Patents

Literature

175 results about "Neodymium magnet" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A neodymium magnet (also known as NdFeB, NIB or Neo magnet), the most widely used type of rare-earth magnet, is a permanent magnet made from an alloy of neodymium, iron and boron to form the Nd₂Fe₁₄B tetragonal crystalline structure. Developed independently in 1982 by General Motors and Sumitomo Special Metals, neodymium magnets are the strongest type of permanent magnet commercially available. Due to different manufacturing processes, they are also divided into two subcategories, namely sintered NdFeB magnets and bonded NdFeB magnets. They have replaced other types of magnets in many applications in modern products that require strong permanent magnets, such as motors in cordless tools, hard disk drives and magnetic fasteners.

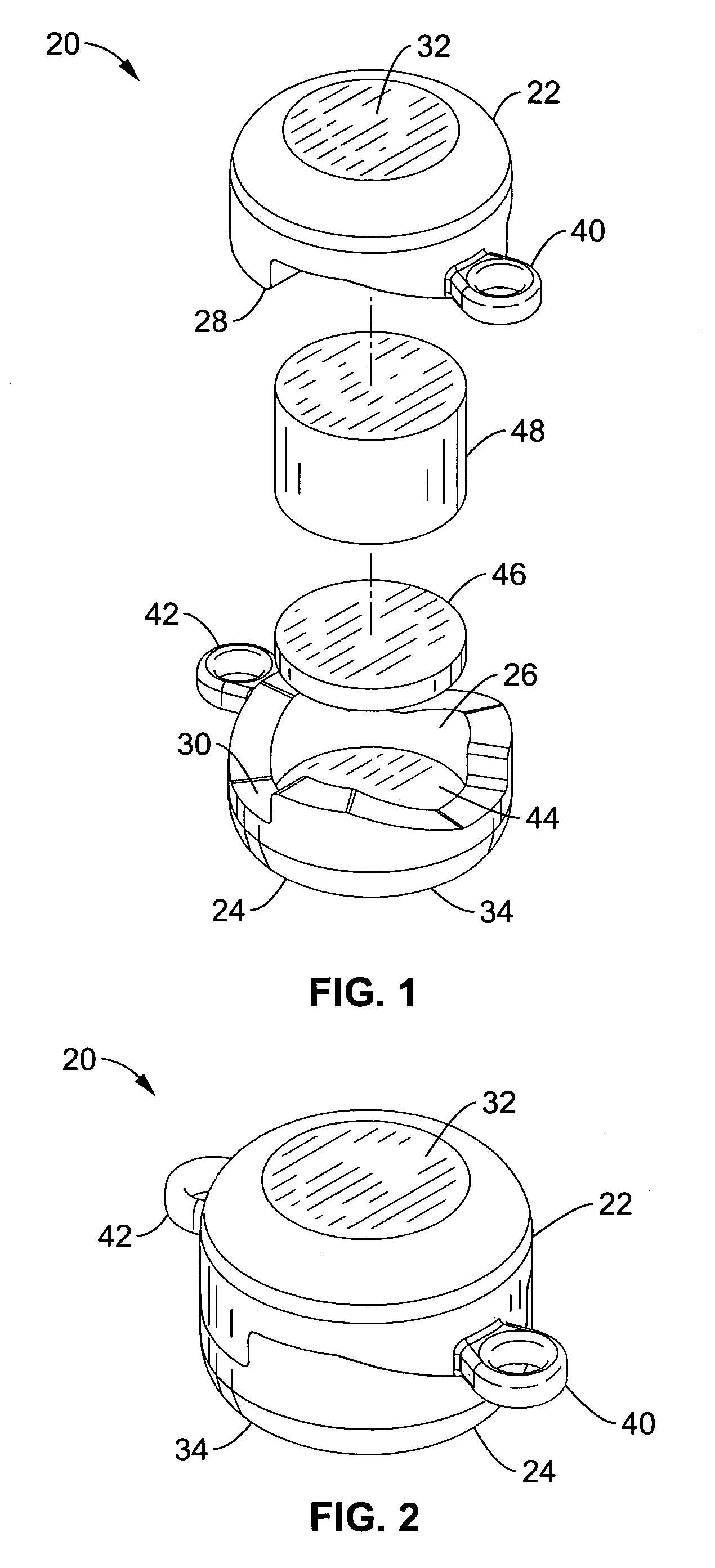

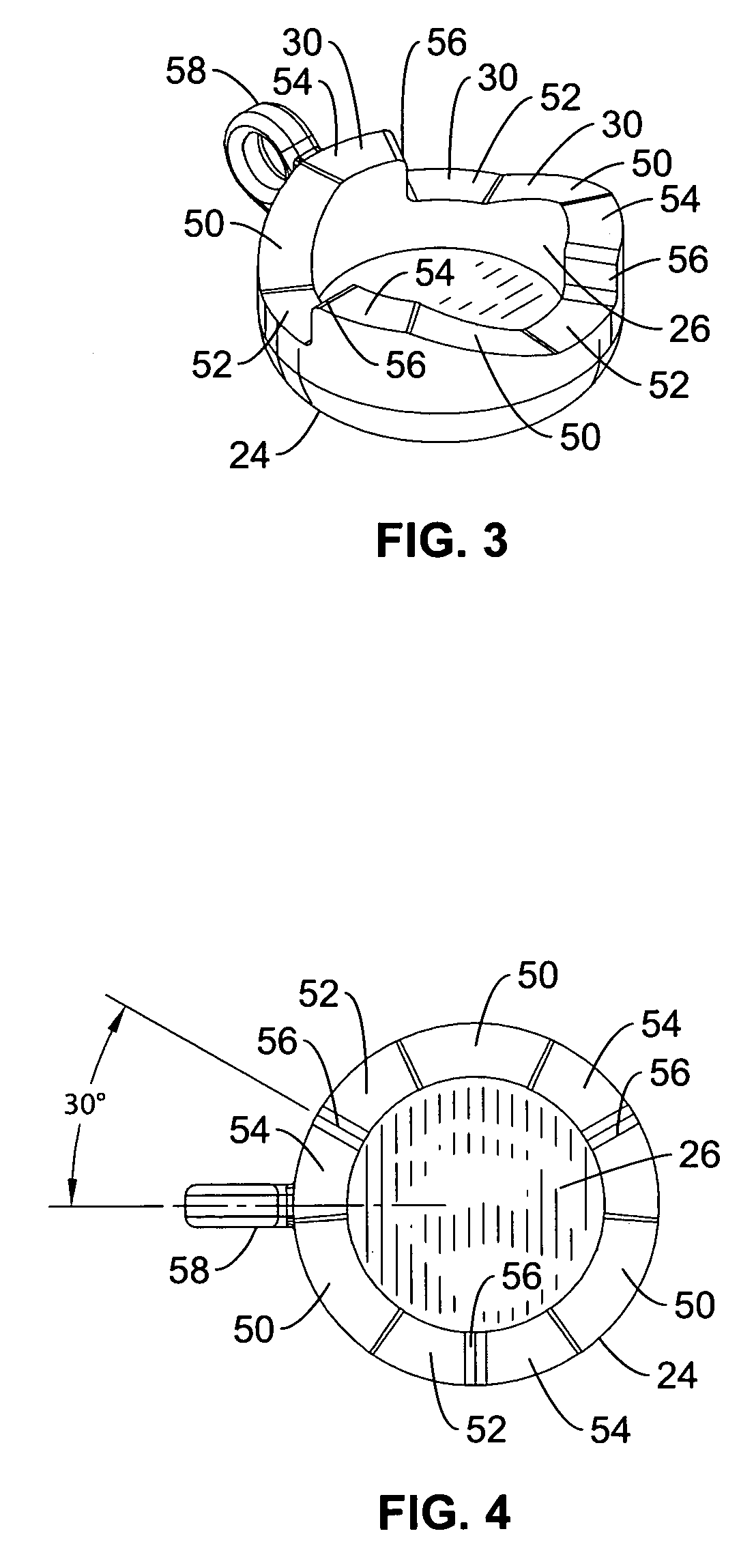

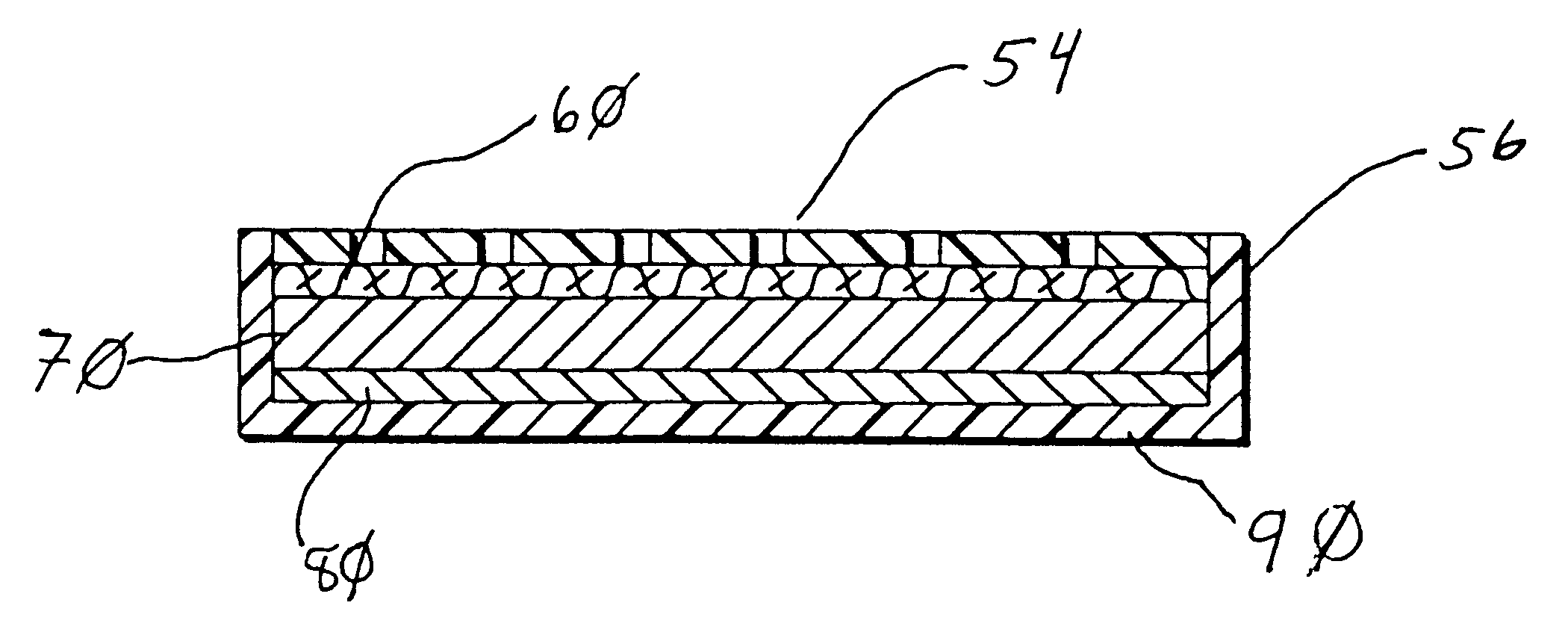

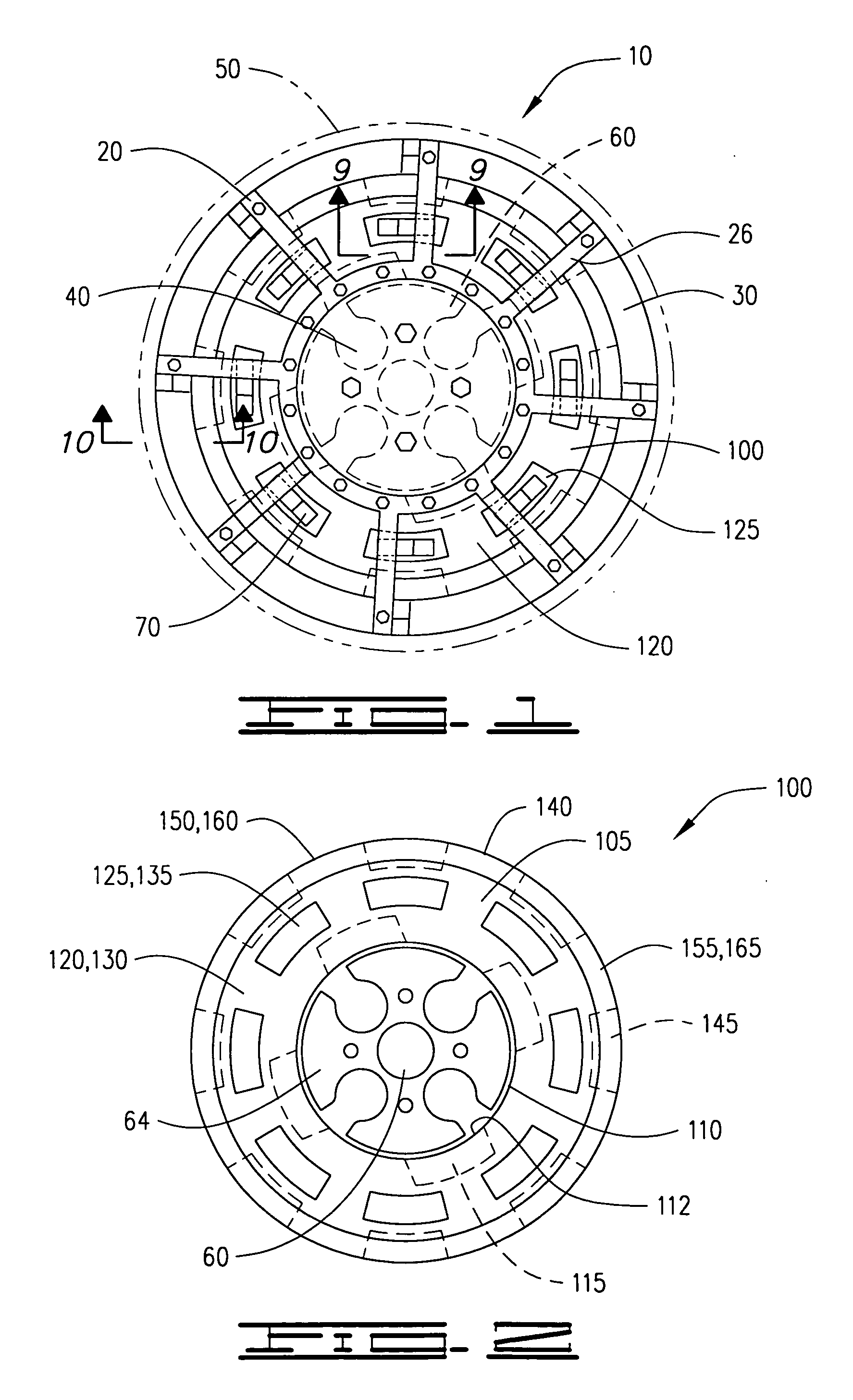

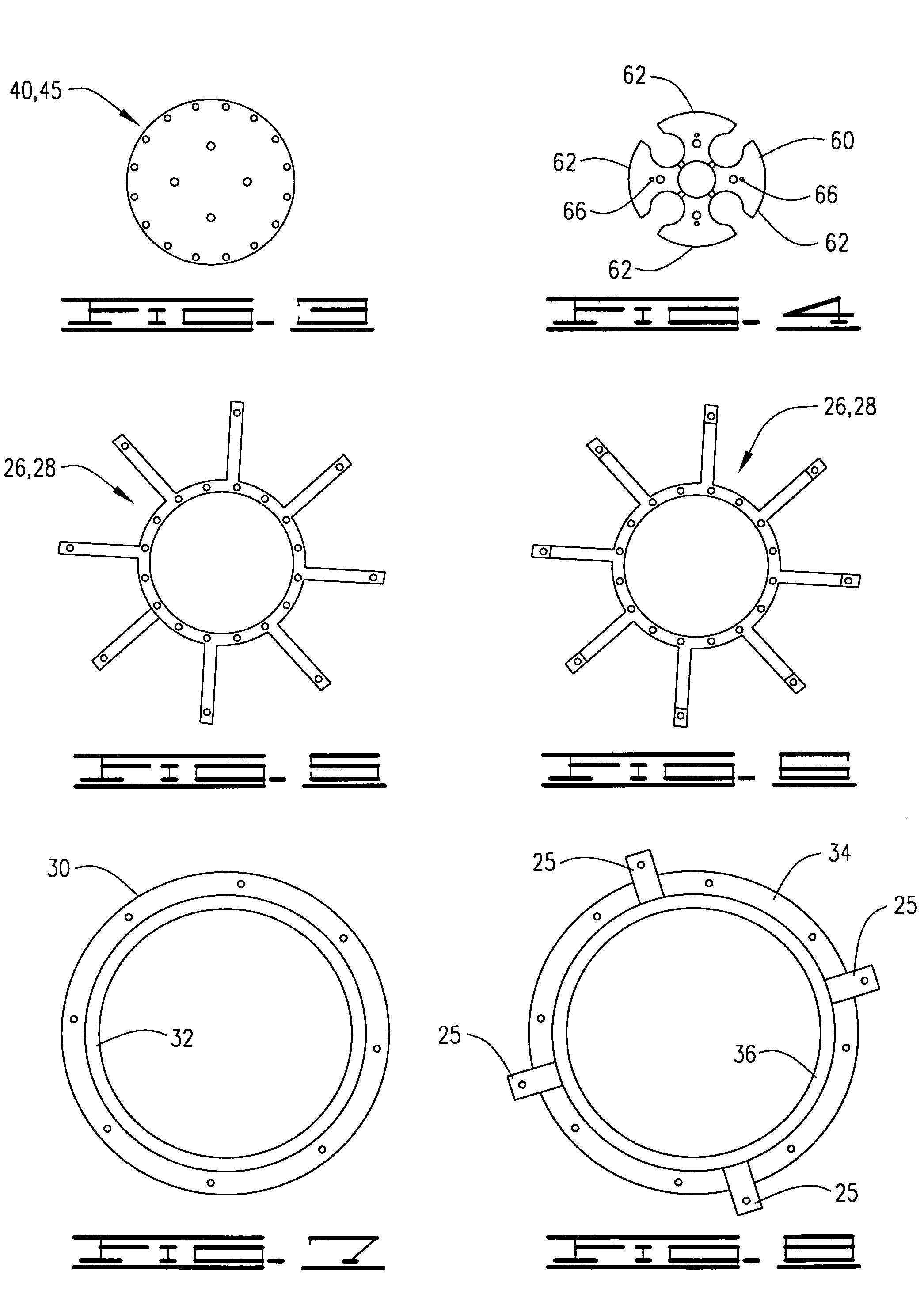

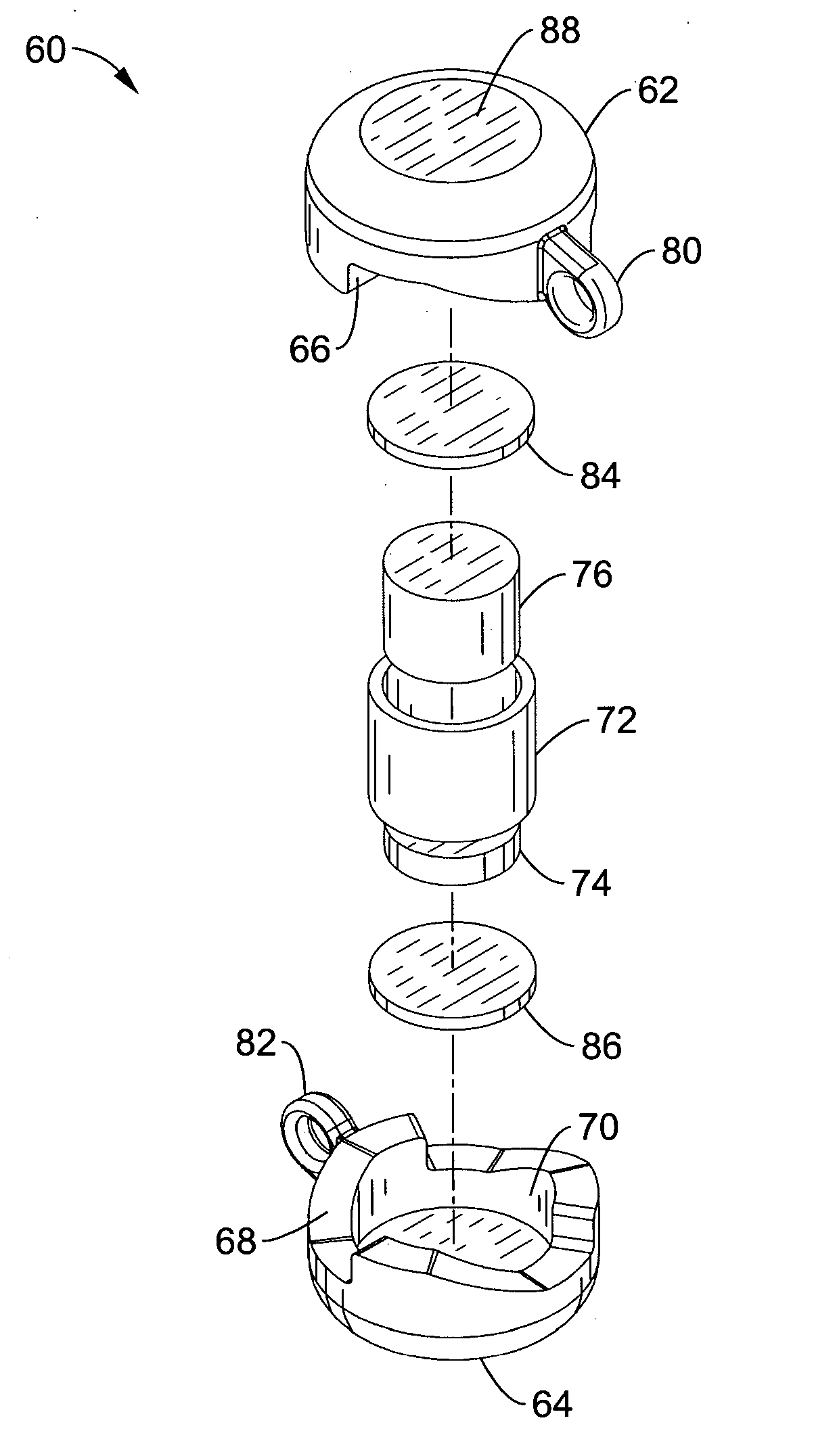

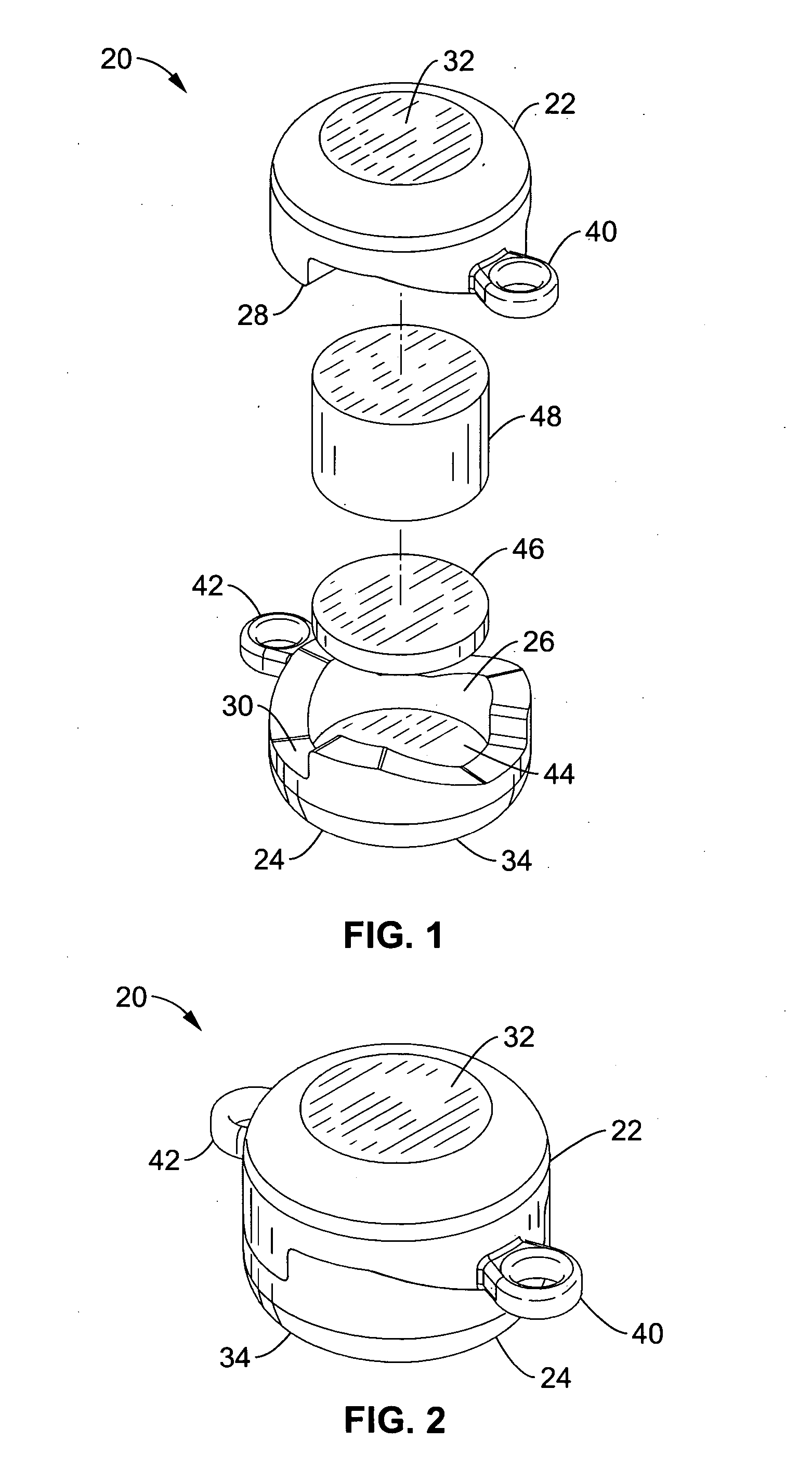

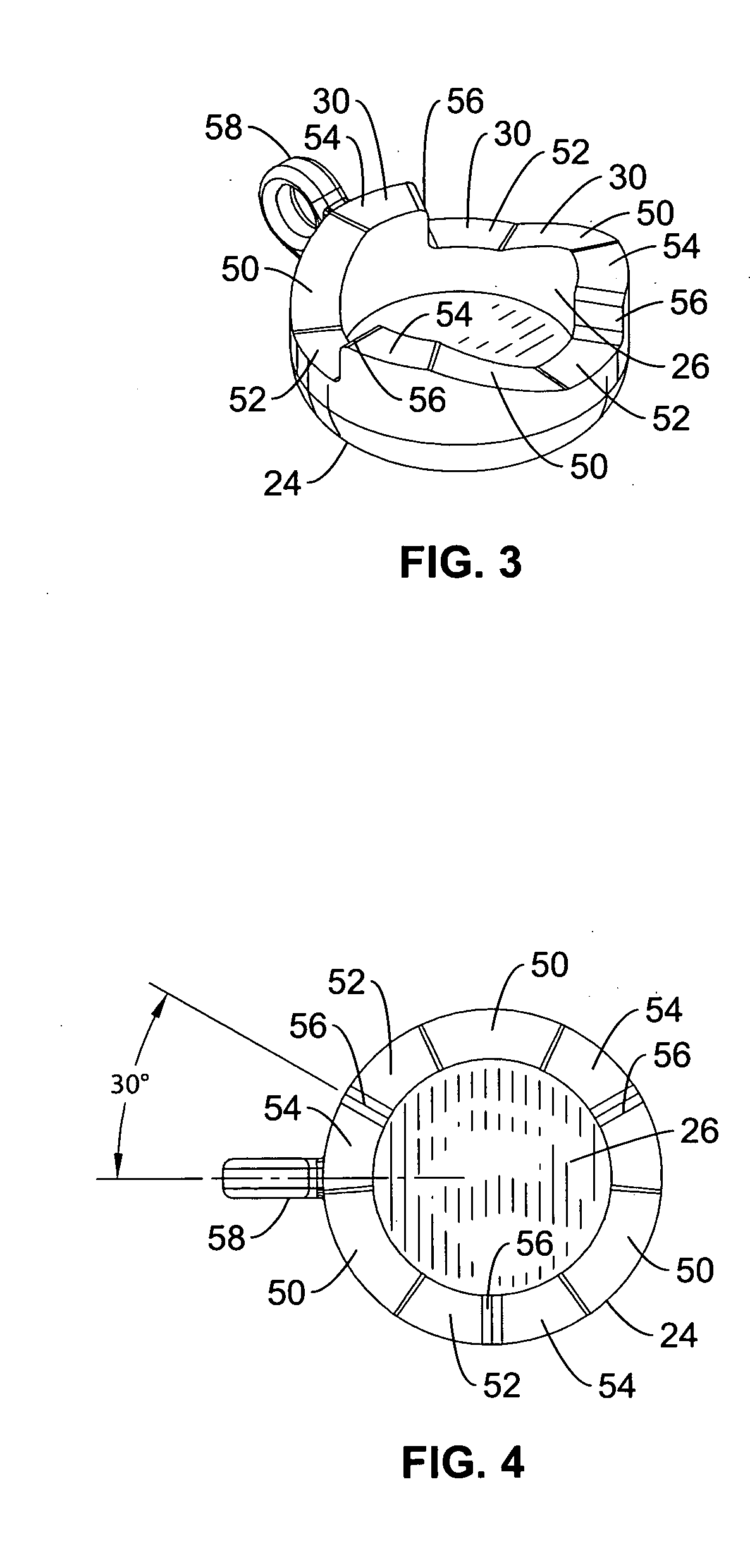

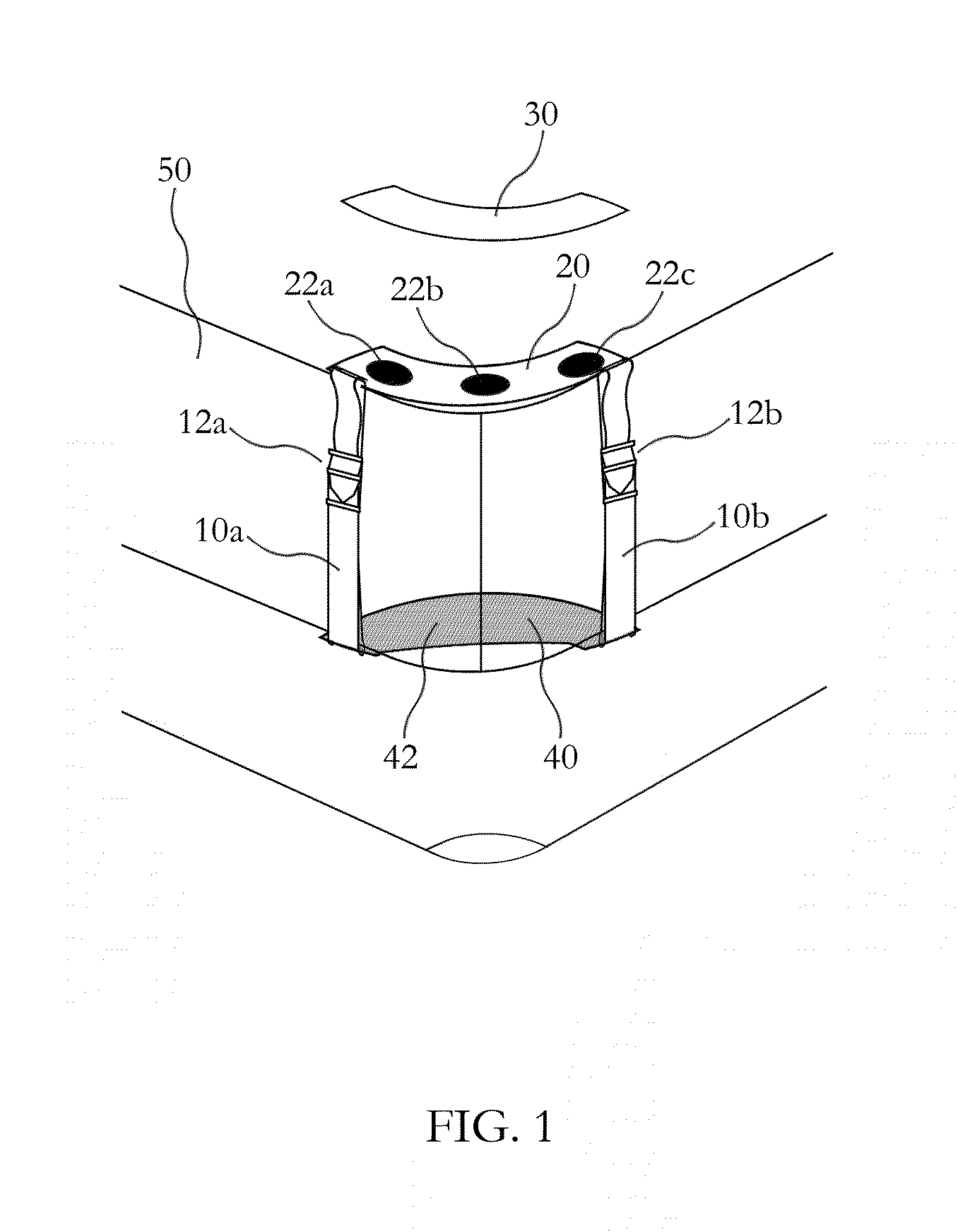

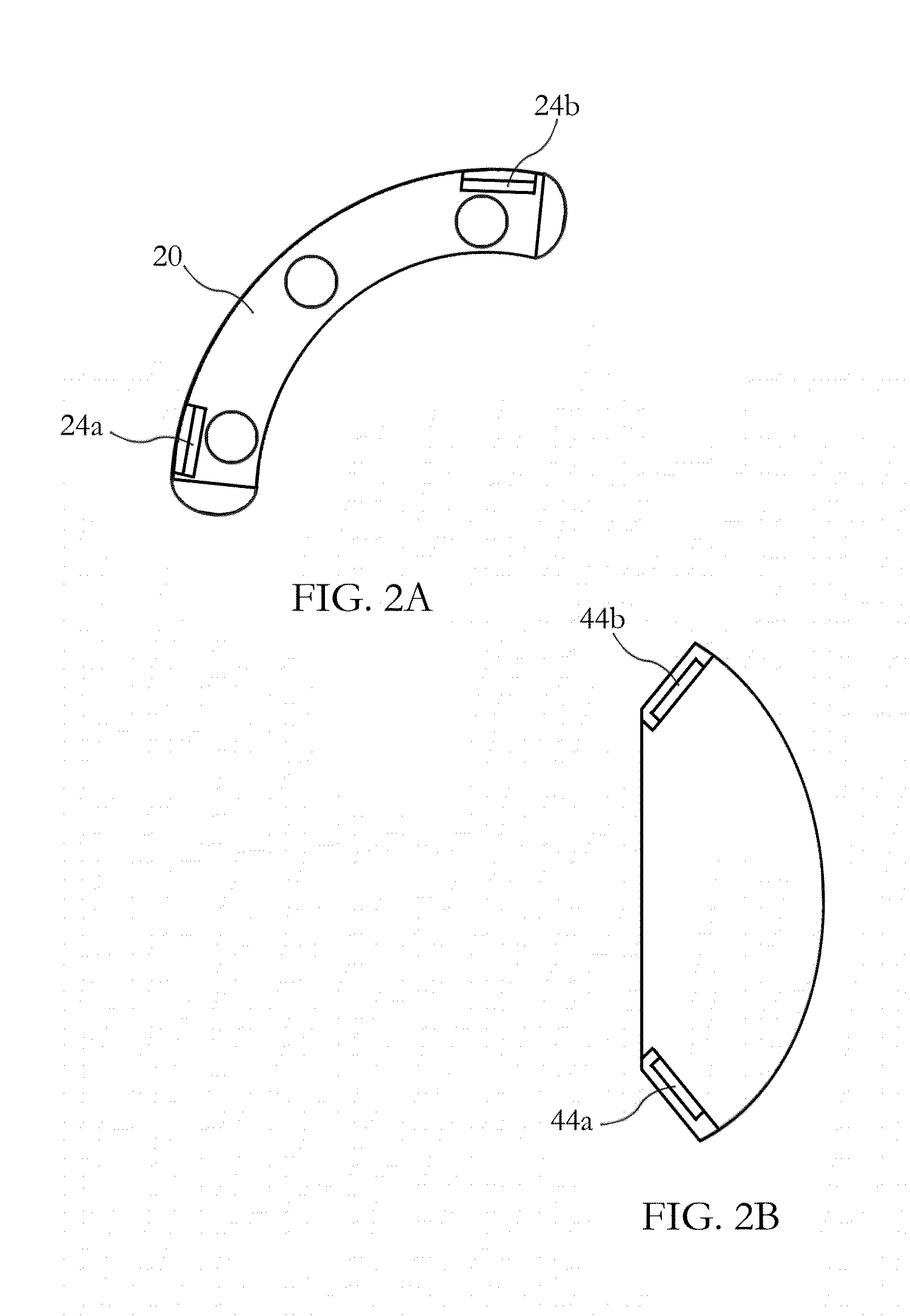

Magnetic clasp apparatus

InactiveUS7207091B2Easy to carryReduce forceSnap fastenersClothes buttonsNeodymium magnetEngineering

A jewelry clasp with top and bottom sections, each section having a bore to receive a magnet, and each section having an interlocking surface on the perimeter of the bore. An eyelet is positioned on the perimeter of each section. The interlocking surfaces consist of mating camber protrusions that will lift and separate the top and bottom sections when the sections are rotated in one direction by the eyelets. One magnet is longer than the other to provide structural resistance to separation at the camber protrusions by opposing force exerted through the eyelets. In another embodiment, a steel tube is positioned in the bore of one section to encase the magnets to redirect magnetic flux and provide additional structural resistance against opposing force through the eyelets. Additional steel shielding can be used to reduce magnetic flux emanating from the clasp. Neodymium magnets coated with gold or silver are preferred.

Owner:DUNAYE GARY

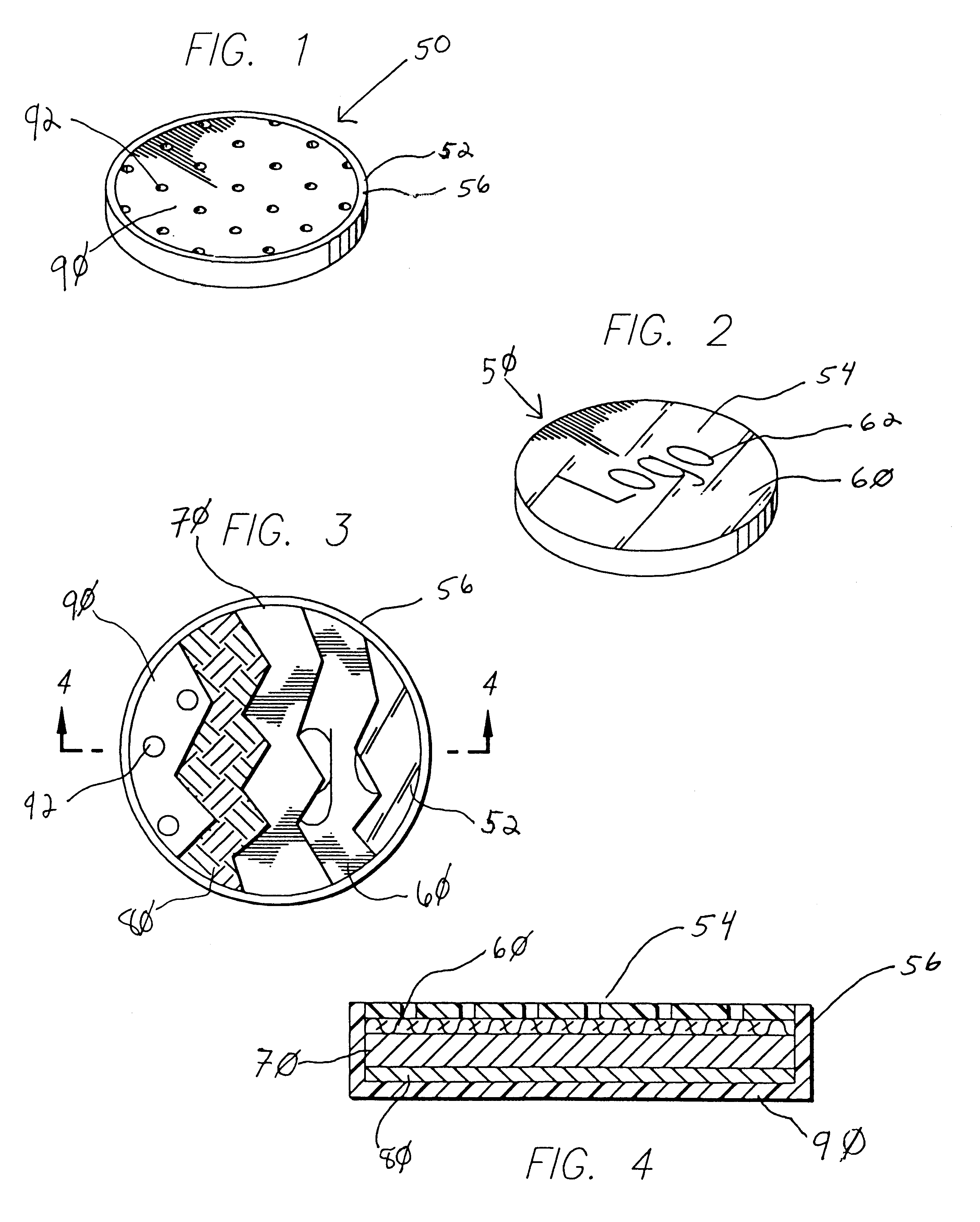

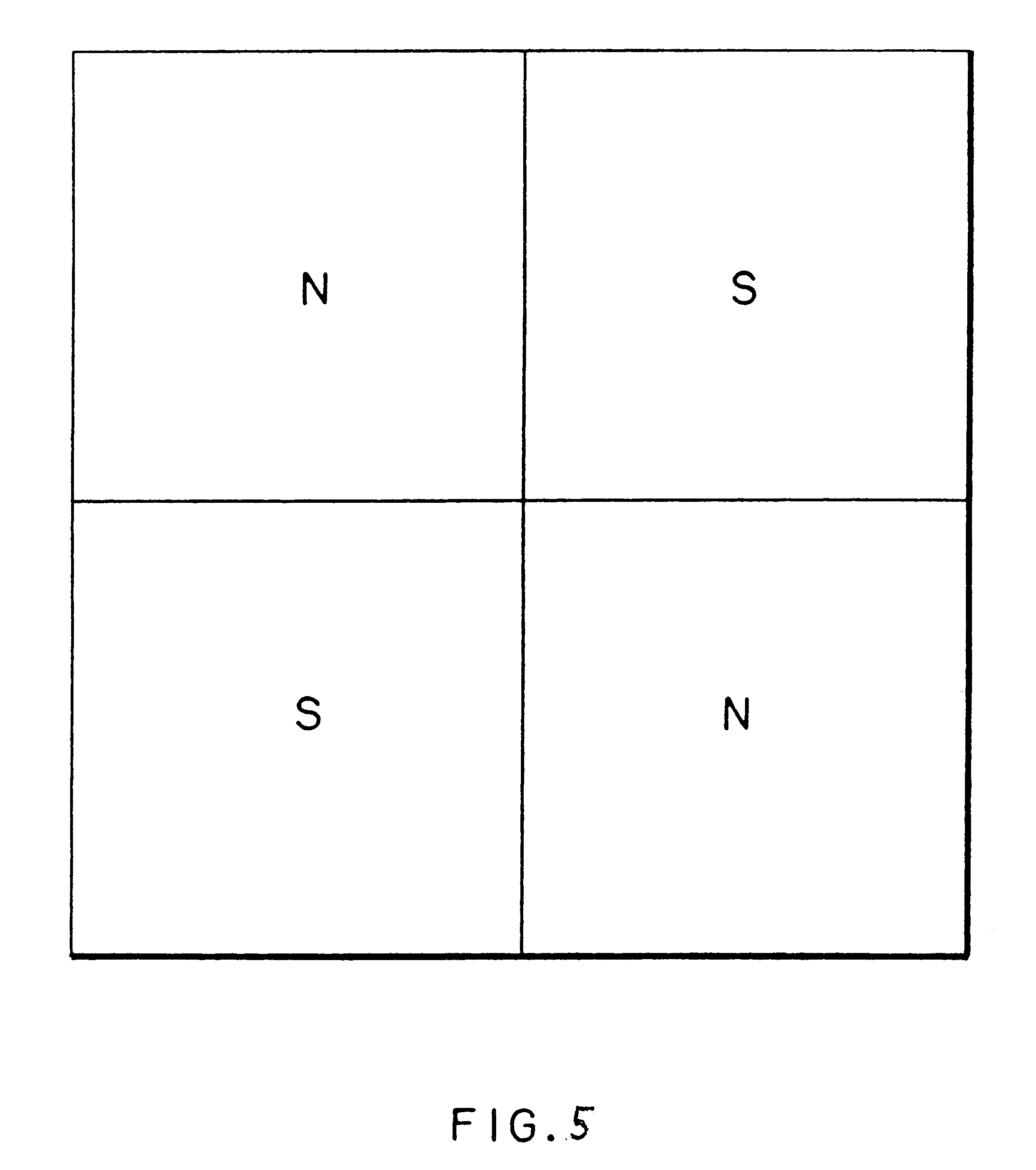

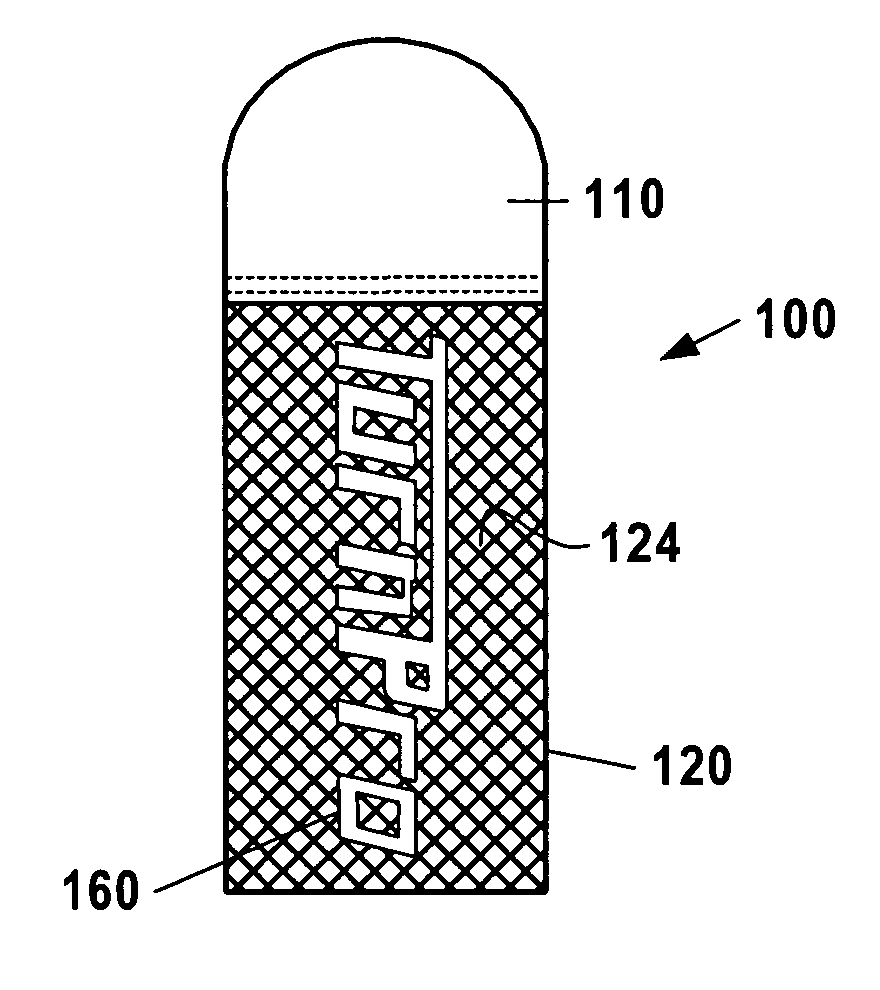

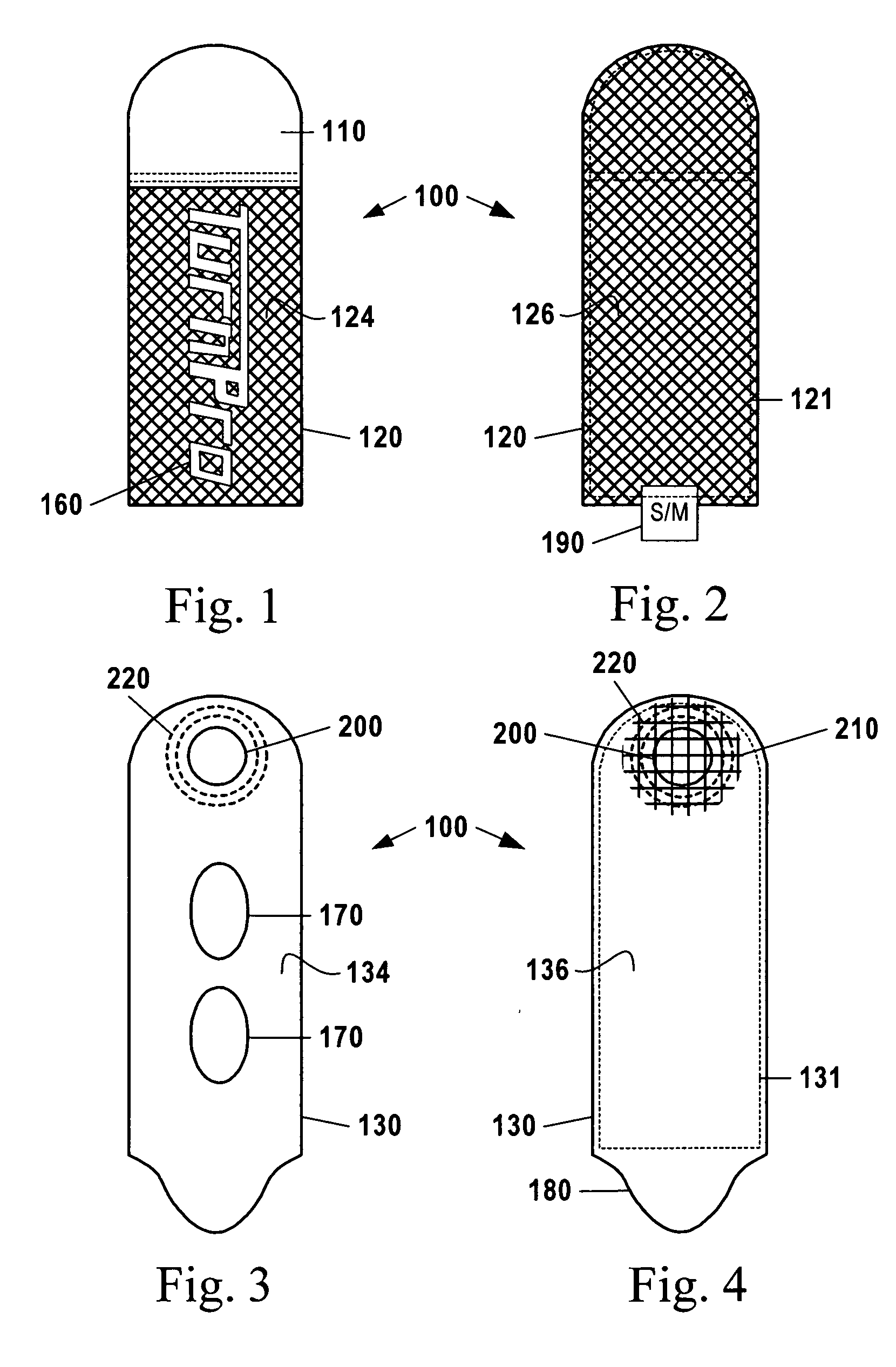

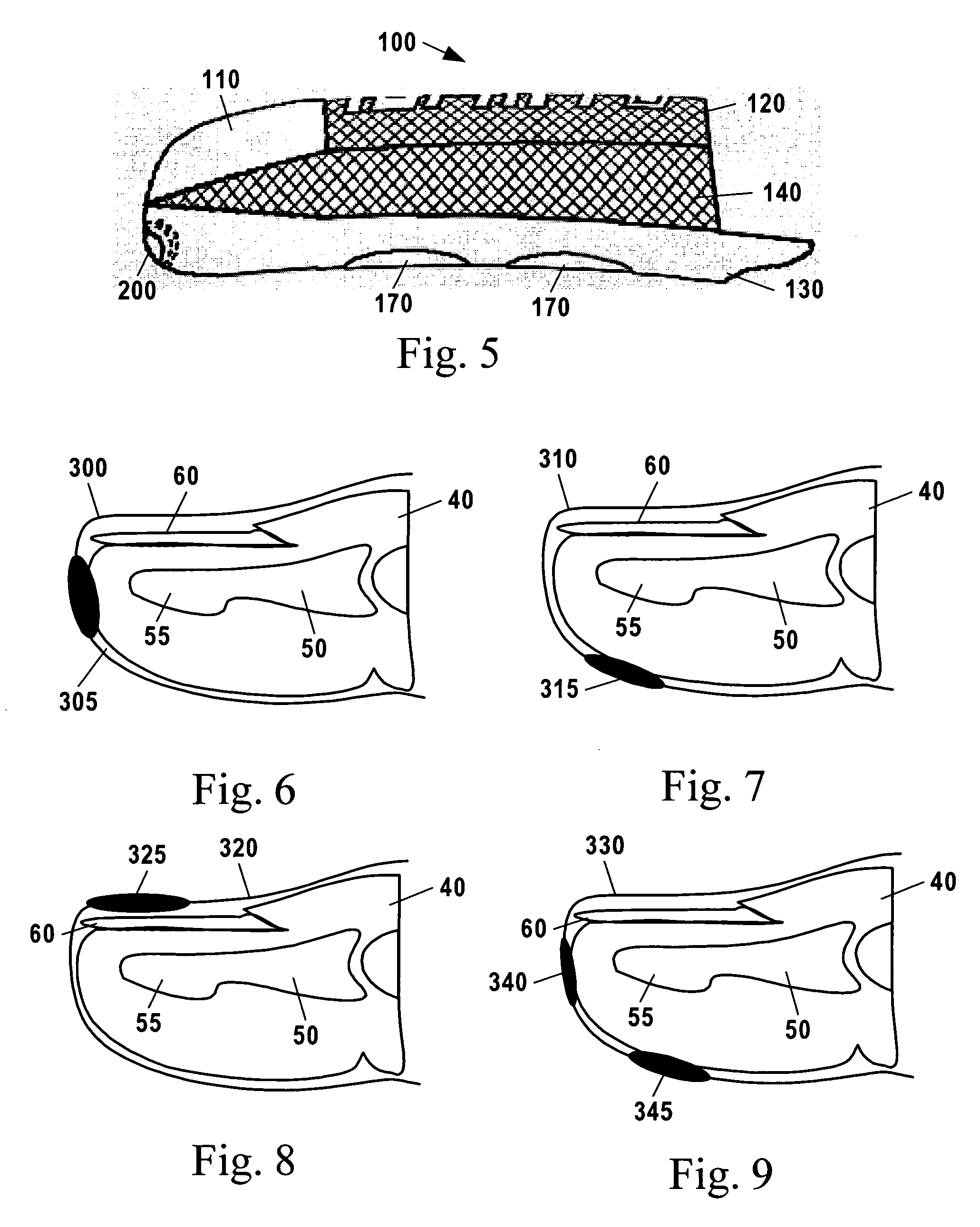

Magnetotherapeutic device with bio-ceramic fibers

InactiveUS6383129B1Convenient Application RequirementsEasy to useElectrotherapySurgeryFiberPolyester

A magnetotherapeutic device incorporates bio-ceramic fibers so as to provide simultaneous magnetotherapy and far infra-red wave therapy. Generally encased in clear plastic or the like, the magnetotherapeutic device of the present invention may take the form of a transparent disk having a plastic rim. A stainless cap may provide an attractive top surface into which a logo or symbol may be embossed. It also enhances the magnetic affects on the side opposite the stainless steel cap, the side that is applied to the body. A strong magnet such as one incorporating neodymium may underlie the stainless steel cap to provide magnetotherapy in the present invention. Bio-ceramic fibers emitting the far infra-red wavelengths of 8-14 microns underlie the strong neodymium magnet. A mat of woven bio-ceramic fibers or the like may provide such a structure. In order to provide ventilation and communication between the environment outside of the magnetotherapeutic device of the present invention, perforated or foramenous mylar may serve as a bottom cover encasing the stainless steel cap, neodymium magnet, bio-ceramic fibers, and the plastic case. The perforated or foramenous mylar may then provide better communication between the thermal radiation of the adjacent body and emittance of far infra-red waves by the bio-ceramic fibers.

Owner:NYUU MAGUNETEIKUSU

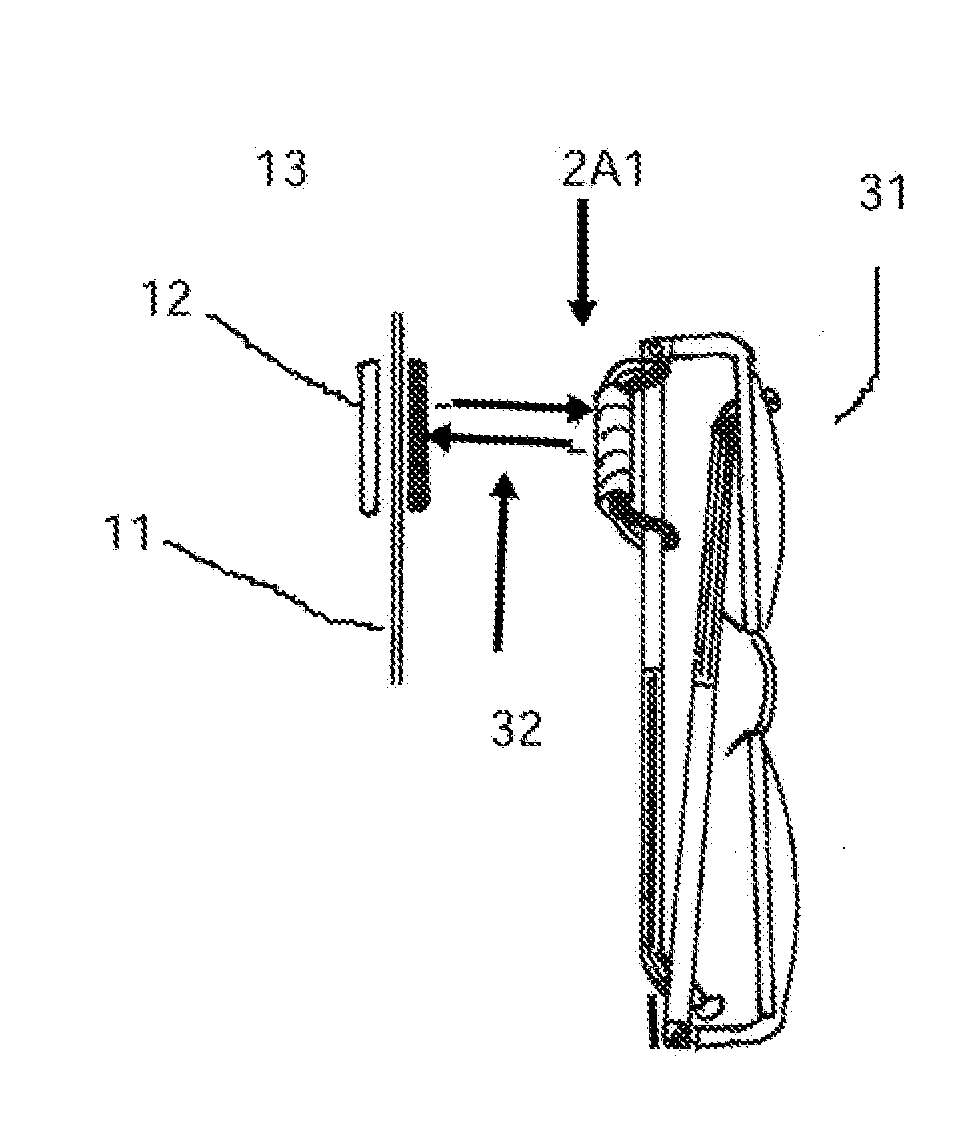

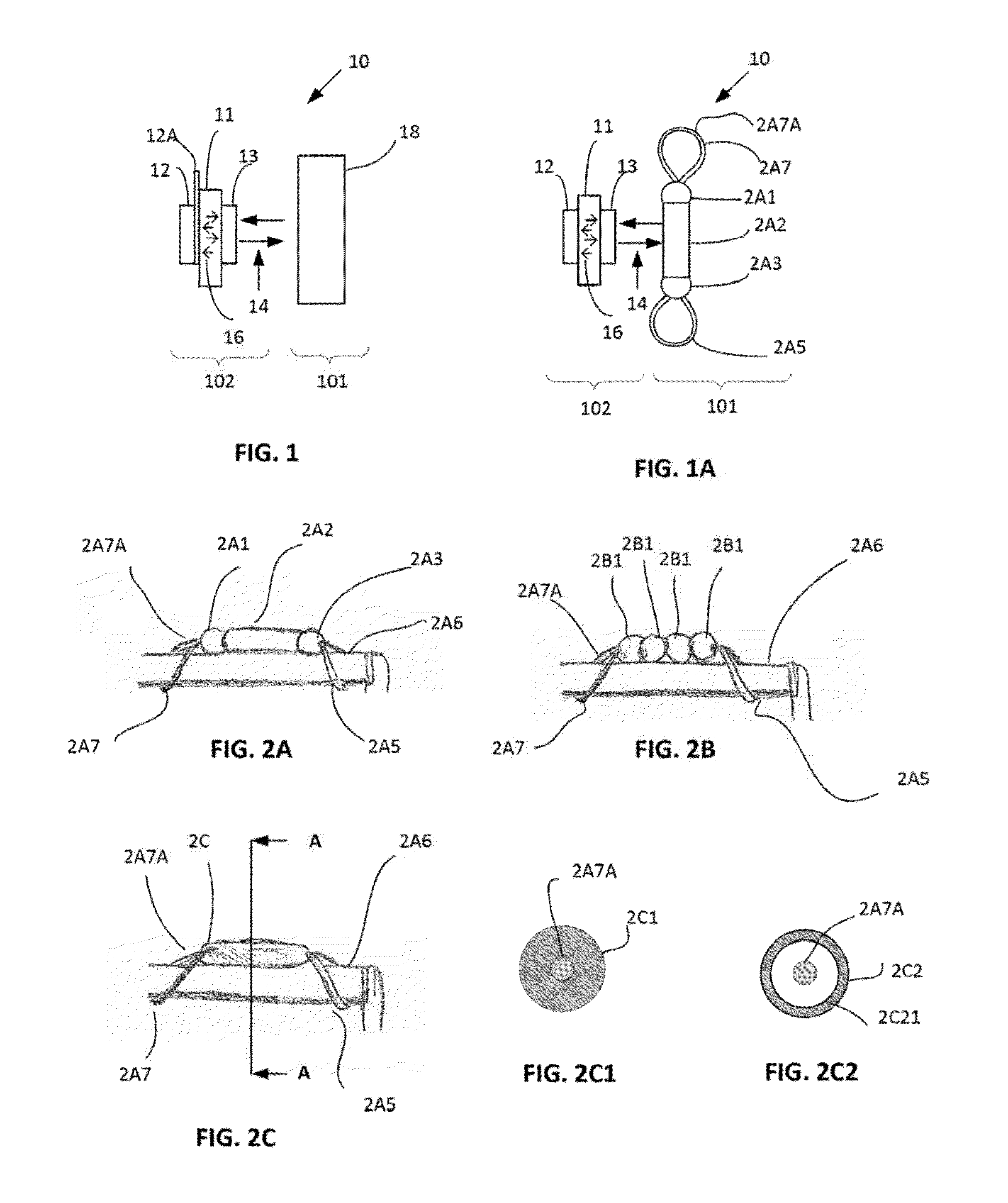

Magnetic Retention System

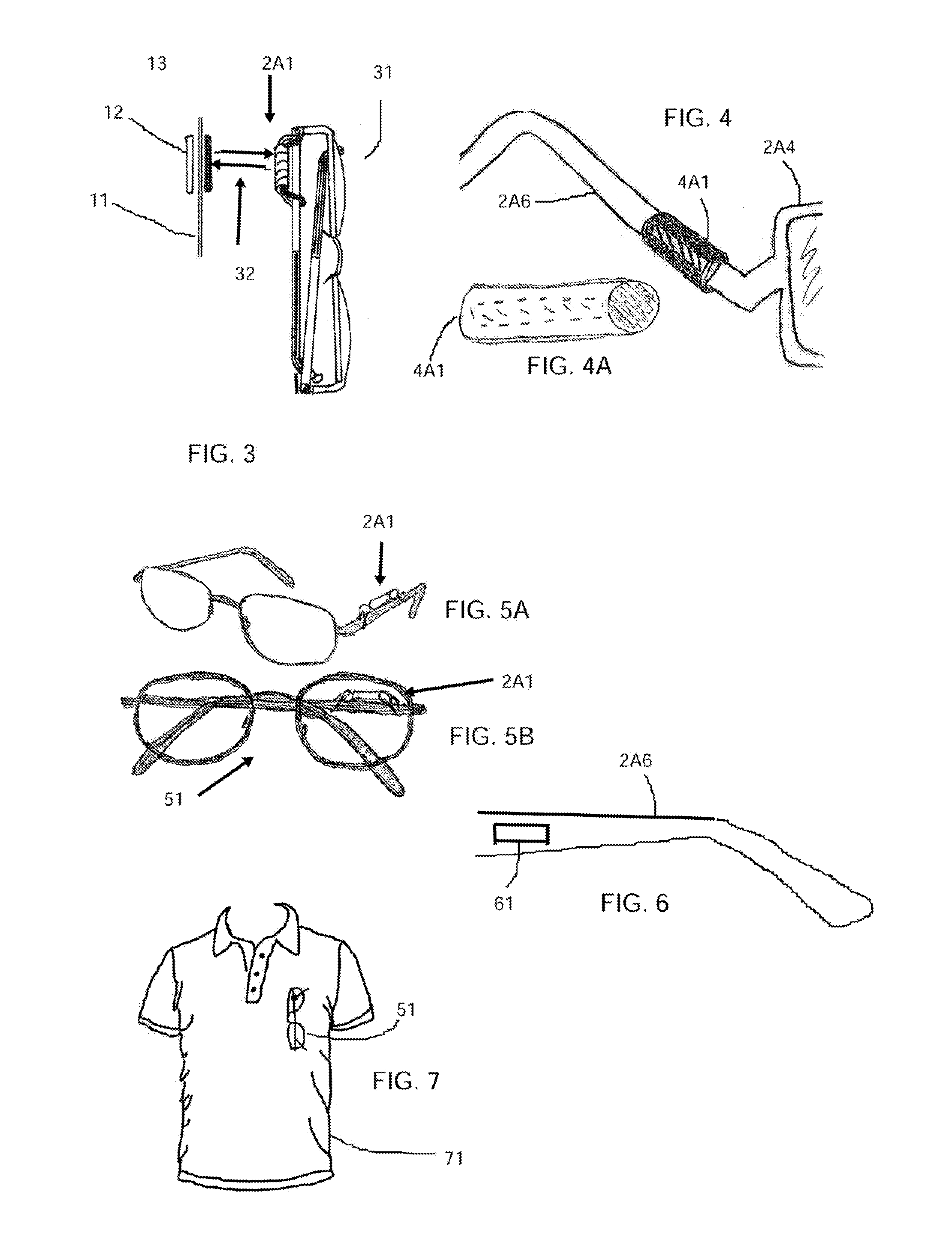

InactiveUS20150234201A1Securely holdSpectales/gogglesNon-optical adjunctsNeodymium magnetEngineering

A magnetic retention system (MRS) for magnetically holding parts, such as an eyewear temple part is provided. The MRS includes a positioning subassembly having a ferromagnetic backing plate and a neodymium magnet, wherein the neodymium magnet is adaptable to magnetic communication with the backing plate. The MRS also includes a retention subassembly having a ferromagnetic retainer adaptable to magnetic communication with the neodymium magnet.

Owner:LEVESQUE DAVID J

Magnetic finger glove

ActiveUS20060185057A1Prevents and minimizesGood touchGlovesProtective garmentCircular discNeodymium magnet

A magnetic finger glove helps persons hold, install, and retrieve small metallic objects, such as nuts or screws, in hard-to-reach places. The finger glove is sized and shaped to sheathe and conform to an adult human index finger. A small round disc neodymium magnet is affixed to a fabric assembly in the region corresponding to the fingertip. The magnet weighs less than 0.002 pounds and is small enough to be confined within an area on the fabric assembly of less than 0.5 square inches. Yet, the magnet has a holding force of at least 1 pound.

Owner:TURNPRO

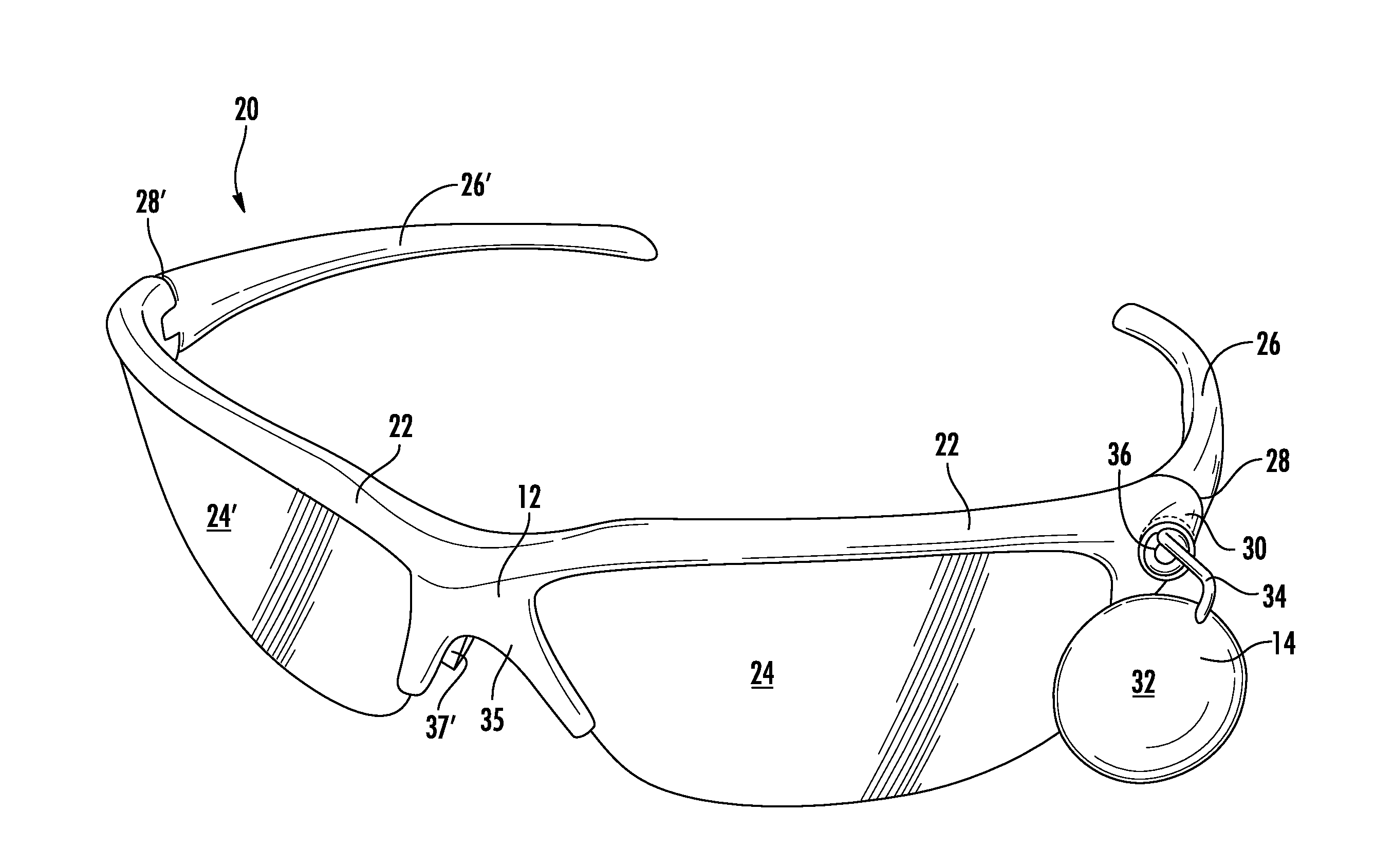

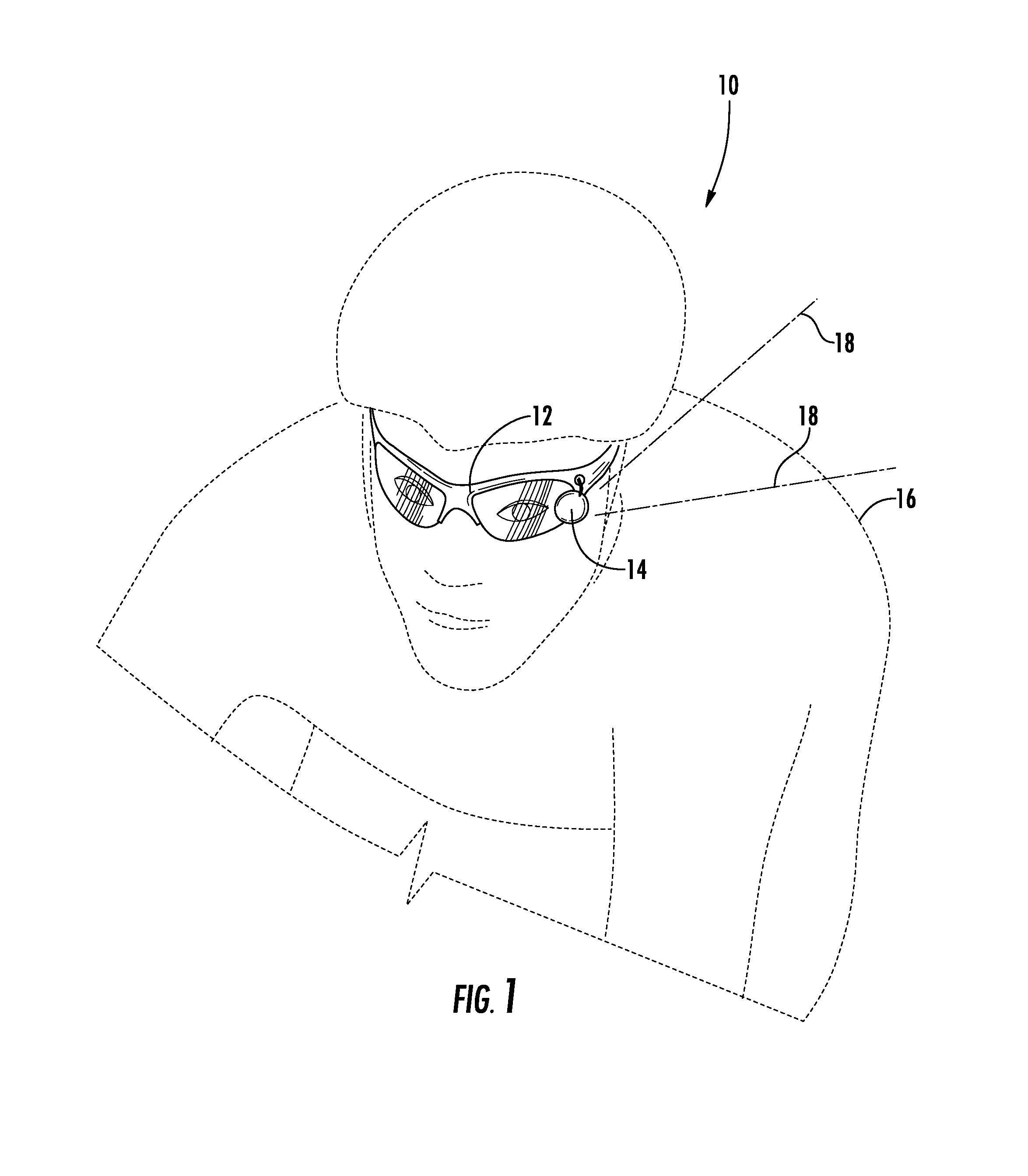

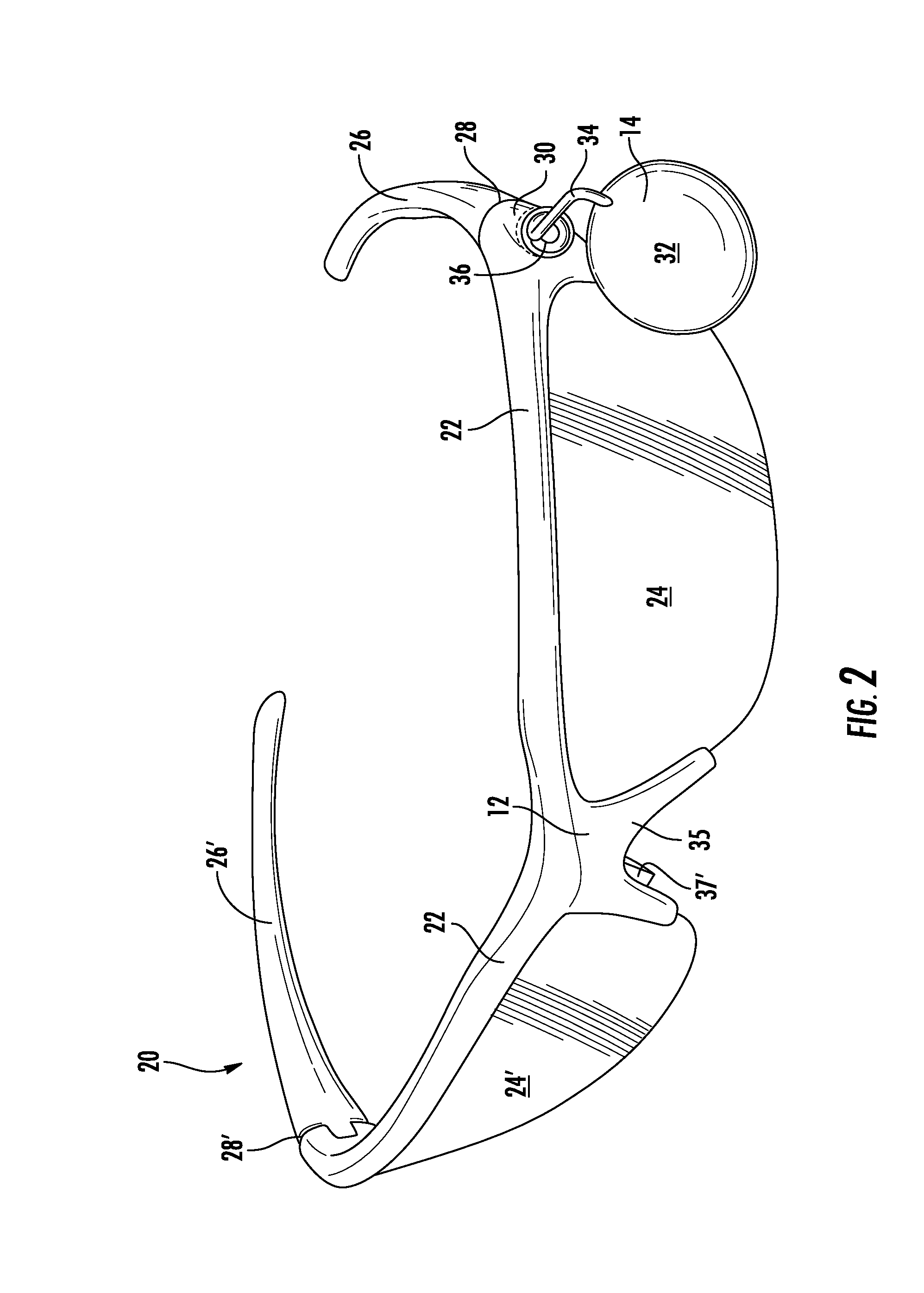

Cycling safety glasses with rearview mirror

InactiveUS20140043580A1Easy to disassembleEasy to adaptOptical partsUses eyeglassesAngle of incidence

Safety glasses for experienced cyclists have a small diameter, unobtrusive, adjustable and removable minor mounted thereon for establishing a rearwardly directed line of sight so that the cyclist can see a vehicle, including an automobile, motorcycle, or another cyclist, approaching from behind. The minor is mounted on a stem that is magnetically attached to the gasses frame and extends forward from the frame. The magnetic attachment is sufficient to allow ready adjustment of the angle of incidence of light to establish the desired rearwardly directed line of sight and to fix the line of sight in place after adjustment. The glasses frame has a small disc-shaped neodymium magnet of from about 1 to 2 or 3 pounds force pull strength embedded in the face frame to the wearer's left and the minor stem has a cooperating corresponding magnet mounted opposite the mirror. Larger mirrors may be desirable for use by less experienced cyclists.

Owner:STEELE HLDG LLC

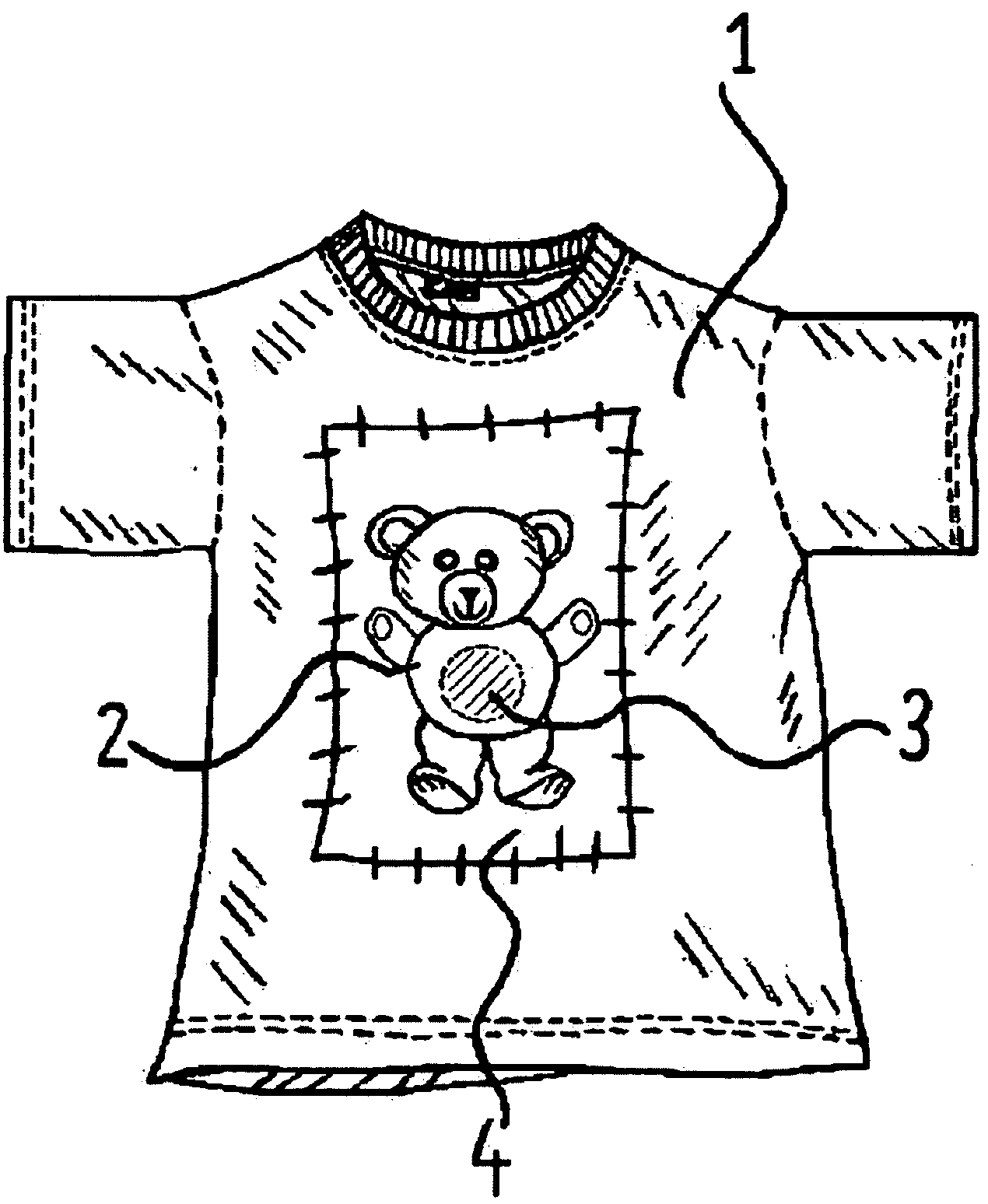

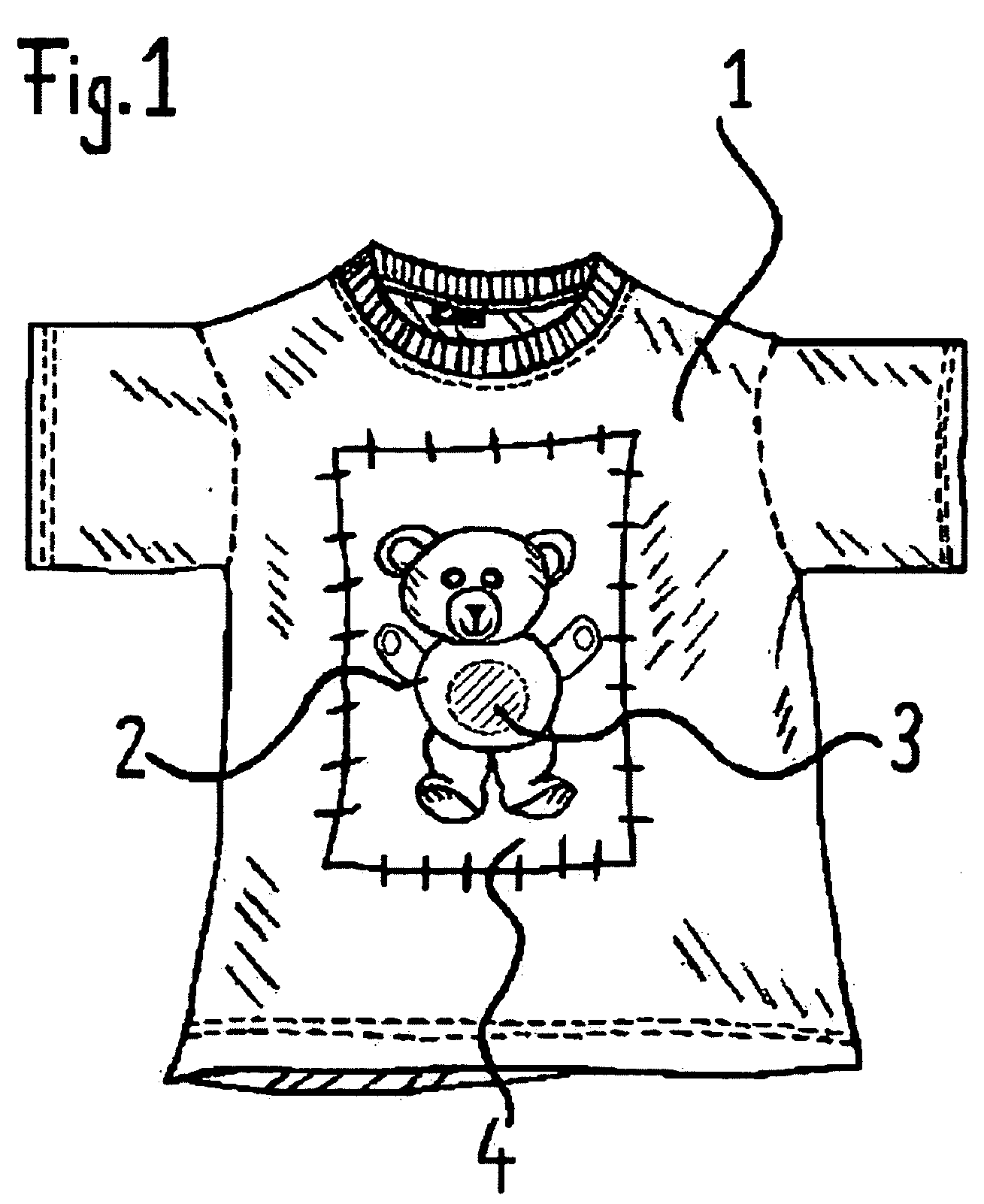

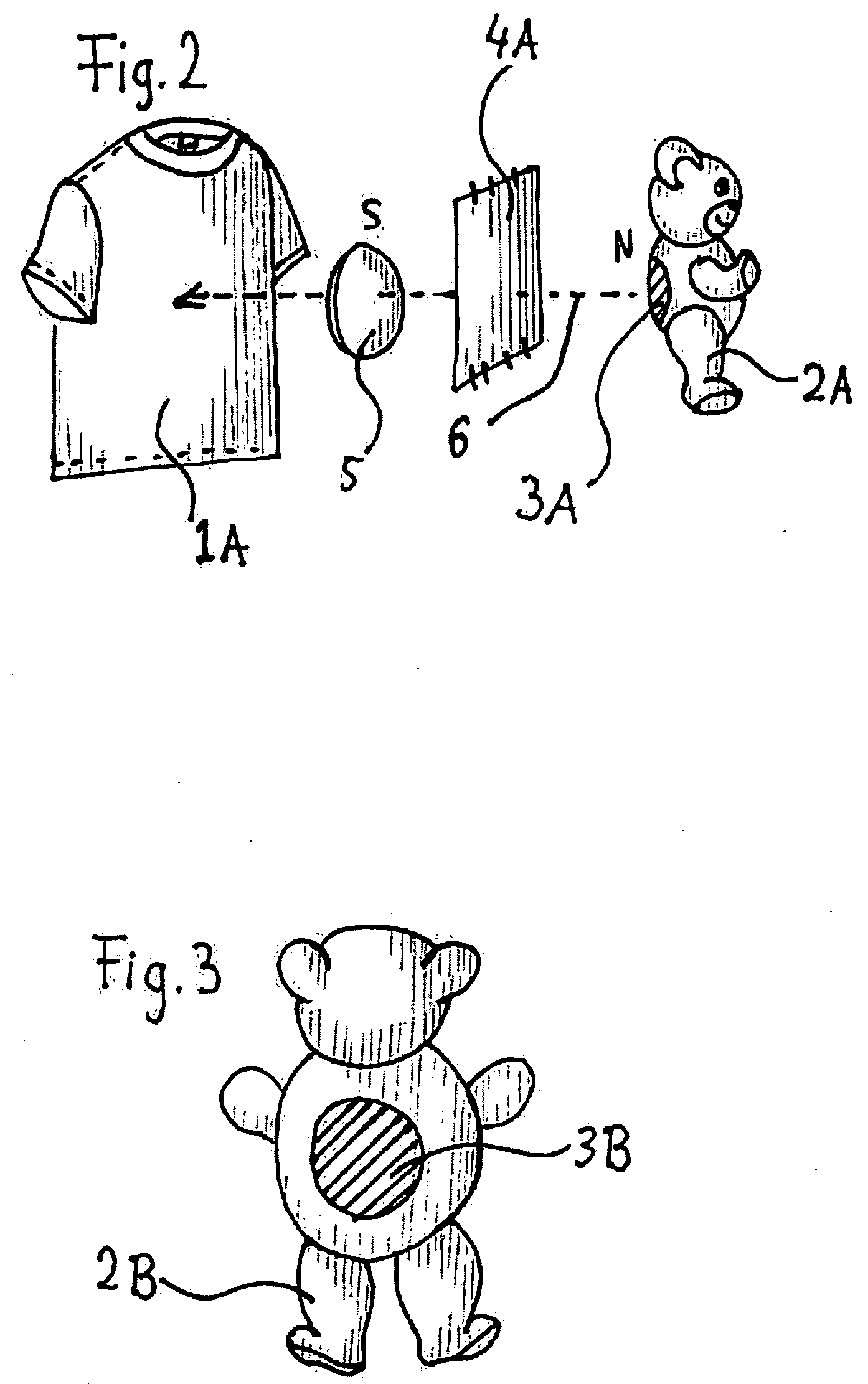

Combination of articles of apparel or bags and magnetic toys

InactiveUS20100167619A1Easy to holdEasy to separateTravelling sacksTravelling carriersNeodymium magnetEngineering

Provided are novelty clothes and bags with neodymium magnets affixed to their material for attaching magnetic toys. Also, provided is a method of decorating clothes or bags, which method is attaching the magnets under patches sewn, or affixed in other way to the material of clothes or bags, and magnetically attaching the magnetic toys to that patches.

Owner:ADAMUS AGNIESZKA ZOFIA

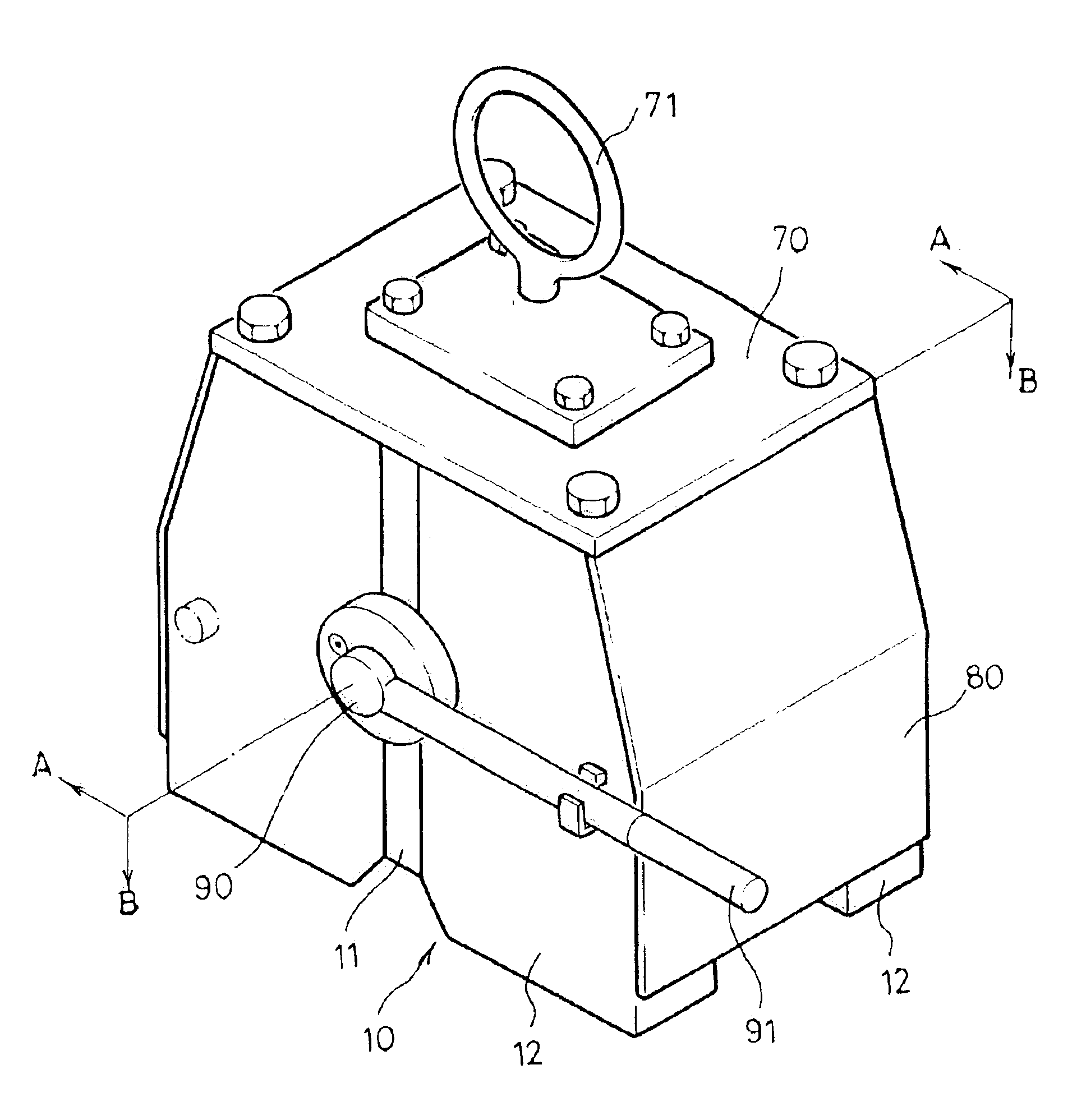

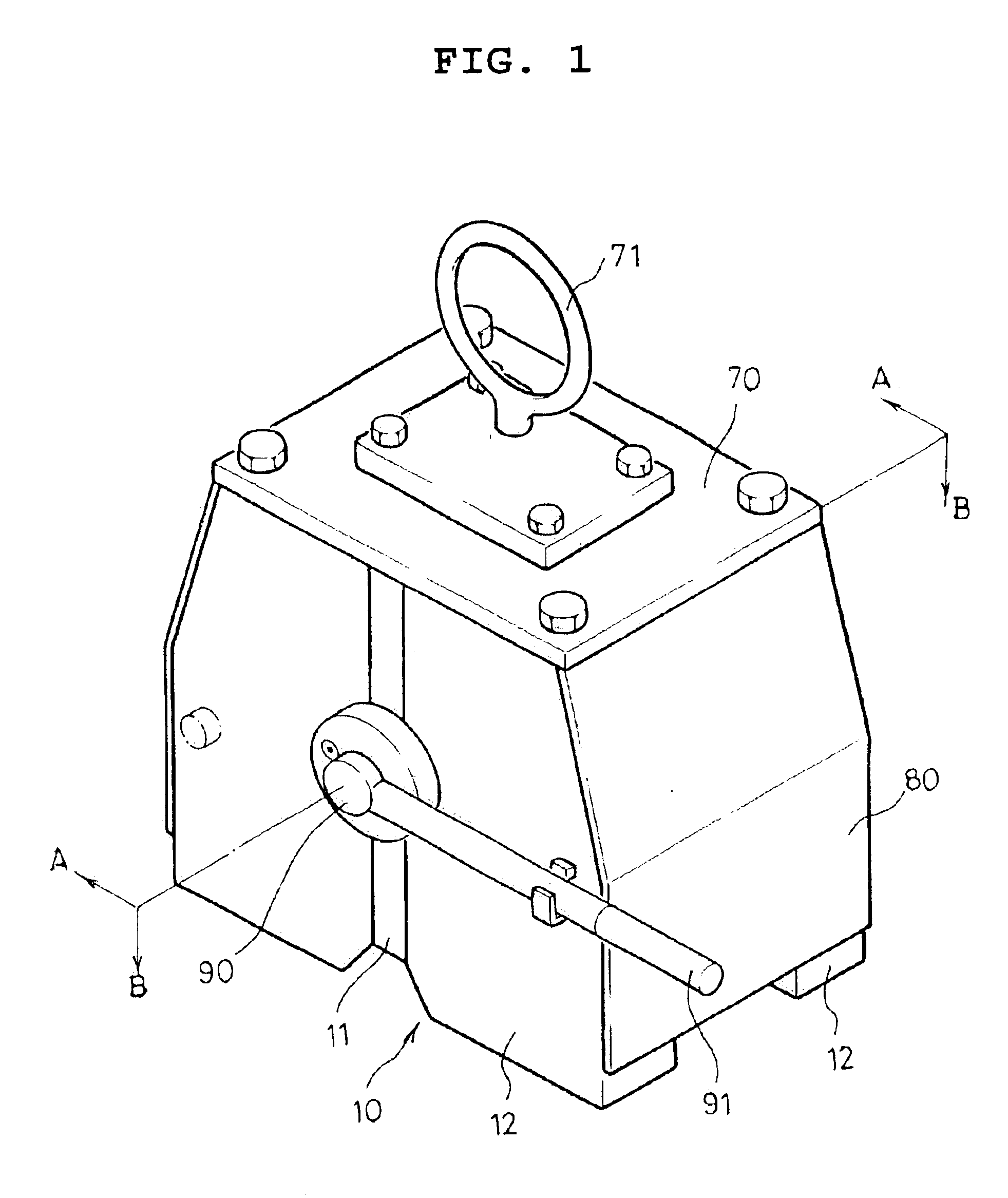

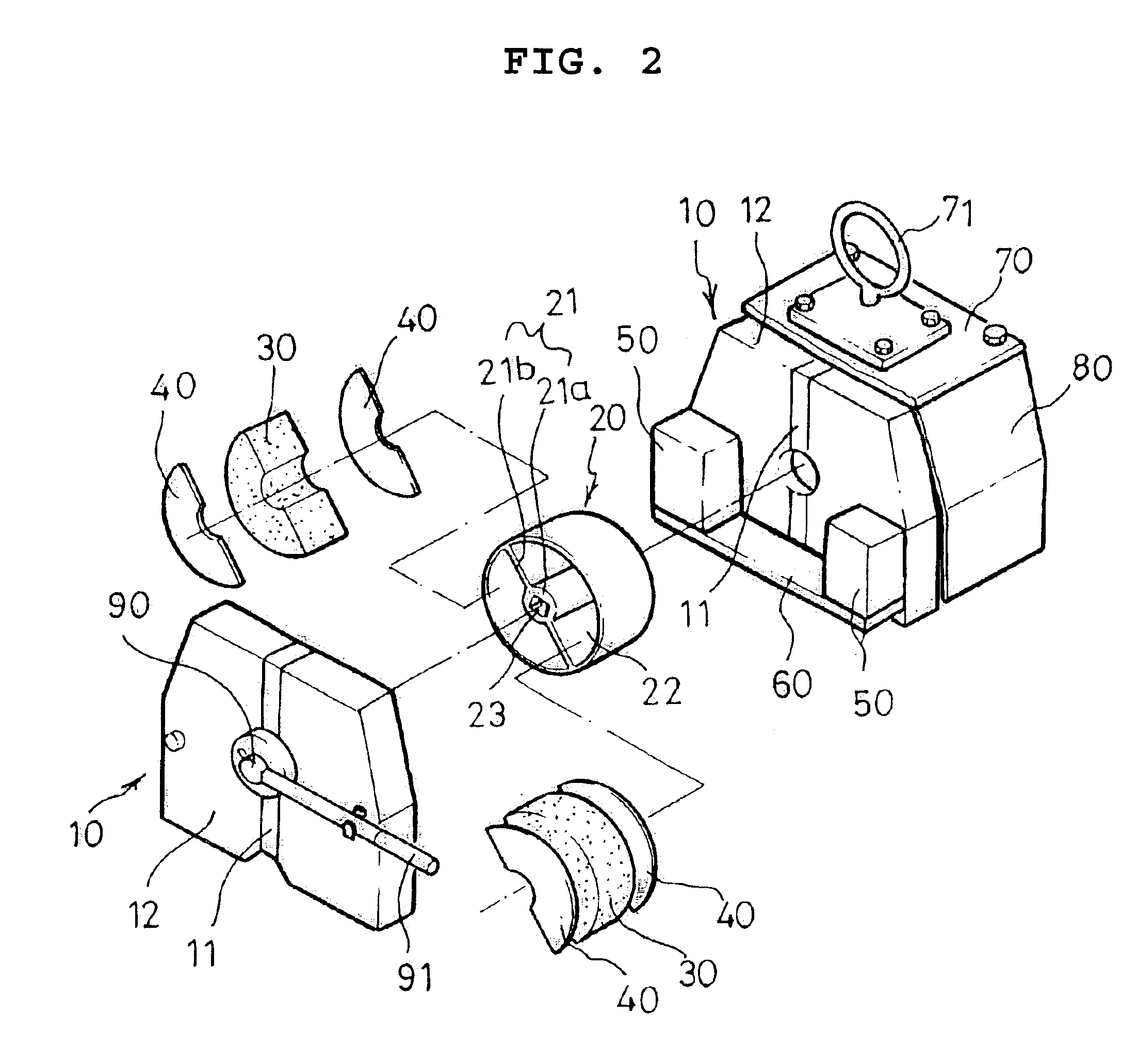

Magnetic lifting machine using neodymium magnets

InactiveUS6854777B2Improve coercive forceImprove comprehensive applicabilityElectromagnets without armaturesGripping headsNeodymium magnetEngineering

A magnetic lifting machine according to the present invention is to prevent an antioxidant film on the surface of neodymium magnets from exfoliation, by having the neodymium magnets not be in direct contact with a pair of polarity plates of the machine but via anti-exfoliation plates made of non-magnetic material. The anti-exfoliation plates are fitted to both sides of a rotor containing the neodymium magnets therein between the polarity plates, and each of the anti-exfoliation plates may include a plurality of holes for oil storage radially therethrough.

Owner:JUNG HYUNG

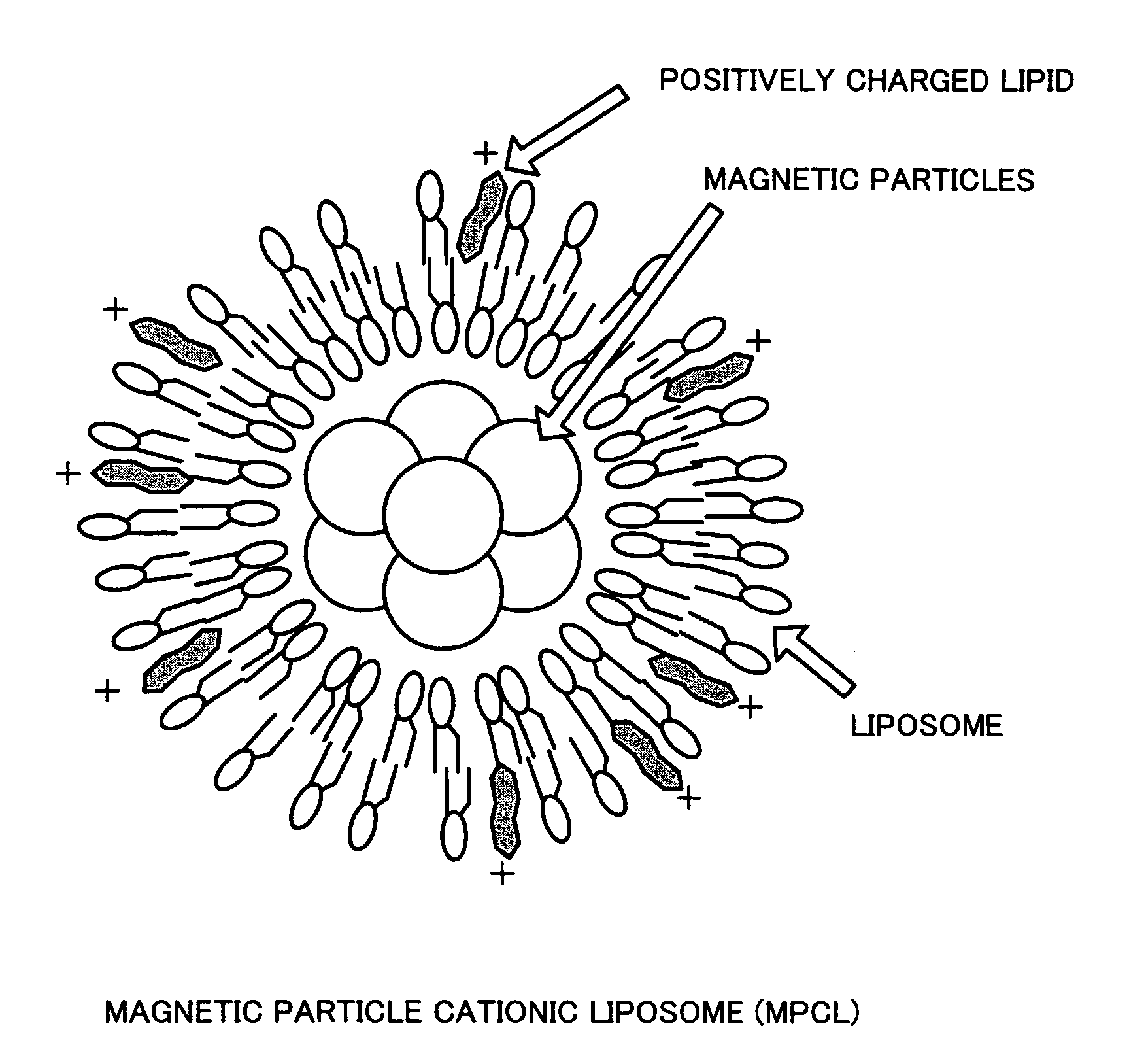

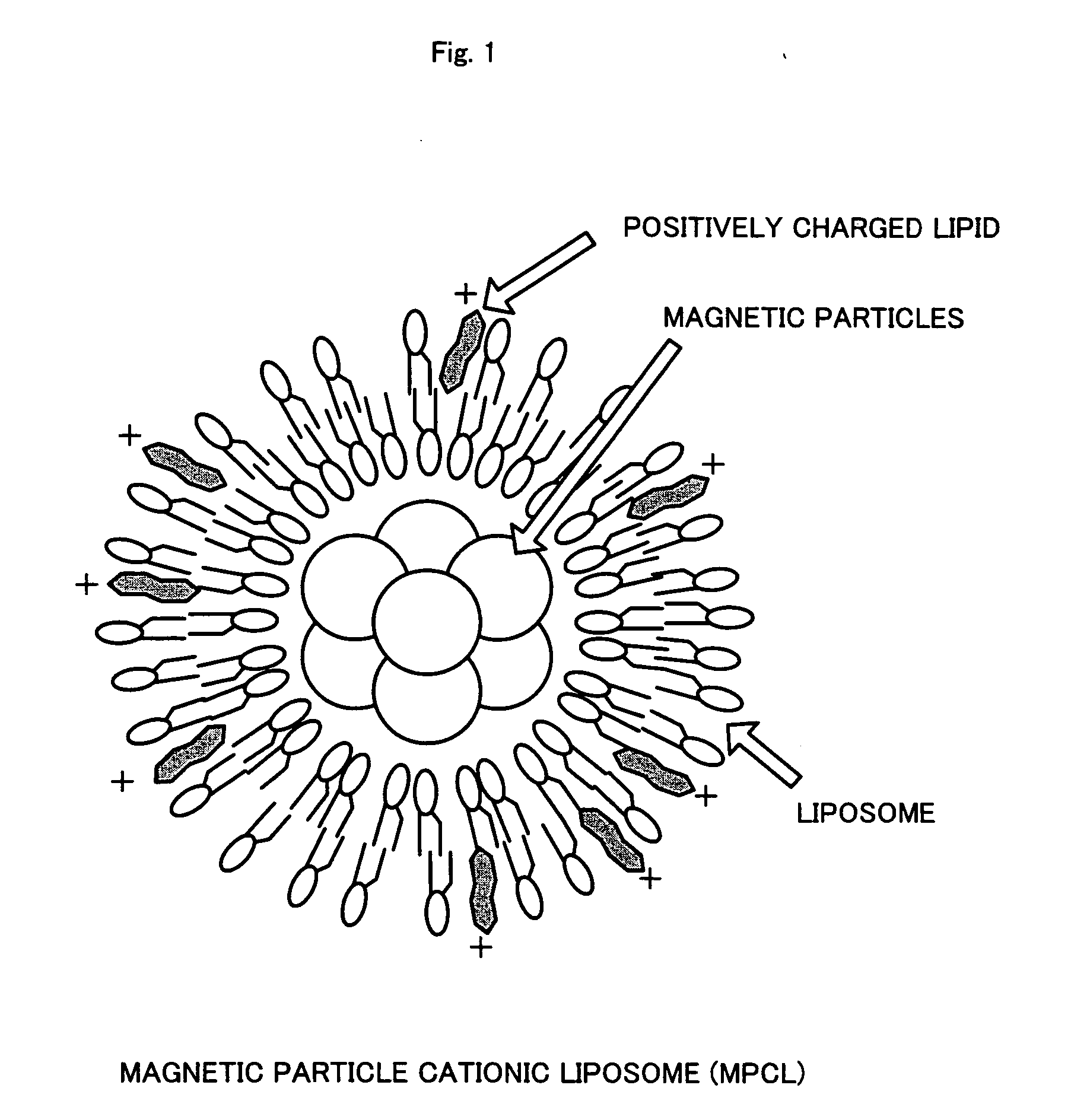

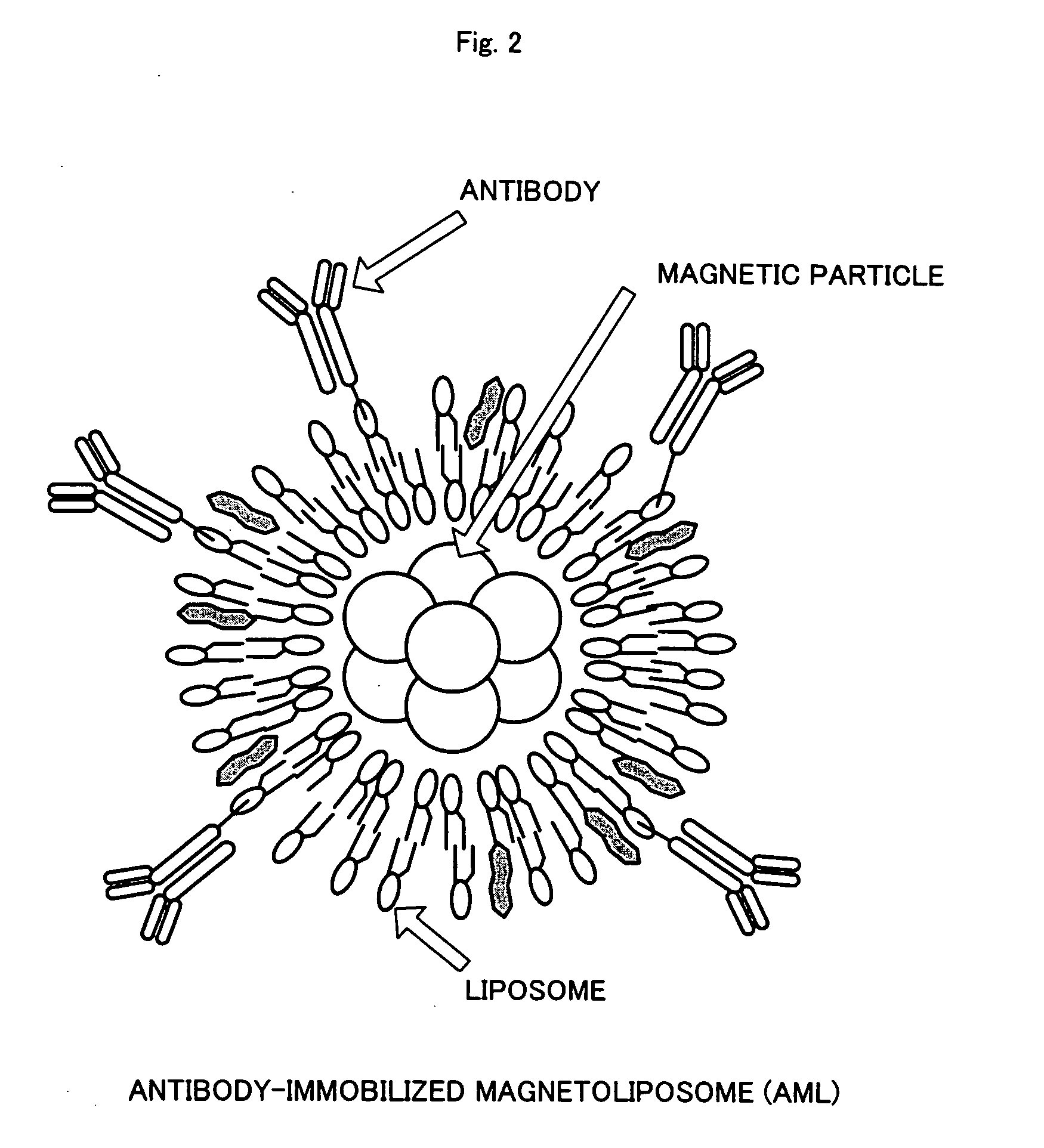

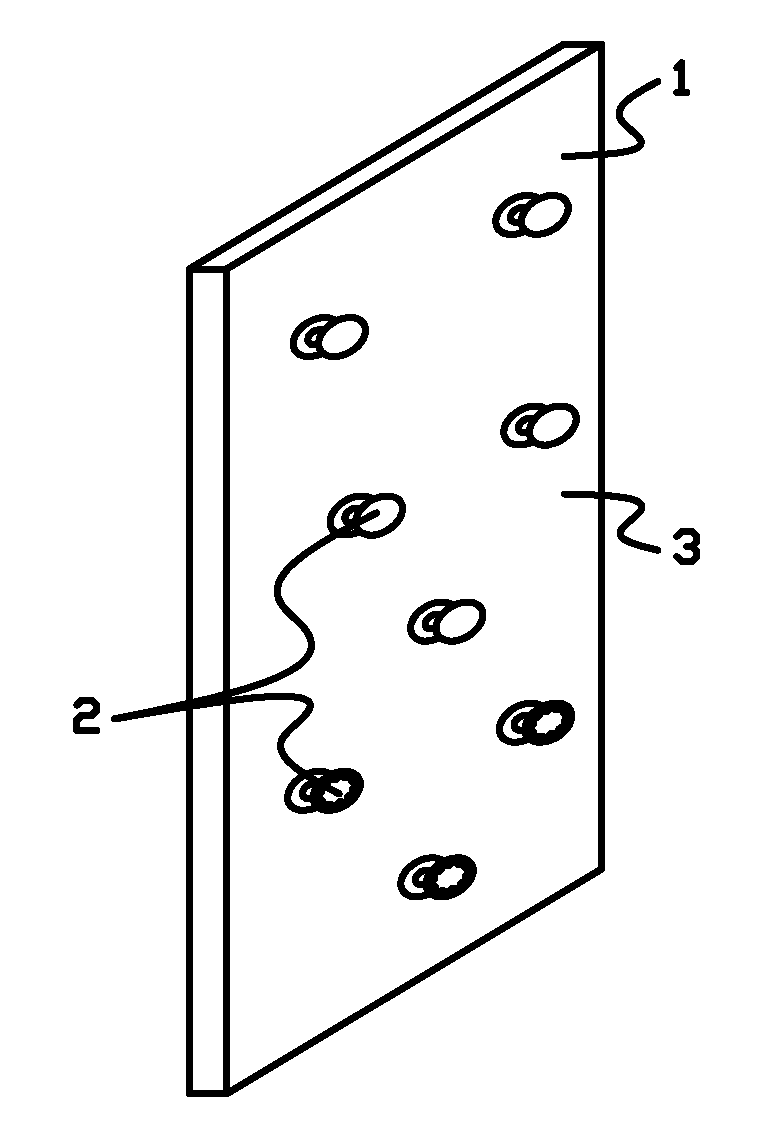

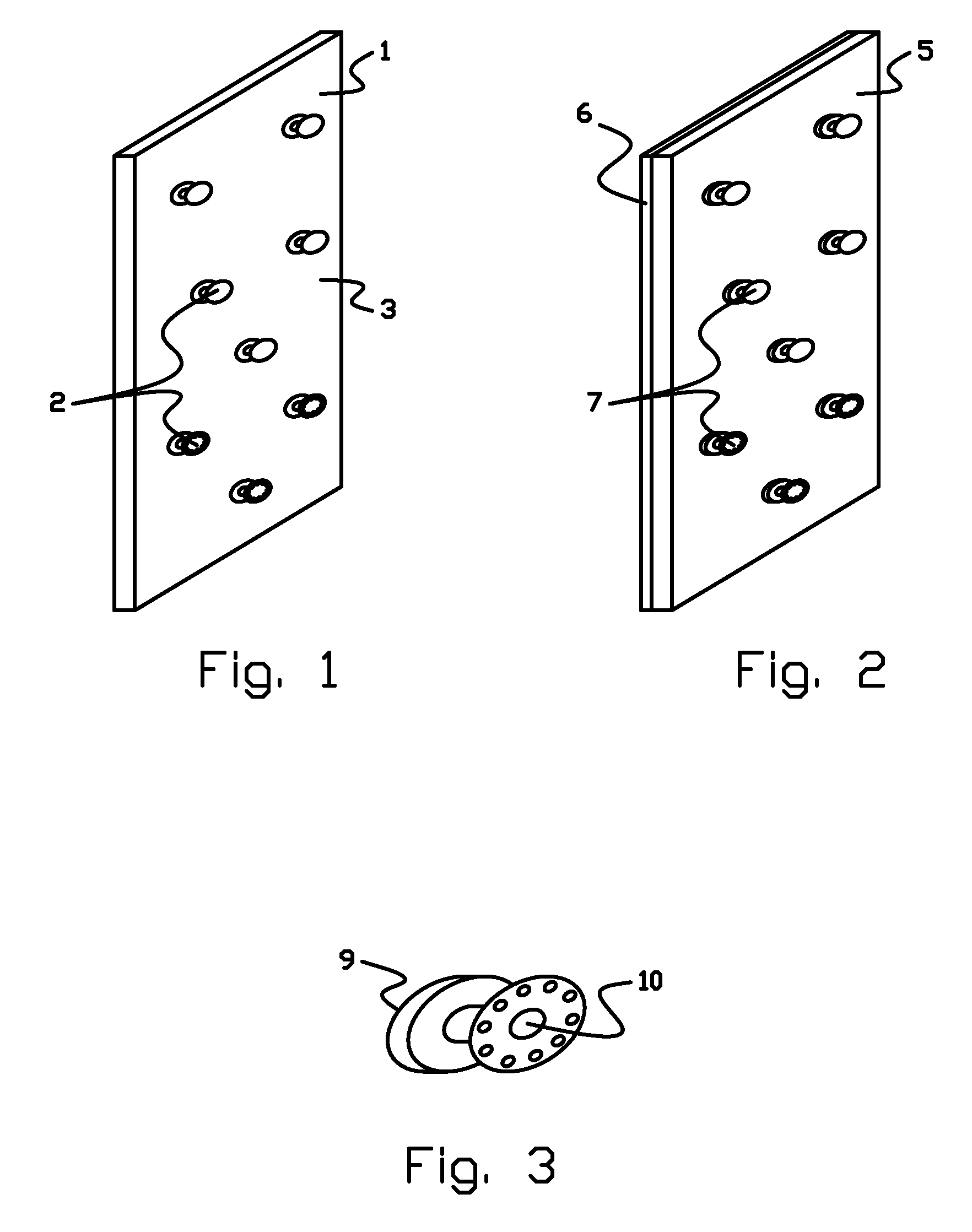

Cell culture method and cell sheet

InactiveUS20060063252A1Facilitated releaseEasily have magnetic propertyBioreactor/fermenter combinationsBiological substance pretreatmentsNeodymium magnetEngineering

Epidermal keratinocytes not incorporating magnetic particles therein and epidermal keratinocytes incorporating magnetic particles therein were seeded in a 24-well ultra-low-attachment plate, and cultured for one day after a neodymium magnet was placed outside the bottom of the well. As a result, control epidermal keratinocytes not incorporating magnetic particles therein did not adhere to the bottom of the well and did not form an undifferentiated cell sheet. On the contrary, epidermal keratinocytes incorporating magnetic particles therein, while being attracted to the bottom of the well by magnetic force, formed a multilayered cell sheet. This cell sheet could be easily recovered by removing the neodymium magnet placed outside the bottom of the well, then bringing a magnet having a hydrophilic film attached thereto close to the cell sheet from upside and to attract it via this hydrophilic film, and lifting it.

Owner:HONDA HIROYUKI +1

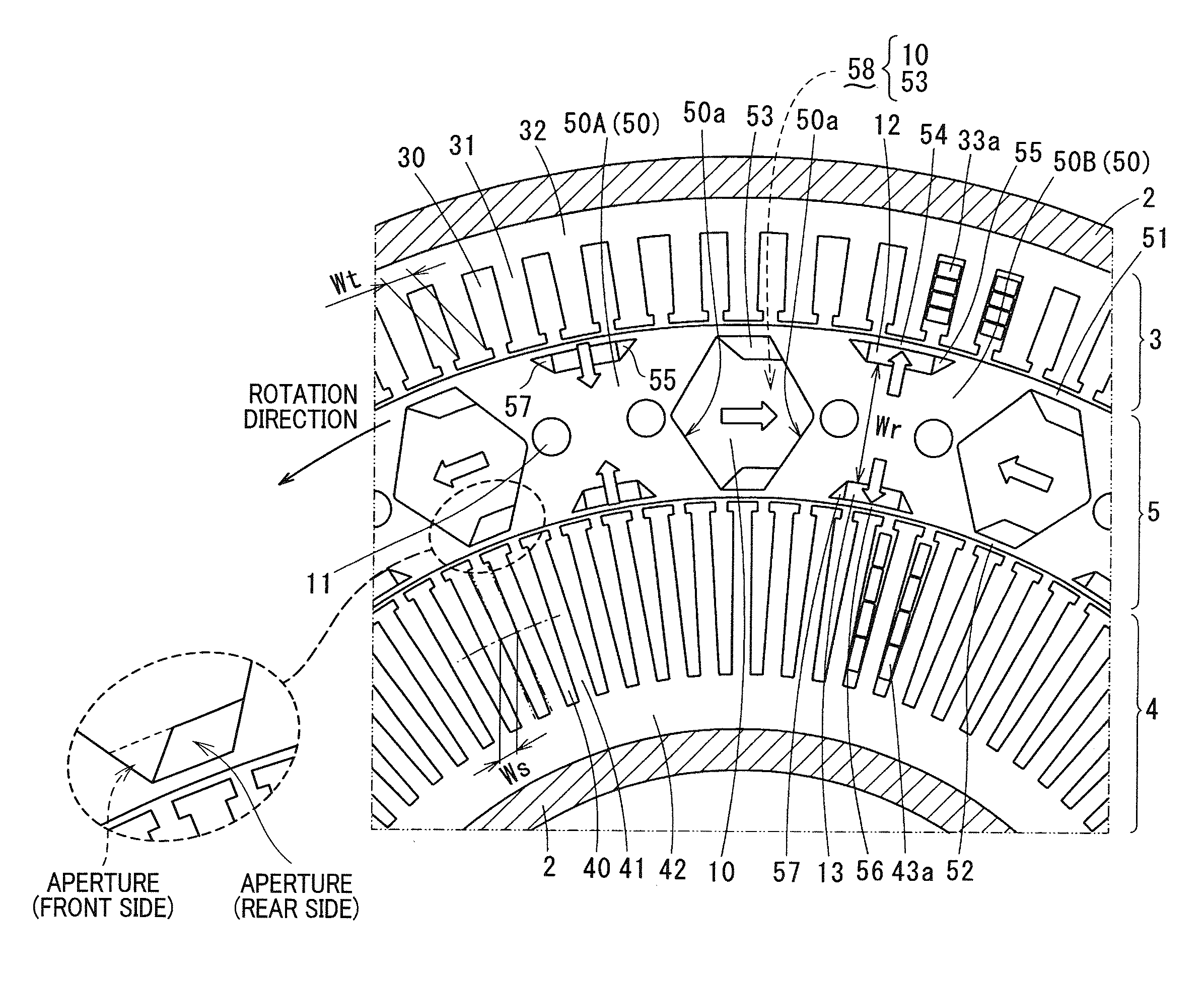

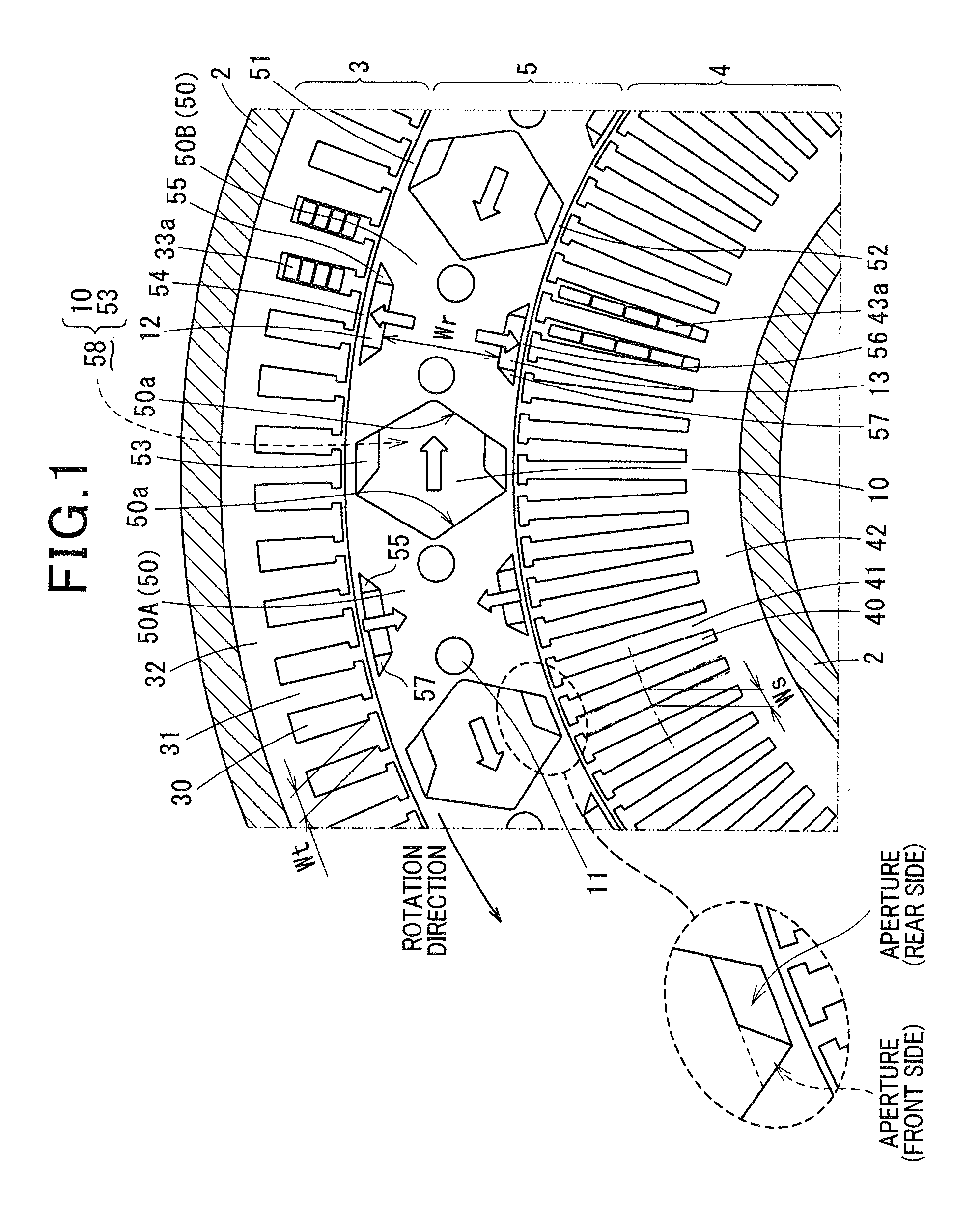

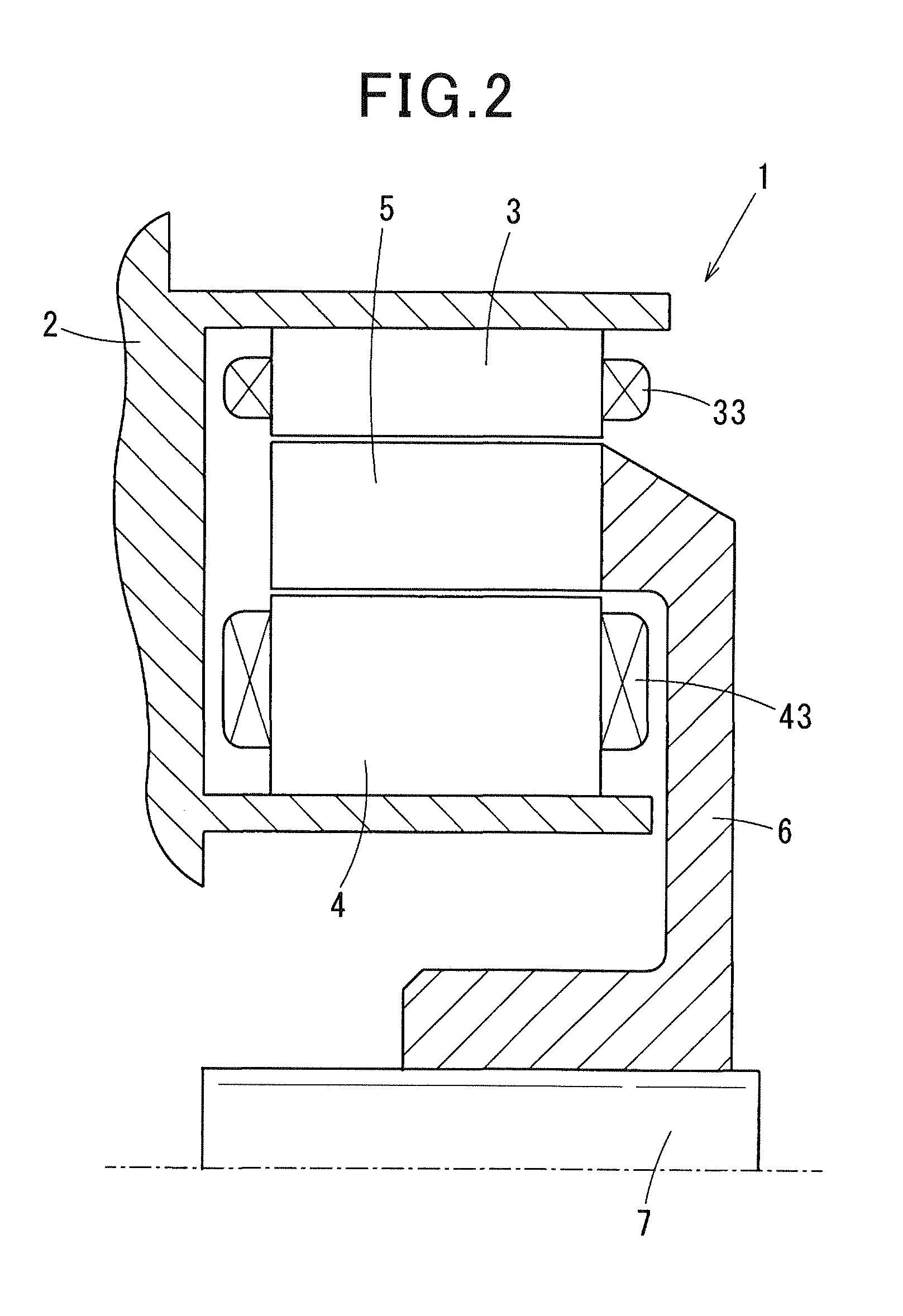

Synchronous motor

InactiveUS20130207498A1Increase output torqueReduce concentrationMagnetic circuit rotating partsMagnetic circuit stationary partsSynchronous motorMagnetomotive force

A double-stator synchronous motor has a rotor, an inner stator and an outer stator. The rotor has segment-magnetic poles arranged in a ring shape. Magnetic poles formed in the inner stator and the outer stator face to each other in a same circumferential position. Each stator has q (q≧2) slots per pole and phase to disperse magnetomodive force. A radially minimum width Wr of each segment magnetic pole is within a range of 1.3q to 2.3q times of a minimum width Wt of outer teeth. A magnetic depth of a magnetic concave section formed in the segment magnetic pole is within a range of not less than an average width Ws of the inner slots. Because this suppresses demagnetization in the permanent magnets caused by stator magnetomotive force, ferrite magnets are used as buried magnets and magnetic-pole central magnets, and suppress the amount of neodymium magnet used in the rotor.

Owner:DENSO CORP

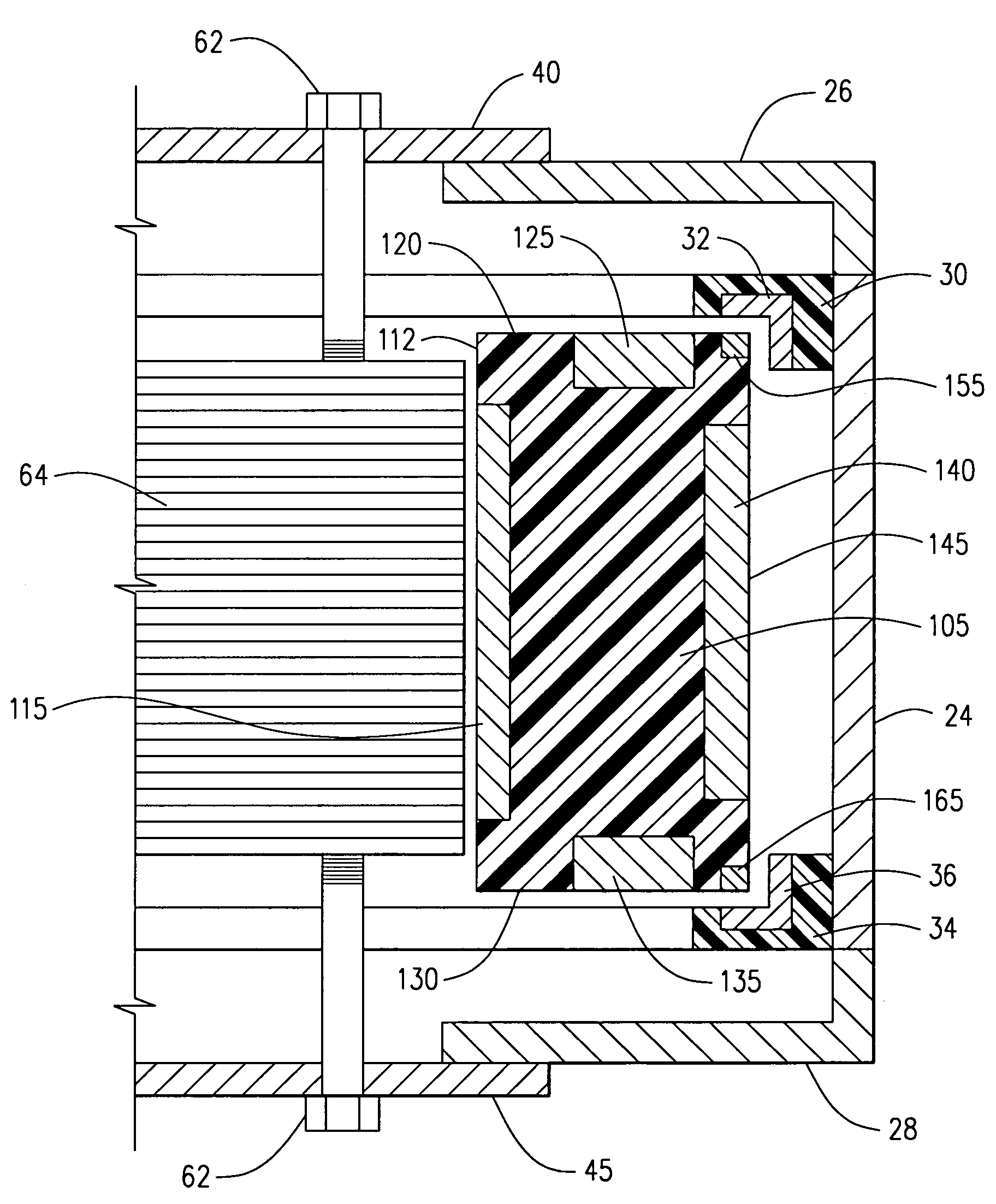

Rotational magnetic electrical generating device

InactiveUS7218025B1Eliminate contactImprove conductivityDC commutatorMechanical energy handlingNeodymium magnetDc current

A rotational magnetic electrical generating device produces an alternating electrical current generated by a central rotational magnetic cylinder with an inner cavity having an central fixed coil operated by a DC current providing a driving rotational force upon a plurality of embedded neodymium magnets within the inner cavity of the central rotational magnetic cylinder, the central rotational magnetic cylinder having an upper outer margin with an upper magnetic ring and a lower outer margin having a lower magnetic ring, the two magnetic rings suspending the central rotational magnetic cylinder between two fixed magnetic fields supported by a frame member, the central rotational magnetic cylinder further having an outer perimeter surface embedded with a plurality of neodymium alloy magnets equally sized and spaced apart, a lower surface embedded with a plurality of neodymium alloy magnets equally sized and spaced apart, and an upper surface embedded with a plurality of neodymium alloy magnets equally sized and spaced apart. A plurality of alternate wound electrical stators are suspended above the upper surface, below the lower surface and around the outer perimeter surface of the central rotational magnetic cylinder, supported by the frame member while insulated from the frame member, each electrical stator connected to external leads to transmit alternating current generated by the spinning central rotational magnetic cylinder, the entire device enclosed within a vacuum.

Owner:CONTIEMPO ENERGY

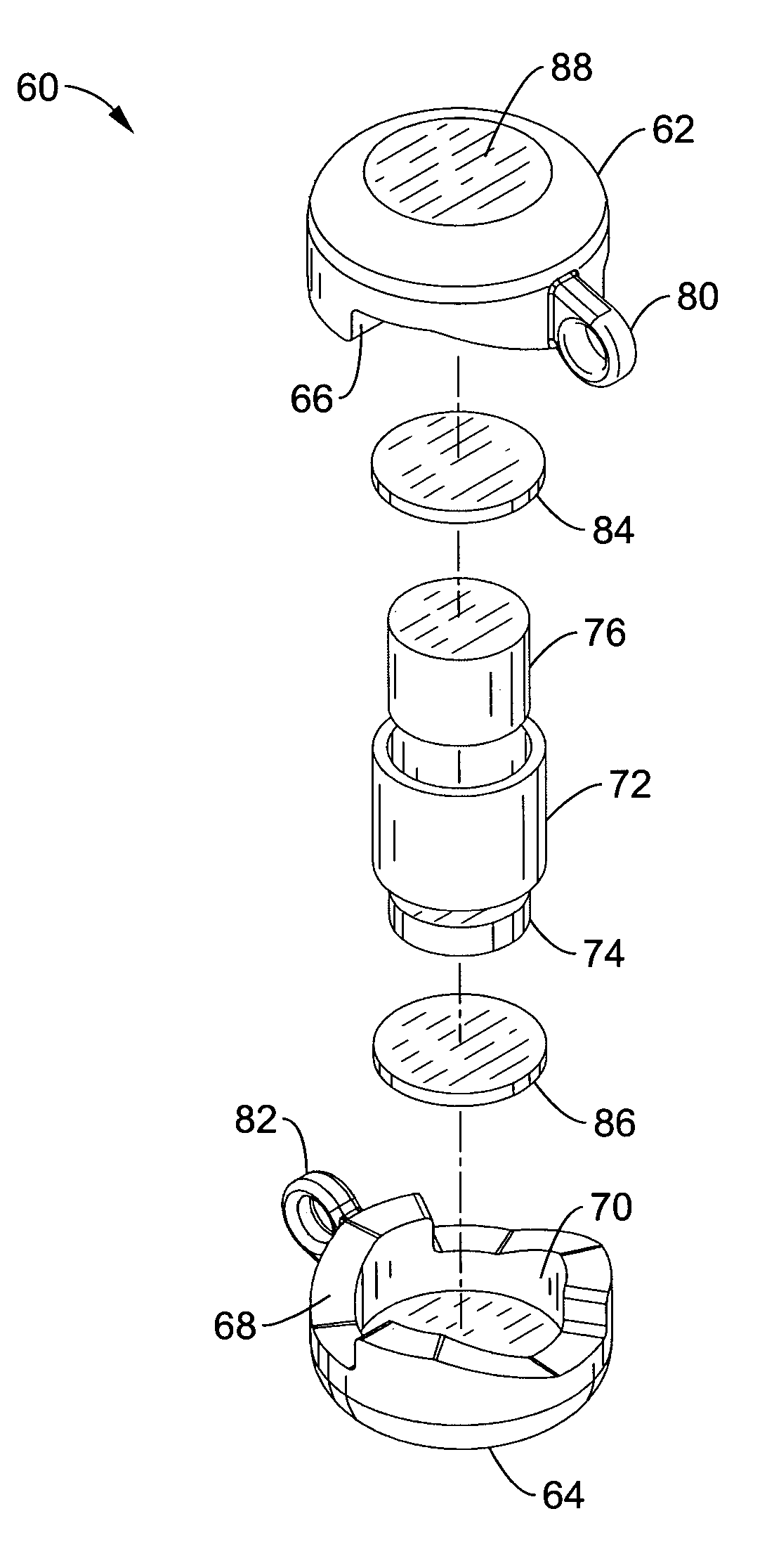

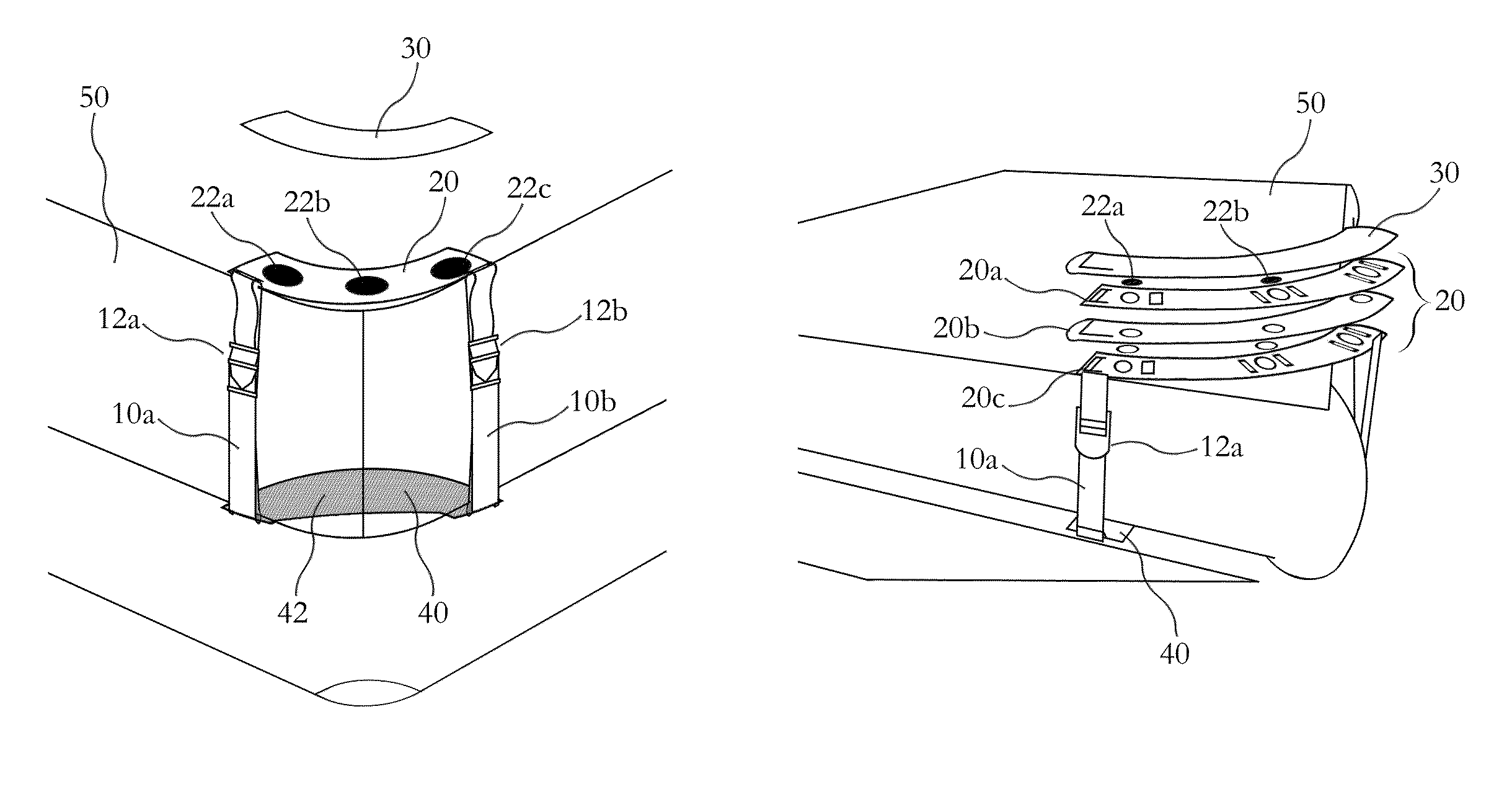

Magnetic clasp apparatus

InactiveUS20050278903A1Increased structure resistanceReduce magnetic fluxSnap fastenersClothes buttonsNeodymium magnetEngineering

A jewelry clasp with top and bottom sections, each section having a bore to receive a magnet, and each section having an interlocking surface on the perimeter of the bore. An eyelet is positioned on the perimeter of each section. The interlocking surfaces consist of mating camber protrusions that will lift and separate the top and bottom sections when the sections are rotated in one direction by the eyelets. One magnet is longer than the other to provide structural resistance to separation at the camber protrusions by opposing force exerted through the eyelets. In another embodiment, a steel tube is positioned in the bore of one section to encase the magnets to redirect magnetic flux and provide additional structural resistance against opposing force through the eyelets. Additional steel shielding can be used to reduce magnetic flux emanating from the clasp. Neodymium magnets coated with gold or silver are preferred.

Owner:DUNAYE GARY

Accessory Storage Mirror

InactiveUS20090194650A1Improve utilizationIncrease valuePicture framesDomestic mirrorsNeodymium magnetRare earth

An accessory storage mirror that includes a mirror and one or more accessory holders attached to or configured to attach to the surface of the mirror. In a preferred embodiment, the mirror includes a magnetically active material backing the mirror, and the accessory holders include magnets. The magnets preferably are rare-earth Neodymium magnets, and the accessory holders include a non-scratch backing. The accessory storage mirror provides an aesthetically pleasing setting for viewing and displaying jewelry and accessories.

Owner:CORVO CHRISTINE +1

Device and method for securing a bed sheet

Owner:ARENSTEIN JON

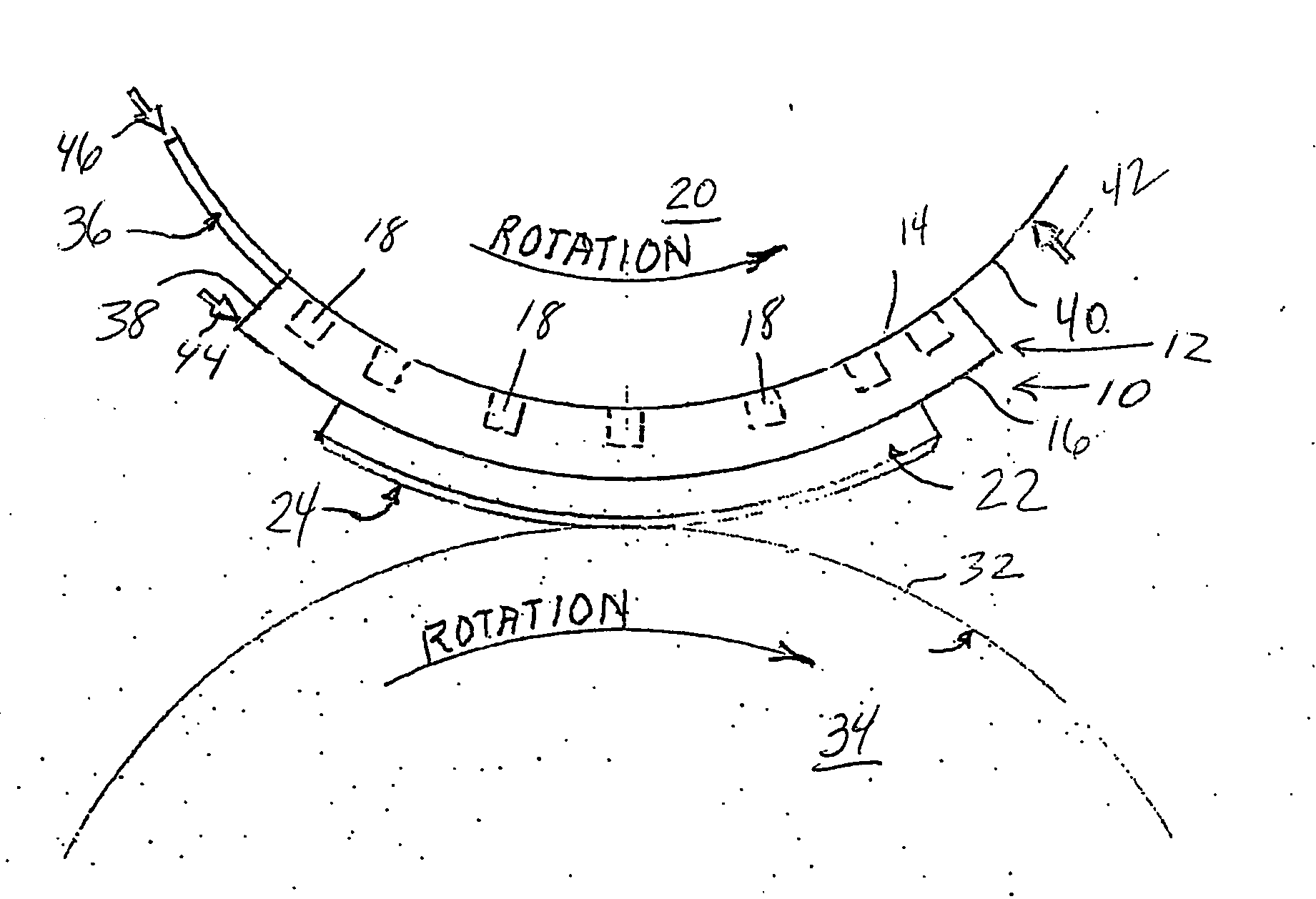

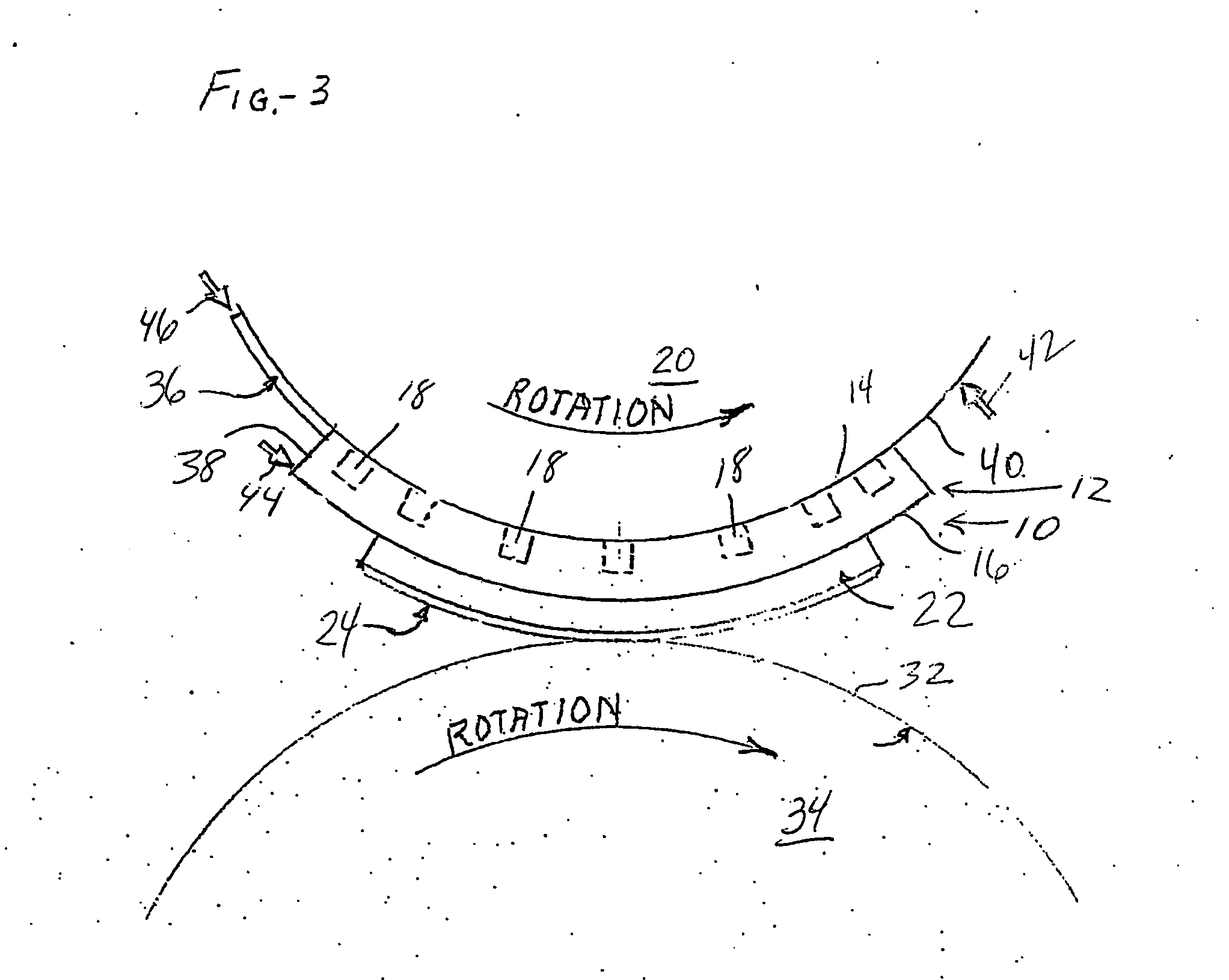

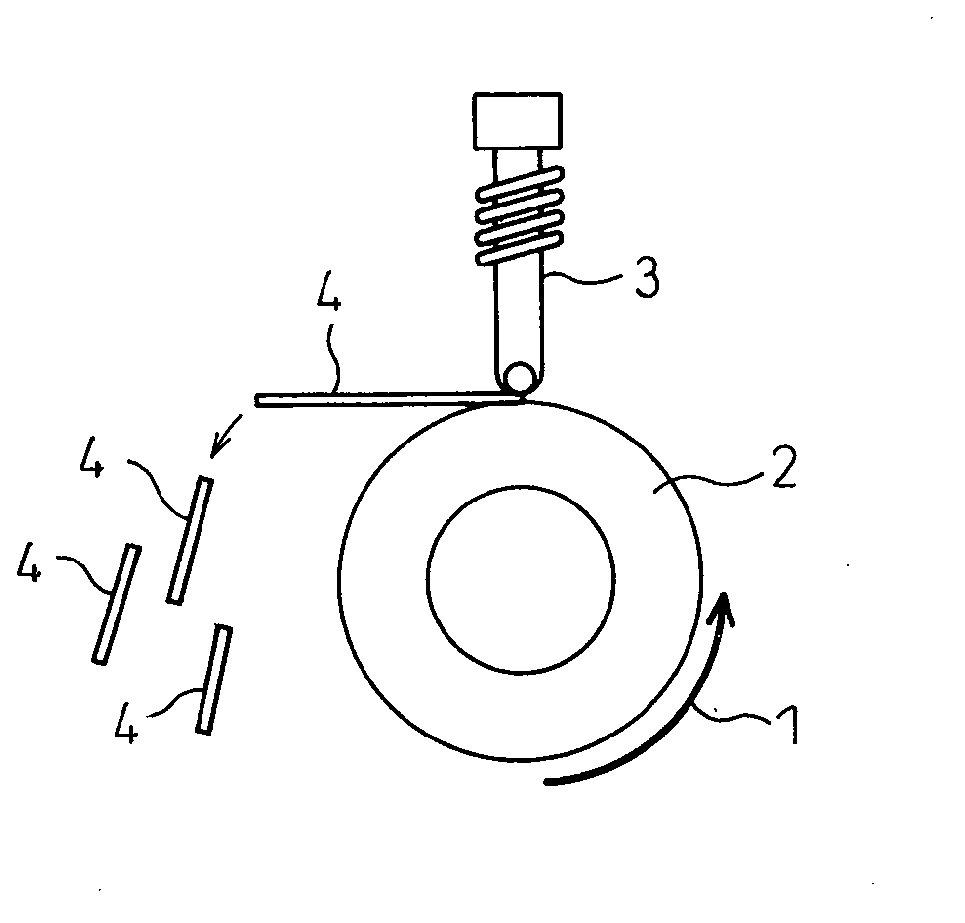

Magnetic rotary die

InactiveUS20050045005A1DifferencePrevent creepStock shearing machinesMetal working apparatusNeodymium magnetKnife blades

A rotary cutting die which is mountable on a metal cylinder. The rotary cutting die includes a rotary die plate having a concave, inner surface which is magnetically attractable and magnetically mountable on a metal cylinder. A cutting blade is mounted on a concave, outer surface of the die plate. Connectors may be engaged with the cutting blade and the die plate. A plurality of magnetic elements, such as neodymium magnets, are in the rotary die plate. The magnetic elements make the inner surface of they die plate magnetically attractable to the metal cylinder, thereby providing that the rotary cutting die is mountable on the metal cylinder without having to use screws, clamps or other mechanical holding devices. To prevent creep of the cutting die during operation, a magnetic member, such as a rubber magnet, may be magnetically mounted on the die cylinder, against the die plate.

Owner:PAPER BENDERS SUPPLY

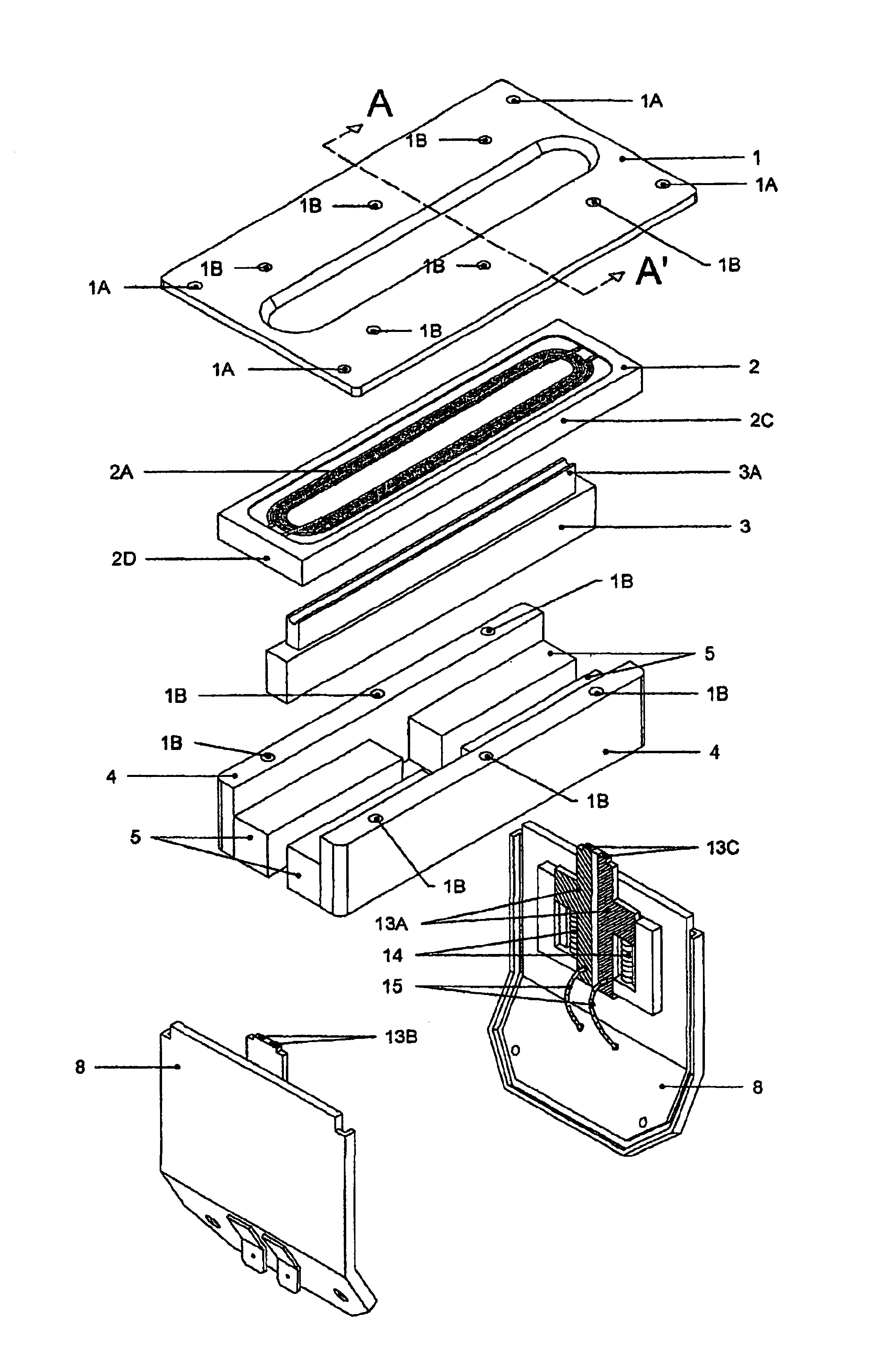

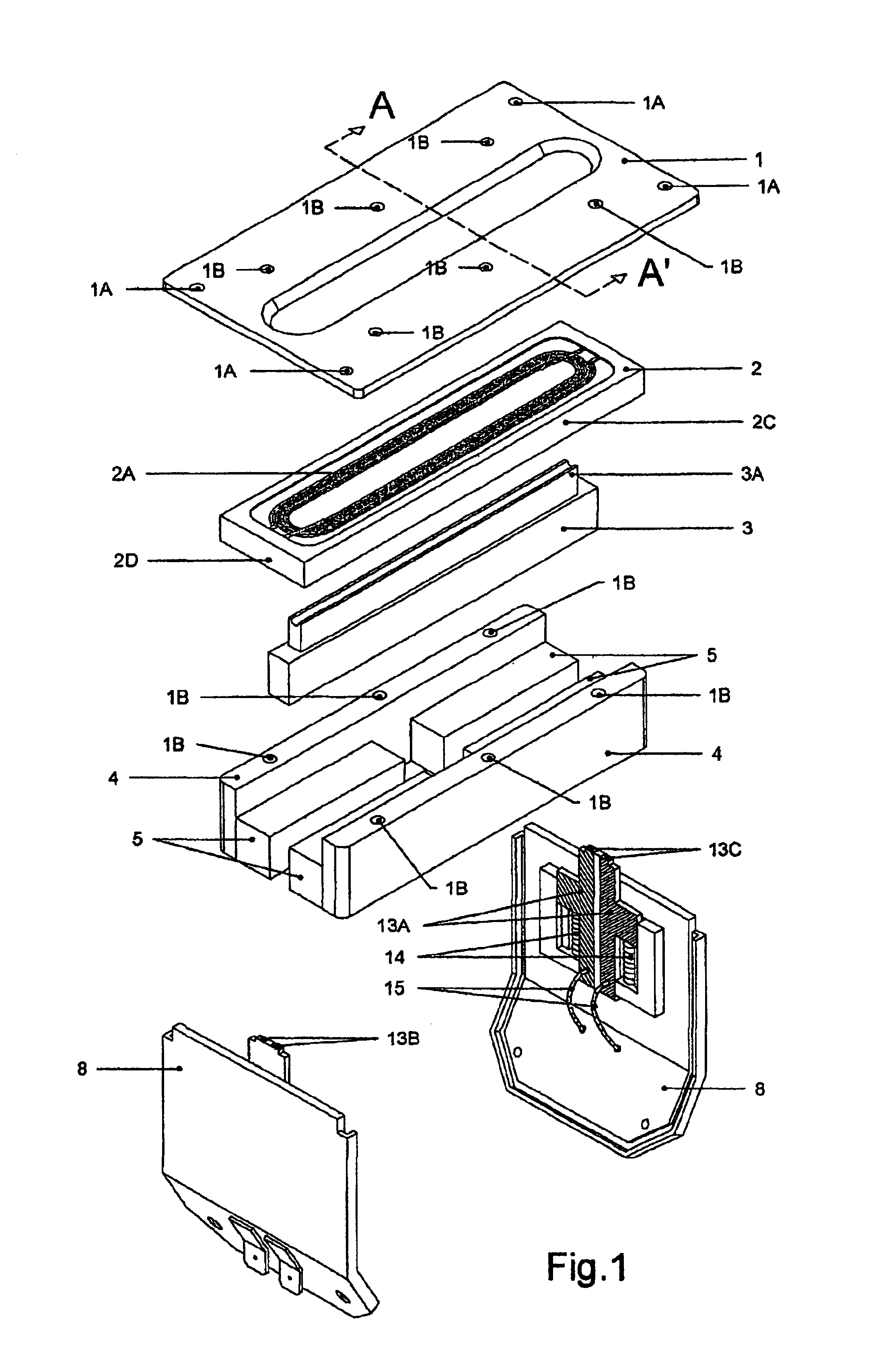

Electroacoustic transducer with field replaceable diaphragm carrying two interlaced coils, without manipulating any wires

InactiveUS6956953B2Improved performance characteristicsSimple and easyTransducer casings/cabinets/supportsDeaf-aid setsElectrical conductorNeodymium magnet

The present invention is directed to a diaphragmatic (planar) electroacoustic transducer that forms a complete sound radiating transducer and provides high efficiency and linearity. The diaphragm is easily exchangeable and rectangular in shape, and may be made of very thin polyamide film with a plurality of aluminum conductors formed on one side of the diaphragm. The plurality of conductors form two identical and symmetrical coils such that conductors of each coil are interlaced. The two sections of the coils are disposed in dense air-gaps of the magnet system, which comprises a plurality of high (BHmax) Neodymium magnets. The binary interlaced coils can be utilized in a number of modes, for the purpose of accomplishing a variety of operating modes.

Owner:MAZARAKIS ANTHONY

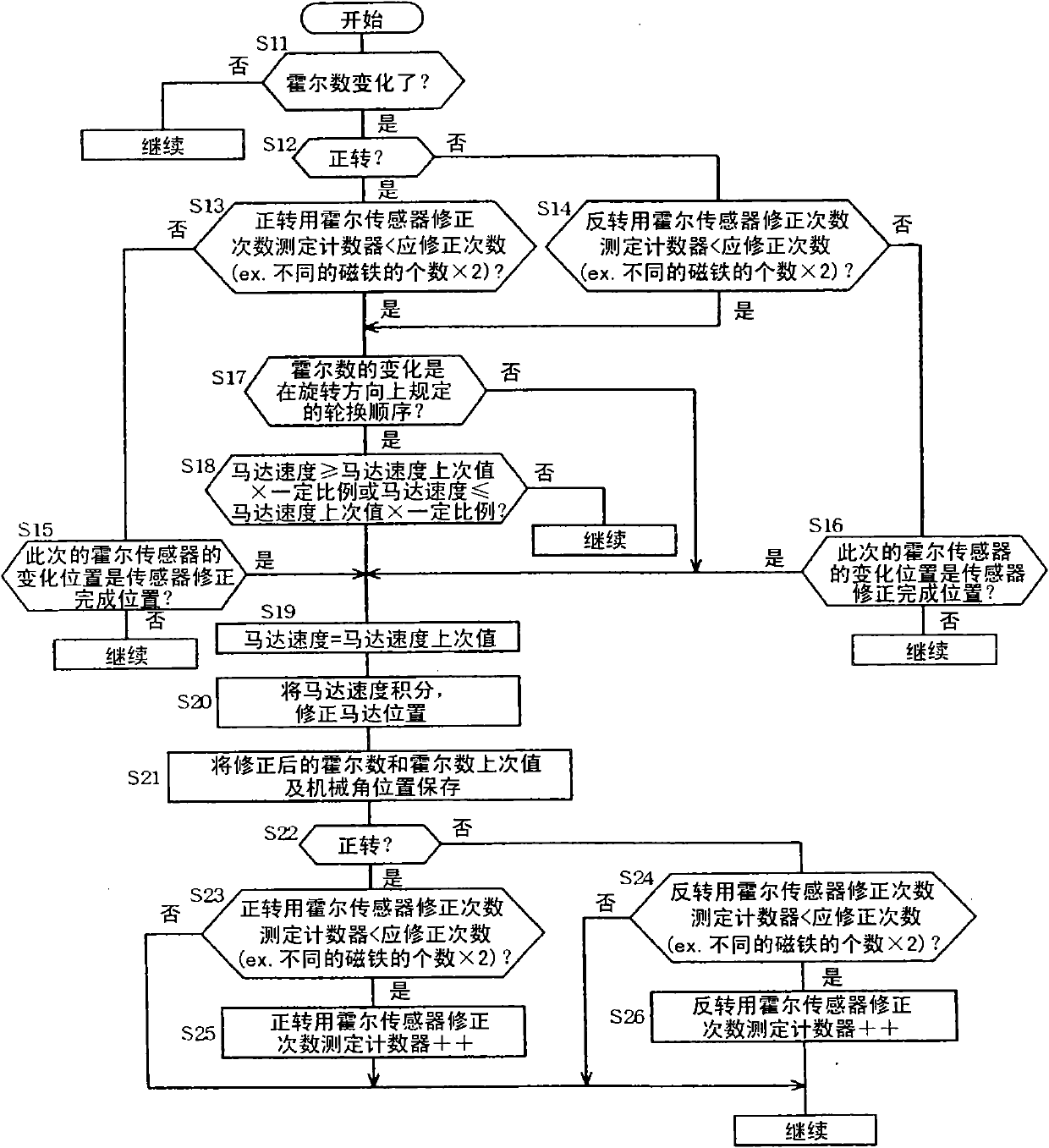

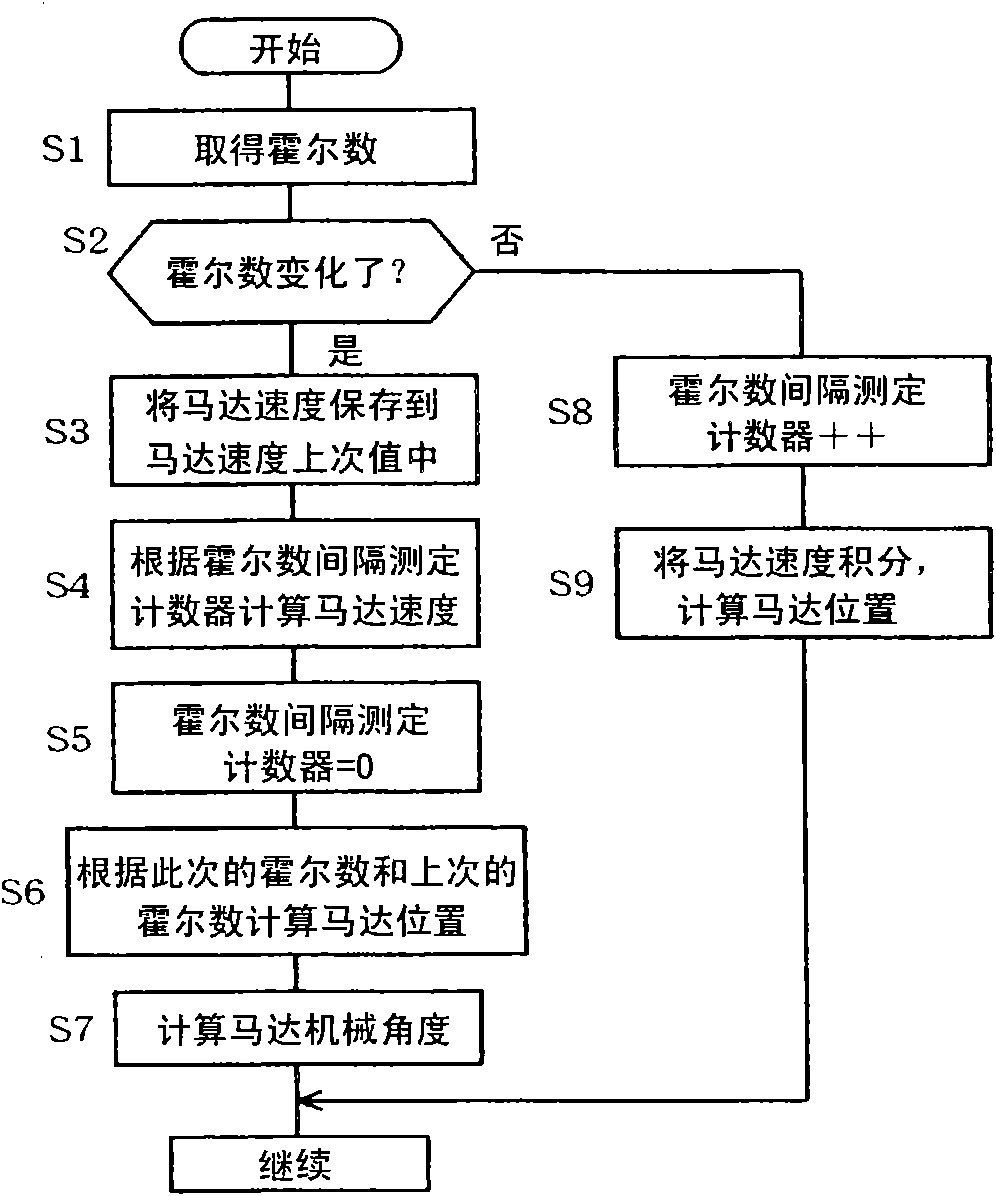

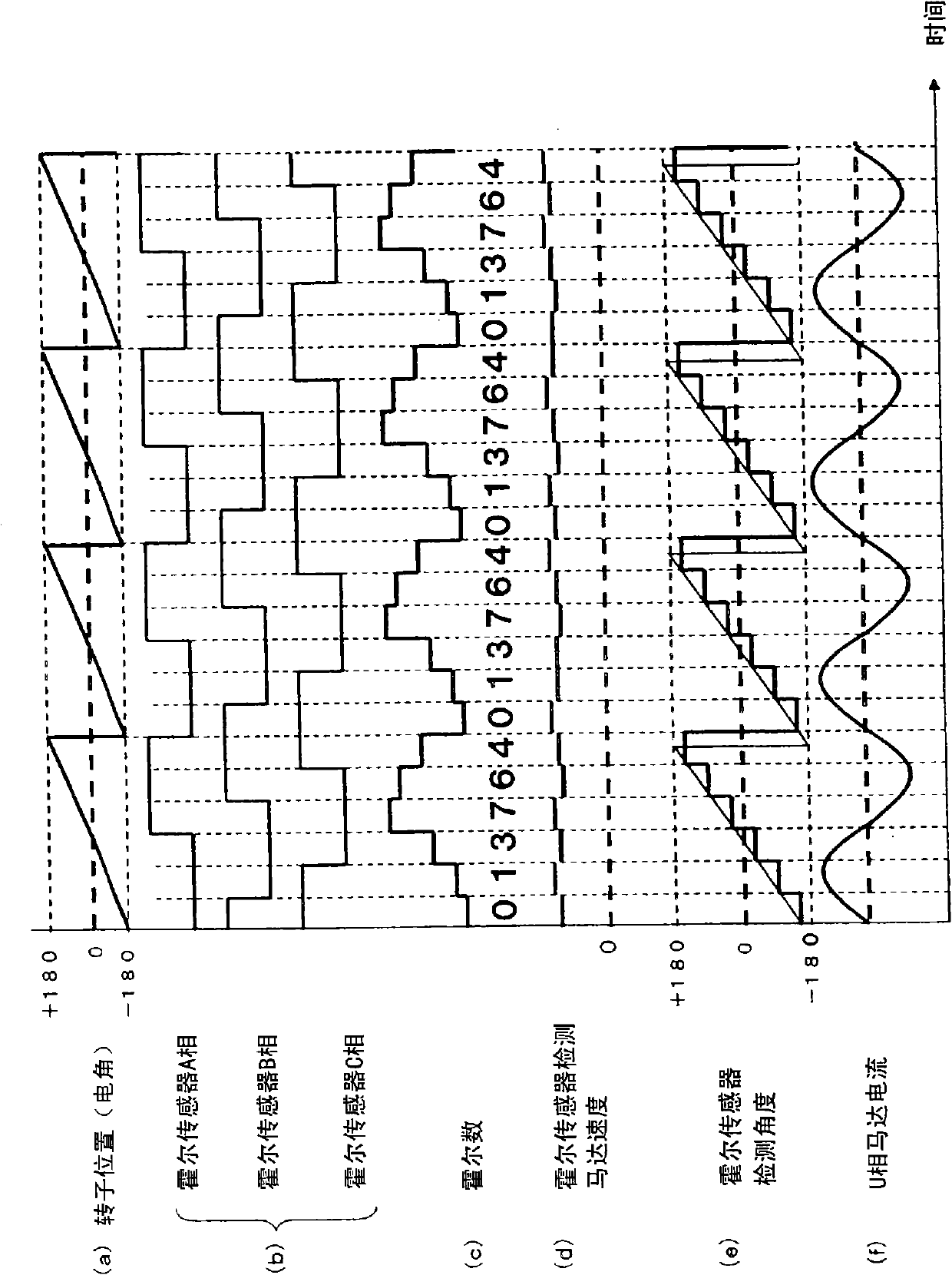

Rotor position detection device

ActiveCN102025252AAccurately getVector control systemsSingle motor speed/torque controlLocation detectionMagnetic tension force

The invention relates to a rotor position detection device. A magnetic detection sensor with low costs can be used to detect the position of a rotor correctly, when a permanent magnet motor disposed in the rotor is provided with a plurality of permanent magnets, parts of which have different magnetic forces. The permanent magnet motor (1) disposed in the rotor (3) is provided with two magnets, one is a neodymium magnet (9a) and the other is an alnico magnet (9b). 3 Hall sensors (68) (A,B,C) can be used by a speed. position detection part (55) to detect the rotation speed of the permanent magnet motor (1), and the position of the rotor (3) can be detected based on the rotation speed. The rotation speed or the position of the rotor, which are detected by the speed. position detection part (55), can be corrected, when the speed. position detection part (55) detects the boundary between the neodymium magnet (9a) and the alnico magnet (9b) according to the changing state of the sensor signal output by the Hall sensors (68).

Owner:TOSHIBA LIFESTYLE PROD & SERVICES CORP +1

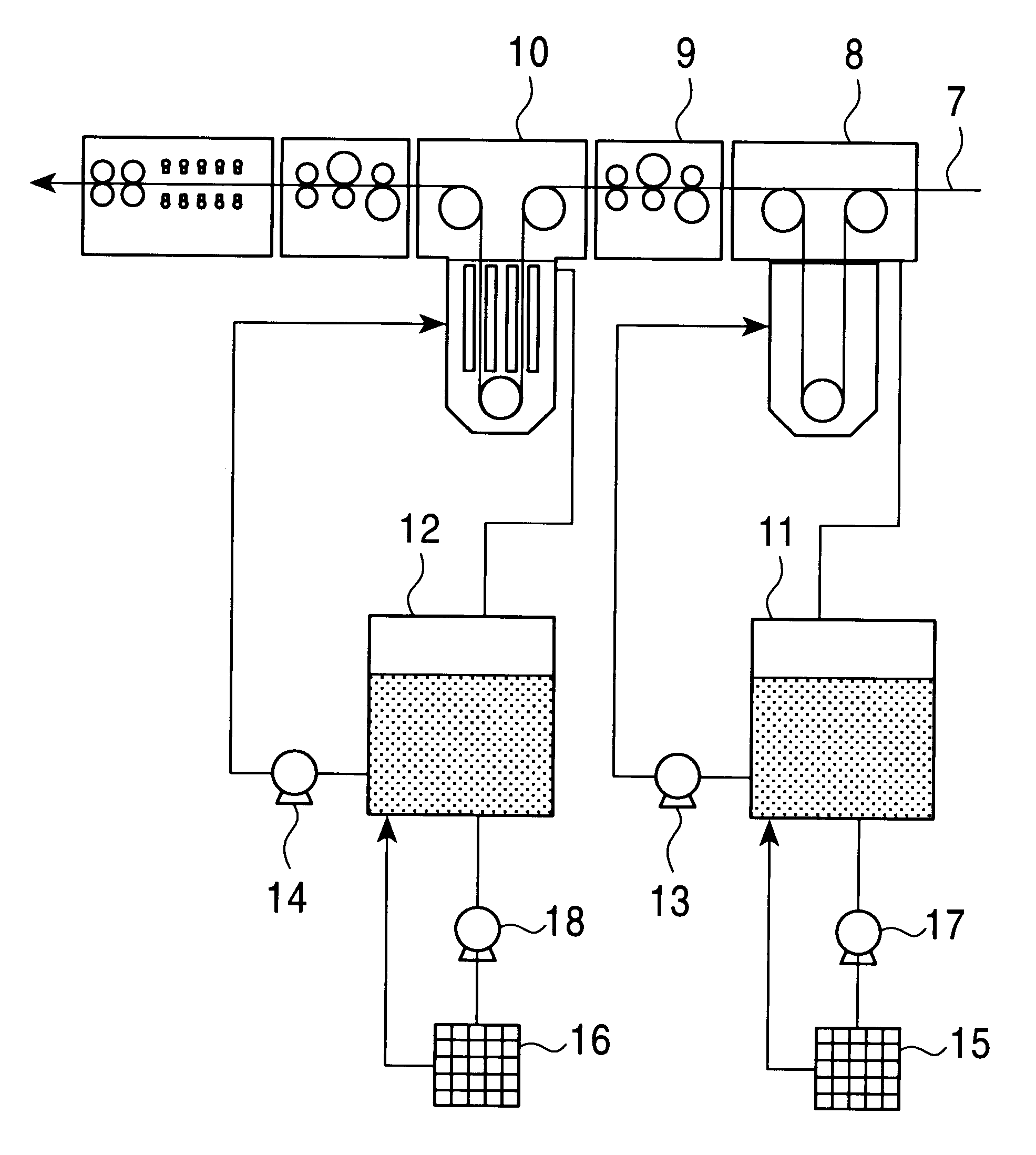

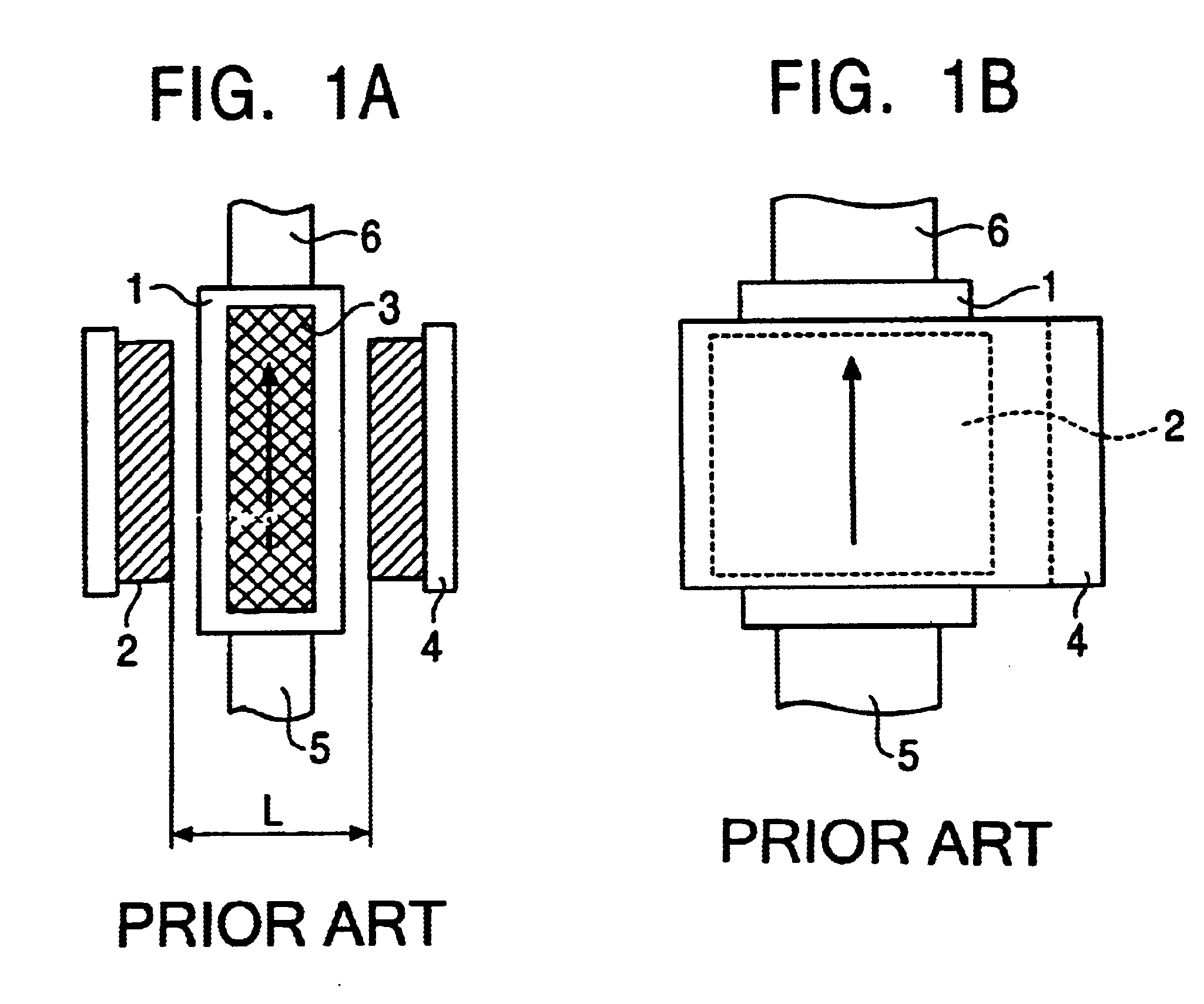

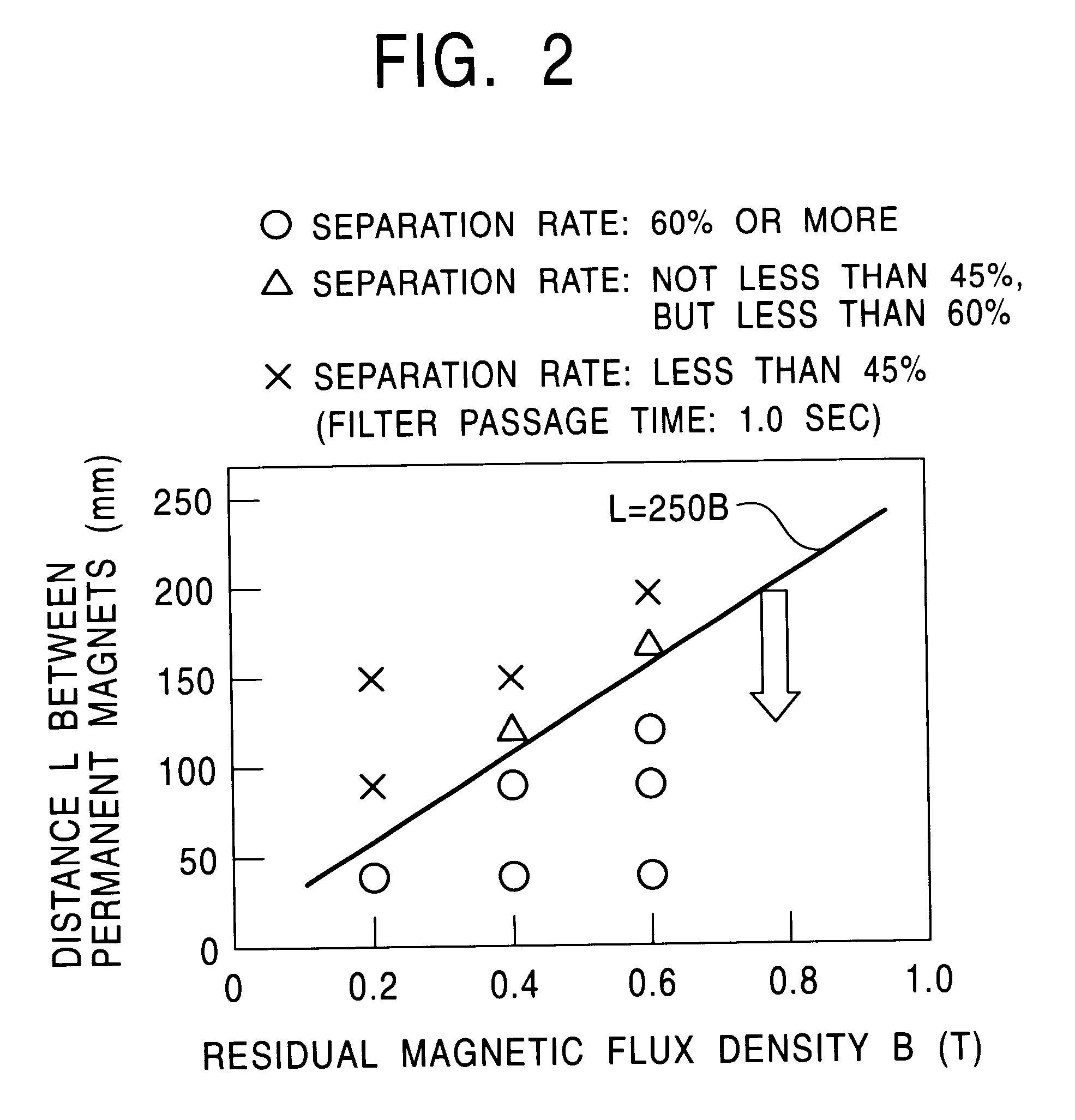

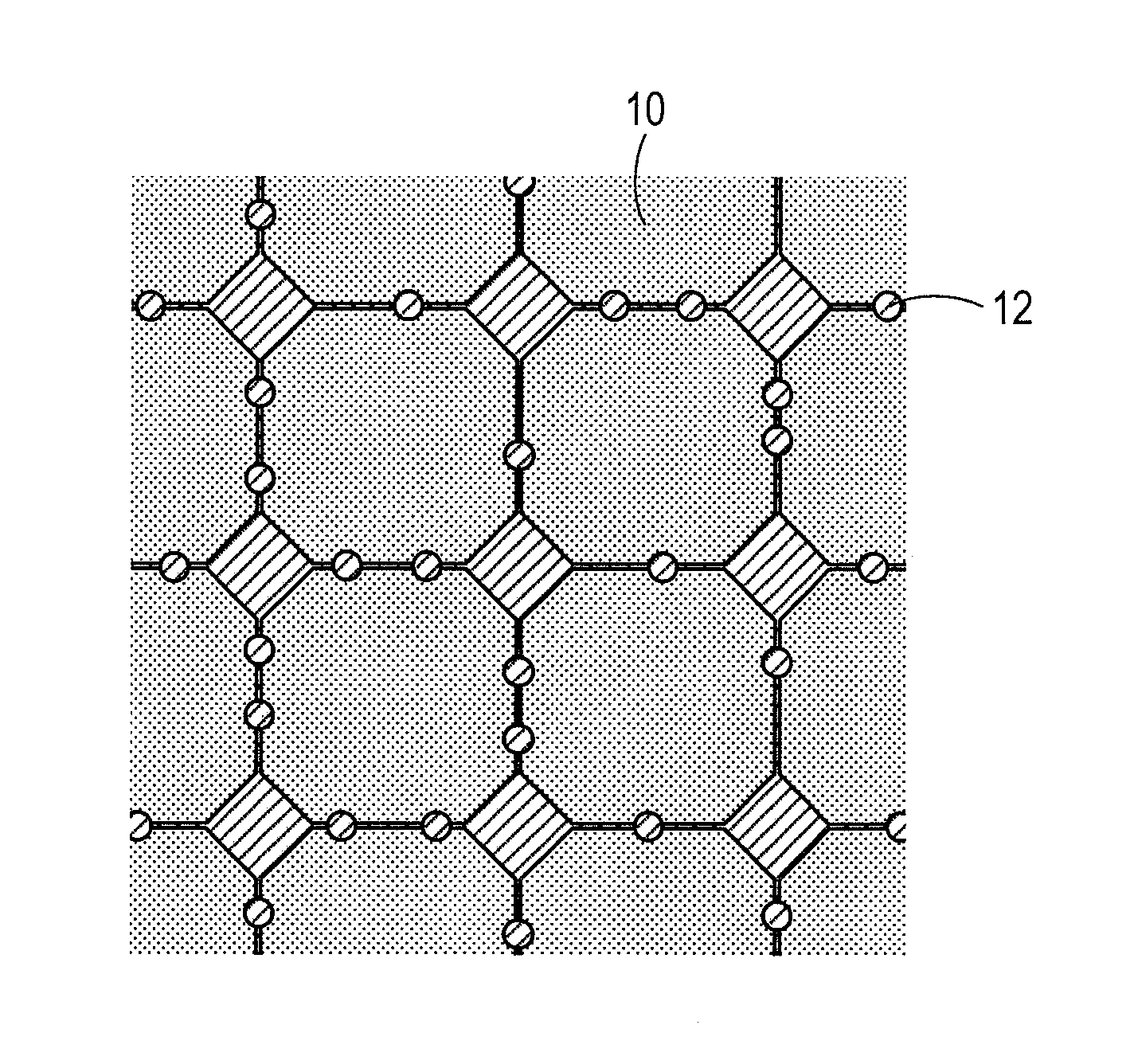

Magnetic filter device

InactiveUS6649054B2Small sizeLow costHigh gradient magnetic separatorsWater/sewage treatment by magnetic/electric fieldsGeneral purposeNeodymium magnet

In a magnetic filter apparatus in which permanent magnets are arranged to oppose each other with a container therebetween so as to generate a magnetic line of force in a direction substantially orthogonal to the moving direction of the fluid in the interior of the container, while regulating a filter passage time of the fluid in the range of 0.5 to 1.5 seconds, the permanent magnets are arranged so that the distance L (mm) between the permanent magnets in relation to the residual magnetic flux density B (T) of the permanent magnets satisfies the relationship:In this manner, the highest possible performance can be obtained from the filter using general-purpose permanent magnets such as ferrite or neodymium magnets, thereby achieving size reduction of the apparatus at low equipment cost.

Owner:JFEENG CORP

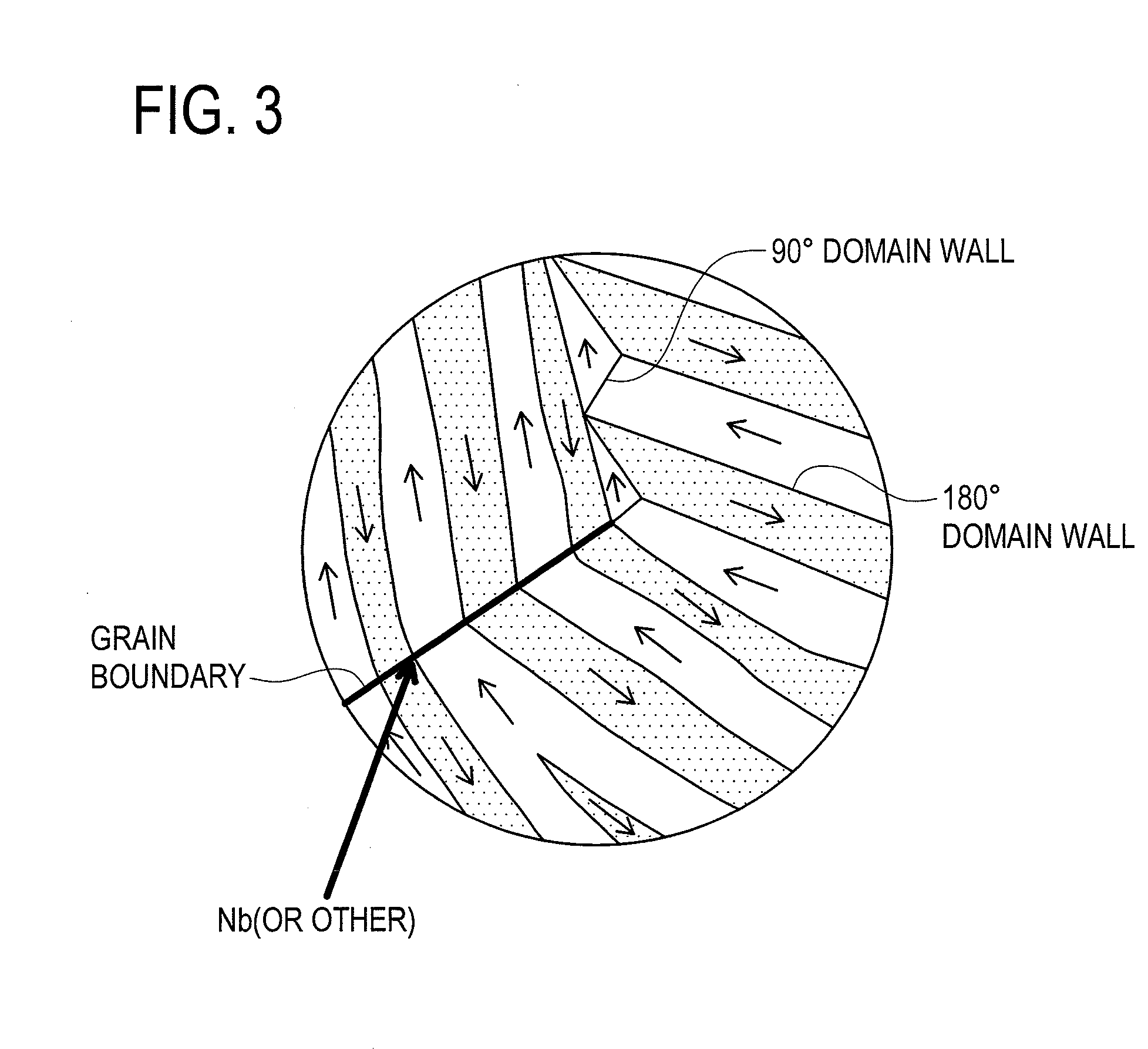

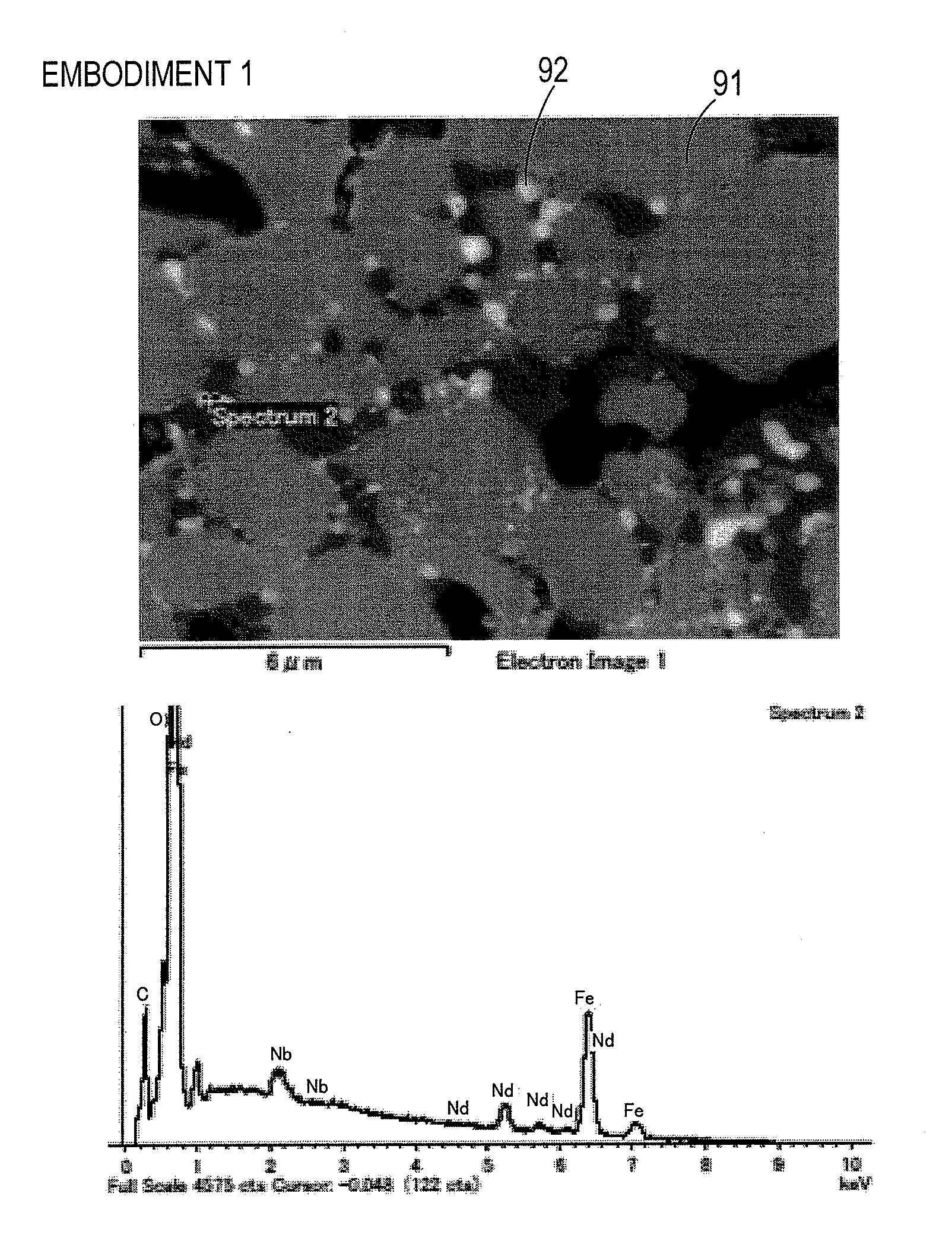

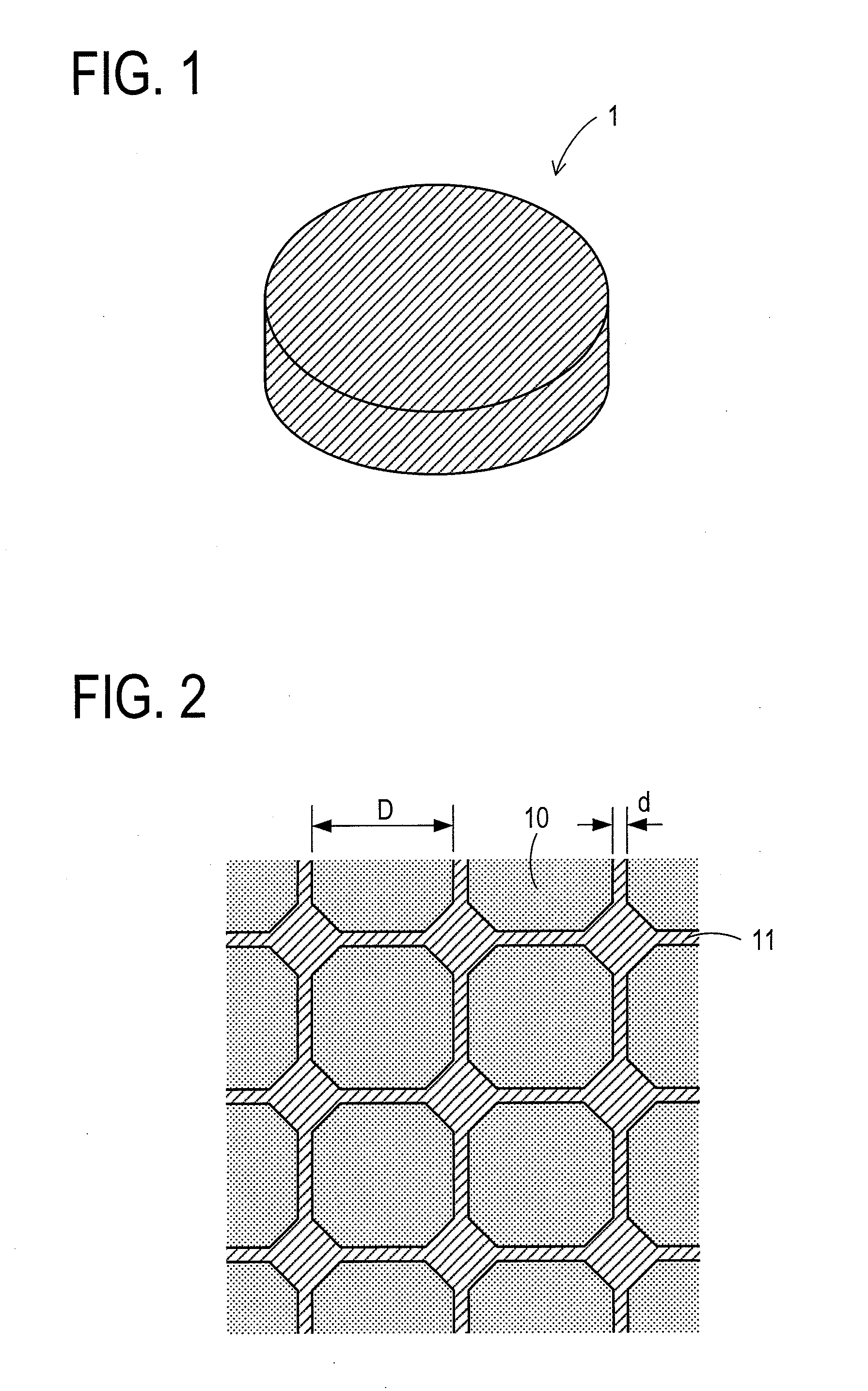

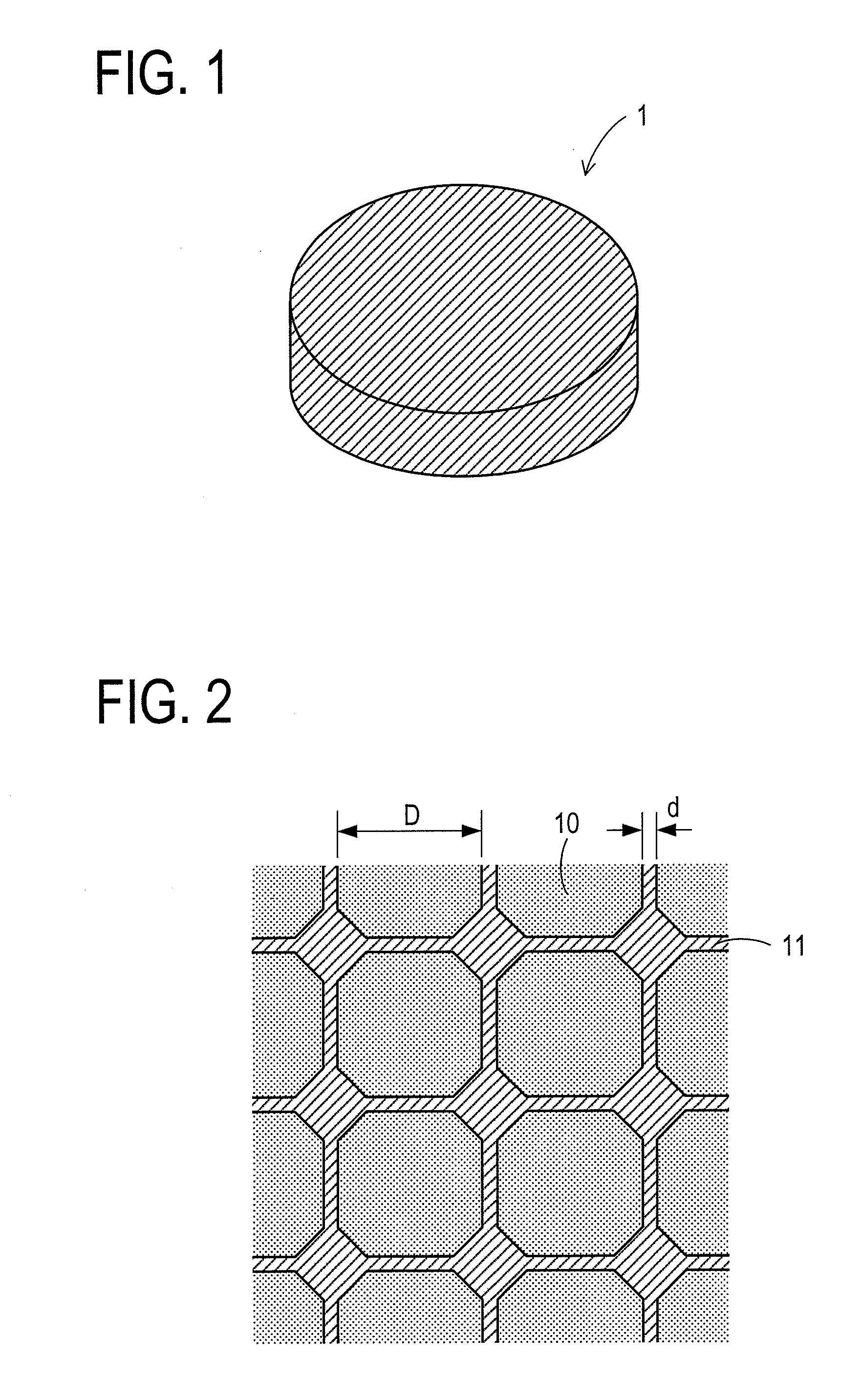

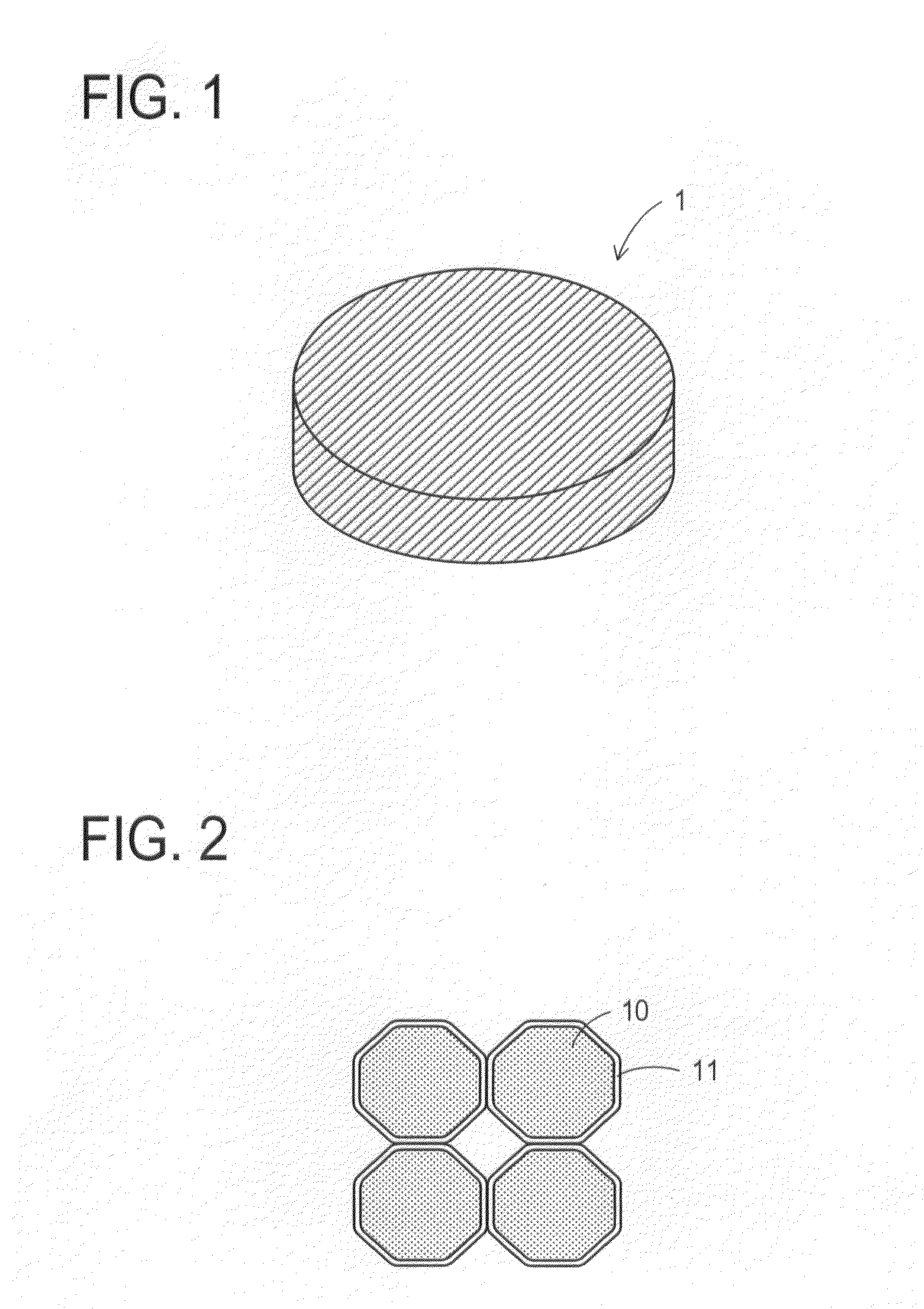

Permanent magnet and manufacturing method thereof

InactiveUS20120182109A1Residual magnetic flux density decreaseImprove magnetic propertiesTransportation and packagingMetal-working apparatusNeodymium magnetStructural formula

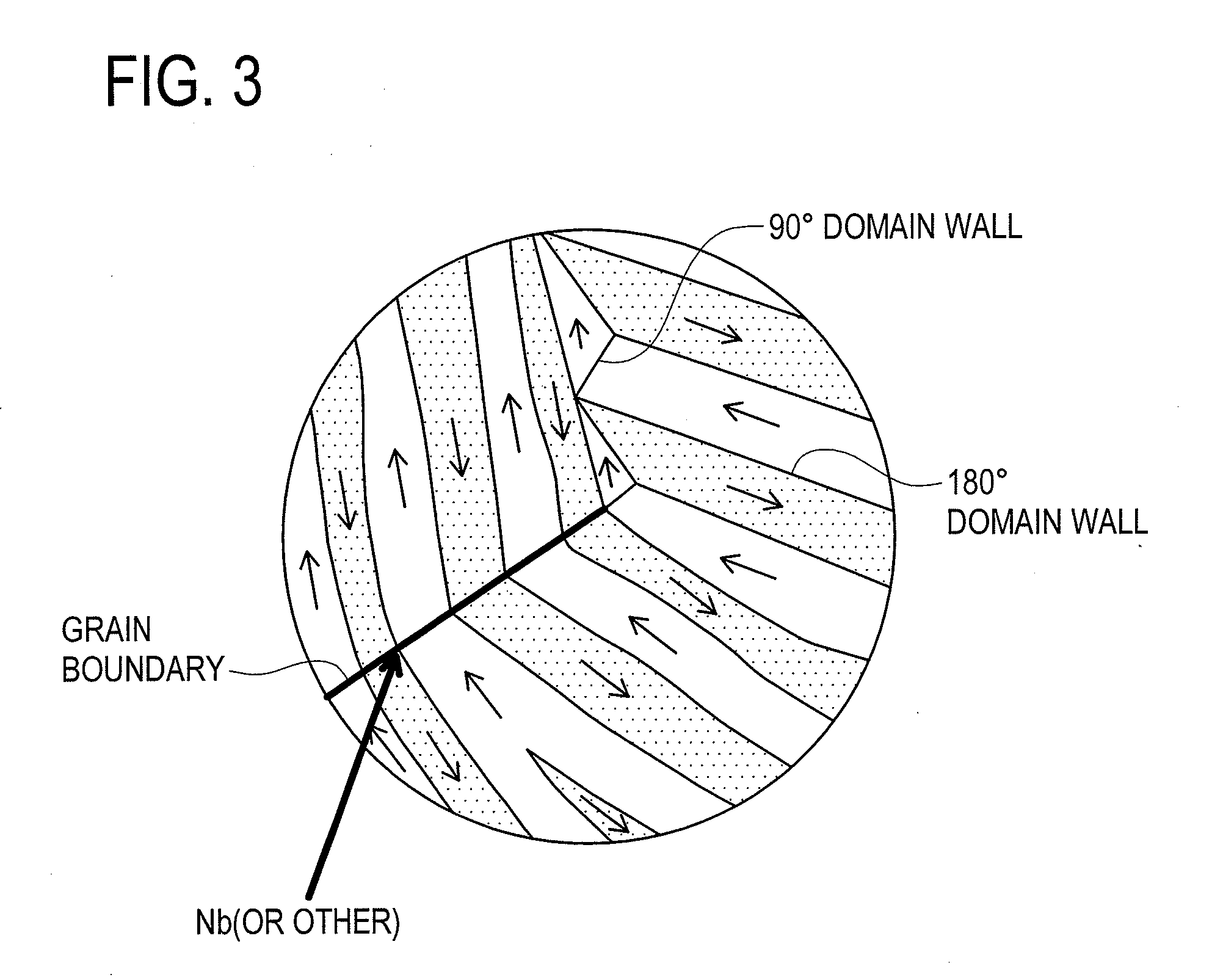

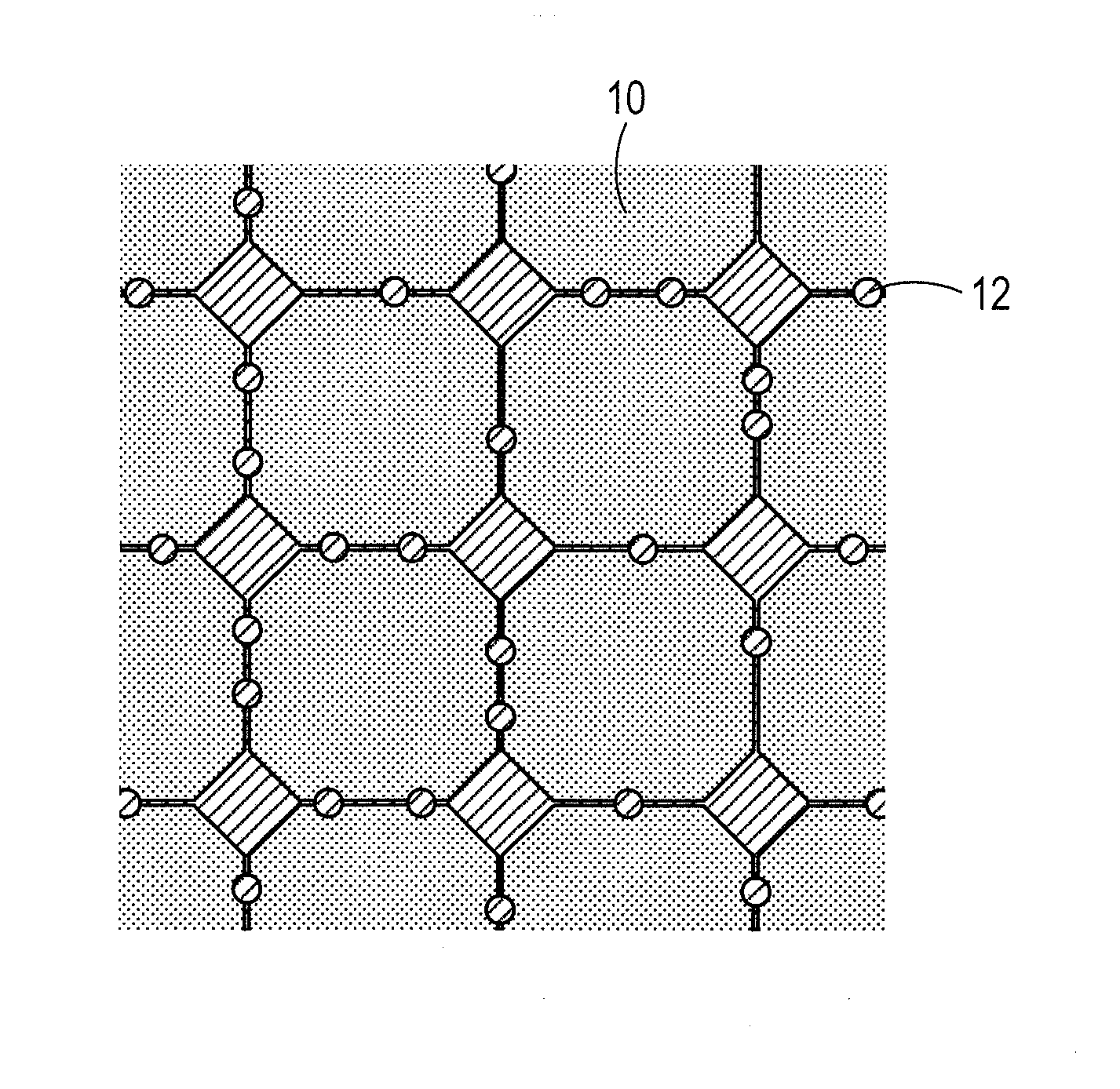

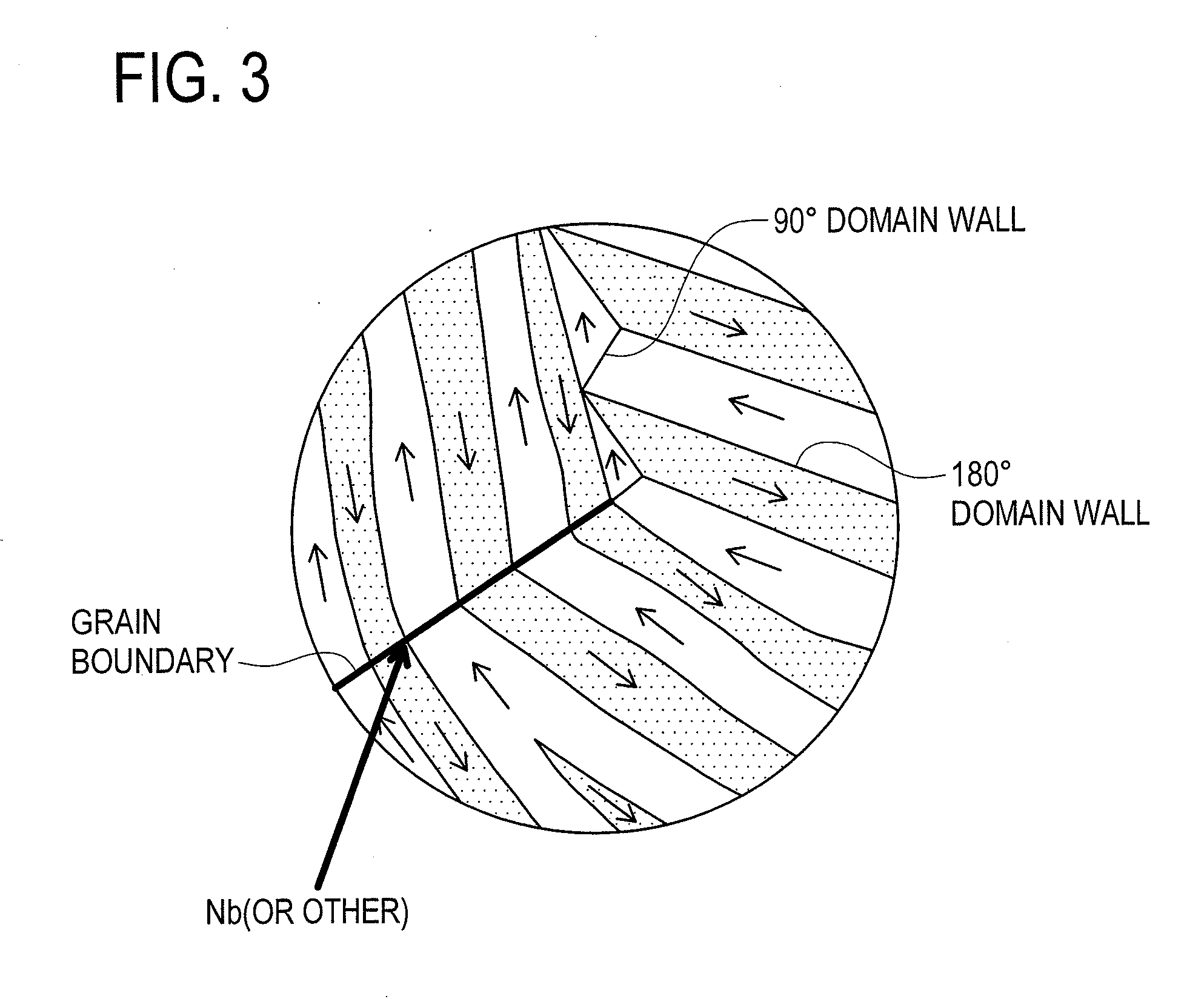

There are provided a permanent magnet and a manufacturing method thereof capable of inhibiting grain growth of magnet grains having single domain particle size during sintering so as to improve magnetic properties. To fine powder of milled neodymium magnet is added an organometallic compound solution containing an organometallic compound expressed with a structural formula of M-(OR)x (M represents V, Mo, Zr, Ta, Ti, W or Nb, R represents a substituent group consisting of a straight-chain or branched-chain hydrocarbon, x represents an arbitrary integer) so as to uniformly adhere the organometallic compound to particle surfaces of the neodymium magnet powder. Thereafter, the desiccated magnet powder is calcined by utilizing plasma heating and the powdery calcined body is sintered so as to form a permanent magnet 1.

Owner:NITTO DENKO CORP

Permanent magnet and manufacturing method thereof

InactiveUS20120182107A1Improve magnetic propertiesResidual magnetic flux density decreaseTransportation and packagingMetal-working apparatusNeodymium magnetCelsius Degree

There are provided a permanent magnet and a manufacturing method thereof that enables concentration of V, Mo, Zr, Ta, Ti, W or Nb contained in an organometallic compound in grain boundaries of the permanent magnet. To fine powder of milled neodymium magnet is added an organometallic compound solution containing an organometallic compound expressed with a structural formula of M-(OR)x (M represents V, Mo, Zr, Ta, Ti, W or Nb, R represents a substituent group consisting of a straight-chain or branched-chain hydrocarbon, x represents an arbitrary integer) so as to uniformly adhere the organometallic compound to particle surfaces of the neodymium magnet powder. Thereafter, a compact body obtained by compacting the magnet powder is held for several hours in hydrogen atmosphere at 200 through 900 degrees Celsius so as to perform a calcination process in hydrogen. Thereafter, through sintering, a permanent magnet is manufactured.

Owner:NITTO DENKO CORP

Permanent magnet and manufacturing method thereof

InactiveUS20120187327A1Improve magnetismResidual magnetic flux density decreaseMagnetic paintsTransportation and packagingNeodymium magnetHydrogen atmosphere

There are provided a permanent magnet and a manufacturing method thereof capable of decreasing an activity level of a calcined body activated by a calcination process. To fine powder of milled neodymium magnet is added an organometallic compound solution containing an organometallic compound expressed with a structural formula of M-(OR)x (M represents V, Mo, Zr, Ta, Ti, W or Nb, R represents a substituent group consisting of a straight-chain or branched-chain hydrocarbon, x represents an arbitrary integer) so as to uniformly adhere the organometallic compound to particle surfaces of the neodymium magnet powder. Thereafter, desiccated magnet powder is held for several hours in hydrogen atmosphere at 200 through 900 degrees Celsius. Thereafter, the powdery calcined body calcined through the calcination process in hydrogen is held for several hours in vacuum atmosphere at 200 through 600 degrees Celsius for a dehydrogenation process.

Owner:NITTO DENKO CORP

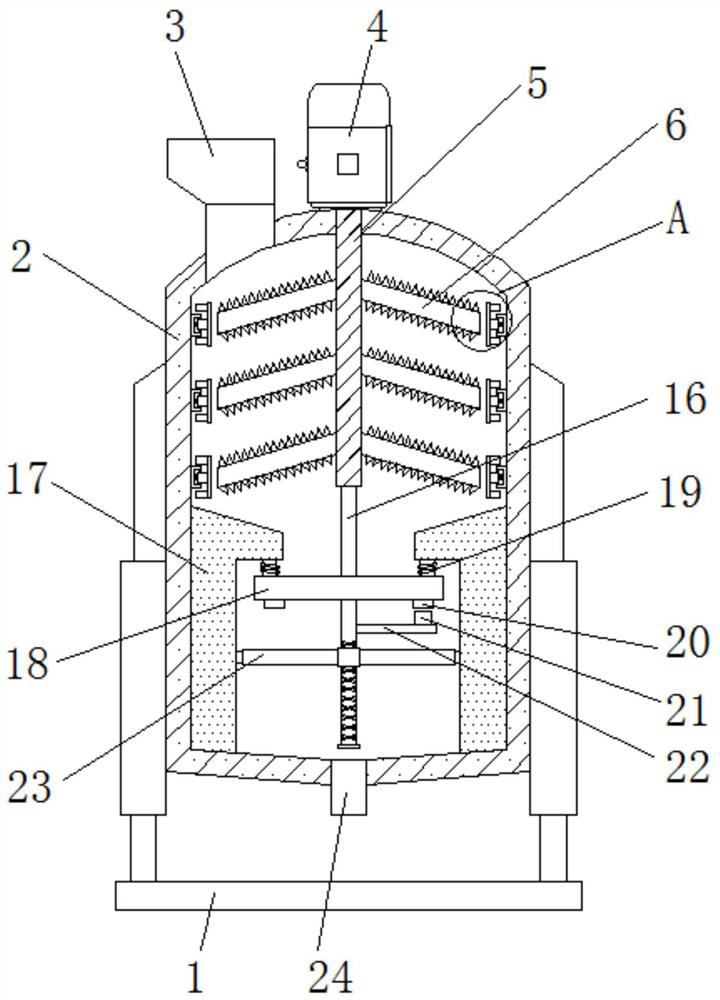

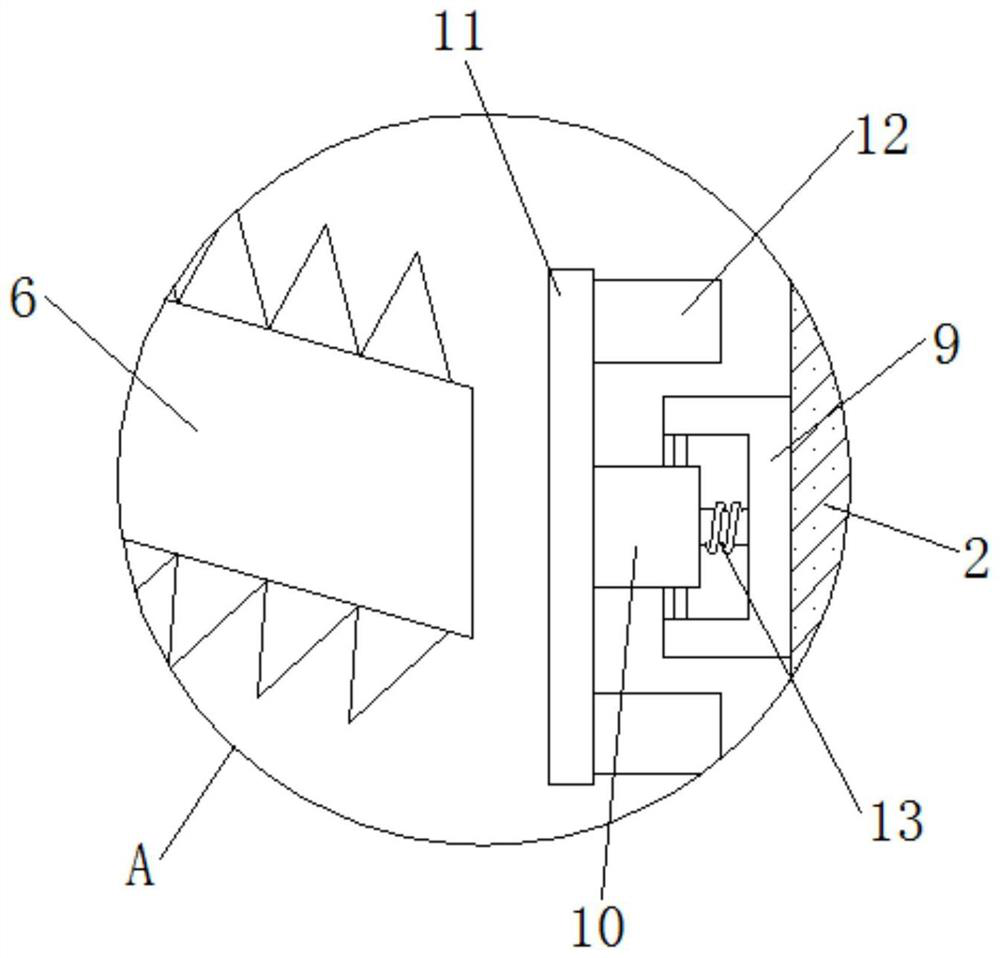

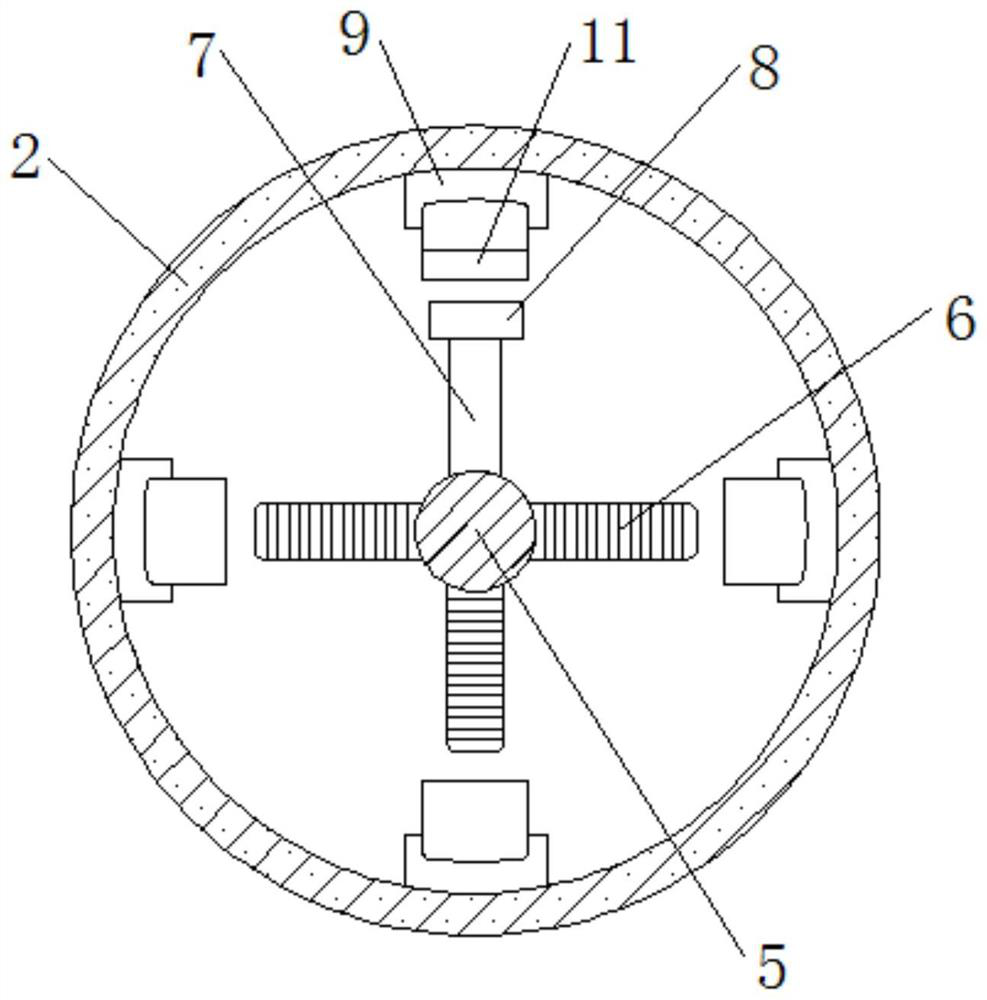

Treatment device capable of automatically cleaning away waste generated during industrial production

The invention discloses a treatment device capable of automatically cleaning away waste generated during industrial production. The device comprises a fixed frame, a motor, a limiting plate and a discharging port, wherein a box body is welded above the fixed frame, a feeding port is formed in the upper left position of the box body, a motor is installed over the box body, a first neodymium magnetis arranged at the end, away from a rotary shaft, of a connecting rod, a fixed rod is installed at the bottom of the rotary shaft, a second screen net is arranged below a supporting rod, and the discharging port is welded to the bottom of the box body. According to the treatment device capable of automatically treating the waste generated during industrial production, the lower half segment of thefixed rod is in a double-thread shape, the fixed rod is in threaded connection with the second screen net, and in this way, when the fixed rod rotates, the second screen net can be driven to move upand down. Moreover, the hole diameter of the second screen net is smaller than that of a first screen net so that the waste can be furthermore screened, and treated more thoroughly.

Owner:张伟

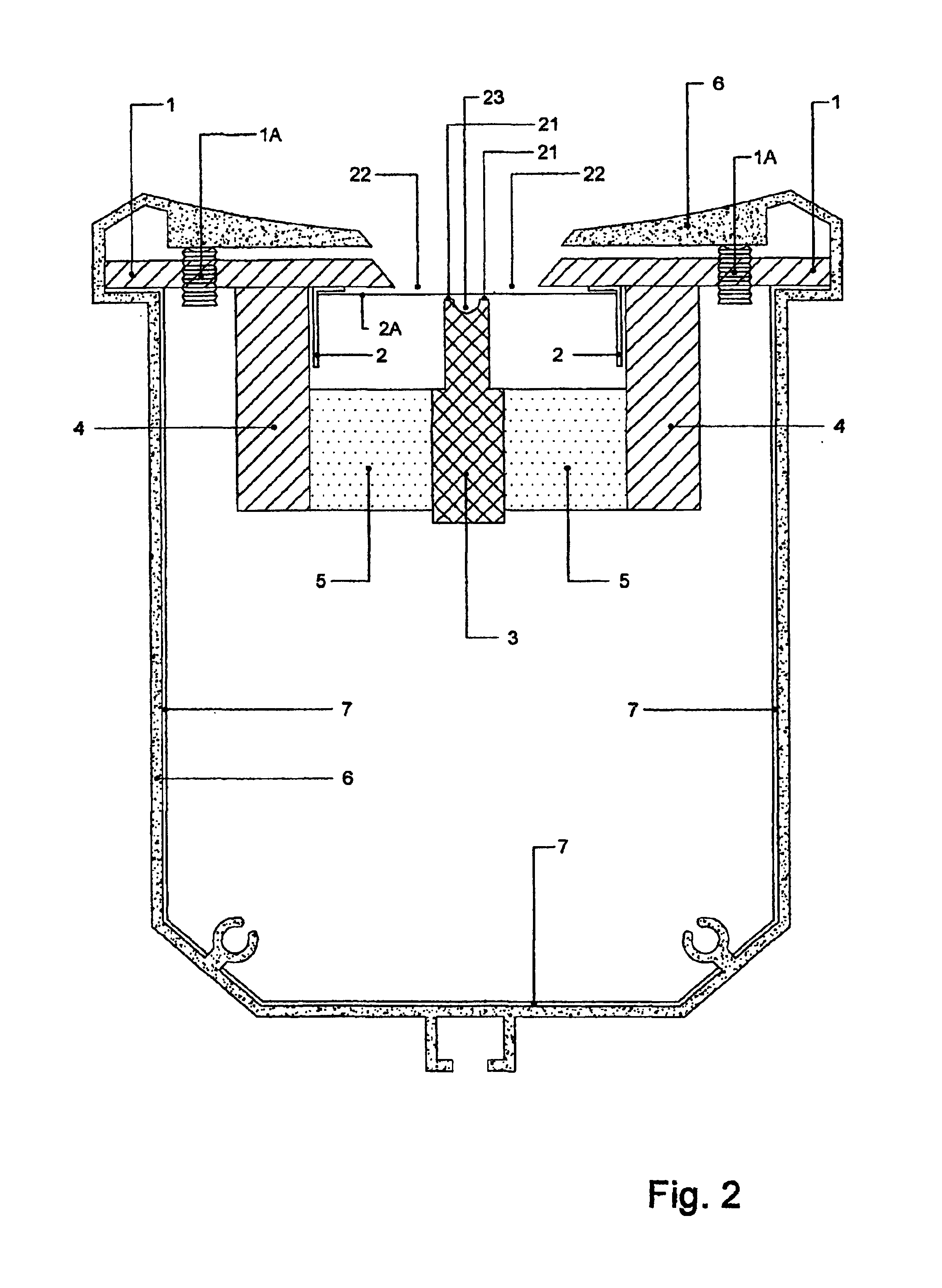

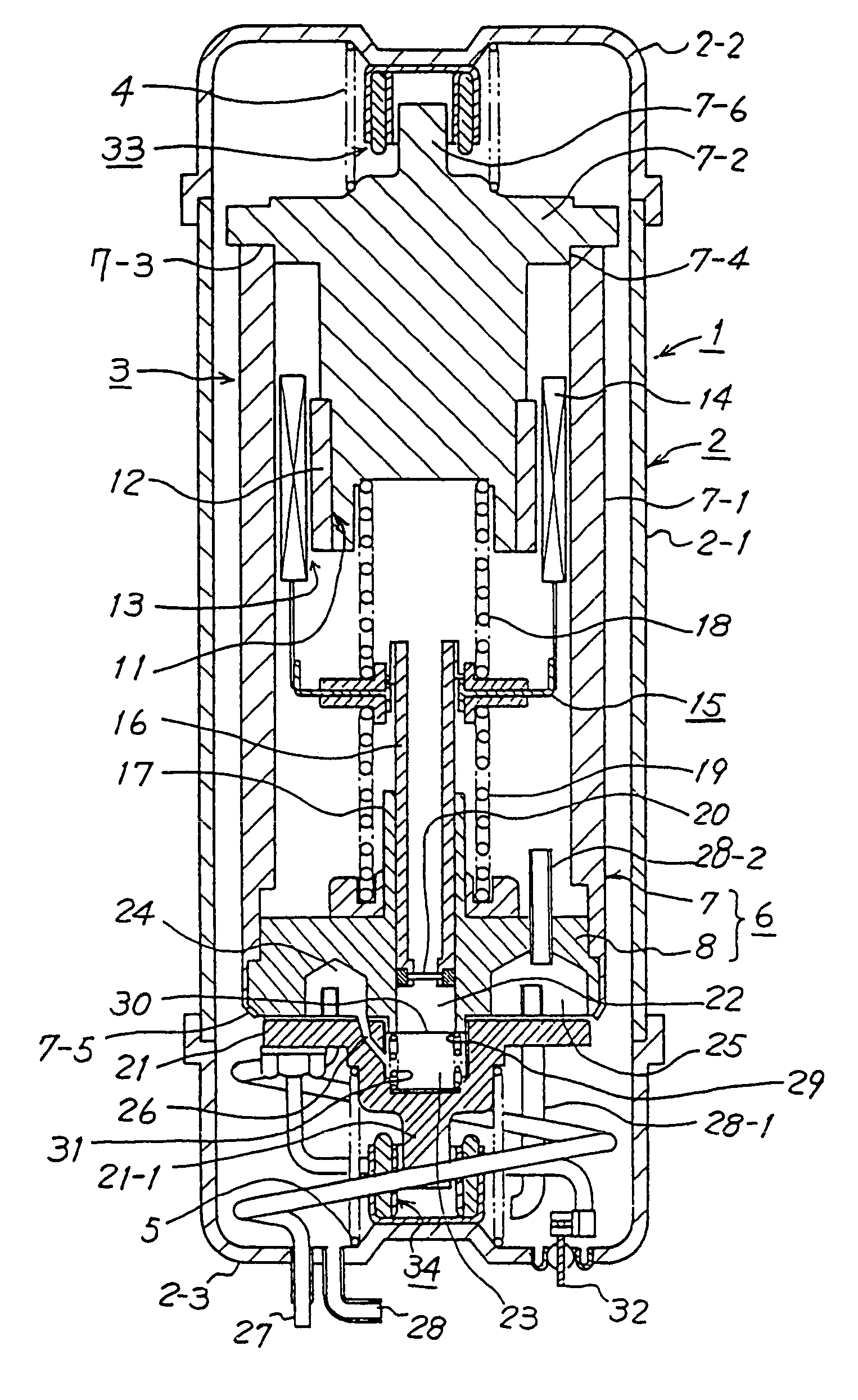

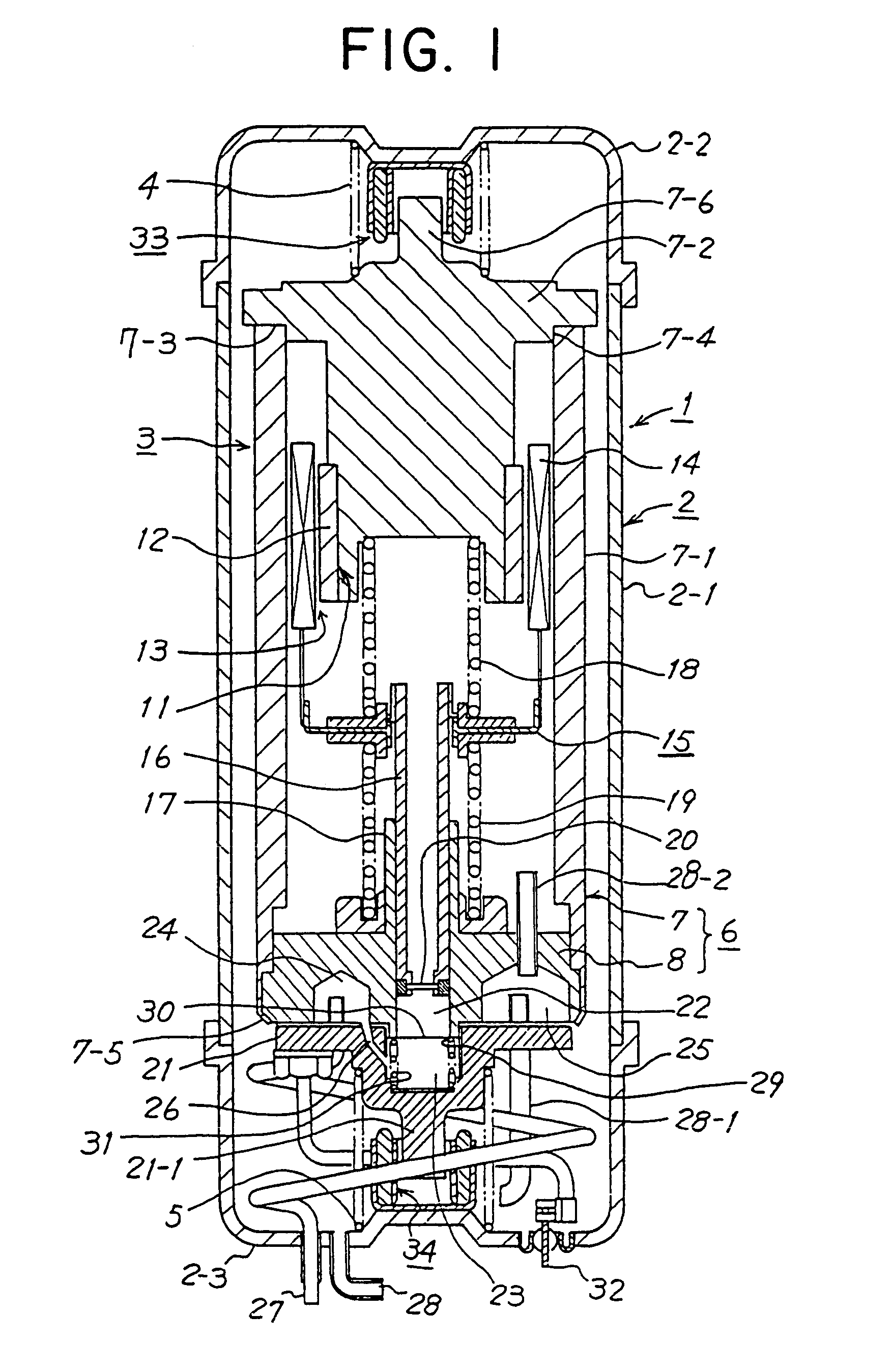

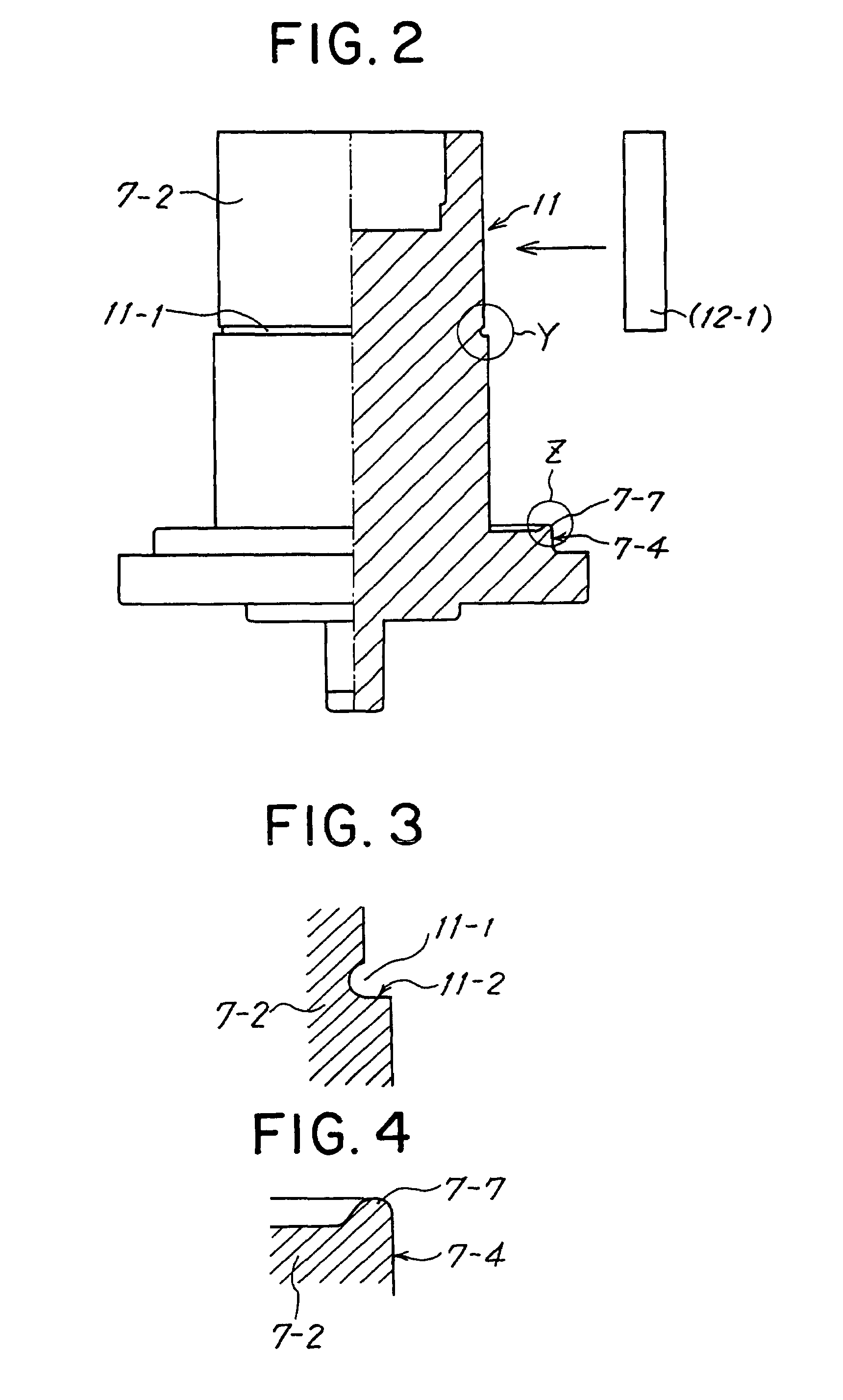

Vibrating type compressor

InactiveUS6994530B2Easy to useImprove vibration efficiencyReciprocating/oscillating/vibrating magnetic circuit partsPiston pumpsNeodymium magnetCylinder block

A vibration type compressor related to the present invention, in which a compressor main body 3 is built into a gastight vessel 2 including a yoke 7-1, a magnetic path member 7 formed from a column-shaped core pole 7-2, a permanent magnet 12 arranged in the magnetic path, an electromagnetic coil 14 which is arranged within an annular magnetic gap 13 between the magnetic path members 7 by being supported by a mechanical vibration system to as to be able to vibrate and is wound around a lead plate to perform the connection treatment of a terminal thereof, a piston 16 connected to the electromagnetic coil 14, and a cylinder block 8 which closes the yoke 7-1 and in the interior of which is formed the cylinder portion 17 housing the piston 16, characterized in that the permanent magnet 12 is formed from a neodymium magnet or a rare-earth magnet and in that the cylindrical permanent magnet 12 is divided into four parts in the axial direction thereof, the four-part divided magnet being bonded and fixed to the side of the core pole 7-2, whereby the vibration type compressor is miniaturized and its efficiency is increased.

Owner:SAWAFUJI ELECTRIC COMPANY

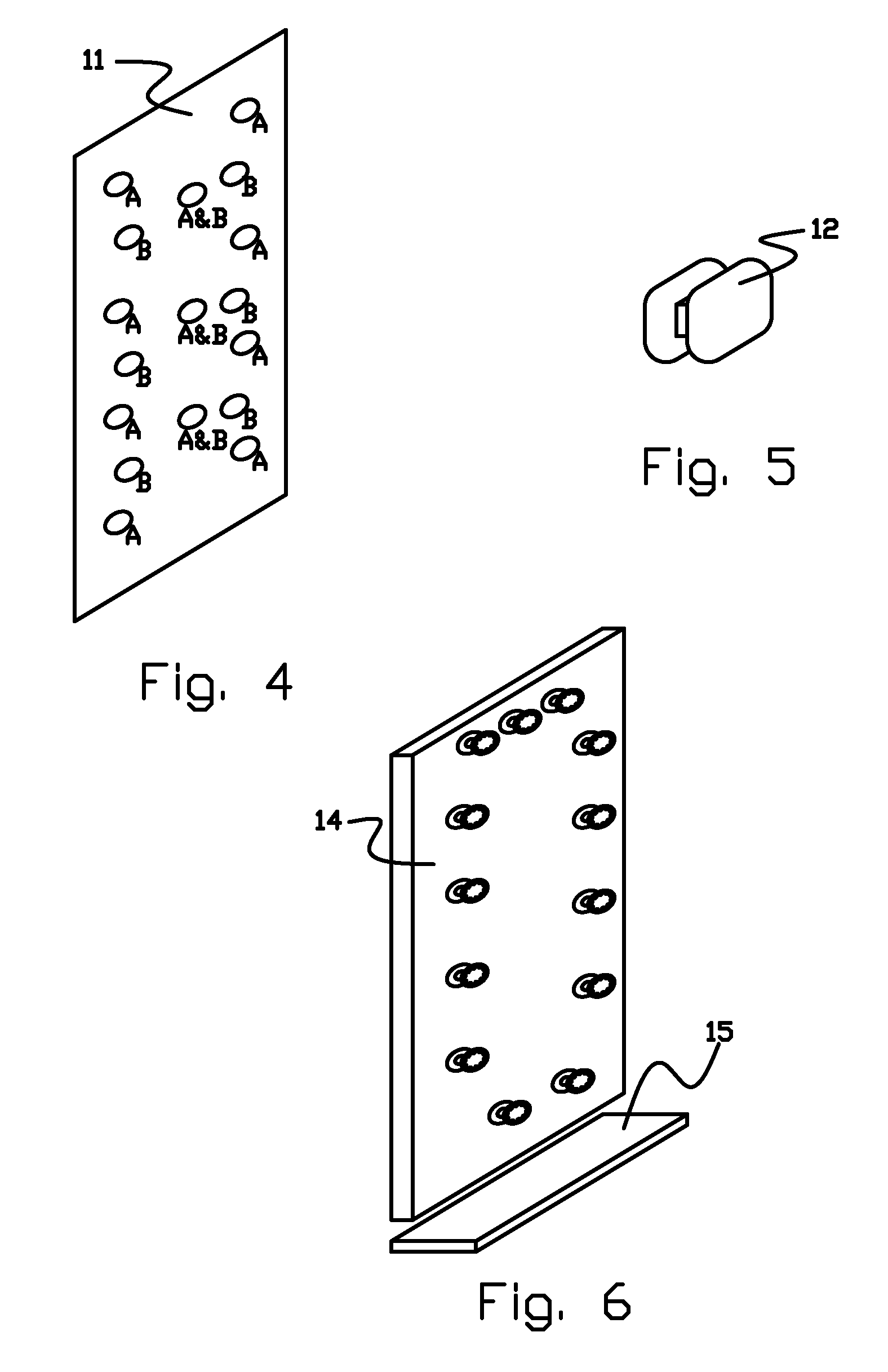

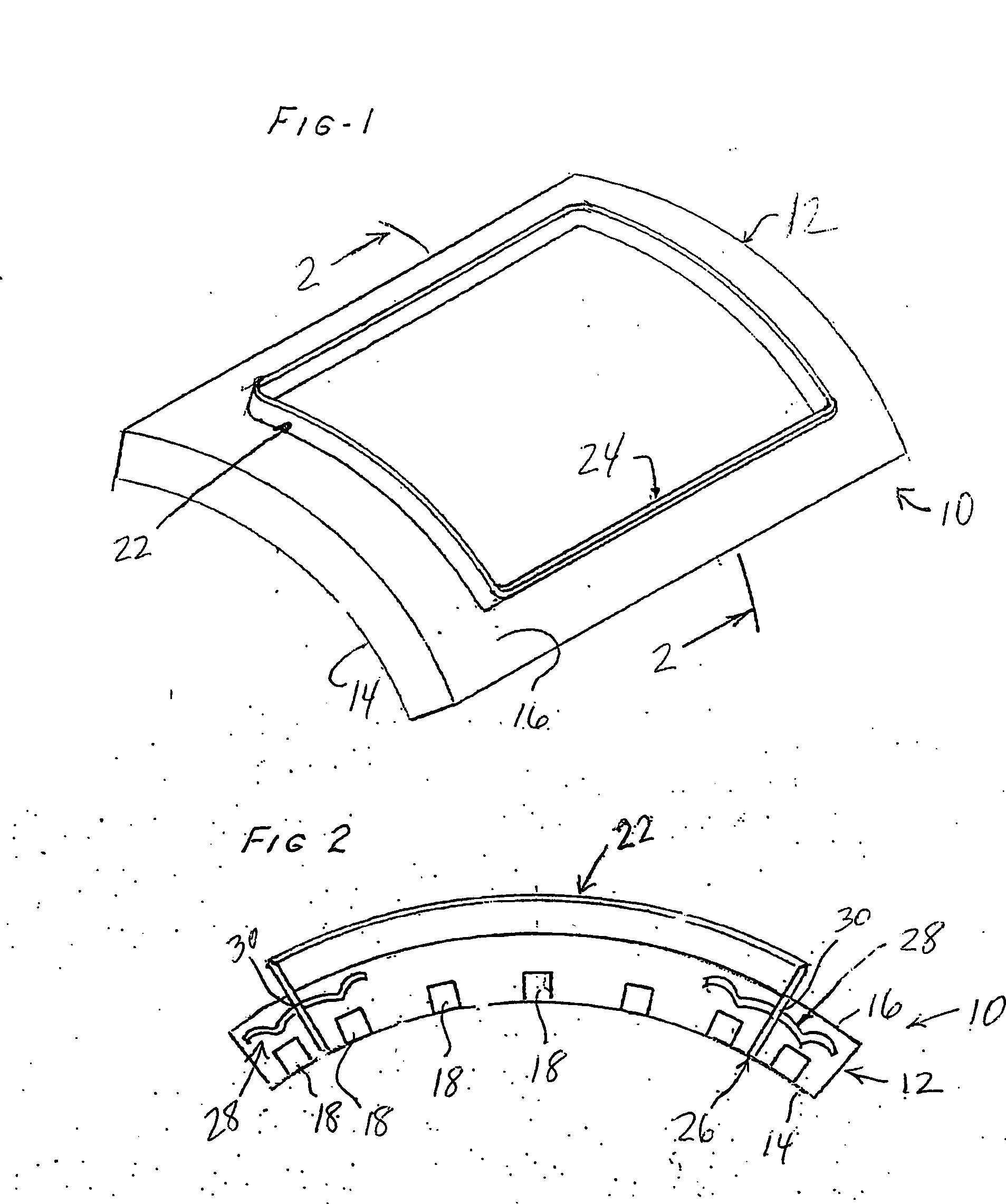

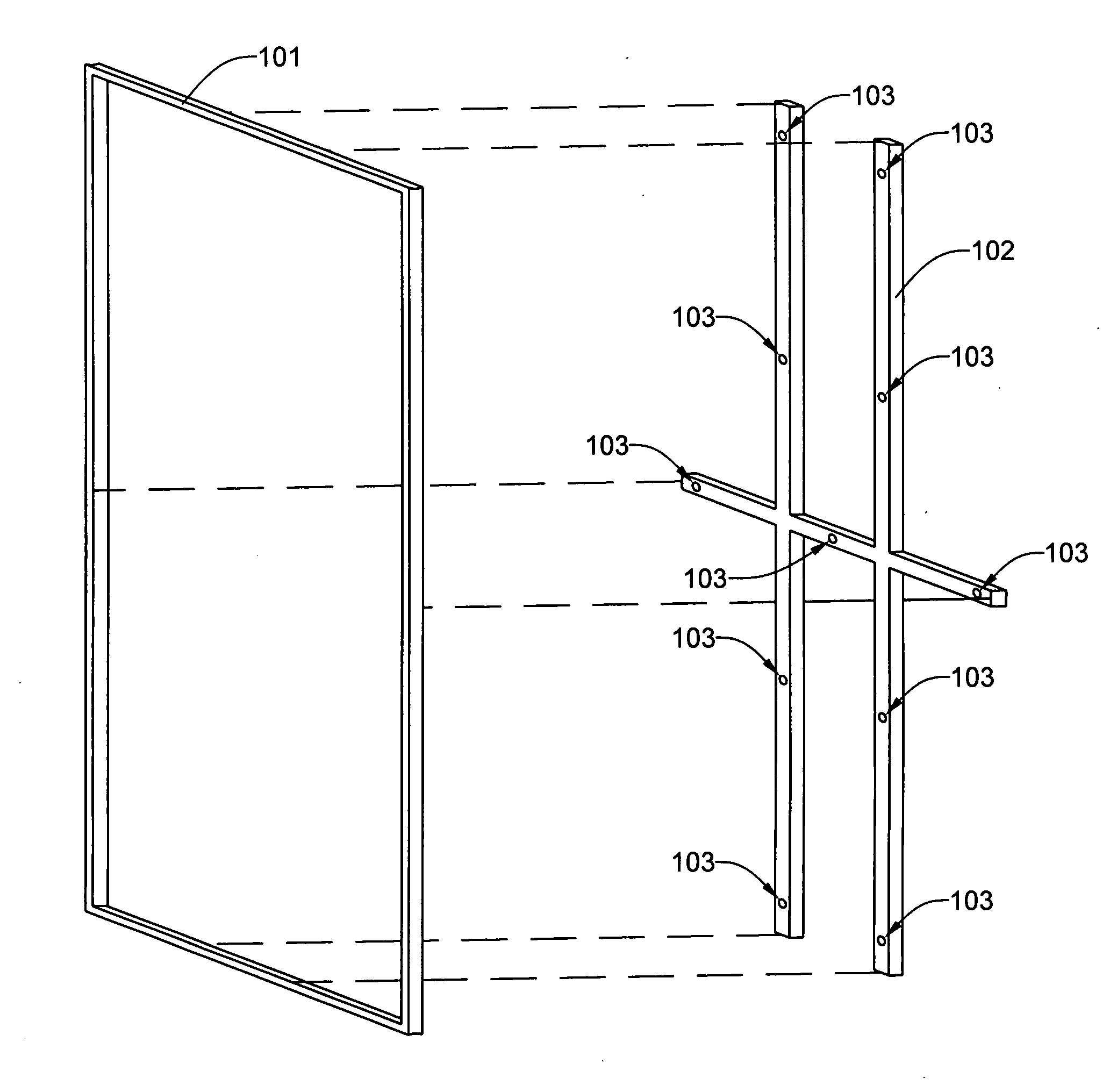

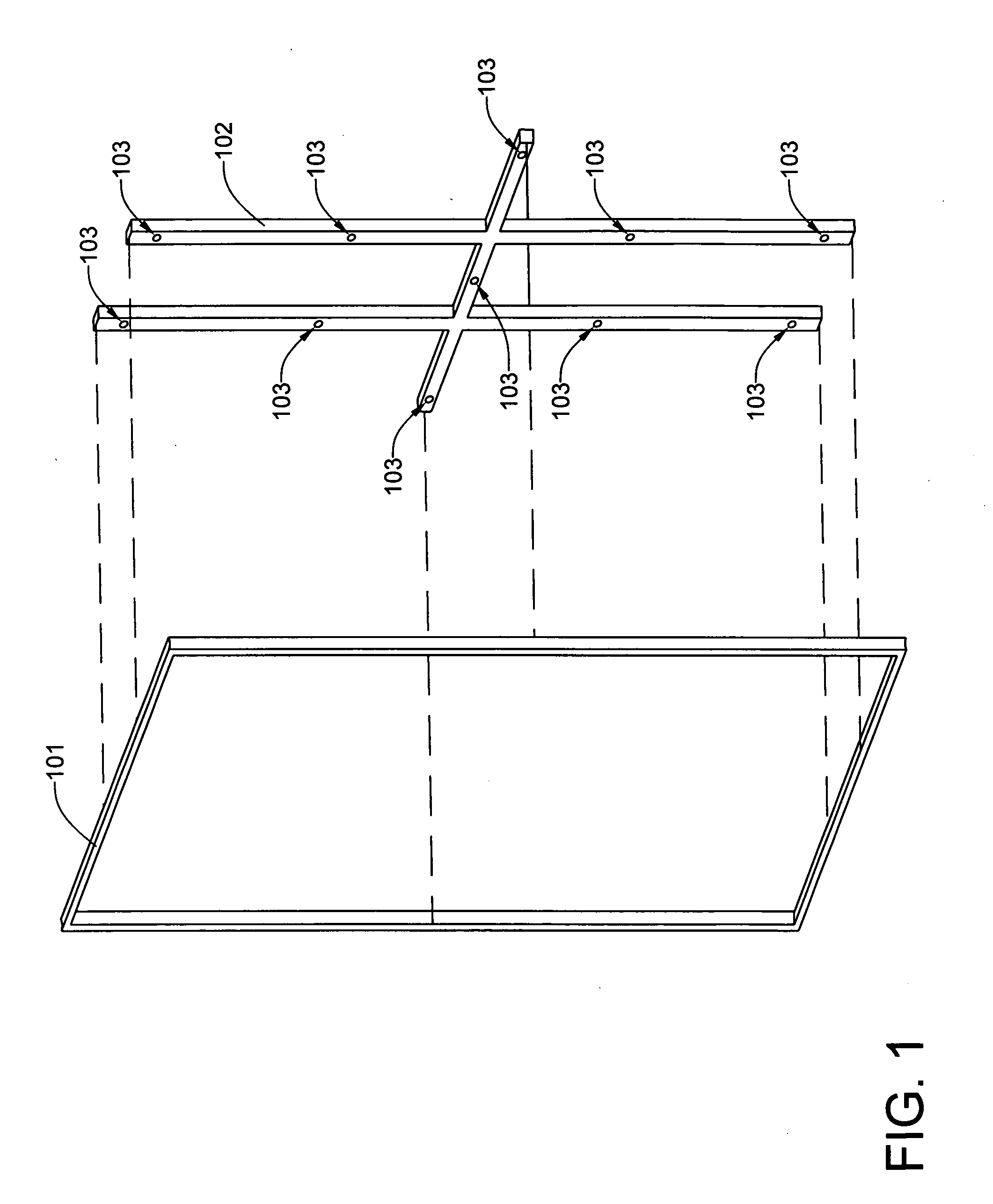

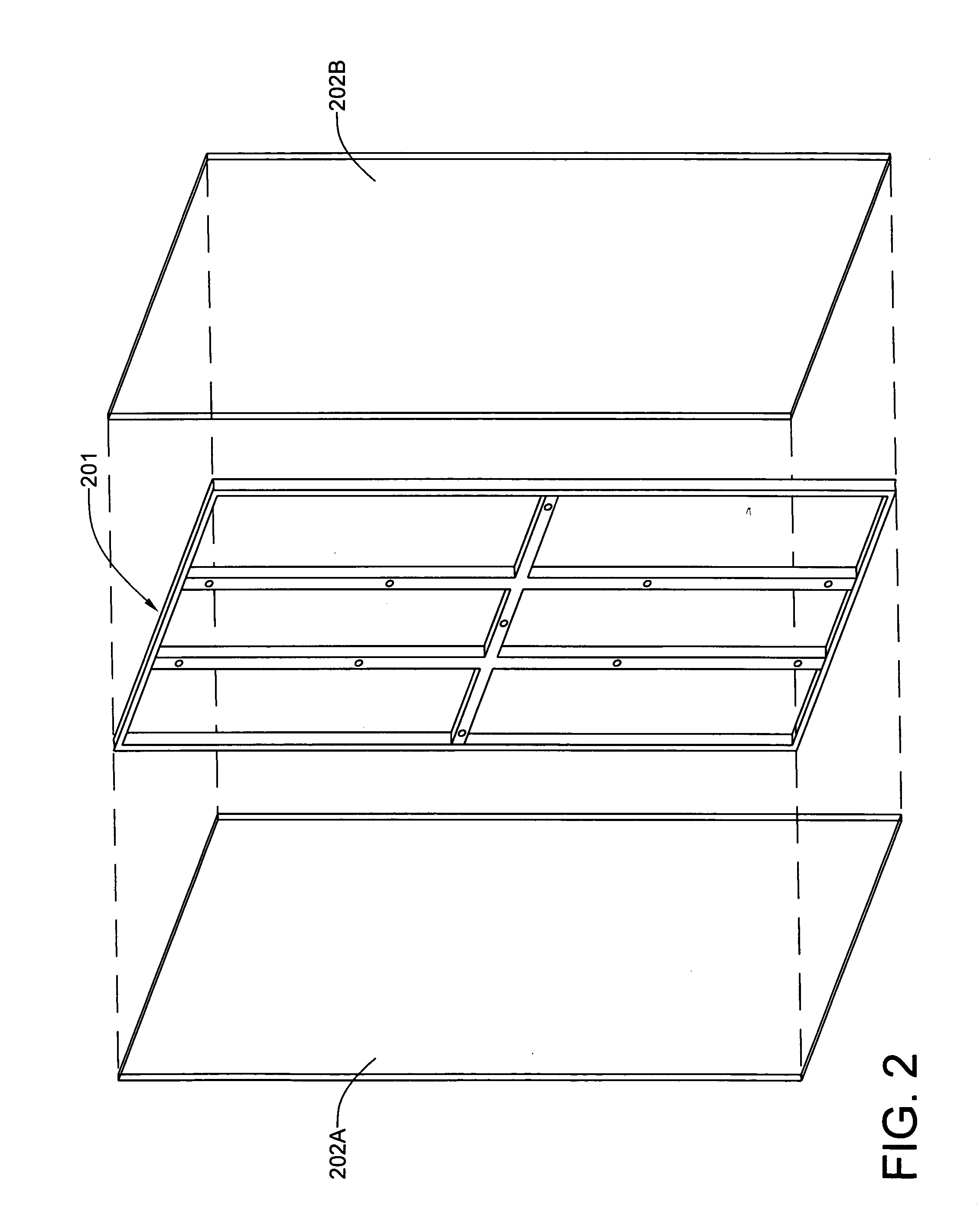

Divided light windows having magnetically-attached grids

An improved simulated authentic divided-light windows, includes an internal muntin grid structure sandwiched between the panes of a double-glazed sealed window pane, and an external muntin grid removably attached to each side of the sealed window pane. The internal grid is equipped with multiple neodymium magnets, which are embedded in the grid structure at regular intervals, while the back side of each of the outer muntin grid structures is equipped with multiple steel or iron inserts which align with the neodymium magnets when the outer grids are positioned, as intended, on the sash. Outer grids used on the inside of a building can be made of wood or plastic. Outer grids used on the exterior of building are preferably made of extruded aluminum or other weather resistant material. The steel or iron inserts are threadably secured or adhesively bonded to apertures in the back side of the grid.(150)

Owner:PARKER ROBERT FLOYD

Method for preparing high-coercive-force neodymium magnet through grain boundary diffusion under constant magnetic field

InactiveCN108831658AImprove coercive forceFacilitated DiffusionInductances/transformers/magnets manufactureMagnetic materialsMaterials preparationNeodymium magnet

The invention discloses a method for preparing a high-coercive-force neodymium magnet through grain boundary diffusion under a constant magnetic field. The method comprises the steps that material preparation is conducted according to NdFeB alloy components, an alloy ingot is obtained through vacuum melting, and the alloy ingot is rapidly quenched to be a strip; material preparation is conducted according to rare earth ternary Re-Al-Cu alloy components, a mother alloy ingot is obtained through vacuum melting, the mother alloy ingot is rapidly quenched to be a strip, and high-energy ball milling is conducted to obtain uniform low-melting-point rare earth ternary Re-Al-Cu nano powder; the free surface and rapid cooling surface of the NdFeB alloy strip are coated with the Re-Al-Cu nano powder; the strip alloy is parallel placed in a constant magnetic field annealing furnace with the magnetic field strength of 1.5T to perform vacuum magnetic field heat processing. According to the method,the low-melting-point rare earth ternary Re-Al-Cu nano alloy is taken as a diffusion source, diffusion heat processing is conducted on the NdFeB alloy under the action of the thermal magnetic field tomake hard magnetic phases in the NdFeB alloy to be arranged along an easy axis of magnetization, and therefore the grain characteristics of the diffused neodymium magnet is improved.

Owner:CHINA JILIANG UNIV +1

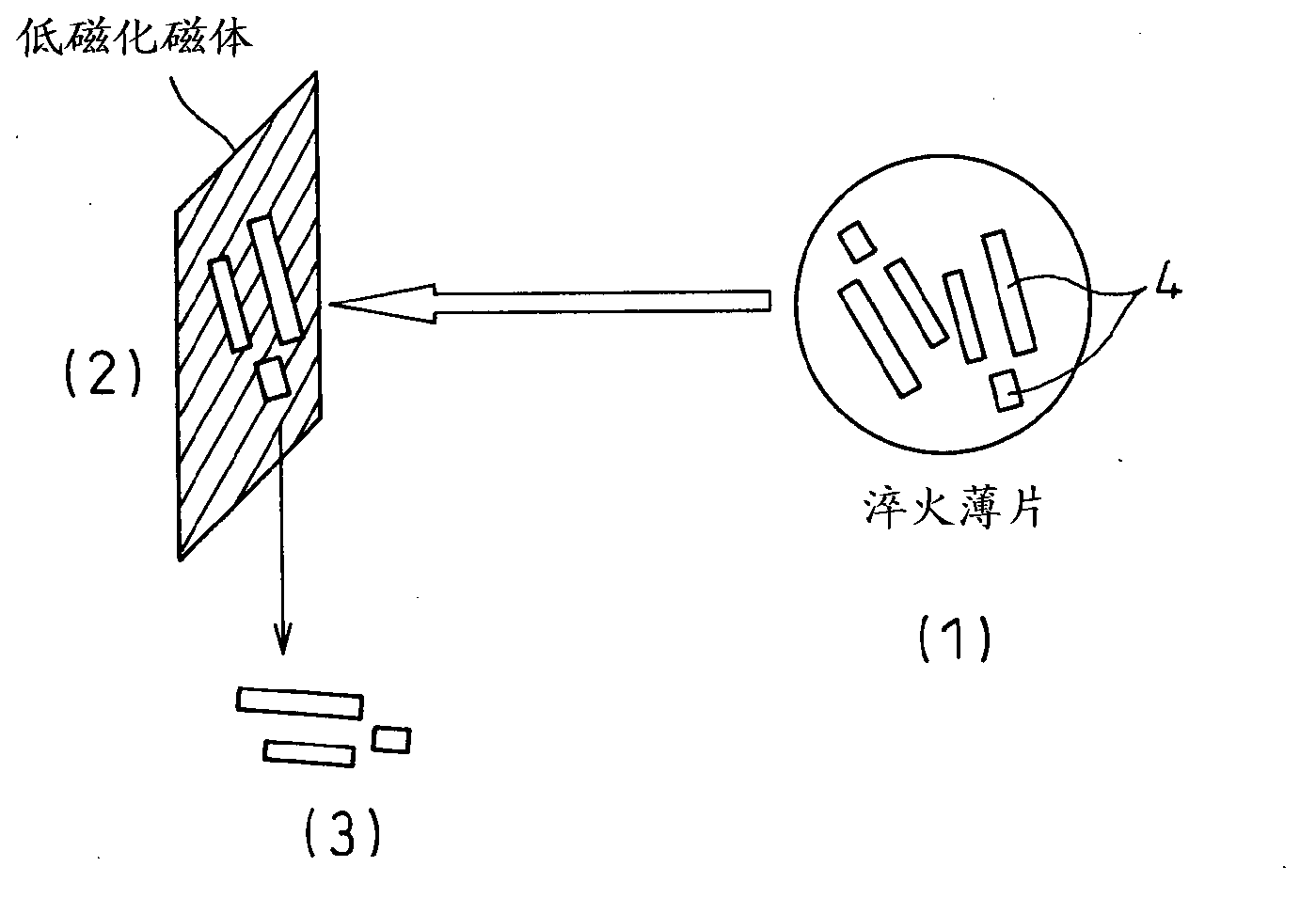

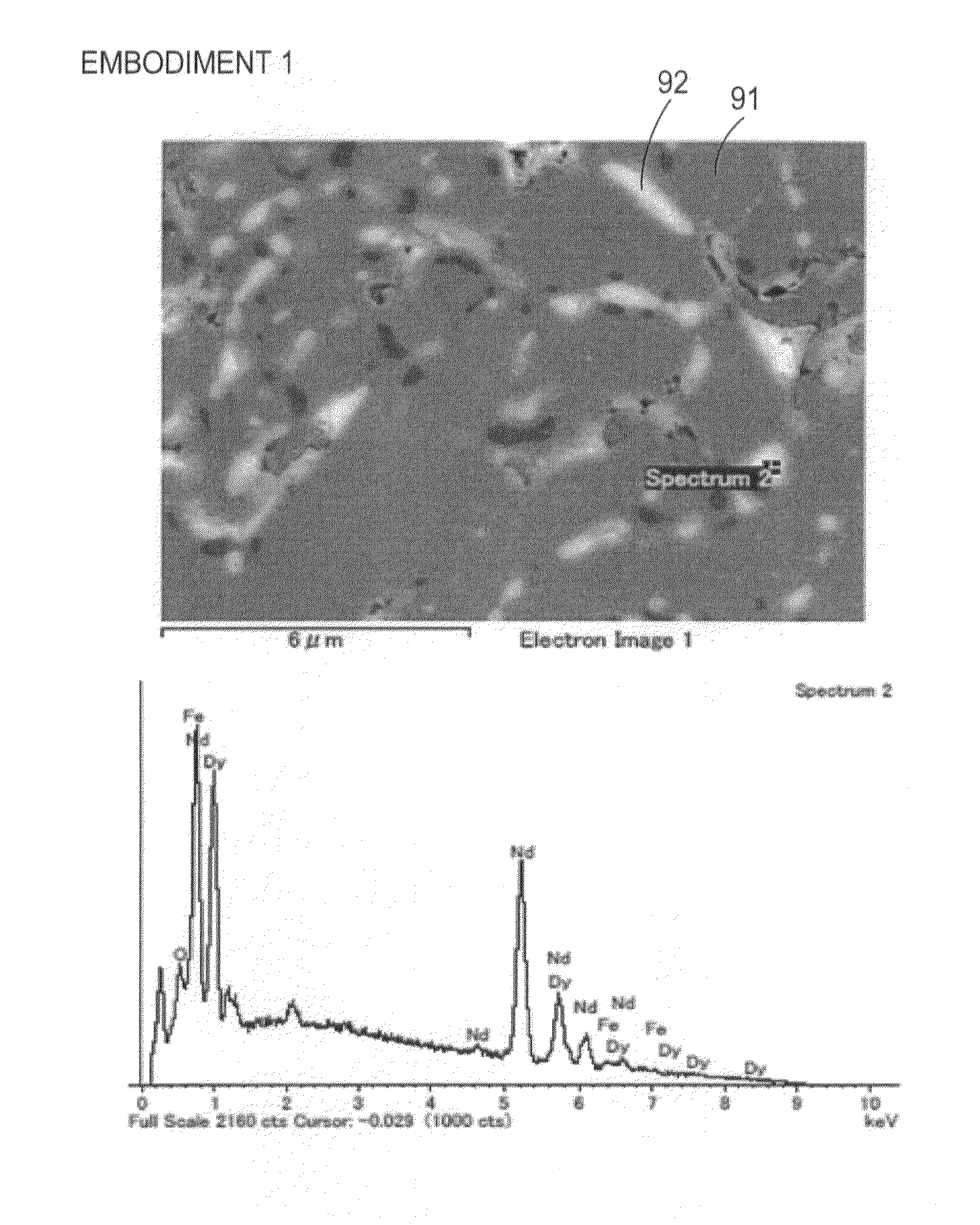

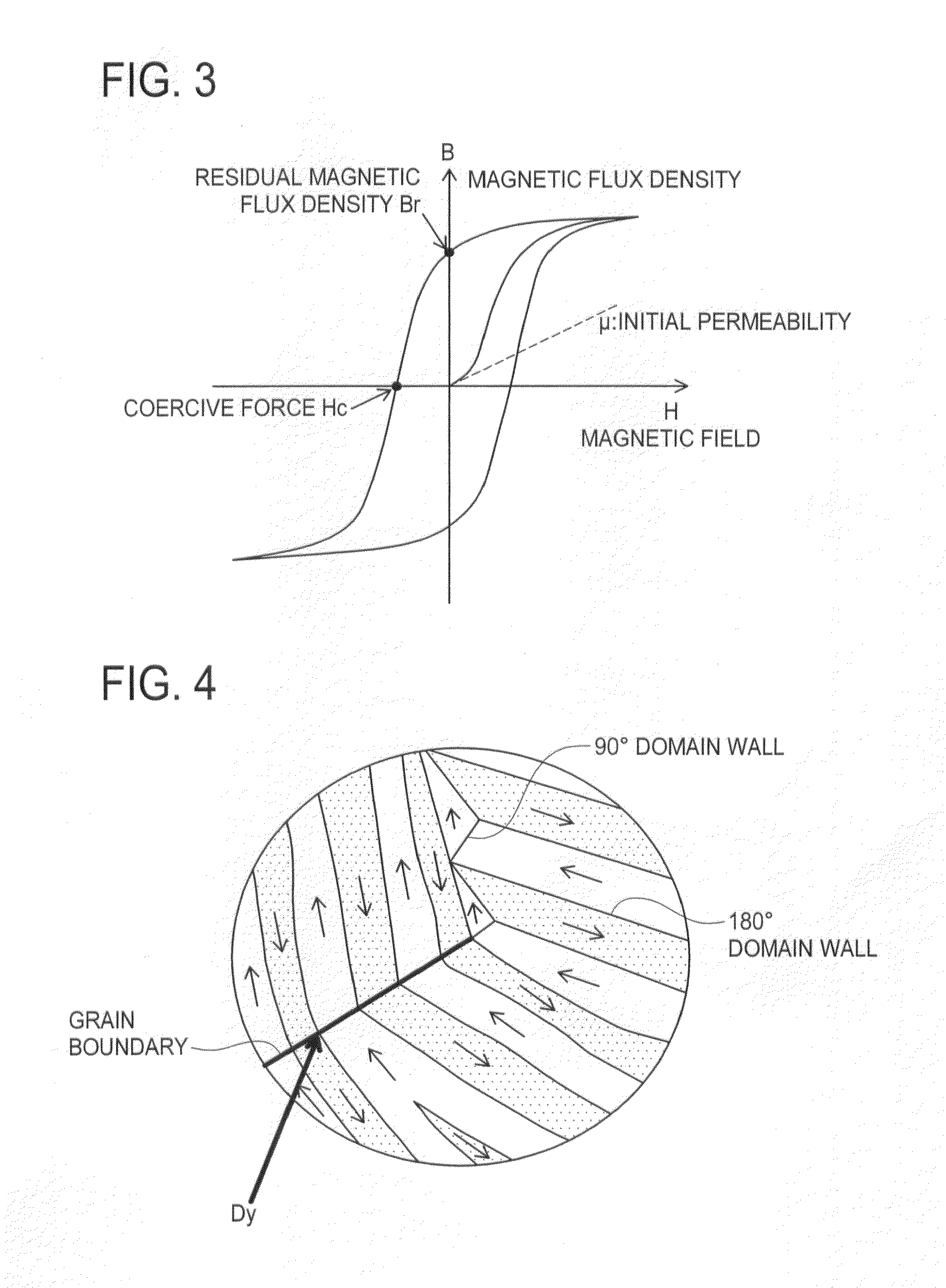

Production method of rare earth magnet

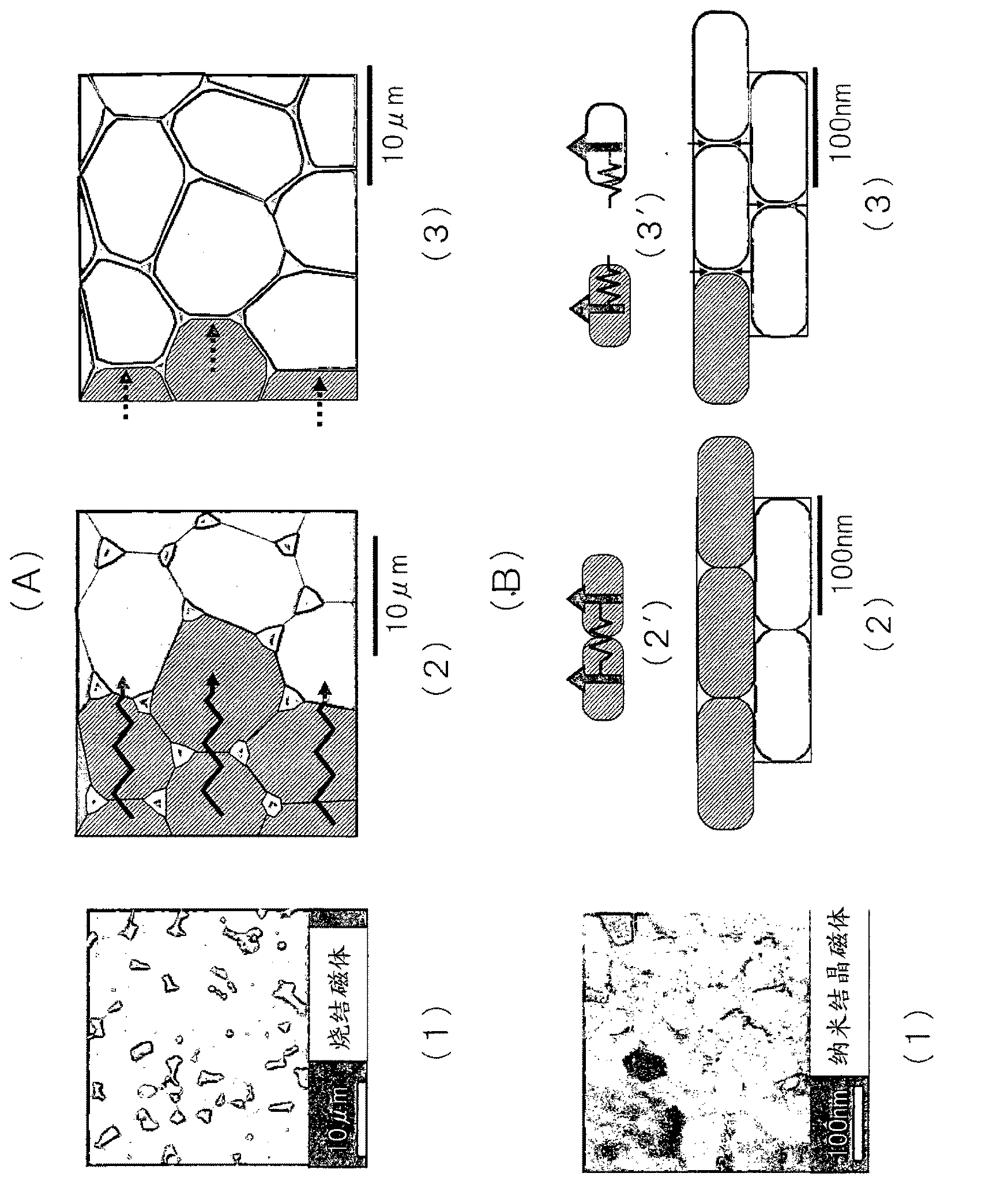

ActiveCN103189943APrevent exchange couplingIncrease the magnetic coercive forceTransportation and packagingMetal-working apparatusRare-earth elementNeodymium magnet

The method of the present invention produces a rare earth magnet, which is represented by a neodymium magnet (Nd2Fe14B) and neodymium magnet films with applications in micro-systems, by using a heat treatment method capable of enhancing the magnetic characteristics, particularly the magnetic coercive force. A method for producing a rare earth magnet, comprising: (a)quenching a molten metal having a rare earth magnet composition to form quenched flakes of nanocrystalline structure; sintering the quenched flakes; subjecting the sintered body obtained to an orientation treatment; and applying a heat treatment with pressurization at a temperature sufficiently high to enable diffusion or fluidization of a grain boundary phase and at the same time, low enough to prevent coarsening of the crystal grains. (b) thick films deposited on a substrate, applying an annealing to crystallize with pressurization at a temperature sufficiently high to enable diffusion or fluidization of a grain boundary phase and, at the same time, low enough to prevent coarsening of the crystal grains. Preferably, an element capable of lowering the temperature at which the grain boundary phase can be diffused or fluidized, is added to the rare earth magnet composition.

Owner:TOYOTA JIDOSHA KK +3

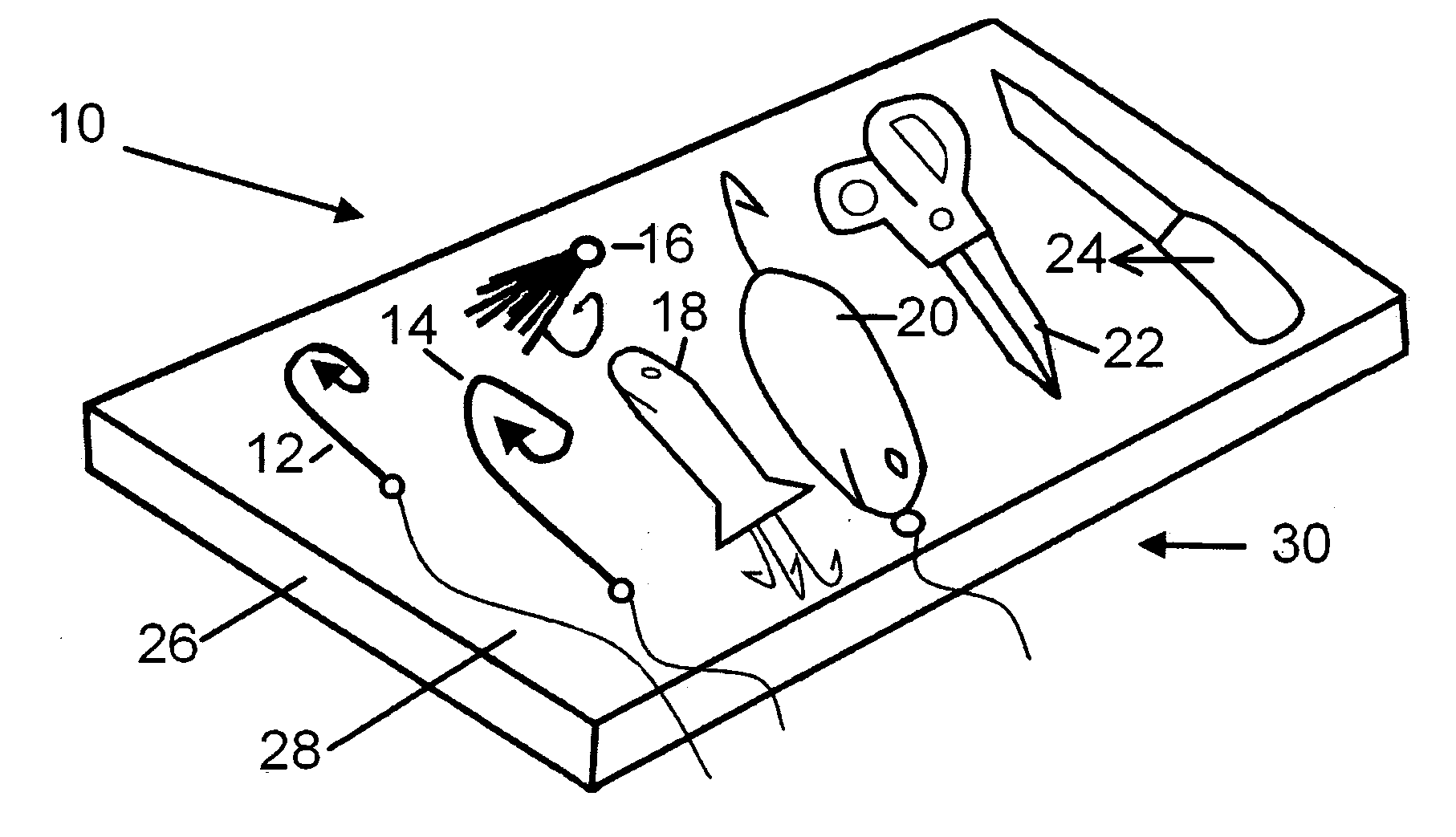

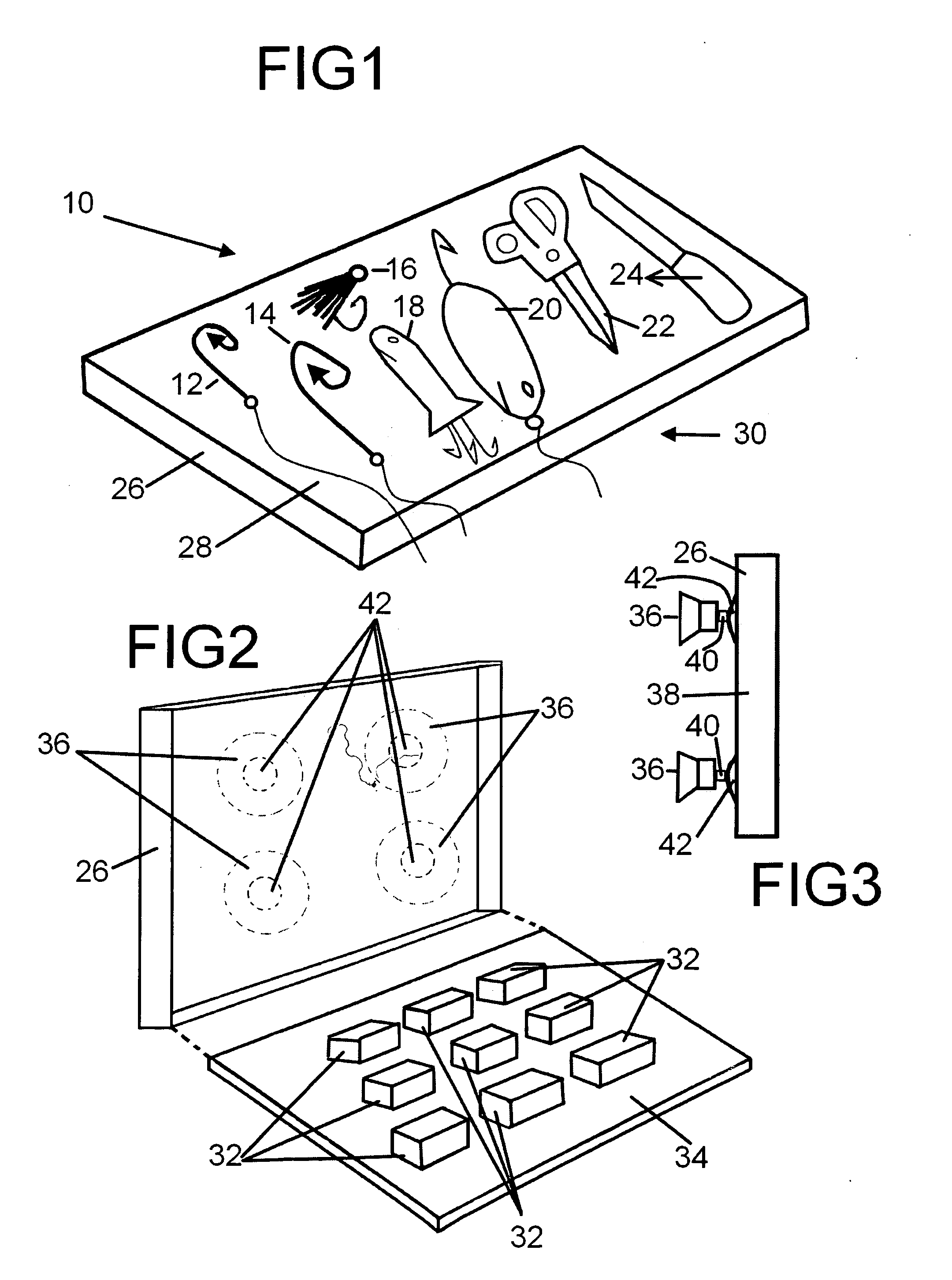

Fishing lure neodymium magnetized holder

A fishing lure neodymium magnetized holder is disclosed including an array of neodymium magnets attached to a flat sheet of iron or steel, preferably iron. The flat sheet of iron and neodymium magnets are housed in a moisture impervious enclosure preferably comprised of a combination of plastic box and a sealed cover of polyurethane or similar durable moisture impervious material attached to the top surface of the flat sheet of iron to completely isolate and protect the flat sheet of iron and neodymium magnets from moisture and resulting corrosion. Preferably, four suction cups are attached to four threaded studs. The threaded studs are then threaded into four receptacle members fixedly attached near the four rear corners of the flat plastic box. The four suction cups allow the holder to be placed and held in any convenient location on smooth surfaces that abound in molded fishing boats. The magnetic attracting force of the neodymium magnets is so powerful that it can penetrate the polyurethane or similar moisture impervious material attached to the top surface of the flat iron sheet and still retain the fishing lures and other fishing accessories securely and safely in any position on the flat surface of the inventive holder.

Owner:GELBER EDWARD CARL

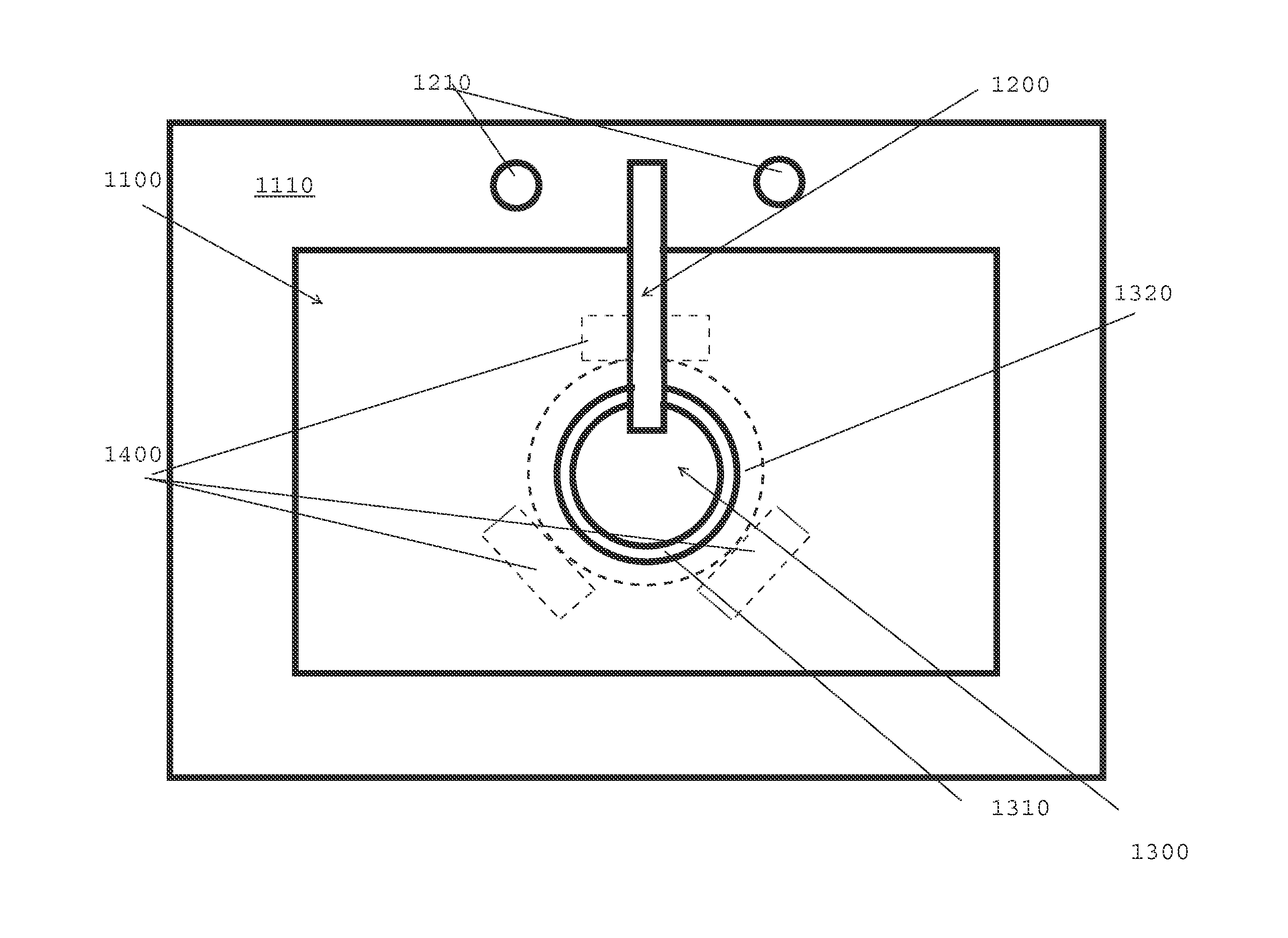

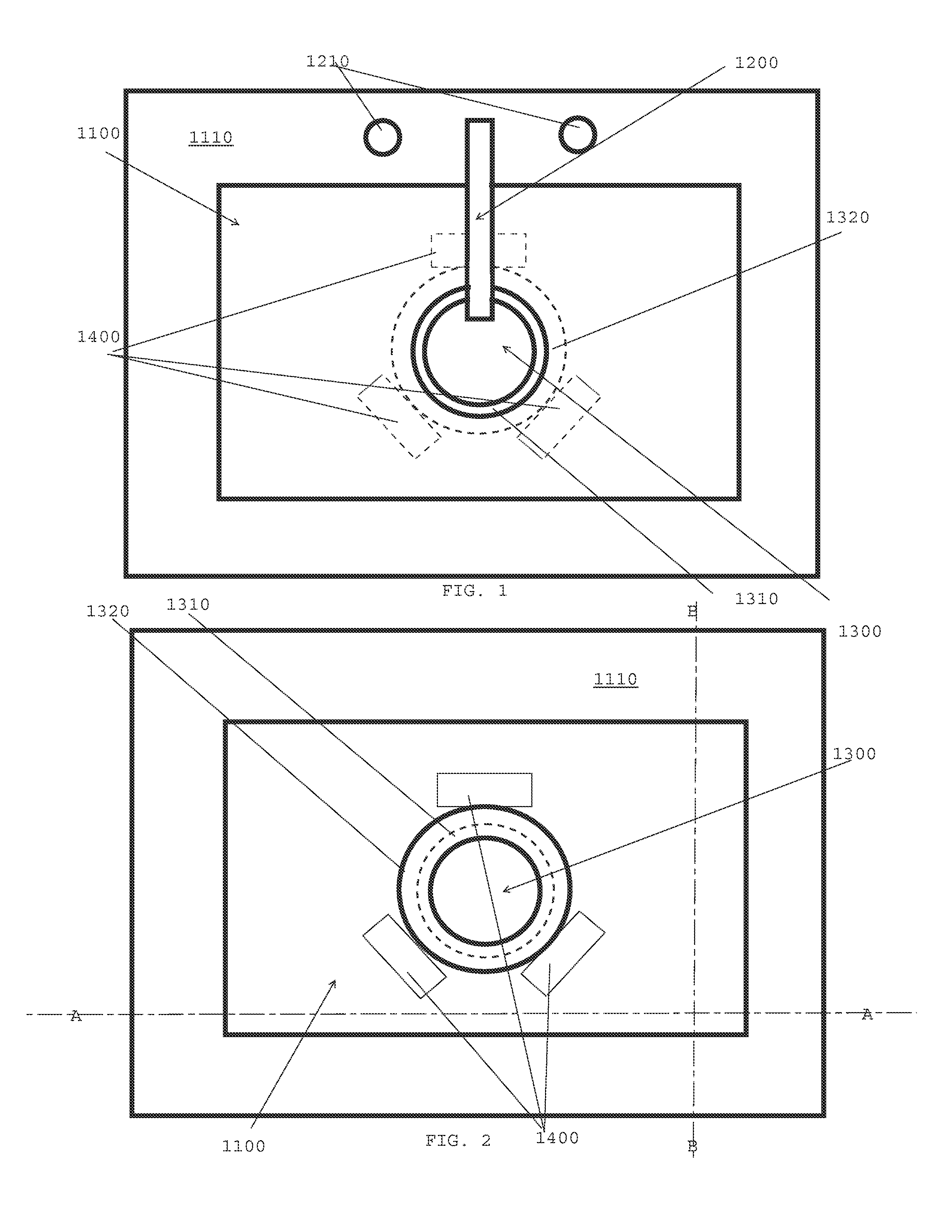

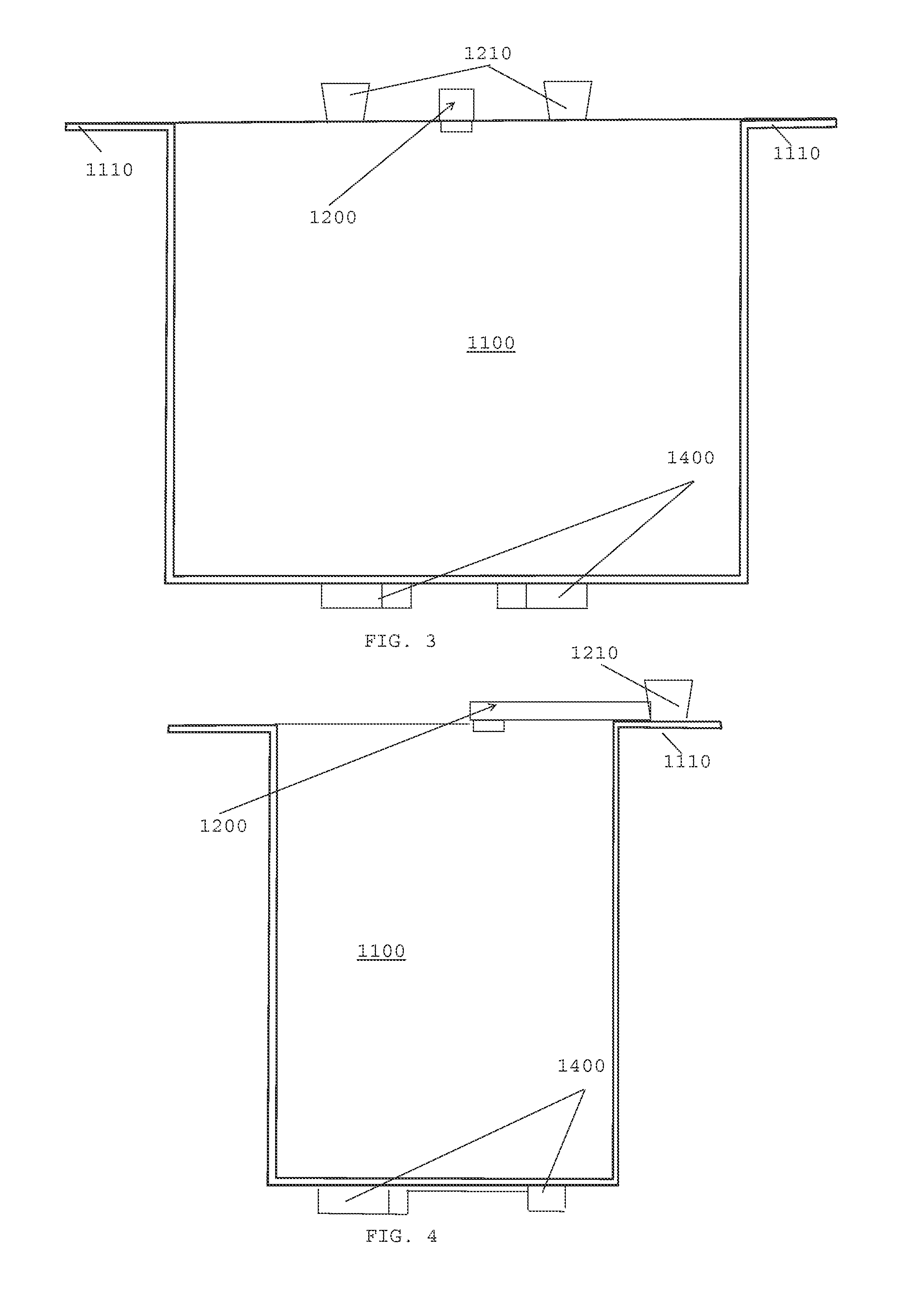

Apparatus for Preventing Flatware from Passing through the Drain of a Wash Basin or Sink, and Related Methods of Use

InactiveUS20140041113A1AccessibilityDomestic plumbingCleaning using toolsNeodymium magnetEngineering

Disclose is a magnetized sink which (a) does not result in the congestion of a sink drain, (b) features at least one neodymium magnet, and (c) assists in the performance of sink activities that are unrelated to flatware. In one embodiment, the sink comprises: a basin; a drain; and a plurality of neodymium magnets secured to an underside of the basin whereby metallic items may be magnetically attracted to the inside the basin. In one mode of operation, the sink is configured to prevent flatware from passing over the drain precipice. In another mode of operation, the disclosed apparatus is configured to assist in the washing of pots and / or pans, wherein pots or pans are held upright via magnetic attraction.

Owner:MOBBS JOE

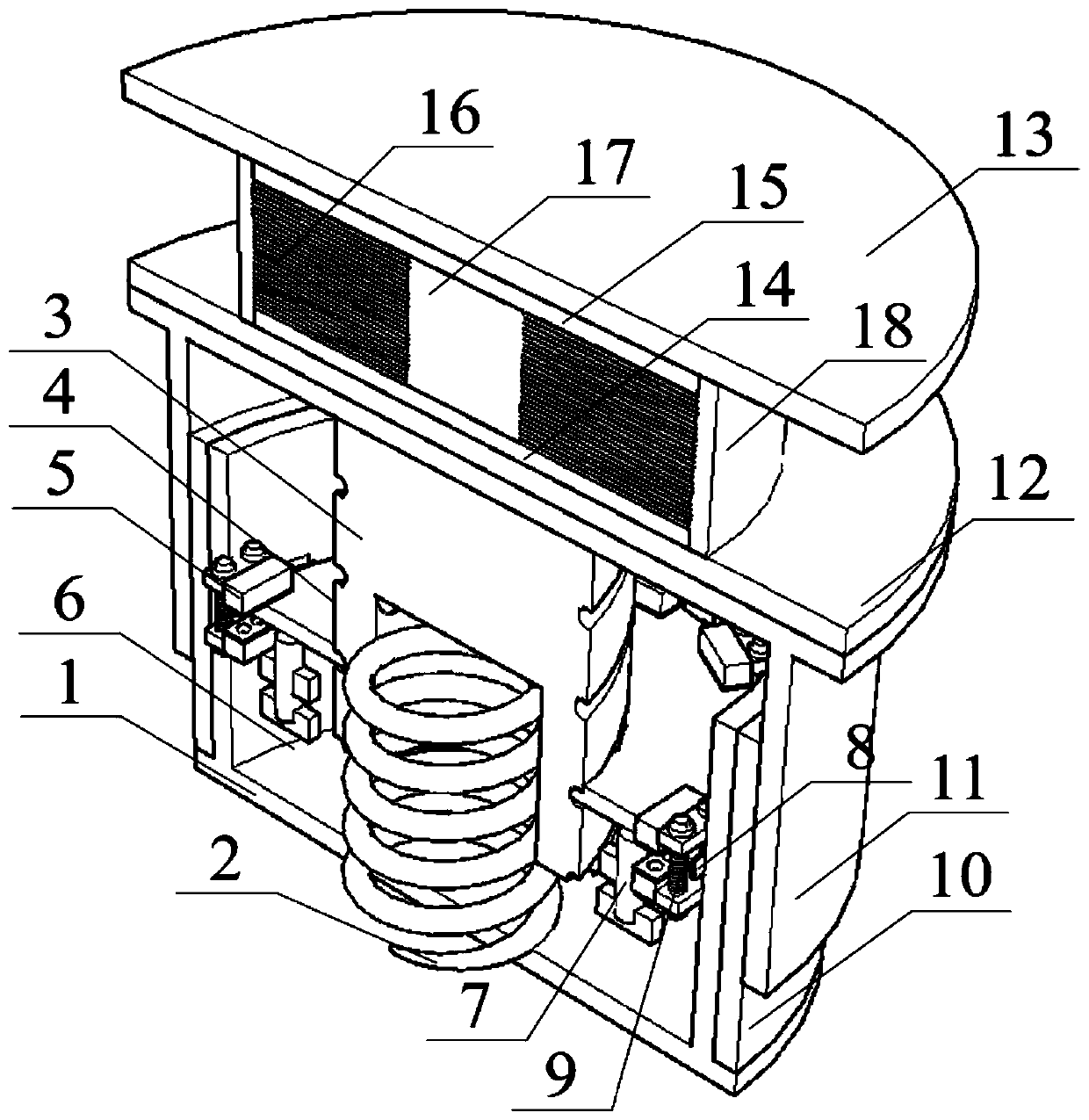

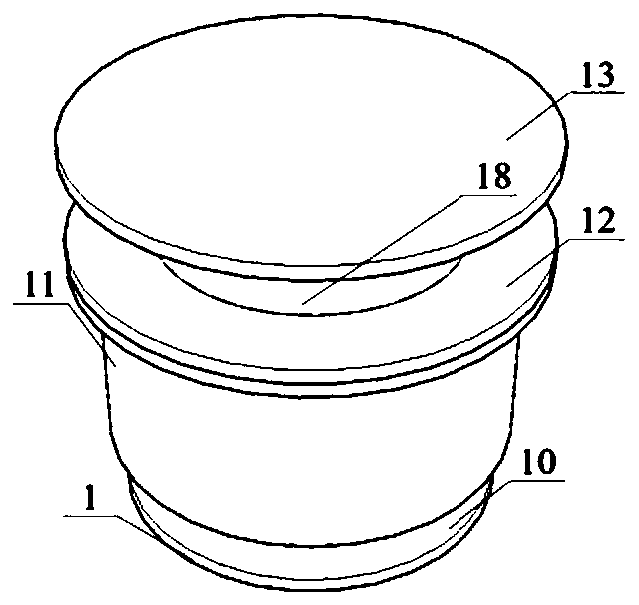

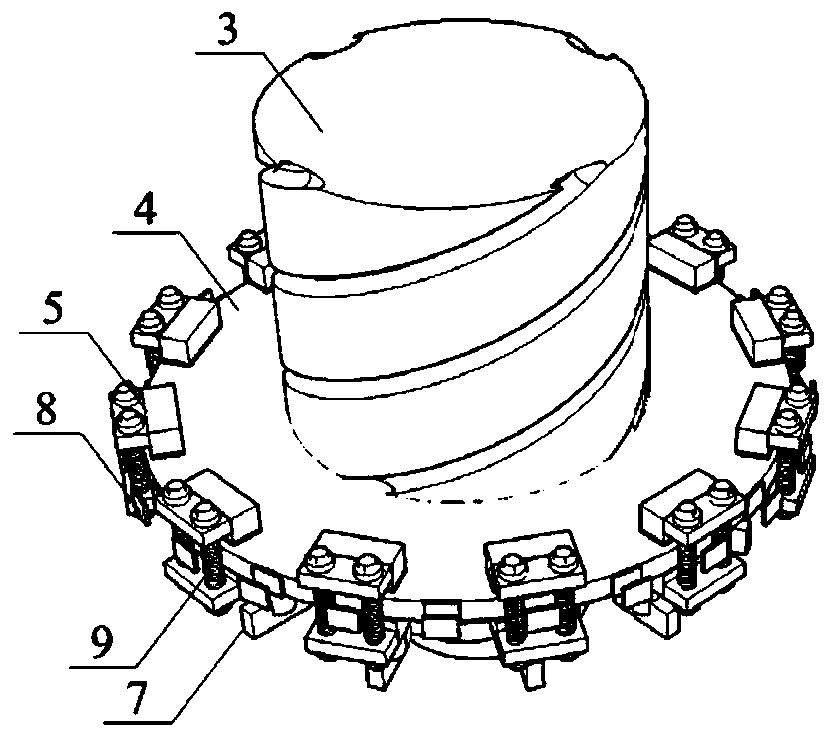

Three-dimensional vibration isolation device combining inerter and rubber support

ActiveCN111305631AImprove bearing capacityAchieve isolationNon-rotating vibration suppressionProtective buildings/sheltersVertical vibrationNoise control

The invention belongs to the field of vibration and noise control, and relates to a three-dimensional vibration isolation device combining an inerter and a rubber support. The three-dimensional vibration isolation device combining the inerter and the rubber support comprises a spiral spring, a rotary shaft, a rotary disc, rotary disc constraint parts, coils, neodymium magnets, damping liquid, damping rods, an upper sleeve, a lower sleeve, a Teflon sleeve, laminated rubber, a lead core, a rubber protective sleeve, an upper connecting plate, a lower connecting plate, a rubber support upper protection plate and a rubber support lower protection plate. According to the three-dimensional vibration isolation device combining the inerter and the rubber support, three-dimensional vibration isolation is achieved by connecting an inerter vibration isolation system and the rubber support in a decoupling mode; and effective vertical vibration isolation can be achieved by connecting the spiral spring and the inerter system in parallel, horizontal vibration isolation can be achieved by the rubber support, and a decoupling system is arranged, so that horizontal vibration isolation and vertical vibration isolation function respectively to achieve three-dimensional vibration isolation. The three-dimensional vibration isolation device combining the inerter and the rubber support is widely applicable to buildings built over a subway and important instruments and equipment with three-dimensional vibration isolation requirements, and the three-dimensional vibration isolation effect is better than that of an existing steel spring vibration isolator.

Owner:TONGJI UNIV

Permanent magnet and manufacturing method thereof

InactiveUS20120187326A1Reduce activity levelDecrease in coercive forceMagnetic paintsInorganic material magnetismNeodymium magnetHydrogen atmosphere

There are provided a permanent magnet and a manufacturing method thereof capable of decreasing an activity level of a calcined body activated by a calcination process. To fine powder of milled neodymium magnet is added an organometallic compound solution containing an organometallic compound expressed with a structural formula of M−(OR)x (M represents Dy or Tb, R represents a substituent group consisting of a straight-chain or branched-chain hydrocarbon, x represents an arbitrary integer) so as to uniformly adhere the organometallic compound to particle surfaces of the neodymium magnet powder. Thereafter, desiccated magnet powder is held for several hours in hydrogen atmosphere at 200 through 900 degrees Celsius. Thereafter, the powdery calcined body calcined through the calcination process in hydrogen is held for several hours in vacuum atmosphere at 200 through 600 degrees Celsius for a dehydrogenation process. Thereafter, through powder compaction and sintering process, the powdery calcined body is formed into a permanent magnet.

Owner:NITTO DENKO CORP

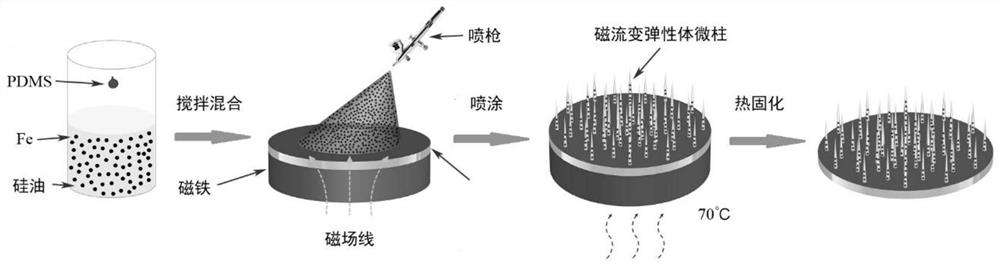

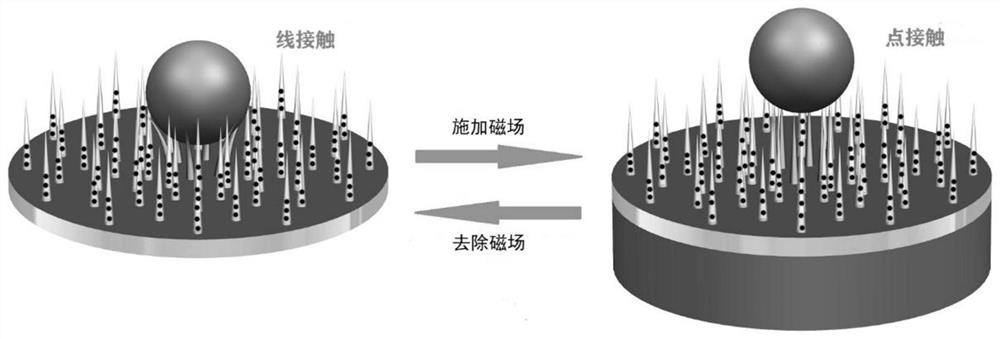

Simple preparation method of magnetic response super-hydrophobic surface

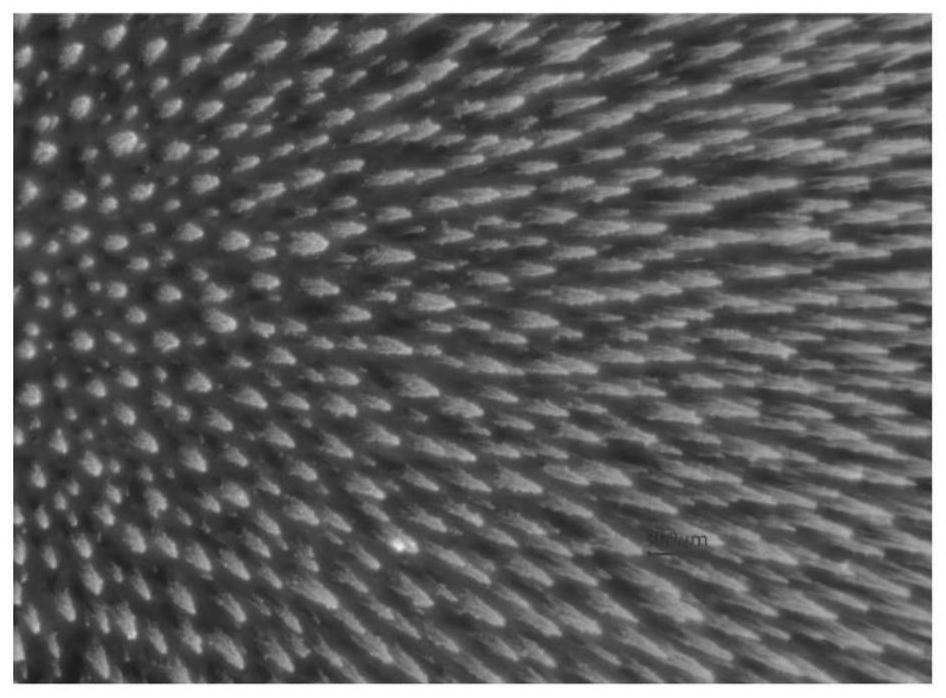

The invention relates to a preparation method of a super-hydrophobic surface, in particular to a simple preparation method of a magnetic response super-hydrophobic surface. The method comprises the following steps: 1, respectively measuring a PDMS prepolymer and a curing agent by using a balance, mixing according to a mass ratio of 10: 1, measuring organic solvent silicone oil by using a measuringcylinder, pouring into a beaker, mixing, and uniformly stirring by using a glass rod; 2, weighing Fe powder with the particle diameter of 1-10 microns by using the balance, pouring the Fe powder intothe beaker, and continuing to violently stir for more than 5 minutes by using the glass rod until the Fe powder is stirred into a uniform black mixed solution; 3, placing a glass sheet substrate on aneodymium magnet, and uniformly spraying the mixed solution prepared in the step 2 onto the glass substrate by using a spray gun; and 4, putting the neodymium magnet in the step 3 and the glass substrate on the neodymium magnet into a drying box to be heated and cured at the heating temperature of 60 DEG C for the heating time of 12 h to volatilize the organic solvent silicone oil and cure the PDMS to obtain a PDMS / iron particle composite columnar array microstructure, and finally obtaining the magnetic response super-hydrophobic surface.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com