Patents

Literature

31results about How to "Efficient preheating" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

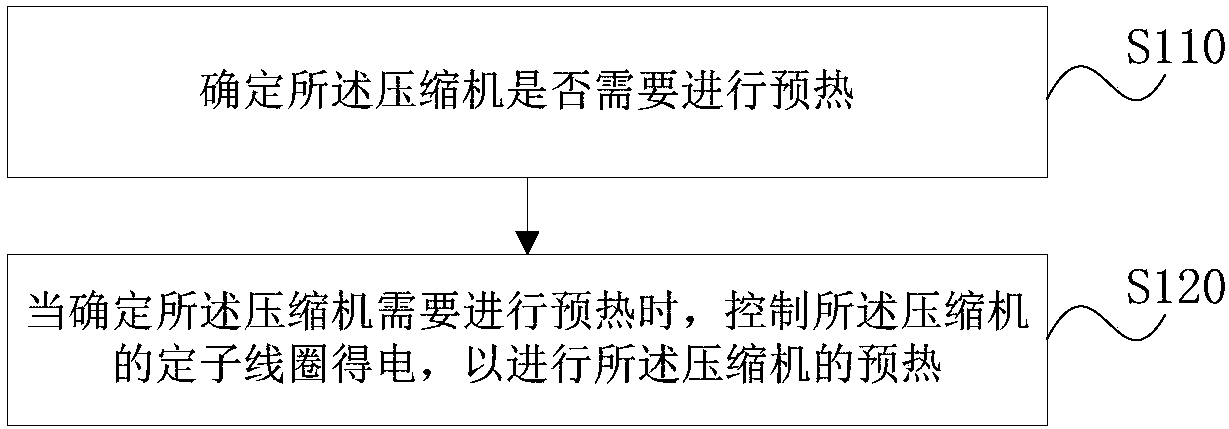

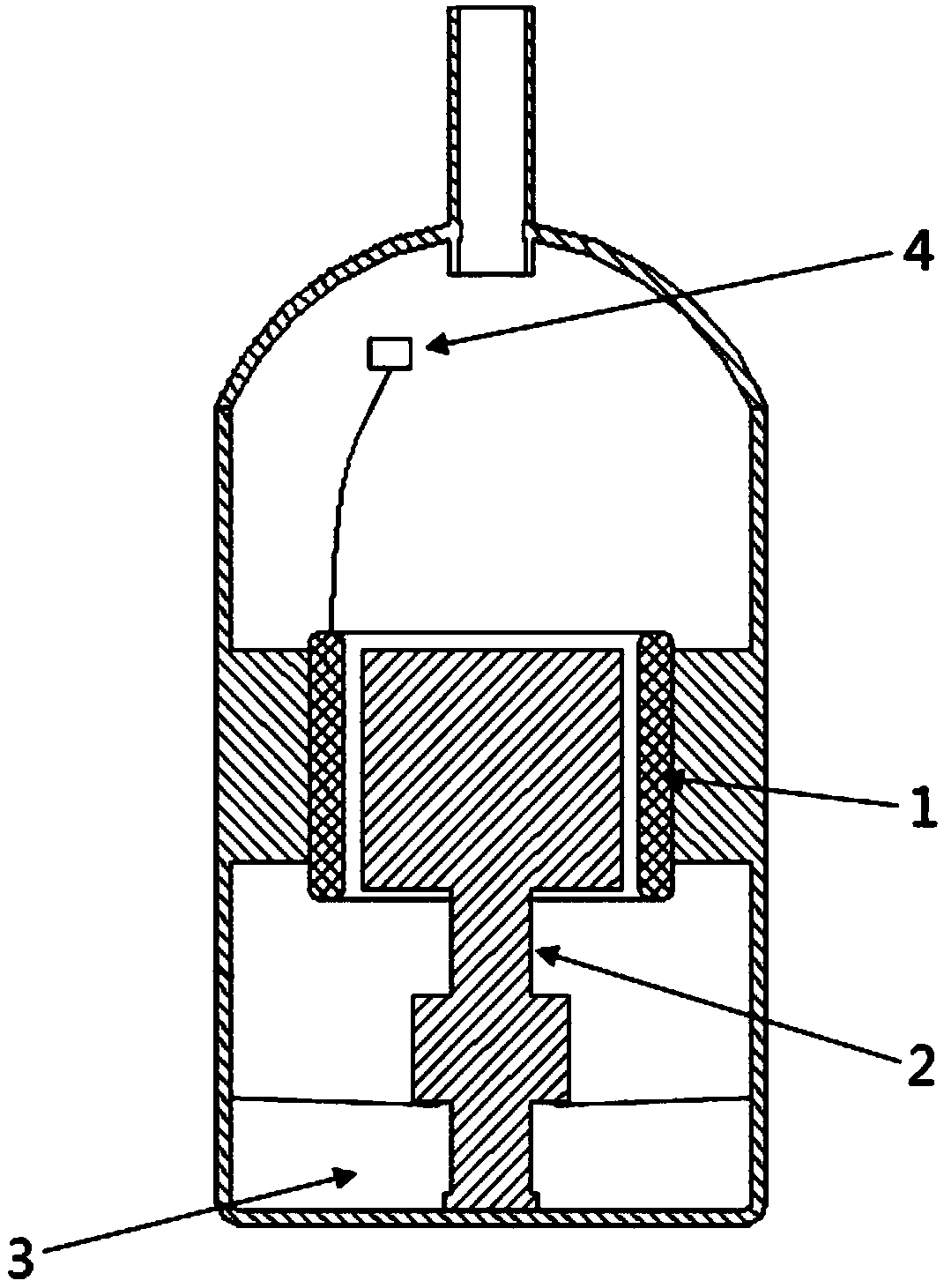

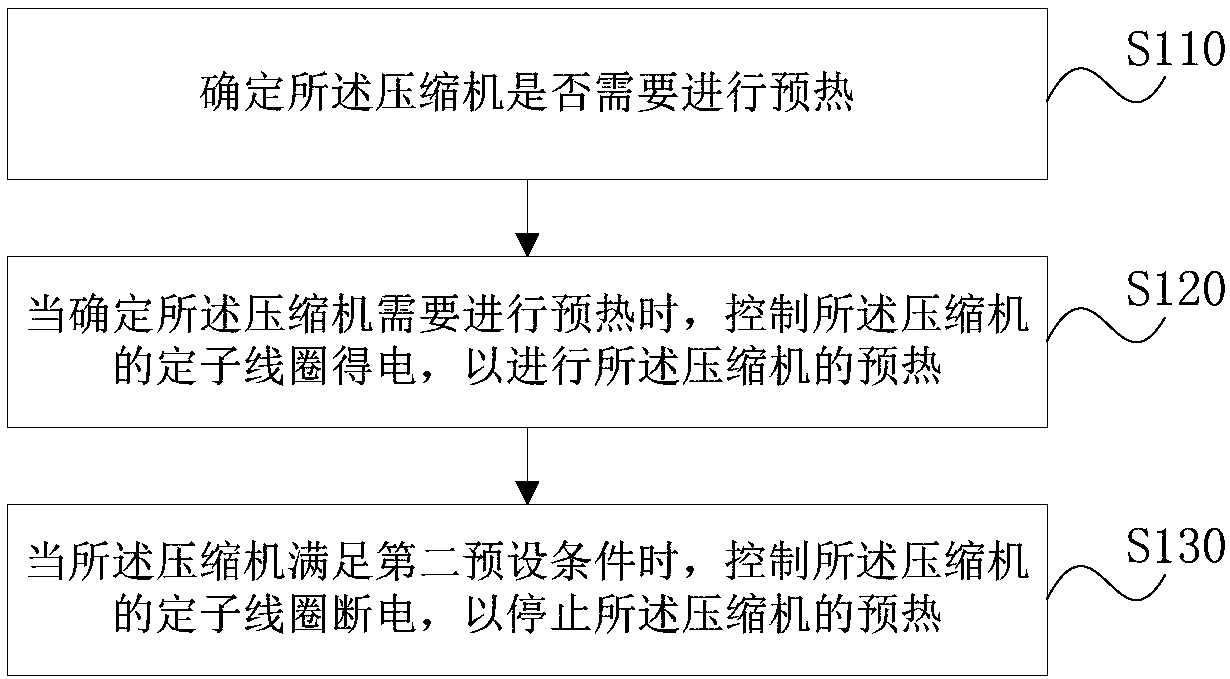

Preheating control method, device, storage medium and device for compressor

InactiveCN108374777AEfficient preheatingPositive displacement pump componentsPump controlElectricityStator coil

The invention provides a preheating control method, a device, a storage medium and a device for a compressor. The preheating control method comprises the following steps that whether the compressor needs preheating or not is determined; when the compressor is determined to be preheated, a stator coil of the compressor is controlled to generate electricity, so that the stator coil emits heat and then the heat is transmitted to an oil pool of the compressor through a rotor crankshaft of the compressor to preheat the compressor. According to the scheme, fast and efficient preheating of the oil temperature of the compressor can be realized and an original oil heating belt can be replaced, the problems of low heating efficiency and slow heating speed when an oil heating belt is used for preheating the compressor are solved.

Owner:GREE ELECTRIC APPLIANCES INC

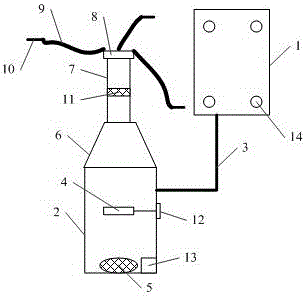

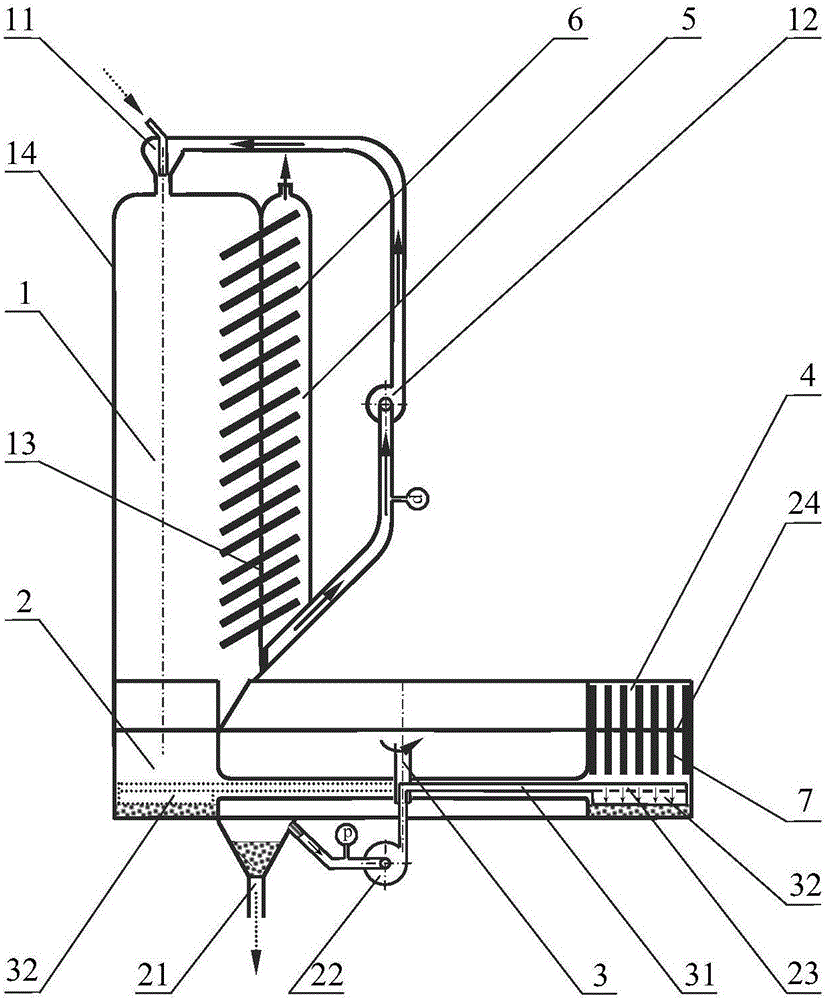

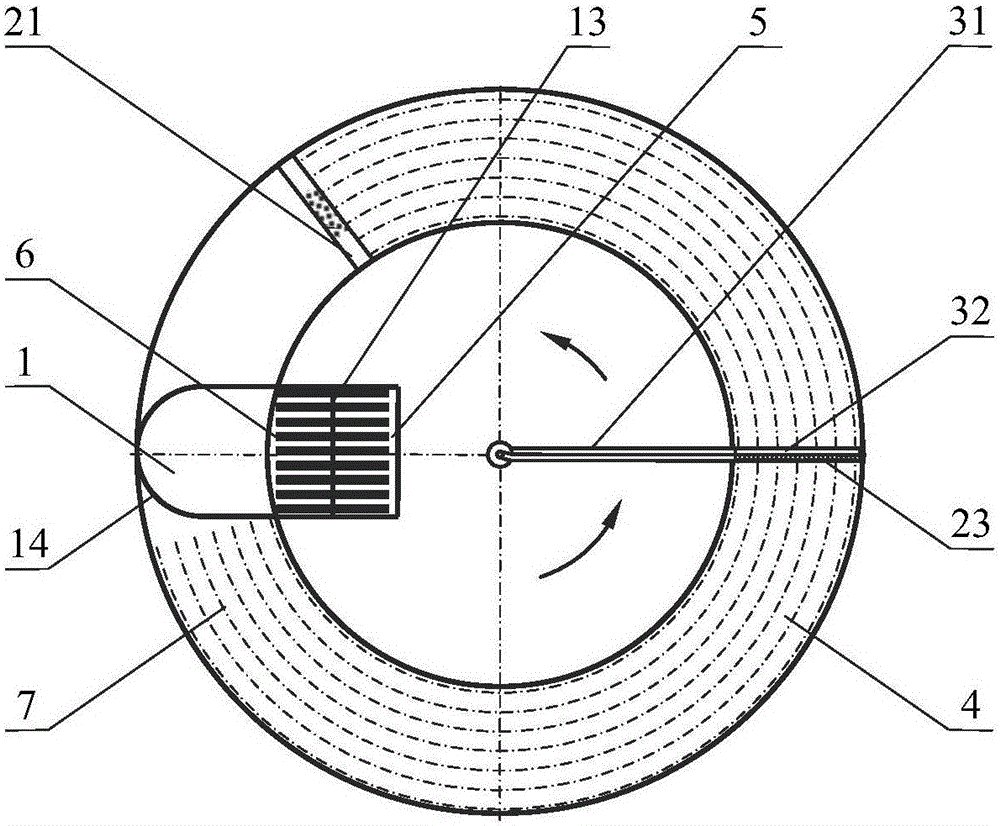

Technology for cleanly and efficiently processing lead-bearing waste residues

PendingCN108950236AGuaranteed temperatureSecurity atmosphereProcess efficiency improvementLead smeltingSmelting process

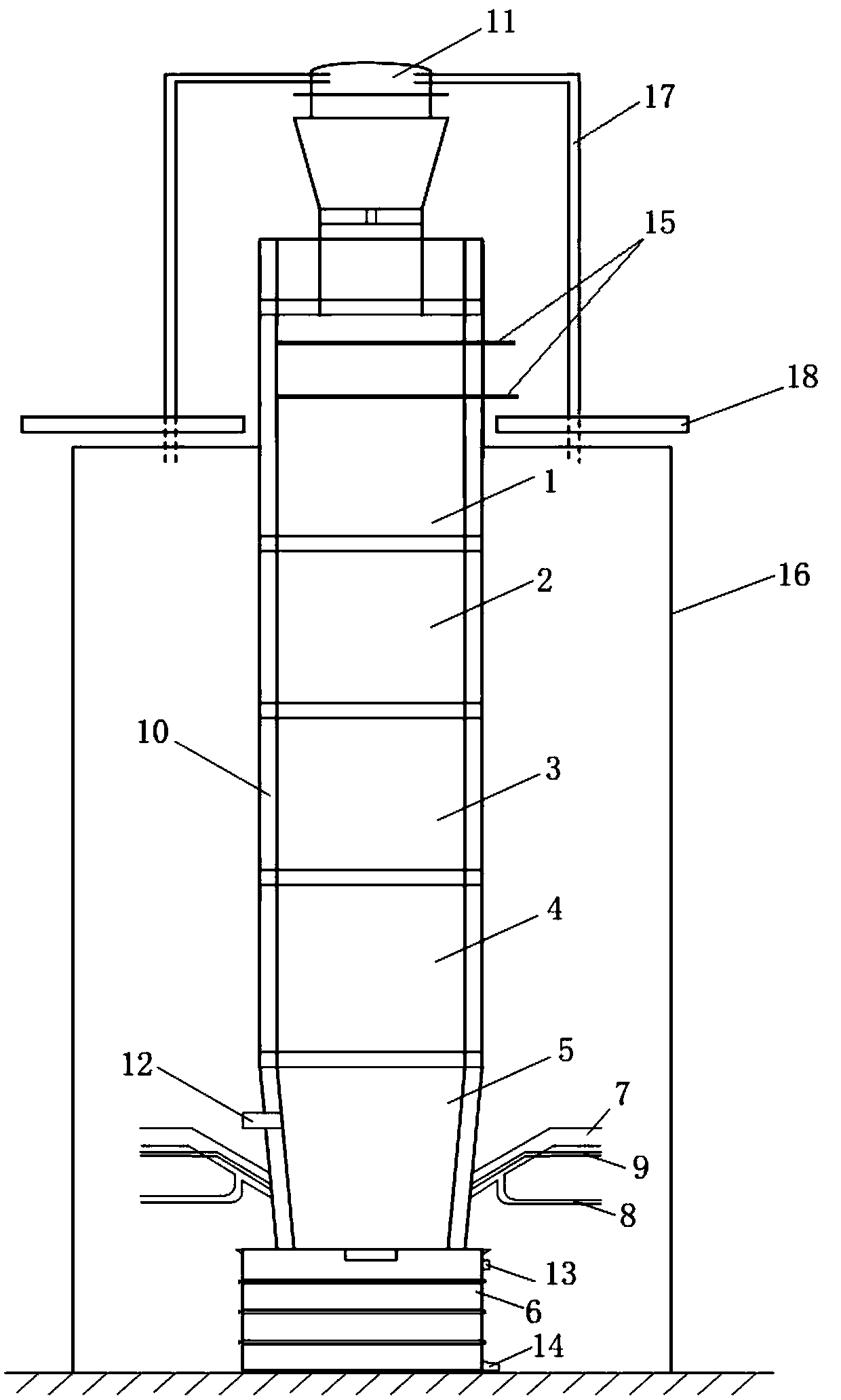

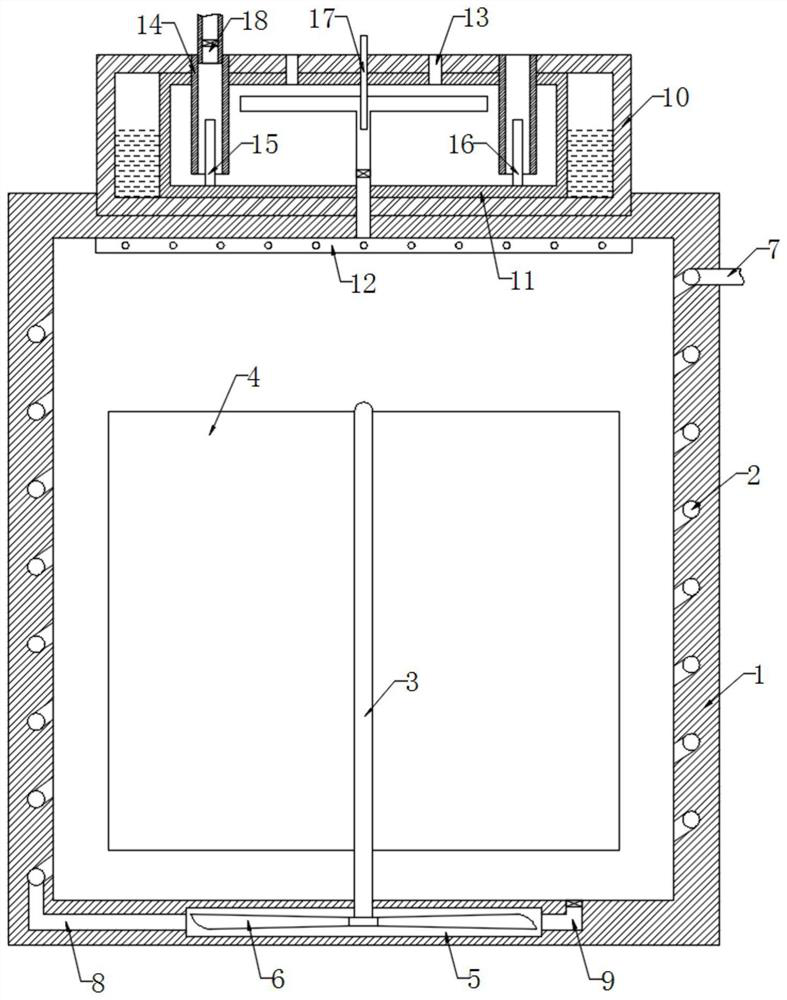

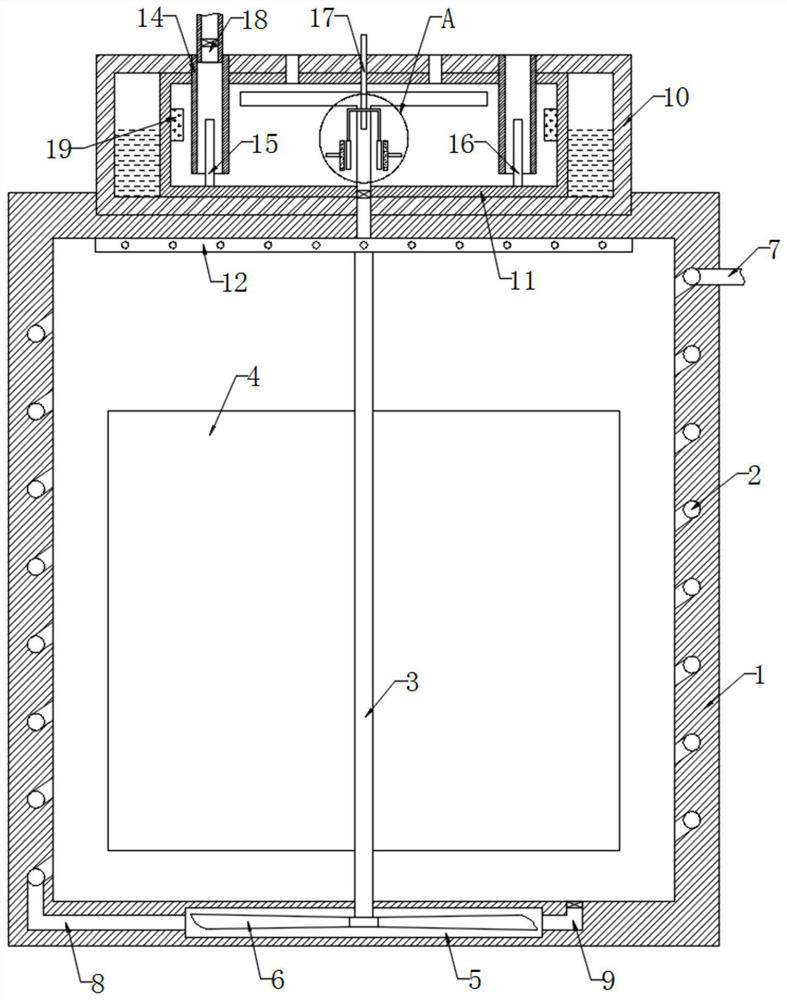

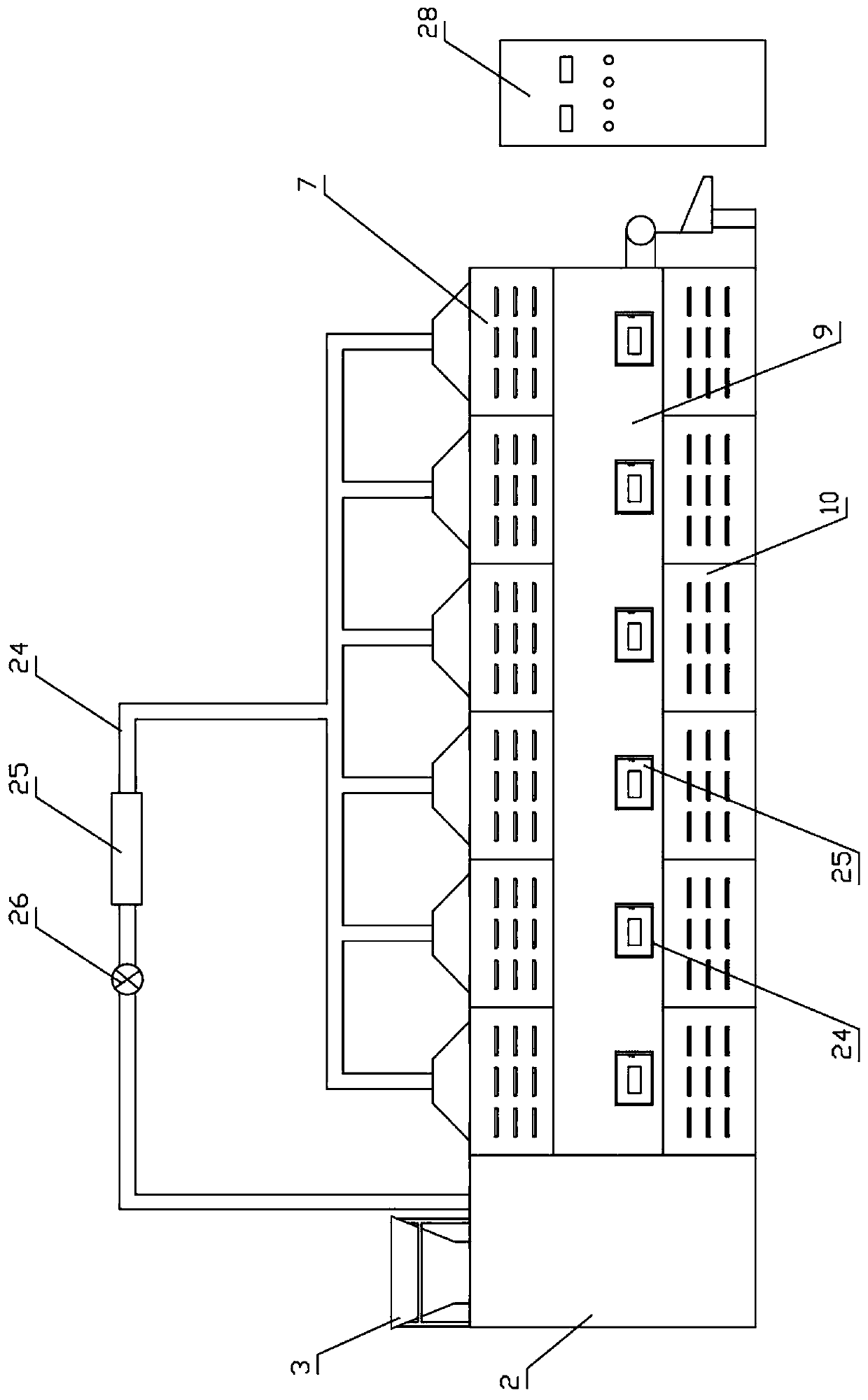

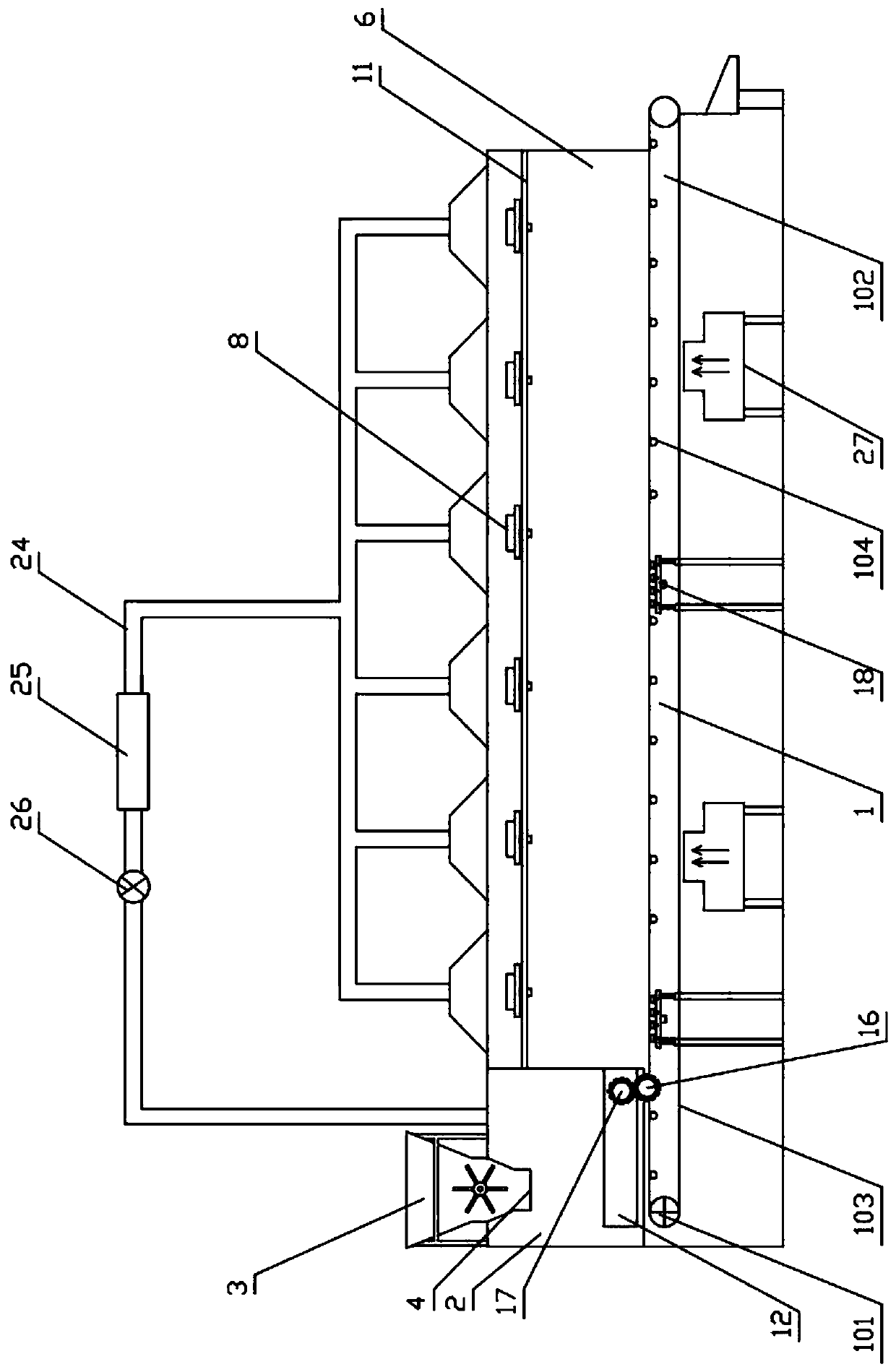

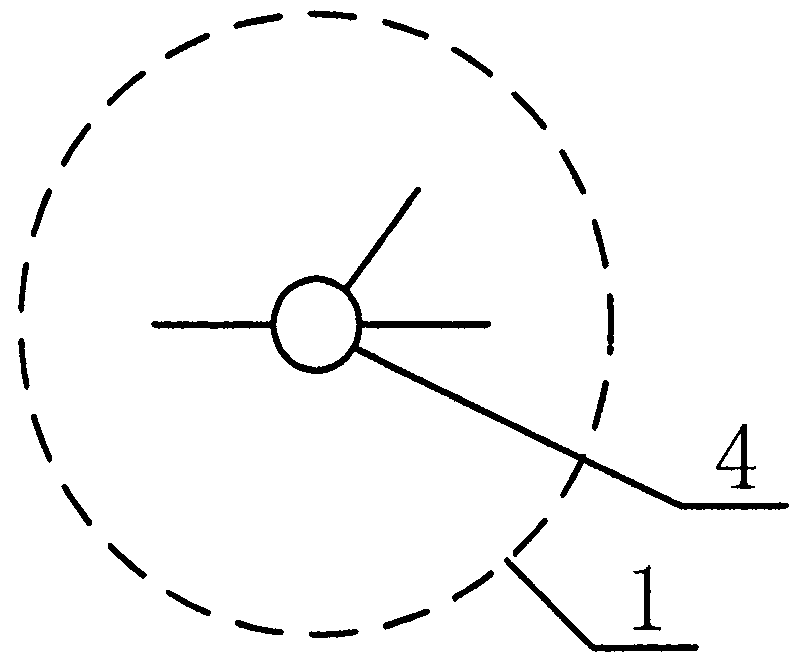

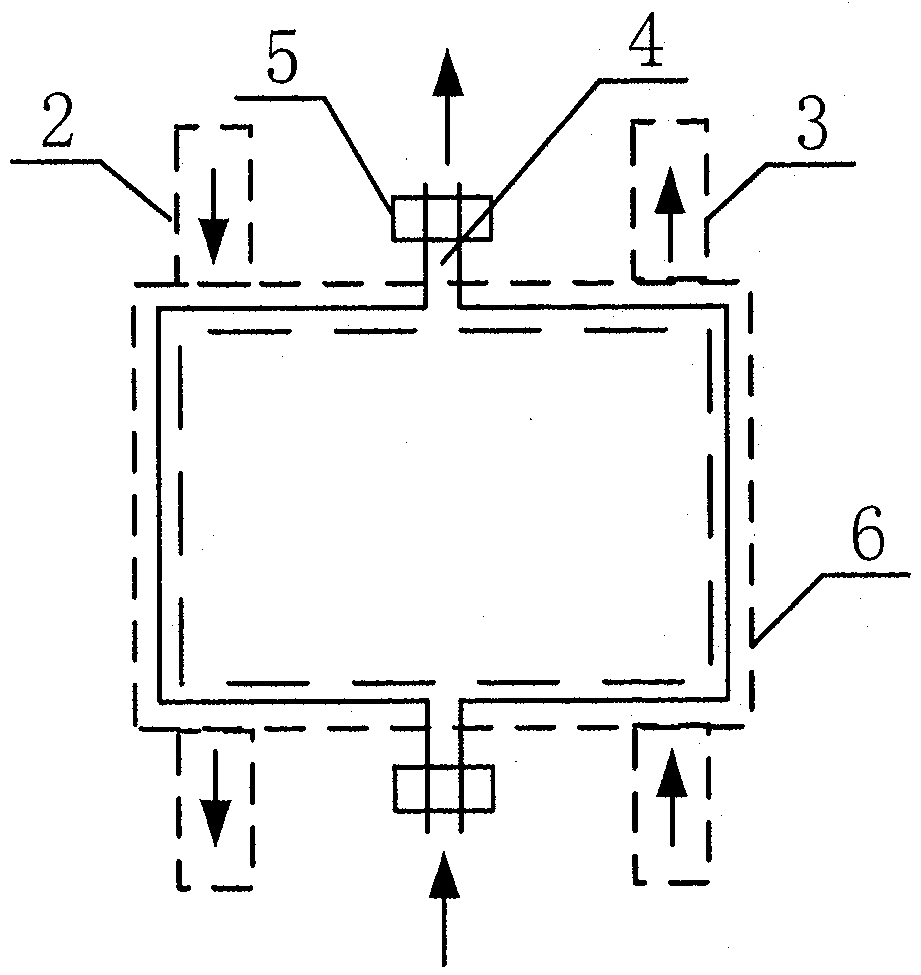

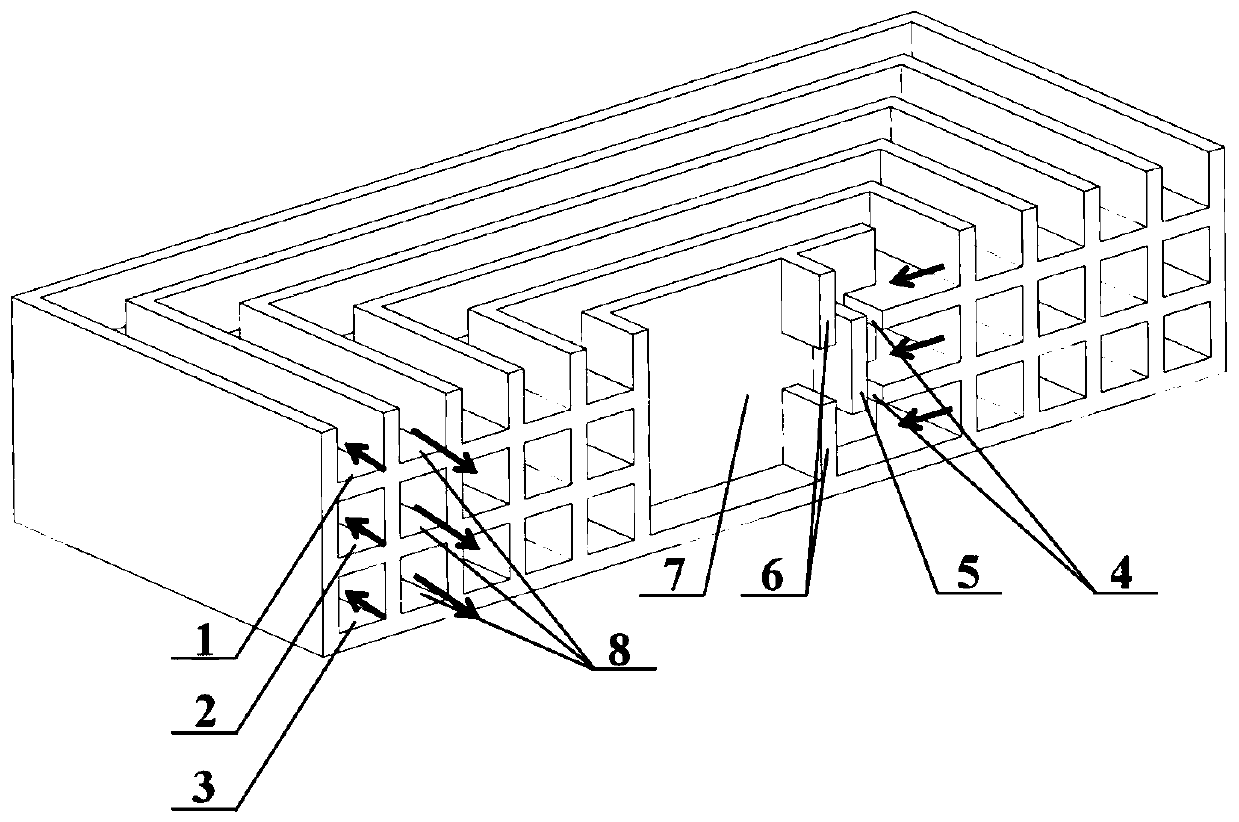

Disclosed is a technology for cleanly and efficiently processing lead-bearing waste residues. The lead-bearing waste residues produced by lead smelting and lime are matched according to the mass ratioof 1:0.03-0.07 and are then pressed into blocky lead-bearing residue blocks, and after natural drying, by mass, 7%-15% of coke, 9%-11% of silica and 74%-84% of the lead-bearing residue blocks are matched. Materials are sequentially added into a five-section integrated type smelting furnace, ignition blowing-in is conducted for oxygen-enriched intensified smelting, materials added from a smeltingfurnace feeding section (1) pass through a preheating section (2), a sintering section (3), a half-melting section (4), a smelting section (5) and a layering section (6), and the smelting process of the materials is completed. Through the technology, material preheating, sintering, smelting and clarification laying are integrated, heavy metal, valuable metal, gangue and the like are selectively separated well, dangerous waste is processed cleanly and efficiently, and the technology has the advantages that the process is short, operation is simple and convenient, and investment is small.

Owner:个旧市沙甸永和冶炼厂

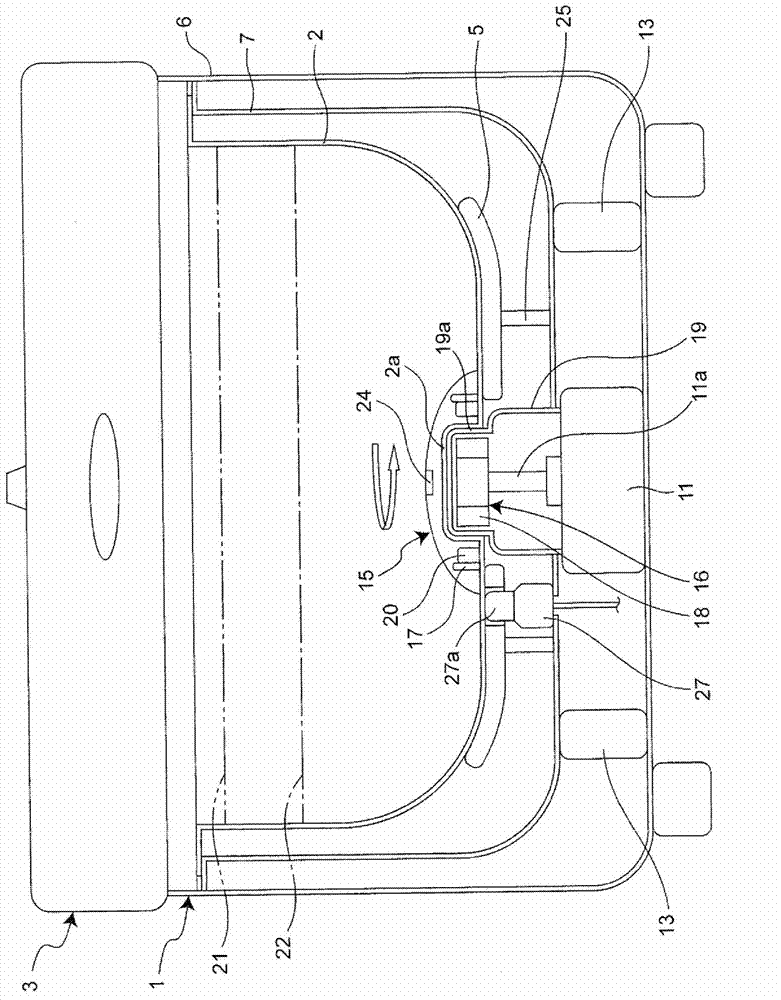

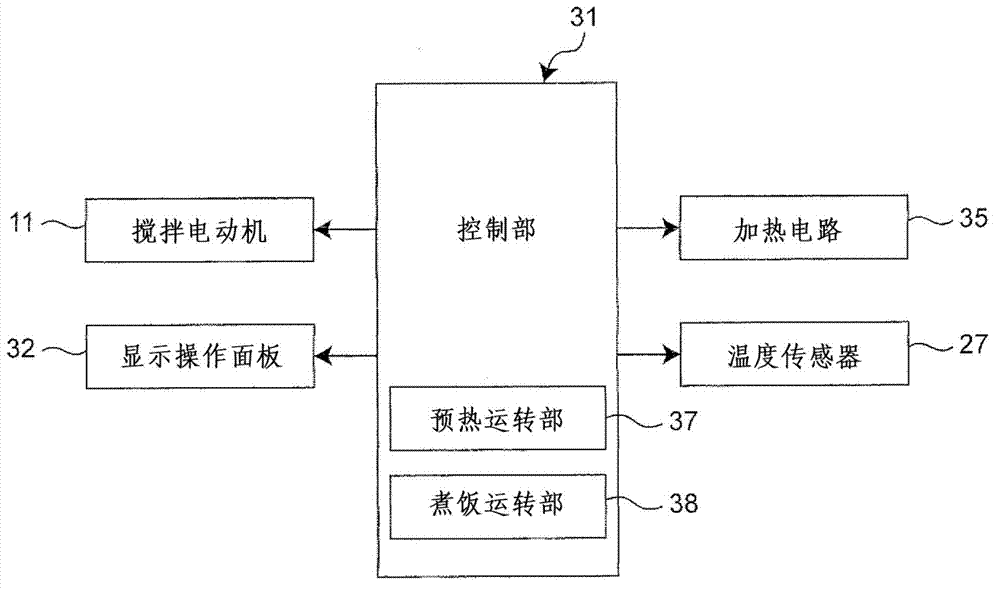

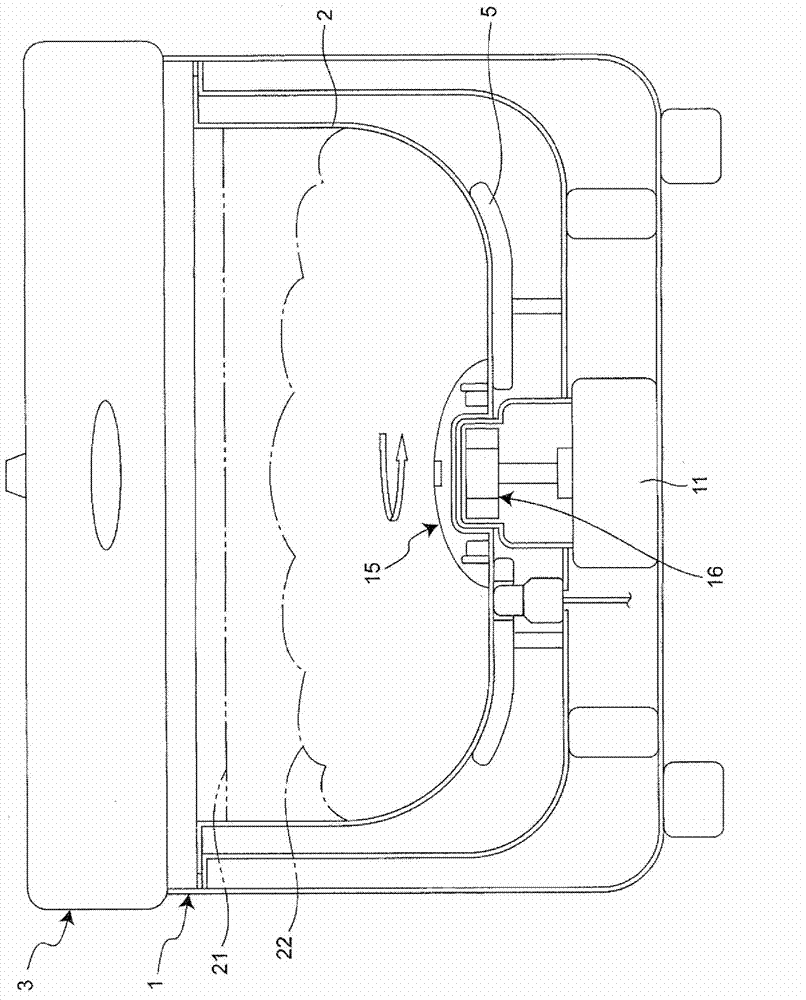

Rice cooking device

InactiveCN102892336AFast heat conductionEfficient preheatingCooking vesselsEngineeringThermal conductivity

Disclosed is a rice cooking device, wherein, in a preheating operation, a preheating operation unit (37) of a control unit (31) heats an inner pot (2) with a heating unit (5), and carries out a first agitation, driving an agitation motor (11) that rotates agitator blades (15) at a first RPM (on the order of 410RPM), and thereafter carries out a second agitation, rotating the agitator blades (15) at a second RPM (on the order of 600-700RPM). With the first agitation, it is possible to agitate rice (22) and water (21) within the inner pot (2) and improve thermal conductivity when heating during a preparatory operation. With the second agitation, the seating state of the rice (22) within the inner pot (2) will have a level shape, wherein the surface has few undulations overall.

Owner:SHARP KK

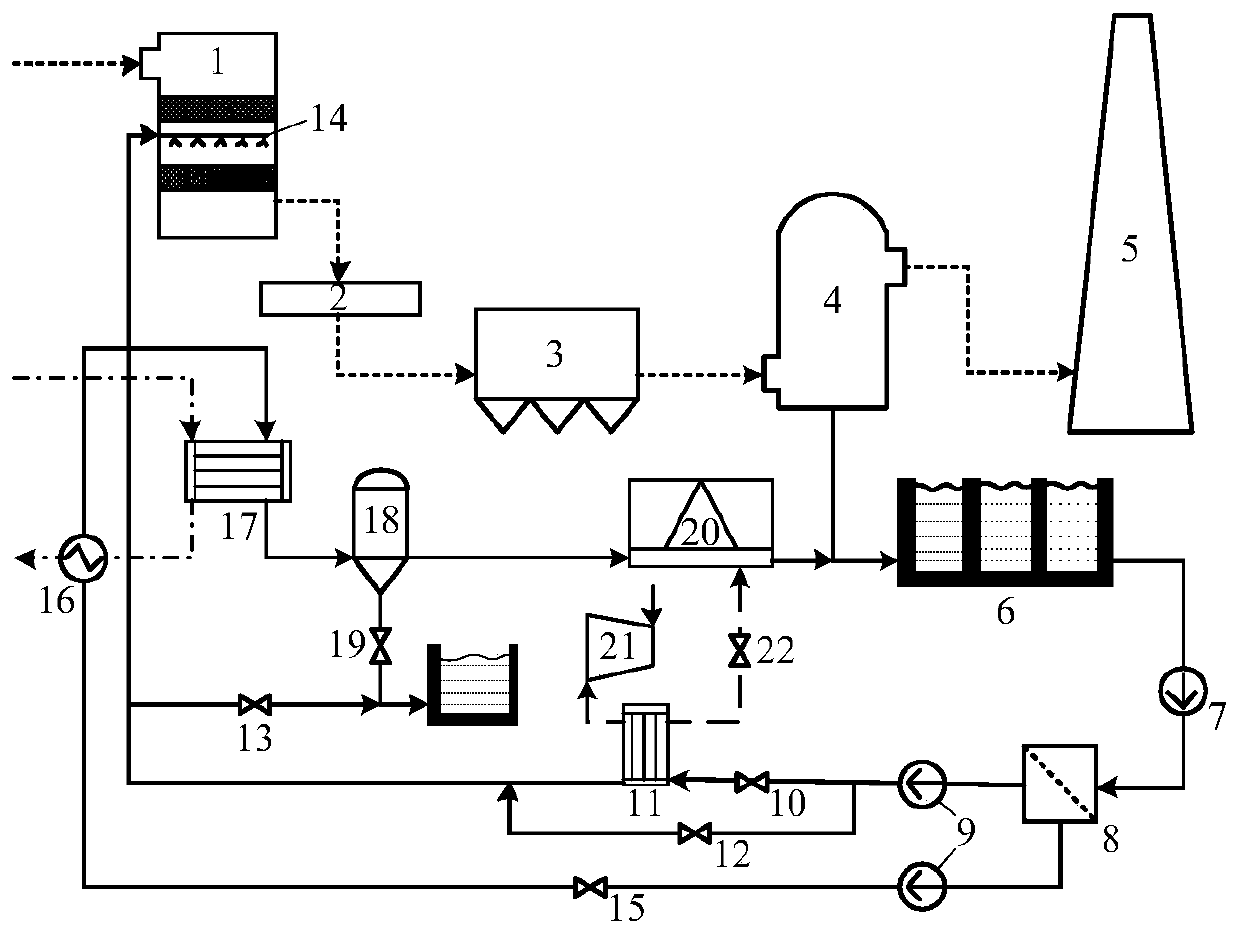

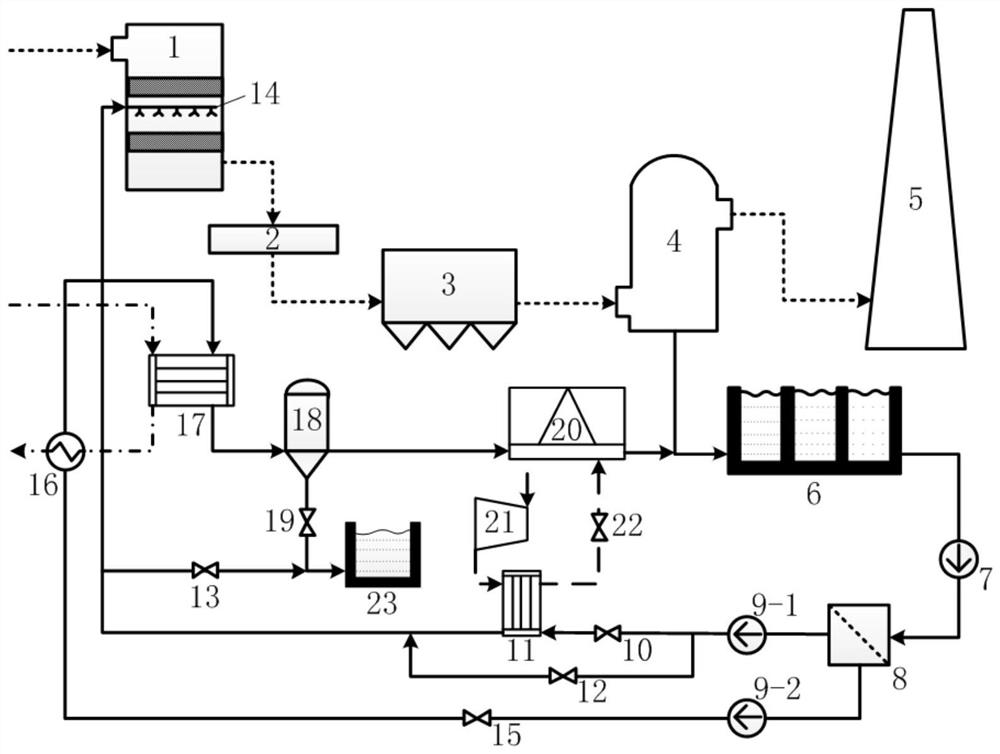

Desulfurization wastewater salt-separation zero-emission synergistic flue gas mercury removal system and method

ActiveCN111068510AAvoid the problem of reduced mercury removal efficiencyRealize resource utilizationGas treatmentDispersed particle separationSteam condensationFlue gas

The invention discloses a desulfurization wastewater salt-separation zero-emission synergistic flue gas mercury removal system and method. The system comprises a pretreatment and nanofiltration system, a chlorine salt solution preheating and flue spraying system, a sulfate solution multi-effect distillation system and a freezing crystallization system. A nanofiltration device is adopted to realizesalt separation of desulfurization wastewater, and a chlorine salt solution is preheated by a condenser and then sprayed into a flue near an SCR to realize synergistic mercury removal; a sulfate solution is frozen and crystallized after multiple-effect distillation and concentration, and a sulfate preheater recovers waste heat of heating steam condensate water. Zero emission of desulfurization wastewater can be realized, the flue gas mercury removal efficiency is synergistically improved and the environmental protection benefit is remarkable; the heat pump is adopted to improve the grade of freezing crystallization waste heat to heat the chlorine salt solution, the condensate water is utilized to preheat the sulfate solution, and concentration energy consumption is effectively reduced; the chlorine salt solution in the desulfurization wastewater is adopted for spraying to promote efficient mercury removal of the flue gas, and good economic benefits are achieved; and desulfurization wastewater salt is recycled through the freezing crystallization system, and desulfurization wastewater resource utilization is achieved.

Owner:XI AN JIAOTONG UNIV

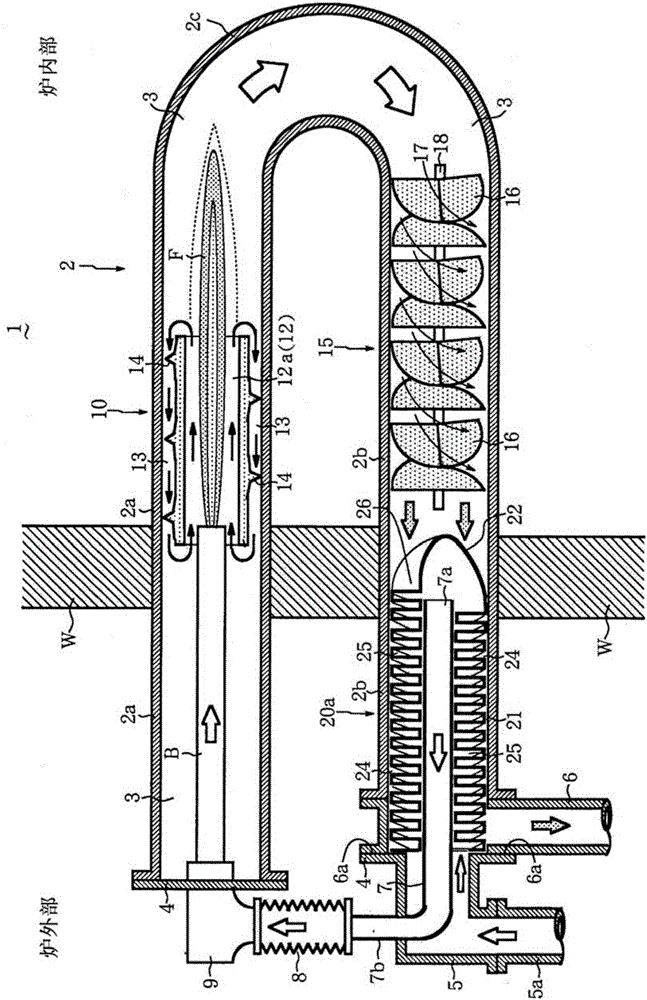

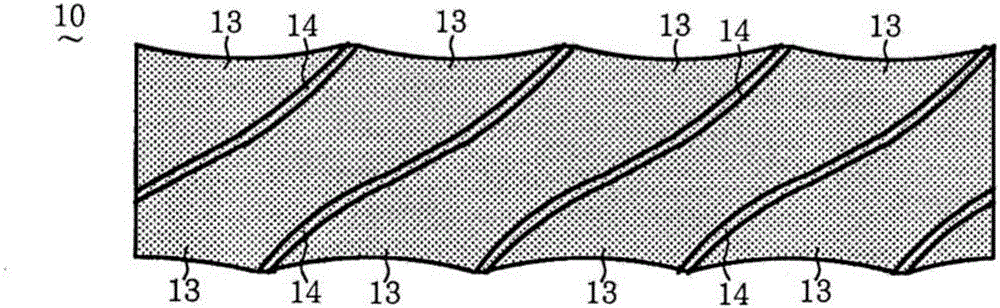

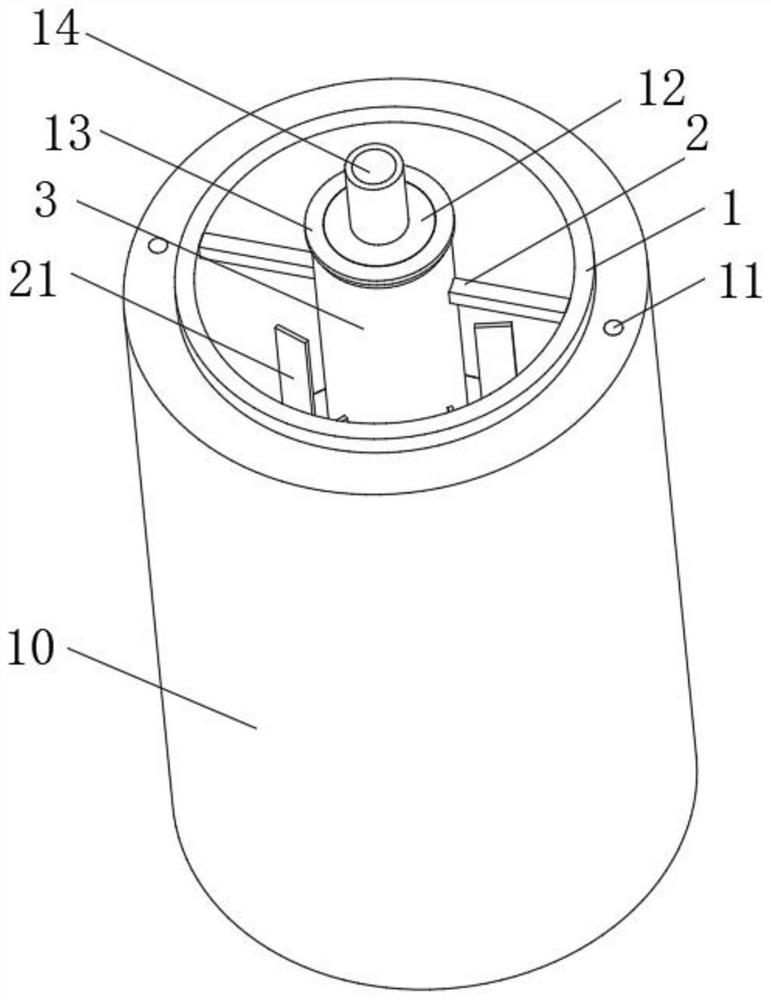

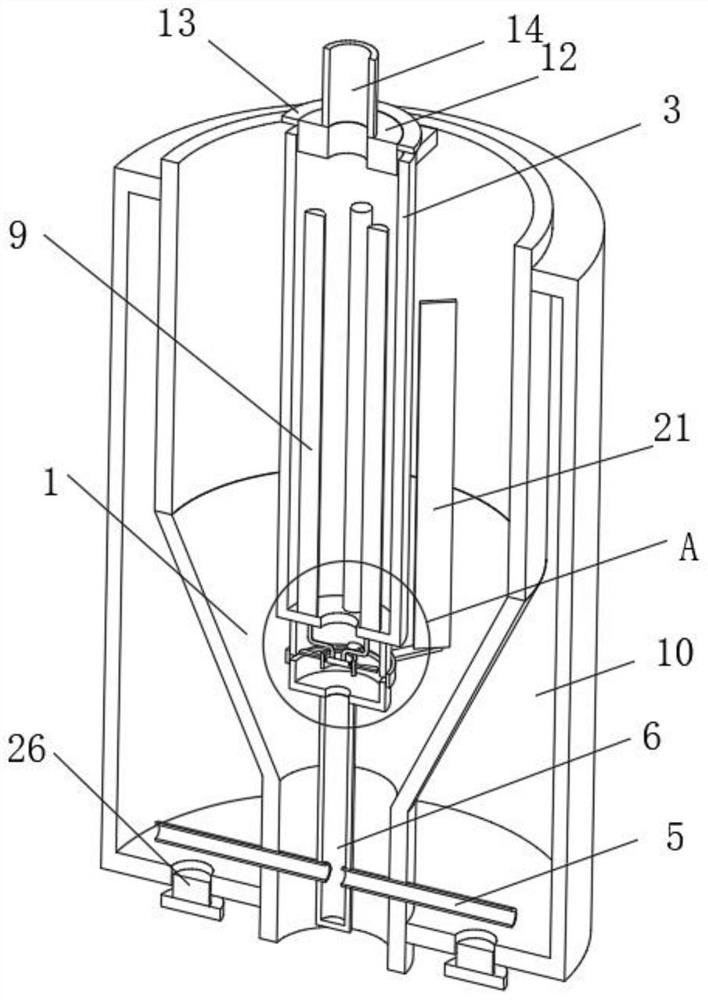

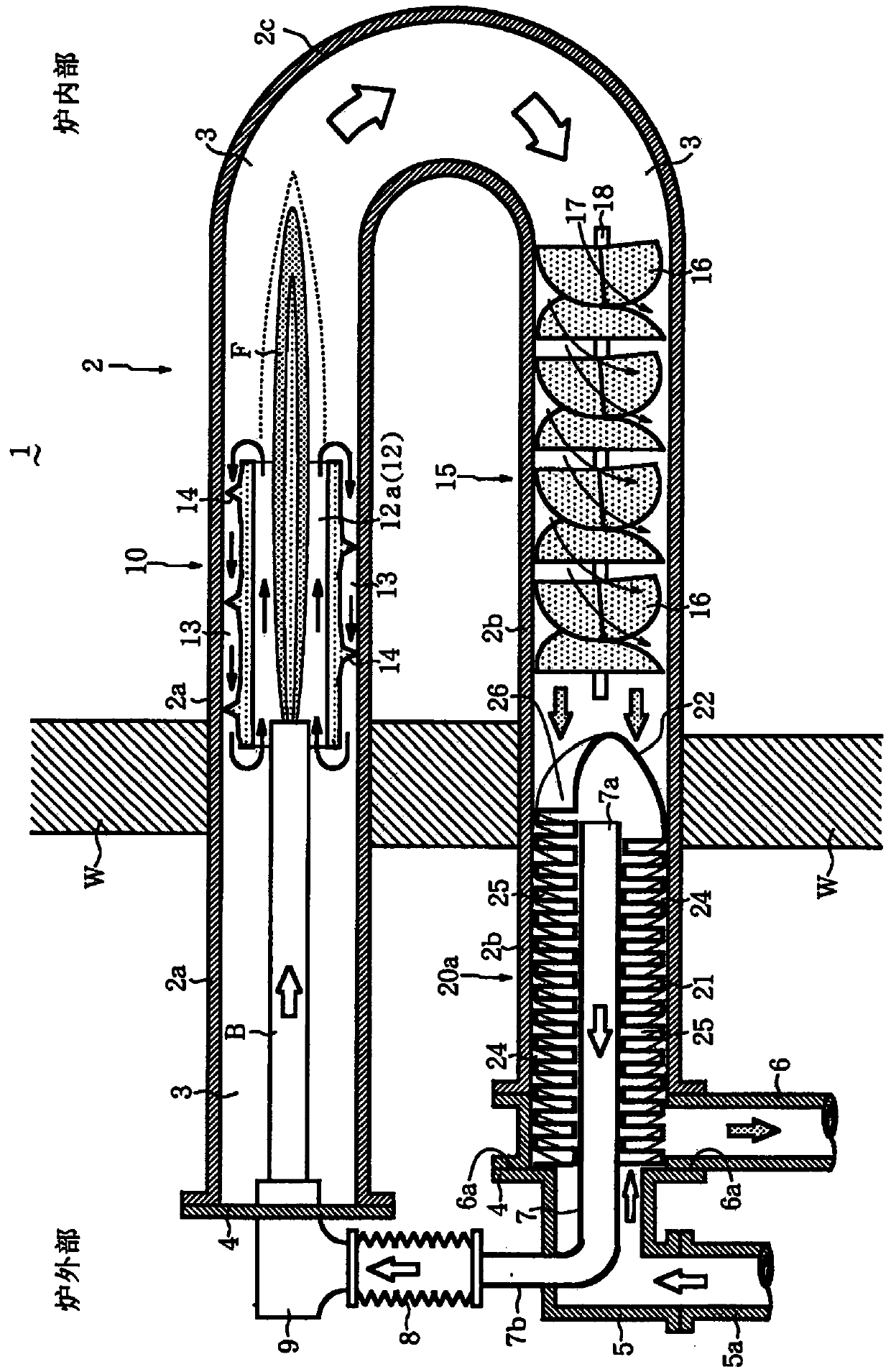

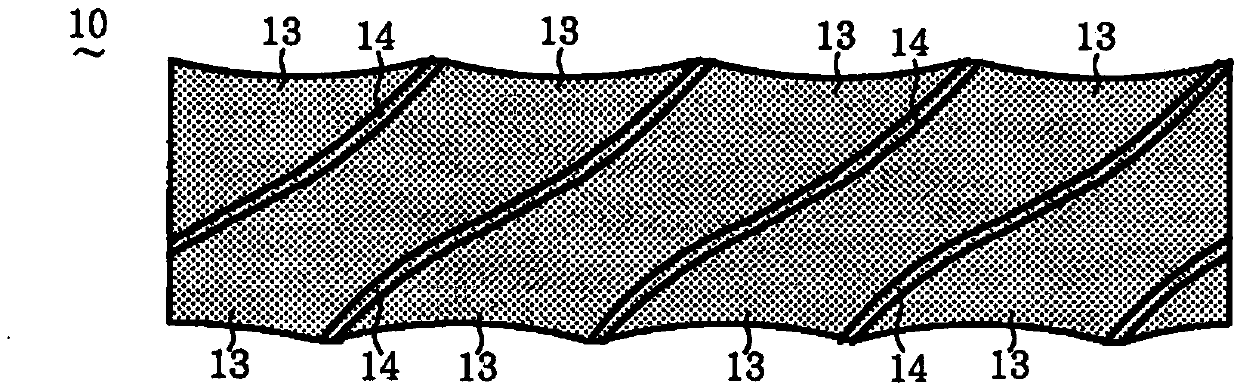

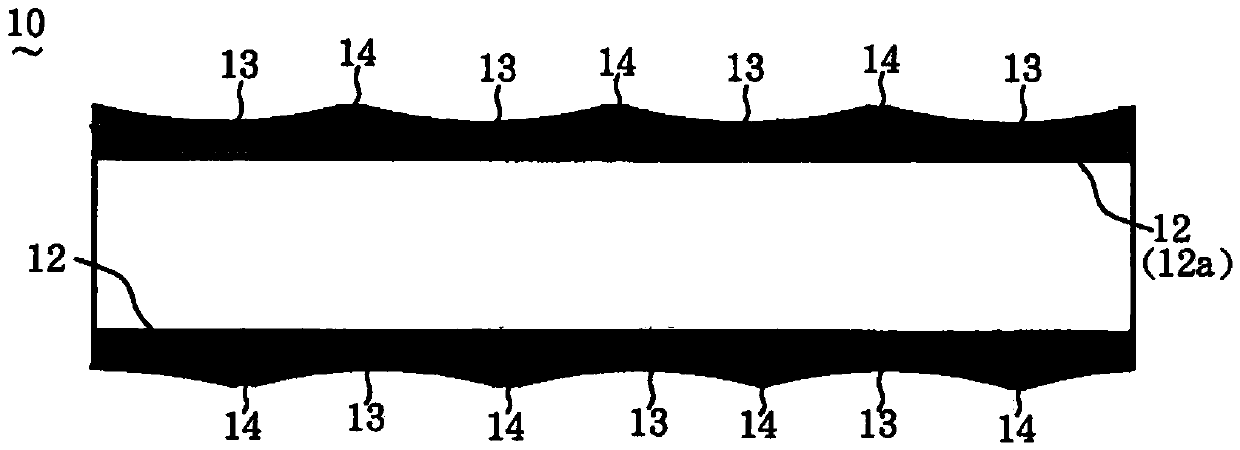

Radiant tube heating device

ActiveCN106051761AInhibition formationInhibition of local elevationIndirect carbon-dioxide mitigationGaseous fuel burnerCombustorNitrogen oxides

The present invention provides a radiant tube heating device capable of achieving at least one or both of suppressing generation of nitrogen oxides (NOx) generated by a combustor and remarkably improving thermal efficiency. The radiant tube heating device(1) comprises a radiant tube (2) having its two ends (2a, 2b) penetrating the furnace wall (furnace) (W), and the bent portion (2c) Protruding into the interior of the furnace;and a burner (B) arranged coaxially in the hollow portion (3) in the central portion of the hollow portion (3) on one end (2a) side of the radiation tube (2); the radiant tube heater (1) further includes a temperature rise suppressing member (10) having a cylindrical shape and arranged at a position around an opening portion on the distal end side of the combustor in a hollow portion of the radiant tube , and a pair of inner and outer flow paths (12a, 13) for flowing combustible gas are formed between the inner wall surface of the radiant tube and the outer peripheral surface of the burner.

Owner:DAIDO STEEL CO LTD

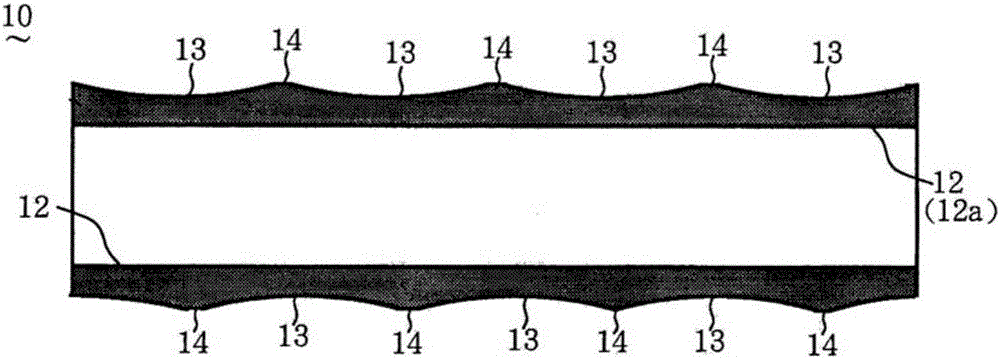

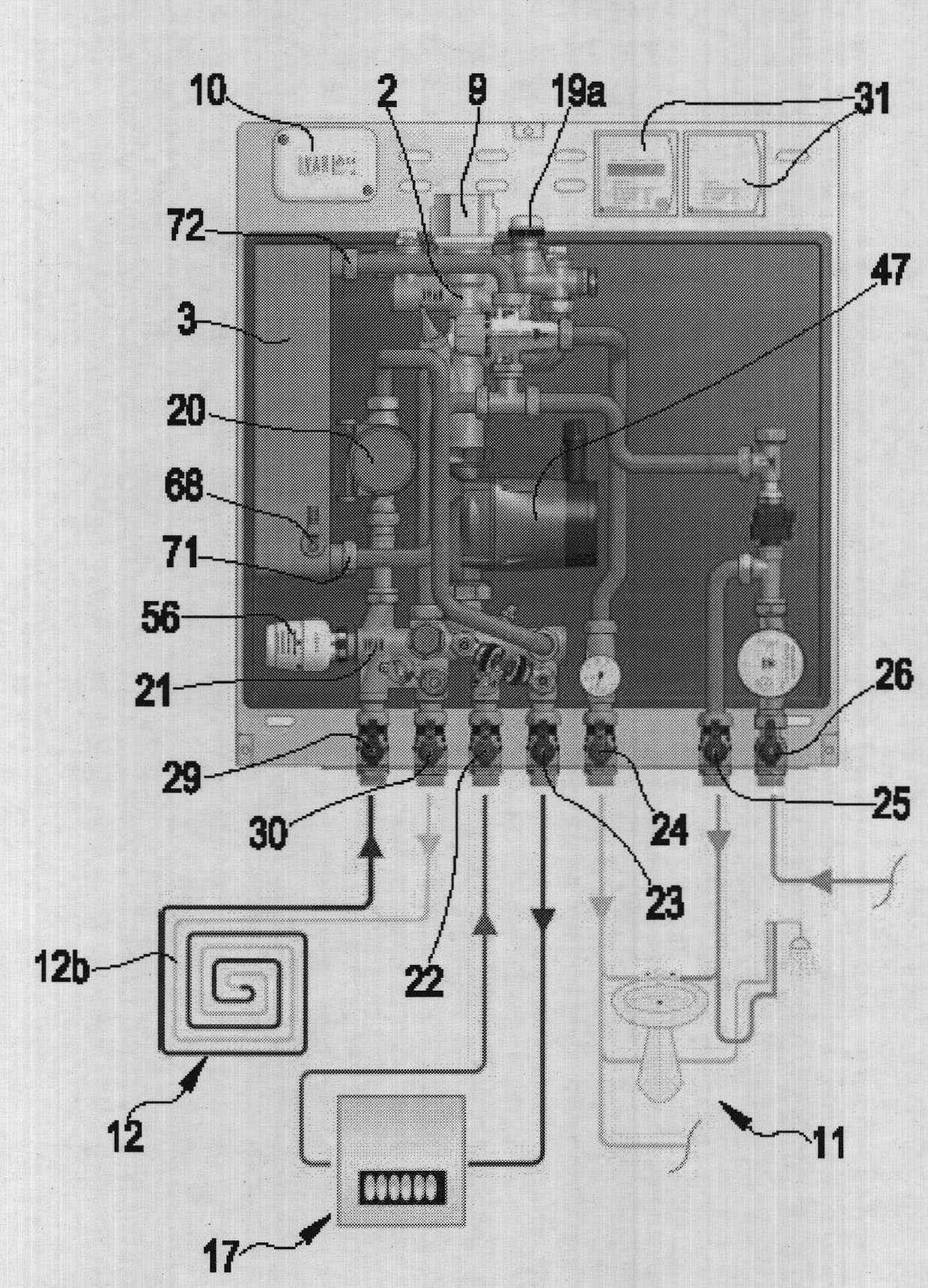

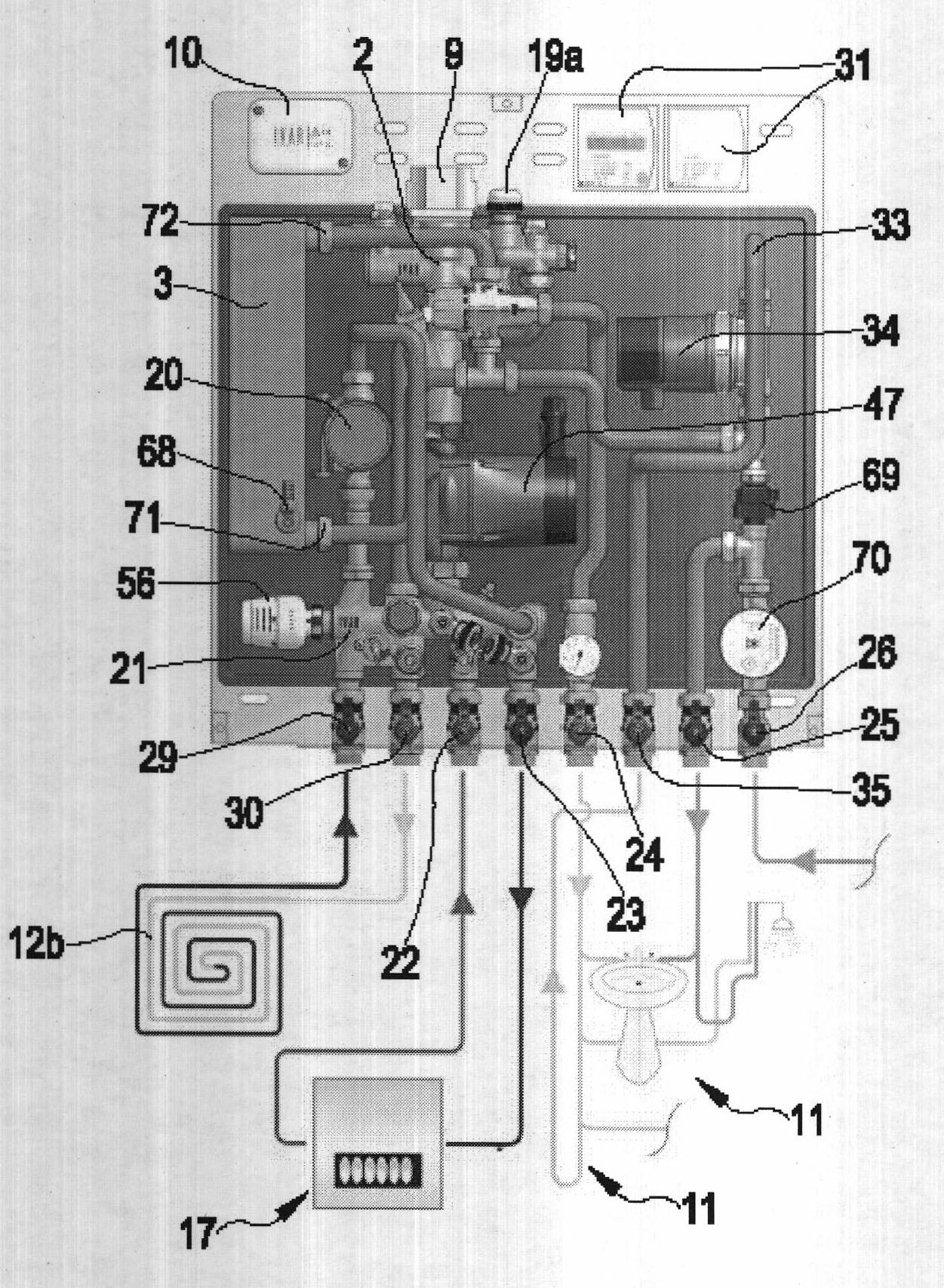

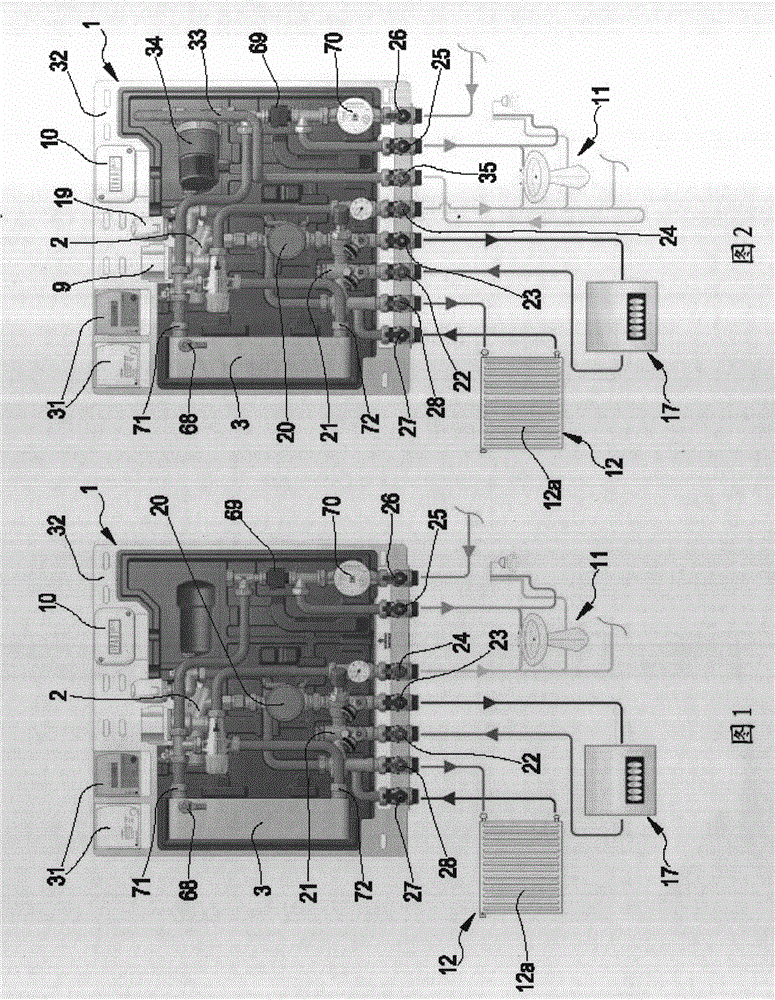

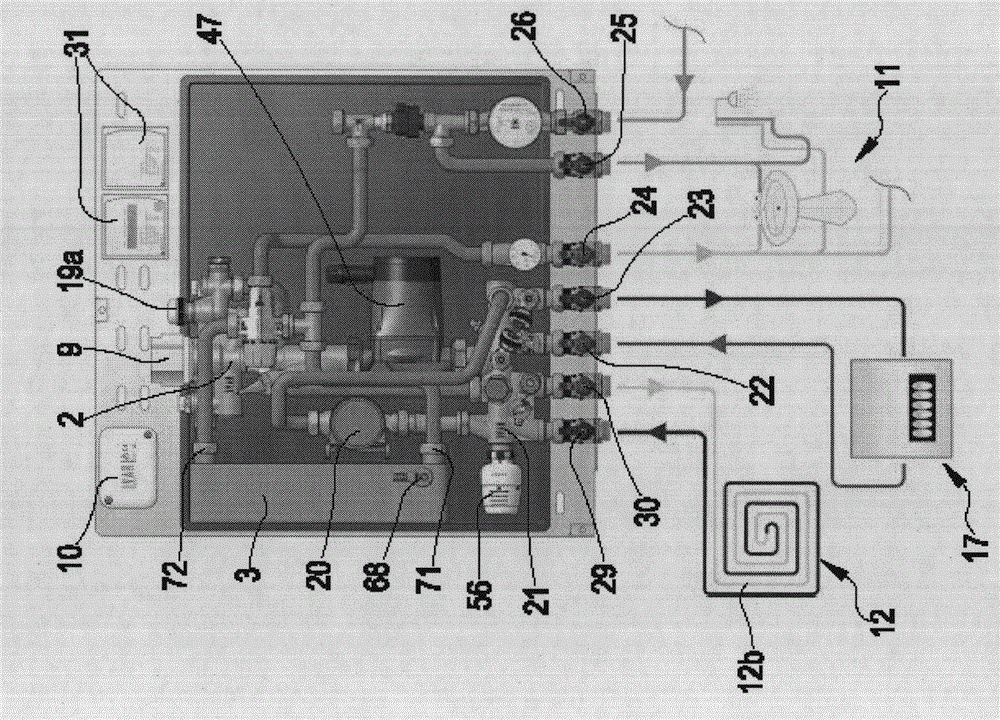

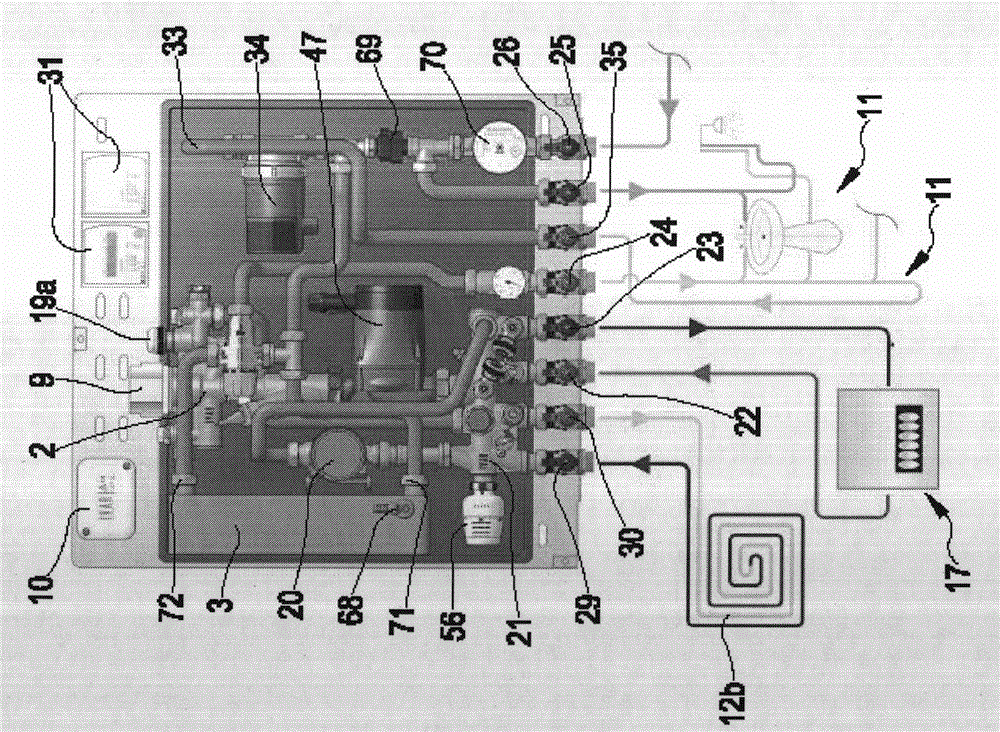

Device for distribution of water for heating

InactiveCN102213462AEfficient allocationReasonable distributionFluid heatersSpace heating and ventilation detailsHeat exchangerHeat-only boiler station

A hydraulic device for distributing water for heating comprising a body (37) in which at least the following are defined: at least a delivery pathway (39) for water for heating and extending from an inlet (38) for the water for heating, destined to be connected to a delivery of a centralised plant (17), to an outlet (49), destined to be connected to a low-temperature heating plant (12b) and / or to a heat exchanger (3) with sanitary water; a first pathway (53) for return water from a low-temperature heating plant (12b) extending from a first inlet (52) for the return water from the low-temperature heating plant (12b) to a first outlet (54) for the return water; a second pathway (63) for the return water extending from a second inlet (62) to a second outlet (64), destined to be connected with a return in the centralised plant (17); and a mixer group (55), arranged between the delivery pathway (39) of the heating water and the first pathway (53), destined to determine a flow of return water to be pre-mixed with the water for heating in the delivery pathway (39) such as to obtain mixed water having an intermediate temperature, suitable for sending into the outlet (49) for water for heating.

Owner:IVAR

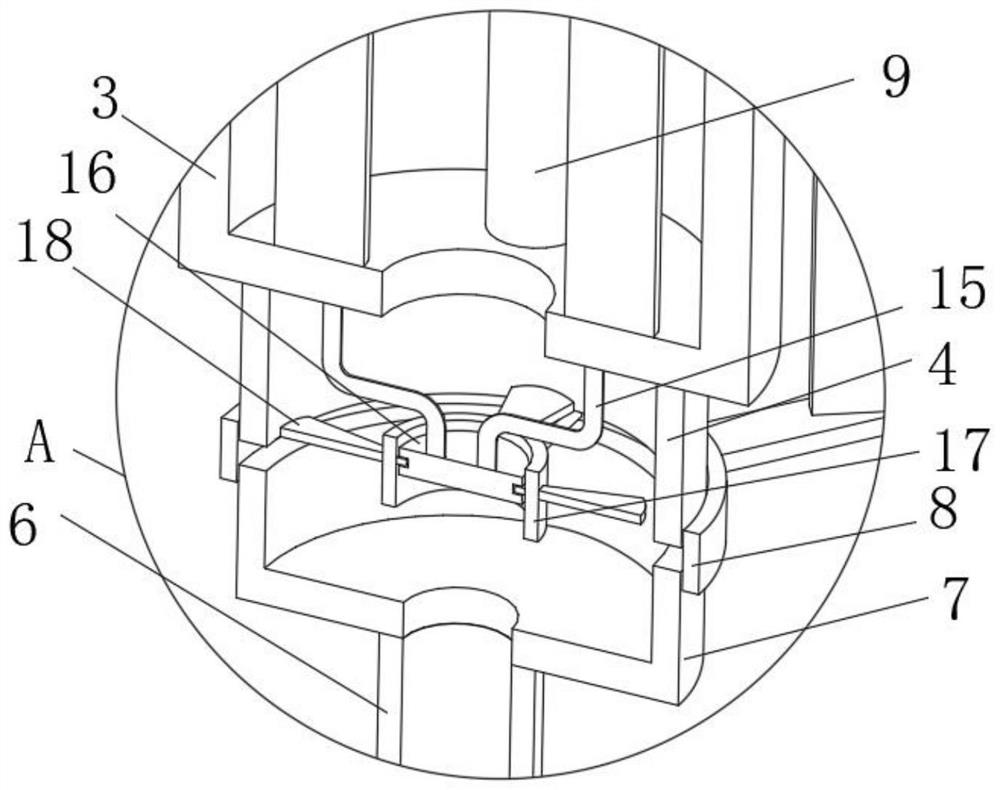

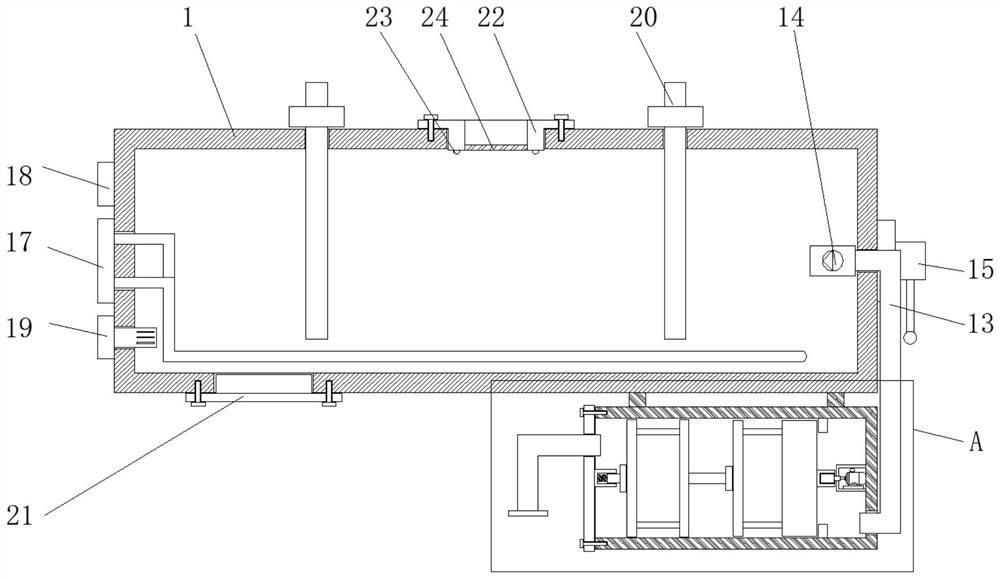

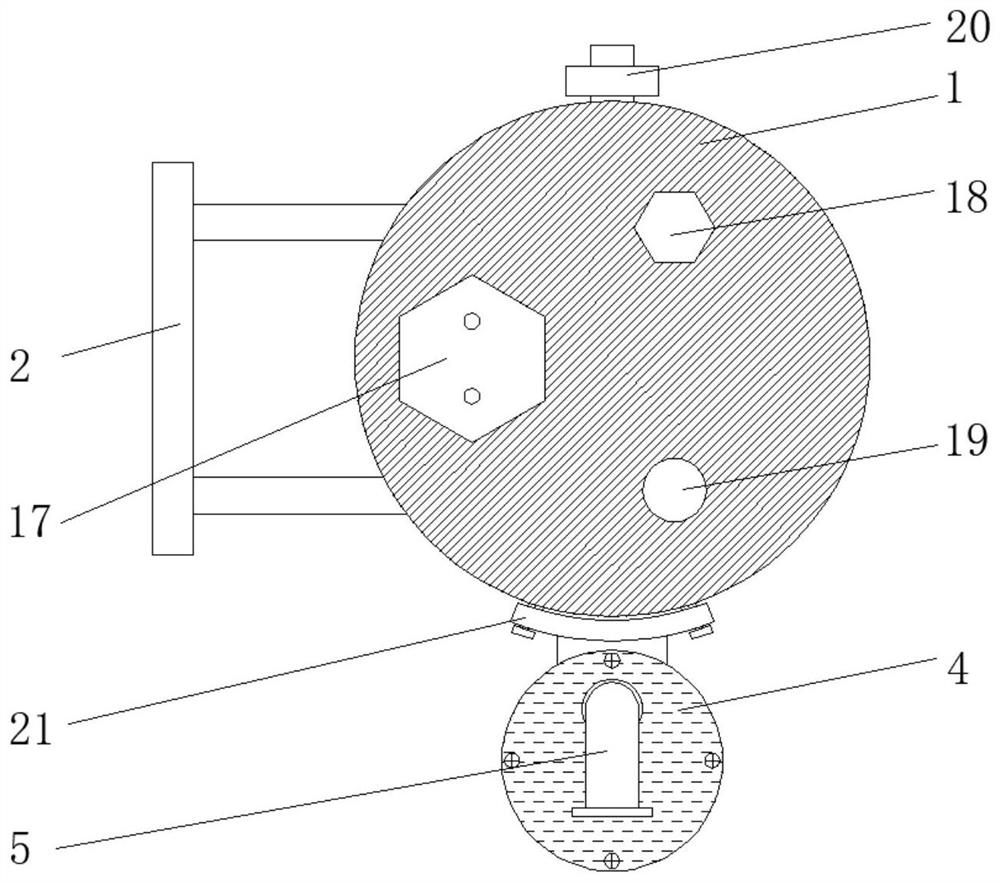

Waste gas catalytic combustion equipment for garbage disposal

PendingCN111664462AImprove catalytic combustion efficiencyIncrease contact areaIncinerator apparatusGenerators/motorsCombustion chamberPtru catalyst

The invention discloses waste gas catalytic combustion equipment for garbage disposal. The waste gas catalytic combustion equipment comprises a combustion chamber, a spiral heating cavity is formed inthe inner wall of the combustion chamber, a rotating shaft is rotationally connected to the bottom in the combustion chamber, a plurality of stirring blades are fixedly connected to the side wall ofthe rotating shaft, a circular cavity is formed in the lower end of the combustion chamber, the lower end of the rotating shaft penetrates through the lower end of the combustion chamber and extends into the circular cavity, a wind wheel is fixedly connected to the lower end of the rotating shaft, and the side wall of the combustion chamber is connected with one end of the spiral heating cavity through an air inlet pipe. According to the waste gas catalytic combustion equipment, the wind wheel rotates to drive the stirring blades to rotate to stir a catalyst in the combustion chamber, so thatwaste gas is in full contact with the catalyst, and the waste gas is subjected to full combustion treatment; and heat contained in water vapor can enable the two ends of a temperature difference powergeneration piece to generate a large temperature difference, so that a positive electrode electrolysis rod and a negative electrode electrolysis rod are used for electrolyzing water, oxygen generatedby water electrolysis enters an incinerator, and the incineration efficiency during garbage incineration is improved.

Owner:曾晓云

Diffusion type porous medium burner

PendingCN108443884AEfficient preheatingPrevent backfireGaseous fuel burnerIndirect carbon-dioxide mitigationInlet channelCombustor

The invention provides a diffusion type porous medium burner, and relates to the technical field of porous medium burning. The burner comprises a burner body, a thermocouple, a sparking electrode anda detection electrode, wherein the body comprises an outer shell, an inner shell and an air inlet channel, and the inner shell is inserted into a first cavity of the outer shell; a second cavity whichcommunicates with the first cavity and is coaxial with the first cavity is formed in the inner shell; an air distribution plate and a gas distribution plate are arranged in the axial direction of thesecond cavity in sequence; a first big-hole foam ceramic plate, a small-hole foam ceramic plate and a second big-hole foam ceramic plate are arranged in the first cavity and in the downstream area ofthe end surface of the gas distribution plate; and the air inlet channel comprises a gas inlet, an air inlet, an air conduit and a gas conduit, the gas inlet communicates with the gas distribution plate through the gas conduit which passes through the air distribution plate, and the air inlet communicates with the air distribution plate through the air conduit. The burner has the functions of effectively preventing from tempering, conveniently monitoring flame, predicting and diagnosing the service condition of porous medium materials.

Owner:WUHAN UNIV OF SCI & TECH

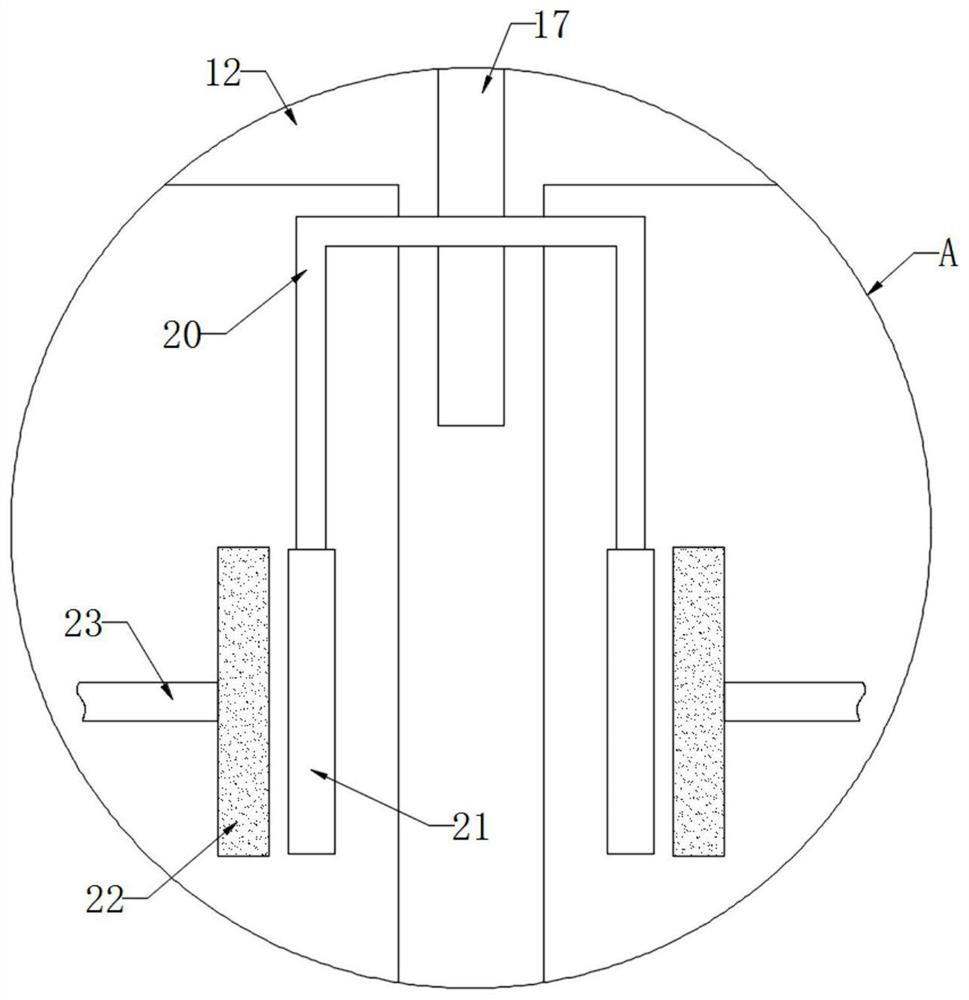

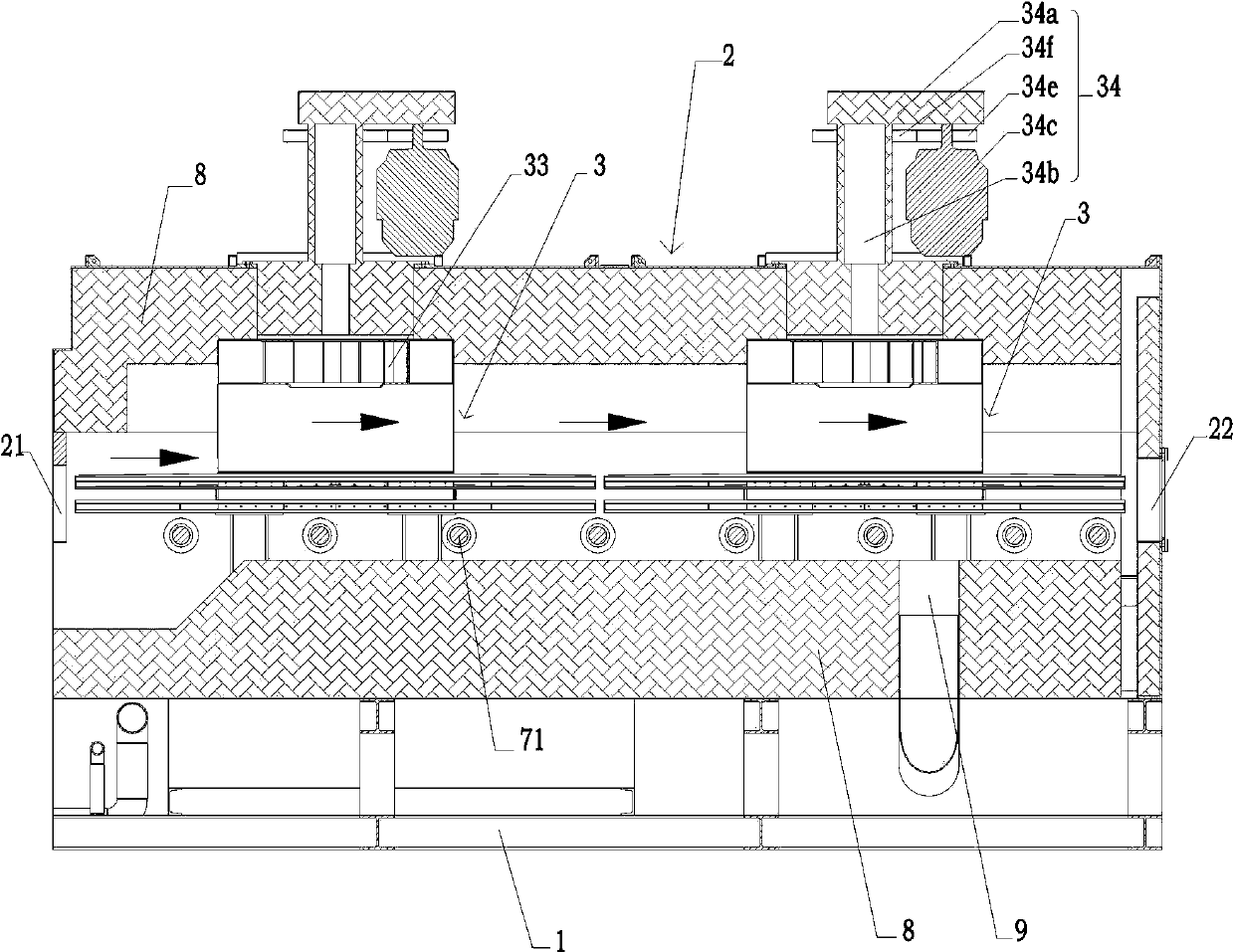

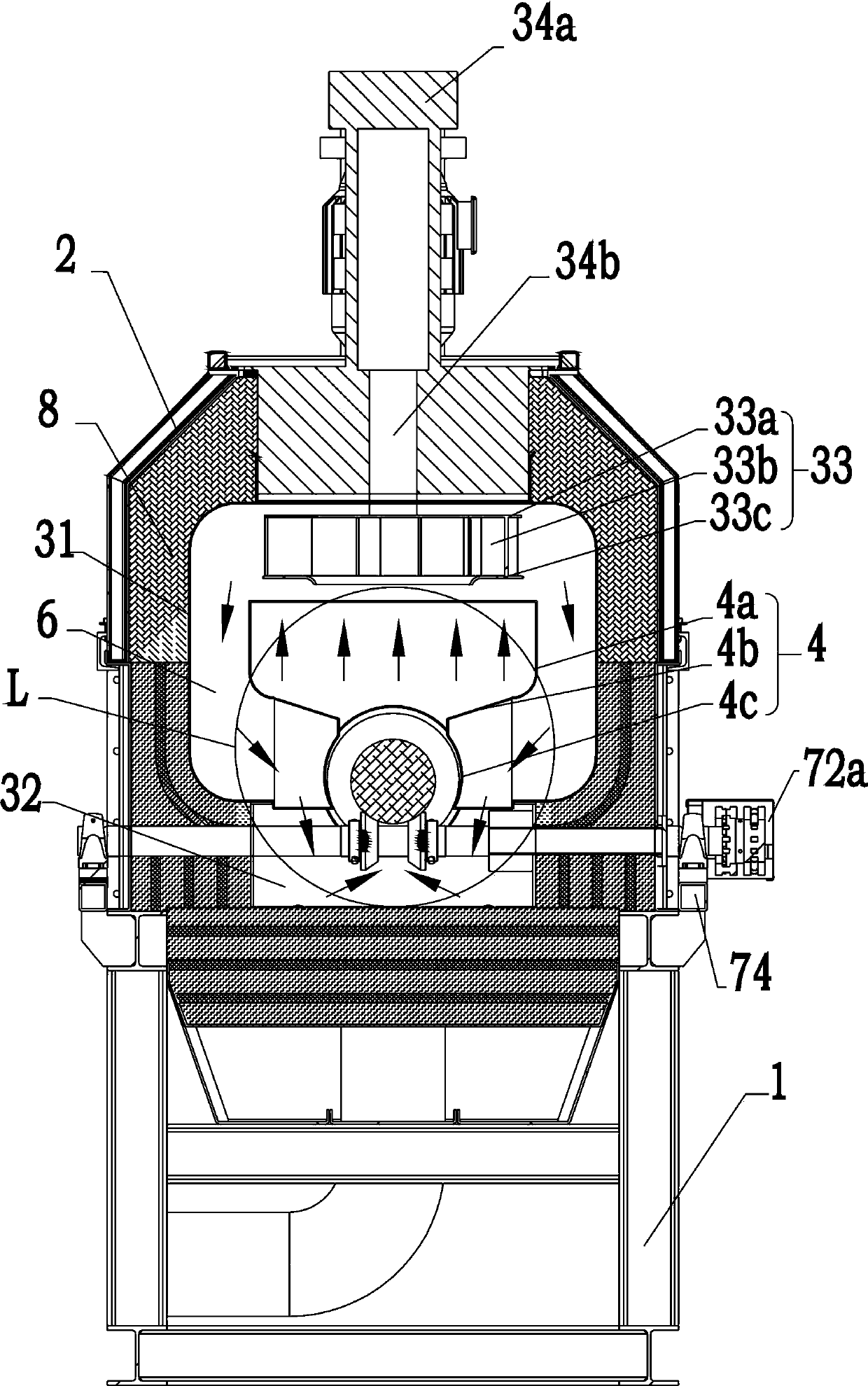

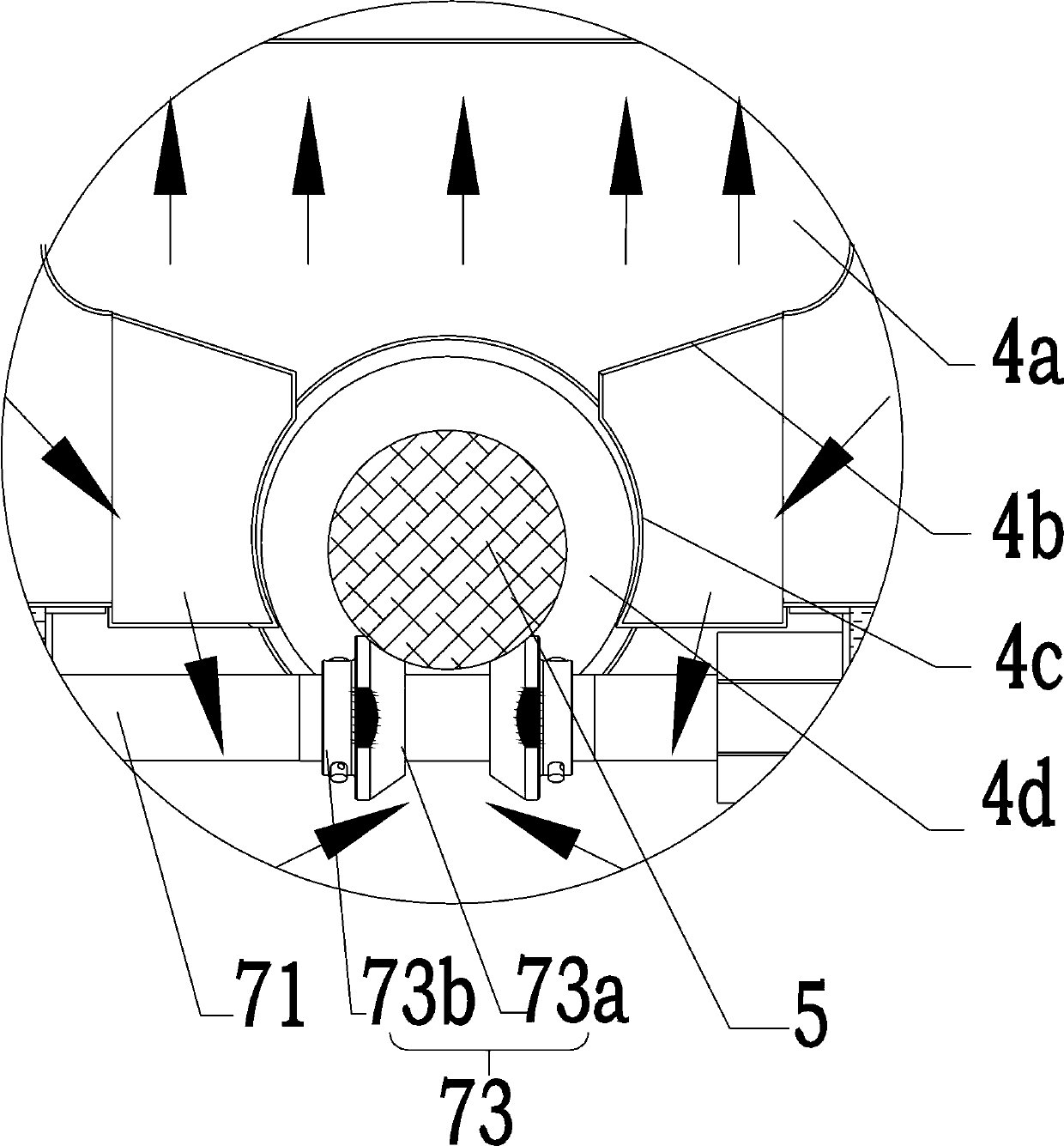

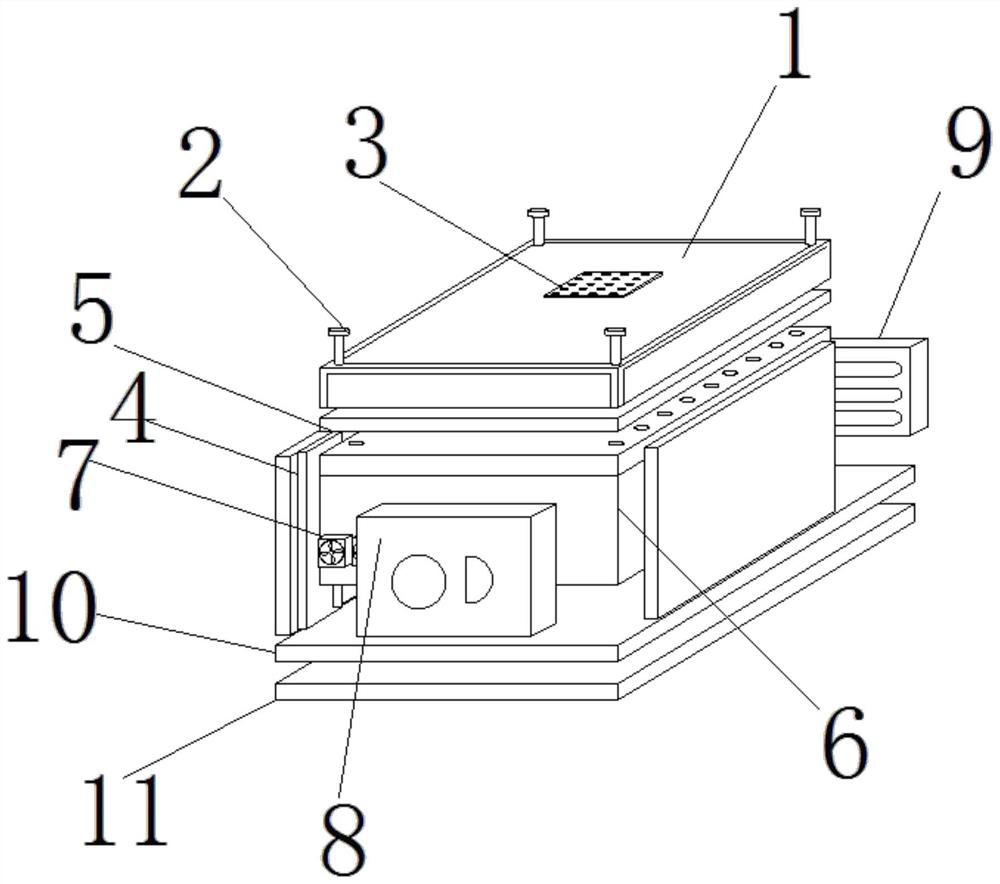

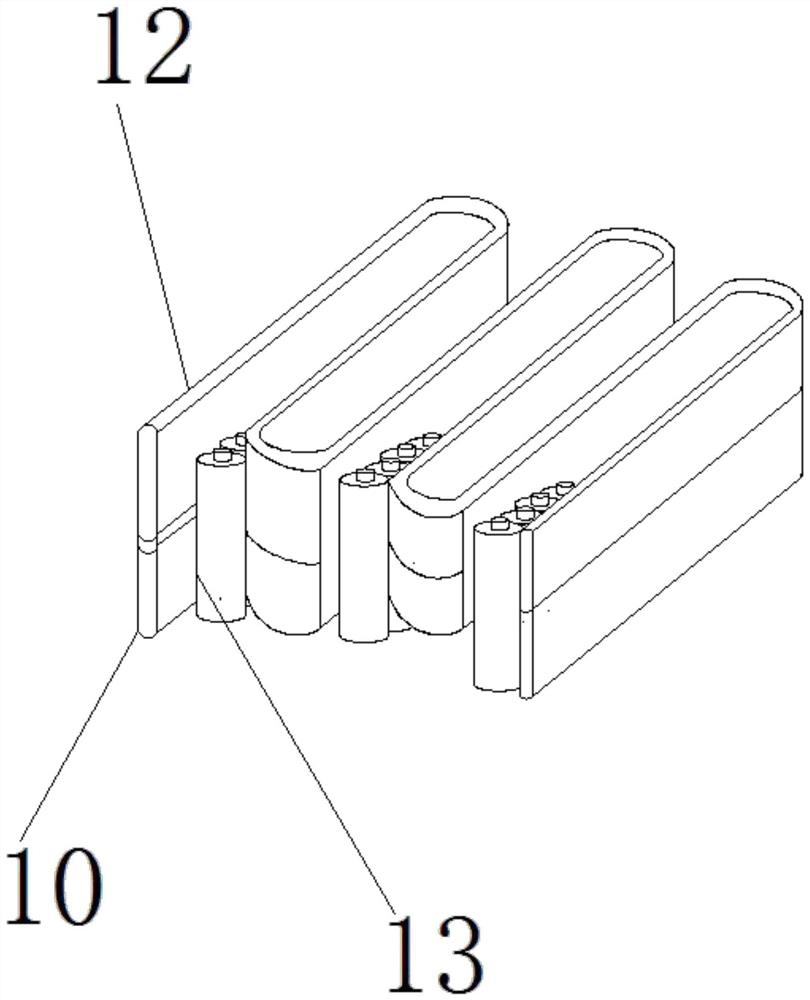

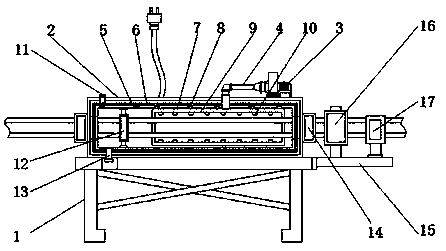

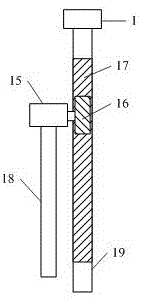

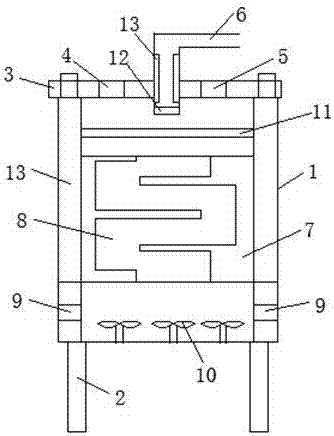

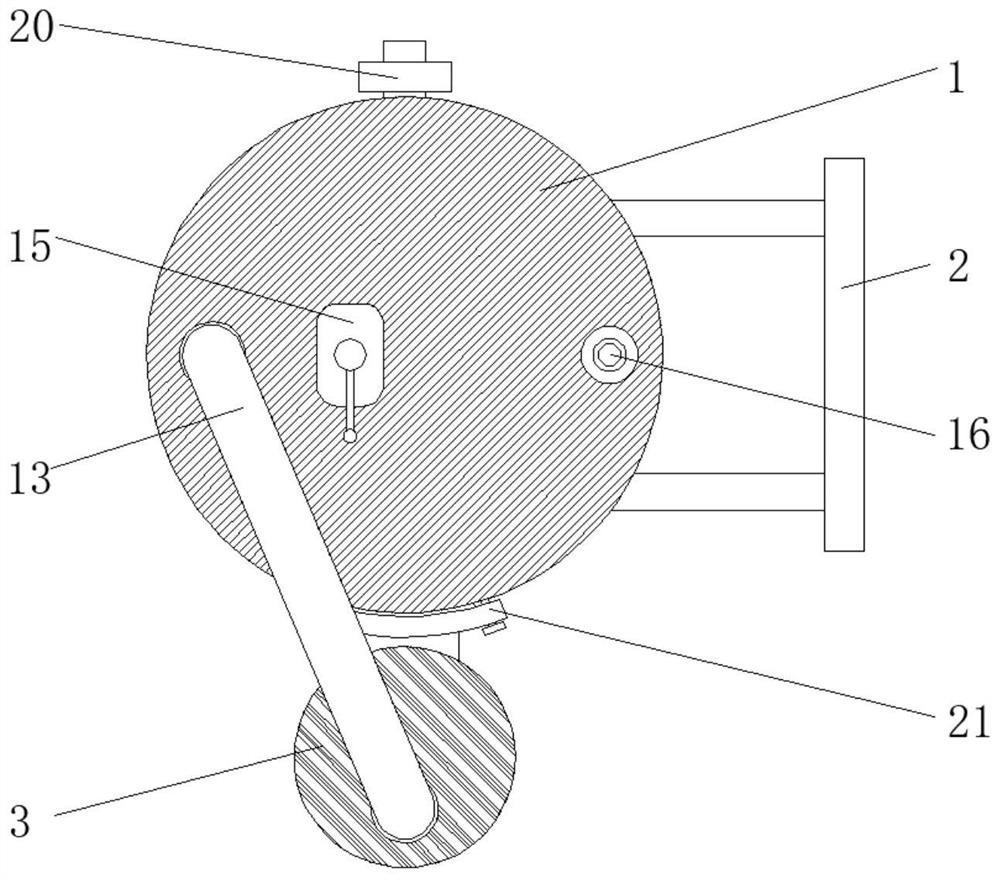

Preheating device of single-bar heating furnace

PendingCN109737757APreheating effective contact with the aluminum rods in the preheating chamber for efficientEfficient preheatingPreheating chargesHeat transfer efficiencyEngineering

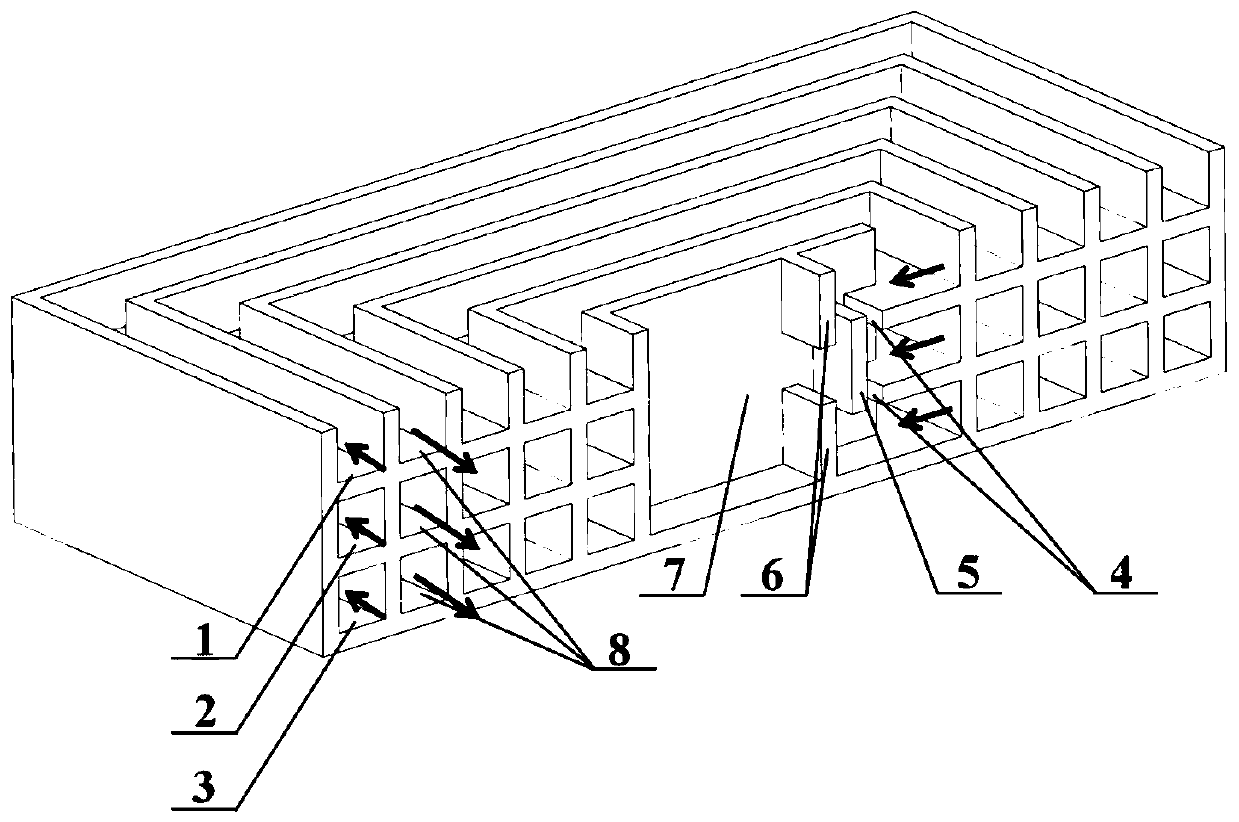

The invention discloses a preheating device of a single-bar heating furnace. A bottom frame and a preheating chamber arranged on the bottom frame are included. A plurality of smoke circulation devicesare arranged in the preheating chamber. Each smoke circulation device comprises an air guiding pipeline, a backflow pipeline, a circulation wind wheel arranged in the air guiding pipeline and a firstdrive mechanism, wherein the air guiding pipeline and the backflow pipeline are mutually connected, the backflow pipeline is arranged on the lower side of the air guiding pipeline, a circulation preheating chamber is arranged below the circulation wind wheel, the bottom end of the circulation preheating chamber communicates with the backflow pipeline, an aluminum bar is arranged in the circulation preheating chamber, a backflow channel is formed by the circulation preheating chamber and the inner wall of the air guiding pipeline, the circulation wind wheel is used for extracting smoke in thecirculation preheating chamber, and smoke enters the circulation preheating chamber through the backflow channel to form smoke cycle. Compared with the prior art, under multi-time flowing cycle of high-temperature smoke, the high-temperature smoke can effectively make contact with the aluminum bars in the preheating chamber for efficient preheating, the staying time of the high-temperature smoke in the preheating chamber is prolonged, the heat transfer efficiency of the high-temperature smoke in the preheating chamber is improved, and the effects of energy saving and emission reducing are achieved.

Owner:FOSHAN LANGDUN ALUMINUM FAB EQUIP

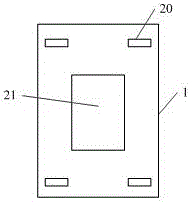

Integrated soft-package quick-charging battery pack

PendingCN112436223AAvoid damageImprove insulation performanceSecondary cellsCell component detailsElectrically conductiveElectrical and Electronics engineering

The invention discloses an integrated soft package fast charging battery pack, and the battery pack comprises a shell; locking nuts are connected to the periphery of the top of the shell in a penetrating mode, a conductive base is fixedly connected to the middle of the top of the shell, foam is fixedly connected to the four walls of an inner cavity of the shell, and an upper heat conduction silicagel sheet is fixedly connected to the top of the inner cavity of the shell; a battery module is fixedly connected to the bottom of the upper heat conduction silica gel sheet, a cooling fan is fixedlyconnected to the left side of the front face of the battery module, a front baffle is fixedly connected to the front face of the battery module, a rear baffle is fixedly connected to the back face ofthe battery module, and a lower heat conduction silica gel sheet is fixedly connected to the bottom of the battery module; a heat dissipation aluminum plate is fixedly connected to the bottom of thelower heat conduction silica gel sheet, a liquid cooling pipe is fixedly connected to the outer wall of the upper heat conduction silica gel sheet, a battery cell is fixedly connected to the inner wall of the liquid cooling pipe, structural adhesives are fixedly connected to the two walls of the battery cell, and an upper cap is fixedly connected to the top of the battery cell.

Owner:湖南电将军新能源有限公司

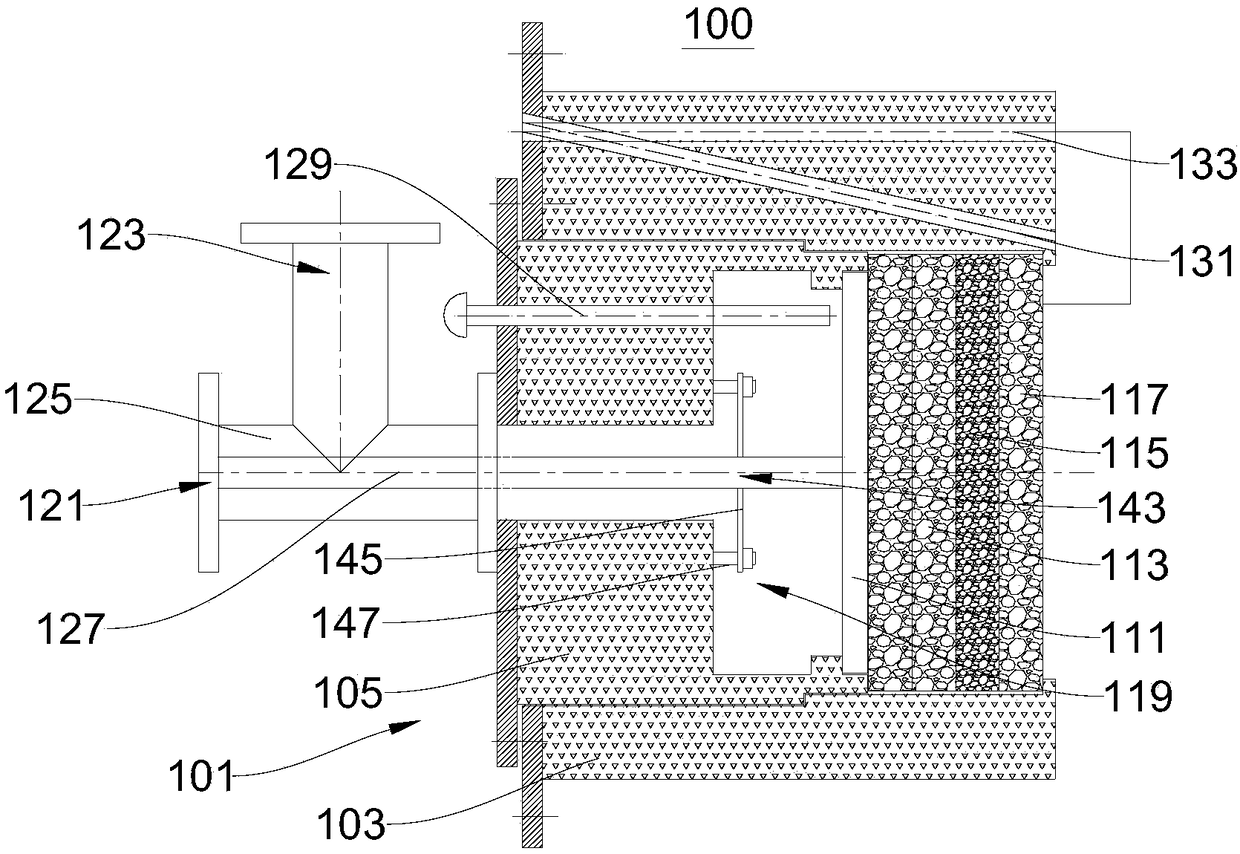

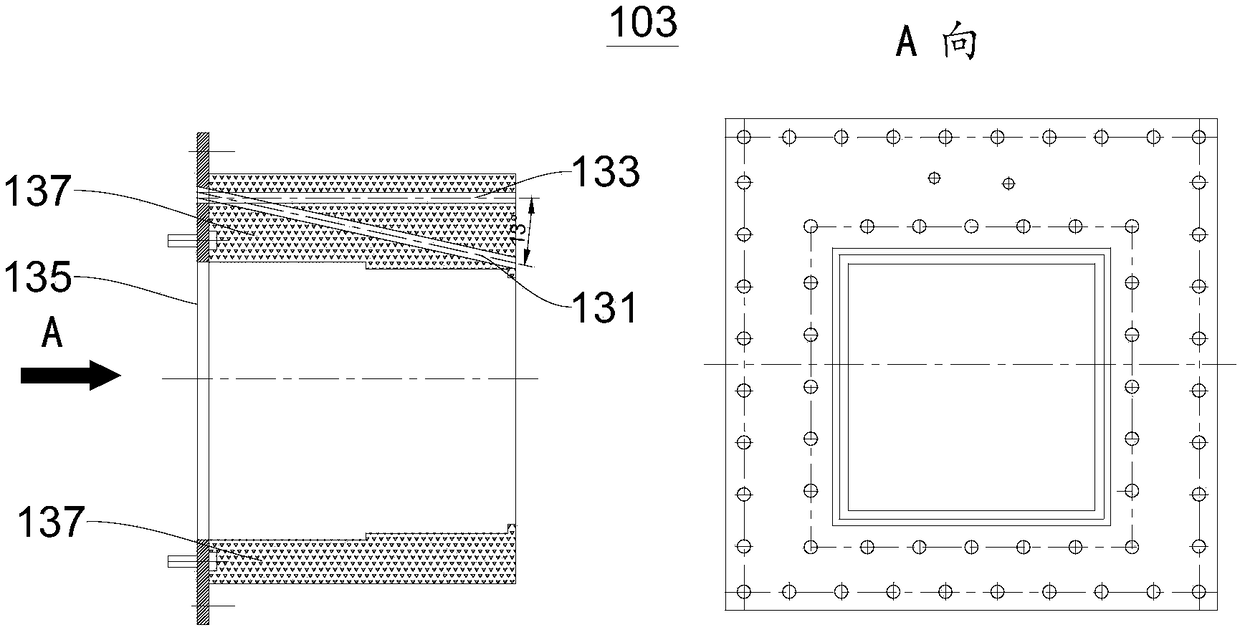

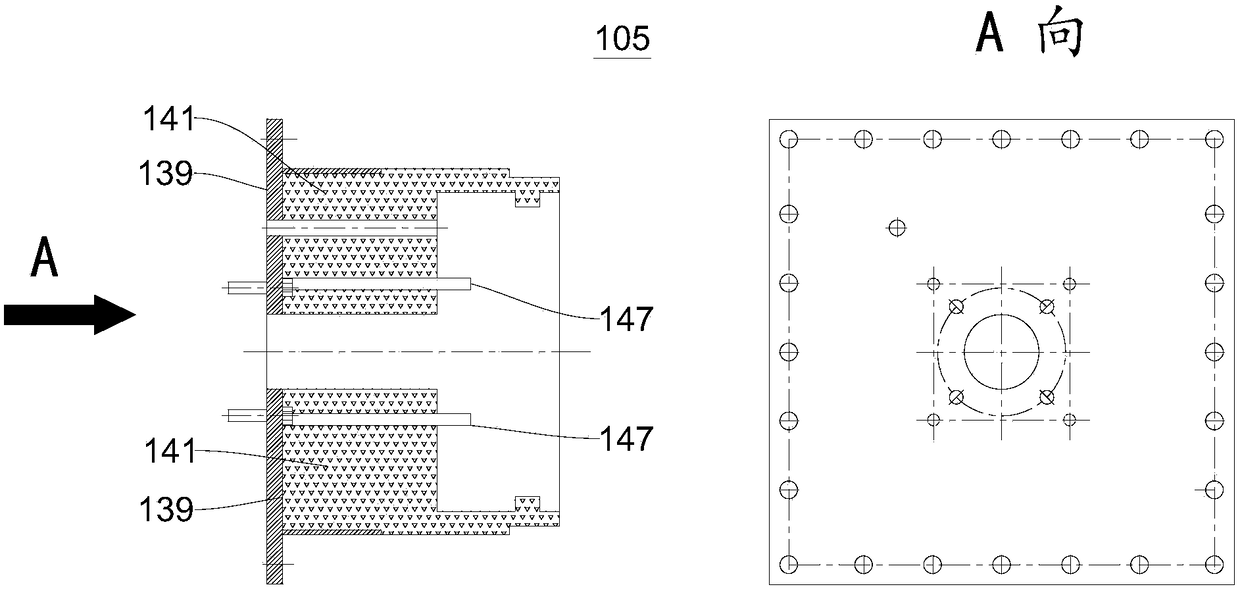

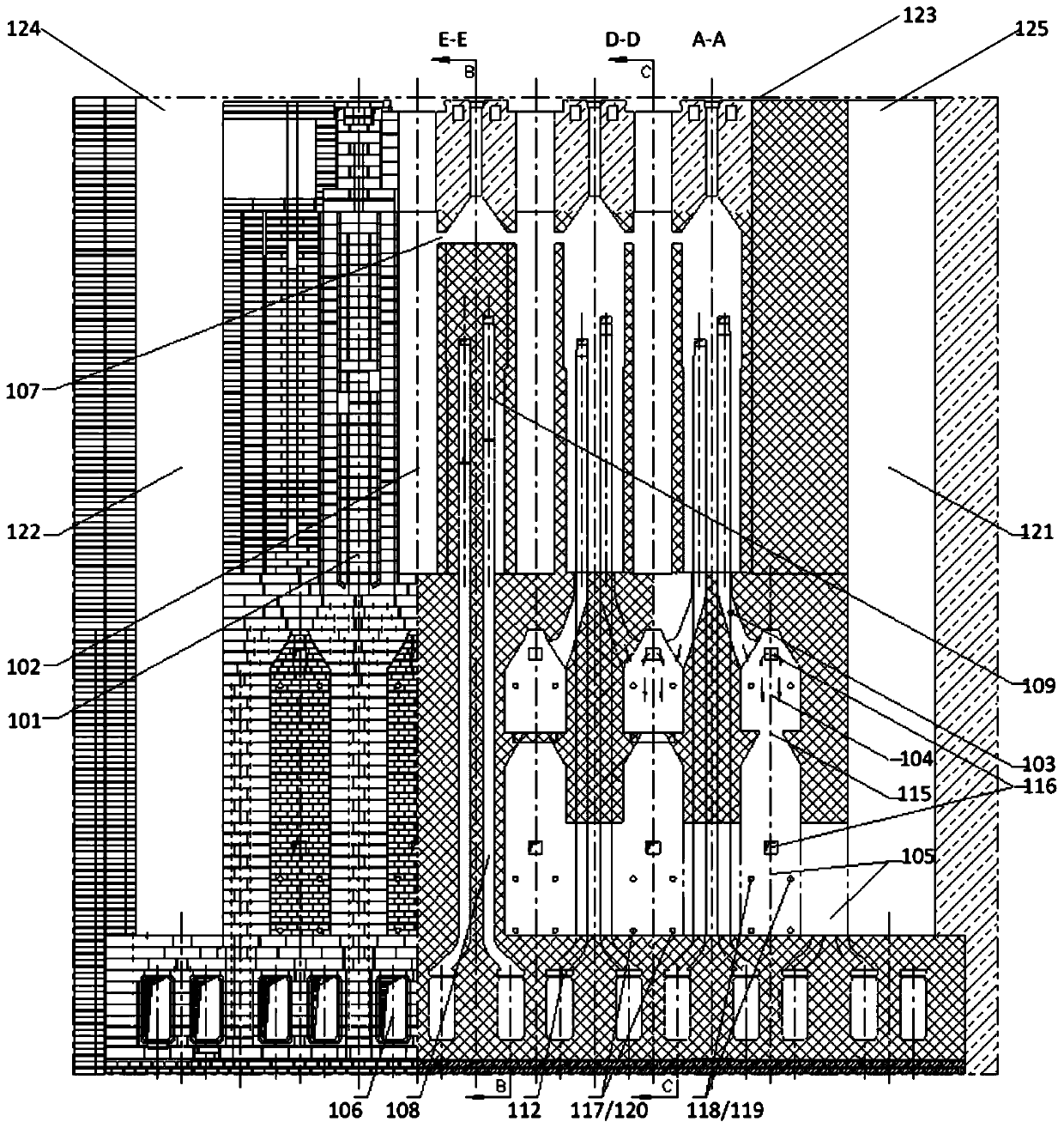

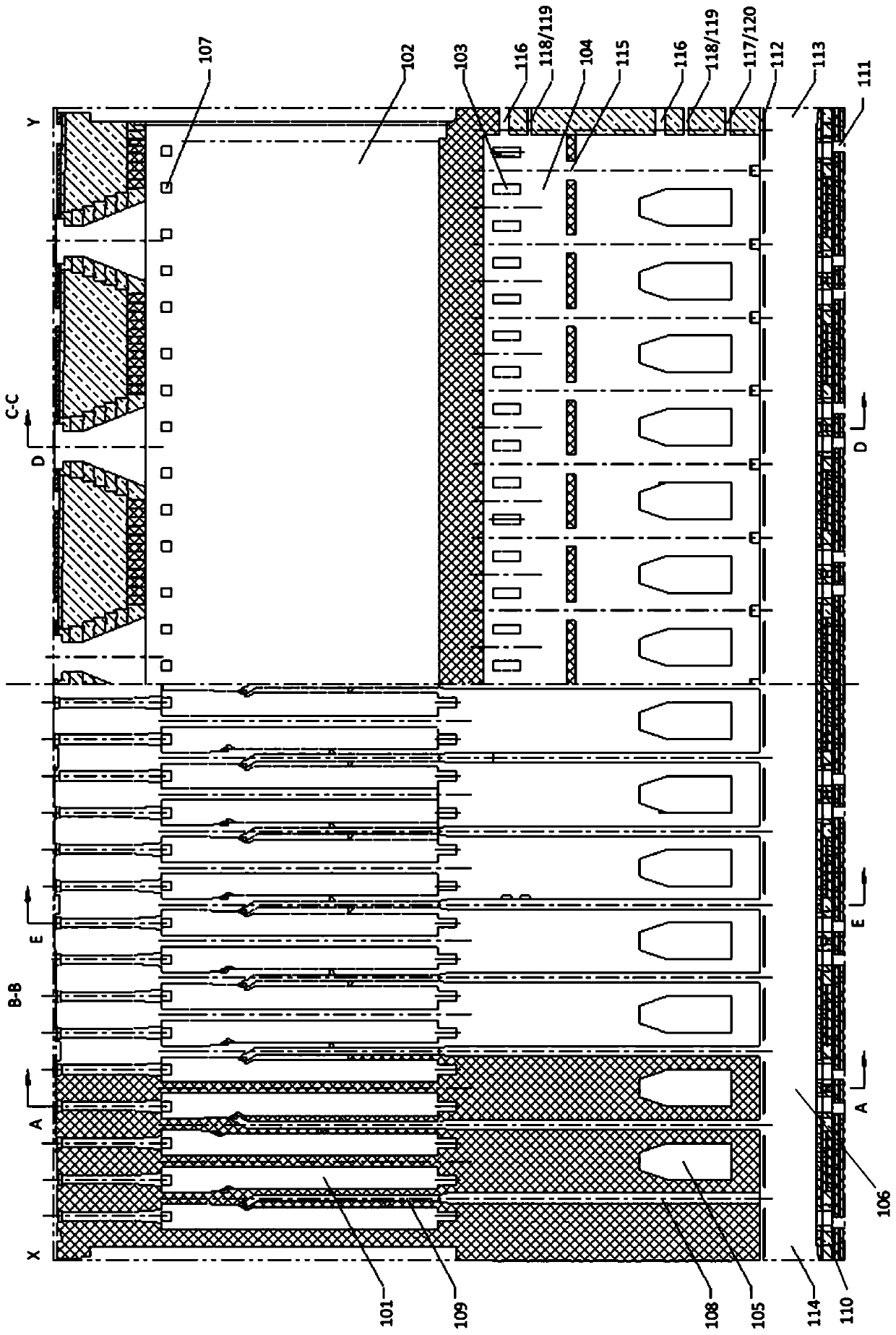

Air-preheating-type heat recovery coke oven

PendingCN110408412AAchieve warm-upEfficient preheatingPreheating coke ovensEnergy inputCombustion chamberCarbonization

The invention relates to an air-preheating-type heat recovery coke oven. The air-preheating-type heat recovery coke oven comprises a combustion chamber, a carbonization chamber, a chute, a pressure balance chamber, a criss-cross exhaust gas flue and a combustion air distribution channel, wherein the chute is connected between the combustion chamber and the pressure balance chamber; the criss-crossexhaust gas flue is arranged at the lower portion of the pressure balance chamber and communicated with the pressure balance chamber; the combustion air distribution channel is arranged at the lowerportion of the criss-cross exhaust gas flue; an air preheating upright channel is arranged in a main wall below the combustion chamber and communicated with the combustion air distribution channel; anupright fire flue partition combustion air channel is arranged in upright fire flue partitions and communicated with the air preheating upright channel; an outlet of the upright fire flue partition combustion air channel is communicated with upright fire flues of the combustion chamber. According to the air-preheating-type heat recovery coke oven, combustion air is uniformly distributed and supplied into the upright fire flues of the combustion chamber and merged with raw coke oven gas in the upright fire flues for combustion after being subjected to sufficient heat transfer and temperature rise with high-temperature exhaust gas, so that the combustion temperature is increased, the coking time is shortened, and the purpose of improving the production efficiency is achieved.

Owner:HUATAI YONGCHUANG BEIJING TECH CO LTD

Low-cost bio-based mutual-modified sustained/controlled-release fertilizer easy to biologically/optically degrade and production devices thereof

PendingCN111470905ADegradation does not affectPromote degradationSpray boothsLayered/coated fertilisersAgricultural engineeringBiological organism

The invention discloses a low-cost bio-based mutually-modified sustained / controlled release fertilizer easy to biologically / optically degrade. The fertilizer comprises fertilizer particles; a modifying layer formed by spraying a surface modifier on the surfaces of the fertilizer particles; and a bio-based polyurethane layer, wherein the bio-based polyurethane layer is formed by spraying a bio-based mutual modified coating material on the modifying layer. The invention also discloses a device for producing the fertilizer and a device for continuously producing the fertilizer. The device for producing the fertilizer comprises a cylinder body and a driving device for driving the cylinder body to rotate, wherein a machine head sealing cover and a machine tail sealing cover are respectively arranged at two ends of the cylinder body, and an infrared monitoring probe and a spraying system are arranged in the cylinder body. According to the present invention, a renewable bio-based material isadopted, such that the environmental protection is achieved, the disadvantages of the existing bio-based coating material are improved through the mutual modification of the two components, the novelprocess technology is provided for the coating of the controlled release fertilizer, and the continuous and automatic production of the fertilizer can be achieved.

Owner:SHANDONG AGRICULTURAL UNIVERSITY

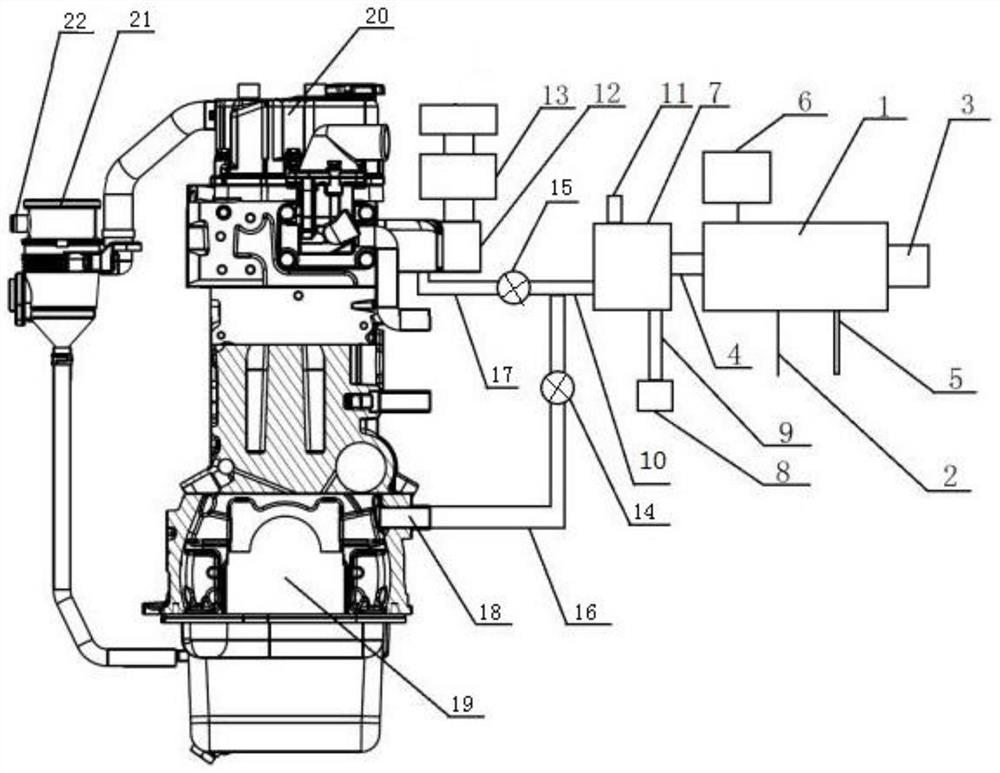

Microwave drying device capable of integrating preheating and strong wind heat dissipation

PendingCN110608597AIncrease profitHeating evenlyDrying solid materials with heatDrying machines with progressive movementsMicrowaveProcess engineering

The invention discloses a microwave drying device capable of integrating preheating and strong wind heat dissipation. The microwave drying device comprises a belt conveyor, wherein a preheating bin isarranged at the starting end of the belt conveyor, a microwave drying bin is fixedly connected with the preheating bin, and at least one microwave generator is fixed on the upper side of the interiorof a microwave heating box; a spiral distributor is arranged at the joint of the preheating bin and the microwave drying bin, a dehumidification device and an axial flow fan are sequentially connected in series on a heat collection pipe, a strong fan is arranged below the belt conveyor, and a control cabinet is connected with the belt conveyor, the microwave generators, the axial flow fan or thestrong fan. Materials are subjected to drying treatment by adopting a microwave heating technology, and rapid drying of the materials can be achieved through microwaves. According to the microwave drying device, in the process of drying the materials, logistics in the microwave drying bin is timely subjected to heat dissipation and dehumidification, the emitted heat in the microwave drying bin isreturned into the preheating bin, the materials are preheated in the preheating bin, and the energy utilization rate is improved.

Owner:山东立威微波设备有限公司

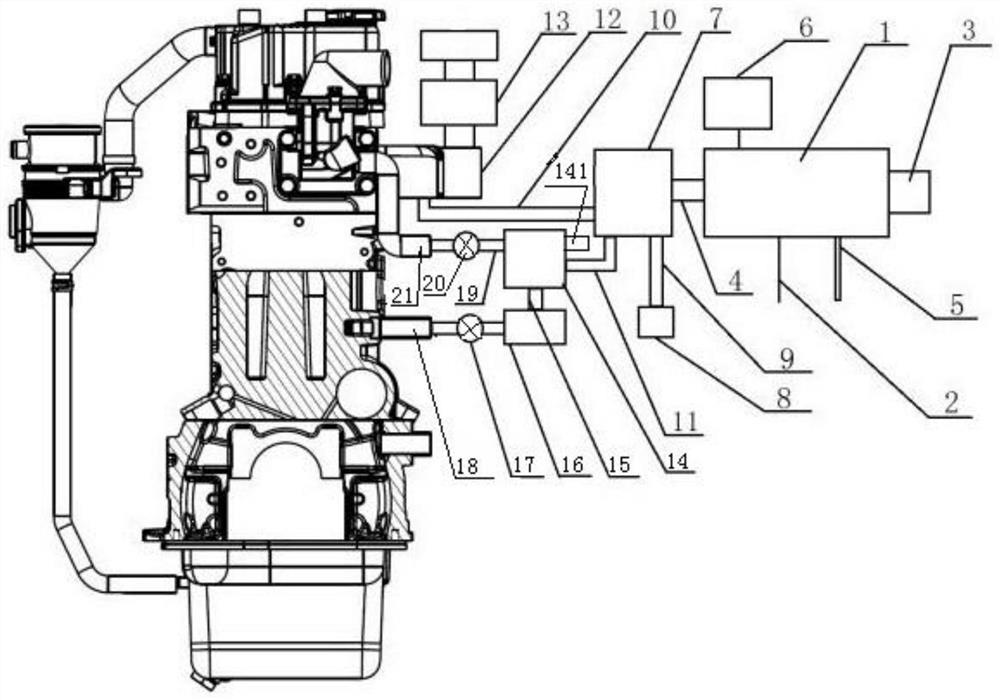

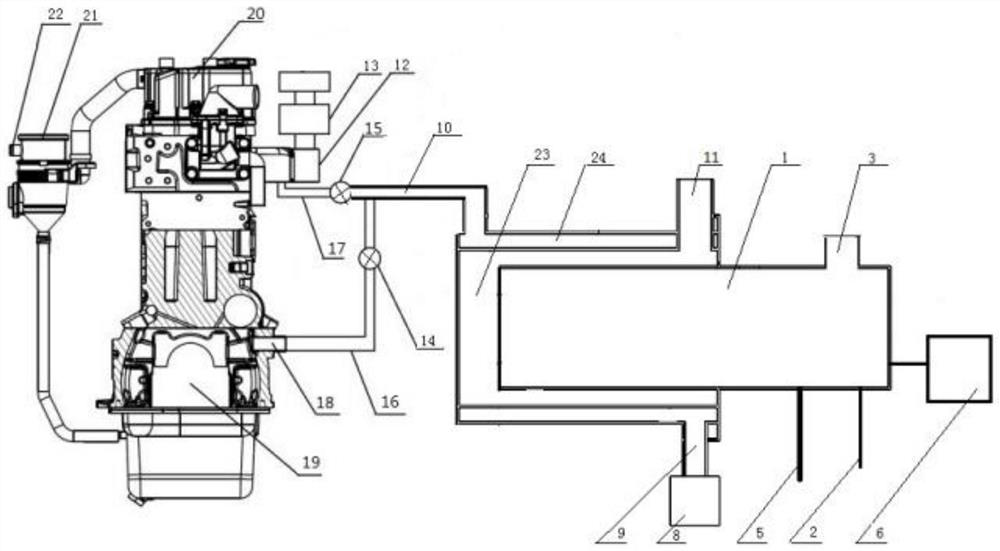

Engine air intake and anti-freezing solution preheating combined system and preheating method thereof

PendingCN111664040AEfficient preheatingReduce friction pair resistanceMachines/enginesThermal treatment of fuelCold airFuel tank

The invention discloses an engine air intake and anti-freezing solution preheating combined system. The system comprises a controller, an air heating device, an anti-freezing solution preheating assembly and a communication pipeline, after external cold air is heated by the air heating device, then high-temperature air is input into an engine air inlet pipe through a pipeline, an anti-freezing solution is heated through the anti-freezing solution preheating assembly and then is transported to an engine water jacket, the air heating device and the anti-freezing solution preheating assembly areelectrically connected with the controller, and the controller is connected with a storage battery on a vehicle to realize power supply. The preheating combined system is independent of the vehicle, can realize air intake and high-efficiency preheating of an engine by using only a small amount of power supply through the storage battery on the vehicle and a small amount of oil supplied by an oil tank, thereby rapidly improving temperatures of air intake and the anti-freezing solution, improving a temperature of an engine oil, reducing a starting torque, and enabling the engine to be smoothly started under harsh low temperature conditions.

Owner:BEIJING GAOXIN GREAT FILTER CO LTD

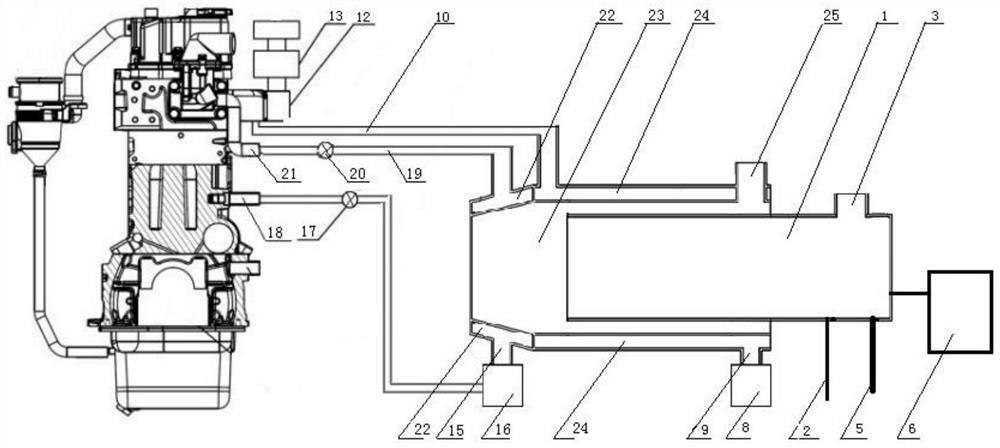

Engine air inlet and crankcase preheating combined system and preheating method thereof

PendingCN111664038ALow starting resistanceDilution does not causeMachines/enginesThermal treatment of fuelCold airCrankcase

The invention discloses an engine air inlet and crankcase preheating combined system. The engine air inlet and crankcase preheating combined system comprises a controller, a cold air preheating assembly and pipelines for communication, wherein outside air is heated through the cold air preheating assembly and then input into an engine air inlet pipe and a crankcase air inlet channel in a crankcasethrough the two parallel pipelines; an air heating device is electrically connected with the controller; and the controller is connected with a storage battery on a vehicle to achieve power supply. The engine air inlet and crankcase preheating combined system is reasonable in structural layout, pipeline connection is smooth, and efficient preheating of engine air inlet and the crankcase is achieved through the design of a heat exchanger; and when an engine is started at a low temperature, the friction resistance between engine moving parts is reduced while the engine air inlet temperature isincreased, the initial starting torque is reduced, and the engine can be rapidly started.

Owner:BEIJING GAOXIN GREAT FILTER CO LTD

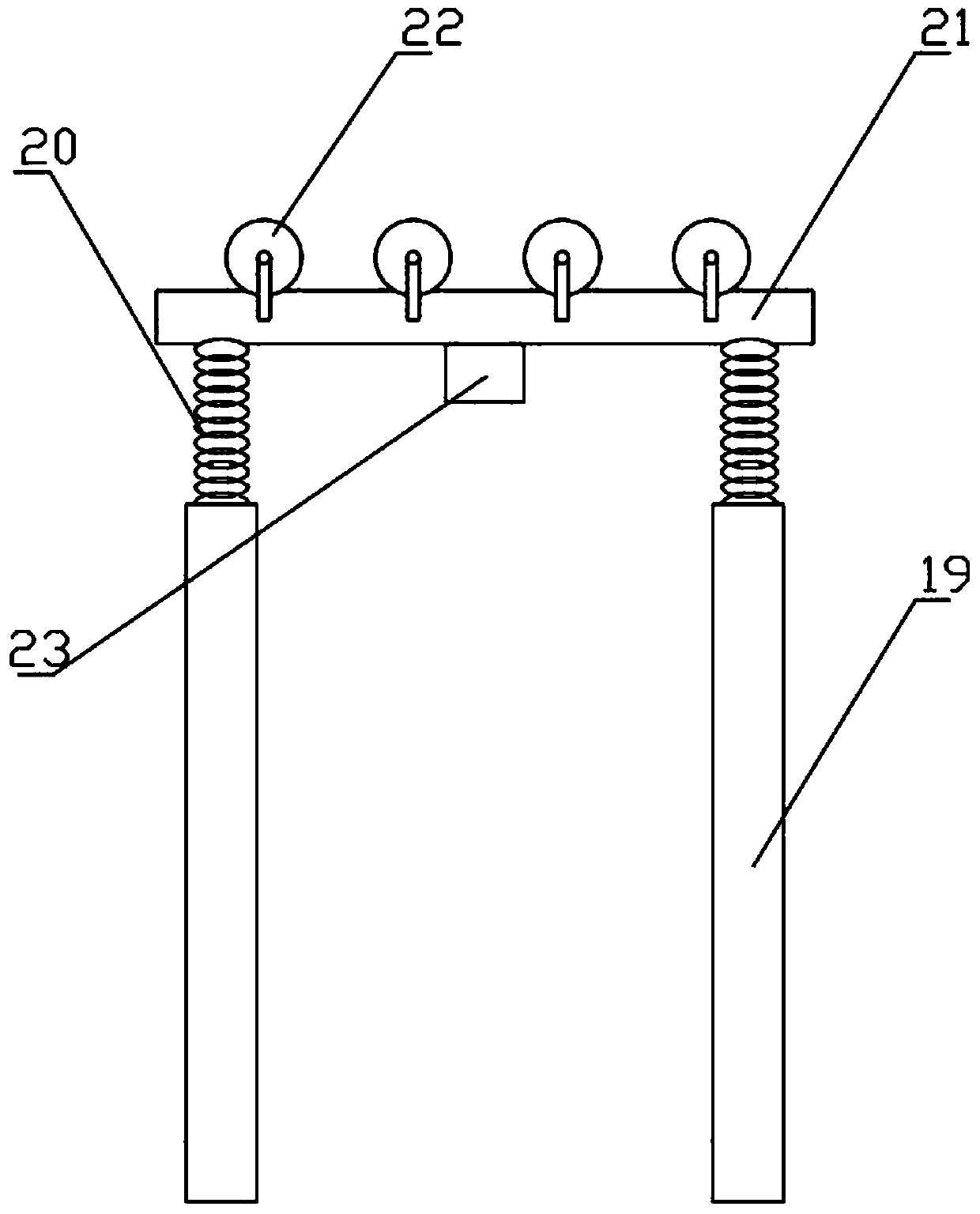

A conductor preheating device for electric wire production

InactiveCN109215887AImprove cleanlinessEasy to limitApparatus for heat treatmentStorage heatersHeating oilElectrical conductor

A conductor preheating device for electric wire production include a first frame, a limit structure, a Dust-removing structure and a water removing structure, the top end of the first frame body is fixedly provided with a device shell, and a blower is installed at the top end of the device housing, a vacuum chamber is arranged inside the device housing, The inner wall of the heating oil bin is uniformly provided with a heating block, the right end of the heating oil bin inner cavity is welded with an air guide pipe body, the bottom end of the heating oil bin is provided with an oil outlet pipe, the middle positions of both sides of the device shell are welded with a finite position structure, and the top ends of the second frame body are sequentially installed with a dust removing structure and a water removing structure from the left to the right. The conductor preheating device for electric wire production utilizes the high temperature in the heating cabin and the fan to accelerate the air flow, so that the hot air preheats the conductor efficiently, and the direct heating structure is also provided. The conductor is cleaned before the preheating, the cleanliness of the conductoris ensured, the limit of the conductor is strengthened, and the friction between the conductor and the device is avoided.

Owner:CHANGGUANG COMM SCI & TECH JIANGSU CO LTD

Infrared thermal image detection device

InactiveCN106197682ASolve the technical problems of slow preheating speed, poor efficiency and easy to get dampWarm up fastRadiation pyrometryHeating or cooling apparatusImage detectionPower equipment

The invention discloses an infrared thermal image detection device. The device comprises an infrared thermal imager, a shell, a first support and a distance adjusting structure. N preheating holes are evenly formed in the surface of the infrared thermal imager. A dry layer is disposed on the inner wall of the infrared thermal imager, an electric heating bar is fixed in the middle in the shell, a fan is fixed to the bottom in the shell, an air inlet in the lower end of an air collecting cover is connected with the open end of the shell, an air outlet in the upper end of the air collecting cover is connected with one end of an exhaust main pipe, the other end of the exhaust main pipe is connected with N exhaust branch pipes through a flow divider, and the other ends of the N exhaust branch pipes are connected with N air needles respectively. The distance adjusting structure comprises a motor, a gear, a rack, a first rod and a second rod. The device has the advantages of being reasonable in design, high in safety during detection of power equipment, high in preheating speed, good in effect and not likely to be affected with damp.

Owner:CHENGDU HANKANG INFORMATION IND

A system and method for desulfurization waste water, salt separation, zero discharge and flue gas mercury removal

ActiveCN111068510BAvoid the problem of reduced mercury removal efficiencyRealize resource utilizationGas treatmentDispersed particle separationFlue gasWastewater

The invention discloses a desulfurization waste water desalination zero discharge cooperative flue gas mercury removal system and method, including pretreatment and nanofiltration system, chlorine salt solution preheating and flue spraying system, sulfate solution multi-effect distillation system and freezing crystallization system. The nanofiltration device is used to realize the separation of desulfurization waste water salt, the chlorine salt solution is sprayed into the flue near the SCR after being preheated by the condenser to realize synergistic mercury removal; the sulfate solution is concentrated by multi-effect distillation and then frozen and crystallized, and the sulfate preheater recovers the heating steam The residual heat of condensate. The invention can realize zero discharge of desulfurization wastewater, and synergistically improve the efficiency of flue gas mercury removal, and has remarkable environmental protection benefits; the heat pump is used to increase the waste heat level of frozen crystallization to heat the chloride salt solution, and the condensed water is used to preheat the sulfate solution, effectively reducing the concentration energy consumption; The use of chlorine salt solution spraying in desulfurization wastewater to promote efficient demercury removal of flue gas has good economic benefits; the salt content of desulfurization wastewater is recovered through the freezing and crystallization system to realize resource utilization of desulfurization wastewater.

Owner:XI AN JIAOTONG UNIV

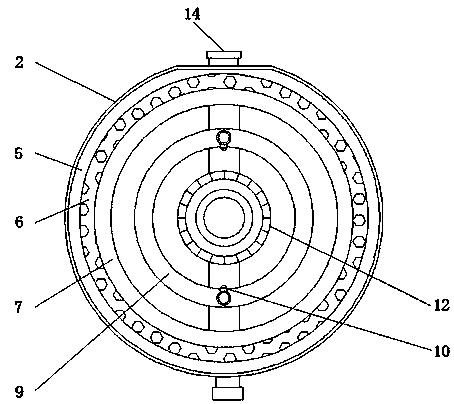

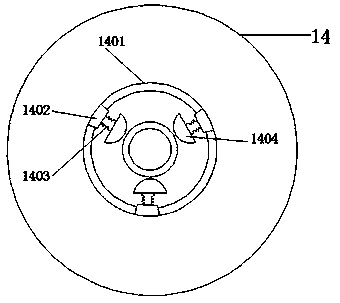

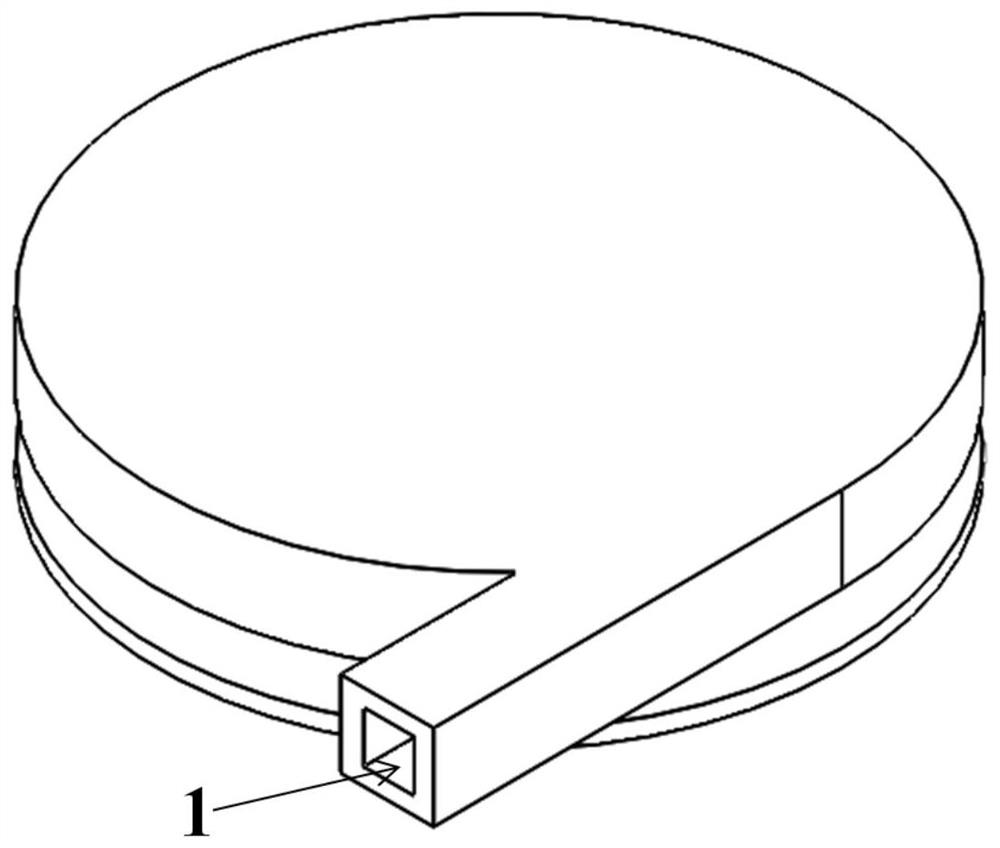

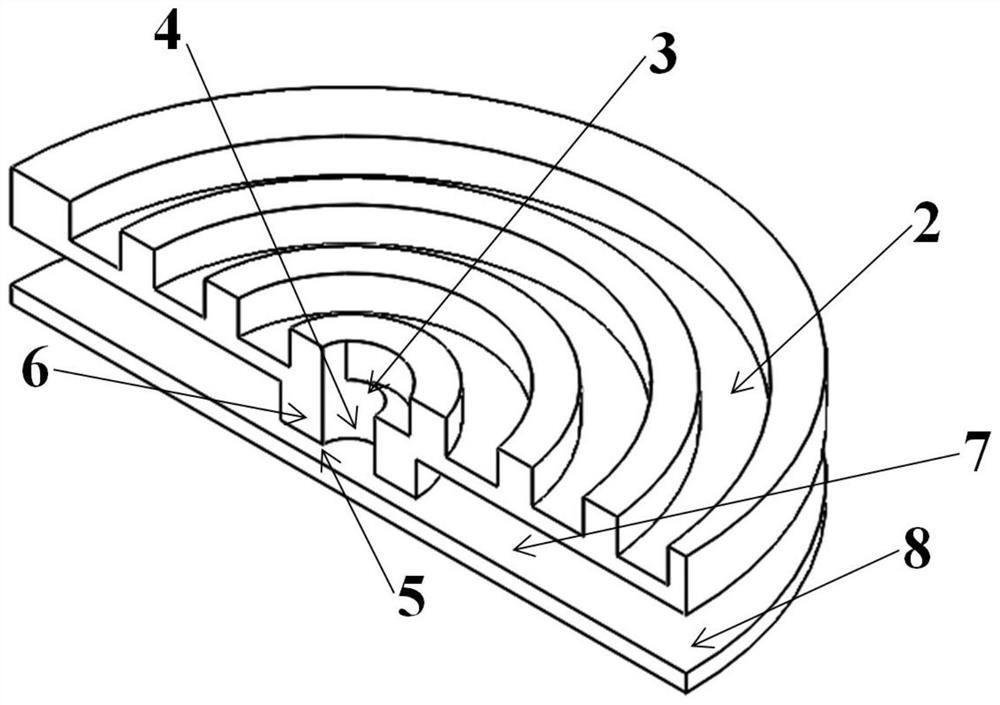

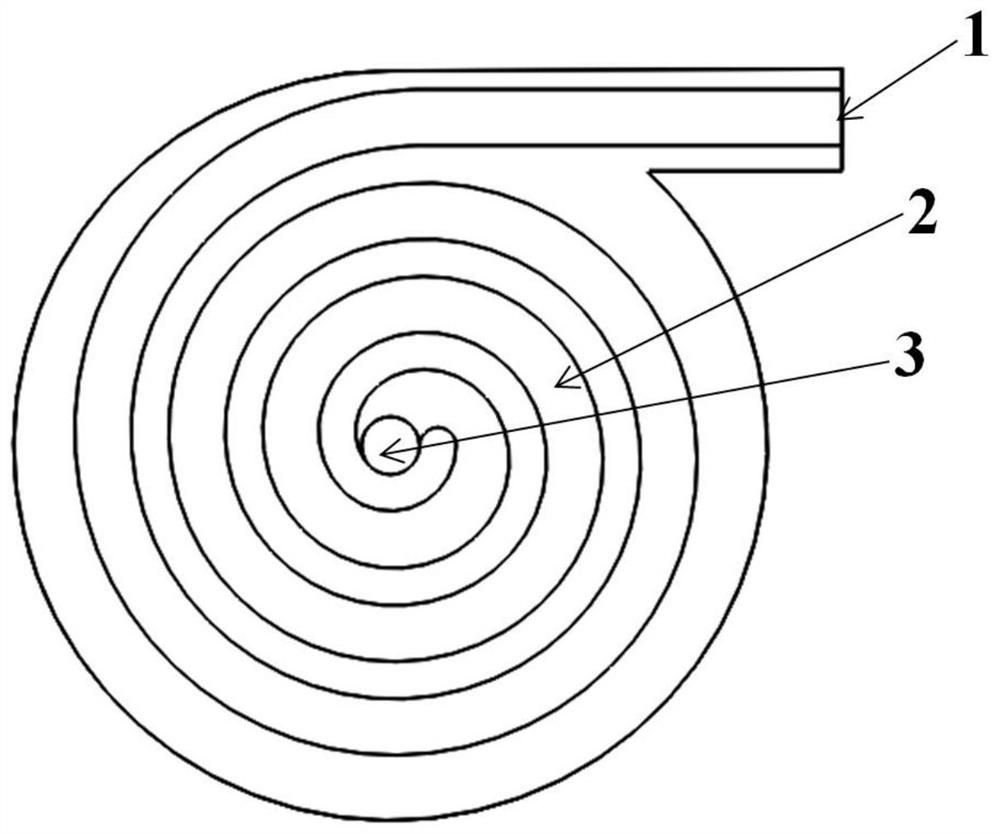

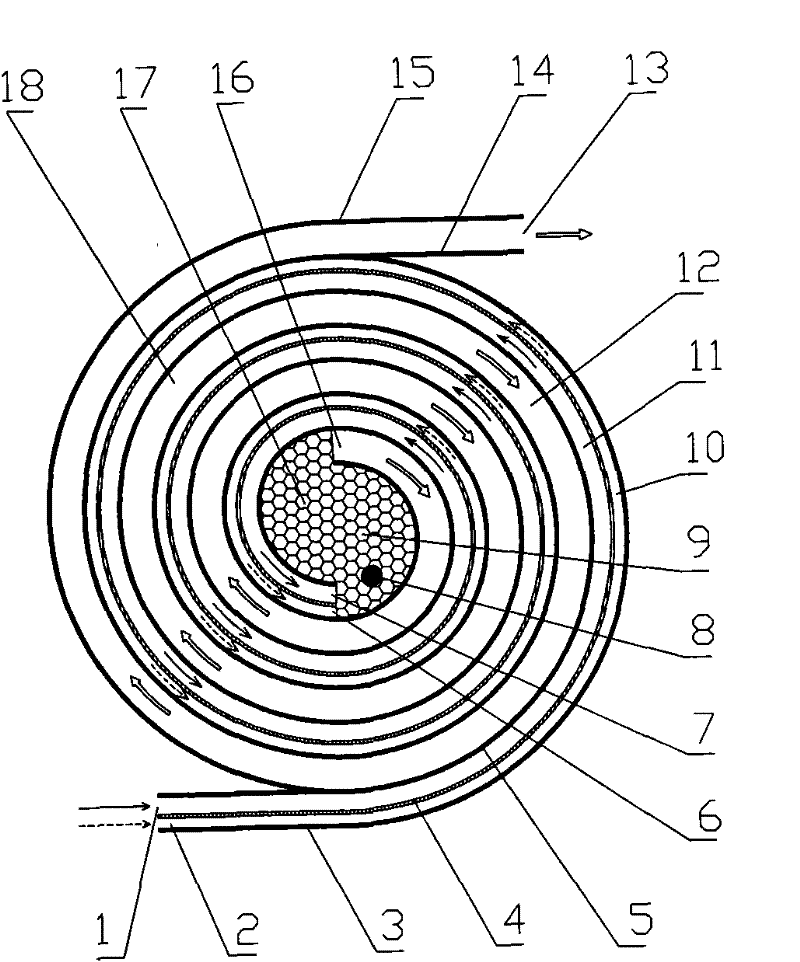

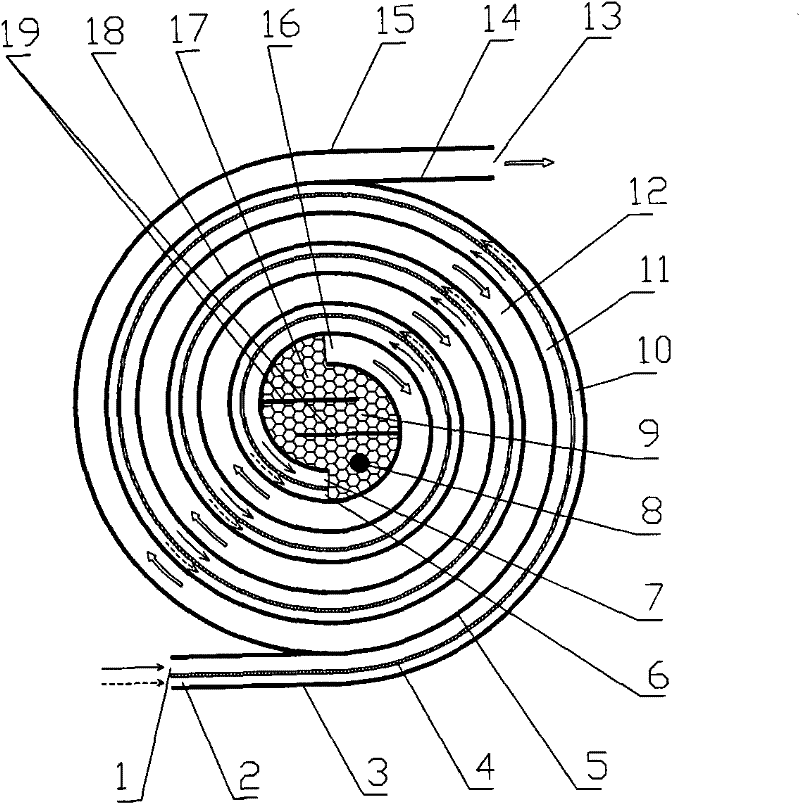

A Small Disc Premixed Burner with Efficient Preheating and Flashback Prevention

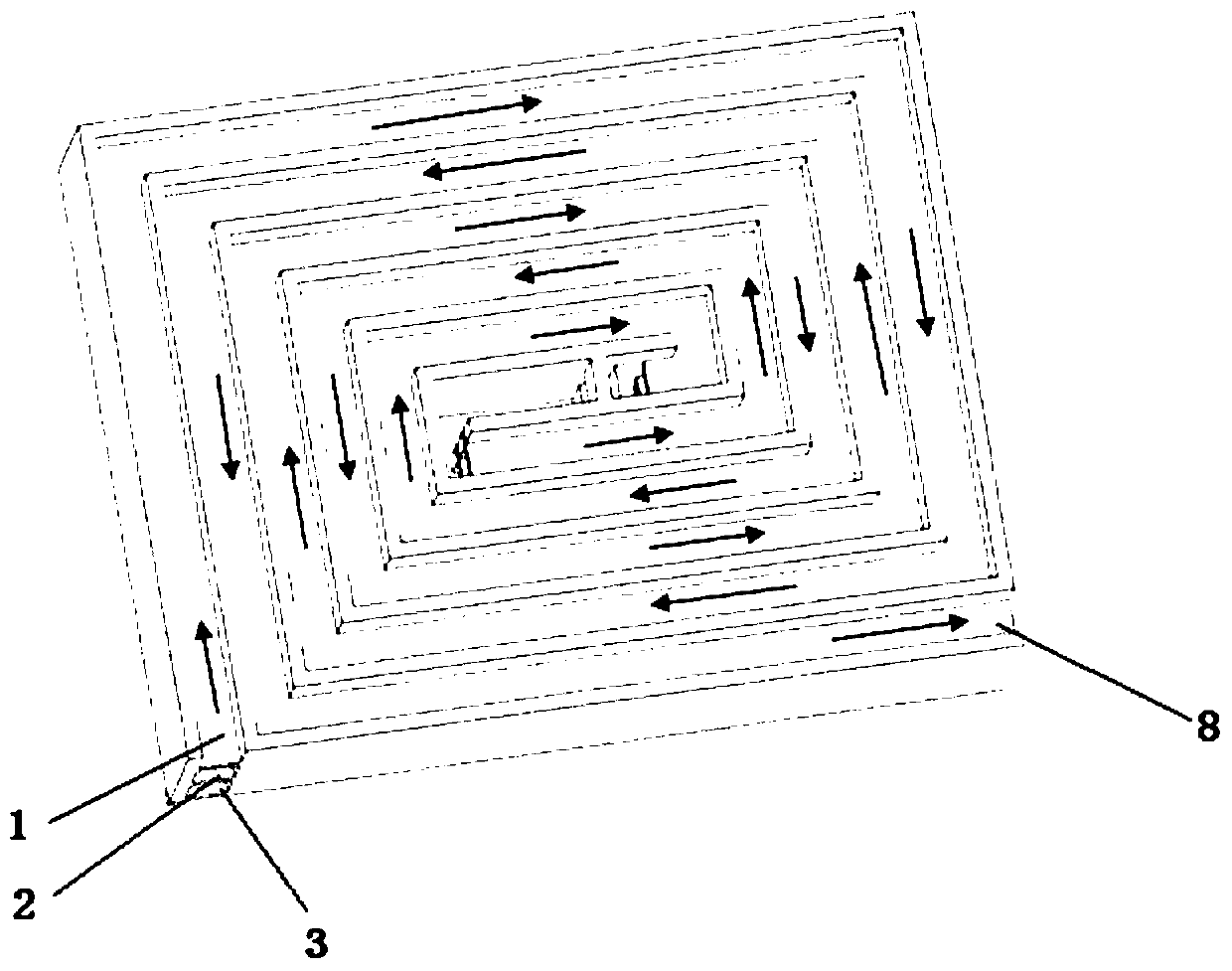

ActiveCN110906328BPrevent backfireRaise the initial temperature of the reactionIndirect carbon-dioxide mitigationGaseous fuel burnerCircular discThermodynamics

The invention belongs to the small-scale combustion technology field, and especially discloses an efficient preheating anti-backfire small disc premixing combustor. The combustor comprises a fuel preheating body, an annular boss and a combustion chamber lower disc. The fuel preheating body comprises an upper cover plate, a lower wall plate and a fuel preheating channel arranged between the upper cover plate and the lower wall plate in a spiral mode. The combustion chamber lower disc and the lower wall plate are arranged at intervals so as to form an annular combustion chamber of the premixingcombustor. One end of the annular boss is fixedly connected with the lower wall plate, the other end and the combustion chamber lower disc are arranged at intervals, and a fuel channel is arranged inthe annular boss. One end of the fuel channel is connected with a through hole which is arranged on the lower wall plate and is used for connecting the annular boss and an air outlet of the fuel preheating channel, and the other end is connected with an inlet of the annular combustion chamber. Efficient preheating and stable and efficient combustion of a fuel premixed gas can be effectively achieved, and the combustor is suitable for various small power or heating devices.

Owner:HUAZHONG UNIV OF SCI & TECH

Devices for distributing heating water

InactiveCN102213462BEfficient allocationReasonable distributionFluid heatersSpace heating and ventilation detailsWater useWater flow

A hydraulic device for distributing water for heating comprising a body (37) in which at least the following are defined: at least a delivery pathway (39) for water for heating and extending from an inlet (38) for the water for heating, destined to be connected to a delivery of a centralised plant (17), to an outlet (49), destined to be connected to a low-temperature heating plant (12b) and / or to a heat exchanger (3) with sanitary water; a first pathway (53) for return water from a low-temperature heating plant (12b) extending from a first inlet (52) for the return water from the low-temperature heating plant (12b) to a first outlet (54) for the return water; a second pathway (63) for the return water extending from a second inlet (62) to a second outlet (64), destined to be connected with a return in the centralised plant (17); and a mixer group (55), arranged between the delivery pathway (39) of the heating water and the first pathway (53), destined to determine a flow of return water to be pre-mixed with the water for heating in the delivery pathway (39) such as to obtain mixed water having an intermediate temperature, suitable for sending into the outlet (49) for water for heating.

Owner:IVAR

Fluid raw material feeding and preheating device for production and processing of injection molding machine

The invention belongs to the technical field of preheating equipment, and discloses a fluid raw material feeding and preheating device for production and processing of an injection molding machine. The fluid raw material feeding and preheating device comprises a feeding pipe, wherein the outer surface of the feeding pipe is fixedly sleeved with a heat preservation pipe, the inner surface of the feeding pipe is fixedly connected with a fixing rod, and the inner end of the fixing rod is fixedly connected with an inner pipe. A flowing liquid raw material exchanges heat with the inner pipe from the inside, flowing heat exchange air is poured into the heat preservation pipe through a fixed pipe, waste heat air obtained after heat exchange is fed into the heat preservation pipe to conduct heat preservation treatment on the outer side of the feeding pipe, efficient preheating and temperature rising of the liquid raw material are achieved from the inside, the radiation distance in the actual radiation heat exchange process is reduced, heat attenuation waste is reduced, efficient preheating and temperature rising are achieved, meanwhile, waste heat is effectively utilized for conducting heat preservation treatment on the feeding pipe, efficient utilization of heat emitted by the heating pipe is improved, the preheating effect of liquid raw materials is greatly improved, the later machining effect of the injection molding machine is improved, and the use effect is good.

Owner:深圳市星凯科技有限公司

High temperature pellet waste heat recovery heat utilization device

InactiveCN104792183BSimple configurationImprove qualityEnergy industryHandling discharged materialBulk cargoCooling chamber

The invention discloses a waste heat recovery heat utilization device for high-temperature particle materials. The waste heat recovery heat utilization device comprises a flash cooling chamber, a slow cooling chamber, a preheating chamber, a reheating chamber and heat tube bundles, wherein a high-temperature draught fan is connected with an exhaust opening in the bottom of the side face of the flash cooling chamber and an air inlet of a Venturi nozzle of the top face of the flash cooling chamber, the slow cooling chamber is cylindrical, a temperature-resistance draught fan is connected with an exhaust opening of the slow cooling chamber and a jetting pipe, the jetting pipe is tightly attached to the rear back face of a bulk cargo plate capable of rotating by 360 degrees in an annular channel of the slow cooling chamber, and the surface of the particle materials is cooled by jetting flow after a particle material pile is scattered by the bulk cargo plate. The bottom face of a splat cooling chamber and the top face of the slow cooling chamber share the same surface. The middle temperature heat tube bundle perpendicularly penetrates through the preheating chamber and the slow cooling chamber, the extension lengths of the middle temperature heat tube bundle at the two ends are the same, the high temperature heat tube bundle obliquely penetrates through the reheating chamber and the flash cooling chamber, and the extension lengths of the high temperature heat tube bundle at the two ends are the same. The waste heat recovery heat utilization device can be used in high-temperature particle material waste heat recovery heat utilization places where waste heat quantity is small or fluctuates. By the adoption of the device, clean and high-quality high temperature air resources can be generated, the particle materials can be cooled to be at the temperature below 100 DEG C, the air is preheated to be at the temperature of 800-900 DEG C, the temperature efficiency is higher than 85%, and the waste heat recovery efficiency is higher than 70%.

Owner:ZHUZHOU FLASHLIGHT IND FURNACE

Distributed natural gas hydrogen production reactor

The invention discloses a distributed natural gas hydrogen production reactor which comprises an annular gas inlet passage and an annular gas discharge passage which are refluent in two directions and formed by a gas inlet passage outer wall sheet and a gas inlet passage inner wall sheet as well as a gas discharge passage outer wall sheet and a gas discharge passage inner wall sheet. The distributed natural gas hydrogen production reactor is characterized in that an annular-stripe shaped gas inlet passage separation sheet is inserted in the gas inlet passage to divide the gas inlet passage into a first gas inlet passage and a second gas inlet passage. By the invention, fuel gas and oxidizing gas which are used in reaction can enter the center of the reactor in a non-premixed state, thereby avoiding flame drafting caused by premixing before the fuel gas and the oxidizing gas enter a porous medium and preventing the explosion hazard because of premixing. The distributed natural gas hydrogen production reactor can be widely applied to combustion reaction devices of low-concentration flammable gases, including oil layer gases in production of coal mine ventilation gas, natural gas, methane and petroleum, or flammable waste gas discharged in chemical production.

Owner:HEFEI UNIV OF TECH

Efficient pre-heating furnace

InactiveCN107228562ASimple structureEfficient preheatingCrucible furnacesWaste heat treatmentHeating furnaceFlue

The invention relates to a high-efficiency preheating furnace, which includes a furnace body and a support frame. The second feed port, the upper end of the furnace body is provided with a fuel delivery pipe; the furnace body is provided with a heating device, and the heating device is provided with a flue gas heating pipe, and the flue gas heating pipe is an "S" type flue gas Gas heating pipeline; the left and right ends of the furnace body are respectively provided with smoke exhaust main pipes, and the smoke exhaust main pipes are arranged below the heating device; the inner lower end of the furnace body is provided with a fan; the furnace body is provided with a first filter screen , the first filter screen is arranged above the heating device; the second filter screen is provided in the fuel delivery pipe; the present invention is a high-efficiency preheating furnace with simple structure, safety and reliability, convenient use and low cost. It can quickly and evenly preheat the metal, effectively improving the preheating efficiency of the metal parts.

Owner:YANCHENG SHENGFENG MACHINERY

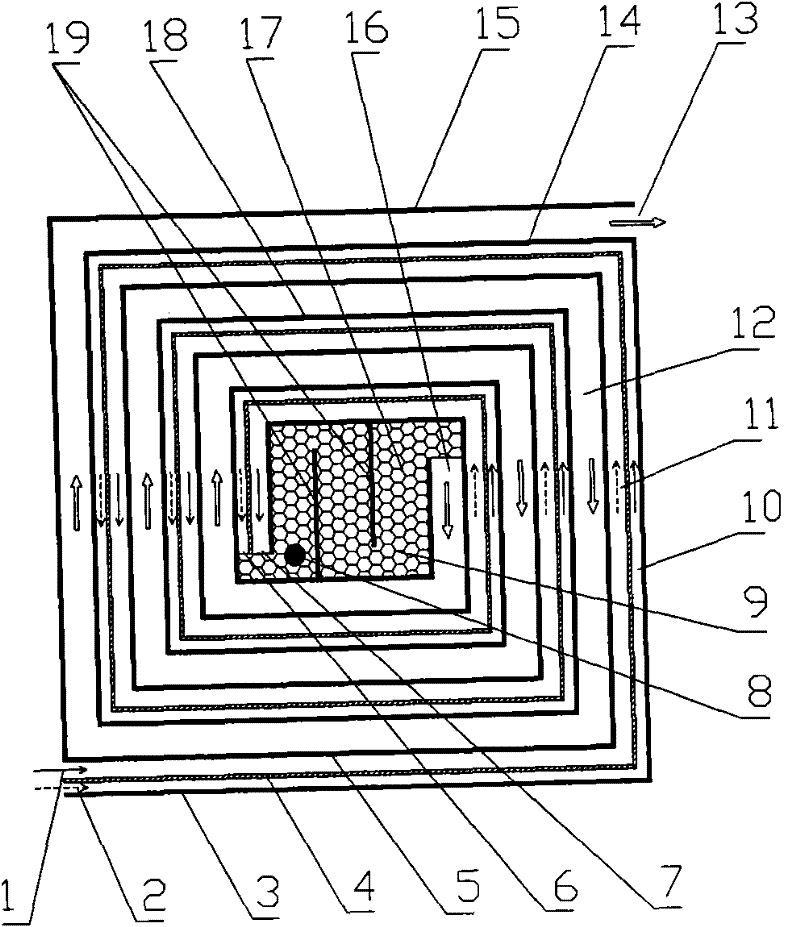

Double preheating rotary regenerative heat exchanger and combustion system

ActiveCN105021075BWarm up safeEfficient preheatingLiquid fuel feeder/distributionIndirect carbon-dioxide mitigationCombustion systemCombustion

A dual-preheating rotation type heat-storage heat exchanger comprises a heat storage body, fluid passageways and a fuel passageway. The heat storage body can rotate. The fluid passageways include the hot fluid passageway and the cold fluid passageway. A hot fluid medium in the hot fluid passageway and a cold fluid medium in the cold fluid passageway can both make contact with the heat storage body. The fuel passageway comprises a passageway pipe which is arranged on the heat storage body. The dual-preheating rotation type heat-storage heat exchanger can safely and efficiently preheat fuel, and therefore the aim of improving the combustion efficiency through dual preheating is achieved. A combustion system comprises a smoke pipeline, a combustion-supporting gas pipeline, a fuel conveying passageway and the dual-preheating rotation type heat-storage heat exchanger. The dual-preheating rotation type heat-storage heat exchanger comprises the hot fluid passageway, the cold fluid passageway and the fuel passageway. The hot fluid passageway is connected with the smoke pipeline in a butt joint manner. The cold fluid passageway is connected with the combustion-supporting gas pipeline in a butt joint manner. The fuel conveying passageway is connected with the fuel passageway in a butt joint manner. The combustion system can preheat combustion-supporting air and fuel at the same time, and the combustion efficiency is improved.

Owner:BEIJING ENJI ENERGY SAVER TECH

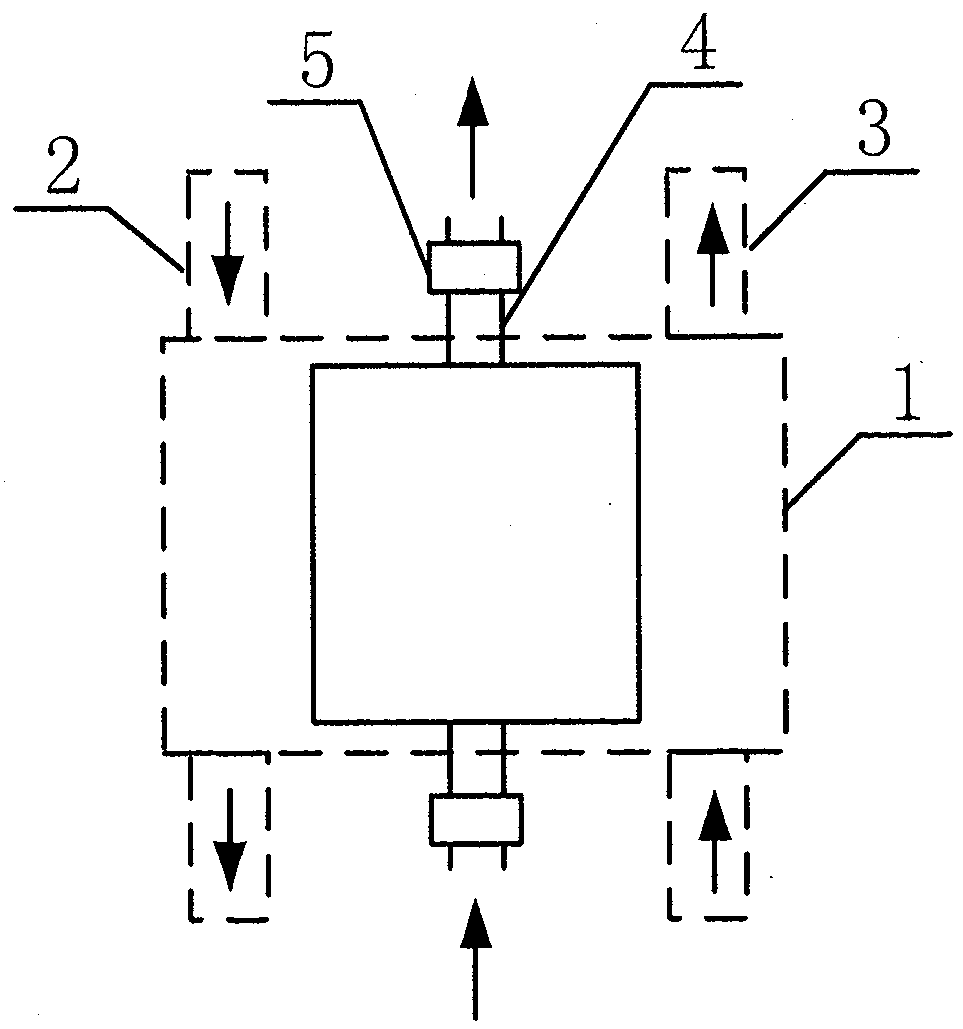

A Small Diffusion Burner with Multi-channel and Efficient Preheating

ActiveCN110195863BAvoid inadequate mixingImprove the mixing effectIndirect carbon-dioxide mitigationGaseous fuel burnerThermodynamicsCombustor

The invention belongs to the technical field of micro-scale combustion, and particularly discloses a multi-channel efficient preheating small diffusion combustor. The combustor comprises a combustor body, an upper cover plate and a lower cover plate. The combustor body comprises a gas inlet channel, a gas outlet channel and a combustion chamber. The gas inlet channel and the gas outlet channel areboth in a spiral shape and arranged in parallel in a spaced mode for transmitting heat carried by flue gas in the gas outlet channel to fuel gas and the oxidizing agent in the gas inlet channel, thegas inlet channel comprises an upper oxidizing agent channel, a fuel channel and a lower oxidizing agent channel which are sequentially arranged in parallel from top to bottom, and a center baffle plate and a wall face baffle plate are arranged in the gas inlet of the combustion chamber. The channels in the combustor body, the specific position of the combustion chamber and the combustion gas mixing mode are researched and designed, the problems that an existing small combustor cannot performing sufficient mixing and tempering is likely to be generated can be effectively solved, and the combustor has the advantages of being good in mixing effect, wide in stable combustion range, high in combustion efficiency and high in energy utilization rate.

Owner:HUAZHONG UNIV OF SCI & TECH

Substrate preheating device and equipment for epitaxial process

PendingCN114334738AMeet temperature requirementsImprove preheating efficiencySemiconductor/solid-state device manufacturingPhysical chemistryEngineering

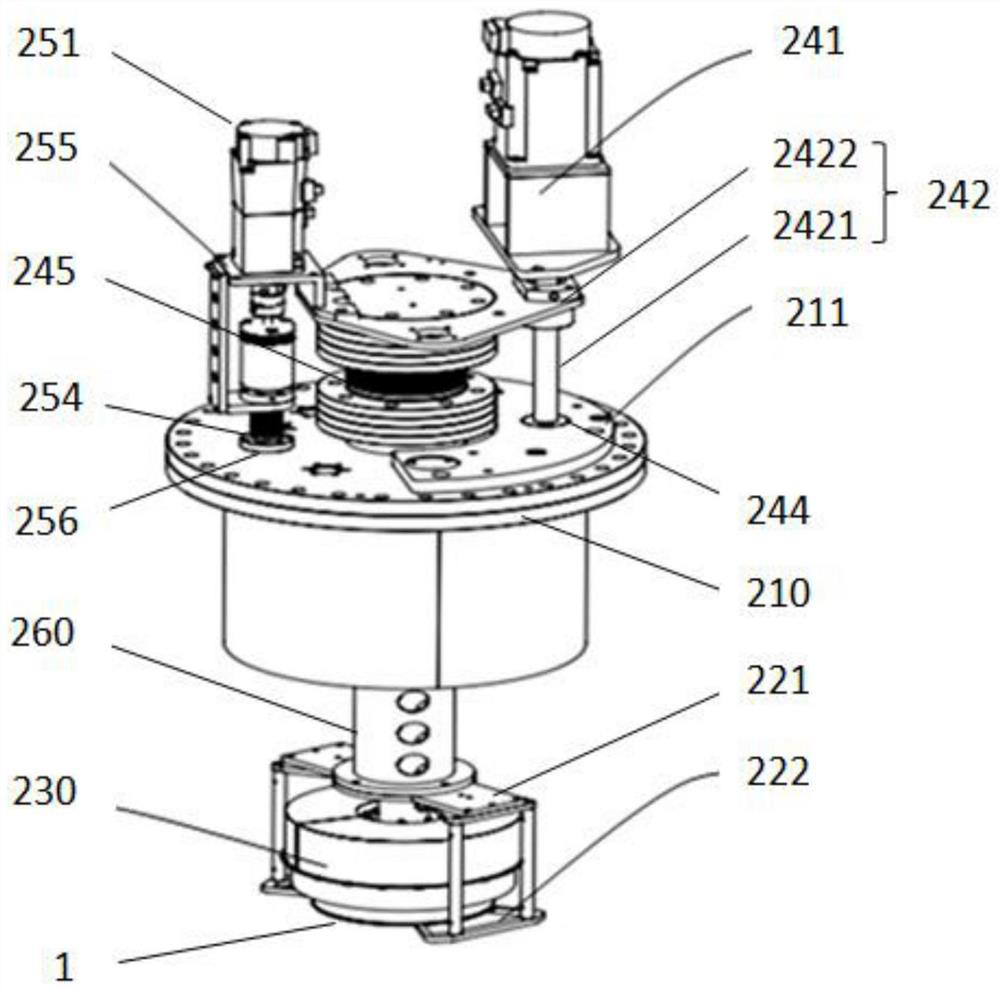

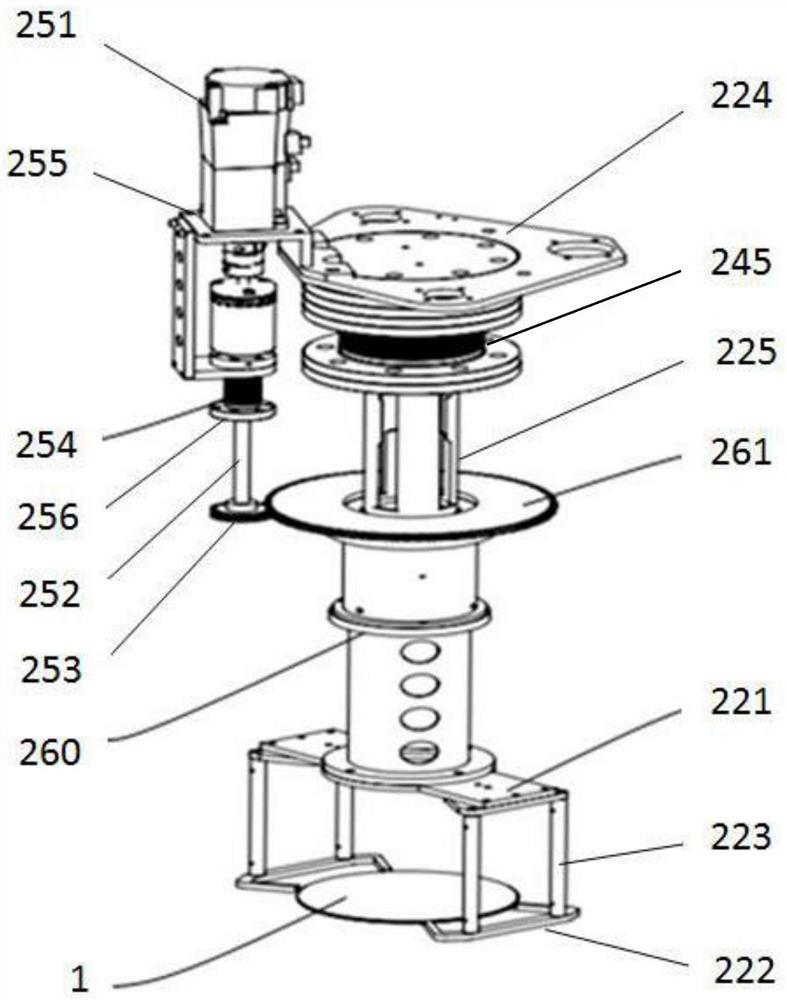

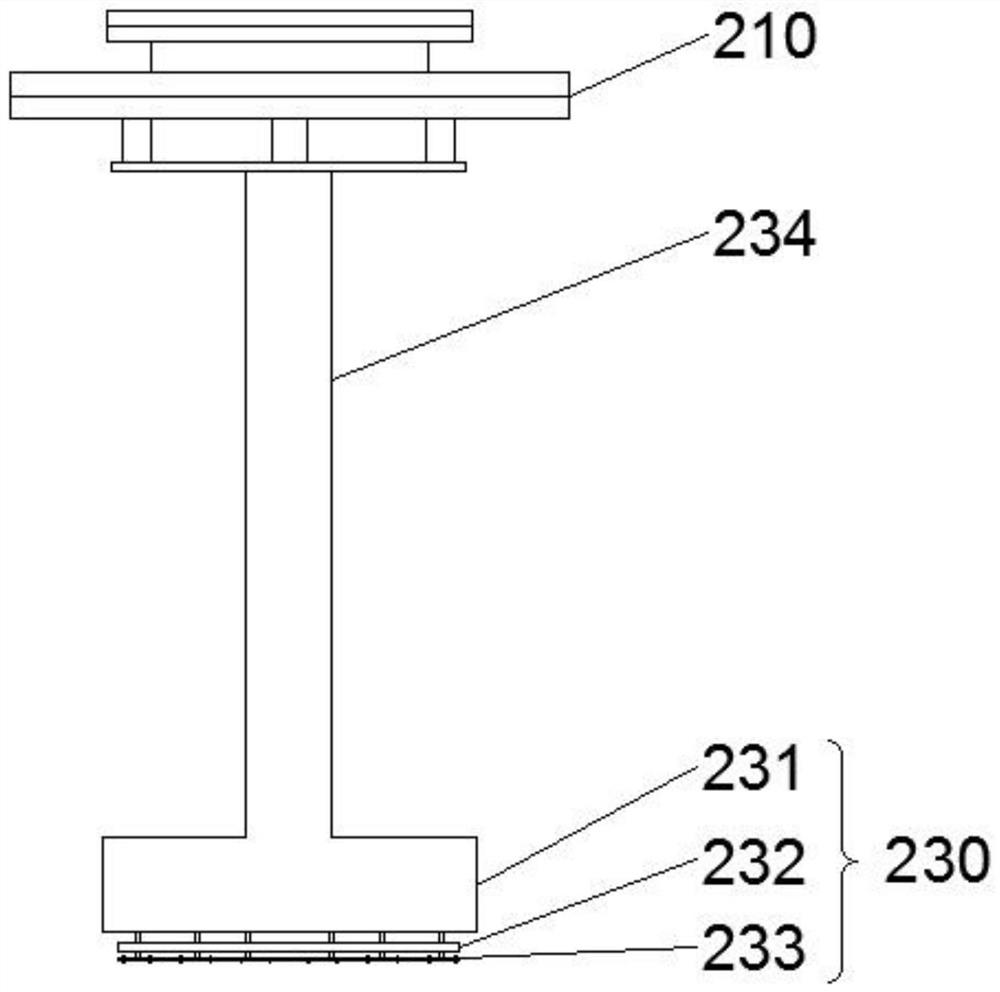

The invention relates to the field of semiconductor manufacturing, in particular to a substrate preheating device and equipment for an epitaxial process, the substrate preheating device for the epitaxial process is used for preheating a substrate before epitaxial growth, and the substrate preheating device for the epitaxial process comprises a base; the substrate taking and placing table is used for loading and fixing a substrate; the substrate heater is used for carrying out preheating treatment on a substrate, the substrate heater is arranged above the substrate, and the substrate heater is fixedly connected to the base; and the lifting driving assembly is used for driving the substrate taking and placing table to do lifting motion, so that the substrate is close to or far away from the substrate heater. According to the substrate preheating device for the epitaxial process, the substrate heater is arranged above the substrate, so that heat emitted by the substrate heater directly acts on the upper surface of the substrate, and the temperature of the upper surface of the substrate meets the temperature requirement of the epitaxial process.

Owner:JIHUA LAB

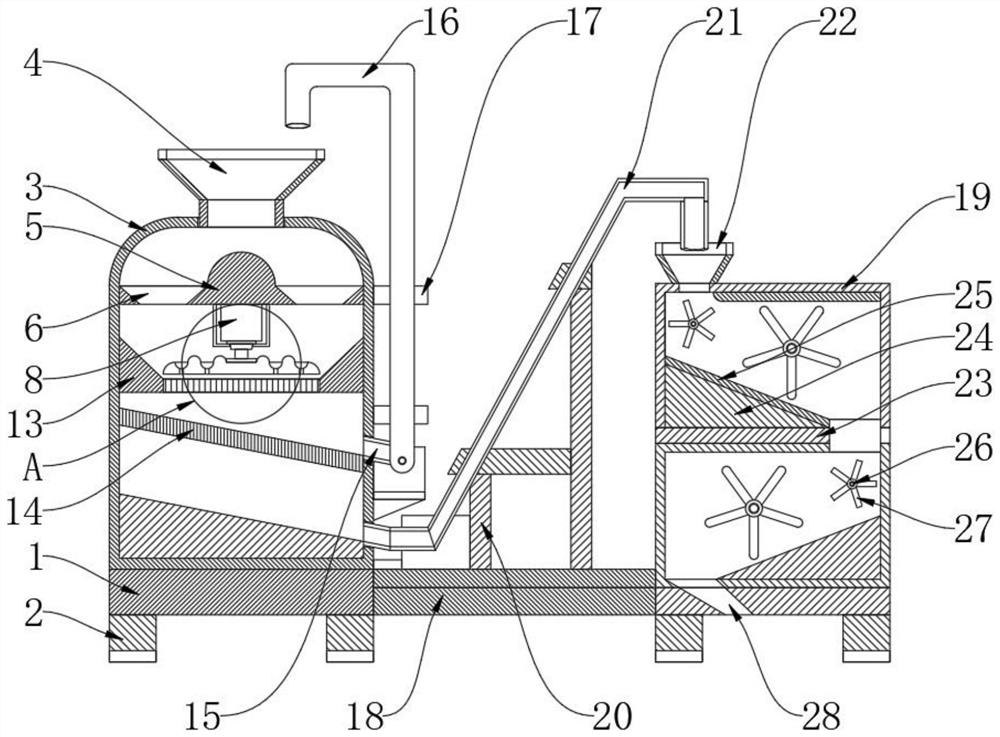

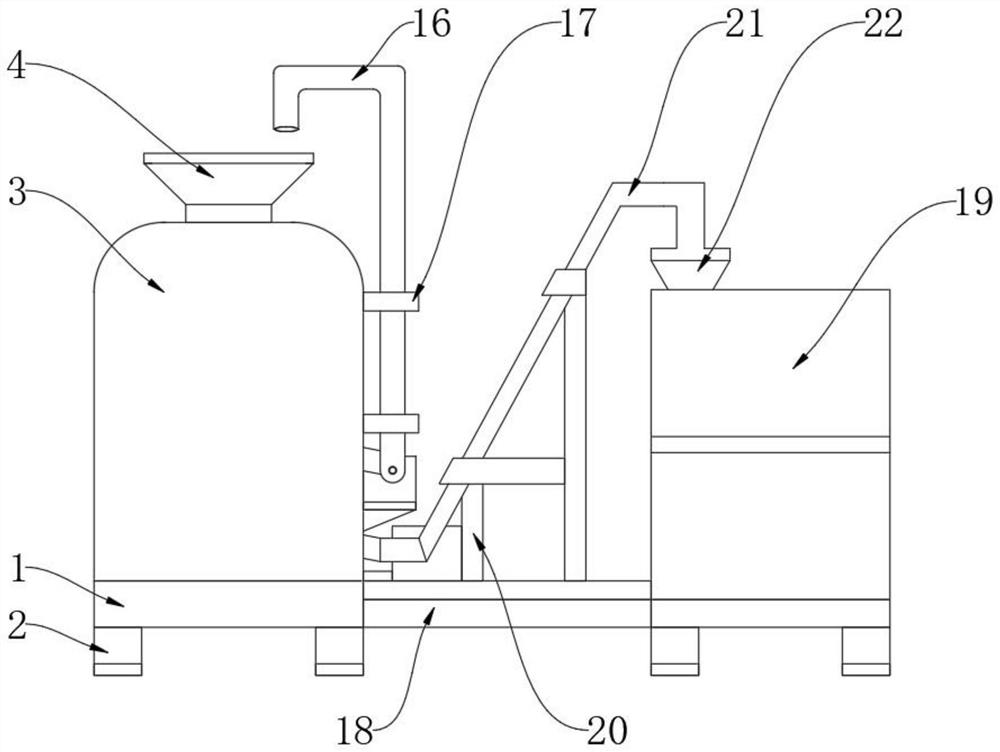

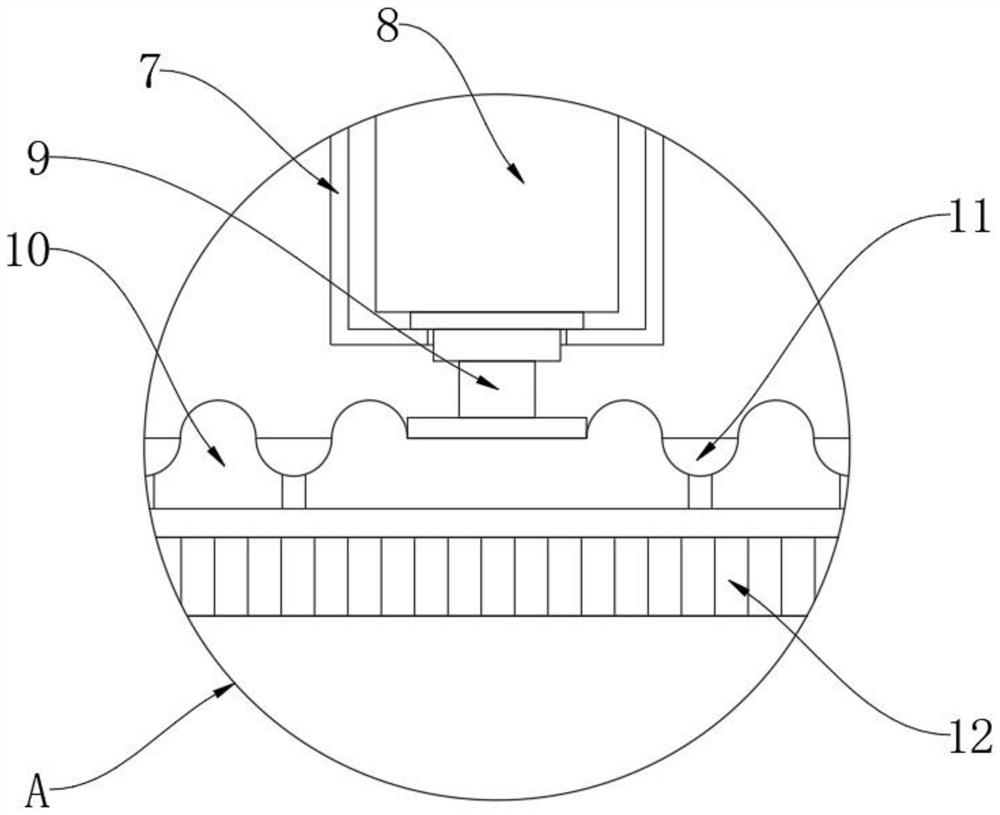

Efficient preheating and pre-reduction device used for iron ore powder production and preparation

InactiveCN111676367AEasy for secondary filtrationAchieve the effect of reprocessingFluidised-bed furnacesCrushed stoneEngineering

The invention discloses an efficient preheating and pre-reduction device used for iron ore powder production and preparation. The efficient preheating and pre-reduction device comprises a bottom plate, wherein the bottom of the bottom plate is fixedly connected with supporting columns; the upper surface of the bottom plate is fixedly connected with a kettle body; the upper surface of the kettle body is fixedly connected with a feeding funnel; the inner wall of the kettle body is fixedly connected with a supporting plate; and the upper surface of the supporting plate is provided with conical holes. According to the efficient preheating and pre-reduction device used for the iron ore powder production and preparation, through the feeding hopper, the supporting plate and the conical holes, materials can conveniently intensively flow into a grinding disc and a filtering plate, then, an electric motor is started to drive a transmission rod and the grinding disc to rotate to grind irregular broken stone on the surface of the filtering plate, so that iron ore powders which fall to a filtering net from the surface of the filtering plate can be subjected to secondary filtering, unqualified iron ore powders are conveyed to the feeding hopper on the surface of the kettle body through a first elevator and are processed in the kettle body again, and therefore, the iron ore powder productionand preparation has a returned material processing effect.

Owner:大冶市都鑫摩擦粉体有限公司

Radiant Tube Heating

ActiveCN106051761BEfficient preheatingHigh heating temperatureIndirect carbon-dioxide mitigationGaseous fuel burnerNitrogen oxidesCombustor

The present invention provides a radiant tube heating device capable of achieving at least one or both of suppressing generation of nitrogen oxides (NOx) generated by a combustor and remarkably improving thermal efficiency. The radiant tube heating device(1) comprises a radiant tube (2) having its two ends (2a, 2b) penetrating the furnace wall (furnace) (W), and the bent portion (2c) Protruding into the interior of the furnace;and a burner (B) arranged coaxially in the hollow portion (3) in the central portion of the hollow portion (3) on one end (2a) side of the radiation tube (2); the radiant tube heater (1) further includes a temperature rise suppressing member (10) having a cylindrical shape and arranged at a position around an opening portion on the distal end side of the combustor in a hollow portion of the radiant tube , and a pair of inner and outer flow paths (12a, 13) for flowing combustible gas are formed between the inner wall surface of the radiant tube and the outer peripheral surface of the burner.

Owner:DAIDO STEEL CO LTD

Efficient preheating boiler

PendingCN113446730AGood lighting effectEasy to installHollow article cleaningTreatment involving filtrationElectric heatingRelief valve

The invention discloses an efficient preheating boiler. The efficient preheating boiler comprises a bearing channel, an abutting mechanism, an auxiliary rotating mechanism, a water pump, water outlet connectors, a bottom plug and a top plug, wherein an end cover is fixed to one side of a water passing channel through bolts, the abutting mechanism is fixed to one end face of the end cover, a top supporting rod is fixed to one side of an electric heating plate, the auxiliary rotating mechanism is fixed to the inner wall of the other side of the water passing channel, the water pump is fixed to the inner wall of one side of the bearing channel, a one-way pressure relief valve and a drainage connector are fixed to the outer end face of one side of the bearing channel, and a temperature controller, an electric heating rod and a temperature sensor are fixed to the outer end face of the other side of the bearing channel. According to the efficient preheating boiler, preheated water enters the bearing channel through a connecting pipeline under the action of the water pump, and then can be further heated through the electric heating rod, finally, hot water can be discharged through the water outlet connectors, and the water outlet efficiency can be higher by using the two water outlet connectors at the same time.

Owner:丹顶鹤智能科技(江苏)有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com