Oily sludge treatment method

A treatment method and sludge technology, which are applied in the pyrolysis treatment of sludge, petroleum industry, special forms of dry distillation, etc., can solve the problems of low pyrolysis efficiency, uneven heating and pyrolysis of materials, etc. The effect of heating up the pyrolysis uniformity and reducing the oxygen content of the material

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

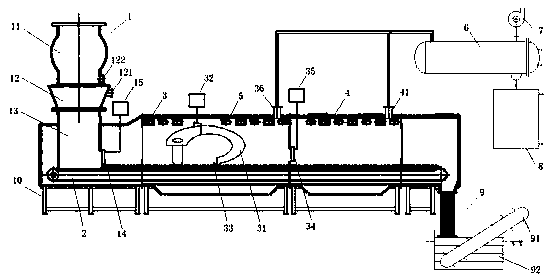

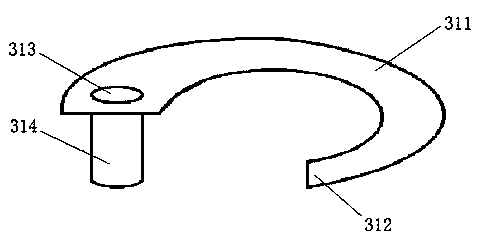

[0043] This embodiment provides a treatment system for oily sludge, which is mainly applied to the harmless and resourceful treatment of oily sludge generated in the petroleum exploitation, refining and petrochemical industries, such as figure 1 As shown, the processing system includes: a feeding device 1, a feeding bin 11, a feeding deoxidizing bin 12, an air inlet 121, an air outlet 122, a feeding bin 13, a feeding bin door 14, a first pushing device 15, Horizontal conveying device 2, main microwave pyrolysis furnace 3, screw conveying device 31, second pushing device 32, temperature detection device 33, main furnace door 34, third pushing device 35, first exhaust port 36, auxiliary microwave pyrolysis device Furnace 4, second exhaust port 41, microwave port 5, condensing device 6, air extraction device 7, oil-water separation device 8, discharging device 9, slag extractor 91, pool 92, rack 10. The feeding bin door 14 , the horizontal conveying device 2 , the main microwave ...

Embodiment 2

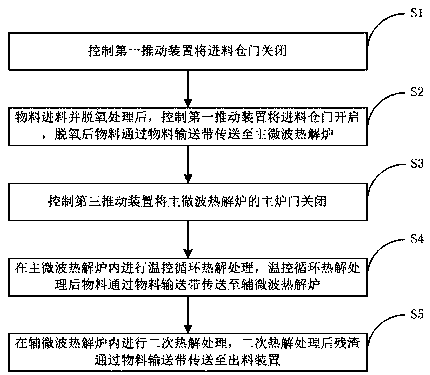

[0059] This embodiment provides a treatment method for oily sludge, which can be applied to the treatment system for oily sludge in Embodiment 1. The treatment method includes the following steps:

[0060] S1, control the first pushing device 15 to close the feeding bin door 14;

[0061] S2. After the material is fed and deoxidized, the first pushing device 15 is controlled to open the feeding bin door 14, and the deoxidized material is transported to the main microwave pyrolysis furnace 3 through the material conveyor belt;

[0062] S3, control the third pushing device 35 to close the main furnace door 34 of the main microwave pyrolysis furnace 3;

[0063] S4, temperature-controlled cyclic pyrolysis treatment is performed in the main microwave pyrolysis furnace 3, and the material after the temperature-controlled cyclic pyrolysis treatment is transported to the auxiliary microwave pyrolysis furnace 4 through the material conveyor belt;

[0064] S5 , performing secondary pyro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com