Method for degrading waste alkaline residues through ozone-light wave catalytic oxidation

A technology of catalytic oxidation and waste alkali residue, applied in chemical instruments and methods, multi-stage water/sewage treatment, water/sludge/sewage treatment, etc., can solve problems such as refractory degradation and no treatment process, and reduce impact , to ensure the effect of normal operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

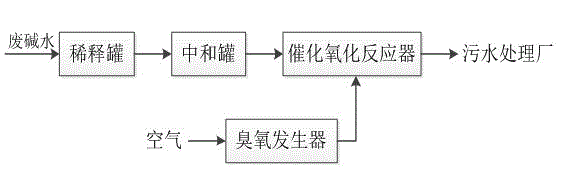

[0022] Put refinery waste alkaline water (7% free NaOH, 3% petroleum, 3450mg / L sulfide, 3000mg / L volatile phenol, 136000mg / L COD) into the dilution tank and dilute it with water at 10:1, and then dilute the diluted The final waste alkaline water is poured into the neutralization tank, and concentrated H 2 SO 4 Adjust the pH value to about 8, and then send it to the ozone-light wave catalytic oxidation reactor.

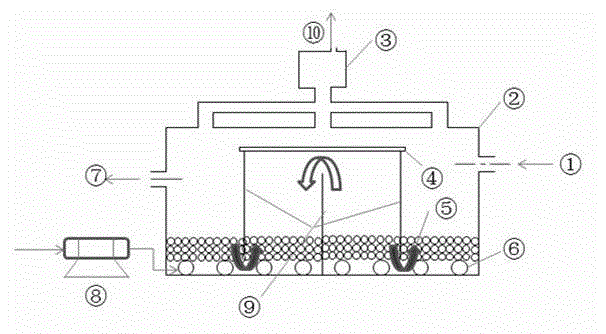

[0023] The neutralized sewage enters the ozone-photocatalytic oxidation reactor from the water inlet ①, and the ozone generator ⑧ converts the air into ozone, and enters the ozone-photocatalytic oxidation reactor through the spherical diaphragm microporous aerator ⑥. The ozone-light wave catalytic oxidation reactor is filled with a solid catalyst ⑤ (Cu-Mn-Co composite heterogeneous catalyst), and the waste alkaline water is fully and uniformly contacted with ozone, catalyst, and ultraviolet light, and a catalytic oxidation reaction occurs, accompanied by A large amou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com