Three-dimensional vibration isolation device combining inerter and rubber support

A rubber bearing, inertial capacity technology, applied in vibration suppression adjustment, non-rotational vibration suppression, building components, etc., can solve problems affecting workers' health and production efficiency, single vibration isolation frequency, workshop vibration, etc., and achieve reasonable energy. Recycling structure, good vibration isolation effect, good energy dissipation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

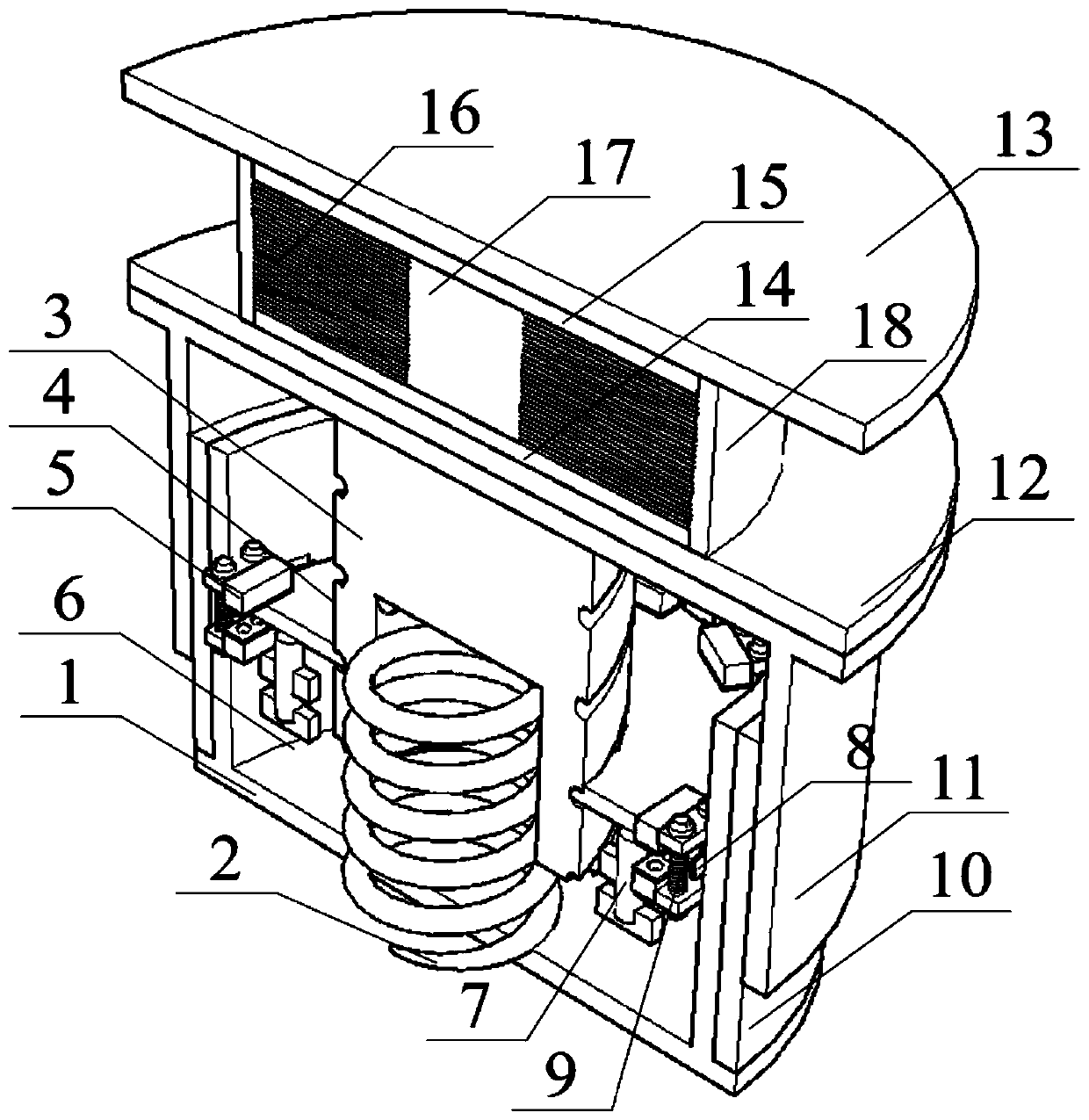

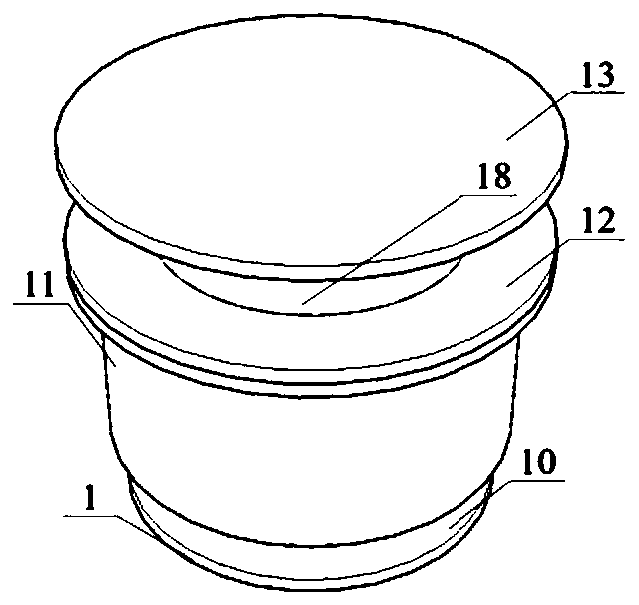

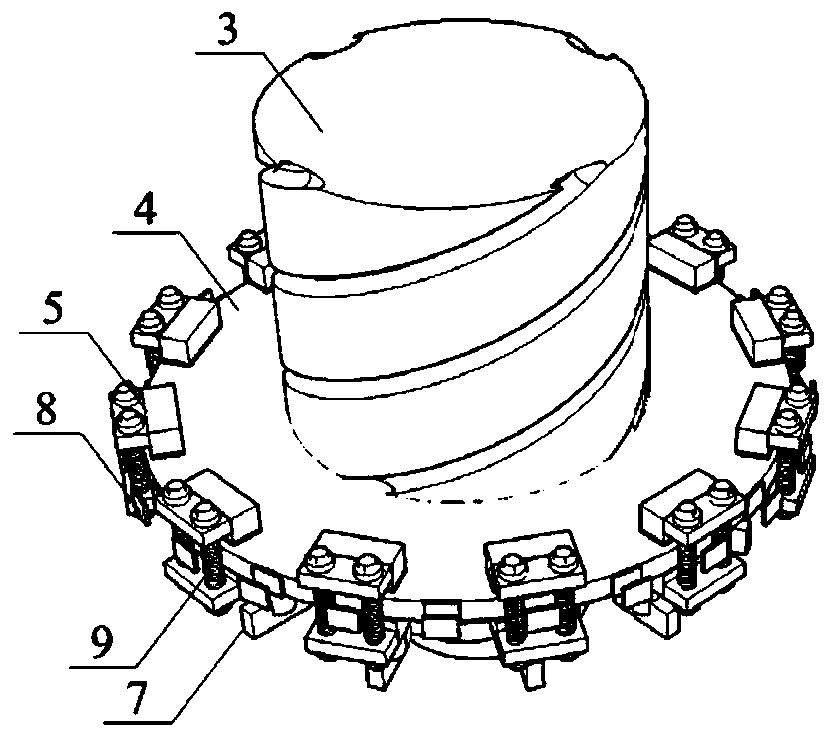

[0049] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings.

[0050] like Figure 1 to Figure 15 Shown:

[0051]A three-dimensional vibration isolation device combined inertial and rubber bearings, including decoupling system, horizontal vibration isolation system and vertical Vibration isolation system , The horizontal vibration isolation system is realized by rubber bearings, and the vertical vibration isolation system is designed and realized by the principle of inertial system. The vertical centerline of the inertial system part and the rubber bearing part is consistent; the rubber bearing is connected with the upper structure; the inertial system is arranged under the rubber bearing and connected with the foundation. When the external three-dimensional vibration excitation is introduced into the device, the three-dimensional vibration is firstly decoupled through the decoupling system, the hori...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com