Pulverized coal coking equipment and method

A pulverized coal and equipment technology, which is applied in pulverized coal coking equipment and coking field, can solve the problems of unstable quality, poor air permeability, and gas can not be discharged smoothly, and achieve the effect of unobstructed gas overflow channel and increased air permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

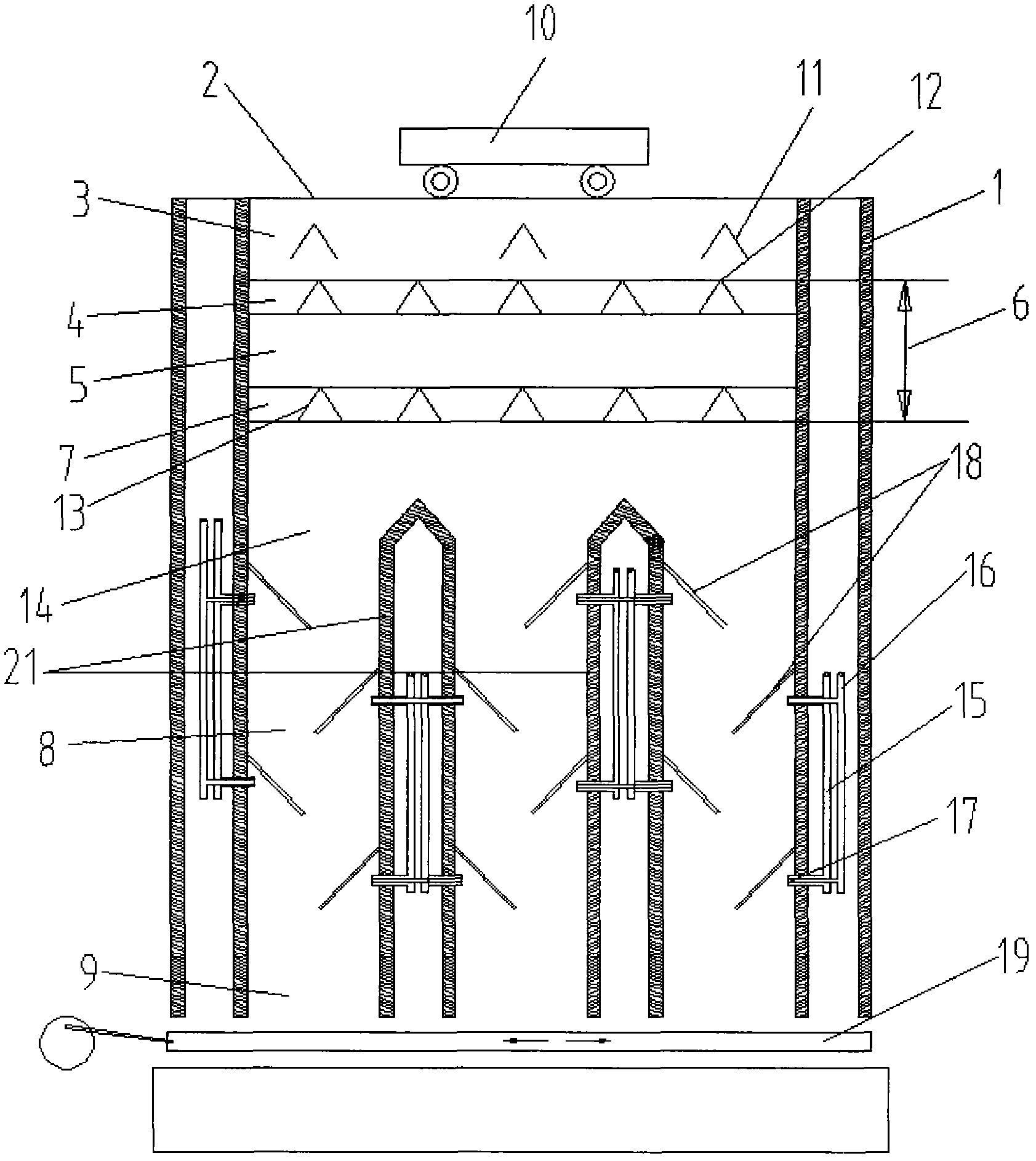

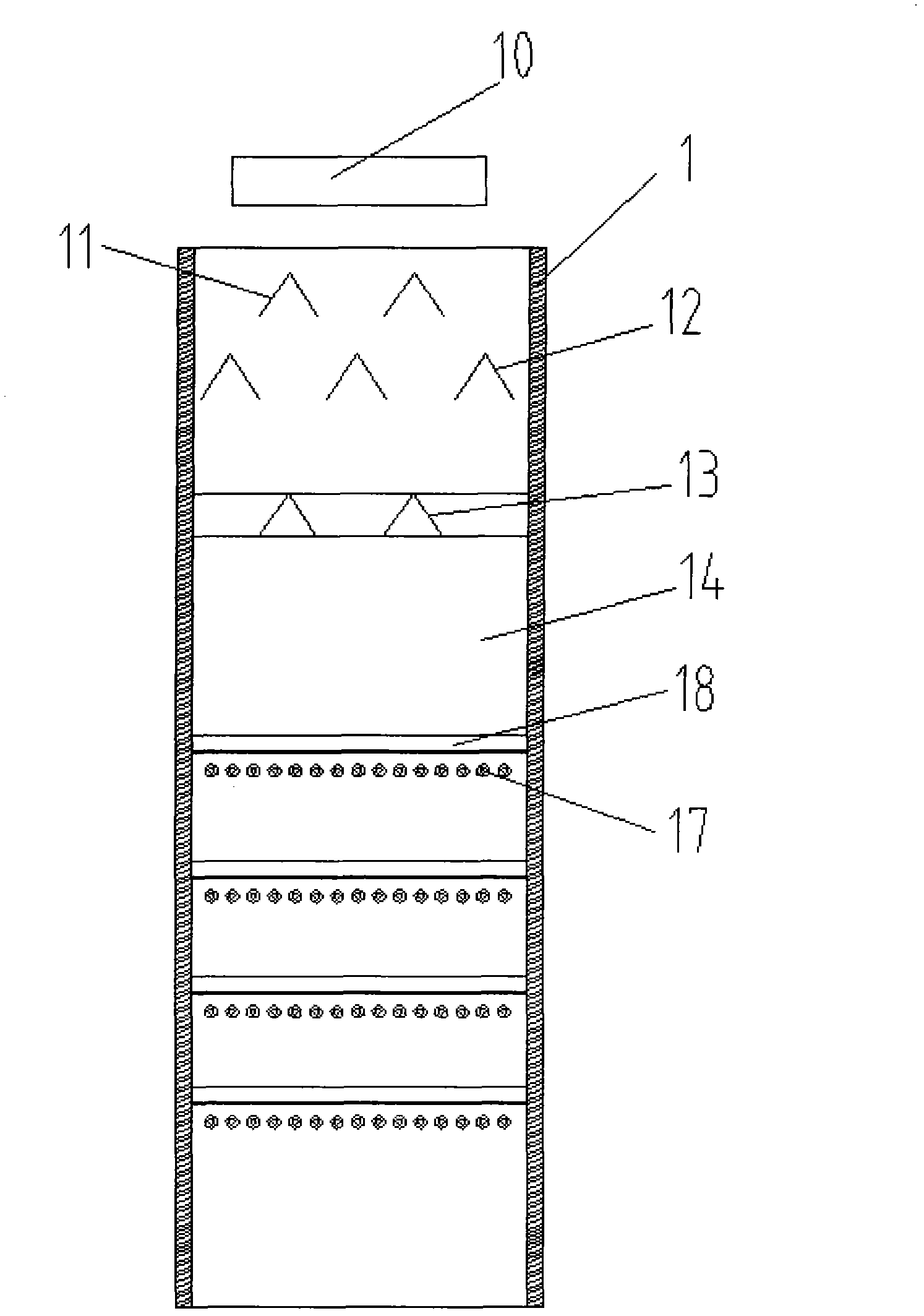

[0036] Embodiment 1 Internal heating type structure

[0037] like figure 1 , figure 2 As shown, the present invention provides a pulverized coal coking equipment, including a pulverized coal semi-coke pyrolysis furnace 1, and the pyrolysis furnace is respectively a charge inlet 2, a feeding and distribution area 3, a gas collection area 4, Gas dust filter zone 5, pulverized coal preheating zone 6, gas divergence zone 7, pulverized coal pyrolysis zone 8 and coke cooling zone 9.

[0038] The top of the pyrolysis furnace is the charge inlet, and a charging cart 10 is installed at the charge inlet.

[0039] The feeding and distributing area is provided with multiple forked and tapered distributing structures 11 .

[0040] The gas collecting area is provided with a plane grid-shaped gas collecting umbrella 12, and a plane grid-shaped gas diverging umbrella 13 is arranged below the gas collecting umbrella as the gas diverging area.

[0041] The coal gas dust filtering belt is a...

Embodiment 2

[0044] Embodiment 2 External heating type structure

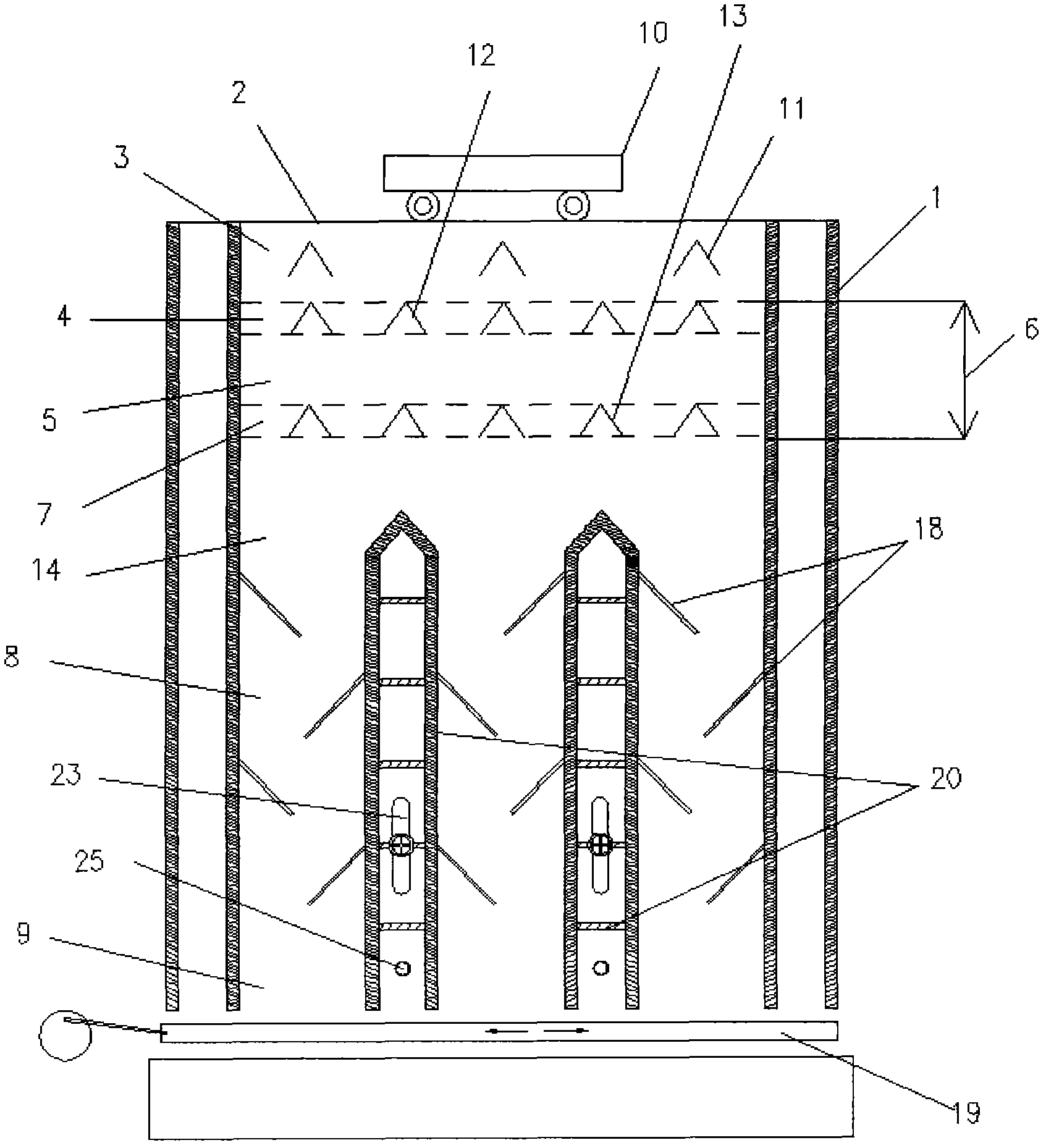

[0045] like image 3 , Figure 4 As shown, the present invention provides a pulverized coal coking equipment, comprising a coal semi-coke pyrolysis furnace 1, the pyrolysis furnace is respectively from top to bottom furnace charge inlet 2, charging and distribution area 3, gas collection area 4, gas Dust filter zone 5, pulverized coal preheating zone 6, gas divergence zone 7, pulverized coal pyrolysis zone 8 and coke cooling zone 9.

[0046] The top of the pyrolysis furnace is the charge inlet, and a charging cart 10 is installed at the charge inlet.

[0047] The feeding and distributing area is provided with multiple forked and tapered distributing structures 11 .

[0048] The gas collecting area is provided with a plane grid-shaped gas collecting umbrella 12, and a plane grid-shaped gas diverging umbrella 13 is arranged below the gas collecting umbrella as the gas diverging area.

[0049] The coal gas dust filtering b...

Embodiment 3

[0054] The present invention also provides a method for making coke from pulverized coal. The method adopts pulverized coal with a particle size of less than 20 mm to make coke, and includes the following steps:

[0055] 1) Distribution: pulverized coal is loaded from the top of the pulverized coal semi-coke pyrolysis furnace, and distributed evenly through the fork and cone-shaped distribution structure through the feeding distribution area;

[0056] 2), preheating: the pulverized coal falls freely from top to bottom in the coal semi-coke pyrolysis furnace, interacts with the upward hot gas, and preheats the pulverized coal;

[0057] 3) Pulverized coal pyrolysis:

[0058] Internally heated semi-coke oven:

[0059] When the internal thermal structure is adopted, in the pulverized coal pyrolysis zone, multiple baffles are built on the inner wall of the furnace, the outer wall of the carbonization and the inner wall of the carbonization, and a space is formed during the downwar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com