Biomass pyrolysis carbonization system equipment

A biomass pyrolysis and system equipment technology, applied in the field of pyrolysis carbonization equipment, can solve the problems of long carbonization time, low efficiency, poor working environment, etc., and achieve the effect of industrialized production, improved working environment, and short carbonization time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

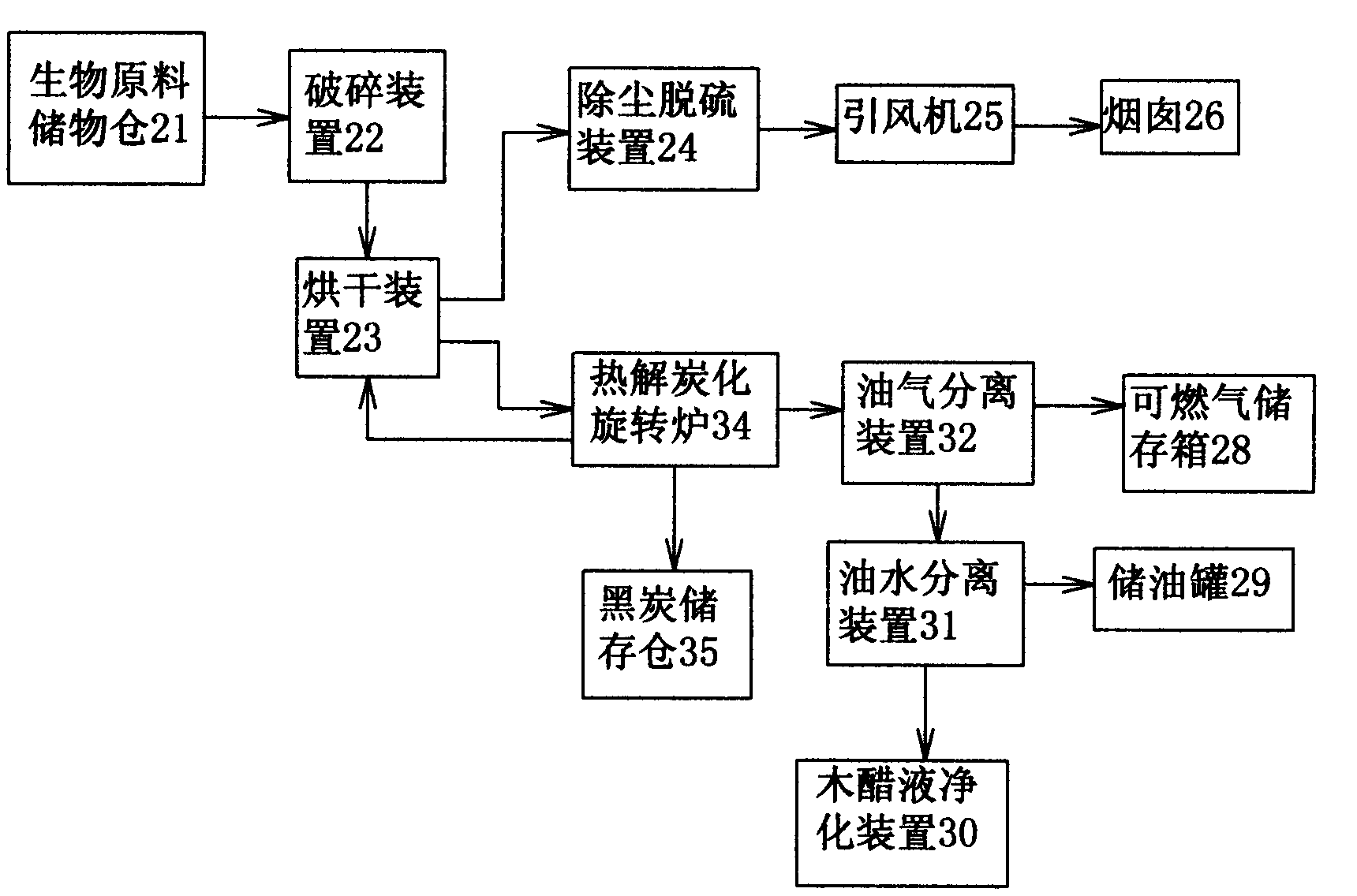

Examples

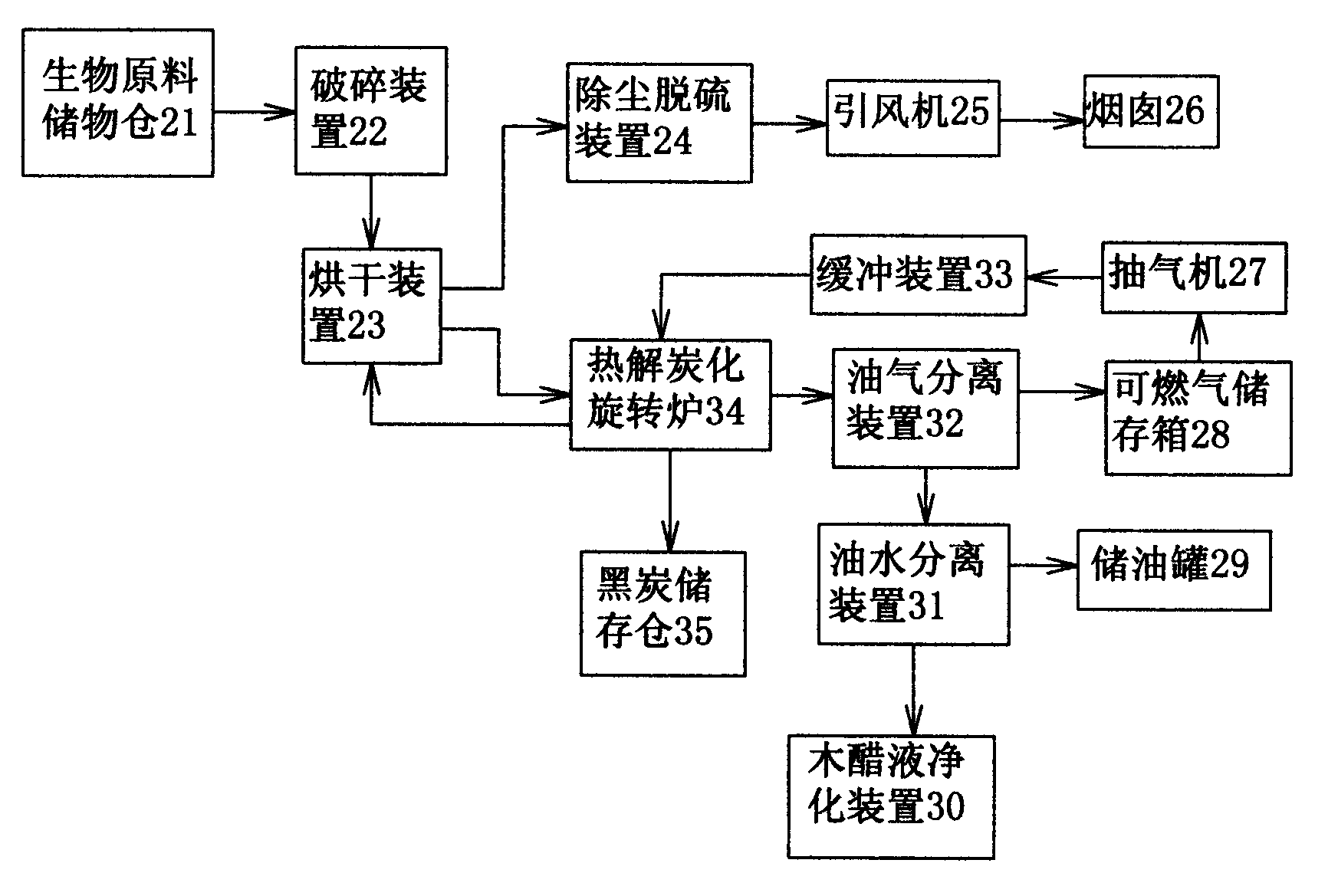

specific Embodiment approach 2

[0034] see figure 2 The difference between this specific embodiment and specific embodiment one is that it also includes an air extractor 27 and a buffer device 33, the combustible gas tank storage box 28 is connected with the air extractor 27, the air extractor 27 is connected with the buffer device 33, and the buffer device 33 is connected with pyrolysis carbonization rotary furnace 34. Other compositions and connections are the same as in the first embodiment.

[0035] The air extractor 27 in this specific embodiment can suck the combustible gas in the combustible gas storage tank 28 into a buffer device 33 such as a compressor, and send it to the pyrolysis and carbonization part through the buffer device 33 to supply heat The decarbonization part generates heat energy for use.

[0036] This specific embodiment can realize the continuous feeding and discharging operation in the process of carbonizing biomass, and ensure the sealing performance between each connecting par...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com