Biomass drum-type carbonization furnace

A carbonization furnace and drum-type technology, which is applied in the field of carbonization furnace and biomass drum-type carbonization furnace, can solve the problems of low conversion efficiency and low thermal efficiency, and achieve the effects of low production cost, improved thermal efficiency, and uniform pyrolysis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

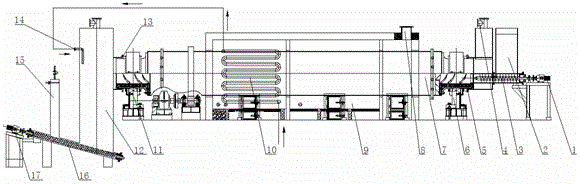

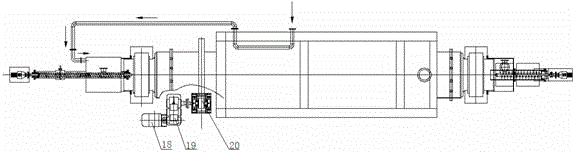

[0021] see Figure 1 to Figure 2 , a biomass drum carbonization furnace, including a feeding device, a carbonization furnace 7, a combustion chamber 9 and a charcoal bin 12. Described feeding device comprises feeding auger motor 1, feeding bin 2 and feeding auger 3, and described feeding auger 3 is arranged in feeding bin 2, and feeding auger 3 and feeding auger The dragon motor 1 is connected; the feed auger 3 is driven by the feed auger motor 1. The outlet of the feed bin 2 is connected to the inlet end of the carbonization furnace 7 , and the outlet end of the carbonization furnace 7 is connected to the carbon outlet bin 12 . The carbonization furnace 7 is a drum type, and a rotary power device is arranged below the carbonization furnace 7, and the rotary power device is connected with the carbonization furnace 7; the rotary powe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com