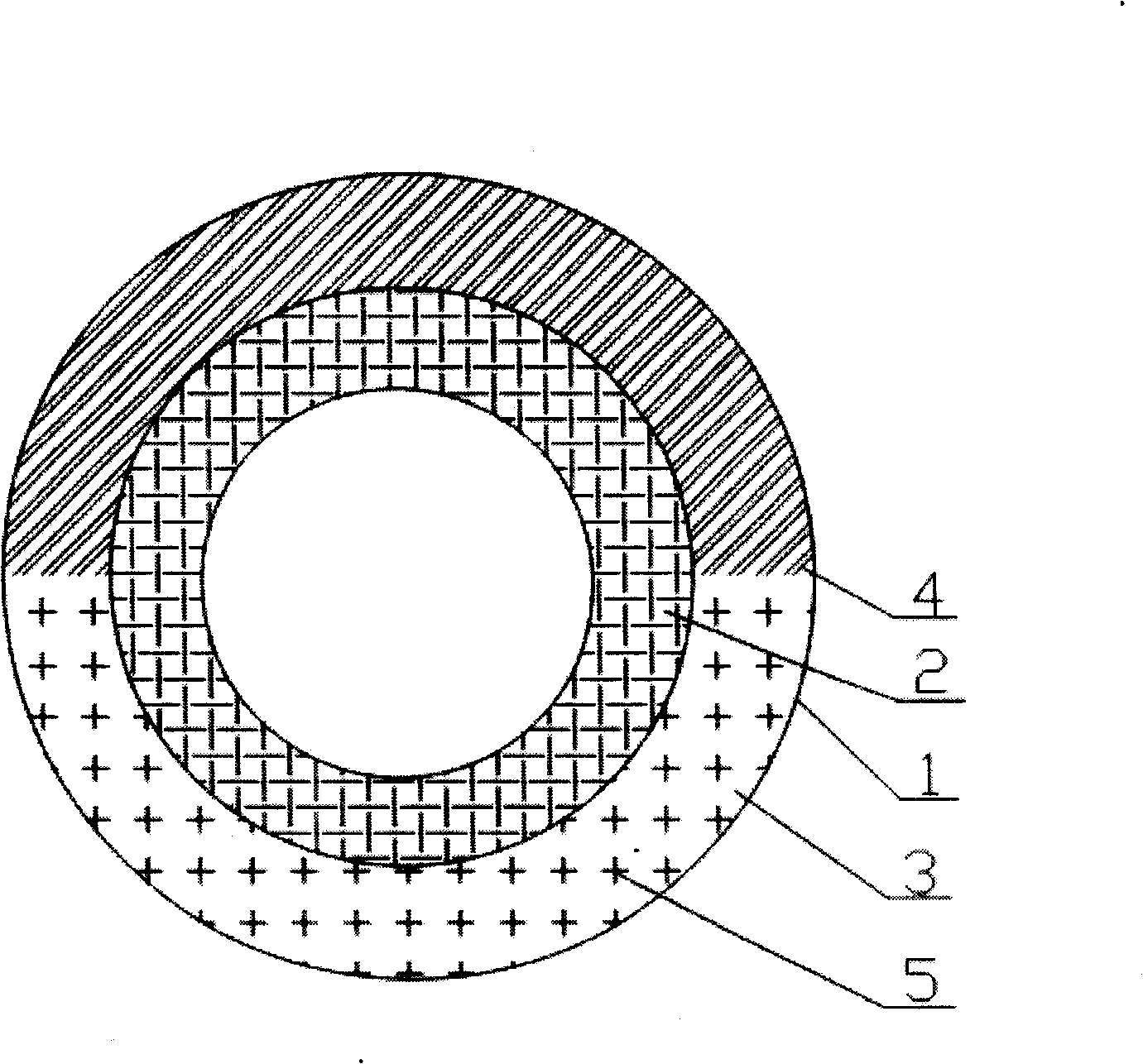

Cleaning type gas collecting pipe for thermal recovery coke oven

InactiveCN101338202AImprove heat resistanceLow heat shrinkageDistillation gas withdrawalBrickMullite

The invention discloses a clean thermal recycling coke oven gas collecting pipe which belongs to the industrial kiln accessory field and comprises an outer casing and a liner. The gas collecting pipe is characterized in that the liner is composed of a primary adiabatic layer and a secondary adiabatic layer which is arranged between the primary adiabatic layer and the outer casing. The primary adiabatic layer is made of carburizing resistance mullite bricks which are packed through high temperature binders. The secondary adiabatic layer is made of insulation silicate material solidified through high aluminum binders. Compared with the prior art, the clean thermal recycling coke oven gas collecting pipe has the characteristics of light weight, high temperature resistance, low heat conduction, etc.

Owner:山东日照焦电有限公司

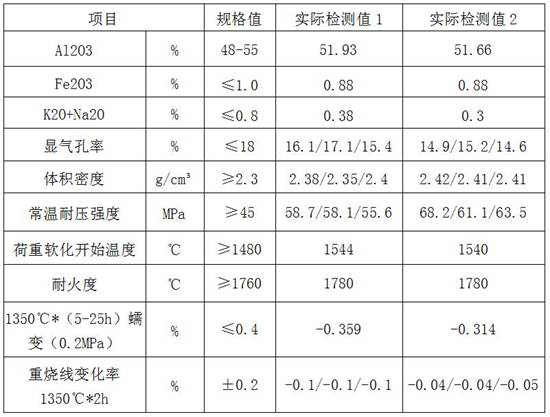

Anti-corrosion compact checker brick for upper part of coke oven regenerative chamber and preparation method thereof

PendingCN112341177AHigh strengthStable structure at high temperatureCoke oven detailsBrickKaolin clay

The invention relates to an anti-corrosion compact checker brick for the upper part of a coke oven regenerative chamber and a preparation method of the anti-corrosion compact checker brick. The anti-corrosion compact checker brick is prepared from the following raw materials in parts by weight: 25-60 parts of low-aluminum mullite particles, 15-25 parts of andalusite, 4-6 parts of high-temperaturealuminum oxide micro powder, 10-15 parts of high-purity kaolin fine powder, 10-15 parts of clay and 5-6 parts of a binder. The anti-corrosion compact checker brick has the characteristics of low porosity, high strength, stable high-temperature structure, high refractoriness under load, excellent high-temperature creep resistance, good CO corrosion resistance and the like, solves the problems of checker hole blockage and softening collapse of the coke oven checker brick in the use process, has the performance superior to that of common clay and semi-silicon checker bricks, and can meet the high-temperature requirement of the top of a large coke oven regenerative chamber.

Owner:SHANDONG REFRACTORIES GRP LUNAI KILN REFRACTORYCO

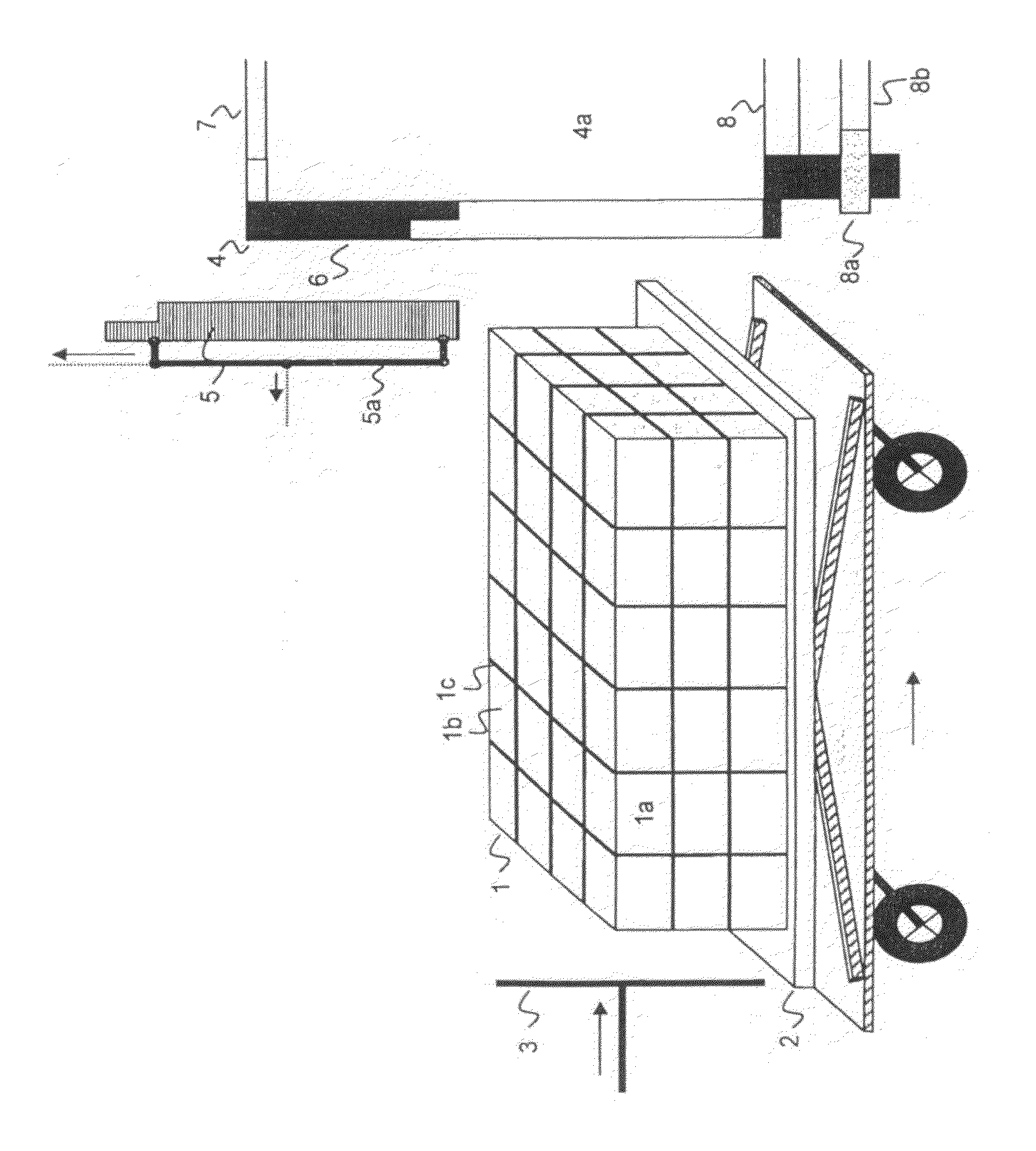

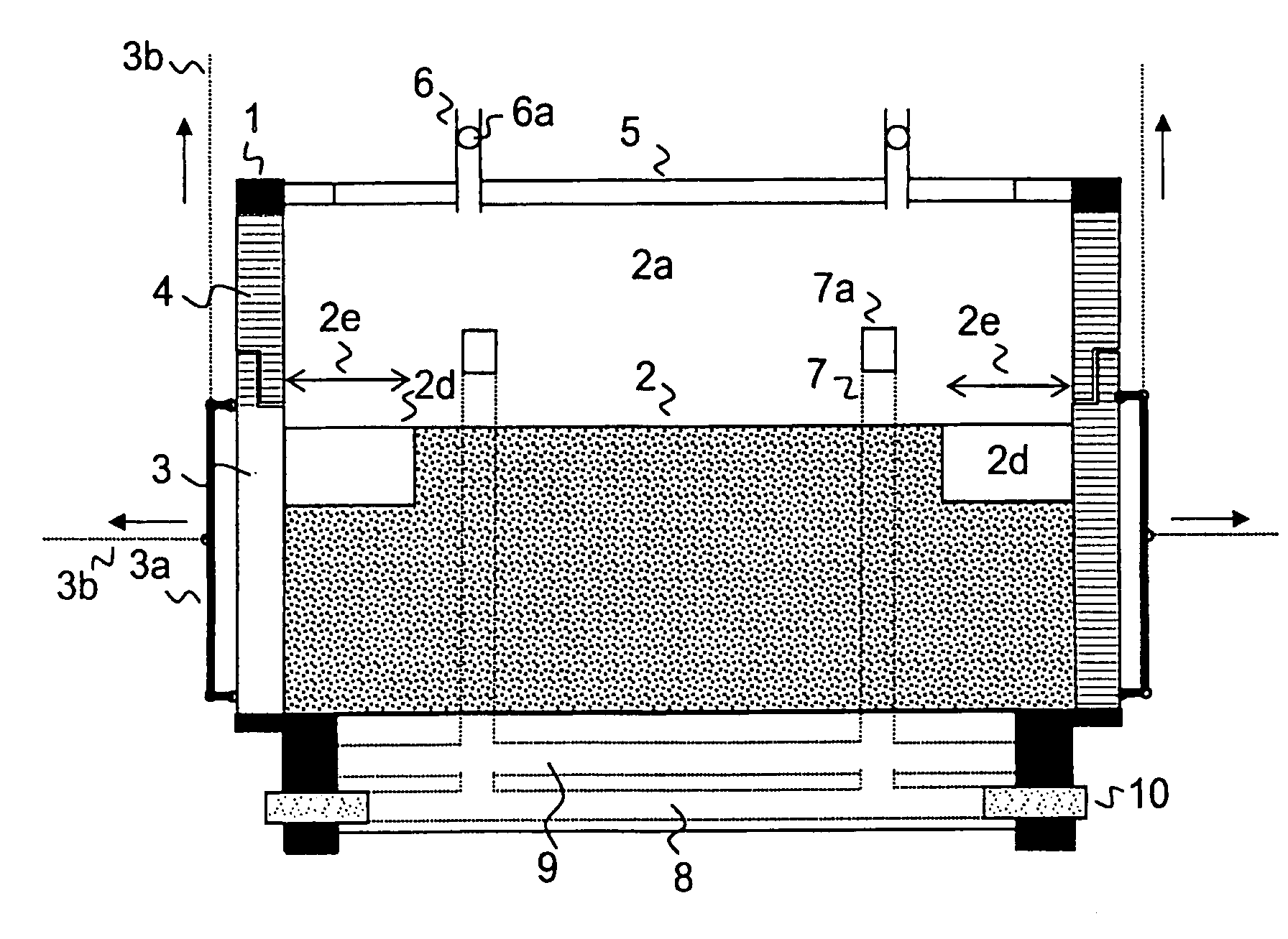

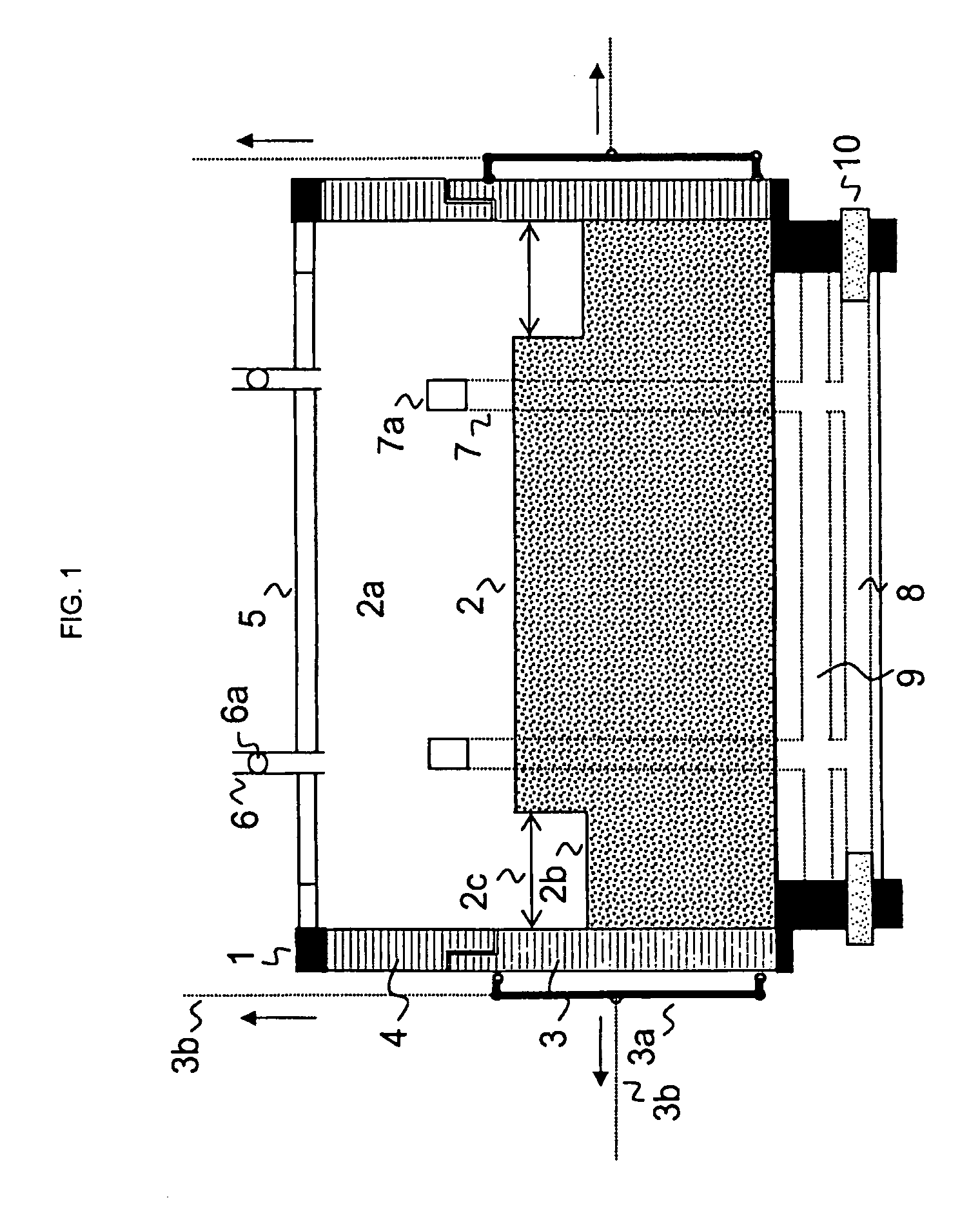

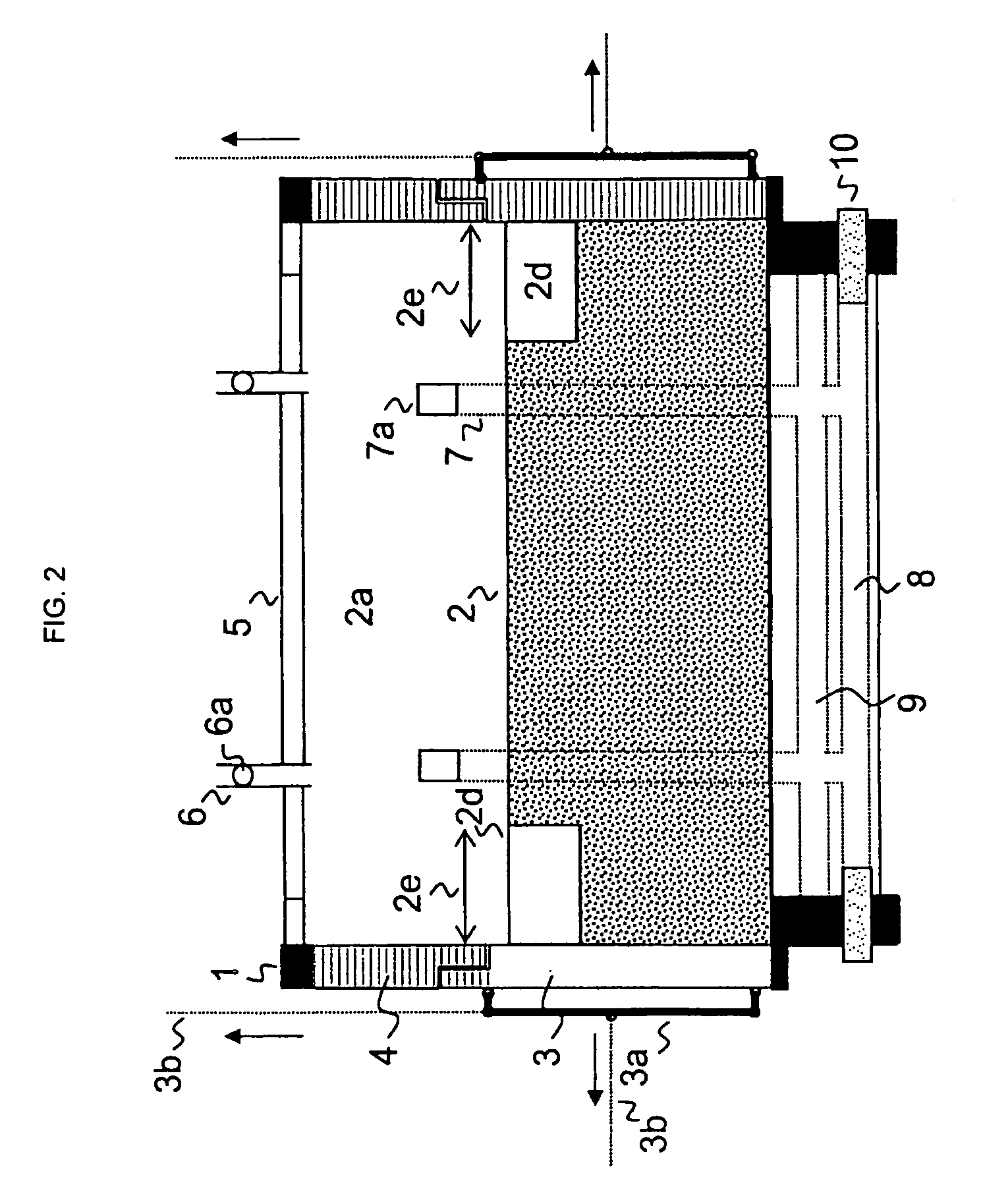

Method for compacting coal in a manner suitable for coke oven chambers

InactiveUS8888960B2Simple productionExcellent capability of storageCharging-discharging device combinationsCarbon compoundsEngineeringCoke oven

A method for compacting coal in a manner suitable for coke oven chambers is described. The coal is initially compressed by means of a suitable compressing device into one or more coal cakes, and the obtained coal cakes are divided into compacted products by a cutting device. The compacted products are stacked on top of the each other such that they can be loaded into a coke oven chamber for coking. The compacted products enable the coke oven chambers to be loaded in a precise and a coal loss-free manner. The coal compacted products are easy to store.

Owner:THYSSENKRUPP IND SOLUTIONS AG

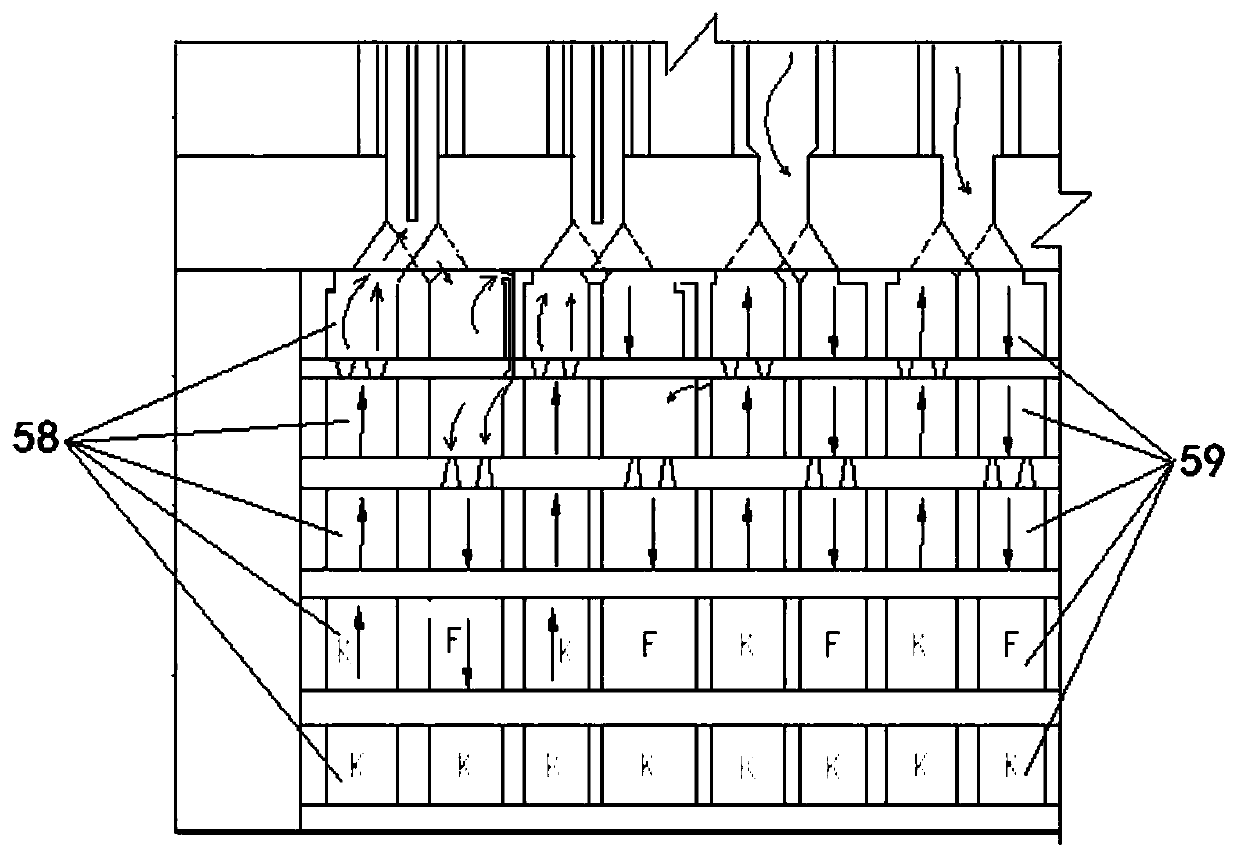

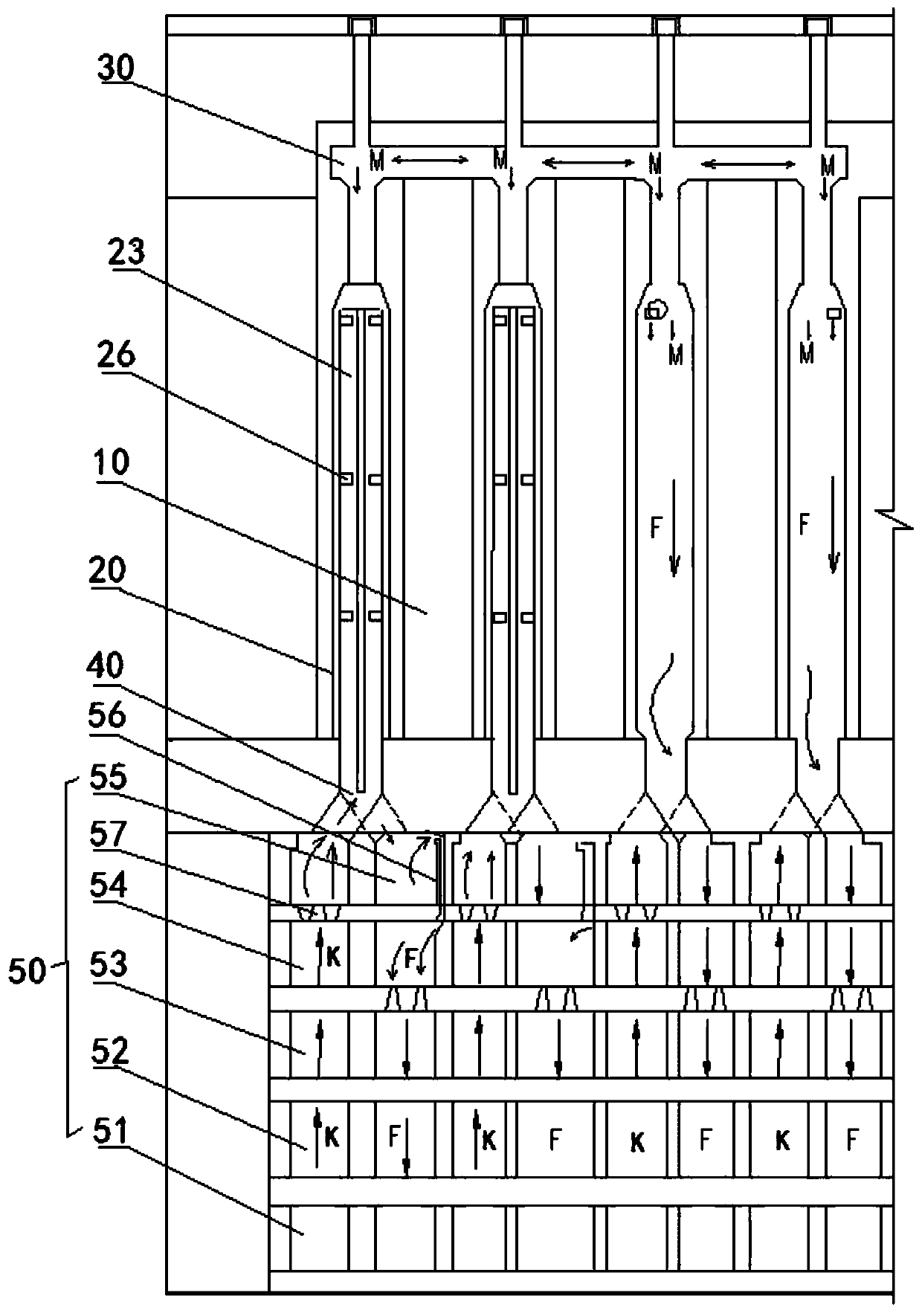

Heat transfer room type heat recovery coke-oven

ActiveCN1242024CContinuous and stable heatingImprove lateral heating uniformityCoke ovensCombustion chamberExhaust fumes

The invention discloses a novel cell-type coking furnace, wherein the coal is subjected to destructive distillation in charring chamber, most of the obtained coal gas enters horizontal gas channel, and is divided to adjacent blast chambers through the coal gas distribution hole, the rest is distributed to each blast chamber. The dedusted thermal waste gas can be used by exhaust-heat boiler to produce steam power generation.

Owner:程相魁

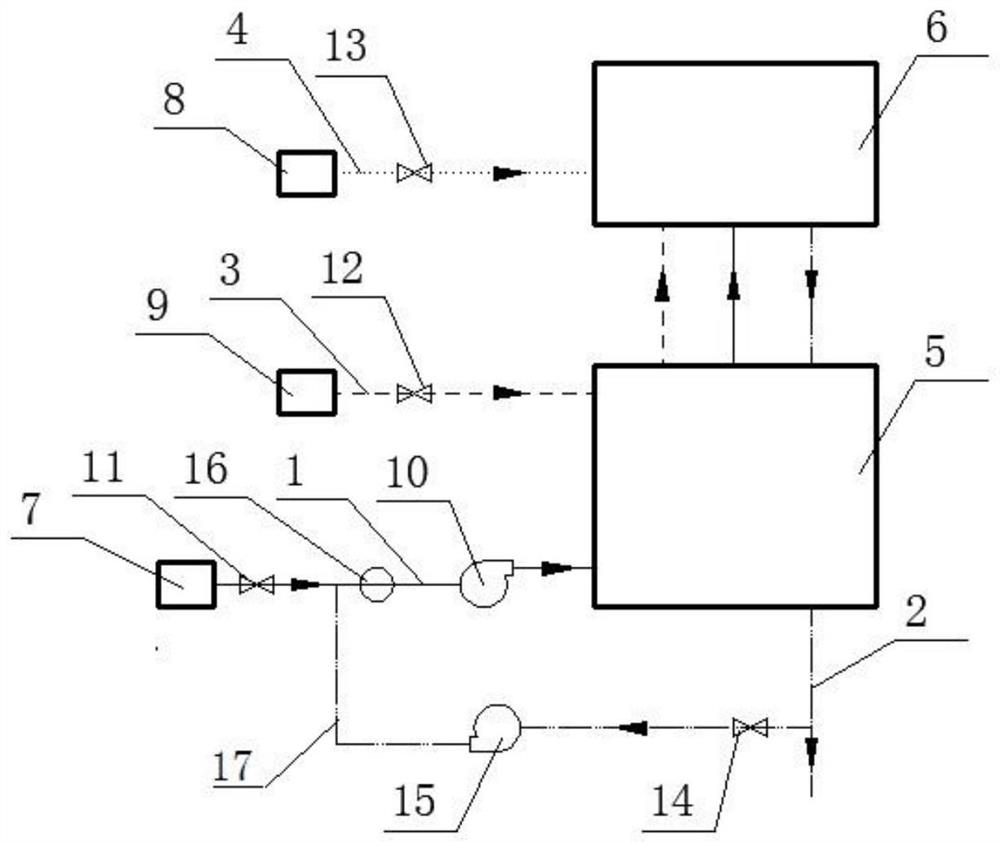

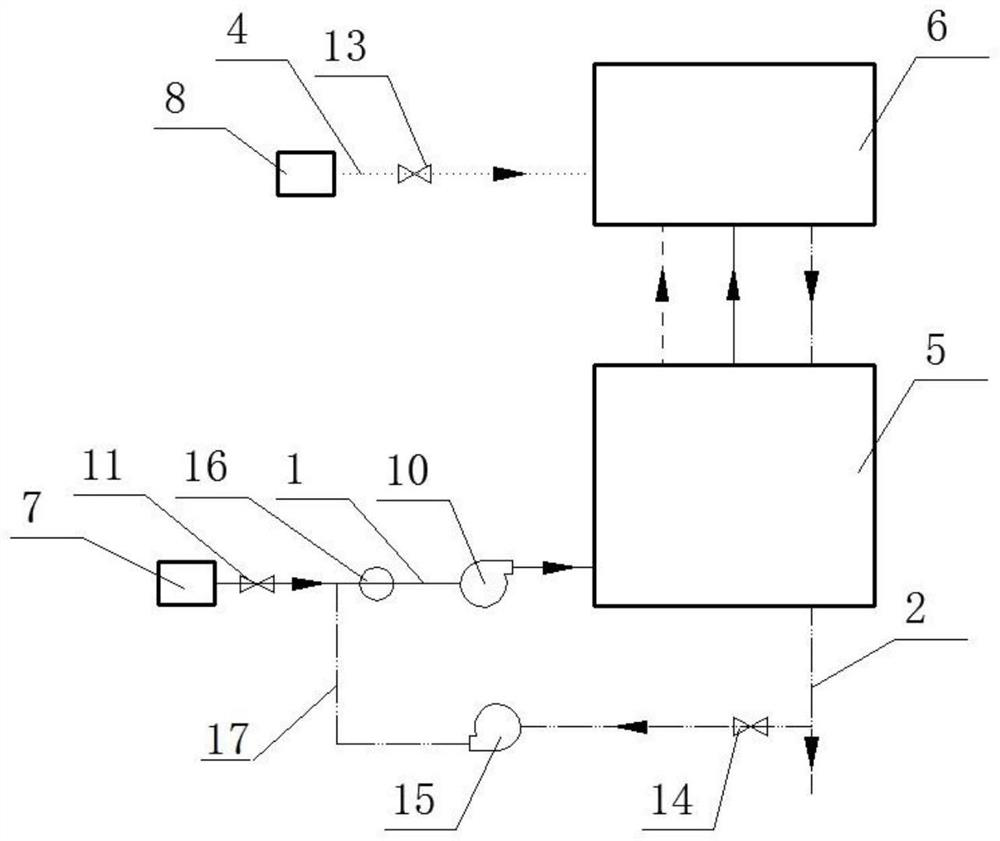

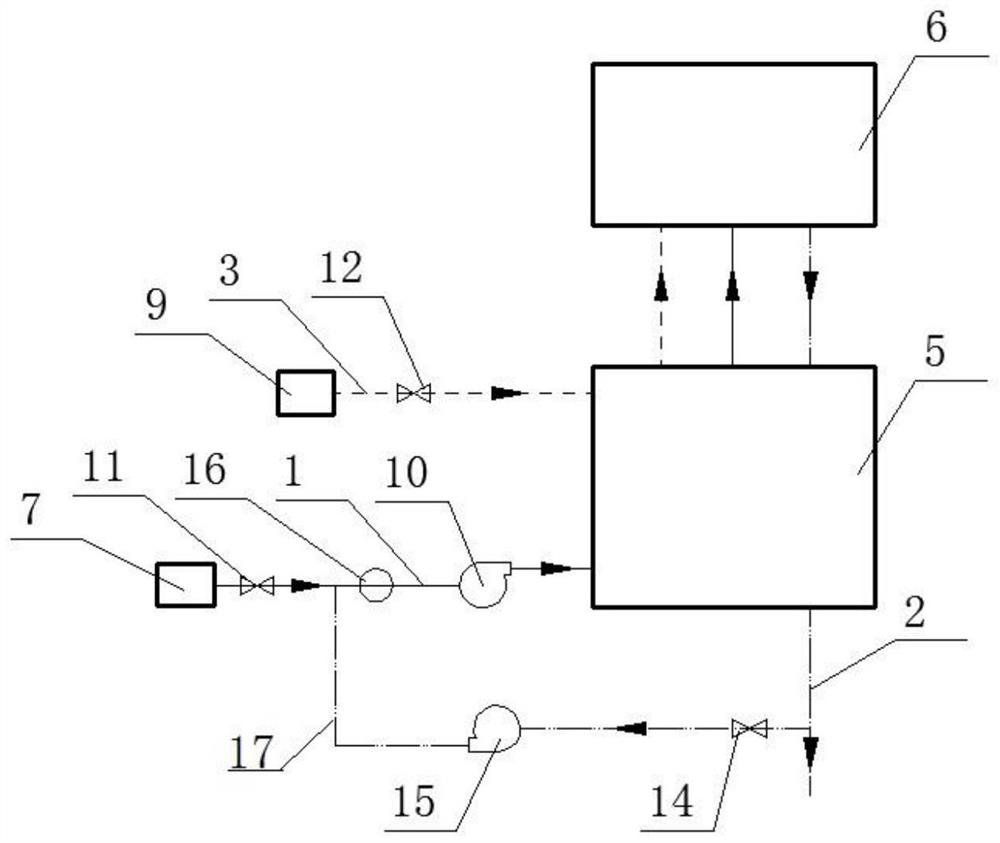

Small constant pressure coking device and constant pressure coking method

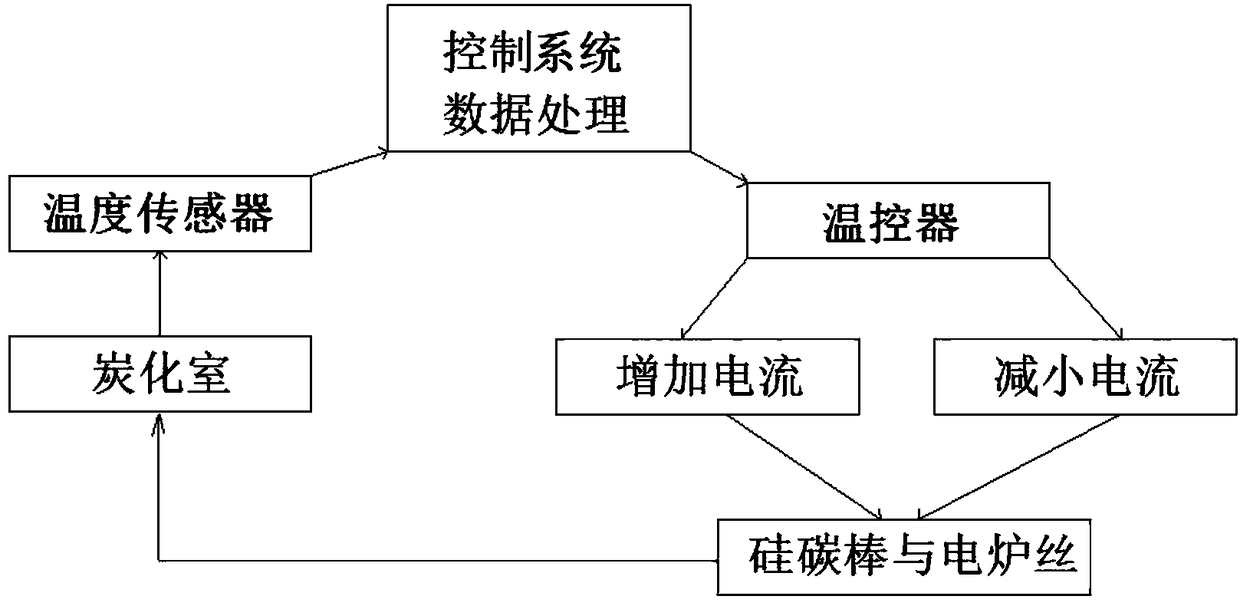

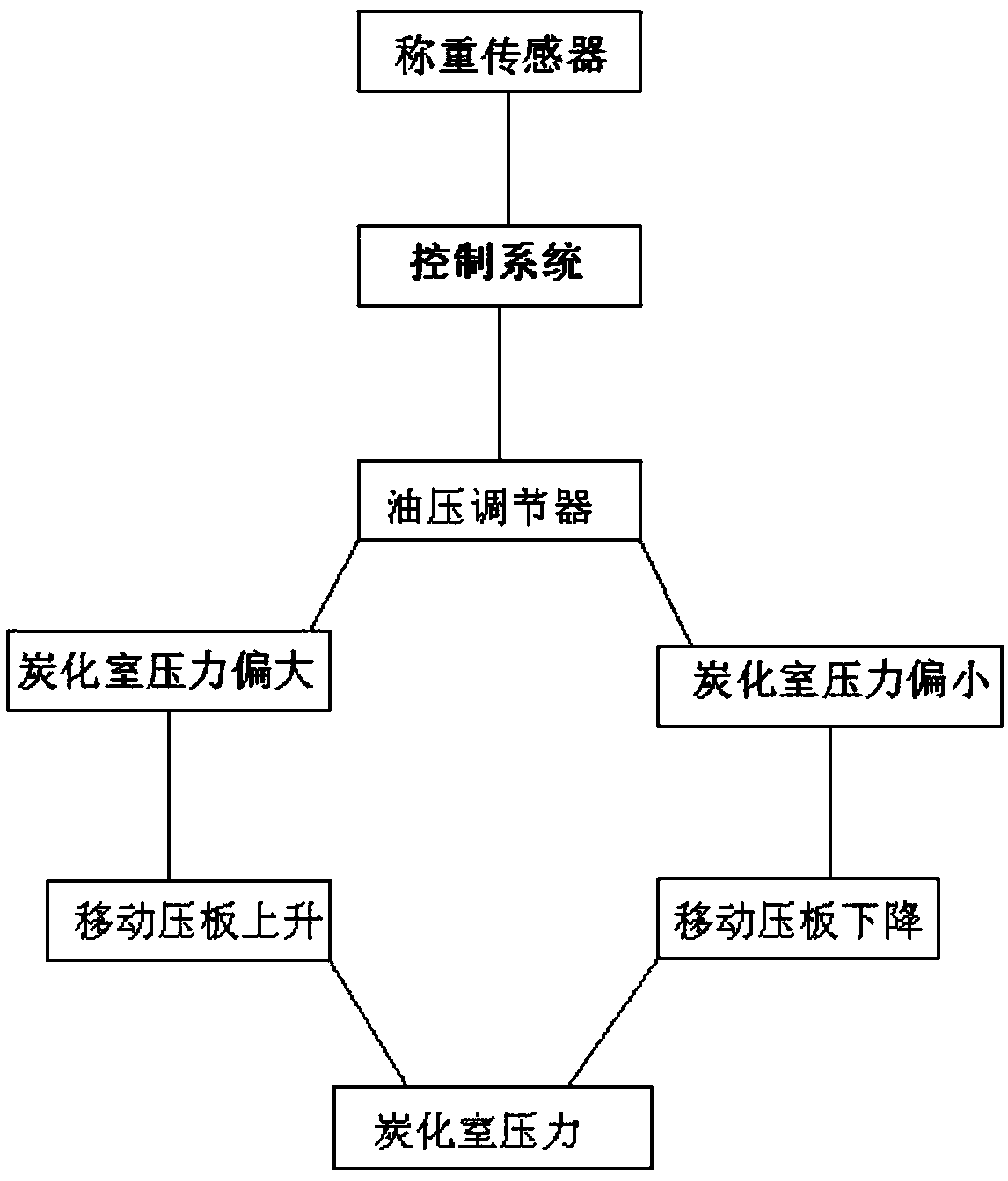

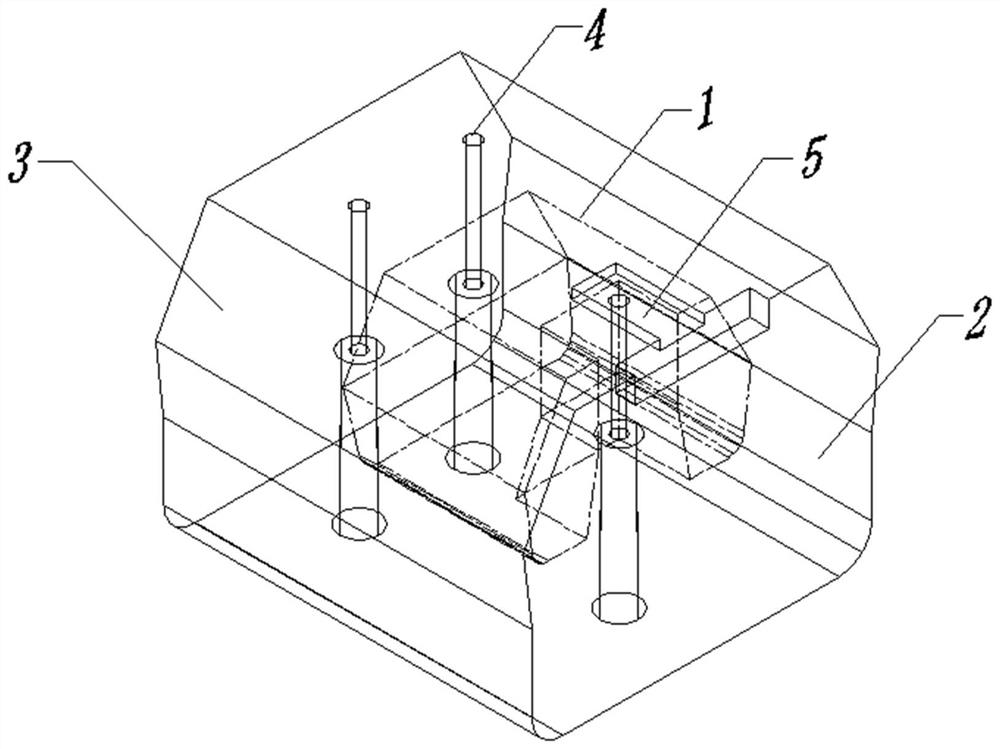

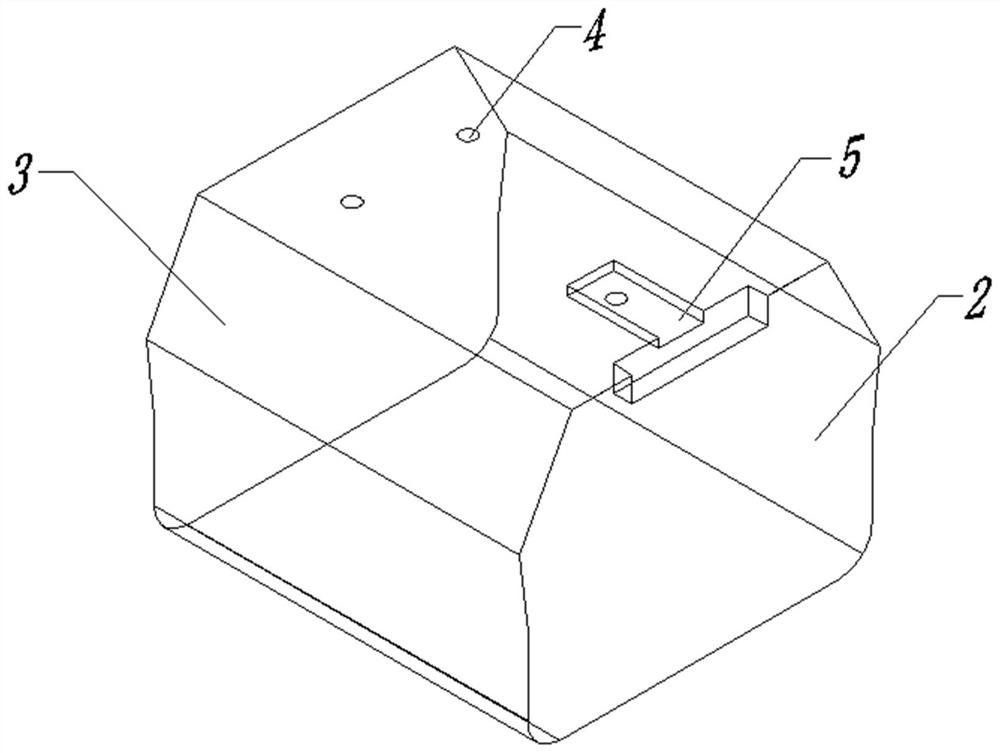

InactiveCN105861002BEvenly heatedIncrease heating rateElectrical coke oven heatingSpecial form destructive distillationInterior spaceControl system

The invention relates to a small constant pressure coking device and a constant pressure coking method, comprising an experimental coke oven, a temperature controller, a constant pressure system and a control system; The system consists of a hydraulic pump, a buffer cylinder and a moving platen. The push rod of the buffer cylinder is connected to the moving platen through the first hollow tube and can drive it to move up and down in the carbonization chamber. The bottom end of the first hollow tube passes through the moving platen and connects to the carbonization chamber for coking. Side internal space; a temperature sensor is installed in the carbonization chamber, a displacement sensor is installed on the top of the experimental coke oven, and an oil pressure regulator is installed on the hydraulic pipeline between the hydraulic pump and the buffer cylinder. The present invention can make coke under constant pressure conditions, so as to obtain the corresponding relationship between pressure and coke quality, or conduct comparative research on the coke quality of different coal types under the same pressure conditions, which is of great guiding significance for coal blending coking and coking mechanism research. To achieve the purpose of optimizing the coking production process, saving coking equipment investment and realizing the effective utilization of resources.

Owner:UNIV OF SCI & TECH LIAONING

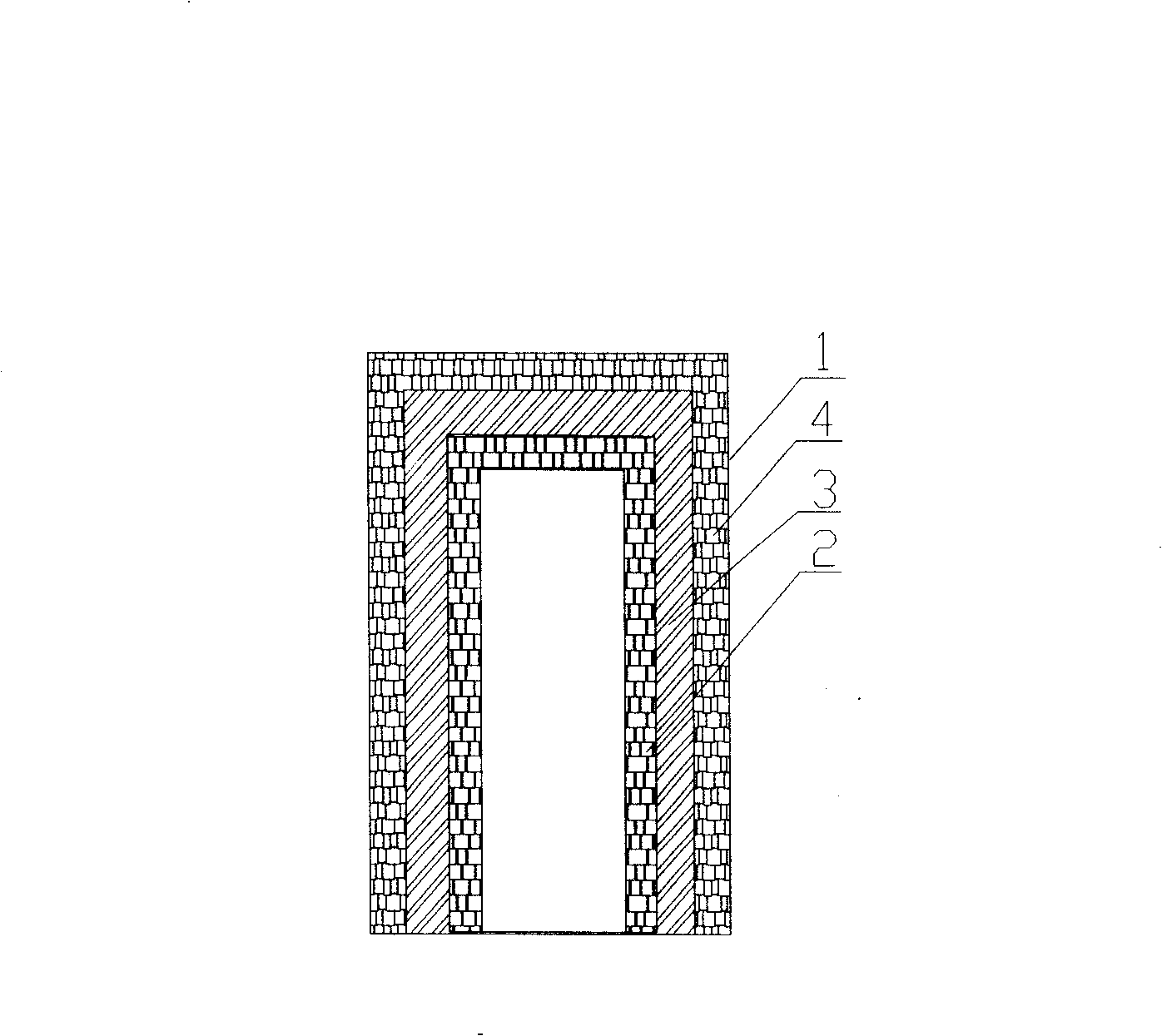

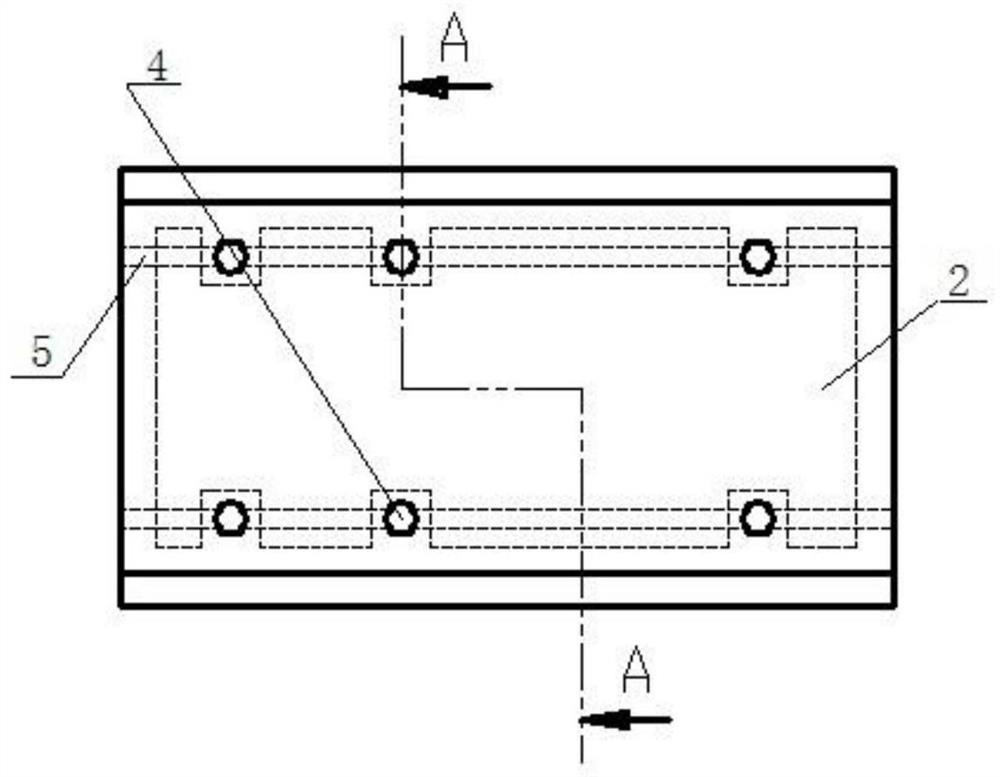

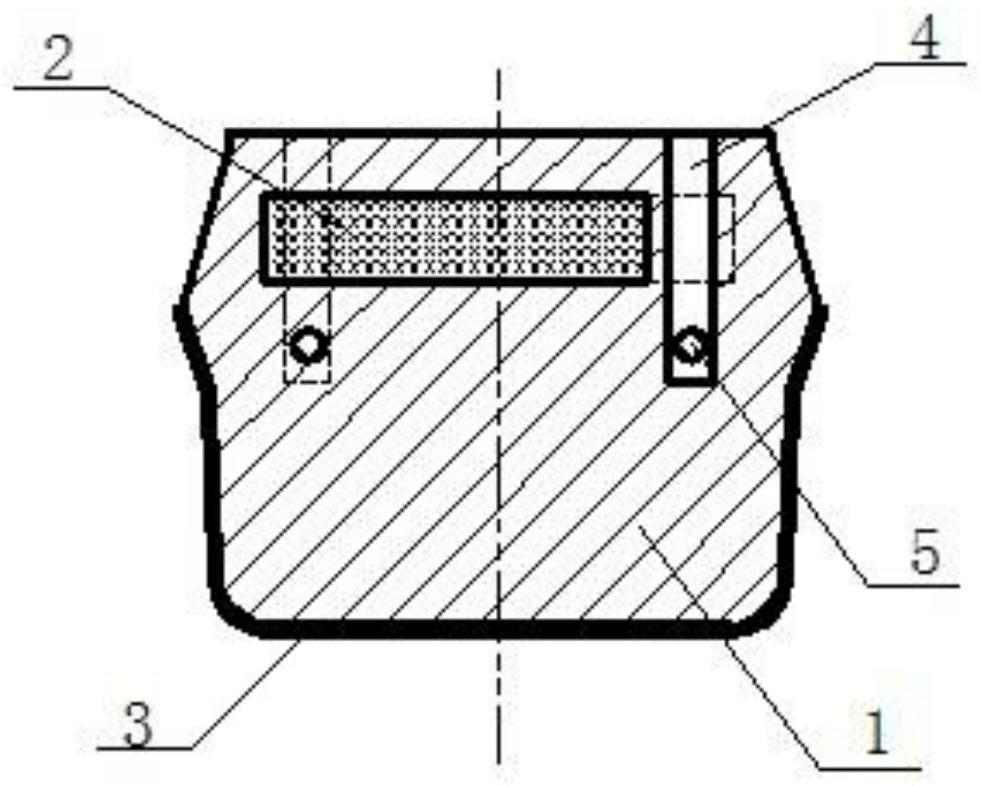

Sandwich type coke oven door prefabricated part and preparation method thereof

InactiveCN112344746AImprove insulation effectSolve the problem of neglecting the otherFurnace componentsLaminationThermal insulationEngineering

The invention provides a sandwich type coke oven door prefabricated part and a preparation method thereof. The sandwich type coke oven door prefabricated part comprises a thermal insulation inner lining and a working outer lining, wherein the working outer lining wraps the thermal insulation inner lining to form a sandwich structure. According to the sandwich type coke oven door prefabricated part, the problem that various coke oven door lining bricks are inconsistent at present is solved, a thermal insulation lining can be effectively prevented from being damaged in the transportation and installation processes, the weight of the oven door prefabricated part and a whole oven door is reduced, the thermal insulation performance of the coke oven door is improved, and the heat loss in a carbonization chamber is reduced; and the maturity of temperature increasing coke heads on the two sides of machine coke is improved, the coking time is shortened, the coke quality is improved while energyis saved, the prefabricated part is firmly combined with the furnace door shell, and the service life is longer.

Owner:北京联合荣大工程材料股份有限公司

Energy-saving coke oven door structure

PendingCN112812786AReduce heat dissipationIncrease temperatureCoke oven doors/closuresProcess engineeringCoke oven

The invention relates to an energy-saving coke oven door structure, which comprises a coke oven door composed of an oven door lining brick and an oven door iron piece, the oven door iron piece comprises an oven door body, an oven door fastening piece, an oven door sliding plate, an oven door knife edge and an oven door web, the end, close to the coke oven body, of the oven door knife edge makes contact with an oven door frame around the oven door, the inner side of the furnace door knife edge is contacted with the furnace door belly edge, and the surfaces of the furnace door lining brick, the furnace door frame, the furnace door web and the furnace door sliding plate are coated with heat insulation material coatings. The heat dissipating capacity of a carbonization chamber furnace end is effectively reduced, and the purposes of saving energy, reducing consumption and improving the energy utilization rate are achieved.

Owner:ACRE COKING & REFRACTORY ENG CONSULTING CORP DALIAN MCC

Dust settling fine coke reblending coal coking method and its technology

This invention discloses a coal blending method and its technology of dust removal coking coal powder using as lean agent to substitute clean coal. It collects coke dry quenching environmental dust removal coking coal powder, coke dry quenching technological dust removal coking coal powder, coking ground dust moving station dust removal powder, mixing them homogeneously, and then putting them into stockhouse, and then transporting into dosage bunker by leather belt transport machine, and then transporting to leather belt transport machine equipped with electronic scale by dosage plate, and then quantitively transporting to leather belt transport machine equipped with dust fall equipment, and at last, sending into crusher together with other coal for coking and mixing them homogeneously in blending coal room for coking at coking chamber of coke oven.

Owner:WUHAN IRON & STEEL GRP ECHENG IRON & STEEL CO LTD

Low-temperature carbonization method of directly heating formed coke

ActiveCN102757806ACompact structureReduce the number of poresCoking carbonaceous materialsMetallurgyNitrogen

The invention discloses a low-temperature carbonization method of directly heating formed coke. The low-temperature carbonization method comprises the steps of: performing advanced co-grinding treatment on asphalt and a certain amount of powder material (the powder material is coke powder or pulverized coal); then adding the mixture into the coke powder to be mixed uniformly; then adding a certain amount of water and a dimethylbenzene activator in the uniformly mixed material; performing normal-temperature briquetting forming and volatilization treatment; and finally directly heating the formed coke to realize low-temperature carbonization of the formed coke, thereby obtaining the carbonized formed coke. Through the measures, the low-temperature carbonization and solidification of the formed coke is realized through direct heating on the premise that the quality of the formed coke is guaranteed. Only by pre-treating the raw materials, can the formed coke be carbonized at low temperature by direct heating under an air, nitrogen or carbon dioxide atmosphere; therefore, the low-temperature carbonization method of directly heating the formed coke, disclosed by the invention, has the advantages of simplifying the subsequent process flow, reducing the production cost and breaking the limitation that the formed coke in the traditional formed coke process must be indirectly heated to a high temperature for the carbonization under a sealing condition.

Owner:CENT SOUTH UNIV

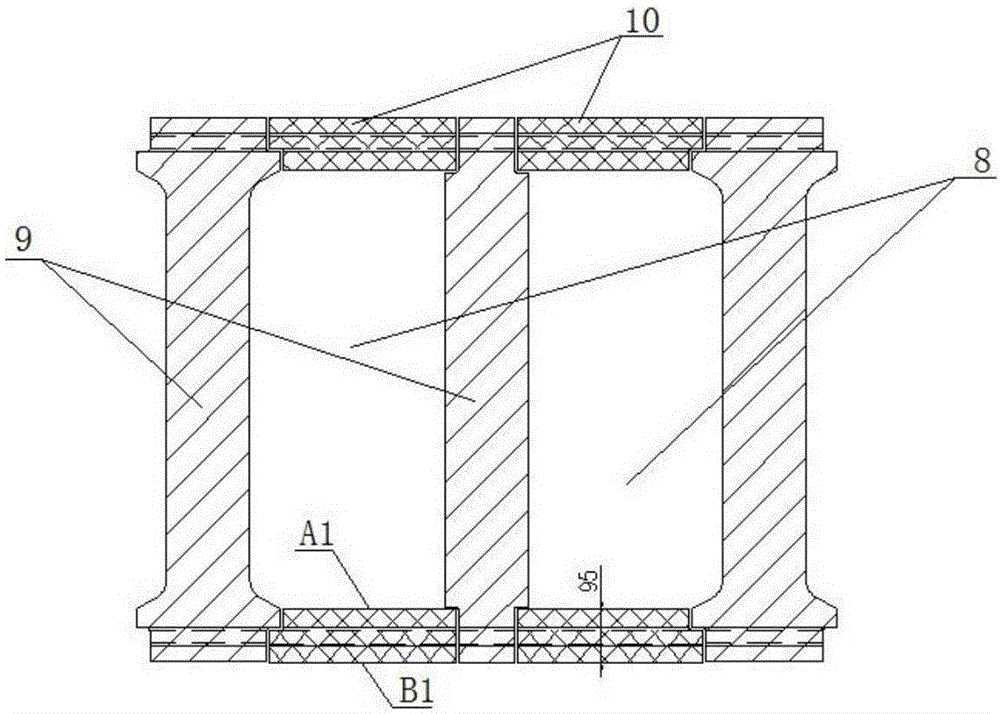

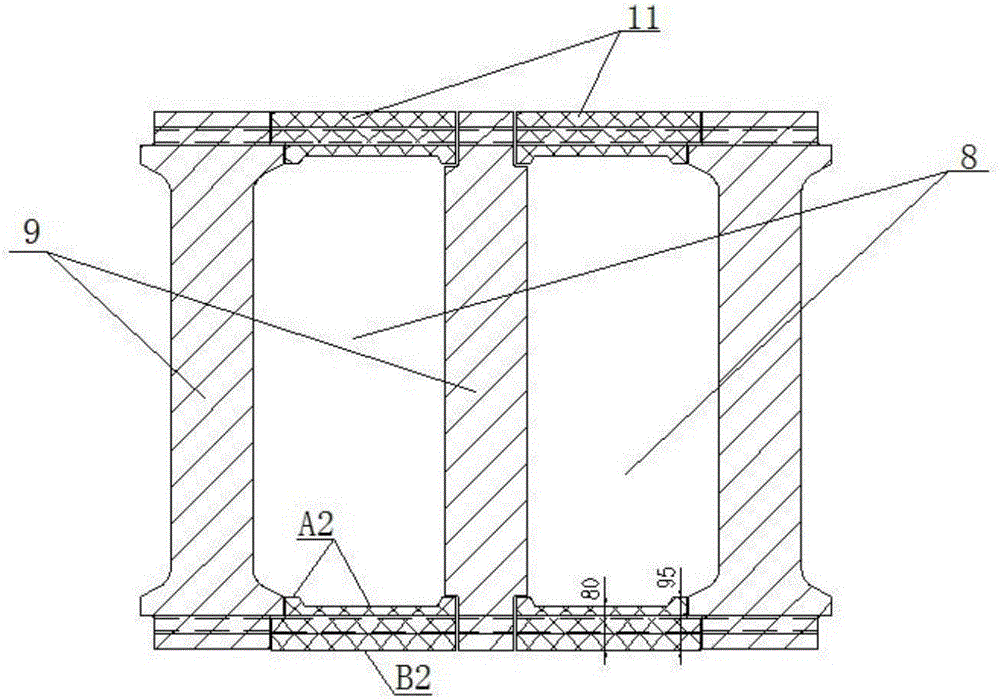

Heat exchange chamber of coke oven and coke oven

PendingCN110982538AImprove stabilityImprove reliabilityDirect heating destructive distillationIndirect and direct heating destructive distillationCombustion chamberFlue gas

The invention discloses a heat exchange chamber of a coke oven. The heat exchange chamber of the coke oven comprises a chamber body, the interior of the chamber body is of a multi-layer structure, anair channel and a flue gas channel are arranged in each layer of the multi-layer structure in a penetrating mode, the layers of the multi-layer structure are sequentially communicated, the air channelis used for being communicated with the external environment, and the flue gas channel is used for being communicated with the external environment. And the flue gas channel is used for communicatingwith a vertical flame path of a combustion chamber in the coke oven. The invention also provides the coke oven adopting the heat exchange chamber. The heat exchange chamber is simple in structure, and the heat exchange efficiency of the coke oven can be effectively improved.

Owner:HUATAI YONGCHUANG BEIJING TECH CO LTD

Cleaning type gas bridge pipe for thermal recovery coke oven

InactiveCN101338203AImprove heat resistanceLow heat shrinkageDistillation gas withdrawalAluminum silicateCoke oven

The invention discloses a clean thermal recycling coke oven bridge pipe which belongs to the industrial kiln accessory field and comprises an outer casing and a liner. The pipe is characterized in that the liner is composed of a clay brick layer, an aluminosilicate insulation carpet layer and an insulation brick layer. The clay brick layer is arranged at the most inner layer of the bridge pipe. The aluminosilicate insulation carpet layer is arranged on the external surface periphery of the clay brick layer. The insulation brick layer is arranged between the outer casing and the aluminosilicate insulation carpet layer. Compared with the prior art, the clean thermal recycling coke oven bridge pipe has the characteristics of light weight, high temperature resistance, low heat conduction, etc.

Owner:山东日照焦电有限公司

Method to reduce heat radiation losses through coke oven chamber doors and walls by adapting the coal cake in height or density

InactiveUS9034147B2Increasing and decreasing heightReduce radiation lossCarbon compoundsCoal charges mechanical treatmentRadiation lossEngineering

A method for reducing the coking time in the oven area near the door or end wall and for improving coke quality and situation of emissions by compensating for radiation losses through coke oven chamber doors and end walls is described. This compensation is accomplished by varying the height of the coal cake in the environment of the frontal coke oven chamber doors. The variation is achieved both by increasing or decreasing the coal cake over part of the length or over the entire length of the coke oven chamber door. The reduction in the height of the coal cake can be generated by omission of coal or coal compacts, the increase in height can be accomplished by stacking of coal and pressing or adding of coal compacts, with it also being envisaged to omit the pressing cycle so as to obtain a recess with a lower coal cake density which also has less heat radiation.

Owner:THYSSENKRUPP IND SOLUTIONS AG

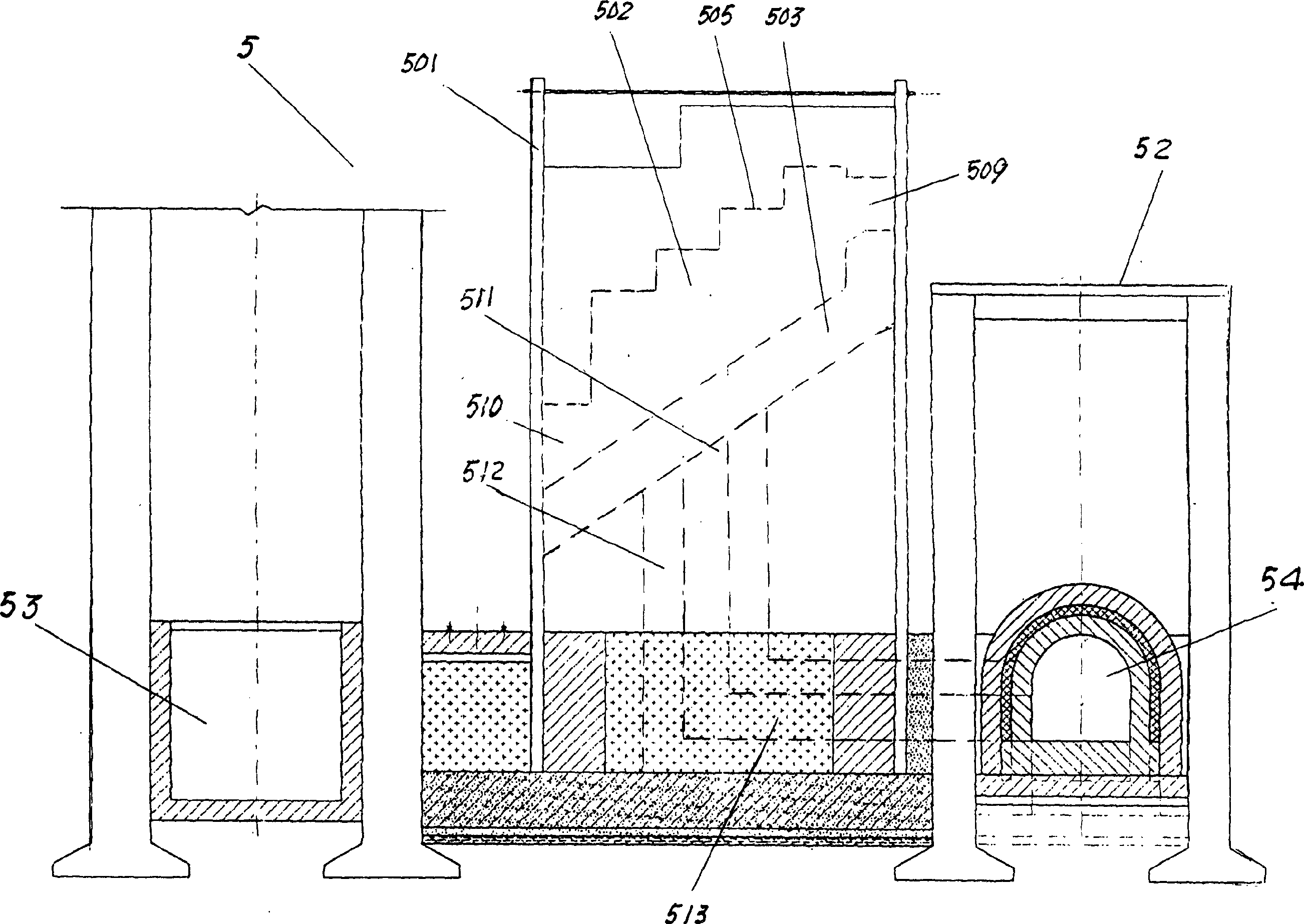

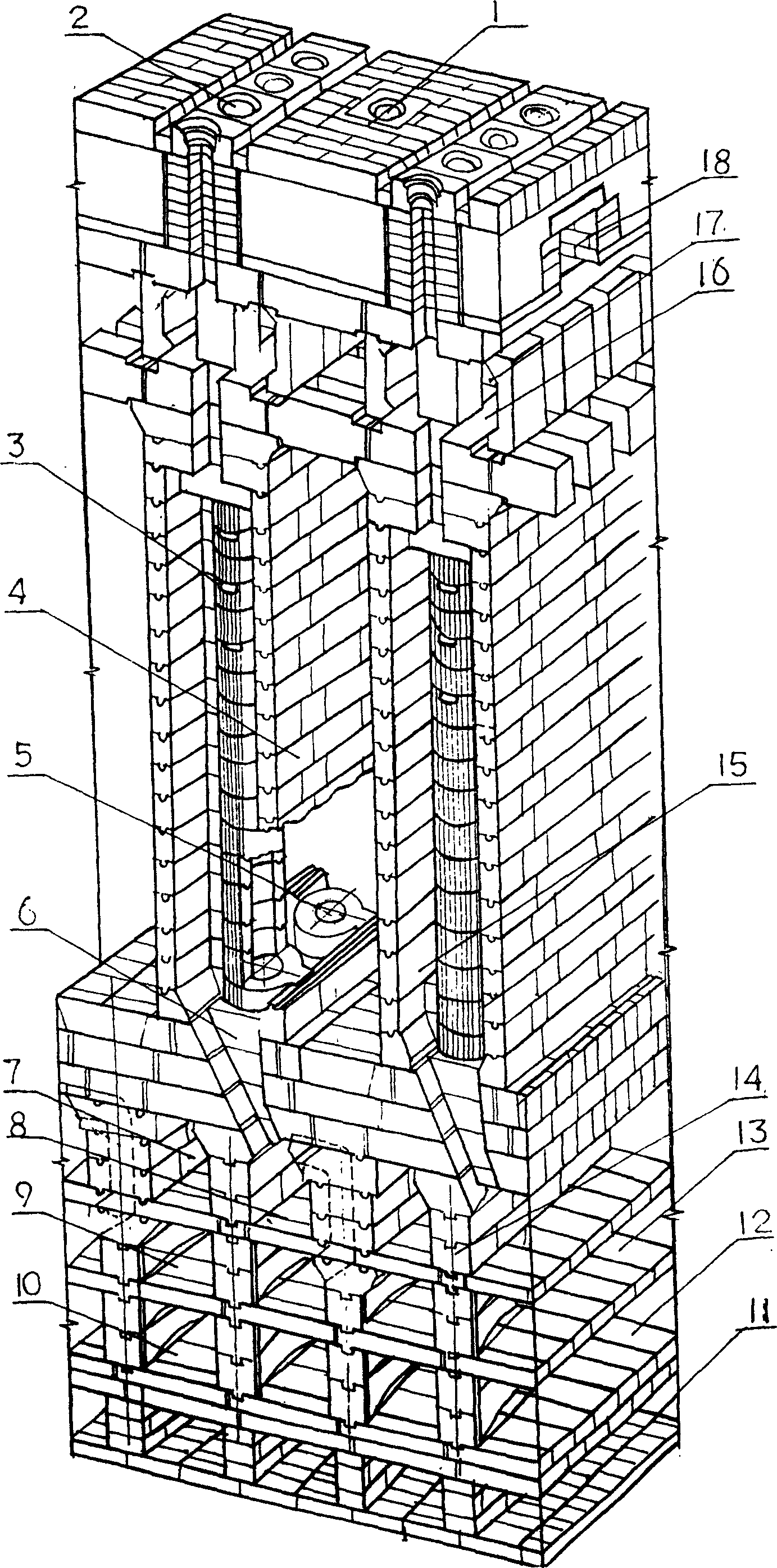

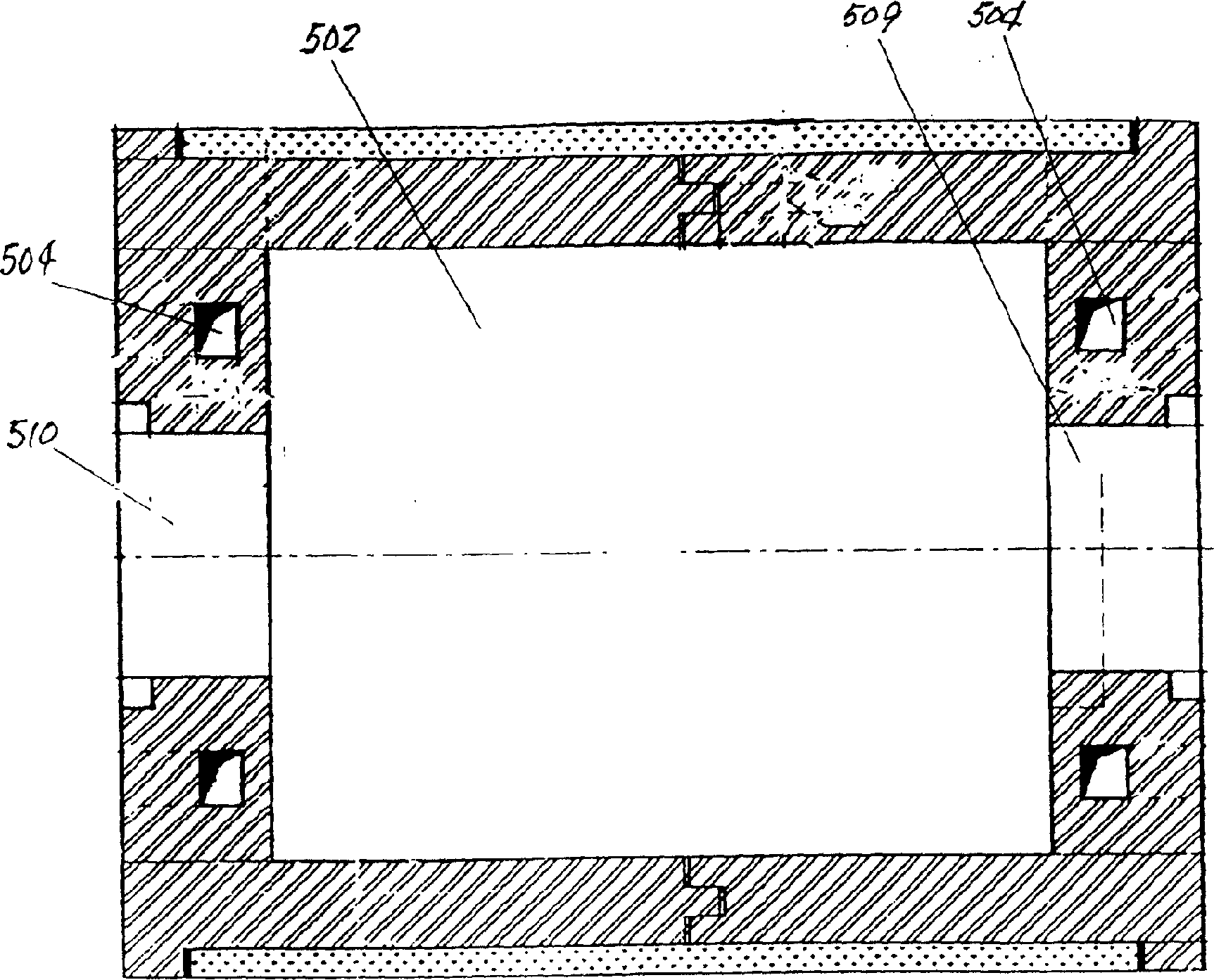

Casting type coke carbonizing furnace

InactiveCN1208425CReasonable force structureEfficient use ofInclined chamber coke ovensStationary retortsThermal energyCombustion chamber

Owner:商丘市普天工贸有限公司煤化工研究所

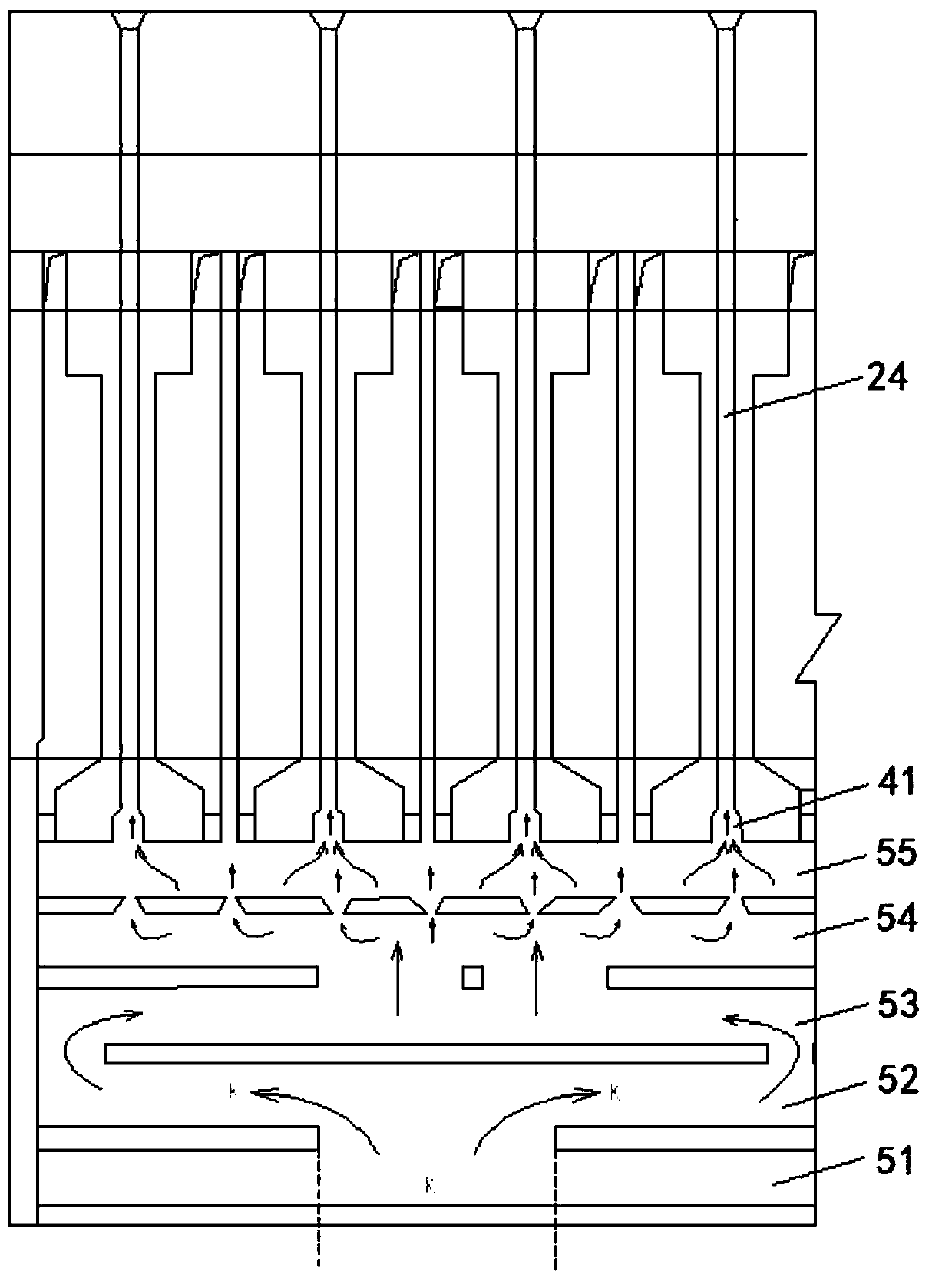

Air-preheating-type heat recovery coke oven

PendingCN110408412AAchieve warm-upEfficient preheatingPreheating coke ovensEnergy inputCombustion chamberCarbonization

The invention relates to an air-preheating-type heat recovery coke oven. The air-preheating-type heat recovery coke oven comprises a combustion chamber, a carbonization chamber, a chute, a pressure balance chamber, a criss-cross exhaust gas flue and a combustion air distribution channel, wherein the chute is connected between the combustion chamber and the pressure balance chamber; the criss-crossexhaust gas flue is arranged at the lower portion of the pressure balance chamber and communicated with the pressure balance chamber; the combustion air distribution channel is arranged at the lowerportion of the criss-cross exhaust gas flue; an air preheating upright channel is arranged in a main wall below the combustion chamber and communicated with the combustion air distribution channel; anupright fire flue partition combustion air channel is arranged in upright fire flue partitions and communicated with the air preheating upright channel; an outlet of the upright fire flue partition combustion air channel is communicated with upright fire flues of the combustion chamber. According to the air-preheating-type heat recovery coke oven, combustion air is uniformly distributed and supplied into the upright fire flues of the combustion chamber and merged with raw coke oven gas in the upright fire flues for combustion after being subjected to sufficient heat transfer and temperature rise with high-temperature exhaust gas, so that the combustion temperature is increased, the coking time is shortened, and the purpose of improving the production efficiency is achieved.

Owner:HUATAI YONGCHUANG BEIJING TECH CO LTD

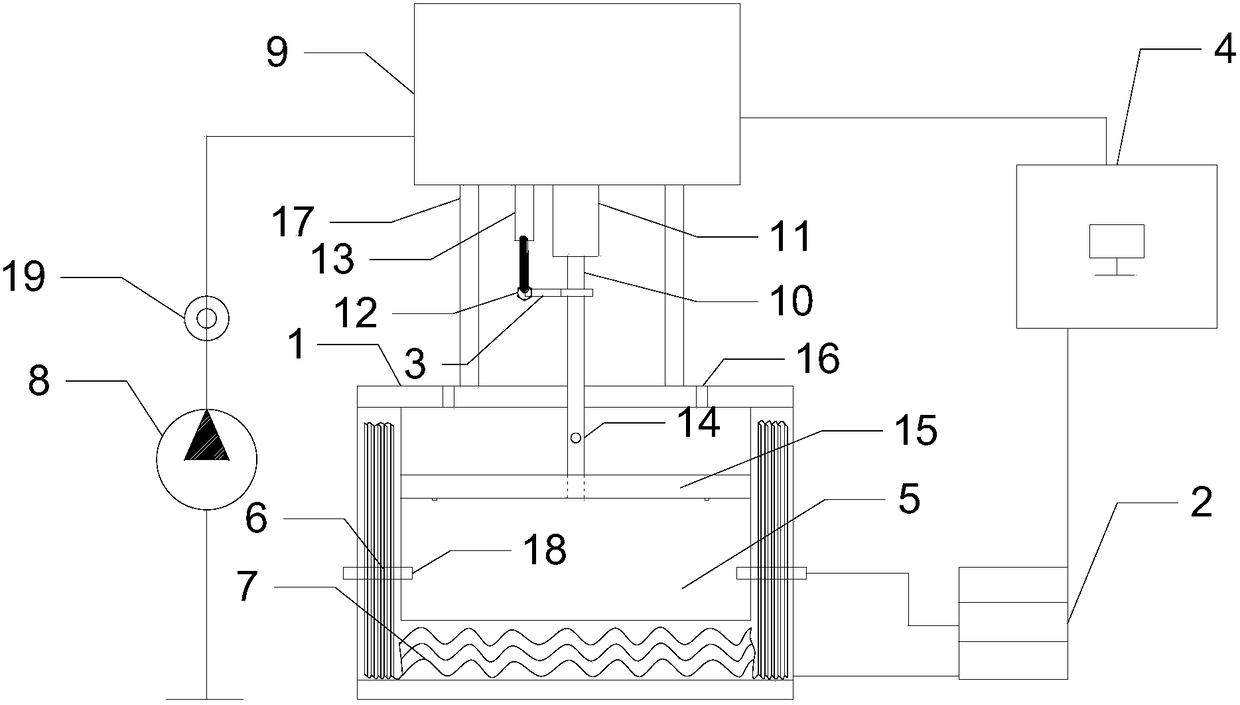

Microwave pretreatment desulfurization coking method and device

InactiveCN103059889BEnhanced mass transferImprove heat transfer performanceCharging devicesMicrowave frequency rangeControl system

The invention discloses a microwave pretreatment desulfurization coking device, and particularly provides a device for coking coal. The device comprises a coal blending process, a coal charging process and a coking process; and the method further comprises a microwave pretreatment process between the coal blending process and the coal charging process. The microwave pretreatment process adopts a microwave pretreatment device with the microwave frequency ranged from 300MHz to 300GHz for irradiating, dewatering and desulfurizing the blended coal; and the temperature of the pretreated coal sample is controlled between 150 and 250 DEG C; and then coal is prepared to be charged into a stove and coked. The microwave pretreatment device comprises a microwave reaction chamber body, a connecting device, a conveyor, an exhaust duct and a detection control system, wherein the connecting device, the conveyor, the exhaust duct and the detection control system are arranged among the microwave reaction chamber body, a coke stove coal tower and a coal charging trolley or a material bin. The device is simple; after being quickly preheated, dewatered and desulfurized, the blended coal can be coked so as to improve the bulk density, shorten the coking time and promote the yield of a single furnace as well as the coal quality; and clean and effective utilization of energy can be realized.

Owner:CHINA UNIV OF MINING & TECH

Composite building structure of coke oven heat accumulation chamber checker brick

ActiveCN108753316AImprove heat exchange efficiencySolve the low temperature problemCoke oven brickworkAndalusiteMullite

The invention discloses a composite building structure of coke oven heat accumulation chamber checker bricks. The composite building structure comprises clay bricks, wherein the lower part of a heat accumulation chamber is made of the clay bricks; the layer number of the heat accumulation chamber accounts for 50-80% of the total building layer number of the heat accumulation chamber; checker bricks made of low-aluminum mullite and andalusite are built on the clay bricks; the layer number of the checker bricks accounts for 20-50% of the total building number of the heat accumulation chamber; the low-aluminum mullite refers to mullite of which the aluminum oxide content is smaller than 60%. The high temperature deformation resistance of the composite building structure of the coke oven heataccumulation chamber checker bricks can be increased by 100-200 DEG C, the service life can be greatly prolonged, the heat exchange efficiency of the heat accumulation chamber can be also improved, agood effect can be achieved for solving low temperature problems of a coke oven heat accumulation chamber of 7.63m, the coking time of a coal layer of each carbonization chamber can be shortened by 1-3 hours, and the composite building structure has a reference function for checker brick structures and materials of other similar coke oven heat accumulation chambers.

Owner:武汉钢铁有限公司

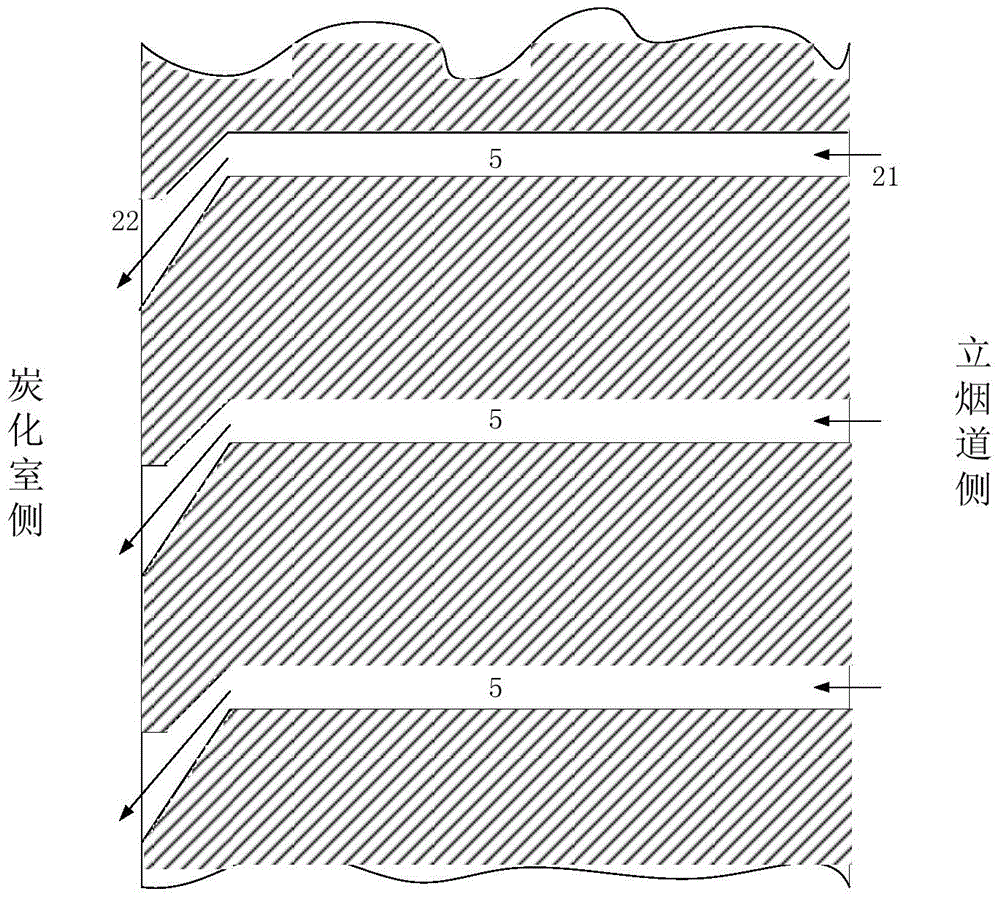

Combustion chamber-carbonization chamber wall structure of coke oven

InactiveCN106833683AGuaranteed structural strengthGuaranteed air tightnessCoke oven brickworkBrickwork leakage repair/preventionCombustion chamberCarbonization

The invention relates to a combustion chamber-carbonization chamber wall structure of a coke oven. A combustion chamber-carbonization chamber is formed by arranging combustion chambers and carbonization chambers alternately, wherein each combustion chamber consists of multiple parallel vertical flame channels; flame channel partitions are arranged among the vertical flame channels, carbonization chamber walls are arranged between the carbonization chambers and the vertical flame channels, and concave-convex meshing structures are arranged in positions where the vertical flame channel partitions in the combustion chambers and the carbonization chamber walls are connected; the inner surface of one side, facing the corresponding vertical flame channel, of each carbonization chamber wall adopts a concave structure, and the thickness of the concave inner surface is 10-15 mm smaller than that of each carbonization chamber wall. The heat transfer efficiency of the combustion chamber-carbonization chamber can be significantly improved while the structural strength of a coke oven body and the air tightness of the combustion chamber-carbonization chamber are guaranteed, the coking time can be shortened, the coke yield can be increased, the production efficiency of the coke oven can be improved, and large-scale development of the coke oven is better facilitated.

Owner:ACRE COKING & REFRACTORY ENG CONSULTING CORP DALIAN MCC

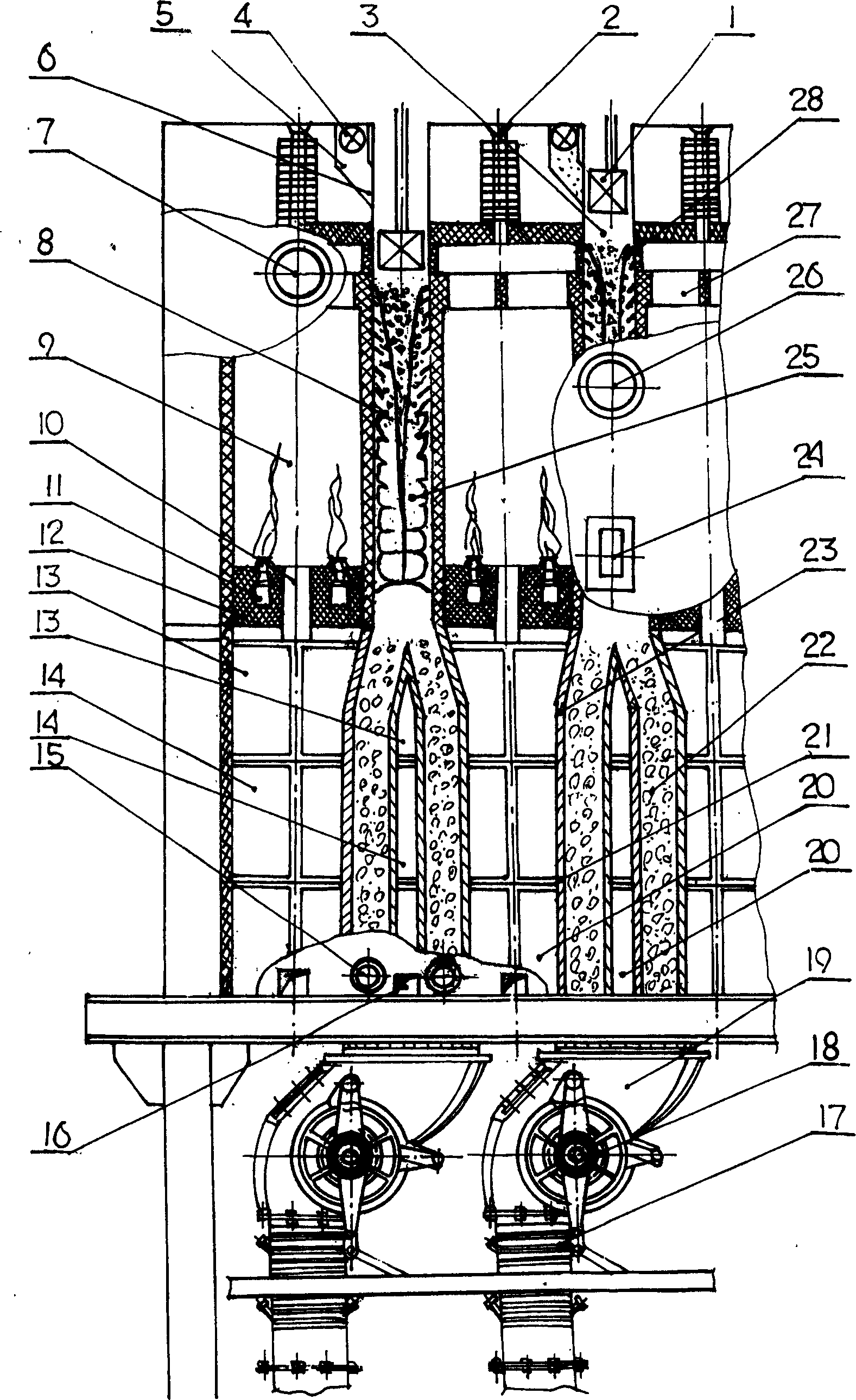

Vertical automatic cokery with cold loading and cold discharge

InactiveCN1249201CSolve the anterograde problemSolve the problem of not being able to smelt cokeVertical chamber coke ovensEnergy inputThermal energyCombustion chamber

This invention is a kind of new-type vertical continuous coke oven, and a high-temperature dry distillation coking device of coal. The main characteristic of this invention is: After the cool furnace roof holds the coal, are urged to fall by the jar of hydraulic pressure of the furnt device, arrange the burnt device, list while being cool by stove bottom finally, dry distillation coal gas a part that course produce melt down and heat, the others support downstream production need; Air after preheating by heat exchanger, is it set up by oblique way fire dish mix burning with coal gas to enter, the high-temperautre waste gas after burning is discharged by the horizontal passway of the waste gas in the top of combustion chamber, retrieve heat energy for the power plant of remaining energy.

Owner:程相魁

Novel energy-saving coke oven door lining brick and manufacturing method thereof

PendingCN112809905AReduce weightLow investment costCoke oven brickworkCeramic shaping apparatusInsulation layerBrick

The invention relates to a novel energy-saving coke oven door lining brick and a manufacturing method thereof. The coke oven door lining brick comprises an oven door lining brick body, a heat insulation layer and a glaze layer, wherein the oven door lining brick body is a refractory castable prefabricated part; the heat insulation layer is arranged in the oven door lining brick body and is completely wrapped by the oven door lining brick body; the inner surface, namely the working surface, of the oven door lining brick body is coated with the glaze layer; a fixed transverse rod hole is formed in the middle of the oven door lining brick body along the length direction; a plurality of fastener connecting holes are formed in the outer side of the oven door lining brick body; the diameter of each fastener connecting hole is greater than that of the fixed transverse rod hole; and the inner end of each fastener connecting hole vertically penetrates through the fixed transverse rod hole. According to the novel energy-saving coke oven door lining brick disclosed by the invention, the heat insulation layer is completely wrapped in the castable prefabricated part, and the working surface of the oven door lining brick body is coated with the glaze layer, so that the purposes of reducing the weight of an oven door and prolonging the service life of the heat insulation layer can be achieved, the heat loss of a furnace end of a carbonization chamber can be stably reduced for a long time, and the temperature of the outer wall of the oven door is reduced.

Owner:ACRE COKING & REFRACTORY ENG CONSULTING CORP DALIAN MCC

Coke oven heating system and method adopting oxygen-enriched combustion

PendingCN114673989AReduce coking energy consumptionReduce lossesMaintainance of heating chambersIndirect carbon-dioxide mitigationGas pipelineEnvironmental geology

The invention relates to a coke oven heating system and method adopting oxygen-enriched combustion. The system comprises a gas-enriched pipeline and / or a lean gas pipeline, an oxygen-enriched gas pipeline and a waste gas return pipeline, a rich gas regulating valve is arranged on the rich gas pipeline, a lean gas regulating valve is arranged on the lean gas pipeline, an oxygen regulating valve, a return distribution waste gas inlet, an oxygen concentration analyzer and an oxygen-enriched fan are arranged on the oxygen-enriched gas pipeline, and the return distribution waste gas inlet is connected with a waste gas pipeline led out of the regenerative chamber through a waste gas return distribution pipeline. And the waste gas return pipeline is provided with a return waste gas regulating valve and a return waste gas fan. The invention can improve the radiation heat transfer efficiency in the furnace, reduce the waste gas amount, reduce the coking energy consumption of the coke oven, shorten the coking time, save high-quality gas resources and reduce the generation of nitrogen oxides in the combustion process.

Owner:ACRE COKING & REFRACTORY ENG CONSULTING CORP DALIAN MCC

Coking method for increasing consumption of weak binding coal and reducing production energy consumption

InactiveCN110923000AEasy to useReduce production energy consumptionCoke ovensCombustion chamberThermodynamics

The invention provides a coking method for increasing the consumption of weak binding coal and reducing production energy consumption. The coking method comprises the following steps: (1) charging blended coal from the coal charging hole of a carbonization chamber, assembling a furnace door, and introducing coal gas and air into a combustion chamber, wherein the coal gas is mixed coal gas of cokeoven coal gas and blast furnace coal gas; (2) transferring heat generated by the combustion of the coal gas and the air to the blended coal in the carbonization chamber through a furnace wall betweenthe combustion chamber and the carbonization chamber; and (3) when the center temperature of the blended coal in the carbonization chamber reaches 1050 DEG C, and smoldering for 1.7-2 hours to obtaincoke, wherein preferably the heat conductivity coefficient of the furnace wall in the step (2) is 2.25-2.55 W / m.K. By utilizing the method, the consumption of weak bonding coal can be effectively increased, the quality of coke is not degraded, the risk of coking coal resource shortage caused by reduction of high-quality coking coal resources can be effectively relieved, and the coke oven yield ina coking process can be effectively increased.

Owner:BAOSHAN IRON & STEEL CO LTD

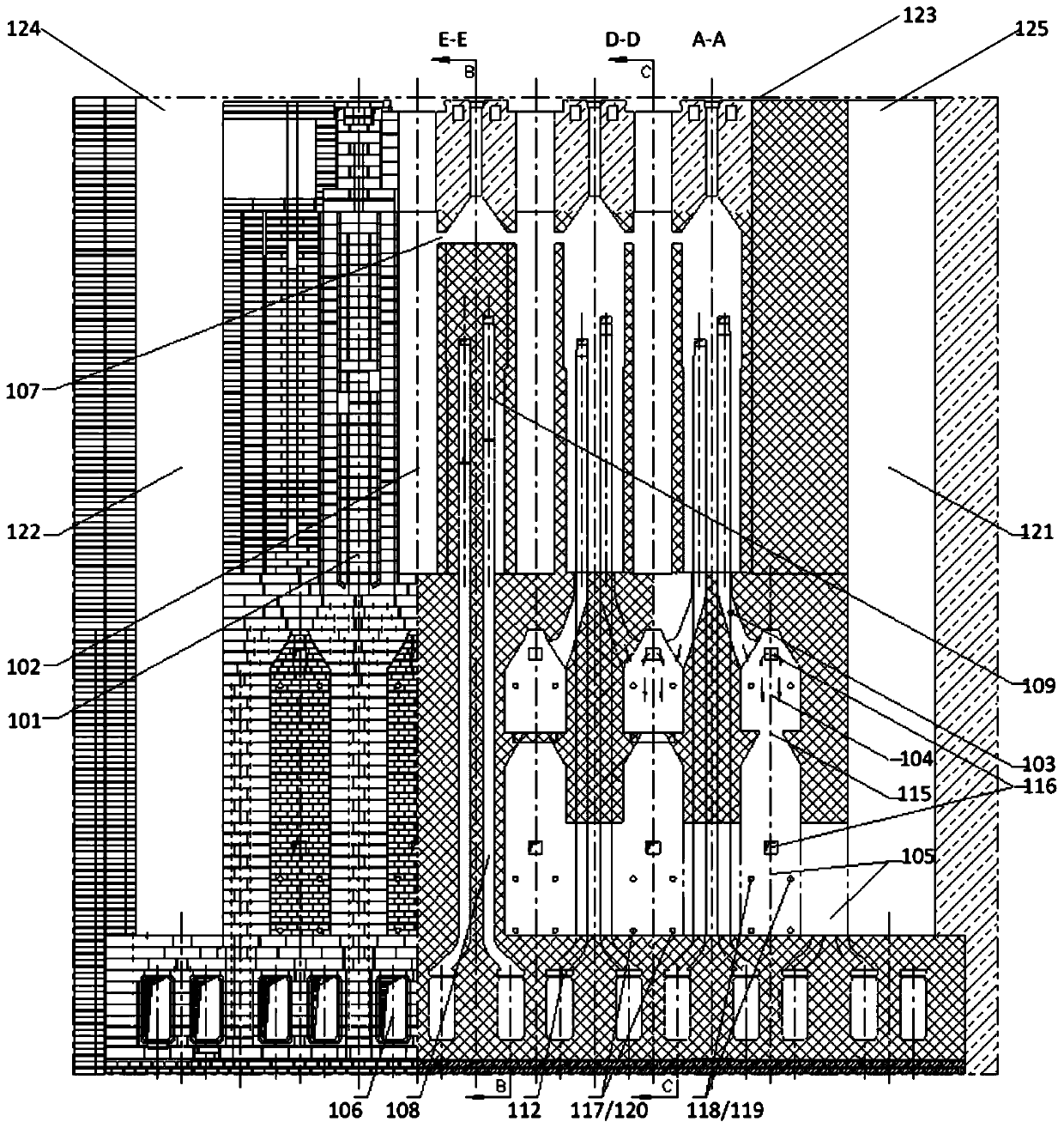

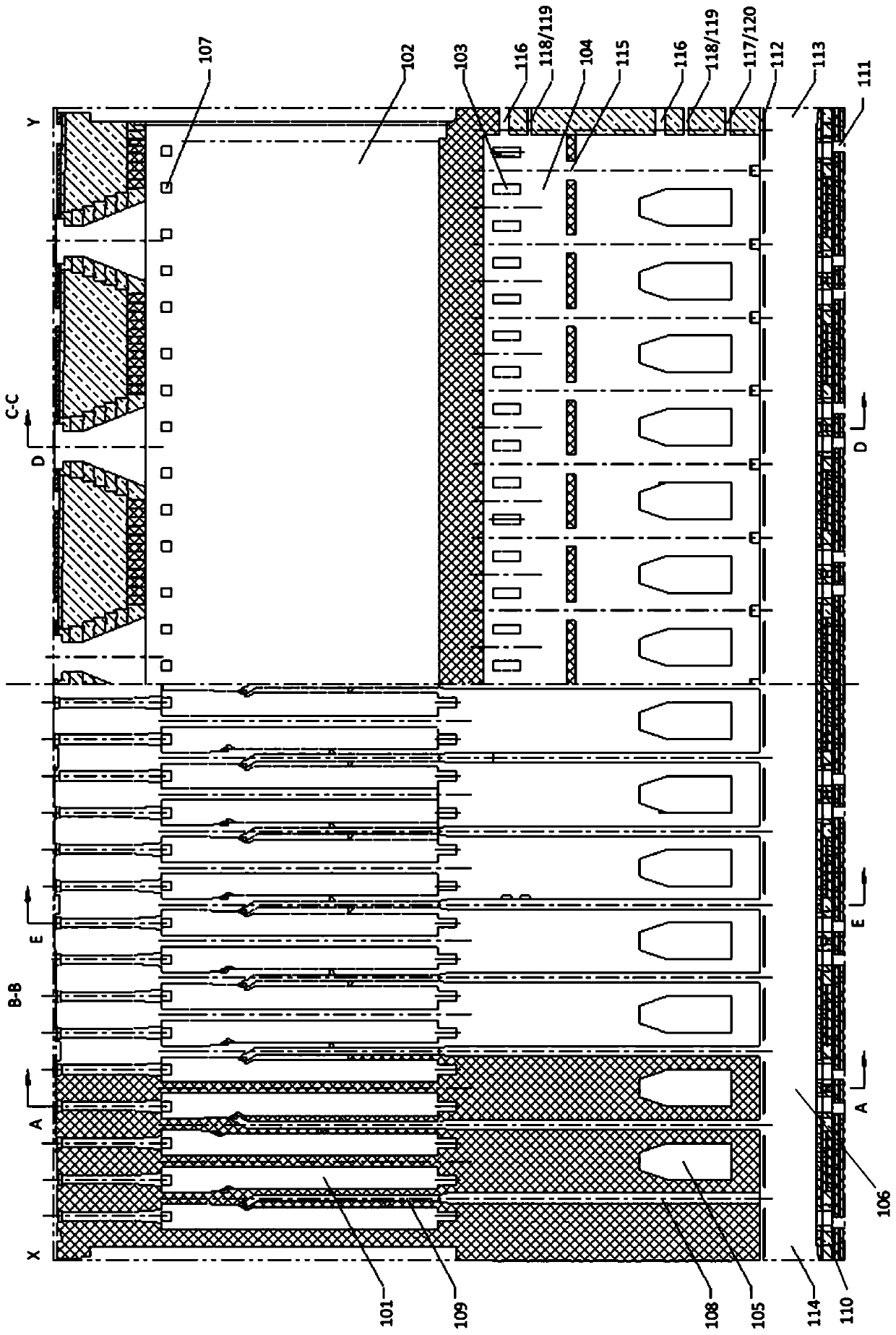

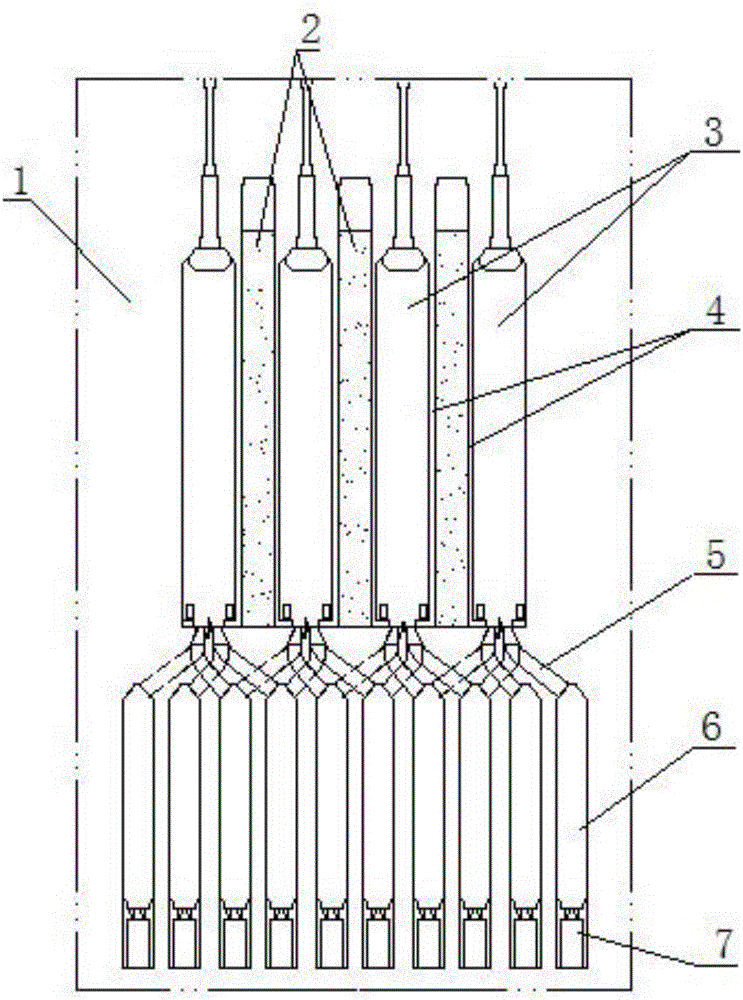

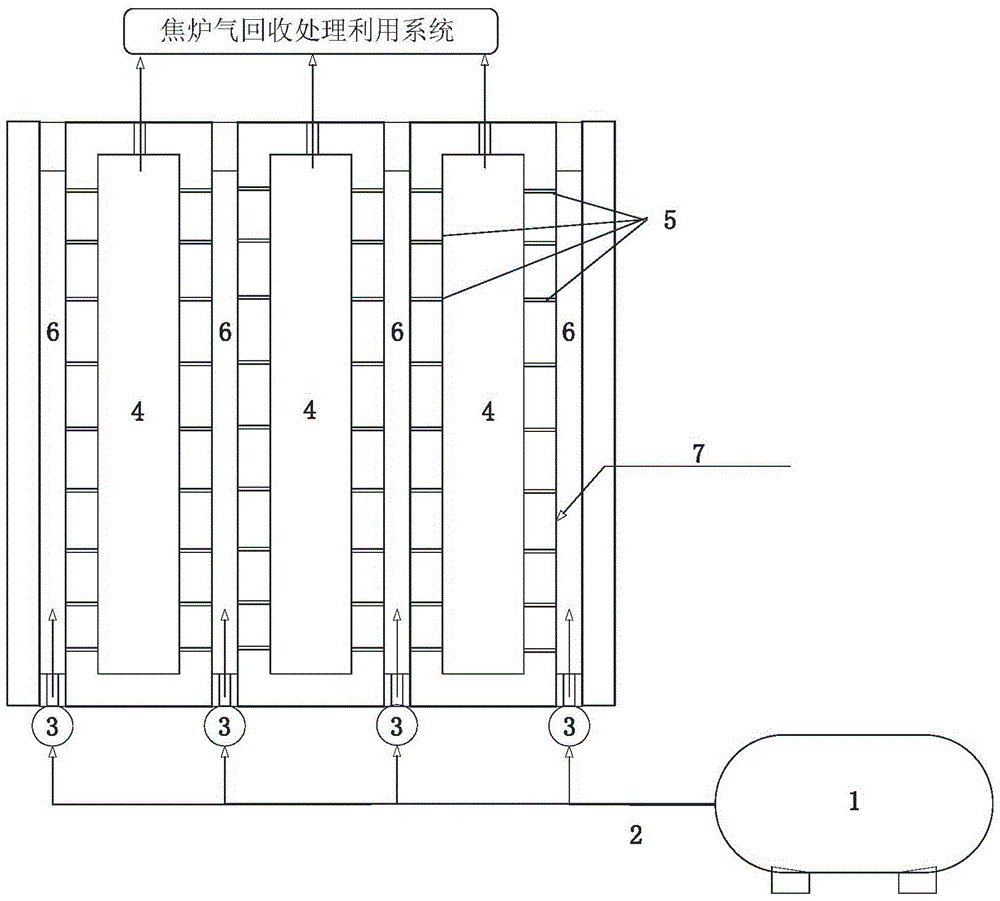

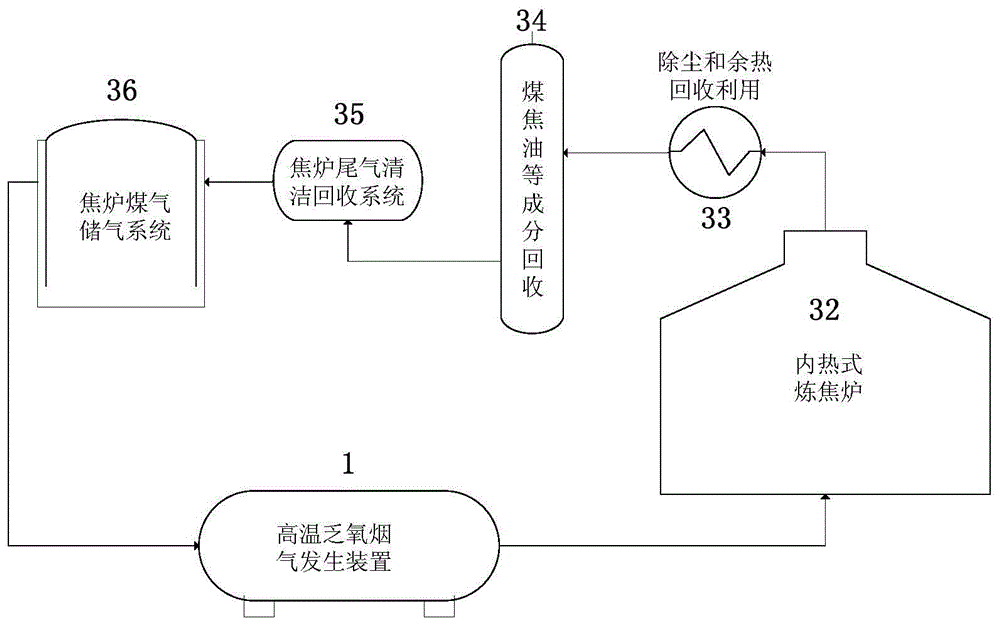

An internal heat type coal dry distillation furnace, an internal heat type coal dry distillation system and a coal dry distillation process

ActiveCN103666507BImprove efficiencyReduce energy consumptionVertical chamber coke ovensDirect heating destructive distillationCarbonizationProcess engineering

The present application relates to a coal internally heated carbonization retort, an internally heated coal carbonization system and process. The resort may comprise one or more carbonization chambers with heating gas conducting walls, one or more heating gas distribution channels and an oxygen-deficient heating gas generator. The carbonization chambers may be arranged in parallel and filled with coals, and the heating gas generator may be configured to generate oxygen-deficient heating gas which is fed into the carbonization chambers through their heating gas conducting walls after the heating gas goes through the transmission and distribution pipes, and distribution channels. The heating gas directly contacts with and heats the coals filled in the chambers for carbonization or coking.

Owner:陈晓辉

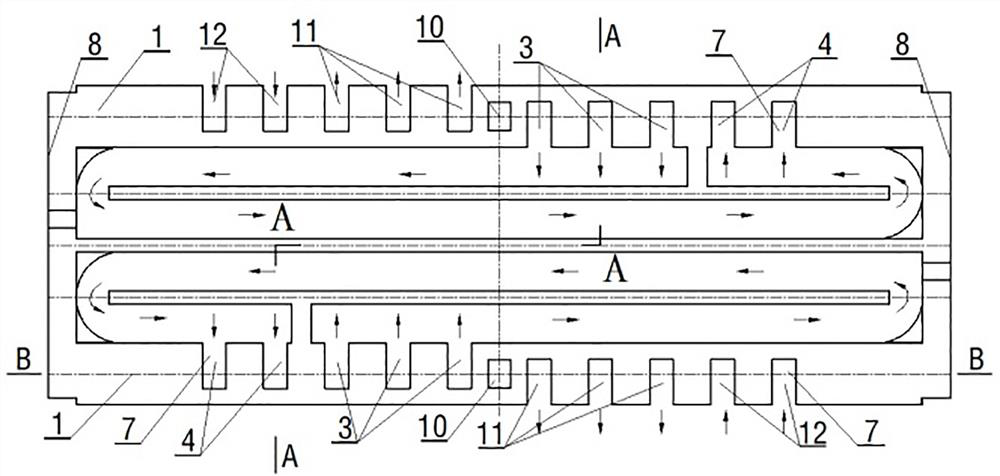

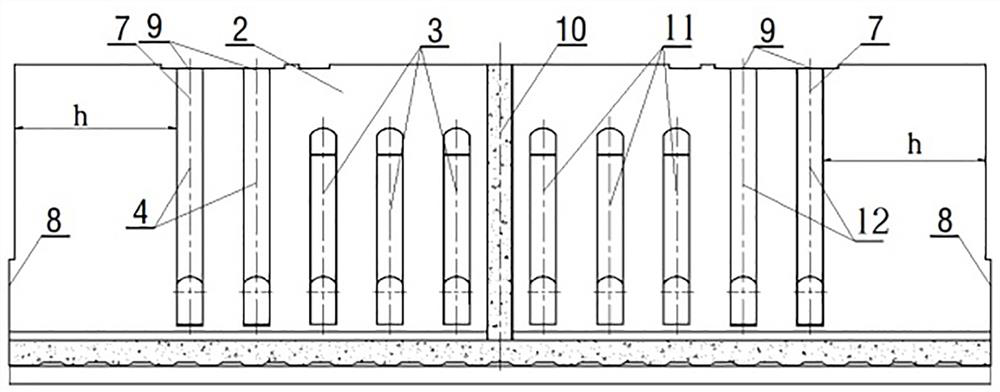

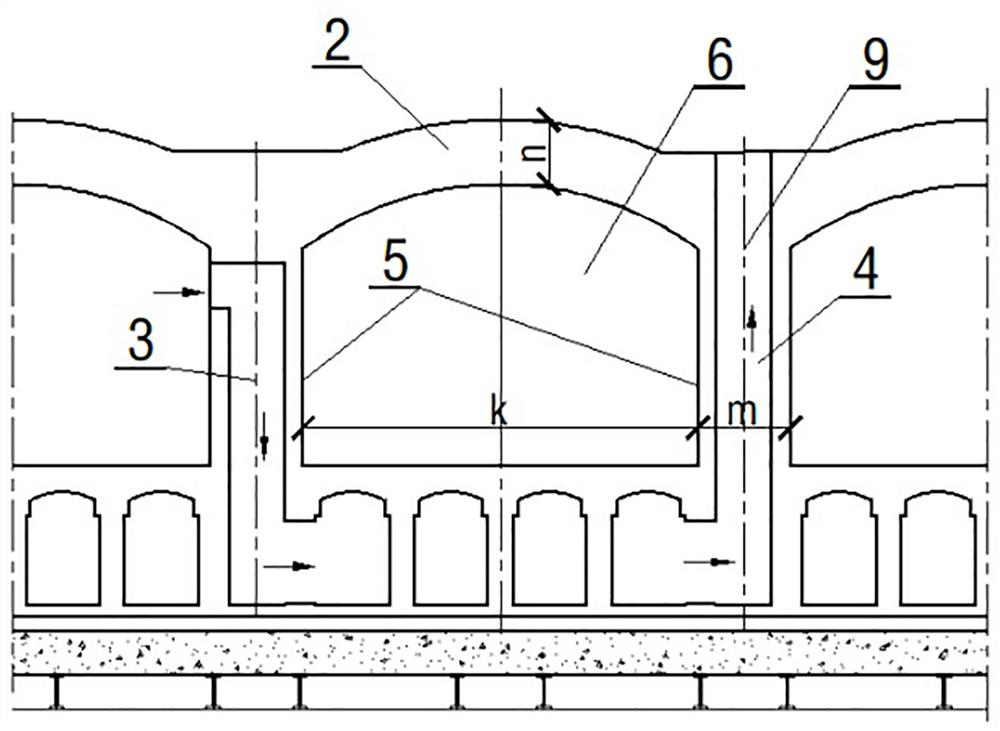

Main wall flame path structure of heat recovery coke oven

PendingCN113388411AImprove heat storage capacityReduce heat storage capacityCombustible gas coke oven heatingCoke oven detailsFurnace temperatureThermodynamics

The invention relates to the technical field of heat recovery coke ovens in the metallurgical industry, in particular to a main wall flame path structure of a heat recovery coke oven. The main wall flame path structure is characterized in that any one carbonization chamber comprises two main oven walls, any one main oven wall is internally provided with a main wall flame path consisting of two ascending flame paths and three descending flame paths of the carbonization chamber and another main wall flame path consisting of two ascending flame paths and three descending flame paths of an adjacent carbonization chamber, the two main wall flame paths are symmetrically arranged on the two sides of a central column, the distance h between a machine-side or coke-side front face line and the nearest side flame path is 2720 + / - 100 mm, and a ratio of the thickness m of the main furnace wall to the width k of the carbonization chamber is 0.2-0.3. The main wall flame path structure of the invention has the advantages that the defect that the furnace wall is thoroughly cold during coke pushing and coal charging of the heat recovery coke oven is effectively overcome, and the purposes of shortening the time for recovering a normal furnace temperature after coal charging and coke discharging, shortening coking time and increasing coke productivity are effectively achieved.

Owner:辽宁科技大学工程技术有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com