Patents

Literature

32results about How to "Continuous feeding" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

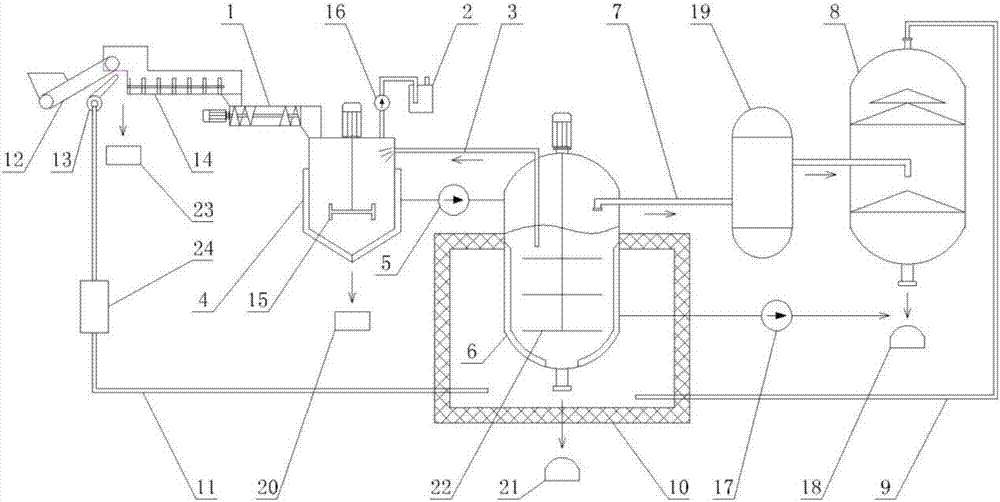

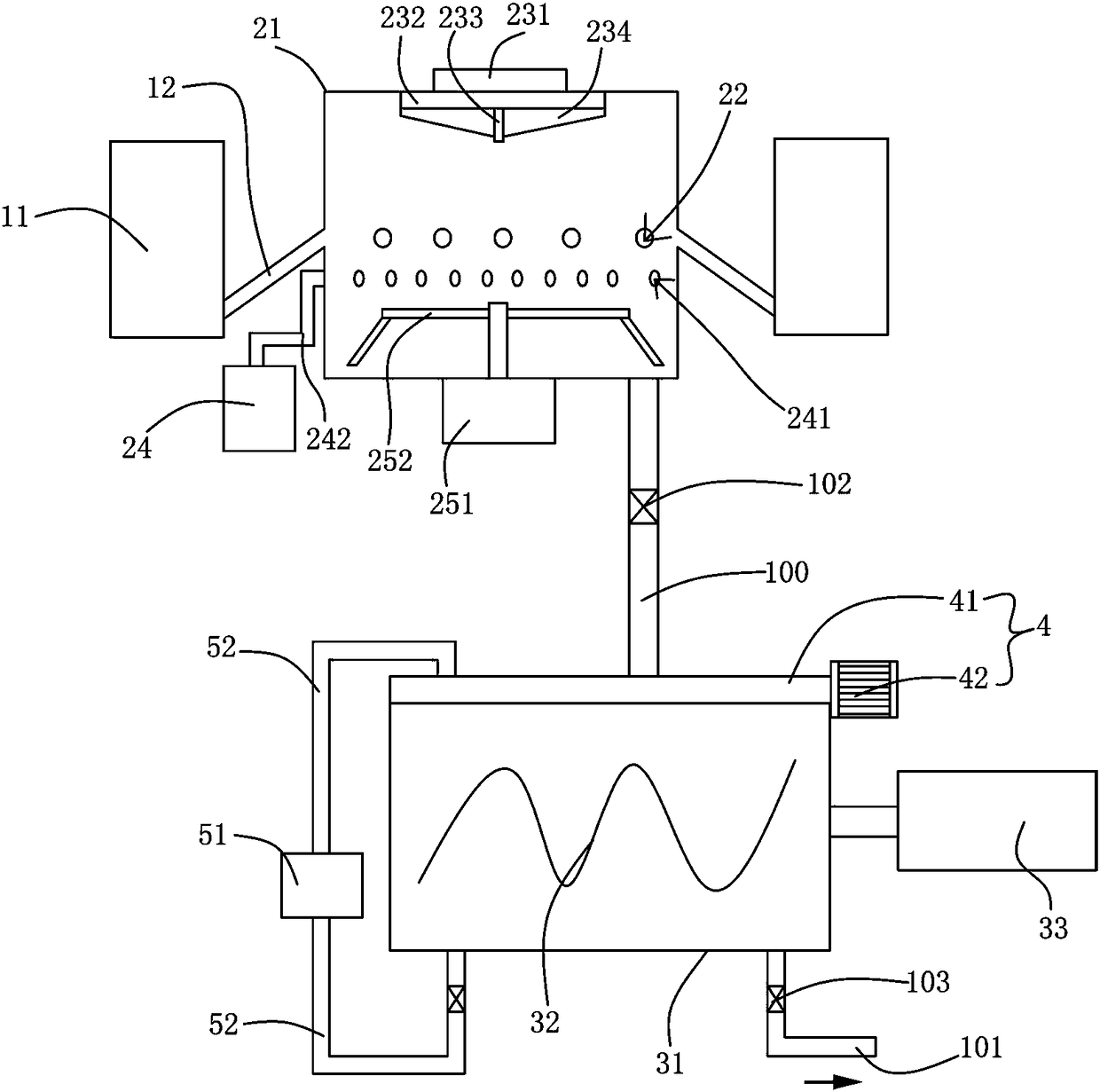

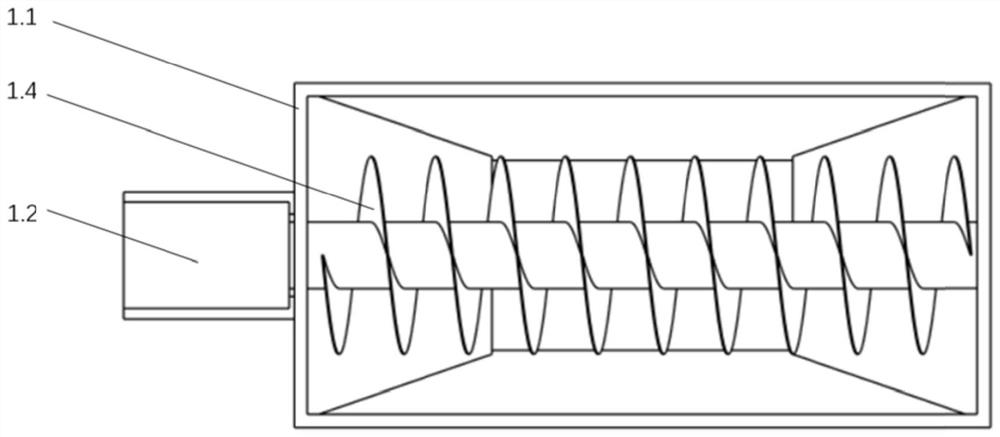

Environmental-protection energy-saving drum biomass coal making process and device

InactiveCN101824350AReasonable structureHigh conversion rate of energy utilizationBiofuelsSolid fuelsThermal energyAutomatic control

The invention discloses an environmental-protection energy-saving drum biomass coal making process. The coal making process comprises the steps of: obtaining high-temperature fume by combusting associated gas generated during biomass coal making process for discharging heat; exchanging heat with the high-temperature fume by using a drum carbonization device to form low-temperature fume; discharging the low-temperature fume after the low-temperature fume is processed by a drum drying device; after starting a system, providing heat energy for biomass coal making by combusting the associated gas; and directing pressing biomass into coal at high temperature after the biomass is processed by a carbonization device. The biomass coal making process is completely automatically controlled. An environmental-protection energy-saving drum biomass coal making device comprises a material transmission system, a material drying system, a material carbonization system and an associated gas combustion waste heat recovery system, which are connected mutually, as well as an automatic control system which is connected with the systems electrically. The invention has the advantages of reasonable structure, high energy utilization and conversion rate, no external energy supply in the biomass carbonization process, no harmful gas emission, energy saving, environmental protection, obtained high-quality biomass coal, no overburning, no half baking, high heat value, complete automatically-controlled process and the like. The invention can be widely used in biomass coal making processes.

Owner:SHENGLI OIL FIELD SHENGLI POWER MACHINERY GRP

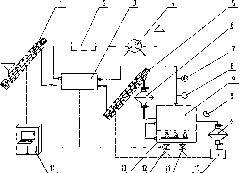

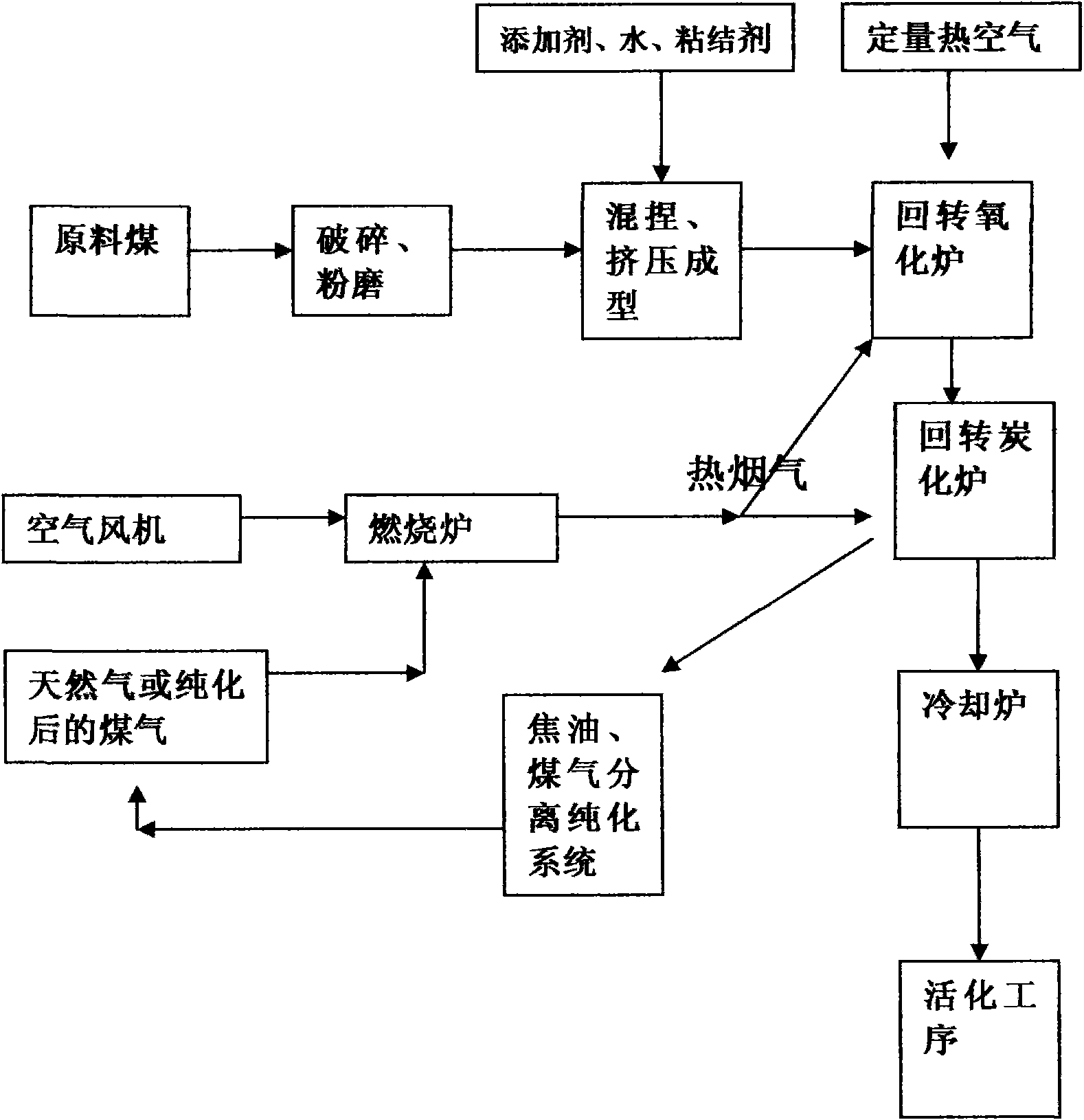

Method for preparing coal-based carbonized material used for preparing active carbon

ActiveCN101812309AImprove oxidation efficiencyHigh calorific valueSolid fuelsSpecial form destructive distillationActivated carbonSlag

The invention provides a method for preparing coal-based carbonized material used for preparing active carbon, which comprises: making raw coal into coal-based briquetted material (amorphous grains); delivering the coal-based briquetted material into an externally heated rotary oxidation furnace to perform the forced oxidization reaction of the coal-based briquetted material and hot air, which iscontinuously and quantitatively added into the barrel of the oxidization furnace, at 150 to 280 DEG C; delivering the oxidized coal-based briquetted oxide material into an externally heated carbonizing furnace; and making the coal-based carbonized material by performing heat treatment and reactions such as destructive distillation, thermal cracking and polycondensation under certain conditions atdifferent temperature stages. The coal-based carbonized material produced by the cracking in the carbonizing furnace is delivered by a delivering device to a follow-up step for cooling. The tail gas of the carbonizing furnace, which is high in calorific value, is separated and purified to be supplied to the oxidization furnace and the carbonizing furnace as a heat source to be recycled. The technical process of the method is simple and free from waste gas, water and slag discharge. The method belongs to an environmental protection and comprehensive utilization project.

Owner:西安三瑞实业有限公司

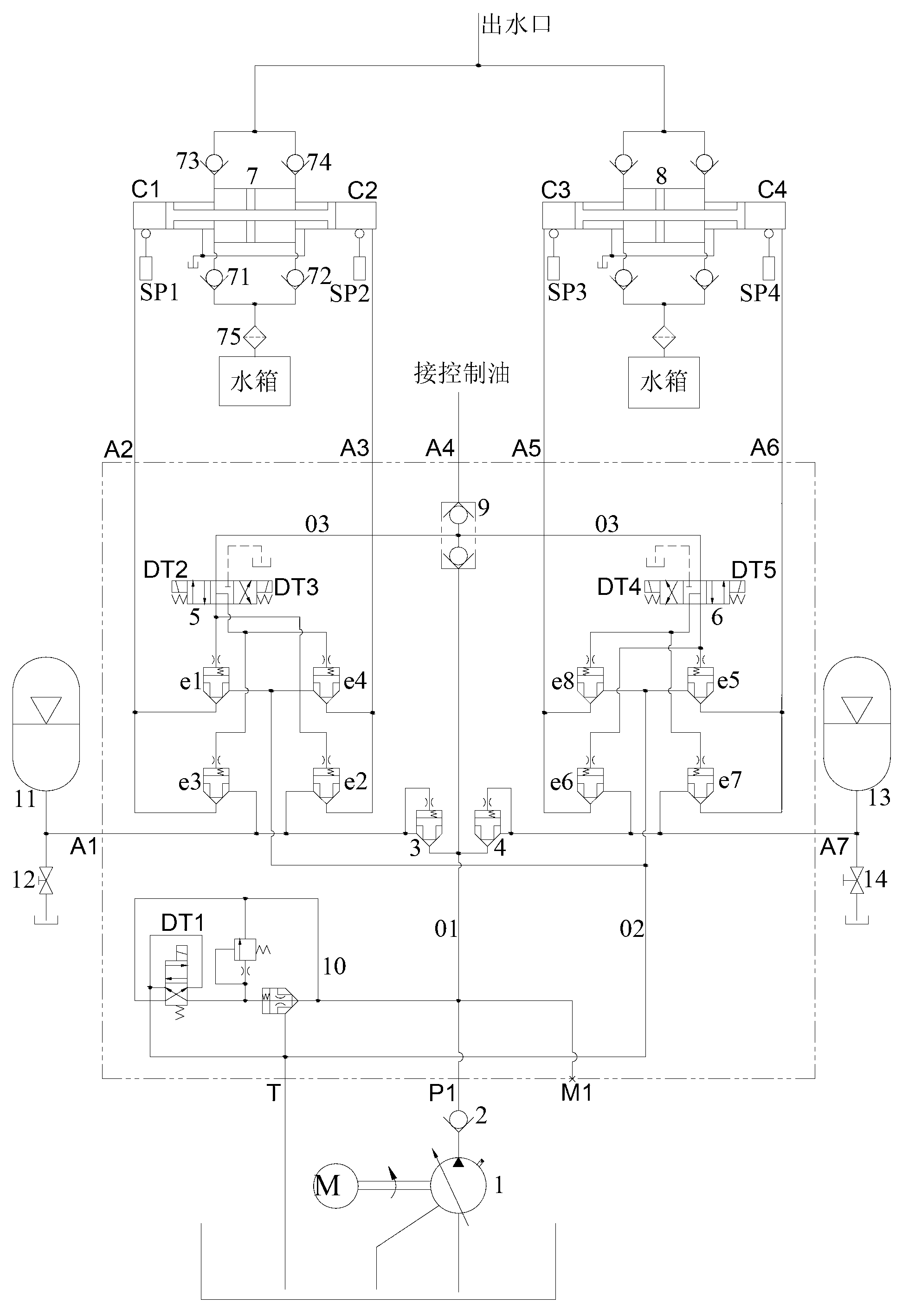

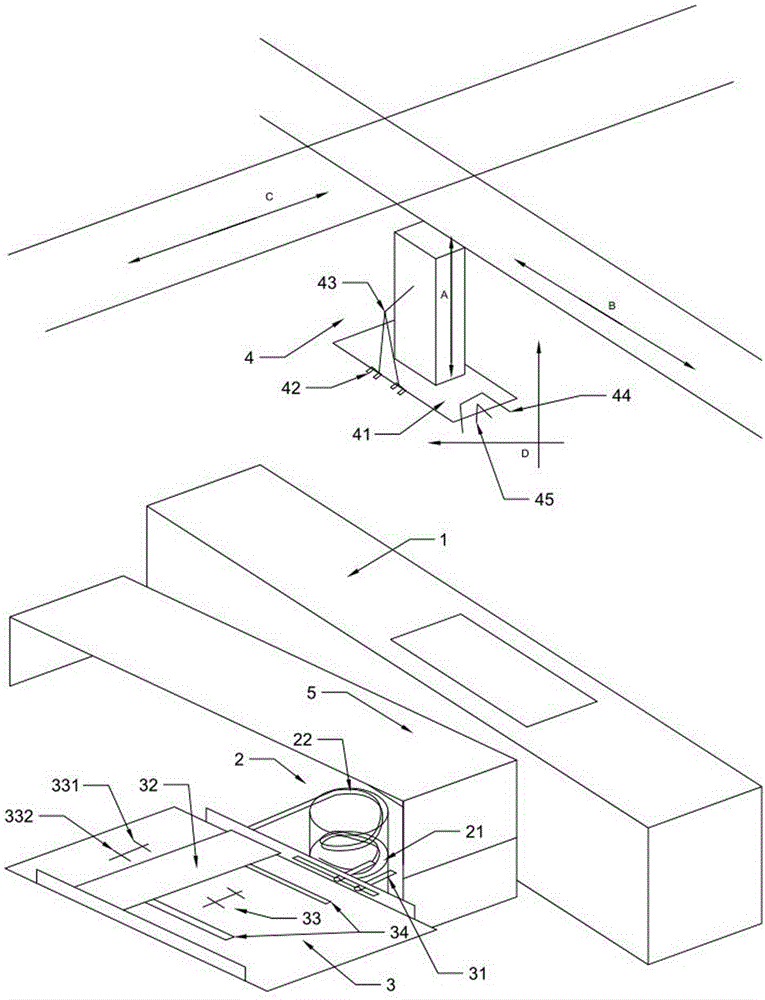

Continuous material feeding system and control method and elevating platform fire truck thereof

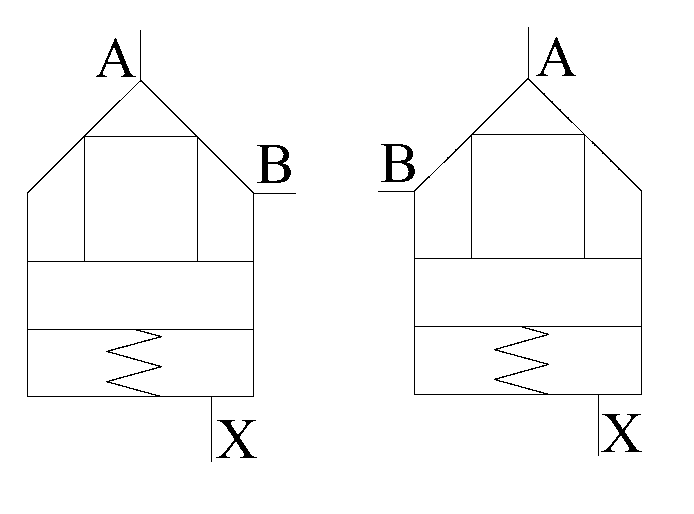

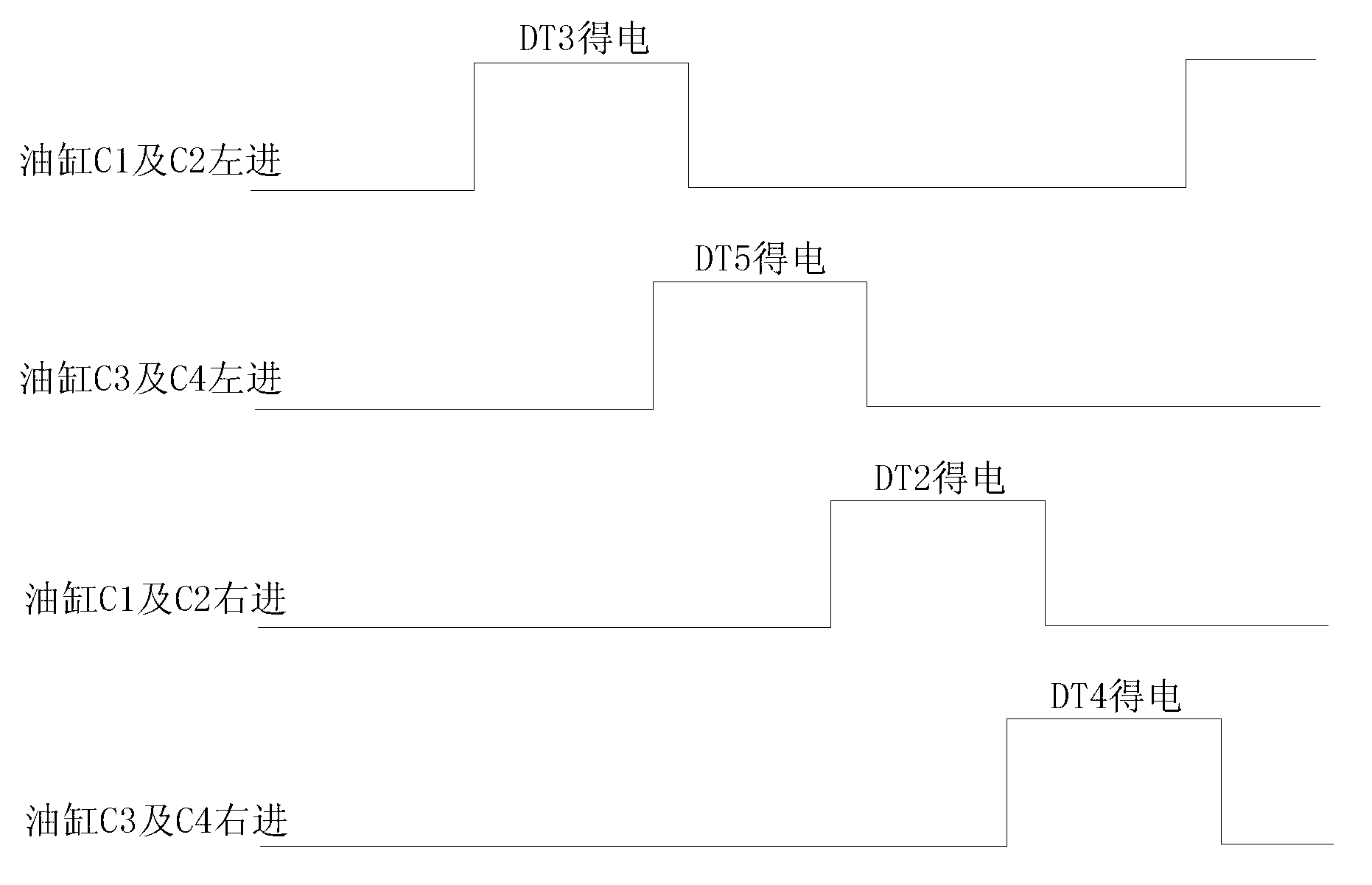

The invention discloses a continuous material feeding system and a control method and an elevating platform fire truck thereof. The control method includes the following steps: A. enabling a piston of a first pump material device to move towards a first limit position of the first pump material device; B. enabling a piston of a second pump material device to move towards the first limit position of the second pump material device before the piston of the first pump material device reaches the first limit position; C. enabling the piston of the first pump material device to move from the first limit position to the second limit position of the first pump material device before the piston of the second pump material device reaches the first limit position of the second pump material device; D. enabling the piston of the second pump material device to move from the first limit position to the second limit position of the second pump material device before the piston of the first pump material device reaches the second limit position of the first pump material device; and E. returning to the step A before the piston of the second pump material device reaches the second limit position of the second pump material device. By means of the system, the method and the truck, driving devices of the two pump material devices can change direction in staggering mode (namely the actions of the two driving devices have certain coincidence area), and flow fluctuation of material outlets is avoided.

Owner:SANY AUTOMOBILE MFG CO LTD

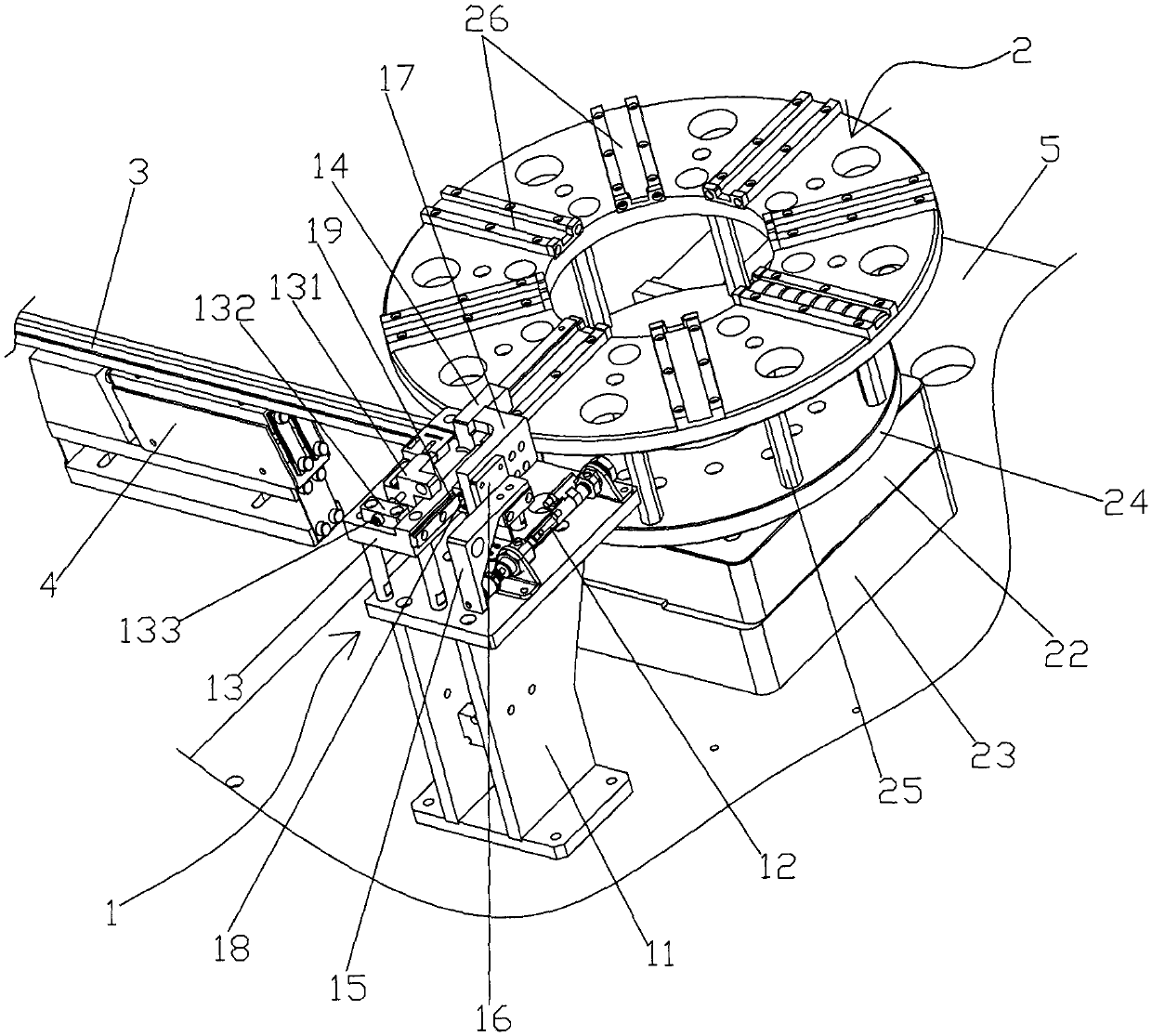

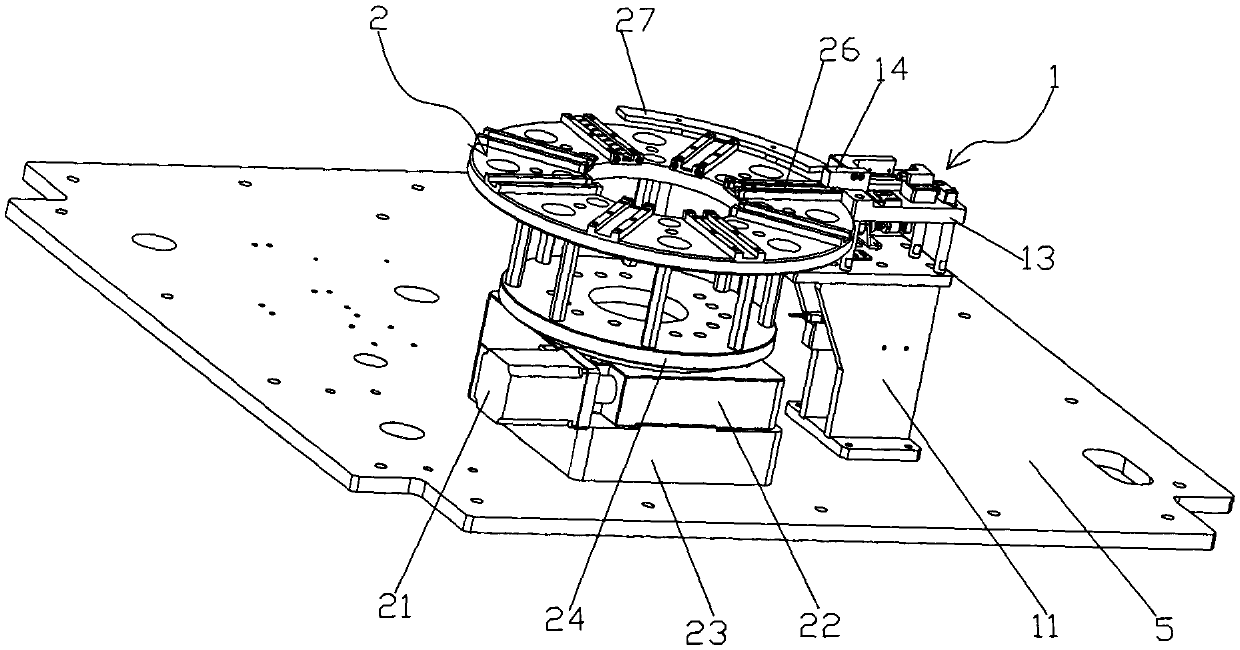

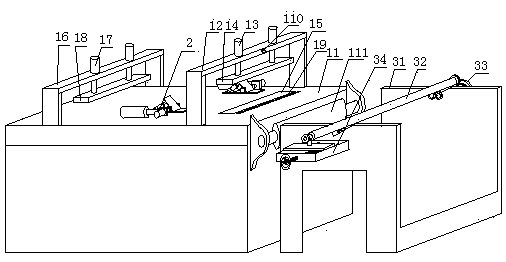

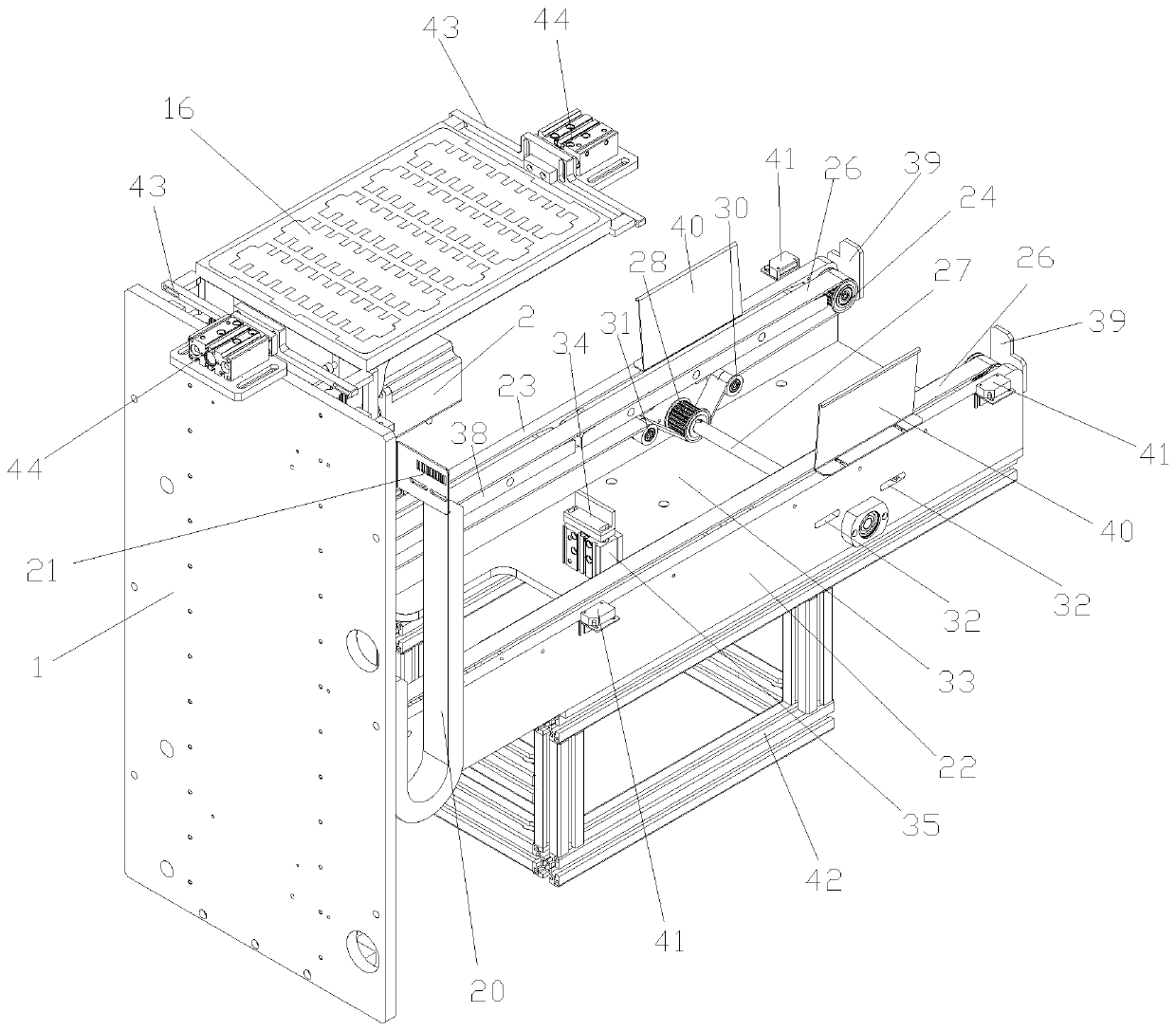

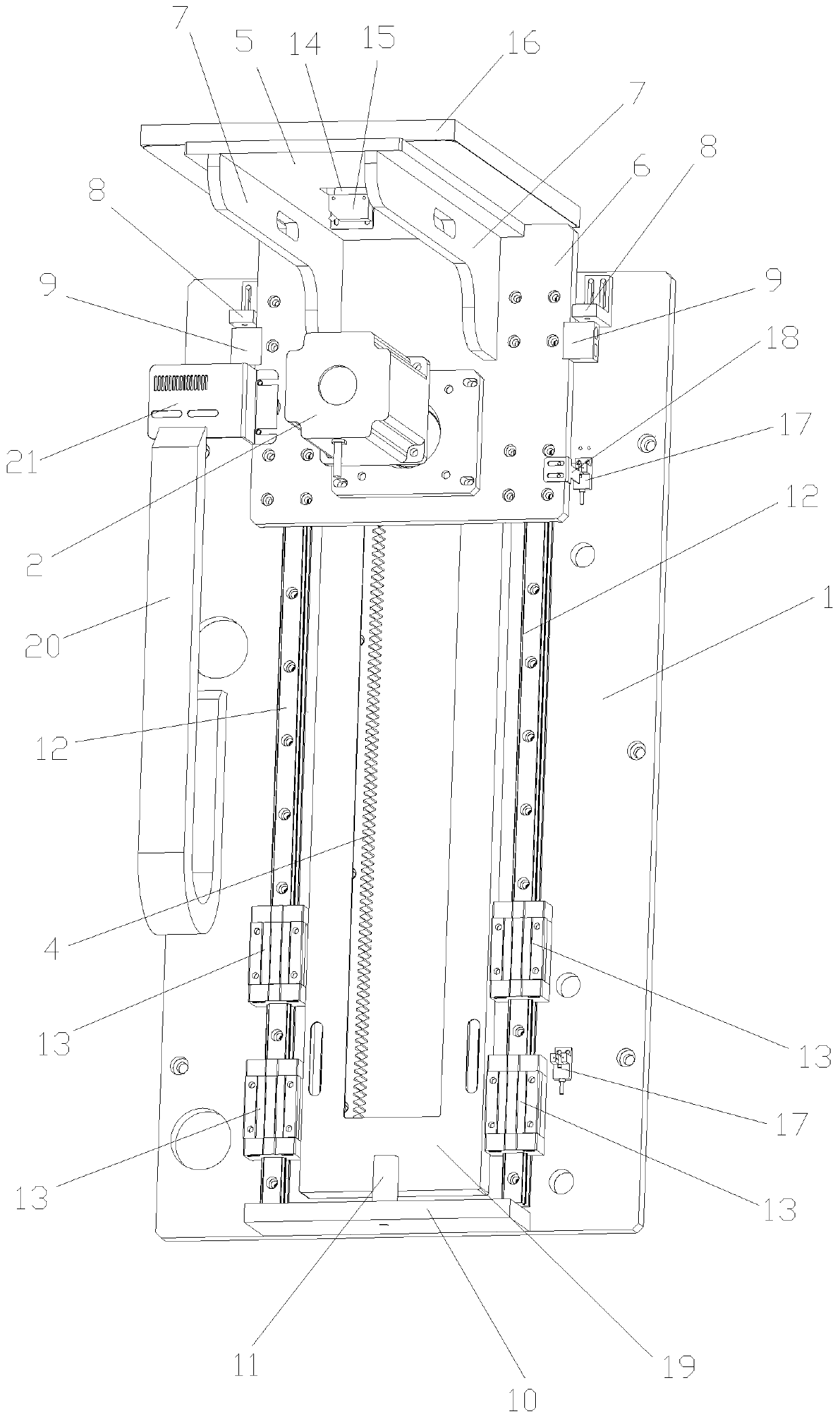

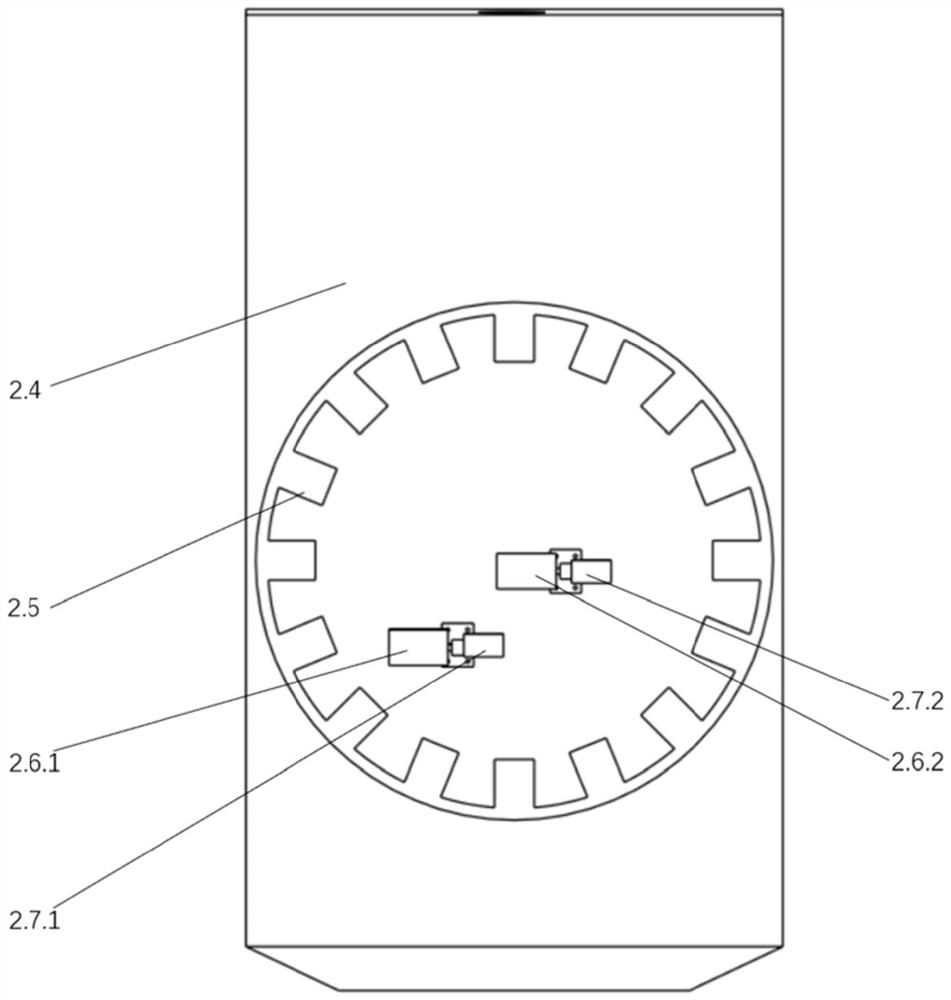

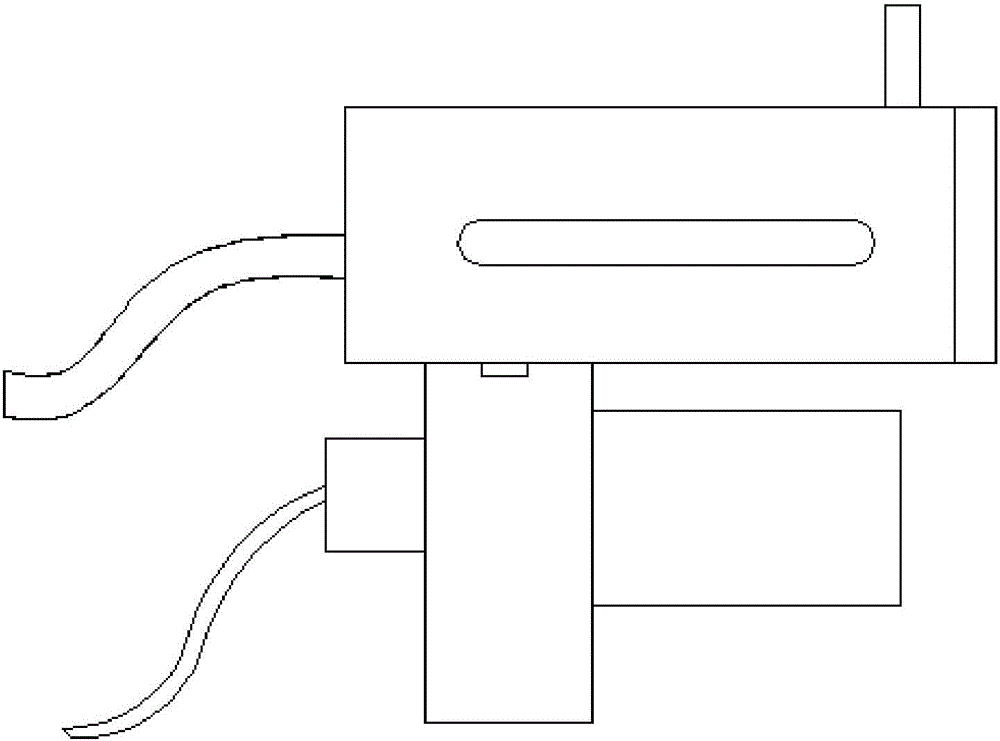

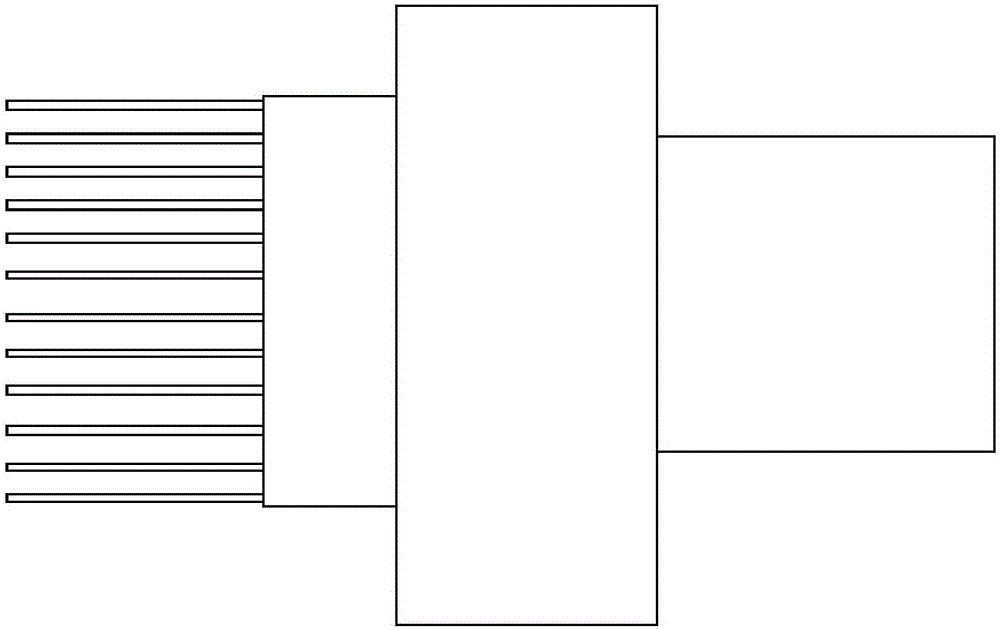

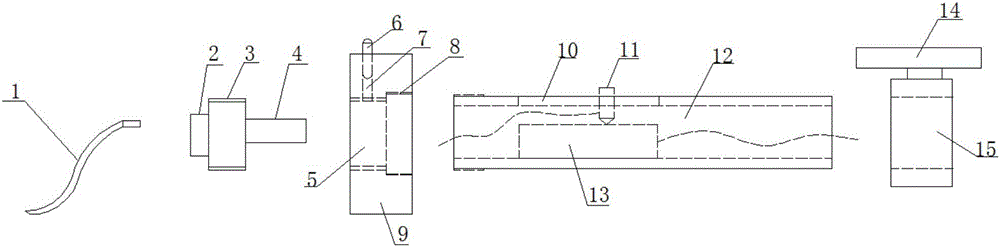

Feeding mechanism for part three-dimensional size measurement machine

InactiveCN105501947AContinuous feedingImprove feeding efficiencyConveyor partsThree Dimensional SizeWork period

The invention discloses a feeding mechanism for a part three-dimensional size measurement machine. The feeding mechanism comprises a feeding pushing assembly and a dividing plate, wherein the feeding pushing assembly comprises a pushing bracket, a pushing air cylinder and a pushing platform; the pushing air cylinder and the pushing platform are arranged on the pushing bracket; the pushing platform is connected with a feeding track; a vibration motor is arranged at the bottom of the feeding track; the pushing air cylinder is connected with a feeding pushing block by a connection assembly; the feeding pushing block is arranged on the pushing platform; a plurality of material storage slots are uniformly distributed in the dividing plate; a dividing plate driving mechanism for driving the dividing plate to rotate is arranged below the dividing plate; the feeding pushing block can be used for continuously pushing parts fed to the pushing platform from the feeding track to the material storage slots in the dividing plate; a plurality of parts can be pushed into each of the material storage slots continuously. By using the feeding mechanism, the continuous feeding can be realized, the working efficiency can be improved, and the work period can be shortened.

Owner:SUZHOU BENISYS ELECTRONICS SYST CO LTD

Pneumatic conveying equipment

The invention discloses pneumatic conveying equipment. The pneumatic conveying equipment comprises a feeding bin, a hopper, a material amount adjusting device, a rubber sealing ring, a mixing tank, afan and a material storage device, wherein the feeding bin is connected with the hopper through the rubber sealing ring, the lower end of the hopper is funnel-shaped, and a discharging port is formedin the bottom of the hopper; the material amount adjusting device comprises a driving lifting device, an adjusting rod and a cross beam, the cross beam is arranged in the hopper, the driving lifting device is fixed on the cross beam, the adjusting rod is connected with the driving lifting device and performs lifting motion under the driving of the driving lifting device, and the bottom of the adjusting rod is in an inverted cone shape; the bottom of the adjusting rod is suspended in the center of the discharging port, the discharging port is connected with the mixing tank, the mixing tank is connected with the material storage device, and the top of the material storage device is connected with the fan. By the adoption of the pneumatic conveying equipment, the function of adjusting the discharging amount of the discharging port in unit time and ensuring the uniform discharging of the hopper can be realized, thereby ensuring uniform conveying of material.

Owner:肇庆市新大力设备制造安装有限公司

Special method for industrial treatment on waste plastic in classified garbage

InactiveCN107446610AHigh degree of automationContinuous feedingProductsReagentsElectric heatingFuel oil

The invention relates to the field of garage treatment and chemical engineering, and to a method for pretreating plastic sorted from living garbage with hot air. The method comprises the following steps: drying moisture of waste plastic through blowing, performing primary decontamination, feeding into a liquidation kettle by using special continuous feeding equipment, performing liquidation in the liquidation kettle, feeding into a splitting kettle, condensing gases of the splitting kettle through a heat exchanger, wherein oil separated from the gases, together with heavy oil in the splitting kettle, are used as raw materials of petrochemical plants, and uncondensed gases separated from the gases are used as heat energy for heating the splitting kettle. The liquidation kettle consists of a heat preservation part and a heating part; heat conduction oil is fed into an interlayer in the heat-preservation kettle; constant temperature is kept through electric heating; the heating part is achieved through returned high-temperature oil after splitting in the splitting kettle. The method is fully automatic, sealing is achieved in the whole process, no pollution is caused, the energy consumption is low, operation is easy to carry out, plastic is rapidly liquidized according to characteristics of plastic in waste treatment plants and is liquidized through high-temperature oil, the problems that waste plastic is easy to coke when being heated, is low in heat conduction rate and the like are solved, and industrial treatment on waste plastic in sorted garbage is achieved.

Owner:BEIJING HAOHAI TIANJI TECH +2

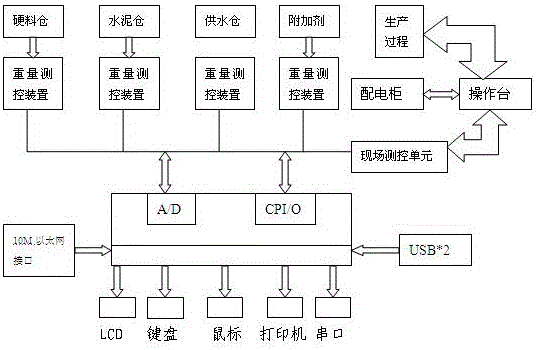

Concrete mixing plant control system construction method

InactiveCN106738356AOvercoming reliabilityOvercome stabilityMixing operation plantOperational systemControl system

The invention discloses a concrete mixing plant control system construction method, overcomes such defects as weak reliability and unstable communication of a traditional mixing plant control system based on an industrial personal computer and a PLC, and makes up the defects in a traditional control system. An embedded concrete mixing plant control system uses an ARM as a processor and an UC / OS-II as an operation system to provide an economical and practical mixing plant embedded control system. Functionally, the mixing plant functions with a traditional industrial personal computer as core can be totally realized, and the metering, the feeding, the mixing and the discharge of all materials can be automatically and continuously controlled according to given formulas. Meanwhile, the system also has such a series of management functions as browse, inquiry, statistics and printing for data.

Owner:刘程秀

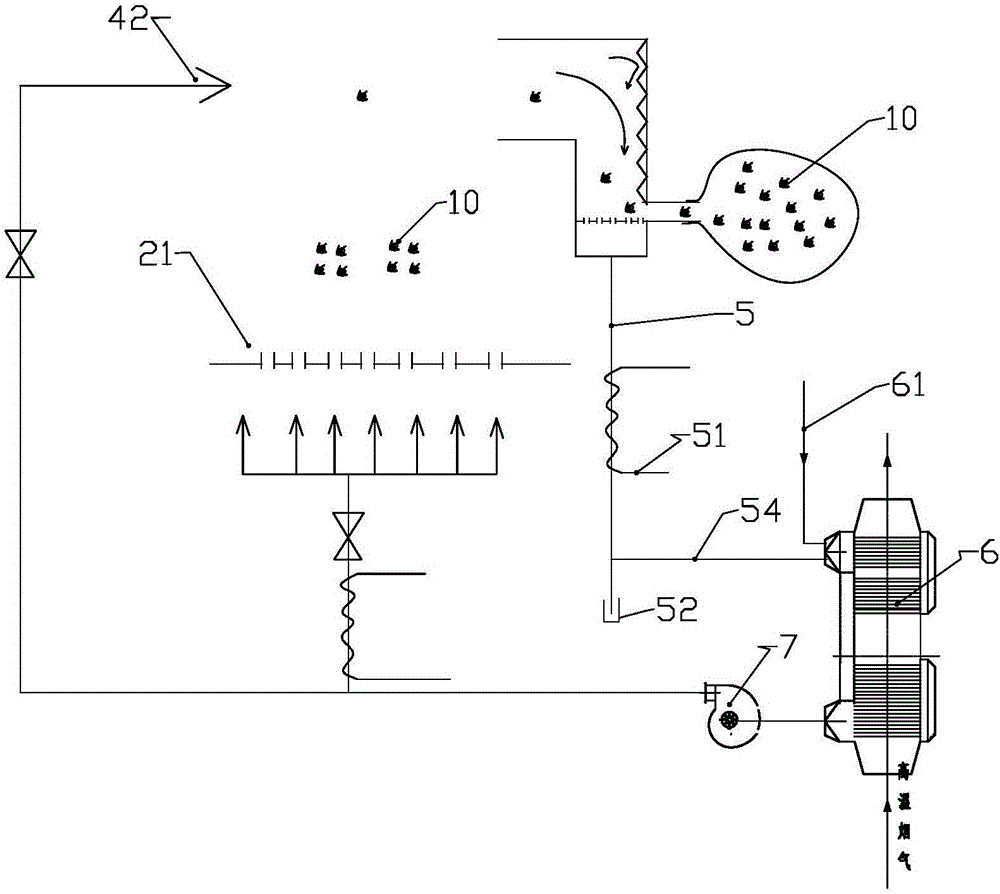

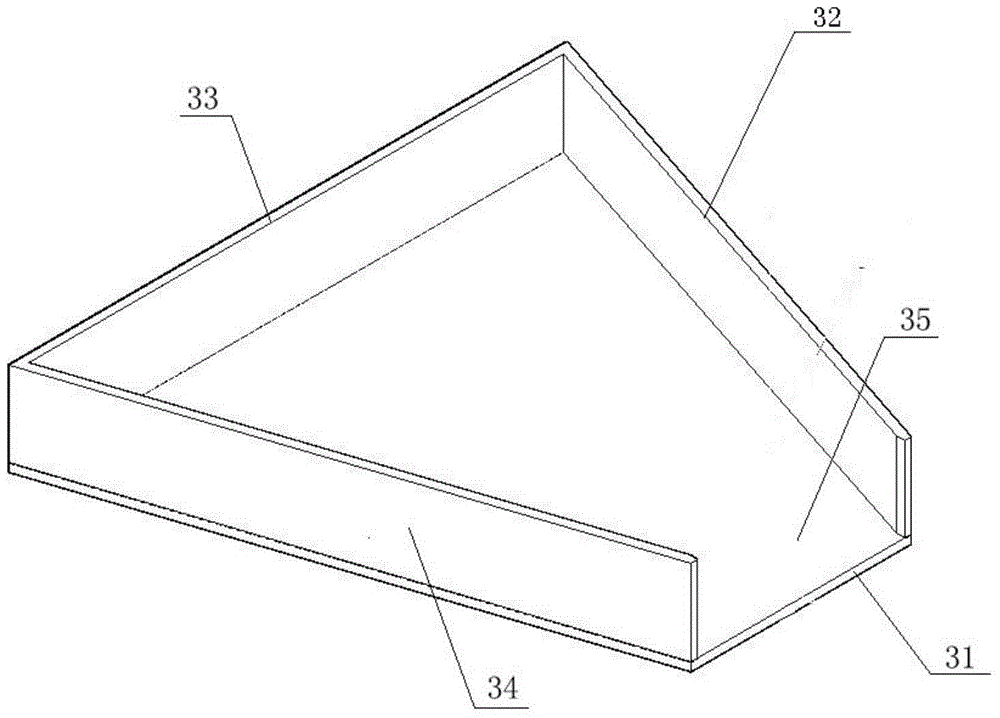

Green tea drying system

ActiveCN105685275ALittle impact on qualityIncreased surface area ratioPre-extraction tea treatmentAir volumeEngineering

The invention relates to a green tea drying system. The green tea drying system comprises a dryer, a fan and a heat pipe exchanger, wherein the interior of the shell of the dryer comprises a first air channel, a second air channel and a floatation region, the first air channel is arranged at the lower part of the inner cavity of a shell inner body, a triangular convex edge gradually increased from an air inlet to a far end is arranged in a lower space of the first air channel, the triangular convex edge is made from a silica gel material, and under the action of air flow, the triangular convex edge forms certain oscillation; and the second air channel is arranged at one side of the first air channel, an arc-shaped plate used for changing air direction is arranged in the second air channel, and a gate used for regulating air volume is arranged between the first air channel and the second air channel. The air flow at the temperature of 60 DEG C is adopted in a drying process, green tea is uniformly dried by virtue of atmospheric flow, surface area ratio is improved, drying speed is improved, and influence on quality of tea leaves in medium temperature field is small, so that quality is improved.

Owner:紫阳县康硒天茗茶业有限公司

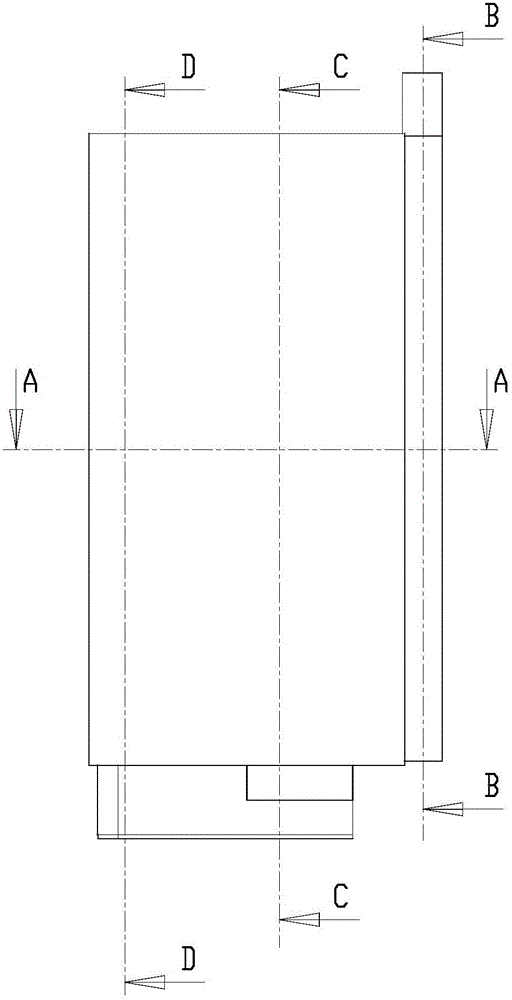

Continuous production process of waterproof coiled material

InactiveCN105365339AContinuous feedingReturn to normal feedingLamination ancillary operationsLaminationEngineeringAsphalt

The invention provides a continuous production process of a waterproof coiled material. The process includes: sending a substrate into a covering component continuously by a winding temporary storage mechanism, coating the upper surface and lower surface of the substrate with asphalt respectively by the covering component, covering the upper surface of the substrate with a PET film, and covering the lower surface of the substrate with an isolating film; then letting the substrate covered with a film on the upper and lower surface respectively enter a rubber extrusion component continuously to conduct excess asphalt extrusion so as to obtain a waterproof coiled material, and passing the waterproof coiled material through a drying component, heating the inner layer asphalt to make the inner layer asphalt coated evenly, and subjecting the waterproof coiled material to cooling molding by a cooling component, thus obtaining the molded waterproof coiled material. The continuous production process of the waterproof coiled material can realize continuous feeding of the substrate, so that the covering component can achieve continuous production without interruption, thus ensuring production continuity and improving the processing efficiency.

Owner:安徽五星凯虹防水建材科技有限公司

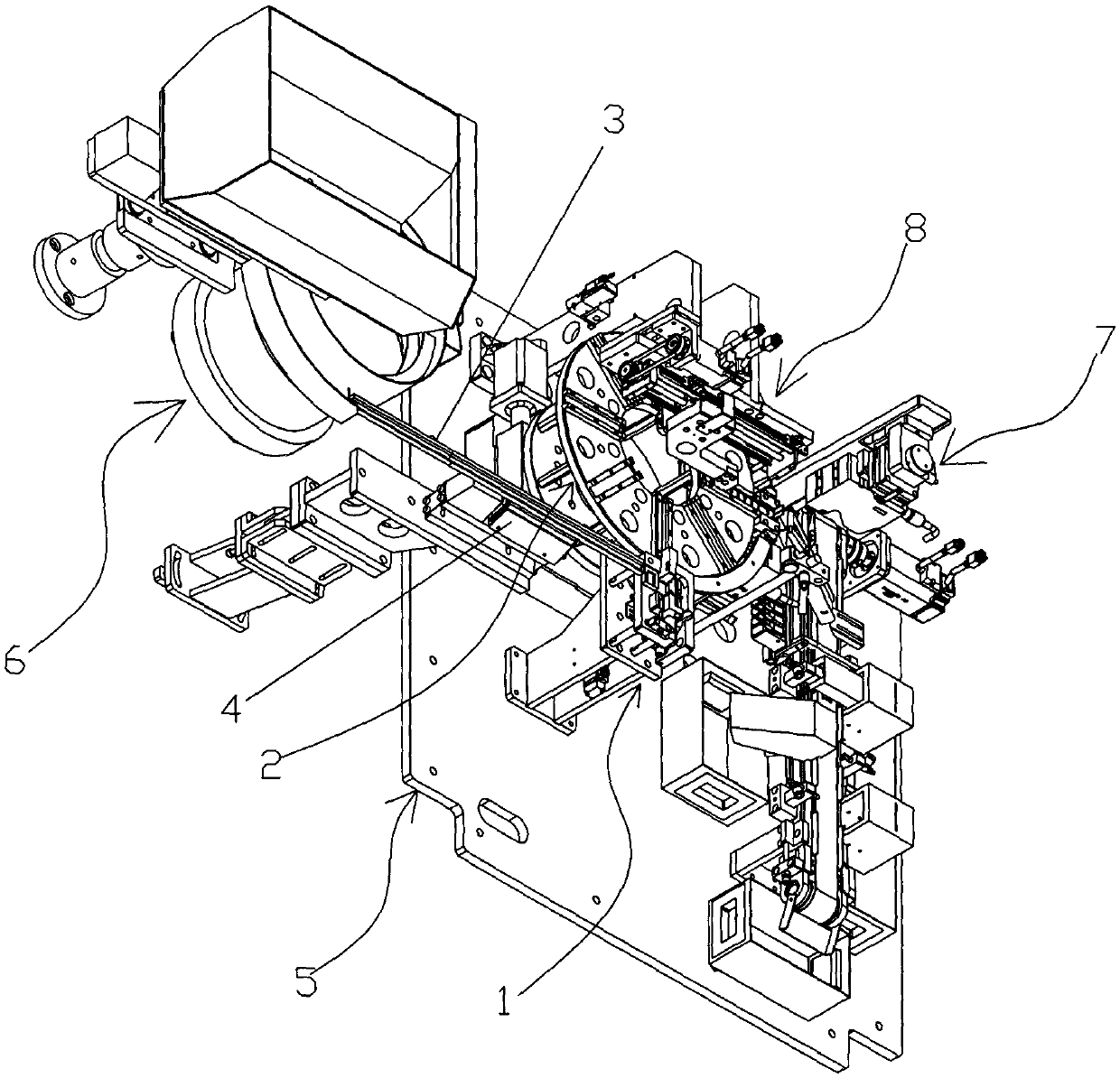

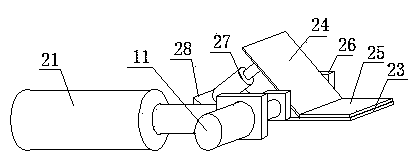

Automated feeding and loading mechanism of plastic car frame inserts

The invention discloses an automated feeding and loading mechanism of plastic car frame inserts. The automated feeding and loading mechanism of the plastic car frame inserts is composed of a vibrating table feeder, a transition loading table and a mechanical arm; the vibrating table feeder is provided with a vibrating table face and a slide way, and the inserts are fed to and arranged at the tail end of the slide way in a flush mode along with vibrating; a carrying chuck is installed on a base plate of the mechanical arm, and the mechanical arm has capacities of triaxial movement and base plate overturning; and the transition loading table is provided with an insert pre-loading-site rod and a fixed-travel sliding plate, and under an running-in state of synchronous rate operation of all parts, the inserts are arranged in a vibrating mode from the vibrating table feeder, fed along the slide way in the flush mode, received by the fixed-travel sliding plate sliding plate of the transition loading table one by one, sent to the insert pre-loading-site rod, and then picked up by the carrying chuck to be sent into an opened mold cavity of an injection molding device by the mechanical arm for completing loading. Through application of the automated feeding and loading mechanism, automatic, accurate and continuous insert feeding and loading are achieved, manual work is thoroughly liberated, and injection molding production efficiency is greatly improved.

Owner:SUZHOU INDAL PARK XIELI PLASTIC

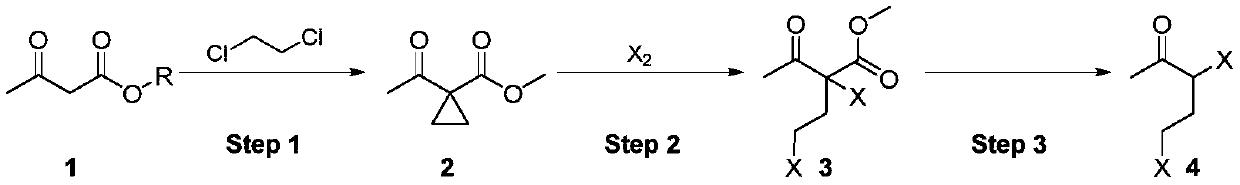

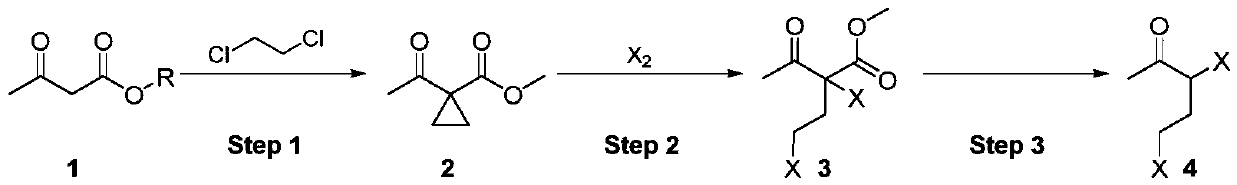

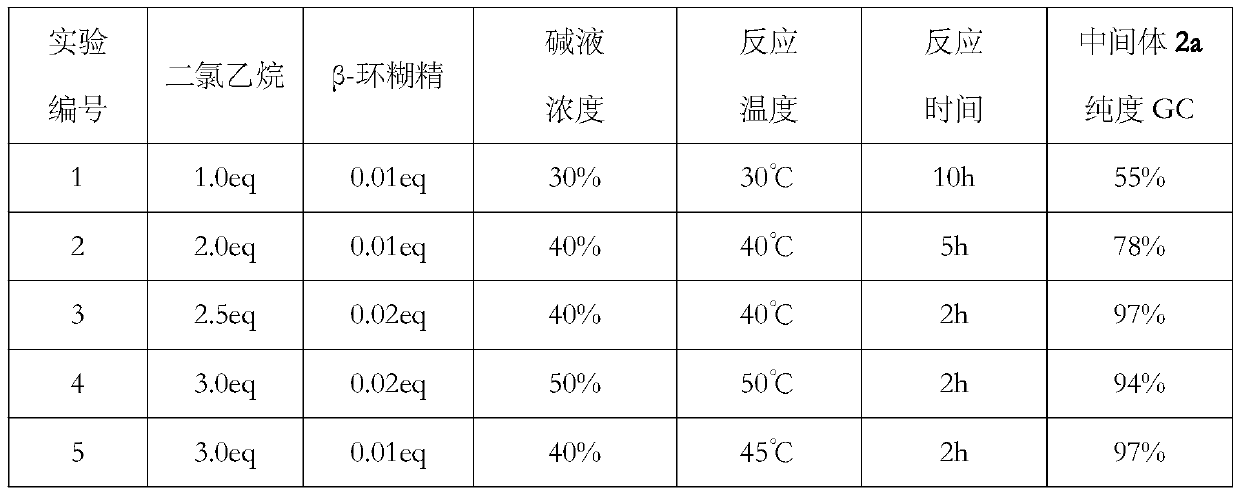

Synthesis method of 3,5-dihalogenated-2-pentanone

ActiveCN111205176ARaw materials are easy to obtainAtom utilization is highOrganic compound preparationCarboxylic acid esters preparationAcetoacetatesPtru catalyst

The invention discloses a synthetic method of 3,5-dihalogenated-2-pentanone, and belongs to the technical field of organic chemistry. According to the method, acetoacetate is taken as a raw material,and cyclopropanation, ring-opening halogenation and hydrolysis decarboxylation reactions are carried out successively so as to obtain 3,5-dihalogenated-2-pentanone. The method has the advantages of simple and accessible raw materials, high atom utilization ratio in the halogenation step and fewer wastes. The reaction conditions of all steps are simple, purification is not needed in the process, continuous feeding can be achieved, cyclic application of the cyclopropanation catalyst can be achieved, and potential industrial amplification prospects are achieved.

Owner:DALIAN JOIN KING FINE CHEM CO LTD

Artificial feed for codling moths and preparation method of artificial feed

InactiveCN103892121AWell developedContinuous feedingAnimal feeding stuffAccessory food factorsTechnical supportSucrose measurement

The invention relates to an artificial feed for codling moths and a preparation method of the artificial feed, and belongs to the technical field of insect feeding, wherein the artificial feed for codling moths is characterized by being prepared from the following components in percent by weight: 2-10 percent of bean pulp, 6-10 percent of whole meal, 1-3 percent of saccharose, 2-5 percent of yeast, 4-8 percent of wheat germ, 1-2 percent of agar, 0-0.5 percent of a sour agent, 68-80 percent of water, 0.3-0.6 percent of ascorbic acid, 0.1-0.5 percent of preservative and 1.5-3 percent of ethyl alcohol. The codling moths fed by using the feed provided by the invention can develop well, and can be continuously fed; an insect source guarantee is provided for indoor research and a technical support is provided for large-scale feeding.

Owner:NORTHWEST A & F UNIV

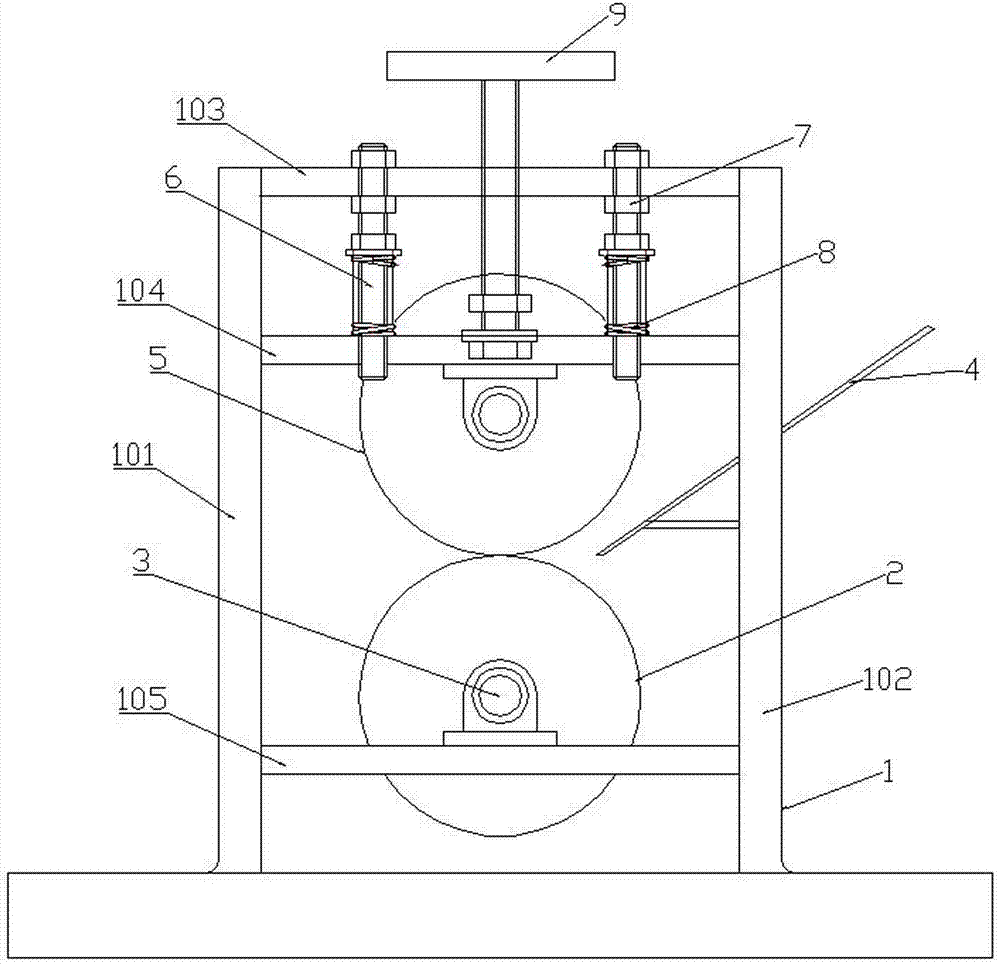

Viscose filament feeding device

The invention discloses a viscose filament feeding device and belongs to the technical field of chemical fiber production equipment. The viscose filament feeding device comprises a rack, a driving roller, a driven roller, a lifting rod playing an adjusting function, fixing units, elastic pieces and the like, wherein the driving roller and the driven roller are arranged on the rack. According to the viscose filament feeding device, by the adoption of the roller type feeding device, by using the friction force formed between the two rollers and pulp, roll pulp is continuously and uniformly conveyed into a pulp machine, and continuous and uniform feeding is achieved; and the elastic pieces are adopted for the two rollers, radial clearance compensation is achieved, the constant friction forcebetween two rotating wheels is guaranteed, and timing, quantitative and continuous feeding is achieved.

Owner:YIBIN GRACE +1

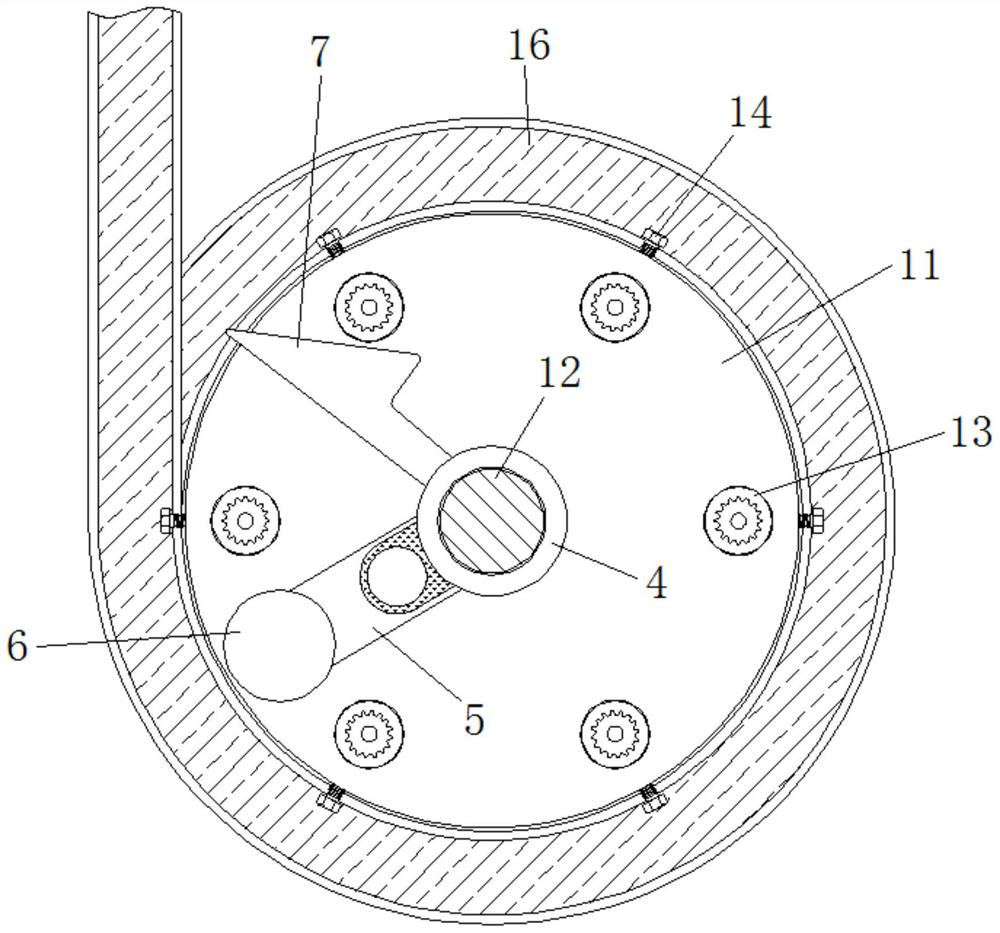

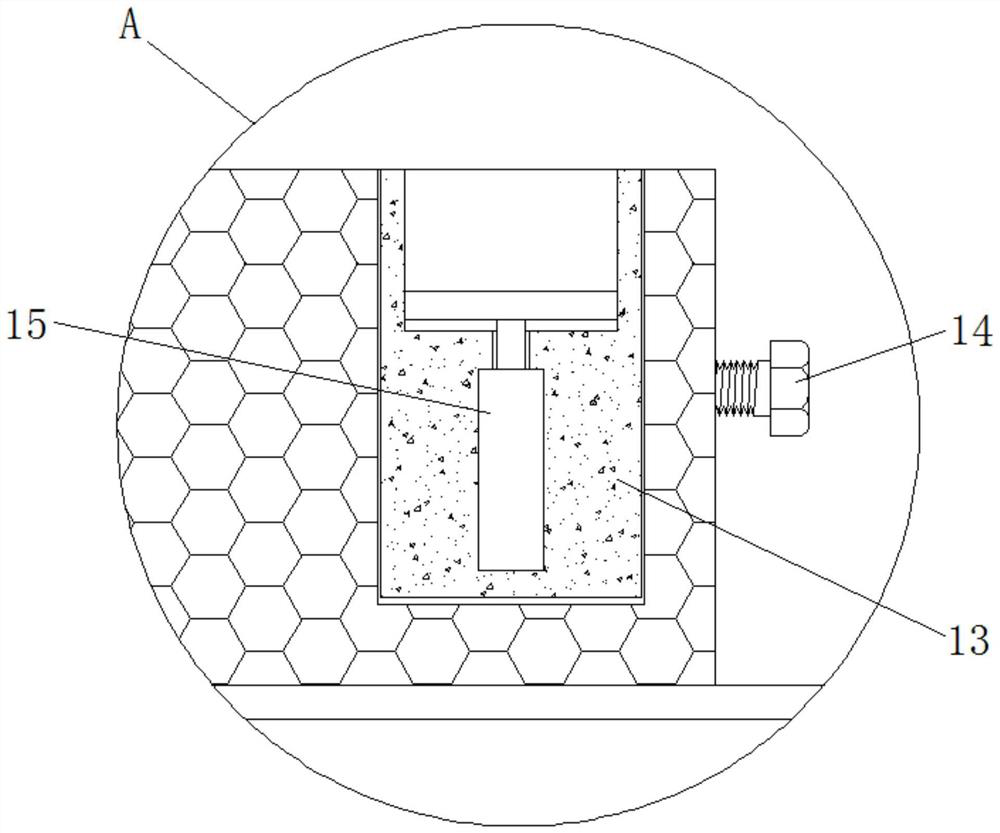

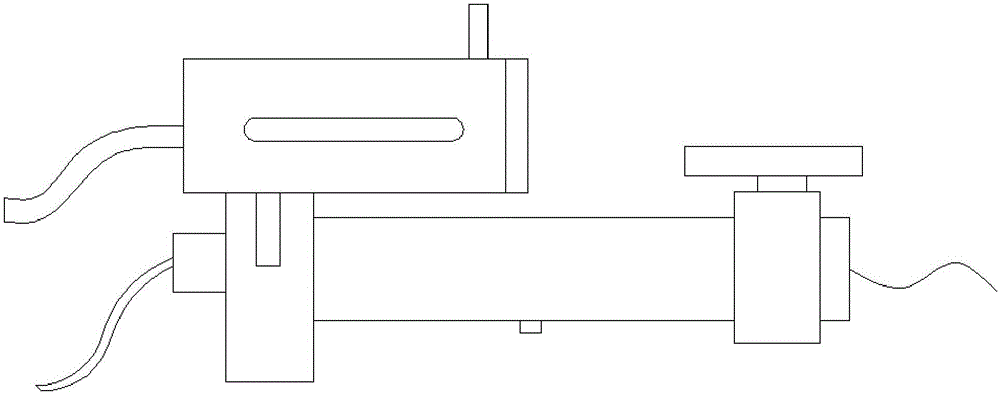

Method and device for continuously feeding and mixing dry powder

PendingCN108057384AContinuous feedingStir wellTransportation and packagingMixer accessoriesEngineeringDry powder

The invention relates to a method and a device for continuously feeding and mixing dry powder. The device comprises a plurality of feeding devices, a vertical mixer and a horizontal mixer. The feedingdevices are communicated with a plurality of first feed inlets in a side wall of the vertical mixer; a first discharge hole of the vertical stirrer is communicated with a second feed inlet of the horizontal mixer; a plurality of first feed inlets upwards inclined at a preset angle are formed in the side wall of the vertical mixer; a circulation feed inlet of a circulating device is communicated with the bottom part of the horizontal mixer; a circulation discharge hole of the circulating device is communicated with the upper part of the horizontal mixer. According to the method and the devicefor continuously feeding and mixing the dry powder provided by the invention, the feeding devices, the vertical mixer and the horizontal mixer are adopted, and during a mixing process, the circulatingdevice conveys mixed dry powder located on the bottom part of the horizontal mixer to the upper part of the horizontal mixer, so that continuous feeding can be realized; after the various dry powderare fully mixed through the vertical mixer and the horizontal mixer, the advantages of uniformity in mixing, high mixing efficiency, capability of continuously feeding and the like are realized.

Owner:SHENZHEN XINYUREN TECH

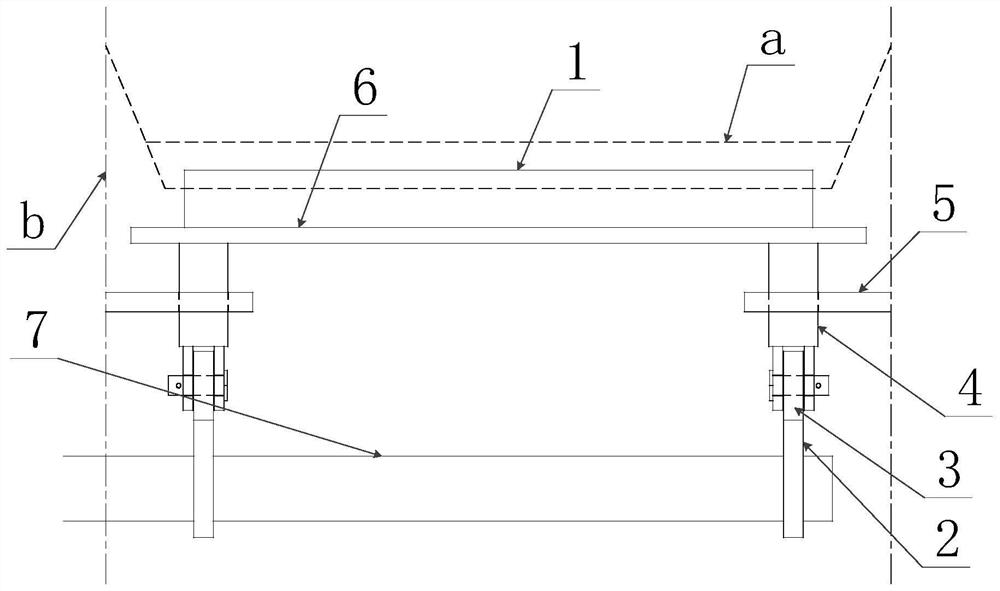

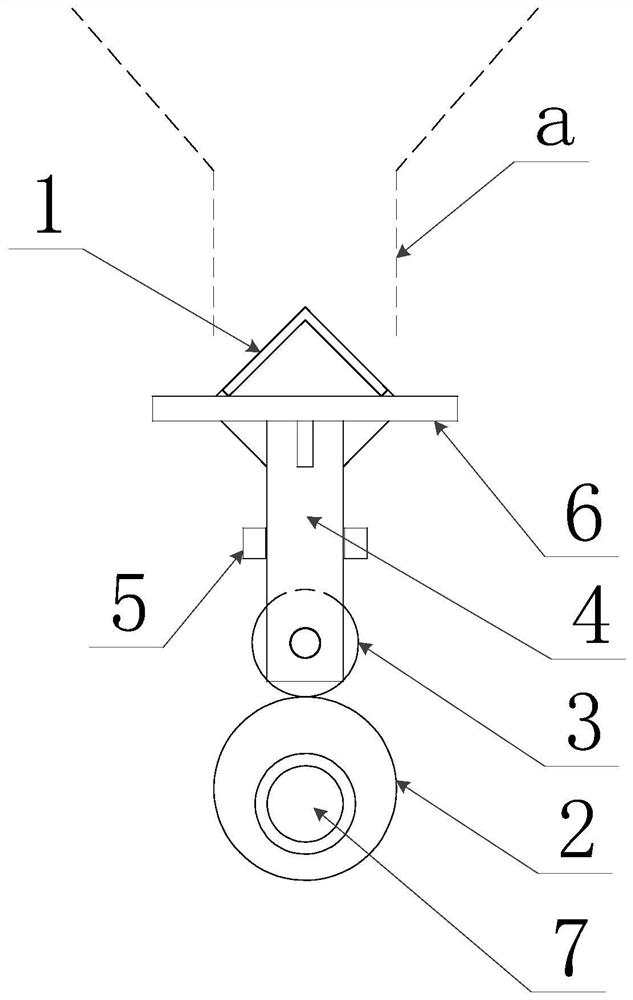

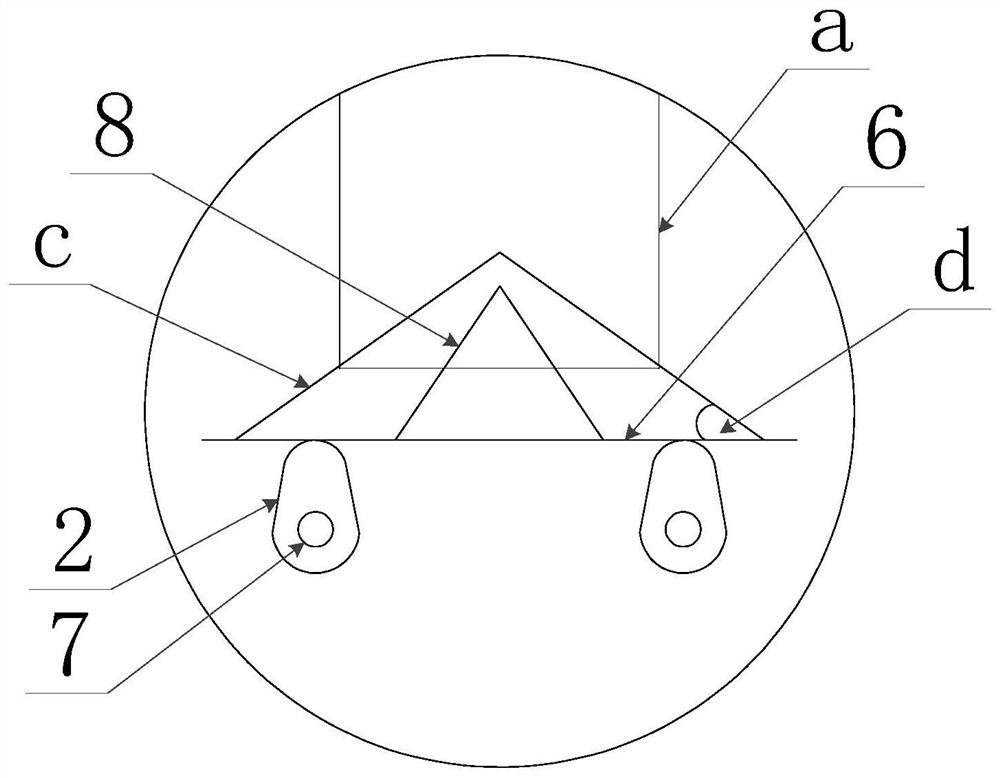

Material conveying equipment

PendingCN110733871AAchieve liftingLow failure rateConveyorsConveyor partsElectric machineryEngineering

The invention discloses material conveying equipment which comprises a vertical material conveying device and a transverse material conveying device arranged vertical to each other. The vertical material conveying device comprises a fixed plate, a bearing frame for placing a material and a first driving mechanism for driving the bearing frame to move. The extension direction of a rack is identicalto the moving direction of the material. An output shaft of the first driving motor is vertical to the fixed plate. The transverse material conveying device comprises a vertical plate, a transmissionmechanism arranged on the vertical plate and a second driving mechanism for driving the transmission mechanism to operate. The transmission mechanisms are arranged on the first vertical plate and thesecond vertical plate. Each transmission mechanism comprises a first rotating wheel, a second rotating wheel and a conveyor belt arranged between the first rotating wheel and the second rotating wheel in a sleeving manner. The material conveying equipment can receive or supply the material continuously and convey the material to an appointed position, so that the production efficiency is improvedeffectively.

Owner:苏州松翔电通科技有限公司

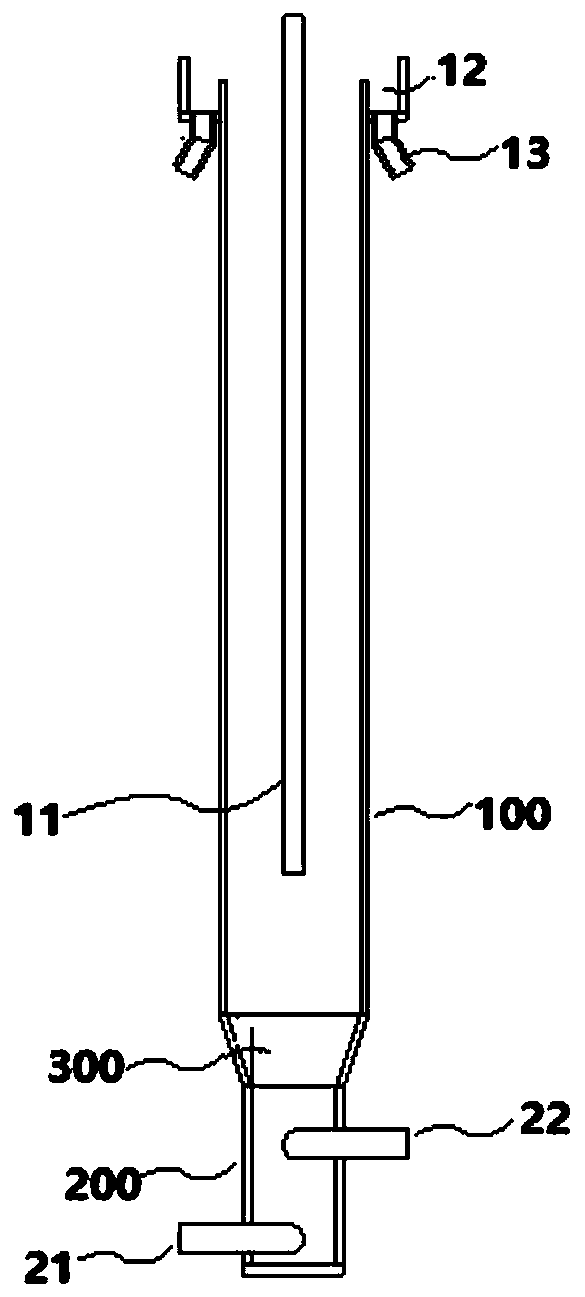

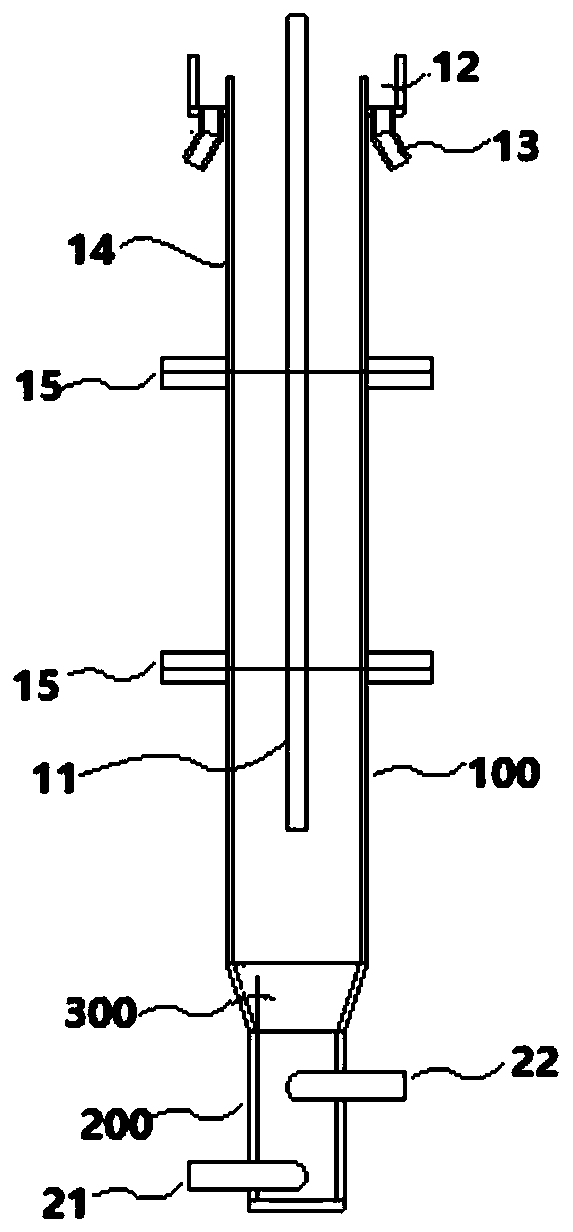

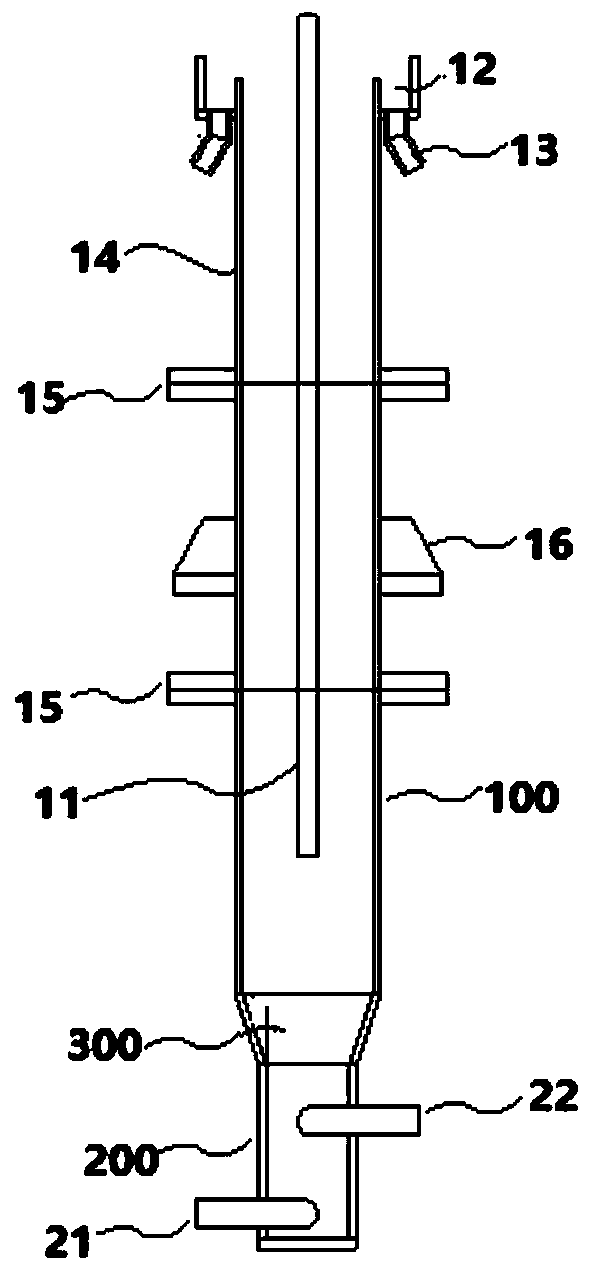

Continuous discharging device with controllable discharging speed, desorption tower and adsorption tower

PendingCN112027379AContinuous feedingFeeding speed controllableGas treatmentDispersed particle separationActivated carbonCam

The invention provides a continuous discharging device with controllable discharging speed, and a desorption tower and an adsorption tower using the continuous discharging device with the controllabledischarging speed. The continuous discharging device with the controllable discharging speed comprises an adjusting part. The adjusting part can move up and down relative to a discharging opening. When the adjusting part moves relative to the discharging opening, the size of a gap between the adjusting part and the discharging opening can be changed, therefore the size of the discharging gap is adjusted, and thus the discharging speed is adjusted. Two discharging control manners can be provided, firstly, the distance between the discharging opening and a blocking plate is adjusted, when the discharging speed meets the requirement, rotating of a cam is stopped, and at the moment, activated carbon is discharged continuously; and secondly, the discharging speed is controlled by means of rotating frequency of the cam, namely, the rotating speed of the cam is fixed, and then control over the discharging speed can be achieved by controlling the rotating frequency of the cam. The device canachieve continuous discharging of materials, and the discharging speed is controllable.

Owner:BEIJING ZHTD ENVIRONMENTAL PROTECTION TECH CO LTD

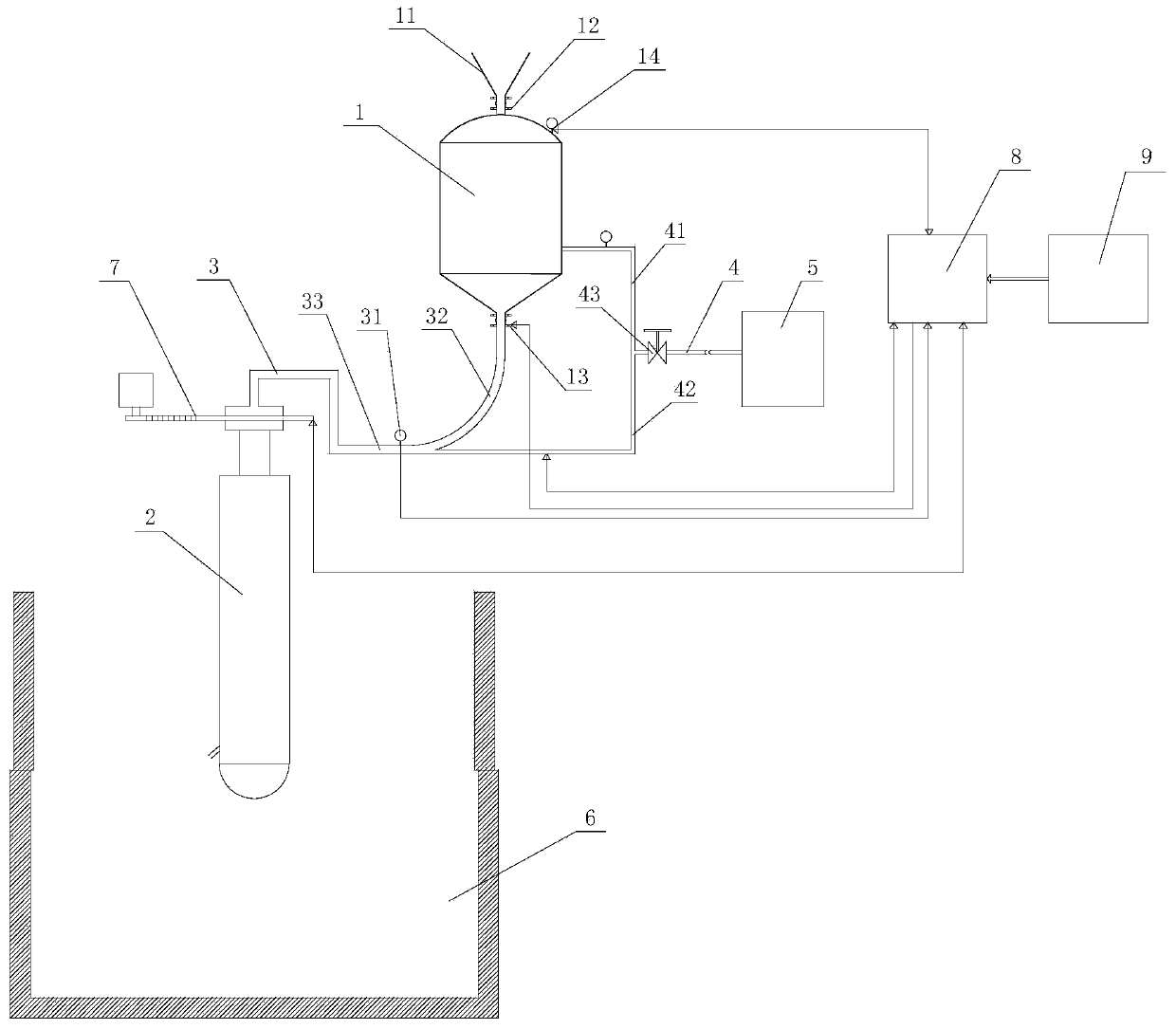

Automatic blowing and spraying device for ferrovanadium refining

The invention discloses an automatic blowing and spraying device for ferrovanadium refining and belongs to the field of iron and steel smelting equipment. The automatic blowing and spraying device forferrovanadium refining comprises a spraying and blowing tank and a spray gun which are connected through a conveying pipeline; the spraying and blowing tank is externally connected to a high-pressureinert gas source through a high-pressure pipe; the spray gun is positioned at an opening at the upper part of a smelting furnace; the upper end of the spray gun is mounted on a rotating device and the lower end of the spray gun is deep into the smelting furnace; in addition, the automatic blowing and spraying device for ferrovanadium refining further comprises a control module; and the control module automatically controls the work of the high-pressure inert gas source, the spray gun and the rotating device. A reducing agent is automatically sprayed and blown into molten slag through the blowing and spraying device, feeding is continuous and uniform and wide in range, so that vanadium oxide in the furnace is subjected to secondary reduction, the vanadium content of the slag is reduced andthe recovery rate of the vanadium is improved; furthermore, part of high-pressure insert gas is carried with the reducing agent sprayed into the smelting furnace and flowing of the molten slag is promoted by continuously stirring the molten slag, so that separation of ferrovanadium alloy and the slag is further promoted and alloy drop settlement is promoted.

Owner:BEIHAI SPECIAL IRON ALLOY PANGANG GROUP

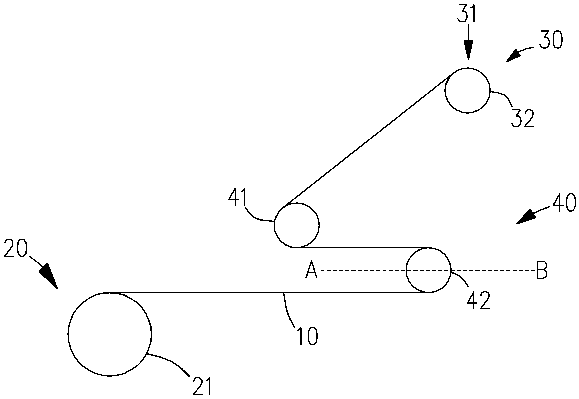

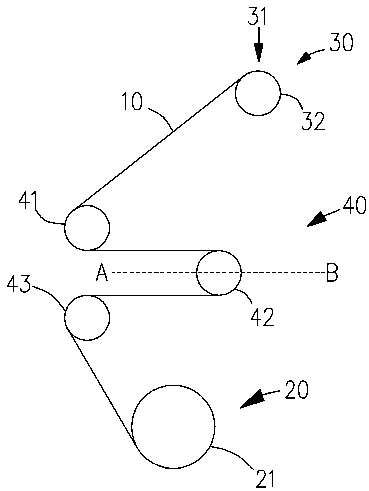

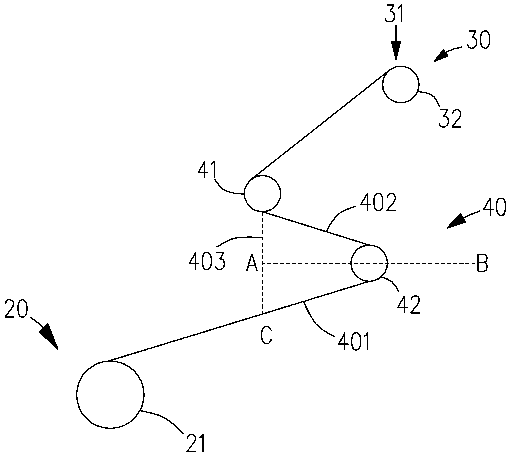

Conveying device, rubberizing device and conveying method

InactiveCN111217180ASlow downIncrease success rateArticle deliveryWebs handlingControl theoryMechanical engineering

The invention relates to a conveying device. The conveying device comprises a discharging mechanism and a conveying mechanism for conveying a material strip to a first preset position from the discharging mechanism. The conveying mechanism comprises a temporary storage mechanism for temporarily storing at least one part of the material strip discharged by the discharging mechanism every other preset time. According to the conveying device, the temporary storage mechanism is arranged, so that the material strip located at the first preset position is static, or the moving speed is reduced, andthe success rate of operation of an operation mechanism on the material strip is increased. Meanwhile, the discharging mechanism is allowed to carrying out discharging continuously, and stable discharging tension is ensured.

Owner:GUANGDONG LYRIC ROBOT INTELLIGENT AUTOMATION CO LTD

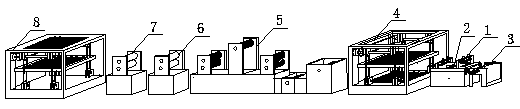

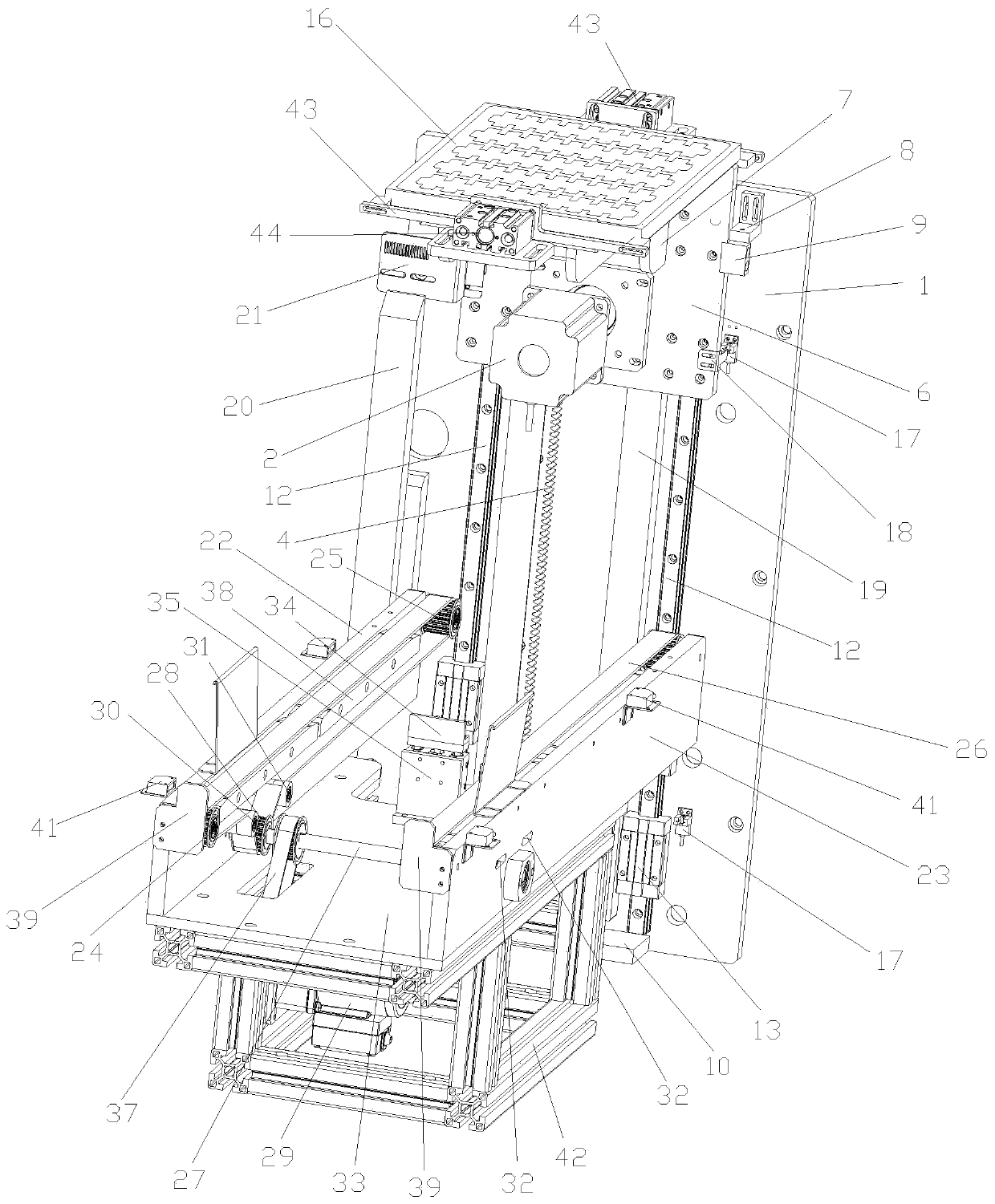

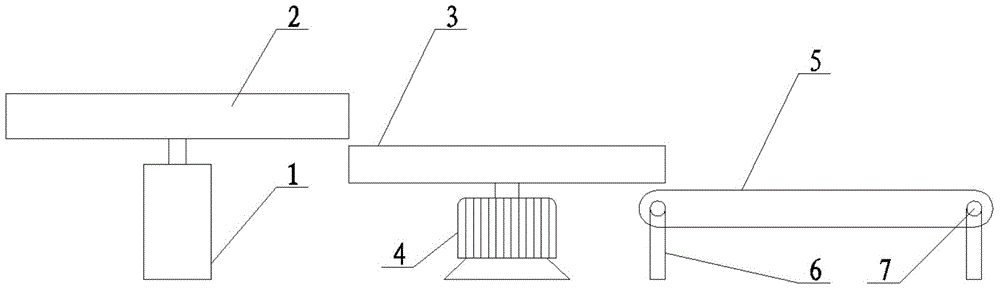

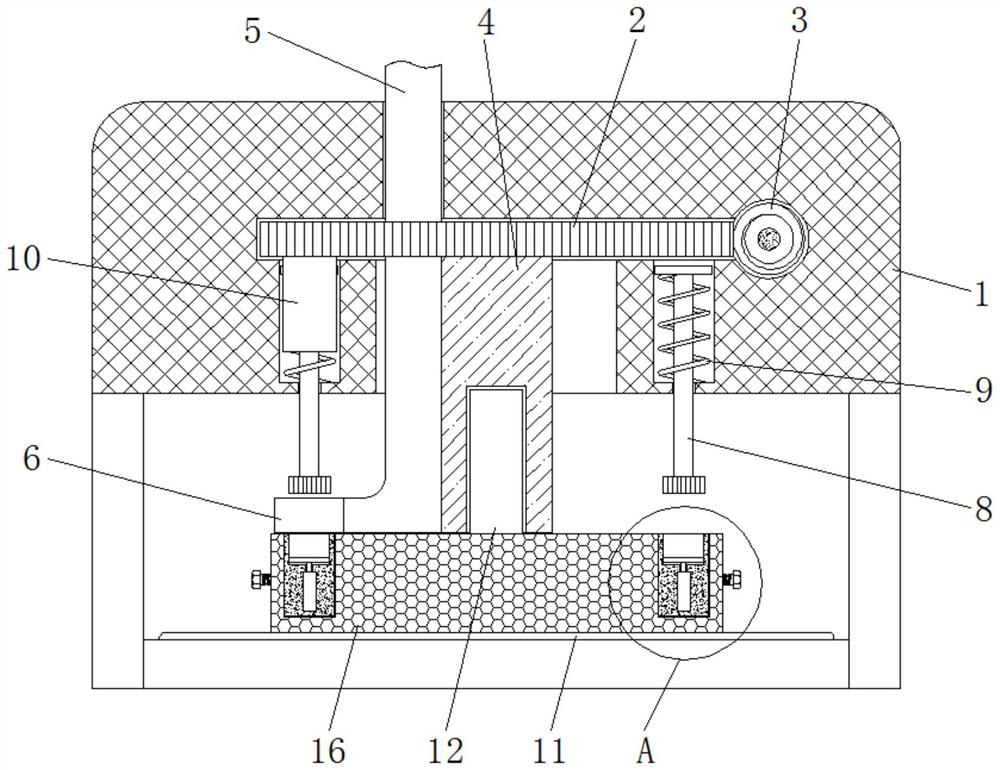

Continuous feeding mechanism for processing medical materials

InactiveCN104627646ARealize continuous feedingAchieve placementConveyorsConveyor partsLeather beltVibration motor

The invention provides a continuous feeding mechanism for processing medical materials. The continuous feeding mechanism for processing the medical materials is characterized by comprising a lifting platform, a conveyor belt and a feeding slot, a cylinder is arranged at the bottom of the lifting platform, the lifting platform is located above the feeding slot after the lifting platform is completely lifted, a vibration motor is arranged at the bottom of the feeding slot which comprises a fist slot wall, a second slot wall and a third slot wall, a cavity is formed by the first slot wall, the second slot wall, the third slot wall and the bottom of the slot, a discharge opening is formed between the first slot wall and the third slot wall, the conveyor belt is located below the discharge opening, and drive rollers which are sleeved with the conveyor belt are arranged on a support. The continuous feeding mechanism for processing the medical materials has the advantages that the structure is simple, the design is exquisite, the feeding efficiency is high, even and continuous feeding can be achieved, and wide application value is achieved.

Owner:XIAN ZHONGKEMAITE ELECTRONICS TECH EQUIP

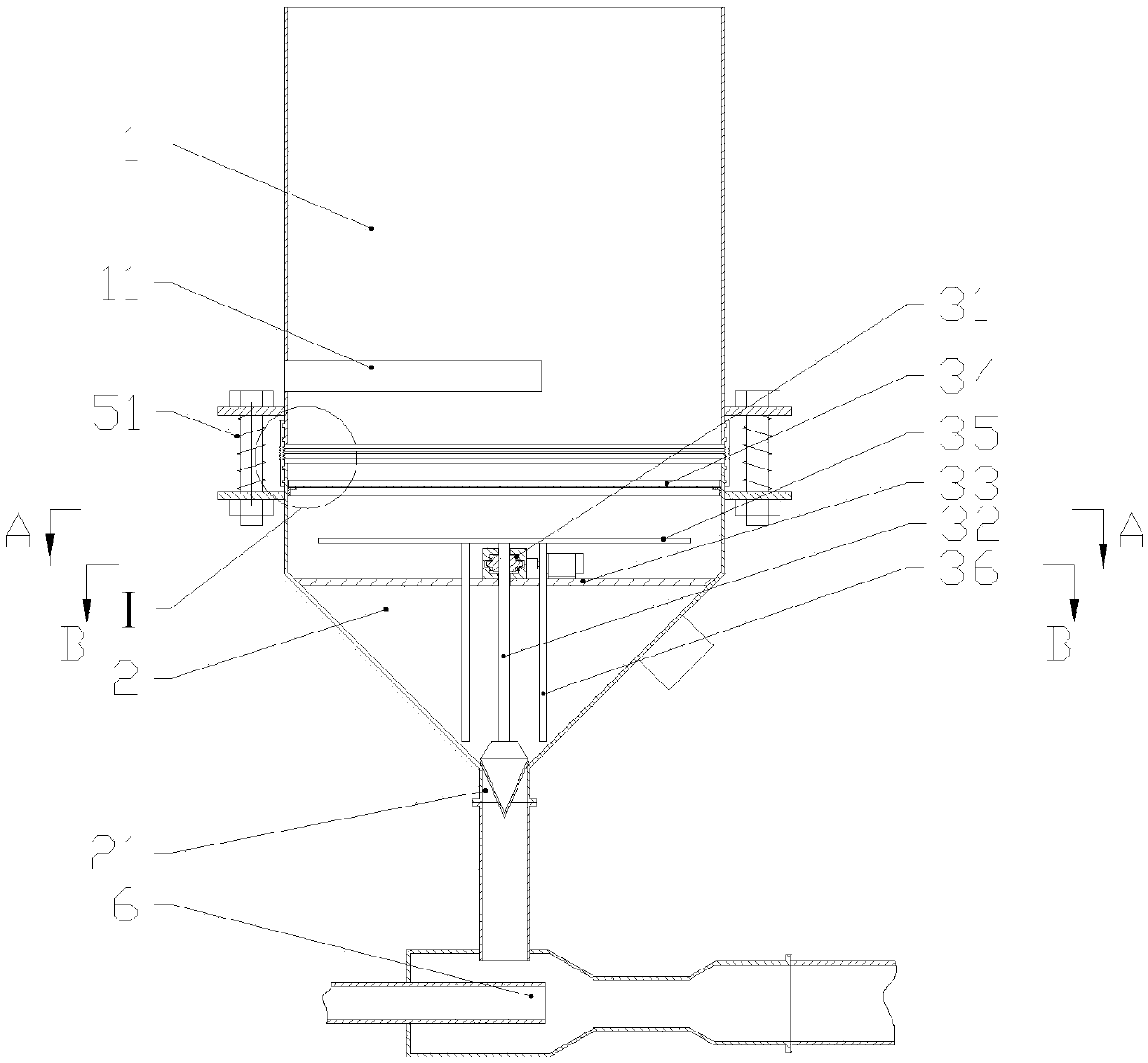

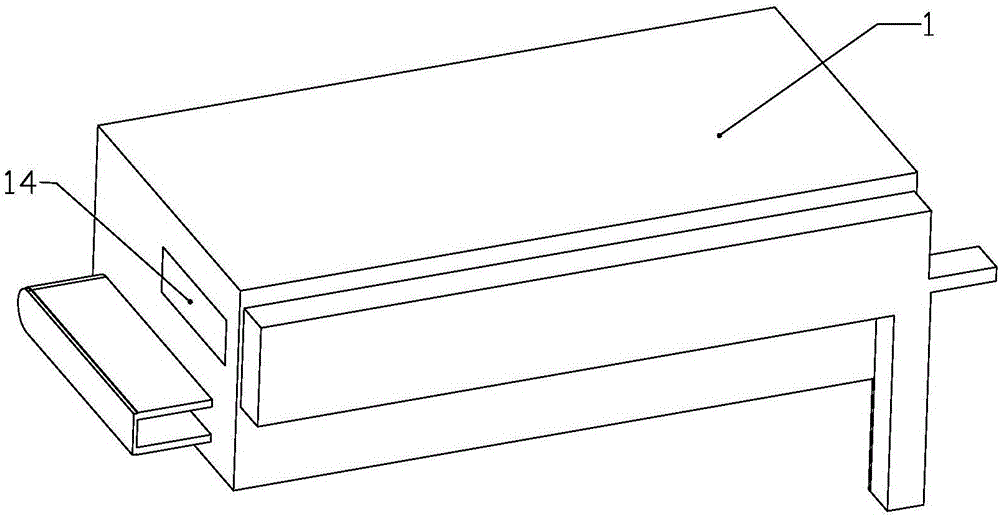

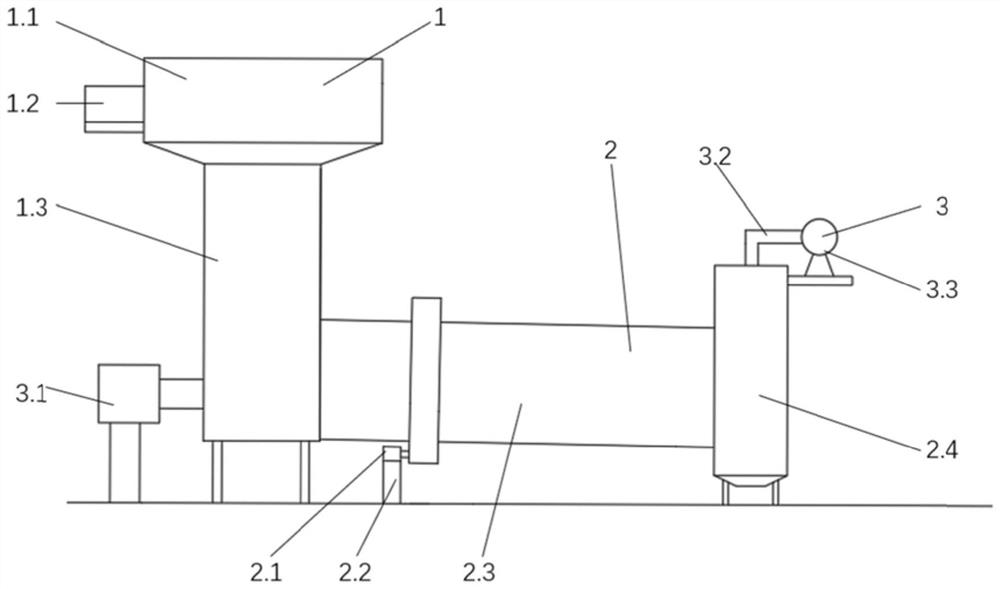

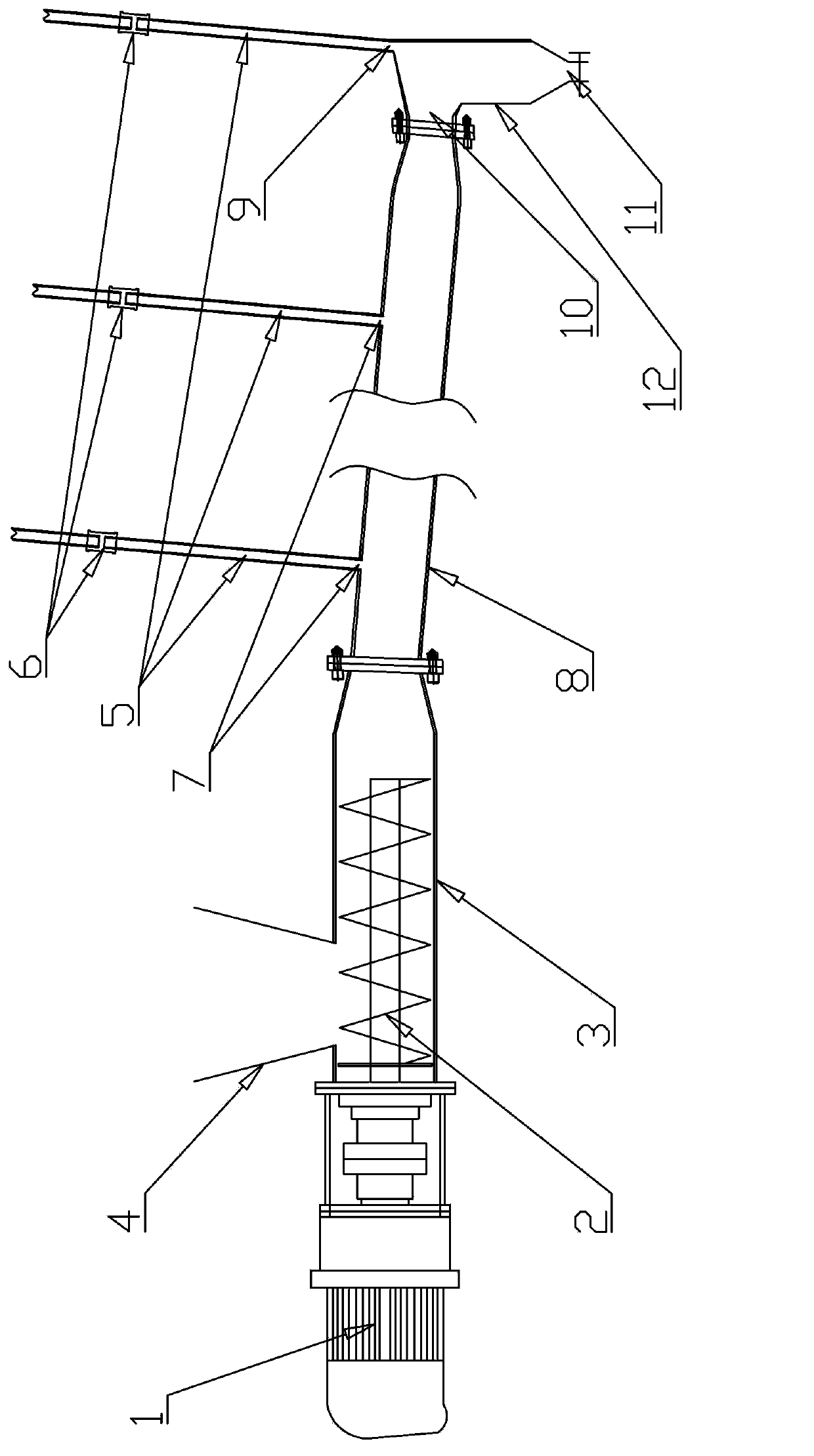

Traditional Chinese medicine drying device capable of achieving weight separation

PendingCN114322489AContinuous feedingGuaranteed uniformityDrying solid materials with heatDrying gas arrangementsMedicinal herbsProcess engineering

The invention provides a traditional Chinese medicine drying device capable of achieving weight separation. The traditional Chinese medicine drying device comprises a continuous feeding mechanism (1), an automatic mass separation discharging mechanism (2) and a drying mechanism (3), and the continuous feeding mechanism (1) is used for continuously adding traditional Chinese medicine particles; the unloading mechanism (2) capable of automatically separating the mass is used for separating the mass of the traditional Chinese medicine blocks and carrying out differential control on the drying time of the traditional Chinese medicine blocks with different masses; the drying mechanism (3) is used for drying the traditional Chinese medicine particles. Medicinal materials with different weights are different in winching distance under the action of the lifting strip, the chain plate machine is reasonably placed for conveying, and the drying uniformity of each medicinal material is guaranteed. And each medicinal material is ensured to have good medicine property, and waste of the medicinal materials is avoided.

Owner:HUNAN UNIV OF CHINESE MEDICINE

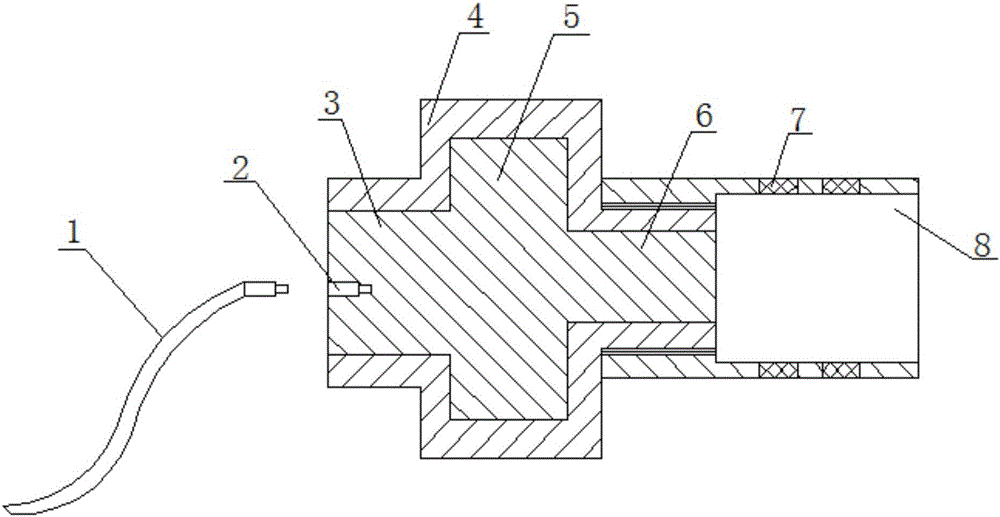

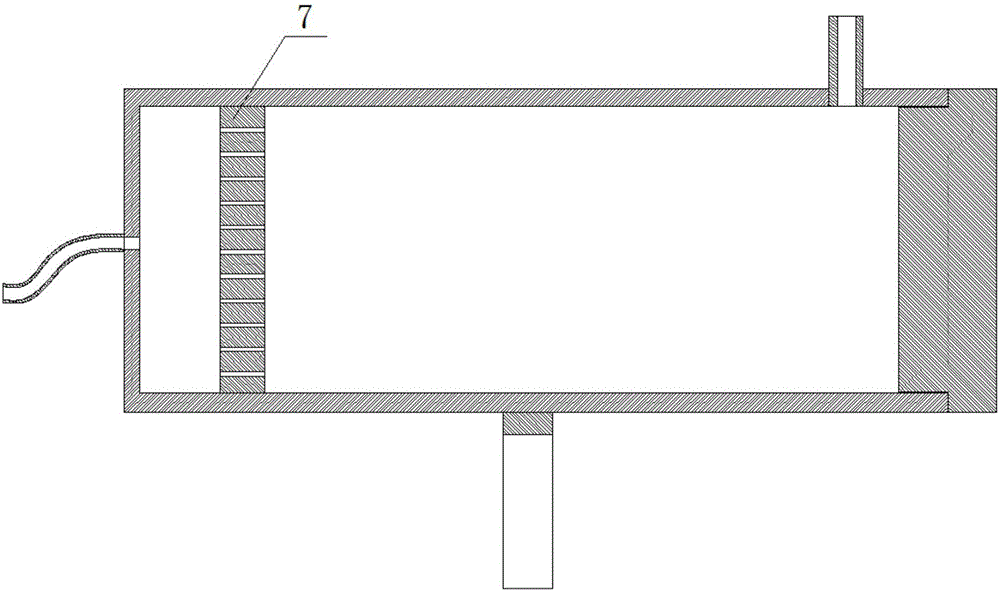

Removable dotting feeding assembly of PCB dotting device

The invention relates to a removable dotting feeding assembly of a PCB dotting device. The removable dotting feeding assembly comprises a dotting joint and a solder feeding device; the dotting connector comprises a metal thermal conduction block; a connection head and a positioning head are formed on the metal thermal conduction block; a plurality of insertion holes are linearly and uniformly formed at one end surface of the connection head; a plurality of metal thermal conduction sheets are inserted into the insertion holes; the external screw thread of the positioning head is connected with a heat insulating connection cylinder; a plurality of permanent magnets are embedded in the heat insulating connection cylinder; the solder feeding device comprises a thermal conduction metal solder cylinder; one end of the thermal conduction metal solder cylinder is provided with a threaded sealing cover; the other end of the thermal conduction metal solder cylinder is communicated with metal hoses; the thermal conduction metal solder cylinder is further provided with a filtering plate; the thermal conduction metal solder cylinder is provided with a transparent observation strip; the circumferential surface of the thermal conduction metal solder cylinder is provided with a thermal conduction metal elastic clamping buckle; and the thermal conduction metal solder cylinder is also provided with a gas communication pipe. With the assembly of the invention adopted, connection points of a plurality of potentials can be compressed and dotted simultaneously. The assembly has the advantages of small dotting error, continuous, simultaneous and quantitative feeding and timely solder transfer.

Owner:CHENGDU YANXINGGUO TECH CO LTD

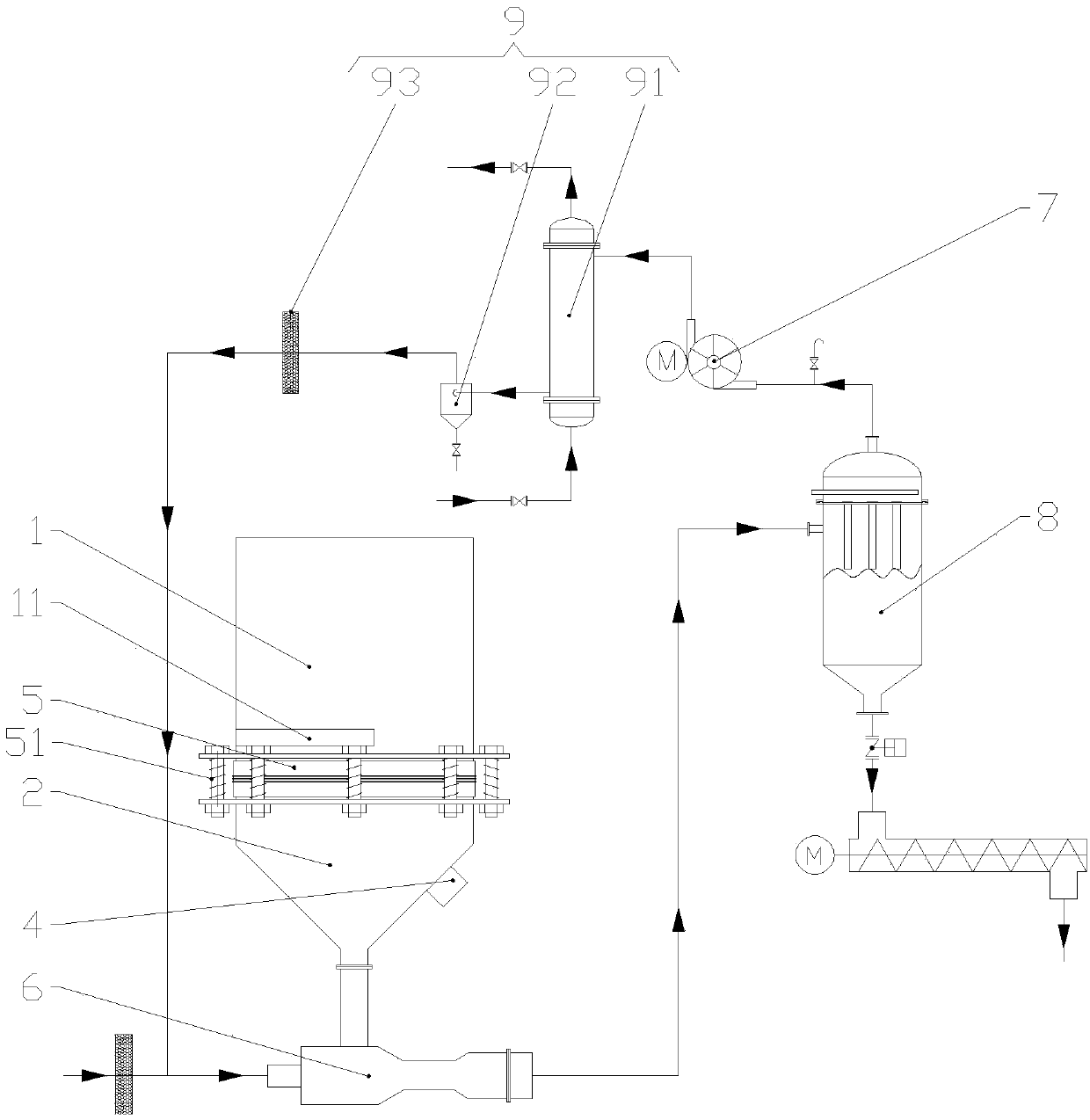

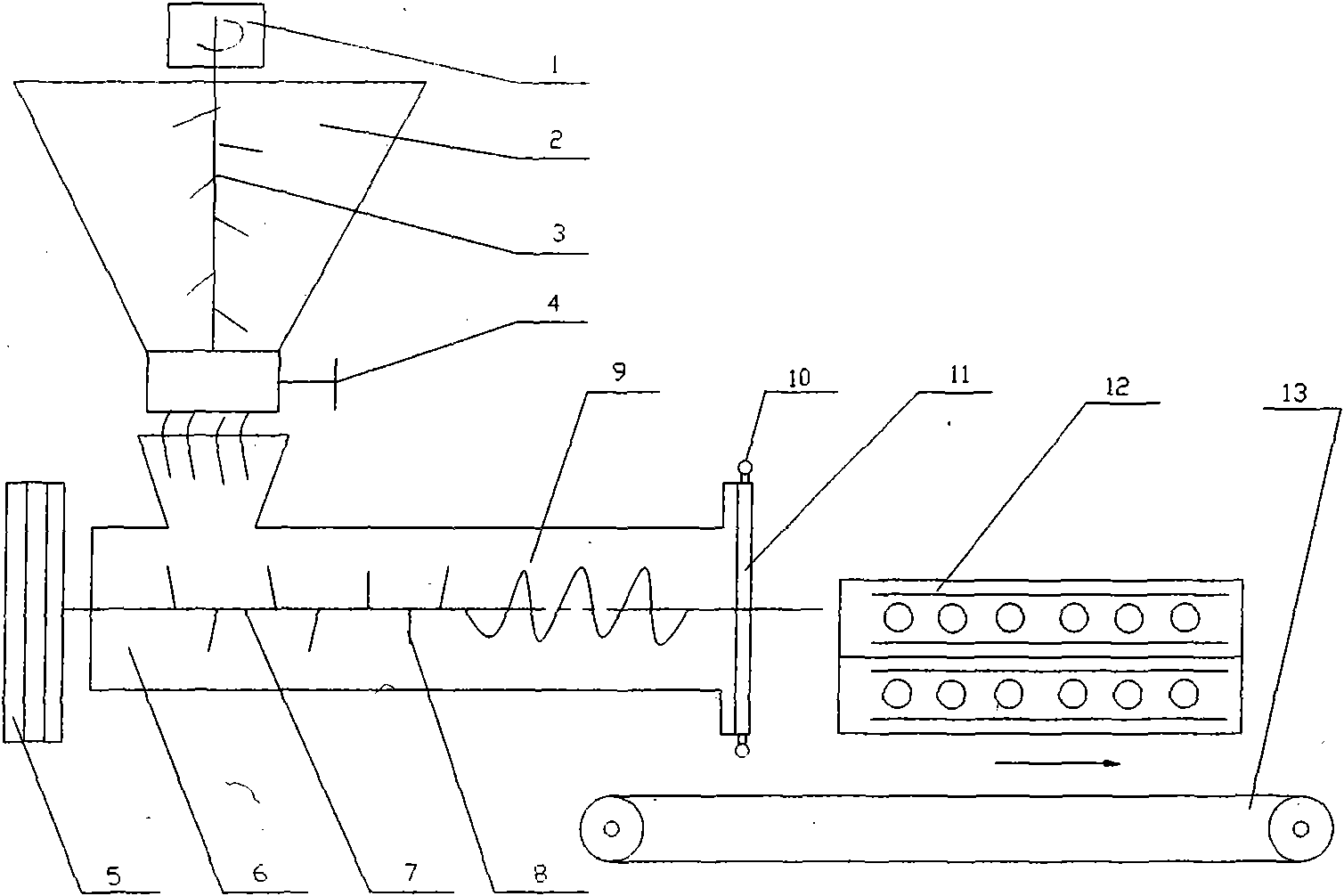

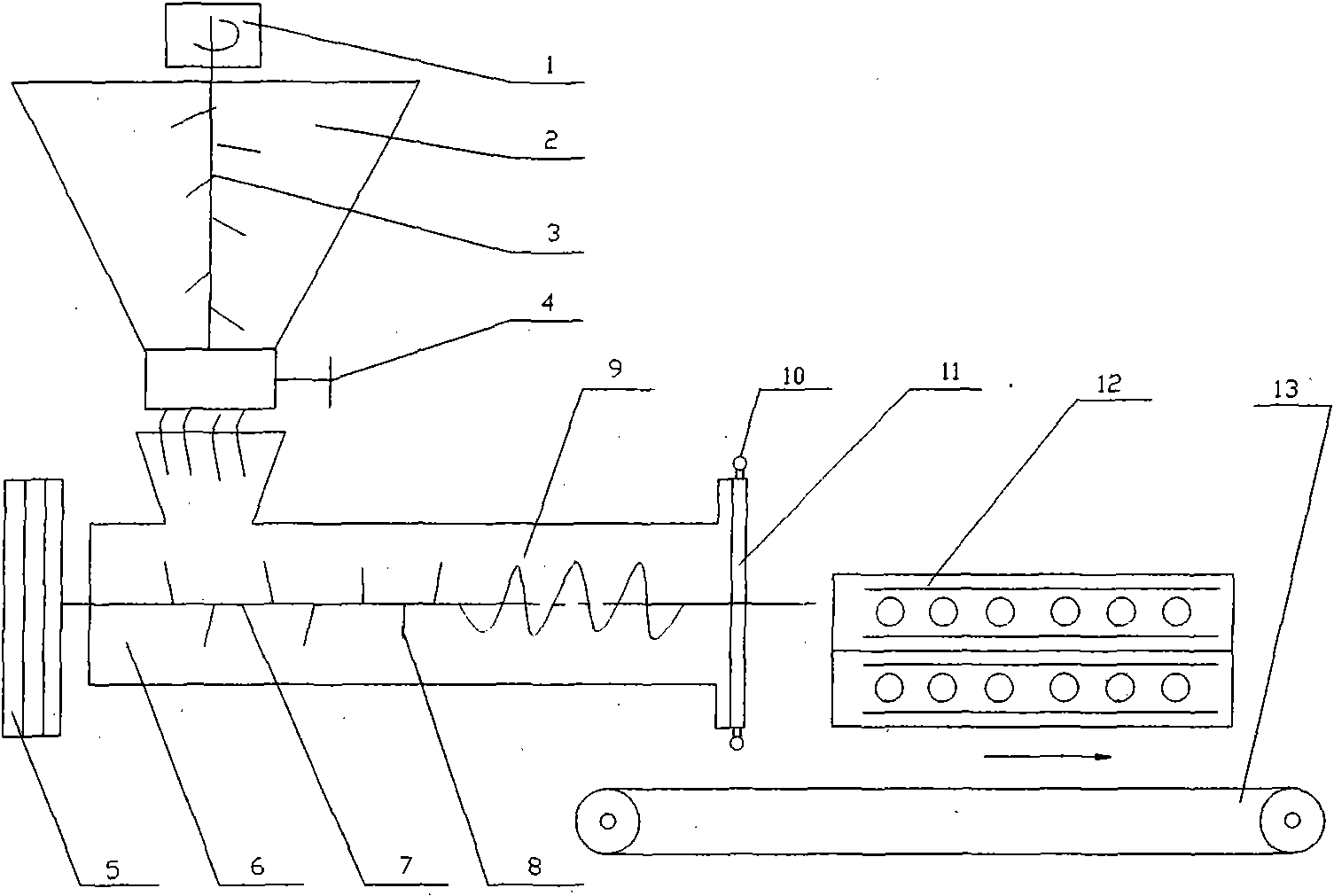

Continuous production device for agricultural water-retaining agent

InactiveCN101856605ASimple structureSmall footprintChemical/physical/physico-chemical stationary reactorsGranulation by material expressionPower beltIn situ polymerization

The invention discloses a continuous production device for an agricultural water-retaining agent prepared by in-situ polymerization and twice grafted polymerization methods. The continuous production device for the agricultural water-retaining agent is implemented through the following technical scheme that: a kettle stirring shaft is arranged in a reaction kettle, and the kettle stirring shaft is connected with a motor; a bottom discharge hole of the reaction kettle is provided with a valve, a barrel feeding hole is positioned under the bottom discharge hole of the reaction kettle, a barrel stirring shaft is arranged in the barrel, the barrel stirring shaft is connected with a power belt pulley and provided with a conveying device and a granulating device in turn, and a barrel discharge hole is provided with a granularity adjusting handle; and one side of the barrel discharge hole is provided with a drying device, and a drying conveying device is positioned under the drying device. The device can realize continuous feed, continuous reaction, continuous granulation and discharge, effectively improves the production efficiency, and meanwhile needs a few workers.

Owner:TIANJIN UNIV OF SCI & TECH

Device for classifying silicon carbide

PendingCN110420750AContinuous feedingImprove classification efficiencyWet separationSpecific gravityMaterials science

The invention discloses a device for classifying silicon carbide. The device for classifying the silicon carbide comprises an upflow cylinder, an underflow cylinder and a transition cylinder, whereinthe top of the upflow cylinder is open and the upflow cylinder comprises a mixed slurry inlet pipe, an overflow groove and an upflow outlet; the mixed slurry inlet pipe extends into the upflow cylinder from the top of the upflow cylinder; the overflow groove is arranged on the outer side wall of the top of the upflow cylinder; and the overflow outlet is arranged at the bottom of the overflow groove. The underflow cylinder comprises a rotary water inlet pipe and an underflow outlet, wherein the rotary water inlet pipe is tangent to the side wall of the lower part of the underflow cylinder; thedischarge direction of the underflow outlet is tangent to the side wall of the upper part of the underflow cylinder; and the underflow outlet is positioned at the upper part of the rotary water inletpipe in the height direction. The transition cylinder is connected with the upflow cylinder and the underflow cylinder. By means of the device for classifying the silicon carbide, the classification of the silicon carbide particles with different specific gravities or different particle diameters can be achieved, and the classifying efficiency of the device for classifying the silicon carbide canbe remarkably improved.

Owner:CHINA ENFI ENGINEERING CORPORATION

Continuous forming device for powder metallurgy based on limiting transmission

InactiveCN111889672AAvoid repetitive reciprocating motionsContinuous implementation collectionReciprocating motionPipe

The invention provides a continuous forming device for powder metallurgy based on limiting transmission, and relates to the technical field of powder metallurgy. The continuous forming device for powder metallurgy based on limiting transmission comprises a frame body, wherein a fluted disc is rotationally connected to the interior of the frame body, a threaded rod is rotationally connected to theright side of the fluted disc in the frame body, a sleeve is fixedly installed at the bottom end of the fluted disc, a conveying pipe is fixedly installed on the outer side of the sleeve, a feeding plate is fixedly installed at the bottom end of the conveying pipe, and a push plate is fixedly installed on the outer side of the sleeve. According to the continuous forming device for powder metallurgy based on limiting transmission, feeding and pressing of a mold and collection of finished products can be continuously realized, the machining efficiency of pressing forming is improved, the repeated reciprocating motion of a single feeding plate and an extrusion rod is avoided, the abrasion is reduced, the service life is prolonged, the use of a complex circuit board is avoided, the manufacturing cost is reduced, and damage is not prone to occurring.

Owner:南知周

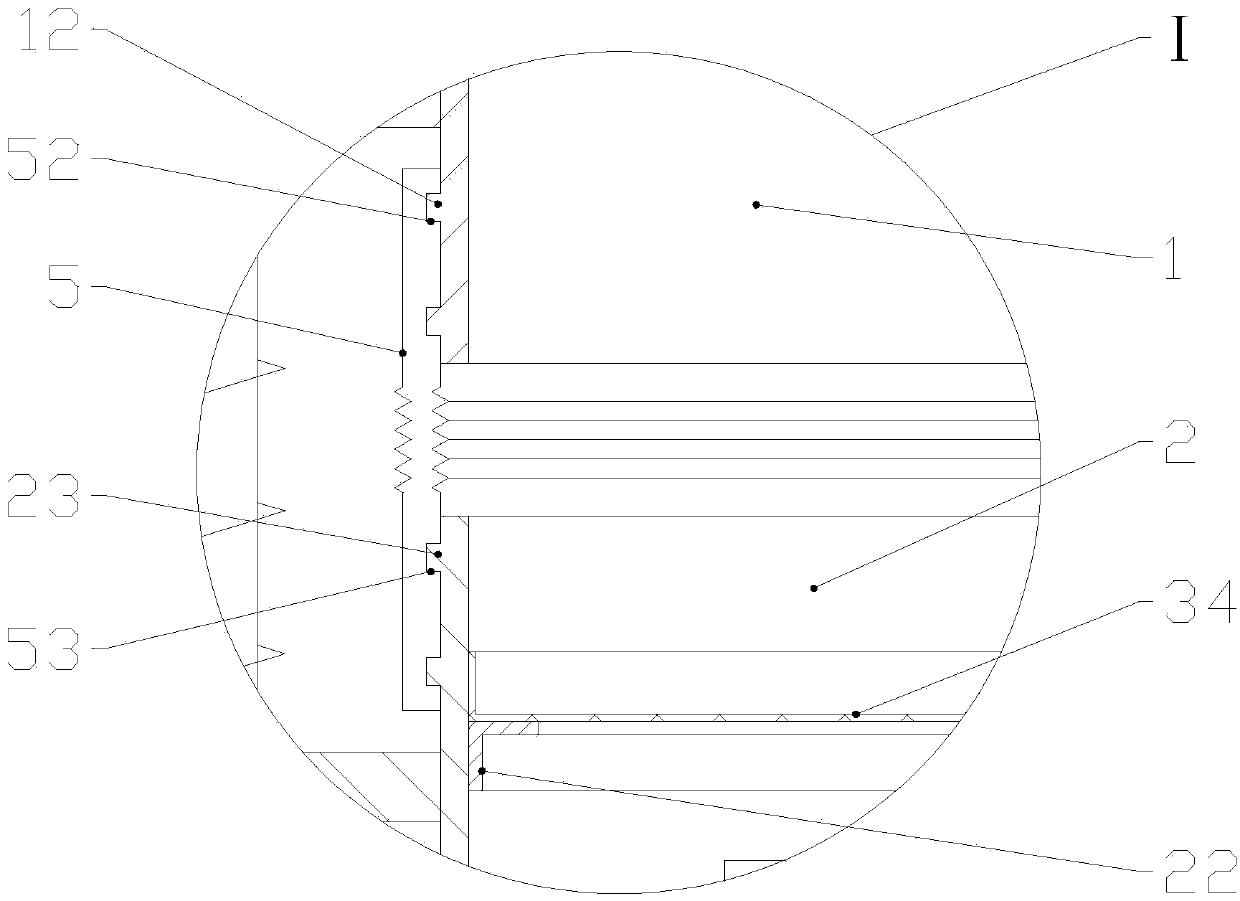

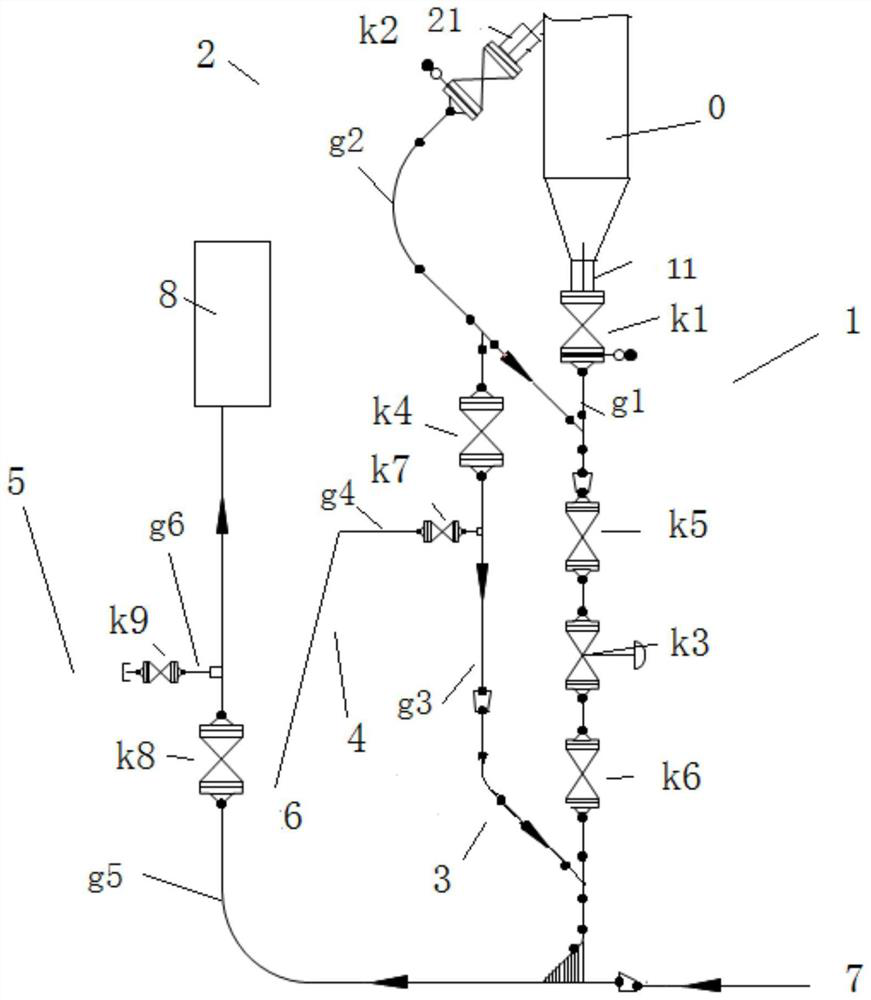

Discharging structure, adsorbent circulating unit and adsorption desulfurization device

PendingCN114762824AContinuous feedingCombustible gas purificationHydrocarbon oils refiningPetrochemicalProcess engineering

The invention relates to the technical field of petrochemical industry, and discloses a blanking structure, an adsorbent circulating unit and an adsorption desulfurization device. The blanking structure comprises a first blanking flow path (1) and a second blanking flow path (2) which are used for blanking of the regenerator (0), a feeding port of the second blanking flow path (2) is located above a feeding port of the first blanking flow path (1), and when blanking at the feeding port of the first blanking flow path (1) is blocked, materials in the regenerator (0) are blanked from the second blanking flow path (2). According to the discharging structure, continuous discharging can be guaranteed, and then the adsorbent circulating unit using the discharging structure can be continuously and stably carried out.

Owner:中国石化海南炼油化工有限公司

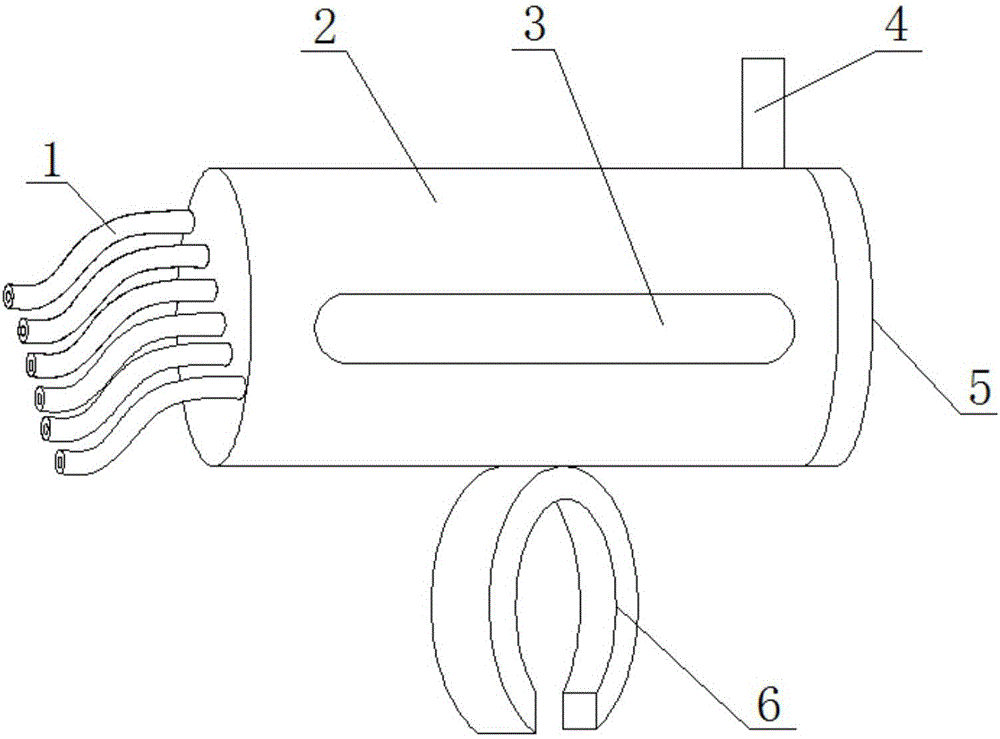

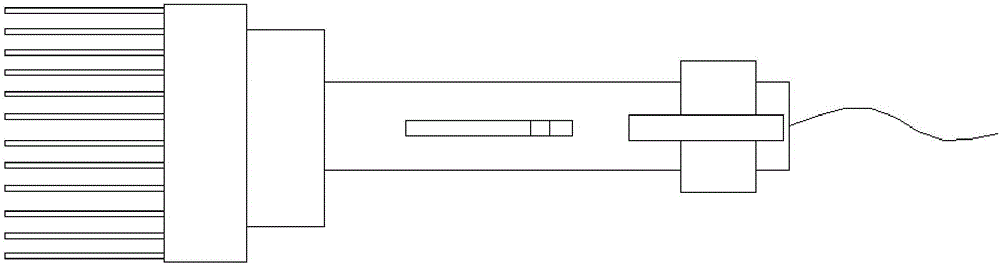

Multi-point-position welding flux feeding device of electronic device welding device

InactiveCN106425004AGuaranteed uptimeComplete RBIWelding/soldering/cutting articlesMetal working apparatusEngineeringMetal

The invention relates to a multi-point-position welding flux feeding device of an electronic device welding device. The multi-point-position welding flux feeding device comprises a heat conduction metal welding flux barrel used for being filled with welding flux. One end of the heat conduction metal welding flux barrel is provided with a threaded sealing cover, and the other end of the heat conduction metal welding flux barrel communicates with metal hoses. The multiple metal hoses are linearly and evenly arranged. The end, communicating with the metal hoses, of the heat conduction metal welding flux barrel is internally further provided with a filtering plate with filtering holes. A transparent observation strip is arranged on the circumference of the heat conduction metal welding flux barrel in the axial direction. A heat conduction metal elastic buckle is further arranged on the circumferential face of the heat conduction metal welding flux barrel. The circumferential face, located at one end of the threaded sealing cover, of the heat conduction metal welding flux barrel is further provided with a ventilation pipe. By means of the multi-point-position welding flux feeding device, multi-point-position discharging and feeding can be conducted at the same time, simultaneous feeding can be achieved when dotting is conducted at multiple point positions at the same time, it is guaranteed that heating and discharging are conducted at the same time, and the multi-point-position welding flux feeding device is extremely convenient and practical to use.

Owner:CHENGDU YANXINGGUO TECH CO LTD

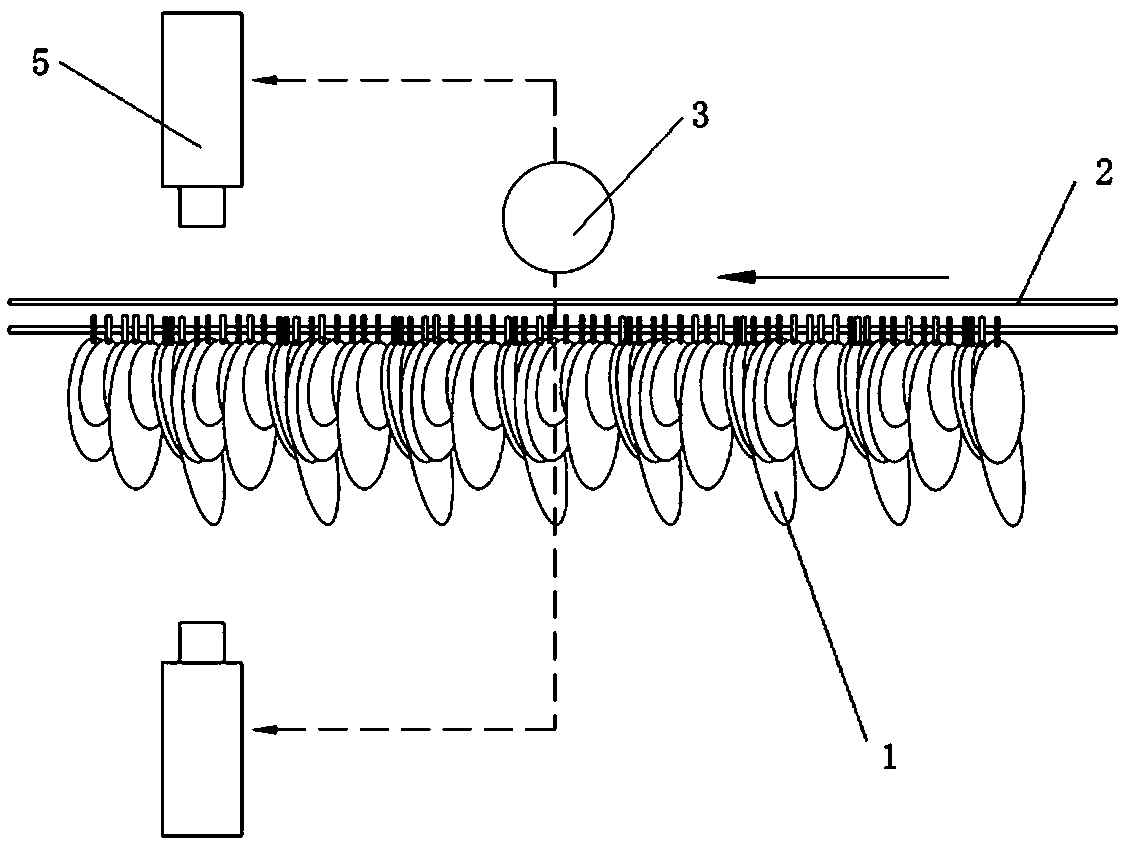

Continuous laminated image acquisition method for sorting large-leaf crops

ActiveCN110430367AContinuous feedingImprove detection efficiencyTelevision system detailsMaterial analysis by optical meansElectricityCrop

The invention relates to an image acquisition method, in particular to a continuous stacked image acquisition method for large-leaf crop sorting. In order to solve the problems in the background art,the invention provides a continuous laminated image acquisition method for sorting large-leaf crops, which comprises the following steps: arranging an encoder in the advancing direction of the large-leaf crops, electrically connecting an encoder with at least two line scanning cameras, and aligning line scanning cameras with the large-leaf crops. An image acquisition method comprises the followingsteps: (1) driving the encoder to rotate when the big-leaf crop advances, outputting square wave signals to the line scanning cameras after the encoder rotates for N circles, and taking the square wave signal as a line frequency signal of the line scanning camera; and (2) after the line scanning cameras receive the square wave signal sent by the encoder, with the line scanning cameras continuously collecting images of the large-leaf crops. The invention has the advantages that stacked continuous feedings of the large-leaf crops can be achieved, and detection efficiency is improved.

Owner:BEIJING FOCUSIGHT TECH

Semi-spiral oblique continuous-charring material-conveying apparatus

ActiveCN103387323AContinuous feedingAvoid normal workSludge treatment by pyrolysisEngineeringHeating furnace

Owner:GUANGDONG INST OF ECO ENVIRONMENT & SOIL SCI

PCB potential connection point dotting device

InactiveCN106455359AReduce mistakesSimple structurePrinted circuit assemblingEngineeringMultiple point

Owner:CHENGDU YANXINGGUO TECH CO LTD

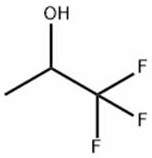

Preparation method of trifluoroisopropanol

ActiveCN113461491AHigh yieldShort reaction processOrganic compound preparationHydroxy compound preparationChemical industryMethylmagnesium chloride

The invention relates to a preparation method of trifluoroisopropanol, in particular to a preparation method of 1, 1, 1-trifluoro-2-propanol, and belongs to the technical field of fluorine chemical industry. According to the preparation method of the 1, 1, 1-trifluoro-2-propanol, disclosed by the invention, the 1, 1, 1-trifluoro-2-propanol is prepared by taking a methylmagnesium chloride Grignard reagent and trifluoropropionaldehyde as reactants through Grignard reaction. The preparation process of the raw materials trifluoropropionaldehyde and methylmagnesium chloride has mild reaction conditions. The reaction yield is high, the conversion rate of trifluoropropionaldehyde reaches 98% or above, and the selectivity of 1, 1, 1-trifluoro-2-propanol reaches 95% or above. The method is short in reaction process, simple in preparation process, safe, environment-friendly and few in side reaction. Continuous feeding can be realized, and large-scale industrial co-production is easy to realize.

Owner:SHANDONG HUAAN NEW MATERIAL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com