Patents

Literature

231results about "Rotary retorts" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Waste conversion process

InactiveUS20060280669A1Good yieldMinimization requirementsBiofuelsIndirect and direct heating destructive distillationEnvironmental engineeringSand granules

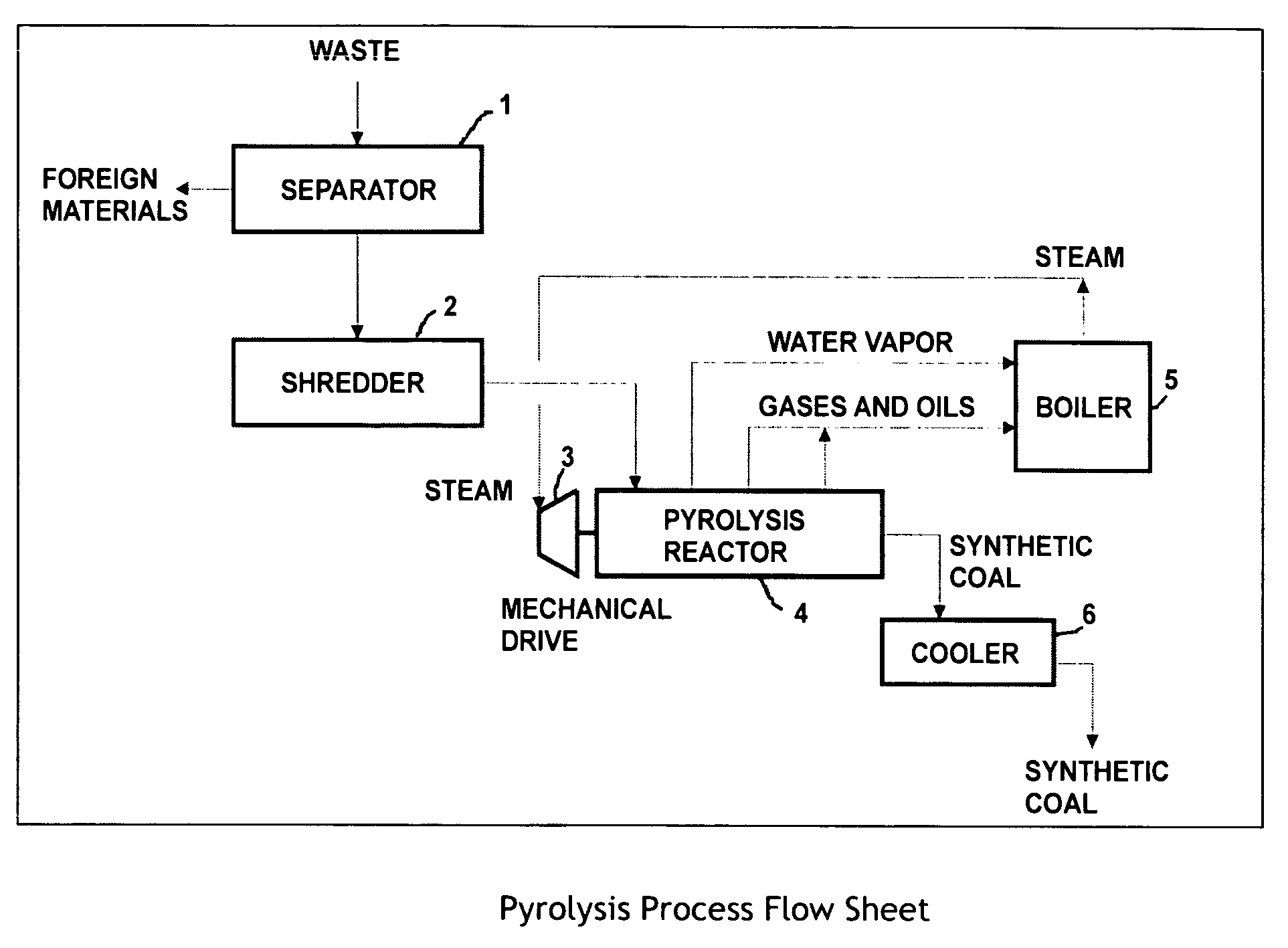

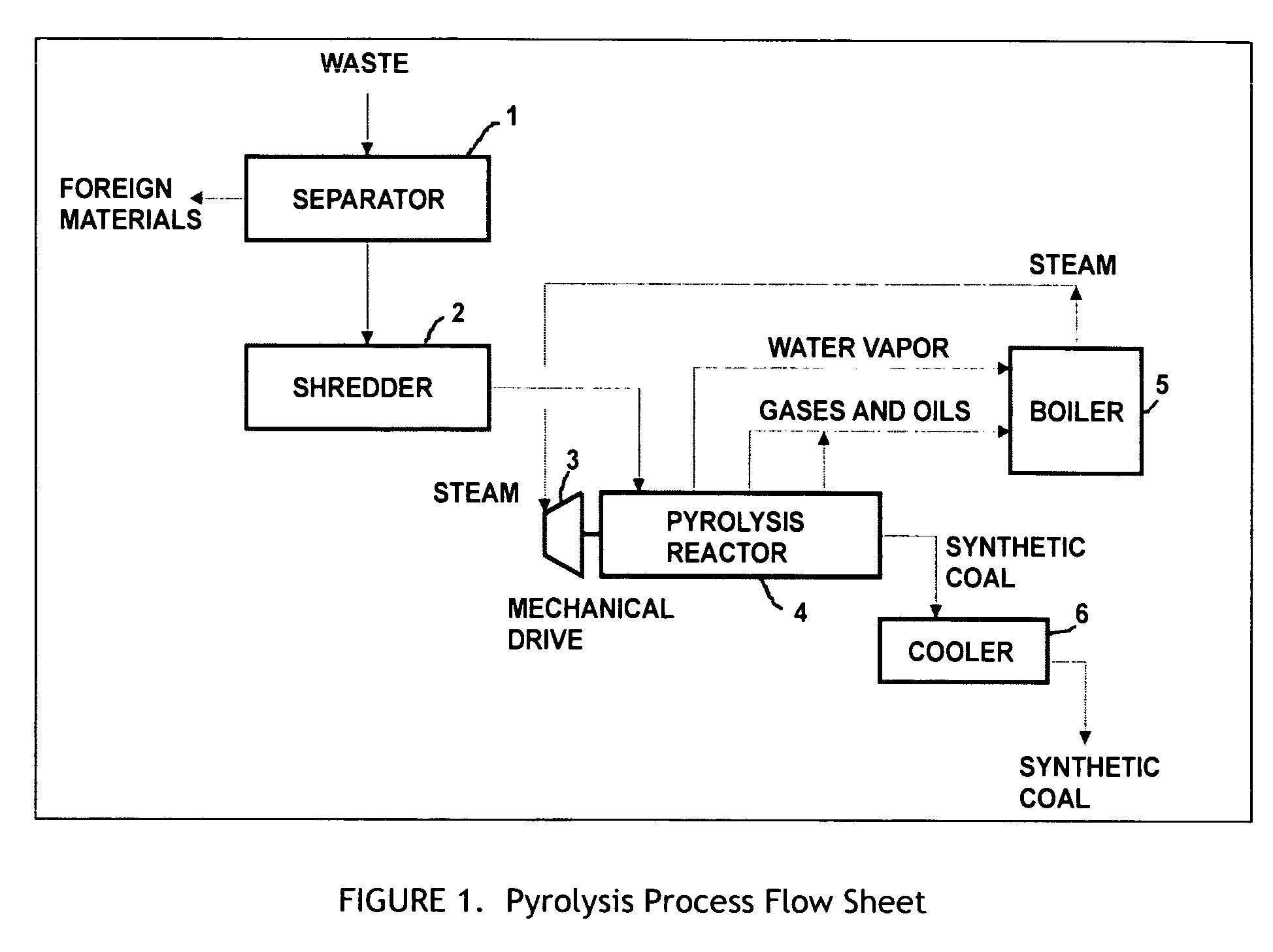

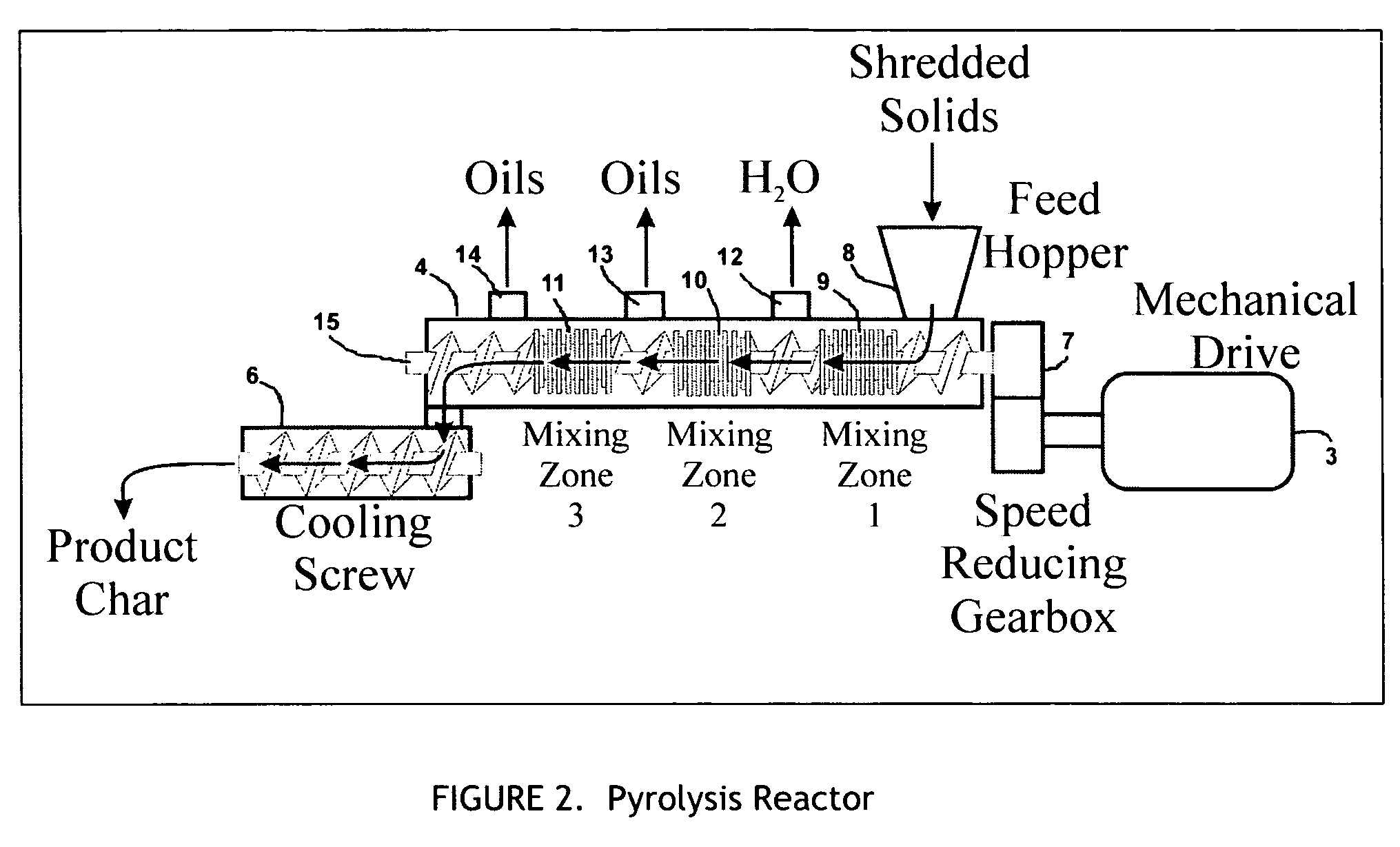

A process for the preparation of high quality char from organic waste materials. The waste is first sorted to remove recyclable inorganic materials of economic value (metals, glass) and other foreign materials that would be detrimental to the quality of the final product (stone, sand, construction debris, etc.). After size reduction, the waste is pyrolyzed at a temperature range of 250 to 600° F., in a high capacity, continuous mixer reactor, using in-situ viscous heating of the waste materials, to produce a highly uniform, granular synthetic product similar in energy content and handling characteristics to, but much cleaner burning than, natural coal.

Owner:ENTROPIC TECH CORP

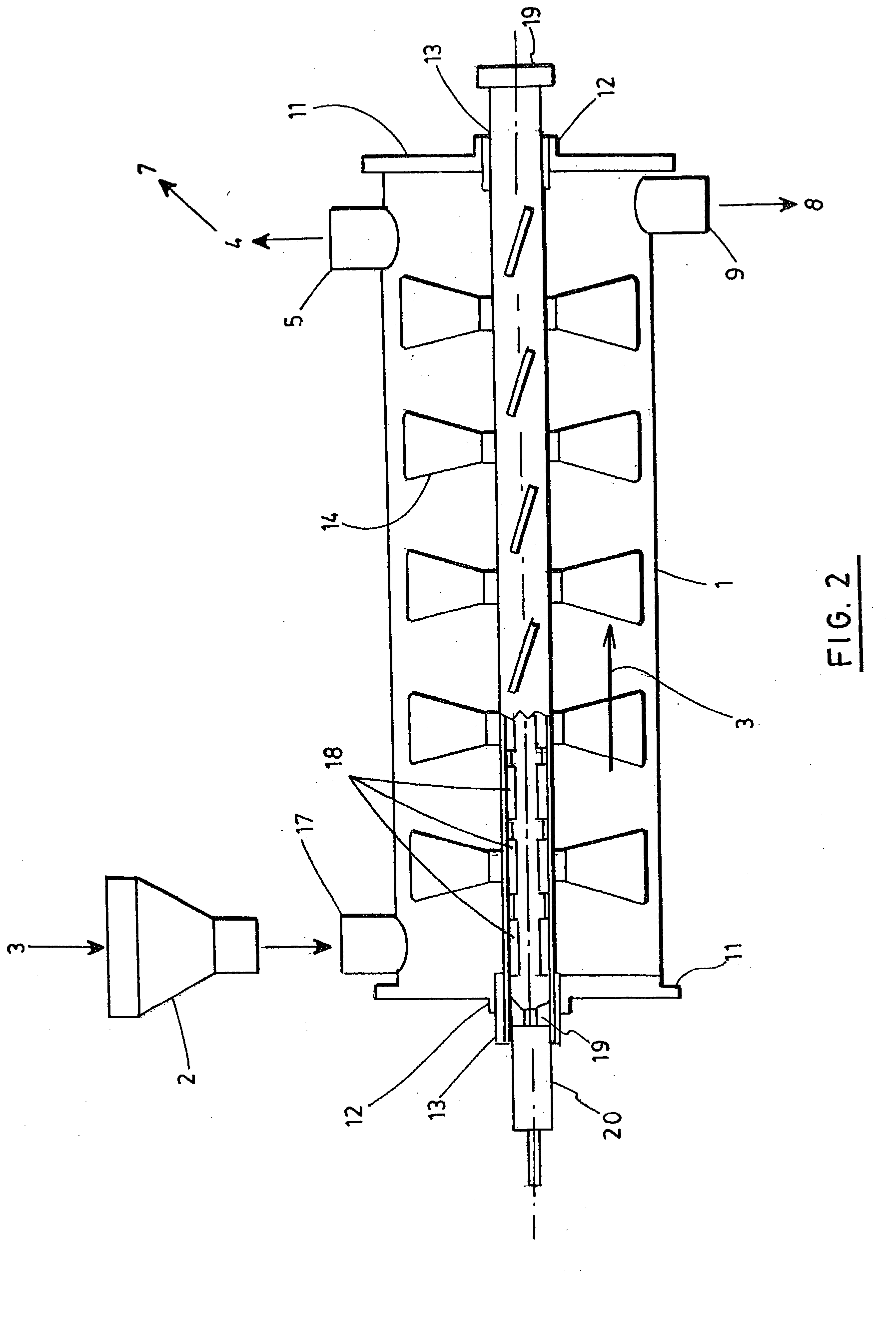

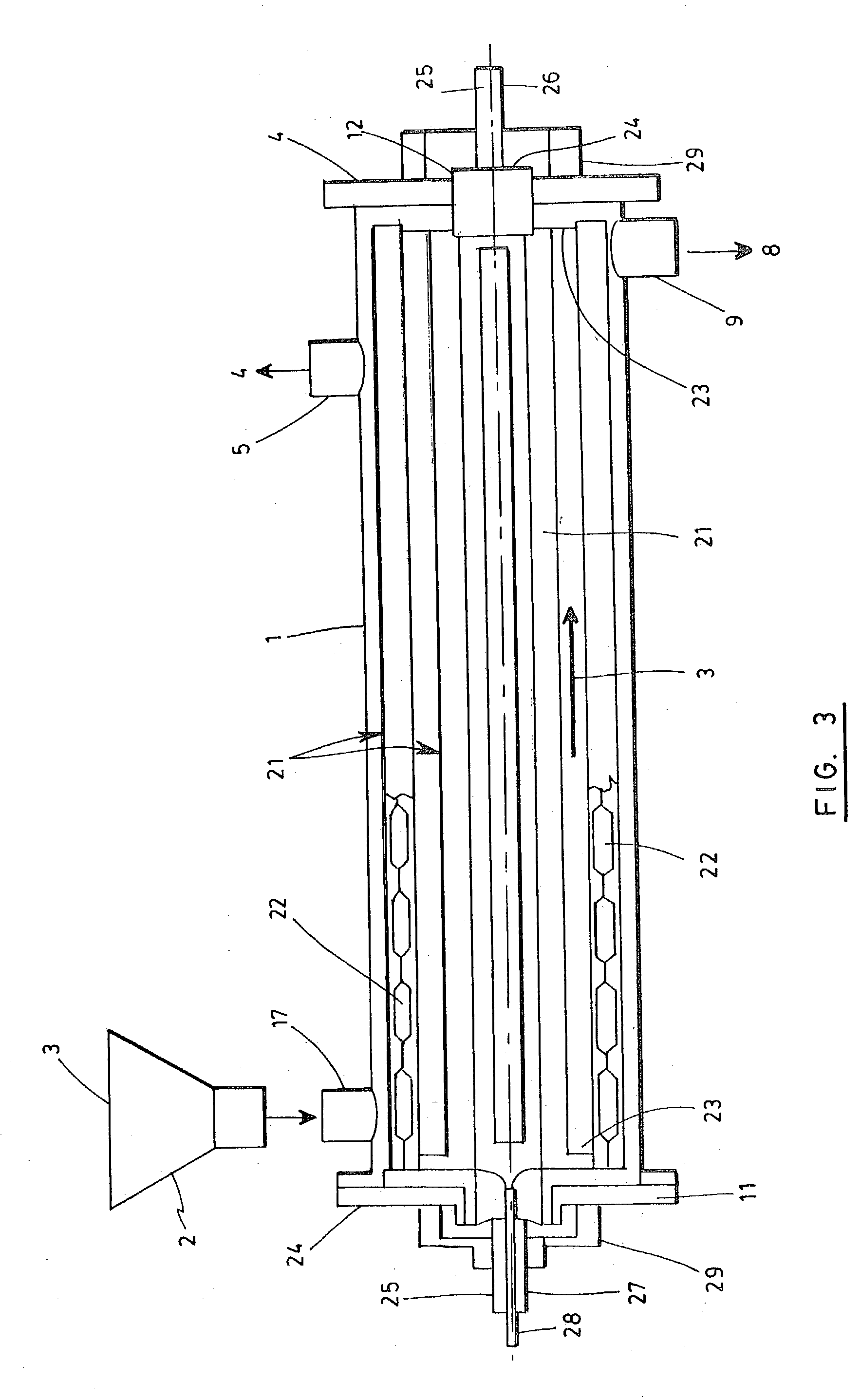

Pyrolysis system

InactiveUS20030138365A1Minimize introduction of airSecure safe and good operationMechanical conveying coke ovensRotating receptacle mixersProduct gasOxygen

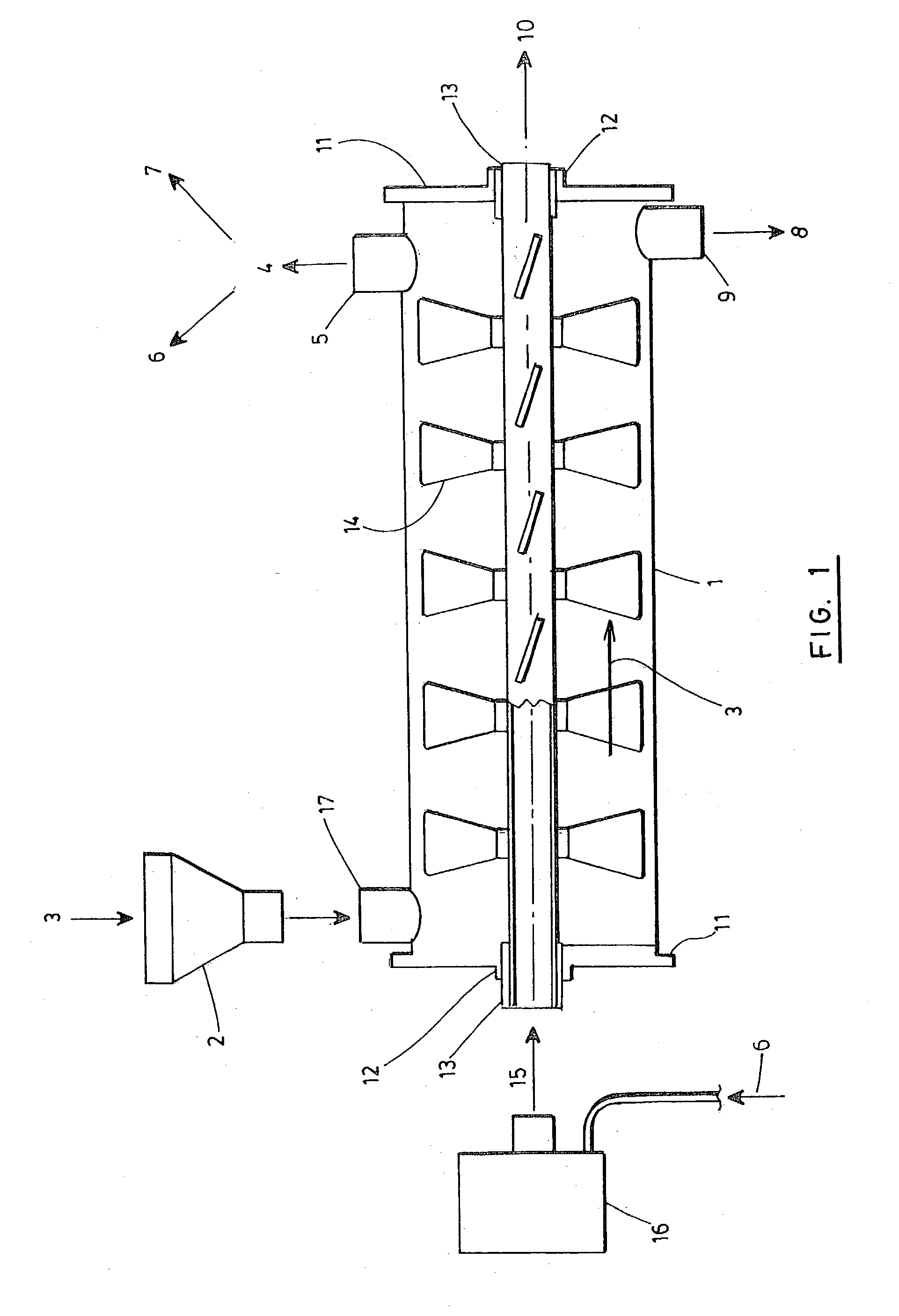

A pyrolysis system includes a generally cylindrical reactor chamber having two opposite ends and a longitudinal axis. The chamber has an inlet for receiving biomass, the inlet being adapted to prevent air from entering the chamber and being located at a first opposite end; a gas outlet for recuperating biogas produced in the reactor chamber, the gas outlet being adapted to prevent air from entering the chamber and being located at a second opposite end; and a solid outlet for recuperating charcoal produced in the reactor chamber, the solid outlet being adapted to prevent air from entering the chamber and being located at the second opposite end. The biomass is then subjected to indirect heating supplied by a heated rotor that decomposes the biomass in the absence of air or oxygen into a biogas and charcoal. A controller for controlling a rate of feed of biomass, extracted carbon residue and a temperature inside the reactor chamber is also provided. In a preferred embodiment, the shaft is heated by a portion of the energy recuperated from the pyrolysis system.

Owner:STRUDES

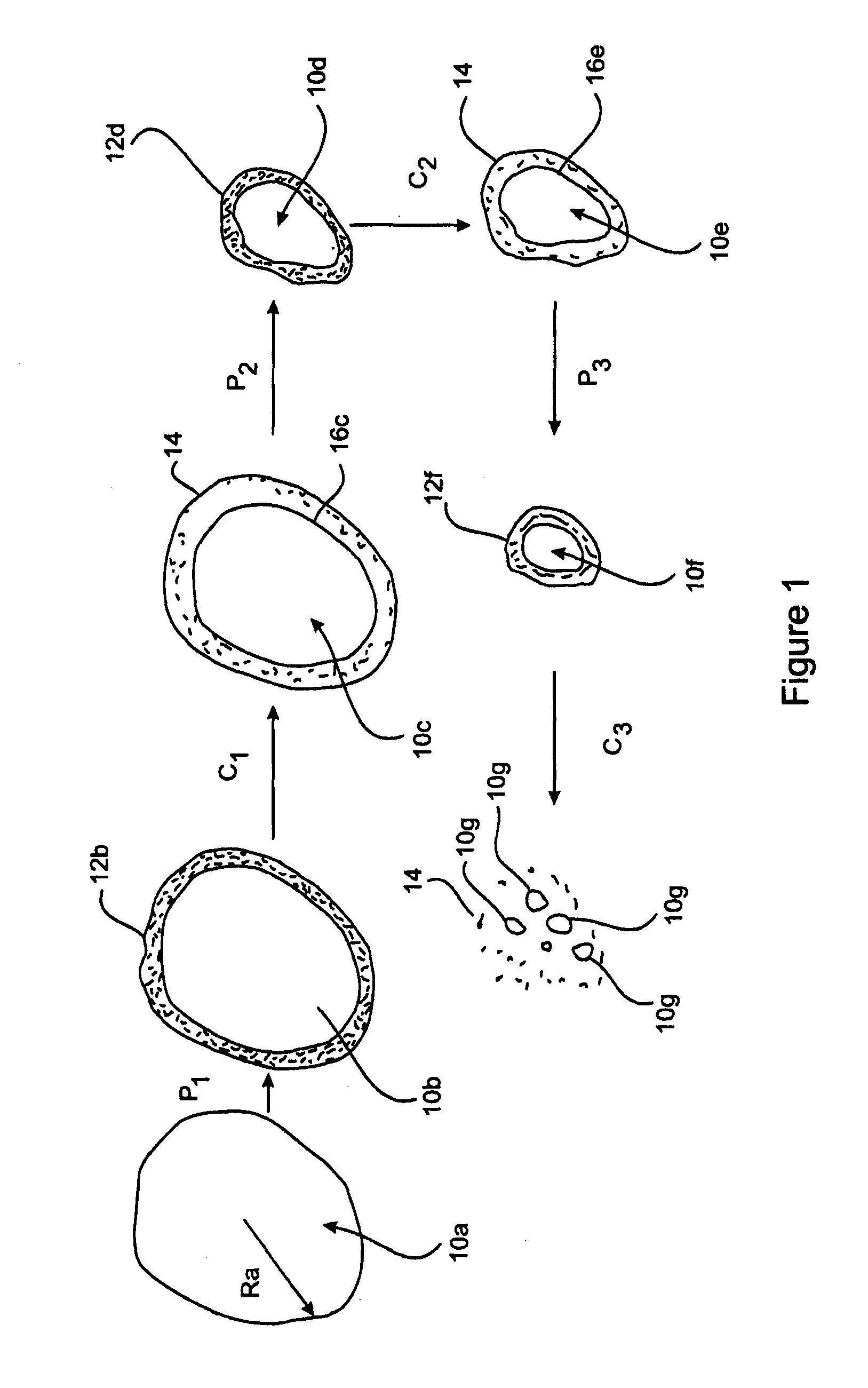

System And Method For Recycling Of Carbon-Containing Materials

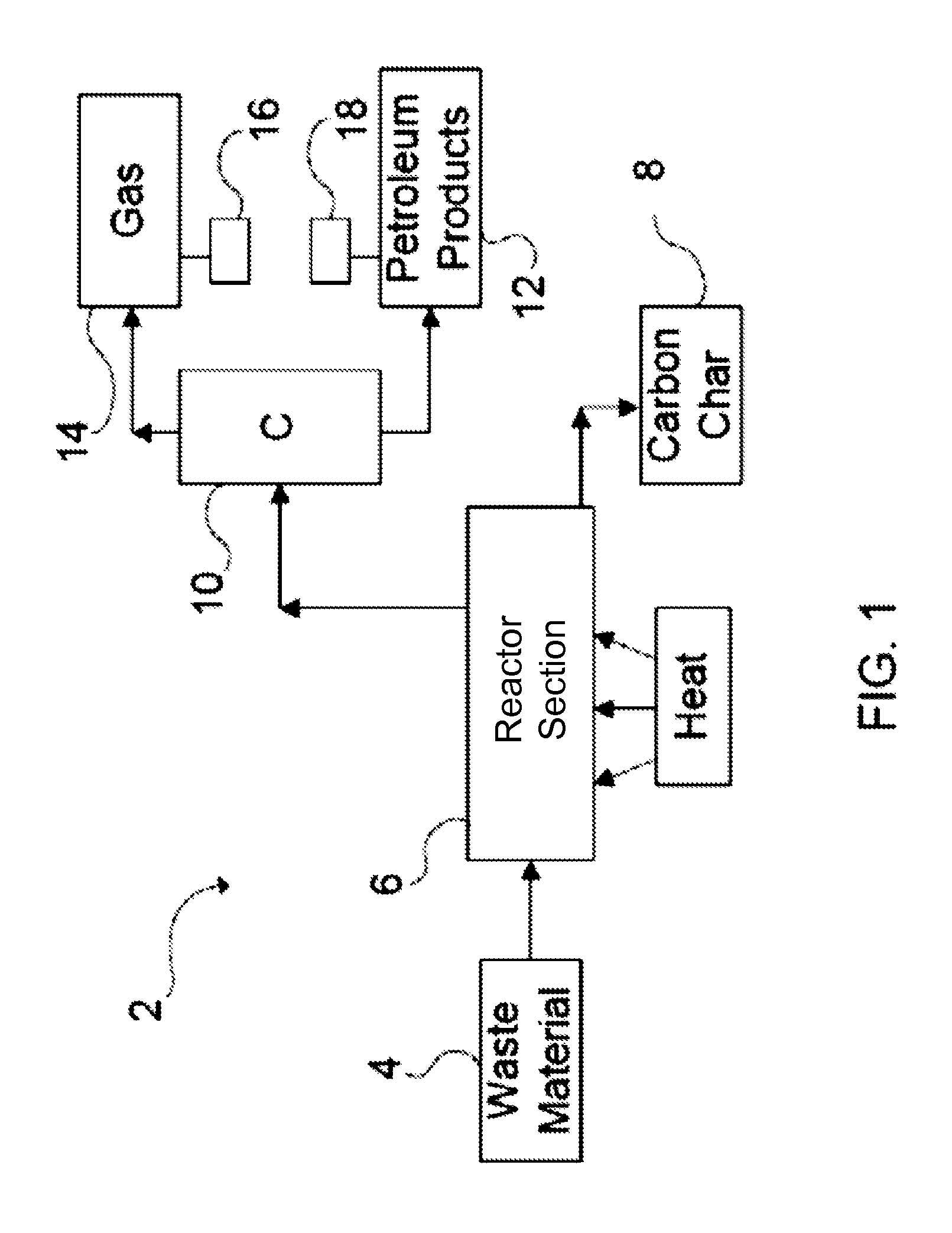

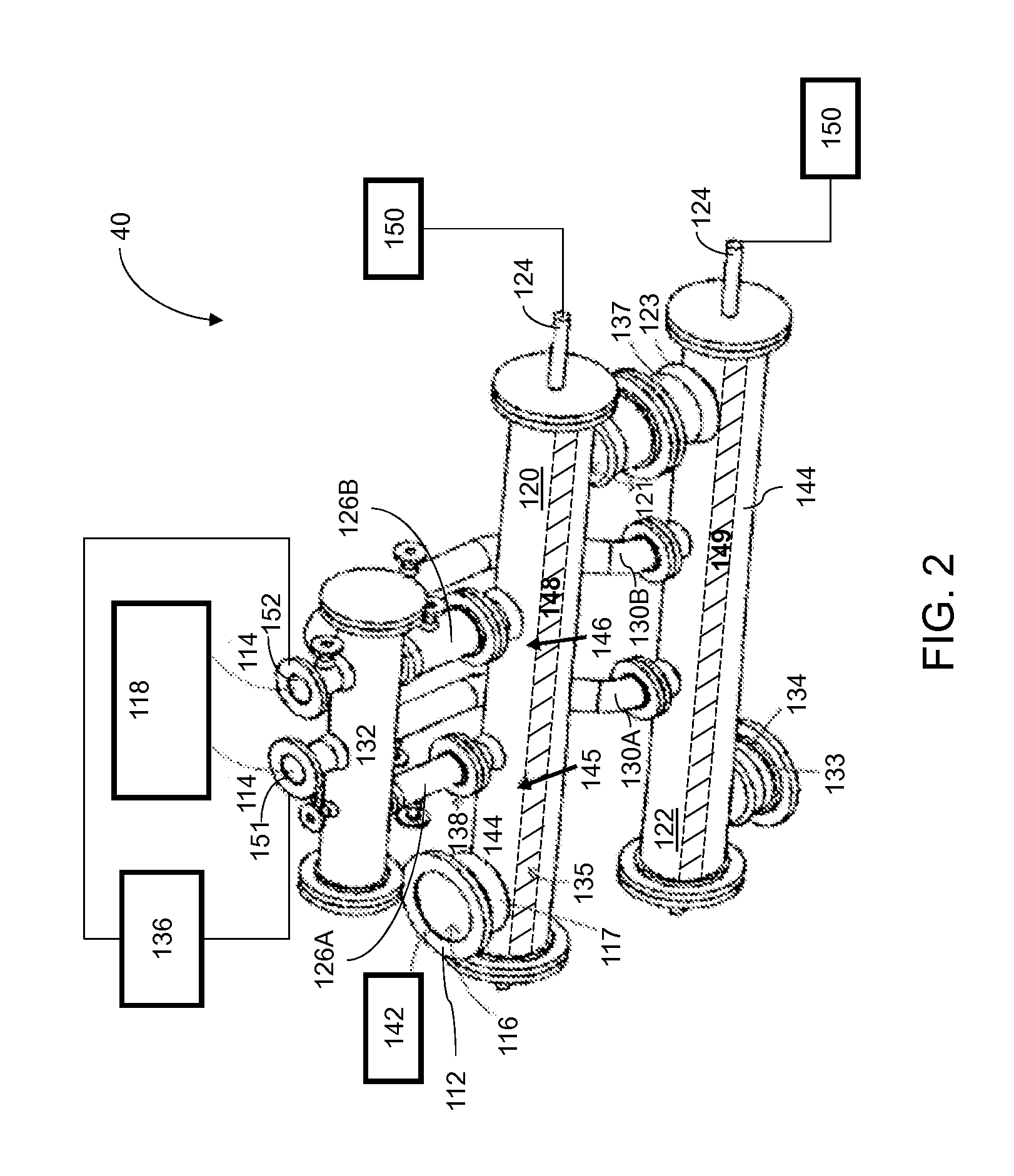

ActiveUS20100133085A1Increase ratingsMaintain internal temperatureCombustible gas coke oven heatingSolid waste disposalPlastic materialsProduct gas

There is described a system and method for recycling carbon-containing material, in particular tyres and plastics materials. The system includes a heating arrangement for anaerobically heating carbon containing material to produce carbon-containing gases. A condensing arrangement is also used to condense a proportion of the carbon-containing gases to provide condensed gases and non-condensed gases. In addition, a recirculating arrangement is provided for recirculating the non-condensed gases into the heating arrangement. Further systems and methods for pre- and post-processing of the carbon-containing material are also disclosed and products of the systems and methods are also described.

Owner:USED TIRE DISTILLATION RES

Staged biomass pyrolysis process and apparatus

InactiveUS20110278149A1Low heating rateReduce tar contentProductsBeehive ovensOxygenThermal treatment

Owner:ASTON UNIV

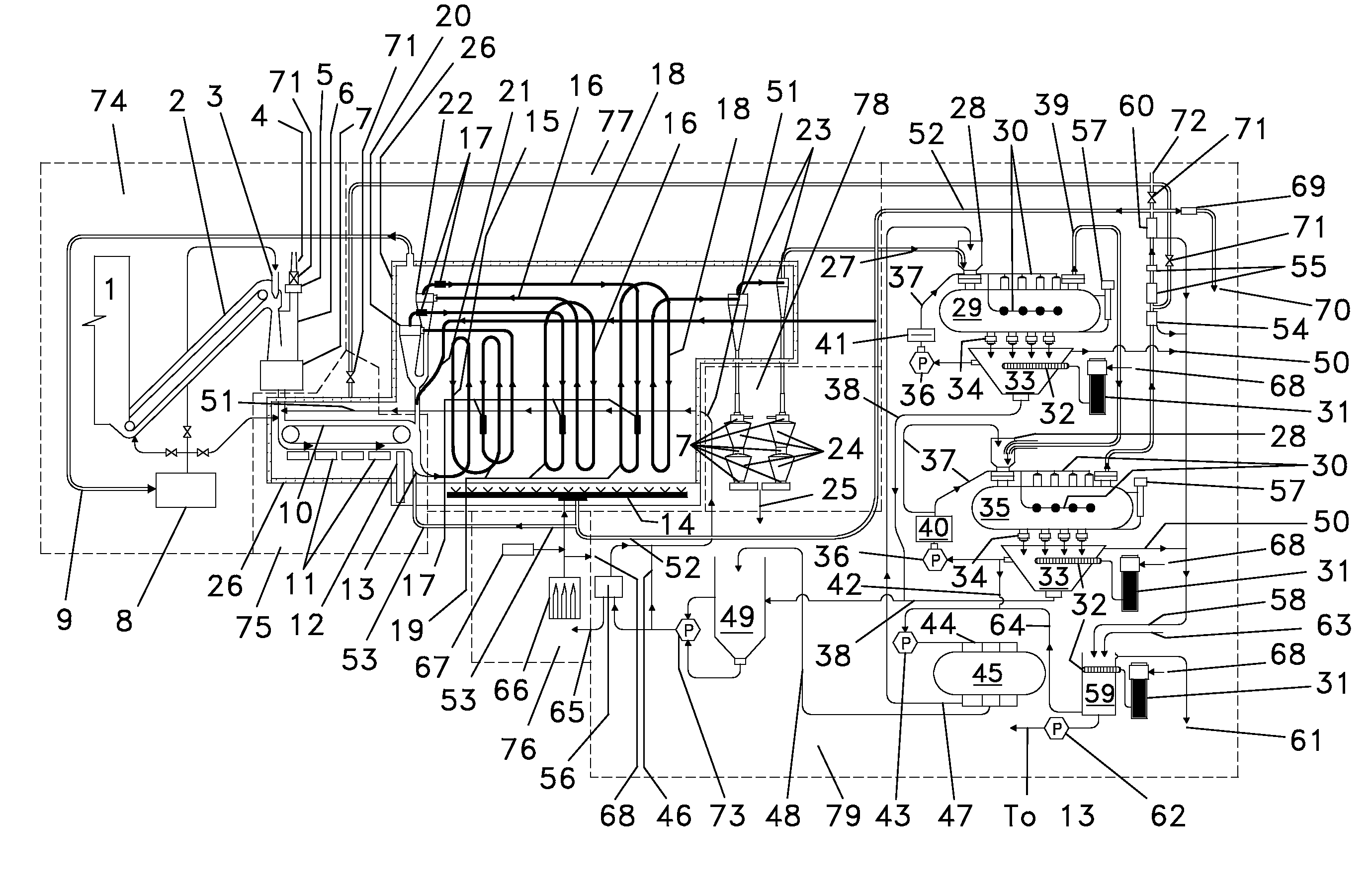

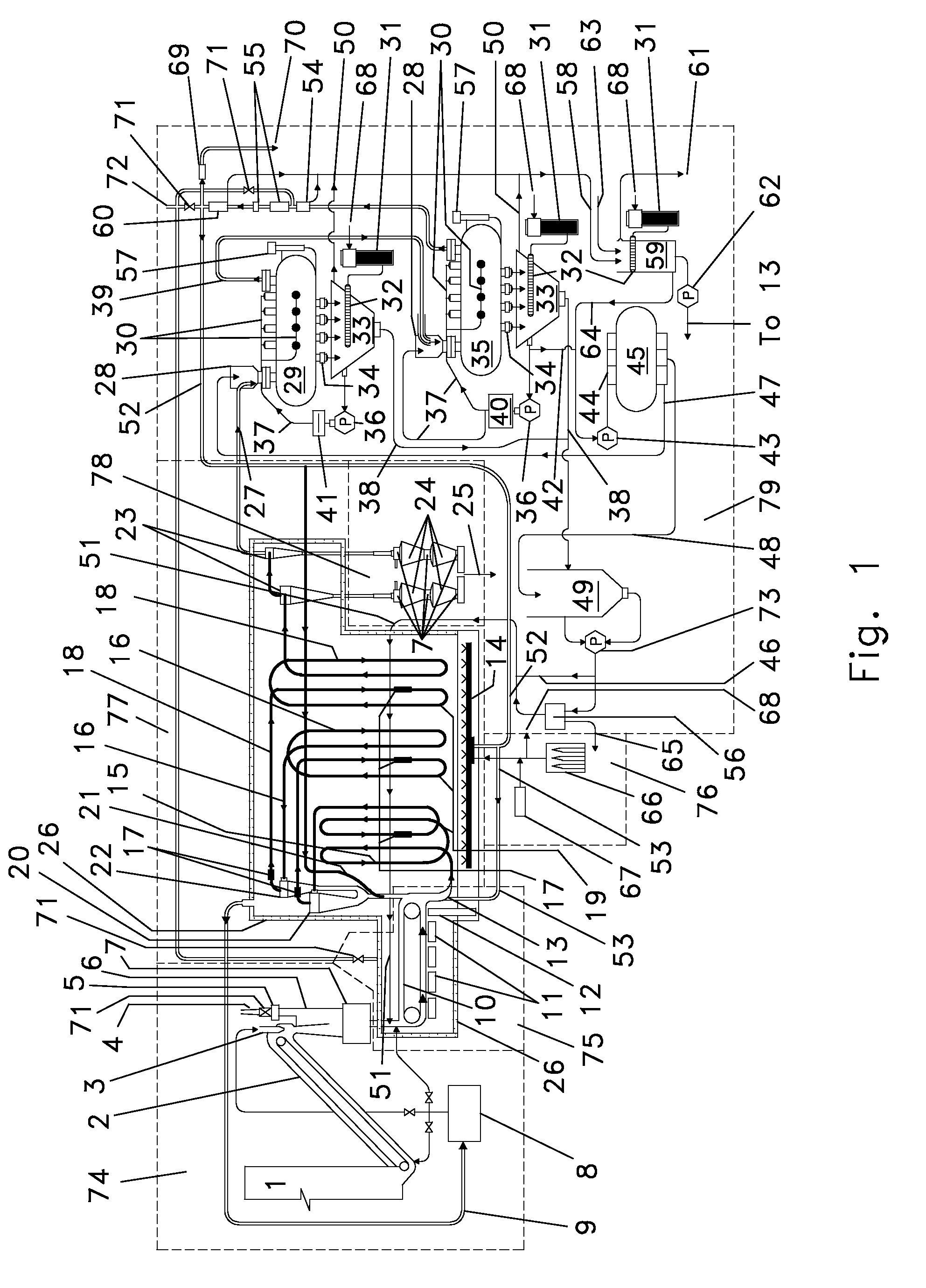

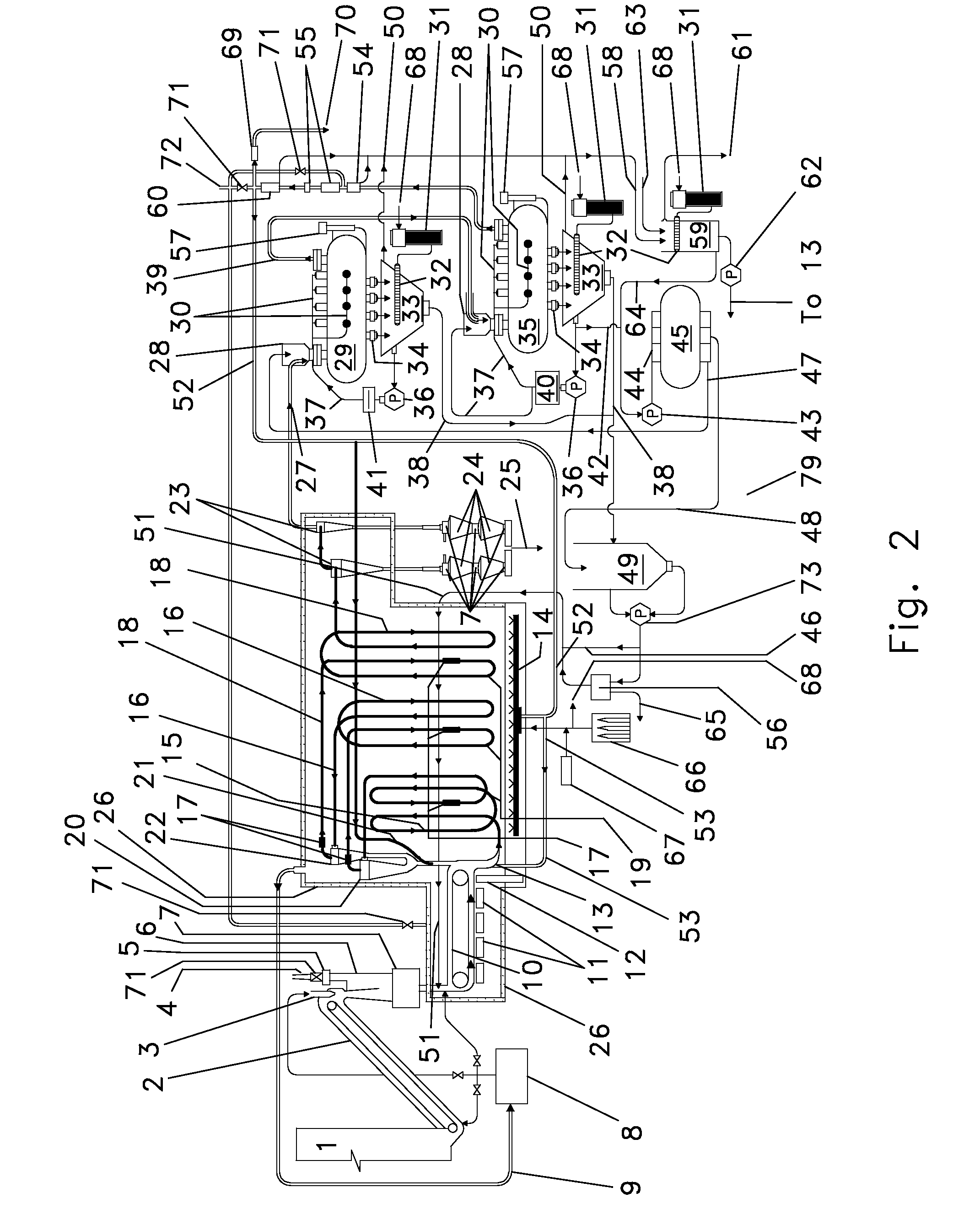

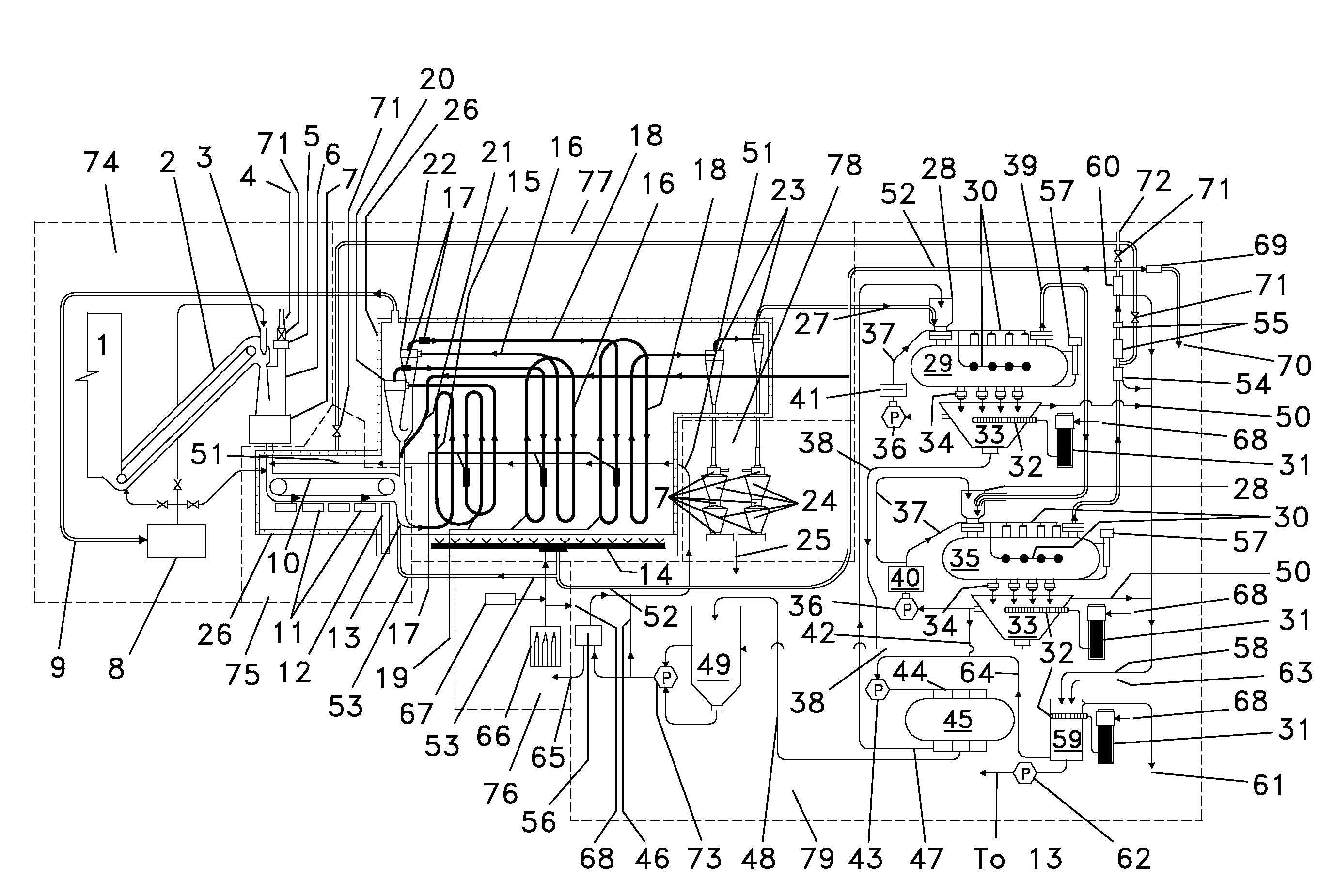

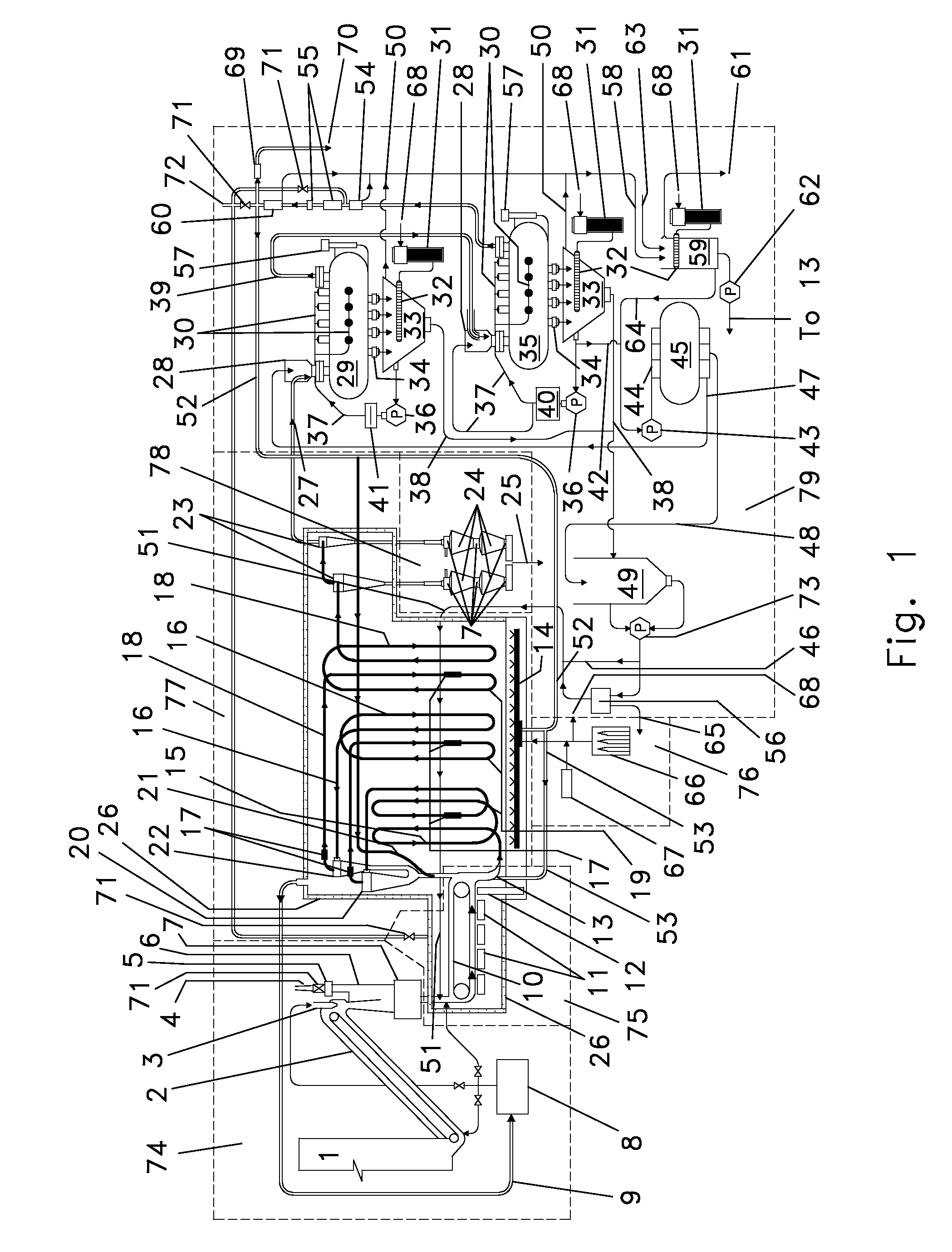

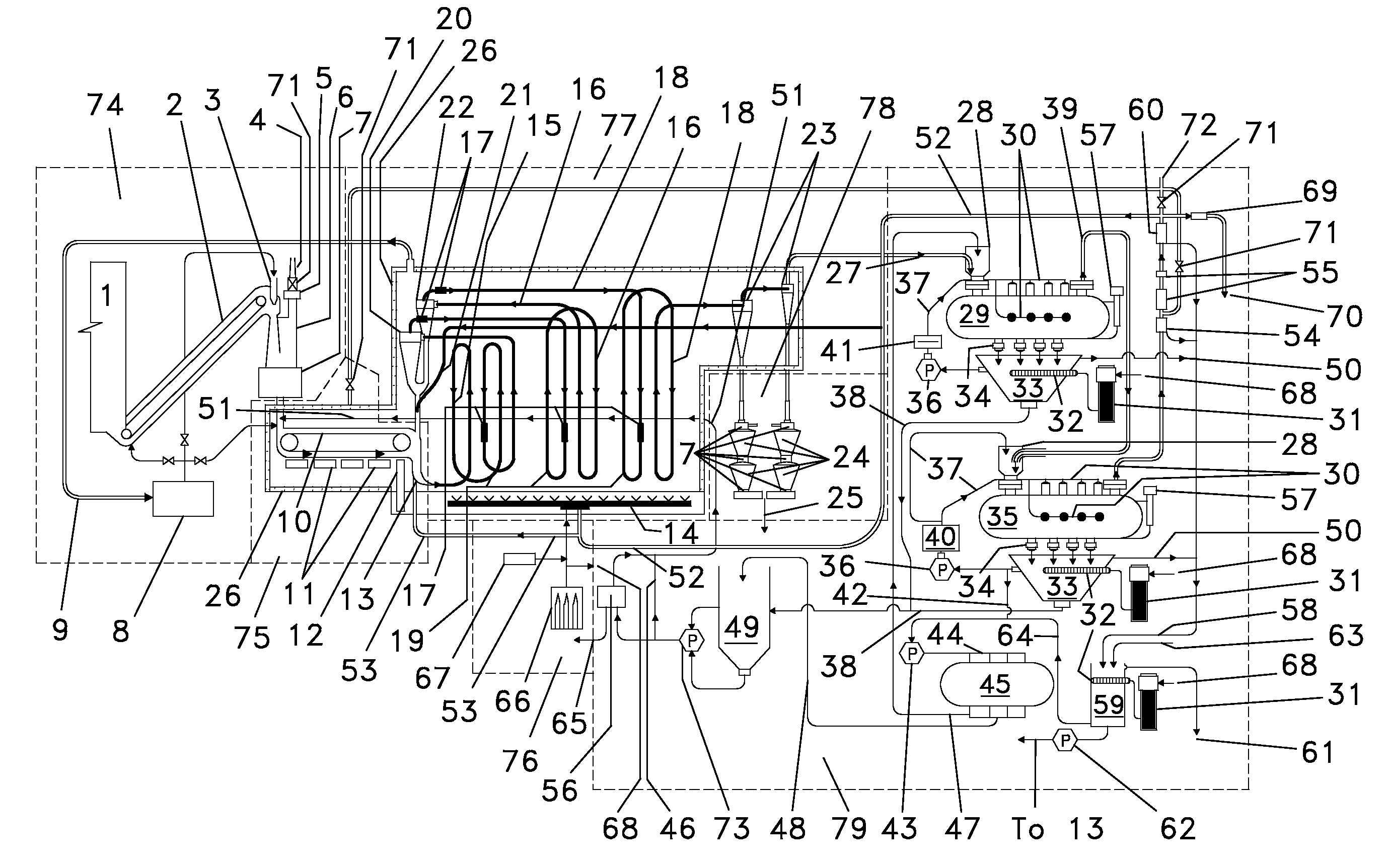

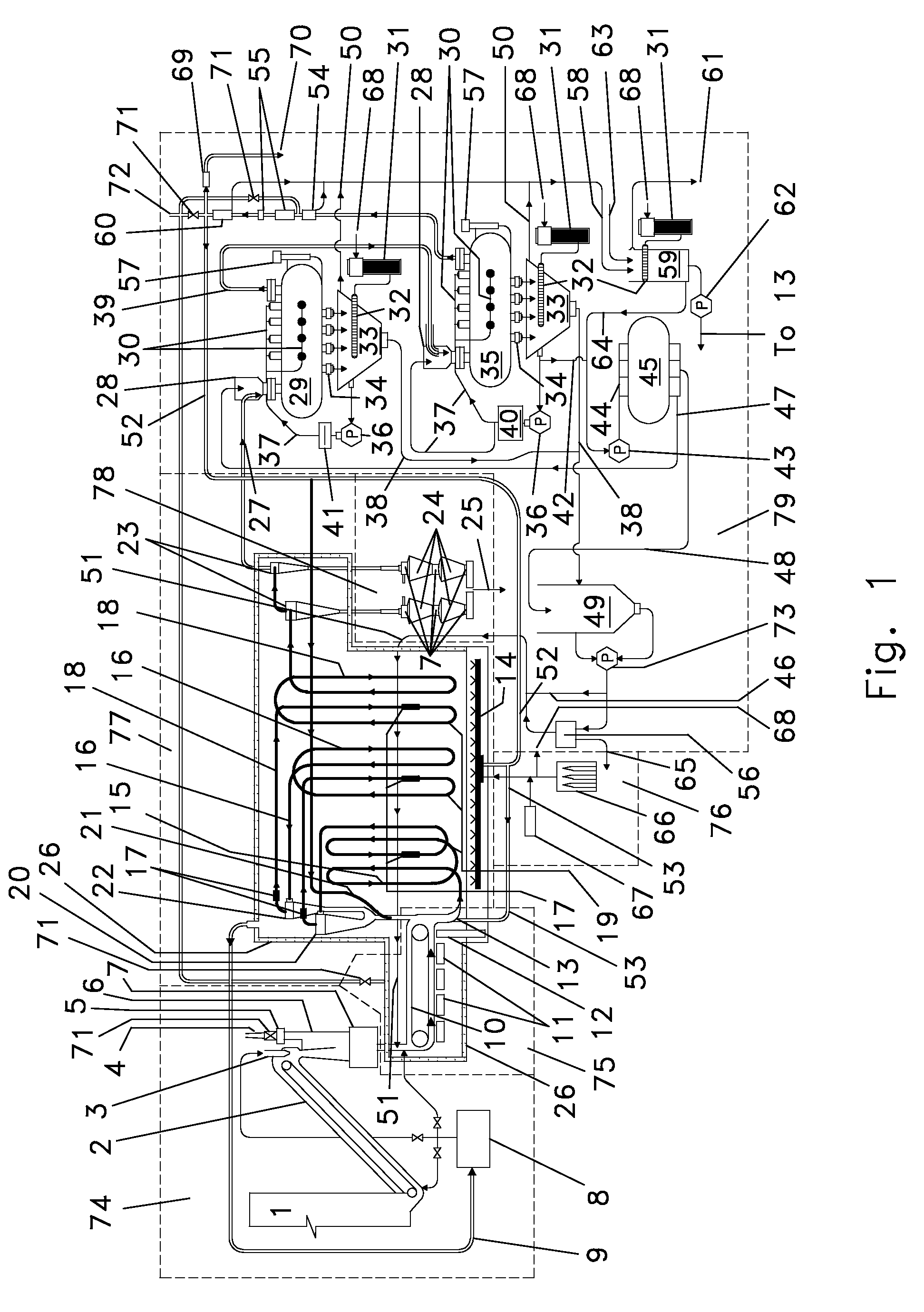

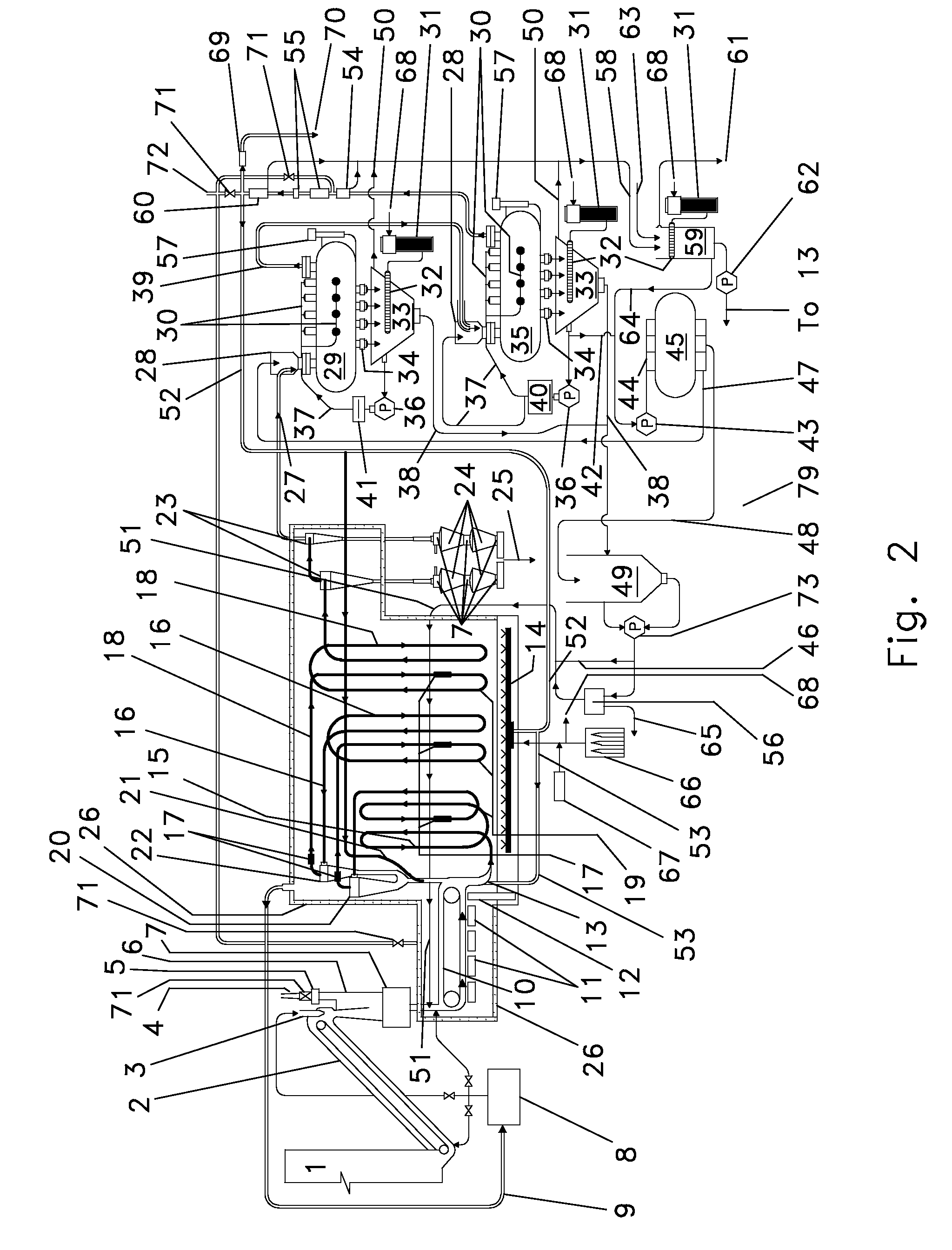

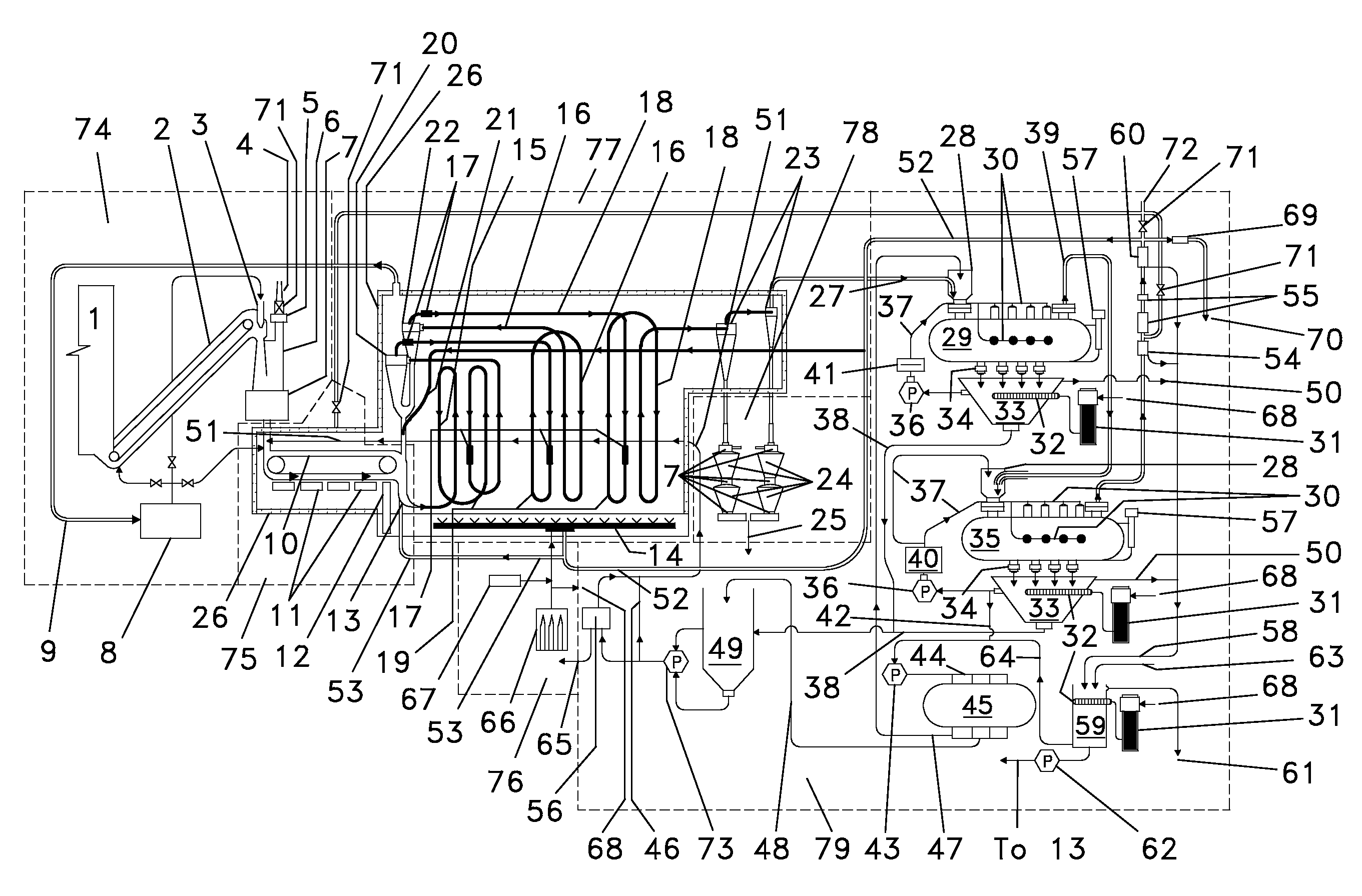

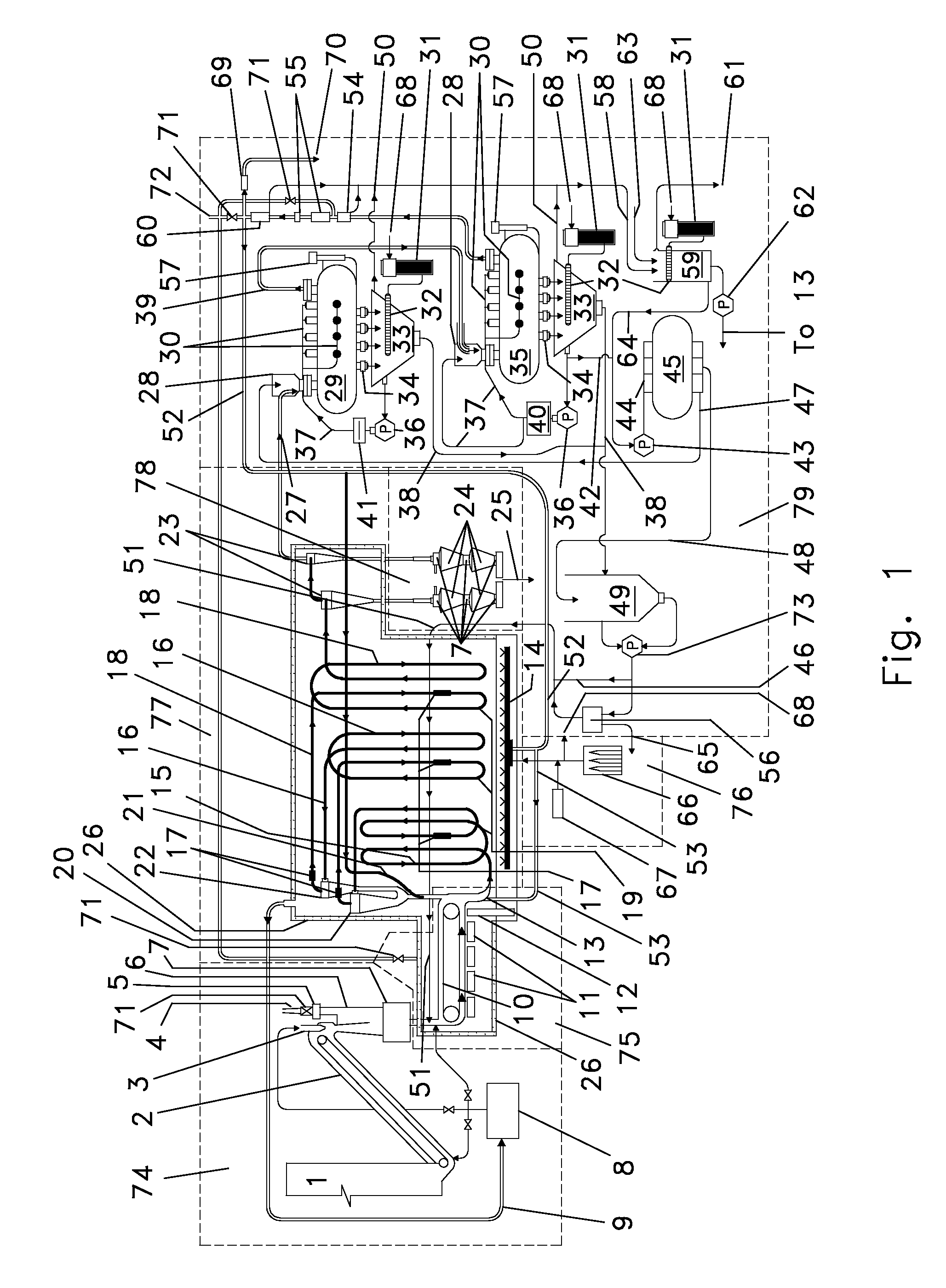

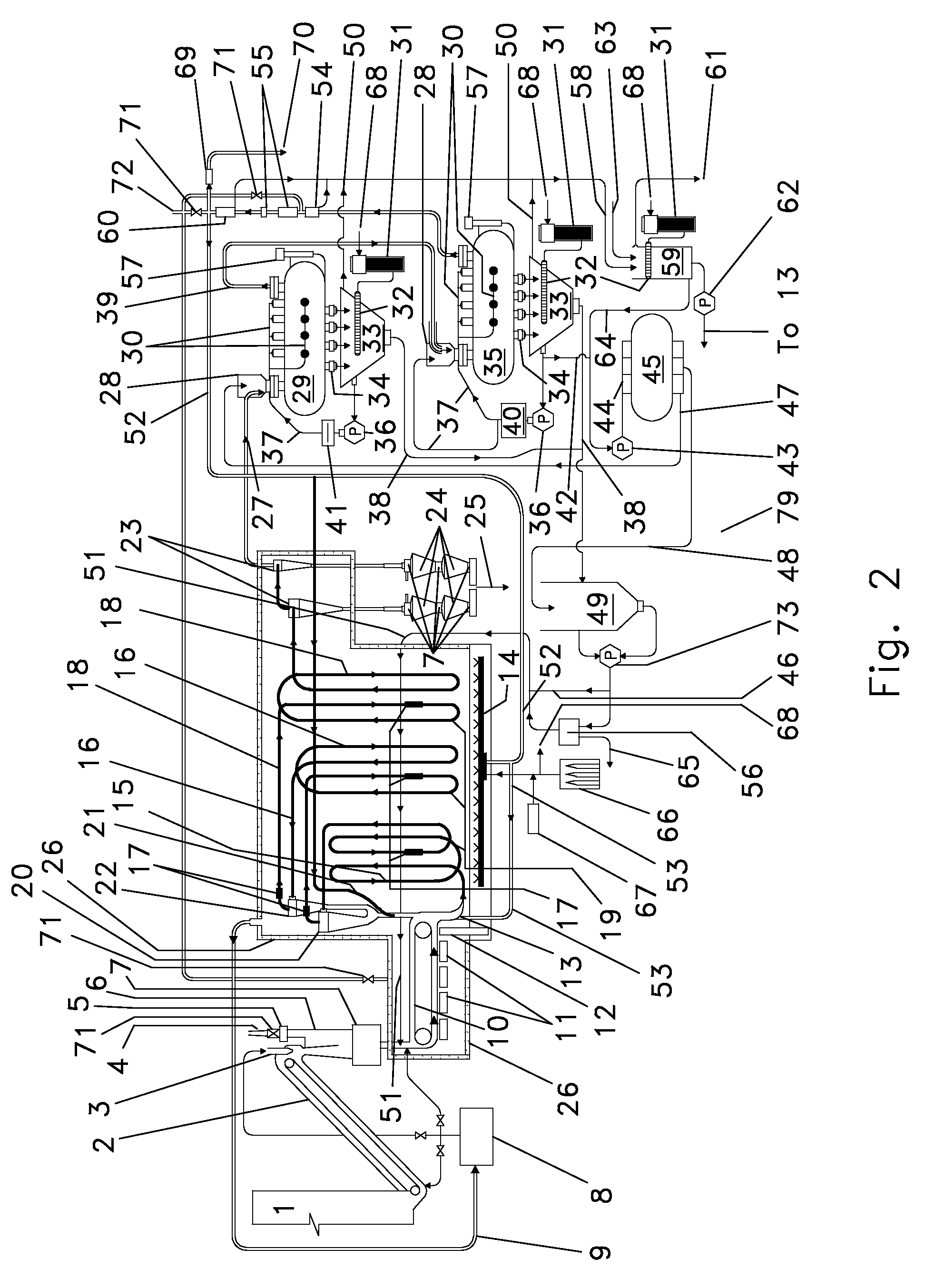

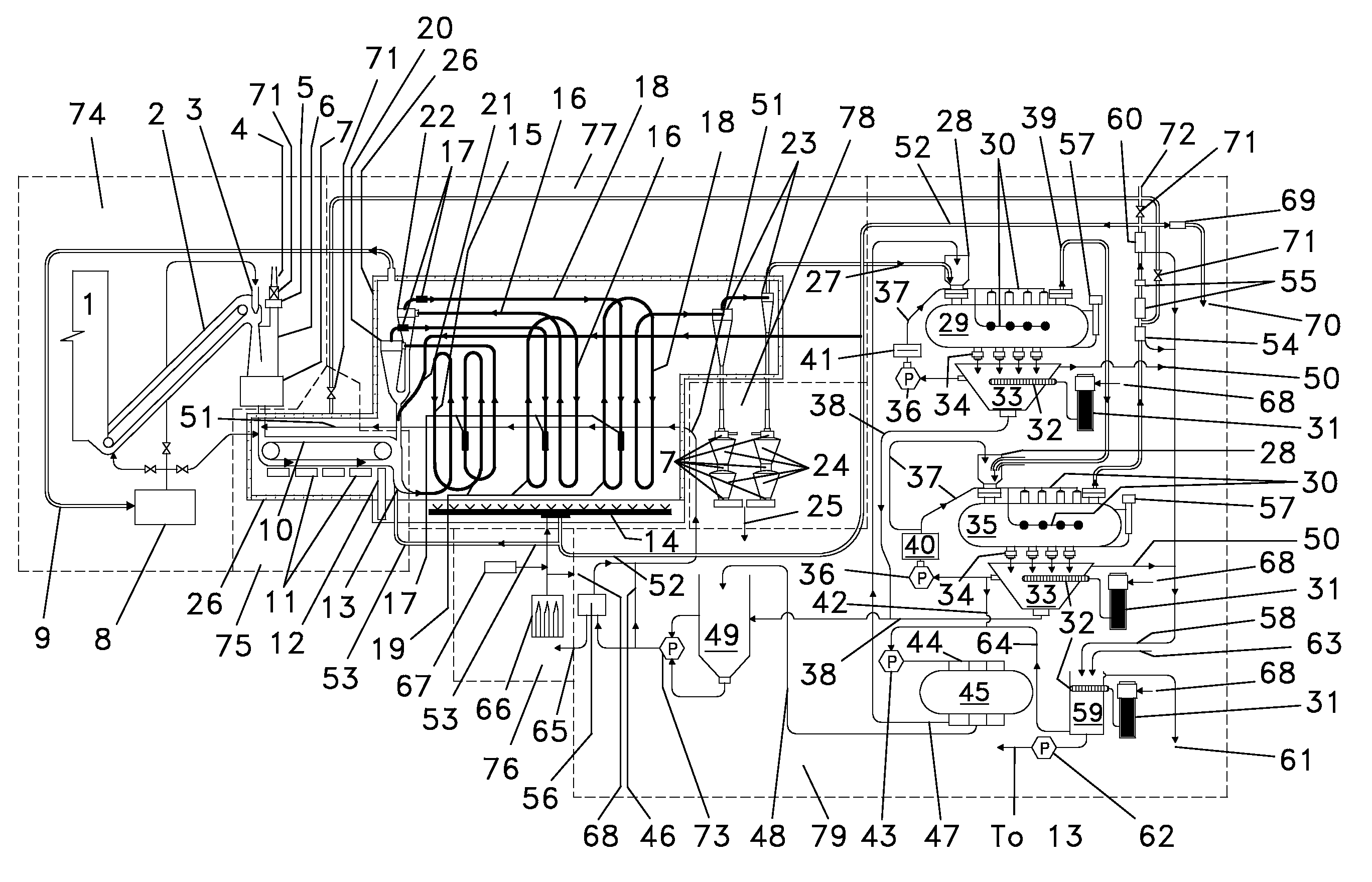

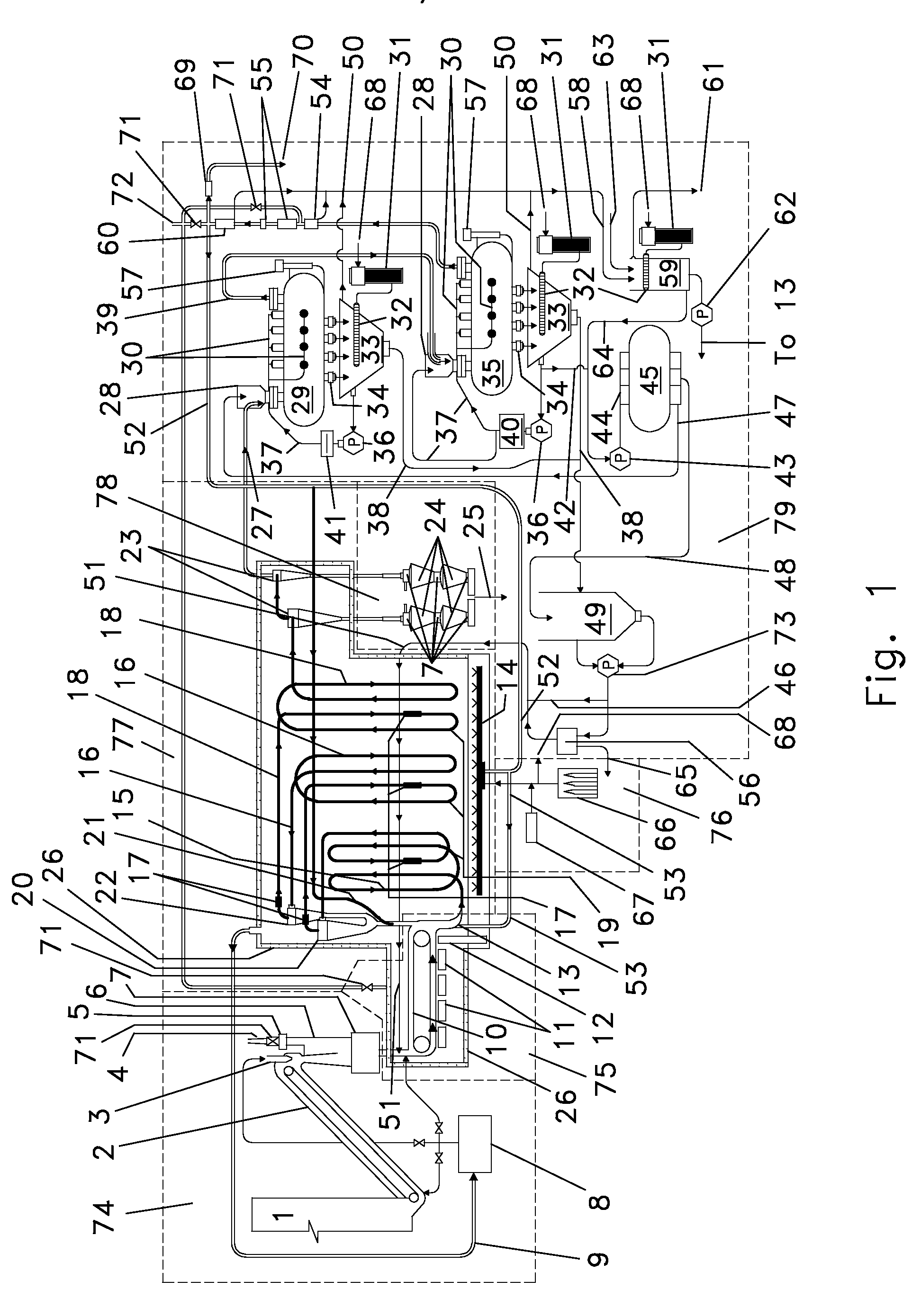

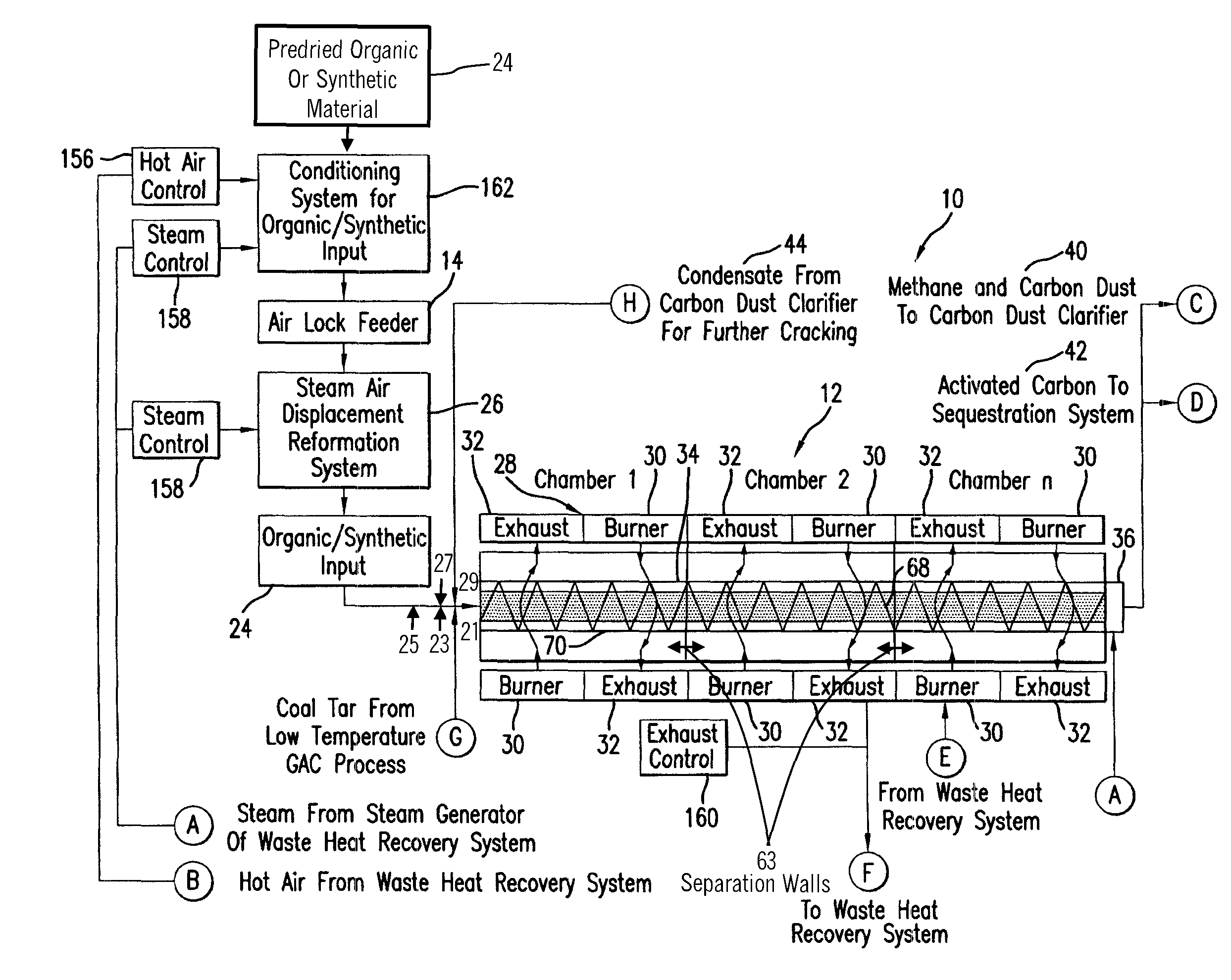

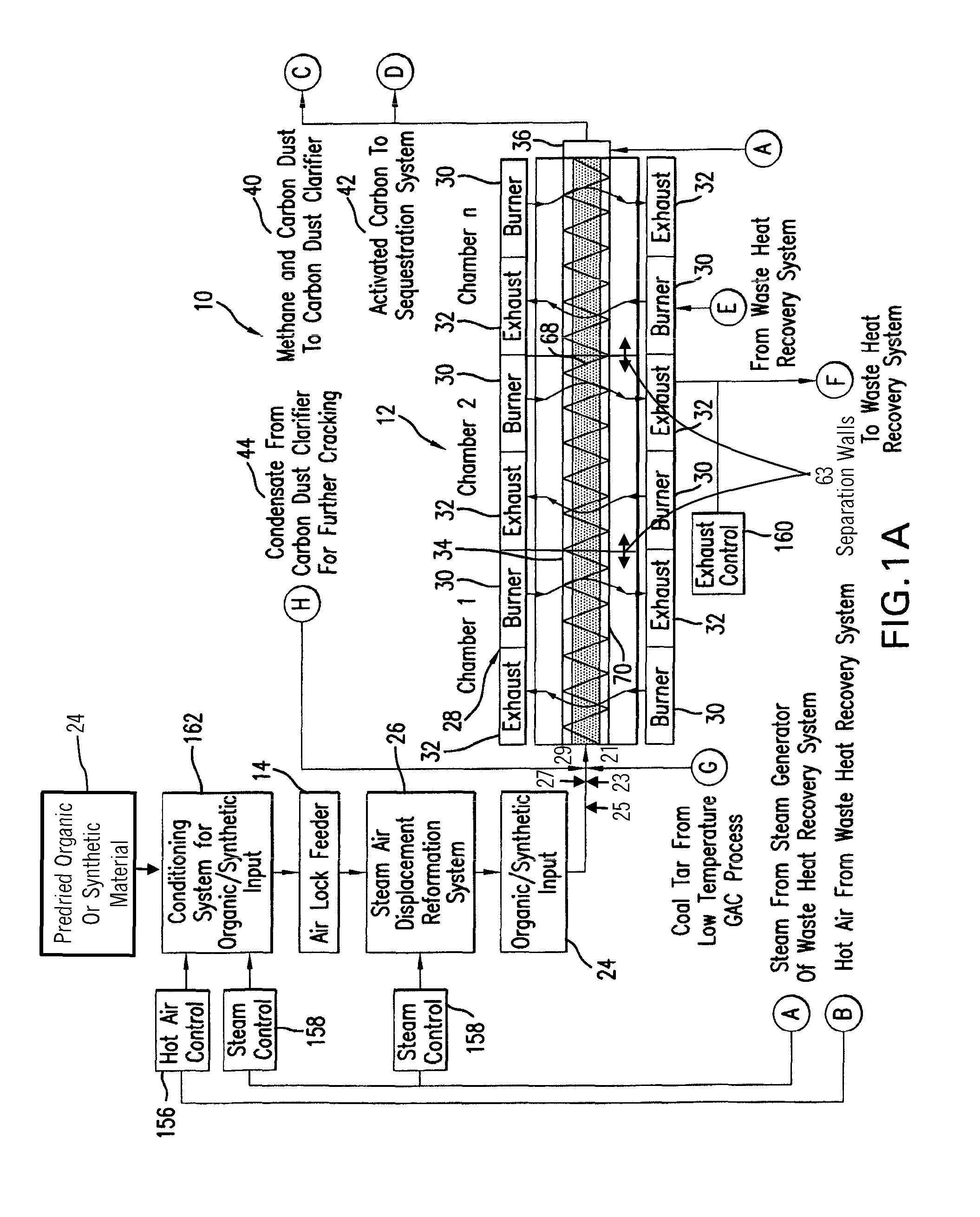

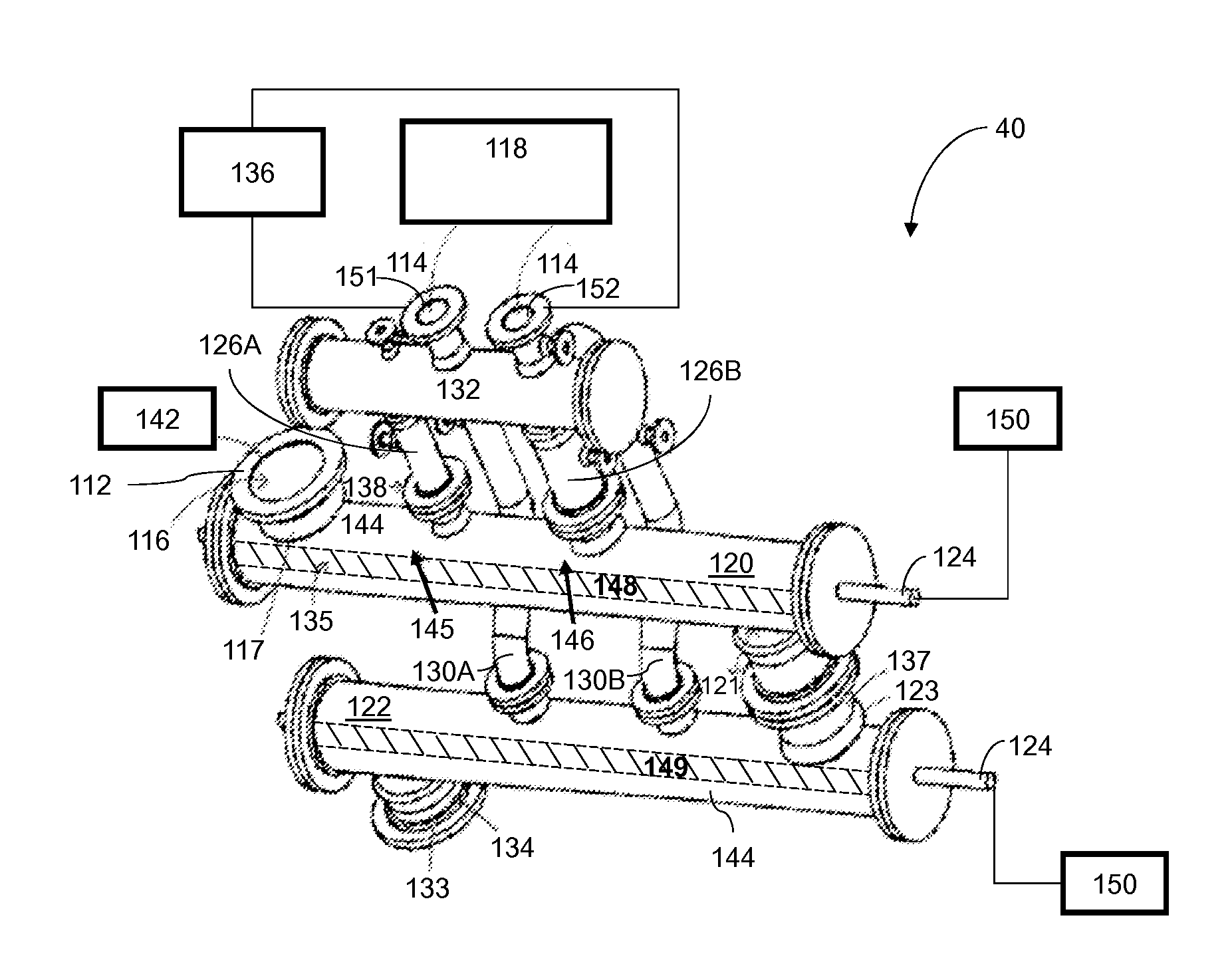

Methods and Apparatus for Solid Carbonaceous Materials Synthesis Gas Generation

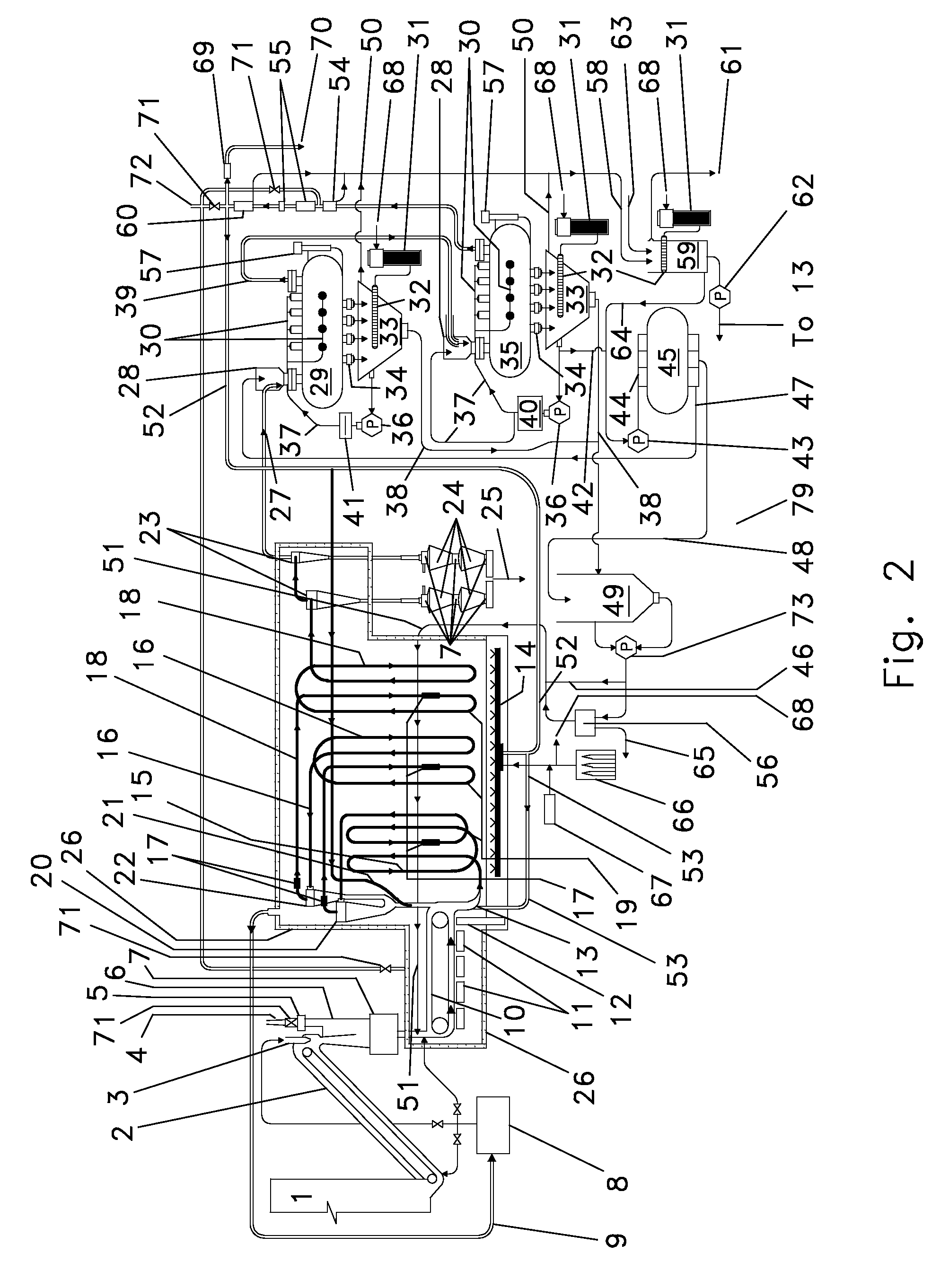

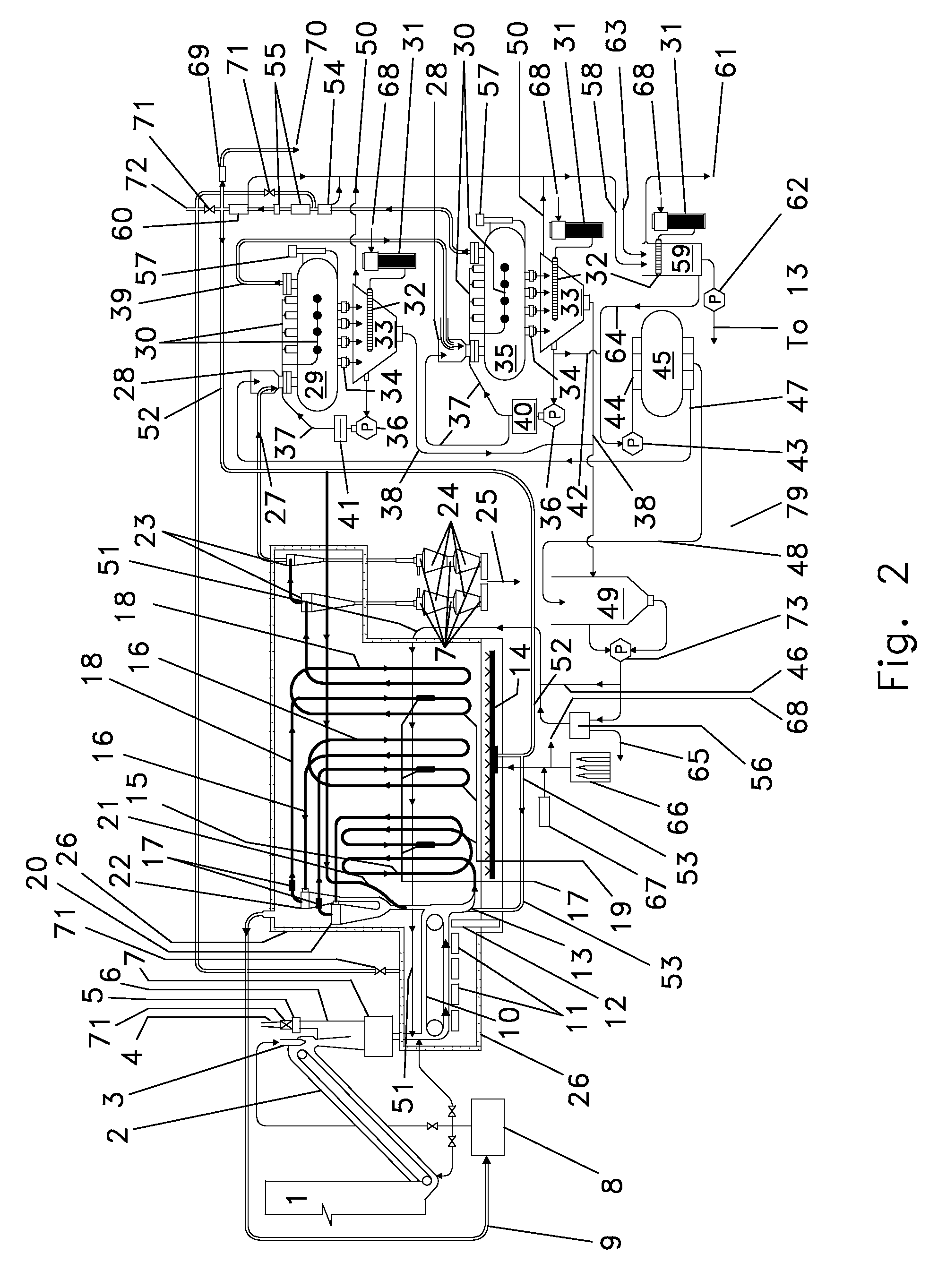

Methods and apparatus may permit the generation of consistent output synthesis gas from highly variable input feedstock solids carbonaceous materials. A stoichiometric objectivistic chemic environment may be established to stoichiometrically control carbon content in a solid carbonaceous materials gasifier system. Processing of carbonaceous materials may include dominative pyrolytic decomposition and multiple coil carbonaceous reformation. Dynamically adjustable process determinative parameters may be utilized to refine processing, including process utilization of negatively electrostatically enhanced water species, process utilization of flue gas (9), and adjustment of process flow rate characteristics. Recycling may be employed for internal reuse of process materials, including recycled negatively electrostatically enhanced water species, recycled flue gas (9), and recycled contaminants. Synthesis gas generation may involve predetermining a desired synthesis gas for output and creating high yields of such a predetermined desired synthesis gas.

Owner:THERMOTEK

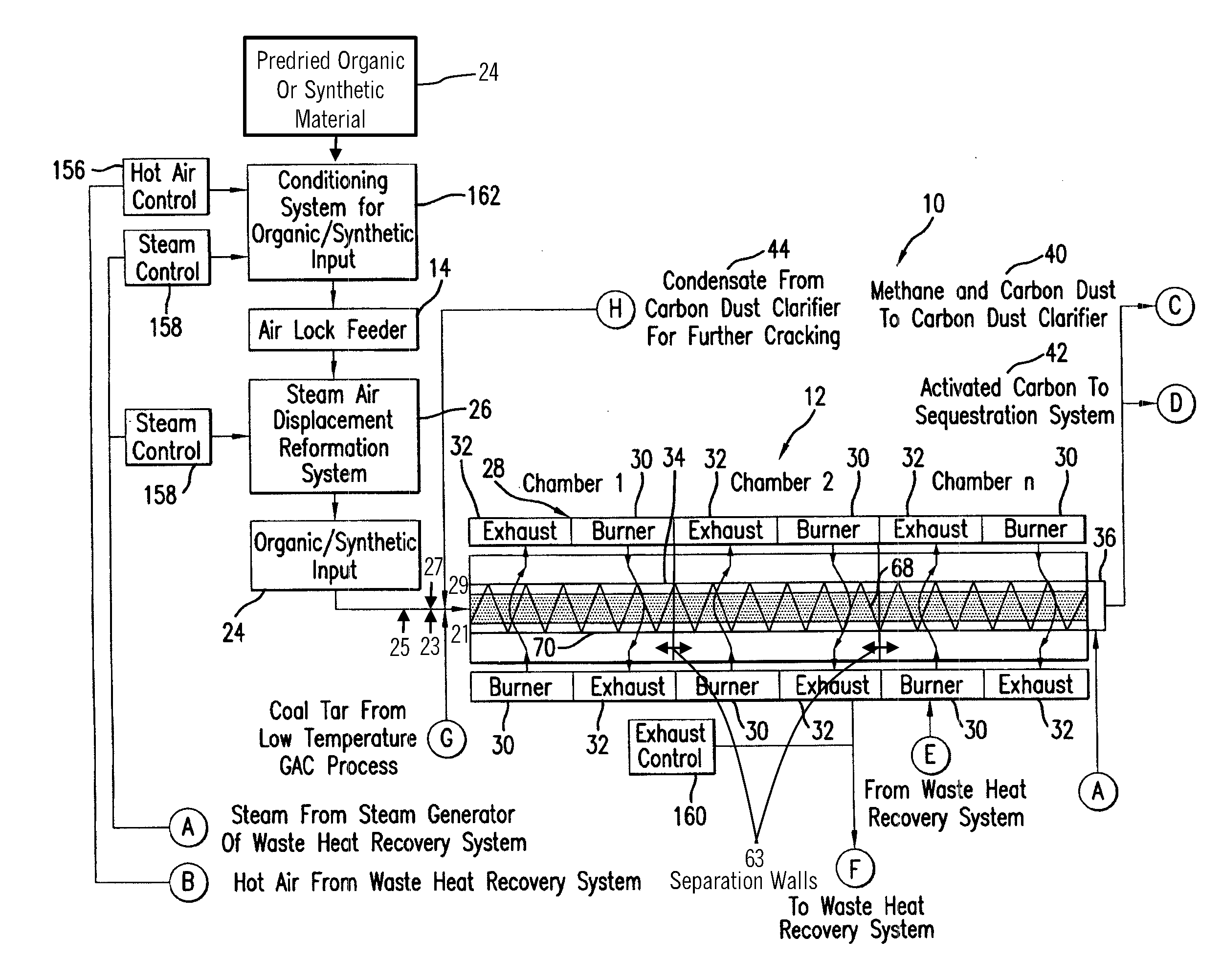

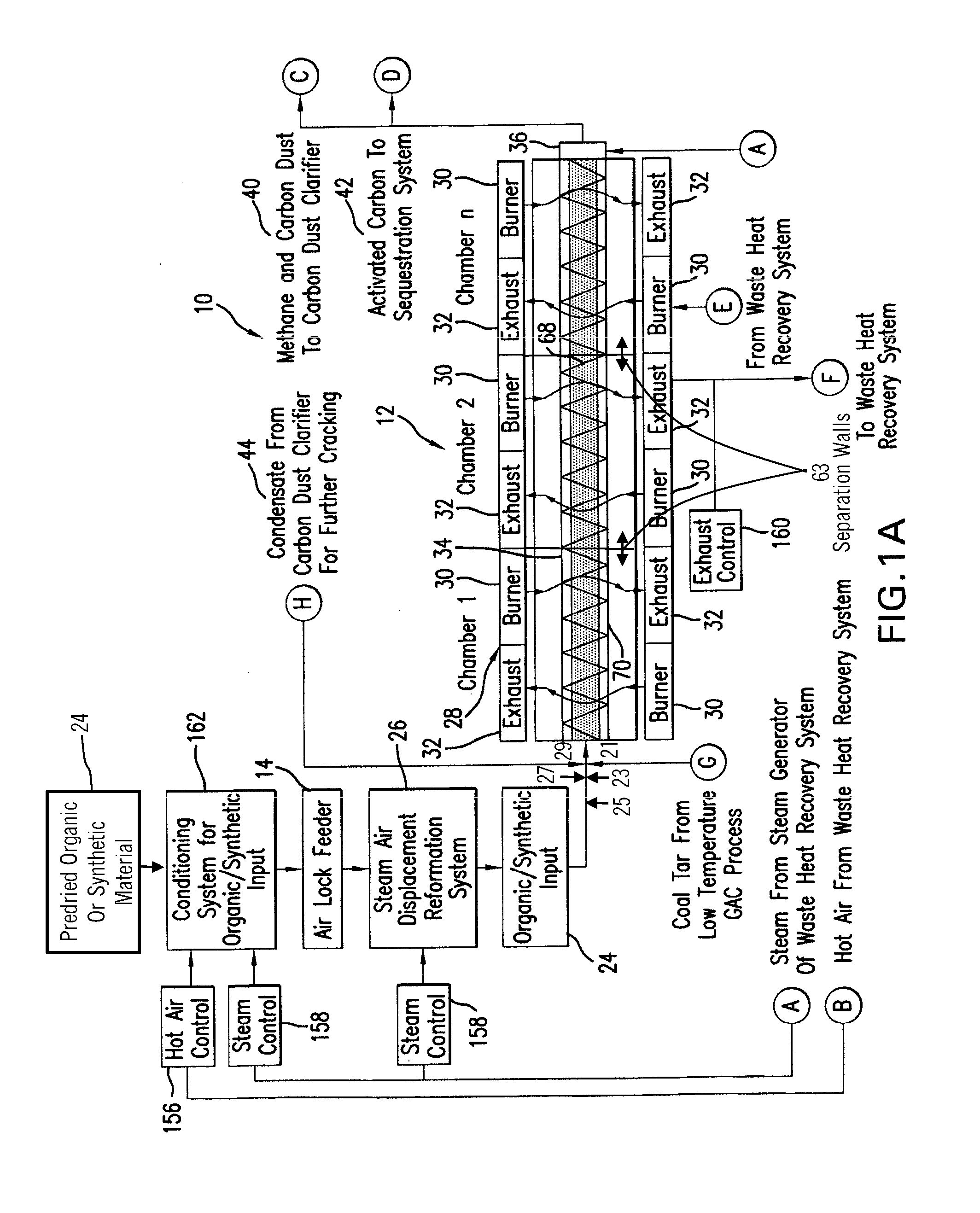

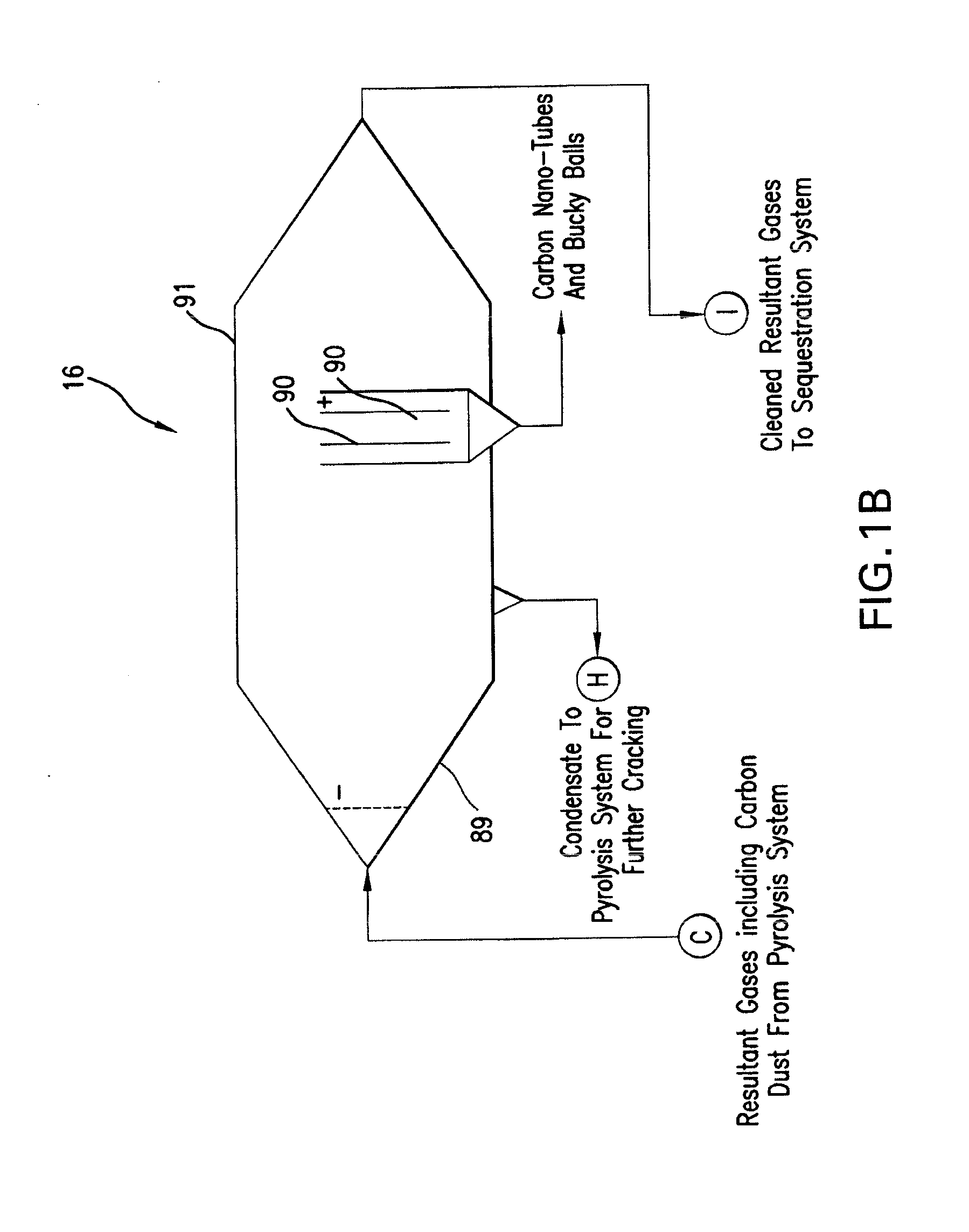

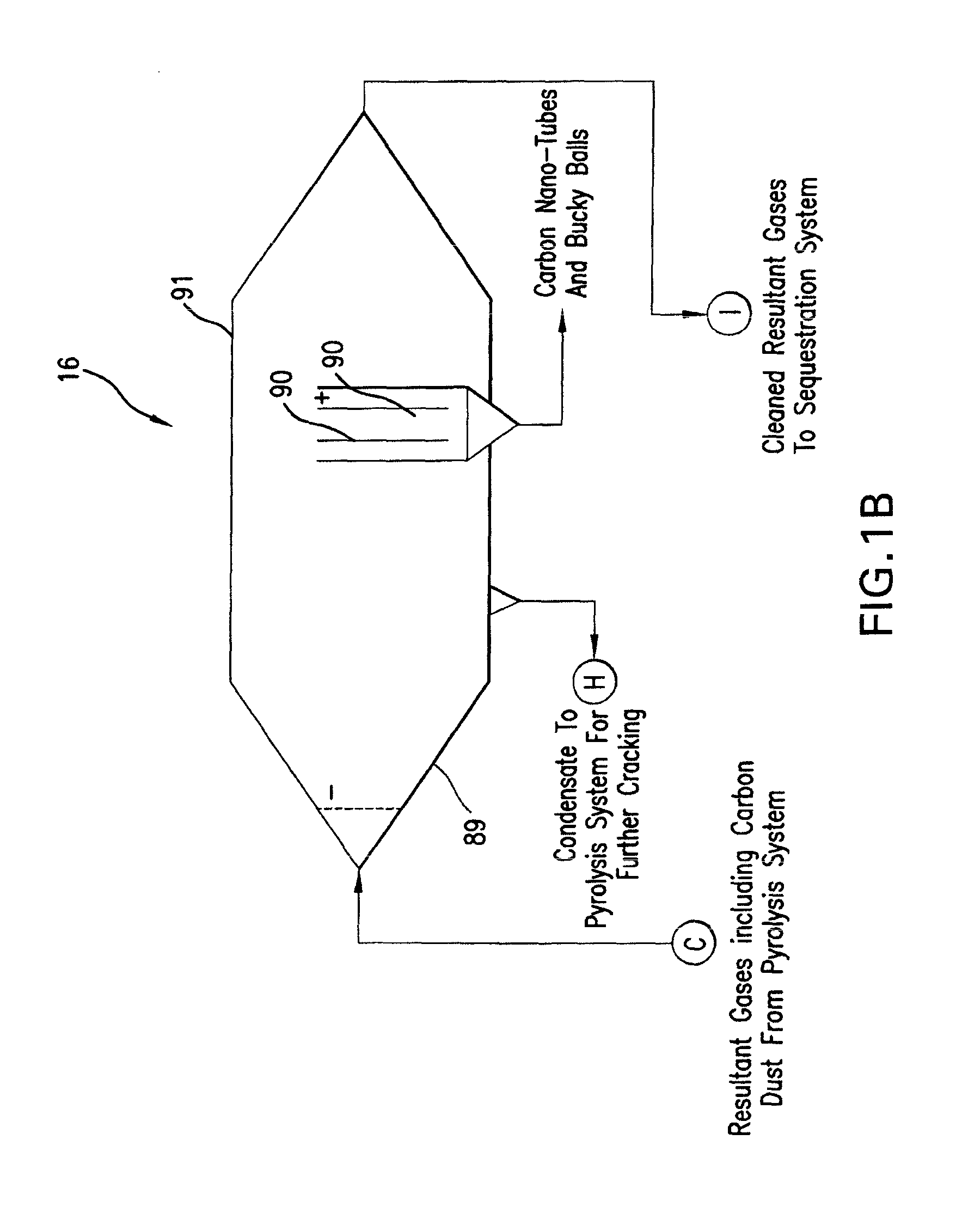

Pyrolysis systems, methods, and resultants derived therefrom

ActiveUS20110136971A1Fit closelyMaterial nanotechnologyDirect heating destructive distillationHazardous substanceProcess engineering

The present invention provides a process for the controlled gasification of a carbonaceous feedstock, including: pyrolizing the feedstock to produce a gas product and a solid product, wherein the gas product includes methane and noxious chemicals and the solid product includes carbon; and controlling the pyrolizing step using feedback related to constituents of the gas product. The present invention also provides a system for the controlled gasification of a carbonaceous feedstock, including: a pyrolysis unit including a heater and a conveyor for transporting the feedstock through the heater; a resultant chamber disposed downstream of the pyrolysis unit for separating gas products and solid products; means for adjusting the temperature of the solid products; and a filter for sequestering noxious materials from the gas products, wherein the filter uses at least some of the solid products to filter at least a portion of the gas products.

Owner:TUCKER RICHARD D

Methods and Apparatus for Solid Carbonaceous Materials Synthesis Gas Generation

Methods and apparatus may permit the generation of consistent output synthesis gas from highly variable input feedstock solids carbonaceous materials. A stoichiometric objectivistic chemic environment may be established to stoichiometrically control carbon content in a solid carbonaceous materials gasifier system. Processing of carbonaceous materials may include dominative pyrolytic decomposition and multiple coil carbonaceous reformation. Dynamically adjustable process determinative parameters may be utilized to refine processing, including process utilization of negatively electrostatically enhanced water species, process utilization of flue gas (9), and adjustment of process flow rate characteristics. Recycling may be employed for internal reuse of process materials, including recycled negatively electrostatically enhanced water species, recycled flue gas (9), and recycled contaminants. Synthesis gas generation may involve predetermining a desired synthesis gas for output and creating high yields of such a predetermined desired synthesis gas.

Owner:THERMOTEK

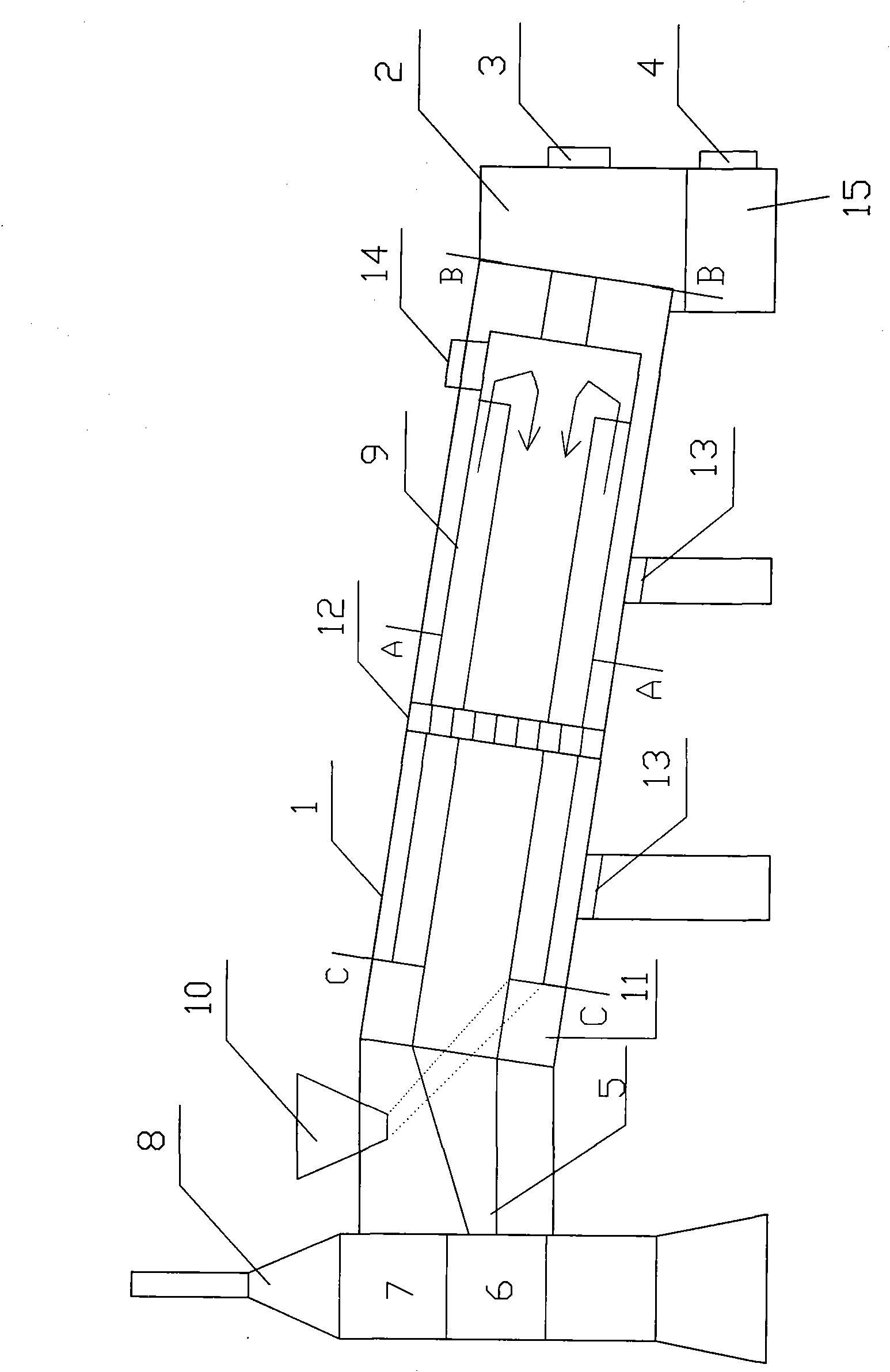

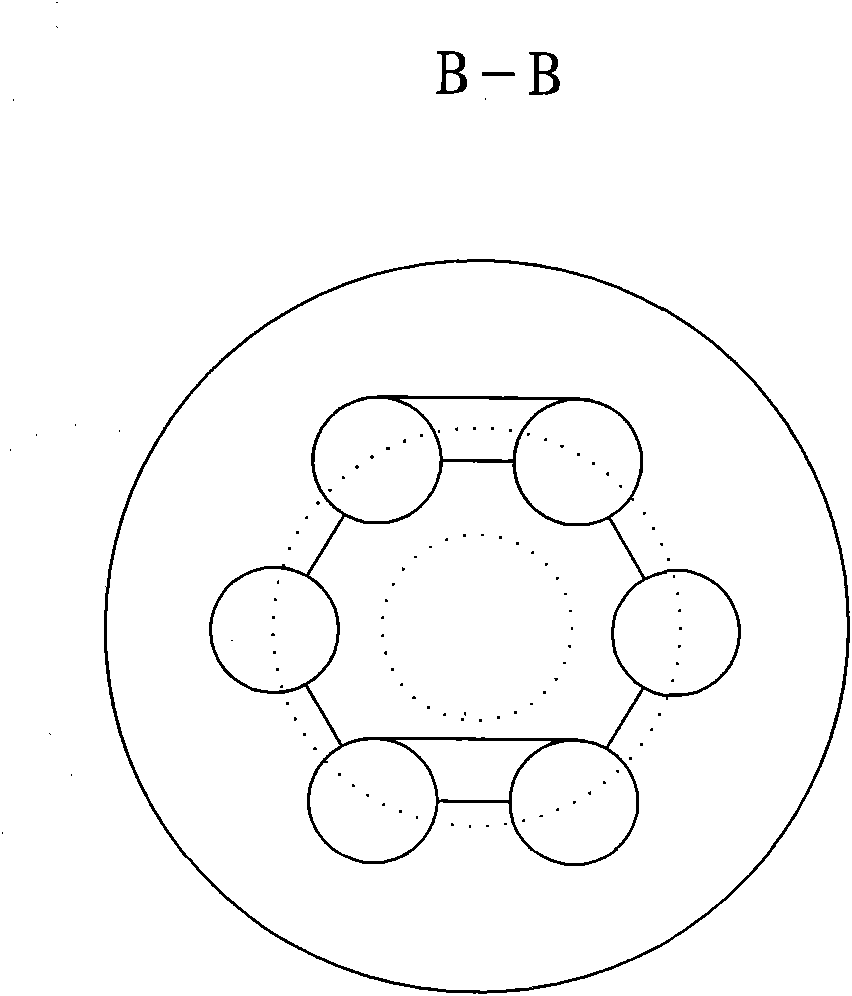

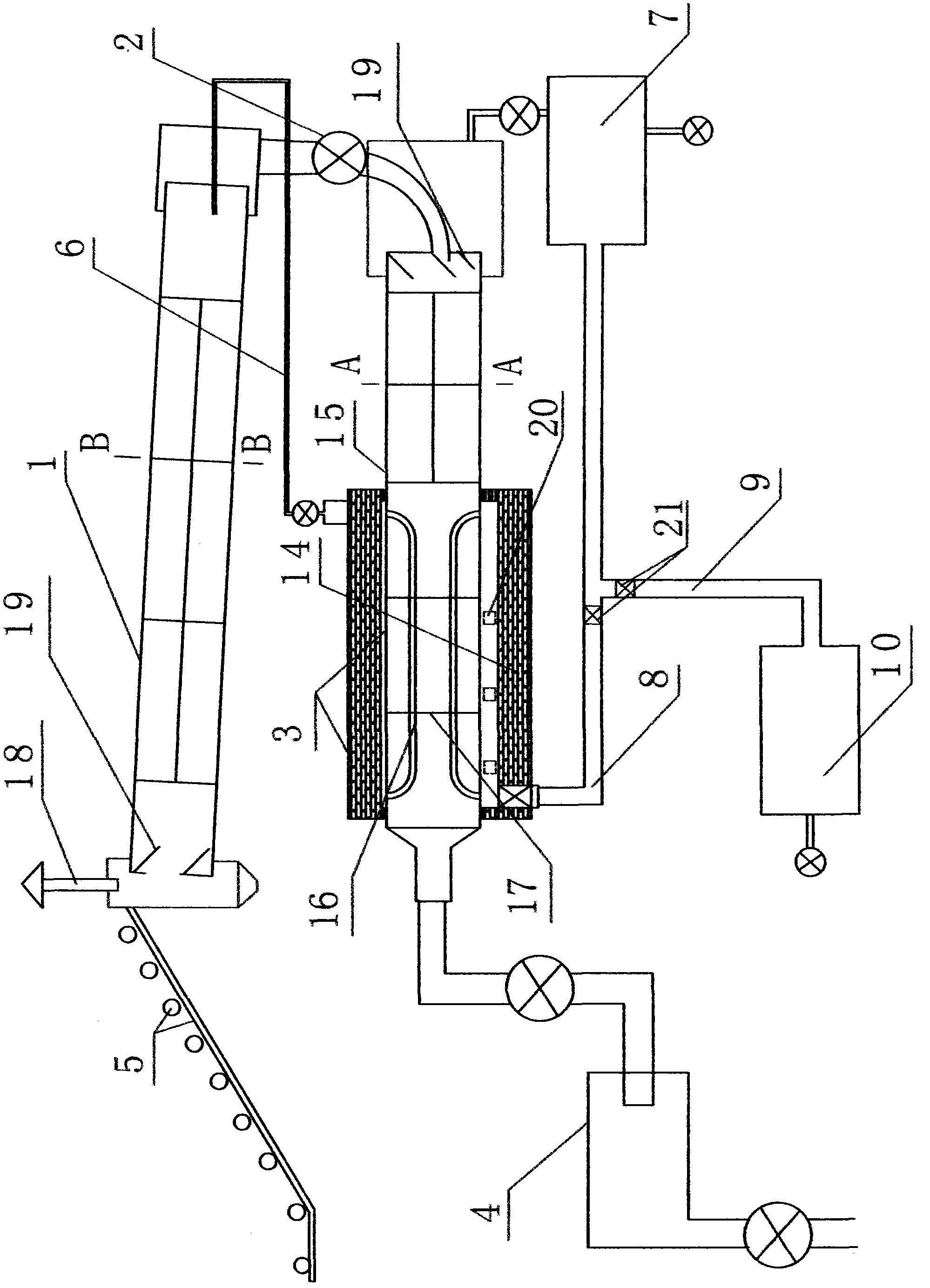

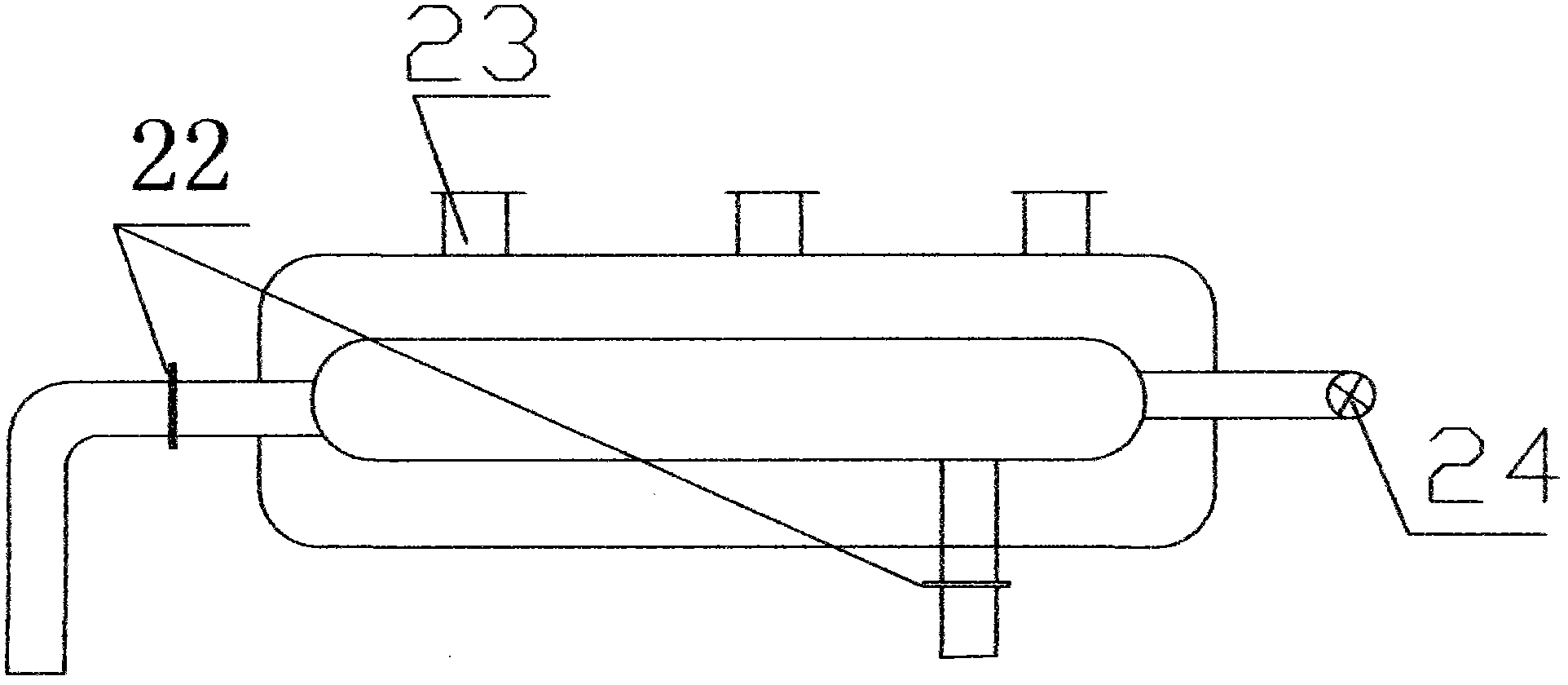

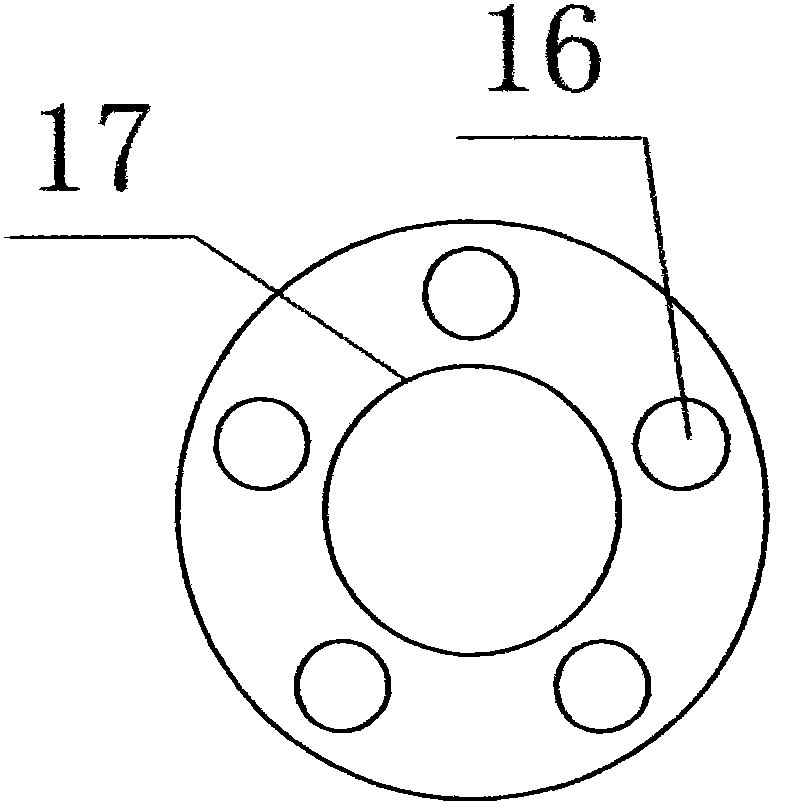

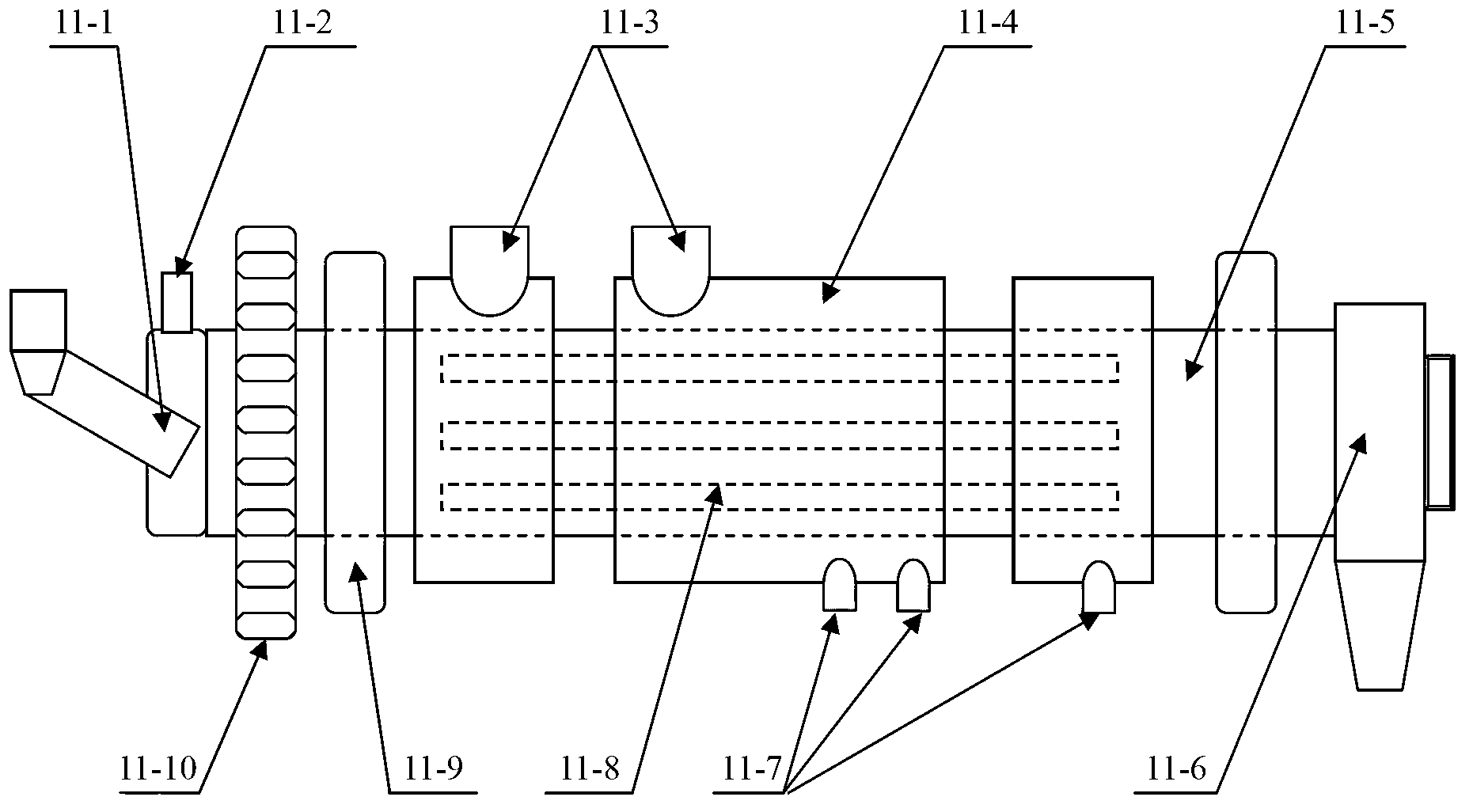

Multi-tube external-heat fume reverse extraction rotary carbide furnace

The invention relates to a multi-tube external-heat fume reverse extraction rotary carbide furnace which is provided with an obliquely horizontal type rotary furnace body (1); the high end side of the furnace body is provided with a feed hopper; the lower end side of the furnace body is provided with a discharge hole (14) and a combustion chamber (2); tube bundles (9) which are annularly distributed along a cross section are arranged in the furnace body; carbonized materials and fume channels are isolated, wherein the tube pass is used for the carbonized materials and the shell pass is used for fume. The invention adopts a tubular carbonizing process, which separates heat generated by the carbonized materials and fuels and avoids the problem of excessive carbonization; moreover, the problem that coal tar in a volatile matter is stuck to the surfaces of the carbonized materials again to influence the appearance of the product and activating effect when the fume is reversely sucked back.

Owner:宝塔国际石化工程技术有限公司

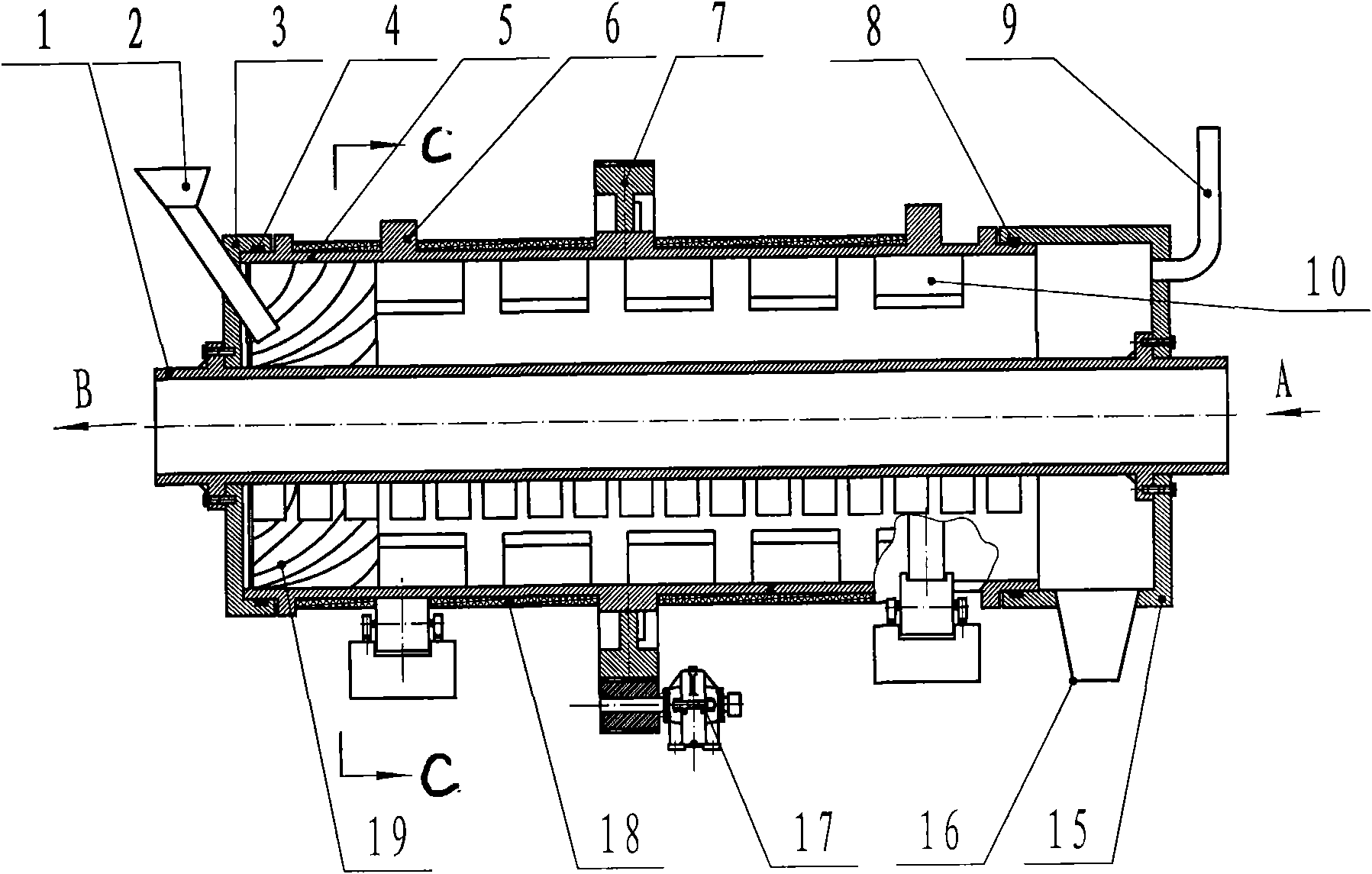

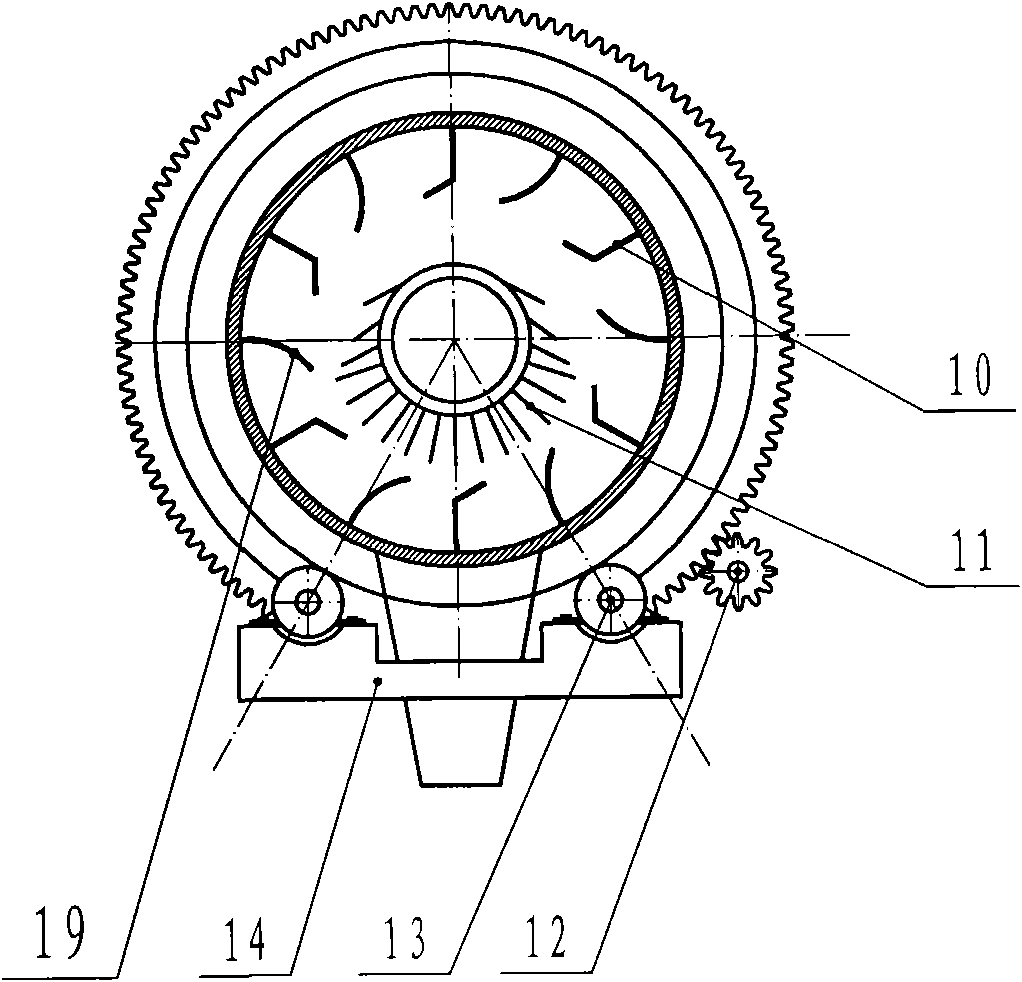

Continuous rotary biomass pyrolytic charring and boiler heat supply integrated equipment

ActiveCN102032553AImprove ergonomicsHigh thermal efficiencyDirect heating destructive distillationBiofuelsCombustion chamberEngineering

The invention discloses continuous rotary biomass pyrolytic charring and boiler heat supply integrated equipment. The equipment comprises raw material conveying equipment, a rotary drying furnace and a rotary charring furnace, and is characterized in that: the raw material conveying equipment is connected with the rotary drying furnace and connected with the rotary charring furnace through a star-like feeder; a material which is pyrolytically charred by the rotary charring furnace is discharged through a charred material outlet; the rotary charring furnace comprises a hearth and a rotary furnace; one path of high-temperature hot gas produced by combustion of an oxygen-containing combustion chamber is conveyed into the hearth of the rotary charring furnace through a flue to enter a charring section; the rotary furnace comprises a barrel, an inner heating tube and a baffle ring; one end head of the inner heating tube is fixed on the barrel wall on one side and passes through the baffle ring to be fixed on the barrel wall on the other side of the baffle ring; after the high-temperature hot gas passes through the hearth through the flue, certain high-temperature hot gas enters one end head of the inner heating tube, is discharged out of the other end head of the inner heating tube, enters a waste heat conveying pipe and is conveyed into the rotary drying furnace through an induced draught fan; and the high-temperature hot gas is conveyed into a biomass boiler through another flue. The equipment can improve the working efficiency of the rotary charring furnace.

Owner:FUJIAN TIANCHUANGLI BIOLOGICAL ENERGY EQUIP

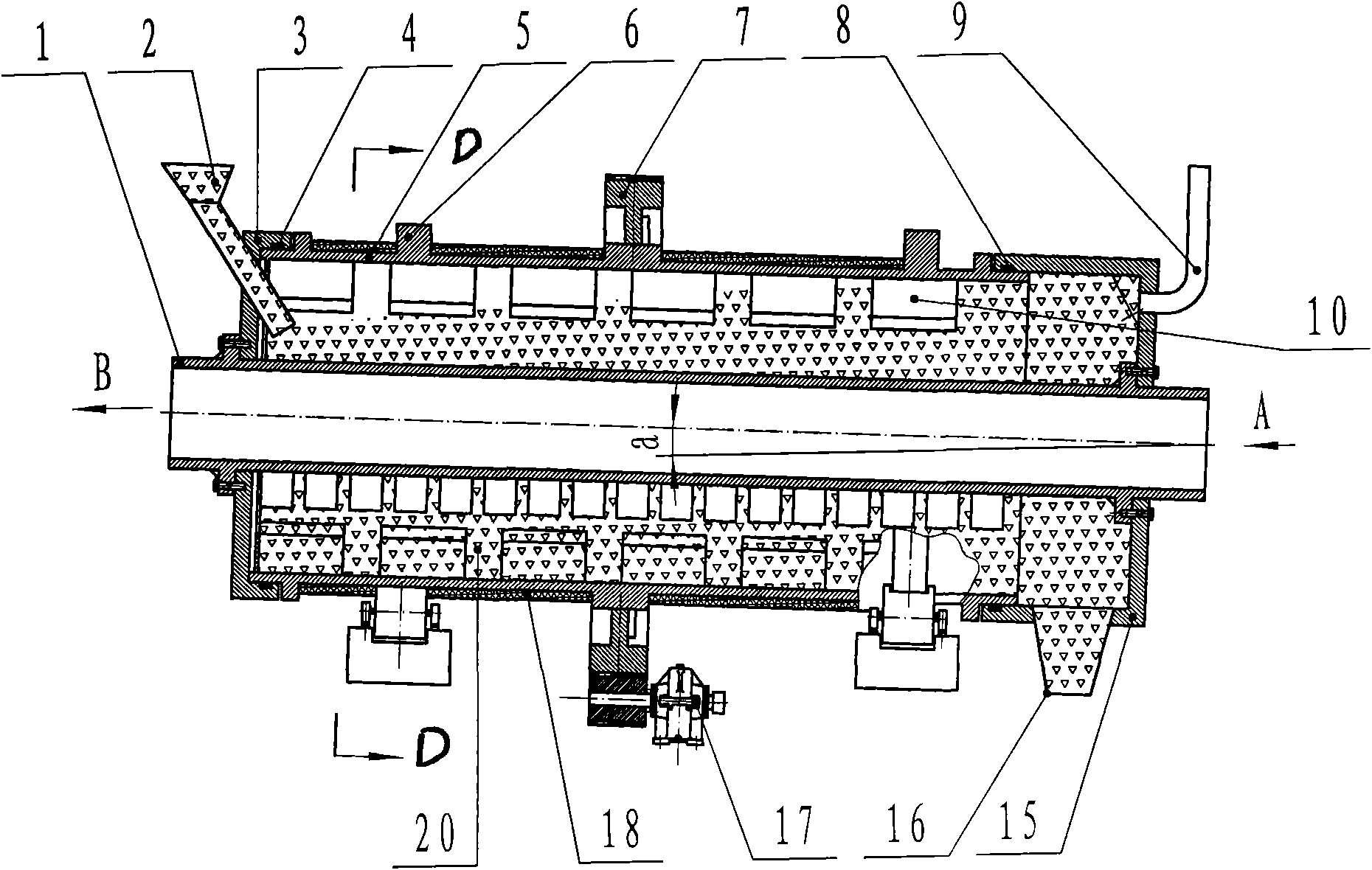

Low-temperature carbonization apparatus and method for oil sand, oil sludge, oil shale and biomass

ActiveCN103160301AIncrease profitReduce energy consumptionDirect heating destructive distillationBiofuelsCarbonizationOil shale gas

The invention discloses a low-temperature carbonization apparatus and method for oil sand, oil sludge, oil shale and biomass. The apparatus comprises a delivery apparatus, a storage bin, a metering apparatus, a drying furnace and a surge bin. The method comprises the following steps: drying, preheating, carbonizing, and cooling. The core of the invention is an external heating type rotary carbonization furnace which realizes the pyrolysis of oil sand, oil shale, oil sludge (oil sludge on the ground, oil sludge at the bottom of a tank and oil-containing sludge from oil refinery) and biomass, and the product is high in purity and low in loss. The invention effectively solves the problems of solid materials such as adhesion, wall accretion and the like in the pyrolysis process by material returning. The technology provided by the invention is simple in process and reliable and stable in operation, and has obvious advantages in the treatment of small particle materials such as oil shale, oil sand, oil sludge (oil sludge on the ground, oil sludge at the bottom of a tank and oil-containing sludge from oil refinery), biomass and the like.

Owner:何建祥

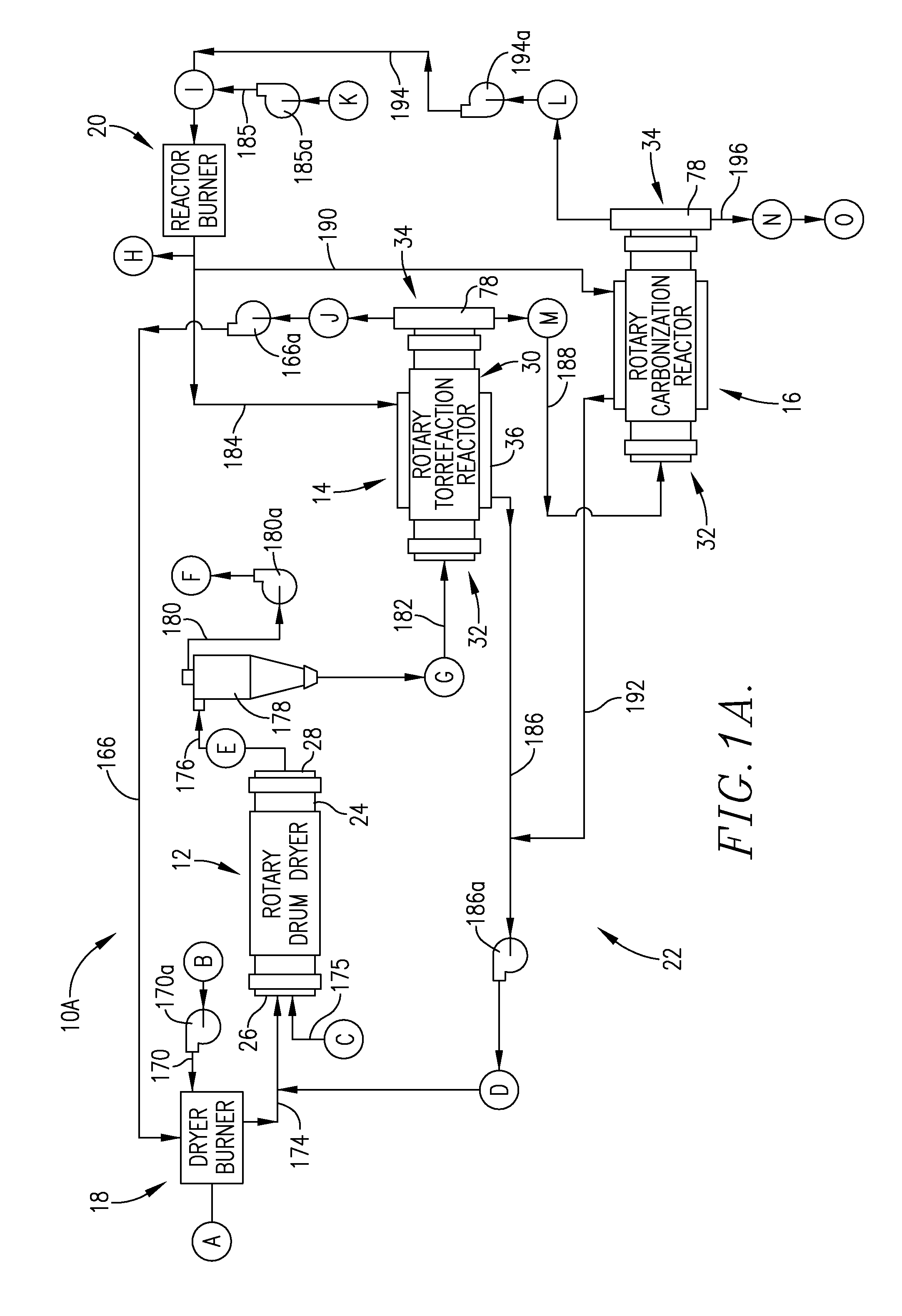

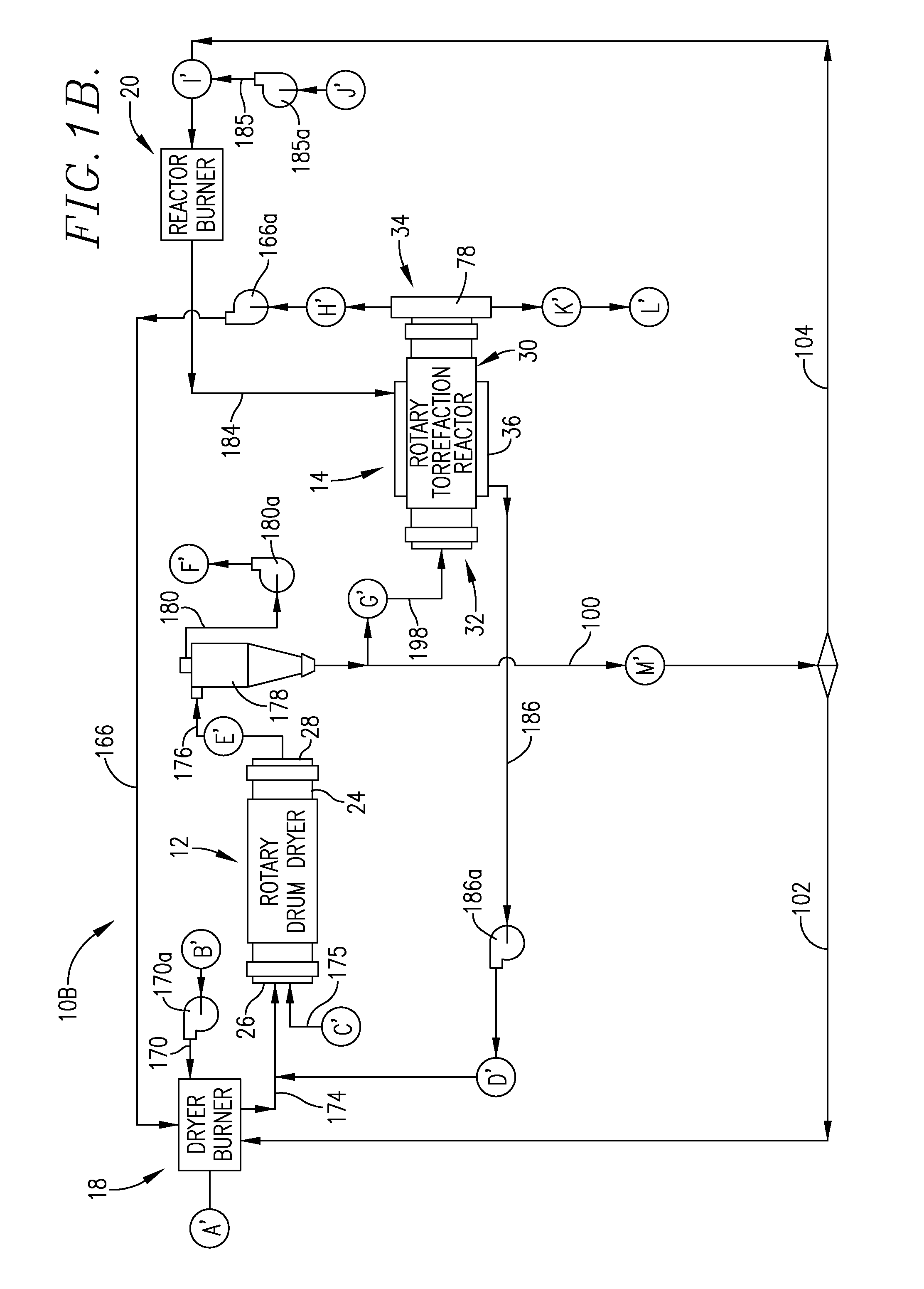

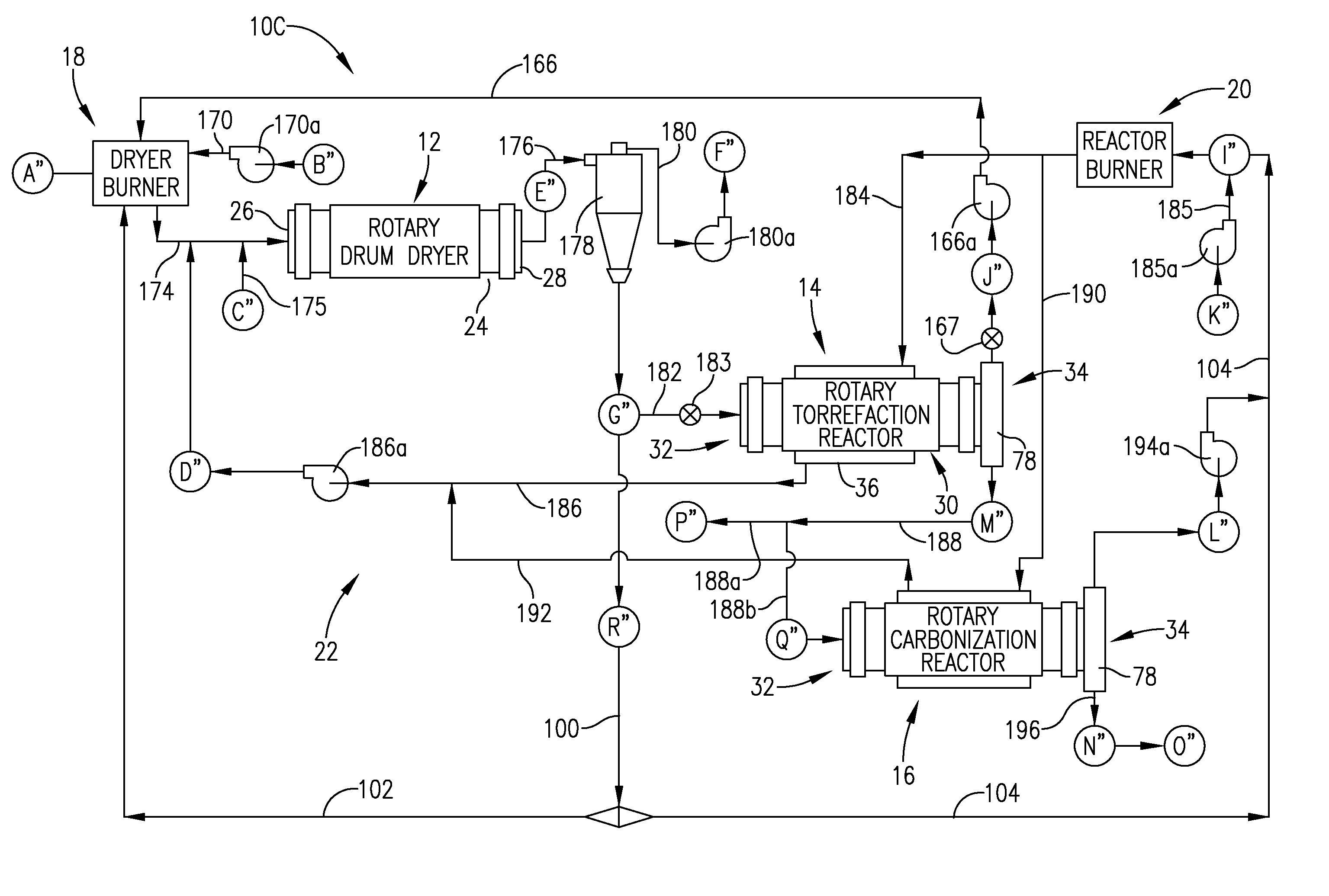

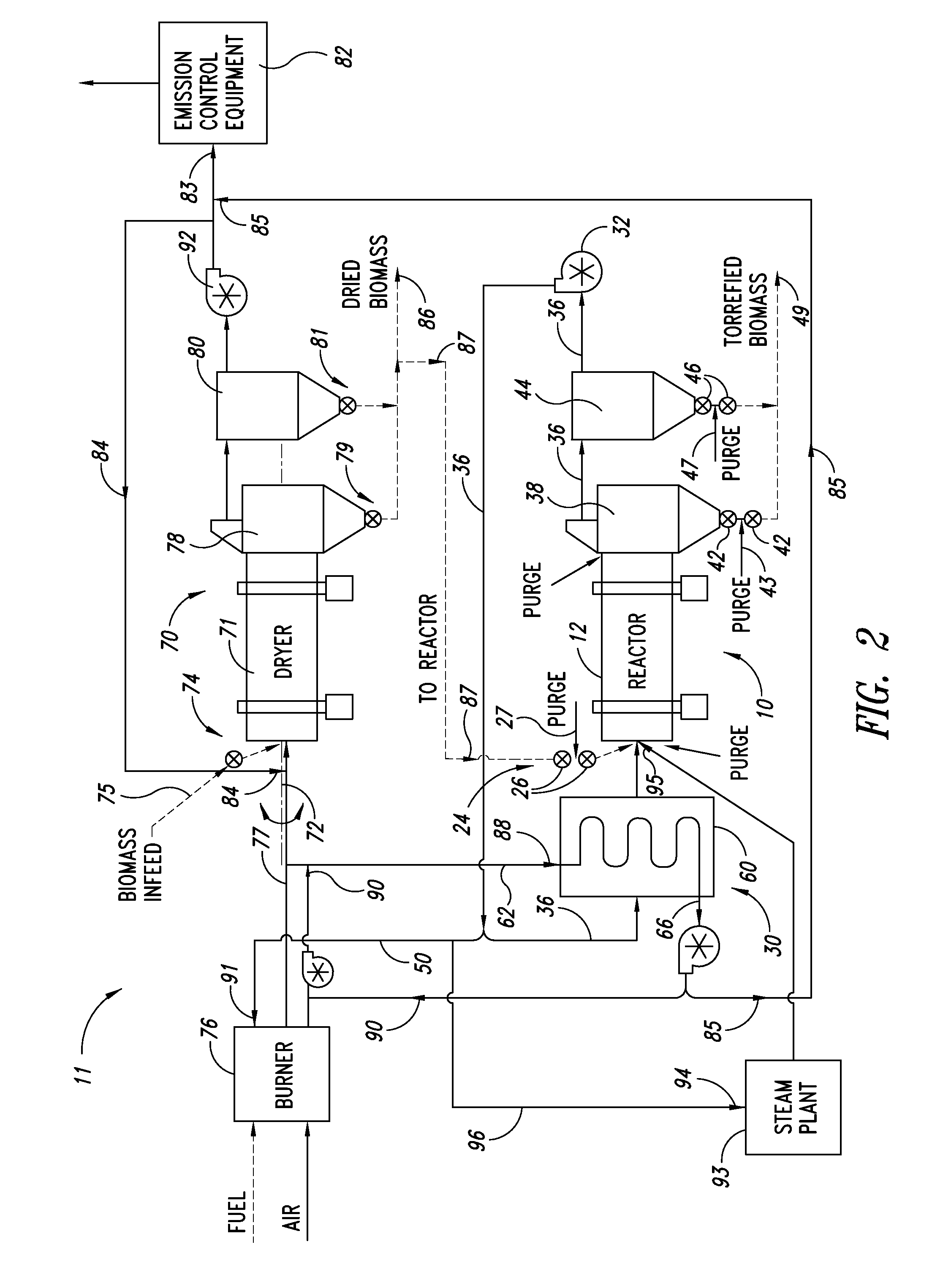

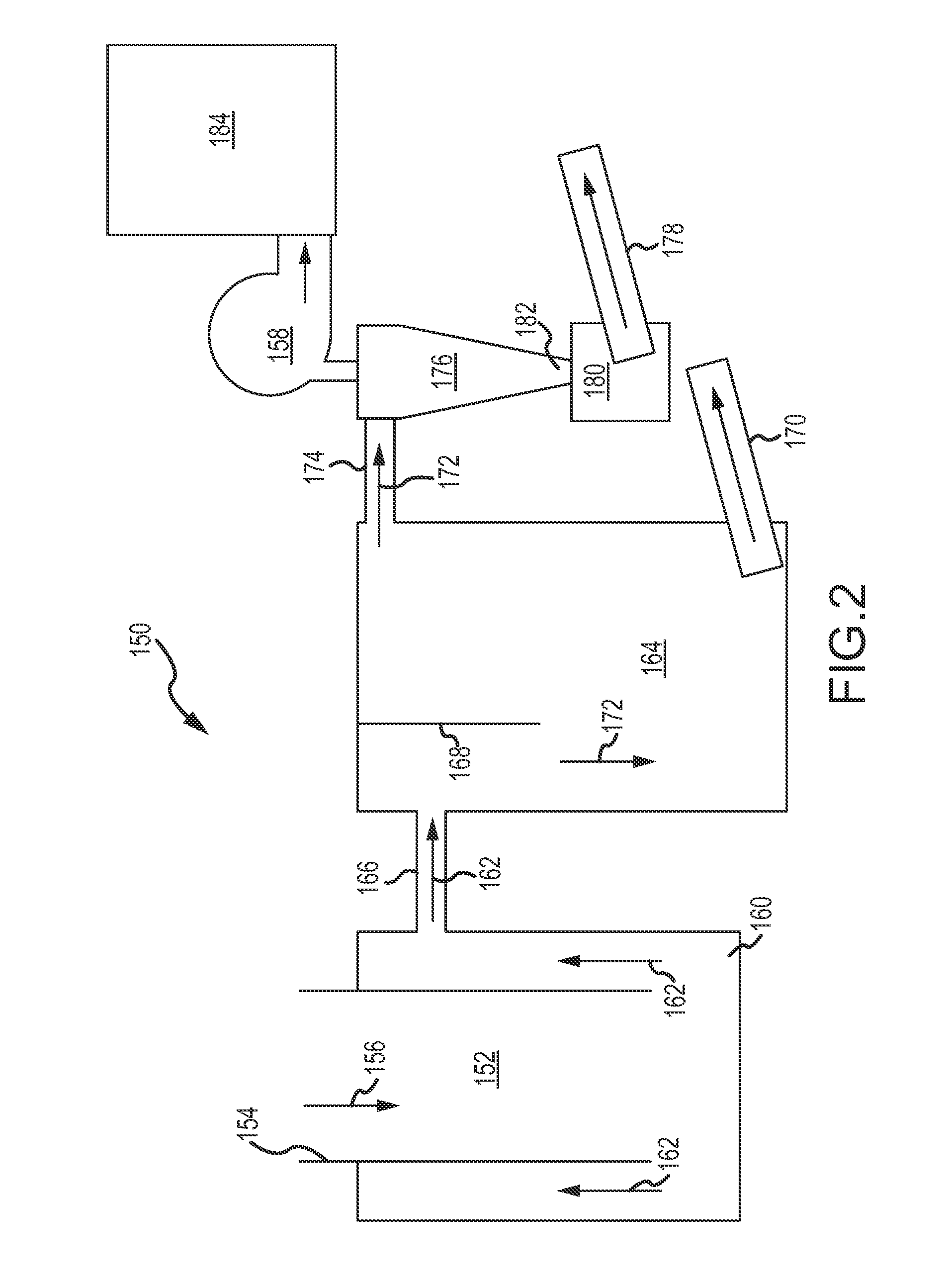

High energy efficiency biomass conversion process

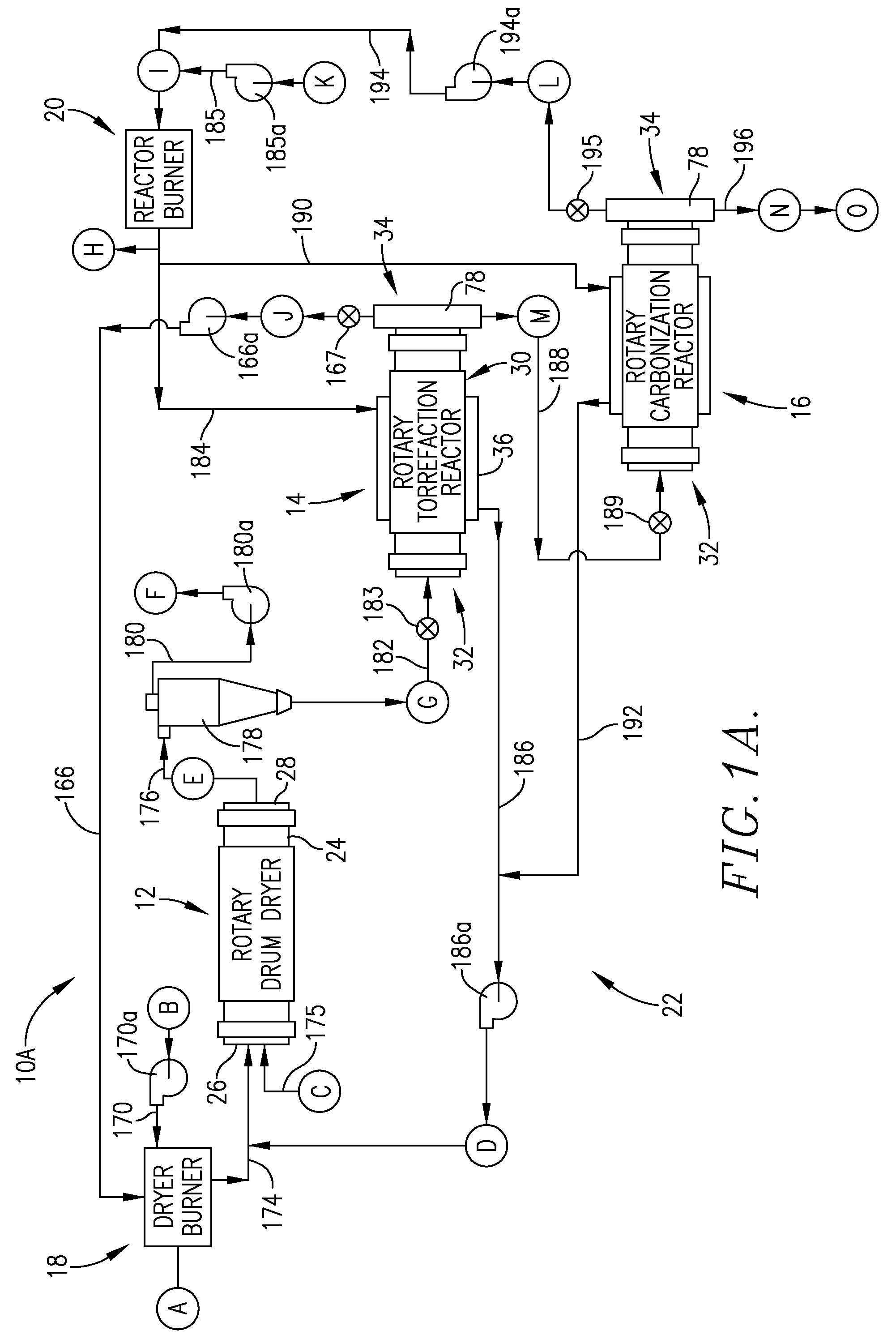

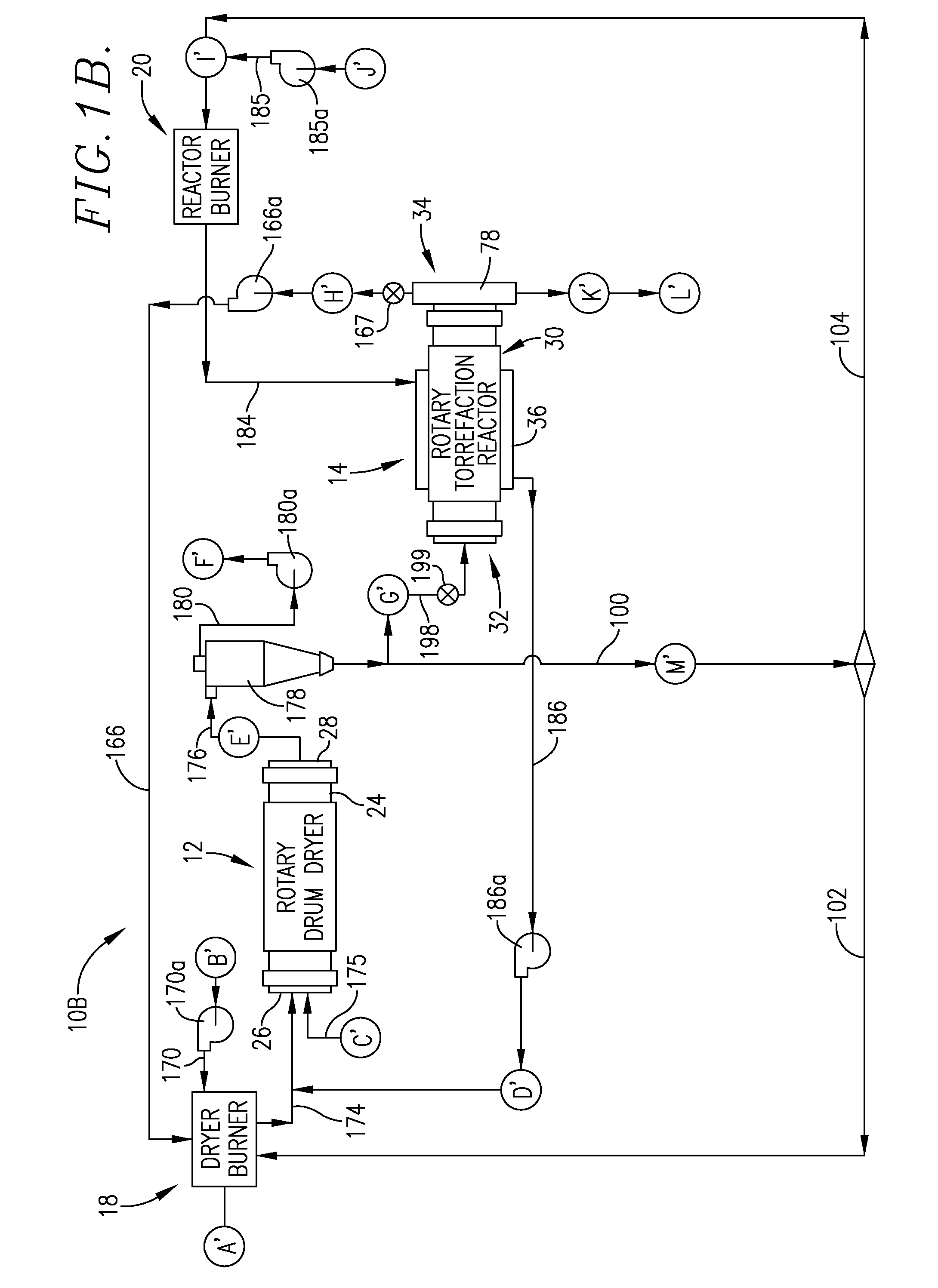

Improved, fuel-efficient systems are provided for the processing of biomass, such as wood or crop residues, food waste or animal waste in order to selectively obtain torrefied and / or carbonized final products. In general, the processes involve thermally drying incoming biomass using a dryer employing the hot gas output of a fuel-operated burner. Next, the dried product is torrefied in an indirect torrefaction reactor so as to evolve light volatile organic compounds which are used as a gaseous fuel source for the burner. The torrefied product can be recovered, or some or all of the torrefied product may be directed to a carbonization reactor coupled with a reactor burner. Carbonization serves to remove most of the remaining VOCs which are used as a gaseous fuel input to the dryer. In certain instances, portions of the dried biomass are directed to the burners, as an additional source of fuel.

Owner:SMART TERRA CARE LLC

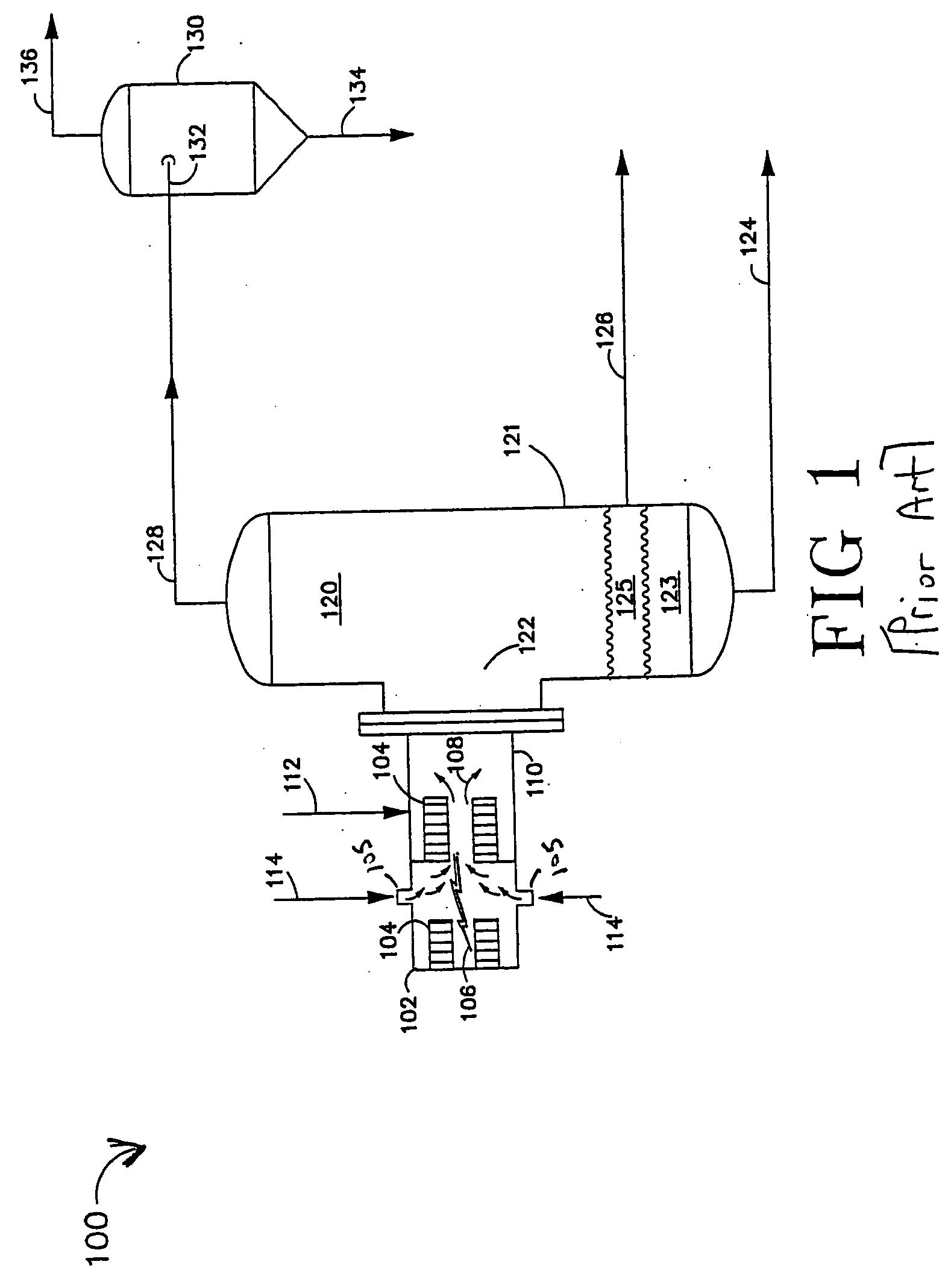

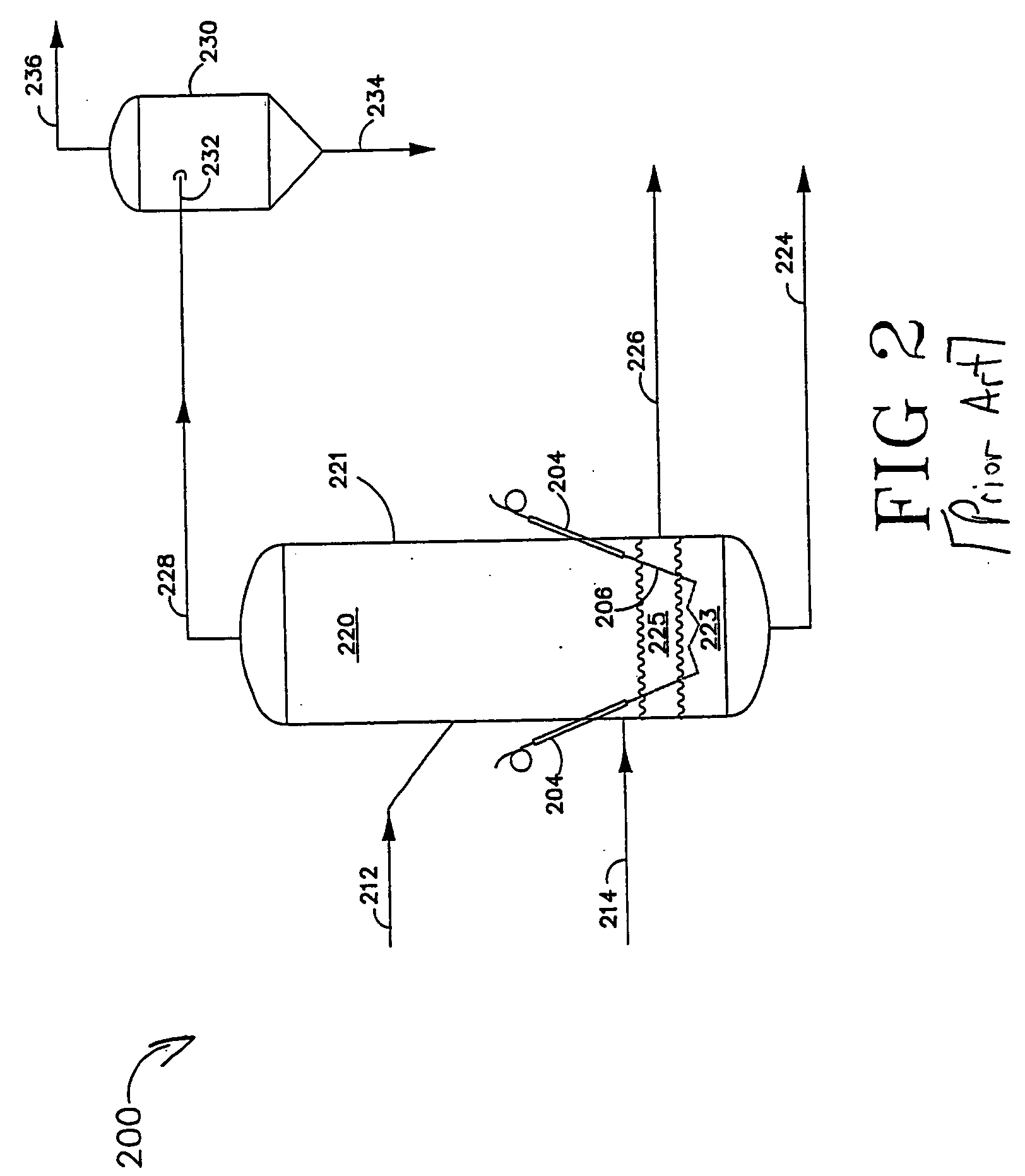

Method and apparatus for processing a waste product

A method and apparatus for processing a waste product and producing a synthesis gas is provided. The system includes a sealed, heated rotatable drum for preheating and preparing the waste material suitable for a plasma reactor, and processing the material in the reactor. The synthesis gas created by the reactor is used to preheat the waste material by circulating the hot synthesis gas around the drum. In an alternative embodiment, the hot synthesis gas flows through the drum to preheat the waste material and to clean the synthesis gas. Different methods of cooling and cleaning the synthesis gas are used. The system may comprise two plasma reactors in combination with a rotating desorber drum.

Owner:CLEAN HARBORS SAN LEON INC

Methods and Apparatus for Solid Carbonaceous Materials Synthesis Gas Generation

Methods and apparatus may permit the generation of consistent output synthesis gas from highly variable input feedstock solids carbonaceous materials. A stoichiometric objectivistic chemic environment may be established to stoichiometrically control carbon content in a solid carbonaceous materials gasifier system. Processing of carbonaceous materials may include dominative pyrolytic decomposition and multiple coil carbonaceous reformation. Dynamically adjustable process determinative parameters may be utilized to refine processing, including process utilization of negatively electrostatically enhanced water species, process utilization of flue gas (9), and adjustment of process flow rate characteristics. Recycling may be employed for internal reuse of process materials, including recycled negatively electrostatically enhanced water species, recycled flue gas (9), and recycled contaminants. Synthesis gas generation may involve predetermining a desired synthesis gas for output and creating high yields of such a predetermined desired synthesis gas.

Owner:THERMOTEK

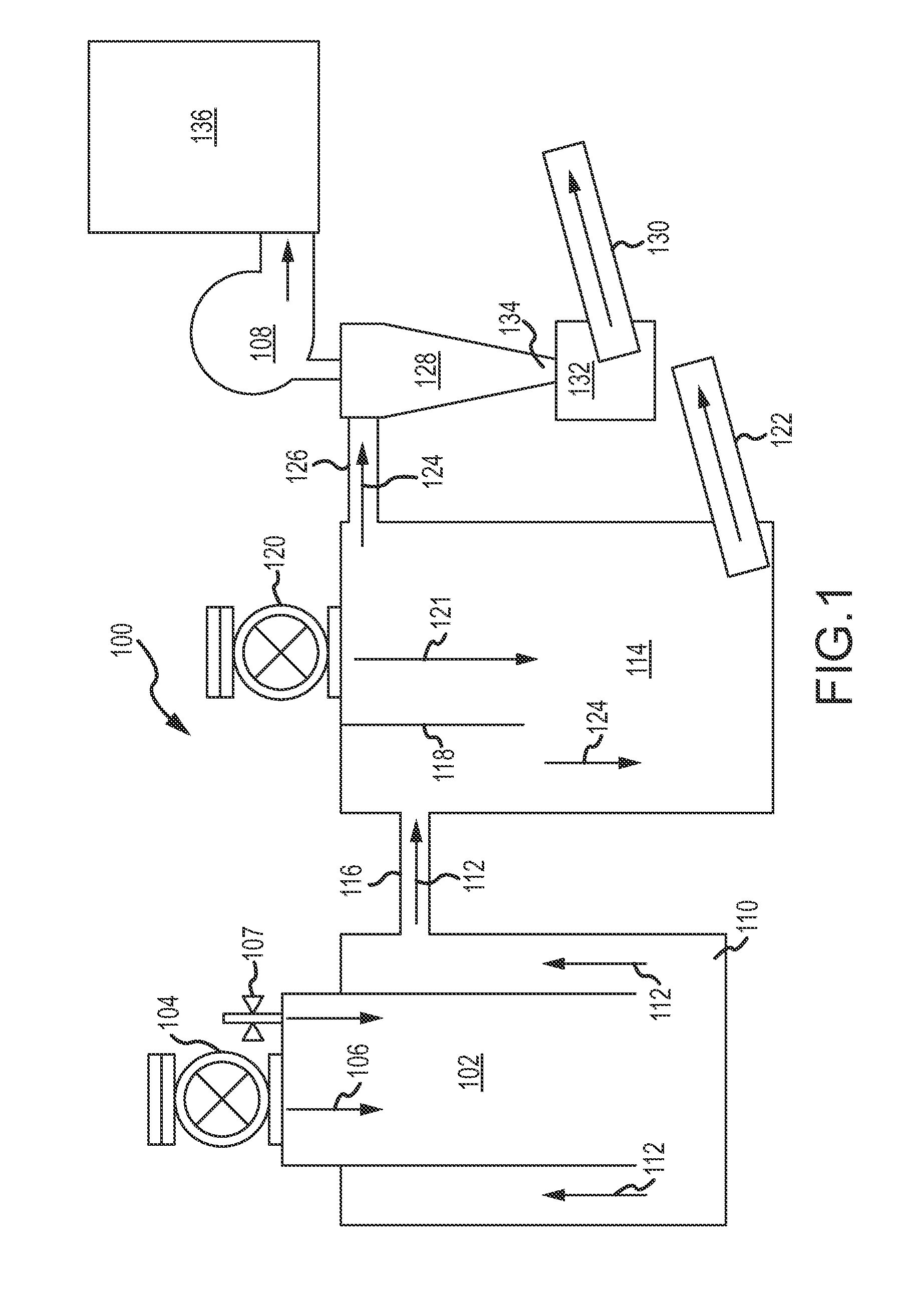

High energy efficiency biomass conversion process

ActiveUS8198493B1Combustible gas coke oven heatingDirect heating destructive distillationCombustorHigh energy

Improved, fuel-efficient systems are provided for the processing of biomass, such as wood or crop residues, food waste or animal waste in order to selectively obtain thermally processed final products, such as a combination of torrefied and carbonized final products. The processes involve thermally drying incoming biomass using a dryer employing the hot gas output of a fuel-operated burner. Next, the dried product is torrefied in an indirect torrefaction reactor so as to evolve light volatile organic compounds which are used as a gaseous fuel source for the burner. Some or all of the torrefied product can be recovered, or some or all of the torrefied product is then directed to a separate carbonization reactor coupled with a reactor burner. Carbonization serves to remove most of the remaining VOCs which are used as a gaseous fuel input to the dryer.

Owner:SMART TERRA CARE LLC

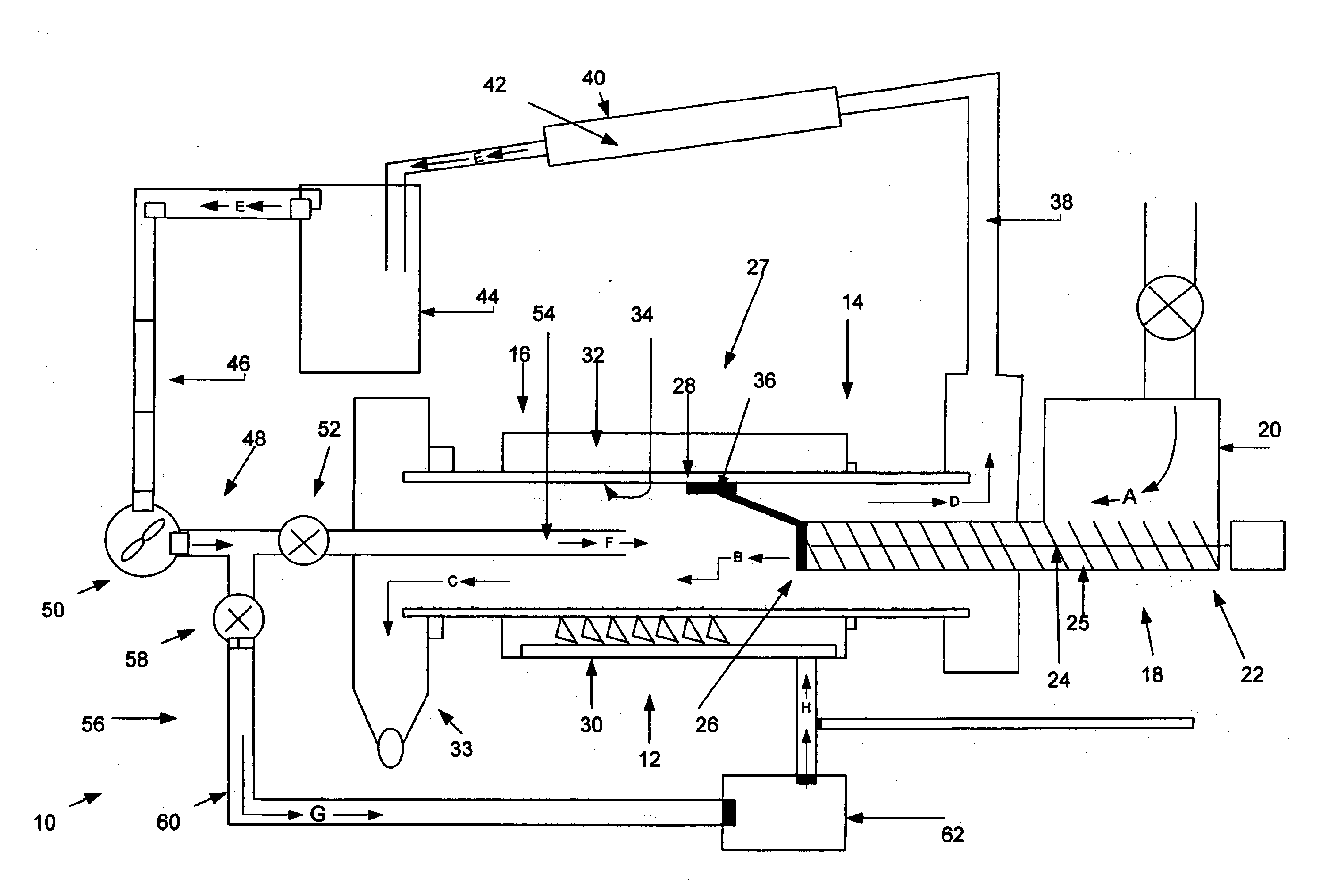

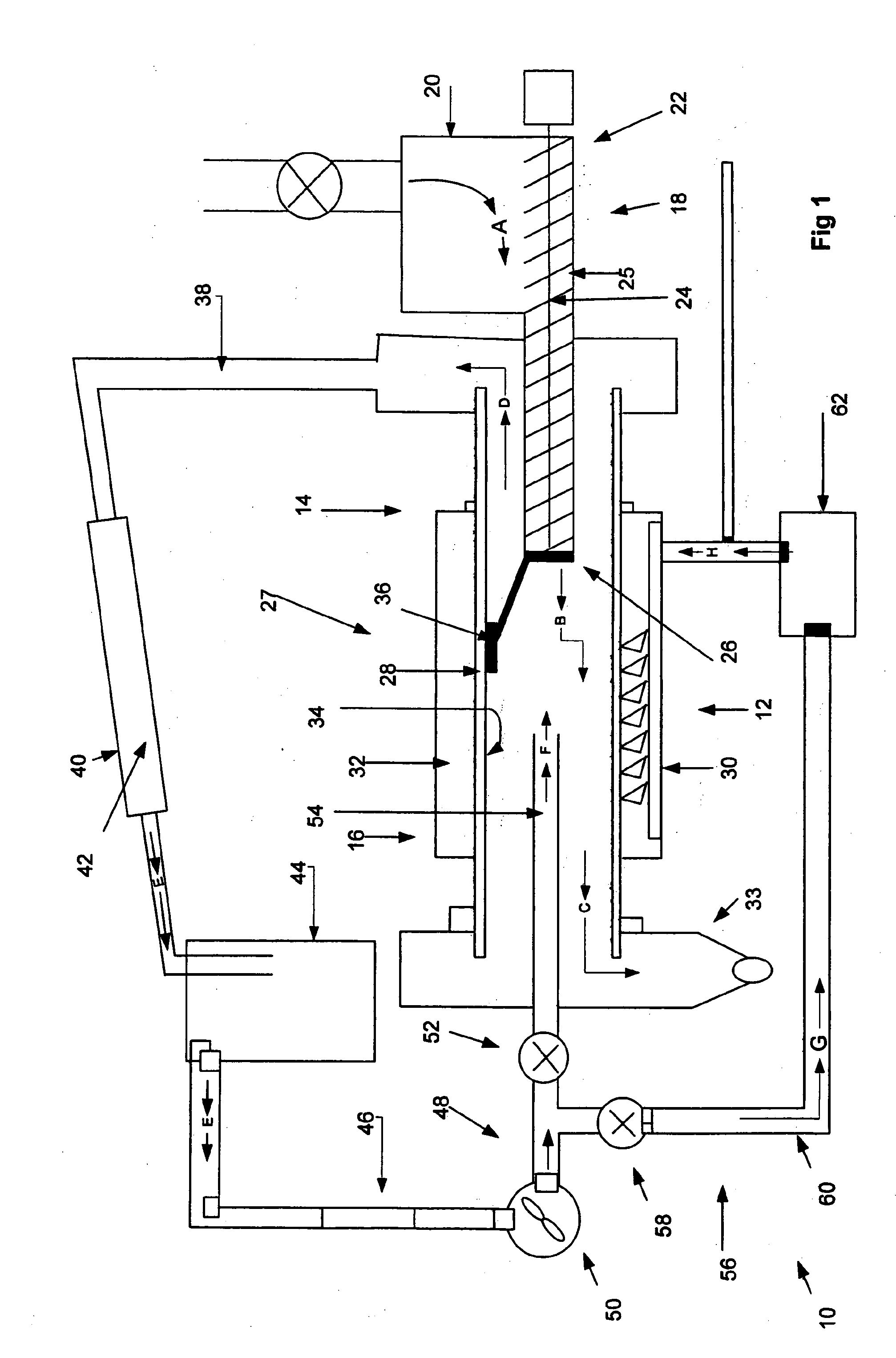

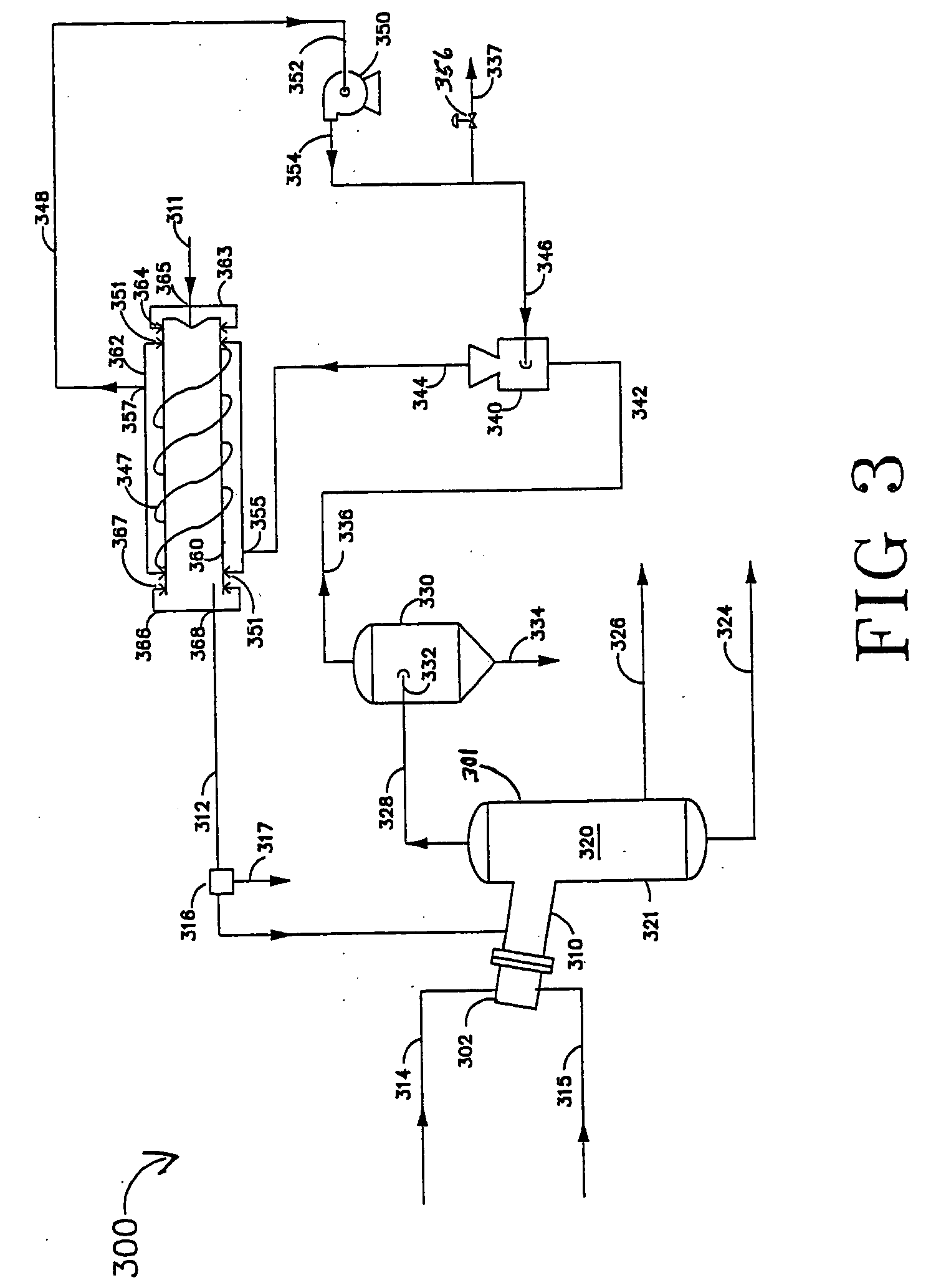

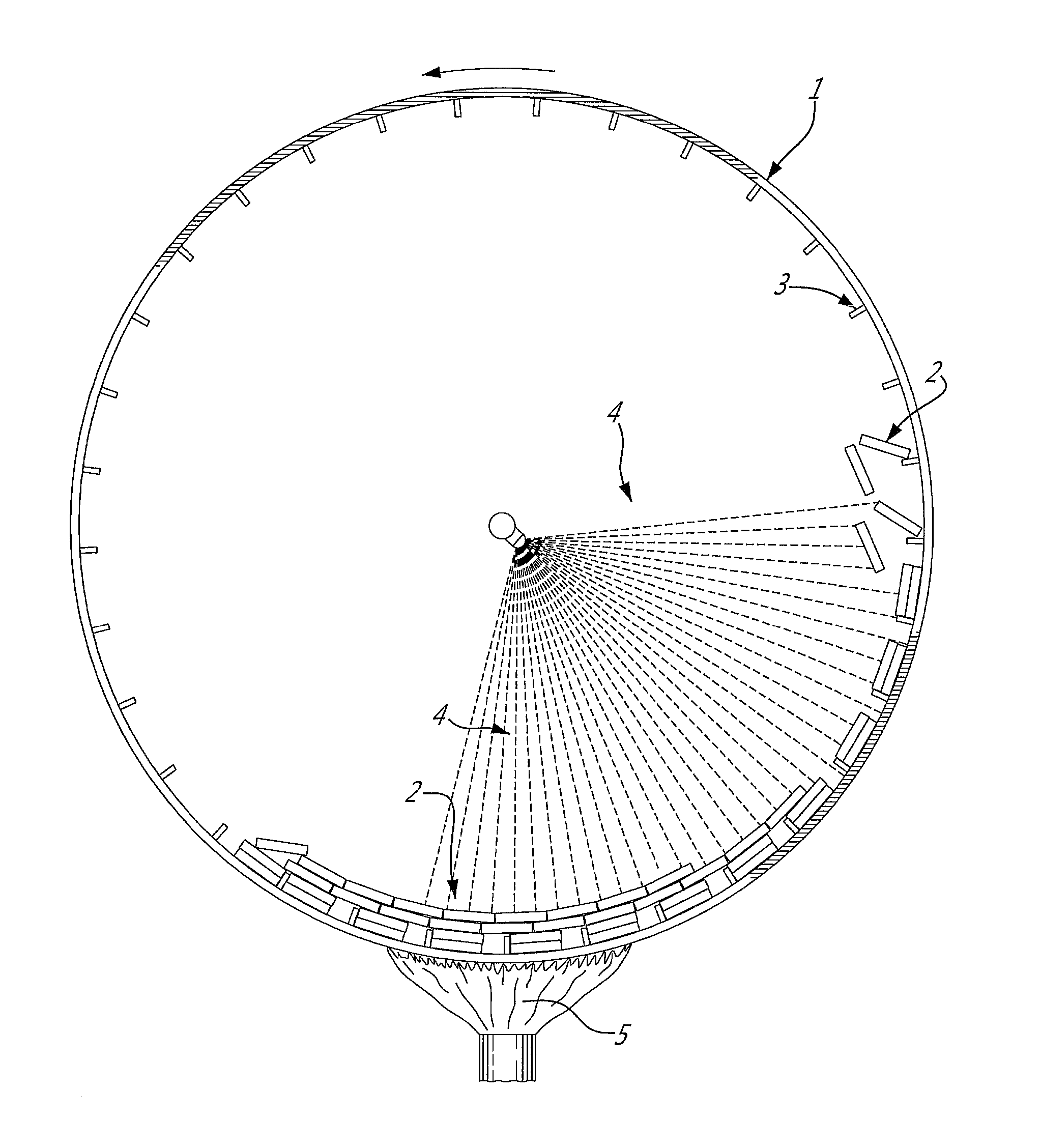

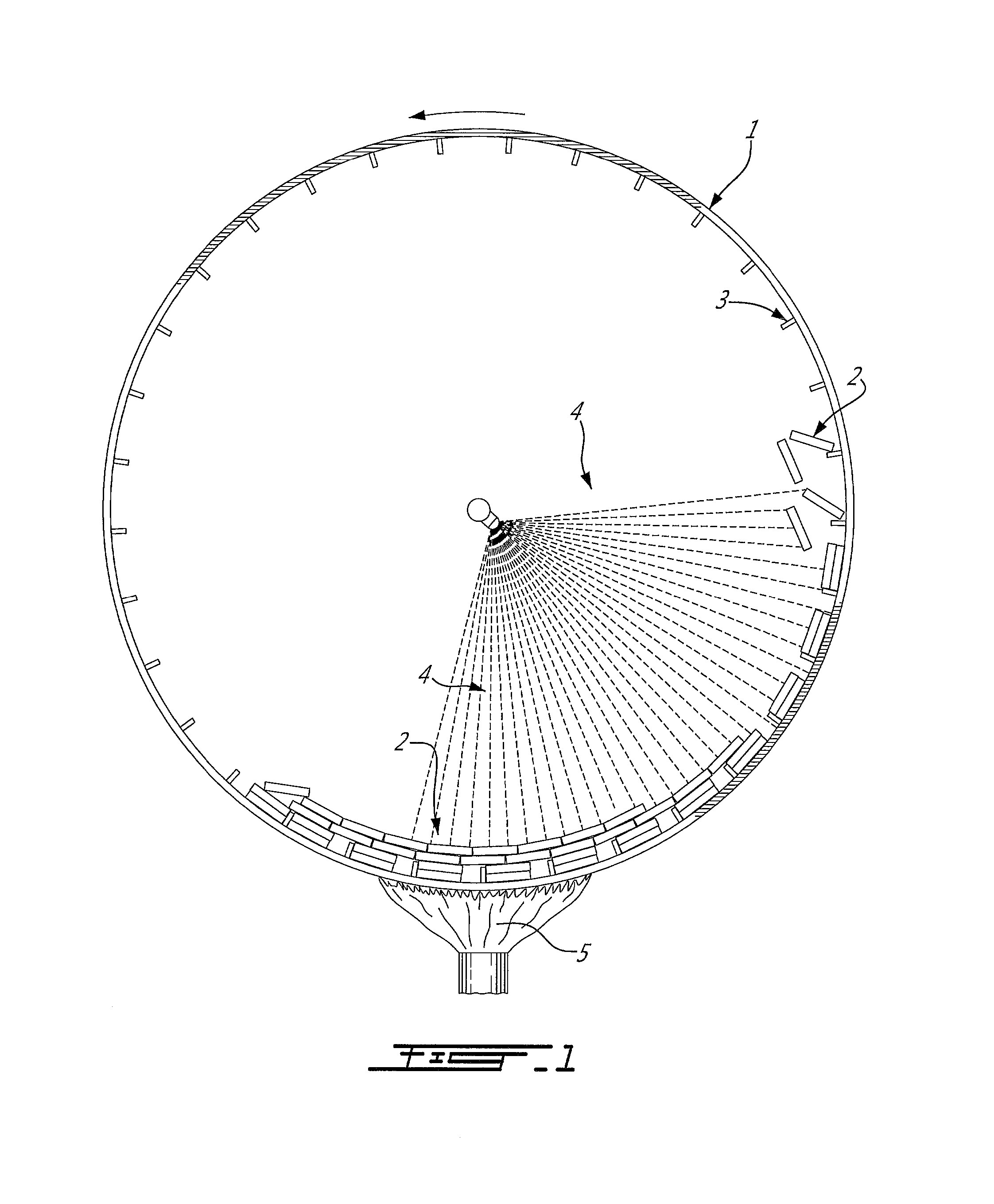

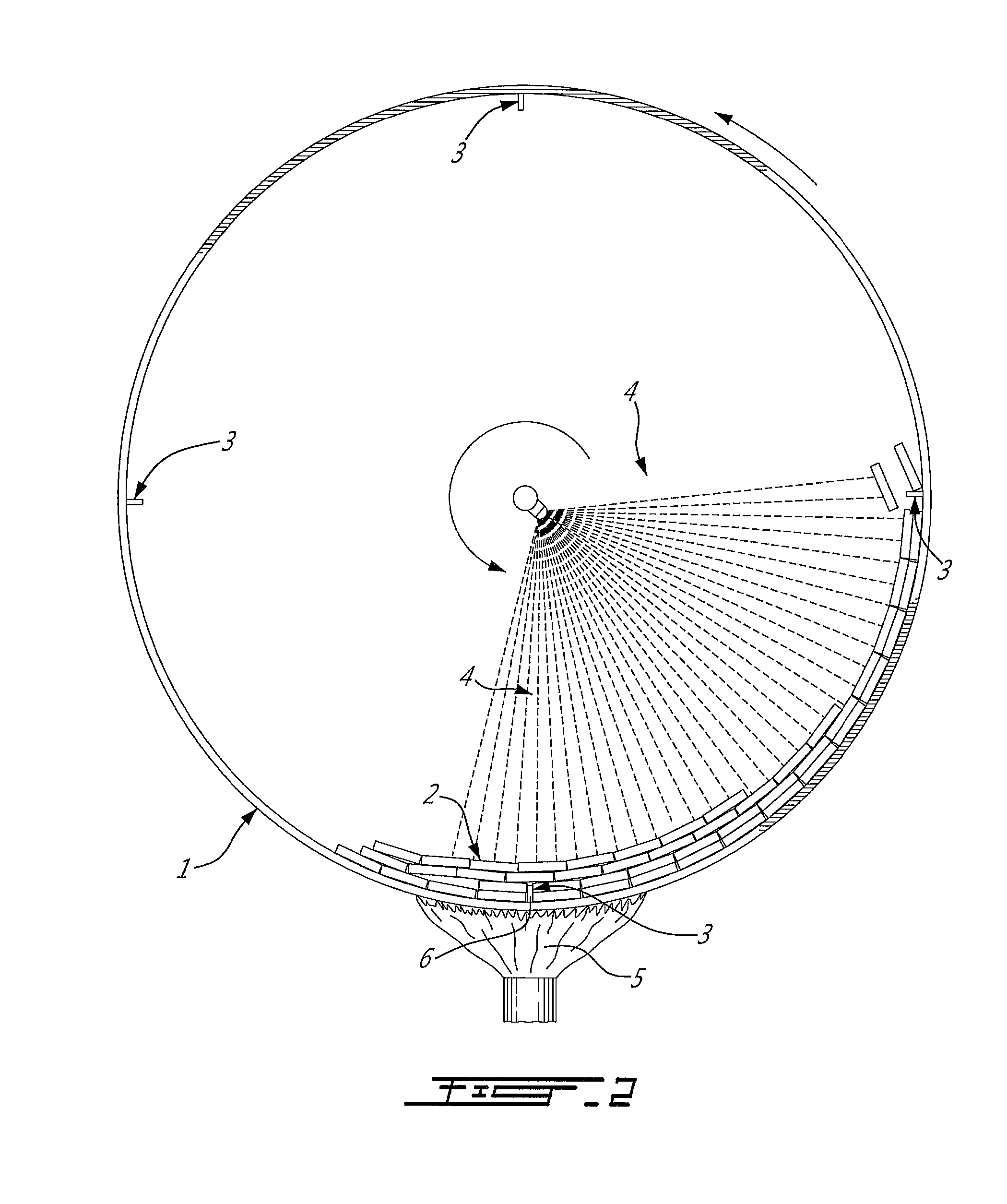

Methods and Apparatus for Solid Carbonaceous Materials Synthesis Gas Generation

ActiveUS20090126270A1Waste based fuelIndirect heating destructive distillationFlue gasMaterial synthesis

Methods and apparatus may permit the generation of consistent output synthesis gas from highly variable input feedstock solids carbonaceous materials. A stoichiometric objectivistic chemic environment may be established to stoichiometrically control carbon content in a solid carbonaceous materials gasifier system. Processing of carbonaceous materials may include dominative pyrolytic decomposition and multiple coil carbonaceous reformation. Dynamically adjustable process determinative parameters may be utilized to refine processing, including process utilization of negatively electrostatically enhanced water species, process utilization of flue gas (9), and adjustment of process flow rate characteristics. Recycling may be employed for internal reuse of process materials, including recycled negatively electrostatically enhanced water species, recycled flue gas (9), and recycled contaminants. Synthesis gas generation may involve predetermining a desired synthesis gas for output and creating high yields of such a predetermined desired synthesis gas.

Owner:THERMOTEK

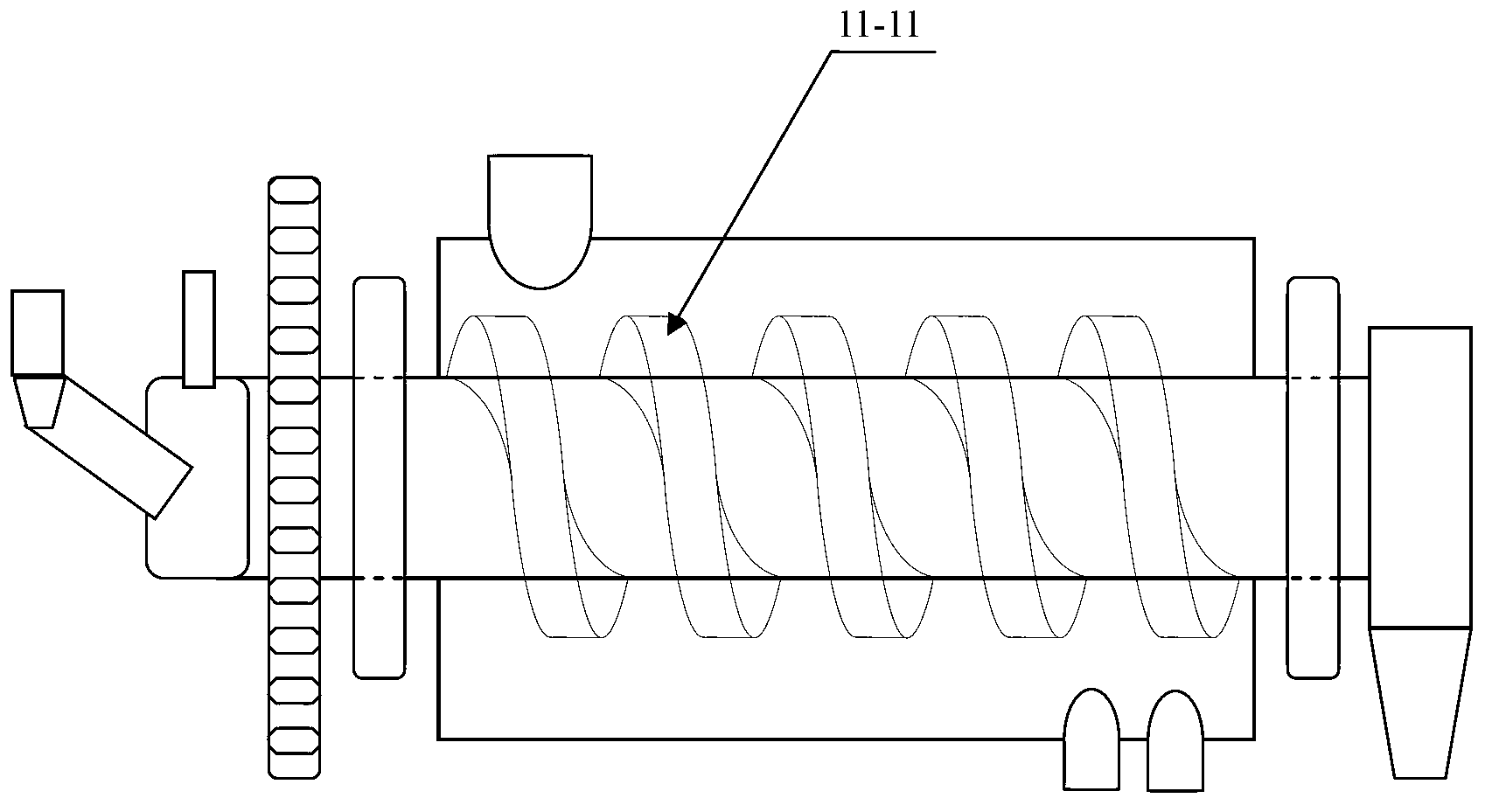

Carbonization furnace for producing biomass charcoal

InactiveCN101899311ASimple processImprove efficiencyBiofuelsSpecial form destructive distillationCoaxial lineCarbonization

The invention discloses a carbonization furnace for producing biomass charcoal. The carbonization furnace comprises a smoke tube, a rotary furnace body, a feeding hopper, a discharging hopper and an oil and gas discharging pipe, wherein the rotary furnace body is supported by rotary supporting rollers; the feeding hopper, the discharging hopper and the oil and gas discharging pipe are arranged on the rotary furnace body; the smoke tube is arranged in the rotary furnace body and is coaxial with the rotary furnace body; and the inner wall of the rotary furnace body is provided with helical blades or an angle which is more than 5 degrees and less than 30 degrees is formed between the coaxial line of the smoke tube and the rotary furnace body and the horizontal plane. The biomass charcoal is produced by the following steps that: a biomass material enters the carbonization furnace from the feeding hopper; a motor drives the carbonization furnace to rotate; the helical blades in the furnace stir the material and push the biomass material to move forwards or from top to bottom; the material absorbs the heat of the outer wall so as to evaporate the moisture; and the biomass material is carbonized and discharged from the discharging hopper. The carbonization furnace has the advantages of realizing continuous production, saving the energy resource, improving the production efficiency and reducing the labor intensity, along with simple production process, high efficiency, low labor consumption and low labor intensity.

Owner:肖国雄

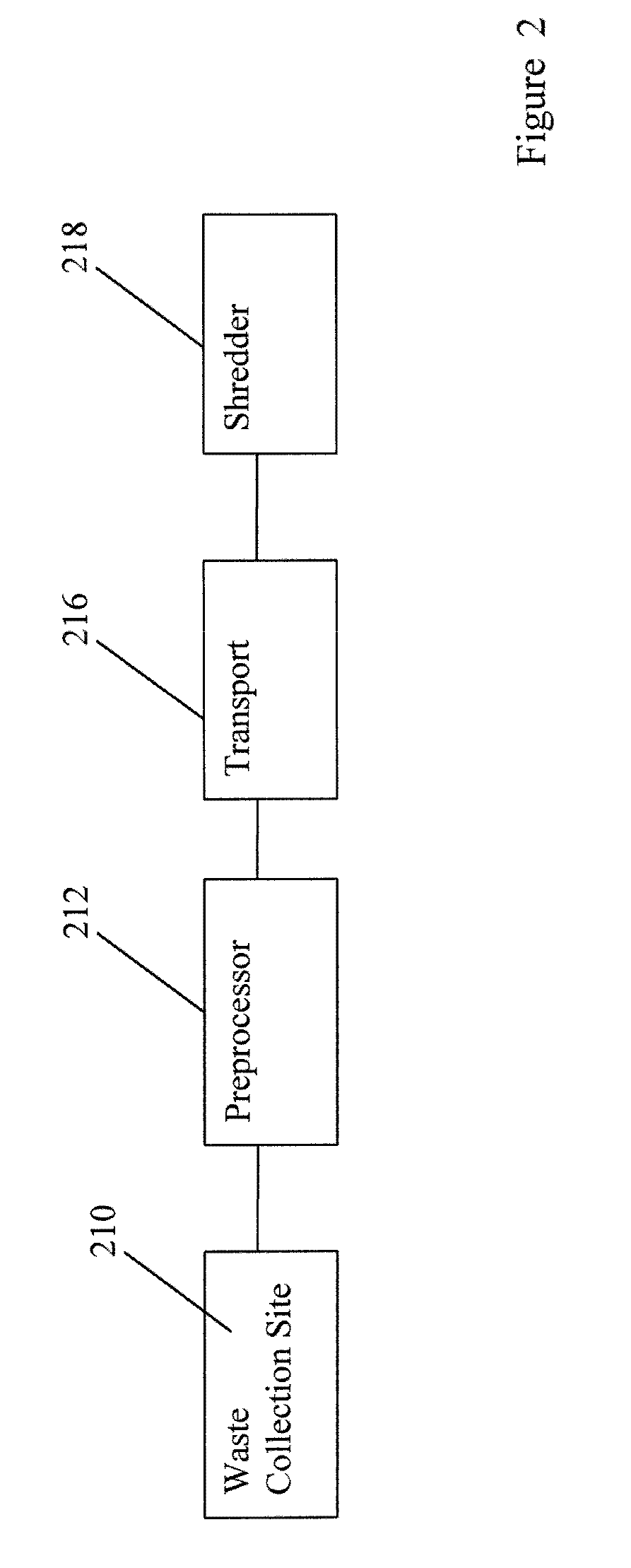

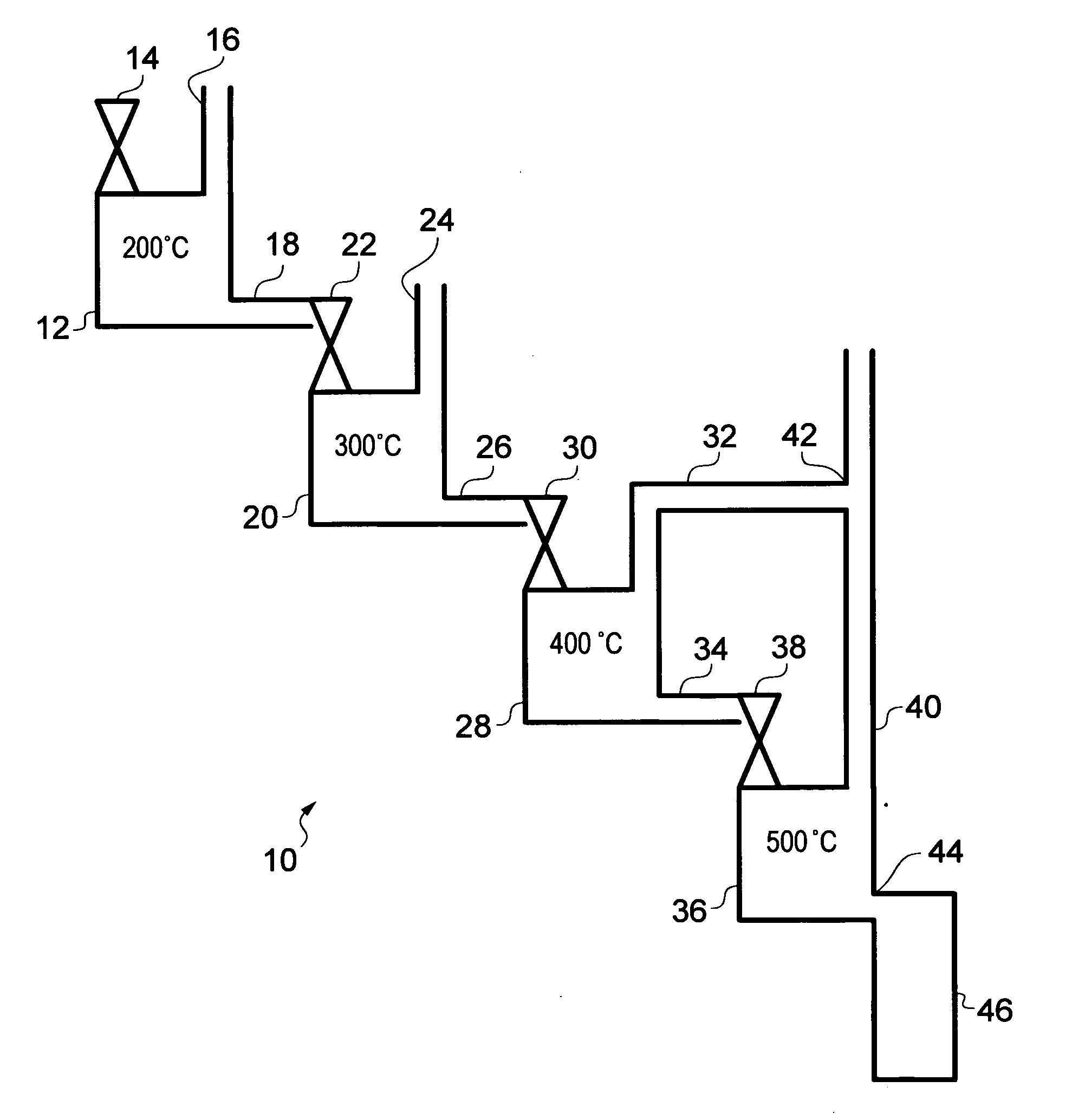

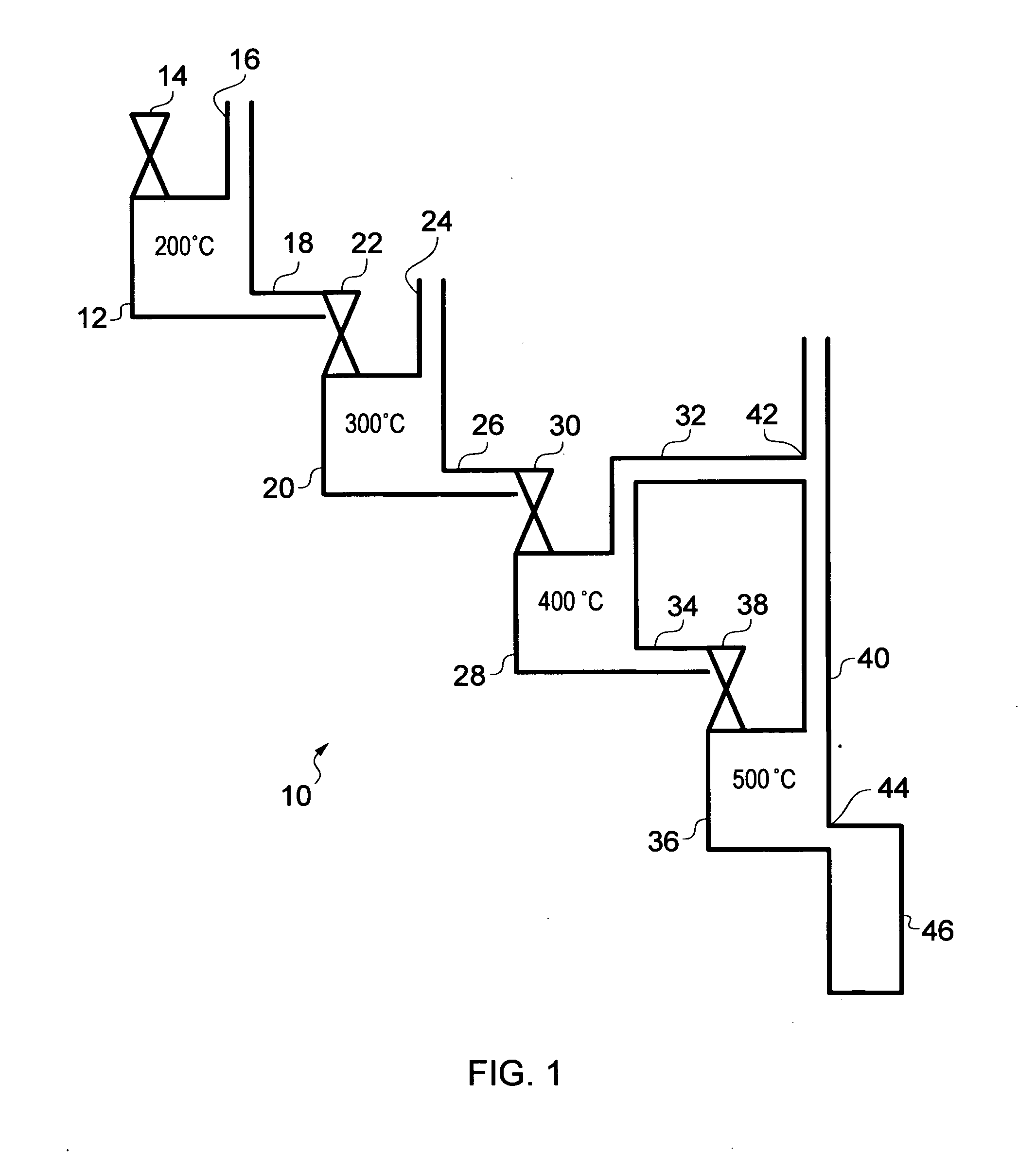

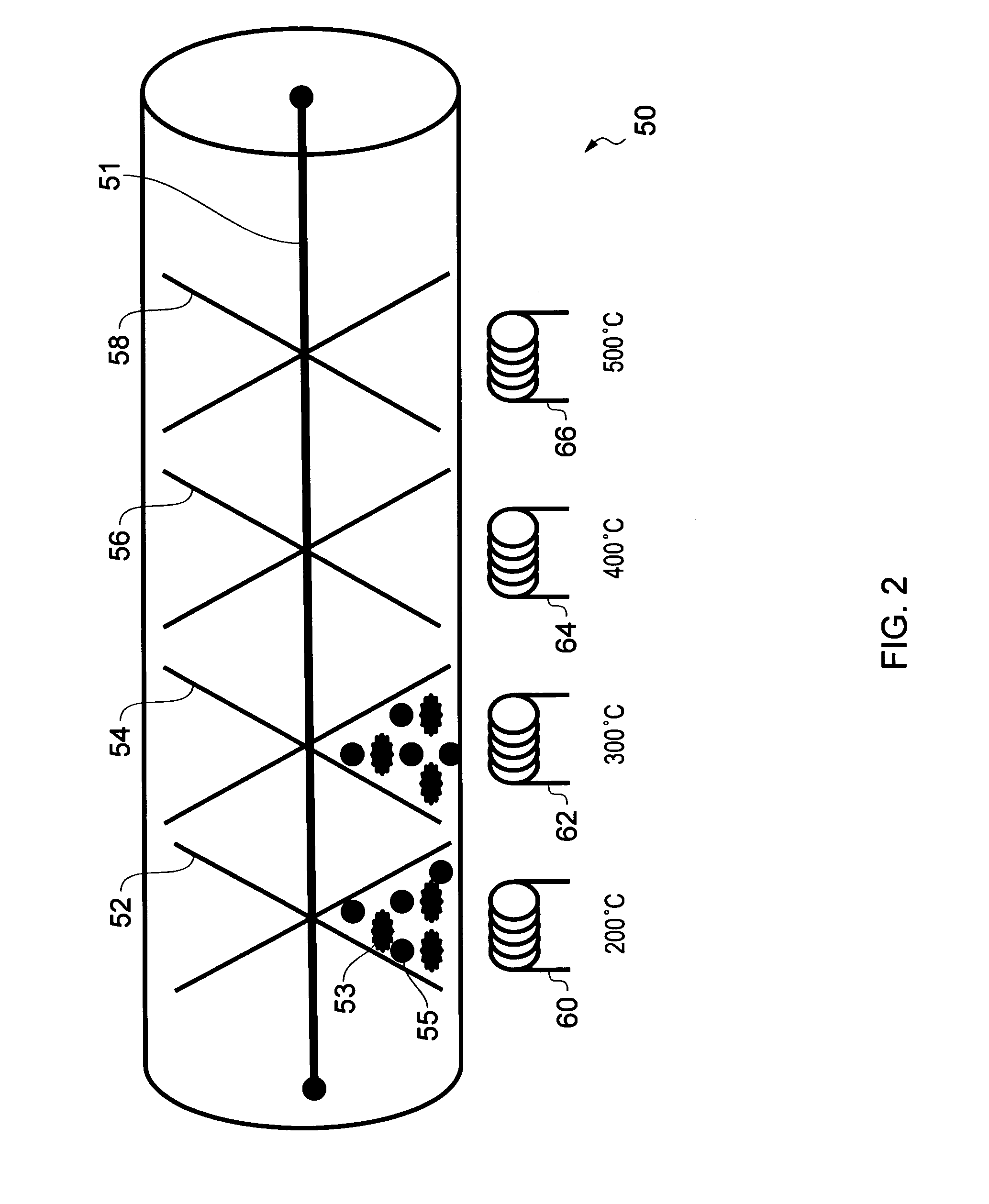

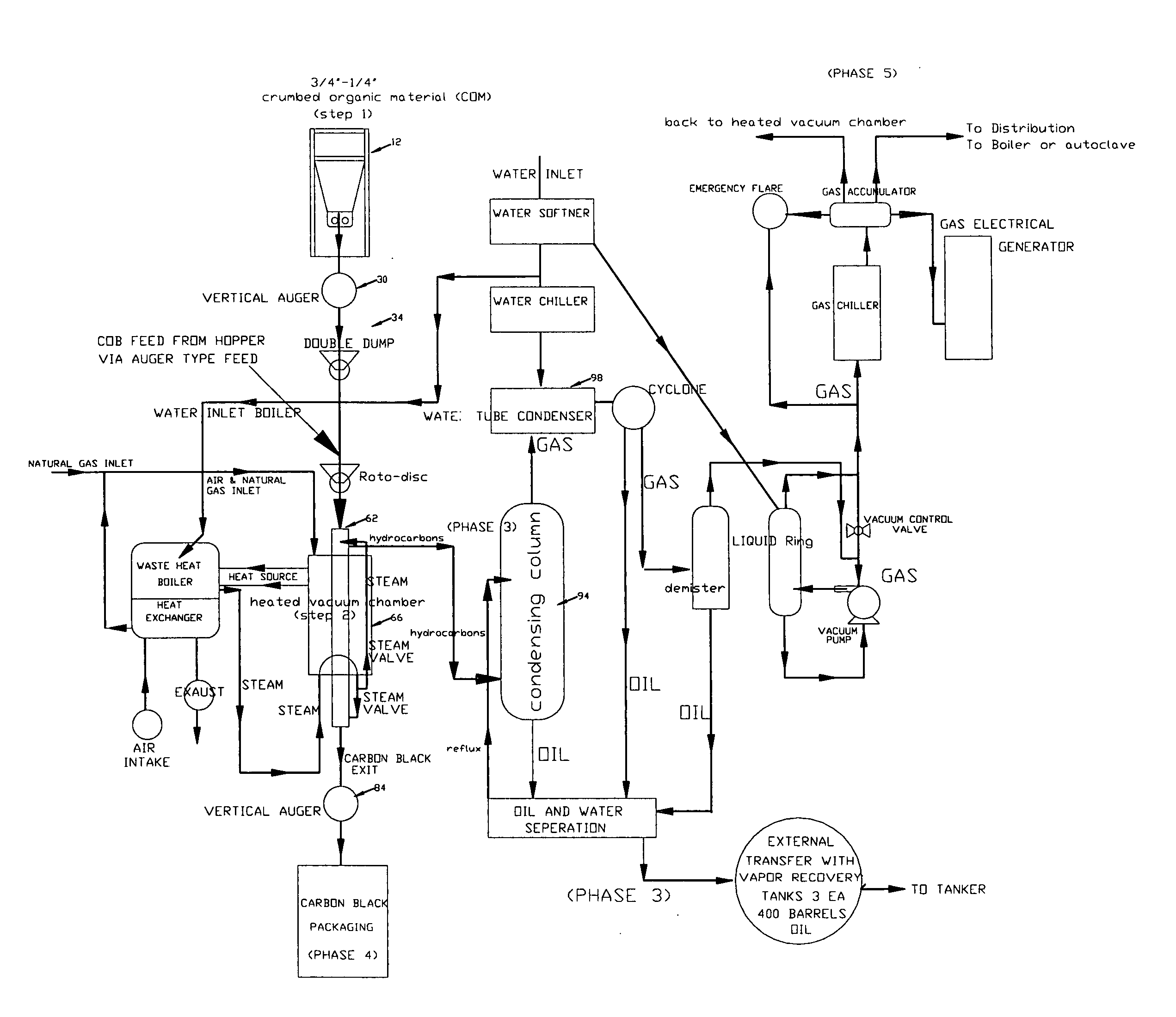

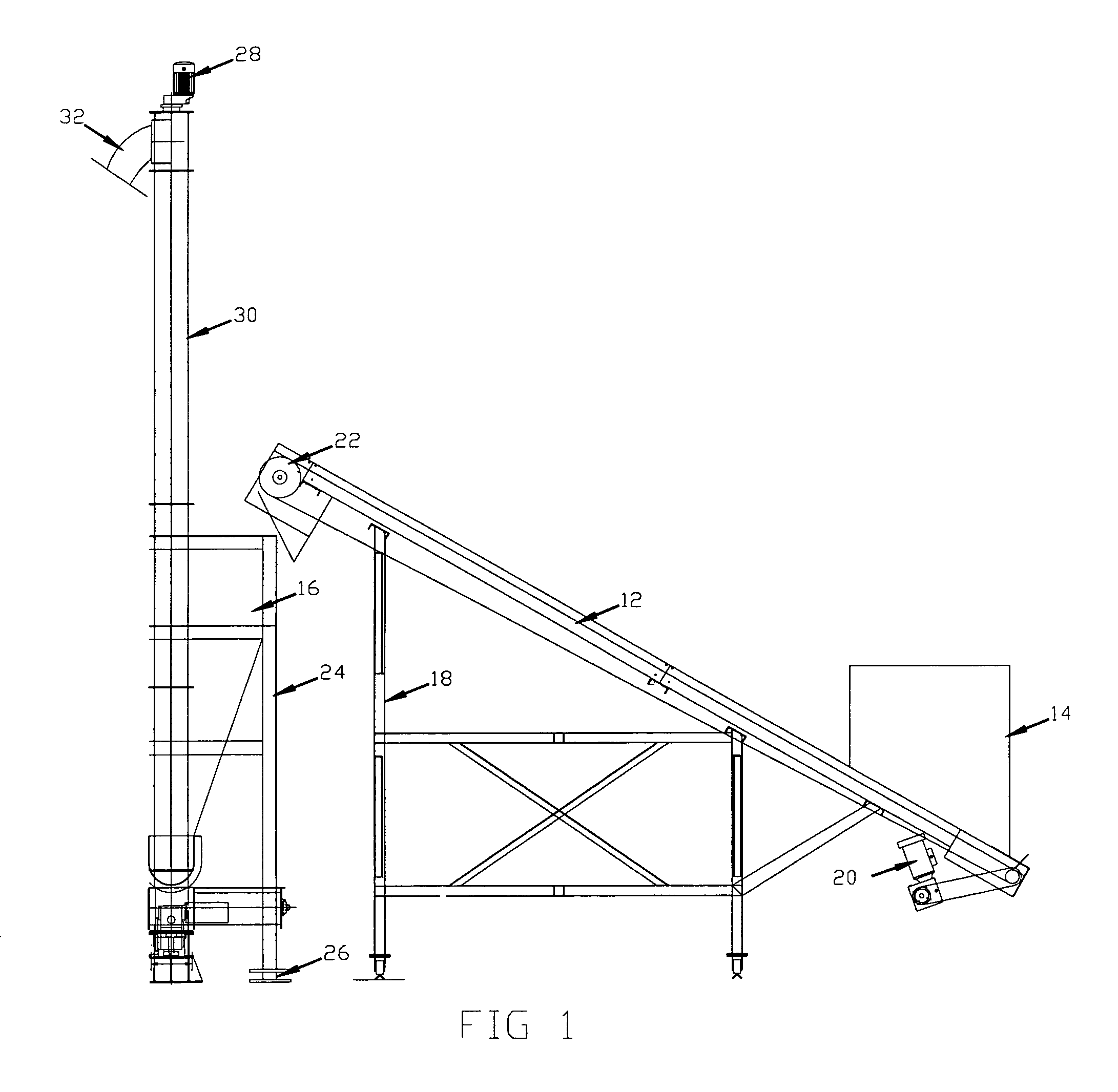

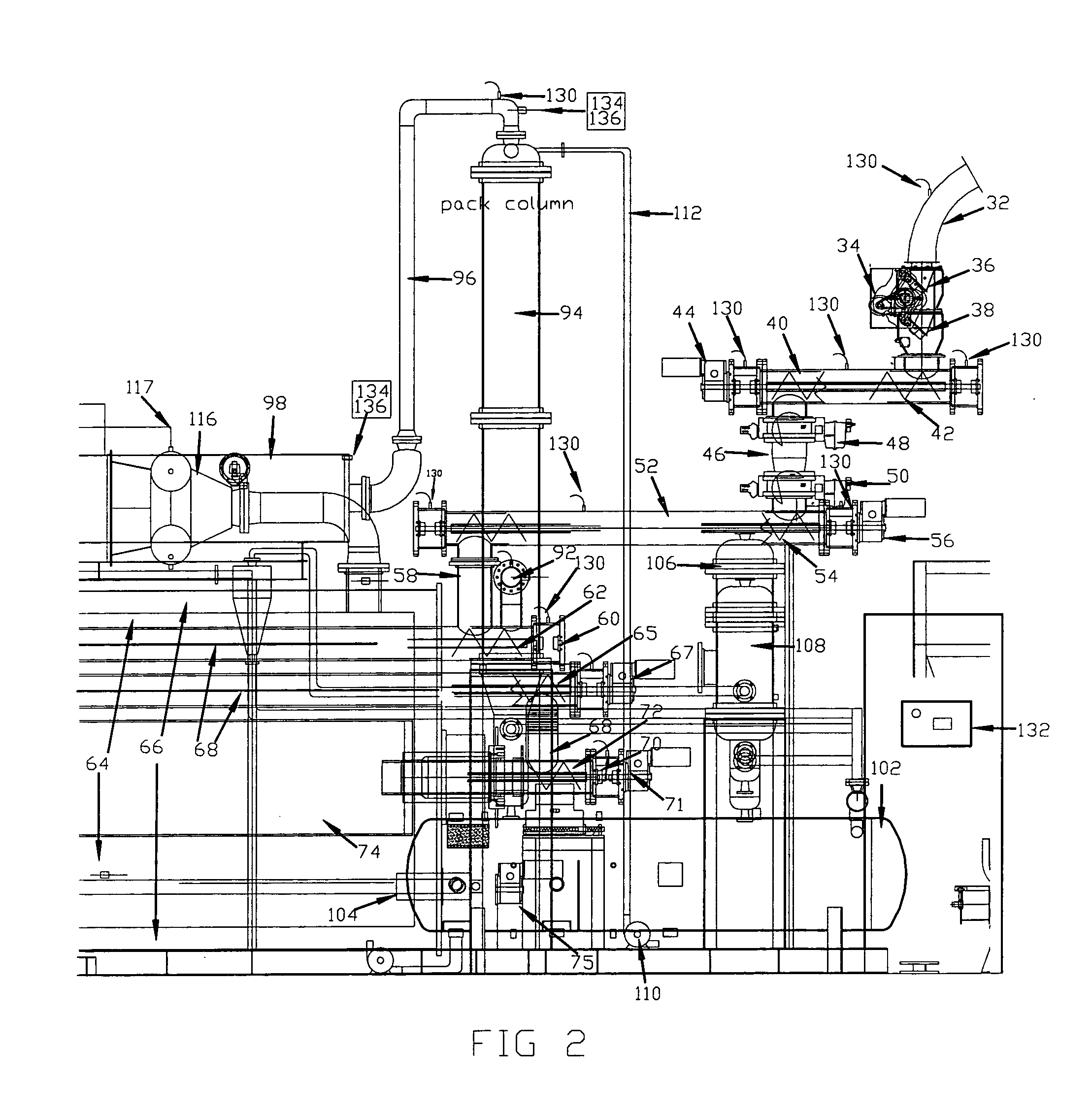

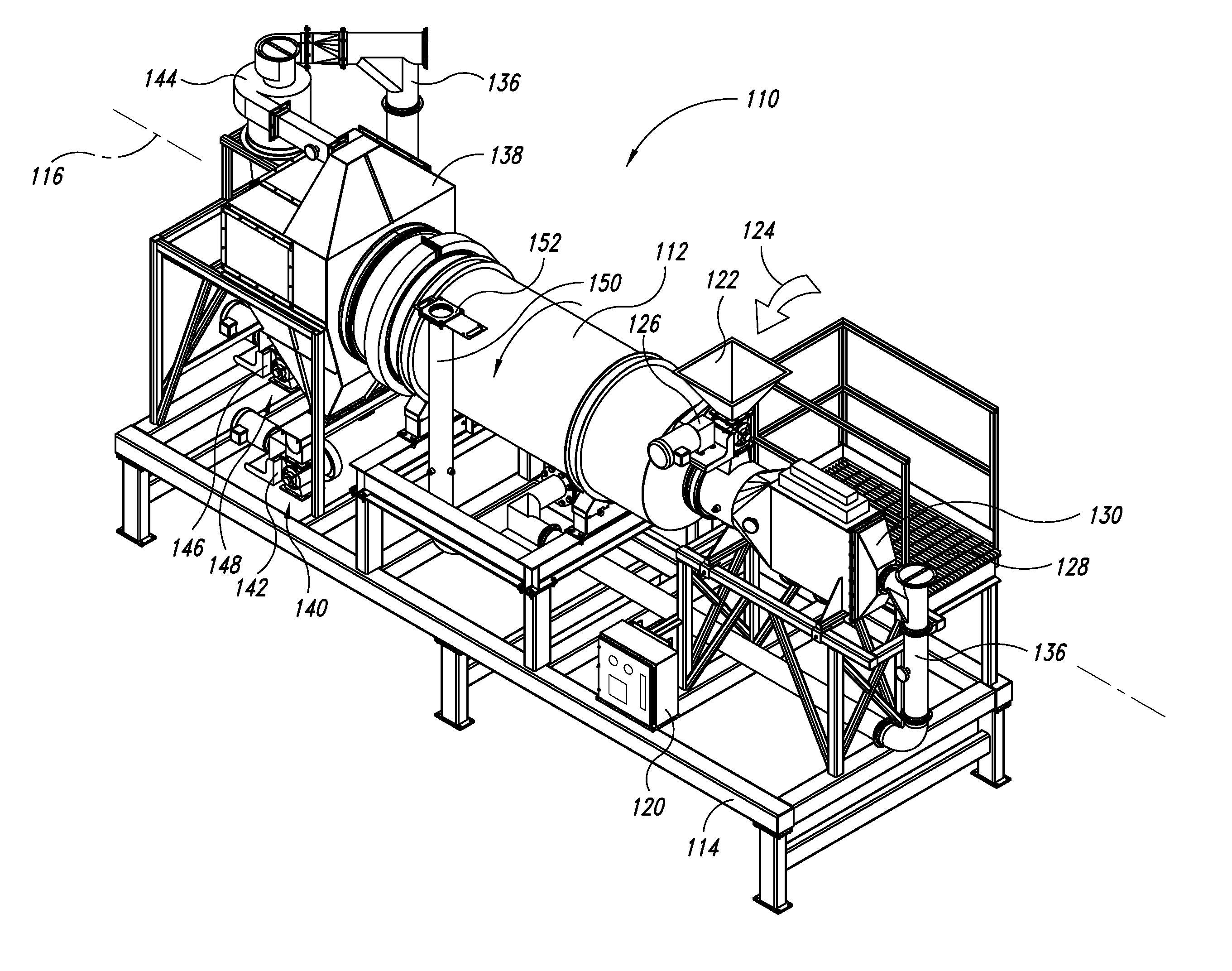

System and method for recycling waste into energy

ActiveUS20070000768A1Combustible gas coke oven heatingTransportation and packagingHydrocotyle bowlesioidesControl valves

A system for recycling solid waste into energy includes a heated enclosure 66, one or more input conveyors 60, 67 move waste materials through the heated enclosure, provide a flow line with a temperature gradient of at least 150F°, and mechanically move the waste particles and the residual solids along the flow line. A heated rotary drum 74 is in fluid communication with the flow line, and condenser unit 94, 98 receive vapors from the flow line and the rotary drum and output hydrocarbons. One or more discharge conveyors 76 discharge carbon black from the rotary drum. Control valves 80, 82 seal a vacuum downstream from the discharge conveyors, and control valves 34, 46 seal vacuum upstream from the one or more input conveyors. Various types of vacuum pumps may be used to maintain a selected vacuum between the control valves.

Owner:EFFICIEN TECH

Biomass torrefaction system and method

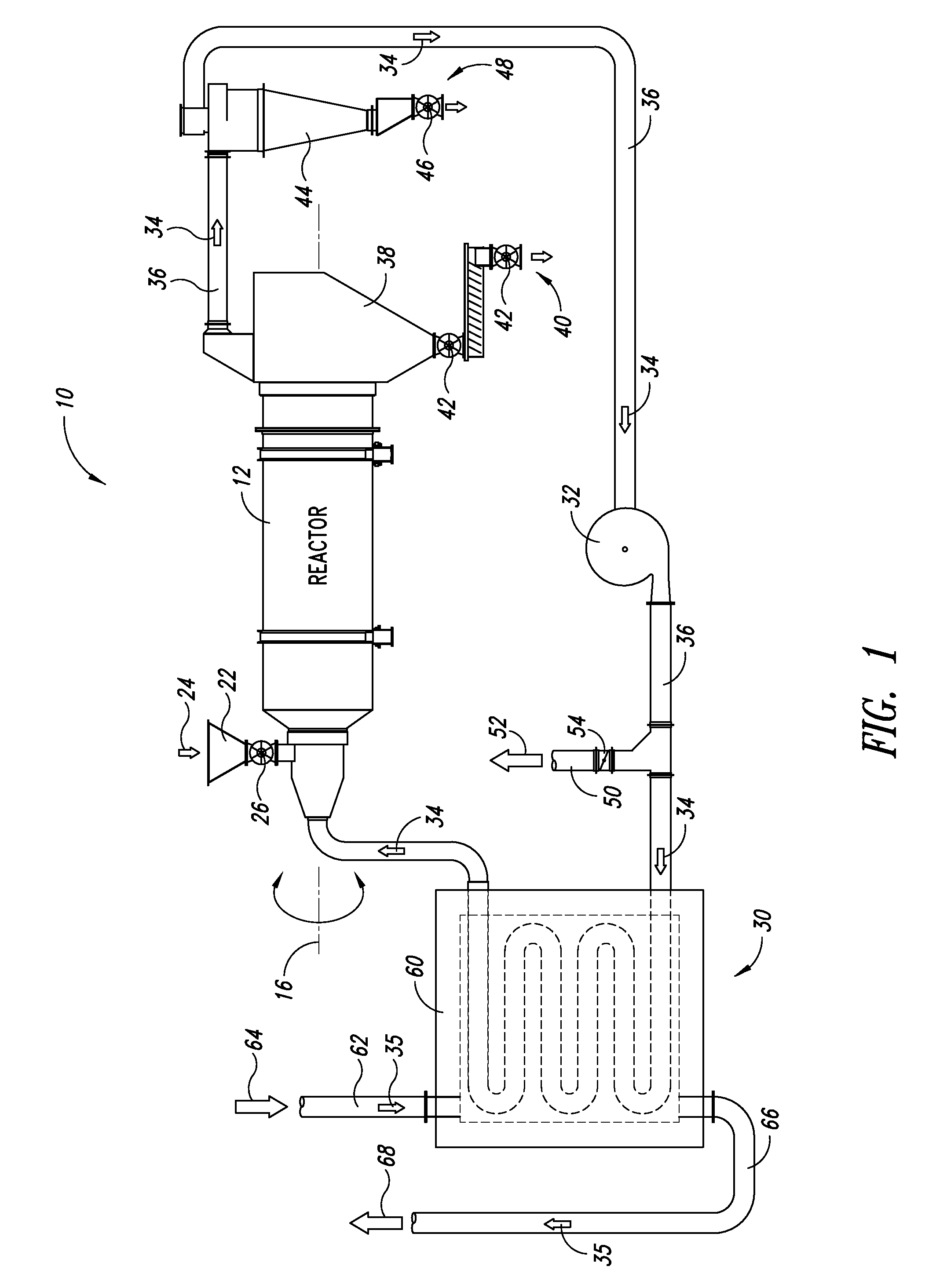

ActiveUS8246788B2Improve scalabilityEasy to controlCombustible gas coke oven heatingDrying solid materials with heatProcess engineeringTorrefaction

A biomass torrefaction system is provided which enables a continuous torrefaction process that involves the introduction of biomass particles into a rotating reactor drum having a low oxygen environment. The particles are conveyed through the drum by a heated gas stream and simultaneously torrefied thereby. Gas exiting the drum is recirculated back to a heat source for reheating the gas prior to reentering the drum. A method of biomass torrefaction is also provided.

Owner:TEAL SALES

Methods and Apparatus for Solid Carbonaceous Materials Synthesis Gas Generation

Methods and apparatus may permit the generation of consistent output synthesis gas from highly variable input feedstock solids carbonaceous materials. A stoichiometric objectivistic chemic environment may be established to stoichiometrically control carbon content in a solid carbonaceous materials gasifier system. Processing of carbonaceous materials may include dominative pyrolytic decomposition and multiple coil carbonaceous reformation. Dynamically adjustable process determinative parameters may be utilized to refine processing, including process utilization of negatively electrostatically enhanced water species, process utilization of flue gas (9), and adjustment of process flow rate characteristics. Recycling may be employed for internal reuse of process materials, including recycled negatively electrostatically enhanced water species, recycled flue gas (9), and recycled contaminants. Synthesis gas generation may involve predetermining a desired synthesis gas for output and creating high yields of such a predetermined desired synthesis gas.

Owner:THERMOTEK

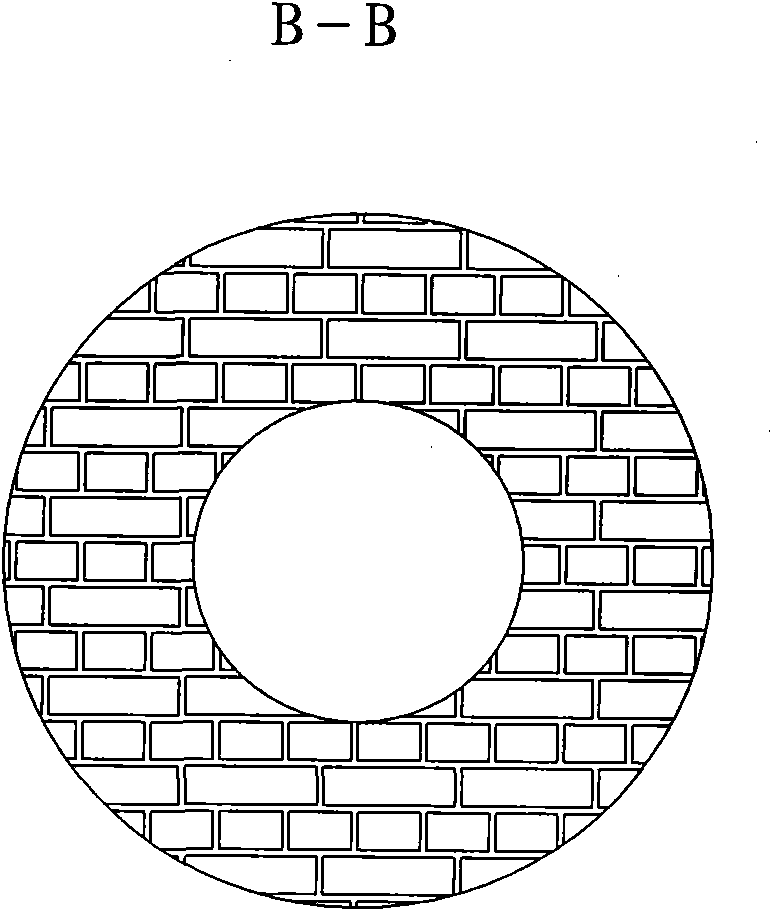

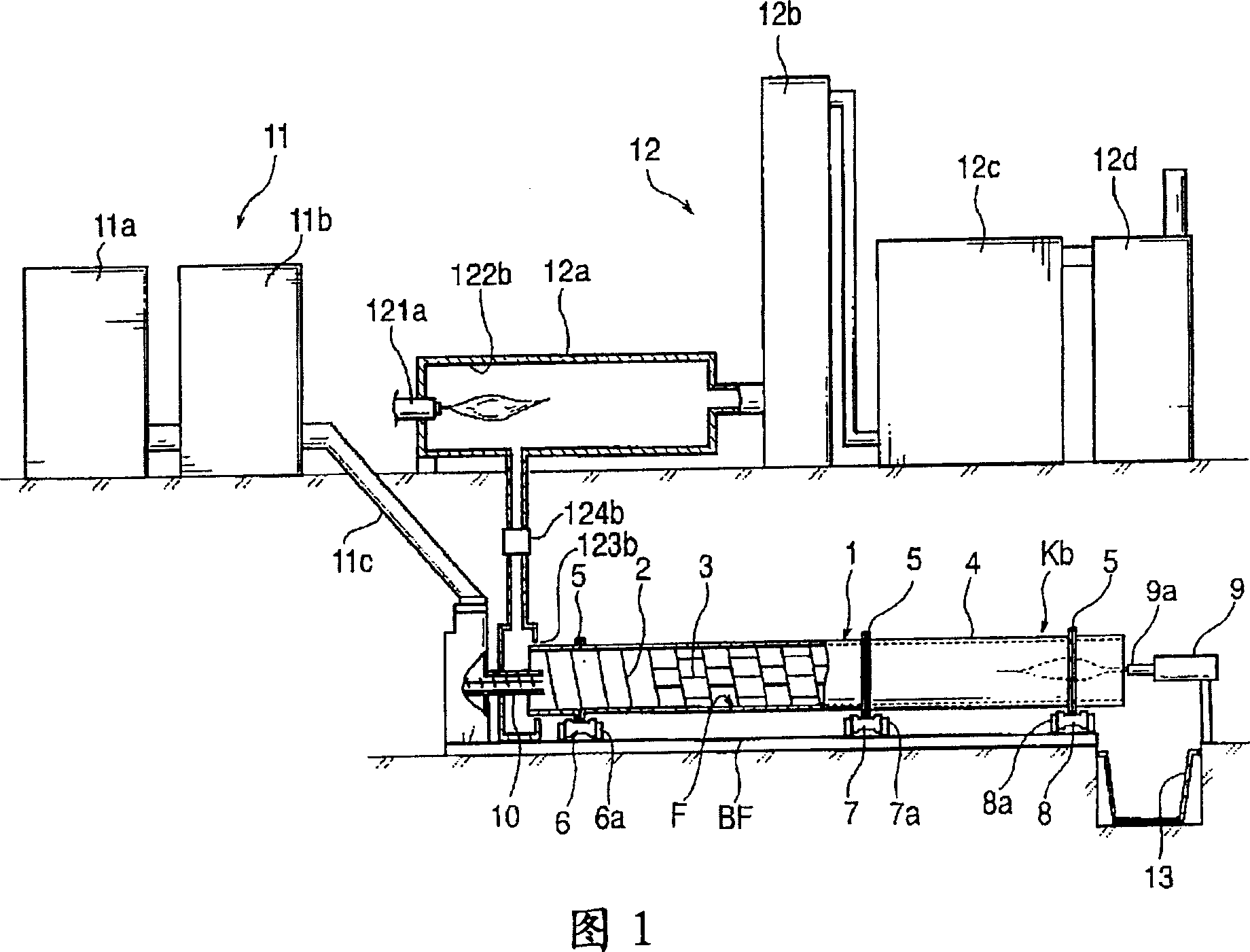

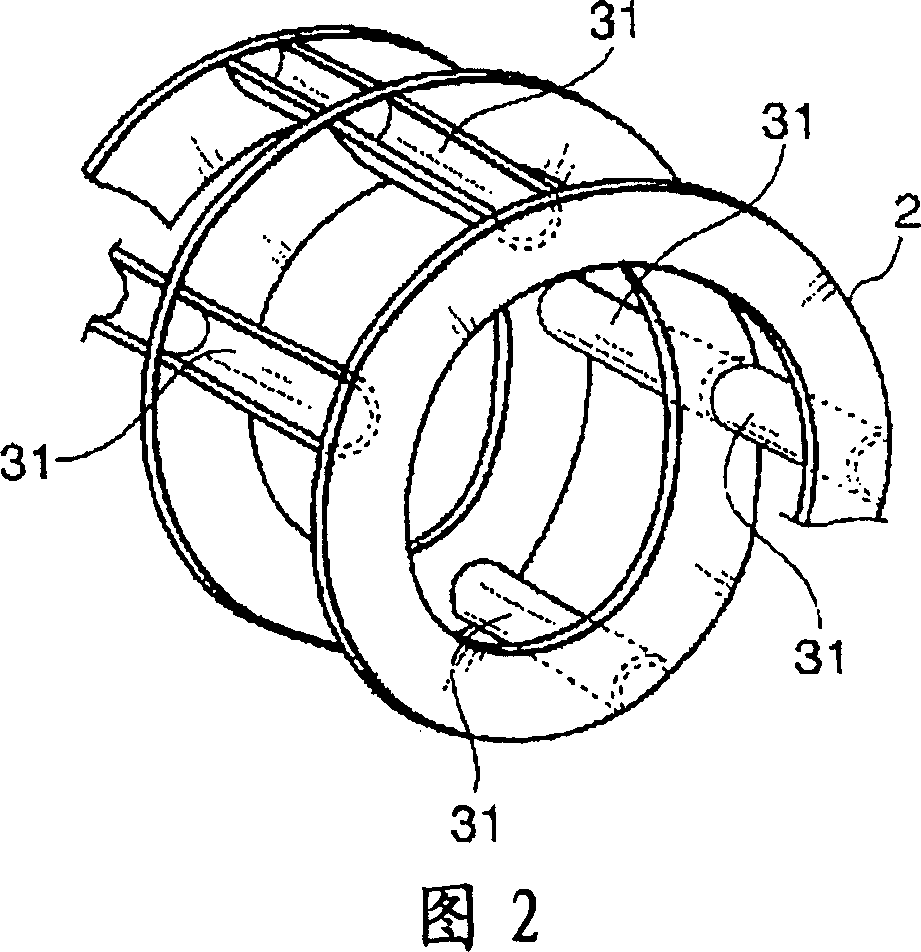

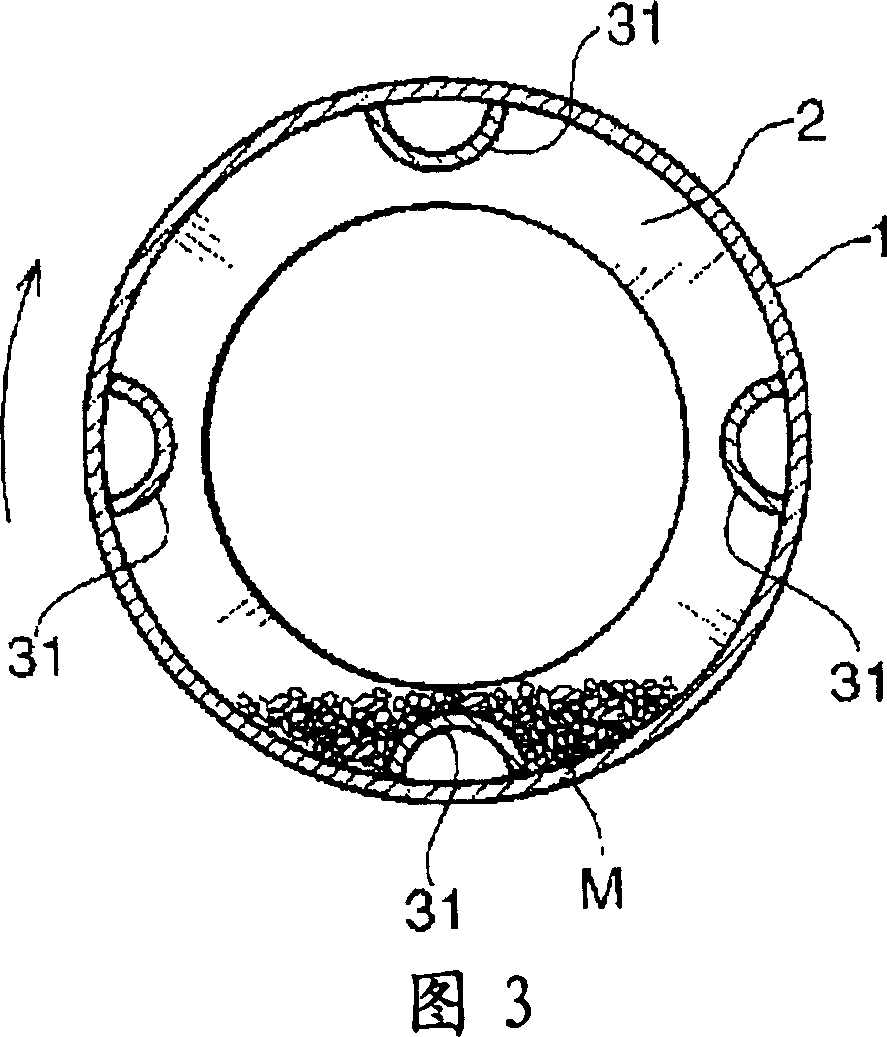

Continuous carbonizing treatment method by internal heating self-combusting mode

The present invention provides a processing method which can process biomass resources to a carbide having a uniformity and including a large amount of high-carbon charcoal, can hold down an initial cost while capable of executing a large amount of process (for example, 100 ton per day), has a low running cost while can suppress a fuel consumption to a significantly low level, and can continuously carbonize a object having a high water content, having an unstable shape and having a high viscosity such as a sewage sludge even being a simple structure. The carbonization processing method has the steps of (i) continuously supplying a processing object M which is not preliminarily treated, or a processing object M which is formed at a predetermined magnitude by a preliminary treatment such as a fragmentation, a water content reduction or the like, from an upstream side of a cylindrical rotary kiln in which a spiral carrier wall is provided in an inner peripheral surface in an entire length and an agitating wall cutting across the carrier wall is formed in the carrier wall in a middle portion from the upstream side at a predetermined unit amount while rotating the rotary kiln, (ii) blowing a flame in an inner portion of the rotary kiln from a downstream side in a carrying direction of the rotary kiln in the state (i), and stopping the blowing of the flame if the processing object M is ignited within the rotary kiln, (iii) supplying an air necessary for burning a combustible gas generated from the processing object M to an inner portion of the rotary kiln from a downstream side, and self burning the combustible gas without supplying any fuel, (iv) sucking a gas generated in the inner portion of the rotary kiln from the upstream side of the rotary kiln so as to detoxify and discharge, and (v) discharging the carbide of the processing object M from an outlet in the downstream side of the rotary kiln so as to cool by executing the operations in the (i) to (iv).

Owner:MAYEKAWA MFG CO LTD

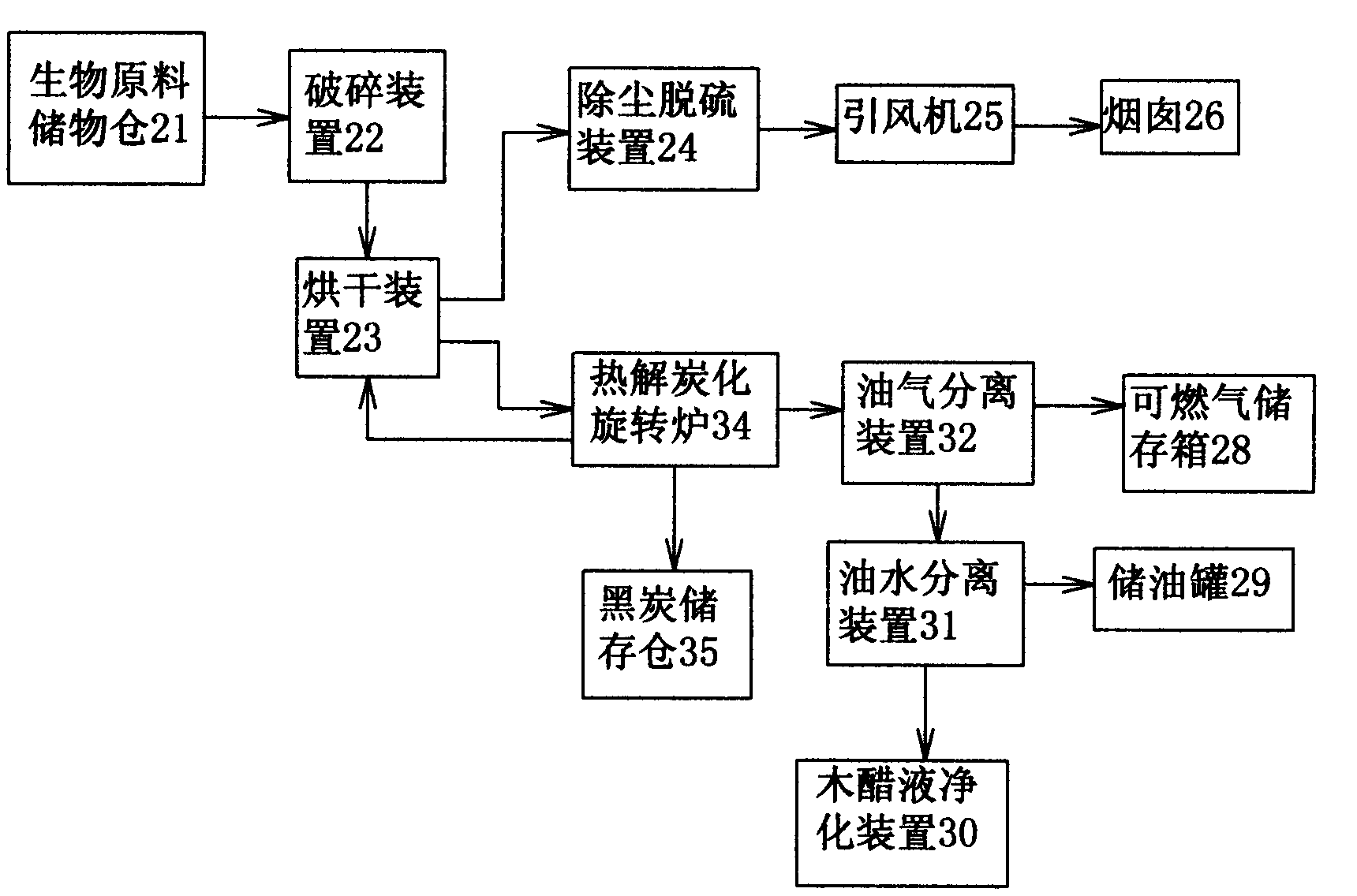

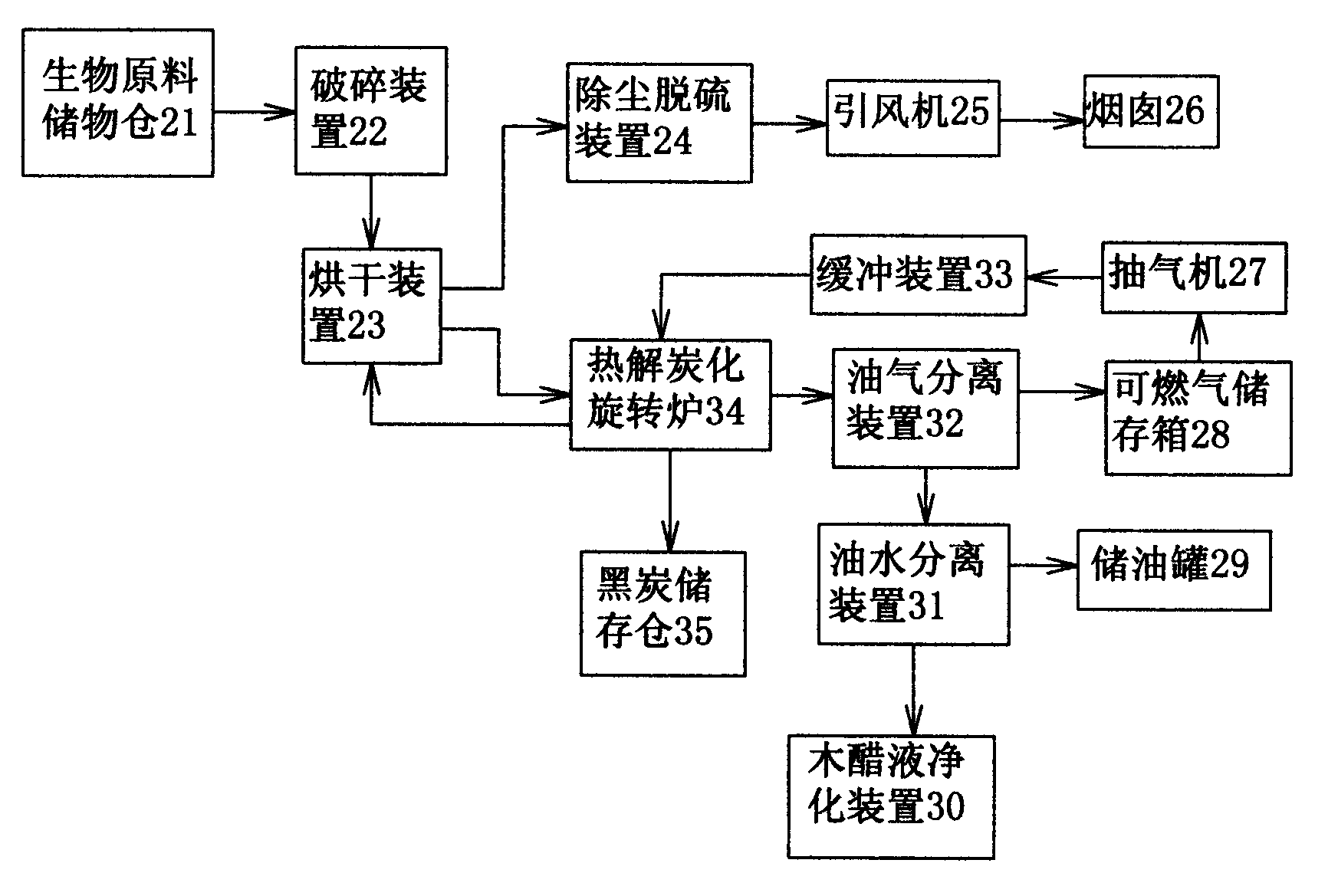

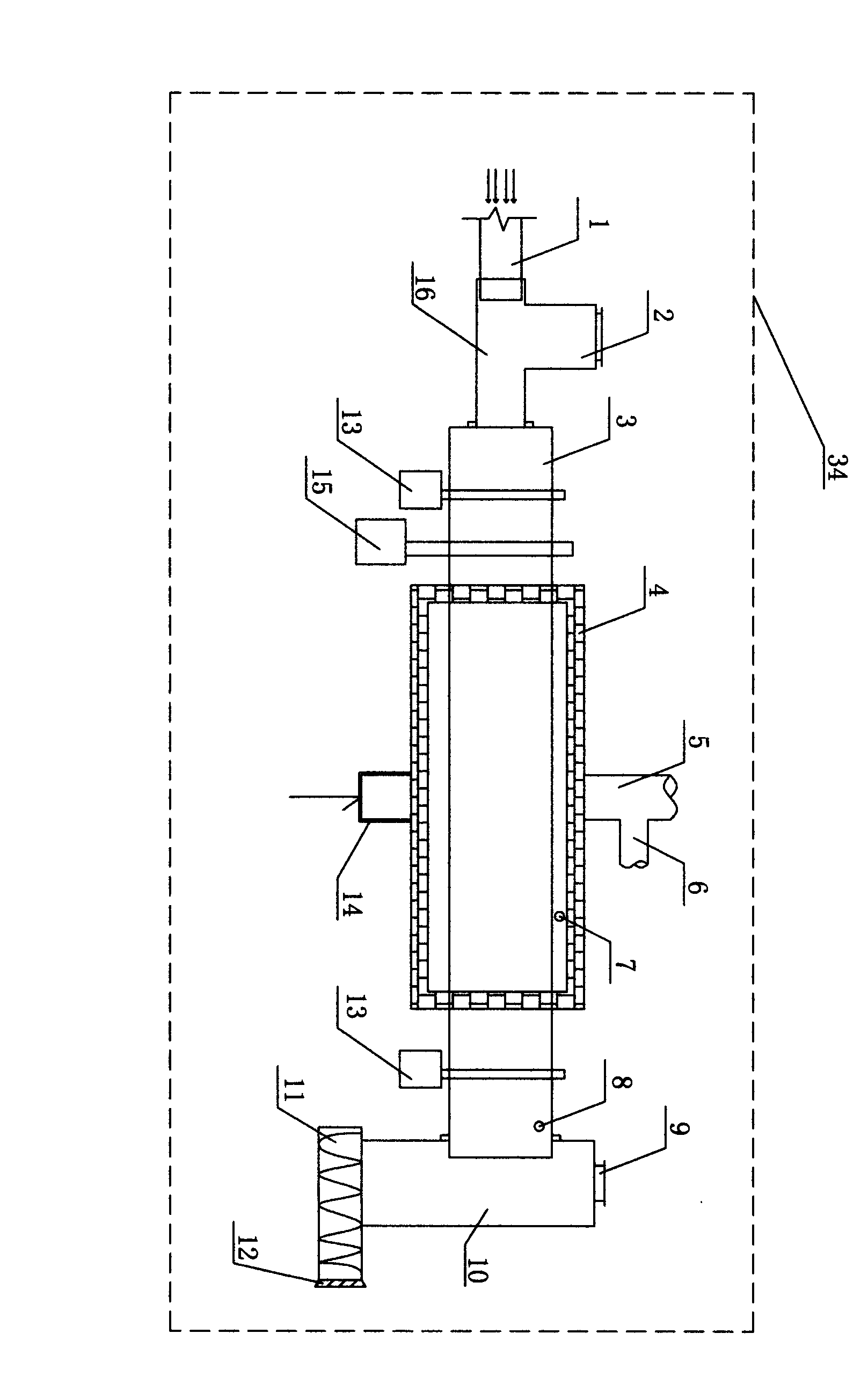

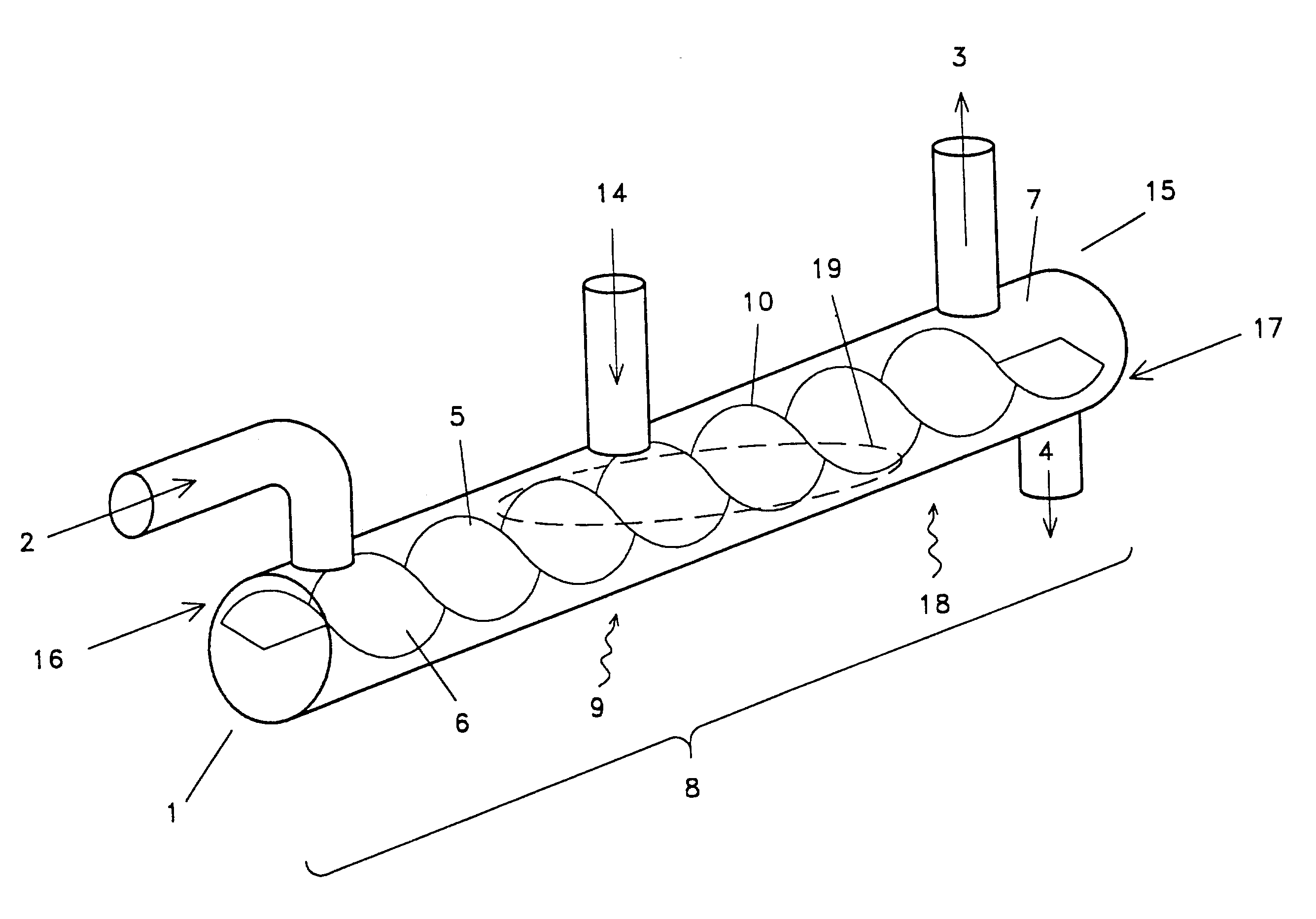

Biomass pyrolysis carbonization system equipment

InactiveCN103627415AGuaranteed tightnessGuaranteed hypoxic environmentBiofuelsIndirect heating destructive distillationAgricultural engineeringCarbonization

The invention discloses biomass pyrolysis carbonization system equipment and relates to the field of pyrolysis carbonization equipment. The biomass pyrolysis carbonization system equipment is characterized in that a biomass raw material storage tank is connected to a breaker; the breaker is connected to a drying device; the drying device is connected respectively to a dust-removal and desulfurization device and a pyrolysis carbonization rotary furnace; the dust-removal and desulfurization device is connected to an induced draft fan; the induced draft fan is connected to a chimney; the pyrolysis carbonization rotary furnace is connected respectively to an oil-gas separation device and a black carbon storage bin; the oil-gas separation device is connected respectively to a combustible gas bottle storage tank and an oil-water separation device; the oil-water separation device is connected respectively to an oil storage tank and a pyroligneous liquor purifier; and the pyrolysis carbonization rotary furnace is connected to the drying device. The biomass pyrolysis carbonization system equipment realizes high-efficiency carbonization treatment on biomass, continuous feeding and continuous discharge, has a high carbon yield, improves a work environment, realizes industrial production, and has short carbonization time and low energy consumption.

Owner:SHANGHAI ZHONGKE ANDA ENERGY SAVING PROD TECH

Continuous coking refinery methods and apparatus

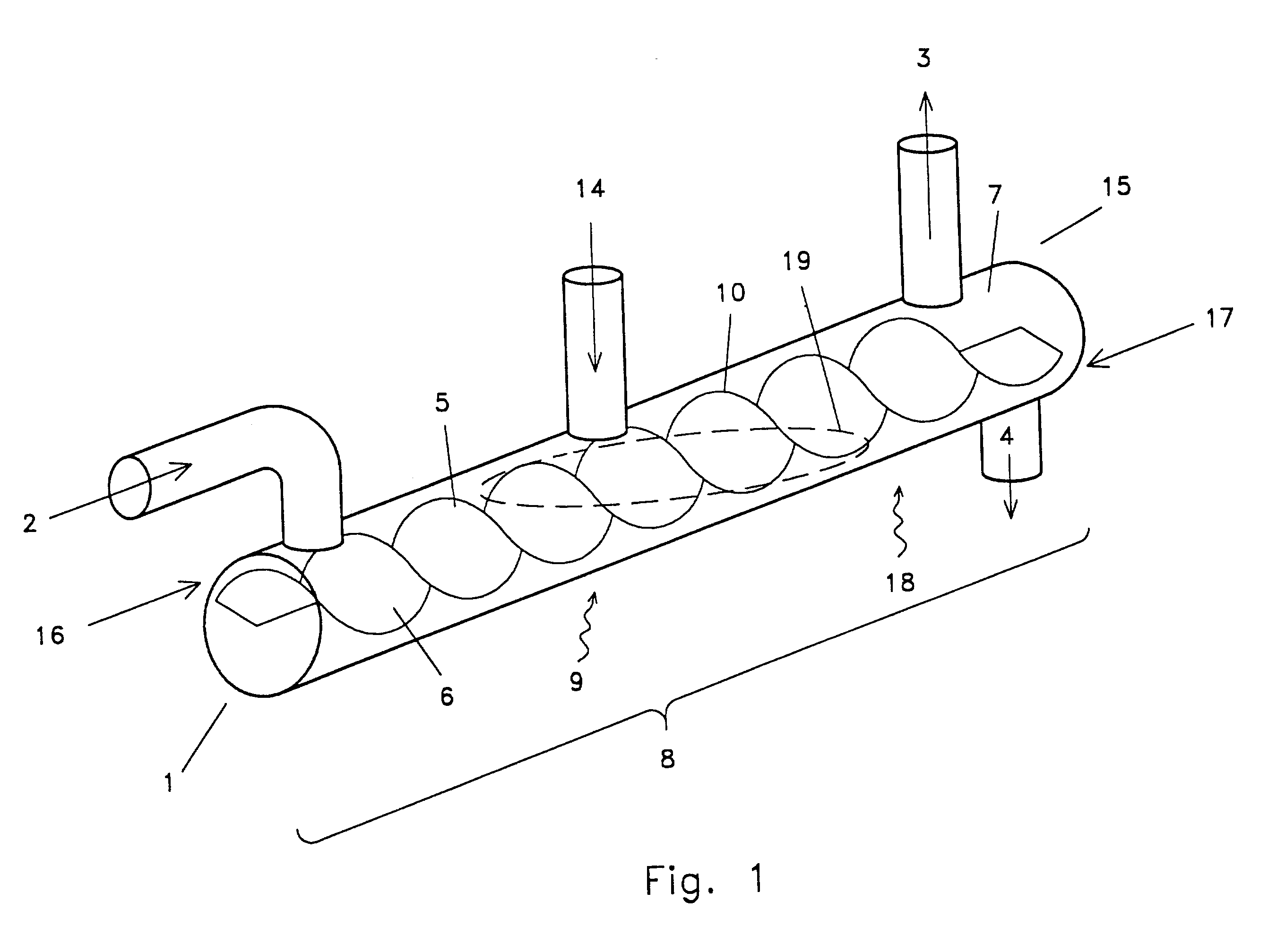

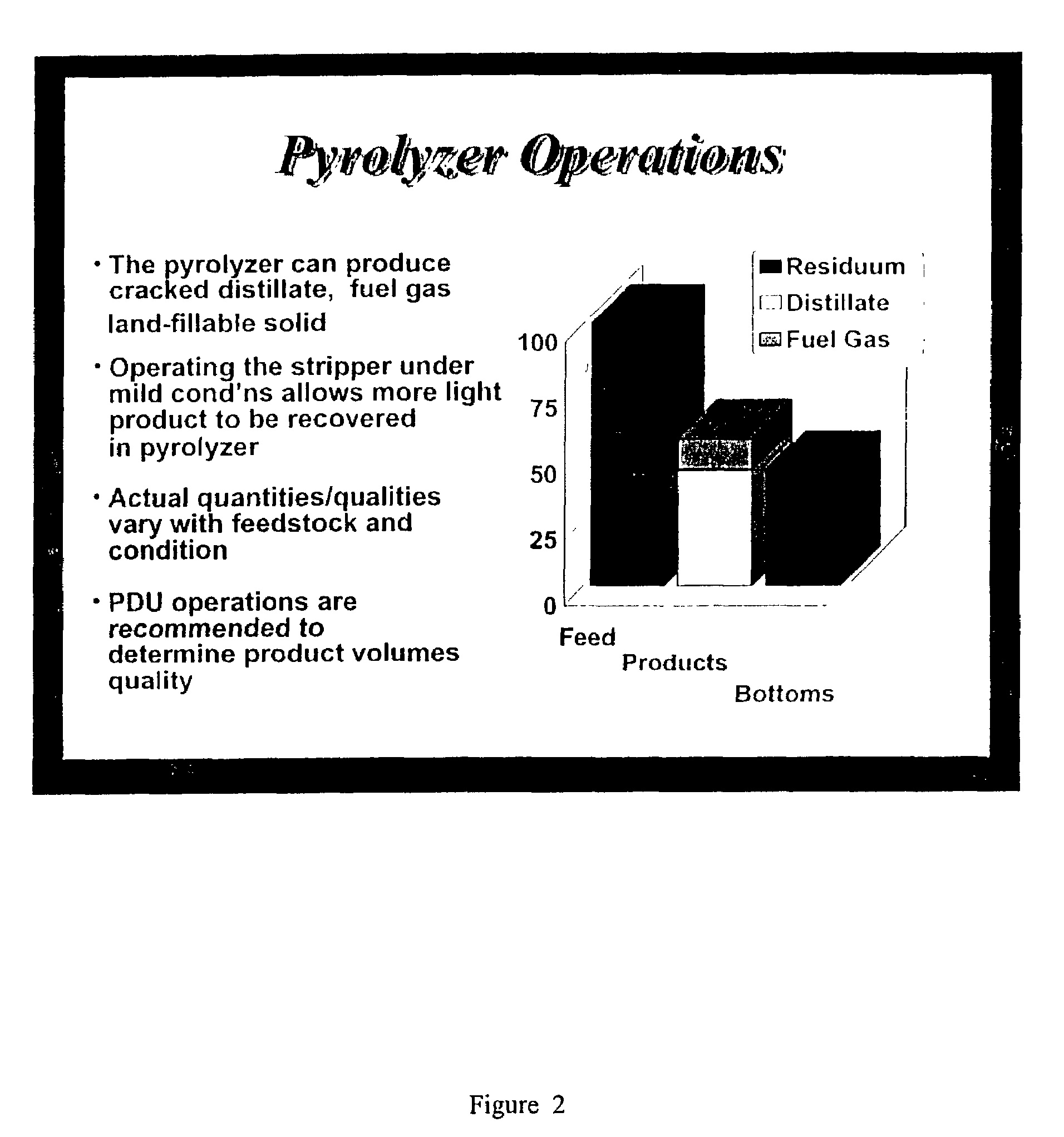

InactiveUS6972085B1Constant and continuousEfficiently conductedThermal non-catalytic crackingCombustible gas coke oven heatingProduct gasProcess engineering

A system for refining hydrocarbon containing materials in a continuous coking mode may provide a pyrolyzer (1) which may be inclined to effect a liquid seal between a liquid conduction environment (6) and a gaseous conduction environment (7). A heat source (9) may heat the material past the coking point and the system may include a screw or auger (10) which can continuously remove the coke while simultaneously outputting refined products.

Owner:WESTERN RES INST INC +2

Method and apparatus for processing a waste product

InactiveUS20040084294A1Mechanical conveying coke ovensCombustible gas coke oven heatingSyngasWaste product

A method and apparatus for processing a waste product and producing a synthesis gas is provided. The system includes a sealed, heated rotatable drum for preheating and preparing the waste material suitable for a plasma reactor, and processing the material in the reactor. The synthesis gas created by the reactor is used to preheat the waste material by circulating the hot synthesis gas around the drum. In an alternative embodiment, the hot synthesis gas flows through the drum to preheat the waste material and to clean the synthesis gas. Different methods of cooling and cleaning the synthesis gas are used. The system may comprise two plasma reactors in combination with a rotating desorber drum.

Owner:DURATHERM

Mobile plant for thermally treating a contaminated or uncontaminated feed stream, processes thereof and uses of products thereof

InactiveUS20150368564A1Reduce transportationVolume of oilThermal non-catalytic crackingElectrical coke oven heatingPositive pressureReactor design

Mobile plant, for thermally treating a feed stream, comprising a first unit designed for heating the feed oil (Unit I); ii. a second unit comprising a rotating reactor designed to perform the thermal processing (pyrolizing) of the feed oil and a vapour solid separator (Unit II); and iii. a third unit (Unit III) that is a product separation unit and that is preferably configured for recycling at least part of the treated feed stream (heavy oil), recovered in Unit III, into Unit I. The first unit and / or the second unit is (are) configured for injecting a sweep gas in the feed oil and / or in the rotating reactor, and / or the second unit is configured in a way that the rotating reactor may work under positive pressure. The processes for thermally treating a feed material by using a mobile plant. The uses of the processes for various environmental and non-environmental applications. Processes for manufacturing the mobile plants. Uses of oil containing resins (such as cracked and / or polarized oils) for cleaning purposes and other specialty applications.

Owner:ENVIROLLEA

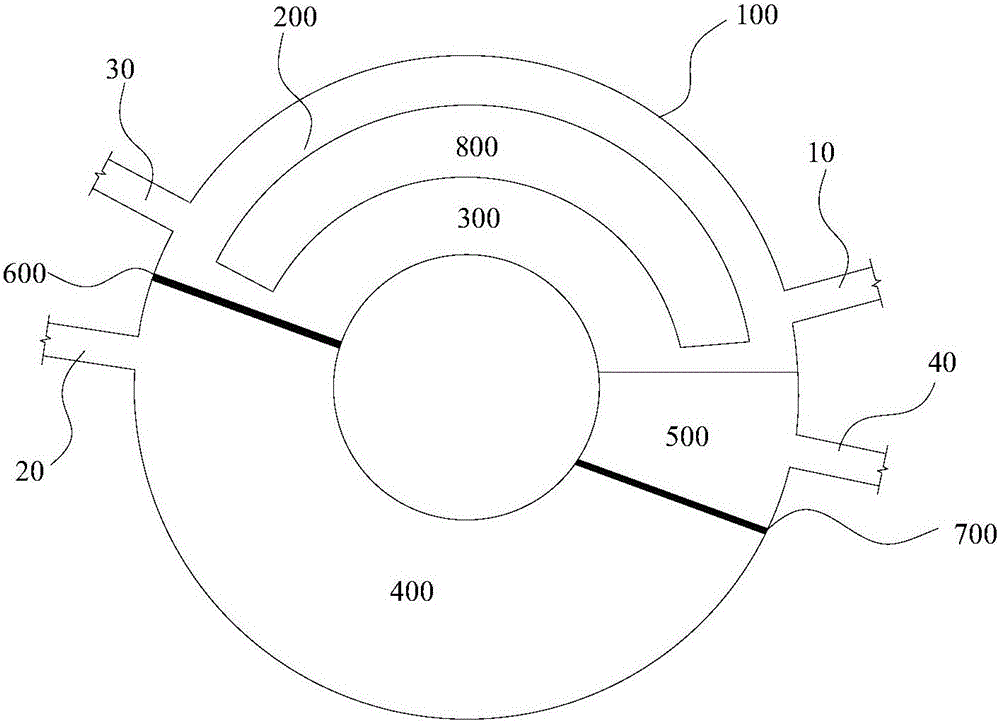

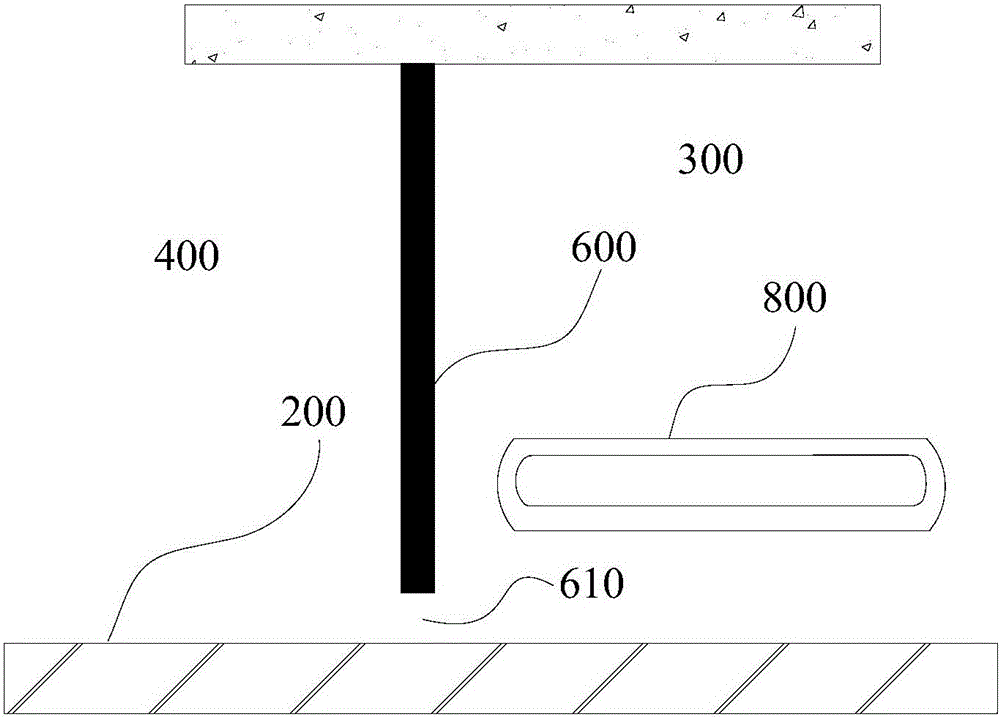

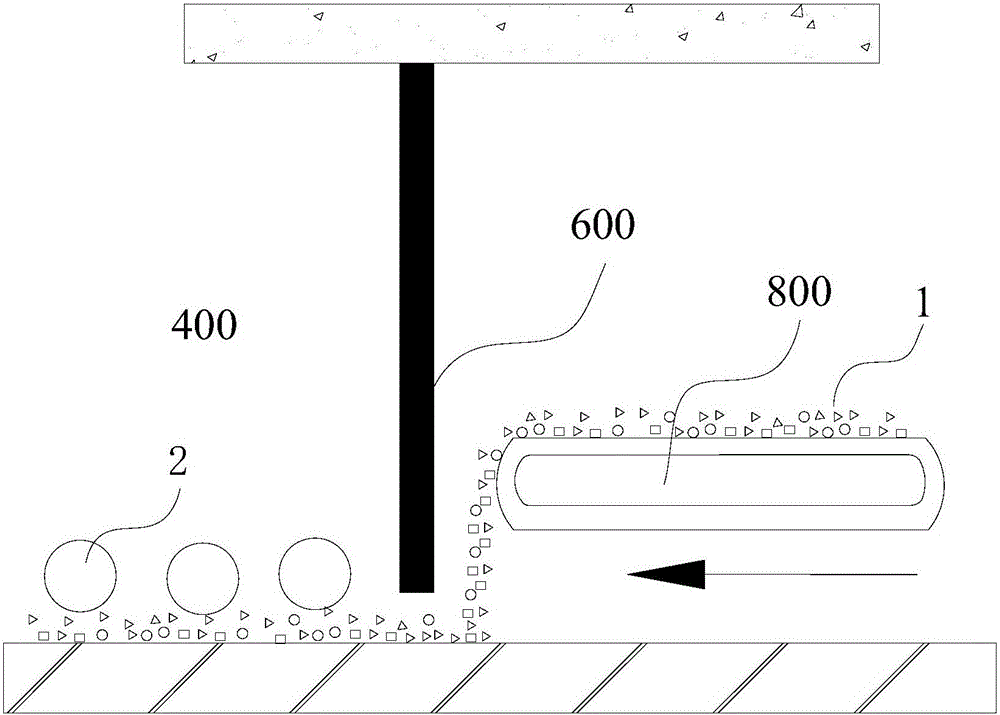

Rotary hearth furnace and method for treating low-rank coal and iron-containing materials

InactiveCN105907405AImprove efficiencyGood effectSpecial form destructive distillationRotary retortsEconomic benefitsHearth

The invention discloses a rotary hearth furnace and method for treating low-rank coal and iron-containing materials. Specifically, the rotary hearth furnace comprises a rotary furnace bottom, a ring-shaped hearth, a first retaining wall, a second retaining wall, a low-rank coal inlet, an iron-containing material inlet, a chain plate device, a pyrolysis oil gas outlet and a reduction product outlet, wherein a pyrolysis area, a reduction area and a discharge area are sequentially formed in the rotating direction of the rotary furnace bottom, a first gap is formed between the bottom end of the first retaining wall and the rotary furnace bottom, a second gap is formed between the bottom end of the second retaining wall and the rotary furnace bottom, and the chain plate device is arranged in the pyrolysis area. Accordingly, the low-rank coal can be utilized comprehensively, pyrolysis oil gas is prevented from being polluted by reducing gas or volatile components generated in the treatment process, and the rotary hearth furnace has at least one of the following advantages of being low in production cost, high in reduction product and pyrolysis oil gas quality, good in economic benefits and the like.

Owner:JIANGSU PROVINCE METALLURGICAL DESIGN INST

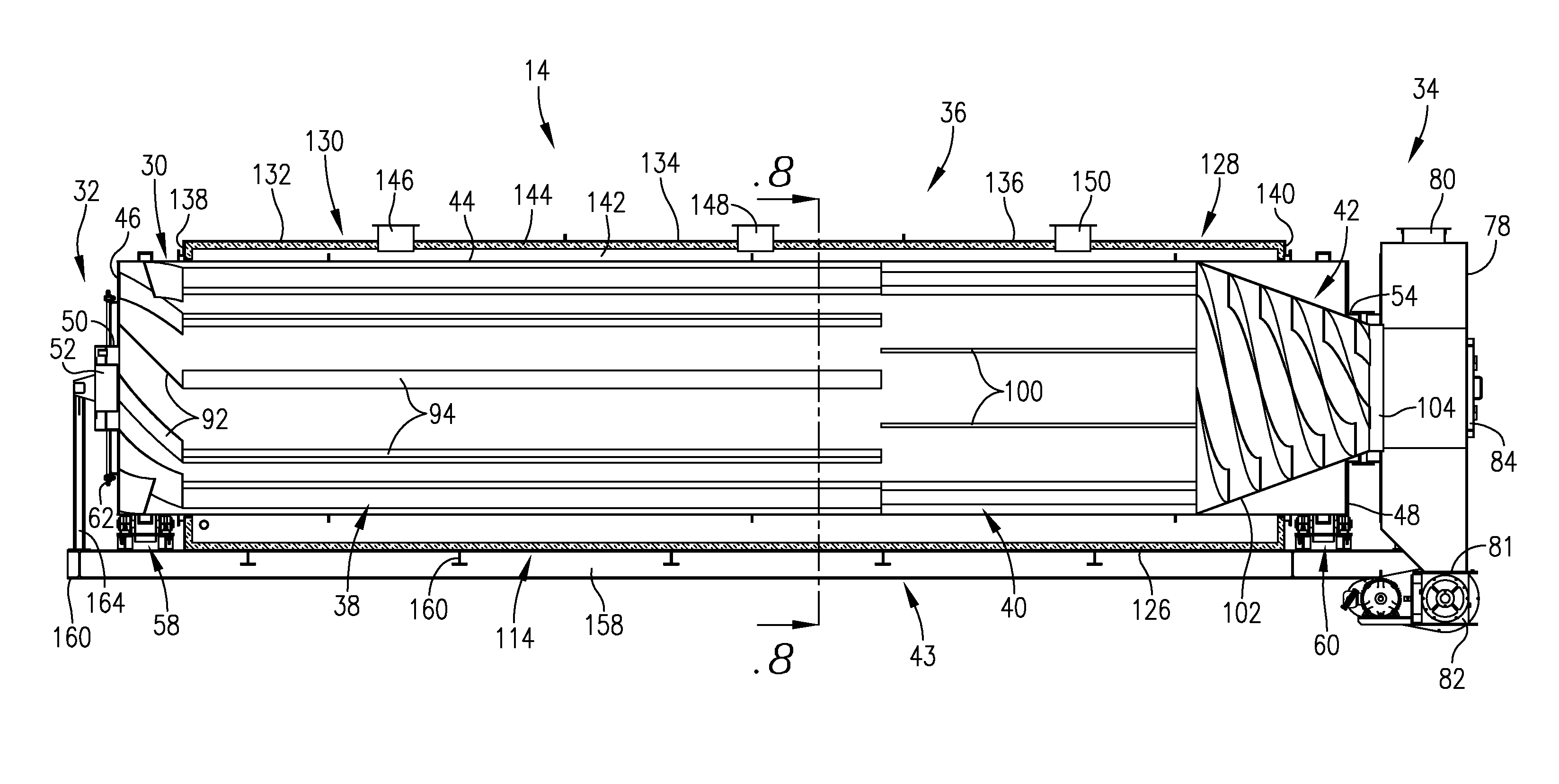

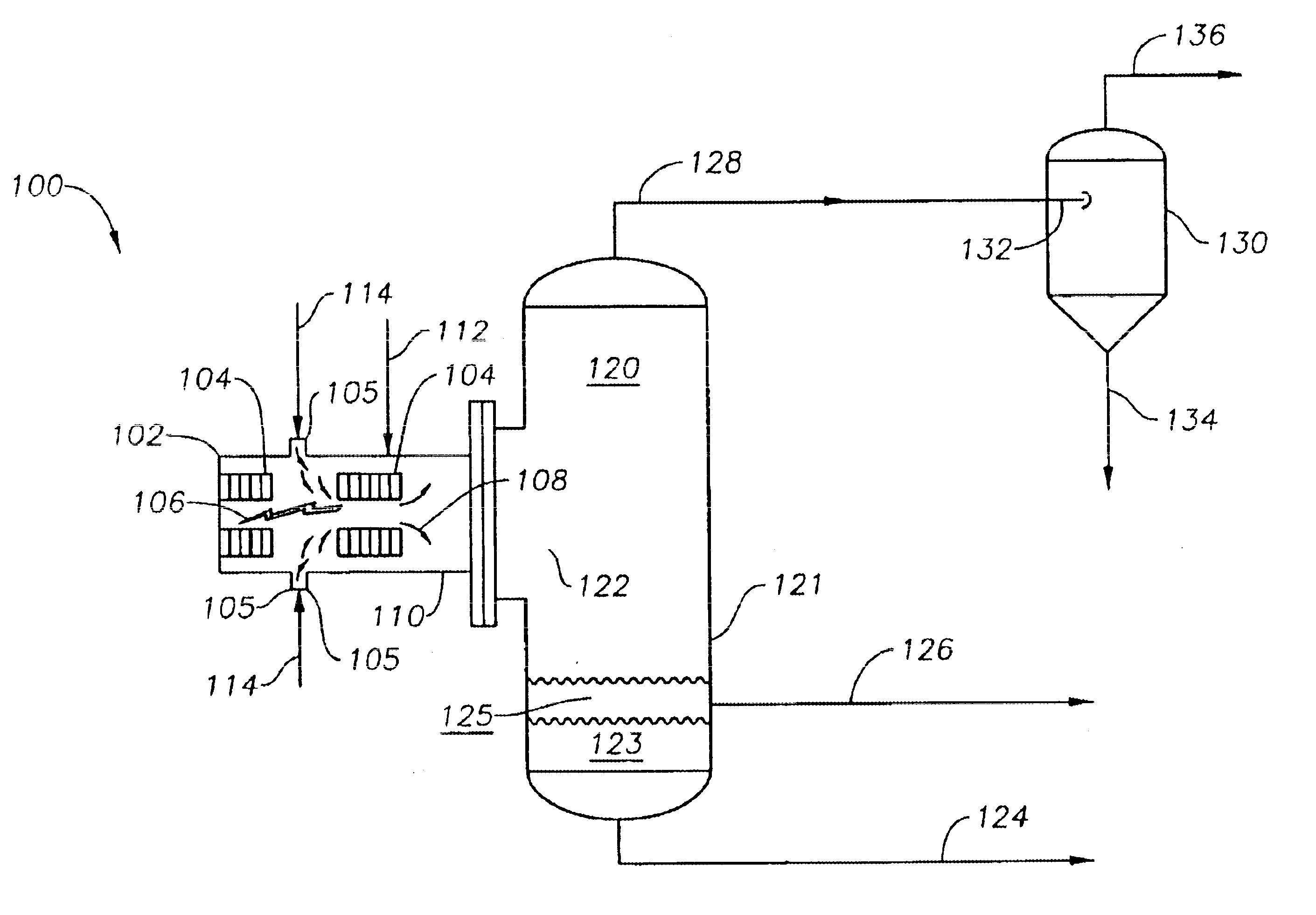

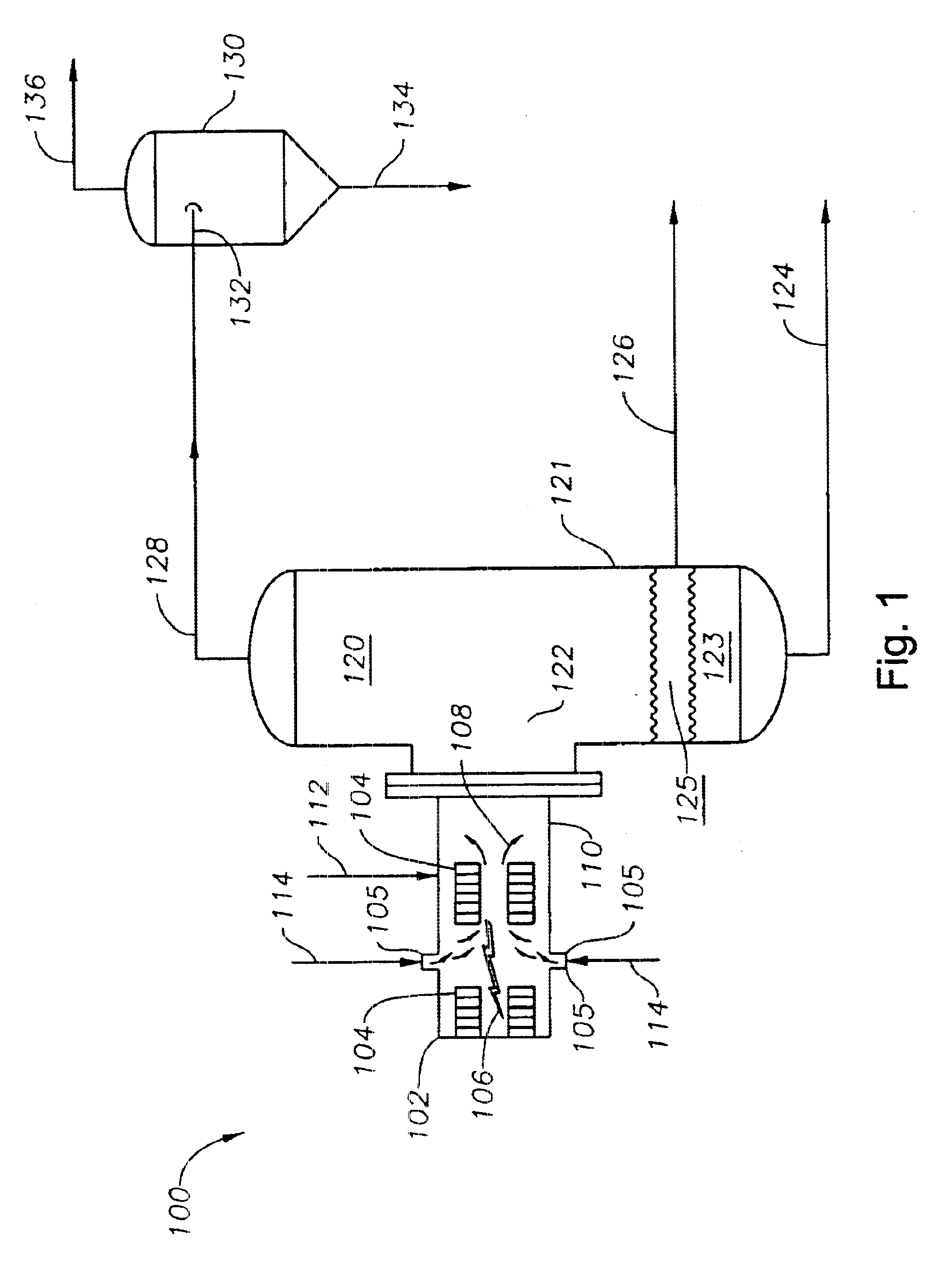

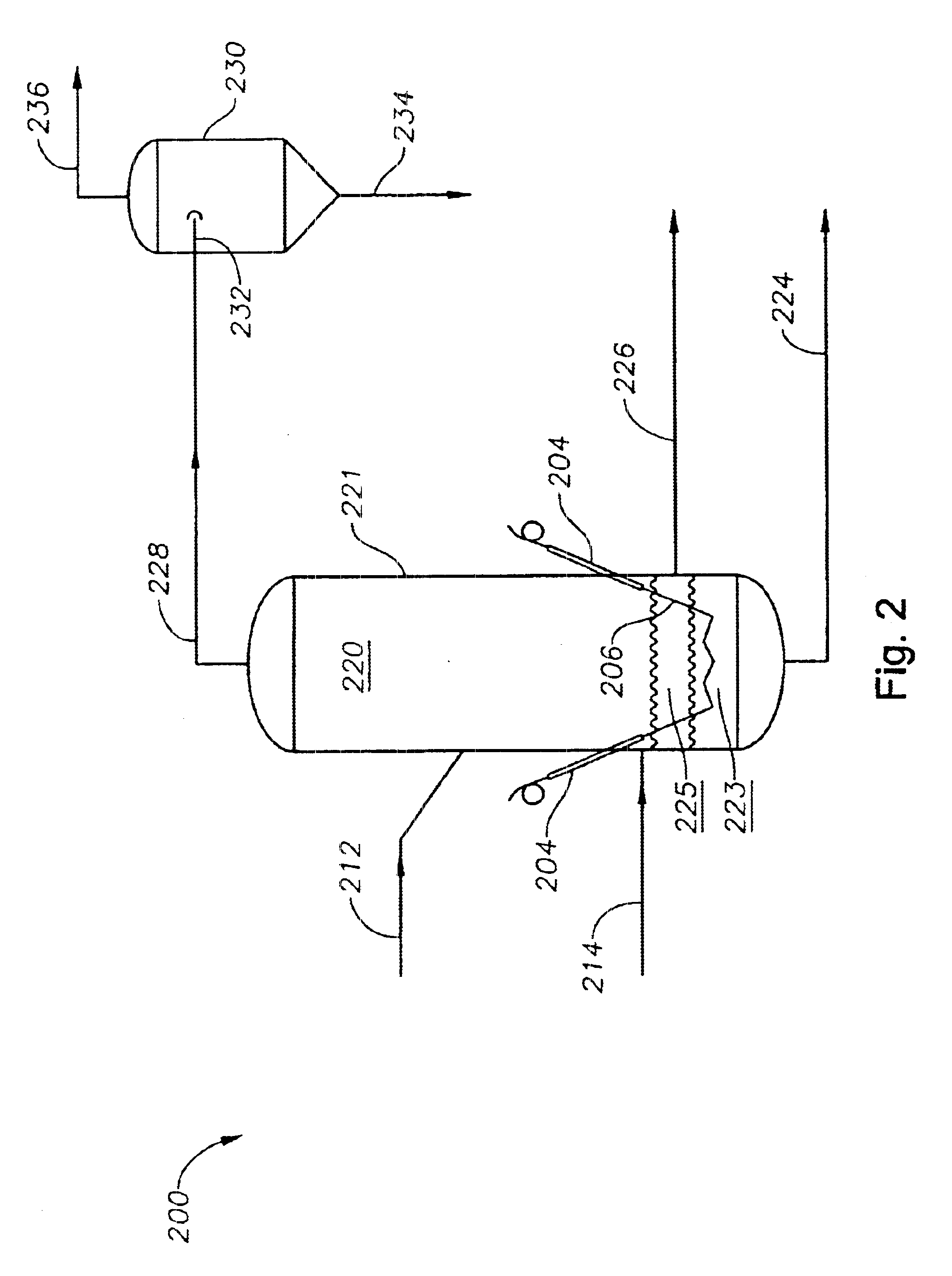

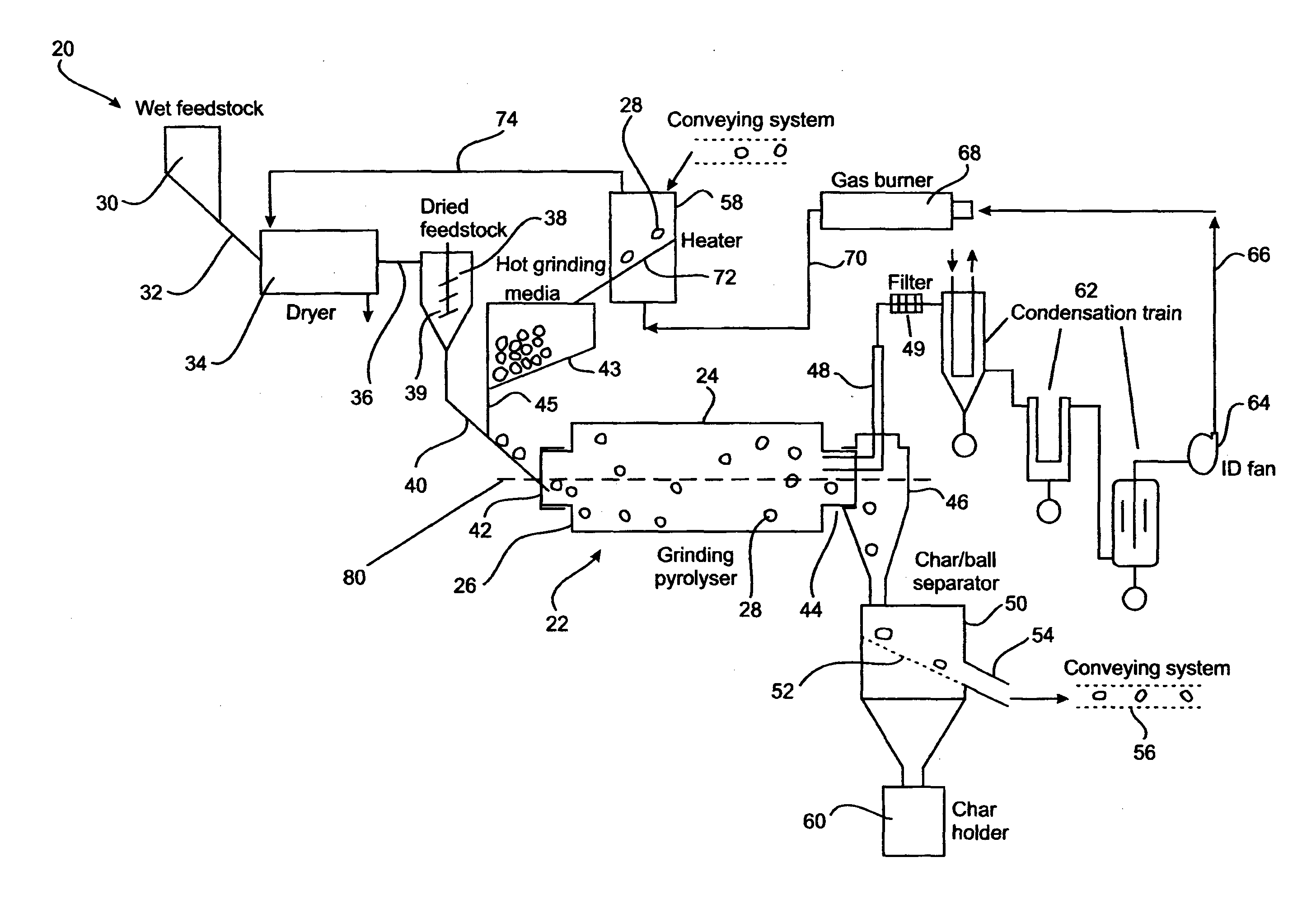

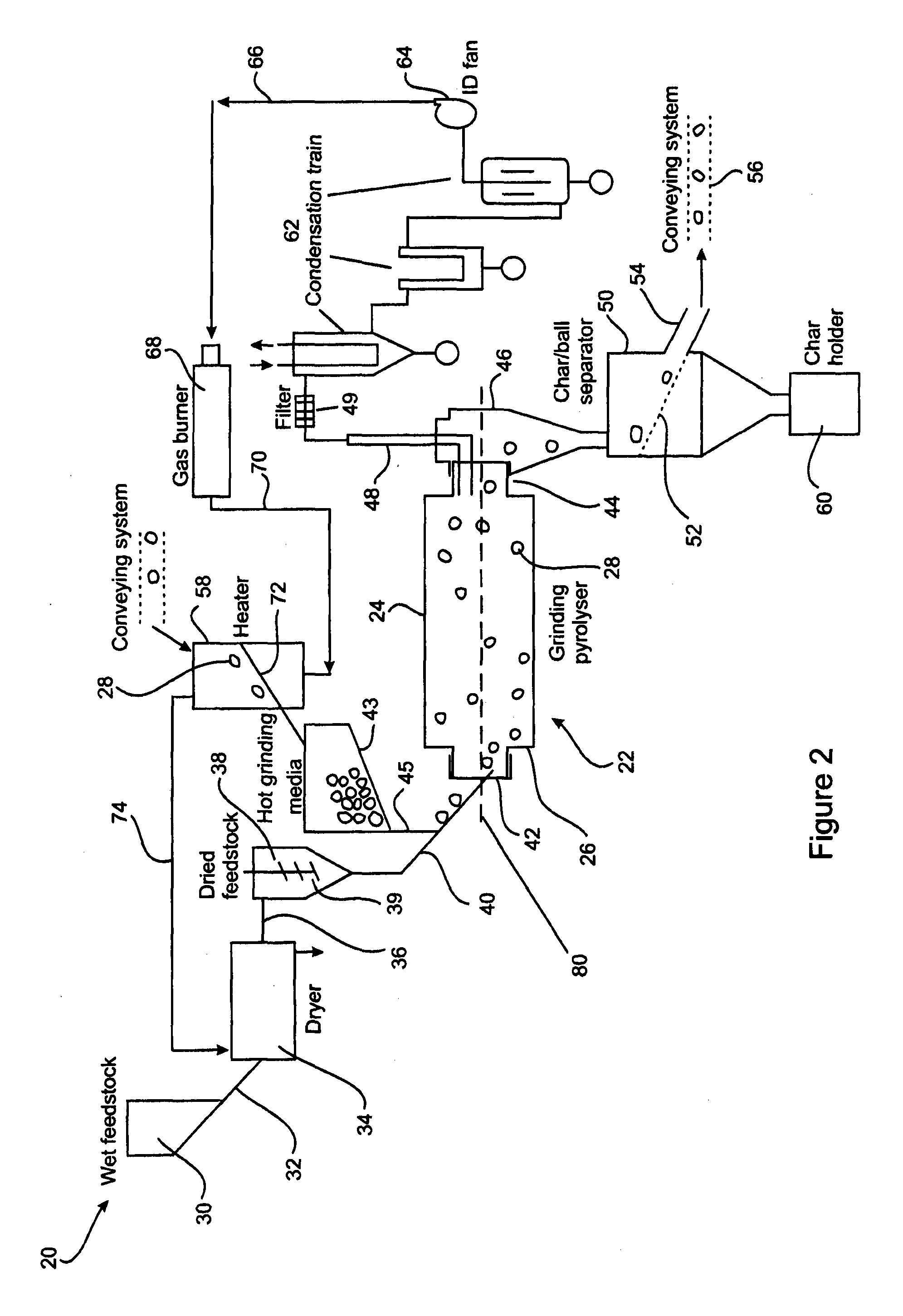

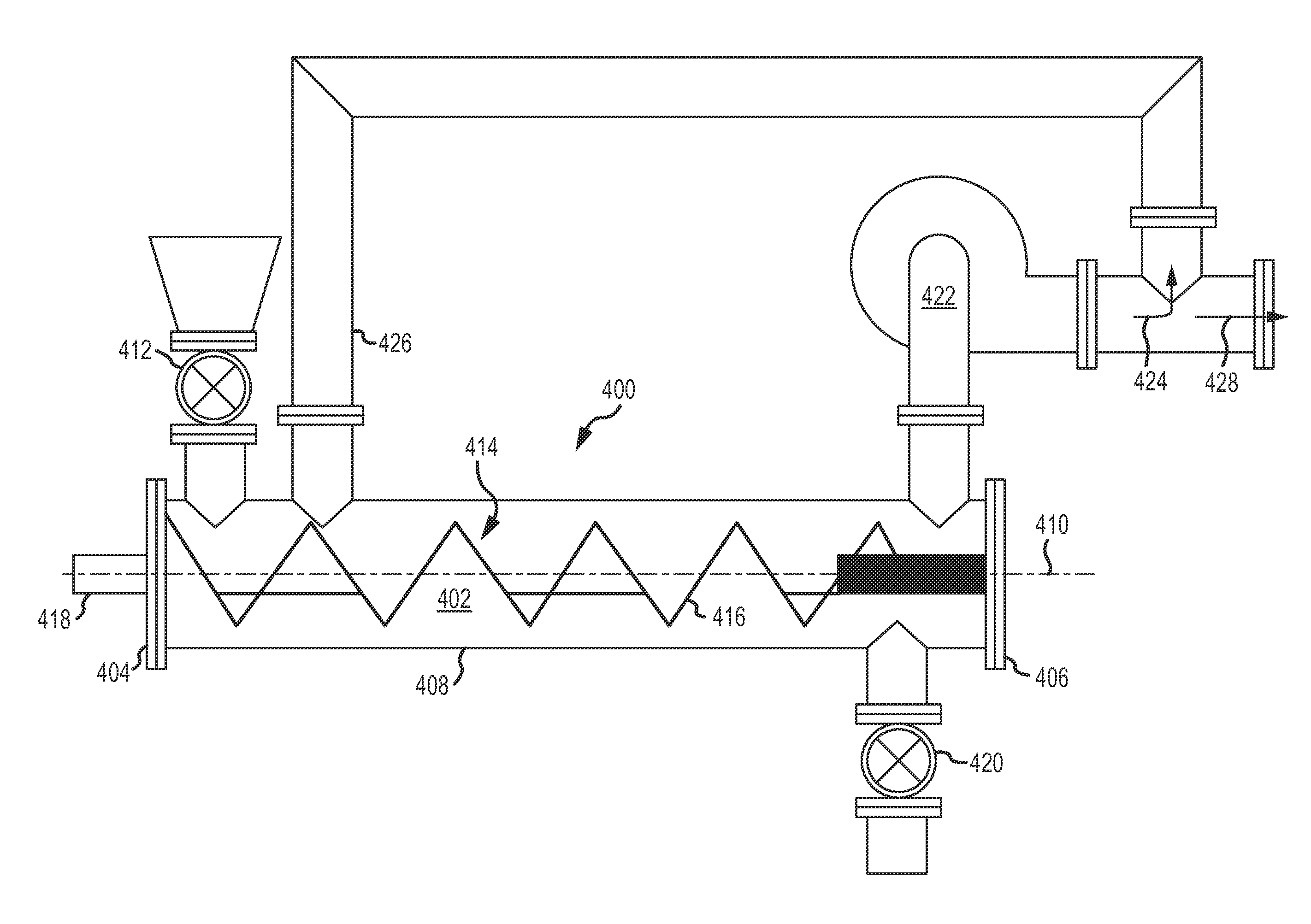

Method of and system for grinding pyrolysis of particulate carbonaceous feedstock

ActiveUS20130199919A1Small particle sizeThermal quenching of pyrolysis vapours is simplifiedCombustible gas coke oven heatingCoal charges mechanical treatmentParticulatesProcess engineering

A pyrolysis plant 20 comprises a grinding pyrolyser 22, being a machine or apparatus in which both particle size reduction and pyrolysis occur simultaneously. Plant 20 also comprises a bin (hopper) 30 for holding wet particulate biomass feedstock. Chute 32 leads from the bin 30 to a biomass dryer 34 which reduces moisture content of the feedstock as low as possible, e.g., to below about 10. Dried feedstock is conveyed from dryer 34 via line 36 to a dried biomass feedstock hopper 38. Dried feedstock is fed from hopper 38 into a chute 40 which leads to an inlet trunnion 42 of grinding pyrolyser 22. A discharge trunnion 44 of grinding pyrolyser 22 leads to a char holder 60 for collecting char particles and a condensation train 62 for condensing vapour generated by the pyrolysis to produce oil.

Owner:RENERGI PTY LTD

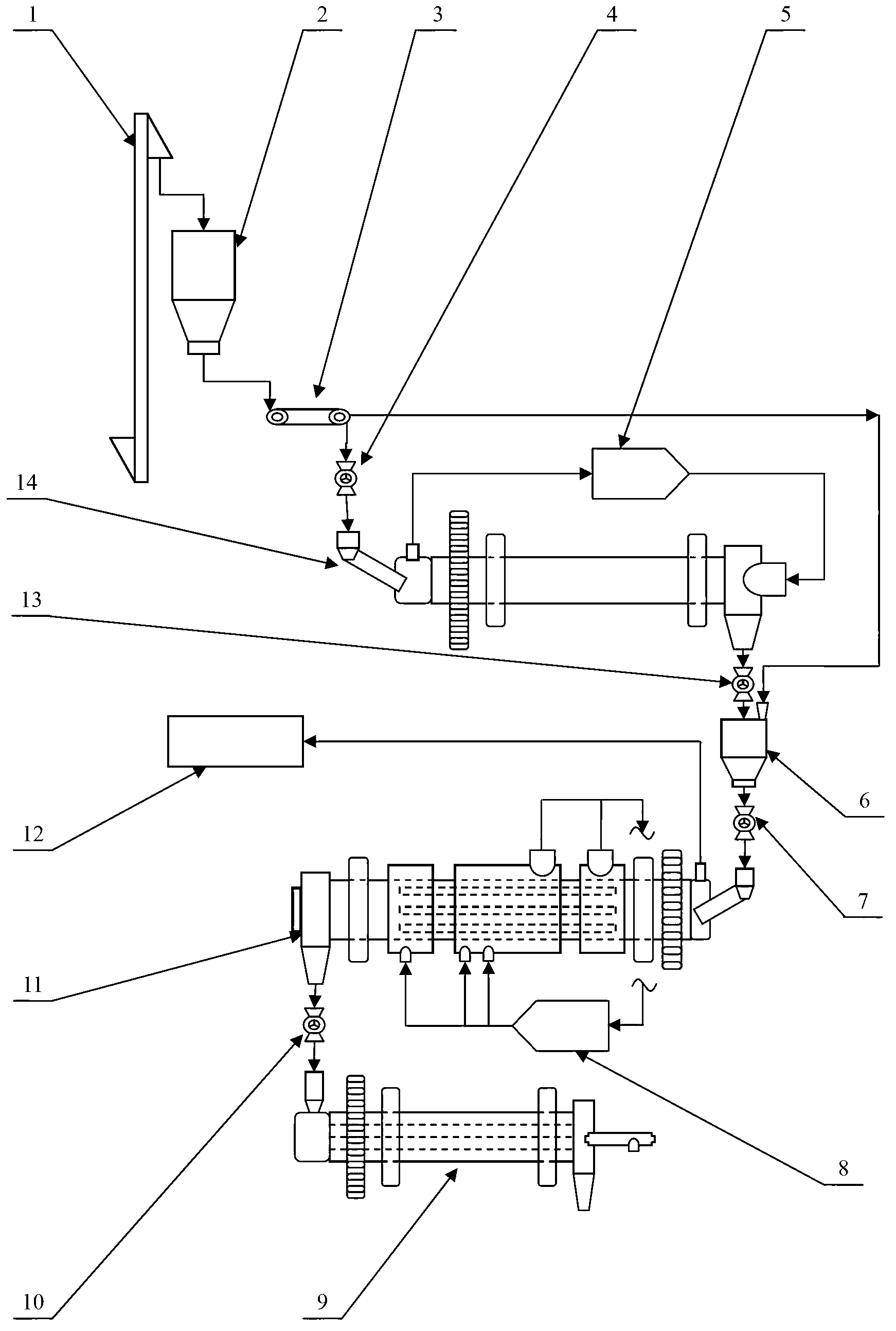

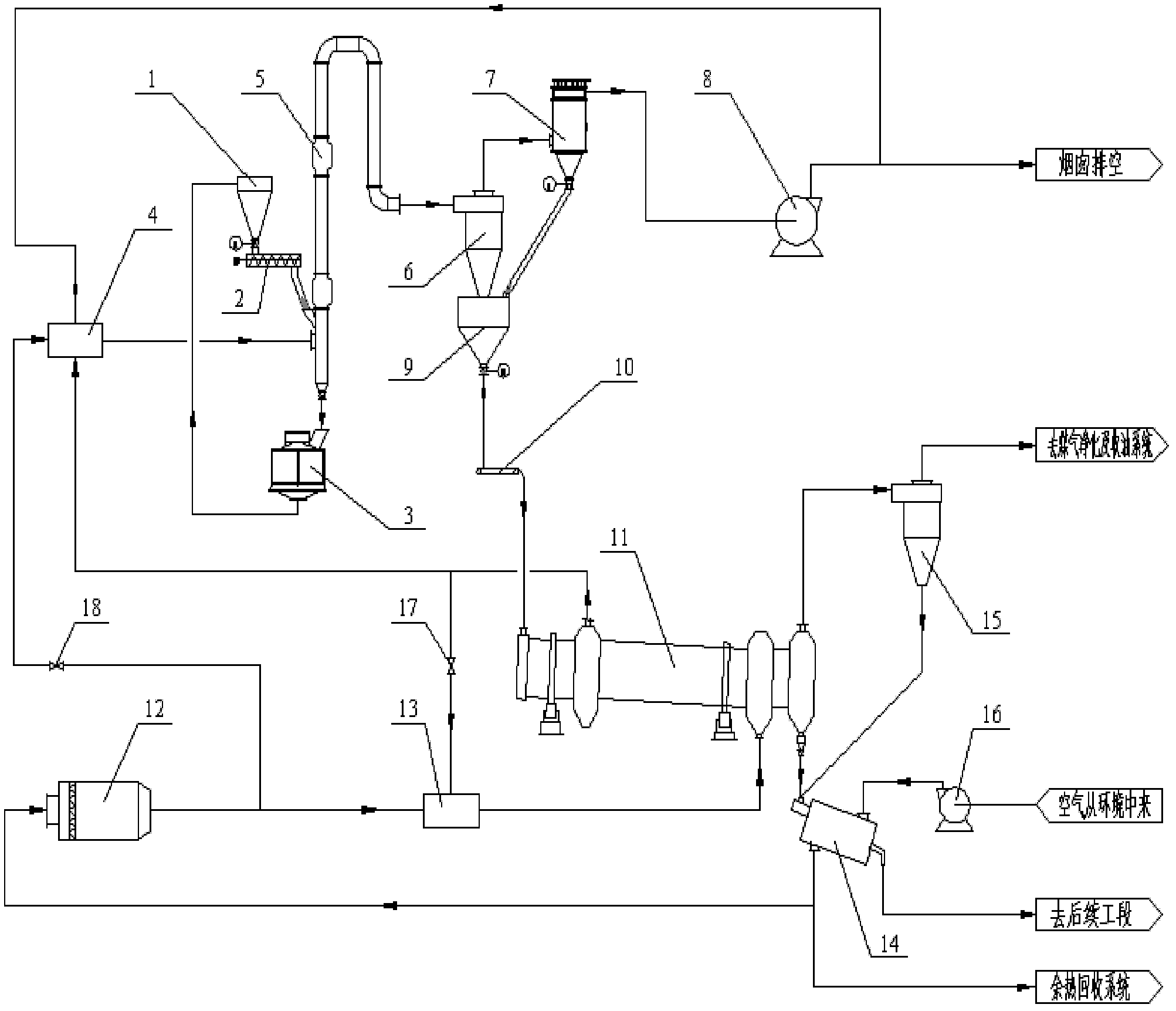

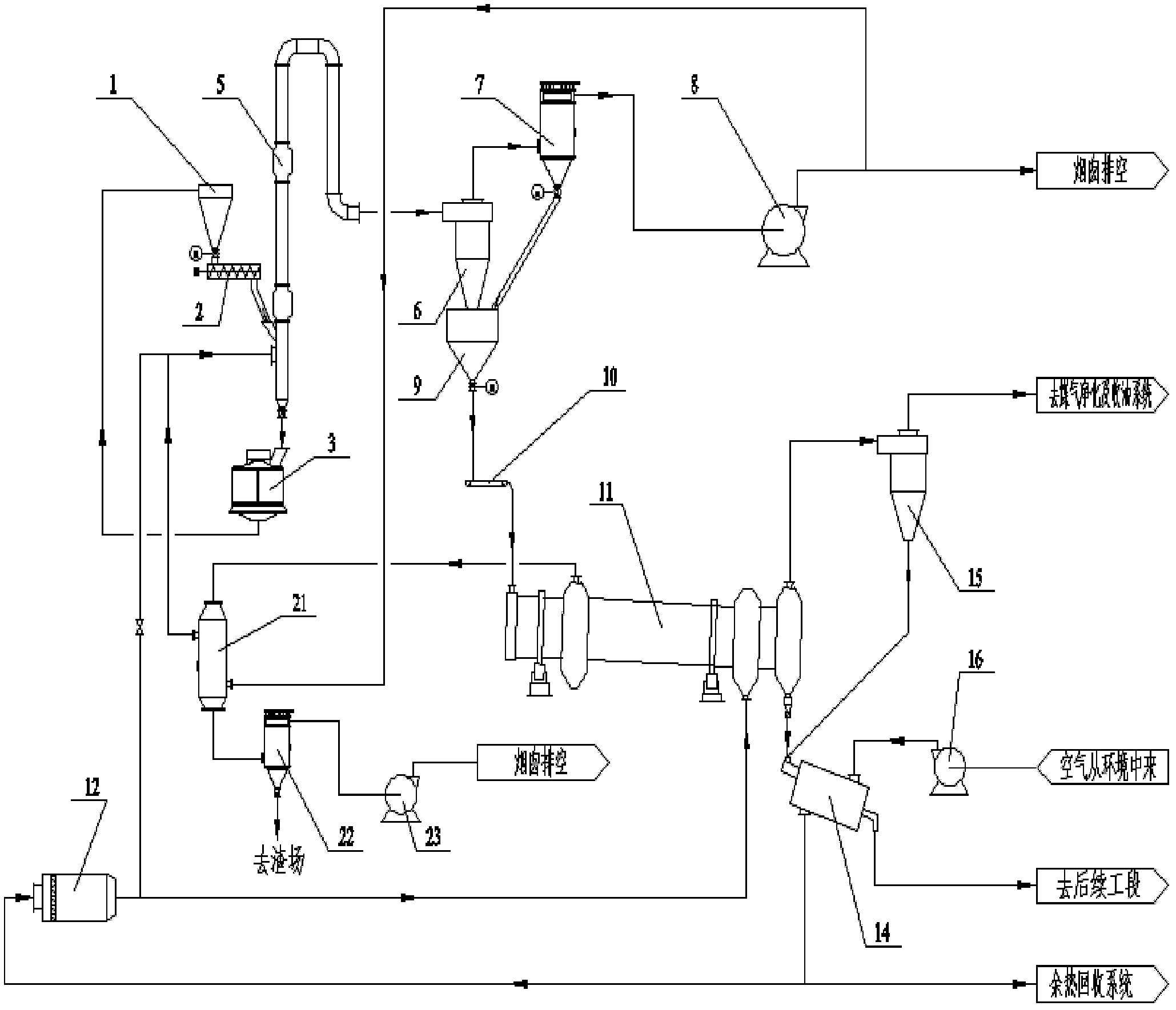

Quality-improving technique combining low-rank coal pneumatic drying with multi-tube revolving destructive distillation and system for same

ActiveCN102433142AEasy dischargeLow investment costCoke quenchingEnergy inputHigh energyCoking wastewater

The invention discloses a quality-improving technique combining a low-rank coal pneumatic drying with a multi-tube revolving destructive distillation and a system for the same, wherein the technique comprises a coal flow and a hot smoke flow, and both of the coal flow and the hot smoke flow comprise a drying process and a destructive distillation process which are connected with each other; the system comprises a gas flow drying system and a multi-tube revolving destructive distillation system which are connected with each other. The quality-improving technique combining a low-rank coal pneumatic drying with a multi-tube revolving destructive distillation and the system for the same disclosed by the invention realize a cascade efficient utilization for a high-temperature smoke, and increase the energy utilization rate of the whole system. The quality-improving technique combining a low-rank coal pneumatic drying with a multi-tube revolving destructive distillation and the system for the same disclosed by the invention have the advantages of high energy utilization rate, safe and stable system, small treatment capacity for destructive distillation gas, small treatment capacity for coking wastewater, high yield of tar, high calorific value of coal gas etc. The quality-improving technique combining a low-rank coal pneumatic drying with a multi-tube revolving destructive distillation and the system for the same disclosed by the invention also can recover chemical raw materials such as coal tar generated during a low-rank coal low-temperature destructive distillation process, and increase the comprehensive utilization rate of coal. Via the technique, a powdery or granular semicoke which is low in volatile matter, high in low caloric value and good in stability is produced by a quality-improving technique using a low-rank coal low-temperature destructive distillation. The technique is suitable for producing a civil or industrial coal gas with a medium caloric value by a quality-improving technique using a low-rank coal low-temperature destructive distillation.

Owner:SHANDONG TIANLI DRYING TECH & EQUIP

Method and Apparatus For Continuous Production of Carbonaceous Pyrolysis By-Products

InactiveUS20110278150A1Reduce needOptimization rangeProductsCombustible gas coke oven heatingProcess engineeringEngineering

A system and method for the continuous production of carbonaceous pyrolysis by-products are provided which include one or more pyrolysis reaction chambers adapted to receive a wide variety of feedstock materials, including biomass feedstock. System operating parameters including feedstock input rate, atmosphere composition and flow rate, temperature, reaction mixture stirring and agitation rate are selectively independently controllable to produce an end by-product having desired properties for specific applications, and gaseous reaction by-products may be recycled as a fuel for the pyrolysis reaction, thereby enhancing overall system operating efficiency.

Owner:CARBON RES & DEV CO

Pyrolysis systems, methods, and resultants derived therefrom

ActiveUS8784616B2Fit closelyMaterial nanotechnologyDirect heating destructive distillationProcess engineeringToxic chemical

Owner:TUCKER RICHARD D

Waste recycling system

A portable reactor system for pyrolysis of waste plastic materials is provided. The reactor system can be easily scaled up or down and can be operated directly at the location where waste plastic materials are generated. Methods converting the plastic materials into fuel and other useful materials are also provided.

Owner:YAGS LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com