Simple preparation method of magnetic response super-hydrophobic surface

A super-hydrophobic surface, magnetic responsive technology, applied in coatings and other directions, can solve the problems of high preparation cost and low applicability, and achieve the effect of high applicability, easy purchase and cost reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

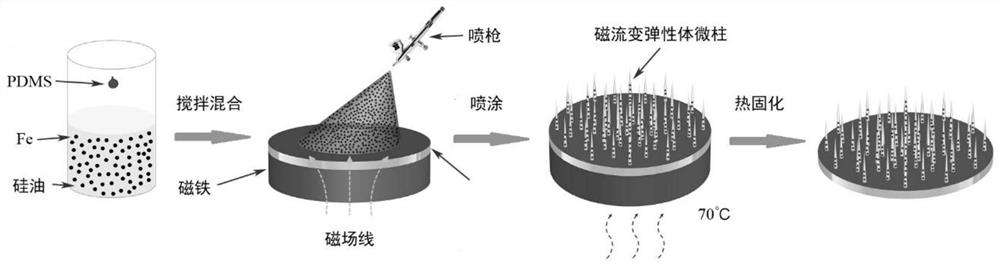

[0035] A simple method for preparing a magnetically responsive superhydrophobic surface, comprising the following steps:

[0036] Step 1. Use a balance to measure the PDMS prepolymer and curing agent respectively. The PDMS prepolymer uses Sylgard184 and select 5g, and the PDMS prepolymer and curing agent are mixed according to the mass ratio of 10:1, and then use a graduated cylinder to measure the organic solvent Silicone oil, wherein the silicone oil is Dow Corning OS-20 silicone oil and 10mL is selected, then poured into a beaker and mixed, and stirred evenly with a glass rod.

[0037] Step 2. Use a balance to measure 5g of Fe powder with a particle diameter of 1-10μm, pour it into a beaker, and continue to stir vigorously with a glass rod for more than 5 minutes until it becomes a uniform black mixed solution, so that the Fe particles are evenly distributed in the mixed solution .

[0038] Step 3. Place the glass substrate on the neodymium magnet, and use a spray gun to e...

Embodiment 2

[0041] A simple method for preparing a magnetically responsive superhydrophobic surface, comprising the following steps:

[0042] Step 1. Use a balance to measure the PDMS prepolymer and curing agent respectively. The PDMS prepolymer uses Sylgard184 and select 25g, and the PDMS prepolymer and curing agent are mixed according to the mass ratio of 10:1, and then use a graduated cylinder to measure the organic solvent Silicone oil, wherein the silicone oil adopts Dow Corning OS-20 silicone oil and selects 50mL, then pours it into a beaker and mixes it, and stirs it evenly with a glass rod.

[0043] Step 2. Use a balance to measure 25g of Fe powder with a particle diameter of 1-10μm, pour it into a beaker, and continue to stir vigorously with a glass rod for more than 5 minutes until it becomes a uniform black mixed solution, so that the Fe particles are evenly distributed in the mixed solution .

[0044]Step 3. Place the glass substrate on the neodymium magnet, and use a spray g...

Embodiment 3

[0047] A simple method for preparing a magnetically responsive superhydrophobic surface, comprising the following steps:

[0048] Step 1. Use a balance to measure the PDMS prepolymer and curing agent respectively. The PDMS prepolymer uses Sylgard184 and select 10g, and the PDMS prepolymer and curing agent are mixed according to the mass ratio of 10:1, and then use a graduated cylinder to measure the organic solvent Silicone oil, wherein the silicone oil adopts Dow Corning OS-20 silicone oil and selects 30mL, then pours it into a beaker and mixes it, and stirs it evenly with a glass rod.

[0049] Step 2. Use a balance to measure 15g of Fe powder with a particle diameter of 1-10μm, pour it into a beaker, and continue stirring vigorously with a glass rod for more than 5 minutes until it becomes a uniform black mixed solution, so that the Fe particles are evenly distributed in the mixed solution .

[0050] Step 3. Place the glass substrate on the neodymium magnet, and use a spray...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com