Coal pyrolysis and activated carbon production integrated device

A technology of activated carbon production and coal pyrolysis, applied in the field of coal pyrolysis, can solve the problems of weakening the production capacity of activated carbon, reducing the quality of activated carbon, increasing the ash content of products, etc., so as to improve the yield and the quality of gas, fully pyrolyze and improve the quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

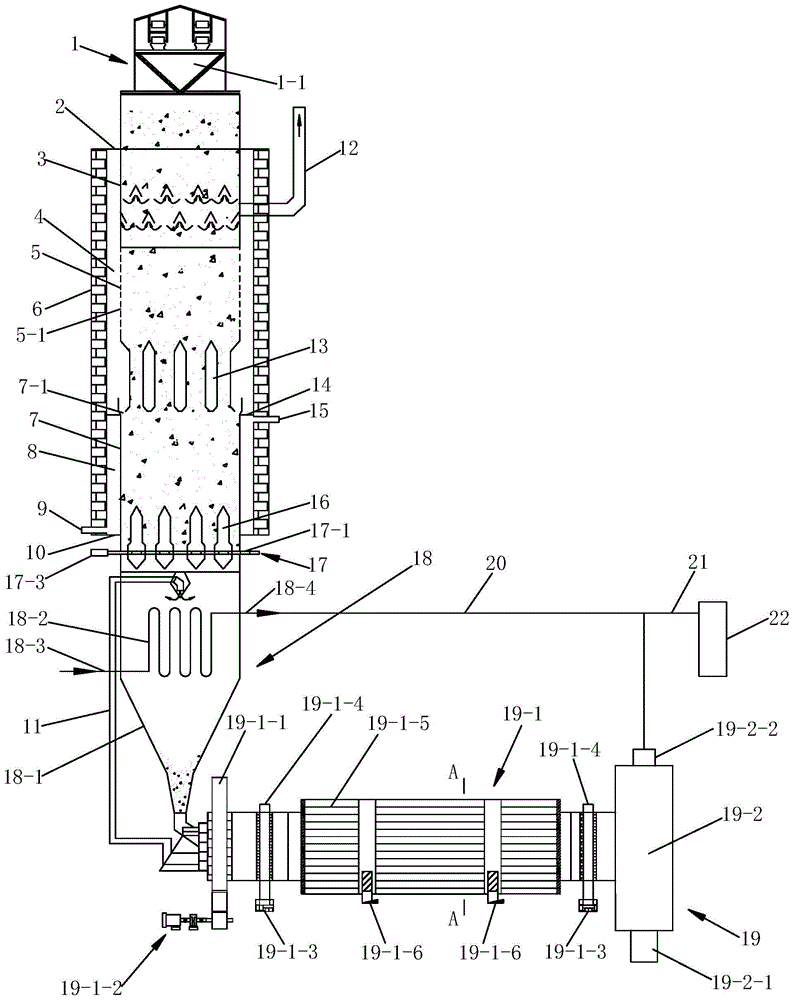

[0043] Such as figure 1An integrated device for pyrolysis of coal and production of activated carbon is shown, including a thermal insulation jacket 6, a preheating furnace body 3 for preheating coal, and a thermal furnace for pyrolyzing preheated coal. Decomposition furnace body 5, activation furnace body 7 for activating semi-coke produced by pyrolysis and activator delivery pipe 11 for inputting gas activator into activation furnace body 7, said preheating furnace body 3, The pyrolysis furnace body 5 and the activation furnace body 7 are sequentially connected from top to bottom, the preheating furnace body 3, the pyrolysis furnace body 5 and the activation furnace body 7 are all arranged in the heat insulation 6, and the activation furnace body 7 and the heat insulation jacket 6 form an activation furnace body heating chamber 8 for accommodating the activated heating gas, and a gas delivery channel 4 is formed between the heat insulation jacket 6 and the pyrolysis furnace ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com