Method for preparing high-coercive-force neodymium magnet through grain boundary diffusion under constant magnetic field

A technology of high coercive force and grain boundary diffusion, which is applied in the direction of magnetic objects, inductor/transformer/magnet manufacturing, magnetic materials, etc., can solve the problems of high production cost of Nd-Fe-B permanent magnetic materials and achieve high coercivity Force, the effect of improving grain boundary characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

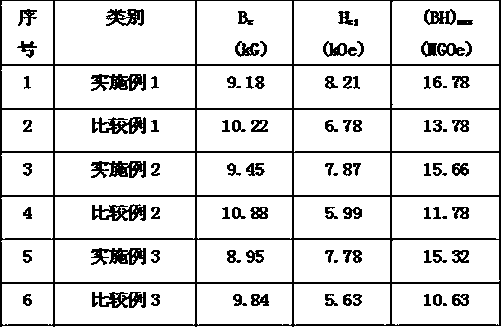

Examples

Embodiment 1

[0018] 1) Weigh and mix the raw materials according to the composition of the NdFeB alloy, vacuum melt the mixed raw materials, and then quickly quench and throw the strips to make alloy thin strips; the composition and mass percentage of the NdFeB alloy are: Nd: 31%, Fe : 66.8%, B: 1.2%, Zr: 0.4%, Co: 0.6%; the quick quenching speed of the described quick quenching strip is 25m / s;

[0019] 2) The low melting point rare earth ternary Ce 50 Al 25 Cu 25 The alloy is weighed and proportioned by atomic percentage, then the mixed raw materials are vacuum smelted, and then the alloy thin strip is made into a quick quenching strip; the rapid quenching speed of the quick quenching strip is 15m / s;

[0020] 3) The Ce prepared in step 2) 50 Al 25 Cu 25 Homogeneous low melting point rare earth ternary Ce 50 Al 25 Cu 25 Nano powder;

[0021] 4) The low melting point rare earth ternary Ce prepared in step 3) 50 Al 25 Cu 25 Nano-powder coating the free surface and quenched surfac...

Embodiment 2

[0026] 1) Weigh and mix the raw materials according to the composition of the NdFeB alloy, vacuum melt the mixed raw materials, and then quickly quench and throw the strips to make alloy thin strips; the composition and mass percentage of the NdFeB alloy are: Nd: 32%, Fe : 65.2%, B: 1.4%, Zr: 0.6%, Co: 0.8%; the quick quenching speed of the described quick quenching strip is 28m / s;

[0027] 2) The low melting point rare earth ternary La 50 Al 25 Cu 25 The alloy is weighed and proportioned by atomic percentage, and then the mixed raw materials are vacuum smelted, and then the alloy thin strip is made into a rapid quenching strip; the rapid quenching speed of the rapid quenching strip is 20m / s;

[0028] 3) The La prepared in step 2) 50 Al 25 Cu 25 After the ribbon is milled by high-energy ball, a uniform low-melting point rare earth ternary La 50 Al 25 Cu 25 Nano powder;

[0029] 4) The low melting point rare earth ternary La 50 Al 25 Cu 25 Nano-powder coating the fr...

Embodiment 3

[0034] 1) Weigh and mix the raw materials according to the composition of the NdFeB alloy, vacuum melt the mixed raw materials, and then quickly quench and throw the strips to make alloy thin strips; the composition and mass percentage of the NdFeB alloy are: Nd: 33%, Fe : 63.4%, B: 1.8%, Zr: 0.8%, Co: 1.0%; the quick quenching speed of the described quick quenching strip is 28m / s;

[0035] 2) The low melting point rare earth ternary Pr 50 Al 25 Cu 25 The alloy is weighed and proportioned by atomic percentage, and then the mixed raw materials are vacuum smelted, and then the alloy thin strip is made into a rapid quenching strip; the rapid quenching speed of the rapid quenching strip is 20m / s;

[0036] 3) The Pr prepared in step 2) 50 Al 25 Cu 25 After the thin ribbon is milled by high-energy ball, a uniform low-melting point rare earth ternary Pr 50 Al 25 Cu 25 Nano powder;

[0037]4) The low melting point rare earth ternary Pr prepared in step 3) 50 Al 25 Cu 25 Na...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com