Method for preparing coal-based carbonized material used for preparing active carbon

A technology for preparing activated carbon and carbonization materials, which is applied in the field of coal chemical industry, can solve problems such as abnormal operation, and achieve the effect of improving oxidation efficiency, increasing calorific value, and continuous discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

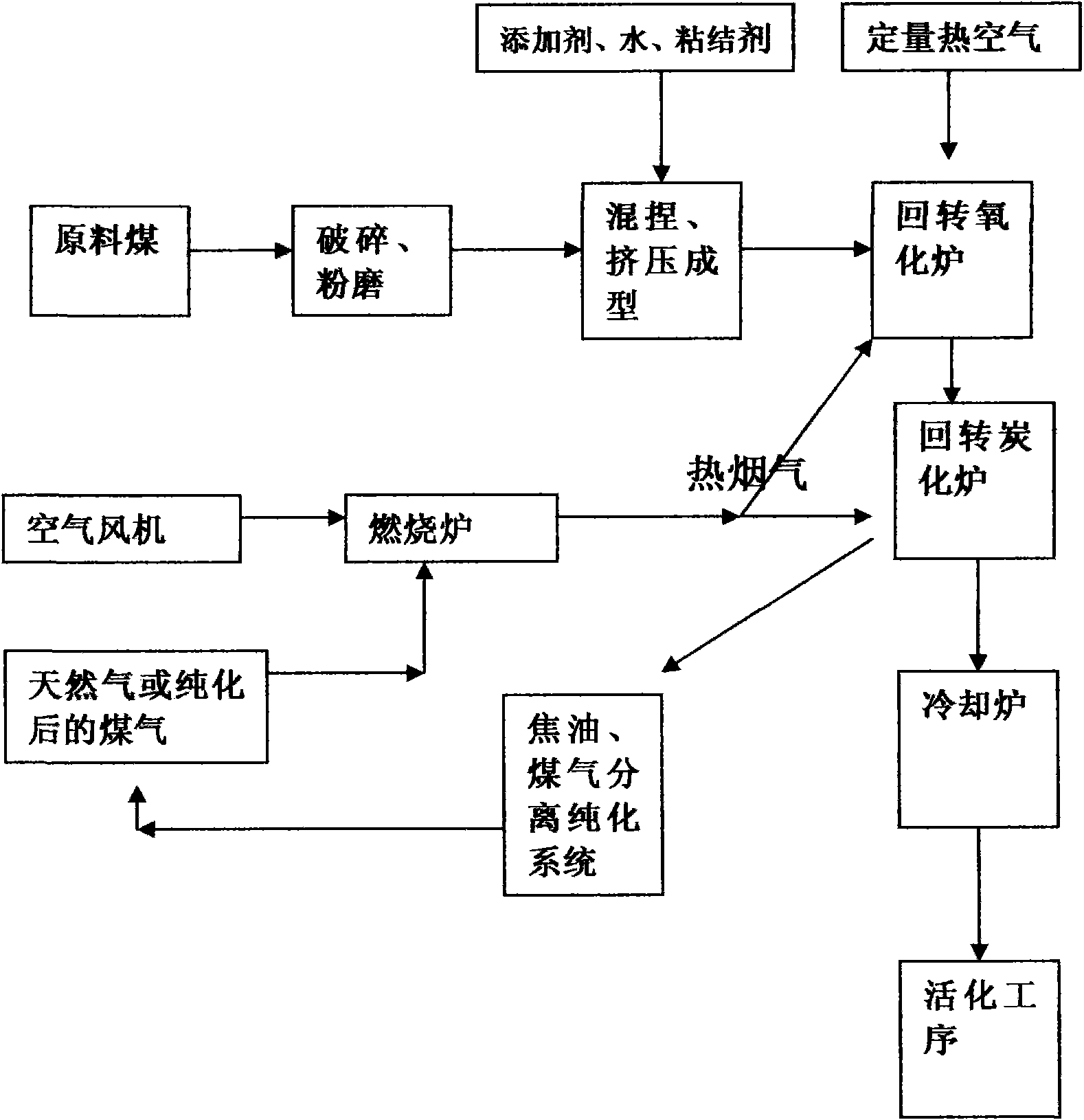

Method used

Image

Examples

Embodiment 1

[0021] Fully oxidize 100kg of coal-based briquette molding material (amorphous granular) with a particle size of 0.60-3.35mm, moisture content ≤ 2%, and volatile content: 30%-40% in an oxidation furnace at 200°C Hour. The coal-based oxidizing material is discharged from the discharge box at the tail of the oxidation furnace into the conveying device and sent to the rotary carbonization furnace. It is carbonized in the carbonization furnace with gradually increasing temperature for 2 hours. The temperature of each section of the carbonization furnace is: 270°C, 330°C, 390°C , 450°C, 510°C and 570°C, the pressure value is controlled at 10mm H 2 O. The produced coal-based carbonized material is sent to the cooling furnace for cooling under the condition of isolating the air, and the cooling furnace adopts the form of circulating water spray cooling. The generated carbonized tail gas is separated and purified to obtain tar and coal gas. After calculation and analysis, the parti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com