Patents

Literature

30results about How to "Uniform pyrolysis" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Efficient selectable pyrolysis system and using method thereof

ActiveCN102634358AGood value for moneyImprove adjustabilityBiofuelsSpecial form destructive distillationNitrogenProcess engineering

The invention discloses an efficient selectable pyrolysis system and a using method thereof, wherein the efficient selectable pyrolysis system comprises a furnace body, a dry distillation kettle, gas nozzles and a cooling device, wherein a furnace chamber in the furnace body is internally provided with the horizontally-arranged dry distillation kettle, wherein the dry distillation kettle comprises an upper side part, a lower side part, a kettle top and a kettle bottom; the part on the upper side part close to the kettle top is communicated with an exhaust pipe; the other end of the exhaust pipe is connected with a diffusion valve; the part on the furnace part close to the exhaust pipe is provided with a temperature meter communicated with the furnace chamber; the lower part of the lower side part is communicated with gas outlets of four staggered gas nozzles; the gas outlets of the gas nozzles are connected with a control valve; the cooling device comprises a nitrogen intake pipe and a nitrogen exhaust pipe, wherein the nitrogen intake pipe is communicated with the kettle top; the nitrogen exhaust pipe is communicated with the upper side part; and when the efficient selectable pyrolysis system is used, if carbon production is emphasized the heating is finished to pyrolysis carbonization stage, and if biomass gas production is emphasized, the heating is finished to the forging stage. The design not only has good adjustability, high cost performance and high heating efficiency, but also the finished product carbon has good quality and high production efficiency.

Owner:武汉天颖环境工程股份有限公司

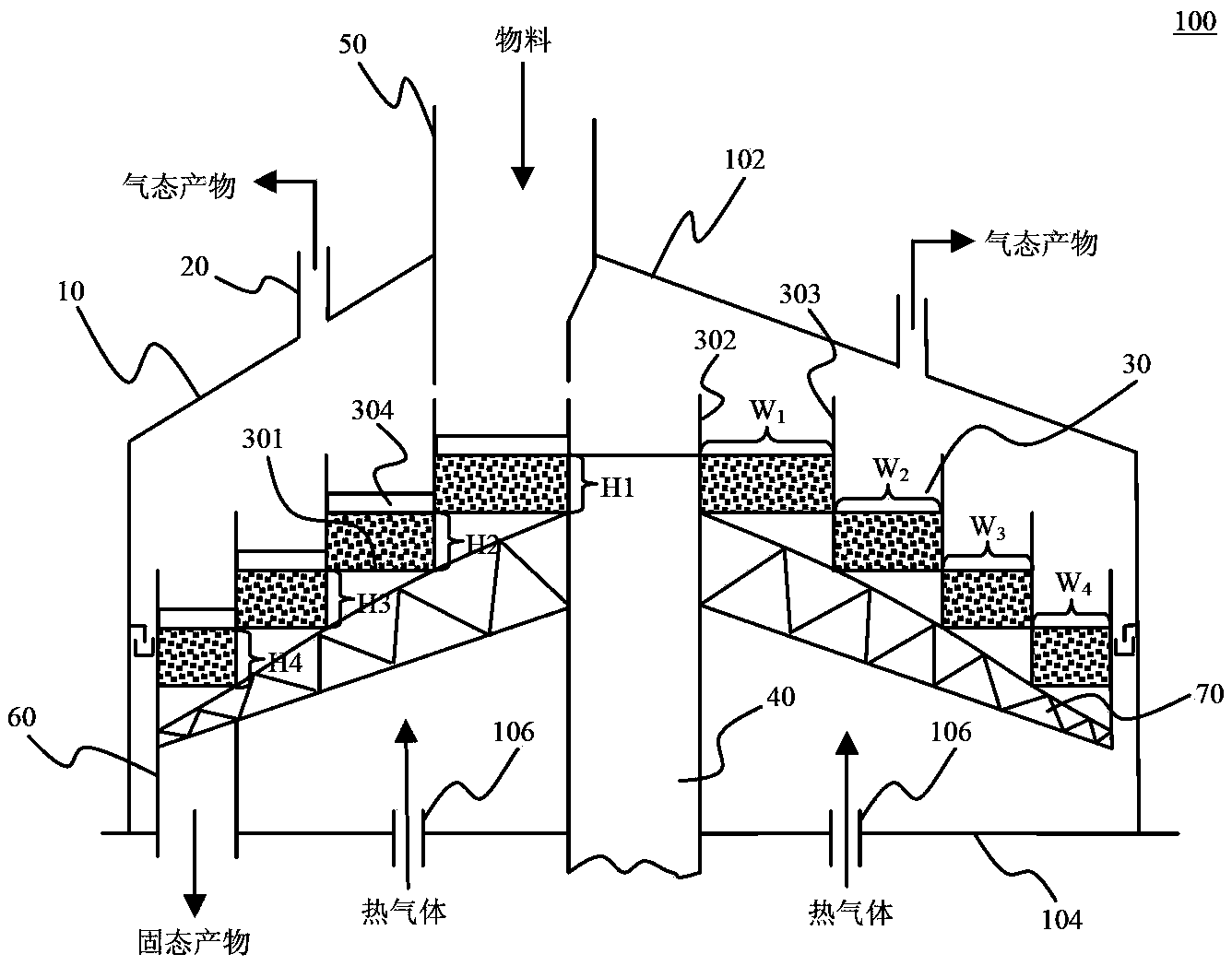

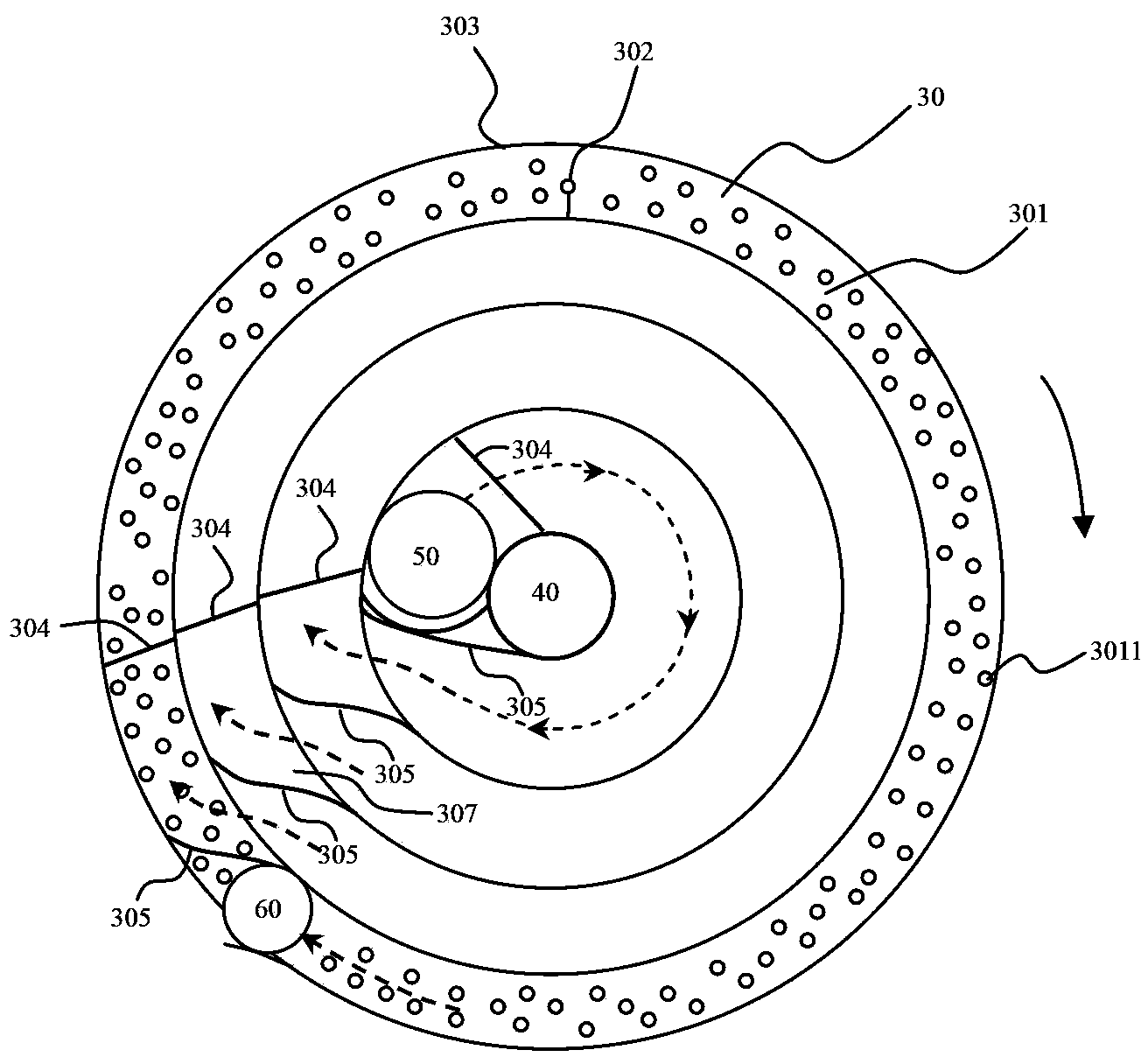

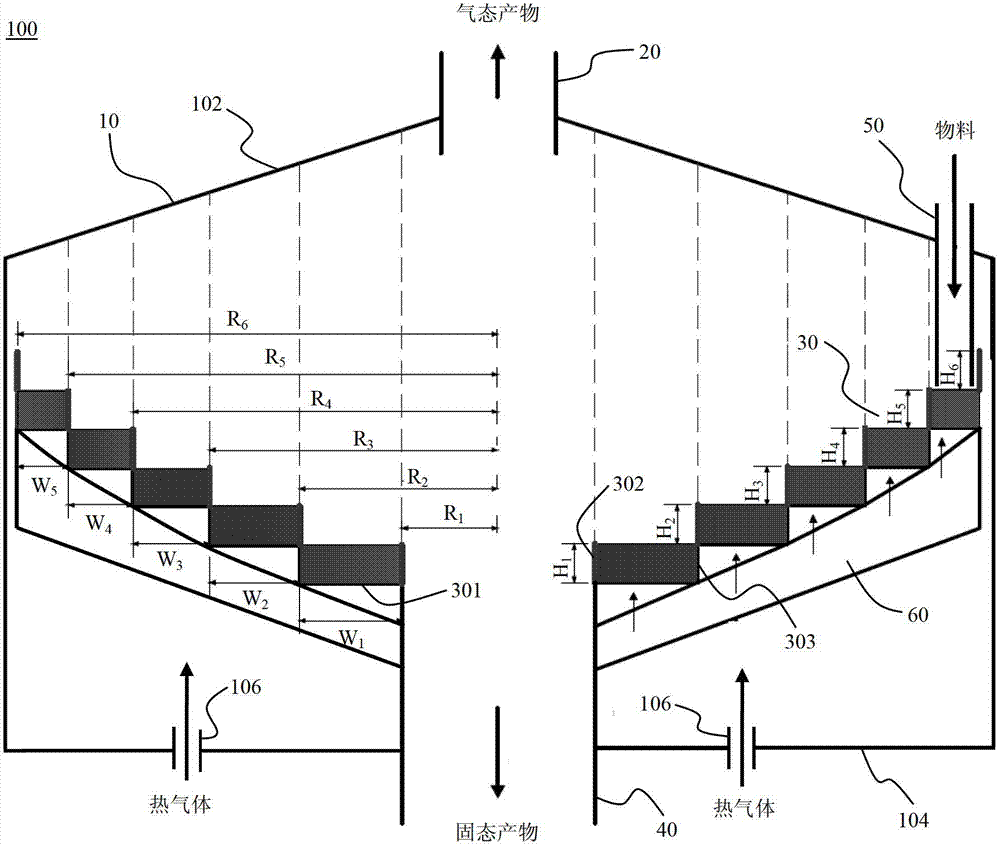

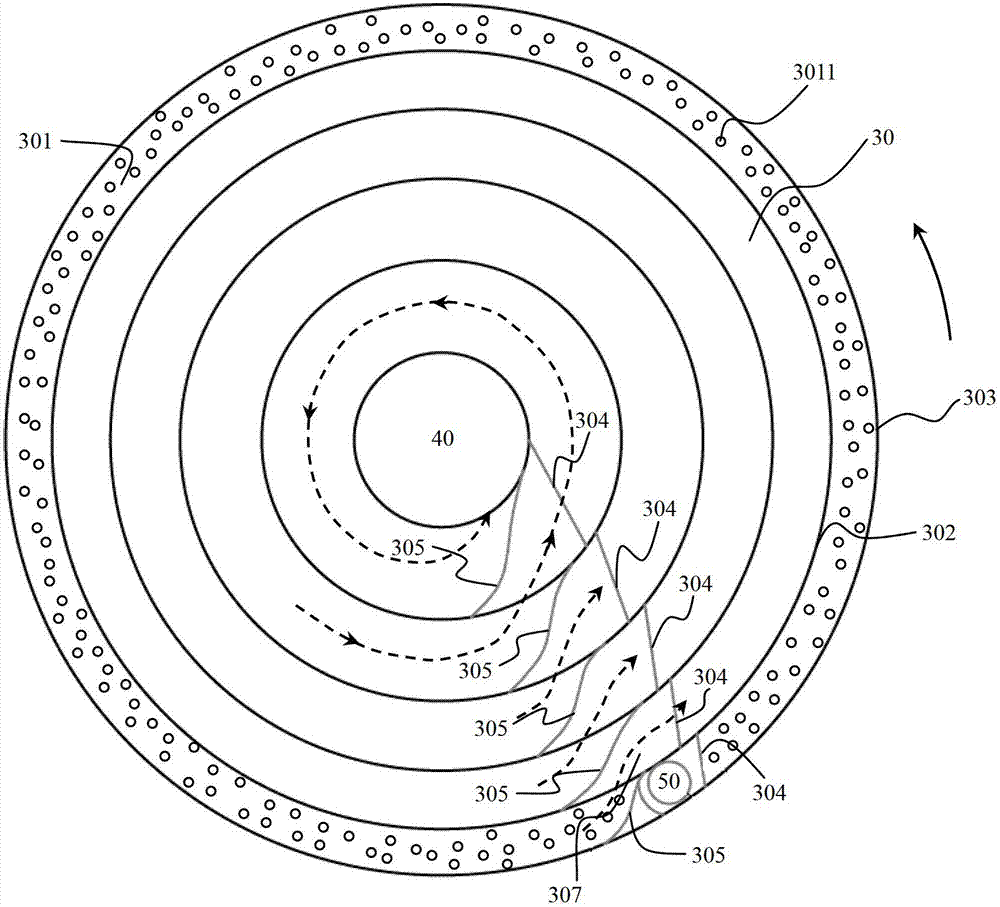

Drying furnace or pyrolyzing furnace with rotary beds

ActiveCN103388980AUniform pyrolysisImprove scalabilityDirect heating destructive distillationFurnace typesEngineeringMechanical engineering

The invention discloses a drying furnace or pyrolyzing furnace with rotary beds. The drying furnace or the pyrolyzing furnace comprises a closed shell, N concentric ring planar rotary beds, a feed port, N stop plates, N discharge ports and at least one pyrolysis gas product outlet and / or one tail gas outlet, wherein the N concentric ring planar rotary beds are positioned in the shell; the two ends of the stop plates are seamlessly connected with the inner walls and the outer walls of the corresponding rotary beds respectively; each rotary bed comprises a rotatable planar bed bottom and an inner wall and an outer wall which are kept still relative to the bed bottom; the bed bottom of each rotary bed is provided with at least one through hole; and the heights of the N rotary beds rise gradually from inside to outside and seamless connection is realized. When a material is rotated to the position of a stop plate along with the bed bottom of a rotary bed, the material is pushed from outside to inside by the stop plate so as to fall into the next joined rotary bed through a discharge port; and thus, the material falls from outside to inside step by step, is conveyed to the position of the discharge port of the innermost rotary bed through the bed bottoms of the N rotary beds and is finally discharged out of the drying furnace or the pyrolyzing furnace through the discharge port.

Owner:CHNA ENERGY INVESTMENT CORP LTD +1

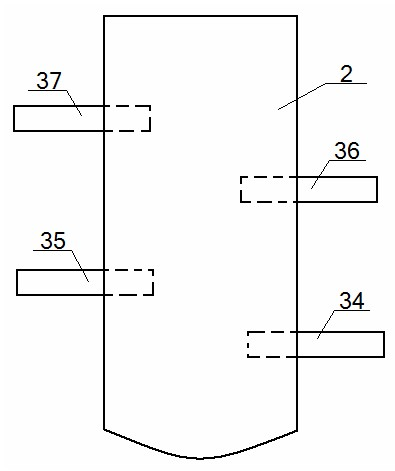

Coal pyrolysis and activated carbon production integrated device

The invention discloses a coal pyrolysis and activated carbon production integrated device. The integrated device comprises a thermal insulation jacket, a preheating furnace, a pyrolysis furnace used for performing pyrolysis on preheated coal, an activating furnace used for activating semi-coke generated after pyrolysis, and an activating agent conveying pipe used for inputting gas activating agents into the activating furnace. The preheating furnace, the pyrolysis furnace and the activating furnace are sequentially communicated from top to bottom. An activating furnace heating cavity is formed between the activating furnace and the thermal insulation jacket. A gas conveying channel is formed between the thermal insulation jacket and the pyrolysis furnace. The activating furnace is provided with an associated gas outlet for associated gas produced through activation of the semi-coke to enter the gas conveying channel. A gas heat carrier inlet for the associated gas to enter the pyrolysis furnace from the gas conveying channel is formed in the side wall of the pyrolysis furnace. The integrated device can effectively improve the pyrolysis and activation efficiency, the tar yield is effectively increased, high-quality coal gas, tar and activated carbon can be produced at the same time, and the additional value for quality-divided processing and utilizing of the coal is improved.

Owner:XIAN UNIV OF SCI & TECH

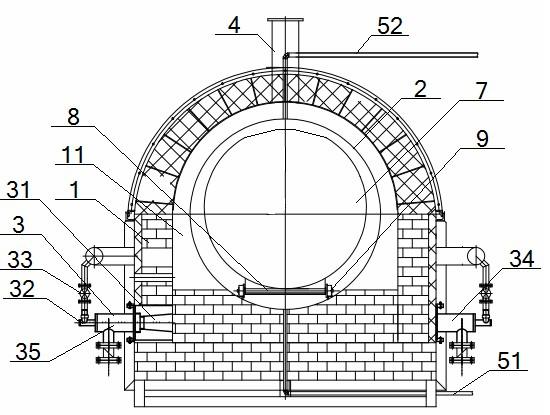

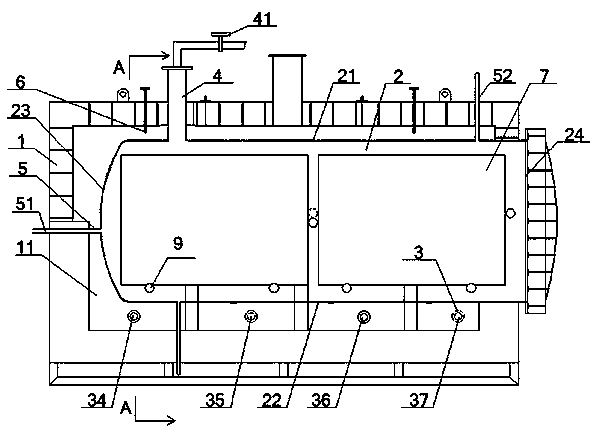

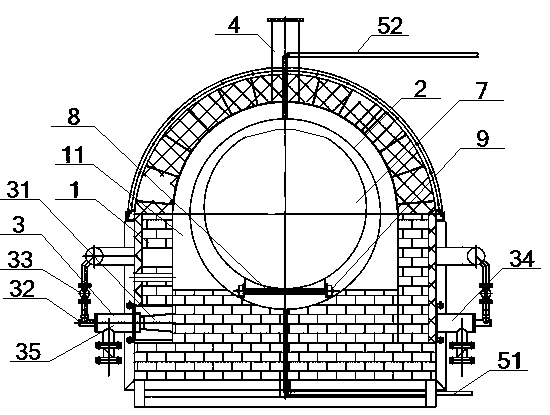

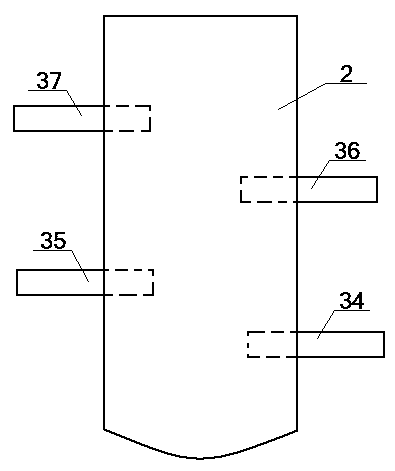

Biomass drum-type carbonization furnace

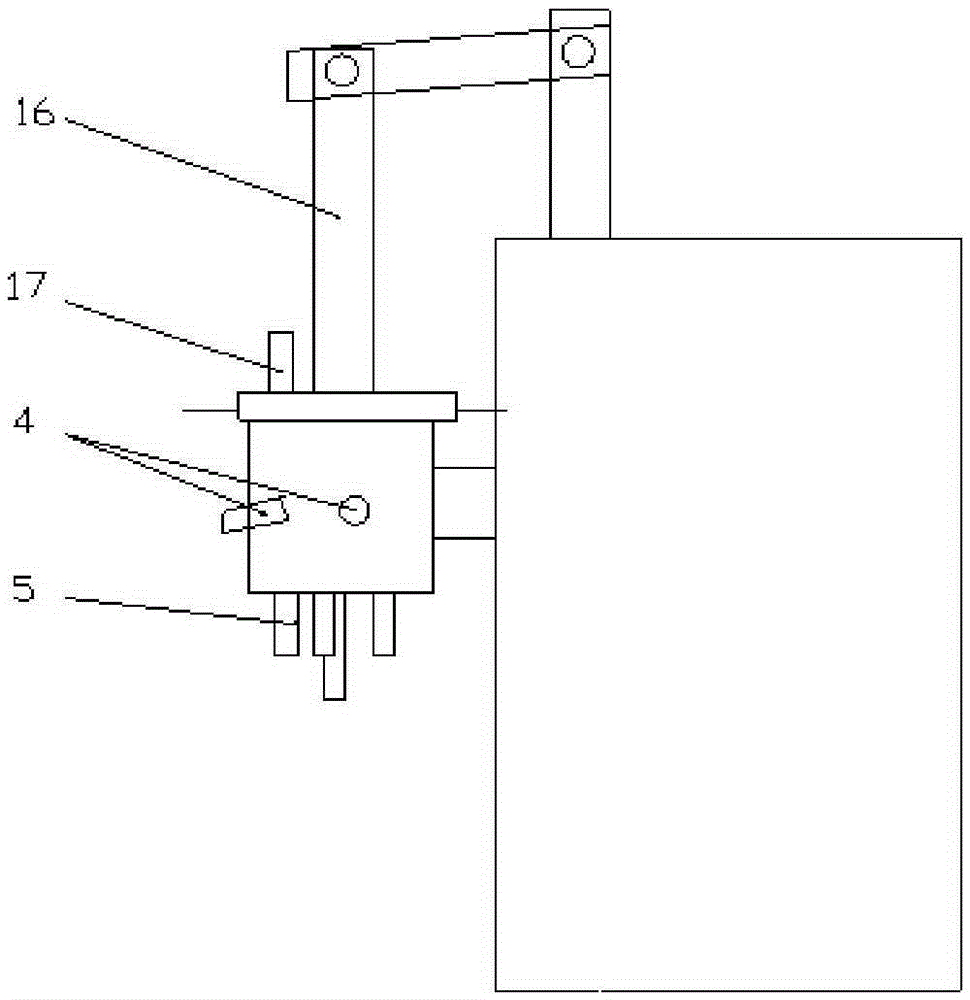

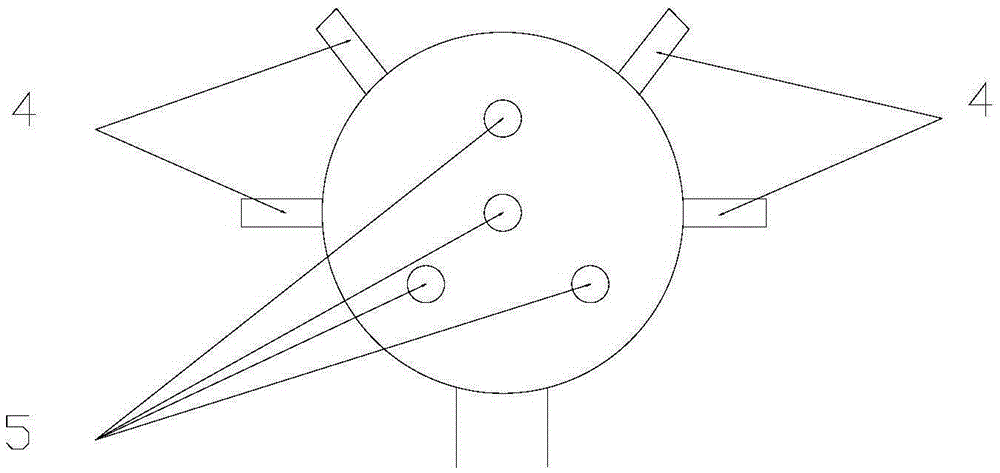

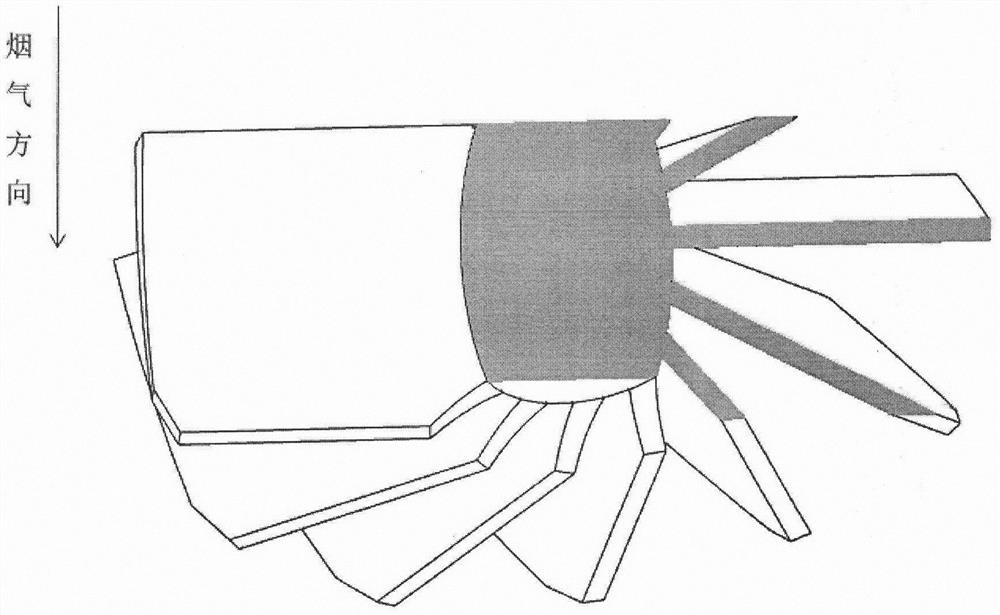

InactiveCN104877691ASmooth recyclingInnovative designCoke quenchingRotary retortsCombustion chamberFlue gas

A biomass drum-type carbonization furnace comprises a feeding device, a carbonization furnace (7), a combustion chamber (9) and a carbon discharging bin (12), wherein the outlet of a feeding bin (2) of the feeding device is connected with the inlet end of the carbonization furnace (7); the outlet end of the carbonization furnace (7) is connected with the carbon discharging bin (12); a pyrolysis gas outlet (4) is formed in the carbonization furnace (7); a flue gas outlet (8) is formed above the combustion chamber (9); the carbonization furnace (7) is a drum-type carbonization furnace; a rotary power device is arranged below and connected with the carbonization furnace (7); a support device (6) is arranged at the inlet end of the carbonization furnace (7); a support device (11) is arranged at the outlet end of the carbonization furnace (7); the furnace body of the carbonization furnace (7) horizontally penetrates through the combustion chamber (9); and material guiding pieces distributed spirally are arranged on the inner wall of the carbonization furnace (7). A direct heating mode is adopted, the heat efficiency is high, and the energy consumption is low.

Owner:武汉光谷蓝焰新能源股份有限公司

Microwave oven device for pyrolysis and pyrolysis method thereof

ActiveCN105276639ASmall volumeReduce the amount of adhesionDomestic stoves or rangesLighting and heating apparatusLower limitMicrowave oven

The invention discloses a microwave oven device for pyrolysis and a pyrolysis method thereof. The microwave oven device comprises a microwave oven body and a reaction cavity formed outside the oven body. A closed end cover is arranged on the top of the reaction cavity. Four side face air inlets are distributed in the circumferential wall of the reaction cavity. Four bottom air inlets are formed in the bottom of the reaction cavity. An electric heating device is arranged on the peripheral wall of the reaction cavity. The reaction cavity is connected with the oven body through a movable connecting rod support. According to the requirement of materials to be pyrolyzed, the number of the side face air inlets or the bottom air inlets is selected, a stop button and a start button are pressed, and after a machine body is operated, the upper limit and lower limit of the temperature and power are set. The reaction time is set according to requirements, and after setting is finished, an electric heating button is pressed to insulate the reaction cavity, and when the actually-measured temperature of a thermocouple reaches 300 DEG C, a microwave button is pressed, and whether the stirring function is started or not is selected according to experiment requirements. After pyrolysis of the materials is finished, a microwave oven is automatically stopped.

Owner:SOUTH CHINA UNIV OF TECH

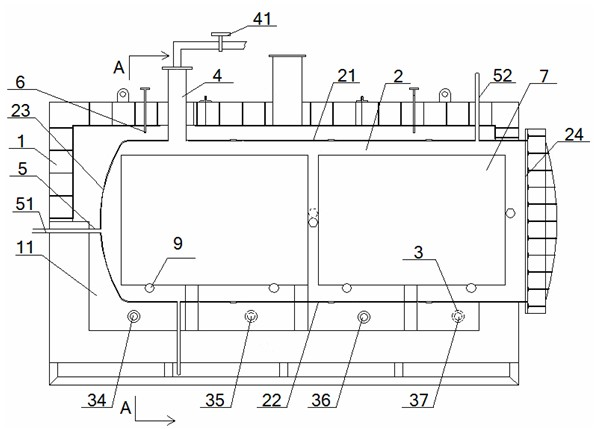

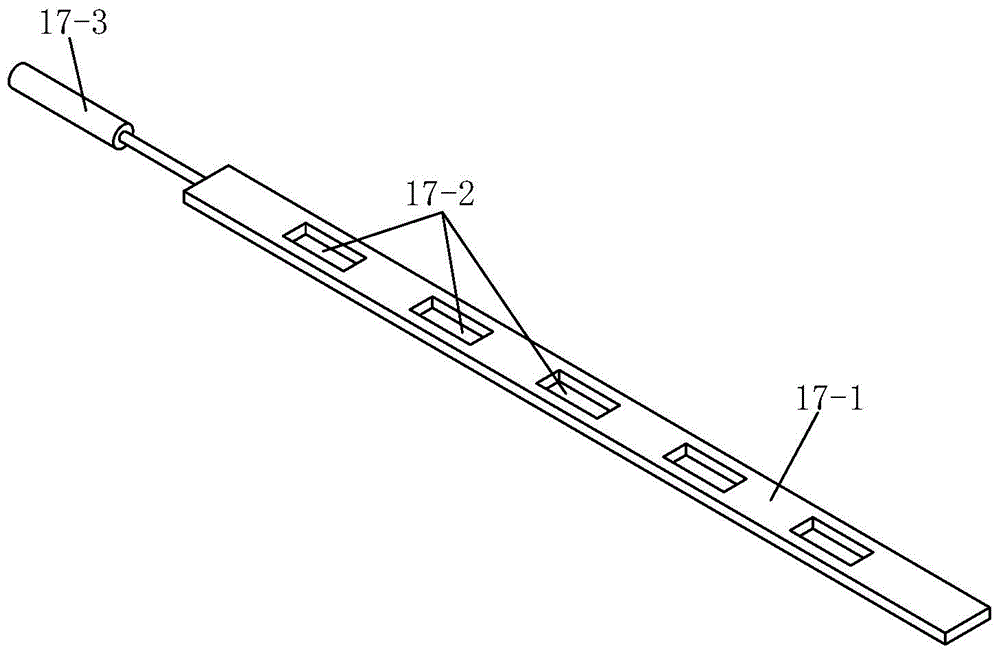

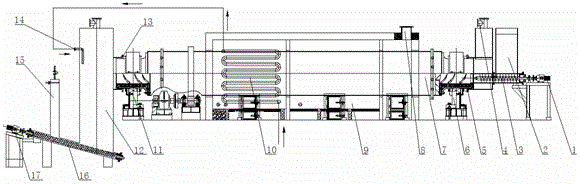

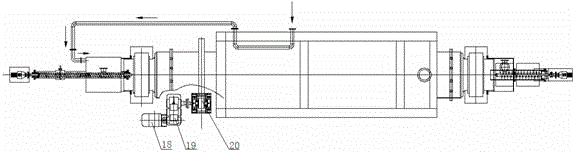

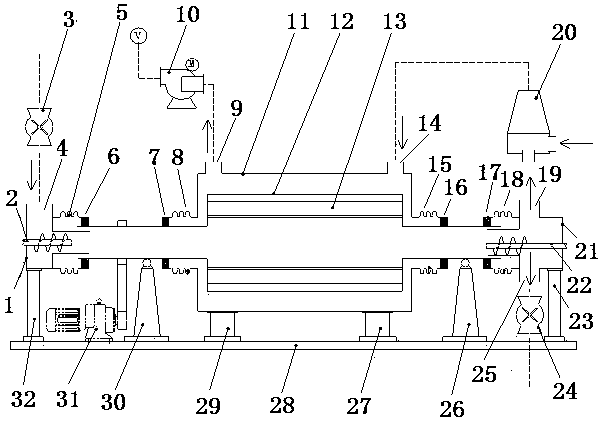

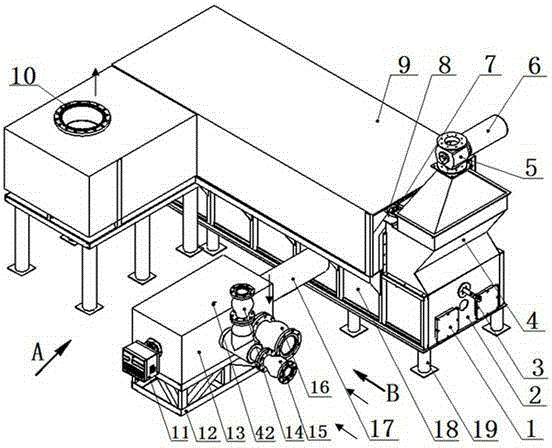

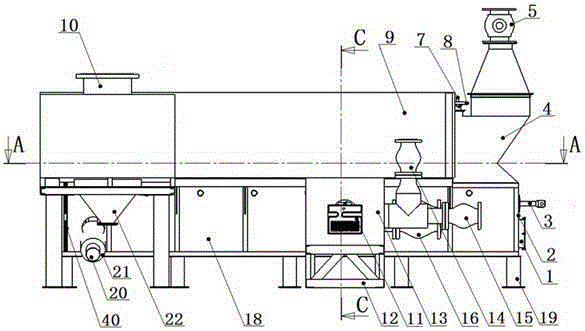

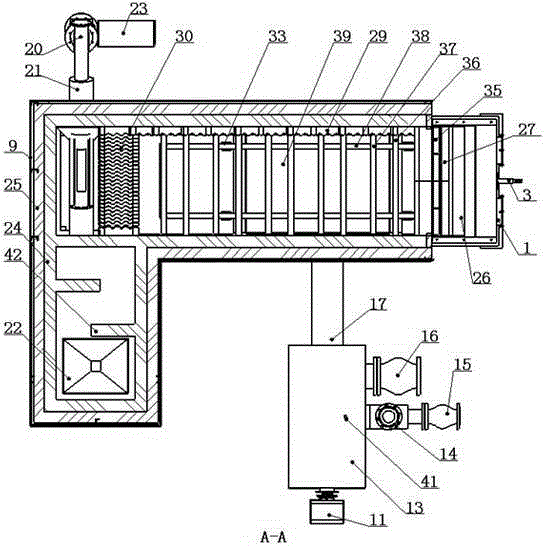

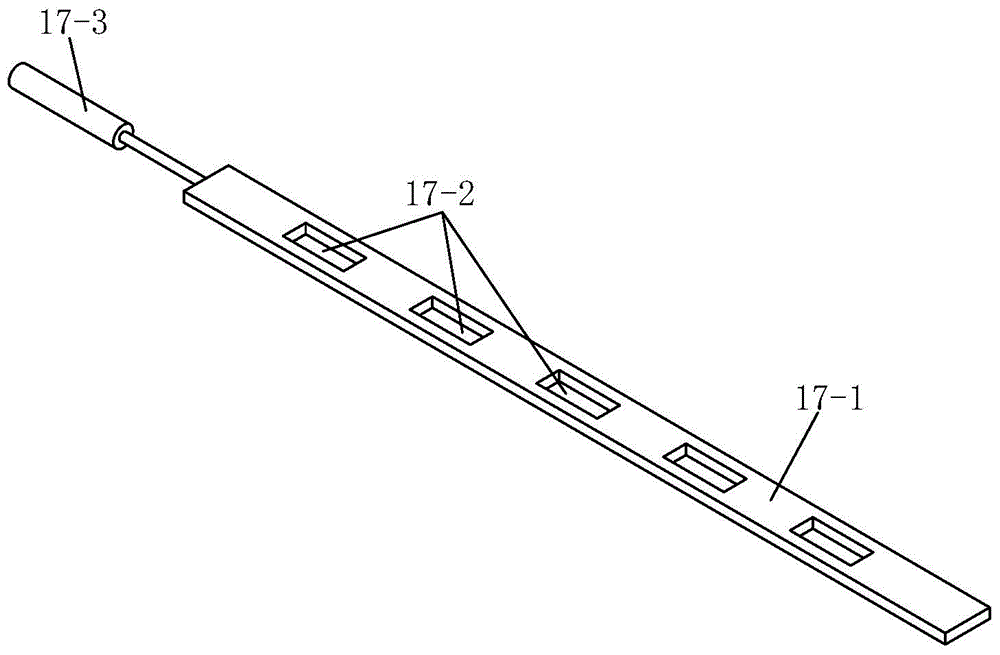

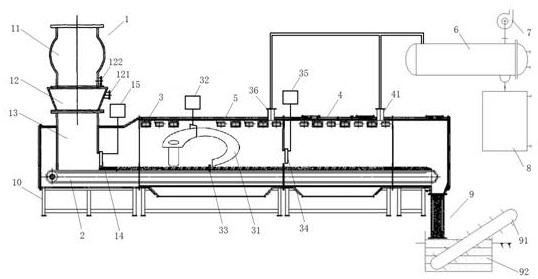

Destructive distillation device of biomass horizontal rotary drum

PendingCN107916119ARealize deliverySimple structureBiofuelsIndirect heating destructive distillationBiomassCombustion

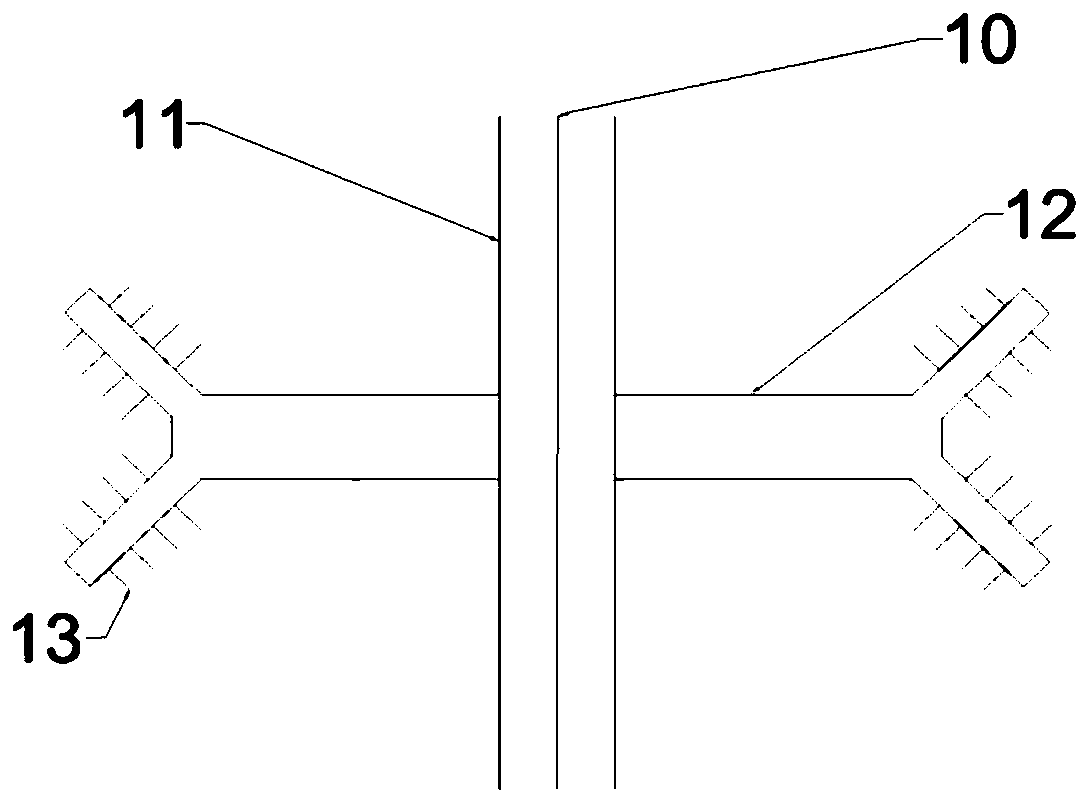

The invention discloses a destructive distillation device of a biomass horizontal rotary drum, which comprises a feeding mechanism, a driving mechanism, a rotary drum mechanism, a discharging mechanism, a public chassis, a retorting gas combustion furnace, an air draft and an assistant part; the feeding mechanism comprises a feeding shell and an internal feeding screw; the rotary drum mechanism comprises an outer drum and an inner drum; by adopting the horizontal setting, the inner part of the inner drum is provided with an oblique turning plate for overturning and conveying materials along with the rotating process of the inner drum; the discharging mechanism comprises a discharging shell and an inner discharging screw; every rotating sealing place adopts an elastic mechanical contact type sealing structure pressed by a graphite disk through a metal expansion joint; the assistant part comprises a first starlike blocking valve and a second starlike blocking valve which are connected tothe feeding opening and the discharging opening. The destructive distillation device is stable in running, long in service life, big in processing amount and can continuously work; the material is uniformly heated and completely burned; the destructive distillation device is leakage-free, safe and reliable, green and environment-friendly.

Owner:SHENGLI OIL FIELD SHENGLI POWER MACHINERY GRP

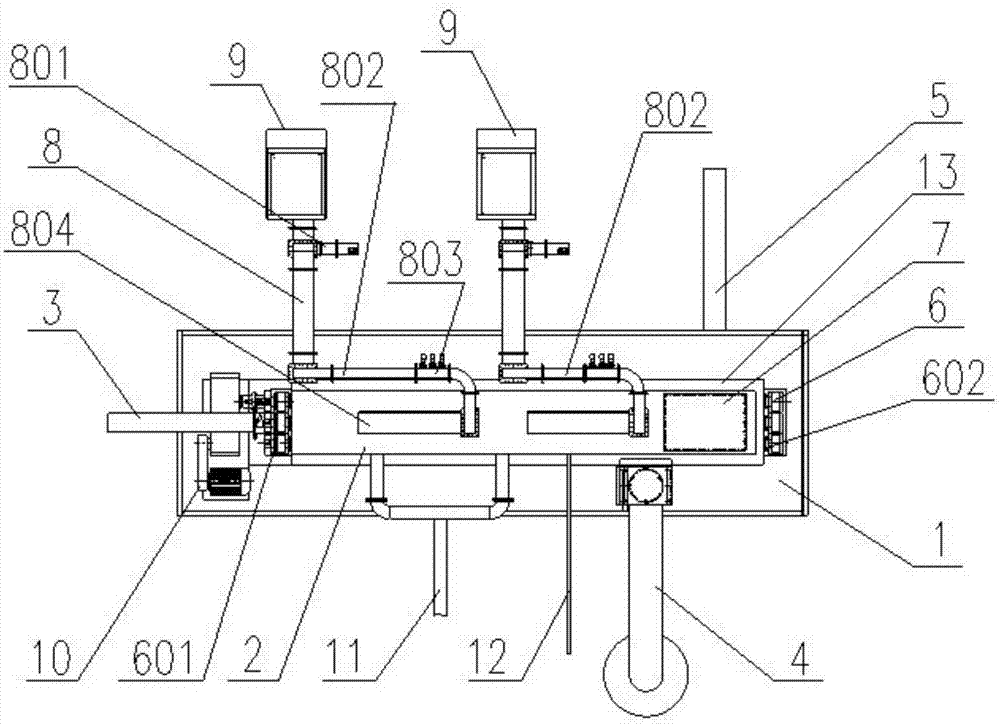

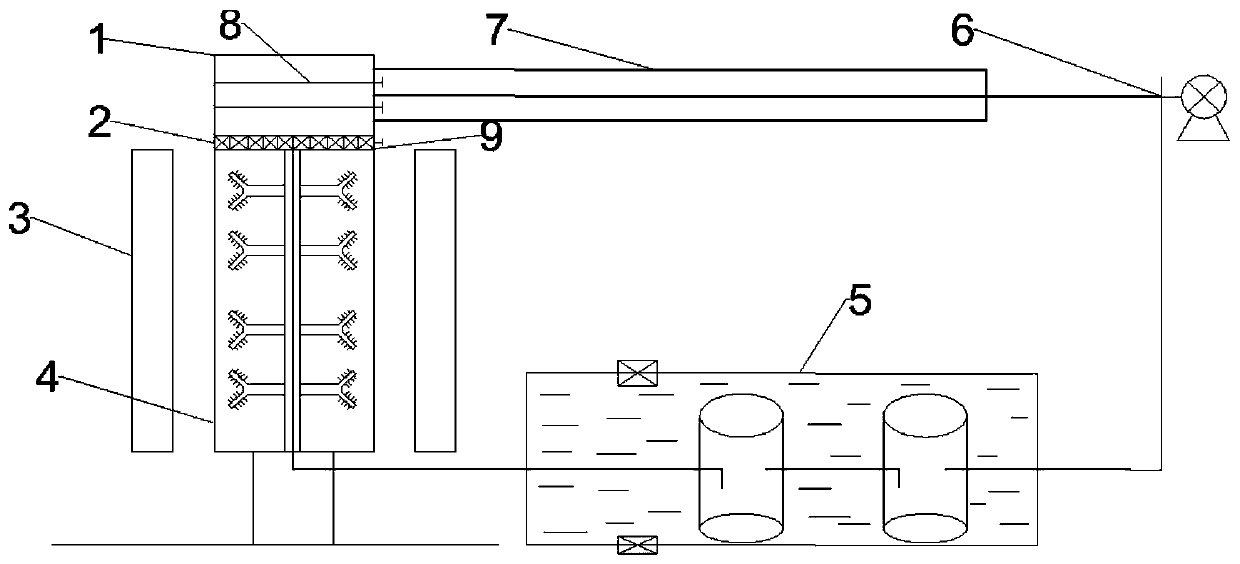

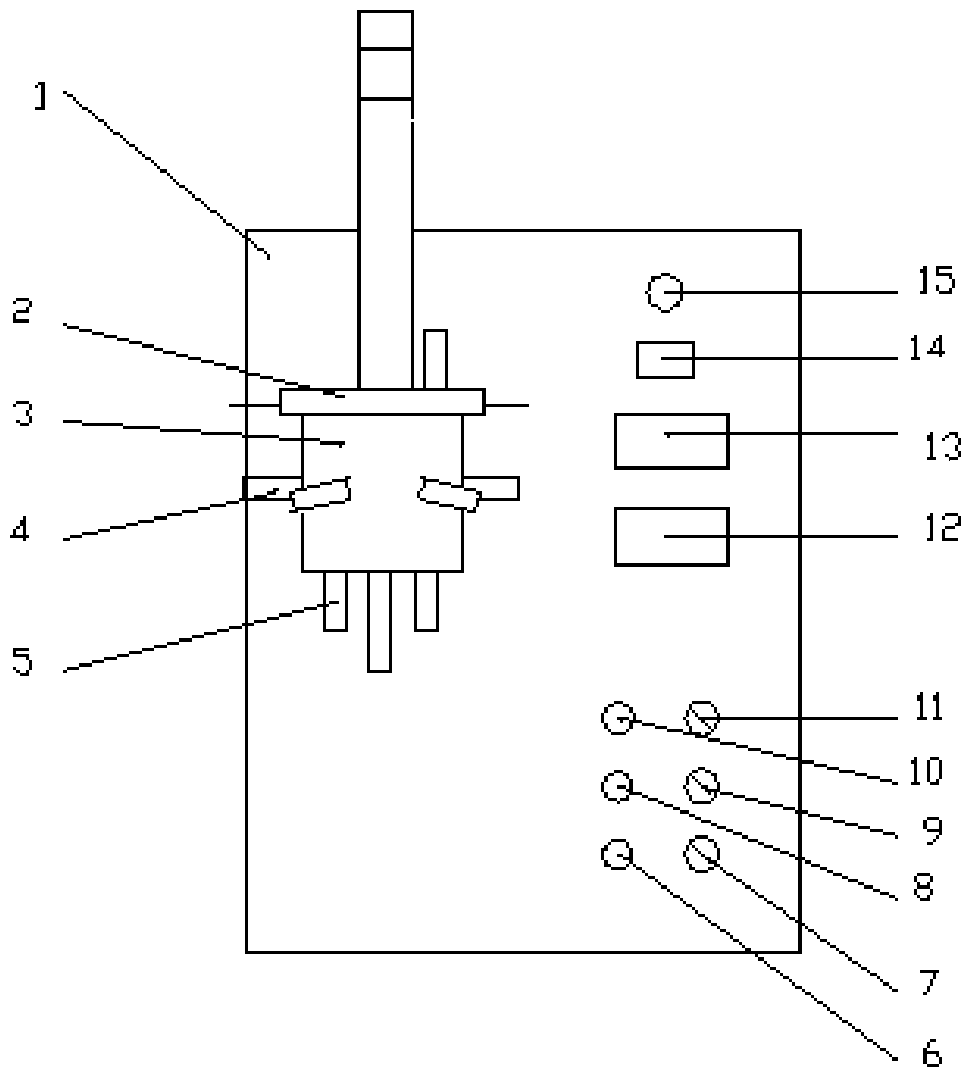

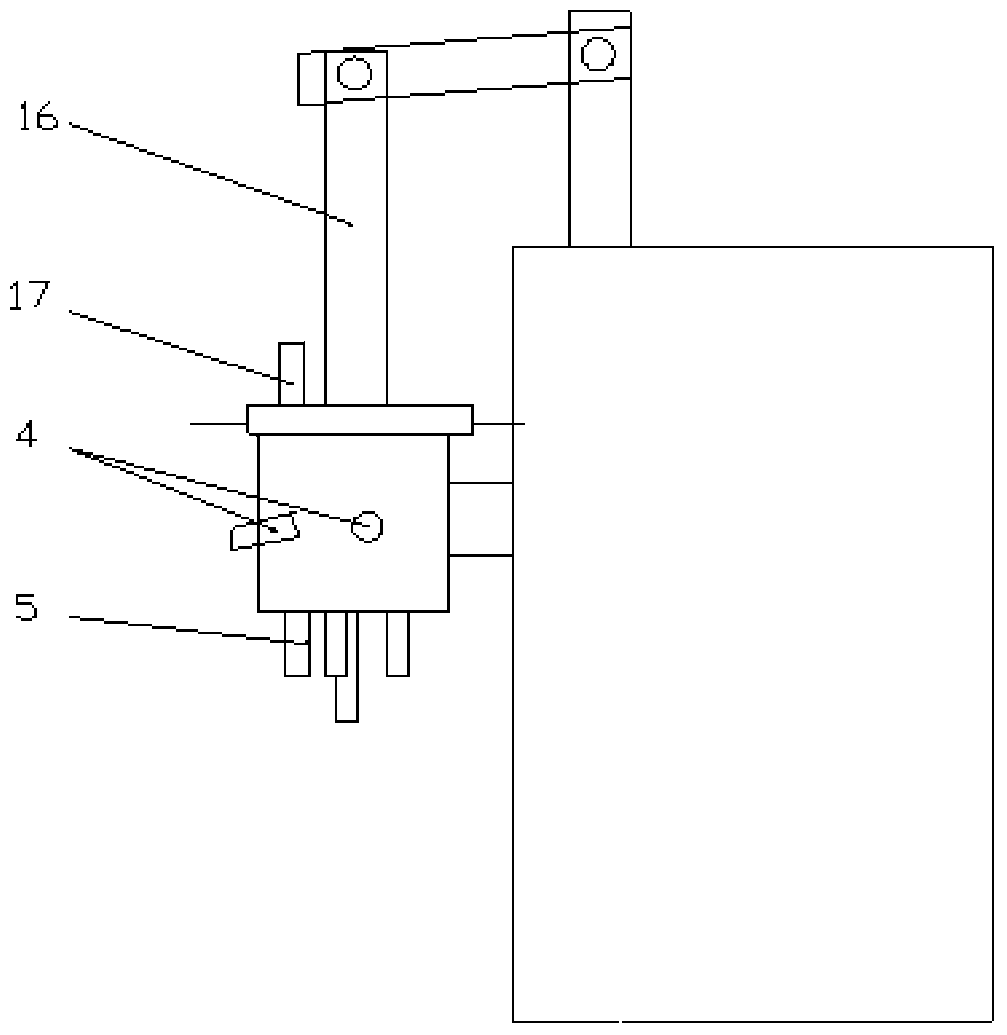

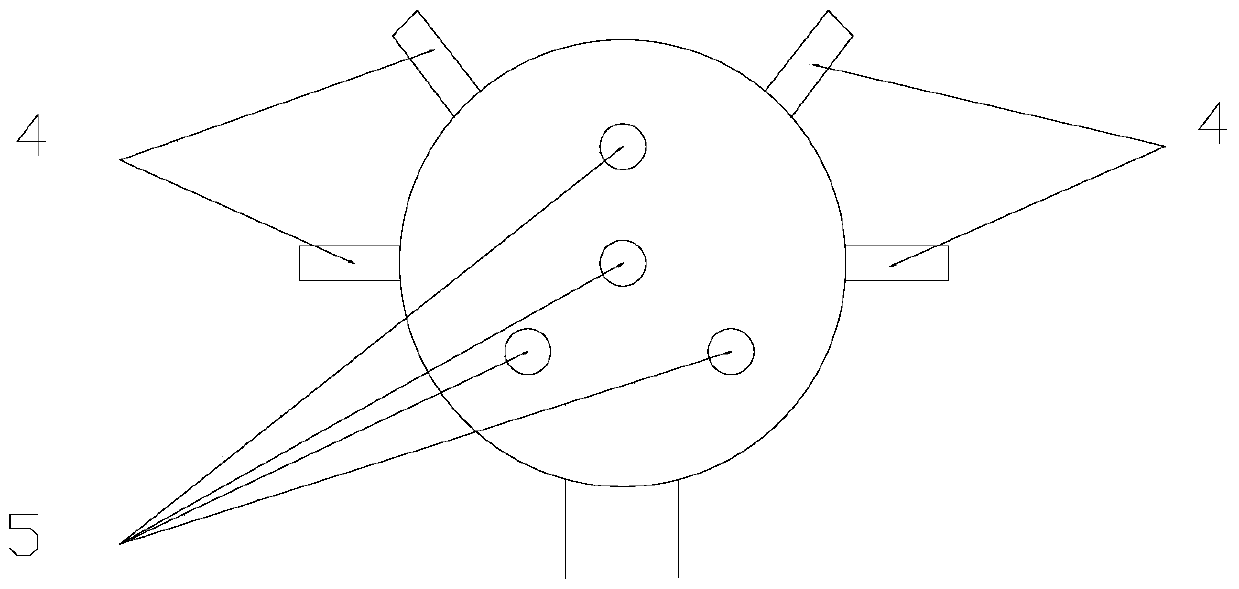

Microwave multi-spiral pyrolyzation equipment

PendingCN107883381AReasonable structural designSolve the problem that the continuous feeding and discharging of materials cannot be producedIncinerator apparatusMicrowave ovenMicrowave pyrolysis

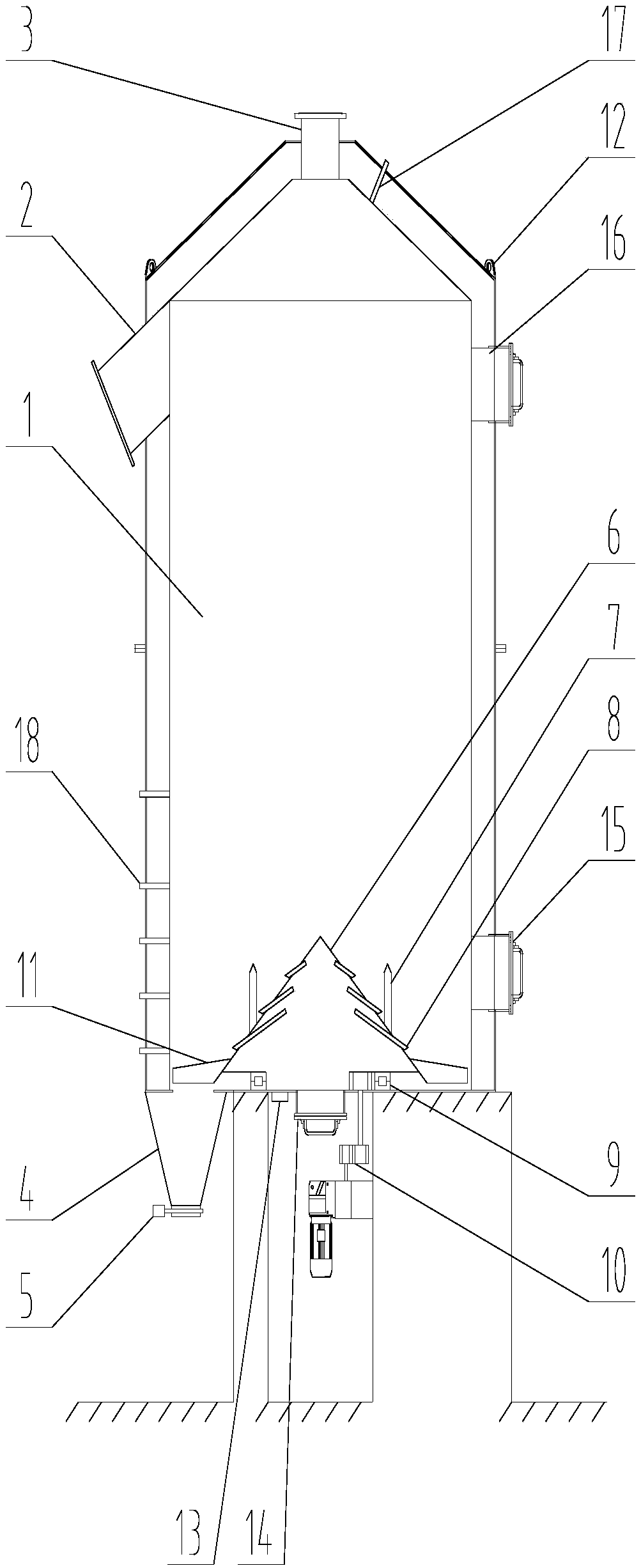

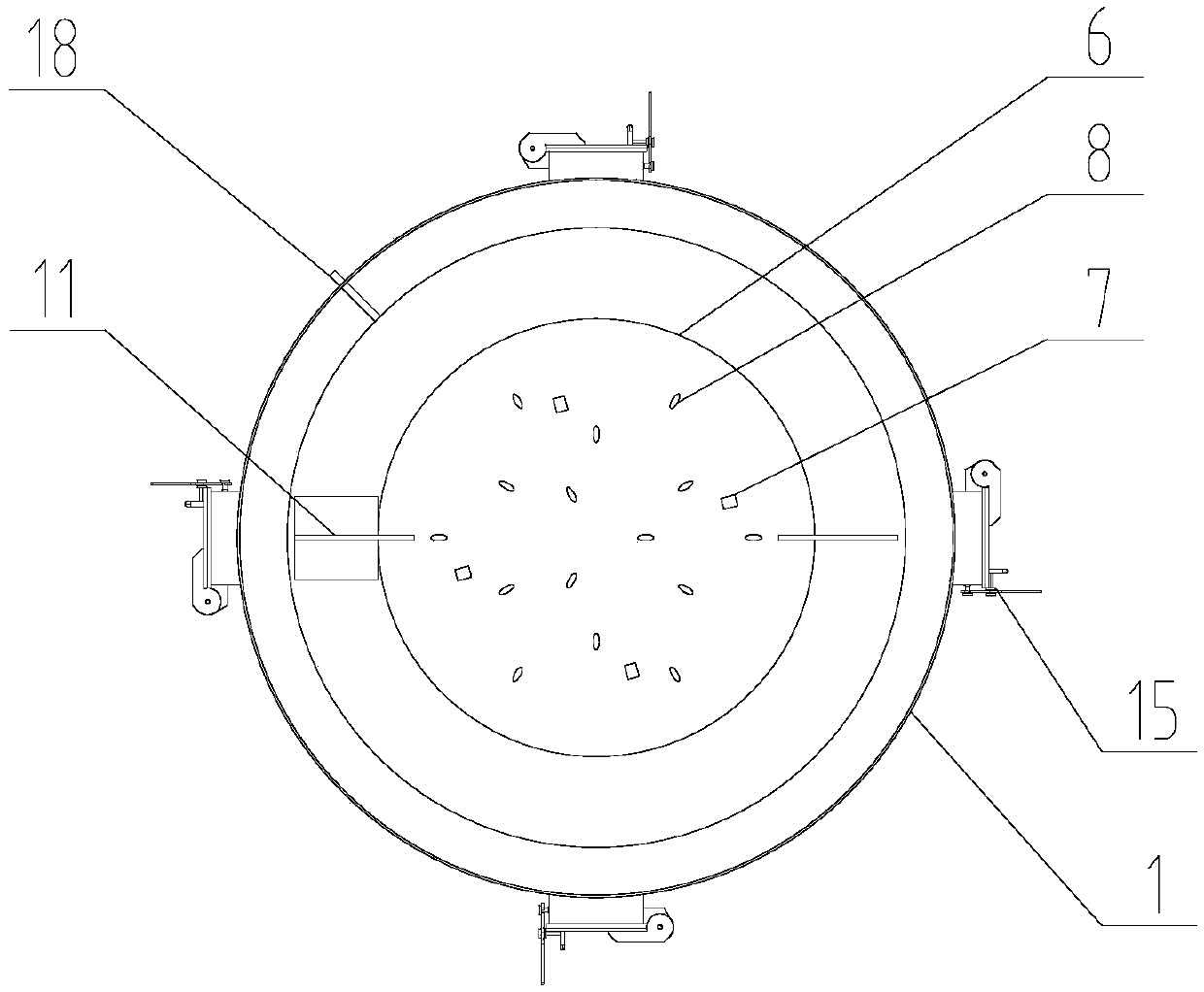

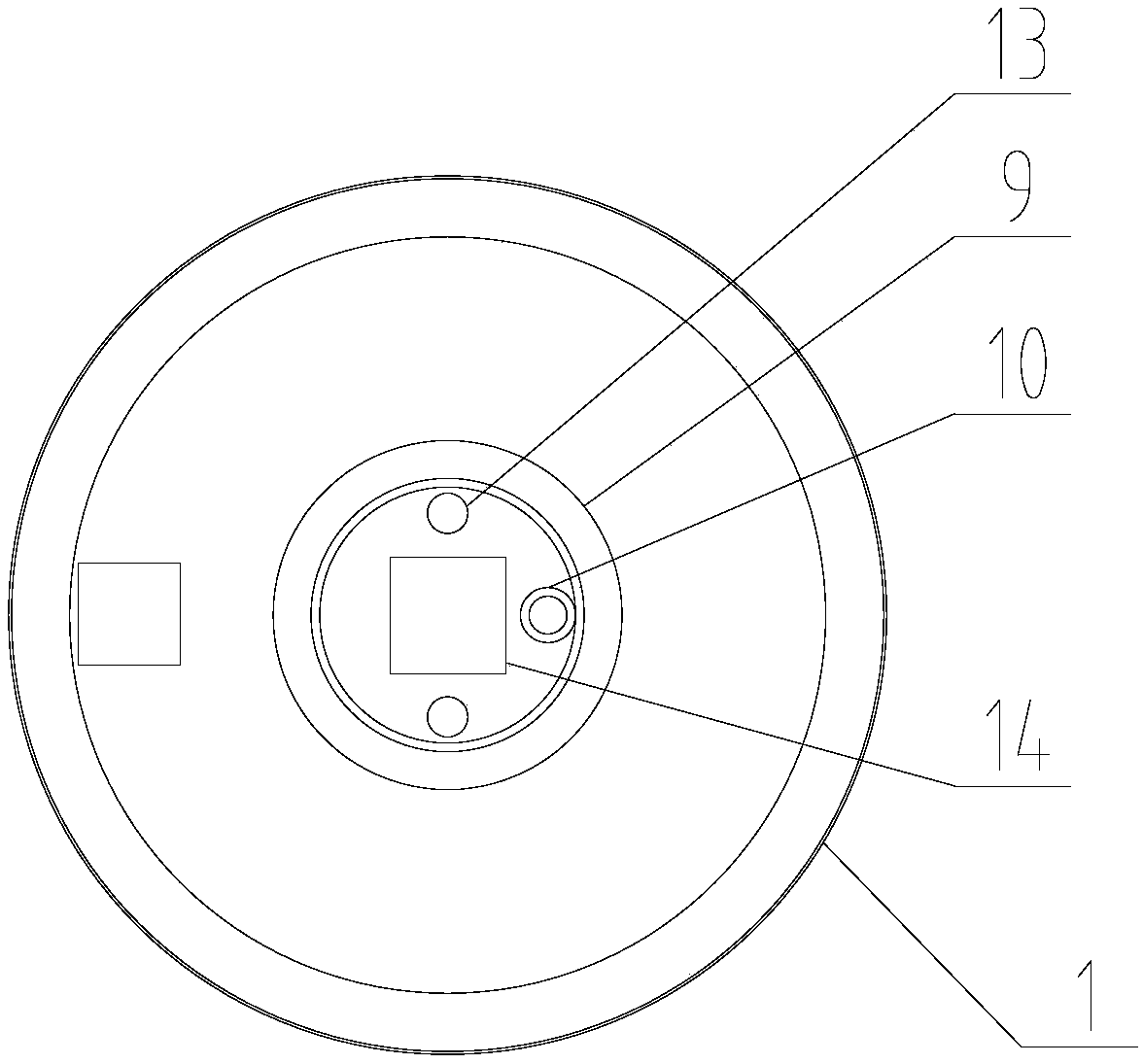

The invention discloses microwave multi-spiral pyrolyzation equipment. The microwave multi-spiral pyrolyzation equipment comprises a rack (1), a microwave pyrolyzation cavity (2) mounted in the rack (1), and a feeding pipeline (3), an explosion venting system (4), a discharging pipeline (5), an exhaust pipeline (11) and a nitrogen inflating pipeline (12) connected to the microwave pyrolyzation cavity (2); a furnace door (7) is mounted on the microwave pyrolyzation cavity (2), the microwave pyrolyzation cavity (2) is connected to a microwave transmission system (8), the microwave transmission system (8) is connected to a microwave energy generator (9), the microwave pyrolyzation cavity (2) is connected to a multi-spiral conveying system (6), and the multi-spiral conveying system (6) is driven by a motor (10) to rotate. The microwave multi-spiral pyrolyzation equipment disclosed by the invention is reasonable in design, uniform in microwave radiation and high in heating efficiency, can heat to 800 DEG C, is good in hermetic oxygen isolating property, has an anti-explosion function, is high in safety, can prevent the inner wall of the furnace body from coking, and can meet microwave treatment at different temperatures of various materials.

Owner:NANJING SANLE MICROWAVE TECH DEV +2

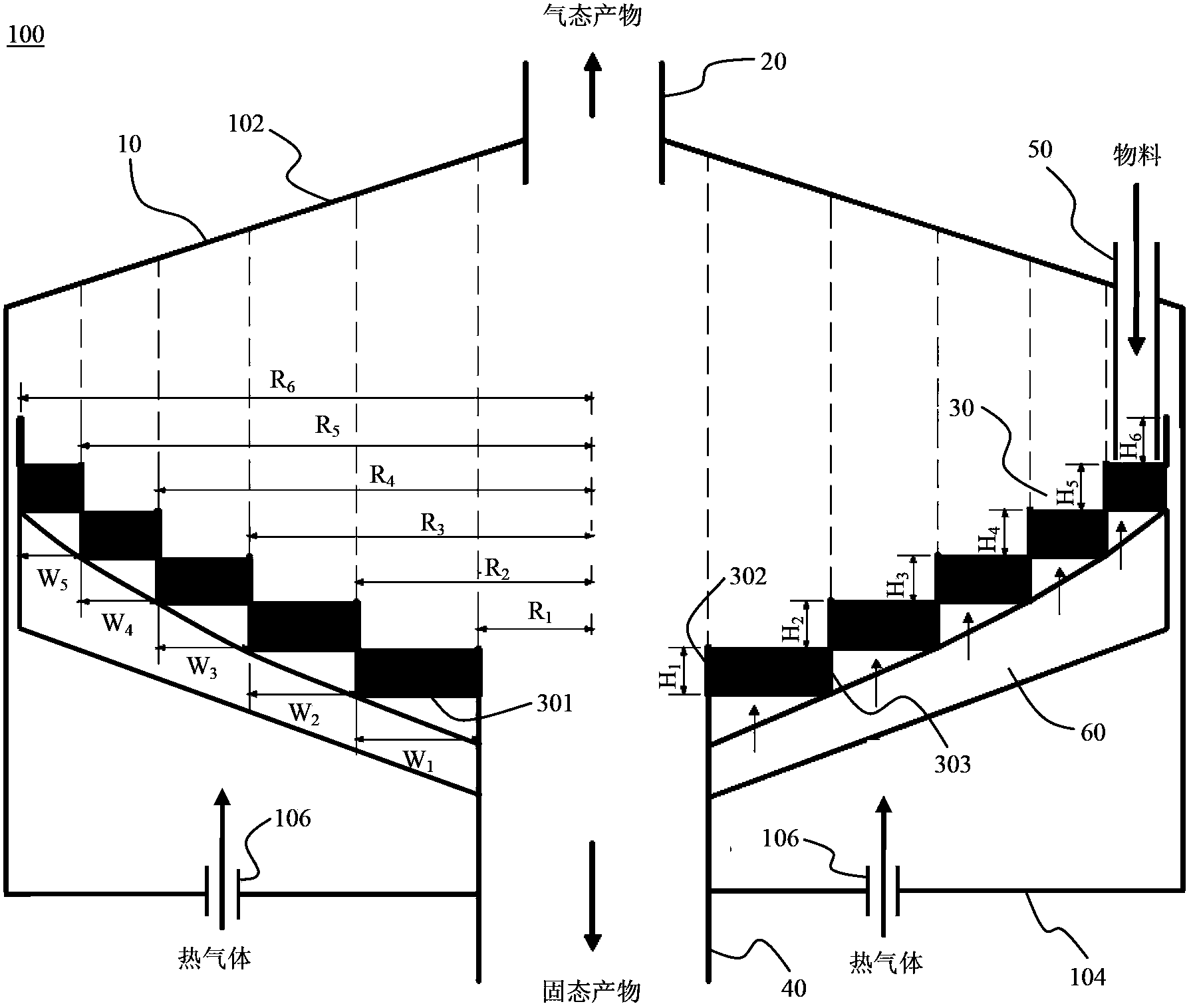

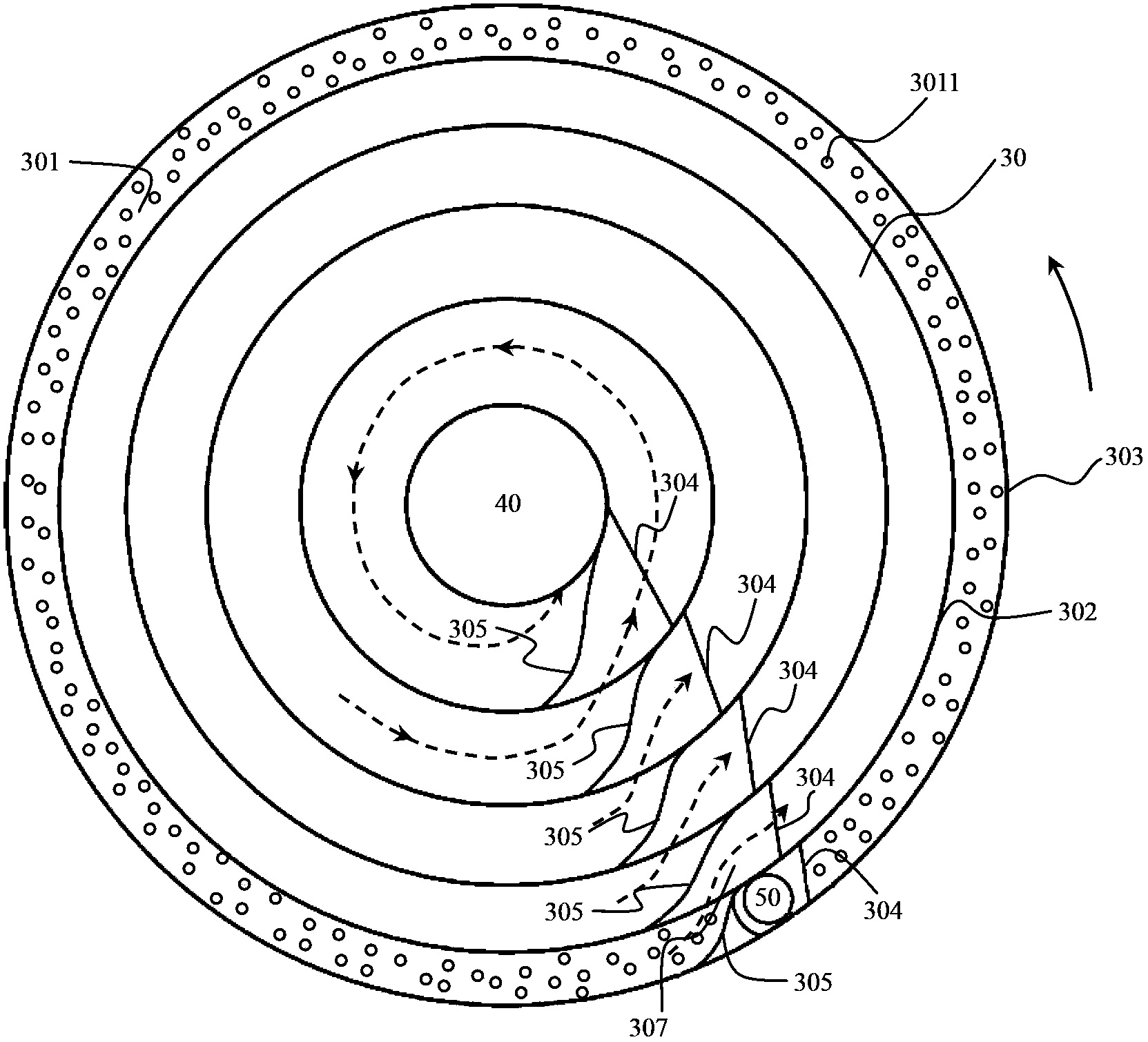

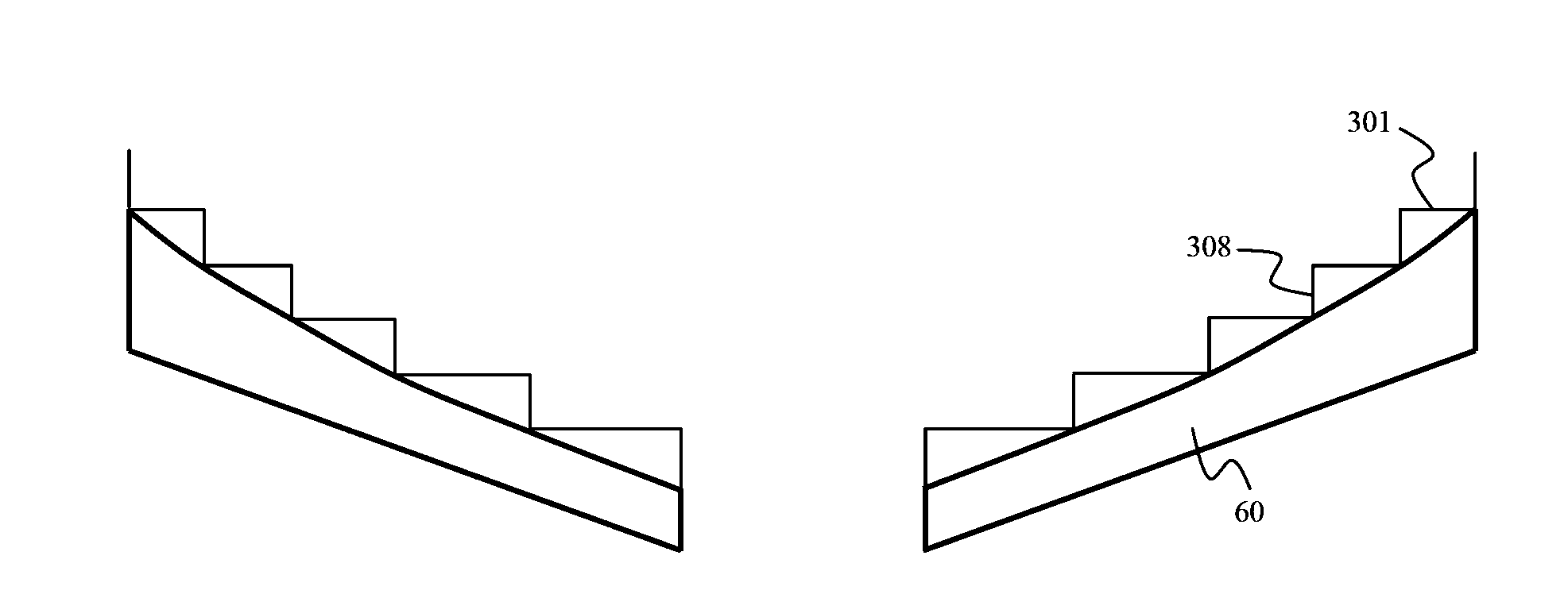

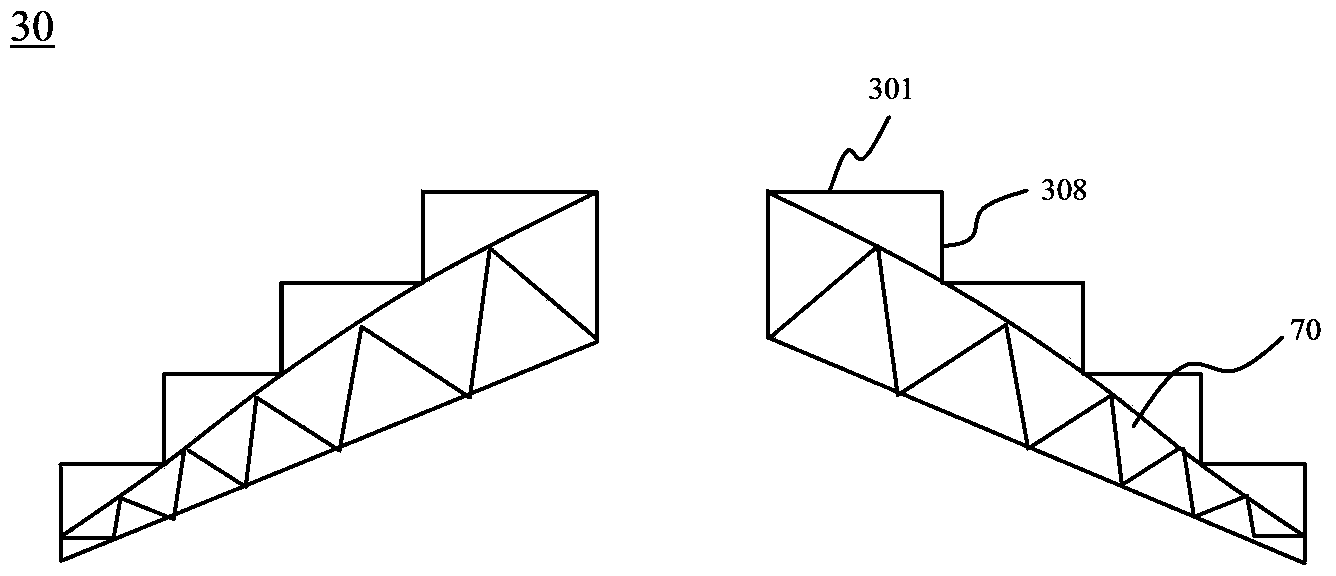

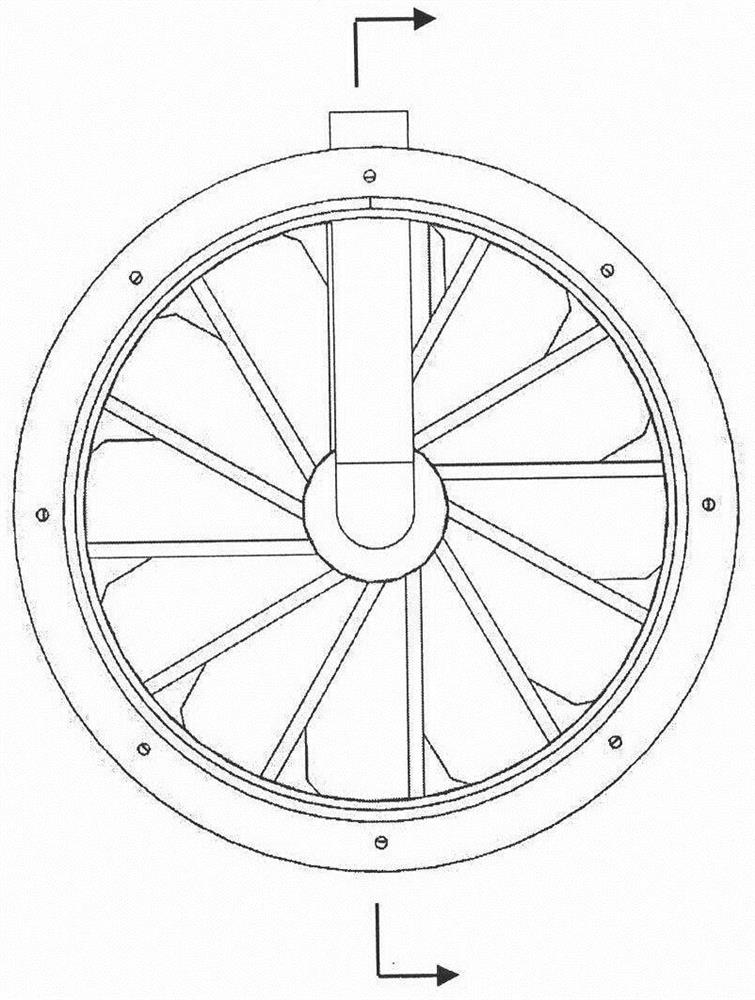

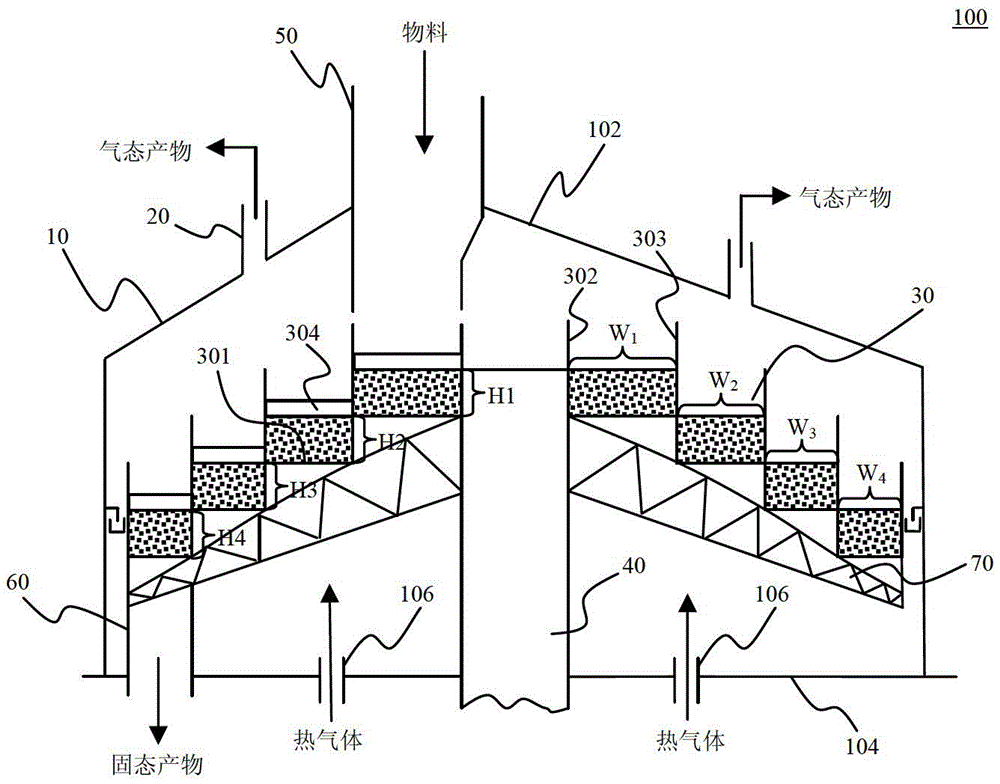

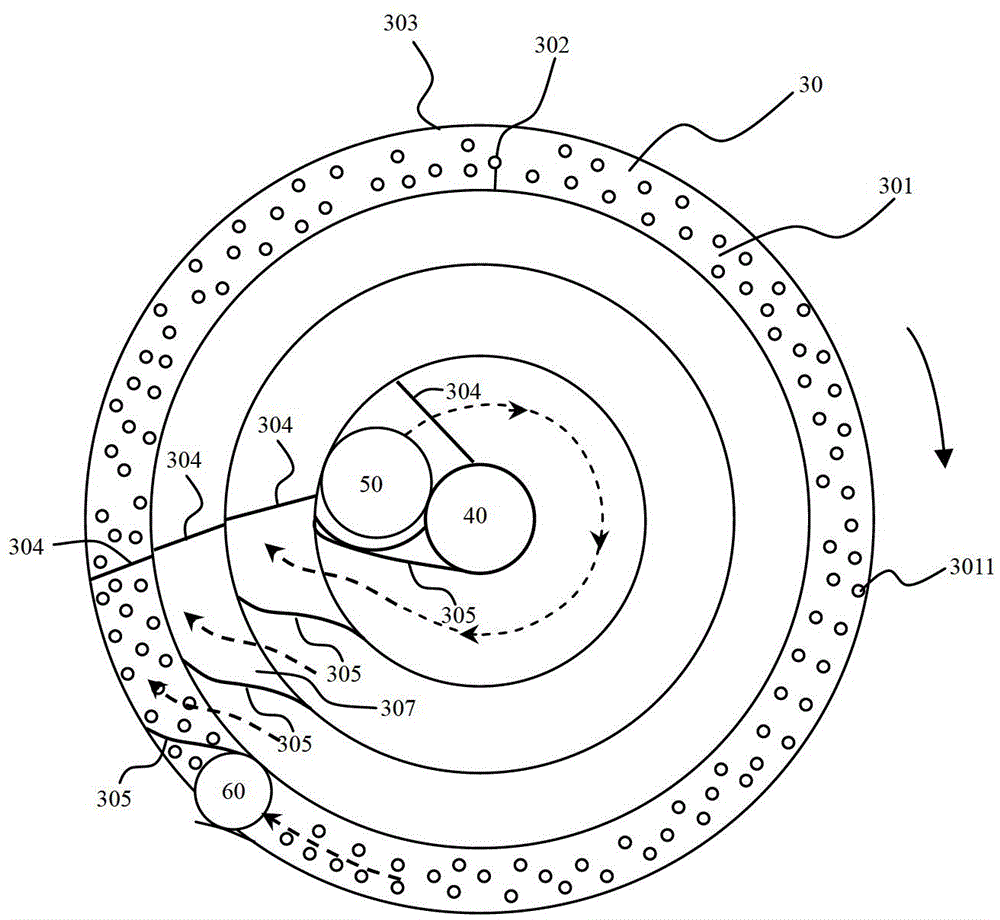

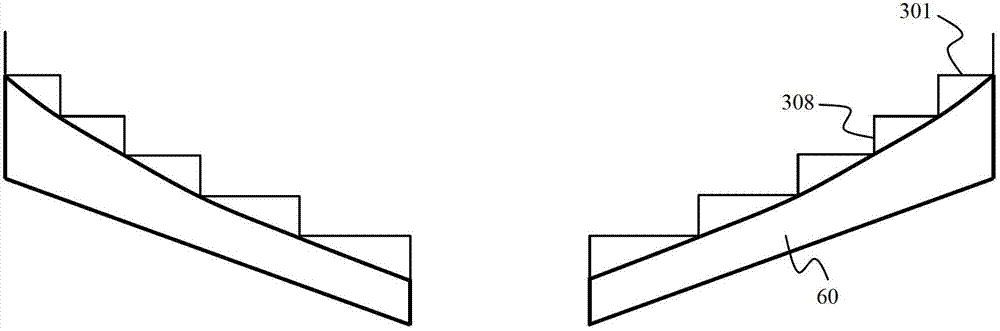

Drying/pyrolysis furnace with rotary material beds

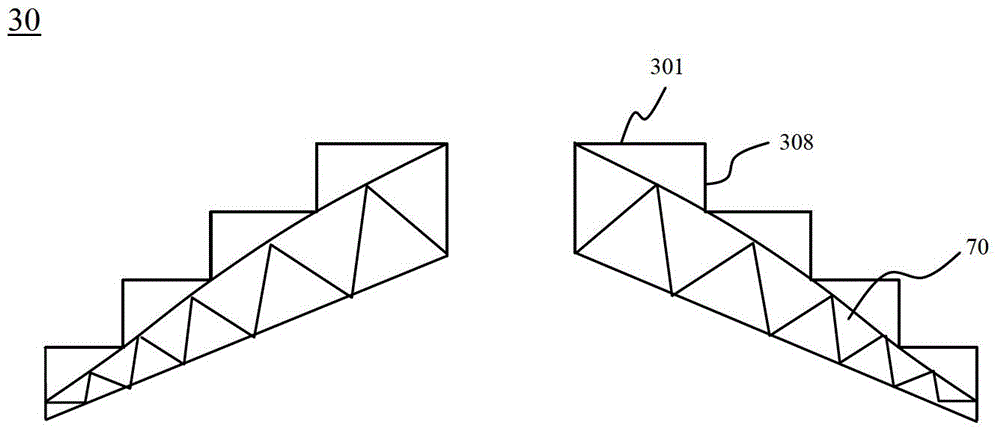

ActiveCN103383187AUniform pyrolysisImprove scalabilityDirect heating destructive distillationFurnace typesMechanical engineeringConcentric ring

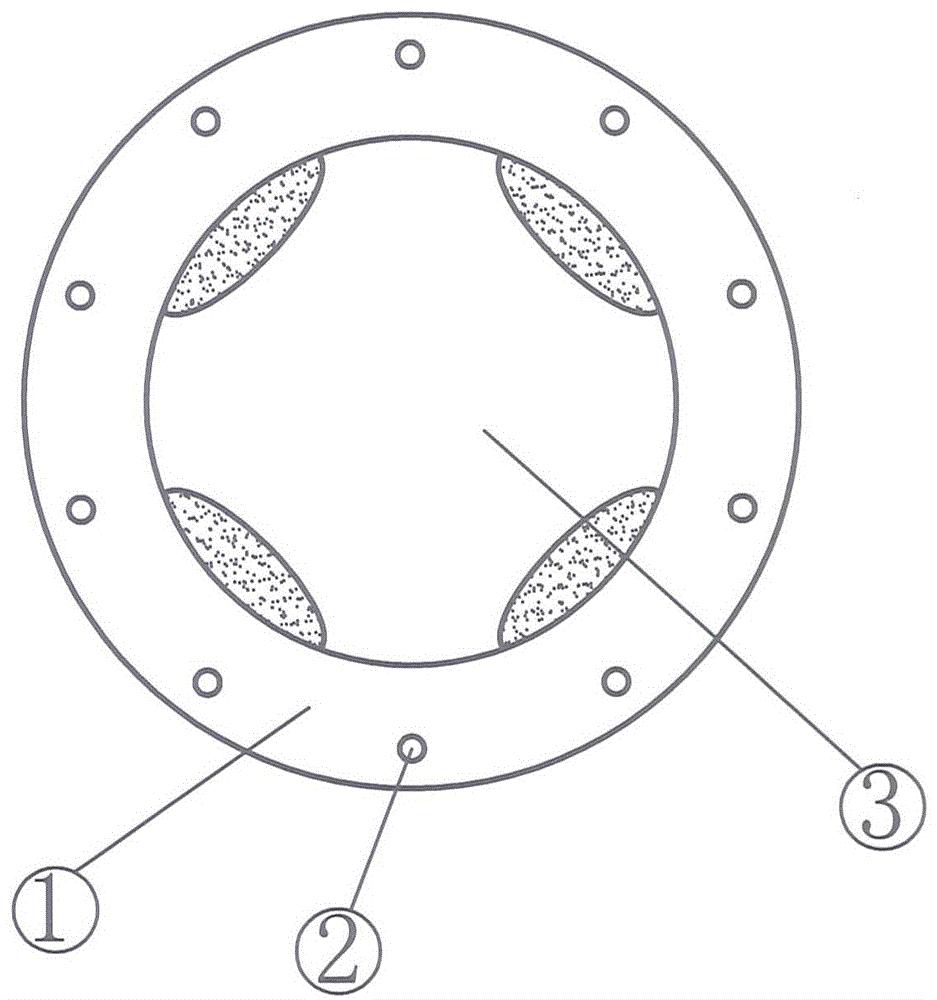

A drying / pyrolysis furnace with rotary material beds comprises a closed casing, N concentric-ring-shaped planar rotary material beds, a feed opening, N material baffles, N material blanking openings, and at least one waste gas outlet and / or pyrolysis gas product outlet, wherein the rotary material beds are arranged in the casing; two ends of each material baffle are in seamless connection with the inner wall and outer wall of a corresponding rotary material bed respectively; each rotary material bed comprises a rotatable planar bed base, as well as the inner wall and the outer wall which stay still relative to the bed base; at least one through hole is formed in the bed base of each rotary material bed; the heights of N rotary material beds reduce gradually from the inside to the outside; seamless connection is realized; being rotated to the position of a material baffle along with the bed base of a corresponding rotary material bed, material is pushed outward by the material baffle, and then falls to the next rotary material bed connected with the former material bed through the material blanking opening of the former material bed; through the manner, the material falls from the inside to the outside, is transported, through the bed bases of the N rotary material beds, to the blanking opening of the outermost rotary material bed, and is finally discharged out of the drying / pyrolysis furnace through the material blanking opening.

Owner:CHNA ENERGY INVESTMENT CORP LTD +1

An oil producing device integrating biomass drying, crushing and pyrolysis

InactiveCN109777464AFull residence timeExtended stayLiquid hydrocarbon mixture productionGrain treatmentsResidual carbonProcess engineering

An oil producing device integrating biomass drying, crushing and pyrolysis is provided. The device includes a fed material storage device, a furnace chamber, a pyrolysis chamber, a crusher, a condenser and a ventilation pipeline. The pyrolysis chamber is disposed in the furnace chamber. A feeding device is disposed on the pyrolysis chamber. The crusher is disposed in the pyrolysis chamber. The inlet of the condenser is connected to the outlet of the pyrolysis chamber, and the outlet of the condenser is connected to the ventilation pipeline. After a raw material is fed into the pyrolysis chamber, the raw material is crushed and stirred by the crusher in the pyrolysis chamber, and a thermocouple in the pyrolysis chamber adjusts the temperature in the pyrolysis chamber through a temperature controller. A pyrolysis product is fed into the condenser from the outlet of the pyrolysis chamber through a pipeline, biological oil after condensation is collected and residual carbon is collected atthe bottom of the pyrolysis chamber. Gas that cannot be condensed is conveyed to the fed material storage device through the ventilation pipeline, and waste heat of the gas is utilized to dry the biomass in the fed material storage device. The oil producing device is beneficial to sufficient biomass pyrolysis, and increases the yield of the biological oil by about 15%, heat can be recycled and air pollution is reduced.

Owner:JIANGSU UNIV

Rotary household garbage low-temperature pyrolyzing furnace

PendingCN109556114AUniform pyrolysisExtended service lifeIncinerator apparatusThermometerEngineering

Owner:GUANGXI NANNING LVZE ENVIRONMENTAL PROTECTION TECH CO LTD

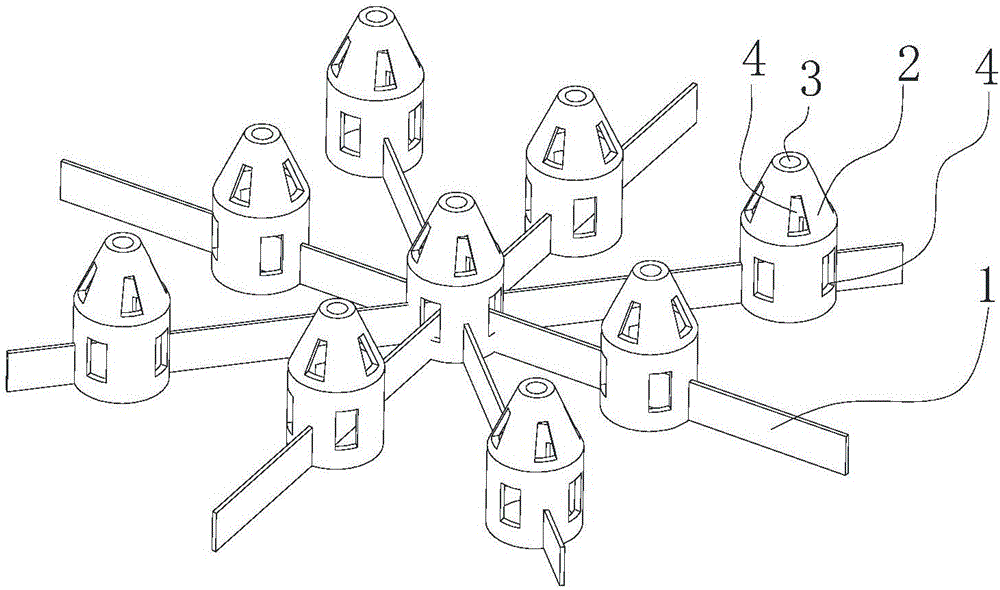

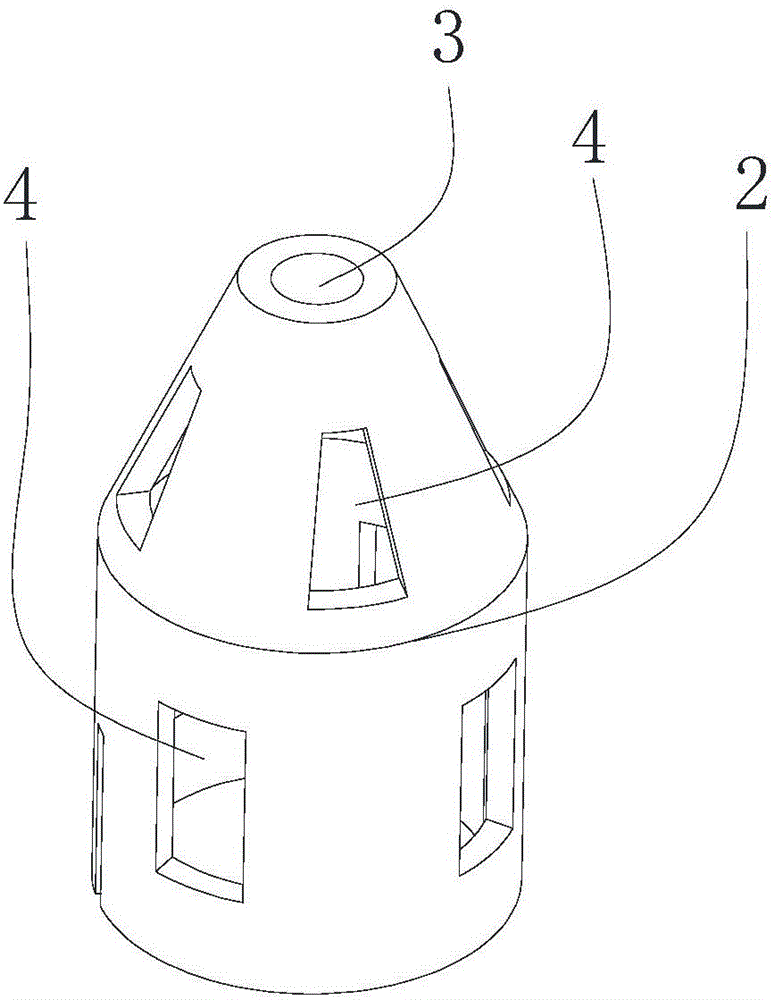

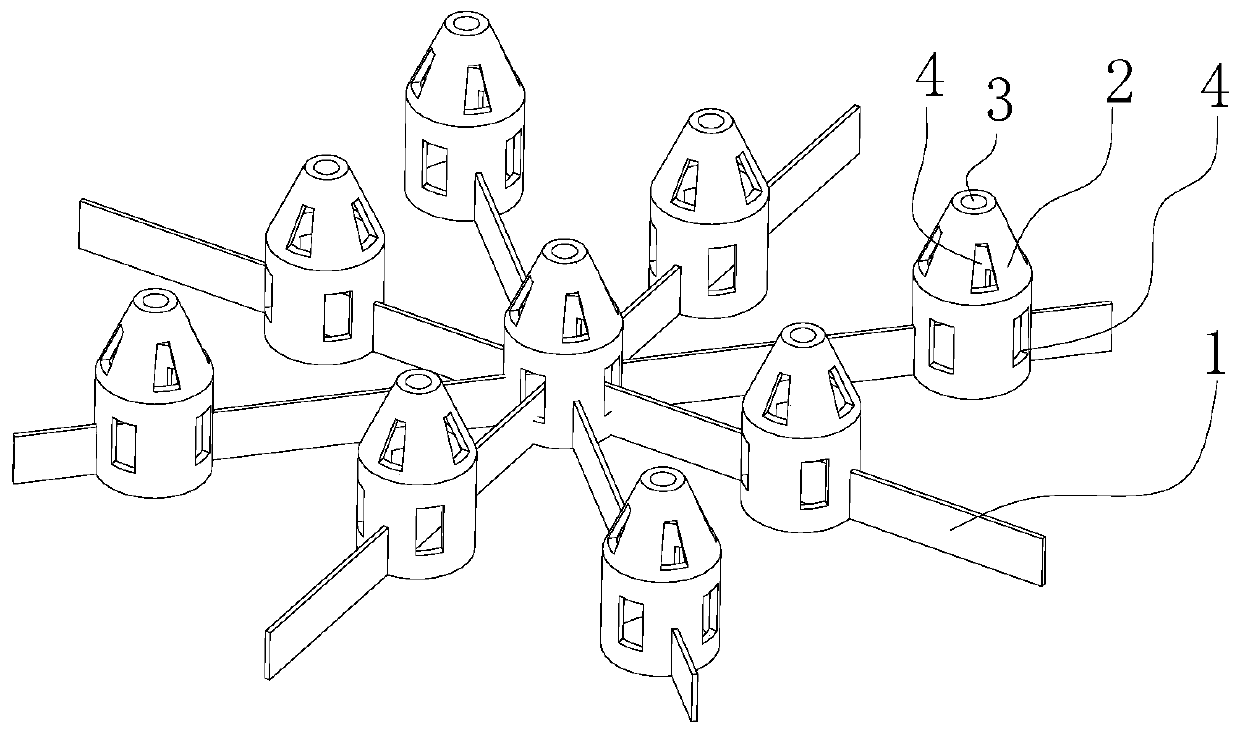

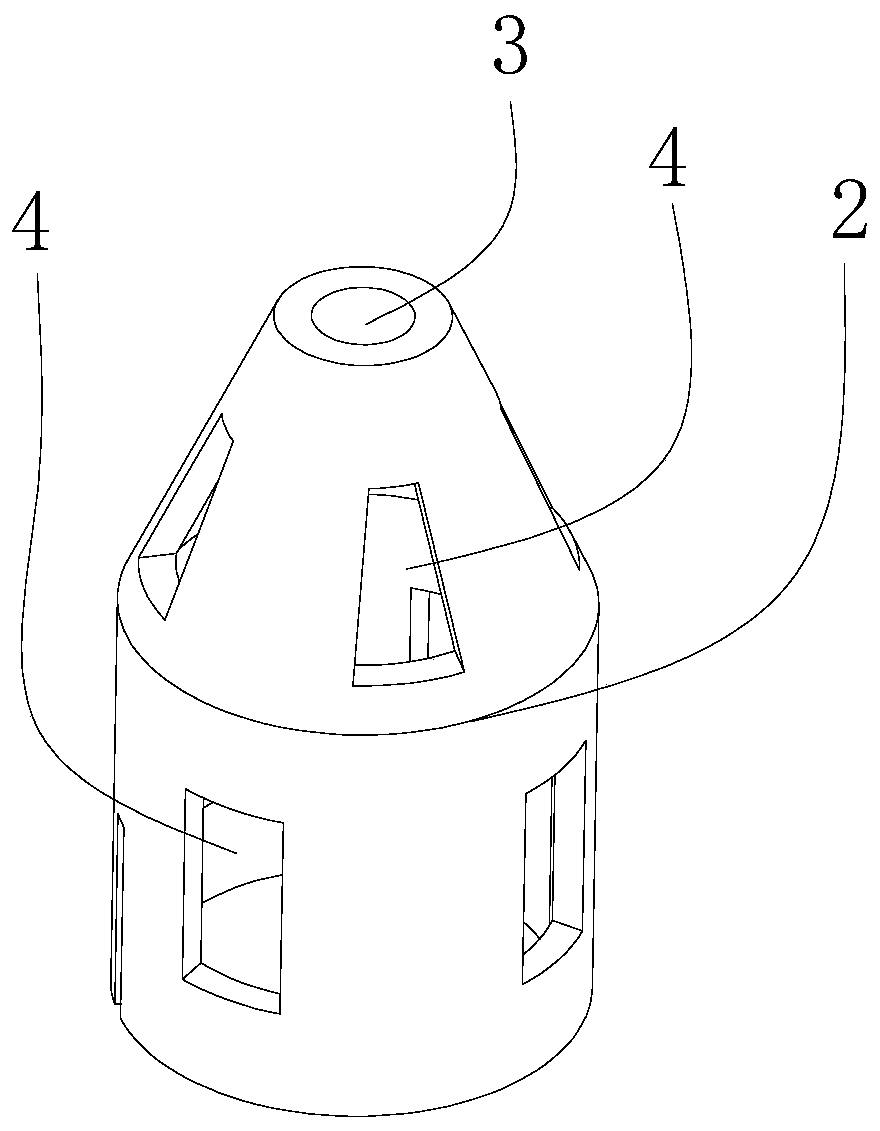

Garbage low-temperature pyrolysis furnace combustion-supporting device

The invention discloses a garbage low-temperature pyrolysis furnace combustion-supporting device. The garbage low-temperature pyrolysis furnace combustion-supporting device is mainly composed of a garbage supporting frame and a plurality of hollow cones; the multiple hollow cones are uniformly installed on the garbage supporting frame, and the bottoms of the hollow cones are provided with openings; and the tops and the surfaces of the hollow cones are provided with vent holes penetrating through the openings of the bottoms. The garbage low-temperature pyrolysis furnace combustion-supporting device has the advantages of being high and uniform in garbage pyrolysis speed, not prone to being extinguished, low in operation cost and the like.

Owner:南宁市绿城环保设备有限责任公司

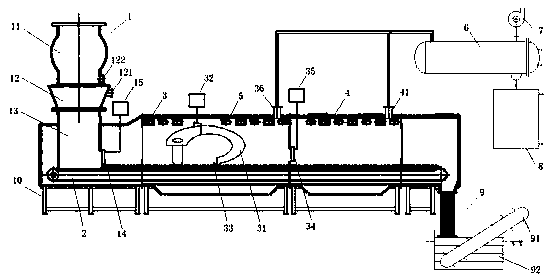

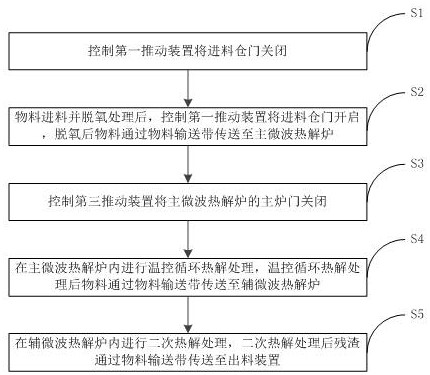

Oily sludge treatment method

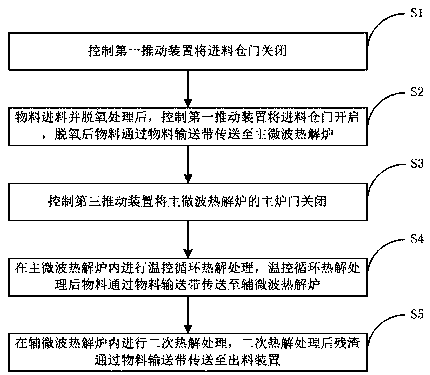

ActiveCN109665688AReduce oxygen contentImprove heating and pyrolysis uniformitySludge treatment by pyrolysisByproduct vaporizationTemperature controlMicrowave pyrolysis

The invention discloses an oily sludge treatment method, and relates to the technical field of garbage treatment. The treatment method includes the steps: controlling a first push device to close a feed bin gate; feeding and deoxidizing materials, controlling the first push device to open the feed bin gate, and conveying the deoxidized materials to a main microwave pyrolysis furnace by a materialconveying belt; controlling a third push device to close a main furnace door of the main microwave pyrolysis furnace; performing temperature control cycling pyrolysis treatment in the main microwave pyrolysis furnace, and conveying the materials after temperature control cycling pyrolysis treatment to an auxiliary microwave pyrolysis furnace by the material conveying belt; performing secondary pyrolysis treatment in the auxiliary microwave pyrolysis furnace, and conveying residues after secondary pyrolysis treatment to a discharging device by the material conveying belt. The oily sludge treatment method has the advantages that the materials in the microwave pyrolysis furnaces are uniformly heated and pyrolyzed, and pyrolysis efficiency is high.

Owner:航天国环技术集团有限公司

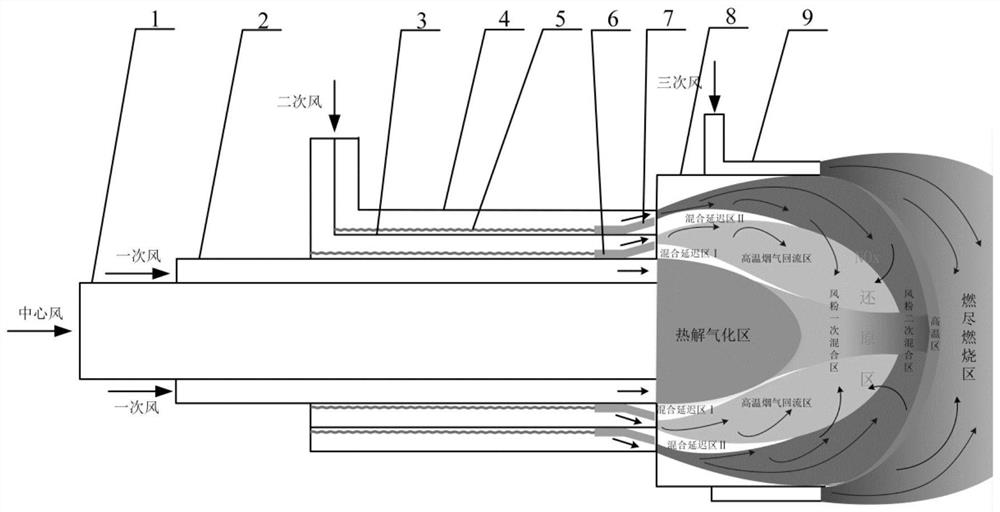

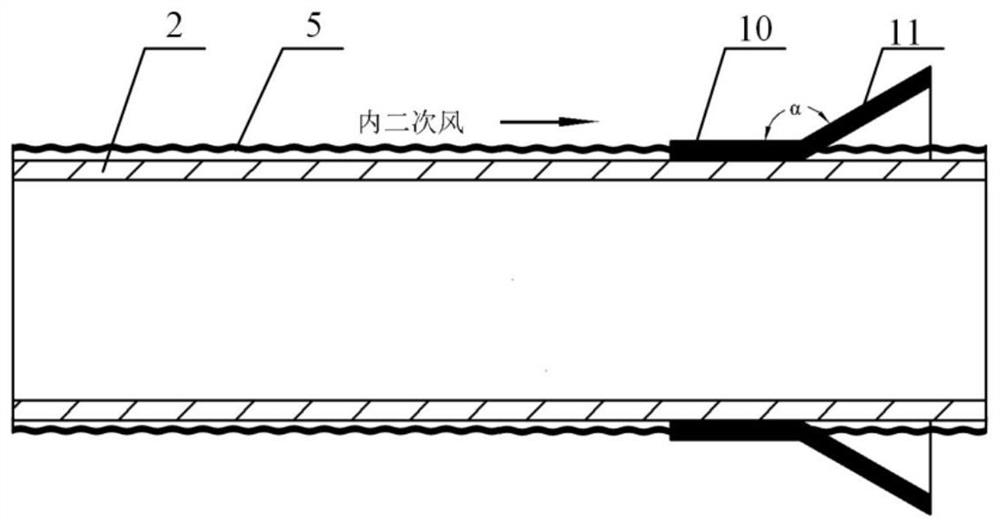

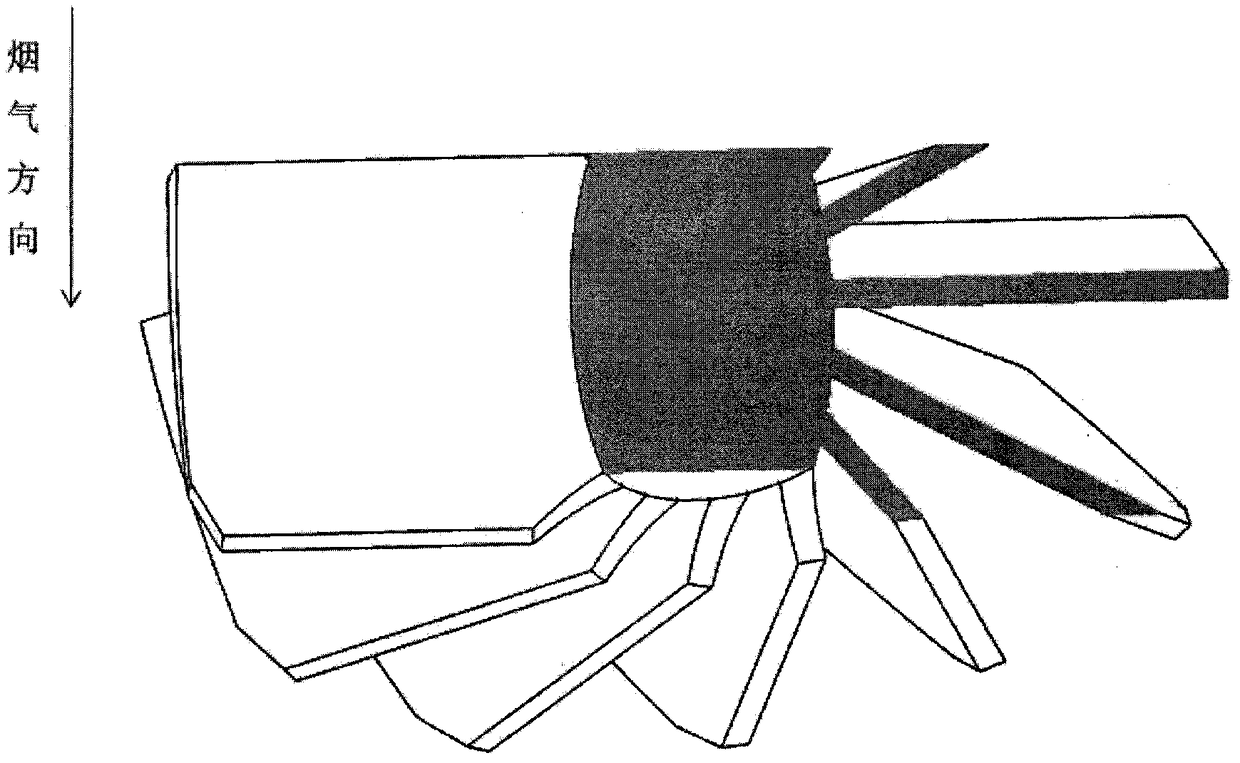

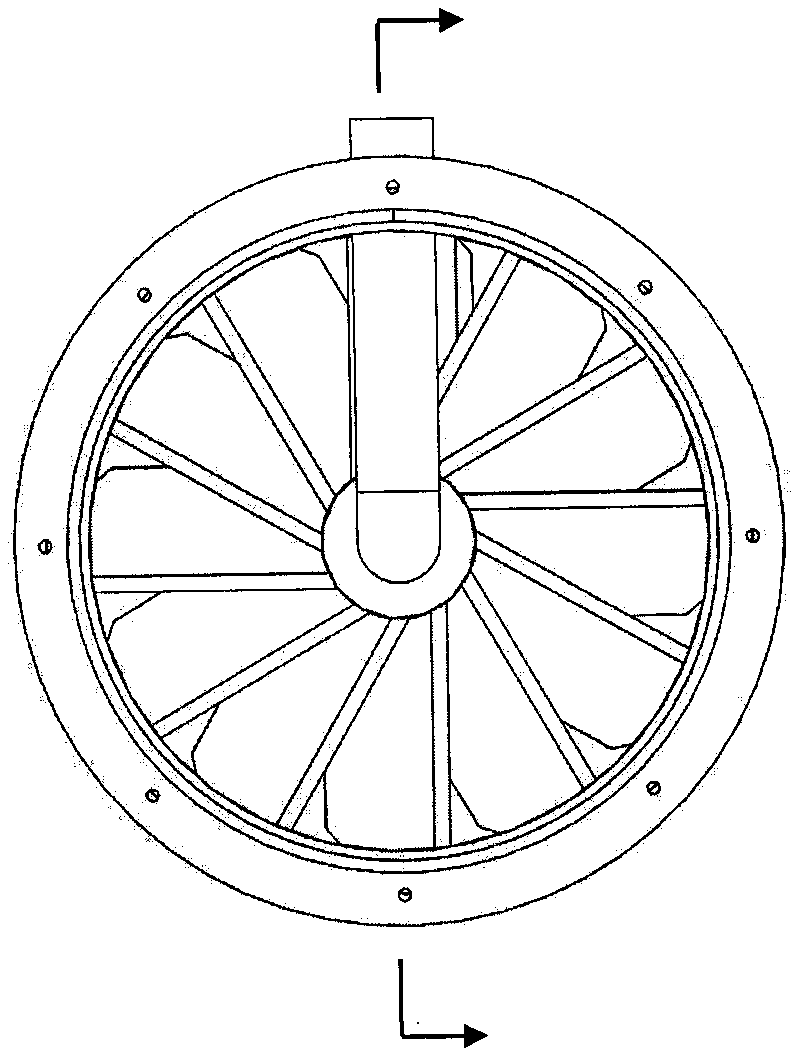

Adjustable air-coal step-by-step mixing low-NOx combustion device

ActiveCN111947141AStable combustionReduce generationFuel supply regulationPulverulent fuel combustion burnersThermodynamicsCombustion chamber

Provided is an adjustable air-coal step-by-step mixed combustion device. The device comprises a central air pipe, a primary air pipe, a rotational flow inner secondary air pipe, and a direct flow outer secondary air pipe which are sequentially arranged from inside to outside. Pre-combustion chambers are arranged at the tails of the air pipes in the airflow direction, and tertiary air pipes are arranged outside the pre-combustion chambers. An annular air flow channel between the primary air pipe and the rotational flow inner secondary air pipe is provided with an air-coal mixing first-stage regulator, and the primary air pipe is sleeved by the air-coal mixing first-stage regulator. An annular air flow channel between the rotational flow inner secondary air pipe and the direct flow outer secondary air pipe is provided with an air-coal mixing second-stage regulator of the same structure as the air-coal mixing first-stage regulator. By controlling the mixing time and the mixing position ofprimary air carrying pulverized coal, rotational flow inner secondary air, and direct flow outer secondary air, stable combustion of the pulverized coal is guaranteed, the production of NOx is remarkably reduced, and the coal type adaptive capacity of the combustion device is improved.

Owner:XI AN JIAOTONG UNIV

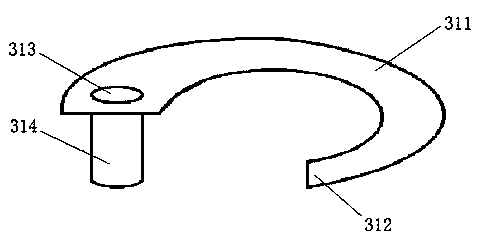

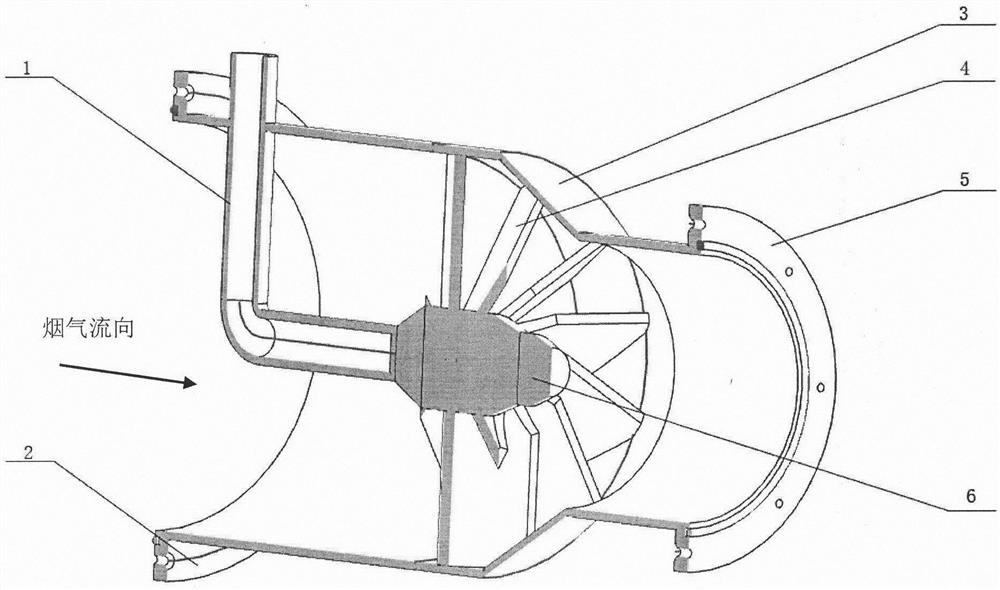

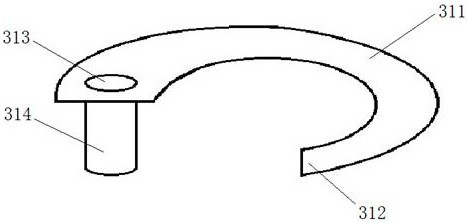

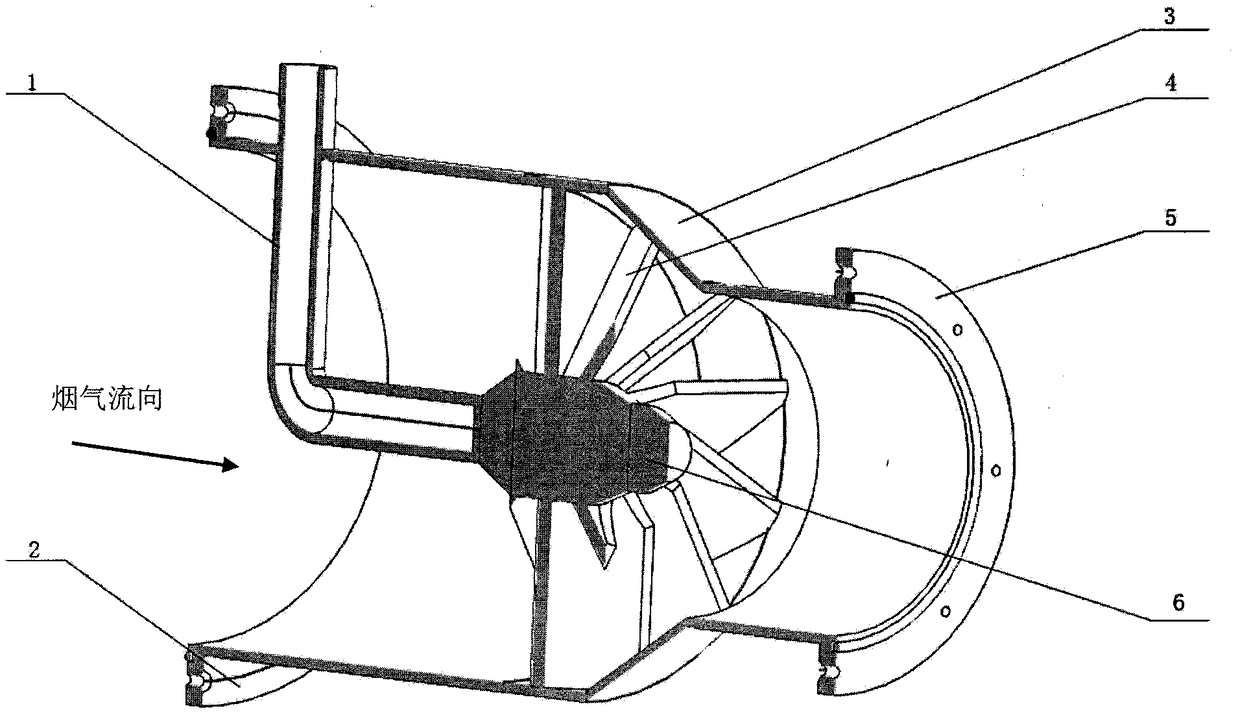

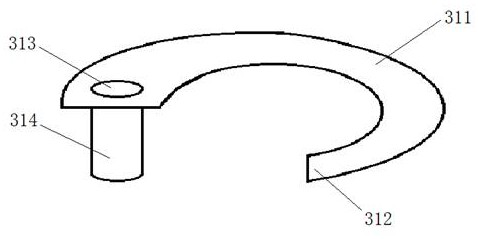

A detachable swirling vehicle scr mixer and nozzle coupling device

ActiveCN109236431BEasy for daily maintenanceMeet the design requirementsInternal combustion piston enginesExhaust apparatusDieselingUrea transport

The invention belongs to the technical field of diesel exhaust aftertreatment, and relates to a novel detachable swirling vehicle SCR mixer and nozzle coupling device. The device comprises a casing. Front and rear flange plates are respectively disposed on two ends of the casing, and a swirling mixer is disposed in the casing. The mixer is designed in a hollow manner and is fixedly connected to the casing. A front flange plate connection port is an air inlet of the device, and a rear flange plate connection port is an air outlet of the device. A urea conveying elbow is arranged between the airinlet and the mixer, and the elbow is connected to the mixer. A urea nozzle is arranged on the rear of the mixer, and a casing section of the urea nozzle is in tapered design. The coupling device isbeneficial to urea pyrolysis, can effectively solve problems of urea cracking, urea crystallization and ammonia distribution uniformity, and the device is convenient to disassemble, and is convenientfor daily maintenance and repair.

Owner:HEBEI UNIV OF TECH

Drying/pyrolysis furnace with rotary material beds

ActiveCN103383187BUniform pyrolysisImprove scalabilityDirect heating destructive distillationFurnace typesEngineeringMechanical engineering

A drying / pyrolysis furnace with rotary material beds comprises a closed casing, N concentric-ring-shaped planar rotary material beds, a feed opening, N material baffles, N material blanking openings, and at least one waste gas outlet and / or pyrolysis gas product outlet, wherein the rotary material beds are arranged in the casing; two ends of each material baffle are in seamless connection with the inner wall and outer wall of a corresponding rotary material bed respectively; each rotary material bed comprises a rotatable planar bed base, as well as the inner wall and the outer wall which stay still relative to the bed base; at least one through hole is formed in the bed base of each rotary material bed; the heights of N rotary material beds reduce gradually from the inside to the outside; seamless connection is realized; being rotated to the position of a material baffle along with the bed base of a corresponding rotary material bed, material is pushed outward by the material baffle, and then falls to the next rotary material bed connected with the former material bed through the material blanking opening of the former material bed; through the manner, the material falls from the inside to the outside, is transported, through the bed bases of the N rotary material beds, to the blanking opening of the outermost rotary material bed, and is finally discharged out of the drying / pyrolysis furnace through the material blanking opening.

Owner:CHNA ENERGY INVESTMENT CORP LTD +1

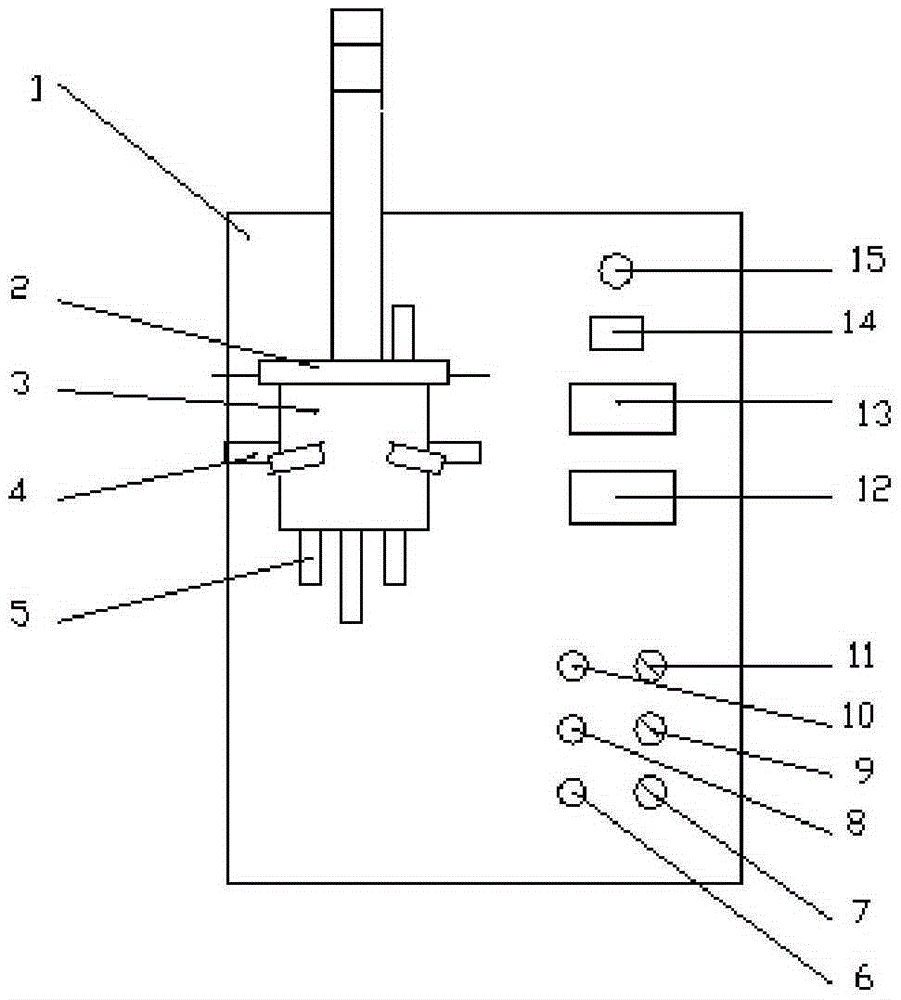

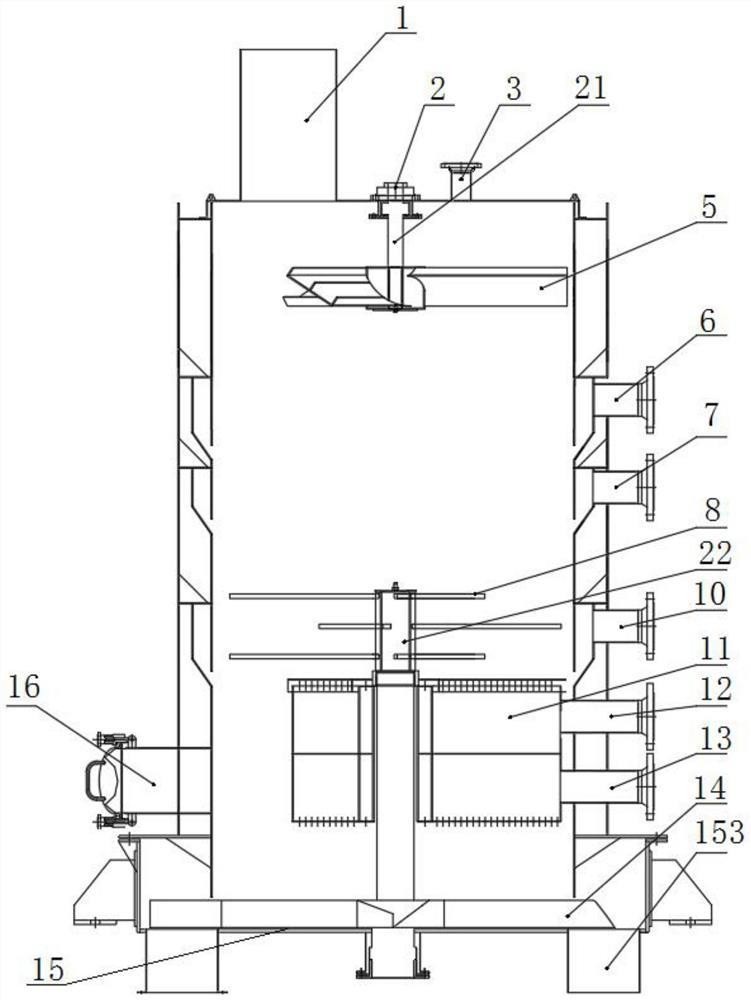

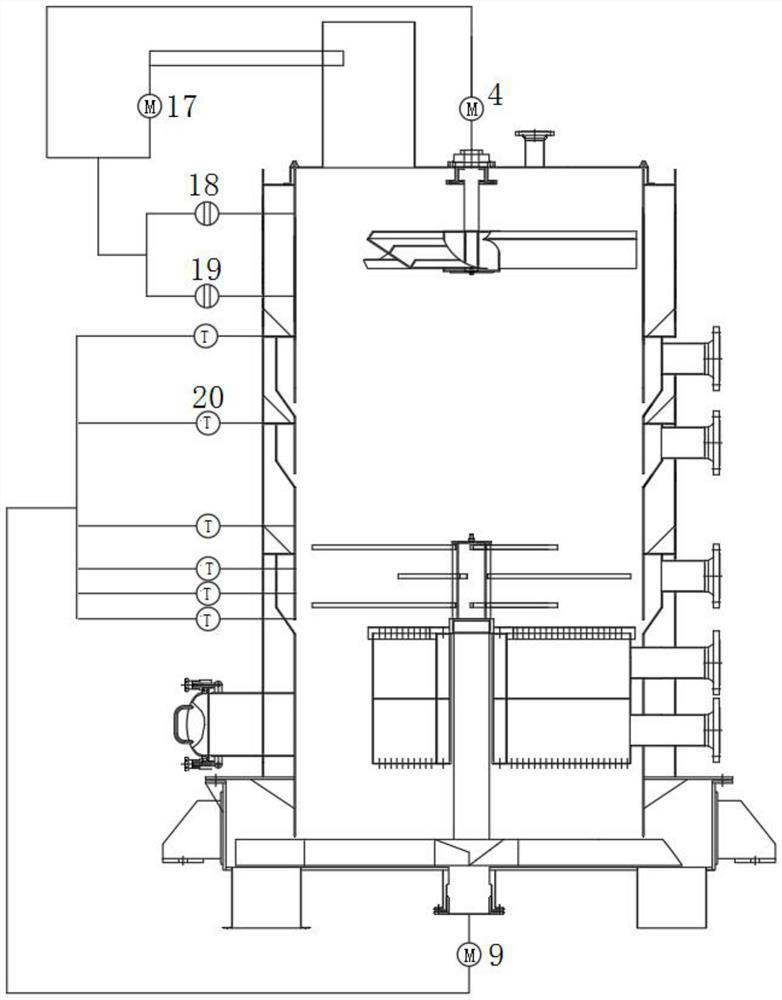

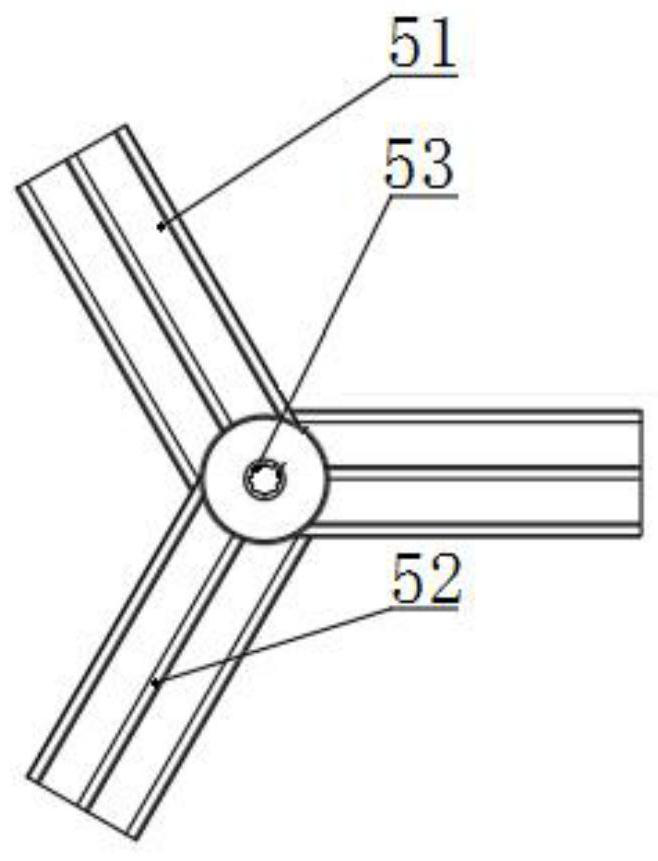

Discharging and stirring system of vertical pyrolyzing furnace

PendingCN111718735ATake advantage ofUniform pyrolysisDirect heating destructive distillationBiofuelsThermodynamicsProcess engineering

The invention discloses a novel discharging and stirring system of a vertical pyrolyzing furnace, belonging to the field of chemical equipment. The novel discharging and stirring system comprises a compaction mechanism, a stirring mechanism and a discharging mechanism which are sequentially arranged in a furnace body from top to bottom, wherein the compaction mechanism has compaction and flattening effects on materials in a compaction area of the compaction mechanism, can effectively prevent the materials in the furnace from being loosely distributed, and guarantees that the inner volume of the furnace is fully utilized; the stirring mechanism can play a role in stirring materials in the furnace to ensure uniform pyrolysis of the raw materials, and can also prevent the furnace from slagging to ensure normal operation of the system; and the discharging mechanism is used for uniformly discharging materials from the inside of the furnace to the outside during discharging, promotes uniformperforming of the pyrolysis process, does not have a discharging function when discharging is not carried out and can be matched with the stirring mechanism to form a double-stirring effect. In addition, a plurality of discharging openings are evenly distributed in the base of the furnace body, and discharging can be guaranteed to be timely and stable. Therefore, the problems that an existing pyrolyzing furnace is uneven in discharging and pyrolyzing, slagging occurs to the pyrolyzing furnace, small-density raw materials are distributed loosely in the pyrolyzing furnace and the like in the prior art are solved; and the practicability of the system is high.

Owner:ACADEMY OF PLANNING & DESIGNING OF THE MINIST OF AGRI

A kind of cobalt-iron alloy, nitrogen co-doped carbon oxygen reduction catalyst and its preparation method and application

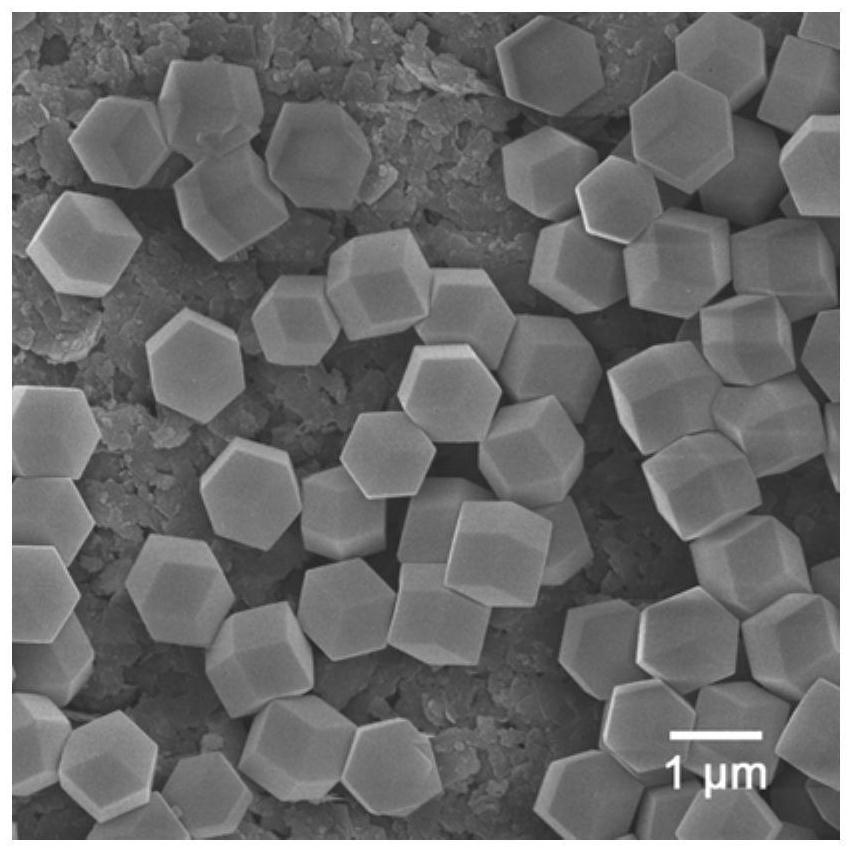

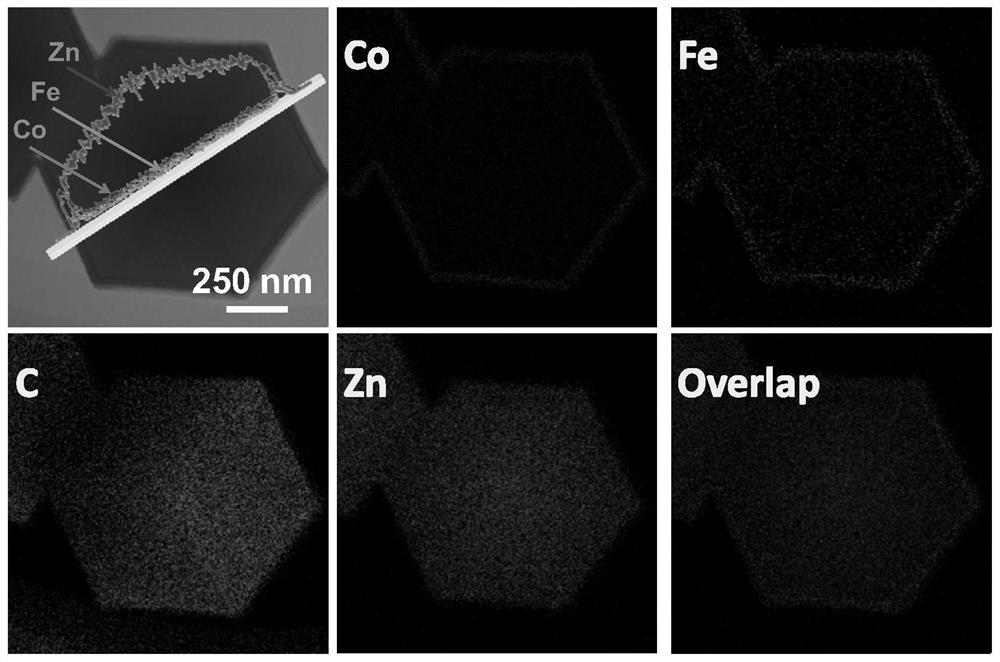

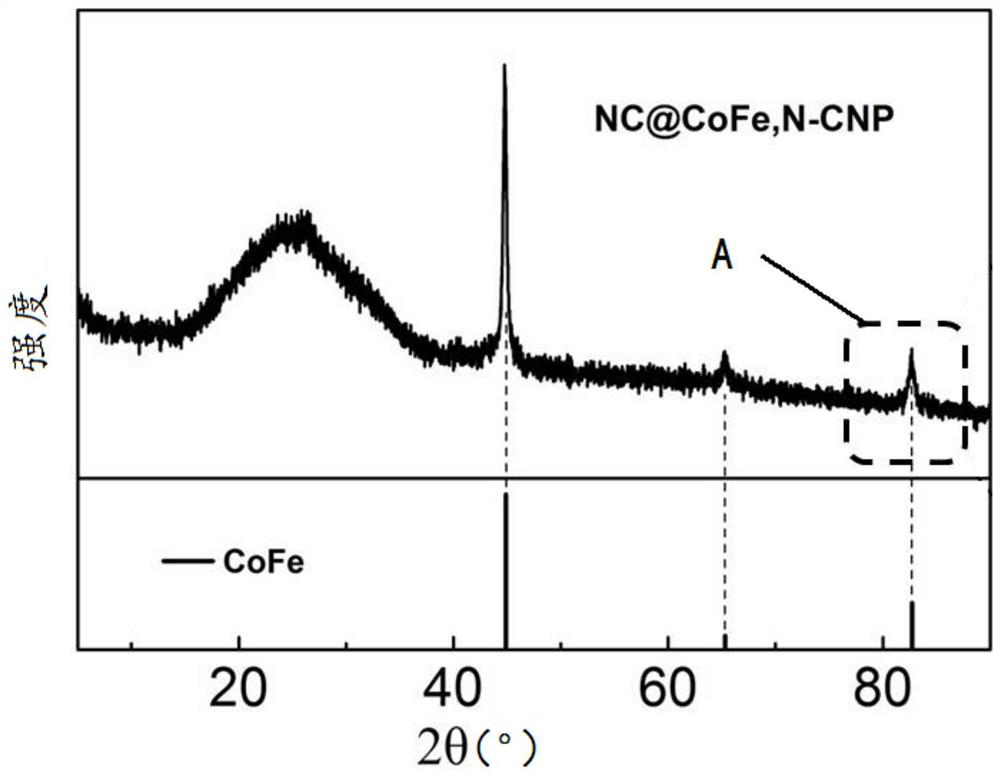

ActiveCN111697239BGuaranteed stabilityAvoid entrapment problemsCell electrodesFuel cellsPtru catalystPhysical chemistry

The invention relates to a cobalt-iron alloy and nitrogen co-doped carbon oxygen reduction catalyst. The precursor of the catalyst is a core-shell structure, wherein the core of the precursor is a material with pore-forming and supporting functions, and the shell of the precursor is Fe, Co-ZIF, the shell of the catalyst is an iron-cobalt alloy. The core of the precursor as a support can ensure the stability of the core-shell structure and avoid the problem of catalyst active sites being embedded due to the collapse of the structure during the pyrolysis process. The hierarchical pore structure that is favorable for mass transfer can also promote the uniform dispersion of metal ions in the shell during the pyrolysis process; the shell uses the synergistic catalytic effect of CoFe alloy and active site N to greatly improve the catalytic activity of oxygen reduction; bimetallic iron Co-doped with cobalt and co-doped with nitrogen in the ZIF shell, the metal and nitrogen are spaced apart, which can promote the uniform dispersion of metal particles after high temperature pyrolysis.

Owner:GLOBAL ENERGY INTERCONNECTION RES INST CO LTD +2

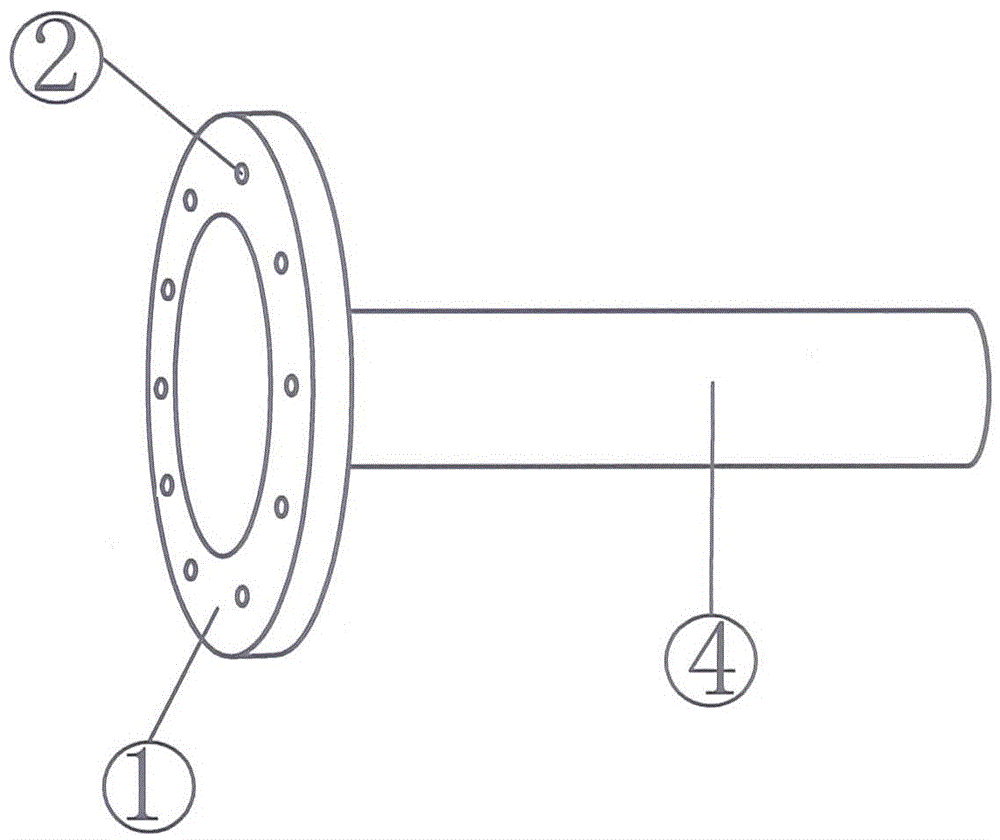

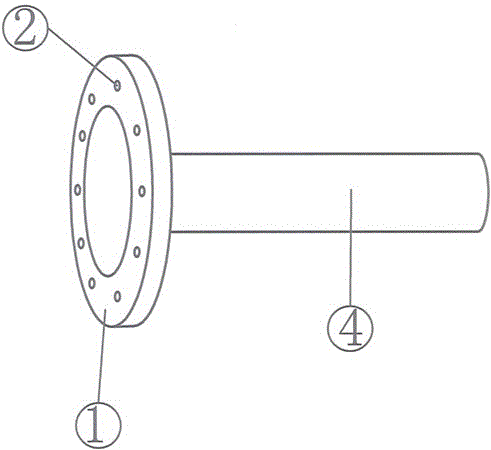

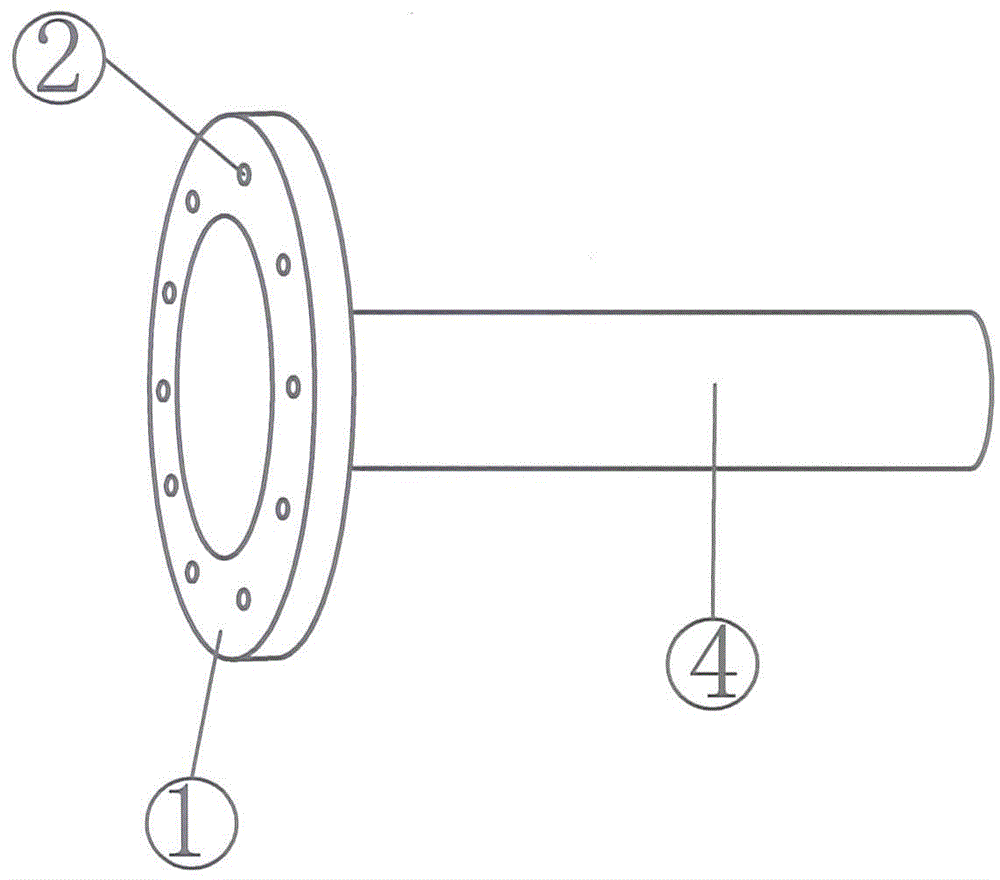

Quadrangular forming die barrel

InactiveCN106635103AUniform pyrolysisImprove breathabilityBiofuelsPyroligneous acid productionTarFlange

The invention relates to a quadrangular forming die barrel, which is formed by extracting a principal component of plant insecticide pesticide from plants, namely a prophase product of wood vinegar plant acid, and processing raw materials in the production and extraction process of wood tar serving as mother liquid. The quadrangular forming die barrel is provided with a ring flange with the outer diameter of 0.2 meter and the thickness of 0.04 meter; a circular barrel body with the length of 0.35 meter and the outer diameter of 0.1 meter is vertically linked to the middle of one plane of the ring flange; identical quadrangular through holes are separately formed in the middles of the ring flange and the circular barrel body, and thus a quadrangular forming die barrel device is formed; a raw material body formed by the quadrangular forming die barrel can form regular rod bodies with identical shape; after the rod body raw materials are charged into an extraction tank, identical gaps can be formed in all the rod bodies.

Owner:宁夏卓越安科技有限公司

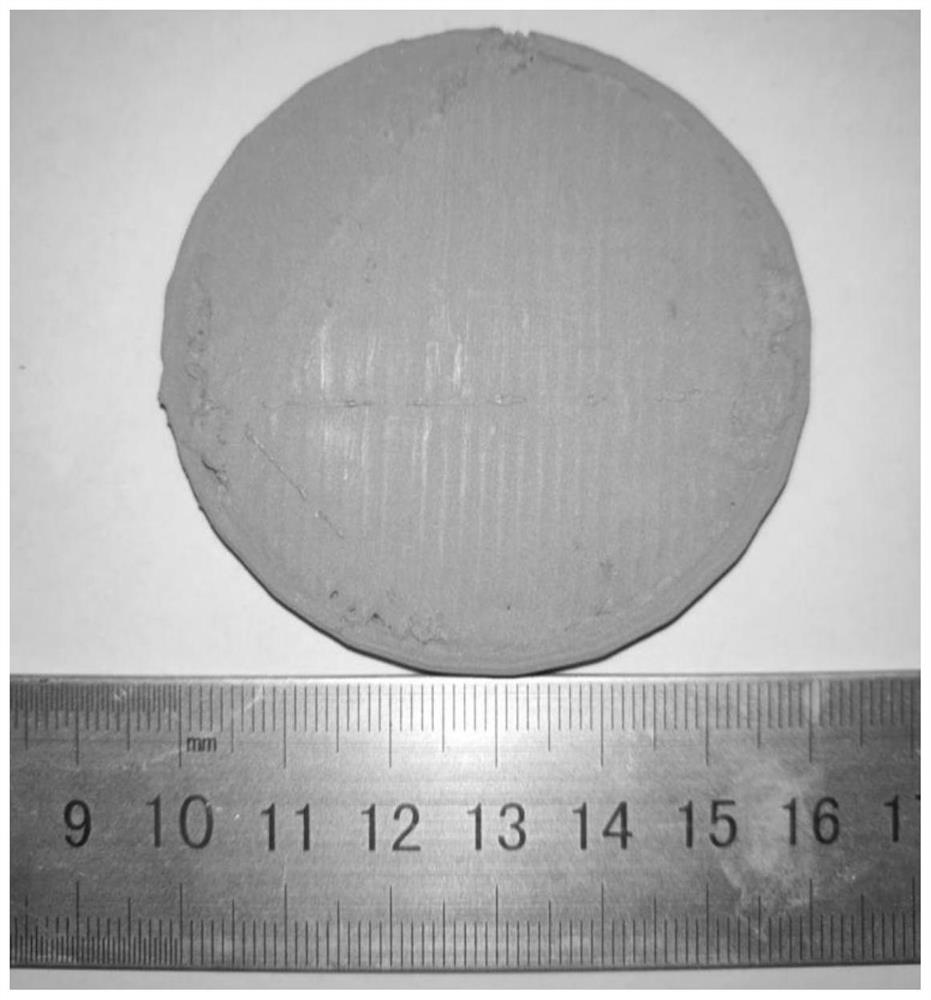

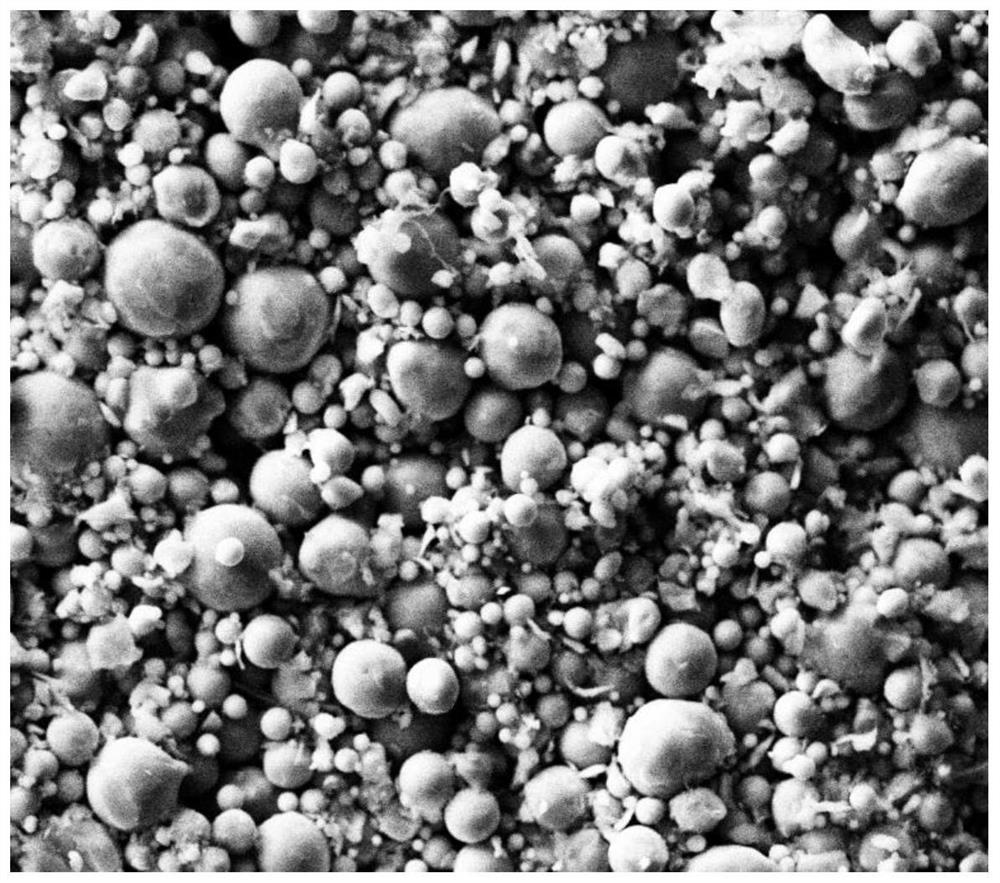

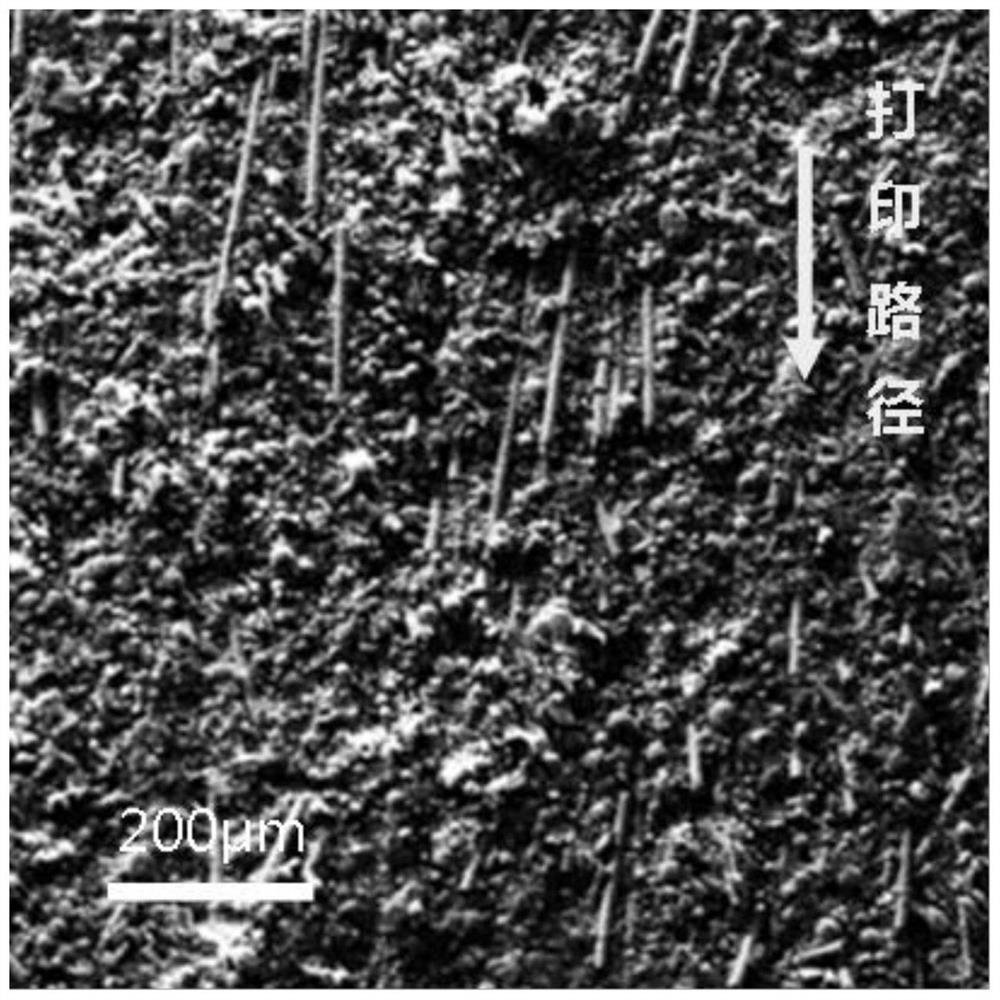

A kind of slurry for extruding 3D printing fiber-reinforced metal matrix composite material and preparation method thereof

ActiveCN112247141BExtrude evenlyVolatileAdditive manufacturing apparatusTransportation and packagingCarbon fibersManufactured material

The invention relates to a slurry of fiber-reinforced metal matrix composite material for extrusion 3D printing and a preparation method thereof. 4-15wt.%, metal powder 45-55wt.%, binder 2-4wt.%, dispersant 30-40wt.%, wherein the binder is polylactic acid, and the dispersant is dichloromethane. The invention is a method for extruding without heating, maintaining the arrangement of fibers in the metal matrix, and improving the performance of fiber-reinforced metal matrix composite materials; after the binder is removed, about 80% of the fibers with a length of 150-300 μm show Good orientation effect, the angle between the arrangement direction and the printing direction is kept within 10°, which maintains the precise orientation arrangement of carbon fibers in the metal matrix, which will greatly improve the mechanical properties of the composite material.

Owner:JILIN UNIV

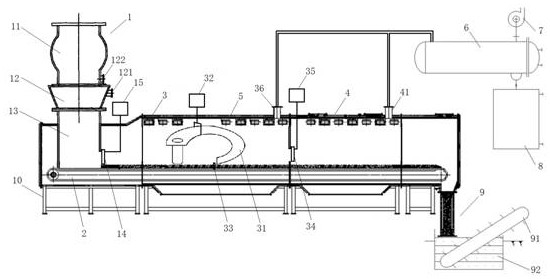

Moving bed biomass pyrolysis equipment

ActiveCN103937515BGuaranteed intakeGuaranteed anaerobicDirect heating destructive distillationBiofuelsEnvironmental engineeringSolid particle

The invention relates to a moving bed biomass pyrolysis equipment, which comprises a pyrolysis furnace body I, a feeding device II arranged at one end of the pyrolysis furnace body I, and a feed device II connected to one side of the pyrolysis furnace body I through an air inlet channel. The air supply device III and the discharge device IV arranged on the other side of the pyrolysis furnace body I, the pyrolysis furnace body I is provided with a transmission mechanism, characterized in that: the transmission mechanism includes The fixed push plate on I, the reciprocating cart, the movable push plate set on the reciprocating cart, the high-leg push plate and the foot push plate, the fixed push plate and the movable push plate are arranged alternately in sequence On the top of the reciprocating cart, the high-leg push-feeding plate and the bottom-foot push-feeder plate are successively overlapped and arranged on one end of the reciprocating cart. The present invention adopts a reciprocating push plate pyrolysis furnace, which not only can fully pyrolyze biomass materials, but also can separate gaseous products and solid particles in time, without causing fouling and blockage on the surface of the equipment, which not only improves the utilization rate of energy, Increased commercial value.

Owner:JILIN UNIV +1

A kind of treatment method of oily sludge

ActiveCN109665688BReduce oxygen contentImprove heating and pyrolysis uniformitySludge treatment by pyrolysisByproduct vaporizationTemperature controlMicrowave pyrolysis

The invention discloses a treatment method for oily sludge, which relates to the technical field of garbage treatment. The treatment method comprises: controlling the first pushing device to close the feed bin door; The bin door is opened, and the deoxidized material is transported to the main microwave pyrolysis furnace through the material conveyor belt; the third pusher is controlled to close the main furnace door of the main microwave pyrolysis furnace; temperature-controlled cycle pyrolysis is carried out in the main microwave pyrolysis furnace After the temperature-controlled cycle pyrolysis treatment, the material is conveyed to the auxiliary microwave pyrolysis furnace through the material conveyor belt; the secondary pyrolysis treatment is carried out in the auxiliary microwave pyrolysis furnace, and the residue after the secondary pyrolysis treatment is conveyed to the outlet through the material conveyor belt. feeding device. The invention has the advantages of uniform pyrolysis and high pyrolysis efficiency when the material is heated and pyrolyzed in the microwave cracking furnace.

Owner:航天国环技术集团有限公司

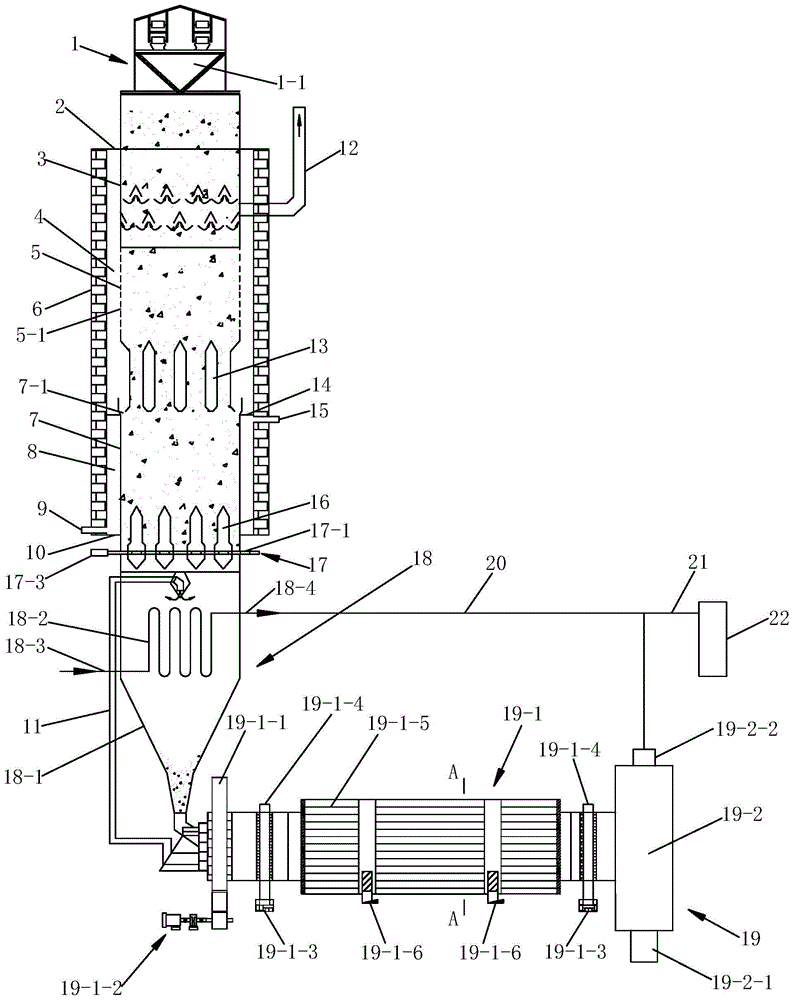

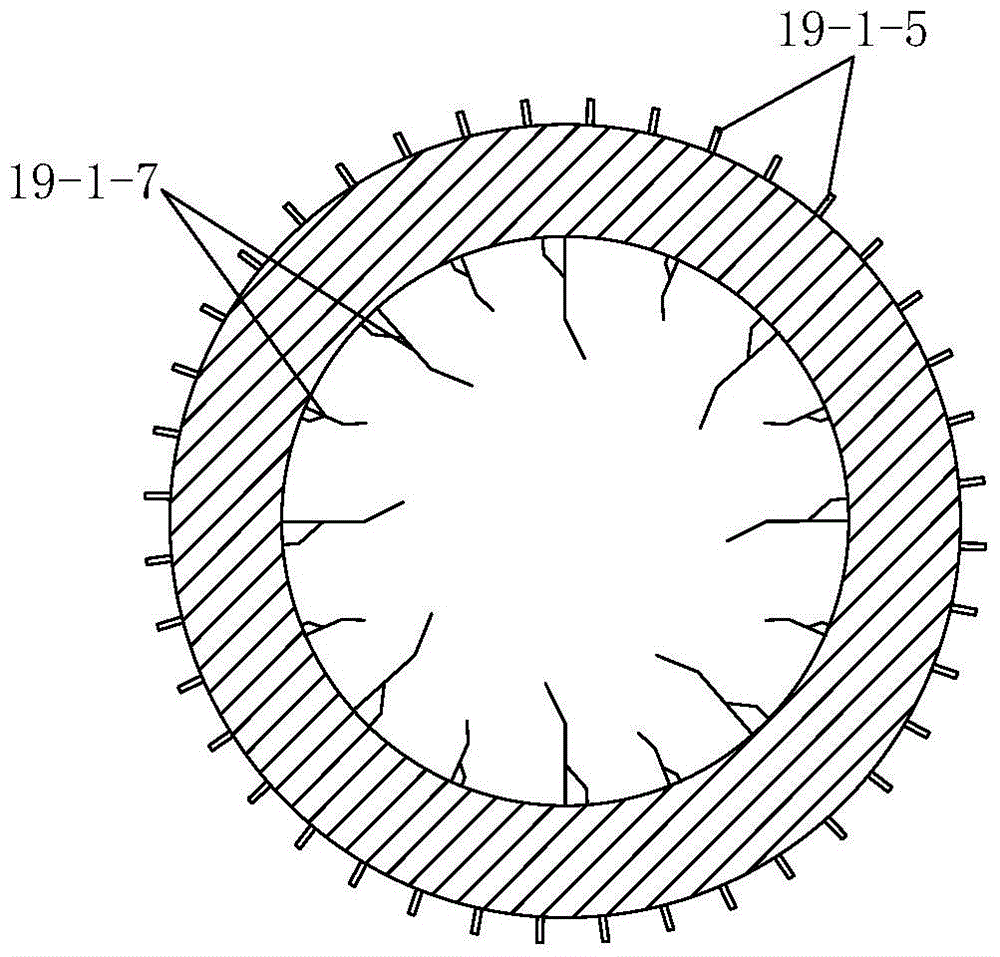

Integrated device for coal pyrolysis and activated carbon production

ActiveCN105036127BSimple structureNovel and reasonable designCarbon compoundsActivated carbonHeat carrier

The invention discloses a coal pyrolysis and activated carbon production integrated device. The integrated device comprises a thermal insulation jacket, a preheating furnace, a pyrolysis furnace used for performing pyrolysis on preheated coal, an activating furnace used for activating semi-coke generated after pyrolysis, and an activating agent conveying pipe used for inputting gas activating agents into the activating furnace. The preheating furnace, the pyrolysis furnace and the activating furnace are sequentially communicated from top to bottom. An activating furnace heating cavity is formed between the activating furnace and the thermal insulation jacket. A gas conveying channel is formed between the thermal insulation jacket and the pyrolysis furnace. The activating furnace is provided with an associated gas outlet for associated gas produced through activation of the semi-coke to enter the gas conveying channel. A gas heat carrier inlet for the associated gas to enter the pyrolysis furnace from the gas conveying channel is formed in the side wall of the pyrolysis furnace. The integrated device can effectively improve the pyrolysis and activation efficiency, the tar yield is effectively increased, high-quality coal gas, tar and activated carbon can be produced at the same time, and the additional value for quality-divided processing and utilizing of the coal is improved.

Owner:XIAN UNIV OF SCI & TECH

Combustion-supporting device for low-temperature pyrolysis furnace of garbage

The invention discloses a garbage low-temperature pyrolysis furnace combustion-supporting device. The garbage low-temperature pyrolysis furnace combustion-supporting device is mainly composed of a garbage supporting frame and a plurality of hollow cones; the multiple hollow cones are uniformly installed on the garbage supporting frame, and the bottoms of the hollow cones are provided with openings; and the tops and the surfaces of the hollow cones are provided with vent holes penetrating through the openings of the bottoms. The garbage low-temperature pyrolysis furnace combustion-supporting device has the advantages of being high and uniform in garbage pyrolysis speed, not prone to being extinguished, low in operation cost and the like.

Owner:南宁市绿城环保设备有限责任公司

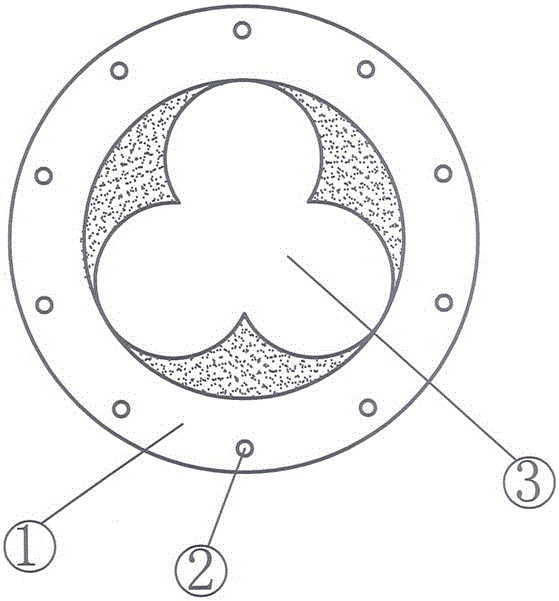

Trigonometric circle forming die barrel

InactiveCN106433716AImprove breathabilityFully evaporatedBiofuelsSpecial form destructive distillationTarEngineering

The invention discloses a trigonometric circle forming die barrel and relates to the trigonometric circle forming die barrel which is used for extracting a main component of an insecticidal plant pesticide from a plant, as a prophase product of wood vinegar plant acid, and processing and forming raw materials in production and extraction processes of mother solution wood tar. The trigonometric circle forming die barrel is provided with a ring flange with the outer diameter of 0.15 meter and the thickness of 0.03 meter; a circular die barrel body with the length of 0.45 meter and the outer diameter of 0.09 meter is vertically linked to the middle part of one plane of the ring flange; a through hole with a trigonometric circle modeling is formed in the middle part of the die barrel body; the depth of the through hole is 0.48 meter, and the inner diameter of the through hole is 0.04 to 0.05 meter; according to a trigonometric circle forming die barrel device, rod bodies with identical and regular shapes can be formed by a raw material body formed by the trigonometric circle forming die barrel; after the rod body raw materials are loaded into an extraction tank, identical gaps can be formed in all the rod bodies.

Owner:宁夏卓越安科技有限公司

Detachable swirling vehicle SCR mixer and nozzle coupling device

ActiveCN109236431ASolving low temperature crystallization problemsGuaranteed crushing effectInternal combustion piston enginesExhaust apparatusFlangeCrystallization

The invention belongs to the technical field of diesel exhaust aftertreatment, and relates to a novel detachable swirling vehicle SCR mixer and nozzle coupling device. The device comprises a casing. Front and rear flange plates are respectively disposed on two ends of the casing, and a swirling mixer is disposed in the casing. The mixer is designed in a hollow manner and is fixedly connected to the casing. A front flange plate connection port is an air inlet of the device, and a rear flange plate connection port is an air outlet of the device. A urea conveying elbow is arranged between the airinlet and the mixer, and the elbow is connected to the mixer. A urea nozzle is arranged on the rear of the mixer, and a casing section of the urea nozzle is in tapered design. The coupling device isbeneficial to urea pyrolysis, can effectively solve problems of urea cracking, urea crystallization and ammonia distribution uniformity, and the device is convenient to disassemble, and is convenientfor daily maintenance and repair.

Owner:HEBEI UNIV OF TECH

A kind of microwave oven device and its pyrolysis method for pyrolysis

ActiveCN105276639BWon't attachUniform pyrolysisDomestic stoves or rangesLighting and heating apparatusLower limitMicrowave oven

Owner:SOUTH CHINA UNIV OF TECH

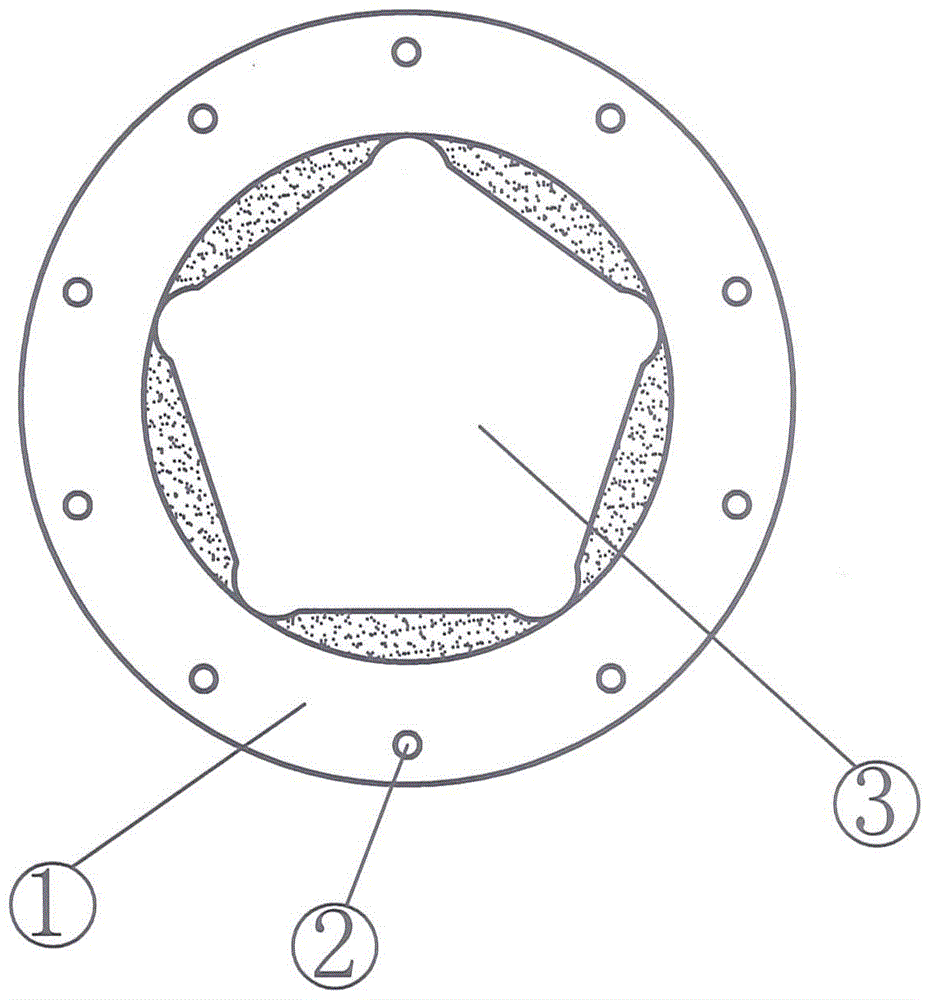

Pentagonal forming die barrel

The invention discloses a pentagonal forming die barrel. The pentagonal forming die barrel is used for extracting a main component as a prophase product of wood vinegar plant acid of an insecticidal plant pesticide from a plant, and processing and forming raw materials extracted from mother liquid wood tar production. The pentagonal forming die barrel is provided with a ring flange with the outer diameter of 0.2 meter and the thickness of 0.035 meter; a circular cylinder body with the length of 0.4 meter and the outer diameter of 0.12 meter is vertically linked to the middle of a plane of the pentagonal forming die barrel; identical pentagonal through holes are separately formed in the middle of the ring flange and the middle of the circular cylinder body; the depth of each through hole is 0.435 meter, and the inner diameter of each through hole is 0.055 to 0.065 meter; according to the formed pentagonal forming die barrel device, rod bodies with identical and regular shapes can be formed by a raw material body formed by the pentagonal forming die barrel; and after rod body raw materials are loaded into an extraction tank, identical gaps can be formed in all the rod bodies.

Owner:宁夏卓越安科技有限公司

Efficient selectable pyrolysis system and using method thereof

ActiveCN102634358BGood value for moneyImprove adjustabilityBiofuelsSpecial form destructive distillationNitrogen gasExhaust pipe

Owner:武汉天颖环境工程股份有限公司

Drying furnace or pyrolyzing furnace with rotary beds

ActiveCN103388980BUniform pyrolysisImprove scalabilityDrying solid materials with heatHearth type furnacesEngineeringMechanical engineering

The invention discloses a drying furnace or pyrolyzing furnace with rotary beds. The drying furnace or the pyrolyzing furnace comprises a closed shell, N concentric ring planar rotary beds, a feed port, N stop plates, N discharge ports and at least one pyrolysis gas product outlet and / or one tail gas outlet, wherein the N concentric ring planar rotary beds are positioned in the shell; the two ends of the stop plates are seamlessly connected with the inner walls and the outer walls of the corresponding rotary beds respectively; each rotary bed comprises a rotatable planar bed bottom and an inner wall and an outer wall which are kept still relative to the bed bottom; the bed bottom of each rotary bed is provided with at least one through hole; and the heights of the N rotary beds rise gradually from inside to outside and seamless connection is realized. When a material is rotated to the position of a stop plate along with the bed bottom of a rotary bed, the material is pushed from outside to inside by the stop plate so as to fall into the next joined rotary bed through a discharge port; and thus, the material falls from outside to inside step by step, is conveyed to the position of the discharge port of the innermost rotary bed through the bed bottoms of the N rotary beds and is finally discharged out of the drying furnace or the pyrolyzing furnace through the discharge port.

Owner:CHNA ENERGY INVESTMENT CORP LTD +1

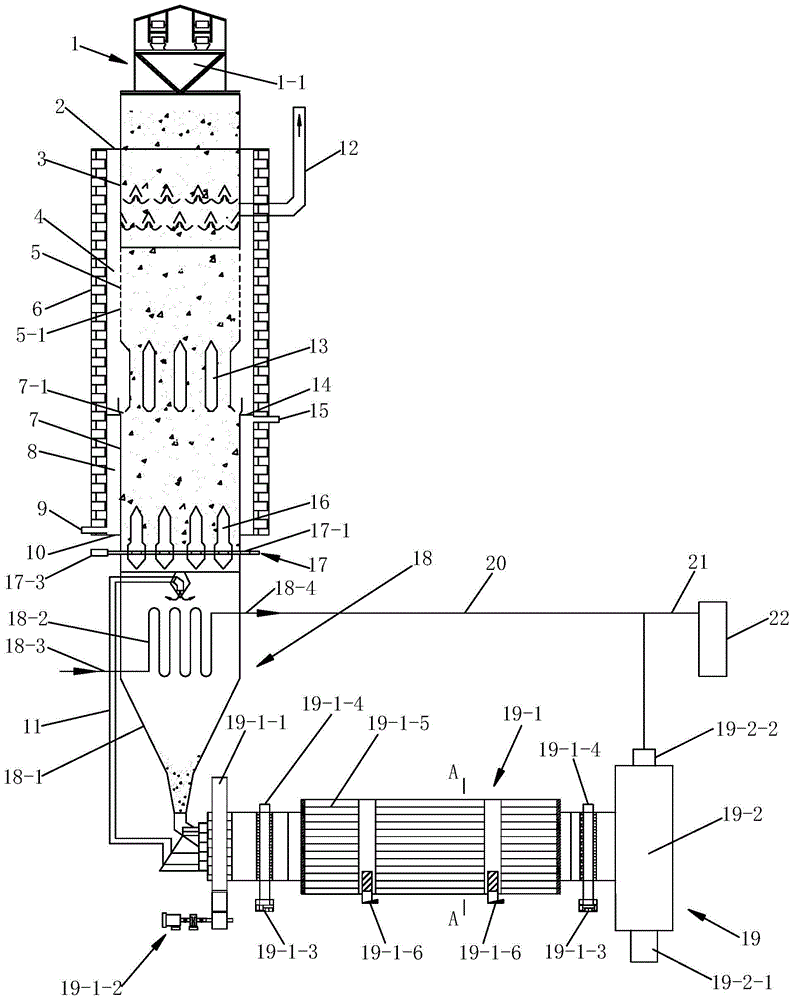

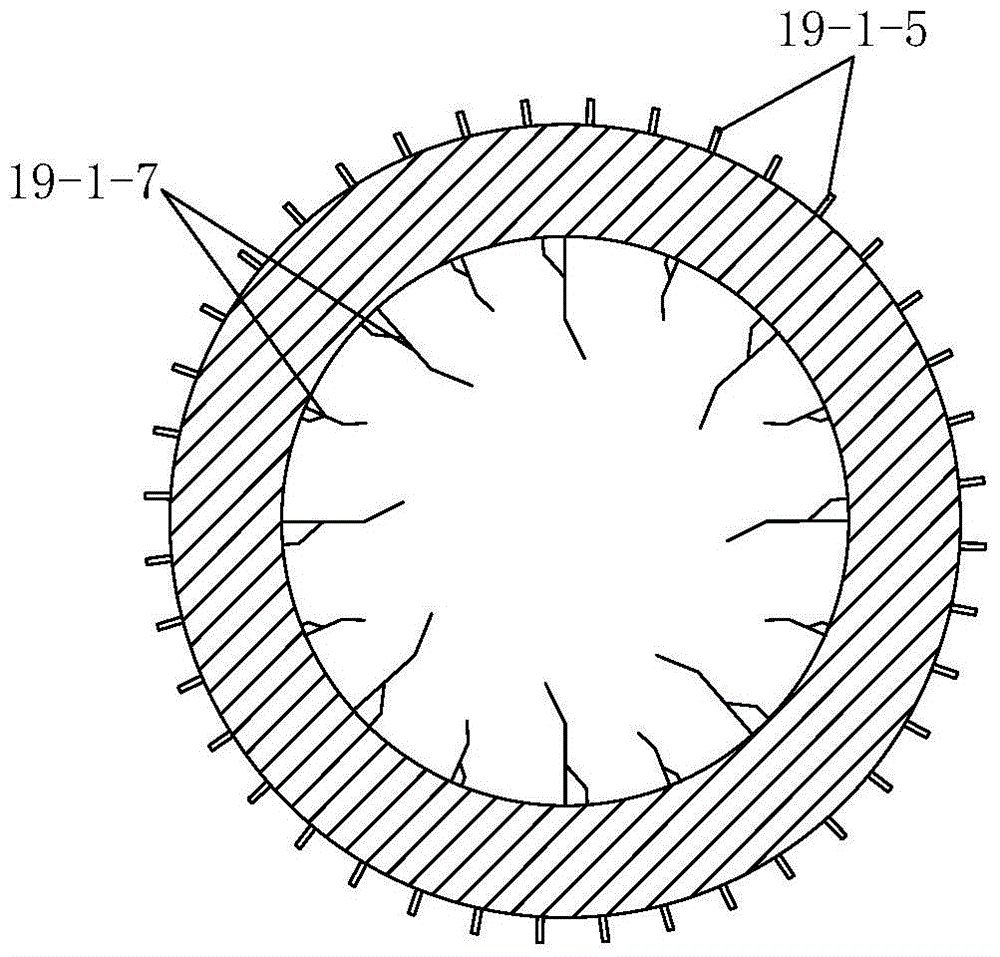

A treatment system for oily sludge

ActiveCN109665687BReduce oxygen contentImprove heating and pyrolysis uniformitySludge treatment by pyrolysisByproduct vaporizationTemperature controlMicrowave pyrolysis

The invention discloses a treatment system for oily sludge, which relates to the technical field of garbage treatment. The treatment system includes: a feeding device, the outlet of the lower part of the feeding device is located above the material conveyor belt of the horizontal conveying device, including a feeding bin door and a first Pushing device; horizontal conveying device, including material conveyor belt, used to transport the materials output from the feed bin door to the main microwave pyrolysis furnace, auxiliary microwave pyrolysis furnace and discharge device in turn; the main microwave pyrolysis furnace, including temperature control The circulation conveying device, the main furnace door and the third pushing device, and the temperature-controlled circulating conveying device are used to detect the temperature of the material in the main microwave pyrolysis furnace in real time and control the material to be circulated in the main microwave pyrolysis furnace according to the temperature of the material until the material reaches Up to the preset temperature; and the discharge device, etc. The invention has the advantages of uniform pyrolysis and high pyrolysis efficiency when the material is heated and pyrolyzed in the microwave cracking furnace.

Owner:航天国环技术集团有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com