Patents

Literature

59results about "Preheating coke ovens" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

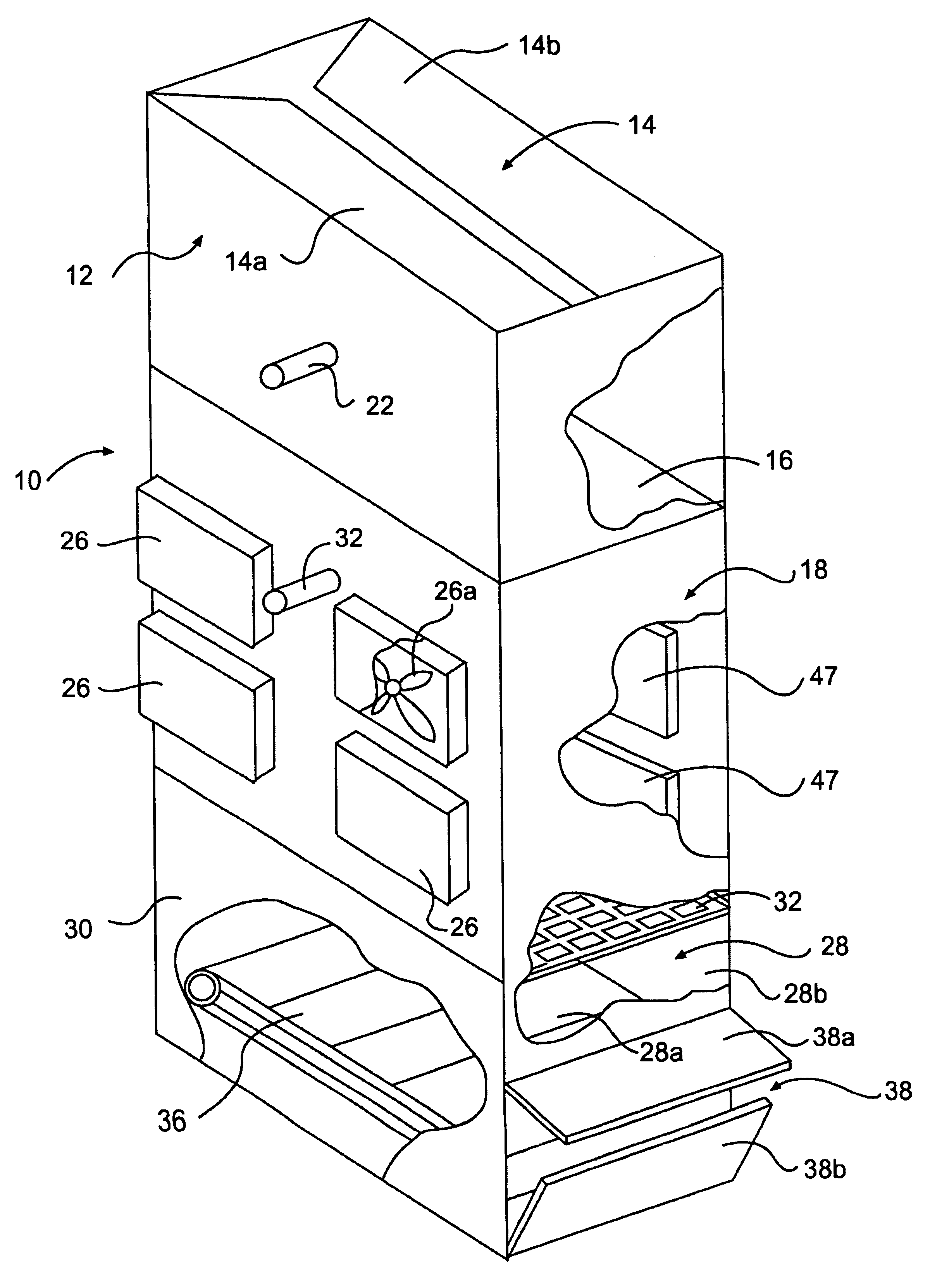

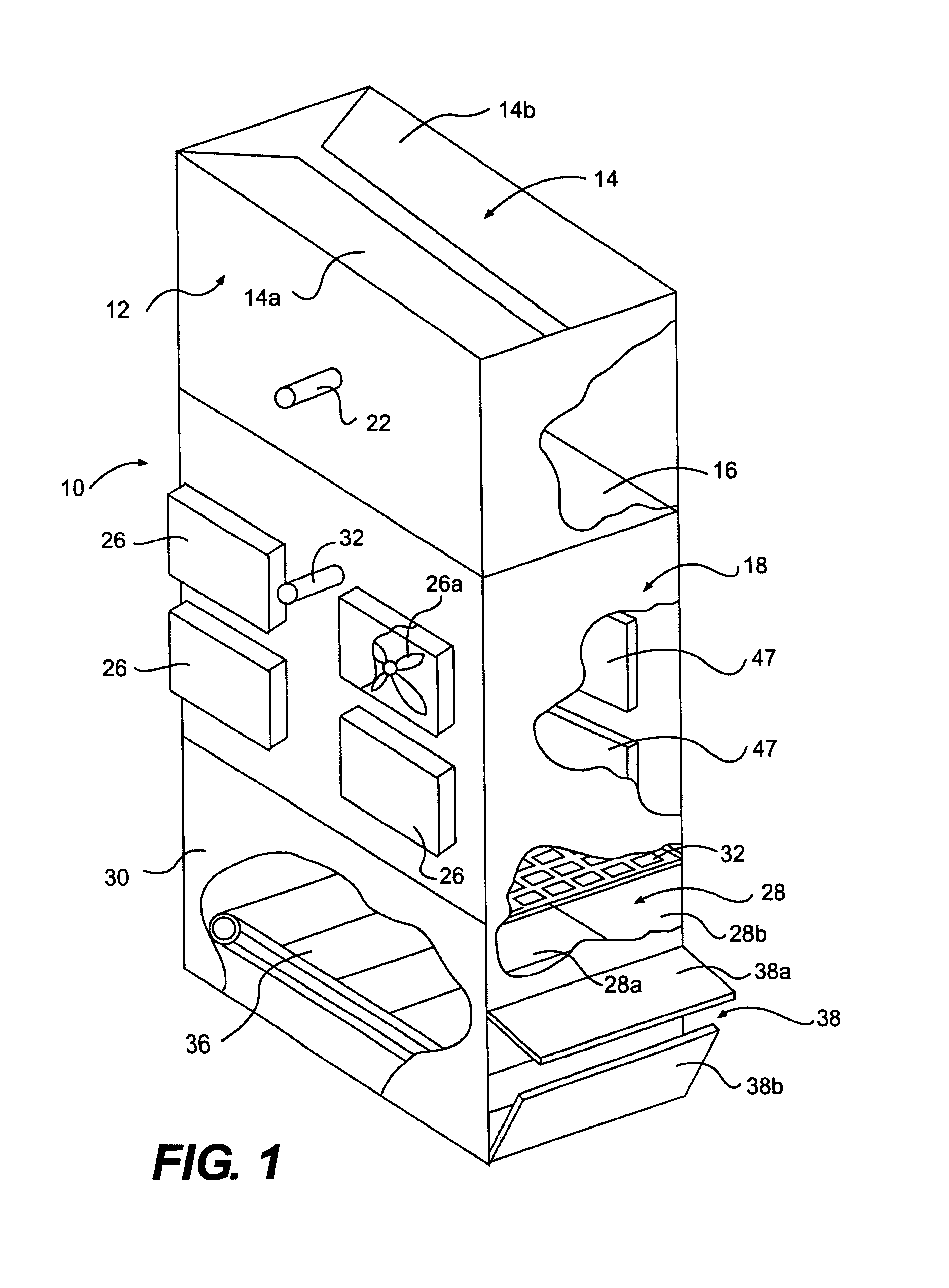

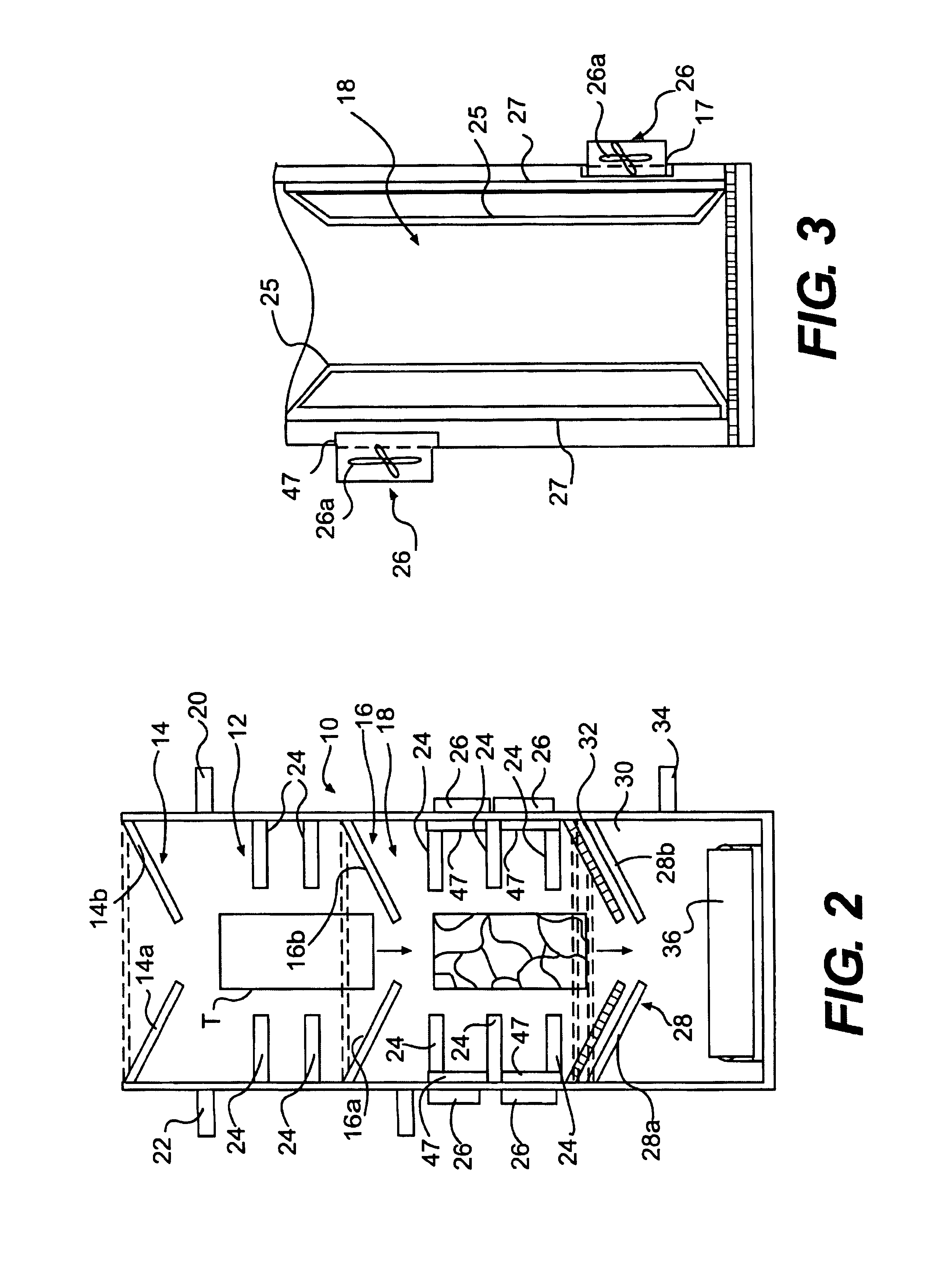

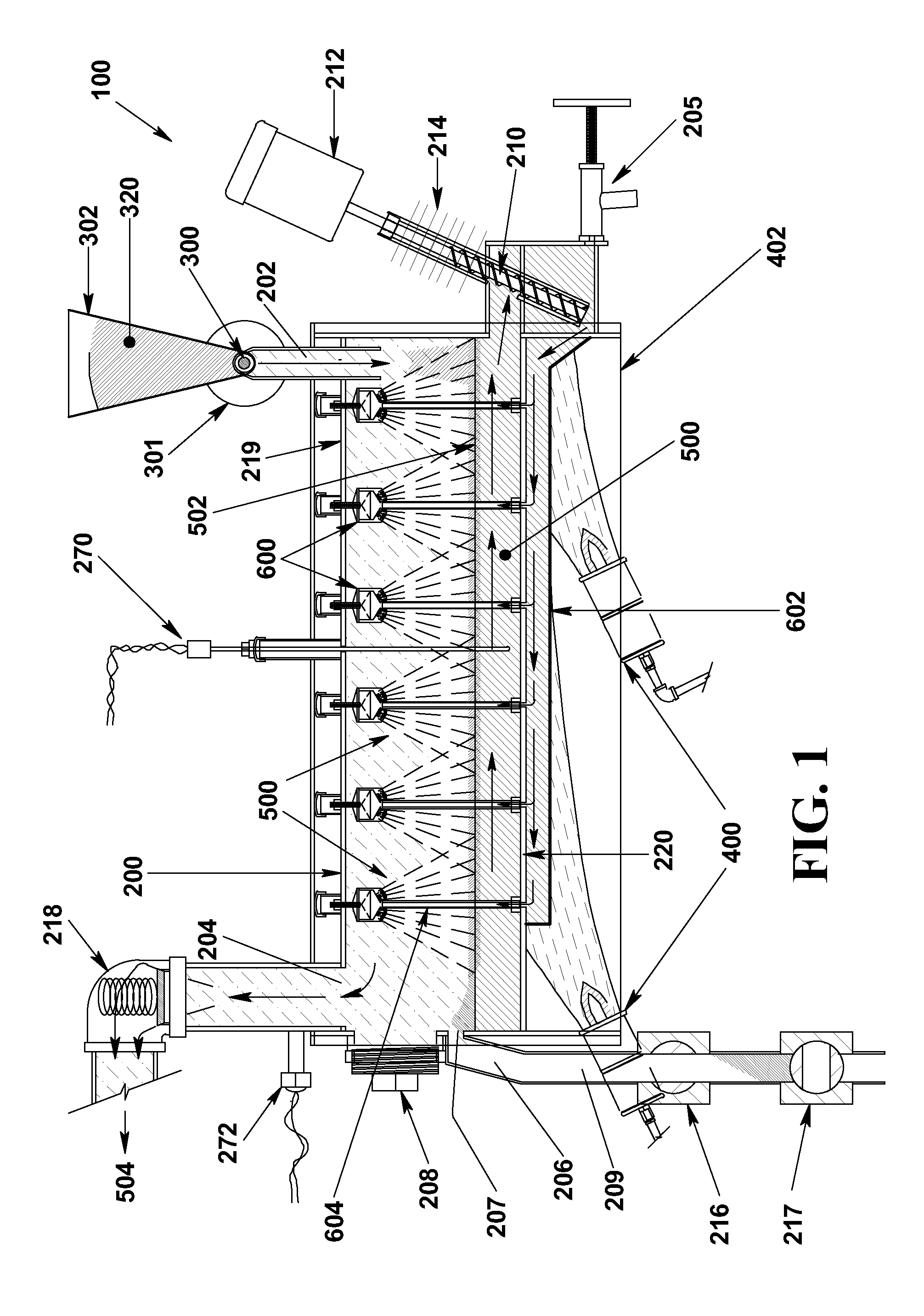

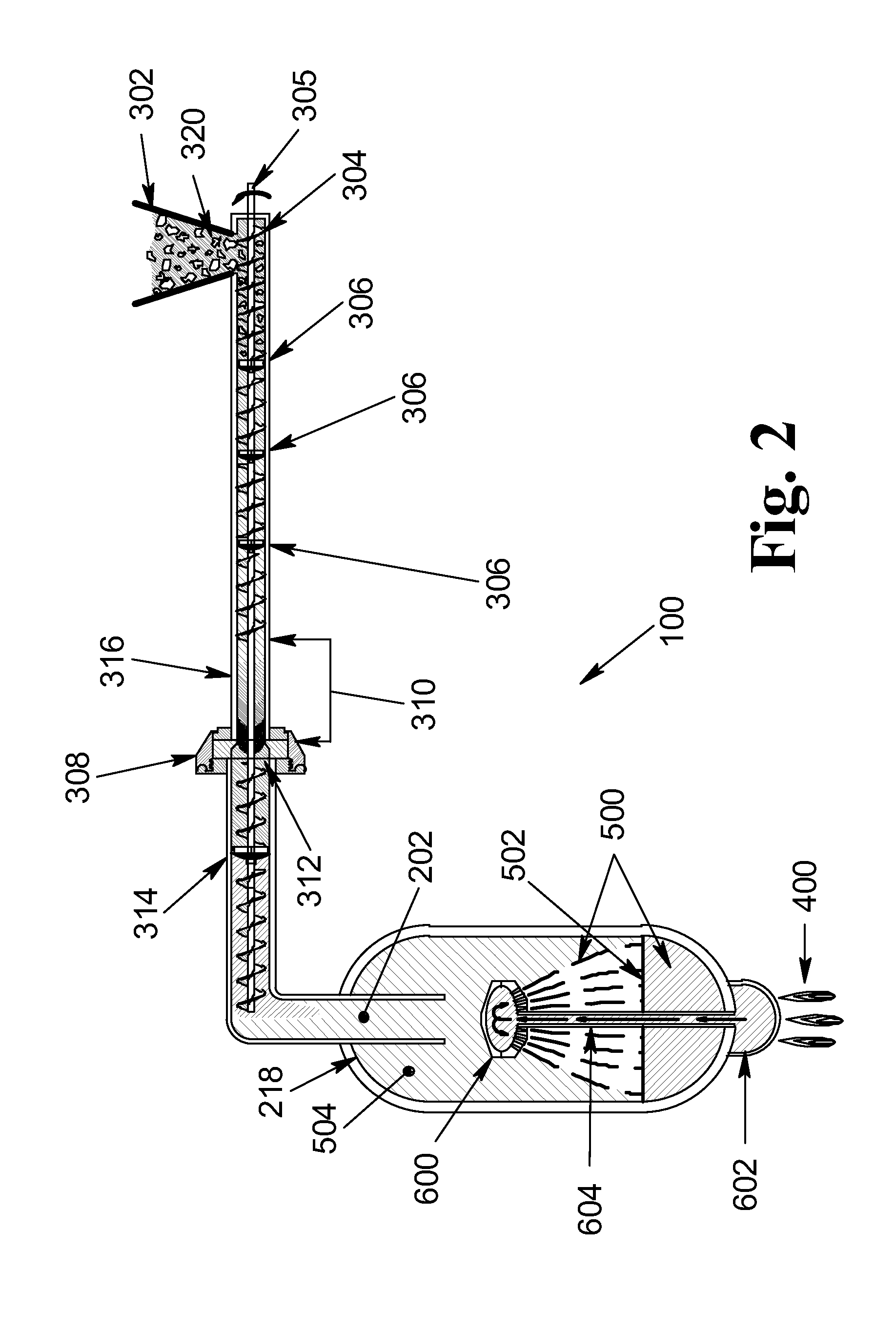

Microwave pyrolysis apparatus for waste tires

InactiveUS7101464B1Electrical coke oven heatingCombustible gas coke oven heatingMicrowave pyrolysisDistillation

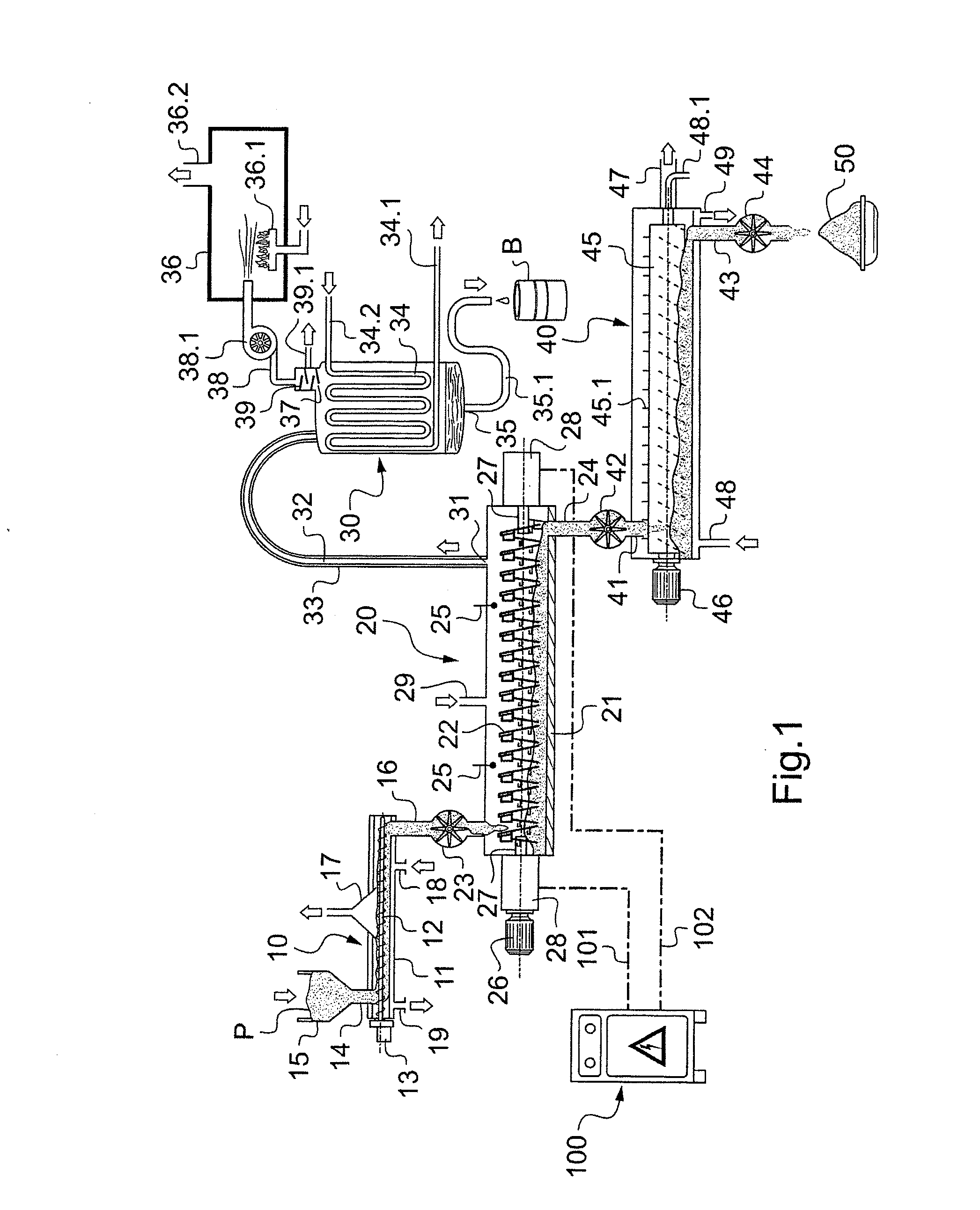

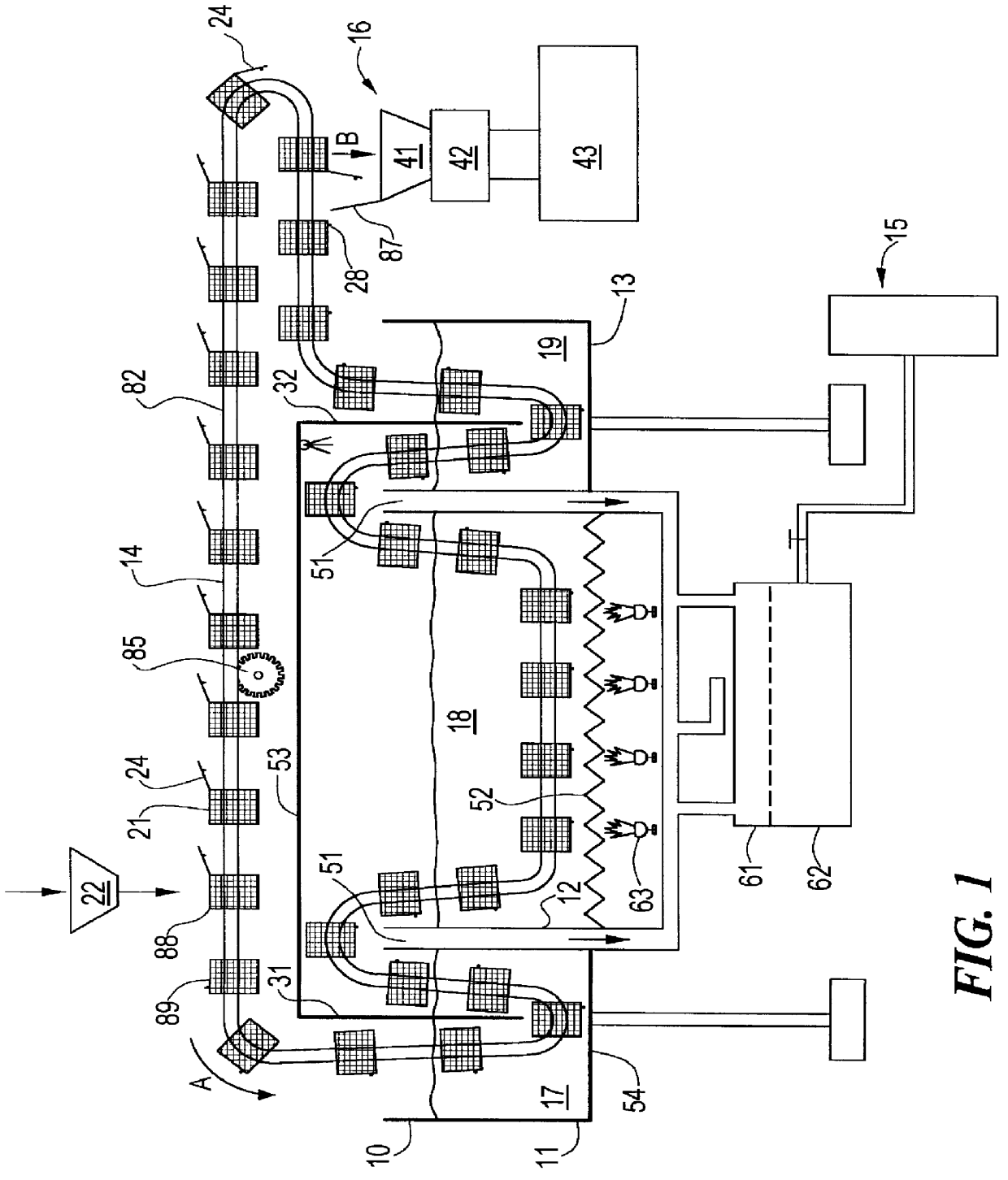

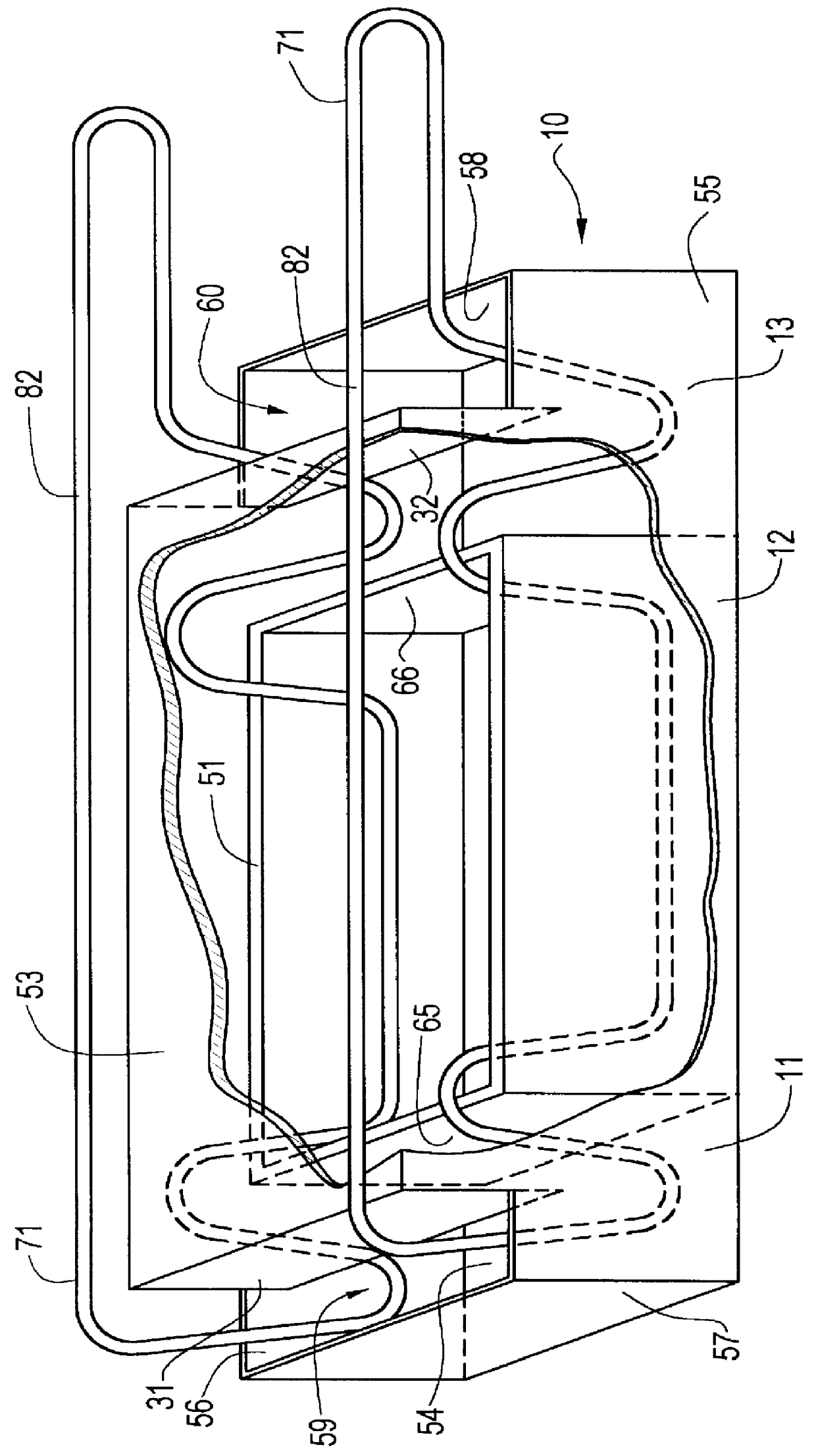

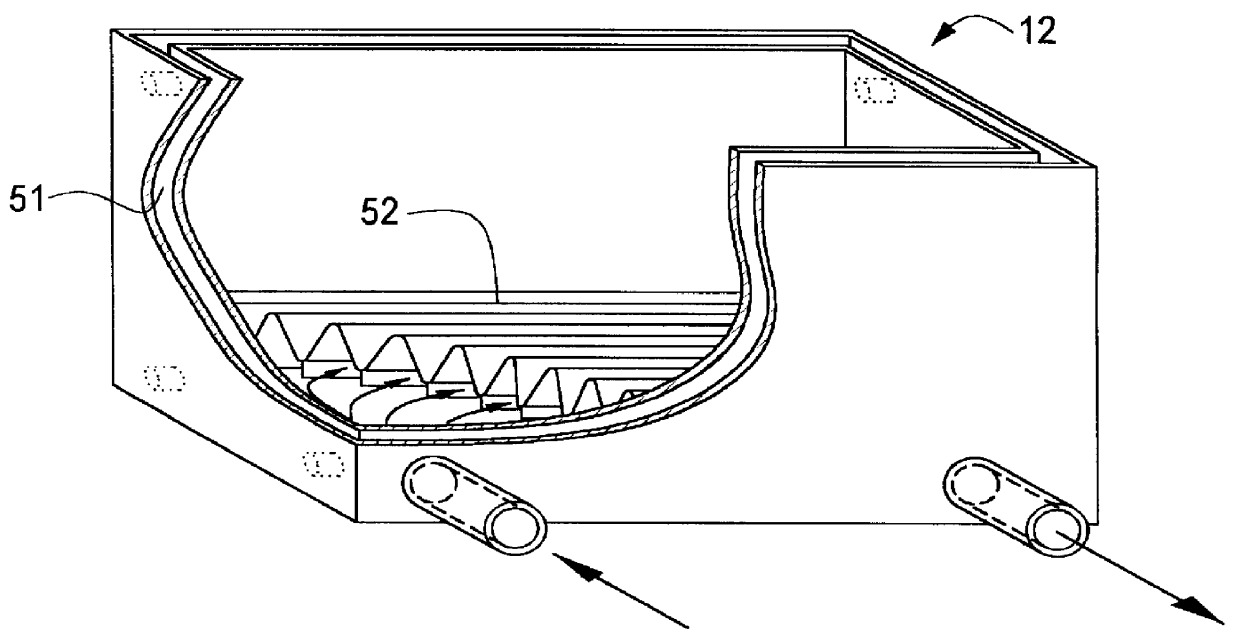

A microwave distillation apparatus provides destructive distillation of whole waste tires. The apparatus includes a housing including a plurality of vertically arranged chambers. A preheat chamber provides preheating of a whole waste tire received therein. An irradiation chamber, located below the preheat chamber and thermally coupled to the preheat chamber such that heat generated in the irradiation chamber creates heat convection currents in the preheat chamber, receives a preheated whole waste tire from the preheat chamber. A microwave energy supply supplies microwave energy to the irradiation chamber to provide destructive distillation of a tire received in that chamber. A cooling chamber, located below the irradiation chamber, receives by-products of the destructive distillation therefrom and provides delivery of the by-products from the housing.

Owner:PRINGLE JOE A MR +1

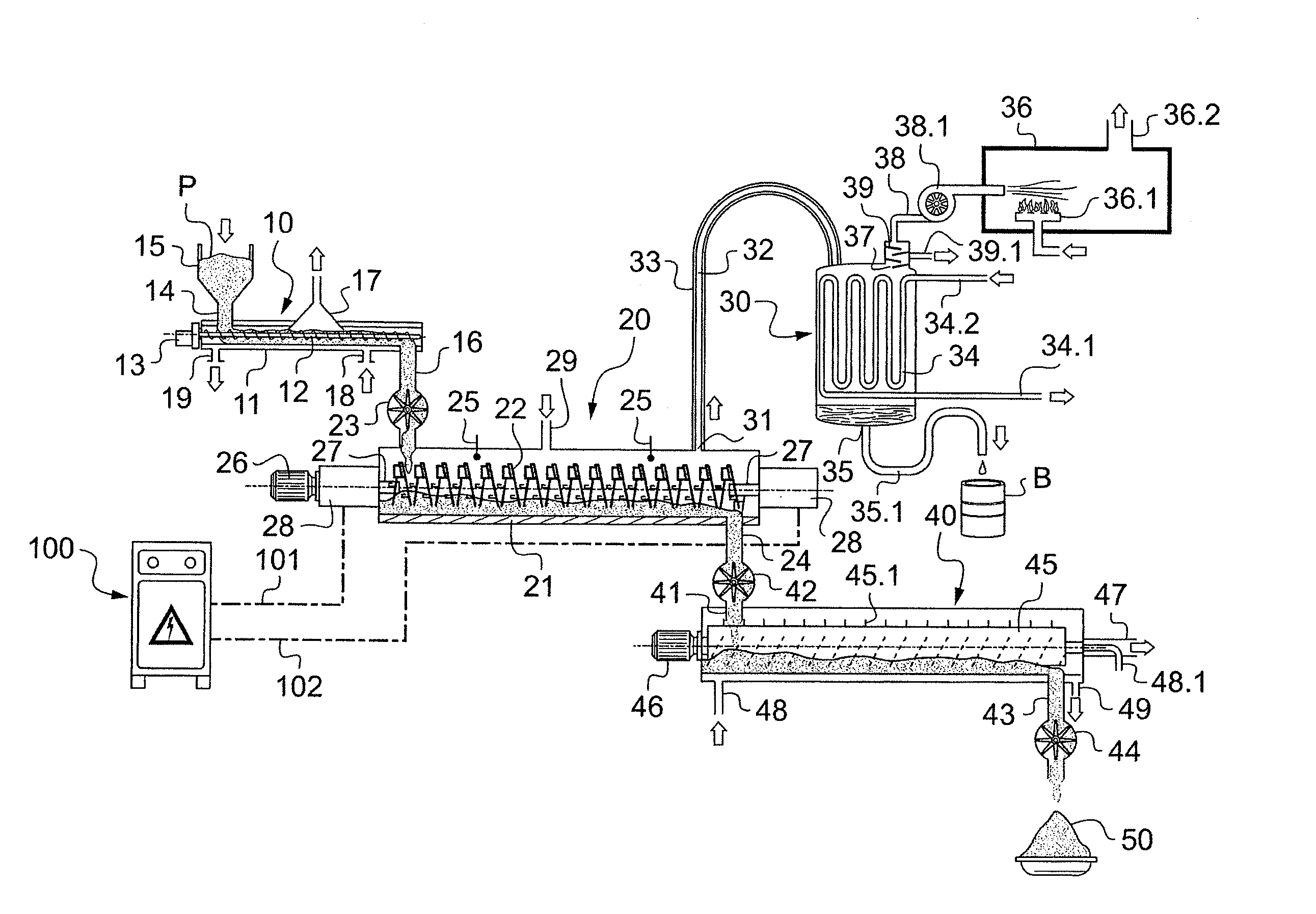

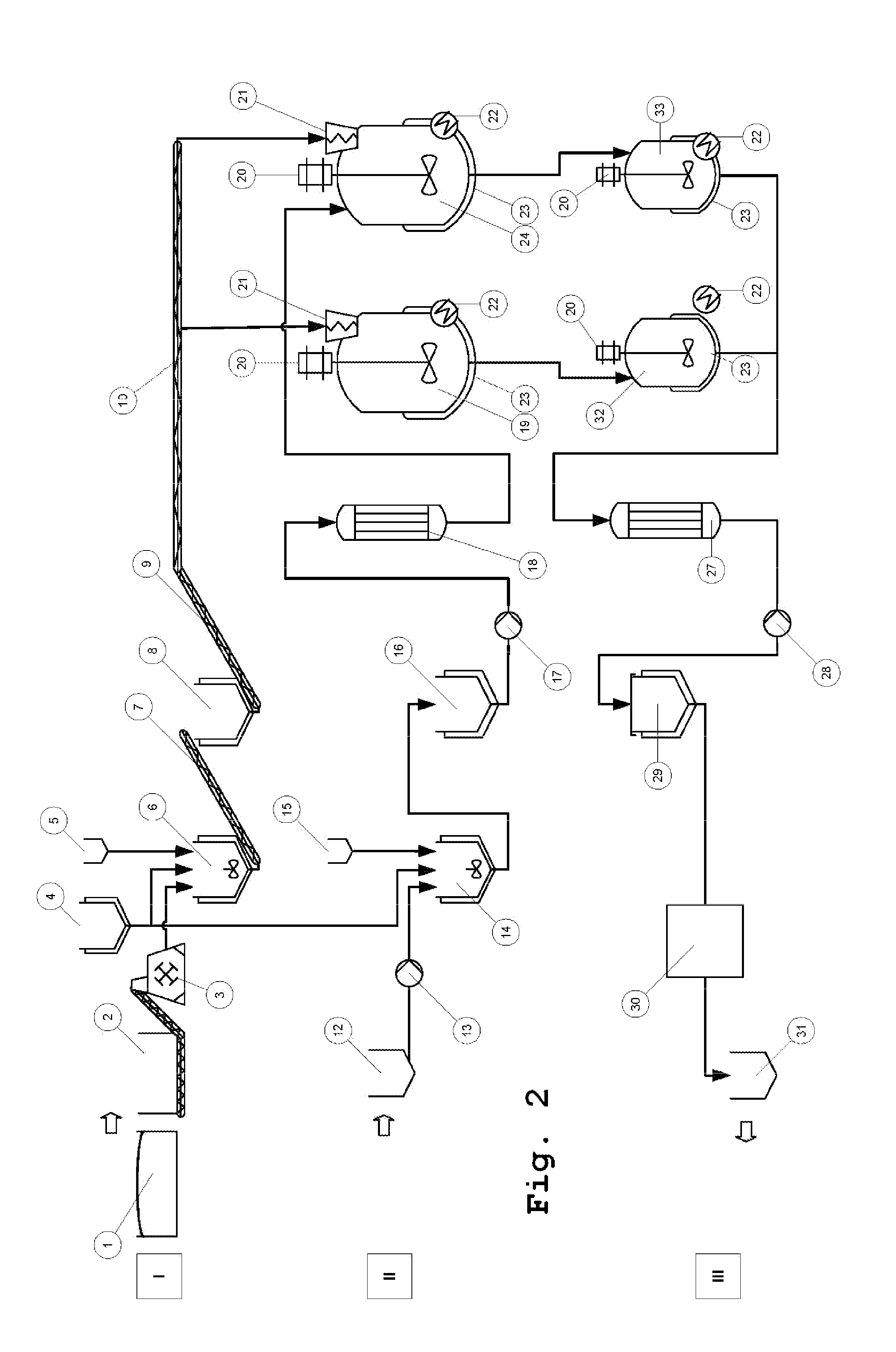

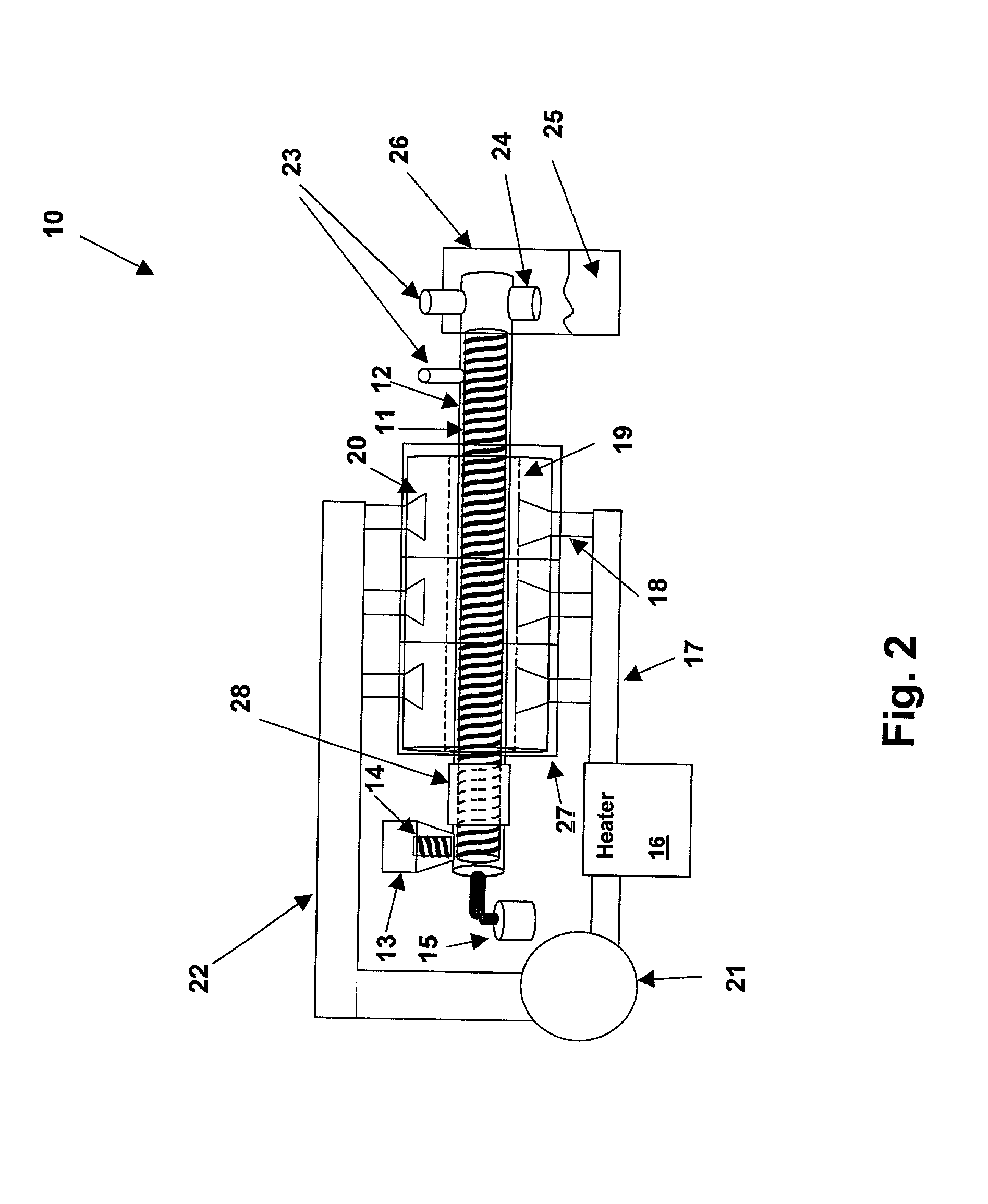

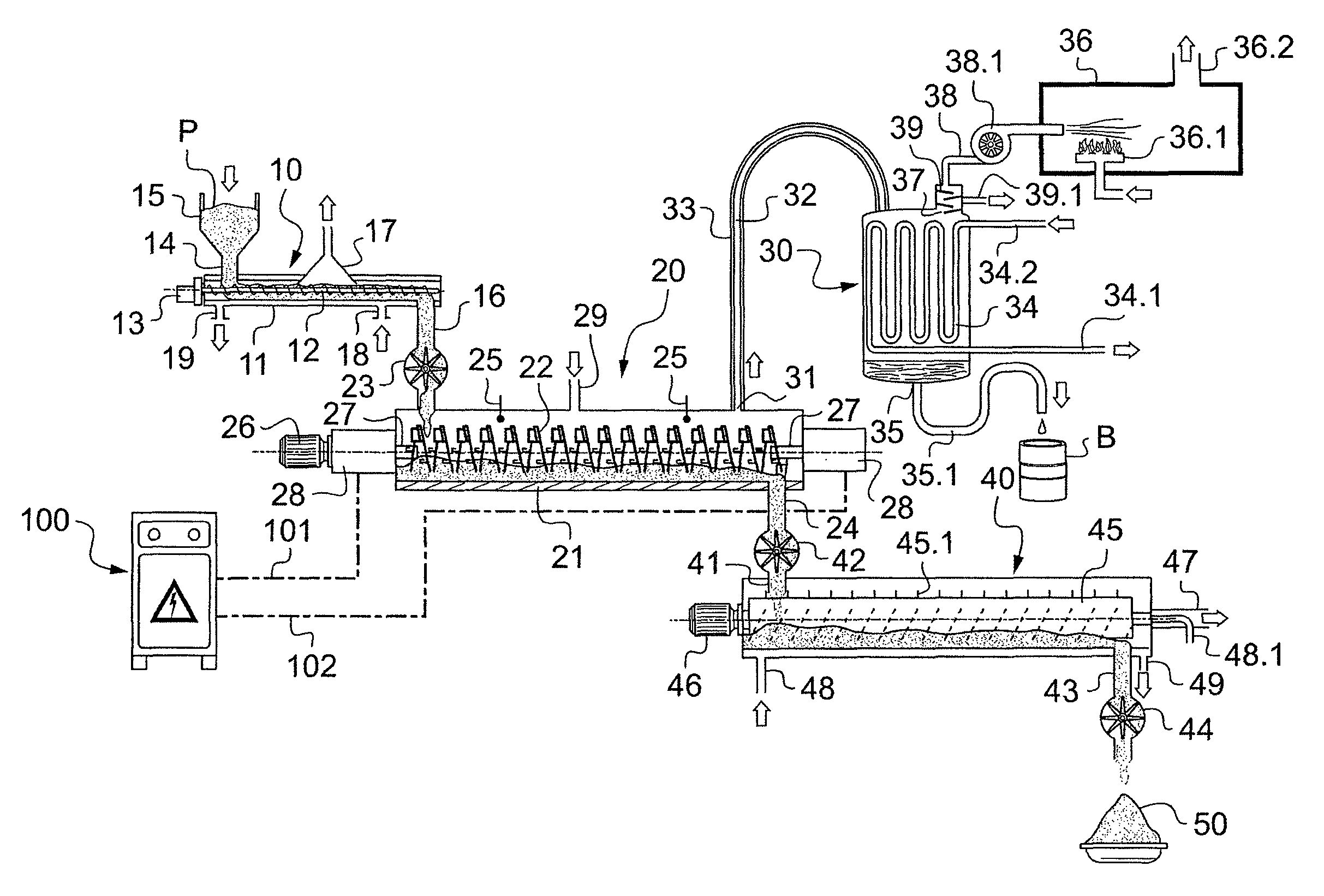

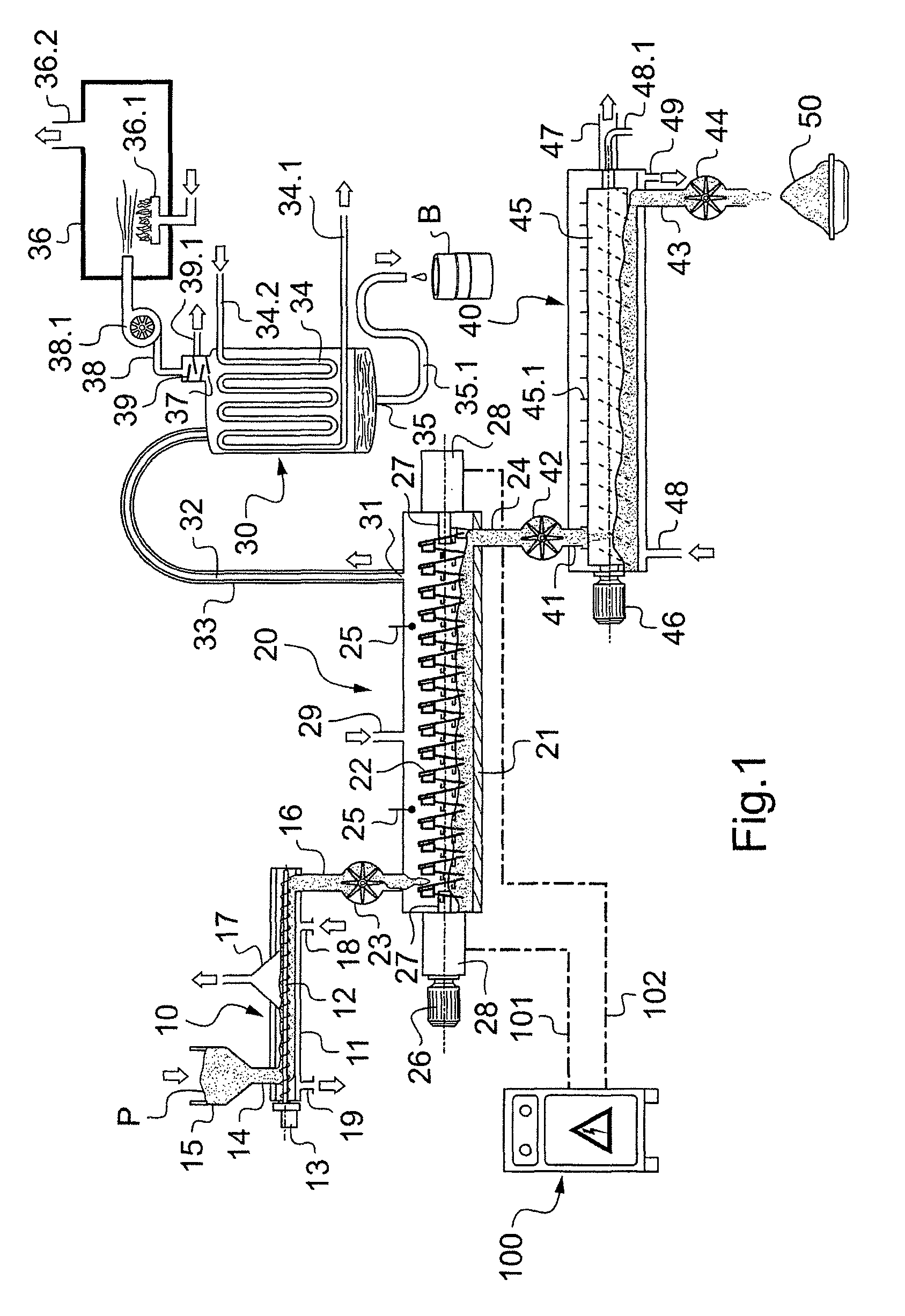

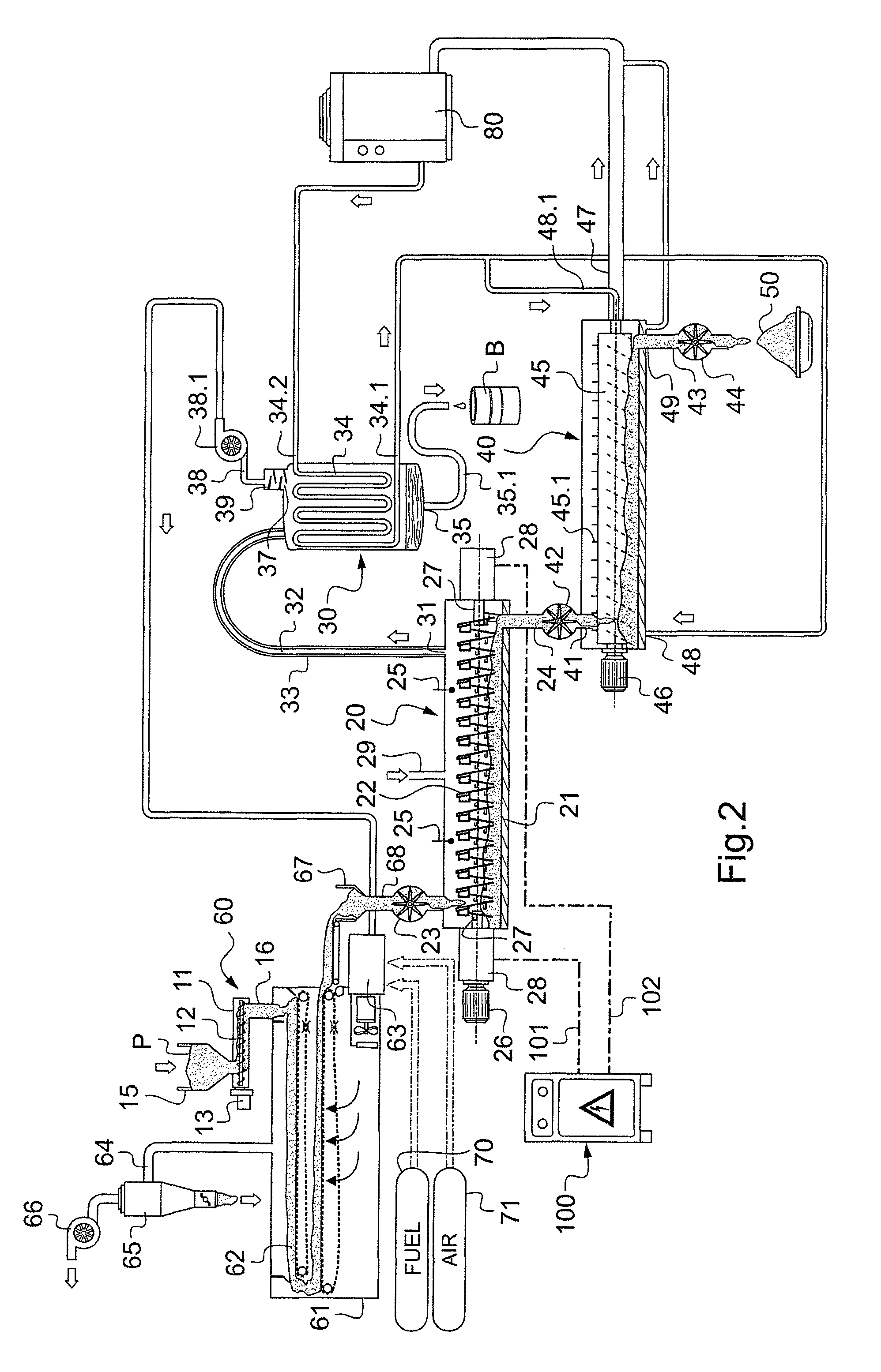

Method and apparatus for the energy densification of a material in the form of divided solids, with a view to obtaining pyrolysis oils for energy purposes

ActiveUS20120043194A1High calorific valueImprove operating conditionsMechanical conveying coke ovensElectrical coke oven heatingPre treatmentRelative humidity

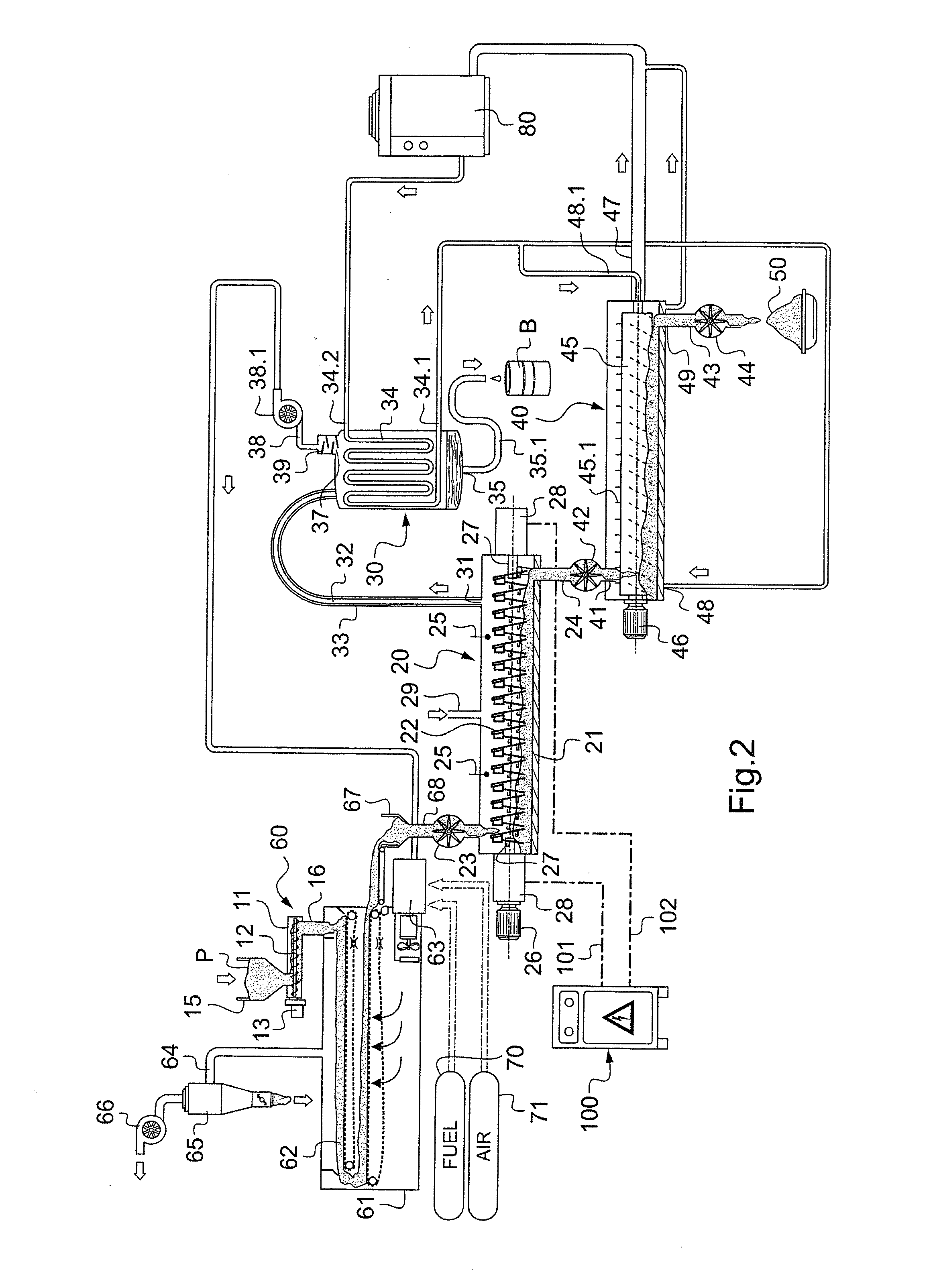

A method and installation for energy densification of a material to obtain pyrolytic oils for energy. The method includes preconditioning the material by heating and drying to raise the material temperature close to 100° C. and a relative humidity not exceeding about 10%; pyrolyzing the material that is subsequently caused to flow through a substantially hermetic reactor containing at least one transfer screw or vibrating tube heated by the Joule effect, the material heated progressively in the range of 300° C. to 850° C., the electrical power passing through the transfer screw or the vibrating tube for providing heating regulated as a function of the material in order to obtain the desired temperature level during the transit time of the material through the reactor; extracting pyrolysis gas from a high portion of the reactor for rapid recondensation in a vertical condenser; and recovering pyrolytic oils from a low portion of the vertical condenser.

Owner:LEPEZ CONSEILS FINANCE INNOVATIONS LCFI +1

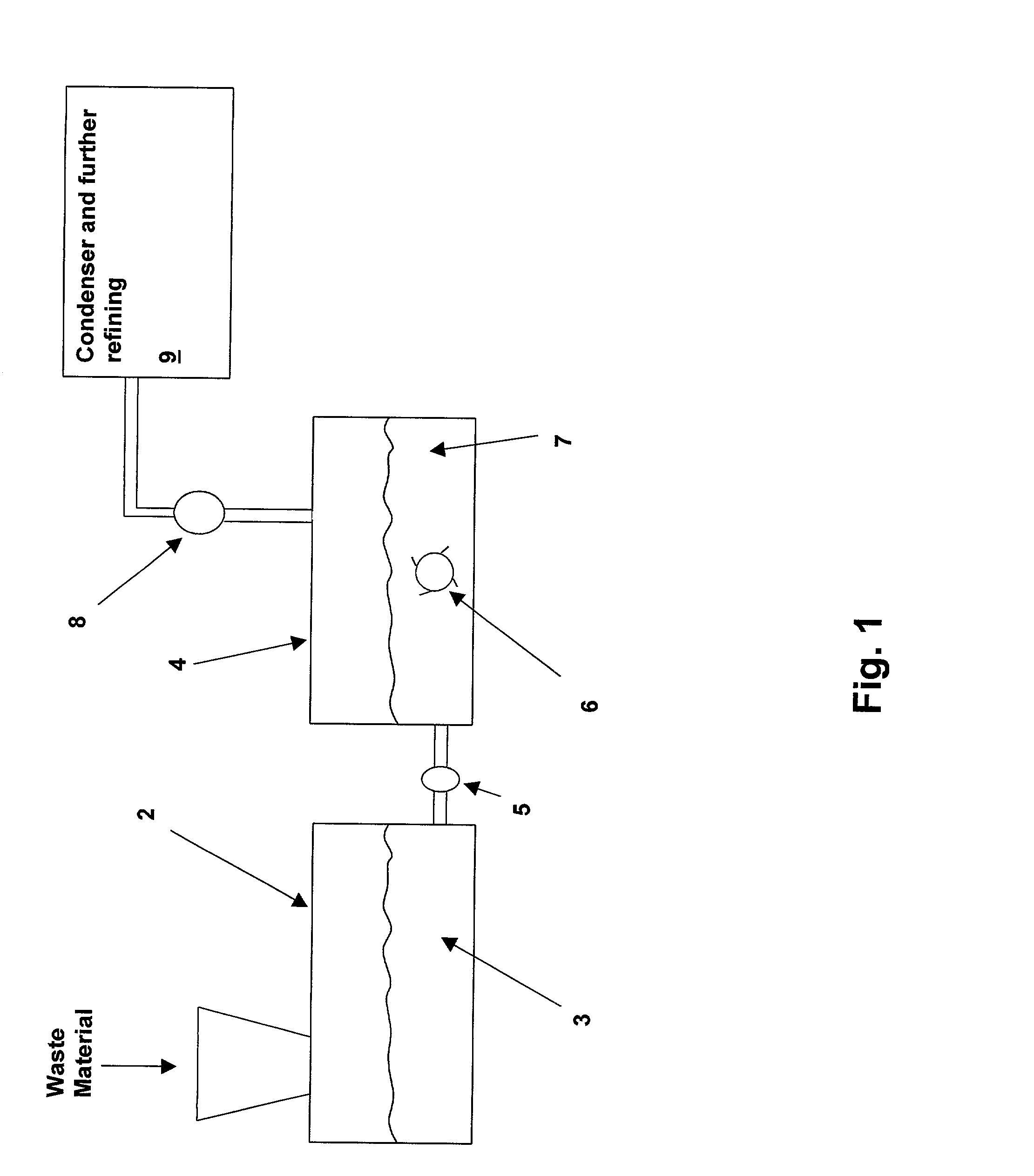

Method And Device For Producing Operating Materials Or Fuels

InactiveUS20110226603A1Simple materialReaction be increasedCharging-discharging device combinationsPreheating coke ovensProcess engineeringHumus

The invention relates to a method and to devices for producing operating materials or fuels, humus, Maillard or similar reaction products from a solid-liquid mixture of water and a carbonaceous component and for treating said mixture, wherein the solid-liquid mixture is treated at a temperature of over 100° C. and a pressure of over 5 bar.

Owner:PEUS DOMINIK

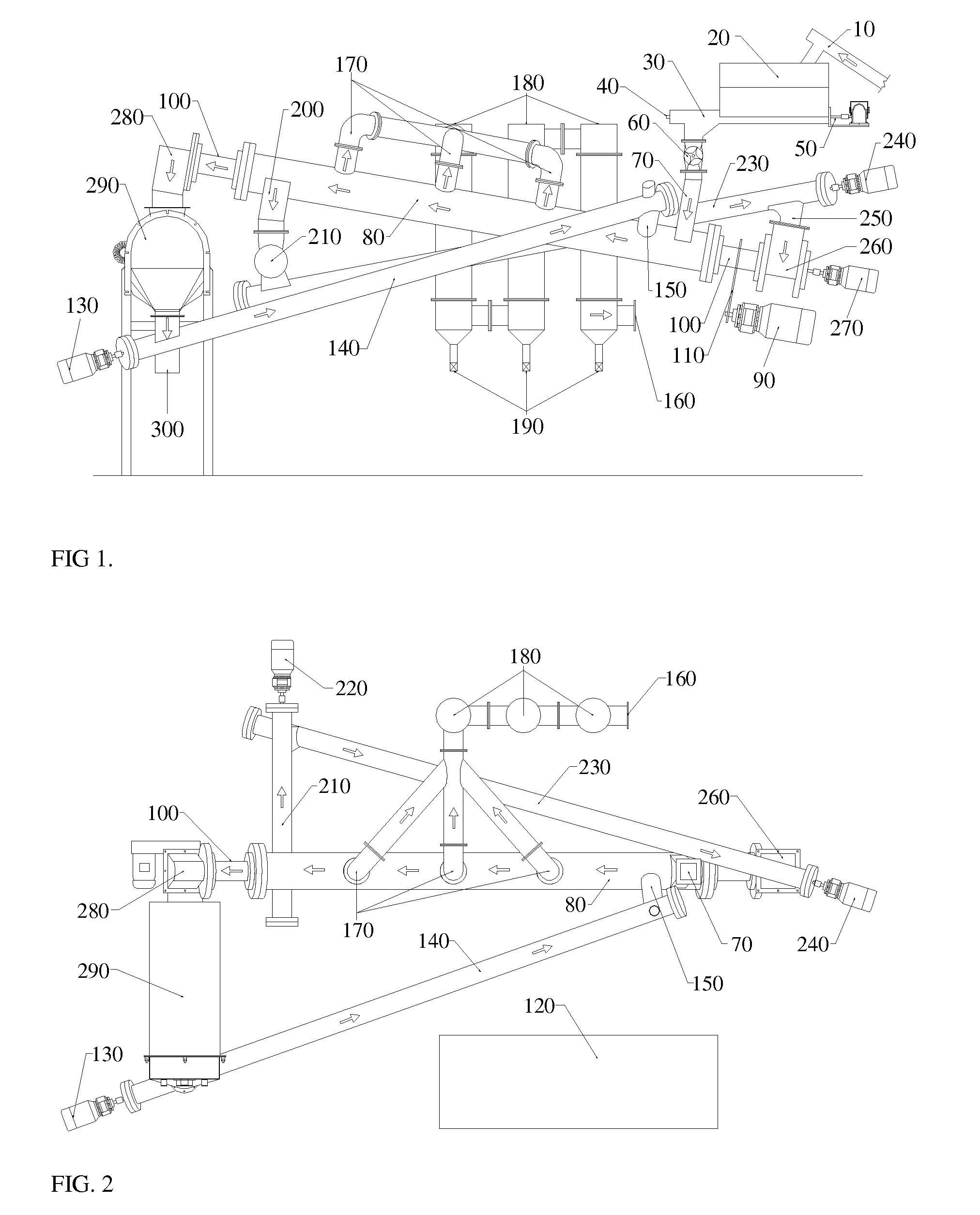

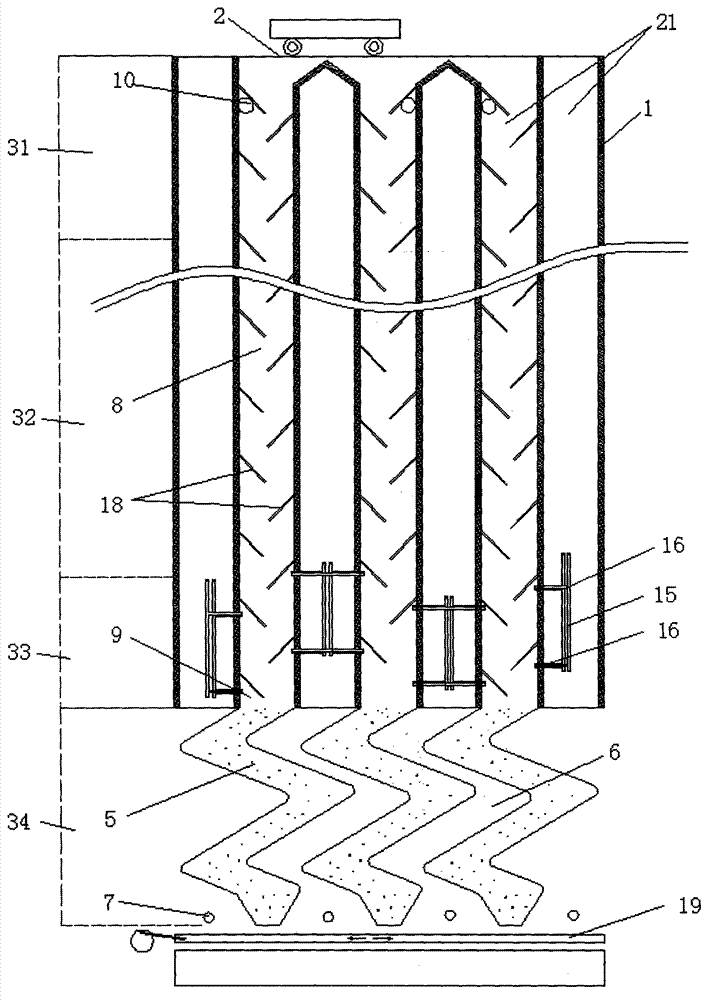

Pulverized coal coking equipment and method

InactiveCN102492432AReduce thicknessPlay a filtering roleCombustible gas coke oven heatingVertical chamber coke ovensCold airTar

The invention discloses pulverized coal coking equipment and method. The equipment comprises a pulverized coal semi-coking pyrolyzing furnace, wherein the pyrolyzing furnace comprises a furnace charge inlet, a feeding and distributing region, a coal gas collecting region, a coal gas dust filtering zone, a pulverized coal preheating zone, a coal gas dispersing zone, a pulverized coal pyrolyzing region and a cooling coke outlet region from top to bottom respectively. The method is used for coking by using pulverized coal of which the particle size is smaller than 20 millimeters, and comprises distributing, preheating, dust filtering, pulverized coal pyrolyzing, coal gas collecting and coke discharging steps. In the method, pulverized coal of which the particle size is smaller than 20 millimeters is used for coking, pyrolysis of pulverized coal is balanced, coal gas produced by pyrolysis can be discharged successfully, and produced tar oil is clean and free from dust. In the method, ascending hot coal gas is used for preheating pulverized coal, and descending semi-coke is used for preheating cold air and coal gas, so that heat energy is fully utilized, and the aims of saving energy and reducing emission are fulfilled.

Owner:XINJIANG MEITE MAGNESIUM

Thermolytic distillation of carbonaceous material

InactiveUS6051110AEquipment is cheapEasy to adaptCharging-discharging device combinationsPreheating coke ovensDistillationClosed loop

In apparatus for thermolytic distillation of lump carbonaceous material, an enclosure contains a degassing bath, a reactor bath and a quenching bath. A closed loop continuous chain conveyor drives a plurality of baskets carrying carbonaceous material through the three baths of the enclosure. The carbonaceous material is degassed in hot distillate, then immersed in molten lead in the absence of oxygen to produce char and vapor by thermolytic distillation. The char is quenched with water in the absence of oxygen. At least a portion of the vapor is condensed to produce combustible distillate.

Owner:TERRAMEX

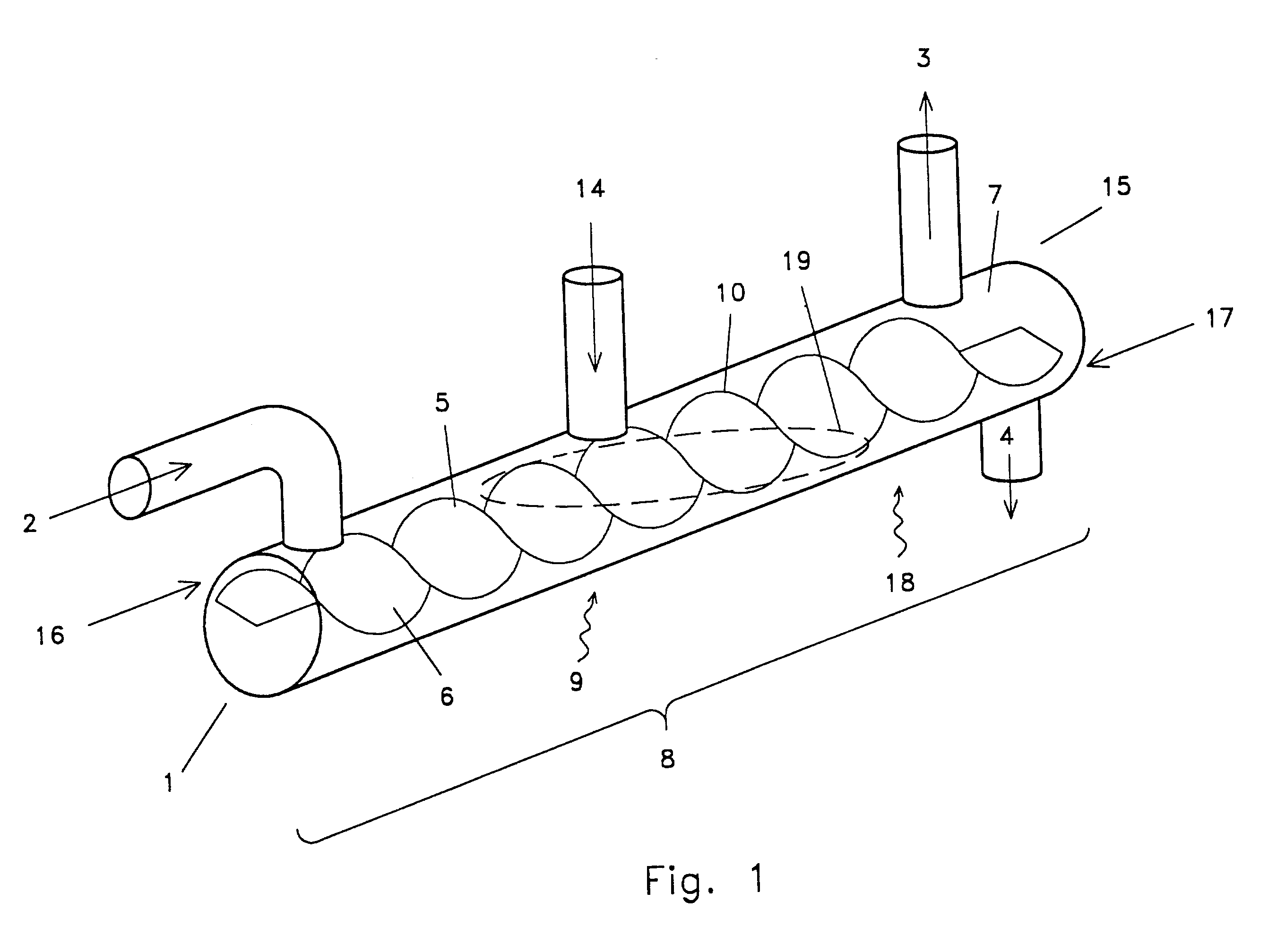

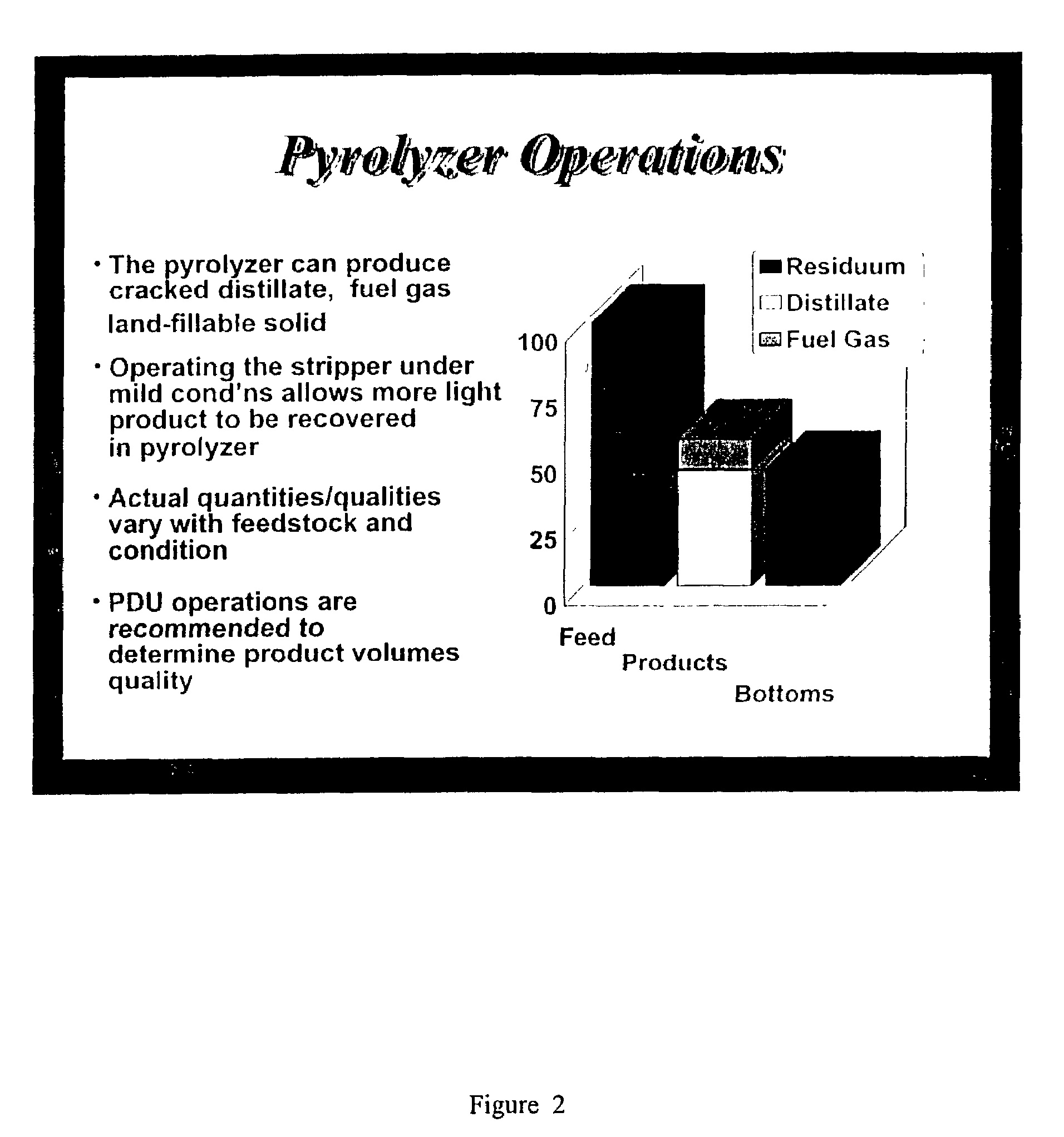

Continuous coking refinery methods and apparatus

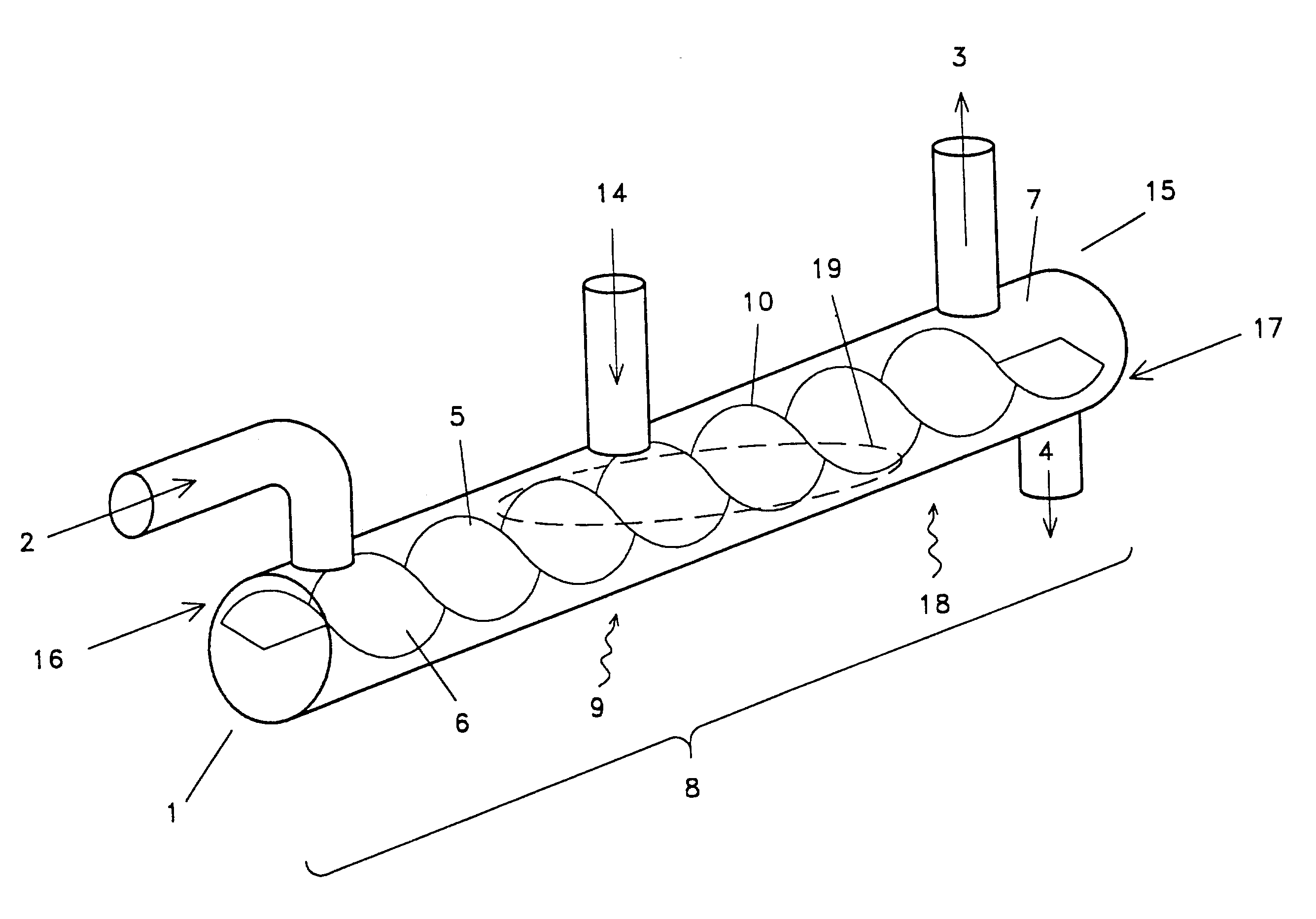

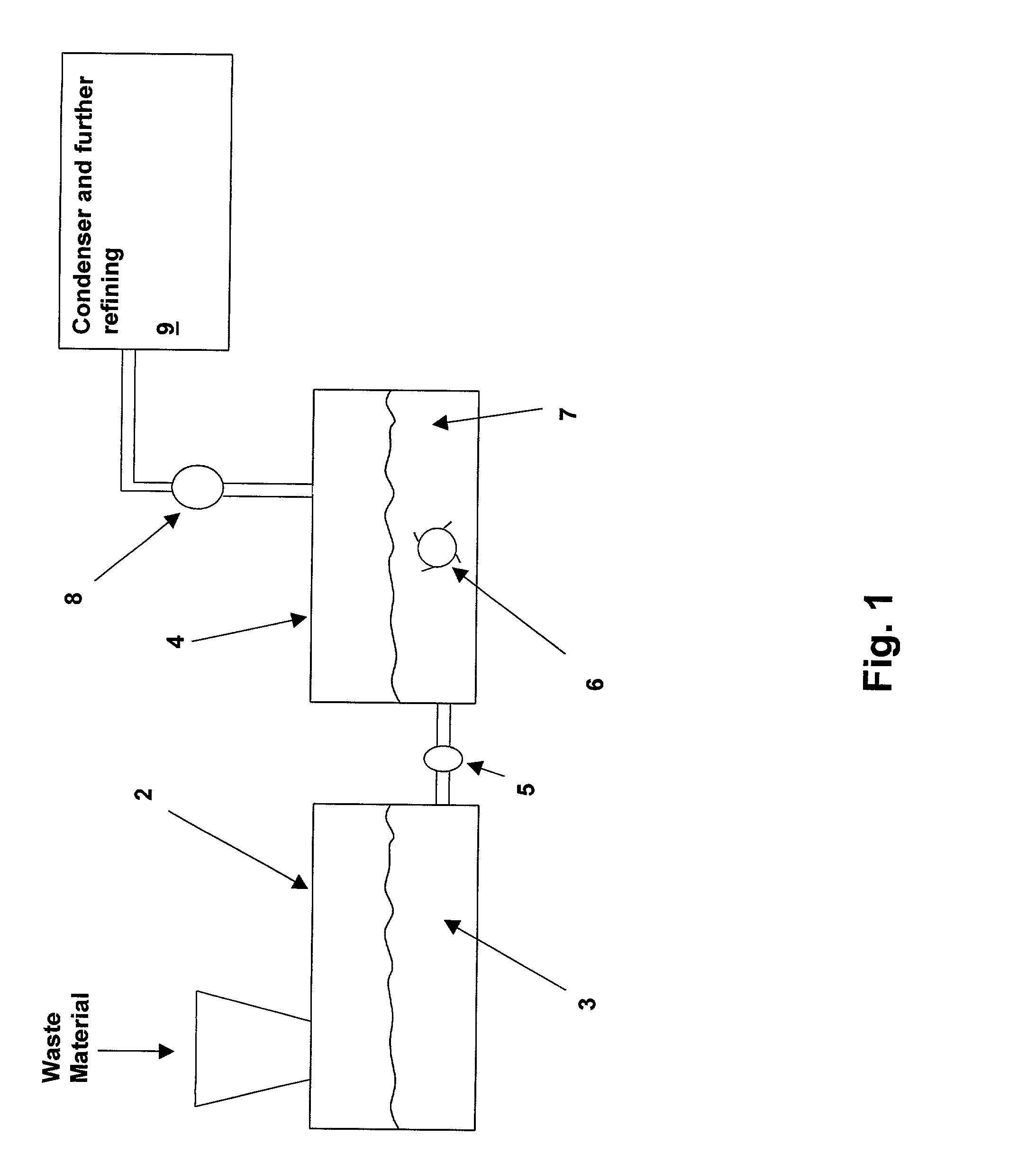

InactiveUS6972085B1Constant and continuousEfficiently conductedThermal non-catalytic crackingCombustible gas coke oven heatingProduct gasProcess engineering

A system for refining hydrocarbon containing materials in a continuous coking mode may provide a pyrolyzer (1) which may be inclined to effect a liquid seal between a liquid conduction environment (6) and a gaseous conduction environment (7). A heat source (9) may heat the material past the coking point and the system may include a screw or auger (10) which can continuously remove the coke while simultaneously outputting refined products.

Owner:WESTERN RES INST INC +2

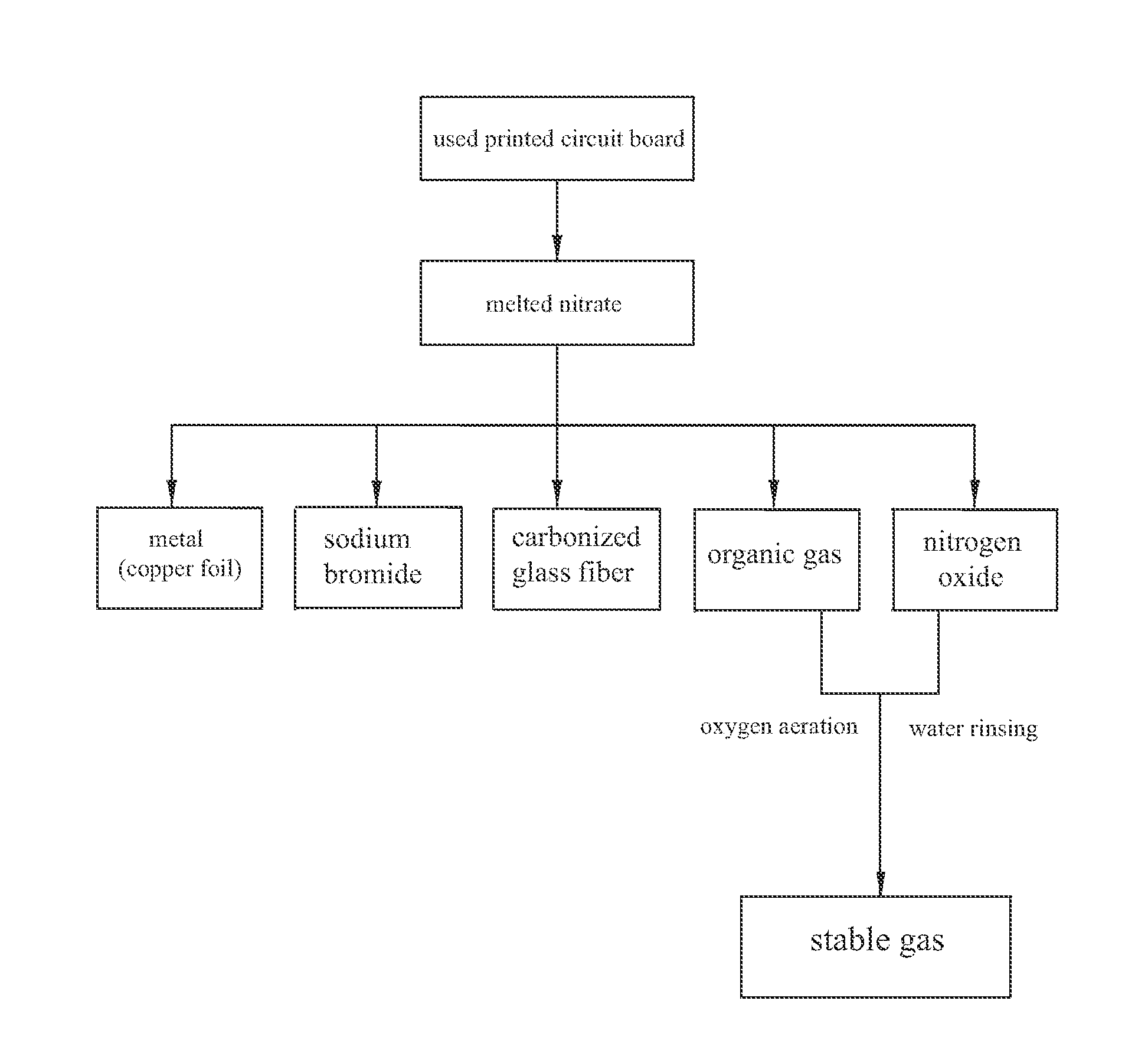

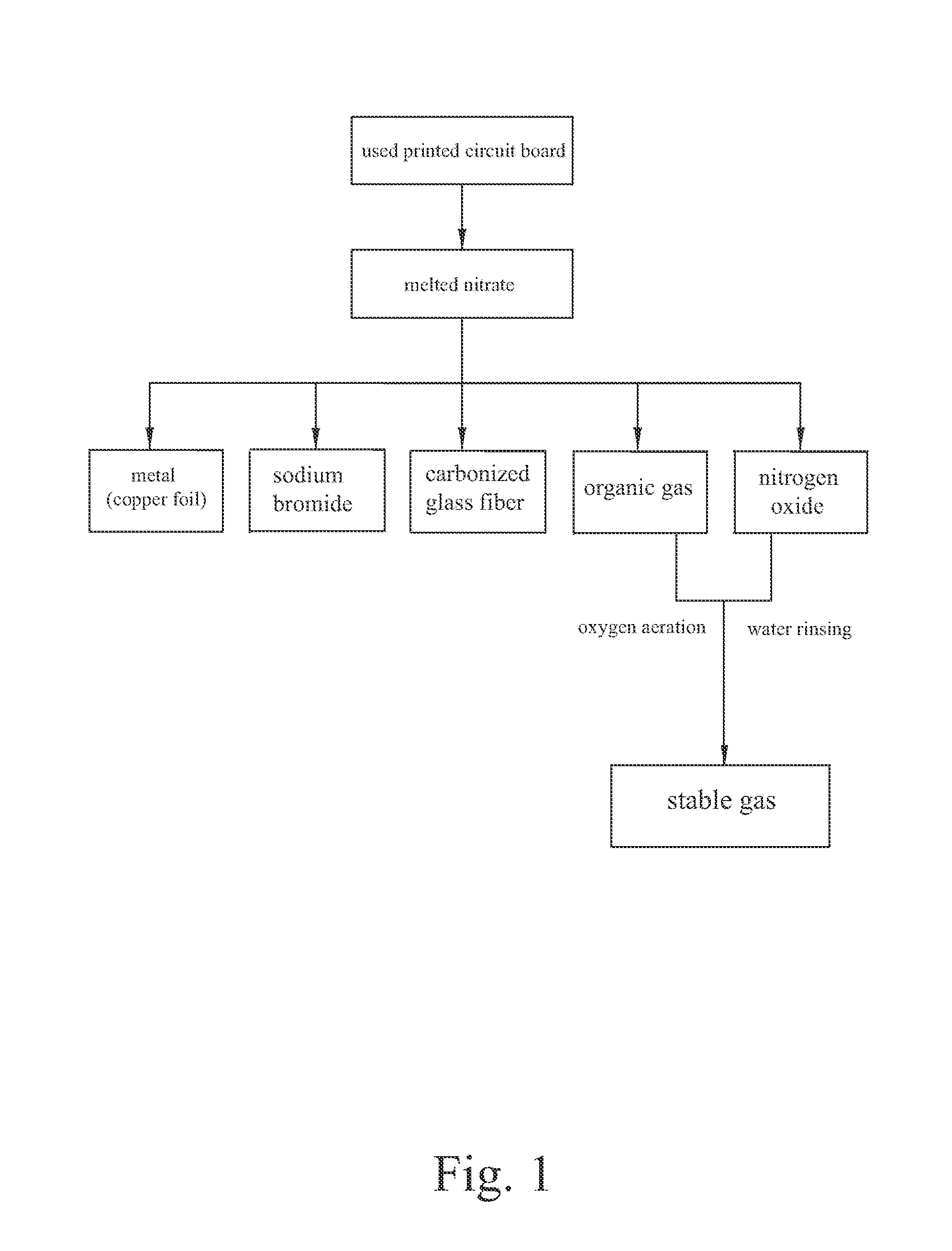

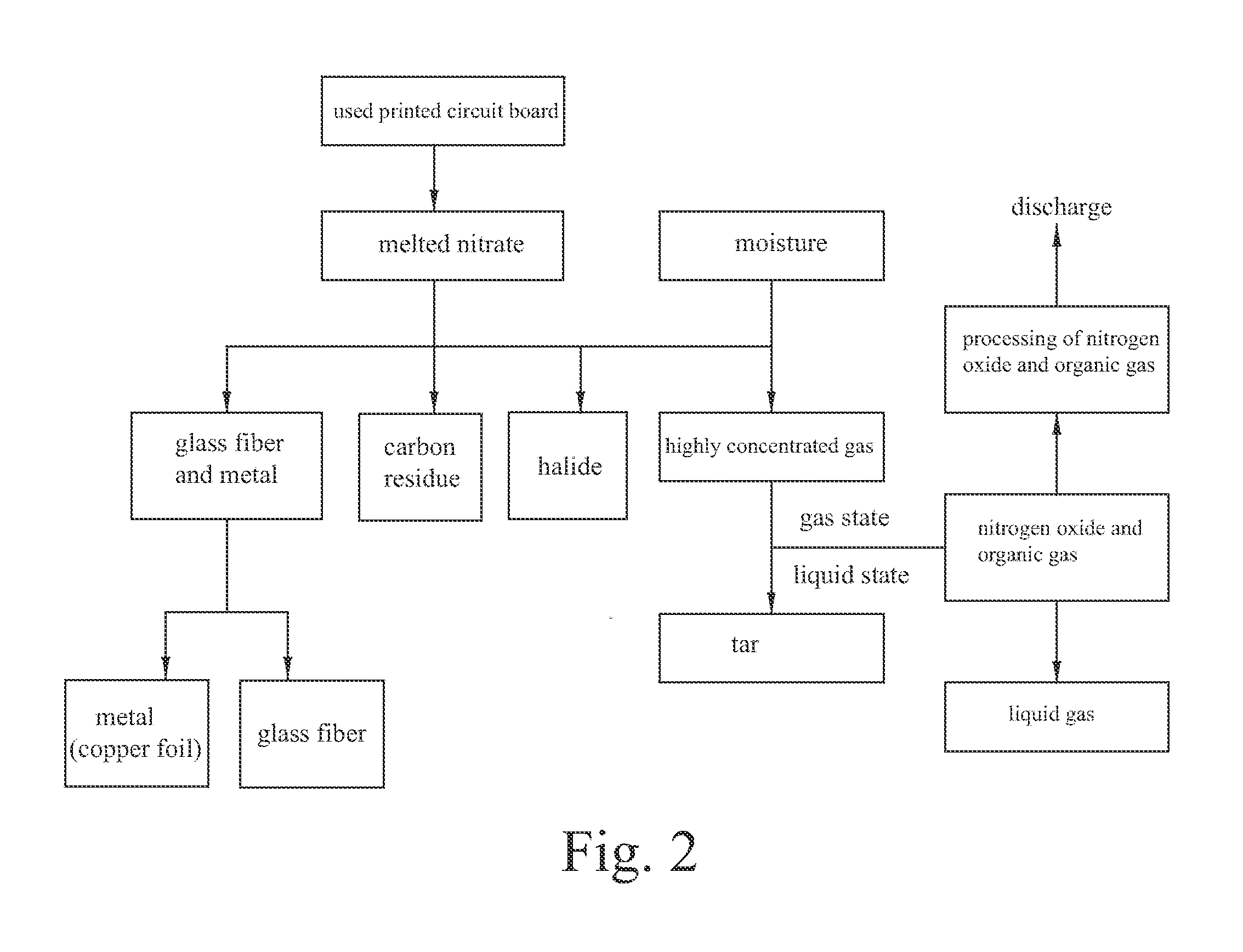

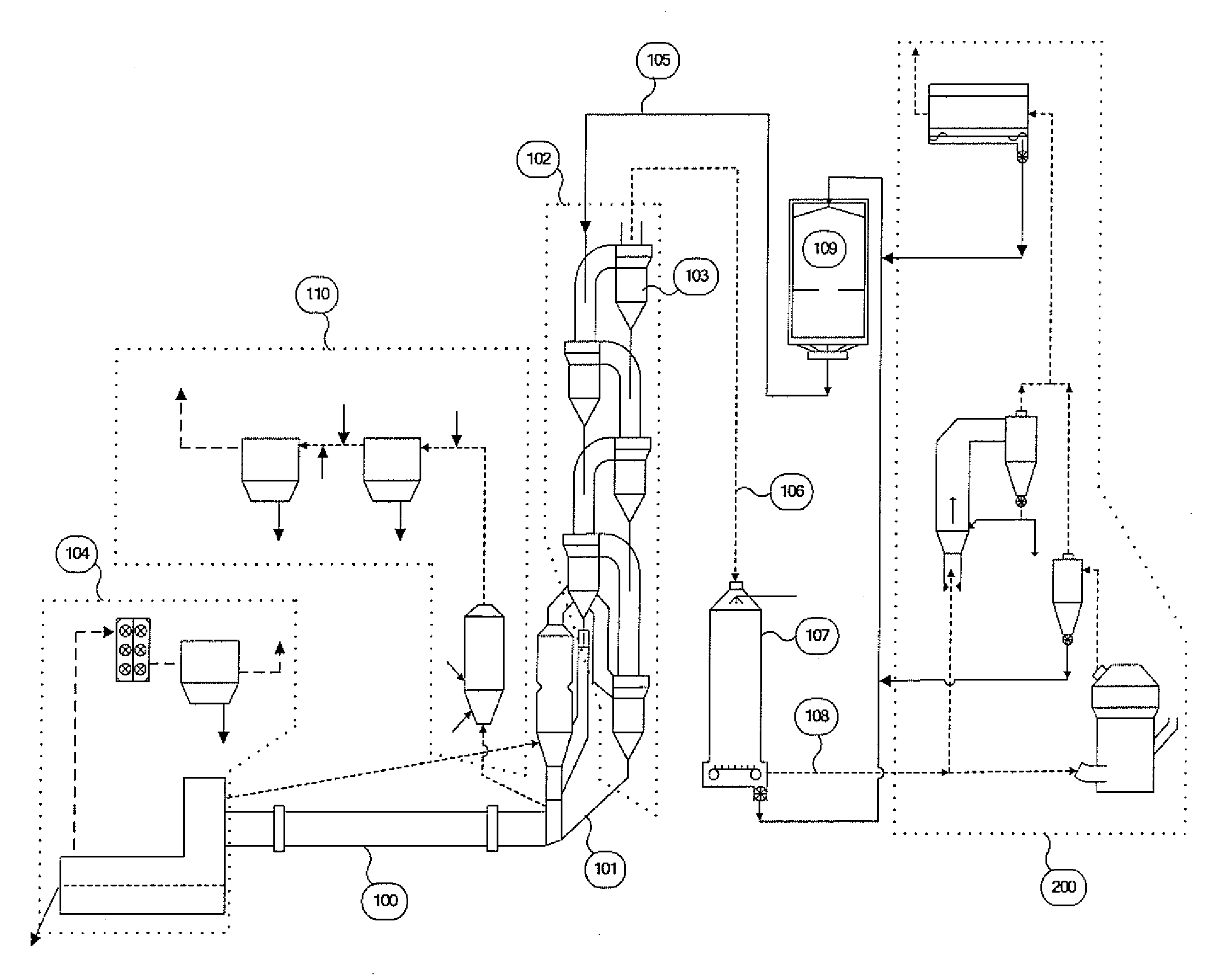

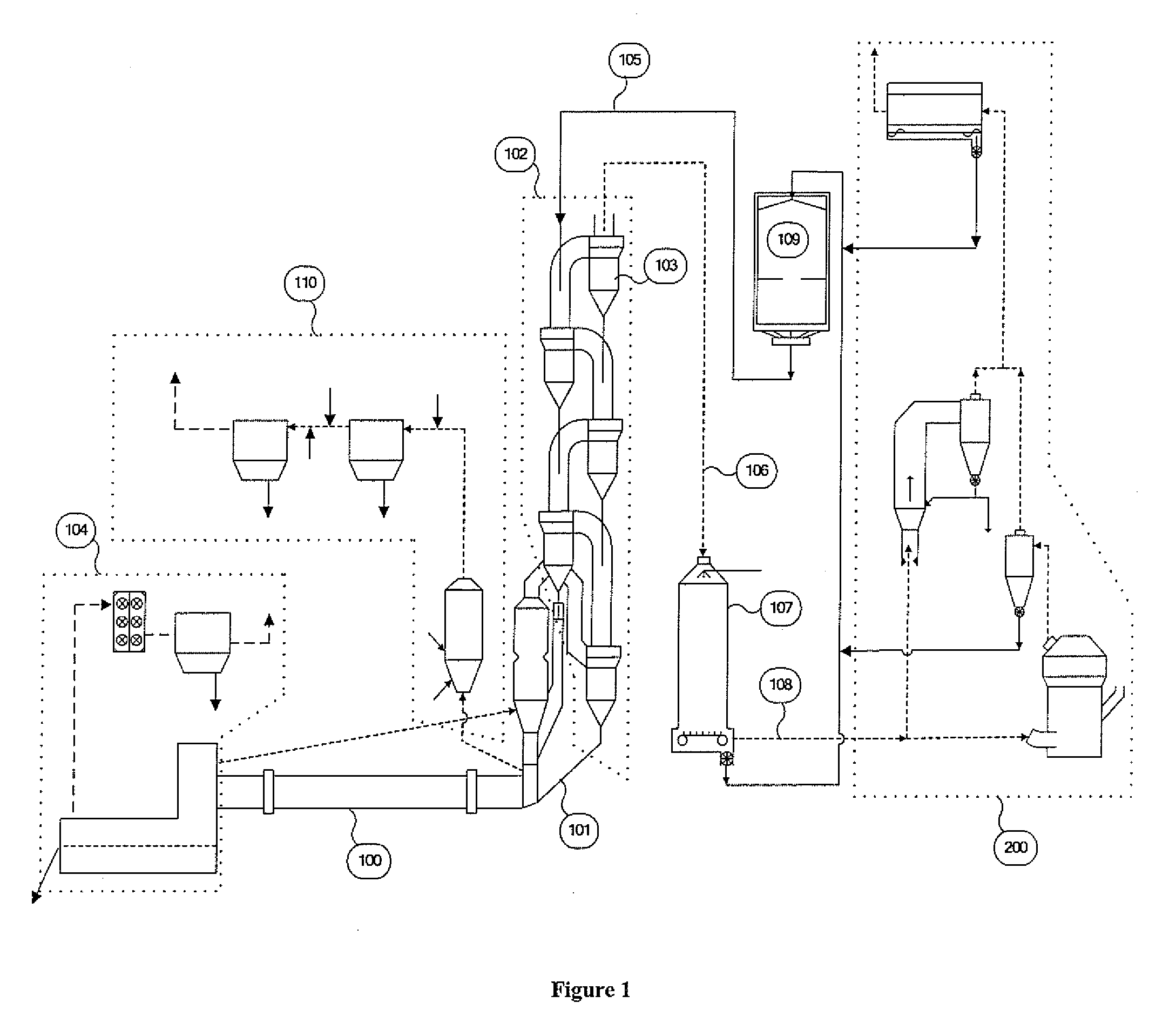

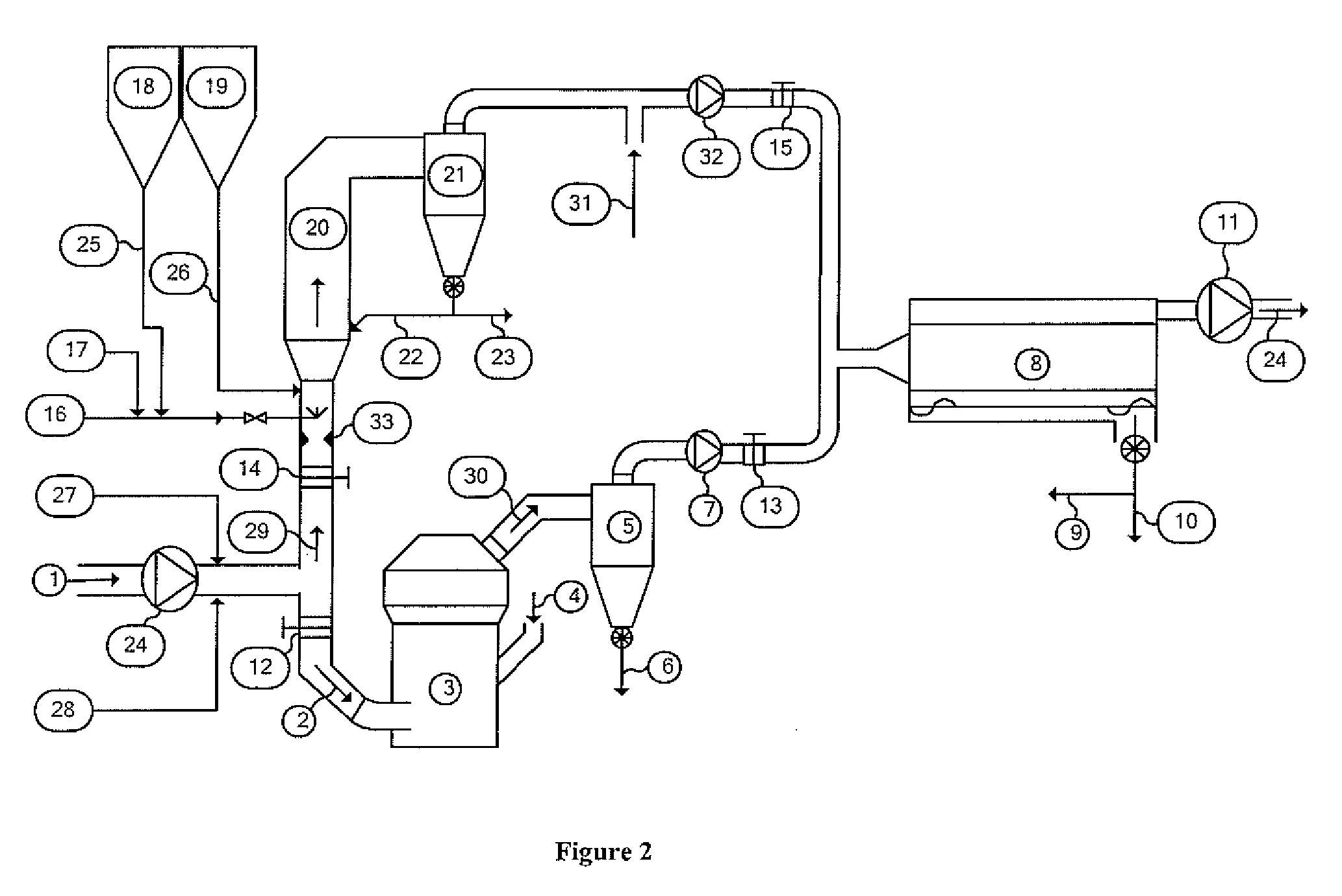

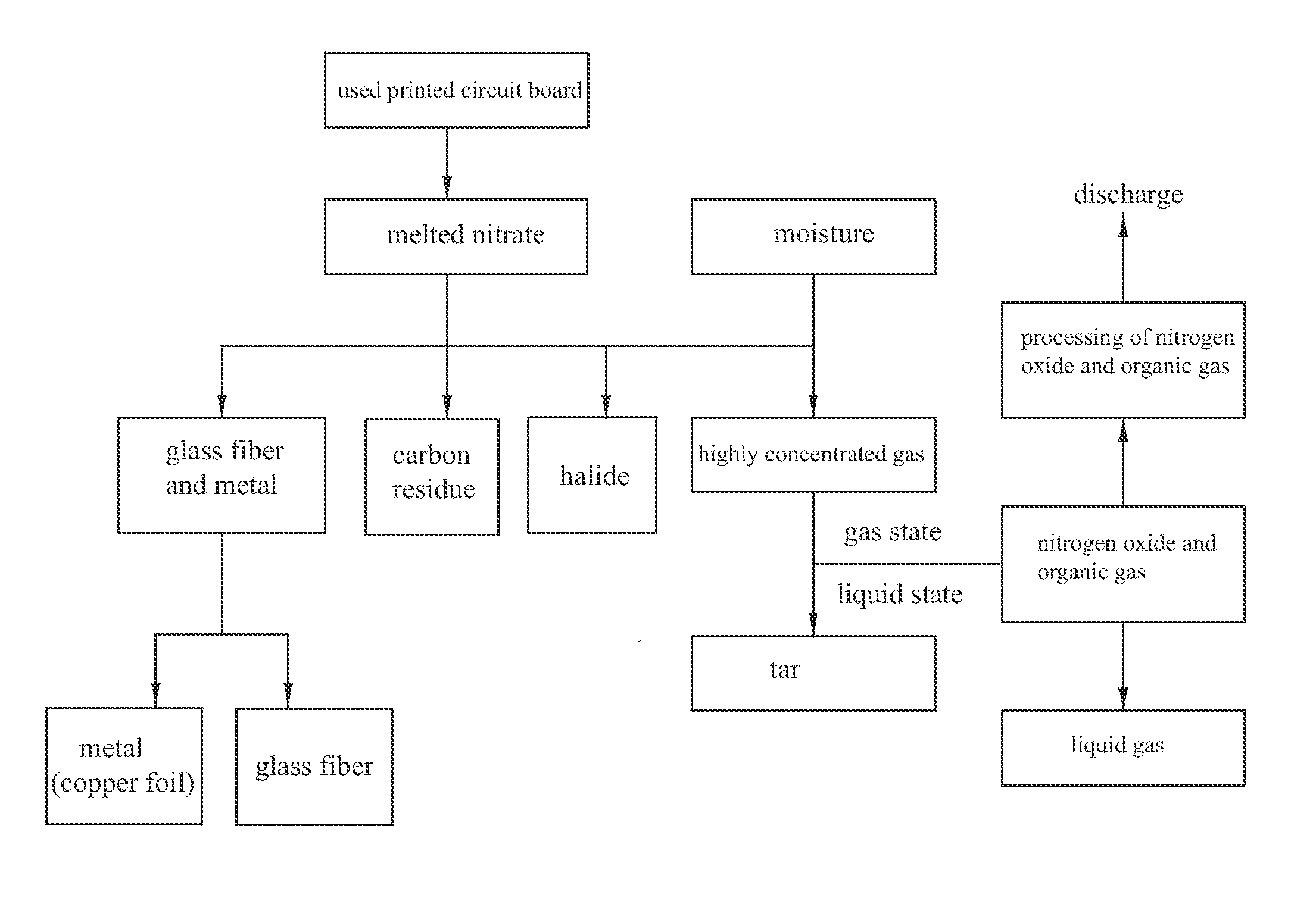

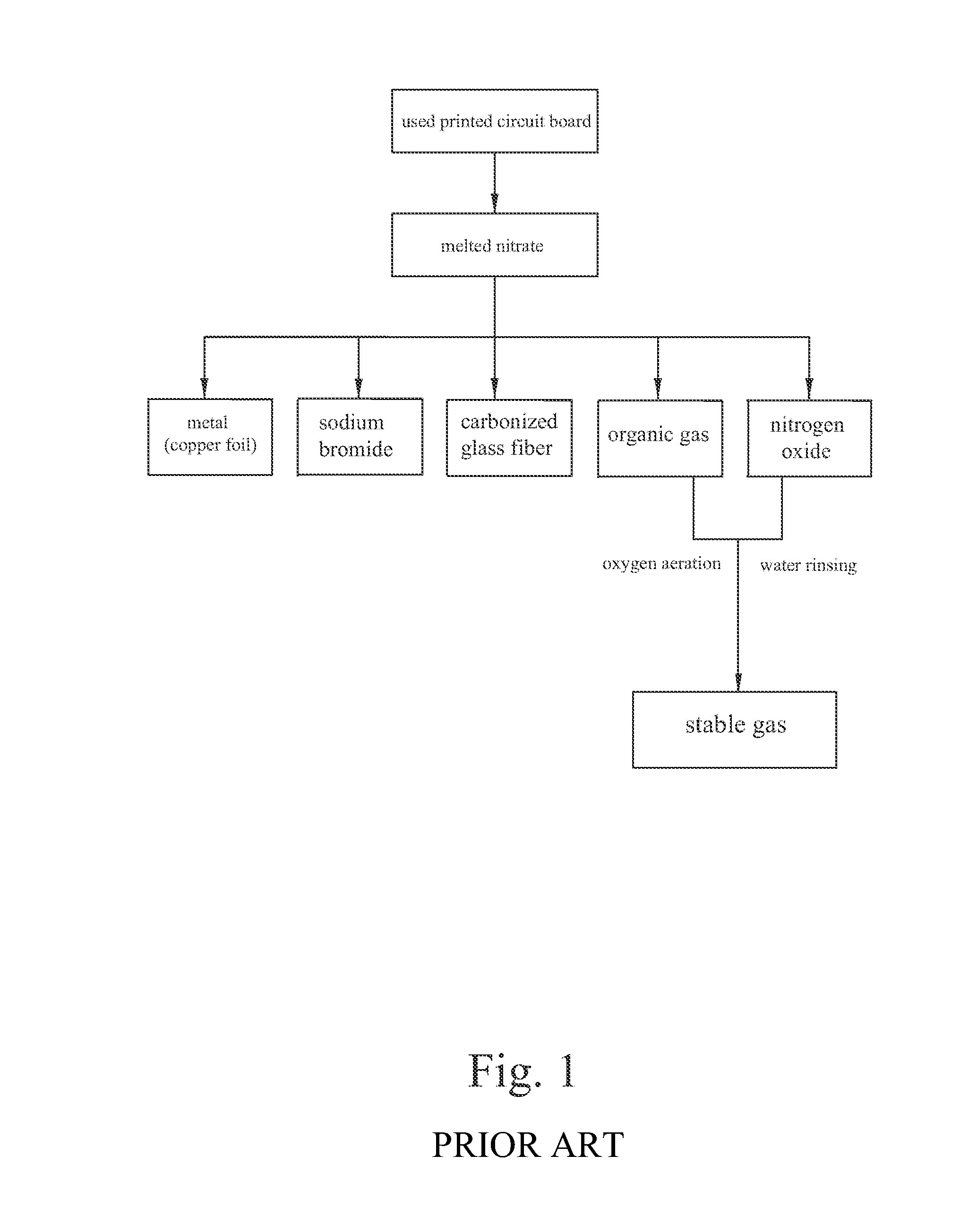

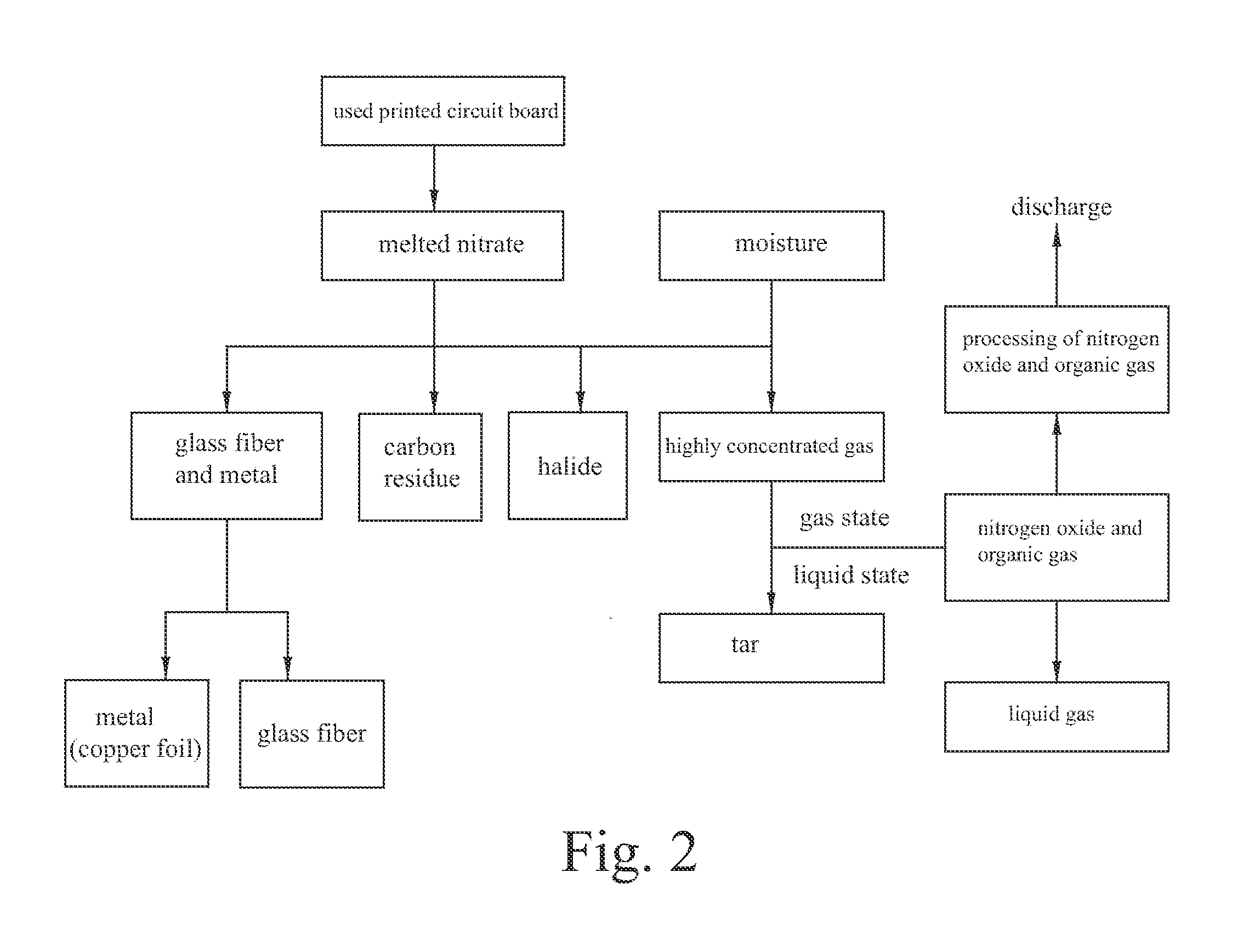

Method and device using pyrolysis for recycling used printed circuit board

ActiveUS20100300865A1Ensure safetyAvoid burnsFinal product manufacturePreheating coke ovensCombustionEngineering

A method and a device using pyrolysis for recycling used printed circuit board are disclosed, in which water (moisture) is introduced in the pyrolysis process and a fully sealed low pressure environment is established to ensure that no combustion is happened in the pyrolysis process to enhance the safety of the process; pyrolysis gases generated in the process is concentrated and purified to provide useful fuels or chemical materials; therefore, the present invention can reduce process cost, improve recycling efficiency and provide processing device with high safety, thereby enhancing industry usability.

Owner:WU HSIEH SEN

Method for Eliminating Spikes of Mercury Emissions

InactiveUS20100300864A1Lower emission levelsLow variabilityGas treatmentPreheating coke ovensEngineeringCement kiln

A method for the reduction of mercury emissions from an industrial plant that utilizes a cement or minerals kiln that has a high level of mercury emissions during specific operating conditions. The invention reduces a large spike in mercury emissions typically seen in cement kiln systems when the in-line raw mill is shut-down and all preheater gases are vented to the stack directly. The invention diverts the preheater gases to a cooling device that functions as an adsorption reactor to provide mercury absorption during periods when the raw mill is not in operation.

Owner:F L SMIDTH & CO AS

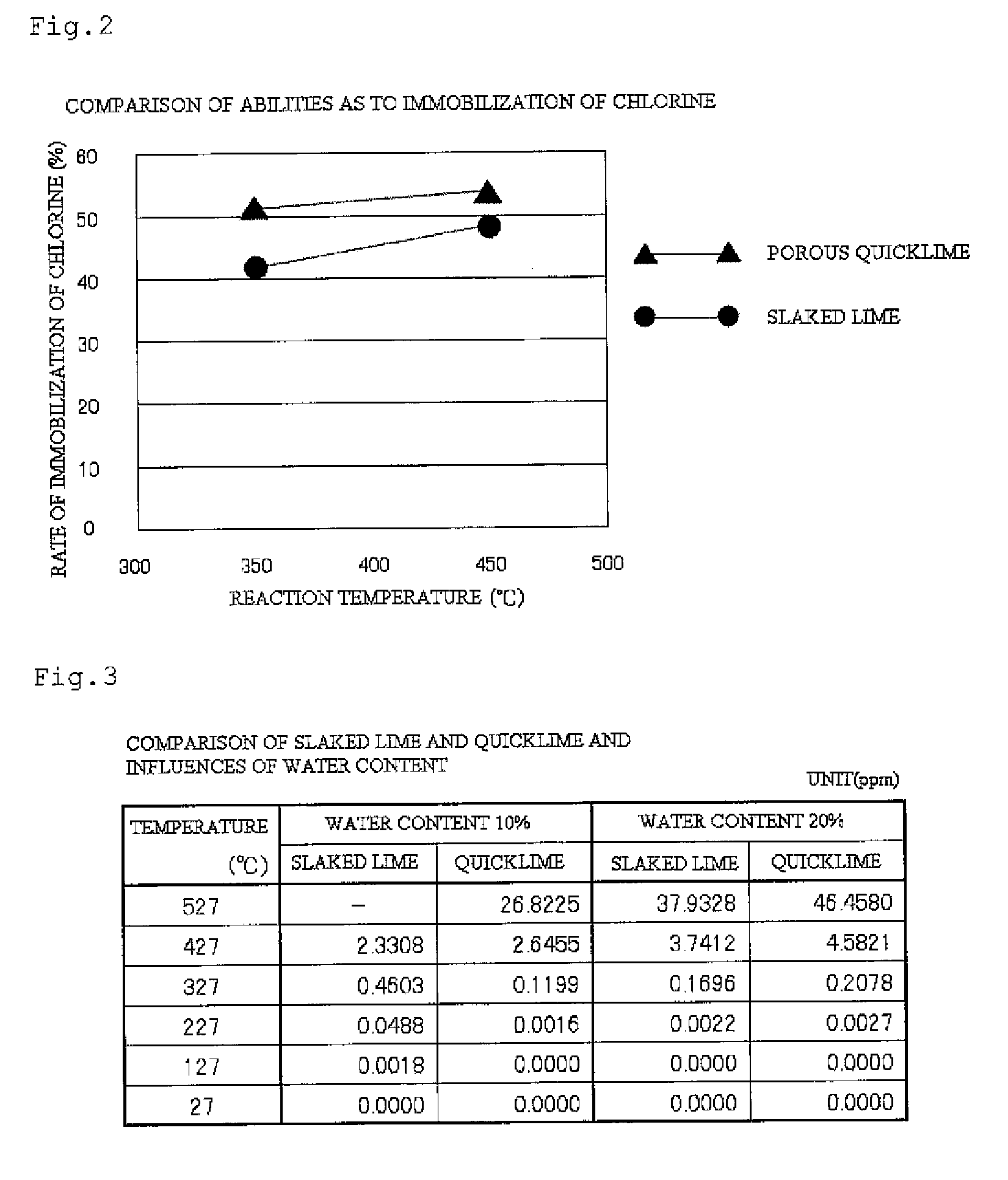

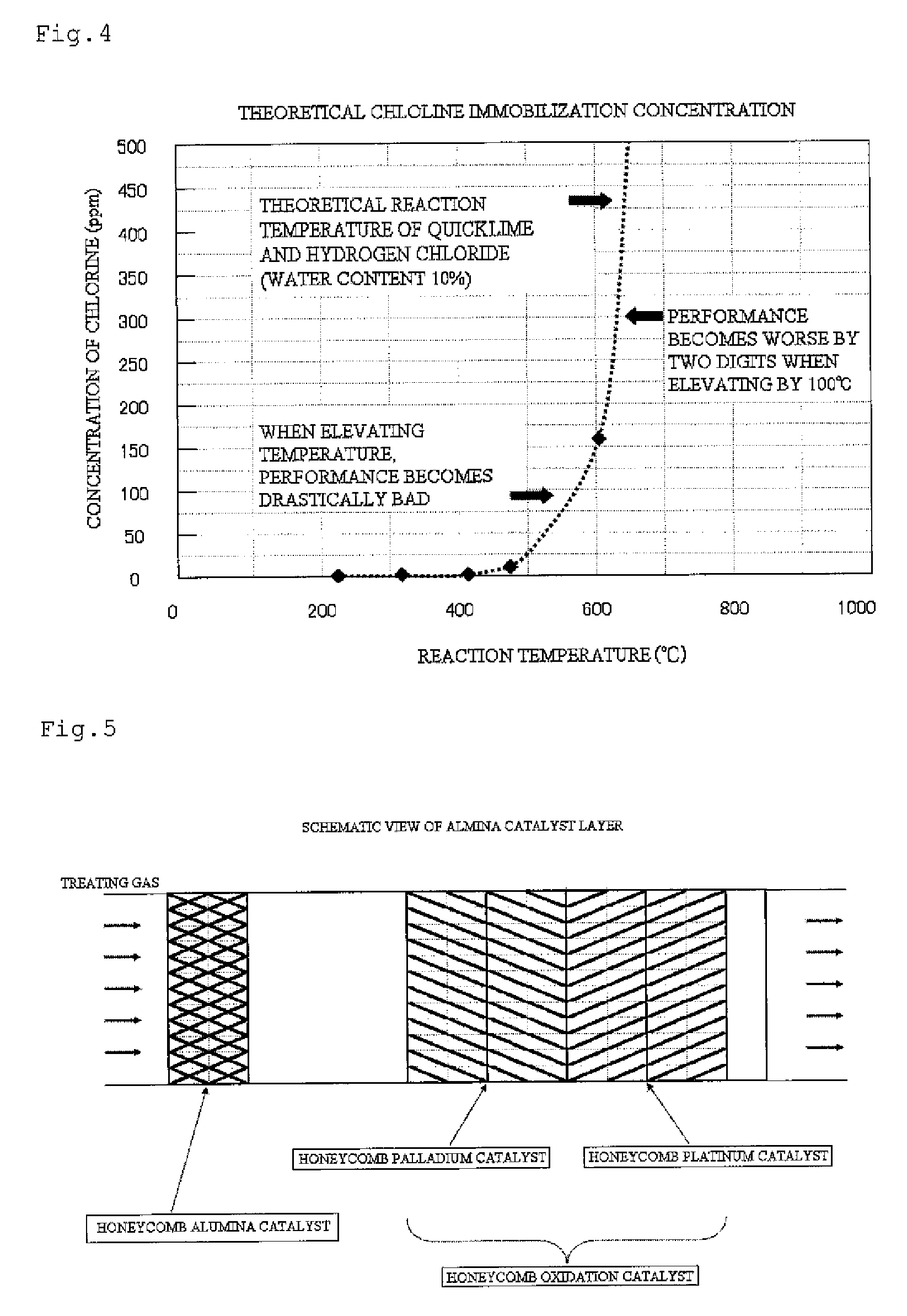

Decomposition Method Of Waste Plastics and Organics

ActiveUS20080099323A1Effective treatmentLittle effectTransportation and packagingSolid waste disposalDecompositionMedical waste

An object of the present invention is to provide a method of efficiently decomposing waste plastics, organics, and particularly medical waste composed of varieties of plastics. The present inventors established a method of efficiently decomposing waste plastics, organics, and particularly medical waste mainly composed of varieties of plastics by optimizing conditions in a decomposition process and introducing a process of adsorbing and removing generated harmful gases, and have completed the present invention.

Owner:RAPAS INT LTD

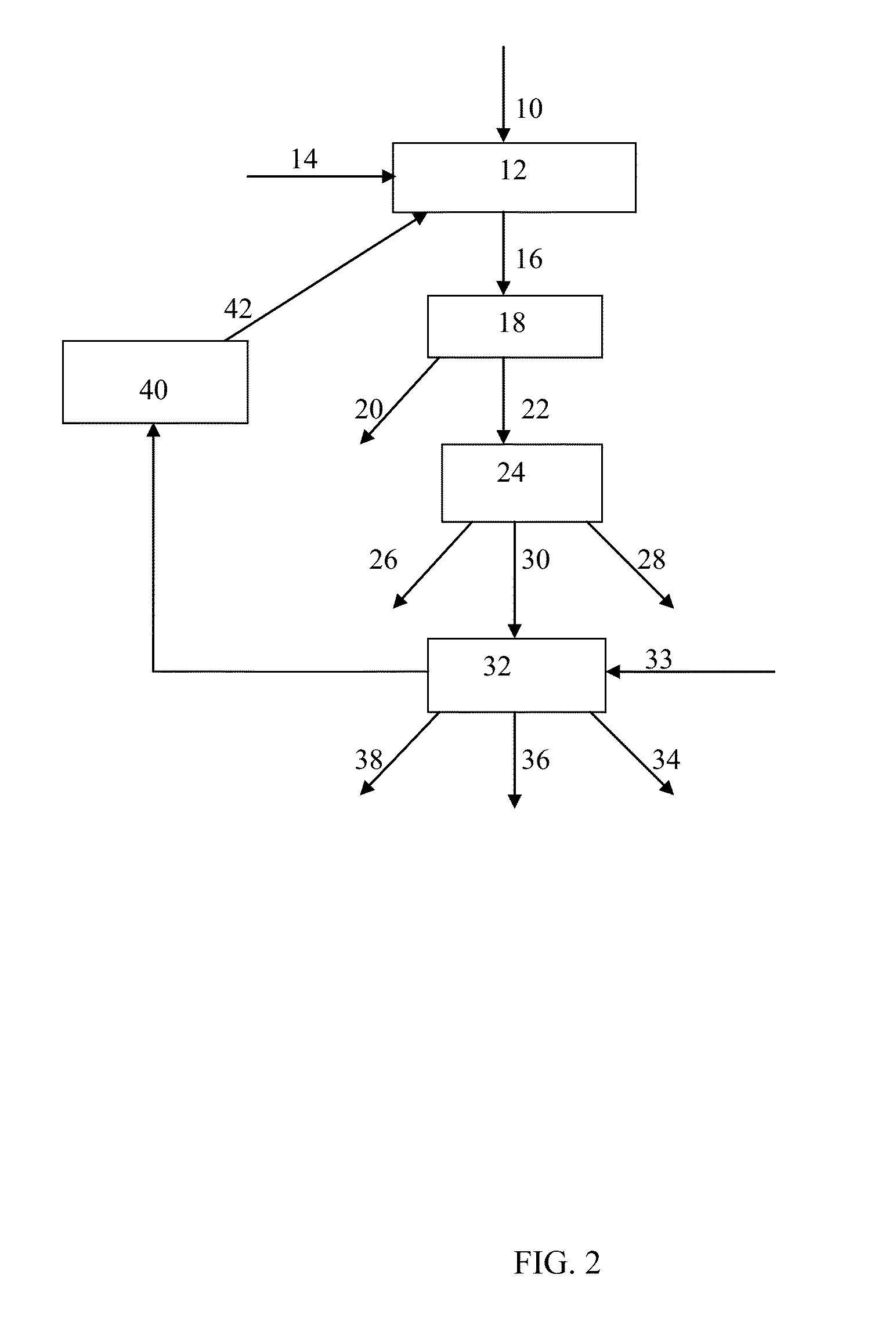

Biomass pyrolysis in refinery feedstock

ActiveUS20110184215A1Accelerated pyrolysisIncrease costPreheating coke ovensDirect heating destructive distillationHot liquidsBiomass

This invention relates to biomass pyrolysis through the use of a hot liquid refinery feedstock as a heat transfer medium, preferably a vacuum gas oil feedstock.

Owner:PHILLIPS 66 CO

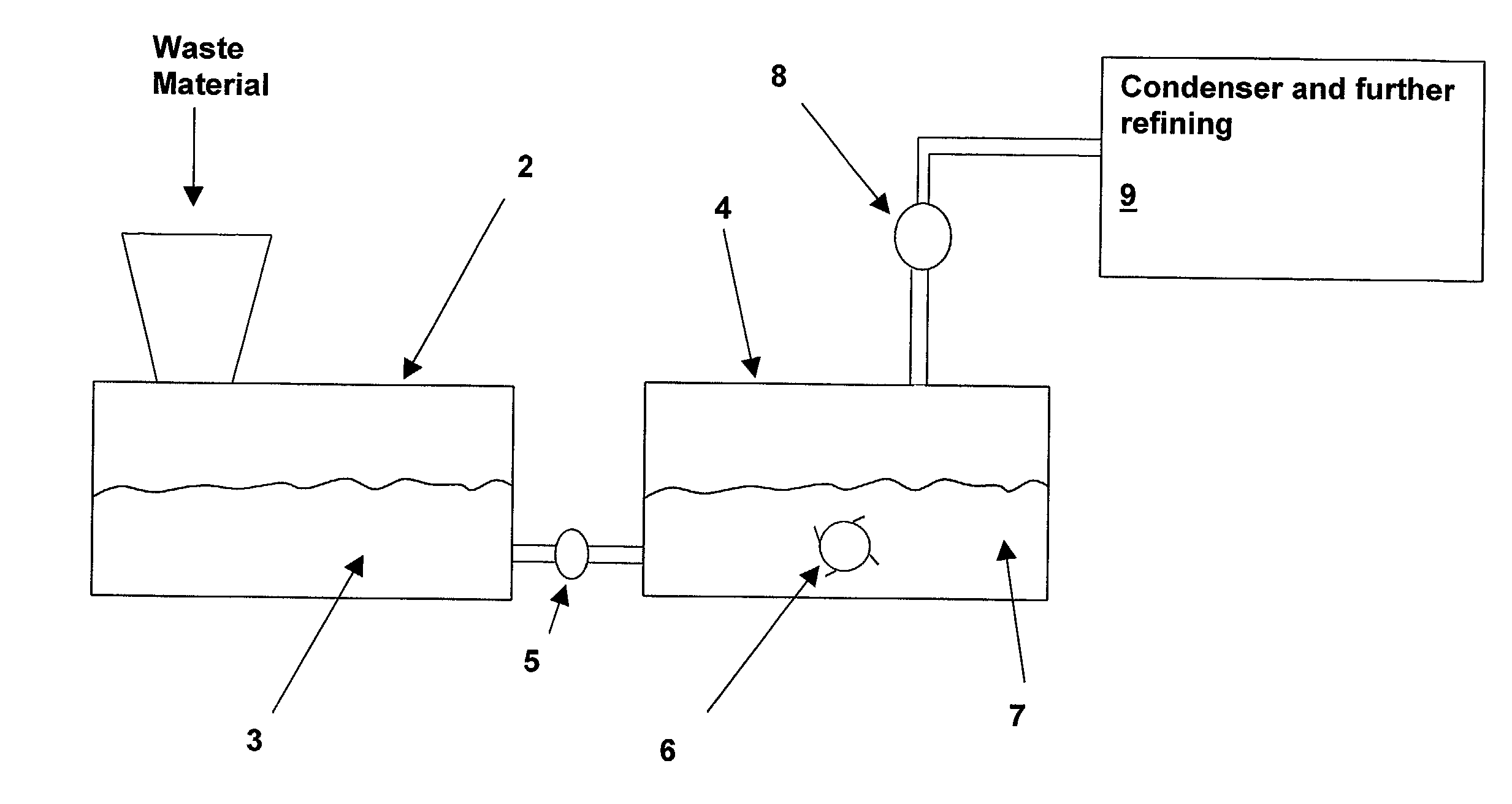

Method and system for extracting hydrocarbon fuel products from plastic material

InactiveUS20030130548A1Combustible gas coke oven heatingPreheating coke ovensRelative pressurePlastic materials

A method and system for extracting hydrocarbon fuel products from plastic material provides extraction of usable fuel components from waste plastic materials. The materials (or hydrocarbon portion thereof) are liquified and introduced to a chamber where the liquid material is agitated and a negative relative pressure (vacuum) is applied. The liquid is maintained at a substantially constant temperature and the vacuum draws the off-gas hydrocarbon products out for condensation and further processing, while unconverted char is removed to an ash dump. An auger feed unit with agitator buckets is used to propel the char through a feed while agitating the liquid to enhance the rate of gas removal.

Owner:MATERIALS RECOVERY CORP

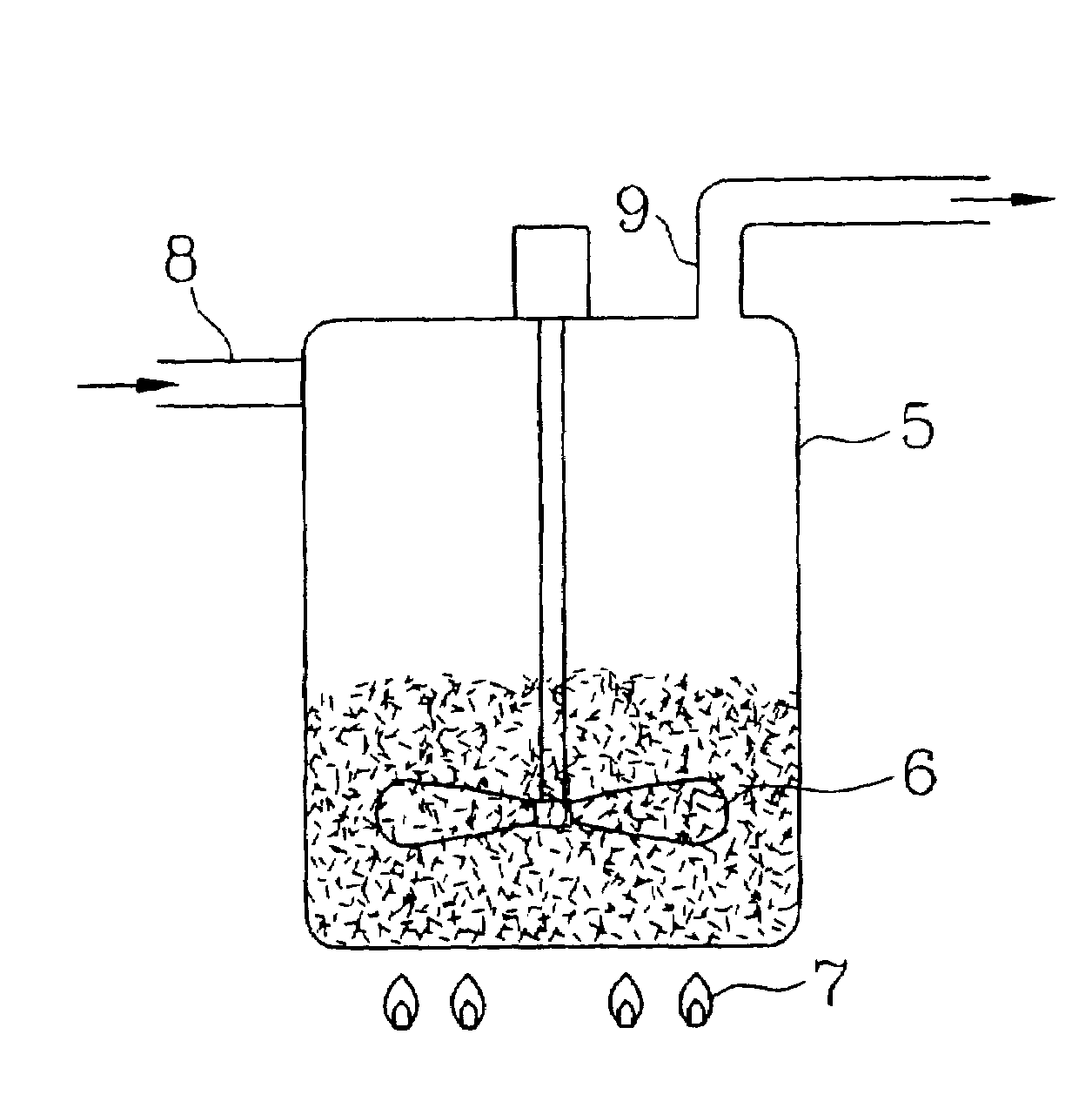

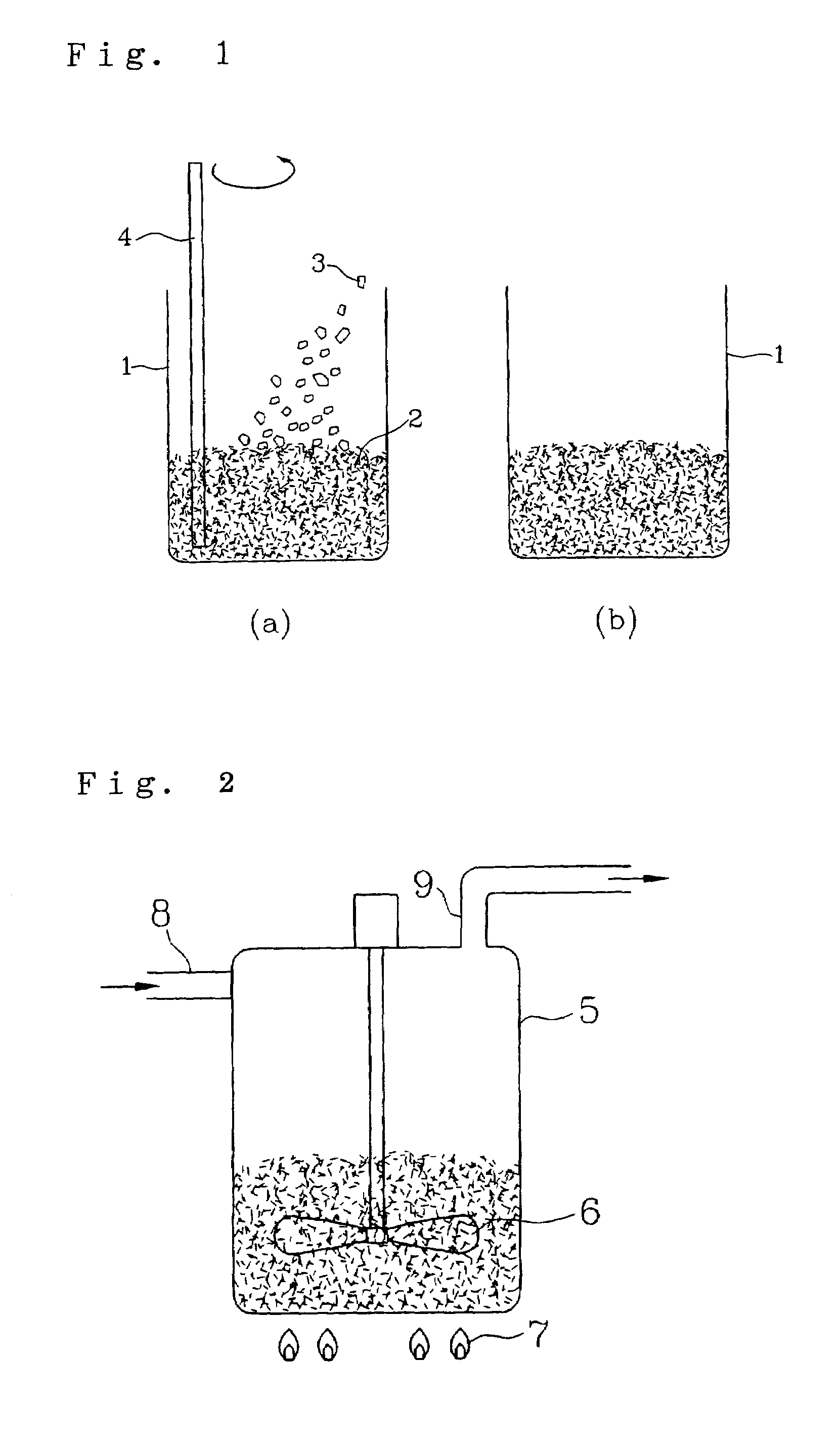

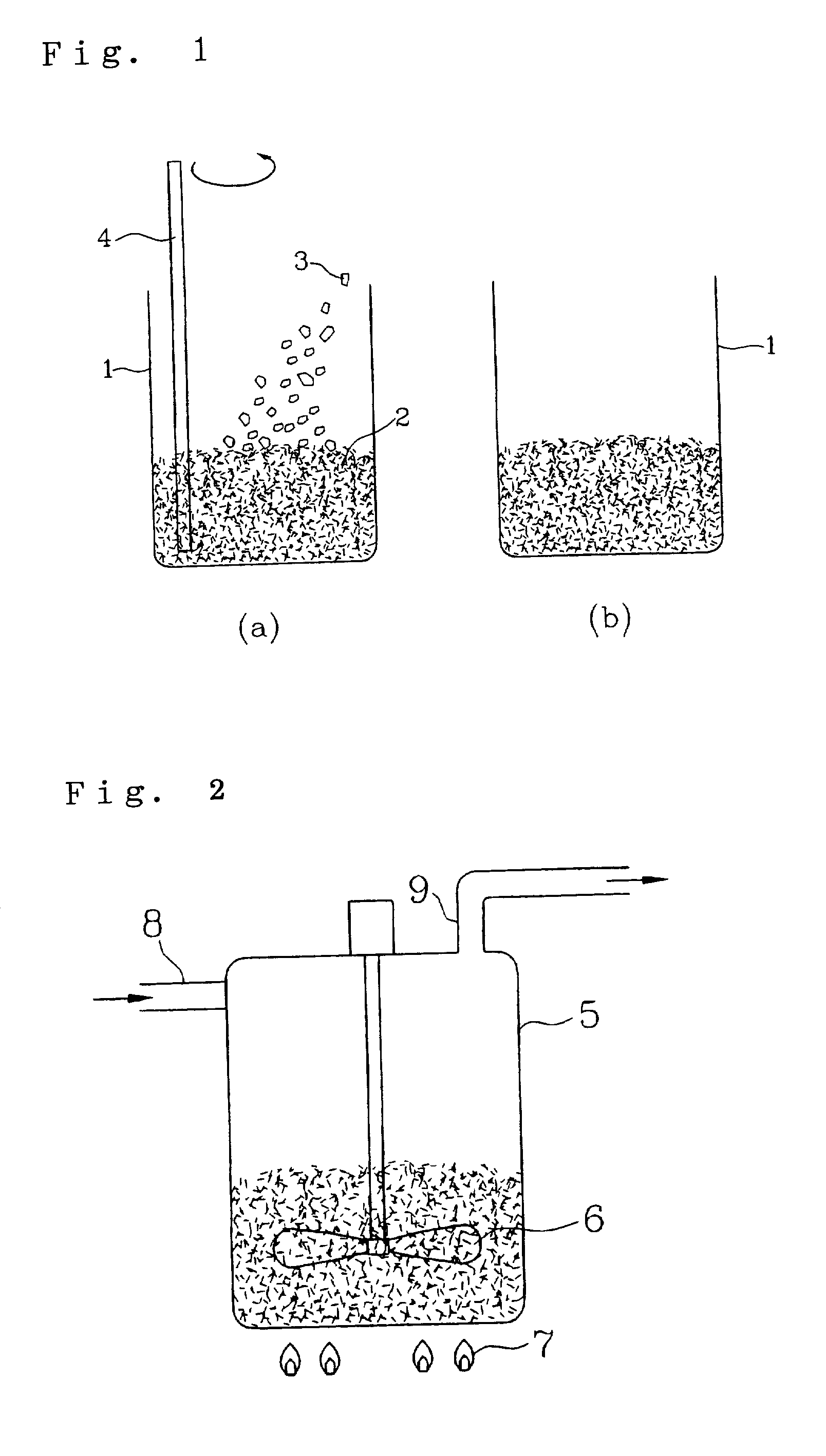

Method for decomposing plastic

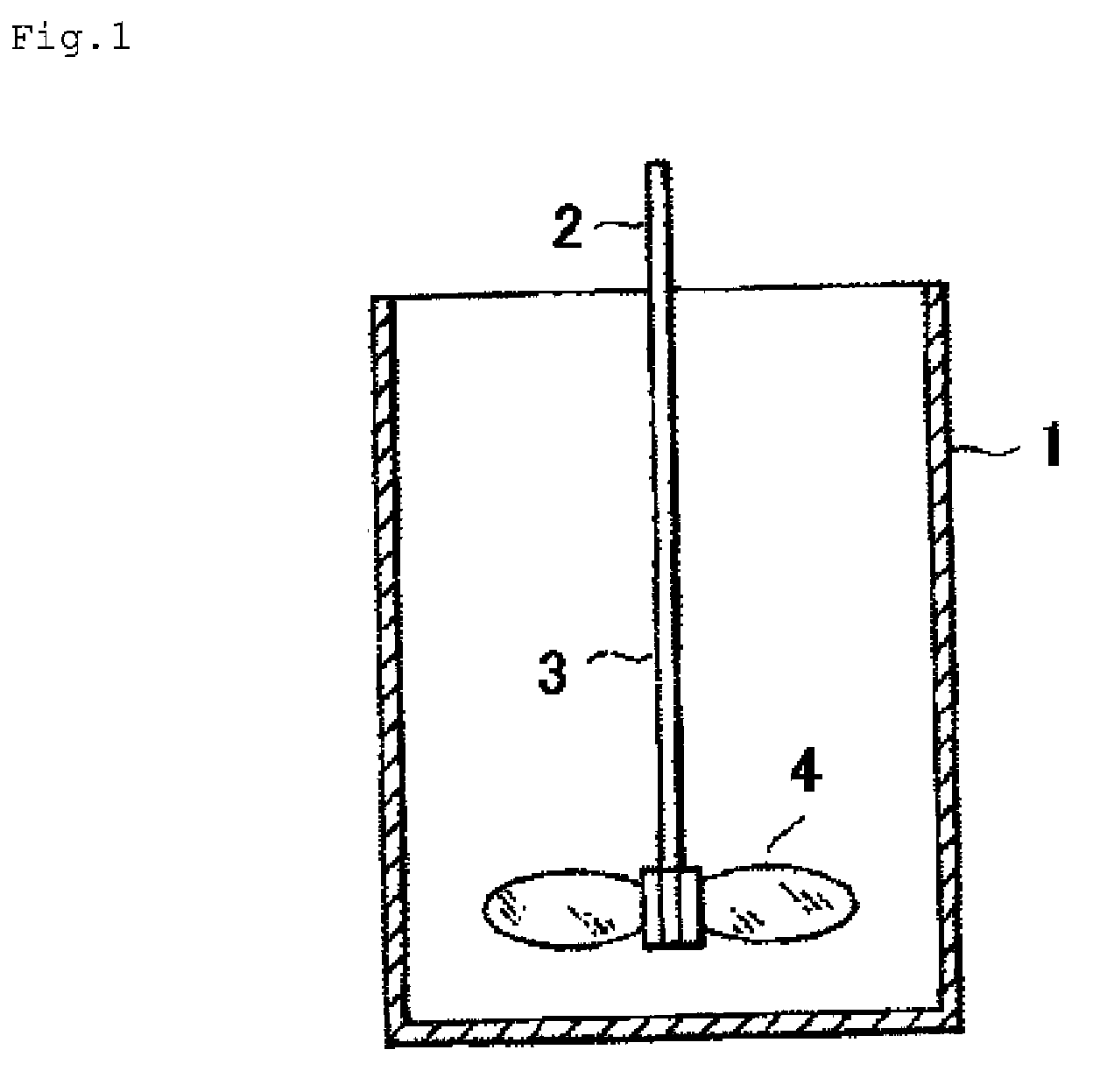

ActiveUS7034198B2Guaranteed mixImprove efficiencyPreheating coke ovensDirect heating destructive distillationAlkalinityAqueous solution

A conventional method of pyrolytically decomposing plastic to make low-molecular compounds is poor in efficiency of use of energy due to high heating temperatures (at least 600° C. and 800° C. at maximum).The invention provides that a functional powder is heated to a predetermined temperature and pieces of plastic to be disposed are caused to be contacted with the heated powder, the functional powder including a powder which does in an aqueous solution state show alkalinity, and a photo-catalyst effect powder.

Owner:OSADA GIKEN

Method and system for extracting hydrocarbon fuel products from plastic material

InactiveUS7048832B2Combustible gas coke oven heatingPreheating coke ovensRelative pressurePlastic materials

A method and system for extracting hydrocarbon fuel products from plastic material provides extraction of usable fuel components from waste plastic materials. The materials (or hydrocarbon portion thereof) are liquified and introduced to a chamber where the liquid material is agitated and a negative relative pressure (vacuum) is applied. The liquid is maintained at a substantially constant temperature and the vacuum draws the off-gas hydrocarbon products out for condensation and further processing, while unconverted char is removed to an ash dump. An auger feed unit with agitator buckets is used to propel the char through a feed while agitating the liquid to enhance the rate of gas removal.

Owner:MATERIALS RECOVERY CORP

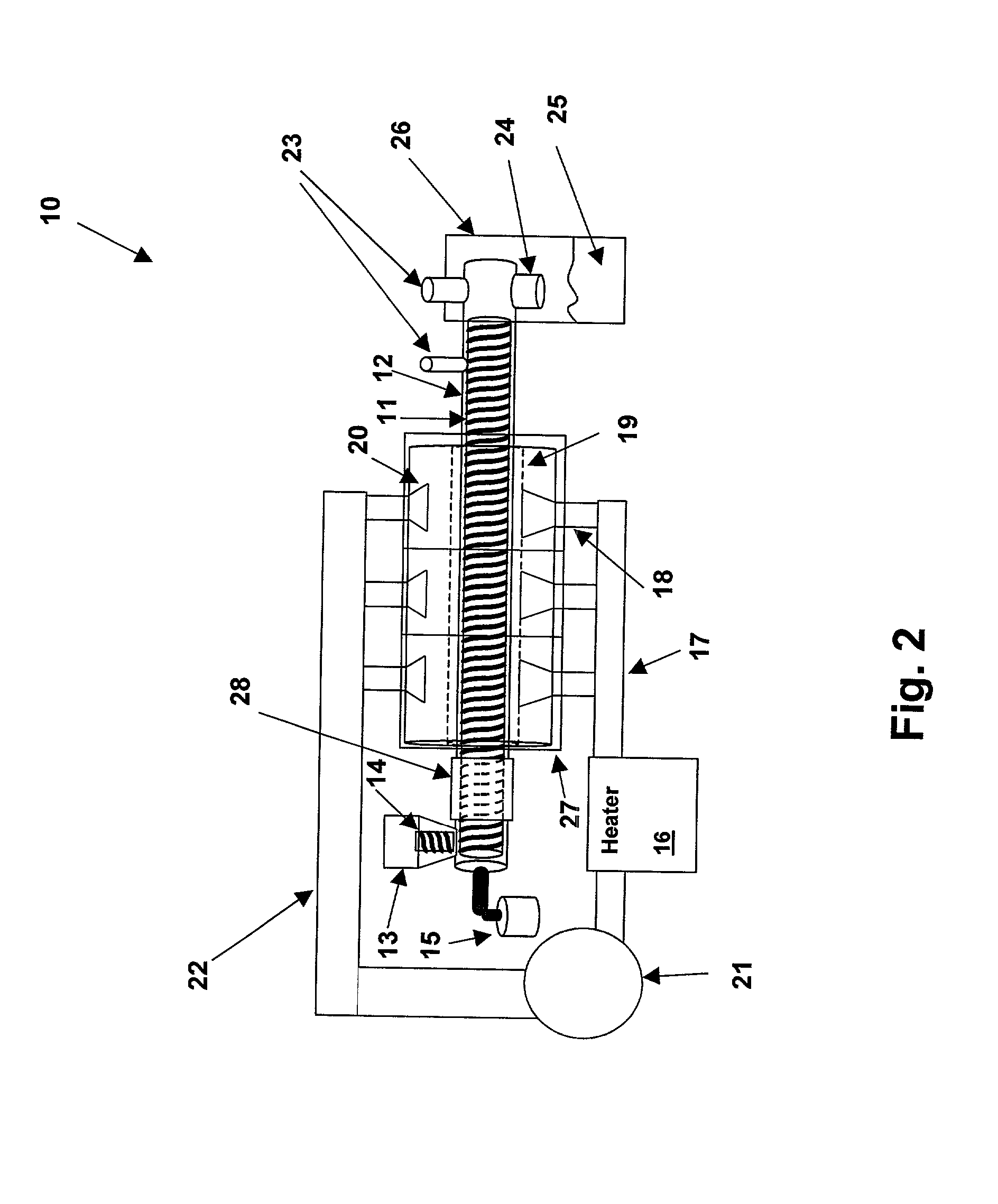

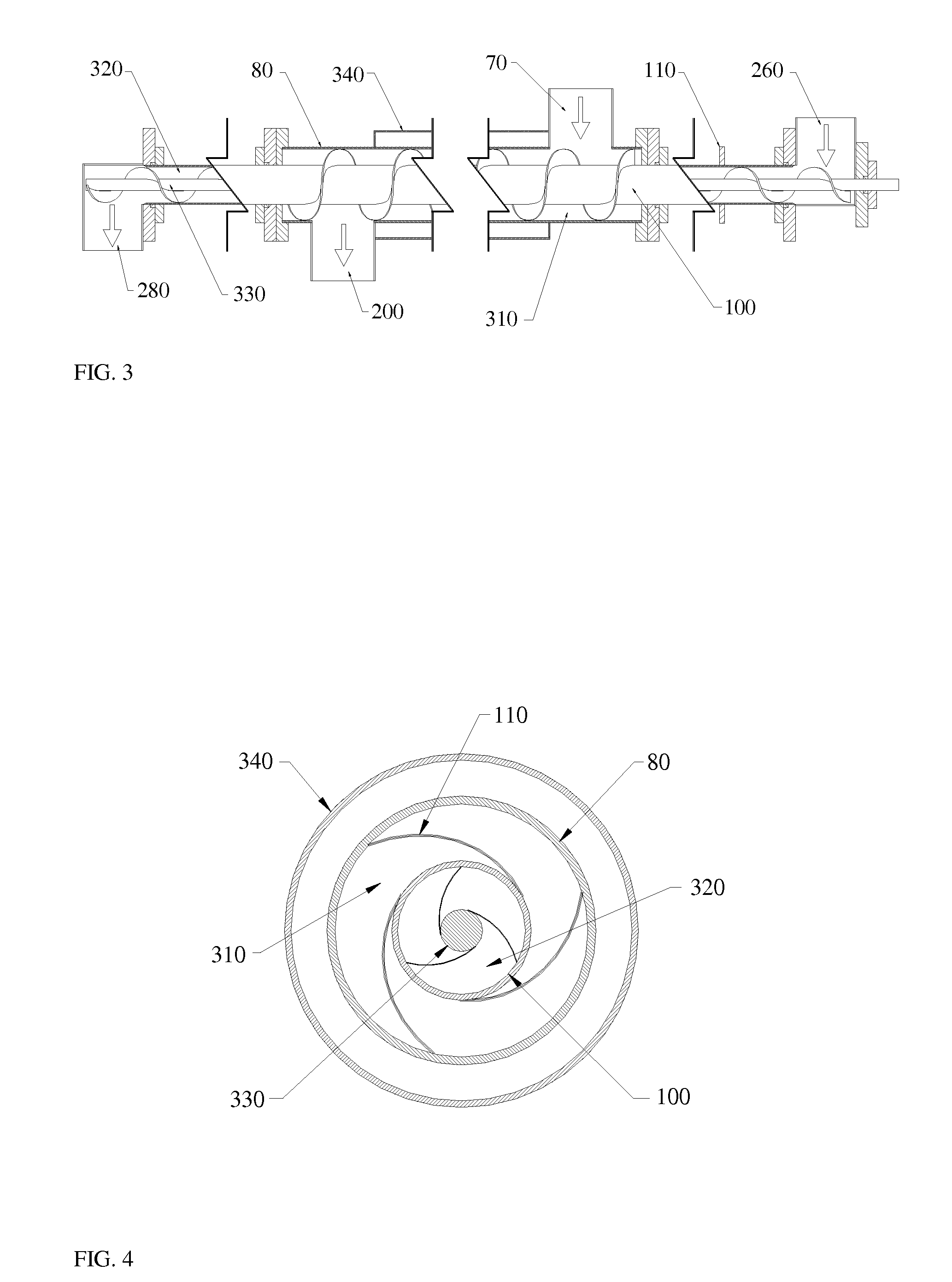

Thermal transfer mechanisms for an auger pyrolysis reactor

InactiveUS20120228112A1Adequate pyrolysis heatAvoid coolingMechanical conveying coke ovensPreheating coke ovensVacuum pressureHeat carrier

An improved method of providing heat to a pyrolysis reactor is disclosed. A solid heat carrier produces fast pyrolysis vapors during transport of the solid heat carrier / feedstock mixture down the shell of the main reactor tube by the reactor tube auger. These vapors are drawn from the main reactor tube by a slight vacuum pressure and are condensed in a multiple condenser train comprised of shell and tube condensers cooled by water or other means.

Owner:MISSISSIPPI STATE UNIVERSITY

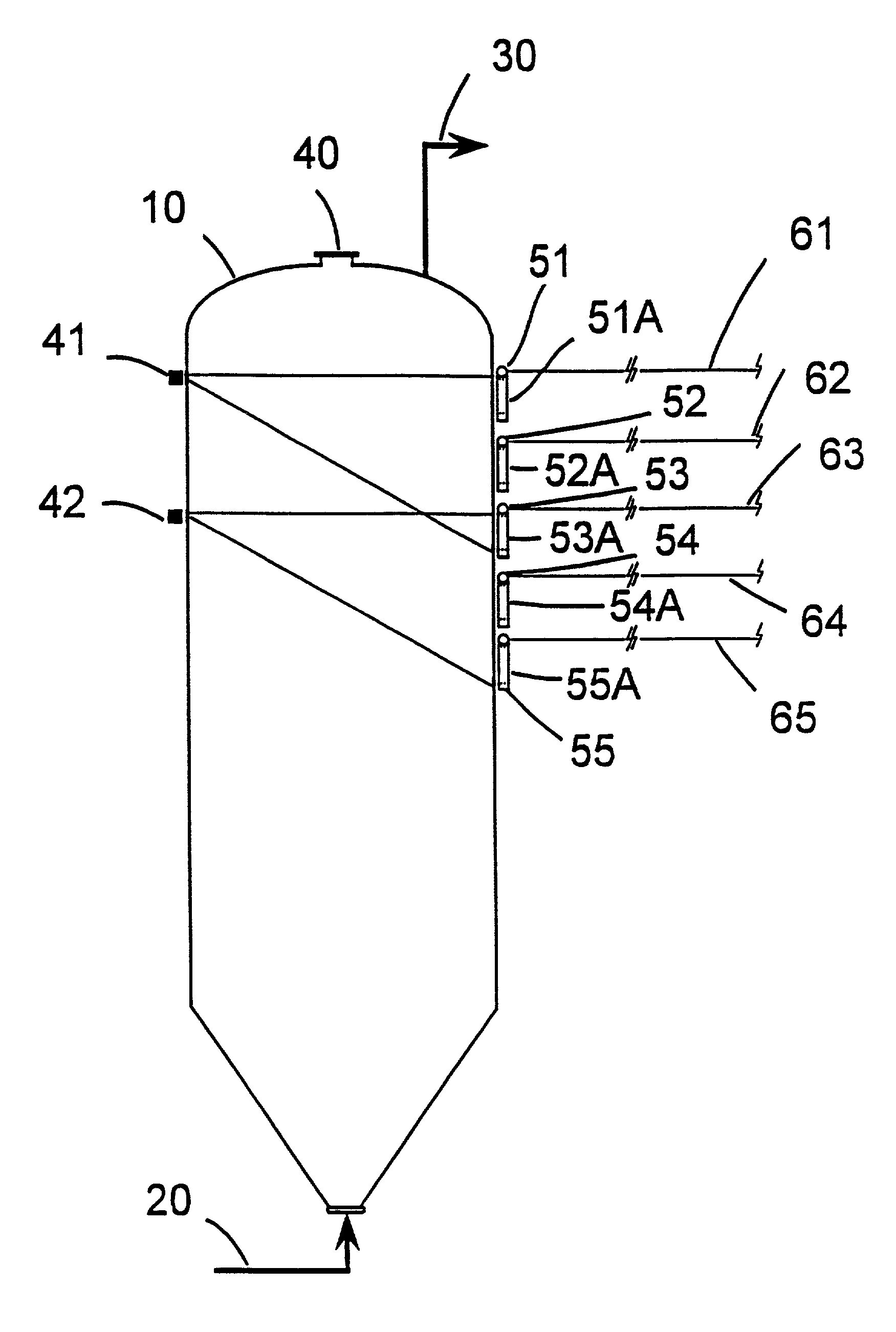

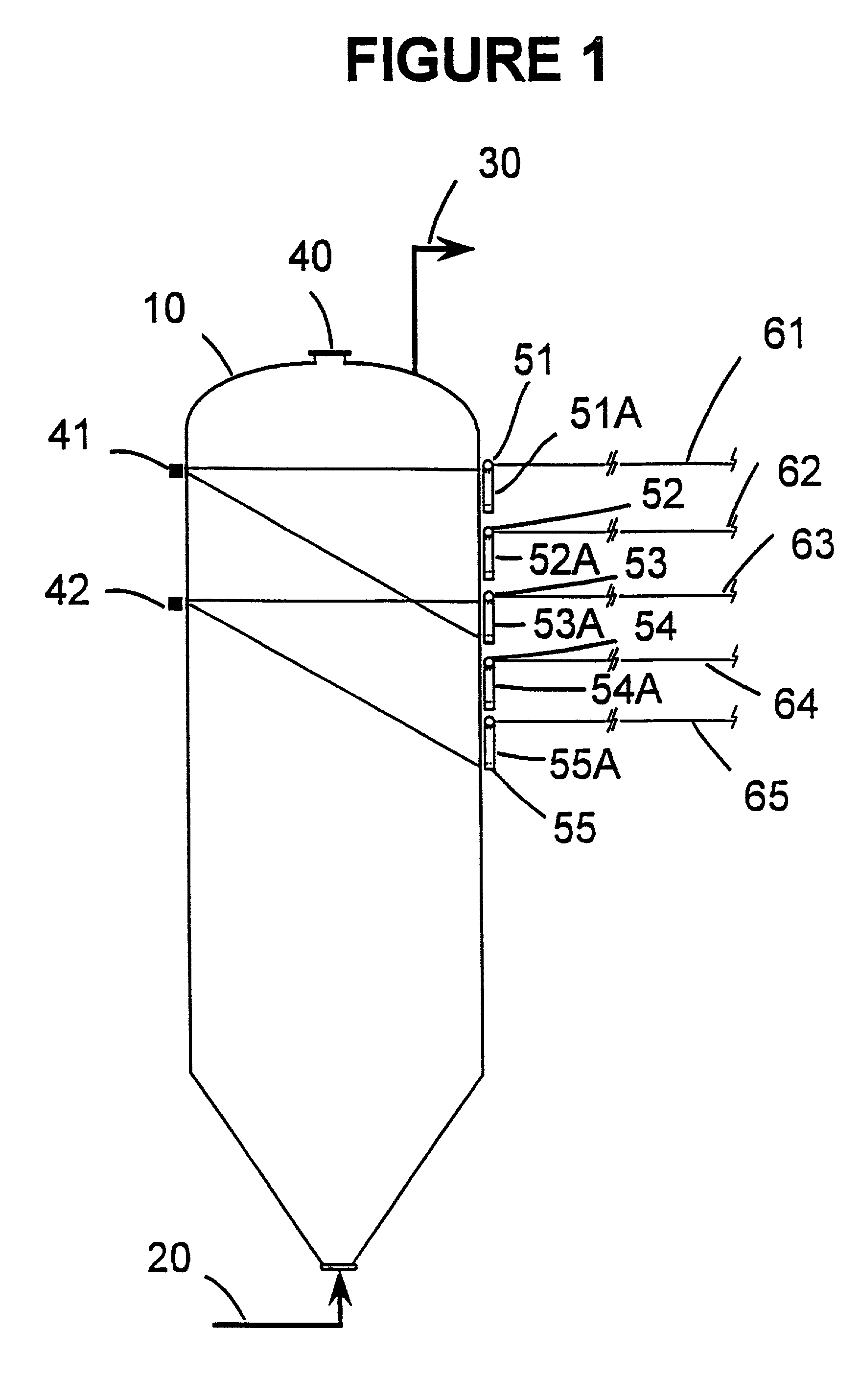

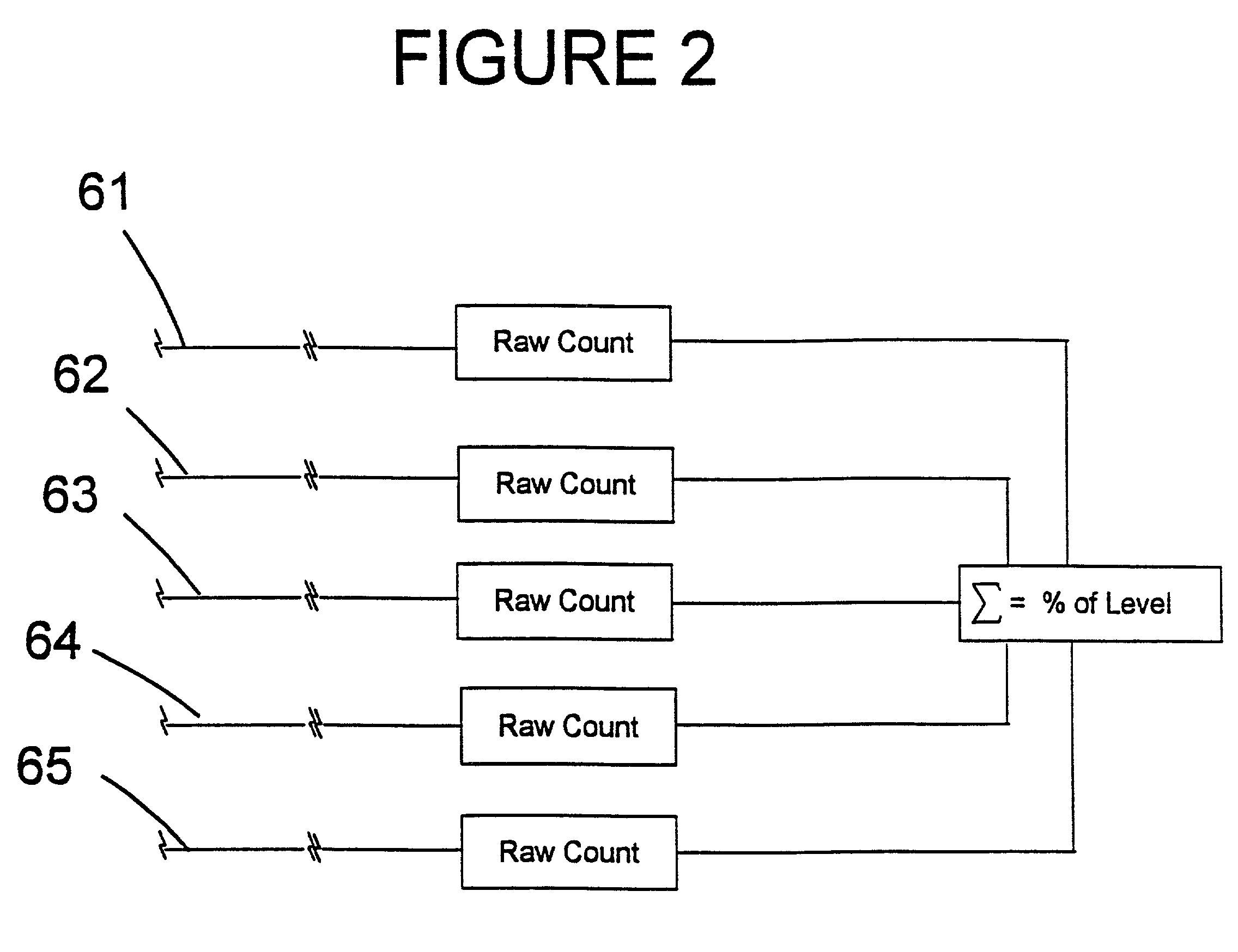

Apparatus and method for determining the level in a coke drum

ActiveUS7128812B1Reduce surface tensionThermal non-catalytic crackingCoke oven safety devicesHigh densityEngineering

A foam level in a delayed coking drum is detected by utilizing the varying density of the boiling mass in the coke drum which has larger bubbles and is less dense at the top and smaller bubbles and a higher density at the bottom. A plurality of radiation detectors are disposed on the drum and calibrated such that zero radiation is equivalent to 100 percent level. The percentage reading for each detector is multiplied by the fraction of height each detector is in relation to the total height of all the detectors to give a product and the products summed to give a level.

Owner:COKE DRUM LEVEL SYST

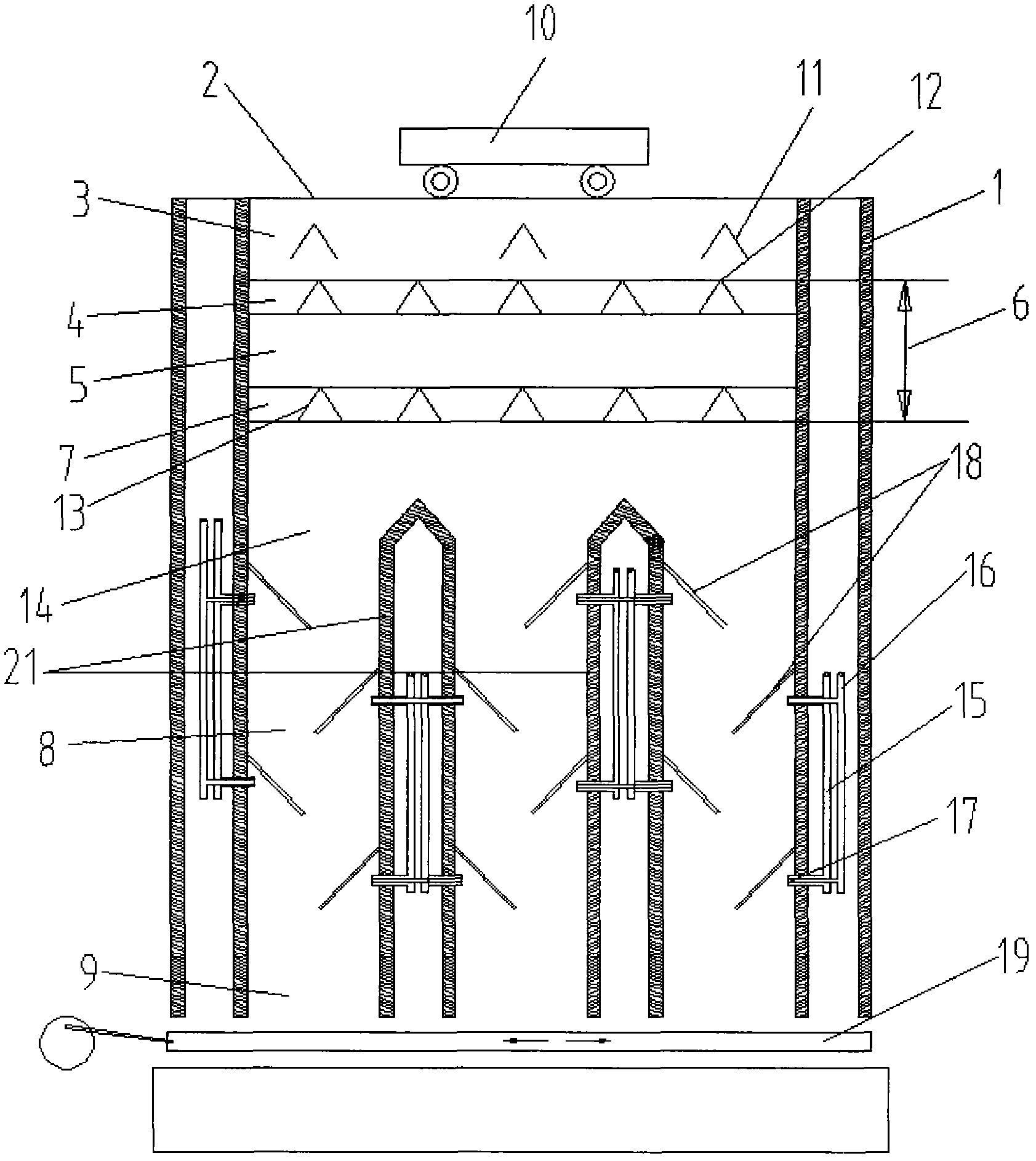

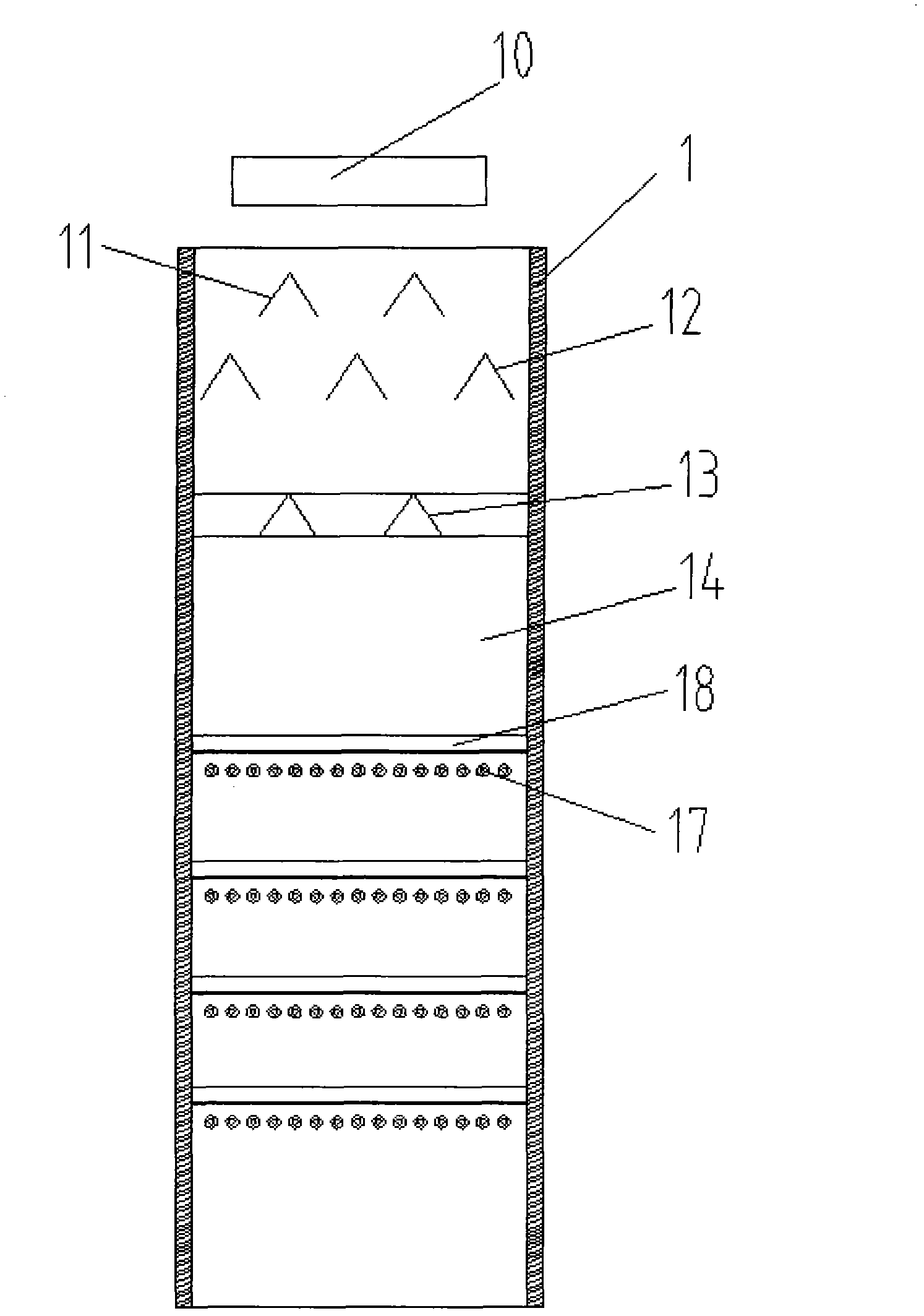

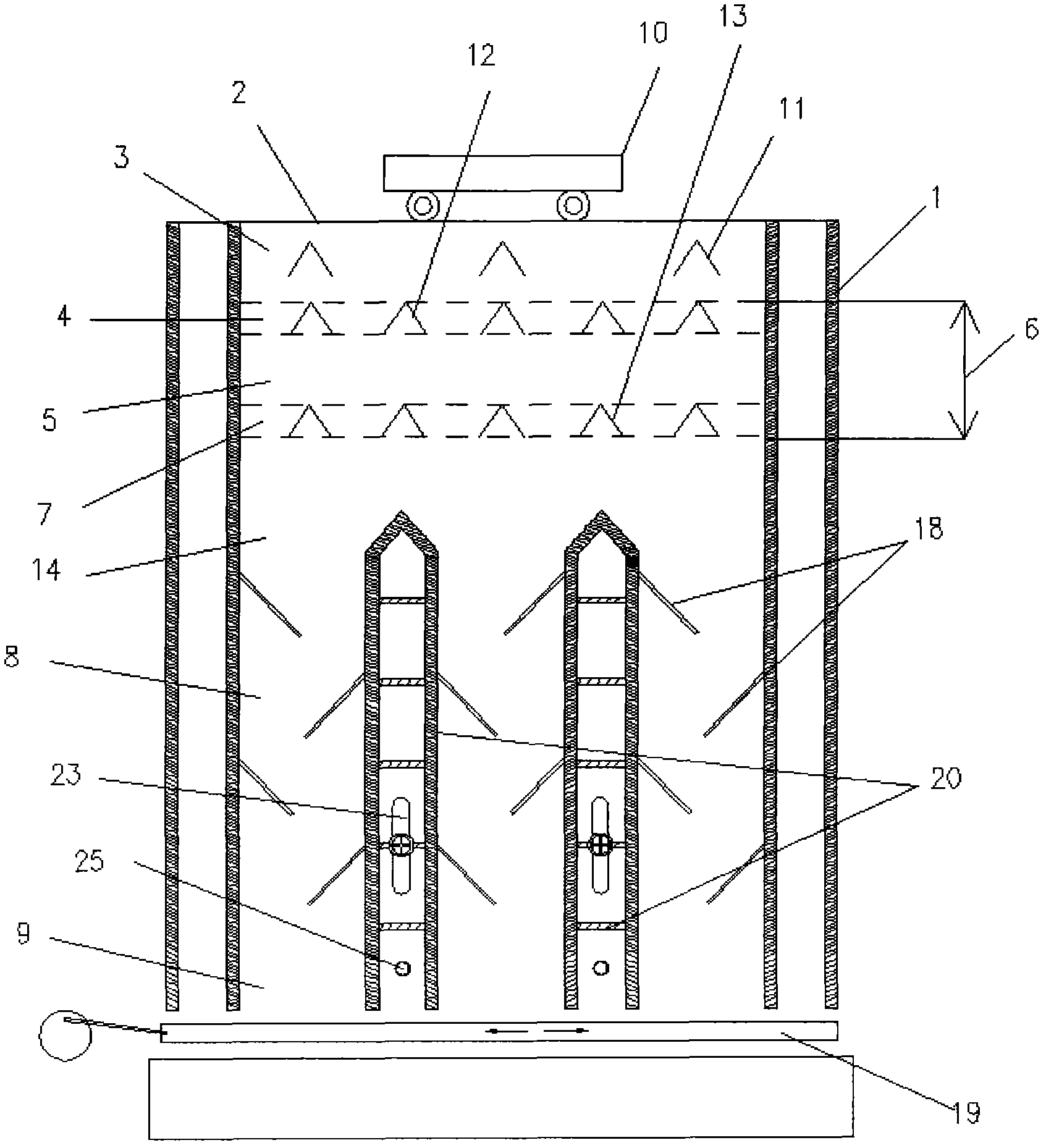

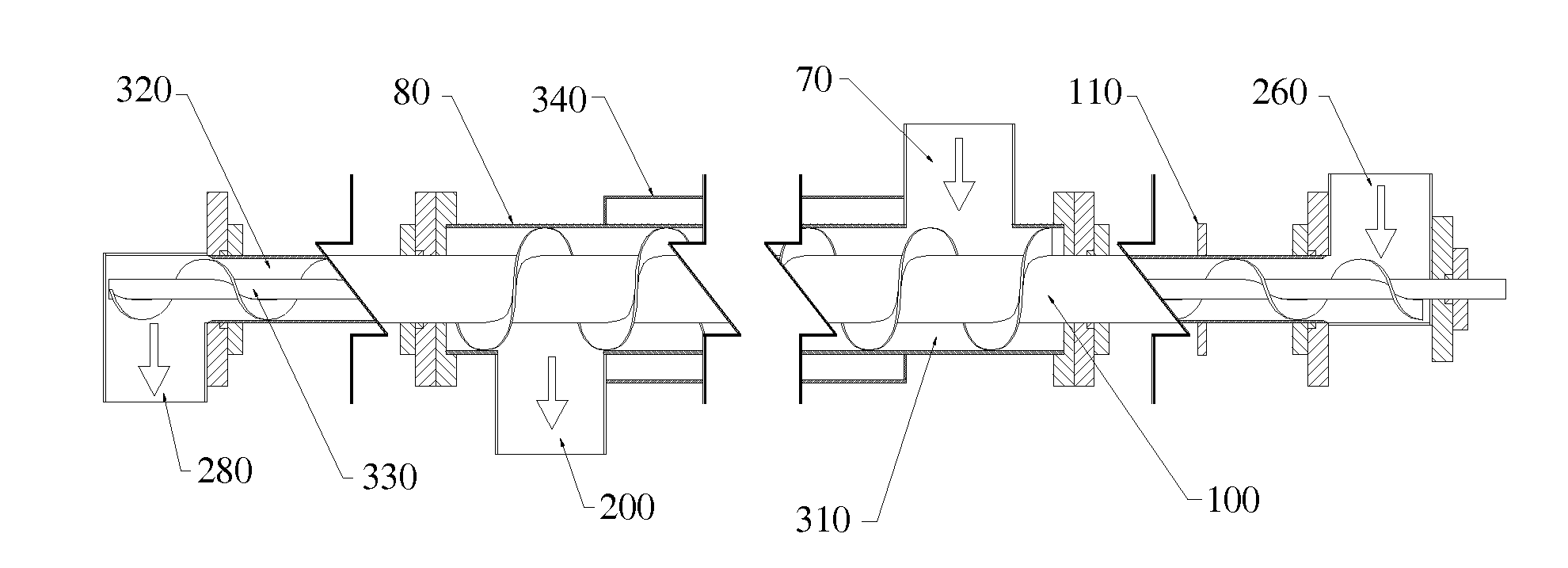

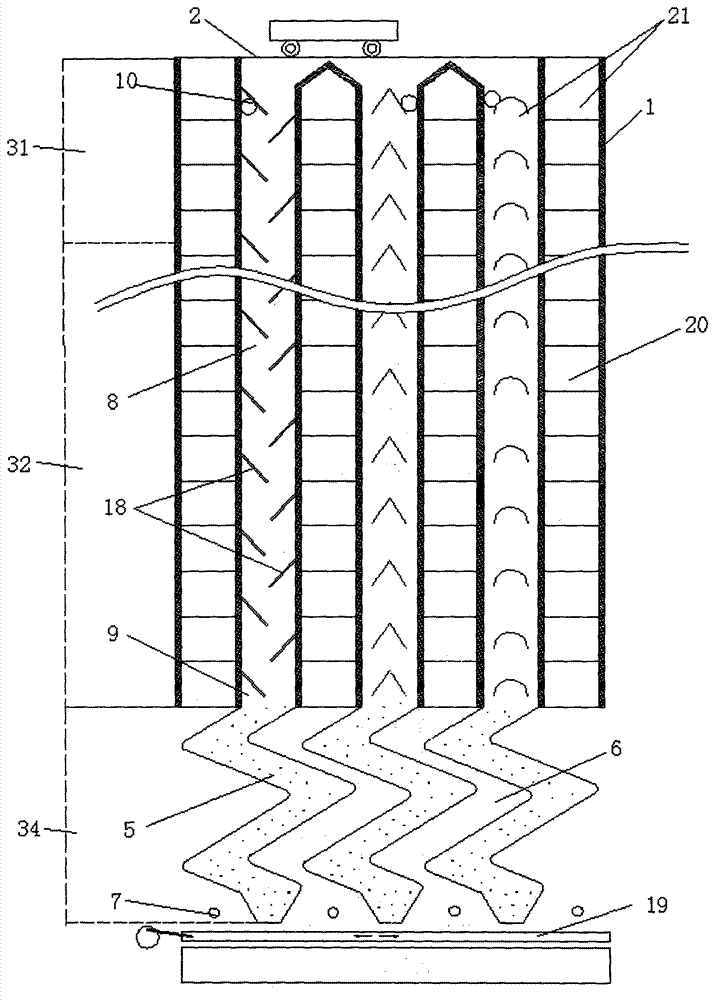

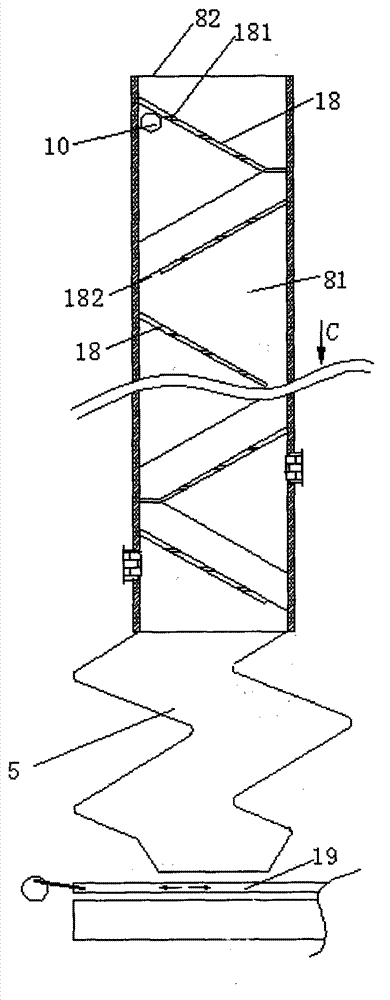

Powdered coal coking device and powdered coal coking method

InactiveCN103160291ACoking went wellEvenly heatedVertical chamber coke ovensPreheating coke ovensCombustionCarbonization

The invention discloses a powdered coal coking device and a powdered coal coking method. The powdered coal coking method includes: installing declivitous powdered coal bearing plates in a carbonization chamber layer by layer; forming multiple layers of heat exchanging units communicated mutually by utilization of the multiple powdered coal bearing plates, wherein a powdered coal accumulation region and a gas flow region which are based on a powdered coal bearing plate are arranged on each layer of heat exchanging unit, so that a powdered coal coking environment is formed in which powdered coal and gas can flow; distributing the powdered coal to each layer of the heat exchanging unit from top to bottom to enable a powdered coal layer distributed in a slanted mode to be accumulated on the powdered coal accumulation region on each heat exchanging unit; and by utilization of the gas flow region of each layer, heat-carrying gas generated through combustion or heating flowing to each heat exchanging region from bottom to top and exchanging heat with the powdered coal layer of each heat exchanging unit to generate powdery semi-coke, coal gas and coal tar.

Owner:XINJIANG MEITE MAGNESIUM

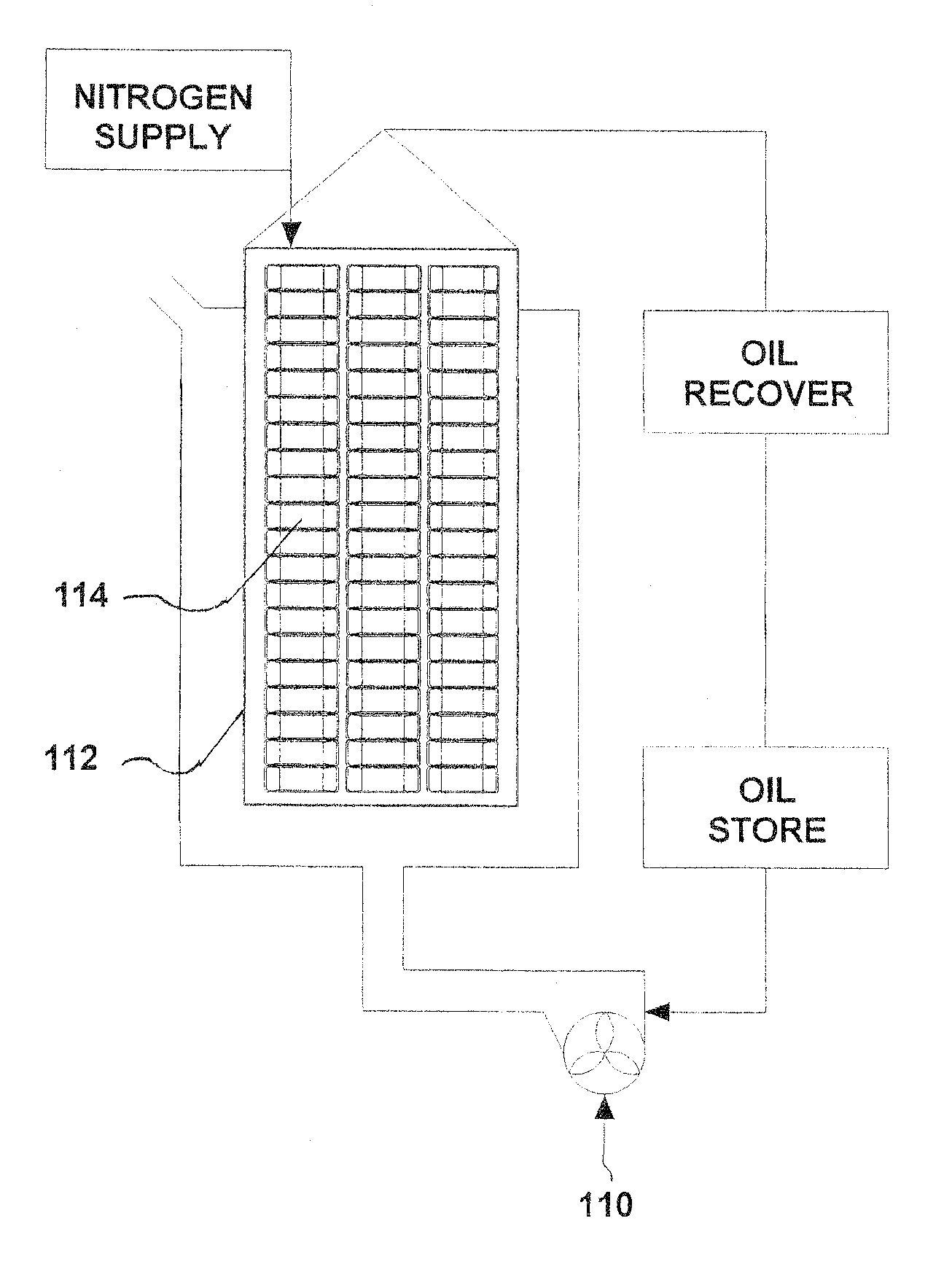

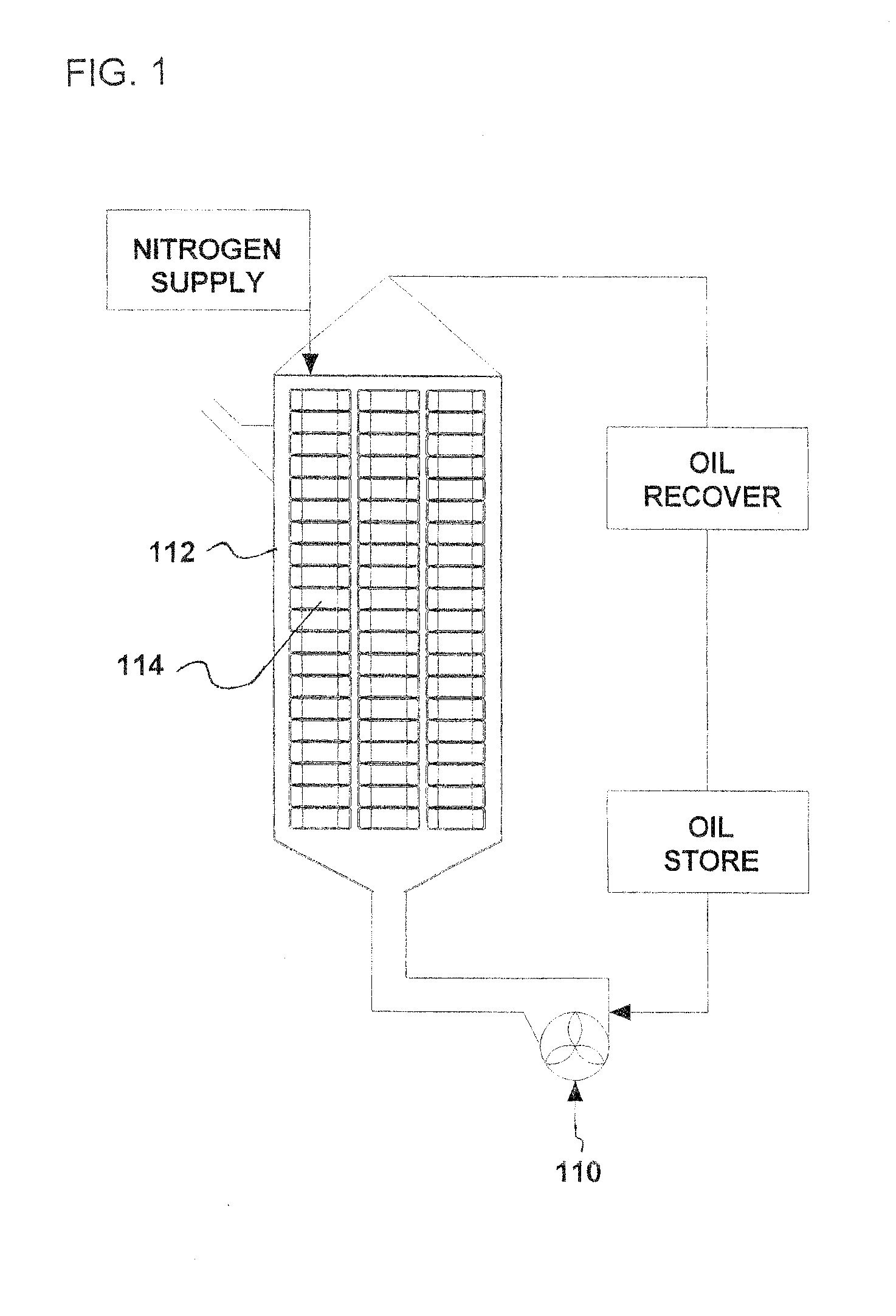

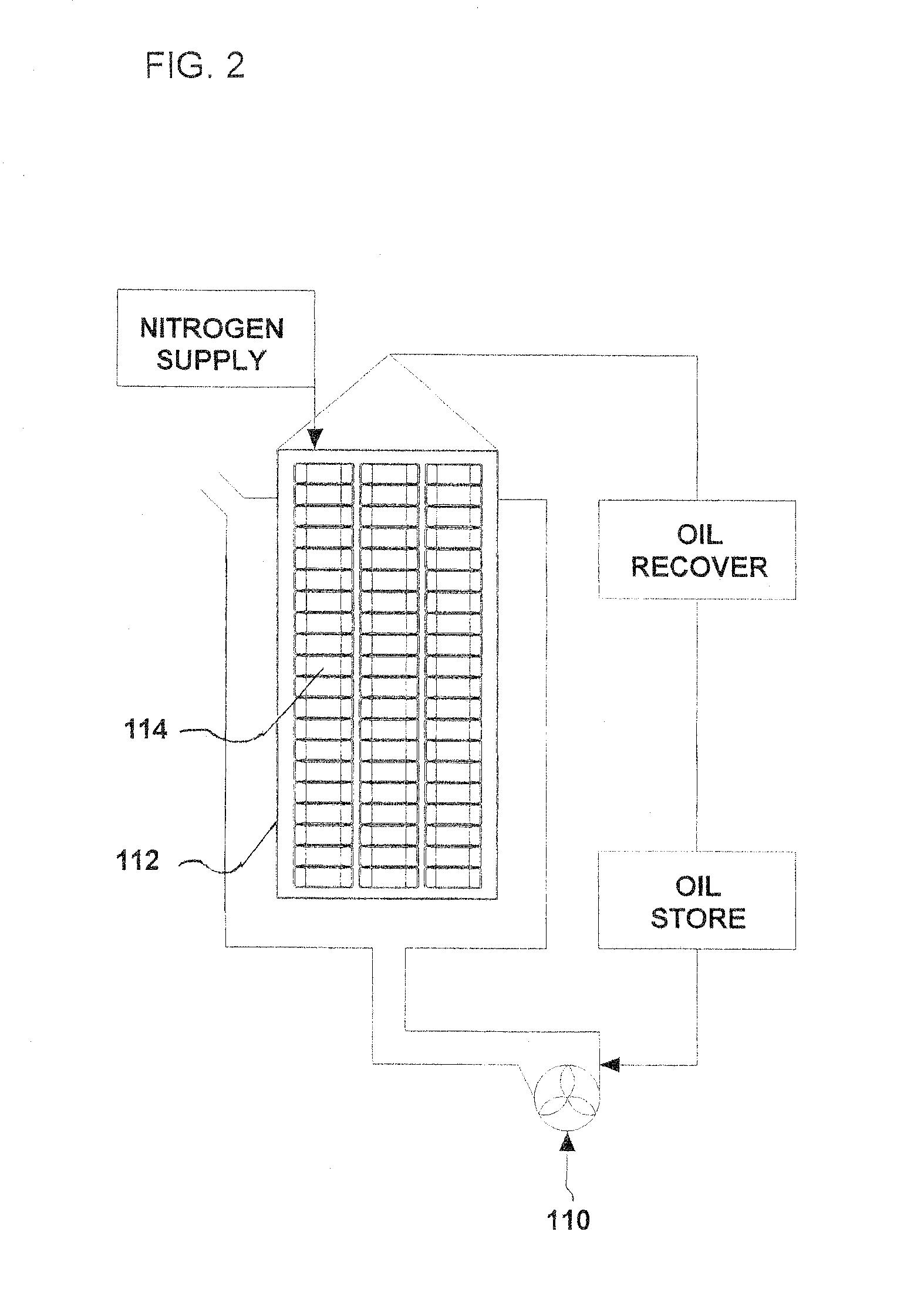

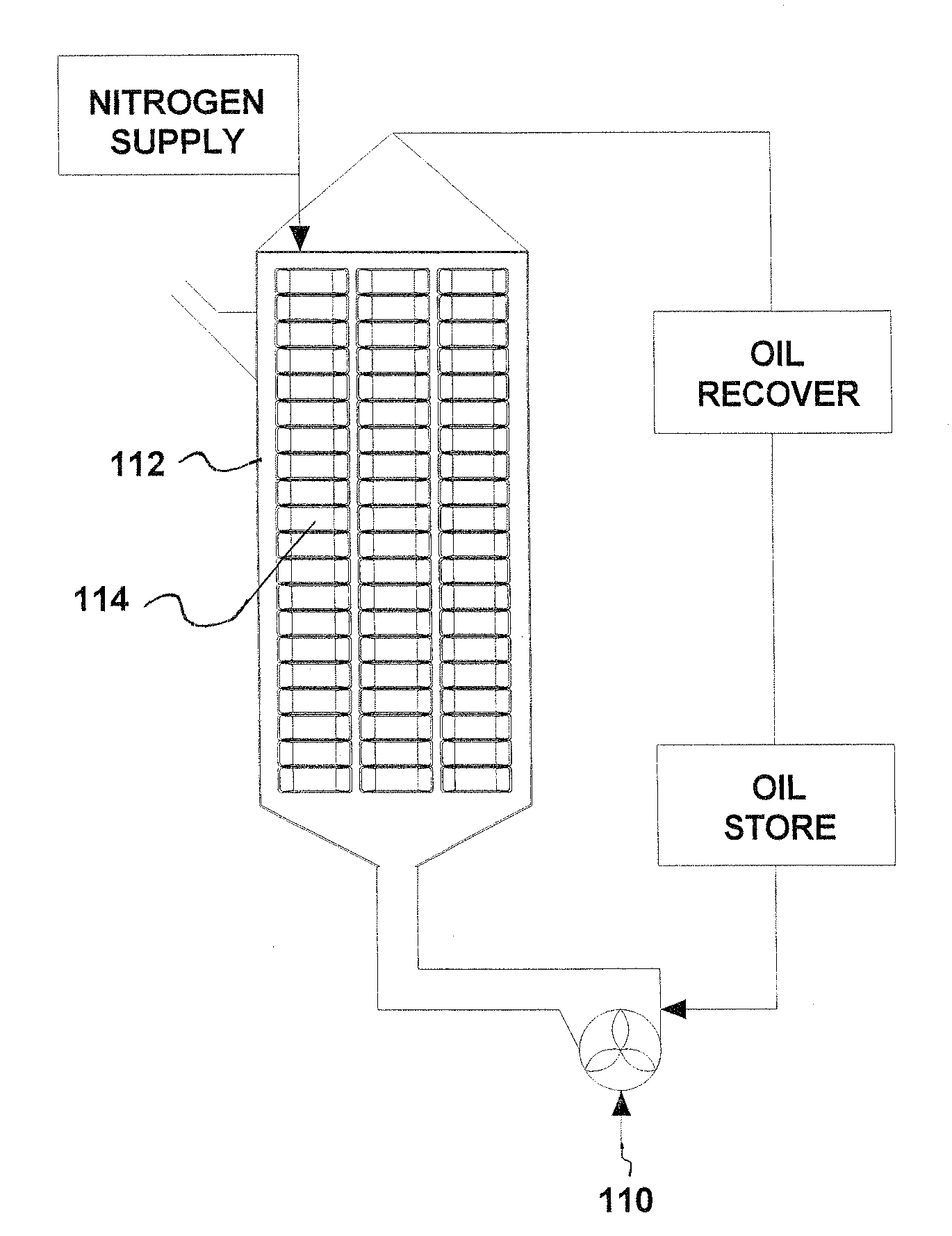

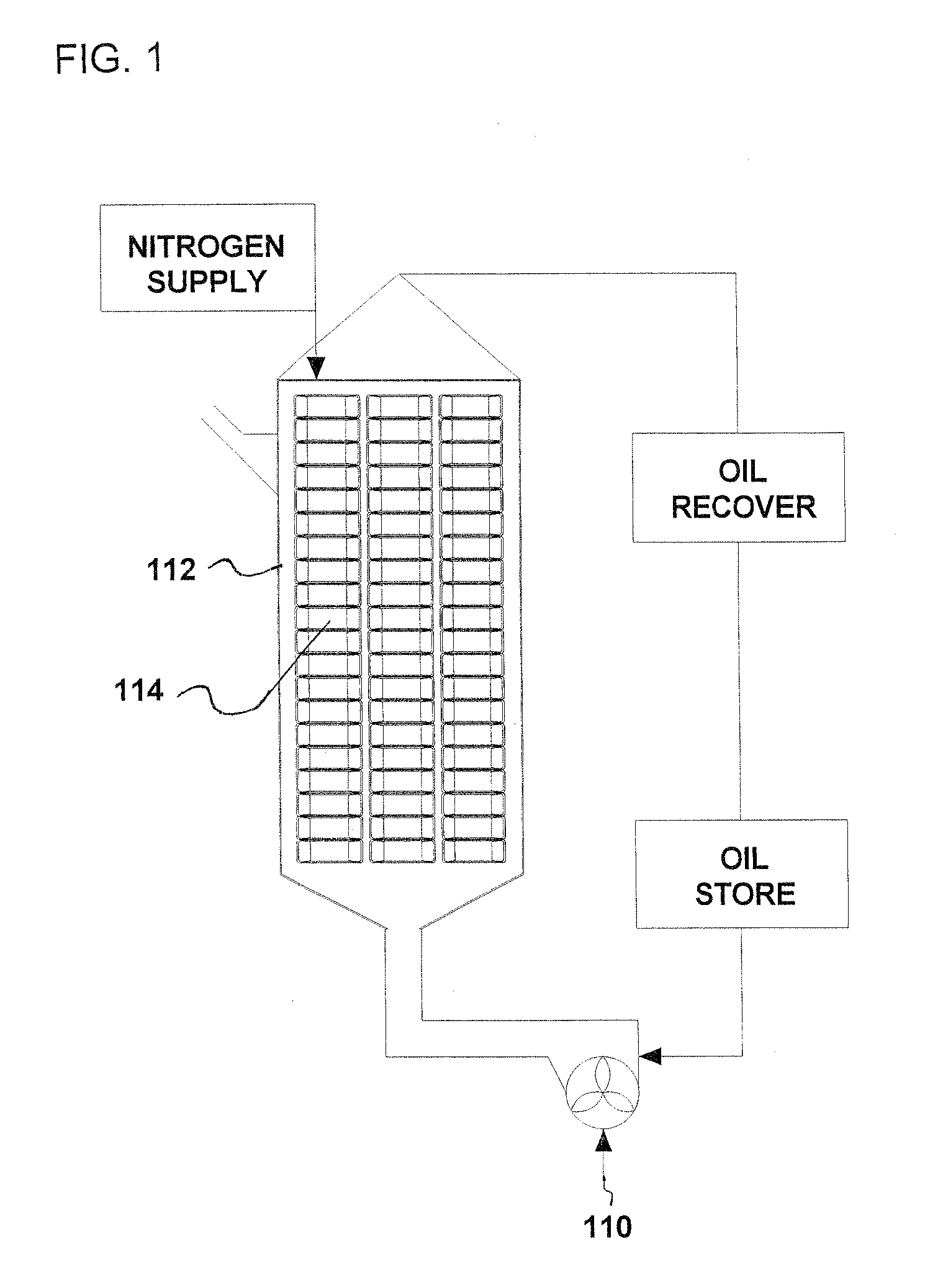

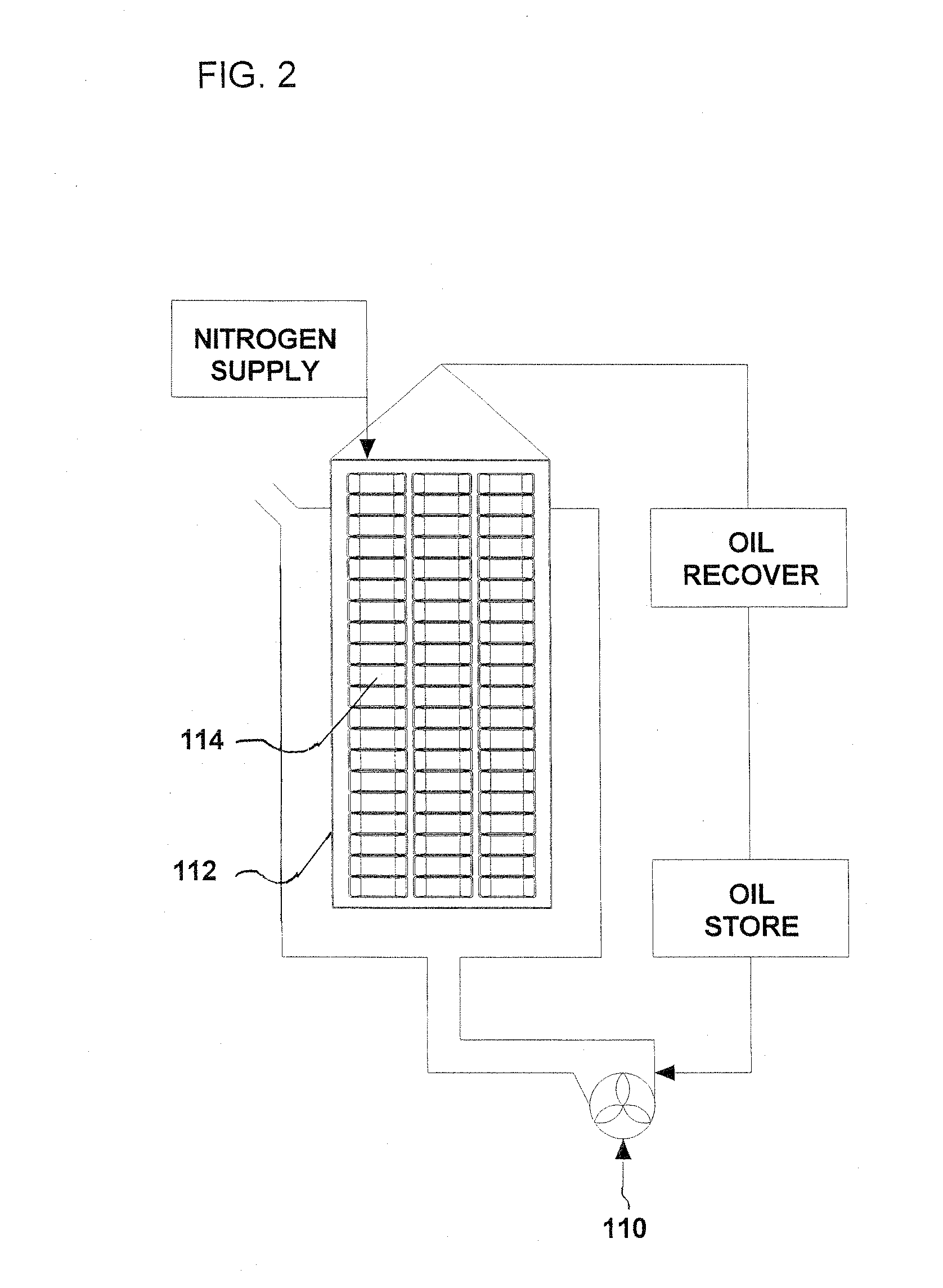

Method and apparatus for separating carbon product from used tire with microwave

InactiveUS7767187B2Improve good performanceMinimize interferenceElectrical coke oven heatingPigmenting treatmentMicrowave ovenDecomposition

An apparatus for separating carbon products from used tires includes a decomposing chamber into which used tires are charged, a nitrogen gas supply device that supplies nitrogen gas into the decomposing chamber, one or more magnetrons that generate microwave of predetermined frequency and one or more phase shifters that removes interference between microwaves generated by the magnetrons, a receiving plate that is adapted to receive carbon black and iron cores generated by the decomposing process, a tire support that is adapted to support used tires, an opening and closing device that opens or closes a door on which used tires are placed, conveyor belt that moves carbon black and iron cores to a desired location after decomposition is complete, and a cooling plate that is provided in an upper portion of the apparatus and cools down gaseous oil that is generated by decomposition by microwave into liquid oil.

Owner:HEALTHWELL MEDICAL INC

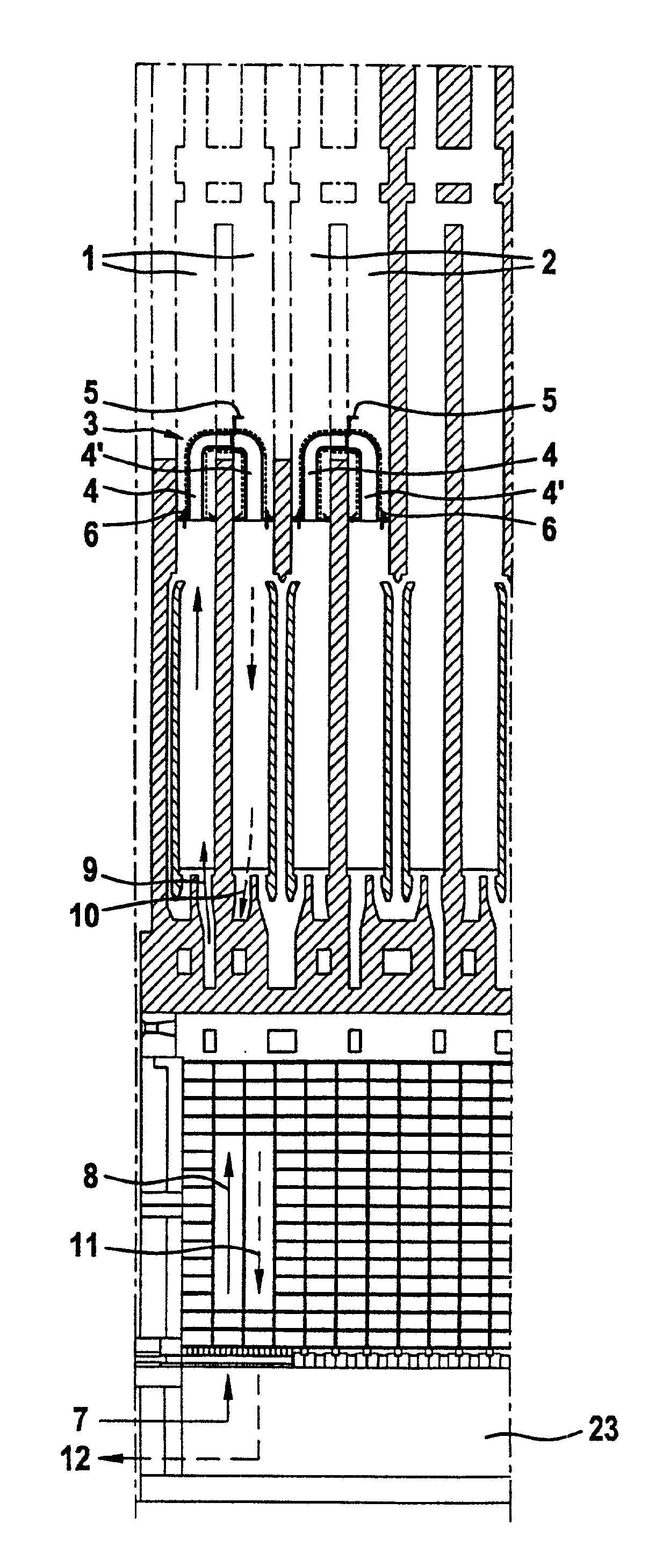

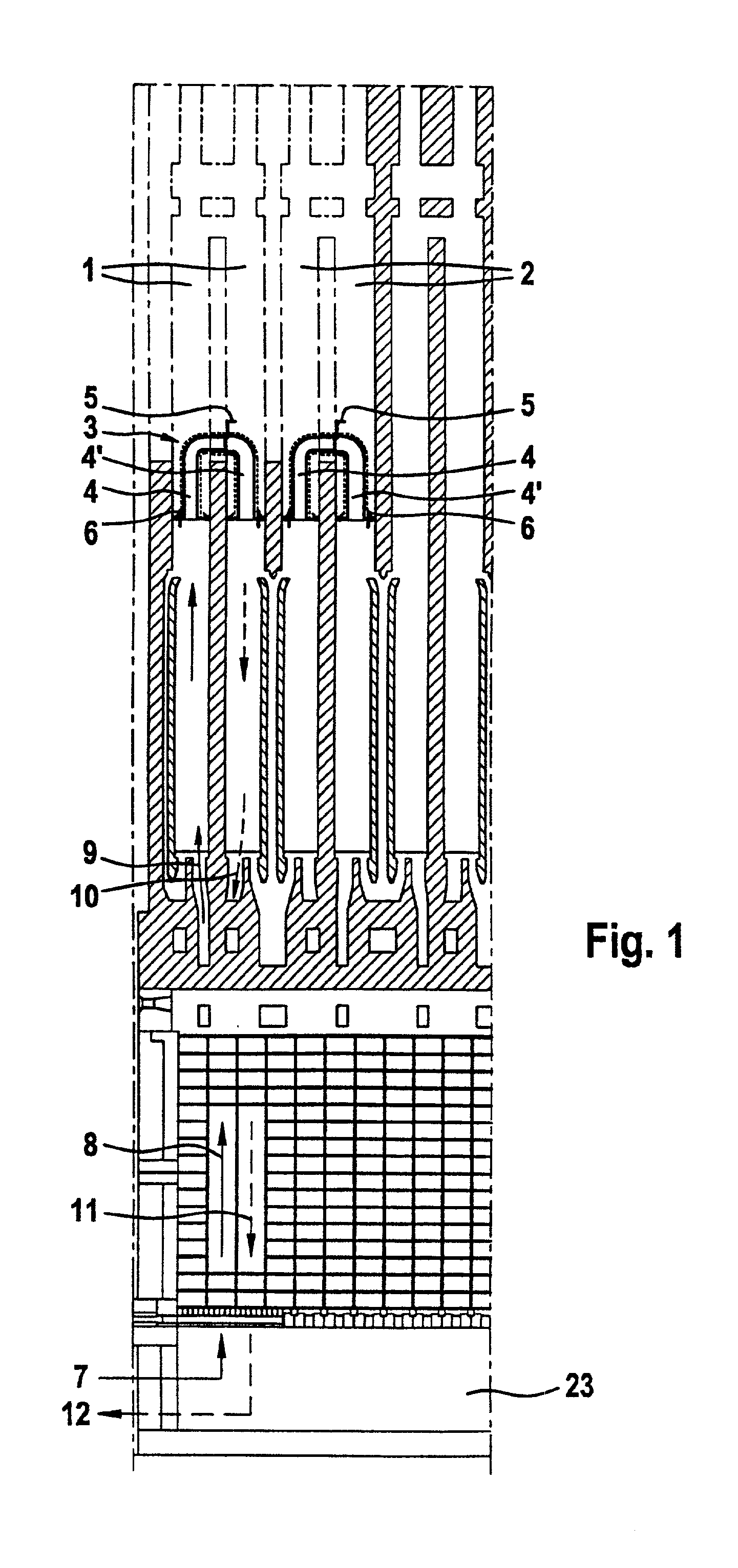

Method of hot-repairing the heating flues of a coke-oven battery and device for carrying out said method

InactiveUS7037409B1Simple and energy-efficient heatingLow costCombustible gas coke oven heatingLinings repairCombustionExhaust fumes

A method and a device for the hot-repairing of the heating flues of a coke-oven battery according to which the completed sections of a heating flue still under construction are heated by means of a heated gas. The heated gas comprises the air usually provided for combustion in the heating flues during coking operations. The air is guided through the flow paths provided for in the coke-oven battery for combustion air and waste gases as well as through the regenerator, heated as it passes through the flow paths and then guided through the heating flues to be repaired. The completed section of the heating flue is separated from the non-completed portion by an air-reversion device that also directs the heated air.

Owner:UHDE GMBH

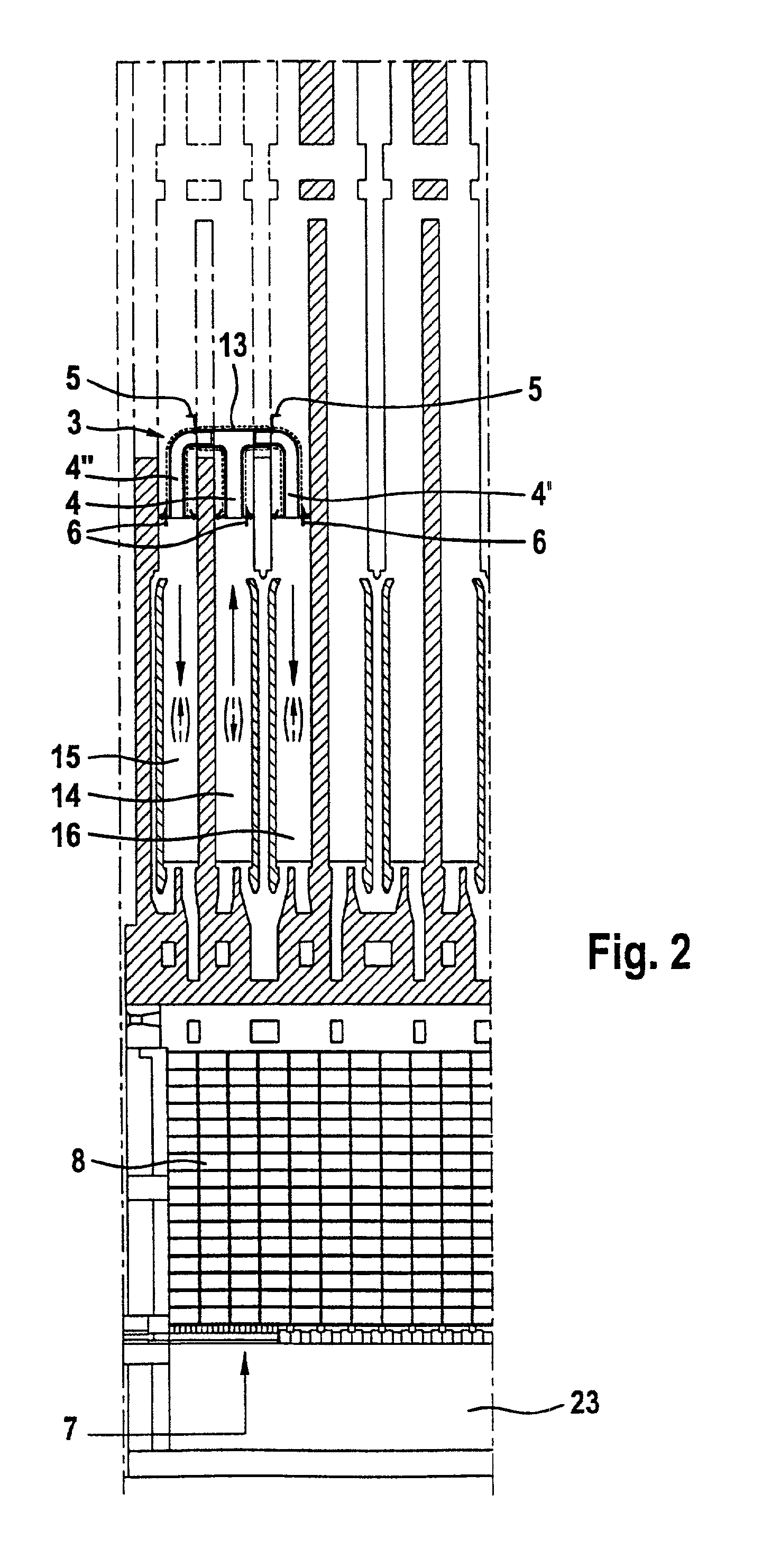

Method and device using pyrolysis for recycling used printed circuit board

ActiveUS8308843B2Ensure safetyAvoid burnsPreheating coke ovensFinal product manufactureCombustionProcess engineering

A method and a device using pyrolysis for recycling used printed circuit board in which water (moisture) is introduced in the pyrolysis process and a fully sealed low pressure environment is established to ensure that no combustion happens in the pyrolysis process to enhance the safety of the process; pyrolysis gases generated in the process are concentrated and purified to provide useful fuels or chemical materials; therefore, the present invention can reduce process cost, improve recycling efficiency and provide processing device with high safety, thereby enhancing industry usability.

Owner:WU HSIEH SEN

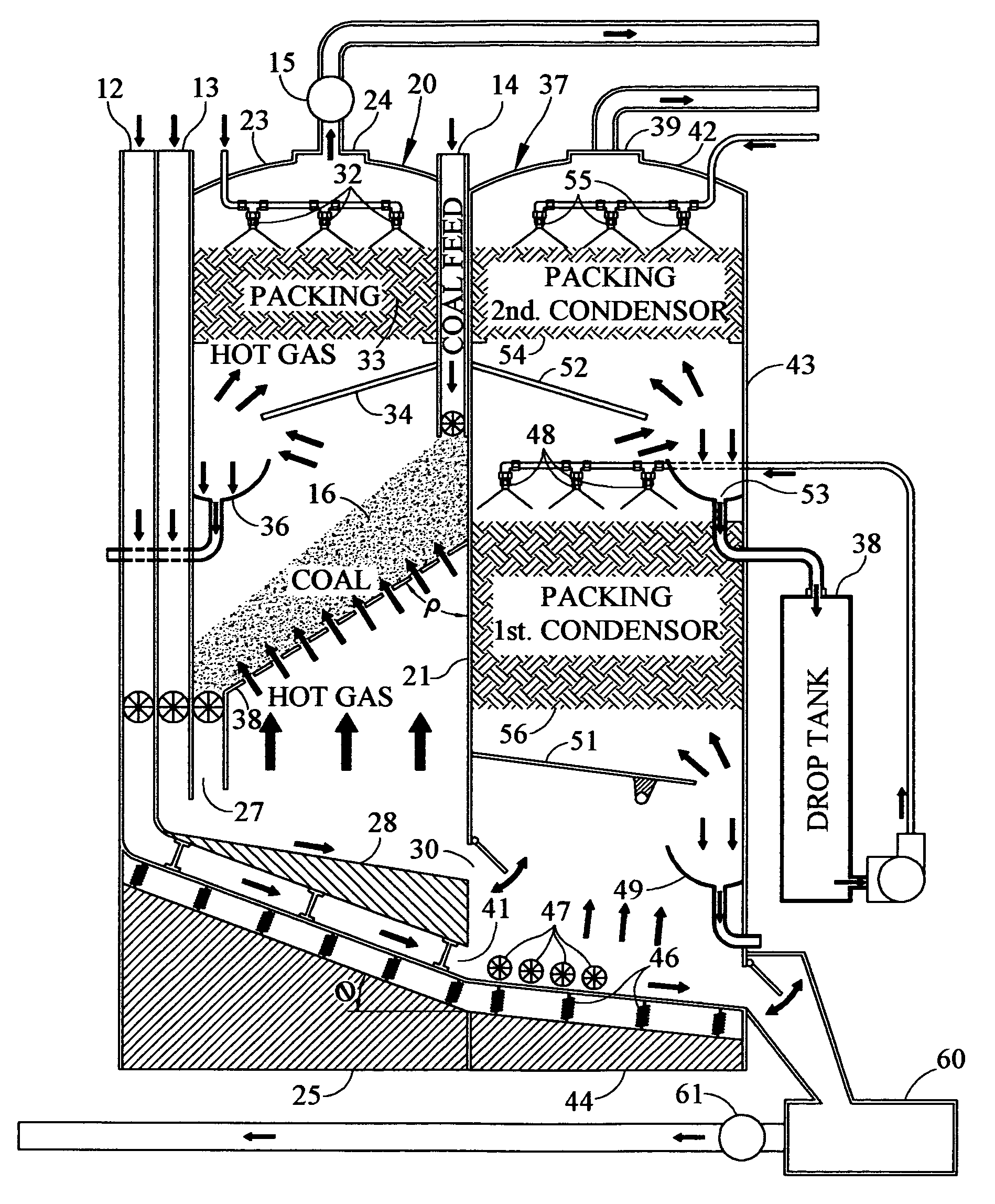

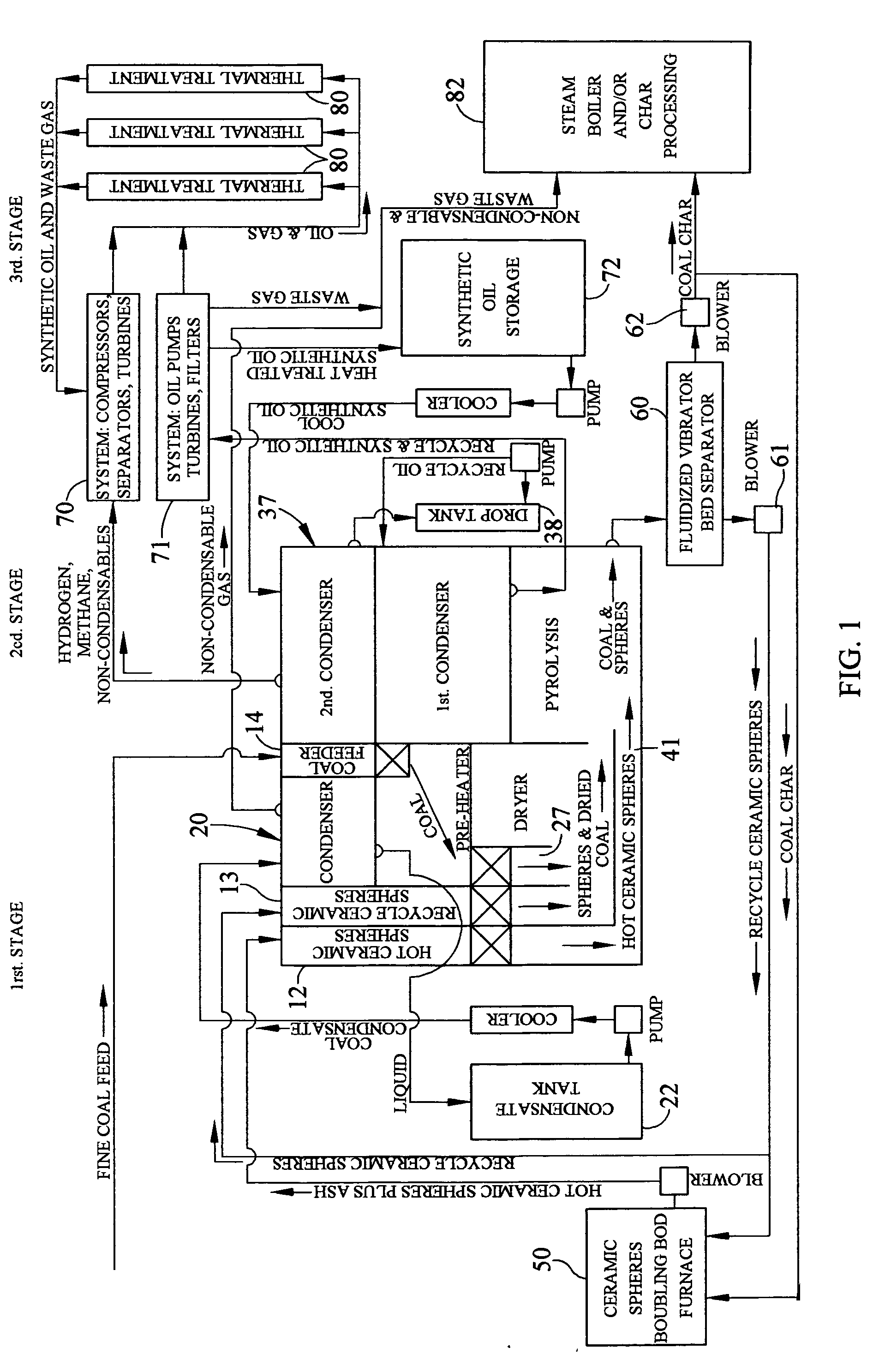

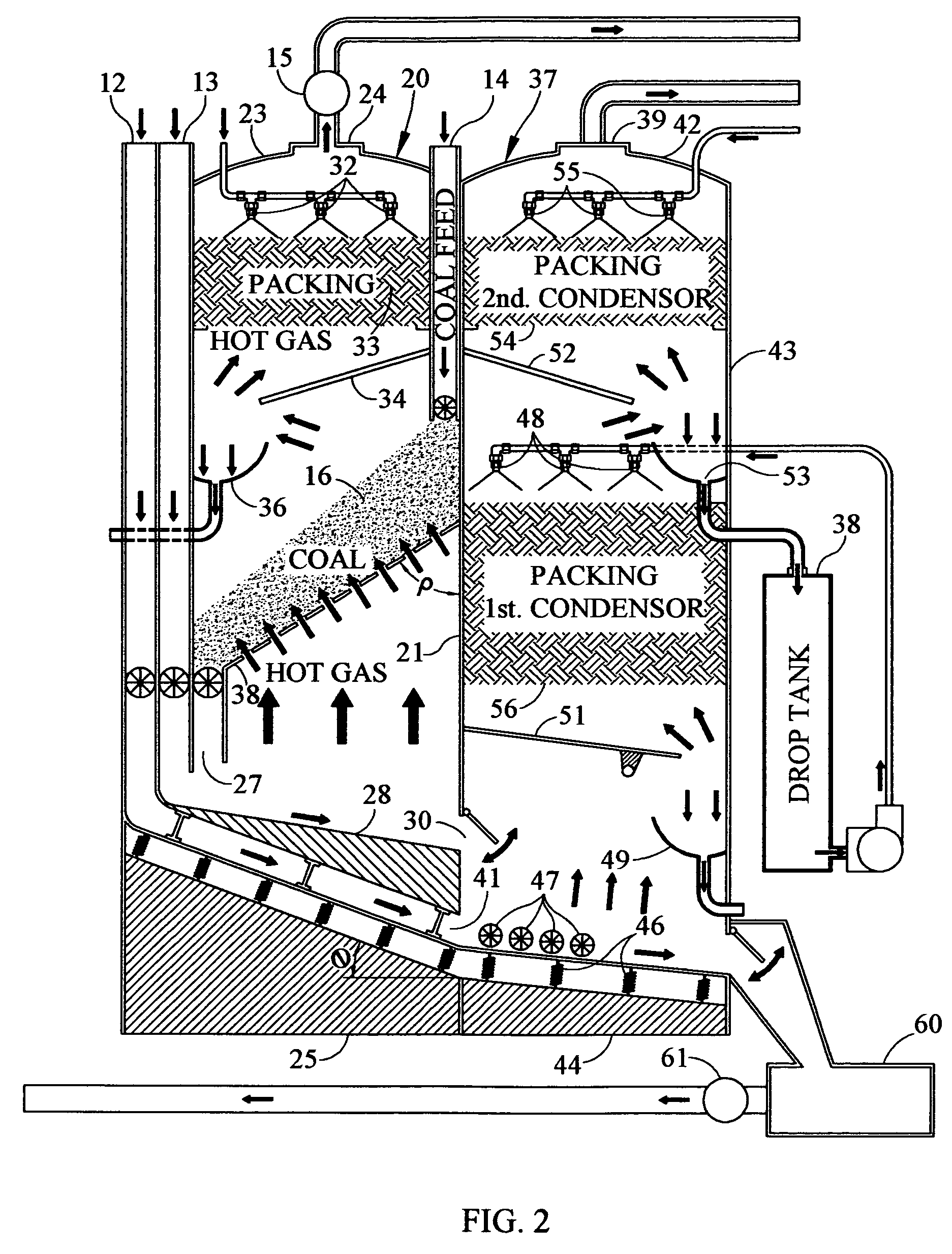

Process for producing synthetic oil from solid hydrocarbon resources

InactiveUS20060219544A1Preheating coke ovensDirect heating destructive distillationHydrocotyle bowlesioidesHydrocarbon

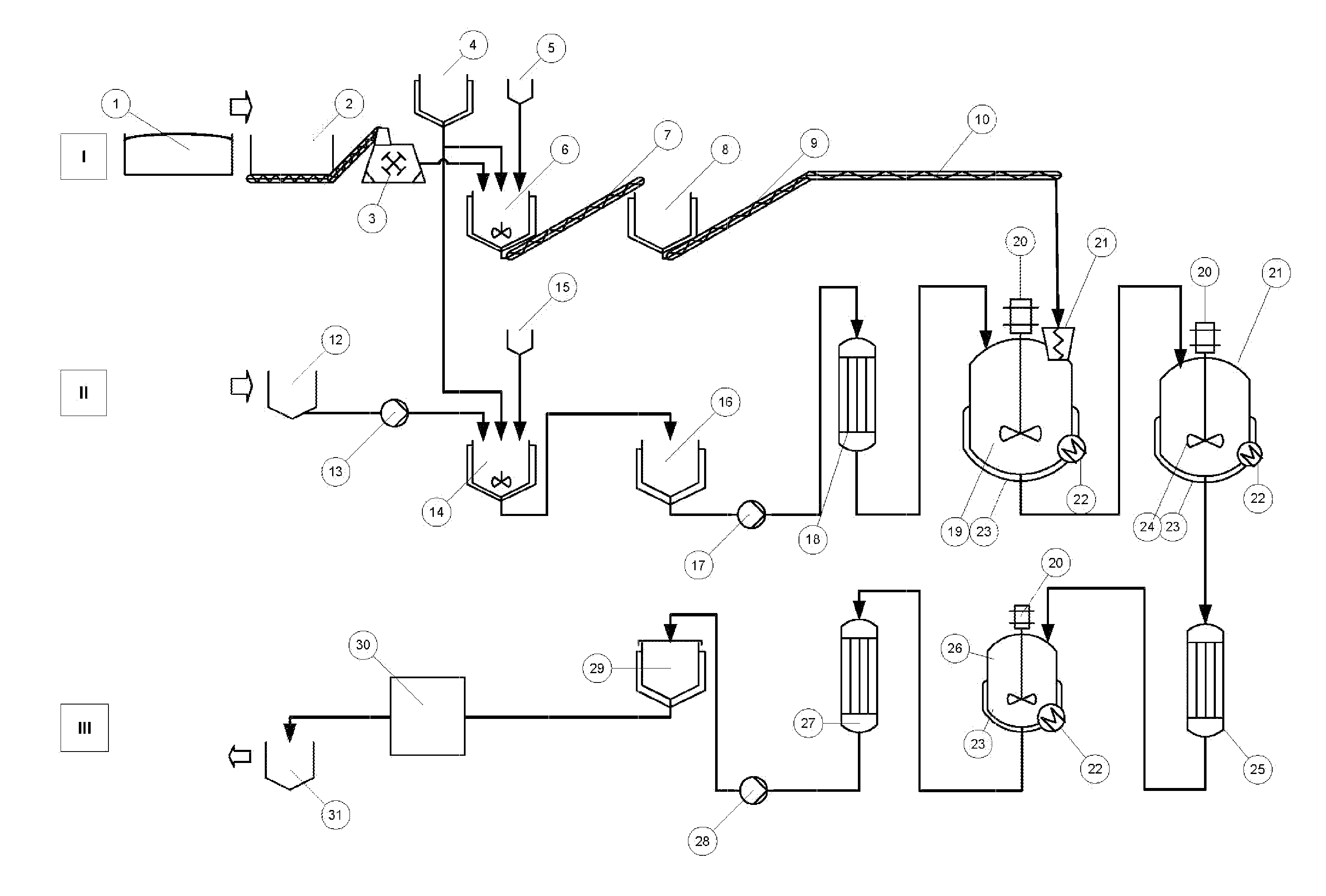

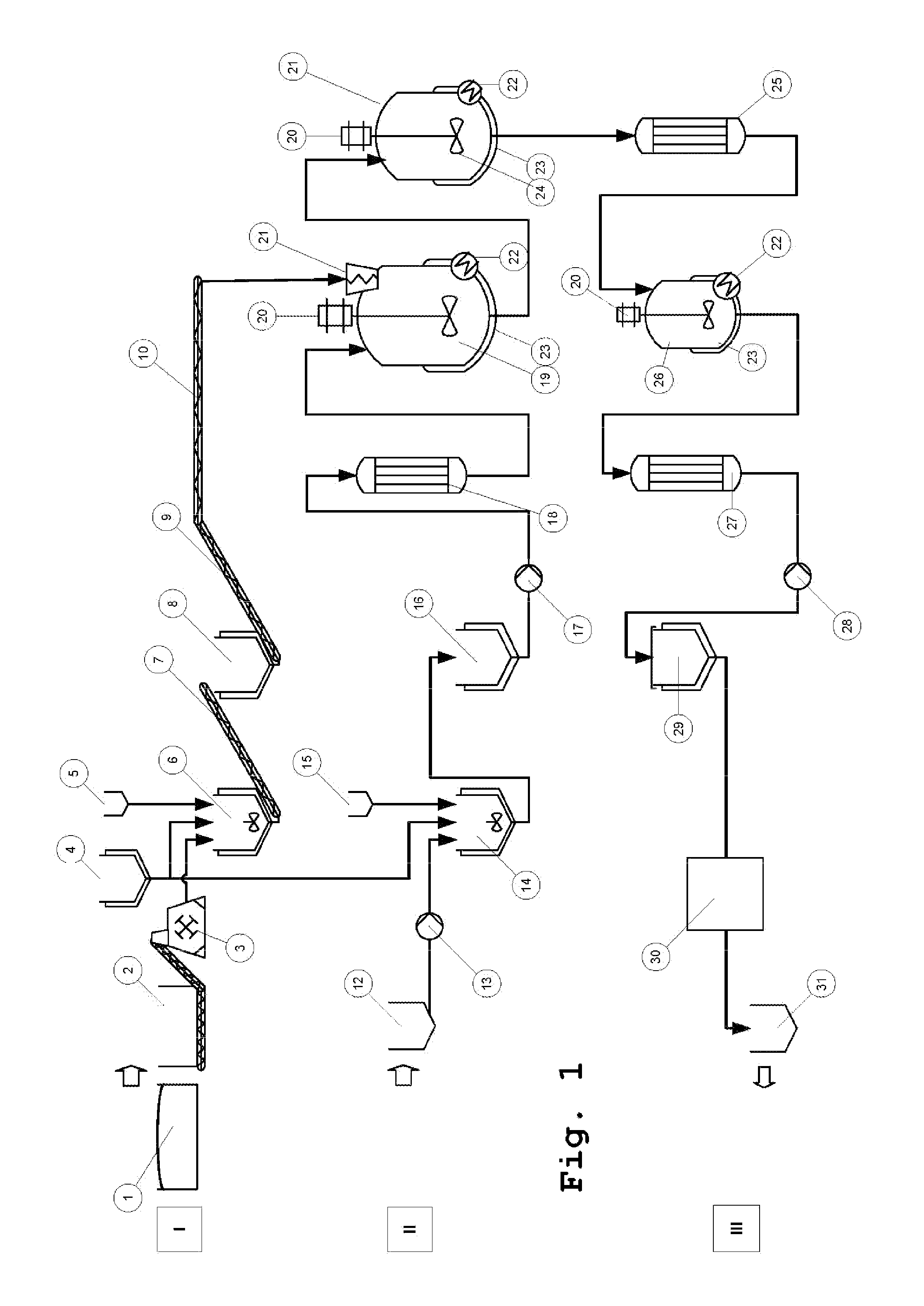

The present development is a multistage process for converting solid hydrocarbon resources into synthetic oil. The process comprises a raw hydrocarbon material treatment stage, followed by a pyrolysis stage, and then a synthetic liquid upgrading stage. Throughout the process, heat is transferred to the hydrocarbon resources via recyclable ceramic spheres.

Owner:DEVORE CLYDE WESLEY

Coke oven drying process

The invention provides a coke oven drying process. The coke oven drying process comprises the following steps: under the condition that the temperature of a coke oven is lower than 800-850 DEG C, combusting gas in a carbonizing room, and uniformly heating a coke oven masonry through heat transfer; under the condition that the temperature of the coke oven reaches 800-850 DEG C, performing heating for 10-15 days through a basement coke oven coal gas system to enable the temperature of the coke oven to slowly rise to 1000-1070 DEG C, wherein the pressure of coal gas in a basement branch pipe is controlled to be not smaller than 500Pa; after the coal gas of the basement coke oven coal gas system is switched on for 7-8min at each time, switching off the coal gas of the basement coke oven coal gas system for 60-70s; cyclically performing the switch-on step and the switch-off step in sequence. The coke oven drying process has the advantages that the operation is simple and practical; the cost input is eliminated or low; the oven drying temperature can be effectively controlled to slowly rise; the damage to an oven body caused by sudden rise and drop of the oven temperature due to interrupted heating is avoided; life prolonging of the coke oven can be promoted.

Owner:攀钢集团西昌钢钒有限公司

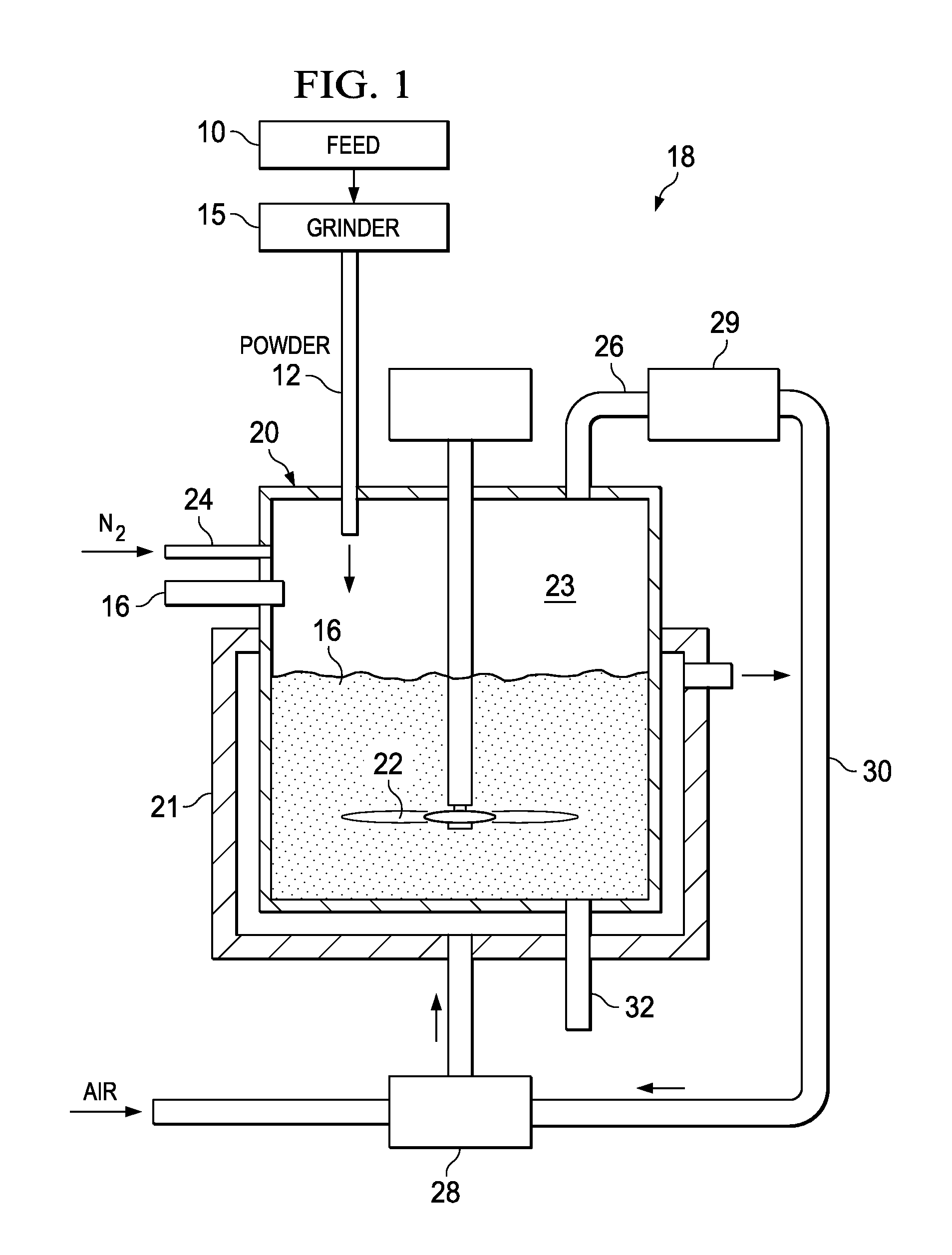

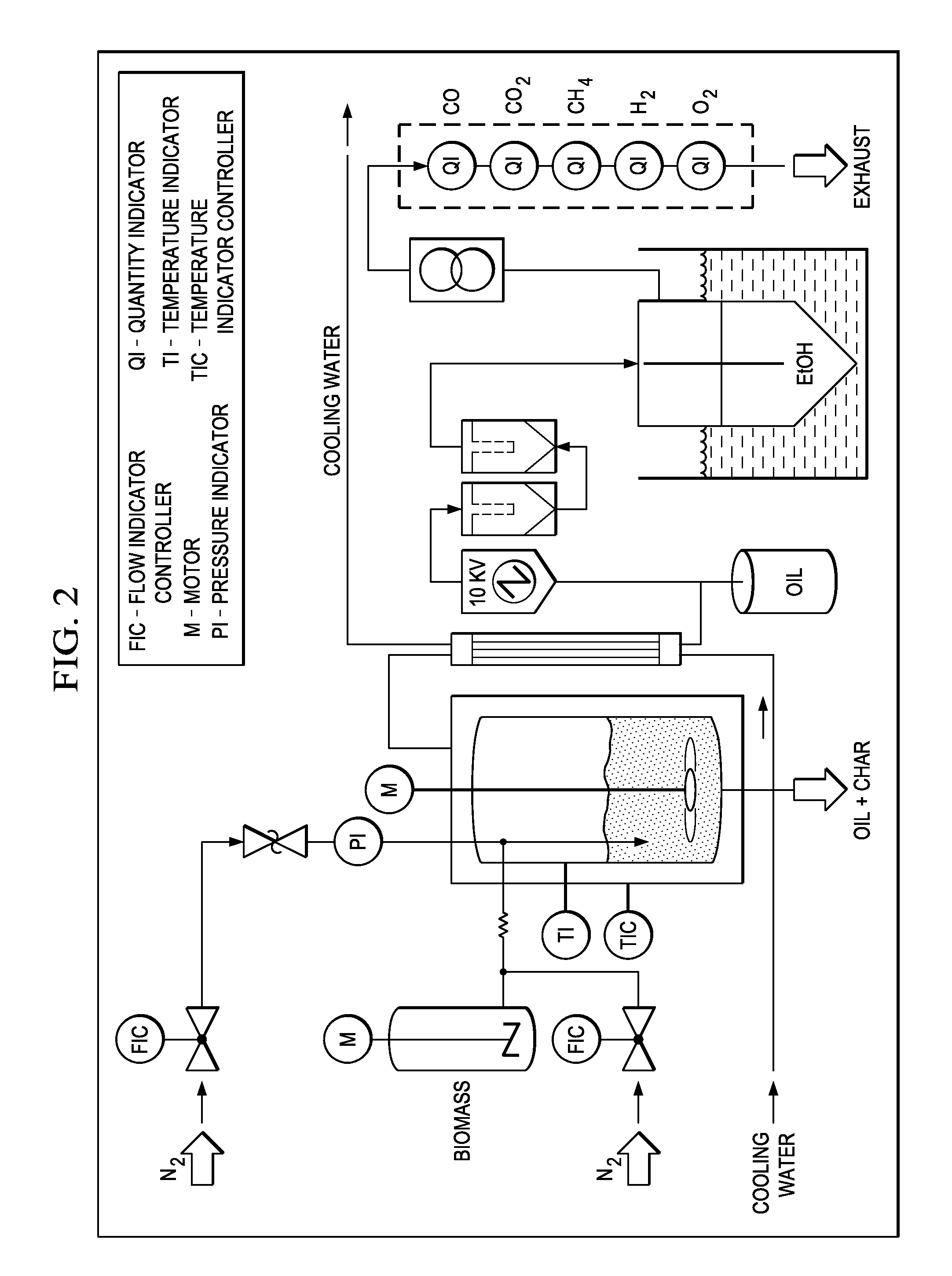

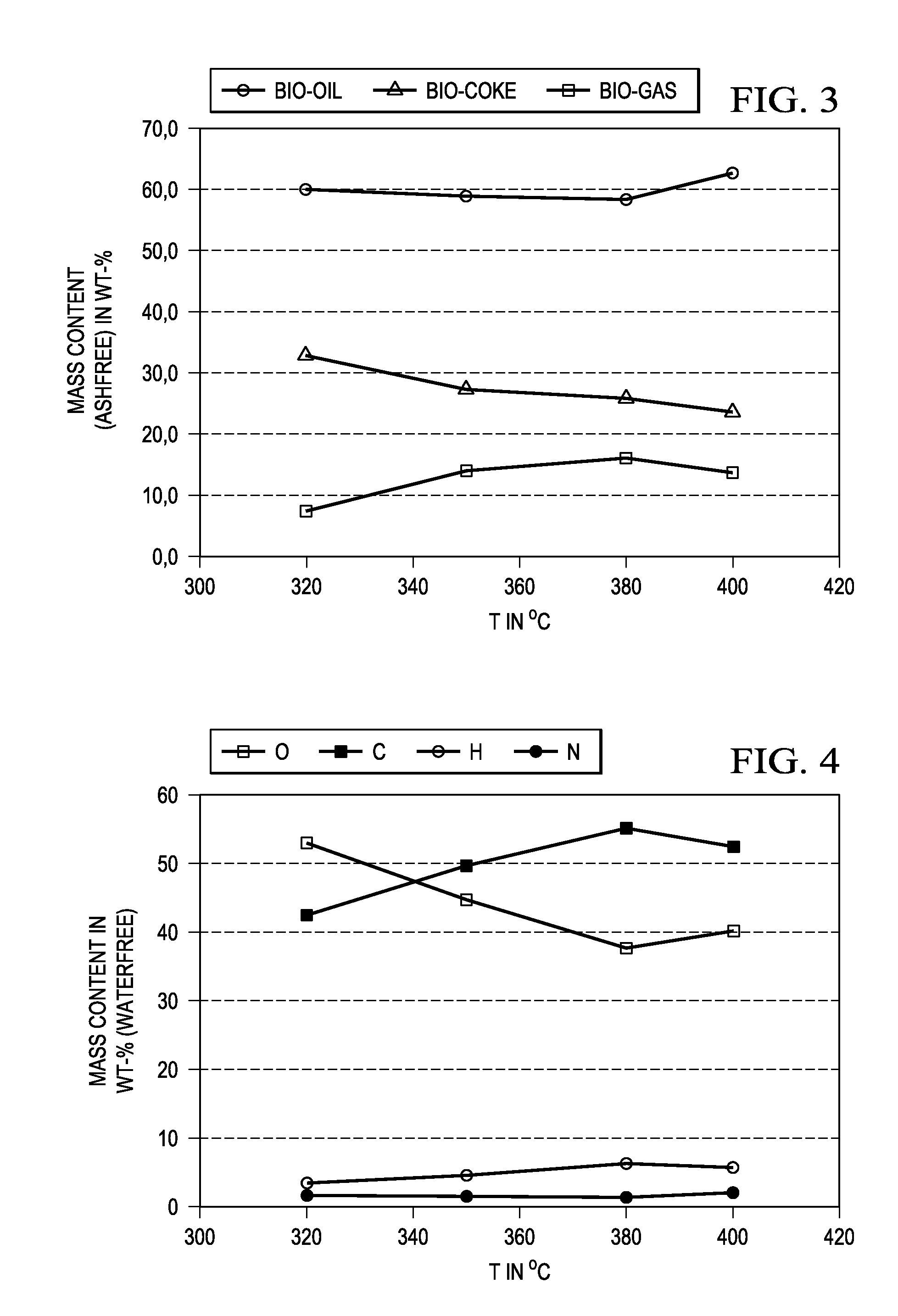

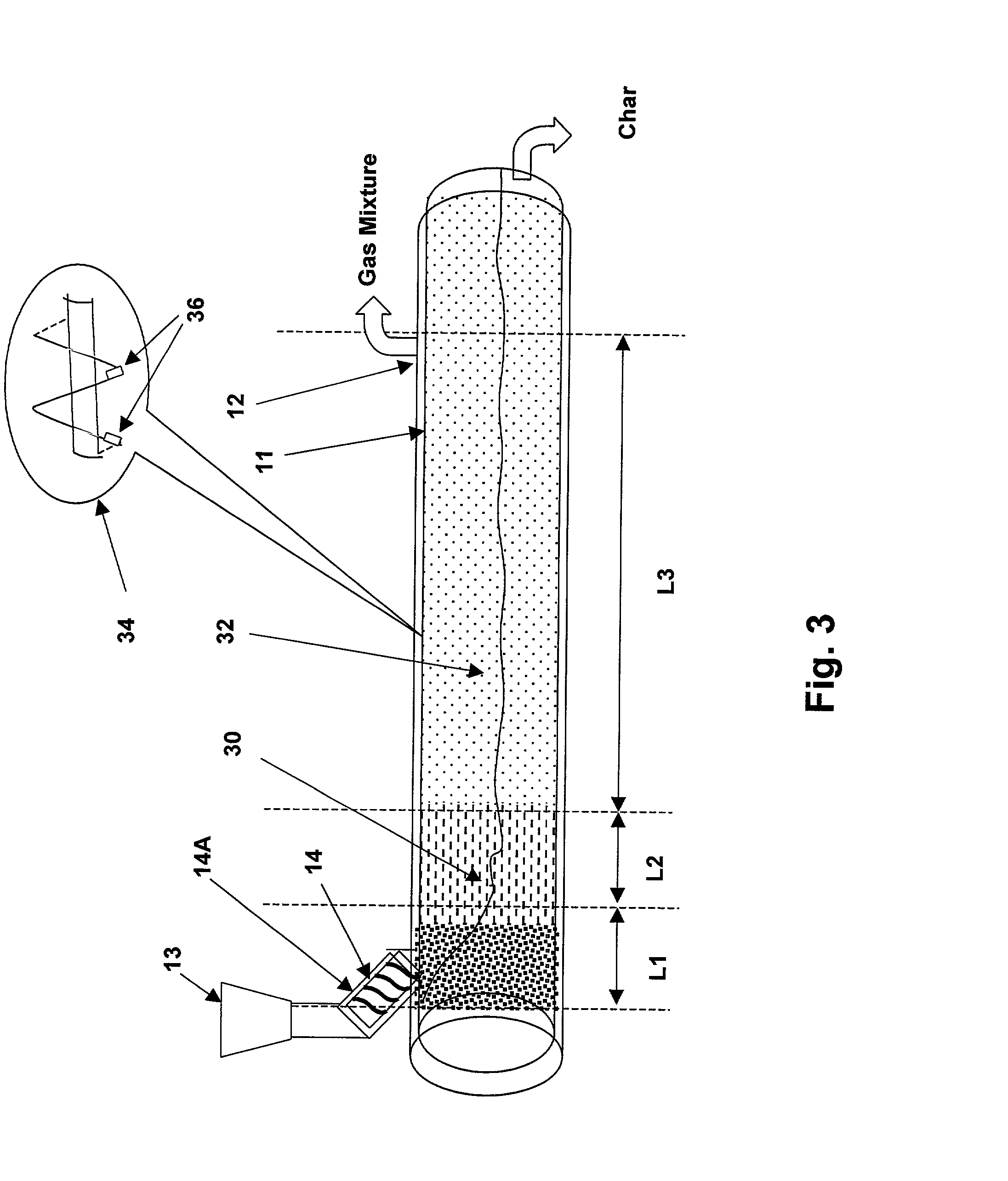

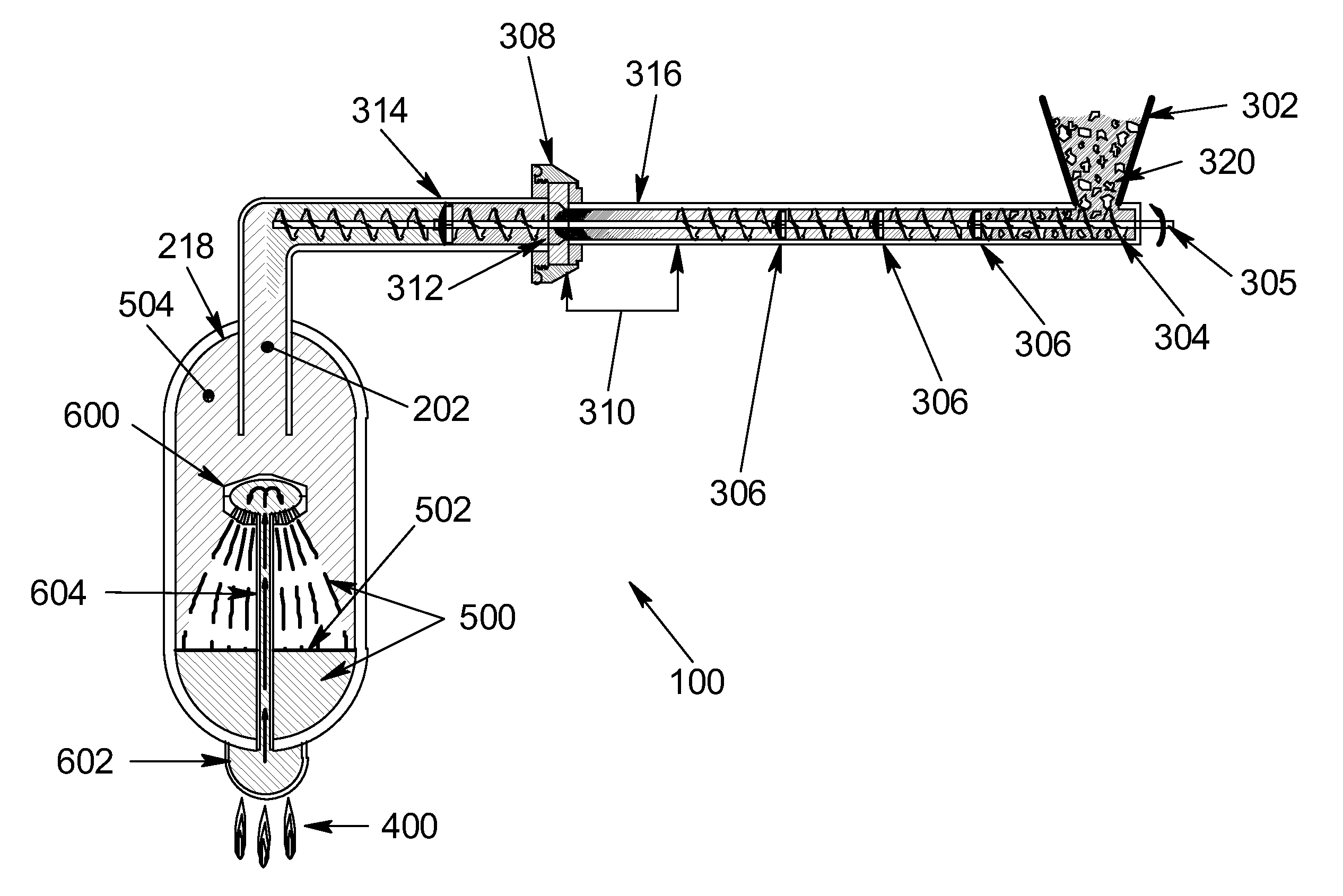

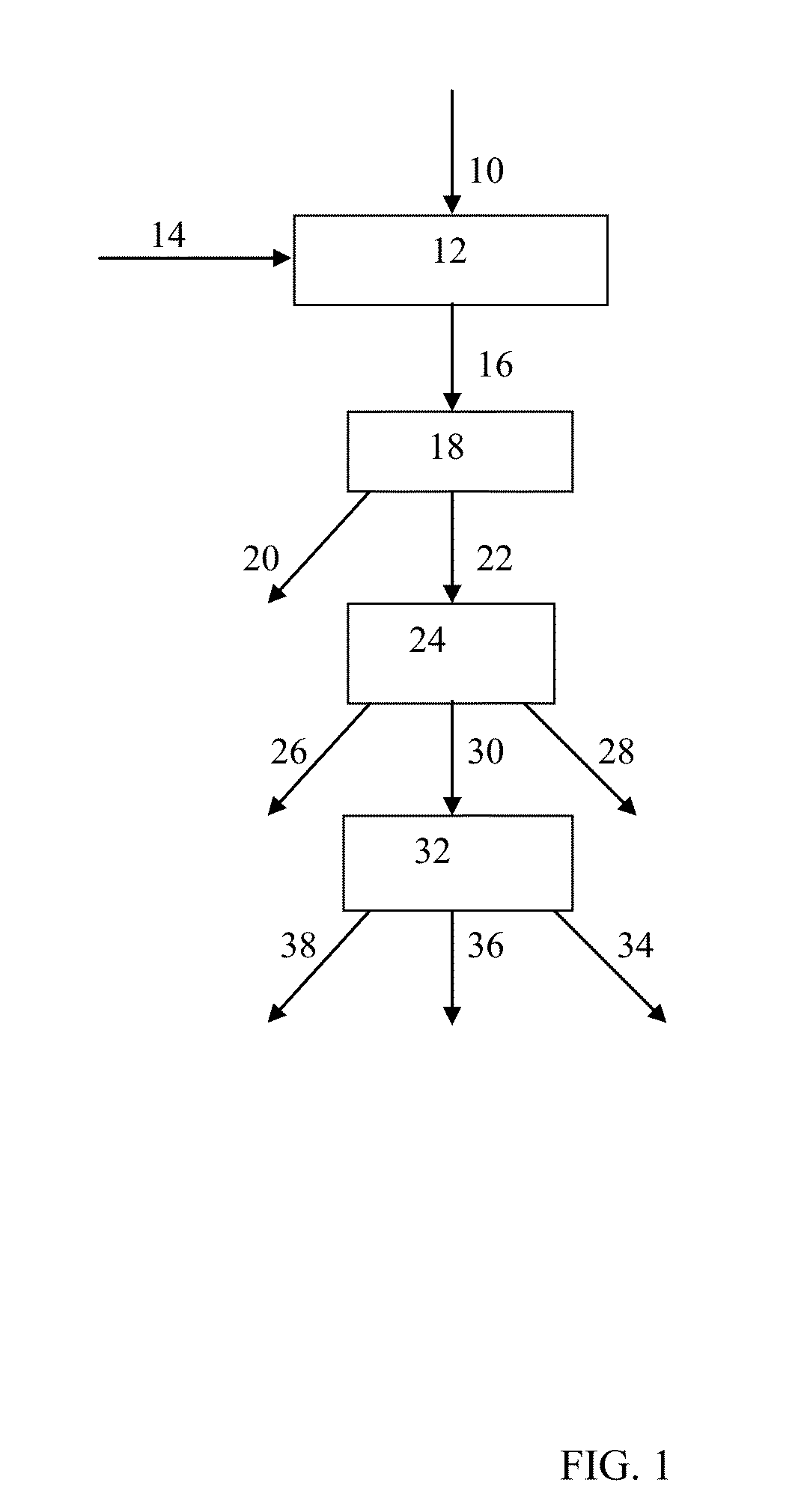

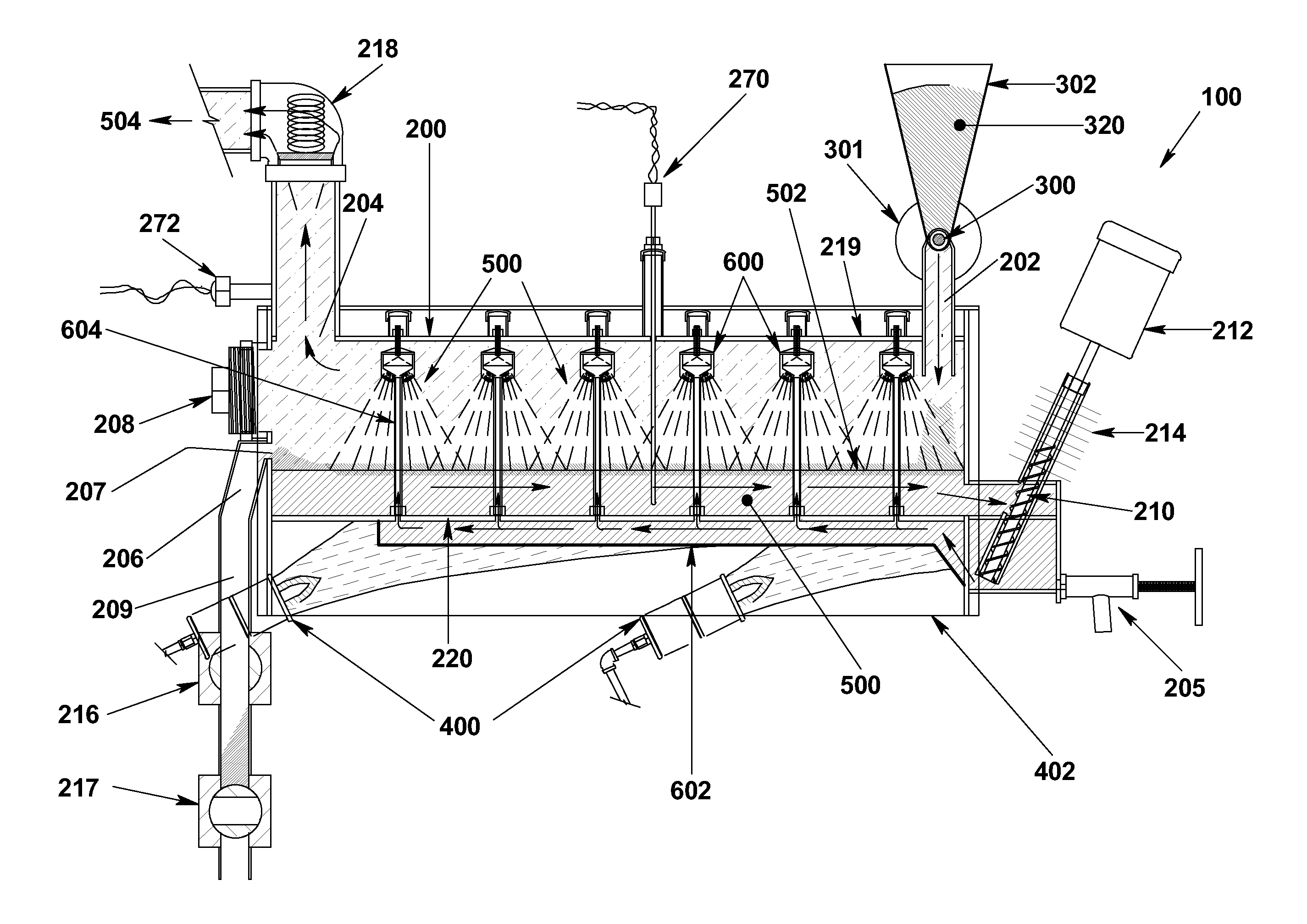

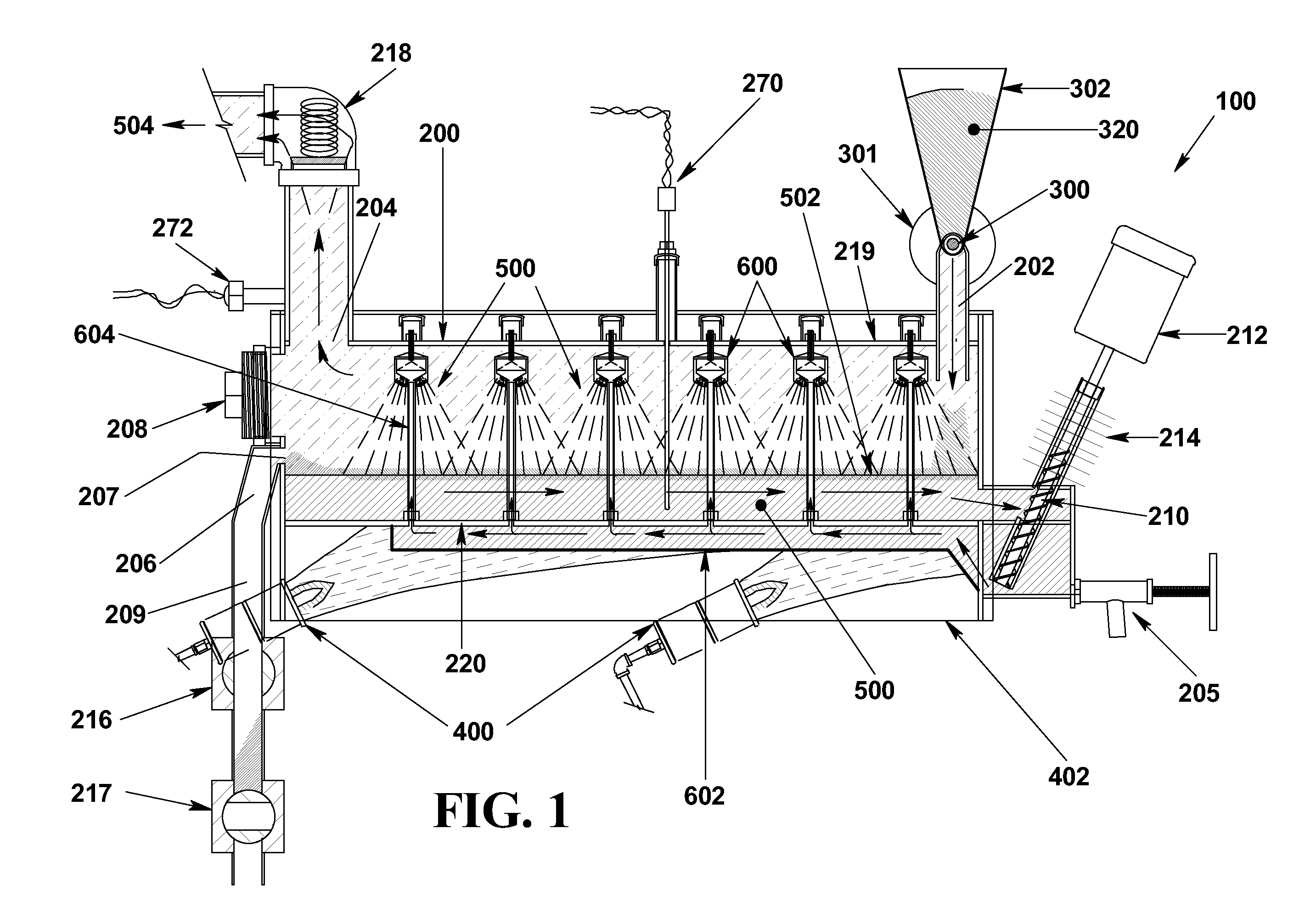

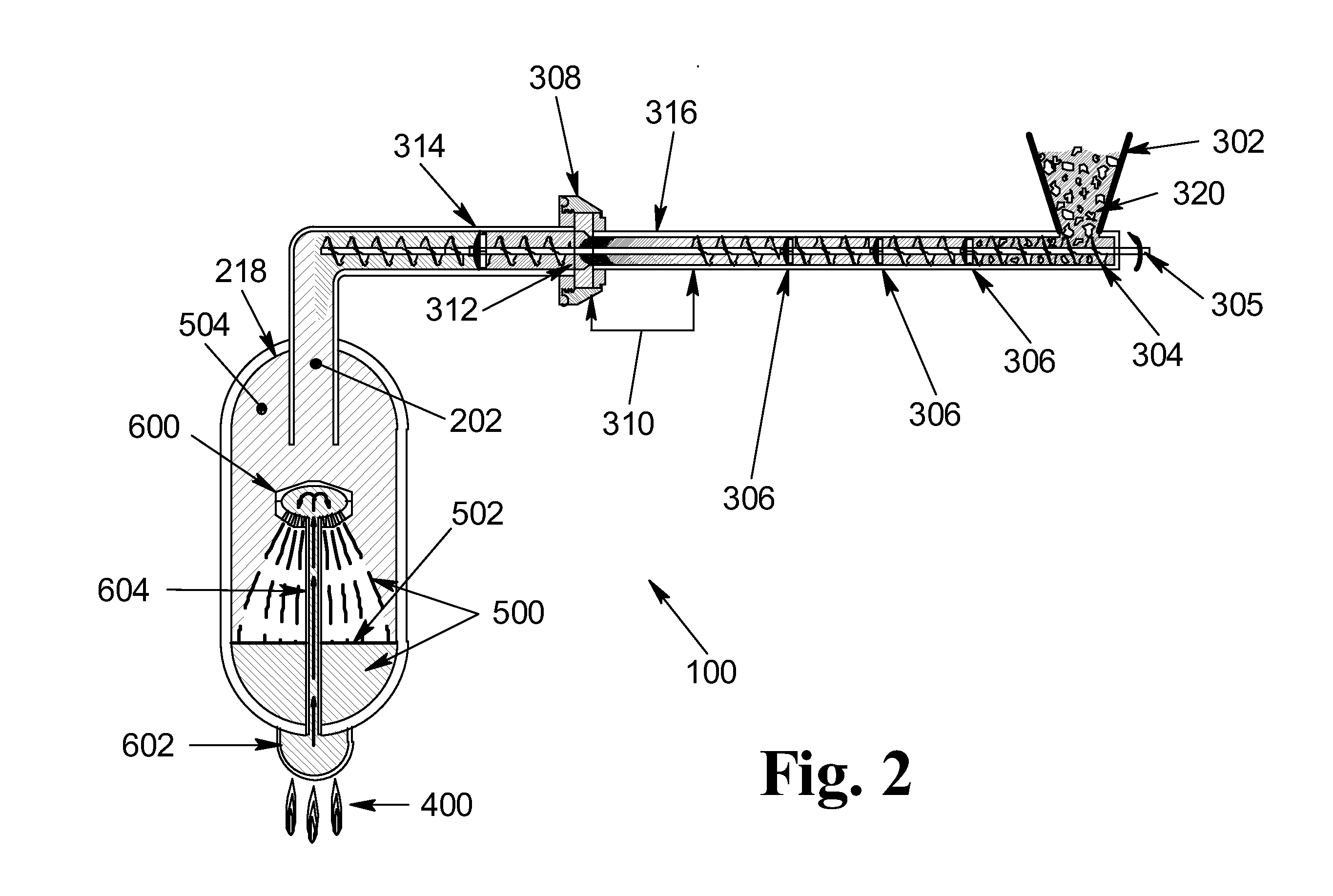

System and method for a constituent rendering of biomass and other carbon-based materials

InactiveUS8808510B2Combustible gas coke oven heatingCharging-discharging device combinationsProcess engineeringFeeding tube

A system and method for a constituent rendering of biomass and other carbon-based materials is provided. The system can be configured for receiving a feedstock material to be rendered into its constituent components, grinding the feedstock to a desired size and / or consistency, and placing the feedstock in contact with a hot mix heat transfer medium within a pressure chamber. In an aspect, the system can utilize a feedstock input system to receive the feedstock material, with the feedstock input system including an auger feed tube, at least one feed stock auger screw, a grinding station with a die configured to interact with the feed stock auger screw, and a movable compression gate. Pyrolysis of the feedstock can lead to a breakdown of the feedstock into constituent components that can then be collected.

Owner:PRIME GRP ALLIANCE

Method and apparatus for separating carbon product from used tire with microwave

InactiveUS20080226539A1Eliminate distractionsImprove good performanceElectrical coke oven heatingPigmenting treatmentMicrowave ovenDecomposition

An apparatus for separating carbon products from used tires includes a decomposing chamber into which used tires are charged, a nitrogen gas supply device that supplies nitrogen gas into the decomposing chamber, one or more magnetrons that generate microwave of predetermined frequency and one or more phase shifters that removes interference between microwaves generated by the magnetrons, a receiving plate that is adapted to receive carbon black and iron cores generated by the decomposing process, a tire support that is adapted to support used tires, an opening and closing device that opens or closes a door on which used tires are placed, conveyor belt that moves carbon black and iron cores to a desired location after decomposition is complete, and a cooling plate that is provided in an upper portion of the apparatus and cools down gaseous oil that is generated by decomposition by microwave into liquid oil.

Owner:HEALTHWELL MEDICAL INC

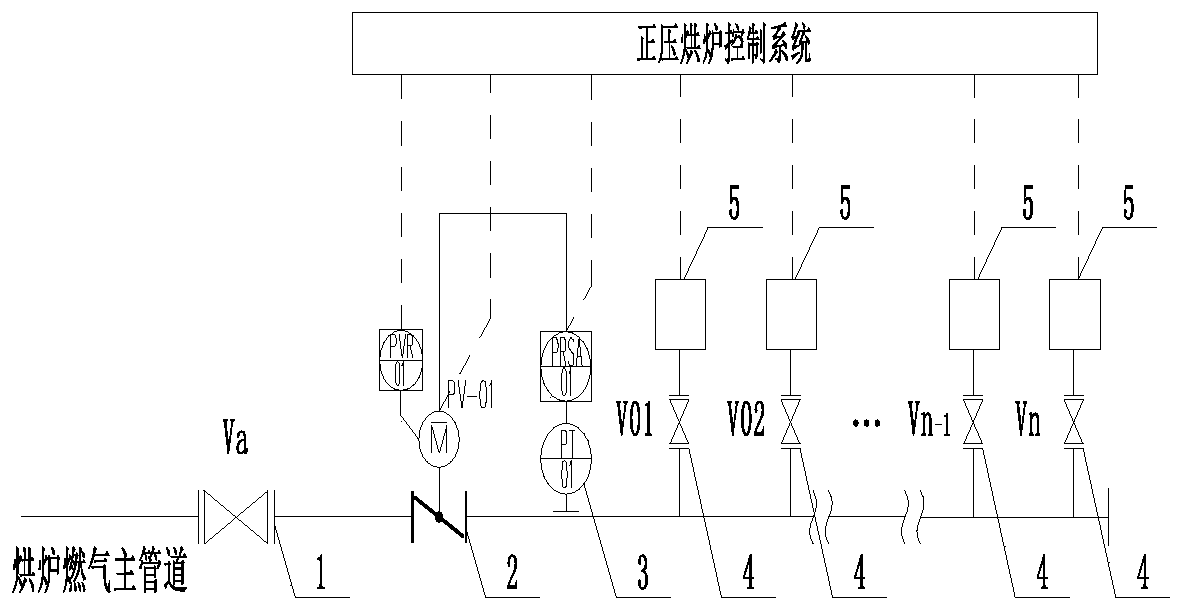

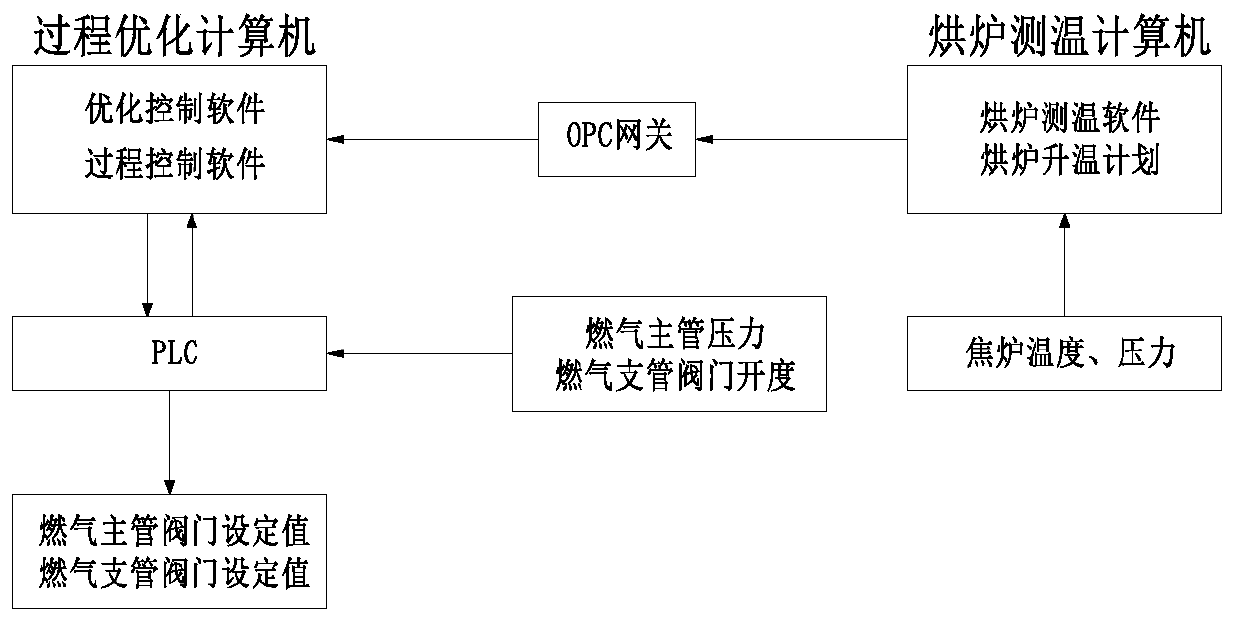

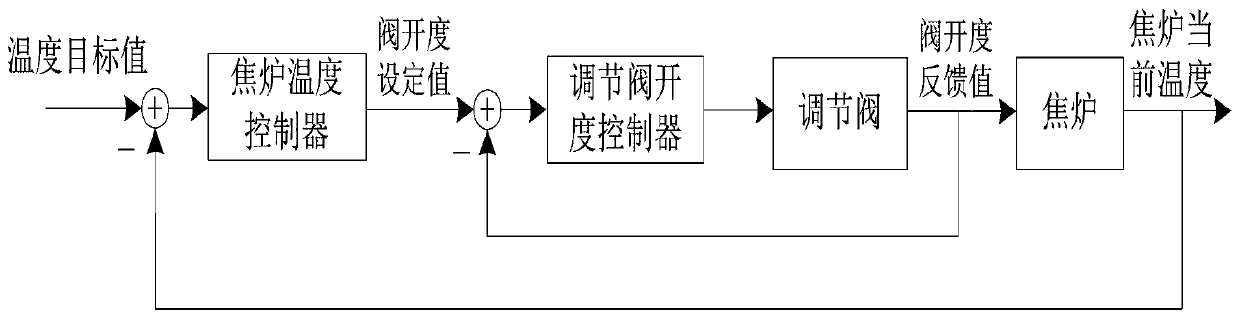

Coke oven positive pressure baking system and temperature control method

InactiveCN110244803AStable pressureAvoid Furnace Temperature FluctuationsCoke oven safety devicesPreheating coke ovensTemperature controlPositive pressure

The invention provides a coke oven positive pressure baking system and a temperature control method. Pressure of a baking gas main pipeline is used as a controlled object, the openness of an electric adjustment valve of the baking gas main pipeline is automatically calculated and adjusted in real time according to deviation between actual pressure and target pressure and deviation changing rate, and the baking gas pressure stability during the whole baking process is ensured; in control of a positive pressure baking device, a feedback value of the openness of a gas branch pipe adjustment valve is introduced to a control loop to form series adjustment, coke oven baking temperature control is used as a main ring, and gas branch adjustment valve openness control is used as a secondary ring; and in control of gas branch adjustment valve openness, idling path difference is eliminated by adding control of setting openness of the adjustment valve, the influence caused by idling path difference of the gas branch adjustment valve of the coke oven positive pressure baking device can be overcome, the baking temperature is accurately controlled, and the automatic temperature control accuracy of the positive pressure baking system is improved.

Owner:ACRE AUTOMATION CO LTD MCC

Decomposition method of waste plastics and organics

ActiveUS7862691B2Effective treatmentPreheating coke ovensSolid waste disposalMedical wasteMedical treatment

A method of decomposing waste plastics, organics, and particularly medical waste composed of a varieties of plastics is described.

Owner:RAPAS INT LTD

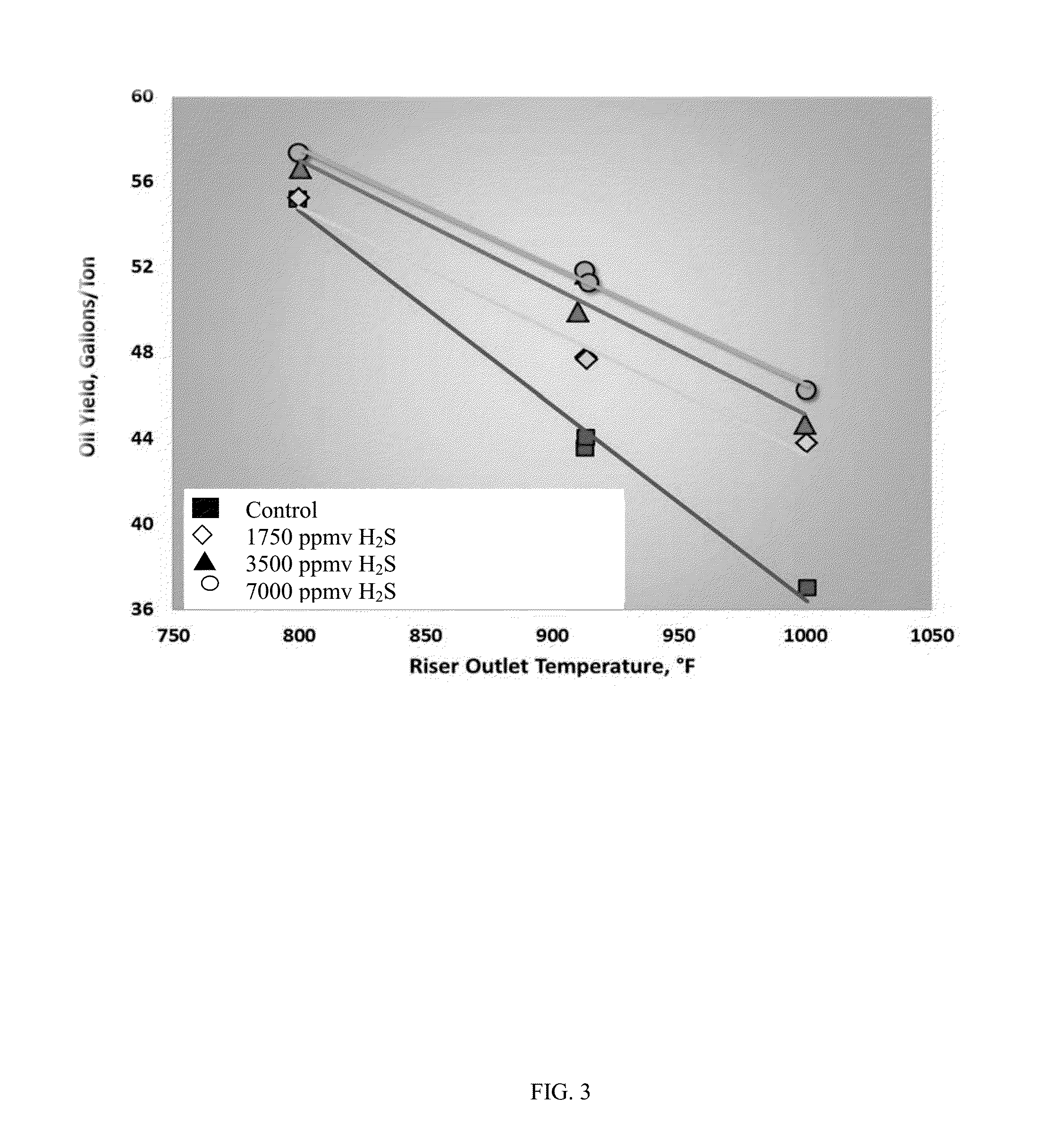

Method of thermolyzing biomass in presence of hydrogen sulfide

ActiveUS20160177185A1Increase productionHigh yieldPreheating coke ovensDirect heating destructive distillationBiomassHydrocarbon

The amount of renewable hydrocarbons produced from biomass may be increased by pyrolyzing the biomass in a biomass conversion unit in the presence of hydrogen sulfide or a sulfiding agent. The formation of deposits of unwanted carbonaceous materials, such as coke, is reduced by the presence of the hydrogen sulfide or sulfiding agent.

Owner:MARD INC

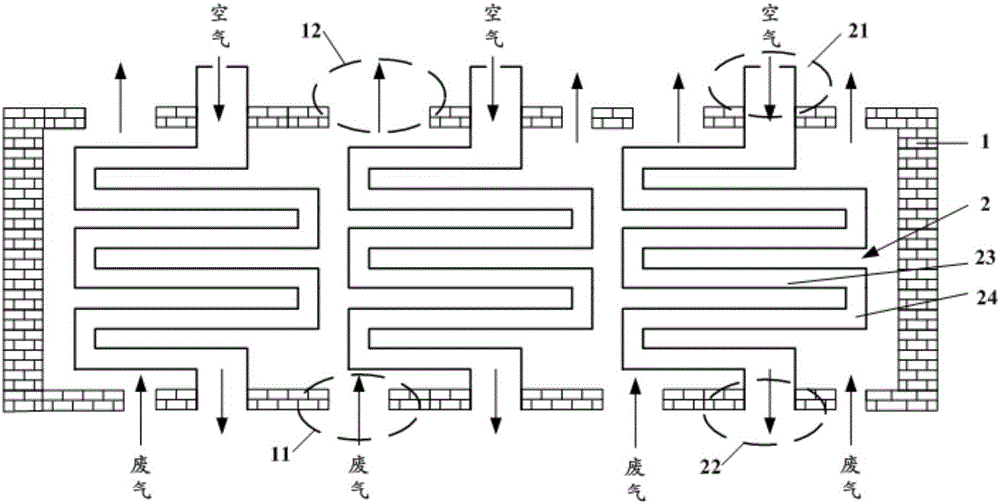

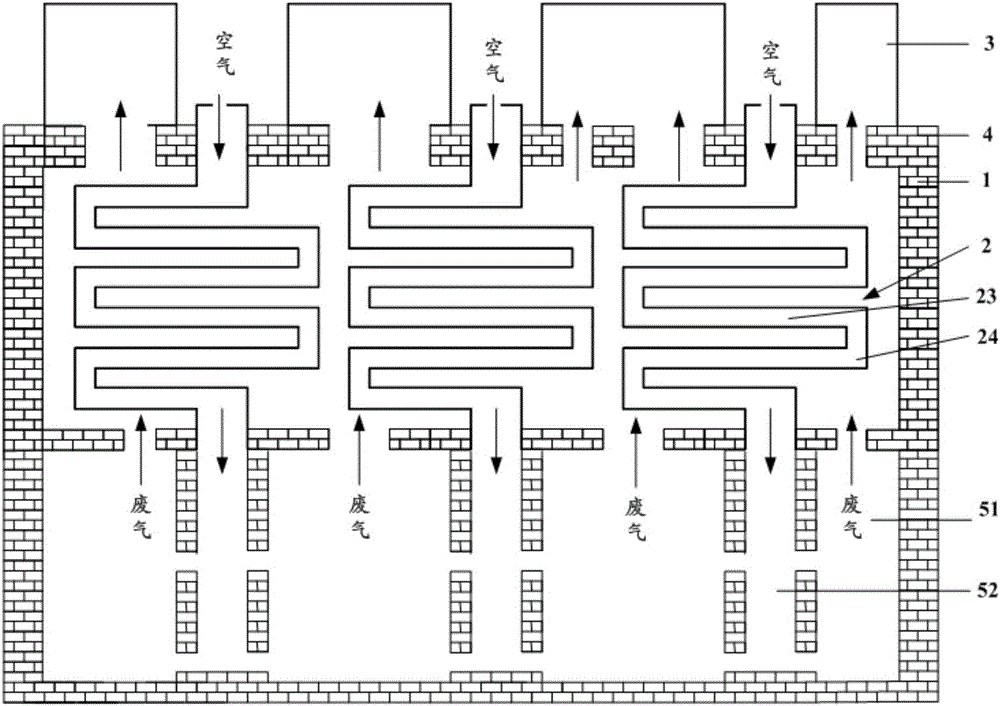

Heat exchanging chamber and coke oven

InactiveCN106679458ASimple processSimplified coke oven systemPreheating coke ovensEnergy inputCoke ovenNitrogen oxide

The invention provides a heat exchanging chamber and a coke oven and belongs to the technical field of coking. The heat exchanging chamber and the coke oven can solve the problems that an existing coke oven exhaust gas waste heat utilization process is complex, and nitrogen oxide emission exceeds standard. The heat exchanging chamber comprises a chamber body and a heat exchanging pipe arranged in the chamber body. The chamber body is provided with an exhaust gas inlet and an exhaust gas outlet. The two ends of the heat exchanging pipe are an air inlet and an air outlet. The heat exchanging chamber can be used for exhaust gas waste heat utilization of the coke oven, and the exhaust gas waste heat utilization process and a coke oven system are simplified. Meanwhile, the burning temperature of air and coal gas in a burning chamber of the coke oven can be reduced, and nitrogen oxide emission can be effectively reduced.

Owner:HUATAI YONGCHUANG BEIJING TECH CO LTD

Method for decomposing plastic

ActiveUS20020179424A1Easily decomposed and formedExcellent meritPreheating coke ovensDirect heating destructive distillationAlkalinityAqueous solution

Owner:OSADA GIKEN

System and method for a constituent rendering of biomass and other carbon-based materials

InactiveUS20100276270A1Increase the proportionCombustible gas coke oven heatingPreheating coke ovensProcess engineeringBiomass

A system and method for a constituent rendering of biomass and other carbon-based materials is provided. The system can be configured for receiving a feedstock material to be rendered into its constituent components, grinding the feedstock to a desired size and / or consistency, and placing the feedstock in contact with a hot mix heat transfer medium within a pressure chamber. Pyrolysis of the feedstock can lead to a breakdown of the feedstock into constituent components that can then be collected.

Owner:PRIME GRP ALLIANCE

Method and apparatus for the energy densification of a material in the form of divided solids, with a view to obtaining pyrolysis oils for energy purposes

ActiveUS9321964B2High process yieldEasy to implementMechanical conveying coke ovensElectrical coke oven heatingPre treatmentRelative humidity

A method and installation for energy densification of a material to obtain pyrolytic oils for energy. The method includes preconditioning the material by heating and drying to raise the material temperature close to 100° C. and a relative humidity not exceeding about 10%; pyrolyzing the material that is subsequently caused to flow through a substantially hermetic reactor containing at least one transfer screw or vibrating tube heated by the Joule effect, the material heated progressively in the range of 300° C. to 850° C., the electrical power passing through the transfer screw or the vibrating tube for providing heating regulated as a function of the material in order to obtain the desired temperature level during the transit time of the material through the reactor; extracting pyrolysis gas from a high portion of the reactor for rapid recondensation in a vertical condenser; and recovering pyrolytic oils from a low portion of the vertical condenser.

Owner:LEPEZ CONSEILS FINANCE INNOVATIONS LCFI +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com