Coke oven positive pressure baking system and temperature control method

A temperature control method and oven technology, which is applied to coke ovens, program control, and preheating coke ovens, etc., can solve problems affecting the quality of ovens, changes in oven temperature, and greater impact, and improve the efficiency of coke oven ovens. quality, improve temperature control accuracy, and avoid furnace temperature fluctuations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The specific embodiments provided by the present invention will be described in detail below in conjunction with the accompanying drawings.

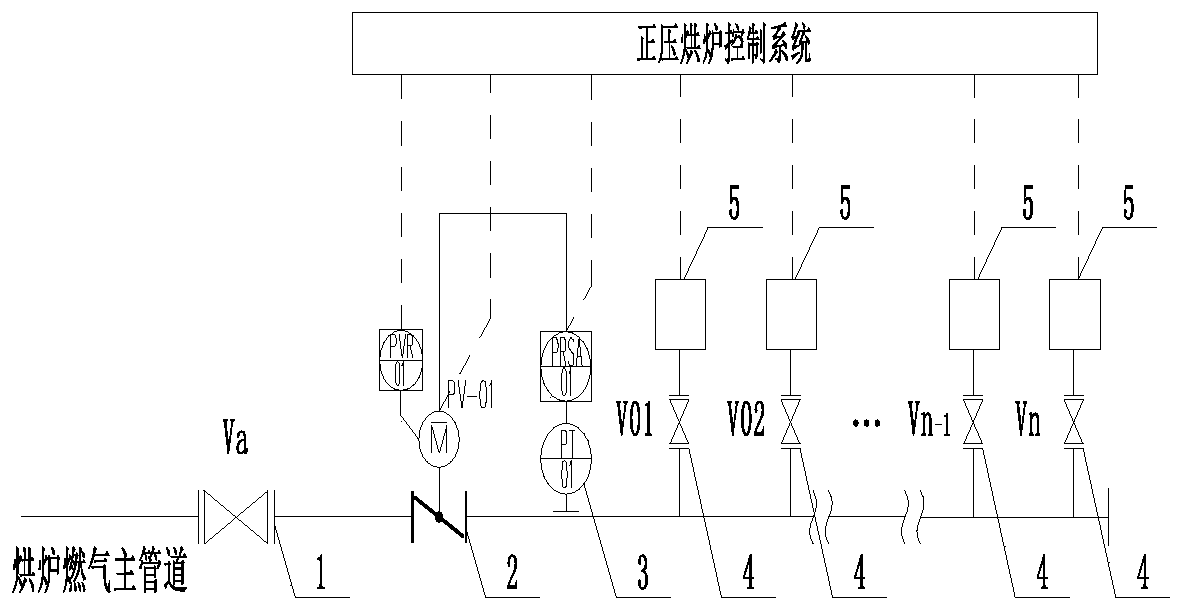

[0033] figure 1 As shown, the coke oven positive pressure oven system includes oven gas main pipeline shut-off valve 1, oven gas main pipeline electric control valve 2, oven gas main pipeline pressure transmitter 3, oven gas branch pipeline shut-off valve 4, Positive pressure oven device 5. Positive pressure oven control system.

[0034] A plurality of gas branch pipes connected to the oven gas main pipeline, each gas branch pipe is connected to one or more gas branch pipe regulating valves of a positive pressure oven device 5; the oven gas main pipeline pressure transmitter 2 and the oven gas main pipeline The pipeline electric regulating valves 3 are all electrically connected with the positive pressure oven control system.

[0035] The positive-pressure oven device can be a positive-pressure oven device in the prior art, such...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com